Steelco VS Sterilizer User and maintenance manual

0398

0051

Steelco VS series

Steelco S.p.A.

Via Balegante, 27

31039 - Riese Pio X (TV)

ITALY

Tel. - +39 0423 7561

Fax. - +39 0423 755528

www.steelcospa.com

Use and Maintenance Manual

1

2

NOTIZIE DI COPYRIGHT

The Copyright 2014 of this document is property of Steelco S.p.A. No part of this document may be copied,

transmitted or divulged to third parties without the written authorization of the president of Steelco S.p.A.

AUTHORS APPROVED

Stefano Beni

Version Request

Modifications

1.0 Emission 08/01/2014 All Martina De Lorenzi

1.1

2.0 Modification 06/03/2014 All Lucia Marletta

2.1 Modification 16/05/2014 All Lucia Marletta

2.2 Modification 24/06/2014 3, 38 Lucia Marletta

Table

modification

10/02/2014 19-21 Martina De Lorenzi

_________________

_________________

PUBLICATION TABLE

Date Pages

affected

Issued

by

2.3 Modification 07/08/2014 3, 18-28 Lucia Marletta

2.4 Modification 10/11/2014

3.0 Modification 10/11/2014

3.1 Modification 04/12/2014

3.2 Modification 12/12/2014 All Lucia Marletta

3.3 Modification 28/01/2015 All Lucia Marletta

All publications must be promptly inserted in this document.

After 5 corrections – with relative publication – this document must be drafted with a higher publication

number.

3, 11, 12,

18-104

3, 11, 12,

18-104

3, 11-29,

27-29, 37,

78, 82-93

Lucia Marletta

Lucia Marletta

Riccardo Carpin

3

CONTENTS

1. INTRODUCTION ...........................................................................................................11

1.1 Dear Customer .....................................................................................................11

1.2 Product Presentation ...........................................................................................11

1.3 Identification of the various model .....................................................................12

1.4 Purpose of the manual .........................................................................................12

1.5 General notices .....................................................................................................13

1.5.1 Clauses of supply ...........................................................................................13

1.6 Conditions of guarantee ......................................................................................14

1.7 Fields of use ..........................................................................................................14

1.8 Applicable Standards ...........................................................................................15

2. CONSTRUCTIONAL CHARACTERISTICS .............................................................16

2.1.1 Autoclaves accessories ..................................................................................42

2.1.2 Steelco VS series performances ...................................................................44

2.1.3 Unit classification (for all versions) .............................................................44

2.1.4 Noise/Vibrations ............................................................................................44

2.1.5 Heat loss of the unit ......................................................................................44

2.1.6 Electromagnetic compatibility .....................................................................45

2.1.7 Warning tags .................................................................................................48

2.2 Table Of Symbols .................................................................................................49

2.3 Characteristics of storage and conservation ......................................................50

2.4 Residual risks .......................................................................................................50

2.5 Options ..................................................................................................................50

2.5.1 Steam generator ............................................................................................50

2.5.2 Number of doors ...........................................................................................51

2.5.3 Technical Compartment ...............................................................................51

2.5.4 Reference pressure transmitter ...................................................................51

2.5.5 Other options .................................................................................................51

3. OPERATOR GUIDE .......................................................................................................52

3.1 Operator position .................................................................................................52

3.2 Control system ......................................................................................................54

3.3 Main menù page ...................................................................................................56

3.3.1 State of the sterilizer .....................................................................................56

3.3.2 Keyboards ......................................................................................................57

3.3.3 “STERILIZATION” Menu ..........................................................................58

3.3.4 “LAST CYCLE” Menu ................................................................................65

3.3.5 “UTILITY” Menu .........................................................................................66

3.3.6 “MAINTENANCE” menu ...........................................................................70

3.3.7 “CONFIGURATION” menu .......................................................................74

3.3.8 Characteristics of the phases of the sterilization programs ......................78

3.4 Graphs ...................................................................................................................83

3.5 PC INTERFACE ..................................................................................................87

4. ALARMS ..........................................................................................................................88

5. MAINTENANCE ...........................................................................................................101

5.1 Periodic Cleaning ...............................................................................................103

5.1.1 External paneling cleaning .........................................................................103

5.1.2 Sterilization chamber cleaning ..................................................................104

5.2 Safety Devices .....................................................................................................105

5.3 Procedure to extract the load in Emergency ...................................................106

6. TREATMENT AND CONSERVATION OF STERILIZED MATERIAL ..............107

6.1 Treatment of Materials Before Sterilization ...................................................107

6.2 Arrangement of the load ...................................................................................108

4

6.3 Conservation of sterilized material ..................................................................109

7. PRINTOUTS ..................................................................................................................110

7.1 Printout management ........................................................................................110

7.2 Complete cycle report ........................................................................................112

7.3 Cycle Report Data ..............................................................................................114

7.4 Cycle Result ........................................................................................................114

7.5 Report Trend ......................................................................................................114

7.6 Digital Inputs/Outputs Status Report ..............................................................114

7.7 Analogical Values Status Report ......................................................................114

7.8 Set Point Report .................................................................................................114

7.9 Machine History Report ....................................................................................114

7.10 Machine Settings Report ...................................................................................114

8. GLOSSARY ...................................................................................................................115

9. ATTACHMENT 1 P&I DRAWING ...........................................................................116

10. ATTACHMENT 2 ELECTRICAL DIAGRAM ........................................................117

5

INDEX OF FIGURES

Figure 1 –Main components ______________________________________________________________________________ 17

Figure 2 – Labelling design ______________________________________________________________________________ 48

Figure 3 – Operator position VS1 _________________________________________________________________________ 53

Figure 4 – Operator position VS12 ________________________________________________________________________ 53

Figure 5 – Operator position VS 18 ________________________________________________________________________ 53

Figure 6 – Load side ____________________________________________________________________________________ 54

Figure 7 – Sterile side ___________________________________________________________________________________ 55

Figure 8 – Main menu __________________________________________________________________________________ 56

Figure 9 – State of the sterilizer ___________________________________________________________________________ 56

Figure 10 – Keyboards __________________________________________________________________________________ 57

Figure 11 – Menu ______________________________________________________________________________________ 58

Figure 12 – Sterilization _________________________________________________________________________________ 58

Figure 13 – Basic program _______________________________________________________________________________ 59

Figure 14 – User program _______________________________________________________________________________ 59

Figure 15 – Work state __________________________________________________________________________________ 60

Figure 16 – Sterilization describe _________________________________________________________________________ 61

Figure 17 – Input and output diagram ______________________________________________________________________ 61

Figure 18 – Parameters diagram __________________________________________________________________________ 62

Figure 19 – Finished cycle _______________________________________________________________________________ 62

Figure 20 – Cycle suspend _______________________________________________________________________________ 63

Figure 21 – Alarm _____________________________________________________________________________________ 63

Figure 22 – Alarm describe ______________________________________________________________________________ 64

Figure 23 – Cycle suspend _______________________________________________________________________________ 64

Figure 24 – Active alerts ________________________________________________________________________________ 64

Figure 25 – Last cycle __________________________________________________________________________________ 65

Figure 26 – Cycle diagram _______________________________________________________________________________ 65

Figure 27 – Utility menu _________________________________________________________________________________ 66

Figure 28 – Machine data _______________________________________________________________________________ 66

Figure 29 – Maintenance state ____________________________________________________________________________ 67

Figure 30 – State I/O ___________________________________________________________________________________ 68

Figure 31 – Inlet _______________________________________________________________________________________ 68

Figure 32 – Outlet _____________________________________________________________________________________ 68

Figure 33 – Graph. state ________________________________________________________________________________ 69

Figure 34 – Printer utility ________________________________________________________________________________ 69

Figure 35 – Maintenance menu ___________________________________________________________________________ 70

Figure 36 – Update clock ________________________________________________________________________________ 70

Figure 37 – Manual control ______________________________________________________________________________ 71

Figure 38 – Disabled manuals ____________________________________________________________________________ 71

Figure 39 – Outlet control _______________________________________________________________________________ 72

Figure 40 – Inlet state ___________________________________________________________________________________ 72

Figure 41 – Graph. state ________________________________________________________________________________ 73

Figure 42 – Constructor data restore _______________________________________________________________________ 73

Figure 43 – Configuration _______________________________________________________________________________ 74

Figure 44 – System data _________________________________________________________________________________ 74

Figure 45 -Temperature _________________________________________________________________________________ 75

Figure 46 – Operators authorized list ______________________________________________________________________ 76

Figure 47 – Insert a new operator _________________________________________________________________________ 76

Figure 48 - Program ____________________________________________________________________________________ 77

Figure 49 – Program management _________________________________________________________________________ 77

Figure 50 – Programs set ________________________________________________________________________________ 78

Figure 51 – Properties phase set __________________________________________________________________________ 78

Figure 52 – Seal control _________________________________________________________________________________ 78

Figure 53 - Homogenization ______________________________________________________________________________ 79

Figure 54 – Sterilization _________________________________________________________________________________ 80

Figure 55 - Aeration ____________________________________________________________________________________ 80

Figure 56 – Vacuum test _________________________________________________________________________________ 81

Figure 57 – Heating ____________________________________________________________________________________ 81

Figure 58 – Cooling ____________________________________________________________________________________ 82

Figure 59 – Electric Control Board _______________________________________________________________________ 106

Figure 60 – Printout of the PLC checking __________________________________________________________________ 110

Figure 61 – Complete Cycle Report Example _______________________________________________________________ 112

6

INDEX OF TABLES

Table 1 – Classification as standard EN 61010-1 _____________________________________________________________ 44

Table 2 – Heat loss _____________________________________________________________________________________ 44

Table 3 – Environmental characteristics ____________________________________________________________________ 50

Table 4 – Alarms ______________________________________________________________________________________ 100

Table 5 – Routine maintenance __________________________________________________________________________ 103

Table 6 – Safety devices ________________________________________________________________________________ 105

Table 7 – Available reports content _______________________________________________________________________ 111

Table 8 – Analogical Data for report ______________________________________________________________________ 113

Table 9 – Values and meaning of Result ____________________________________________________________________ 113

7

WARNINGS

Please note that the use of this manual and attached documents is for the exclusive use of the personnel

specified for each skill and in the environment where the autoclave is installed.

These restrictions for use are underlined and

UNAUTHORIZED COPYING IS STRICTLY FORBIDDEN

And their distribution particularly to other companies.

Steelco S.p.A. Reserves the right to act under the law should these warnings not be complied with.

Steelco S.p.A. warns that all operations concerning software and hardware must be carried out with the

utmost care. Such operations can lead to the machine not behaving as required, to be damaged or to treat the

load in a different way.

Any exception must have the authorization of

Steelco S.p.A.

8

SALE AND SUPPORT CENTERS

Steelco S.p.A.

Via Balegante, 27

31039 Riese Pio X (TV)

www.steelcospa.com

Tel. 0039 0423 7561

Fax 0039 0423 755528

9

REFERENCE NOTES

The warning conditions are highlighted in the following way:

Operators must pay due care to these types of messages.

In the manual, the term operator describes the person in charge of usually operating the machine, and who

has the following tasks:

For other technical terms, please refer to the GLOSSARY on page 115.

NOTES

This machine requires trained personnel even for normal loading and pick up operations.

Description of warning

1. Loading and picking up the product;

2. Cycle selection;

3. Cycle start and cycle reset;

4. Alarms reset;

5. Stop the cycle by using the emergency push buttons, when required.

10

1. INTRODUCTION

1.1 Dear Customer

Thank you for placing your trust in Steelco S.p.A. We hope that the performance of this product will meet

your complete satisfaction.

Here you will find a description of all procedures for proper safe use and how to take full advantage of the

features of this unit.

Important notes:

1.2 Product Presentation

The new range of Steelco VS Series autoclaves includes models with 1, 1.5, 2, 3, 4, 6, 8, 10, 12, 12H, 15H,

18H sterilization units.

Steelco VS Series is characterized by an innovative line and a careful and flexible design. The models are

available both with a single and double door, and left- or right- technical compartment.

Ergonomic load height and integrated railways allow the easy positioning of the load.

Into the front panel is mounted a monitor LCD “Touch-screen” and a push-button membrane with six button

for setting. The LCD monitor depending on the position of state: program or management, displays some

buttons that selected by press in the display area what they check specific control functions. It indicates the

various phases, the parameters of the cycle both in numeric form and graphic form, any anomalies or

failures, audit-trails etc. Each sterilization cycle is automatically recorded into the physics memory of the

computer . At the end of the cycle a report containing the identification data and the graphical trend of the

pressure and temperature is printed in compliance with the requirements of the technical standard UNI EN

285 on a 112 mm thermal printer also installed on the front panel of the machine (access to the autoclave is

managed using passwords with different access levels).

Maximum integration with the client’s IT systems.

Information found in this manual is subject to modifications without prior notice

Steelco S.p.A. is not liable for direct, indirect, accidental or other damages regarding the issue and use

of this information

Reproduction, adaptation or translation of this document or any part of it without prior written

consent by Steelco S.p.A.. is strictly forbidden.

The figures contained in this manual are purely for indicative purposes.

This manual must always be available to the sterilization operator

The key to turn on the sterilizer, where applicable, must be available to the sterilization

operator, and must be removed if the unit is not in operation.

External panels must always be closed, the keys must be removed and kept by the person

responsible for the sterilizer

11

1.3 Identification of the various model

The machine model described in this manual is identified by the symbol "VS" followed by:

The first number indicates the capacity of the sterilization chamber:

1 sterilization units

1,5 sterilization units

2 sterilization units

3 sterilization units

4 sterilization units

6 sterilization units

8 sterilization units

10 sterilization units

12 sterilization units

15 sterilization units

18 sterilization units

The letter “H” in case of high machine only for size 12, 15, 18

The second number indicates the number of doors:

1 = single front door, “Single Door Models”

2 = two doors, one opposite the other, “Double Door Models”

The letter, if applicable, indicate the type of steam generator:

E = internal generator with Electric heating

V = direct centralized steam ("Vapour") without internal generator

I = internal generator with Indirect steam heating

EV = internal generator with Electric heating + direct steam ("Vapour")

EI = internal generator with Electric heating + Indirect steam ("Vapour")

Example:

Autoclave Model VS 4/1 E

VS Series

4 Indicates the range's smallest model (4 units)

1 Single Door Model

E Generator equipped with electric heating

1.4 Purpose of the manual

The purpose of this manual is to provide the operator with instructions for:

- General product knowledge;

- Safe and efficient use;

- Treatment of the material before and after sterilization;

- Cleaning and maintenance;

- Analysis of problems and alarms, and how to deal with them;

- Operating diagrams.

12

1.5 General notices

The product and/or its accessories must always be used in compliance with the procedures set forth in this

manual. They must never be used for other than their intended purposes.

1.5.1 Clauses of supply

Concerning installation and assembly carried out by third parties, the manufacturer shall in no way be held

liable for:

a) work carried out improperly, not in accordance with good construction practices, concerning:

- pipes and accessories for the adding and discharge of various fluids,

- electrical connections,

b) work or modifications of any sort carried out on the unit and its accessories without advance written

approval from the manufacturer,

c) associated stresses (seismic, wind, etc.) or dynamic loads originating outside the unit,

d) ladders, metallic structures, foundations, masonry work in general and protective structures, realized by

third parties specifically for the unit,

e) removal of panels and electrical protective parts,

f) insertion of metallic objects in the unit,

g) for special installation (e.g. unit installed in pre-existing service compartment, recessed, placed along side

other units), all internal parts of the machine must be protected in such a way that they cannot be directly

accessed by unqualified personnel (inspection doors with keys or other locking methods that require a

tool for opening). Check the installation diagram and if necessary contact the manufacturer for further

clarification.

The legal representatives of the health and private structures, and public and private health

providers, on the basis of what they detect in carrying out their activities, must immediately notify the

Ministry of Health, directly or via the relevant health structure, any alteration to the characteristics

In order to prevent hazardous situations, with possible damage to individuals and/or property, please

observe the following precautions:

and performance of a device, or the unsuitableness of the instructions for use that may cause the death

of a patient or an operator or their health condition to worsen.

The Ministry of Health notifies the manufacturer.

(excerpt from Legislative Decree dated 24/02/97 n° 46, art. 9 and 10; 93/42 EEC)

The user is responsible for legal obligations connected with installation and use of the product. If the

product is not installed, used, and maintained properly by qualified personnel authorized by the

manufacturer, the manufacturer shall no longer be bound by any sort of responsibility. The unit's

guarantee is to be considered void and the manufacturer shall not be held liable for any breakdowns,

malfunctions, or direct or indirect damage to individuals or property.

Do NOT pour water or other liquids on the unit.

Do NOT pour flammable liquids onto the machine.

Do not apply alcohol or any substance containing it on the Plexiglas panels.

Do NOT use the machine if there are explosive or flammable gases or vapours present.

Before carrying out any maintenance or cleaning, always disconnect the electrical power supply.

Make sure the electrical system is provided with an earth connection in compliance with current laws

and/or standards

Do NOT remove any label or tag from the machine. If this is necessary, ask for new ones

13

1.6 Conditions of guarantee

The following guarantee conditions are offered:

- 12 months from the date of testing and commissioning of the machine;

- 18 months from the date of shipment.

1.7 Fields of use

The Steelco VS series autoclaves are designed for hospital sterilization, i.e. they are suitable to operate

on porous and rubber materials, on surgical instruments, on materials pre-packaged into bags, provided they

can withstand working temperatures of up to 140°C and maximum pressure of 2.5 bar.

It is preferable to avoid sterilizing materials that include additives and/or chemical solvents.

Use only original spare parts

Failure to comply with the measures outlined above relieves the manufacturer of any liability

The guarantee is not applicable to expendable materials and routine maintenance.

The use of sterilizing autoclaves must be entrusted to responsible personnel

It is advisable to carry out the Bowie & Dick test to check the effectiveness of the sterilization process.

It is possible to sometimes carry out the test to check for vacuum seal, to see if the machine has any

seal problems.

If the Bowie & Dick test is successful, the machine can be used (each cycle should in any case be

validated by a manager, and the result of the Bowie & Dick test does not exempt the user from the

obligation of validating the entire sterilization process as required by the technical standard UNI EN

ISO 17665-1).

Warning: test documentation must be conserved in compliance with current legislation.

Improper use of the autoclave relieves the manufacturer of any liability

14

1.8 Applicable Standards

The sterilizers dealt with by this document comply with directives 97/23/EC and standards:

- ASME VIII div 1 & div 2 - Rules for Construction of Pressure Vessels

- EN13445-3 annex B & C – EN13445-3 Cl.18 - Pressure Vessel Code

- UNI EN 288-3 / EN15614-1 - Manufacturing and control procedure for welded joints

- UNI EN 473 - Qualification of personnel responsible for non-destructive controls

- UNI EN ISO 9712:2012 - non-destructive testing — qualification and certification of ndt personnel

- UNI EN ISO 5817:2008 - Welding - Fusion-welded Joints In Steel, Nickel, Titanium And Their Alloys

(beam Welding Excluded) - Quality Levels For Imperfections

- EN10028-7 :2008 - Flat products made of steels for pressure purposes. Part 7: Stainless steels

- EN571-1 - Non-destructive tests - examination with penetrating liquids

- EN1435 A1 - - non-destructive control of welds – radiographic testing of welded joints

- UNI EN ISO 17637 - Non-destructive testing of welds-visual testing of fusion-welded joints

- EN 287.1:2012 – Qualification test of welders - fusion welding - part 1: steels

- UNI EN ISO 15609-1:2006 – Specification And Qualification Of Welding Procedures For Metallic

Materials - Welding Procedure Specification - Part 1: Arc Welding

The sterilizers dealt with by this document comply with directives 93/42/CEE+2007/47/CE and standards:

- EN 285:2009 – Steam sterilizers – Large sterilizers

- CEI EN 61010-1:2011 – Safety requirements for electrical equipment for measurement, control and

laboratory use – General requirements

- CEI EN 61010-2-040:2005 – Safety requirements for electrical equipment for measurement, control and

laboratory use – Parte 2-040: Particular requirements for sterilizers and washer-disinfectors used to treat

medical materials.

- UNI EN ISO 14971:2012 Medical devices – Application of risk management to medical devices.

- CEI EN 60601-1-6:2010 Medical electrical equipment Part 1: General requirements for basic safety and

essential performance – Collateral standard: Usability.

- UNI EN ISO 17665 – 1:2007 Sterilization of health care products - Moist heat - Part 1: Requirements for

the development, validation and routine control of a sterilization process for medical devices.

- CEI IEC 60601-1-2:2007 Medical electrical equipment .Part 1-2:General requirements for basic safety

and essential performance .Collateral standard: Electromagnetic compatibility .Requirements and tests

- EN 62366:2008-01 “Medical devices – Application of usability engineering to medical devices”

- GAMP5 (Good Automated Manufacturing Practice - Version 5)

- EN 61326-1 Electrical equipment for measurement, control and laboratory use - EMC requirements -

Part 1: General requirements

- CEI EN 60204-1/2006 - Safety of machinery. Electrical equipment of machines. General requirements

15

2. CONSTRUCTIONAL

CHARACTERISTICS

The new Steelco VS series autoclaves are characterized by a body completely in stainless steel AISI

316L/316Ti with parallelepiped chamber and tilting towards the drain, with cylindrical chamber for models

1-1,5-2; thermal insulation is guaranteed by an innovative and practical textile cover.

The vertical sliding doors are molded and do not have any welding. The doors' vertical movement is carried

out by a toothed belt motorized system or chain (models 1-1,5). This system is more precise and quieter

during opening and closing. The doors' anti-crushing plate, compliant with safety standards CEI EN 61010-1

and CEI EN 61010-2-040, is characterized by a new design that is easy to clean. In addition, it is sufficient

to apply minimum pressure to stop the door, maximizing the responsiveness of the safety system.

The new Steelco VS series autoclaves guarantee excellent performance in sterilization cycles whilst

optimizing water and steam consumption.

Tri-clamp hydraulic connections make it easy to maintain the systems which have been arranged on the

front part of the autoclave. The vacuum pump has two-stages; electrical versions are equipped with a new

steam generator with power up to 64 kW. The autoclave's front part houses a tray for the vacuum pump,

which allows the latter to be easily extracted for maintenance (when necessary).

The base is equipped with guides for pallet hand trucks (when necessary), in order to be able to lift the

autoclave and transport it safely and easily. The load-bearing structure rests on 4 height-adjustable feet to

ensure that the unit is balanced.

The autoclave, except for models 1-1,5-2, is designed to rapidly reduce the total width to just 950 mm, to

allow easy access to the technical panels, which can be placed on both the right and left side.

Temperatures of accessible parts and internal parts are within the limits set forth by safety standards CEI EN

61010-1 and CEI EN 61010-2-040 and by product standard UNI EN 285;

Manifolds compliant with technical standard UNI EN 285 for insertion of additional probes (in the

sterilization chamber or in the well) and for connection of instruments required for physical qualification

required by technical standard UNI EN ISO 17665-1;

The seal of the autoclave is obtained via a silicon gasket, housed in a cavity obtained by precision working

of a ring welded to the body, pushed against the door by steam injection. Before the door is opened, a

vacuum is created in the cavity that houses the gasket so that the gasket is detached from the door before it

is possible to move the door (reducing wear).

Control of fluids with pneumatic valves installed with fittings with mechanical seal;

Equipped with sterile filters with degree of filtering of 99.999% according to D.O.P. test;

Equipped with the following indicator instruments: gauge to indicate pressure in the chamber (scale 0÷6 bar

relative); gauge to indicate pressure in jacket (scale -1÷5 bar relative) and gauge to indicate the pressure of

the steam (scale 0÷6 bar relative);

Instruments for measuring temperature and pressure of both control system and recording system compliant

with the requirements of technical standard UNI EN 285;

Equipped with a pressure safety switch for chamber pressure, a safety pressure switch for pressure in the

generator (if installed), a service pressure switch for gasket pressure; a safeguard pressure switch for water

supply and a safeguard pressure switch for compressed air supply;

Equipped with internal guides for any mobile load structures (optional).

The design pressure of the pressurized containers goes from vacuum to 3 bar relative.

16

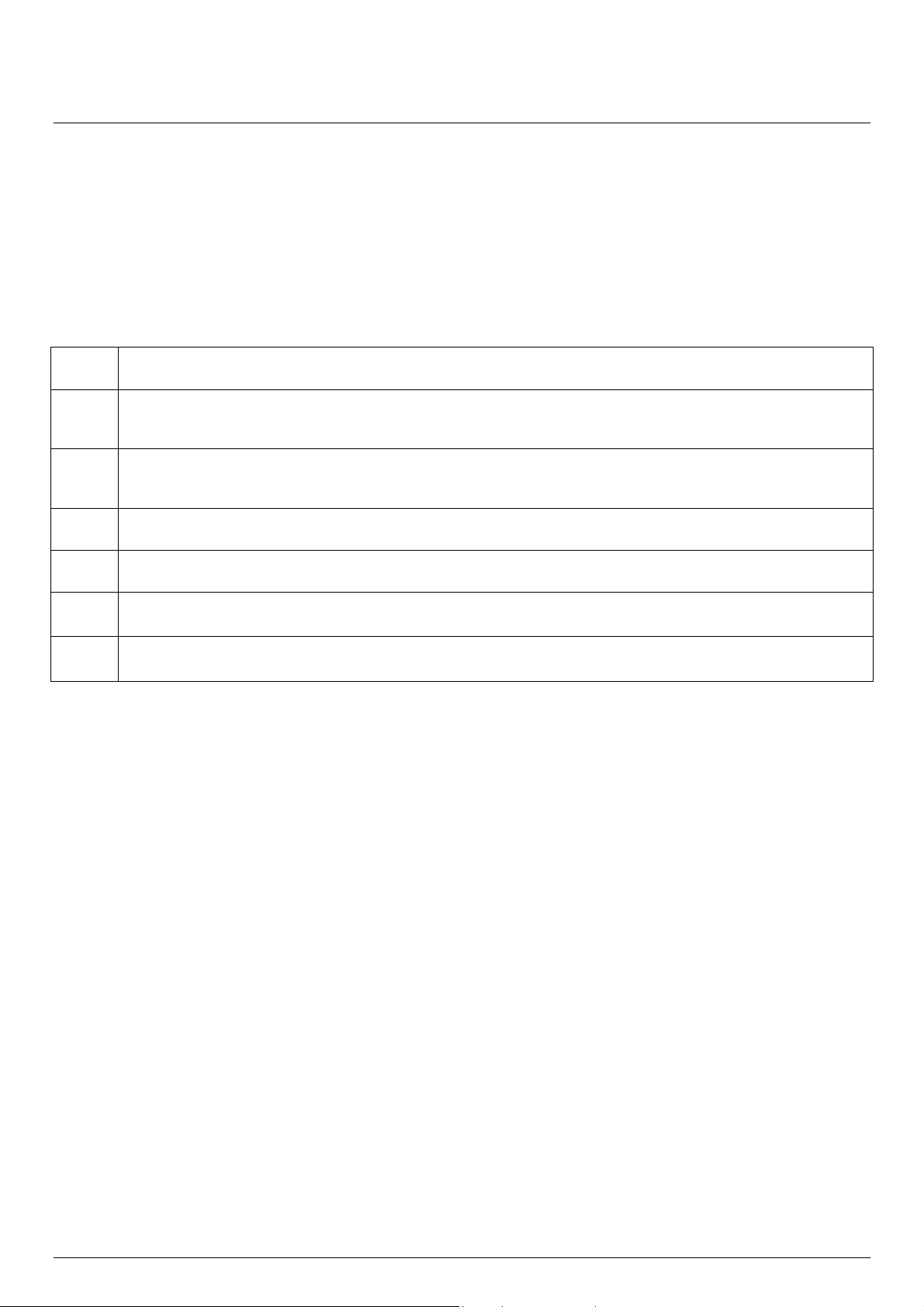

Sterilization chamber

Electrical panel

Technical compartment

containing the hydraulic system

Control panel

Steam generator

(only versions “E”, “I”, “EV” and “EI” )

Figure 1 –Main components

Upon the client's request at the moment of the order, the electrical panel, the technical compartment

containing the hydraulic system and the control panel can be installed on the left side of the sterilization

chamber instead of the right side.

For the smallest models, where the technical compartment is much smaller, the electrical panel may be

placed other than as illustrated.

17

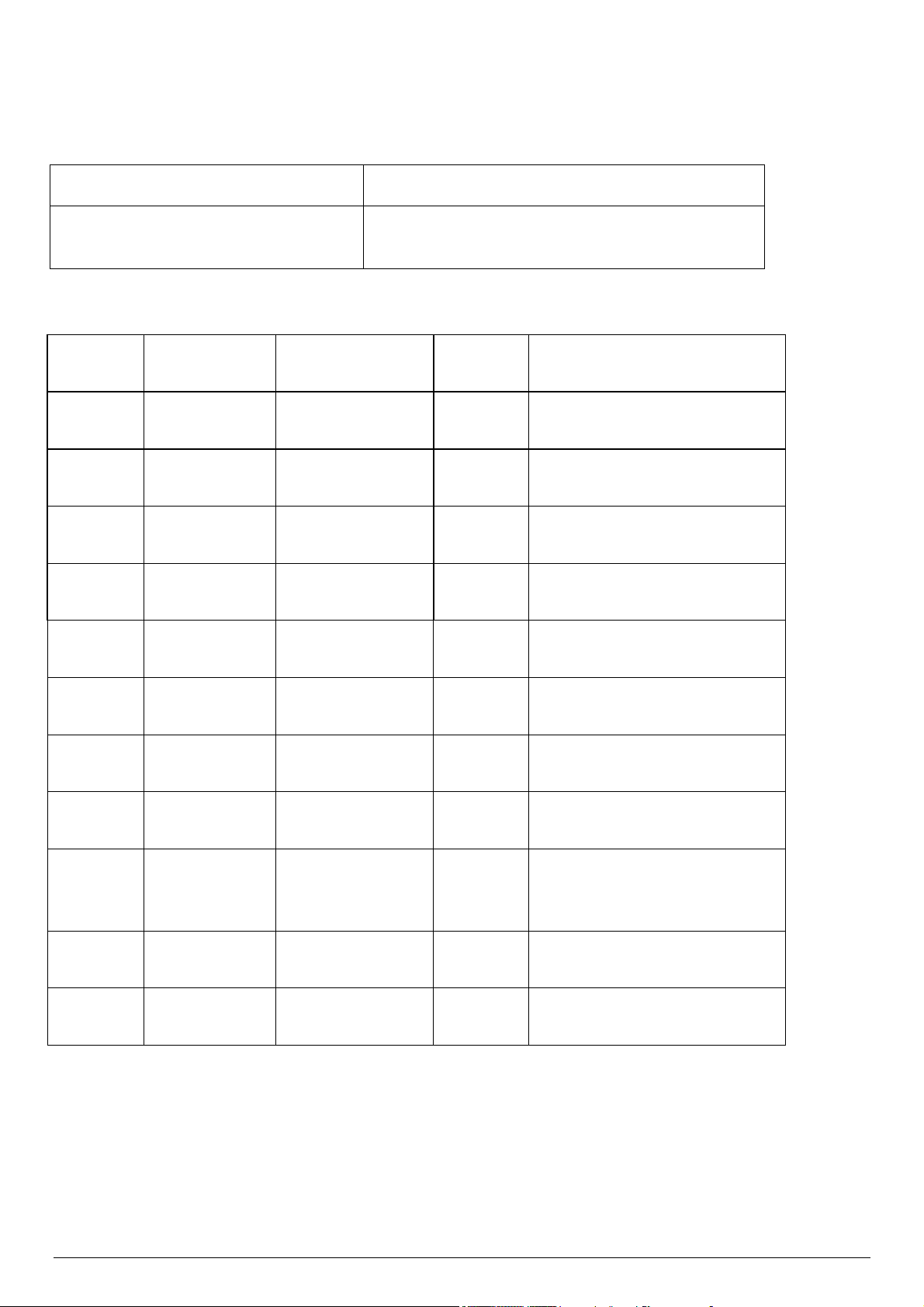

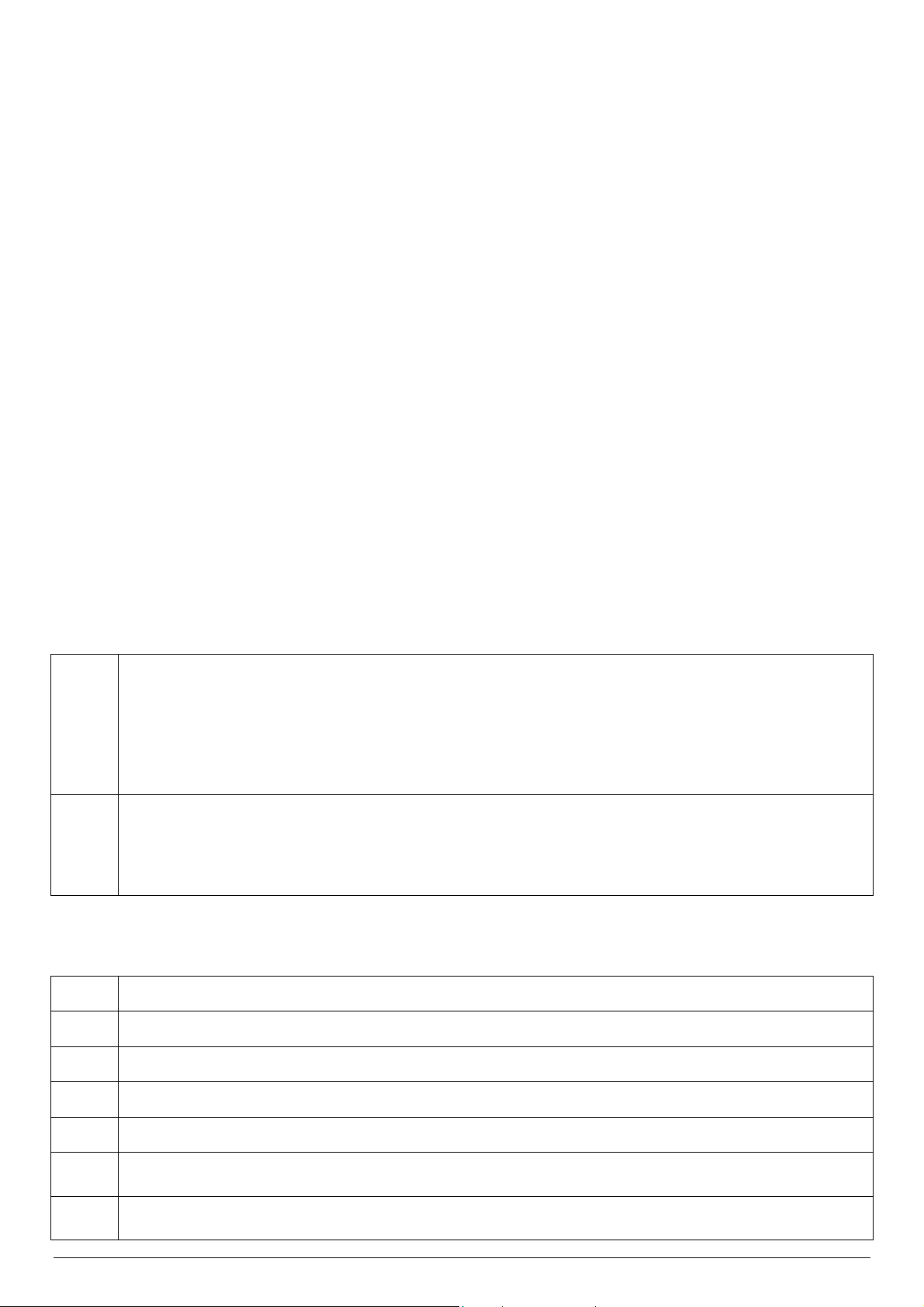

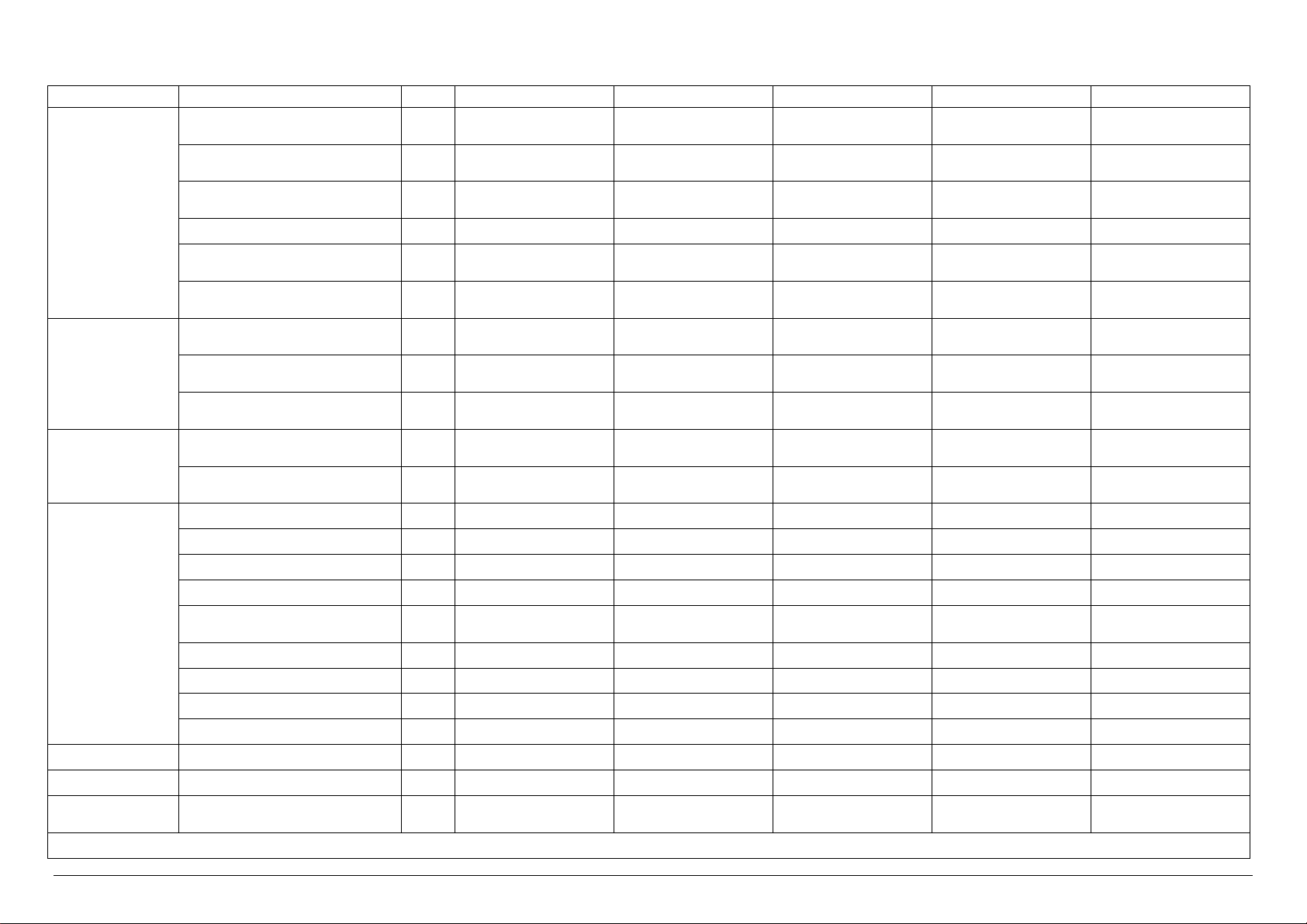

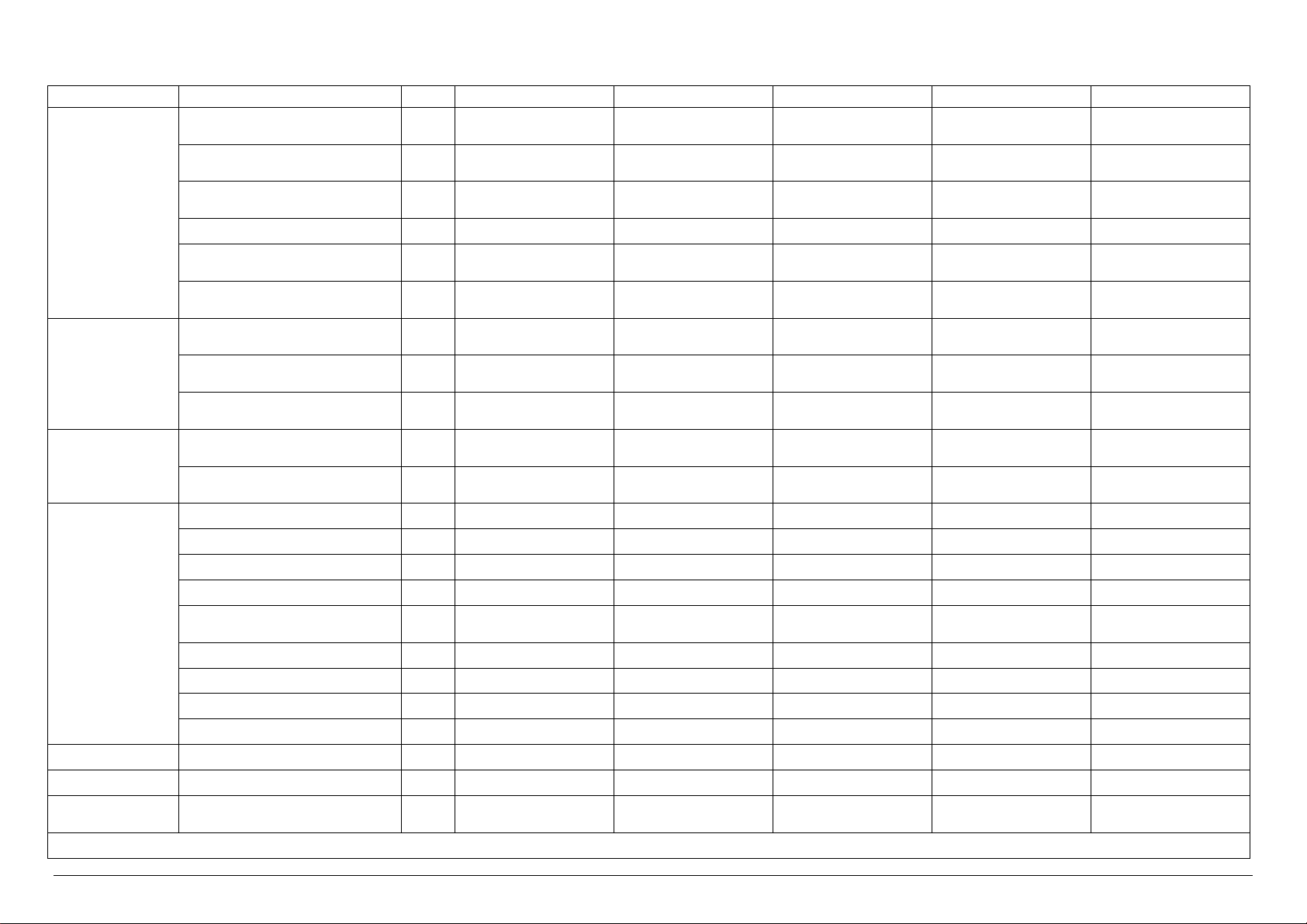

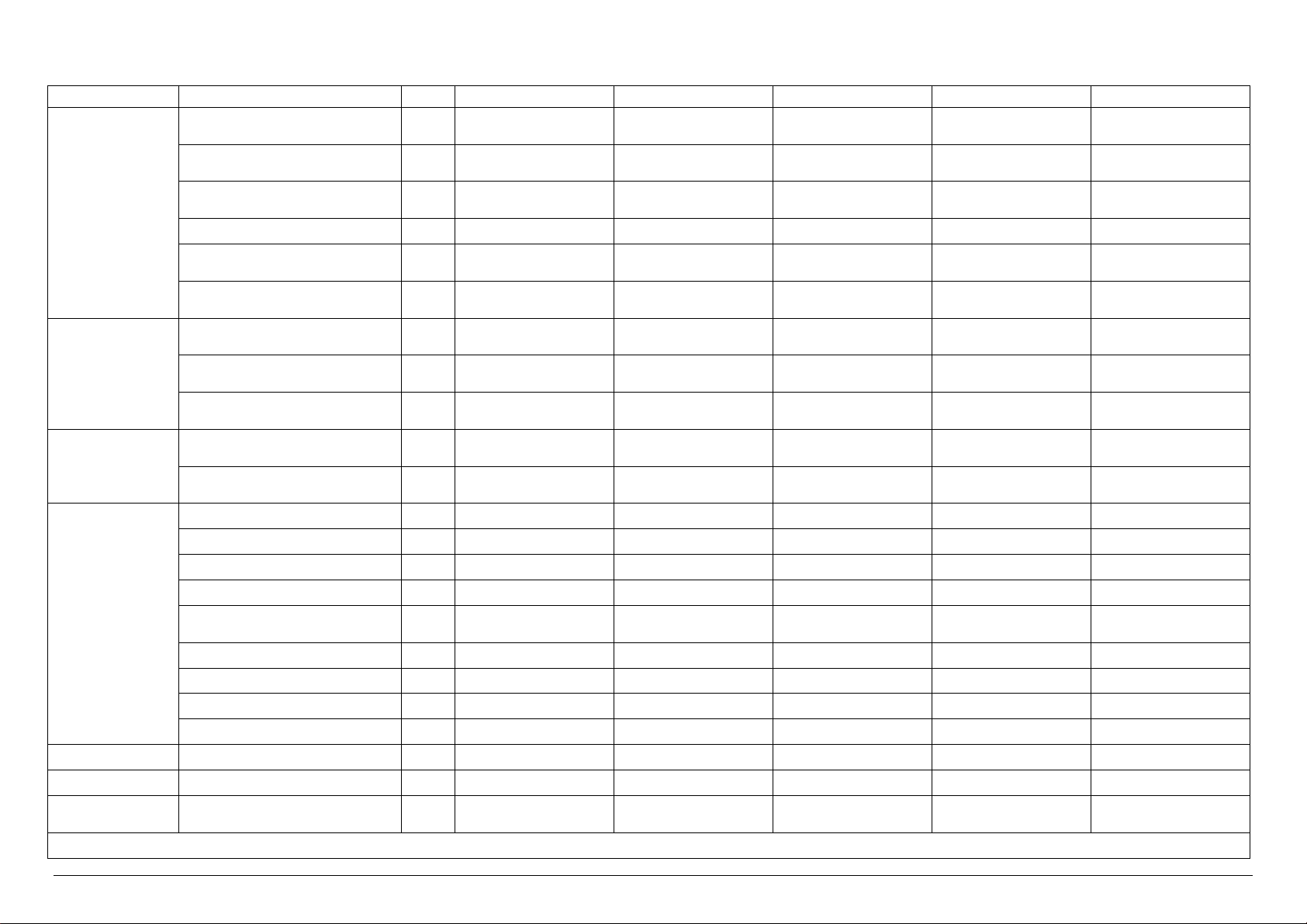

Technical characteristics of VS 1 VERSIONS

Chamber

dimensions

Footprint

dimensions

Weights

Connections

Electrical Power kW 14.0 2.0 2.0 14.0 14.0

Electrical Current A 20.0 5.0 5.0 20.0 20.0

Steam Consumption

* Upon the client’s request, it is possible to have the same models with power supply at 480V 3~ +T 60 Hz

MODEL

Width

Height

Depth

Sterilization Unit N° 1 1 1 1 1

Usable Volume

Total Volume

Width

Height

Depth

Net Weight

Hydraulic Test Weight

A-General Drain / 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32

B-Safety Valve Drain / n°3 Ø 18 n°3 Ø 18 n°3 Ø 18 n°3 Ø 18 n°3 Ø 18

C-Condensation Discharge / - - ½” male DN 15 - ½” male DN15

D-Steam Input / - ½” male DN 15 - ½” male DN15 -

E-Softened Water Input

Demi Water Input

F-Compressed Air Input / ¼” male ¼” male ¼” male ¼” male ¼” male

G-Power Supply / 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz*

H-City Water Input / ¾” male DN 20 ¾” male DN 20 ¾” male DN 20 ¾” male DN 20 ¾” male DN 20

I-Steam Input / - - ½” male DN 15 - ½” male DN15

U.M. VS1/1E VS1/1V VS1/1I VS1/1EV VS1/1EI

mm

inch

mm

inch

mm

inch

litres

Cft

litres

Cft

mm

inch

mm

inch

mm

inch

kg

lb

kg

lb

/ ¾” male DN20 - ¾” male DN 20 ¾” male DN 20 ¾” male DN 20

kg/h

lb/h

-

Ø 420.0

Ø 16.5

Ø 420.0

Ø 16.5

782.0

30.8

68.0

2.4

108.0

3.8

800.0

31.5

1700.0

66.9

1000.0

39.4

400.0

881.8

515.0

1135.4

Ø 420.0

Ø 16.5

Ø 420.0

Ø 16.5

782.0

30.8

68.0

2.4

108.0

3.8

800.0

31.5

1700.0

66.9

1000.0

39.4

357.0

787.0

473.0

1042.8

25.0

55.1

Ø 420.0

Ø 16.5

Ø 420.0

Ø 16.5

782.0

30.8

68.0

2.4

108.0

3.8

800.0

31.5

1700.0

66.9

1000.0

39.4

400.0

881.8

515.0

1135.4

30.0

60.1

Ø 420.0

Ø 16.5

Ø 420.0

Ø 16.5

782.0

30.8

68.0

2.4

108.0

3.8

800.0

31.5

1700.0

66.9

1000.0

39.4

400.0

881.8

515.0

1135.4

25.0

55.1

Ø 420.0

Ø 16.5

Ø 420.0

Ø 16.5

782.0

30.8

68.0

2.4

108.0

3.8

800.0

31.50

1700.0

66.9

1000.0

39.4

400.0

881.8

515.0

1135.4

30.0

60.1

18

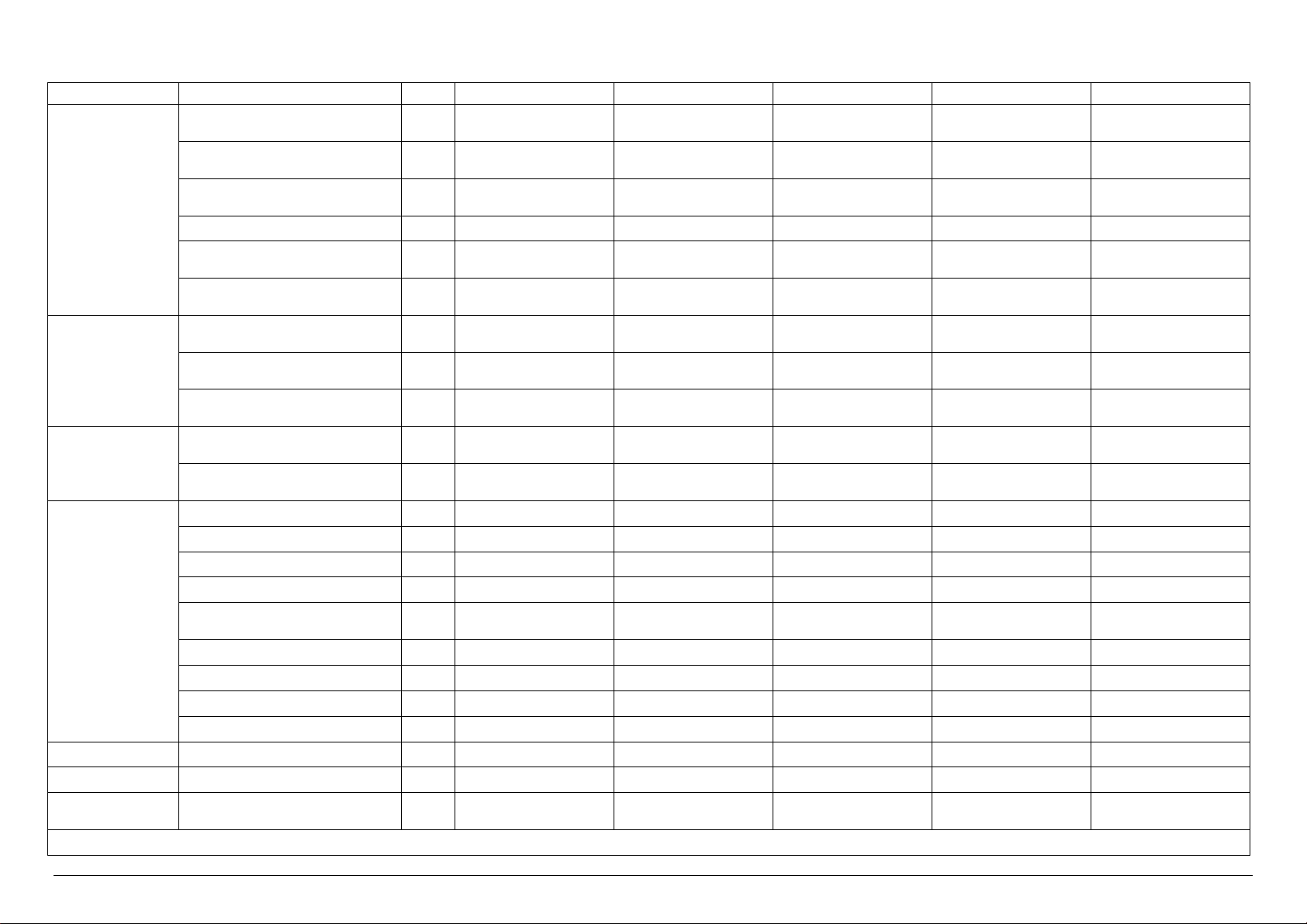

MODEL

Width

Height

Chamber

dimensions

Footprint

dimensions

Weights

Connections

Electrical Power kW 14.0 2.0 2.0 14.0 14.0

Electrical Current A 20.0 5.0 5.0 20.0 20.0

Steam Consumption

* Upon the client’s request, it is possible to have the same models with power supply at 480V 3~ +T 60 Hz

Depth

Sterilization Unit N° 1 1 1 1 1

Usable Volume

Total Volume

Width

Height

Depth

Net Weight

Hydraulic Test Weight

A-General Drain / 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32

B-Safety Valve Drain / n°3 Ø 18 n°3 Ø 18 n°3 Ø 18 n°3 Ø 18 n°3 Ø 18

C-Condensation Discharge / - - ½” male DN 15 - ½” male DN15

D-Steam Input / - ½” male DN 15 - ½” male DN15 -

E-Softened Water Input

Demi Water Input

F-Compressed Air Input / ¼” male ¼” male ¼” male ¼” male ¼” male

G-Power Supply / 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz*

H-City Water Input / ¾” male DN 20 ¾” male DN 20 ¾” male DN 20 ¾” male DN 20 ¾” male DN 20

I-Steam Input / - - ½” male DN 15 - ½” male DN15

U.M. VS1/2E VS1/2V VS1/2I VS1/2EV VS1/2EI

mm

inch

mm

inch

mm

inch

litres

Cft

litres

Cft

mm

inch

mm

inch

mm

inch

kg

lb

kg

lb

/ ¾” male DN20 - ¾” male DN 20 ¾” male DN 20 ¾” male DN 20

kg/h

lb/h

-

Ø 420.0

Ø 16.5

Ø 420.0

Ø 16.5

718.0

28.3

68.0

2.4

100.0

3.5

800.0

31.5

1700.0

67.0

1000.0

39.4

447.0

985.5

554.0

1221.4

Ø 420.0

Ø 16.5

Ø 420.0

Ø 16.5

718.0

28.3

68.0

2.4

100.0

3.5

800.0

31.5

1700.0

67.0

1000.0

39.4

404.0

890.7

512.0

1128.8

25.0

55.1

Ø 420.0

Ø 16.5

Ø 420.0

Ø 16.5

718.0

28.3

68.0

2.4

100.0

3.5

800.0

31.5

1700.0

67.0

1000.0

39.4

447.0

985.5

554.0

1221.4

30.0

60.1

Ø 420.0

Ø 16.5

Ø 420.0

Ø 16.5

718.0

28.3

68.0

2.4

100.0

3.5

800.0

31.5

1700.0

67.0

1000.0

39.4

447.0

985.5

554.0

1221.4

25.0

55.1

Ø 420.0

Ø 16.5

Ø 420.0

Ø 16.5

718.0

28.3

68.0

2.4

100.0

3.5

800.0

31.50

1700.0

67.0

1000.0

39.4

447.0

985.5

554.0

1221.4

30.0

60.1

19

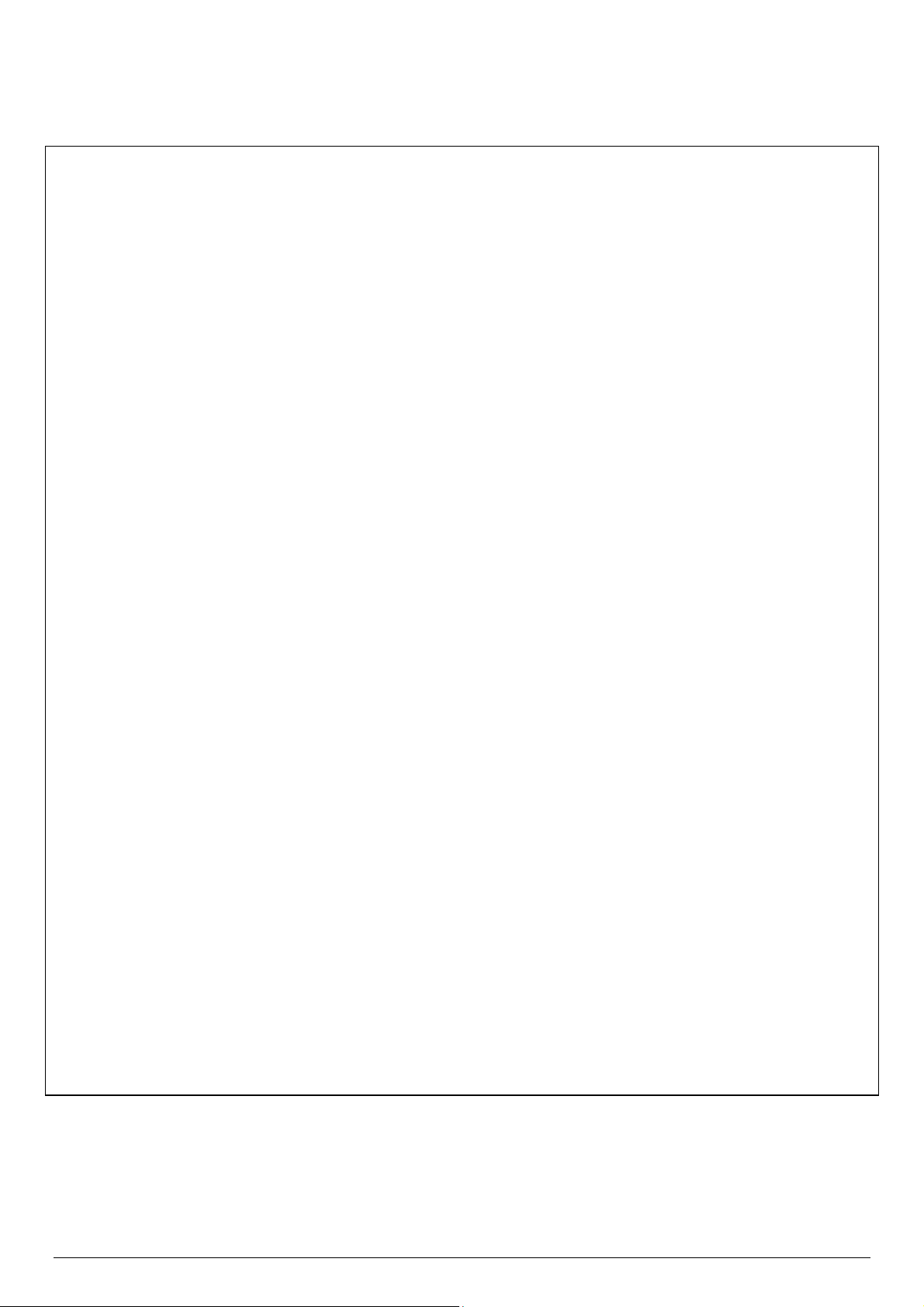

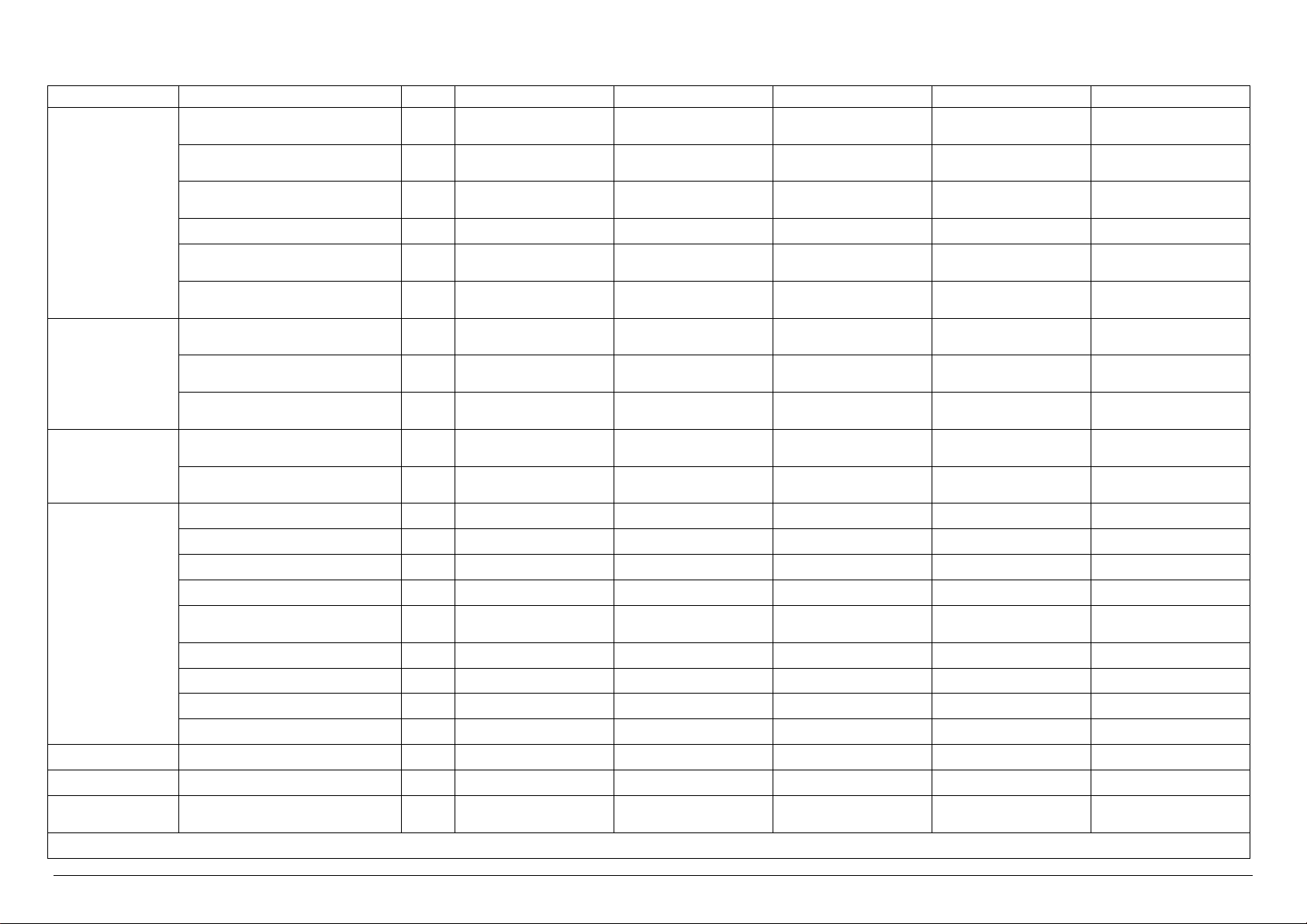

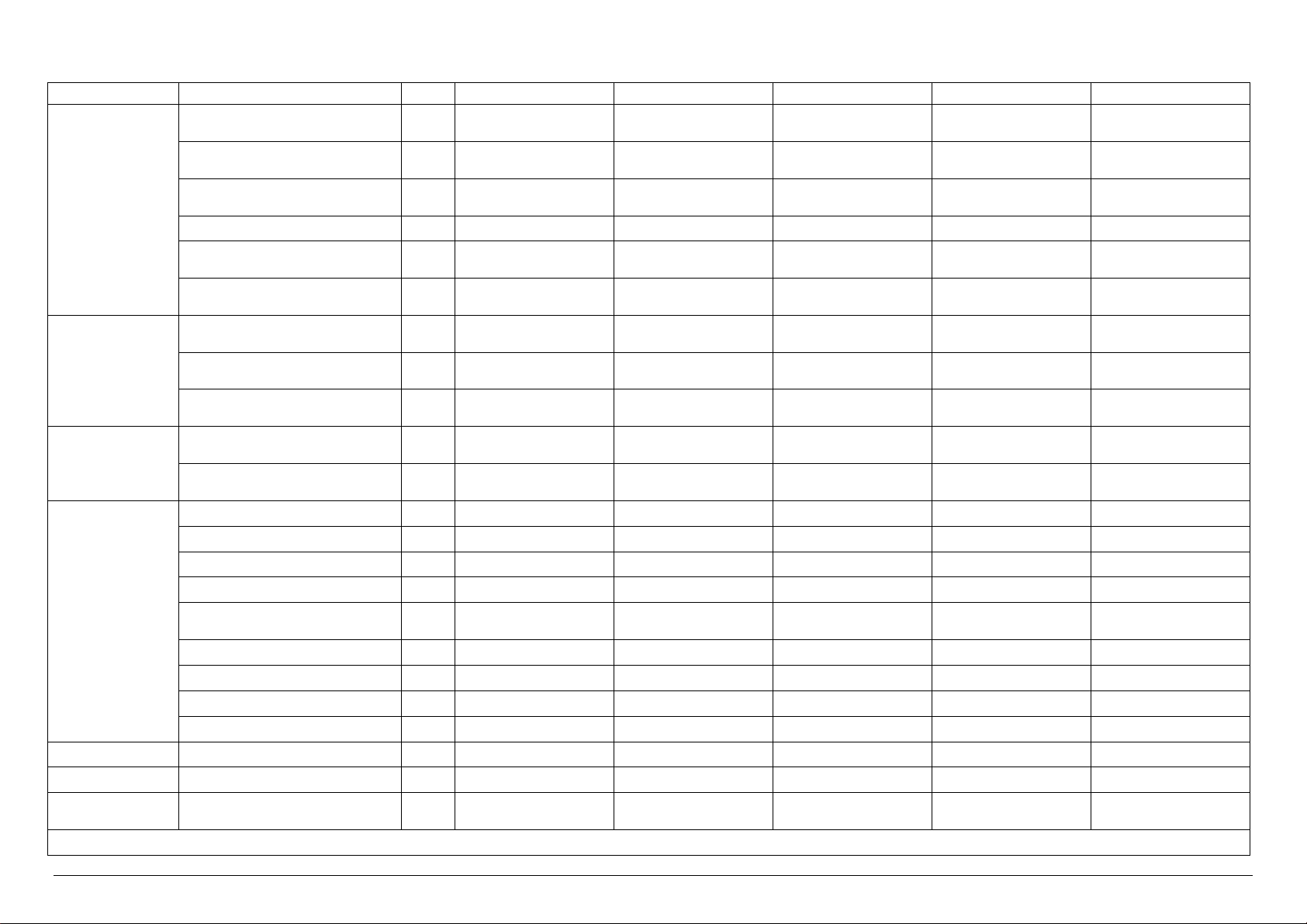

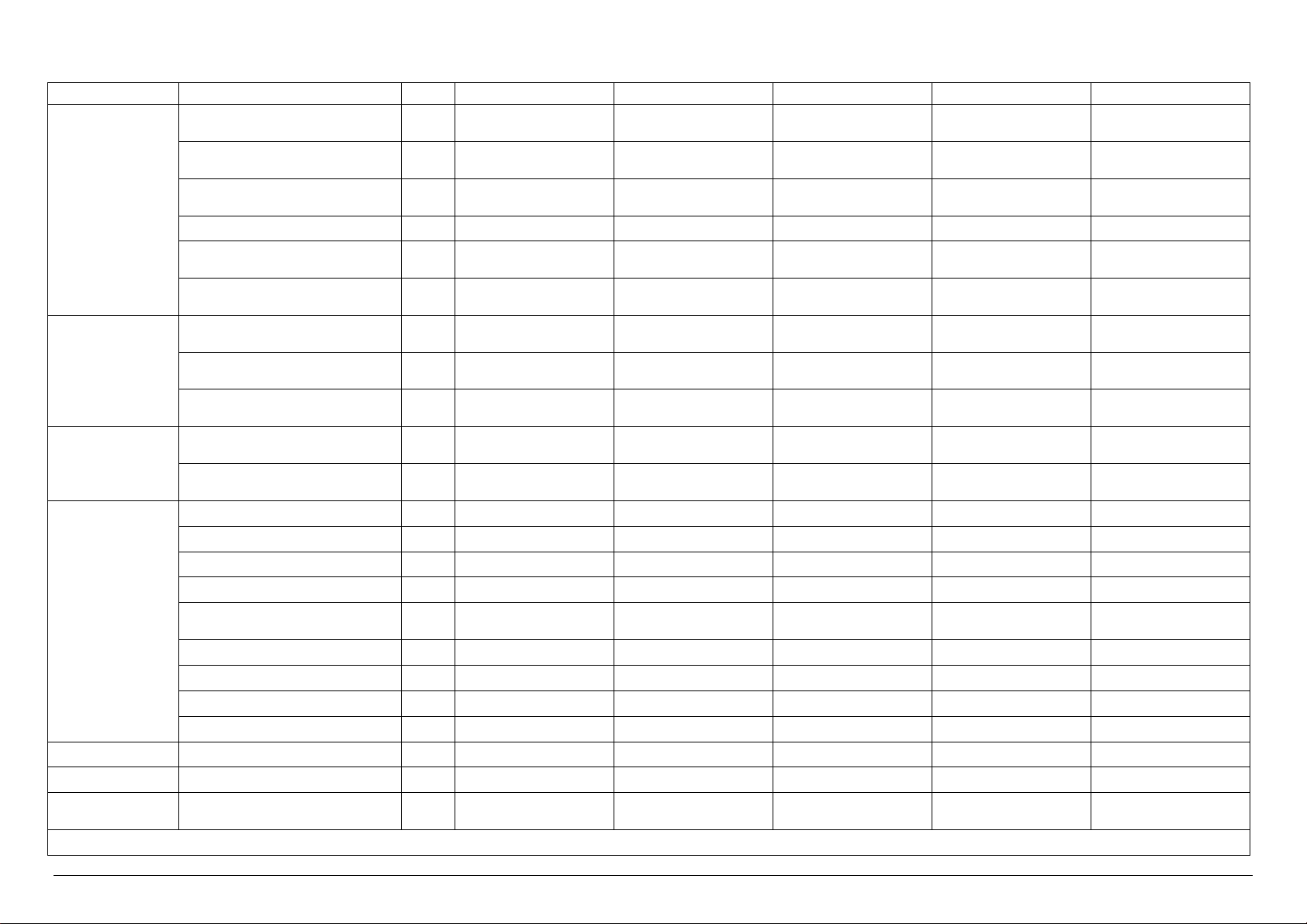

Technical characteristics of VS 1,5 VERSIONS

Chamber

dimensions

Footprint

dimensions

Weights

Connections

Electrical Power kW 14.0 2.0 2.0 14.0 14.0

Electrical Current A 20.0 5.0 5.0 20.0 20.0

Steam Consumption

* Upon the client’s request, it is possible to have the same models with power supply at 480V 3~ +T 60 Hz

MODEL

Width

Height

Depth

Sterilization Unit N° 1.5 1.5 1.5 1.5 1.5

Usable Volume

Total Volume

Width

Height

Depth

Net Weight

Hydraulic Test Weight

A-General Drain / 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32

B-Safety Valve Drain / n°3 Ø 18 n°3 Ø 18 n°3 Ø 18 n°3 Ø 18 n°3 Ø 18

C-Condensation Discharge / - - ½” male DN 15 - ½” male DN15

D-Steam Input / - ½” male DN 15 - ½” male DN15 -

E-Softened Water Input

Demi Water Input

F-Compressed Air Input / ¼” male ¼” male ¼” male ¼” male ¼” male

G-Power Supply / 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz*

H-City Water Input / ¾” male DN 20 ¾” male DN 20 ¾” male DN 20 ¾” male DN 20 ¾” male DN 20

I-Steam Input / - - ½” male DN 15 - ½” male DN15

U.M. VS1.5/1E VS1.5/1V VS1.5/1I VS1.5/1EV VS1.5/1EI

mm

inch

mm

inch

mm

inch

litres

Cft

litres

Cft

mm

inch

mm

inch

mm

inch

kg

lb

kg

lb

/ ¾” male DN20 - ¾” male DN 20 ¾” male DN 20 ¾” male DN 20

kg/h

lb/h

-

Ø 420.0

Ø 16.5

Ø 420.0

Ø 16.5

1082.0

42.6

96.0

3.4

150.0

5.3

800.0

31.5

1700.0

66.9

1300.0

51.2

450.0

992.1

612.0

1349.2

Ø 420.0

Ø 16.5

Ø 420.0

Ø 16.5

1082.0

42.6

96.0

3.4

150.0

5.3

800.0

31.5

1700.0

66.9

1300.0

51.2

407.0

897.3

569.0

1254.4

35.0

77.2

Ø 420.0

Ø 16.5

Ø 420.0

Ø 16.5

1082.0

42.6

96.0

3.4

150.0

5.3

800.0

31.5

1700.0

66.9

1300.0

51.2

450.0

992.1

612.0

1349.2

40.0

88.2

Ø 420.0

Ø 16.5

Ø 420.0

Ø 16.5

1082.0

42.6

96.0

3.4

150.0

5.3

800.0

31.5

1700.0

66.9

1300.0

51.2

450.0

992.1

612.0

1349.2

35.0

77.2

Ø 420.0

Ø 16.5

Ø 420.0

Ø 16.5

1082.0

42.6

96.0

3.4

150.0

5.3

800.0

31.50

1700.0

66.9

1300.0

51.2

450.0

992.1

612.0

1349.2

40.0

88.2

20

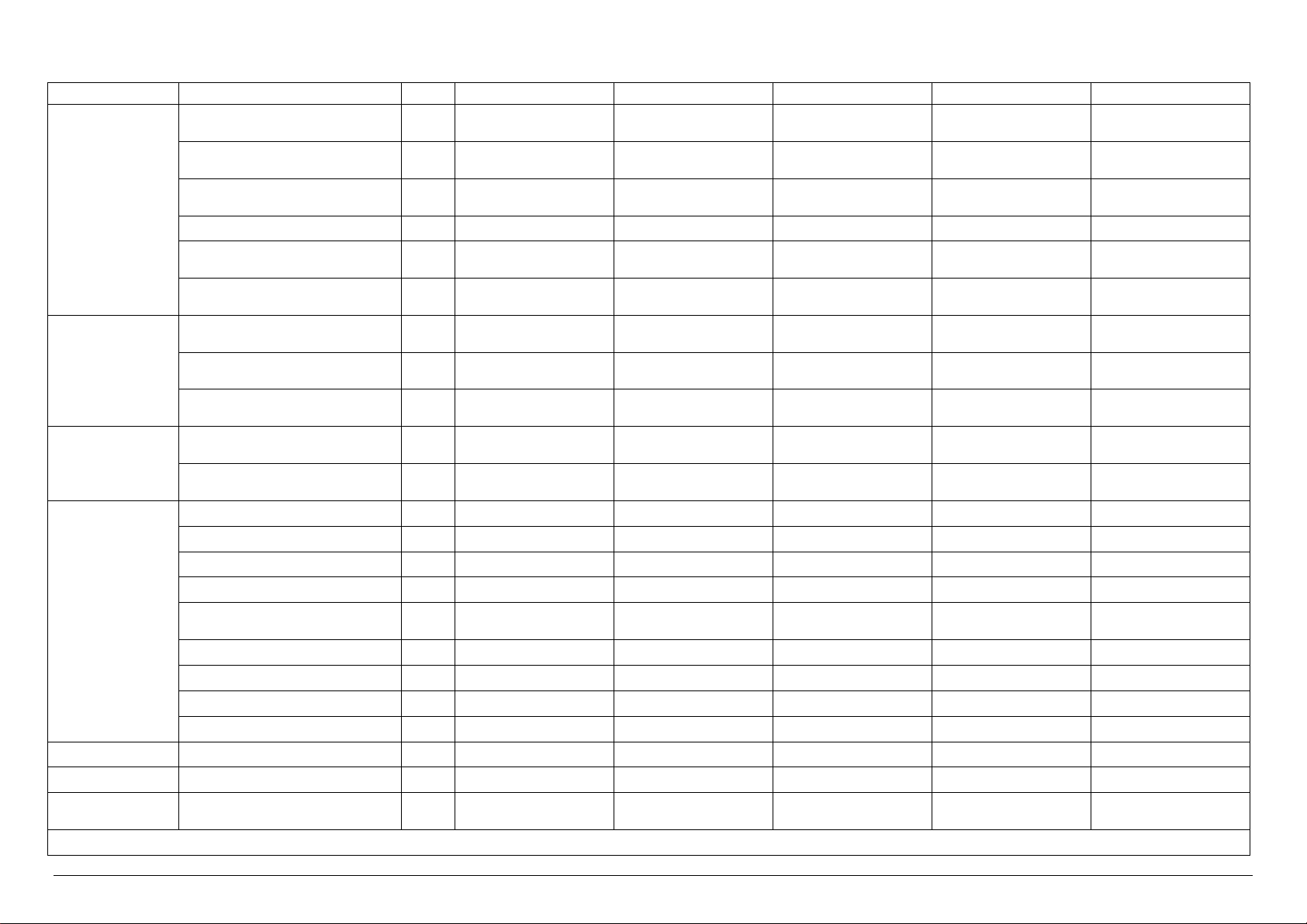

MODEL

Width

Height

Chamber

dimensions

Footprint

dimensions

Weights

Connections

Electrical Power kW 14.0 2.0 2.0 14.0 14.0

Electrical Current A 20.0 5.0 5.0 20.0 20.0

Steam Consumption

* Upon the client’s request, it is possible to have the same models with power supply at 480V 3~ +T 60 Hz

Depth

Sterilization Unit N° 1.5 1.5 1.5 1.5 1.5

Usable Volume

Total Volume

Width

Height

Depth

Net Weight

Hydraulic Test Weight

A-General Drain / 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32

B-Safety Valve Drain / n°3 Ø 18 n°3 Ø 18 n°3 Ø 18 n°3 Ø 18 n°3 Ø 18

C-Condensation Discharge / - - ½” male DN 15 - ½” male DN15

D-Steam Input / - ½” male DN 15 - ½” male DN15 -

E-Softened Water Input

Demi Water Input

F-Compressed Air Input / ¼” male ¼” male ¼” male ¼” male ¼” male

G-Power Supply / 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz*

H-City Water Input / ¾” male DN 20 ¾” male DN 20 ¾” male DN 20 ¾” male DN 20 ¾” male DN 20

I-Steam Input / - - ½” male DN 15 - ½” male DN15

U.M. VS1.5/2E VS1.5/2V VS1.5/2I VS1.5/2EV VS1.5/2EI

mm

inch

mm

inch

mm

inch

litres

Cft

litres

Cft

mm

inch

mm

inch

mm

inch

kg

lb

kg

lb

/ ¾” male DN20 - ¾” male DN 20 ¾” male DN 20 ¾” male DN 20

kg/h

lb/h

-

Ø 420.0

Ø 16.5

Ø 420.0

Ø 16.5

1018.0

40.1

96.0

3.4

141.0

5.0

800.0

31.5

1700.0

66.9

1300.0

51.2

497.0

1095.7

650.0

1433.0

Ø 420.0

Ø 16.5

Ø 420.0

Ø 16.5

1018.0

40.1

96.0

3.4

141.0

5.0

800.0

31.5

1700.0

66.9

1300.0

51.2

454.0

1000.9

607.0

1338.2

35.0

77.2

Ø 420.0

Ø 16.5

Ø 420.0

Ø 16.5

1018.0

40.1

96.0

3.4

141.0

5.0

800.0

31.5

1700.0

66.9

1300.0

51.2

497.0

1095.7

650.0

1433.0

40.0

88.2

Ø 420.0

Ø 16.5

Ø 420.0

Ø 16.5

1018.0

40.1

96.0

3.4

141.0

5.0

800.0

31.5

1700.0

66.9

1300.0

51.2

497.0

1095.7

650.0

1433.0

35.0

77.2

Ø 420.0

Ø 16.5

Ø 420.0

Ø 16.5

1018.0

40.1

96.0

3.4

141.0

5.0

800.0

31.50

1700.0

66.9

1300.0

51.2

497.0

1095.7

650.0

1433.0

40.0

88.2

21

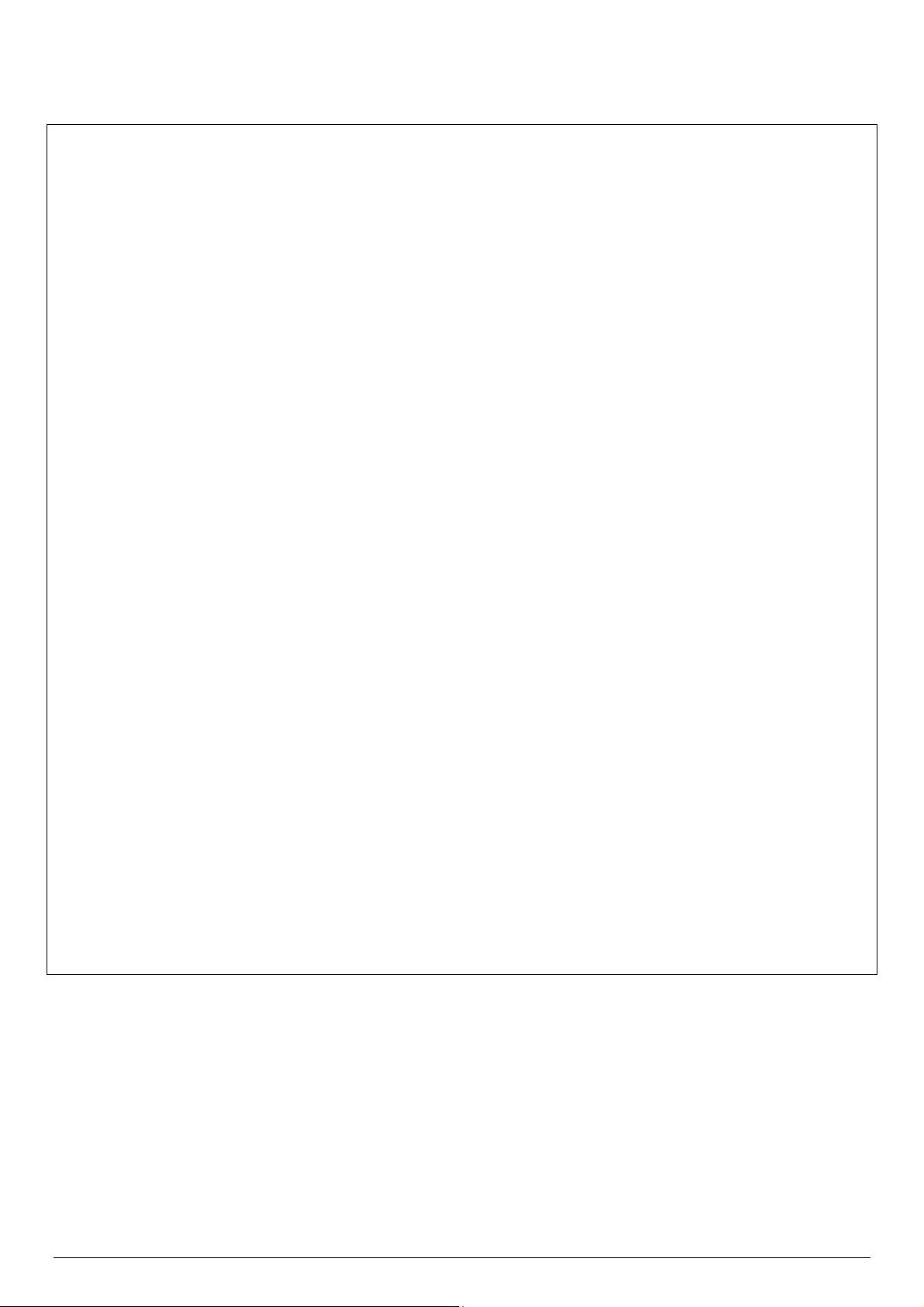

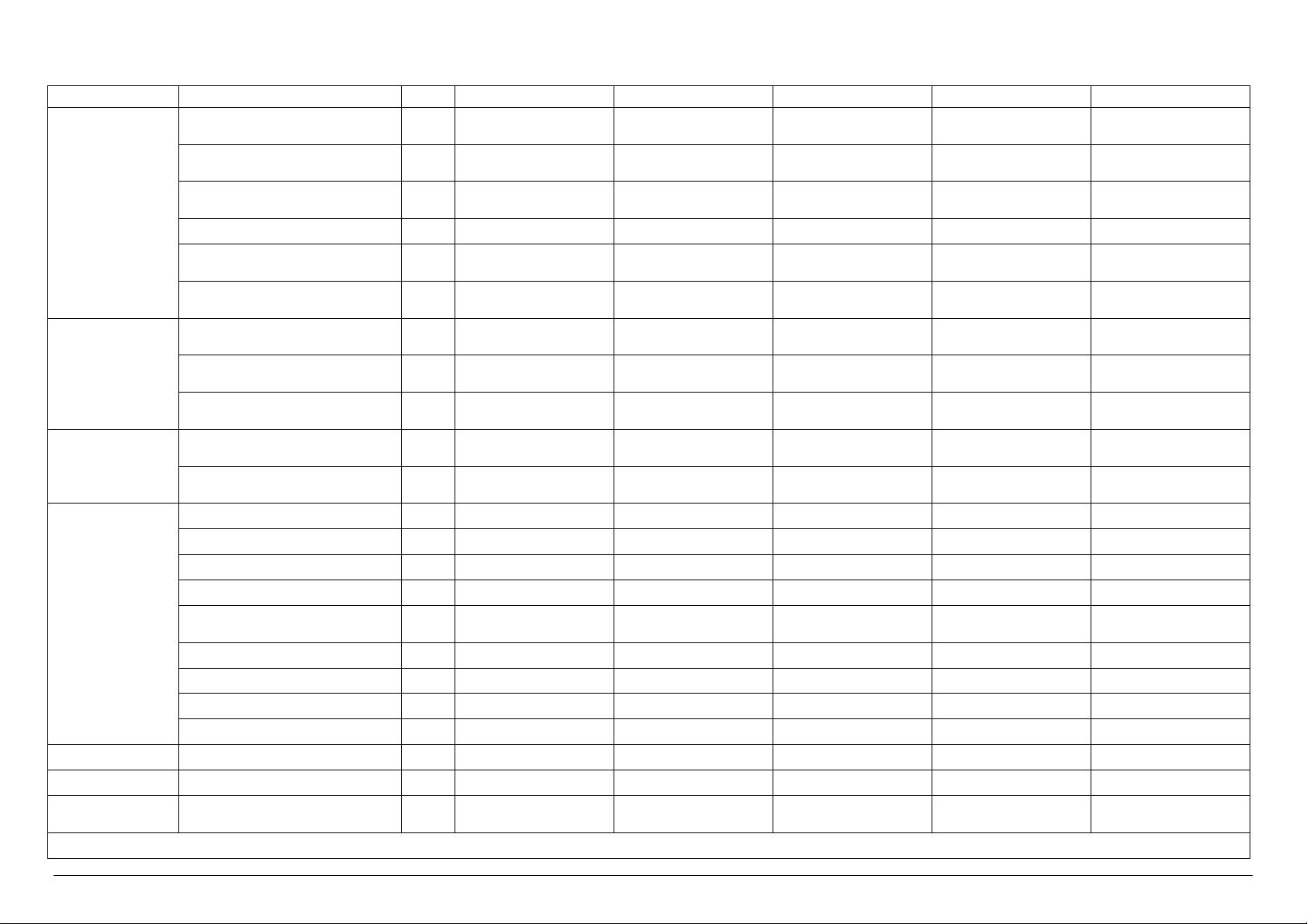

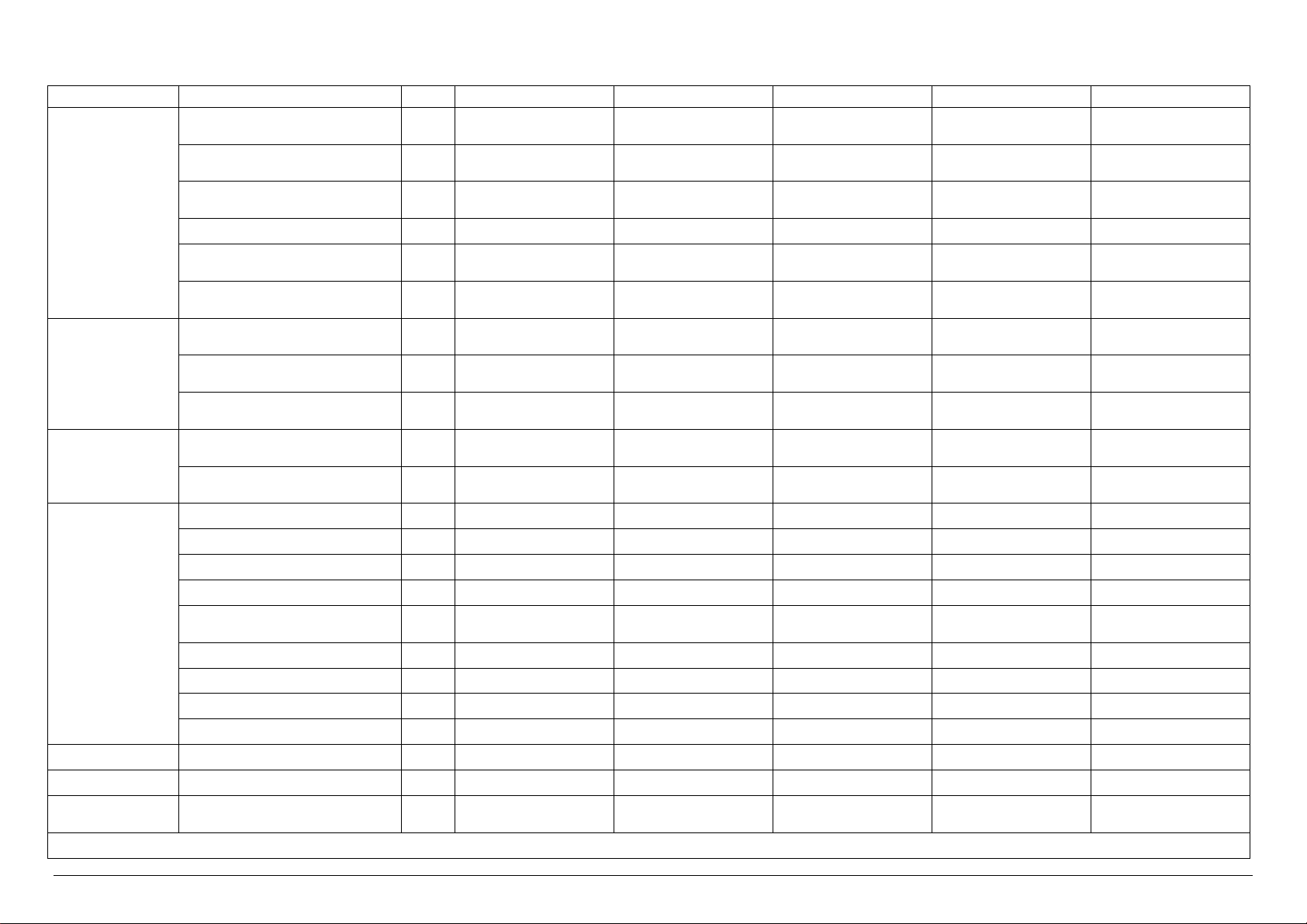

Technical characteristics of VS 2 VERSIONS

Chamber

dimensions

Footprint

dimensions

Weights

Connections

Electrical Power kW 26.0 2.0 26.0 26.0 26.0

Electrical Current A 41.5 5 5 41.5 41.5

Steam Consumption

* Upon the client’s request, it is possible to have the same models with power supply at 480V 3~ +T 60 Hz

MODEL

Width

Height

Depth

Sterilization Unit N° 2 2 2 2 2

Usable Volume

Total Volume

Width

Height

Depth

Net Weight

Hydraulic Test Weight

A-General Drain / 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32

B-Safety Valve Drain / n°3 Ø 18 n°3 Ø 18 n°3 Ø 18 n°3 Ø 18 n°3 Ø 18

C-Condensation Discharge / - - ½” male DN 15 - ½” male DN15

D-Steam Input / - ½” male DN 15 - ½” male DN15 -

E-Softened Water Input

Demi Water Input

F-Compressed Air Input / ¼” male ¼” male ¼” male ¼” male ¼” male

G-Power Supply / 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz*

H-City Water Input / ¾” male DN 20 ¾” male DN 20 ¾” male DN 20 ¾” male DN 20 ¾” male DN 20

I-Steam Input / - - ½” male DN 15 - ½” male DN15

U.M. VS2/1E VS2/1V VS2/1I VS2/1EV VS2/1EI

mm

inch

mm

inch

mm

inch

litres

Cft

litres

Cft

mm

inch

mm

inch

mm

inch

kg

lb

kg

lb

/ ¾” male DN20 - ¾” male DN 20 ¾” male DN 20 ¾” male DN 20

kg/h

lb/h

-

440.0

17.3

700.0

27.6

645.0

25.4

196.0

6.9

200.0

7.1

1000.0

39.4

1900.0

74.8

992.0

39.1

600.0

1322.8

800.0

1763.7

440.0

17.3

700.0

27.6

645.0

25.4

196.0

6.9

200.0

7.1

1000.0

39.4

1900.0

74.8

992.0

39.1

557.0

1228.0

757.0

1668.9

40.0

88.2

440.0

17.3

700.0

27.6

645.0

25.4

196.0

6.9

200.0

7.1

1000.0

39.4

1900.0

74.8

992.0

39.1

600.0

1322.8

800.0

1763.7

45.0

99.2

440.0

17.3

700.0

27.6

645.0

25.4

196.0

6.9

200.0

7.1

1000.0

39.4

1900.0

74.8

992.0

39.1

600.0

1322.8

800.0

1763.7

40.0

88.2

440.0

17.3

700.0

27.6

645.0

25.4

196.0

6.9

200.0

7.1

1000.0

39.4

1900.0

74.8

992.0

39.1

600.0

1322.8

800.0

1763.7

45.0

99.2

22

MODEL

Width

Height

Chamber

dimensions

Footprint

dimensions

Weights

Connections

Electrical Power kW 26.0 2.0 2.0 26.0 26.0

Electrical Current A 41.5 5.0 5.0 41.5 41.5

Steam Consumption

* Upon the client’s request, it is possible to have the same models with power supply at 480V 3~ +T 60 Hz

Depth

Sterilization Unit N° 2 2 2 2 2

Usable Volume

Total Volume

Width

Height

Depth

Net Weight

Hydraulic Test Weight

A-General Drain / 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32

B-Safety Valve Drain / n°3 Ø 18 n°3 Ø 18 n°3 Ø 18 n°3 Ø 18 n°3 Ø 18

C-Condensation Discharge / - - ½” male DN 15 - ½” male DN15

D-Steam Input / - ½” male DN 15 - ½” male DN15 -

E-Softened Water Input

Demi Water Input

F-Compressed Air Input / ¼” male ¼” male ¼” male ¼” male ¼” male

G-Power Supply / 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz*

H-City Water Input / ¾” male DN 20 ¾” male DN 20 ¾” male DN 20 ¾” male DN 20 ¾” male DN 20

I-Steam Input / - - ½” male DN 15 - ½” male DN15

U.M. VS2/2E VS2/2V VS2/2I VS2/2EV VS2/2EI

mm

inch

mm

inch

mm

inch

litres

Cft

litres

Cft

mm

inch

mm

inch

mm

inch

kg

lb

kg

lb

/ ¾” male DN20 - ¾” male DN 20 ¾” male DN 20 ¾” male DN 20

kg/h

lb/h

-

440.0

17.3

700.0

27.6

670.0

26.4

204.0

7.2

205.0

7.2

1000.0

39.4

1900.0

74.8

992.0

39.1

665.0

1466.1

870.0

1918.0

440.0

17.3

700.0

27.6

670.0

26.4

204.0

7.2

205.0

7.2

1000.0

39.4

1900.0

74.8

992.0

39.1

622.0

1371.3

827.0

1823.2

40.0

88.2

440.0

17.3

700.0

27.6

670.0

26.4

204.0

7.2

205.0

7.2

1000.0

39.4

1900.0

74.8

992.0

39.1

665.0

1466.1

870.0

1918.0

45.0

99.2

440.0

17.3

700.0

27.6

670.0

26.4

204.0

7.2

205.0

7.2

1000.0

39.4

1900.0

74.8

992.0

39.1

665.0

1466.1

870.0

1918.0

40.0

88.2

440.0

17.3

700.0

27.6

670.0

26.4

204.0

7.2

205.0

7.2

1000.0

39.4

1900.0

74.8

992.0

39.1

665.0

1466.1

870.0

1918.0

45.0

99.2

23

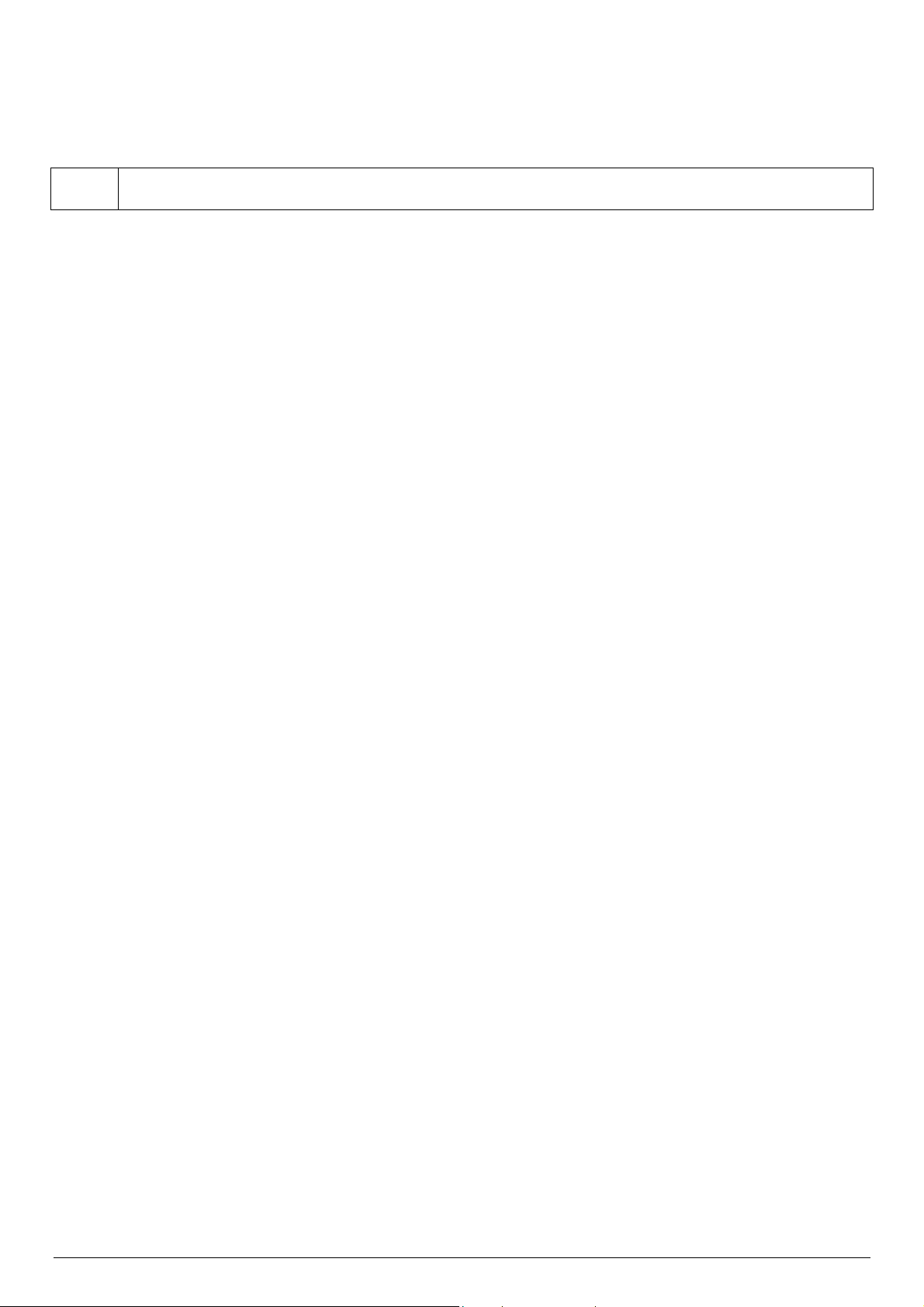

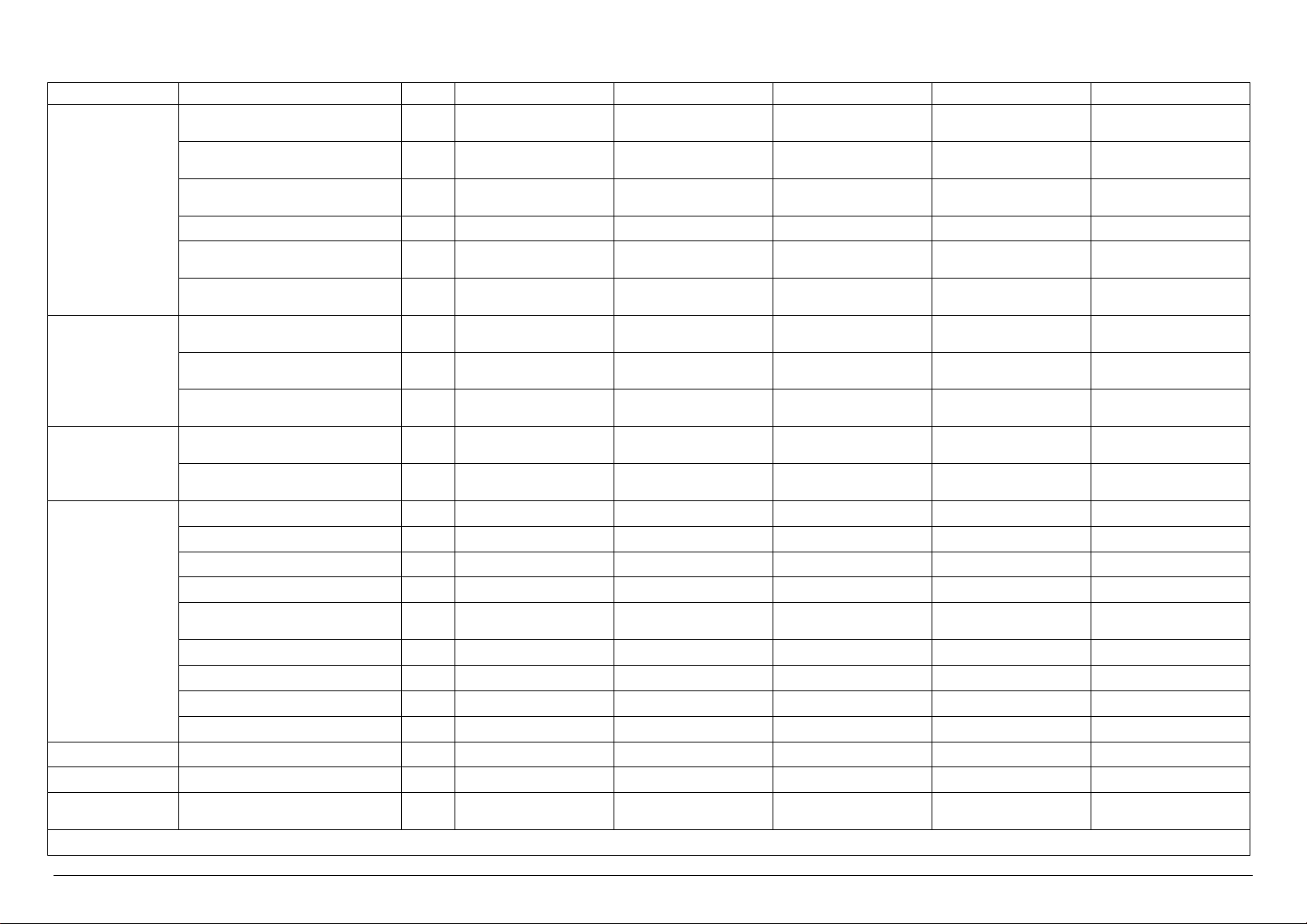

Technical characteristics of VS 3 VERSIONS

Chamber

dimensions

Footprint

dimensions

Weights

Connections

Electrical Power kW 34.0 2.0 34.0 34.0 34.0

Electrical Current A 50.0 5.0 5.0 50.0 50.0

Steam Consumption

* Upon the client’s request, it is possible to have the same models with power supply at 480V 3~ +T 60 Hz

MODEL

Width

Height

Depth

Sterilization Unit N° 3 3 3 3 3

Usable Volume

Total Volume

Width

Height

Depth

Net Weight

Hydraulic Test Weight

A-General Drain / 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32

B-Safety Valve Drain / n°3 Ø 18 n°3 Ø 18 n°3 Ø 18 n°3 Ø 18 n°3 Ø 18

C-Condensation Discharge / - - ½” male DN 15 - ½” male DN15

D-Steam Input / - ½” male DN 15 - ½” male DN15 -

E-Softened Water Input

Demi Water Input

F-Compressed Air Input / ¼” male ¼” male ¼” male ¼” male ¼” male

G-Power Supply / 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz*

H-City Water Input / ¾” male DN 20 ¾” male DN 20 ¾” male DN 20 ¾” male DN 20 ¾” male DN 20

I-Steam Input / - - ½” male DN 15 - ½” male DN15

U.M. VS3/1E VS3/1V VS3/1I VS3/1EV VS3/1EI

mm

inch

mm

inch

mm

inch

litres

Cft

litres

Cft

mm

inch

mm

inch

mm

inch

kg

lb

kg

lb

/ ¾” male DN20 - ¾” male DN 20 ¾” male DN 20 ¾” male DN 20

kg/h

lb/h

-

440.0

17.3

700.0

27.6

945.0

37.2

287.0

10.1

290.0

10.2

1000.0

39.4

1900.0

74.8

1292.0

50.9

750.0

1653.5

1040.0

2292.8

440.0

17.3

700.0

27.6

945.0

37.2

287.0

10.1

290.0

10.2

1000.0

39.4

1900.0

74.8

1292.0

50.9

707.0

1558.7

997.0

2198.0

45.0

99.2

440.0

17.3

700.0

27.6

945.0

37.2

287.0

10.1

290.0

10.2

1000.0

39.4

1900.0

74.8

1292.0

50.9

750.0

1653.5

1040.0

2292.8

60.0

132.3

440.0

17.3

700.0

27.6

945.0

37.2

287.0

10.1

290.0

10.2

1000.0

39.4

1900.0

74.8

1292.0

50.9

750.0

1653.5

1040.0

2292.8

45.0

99.2

440.0

17.3

700.0

27.6

945.0

37.2

287.0

10.1

290.0

10.2

1000.0

39.4

1900.0

74.8

1292.0

50.9

750.0

1653.5

1040.0

2292.8

60.0

132.3

24

MODEL

Width

Height

Chamber

dimensions

Footprint

dimensions

Weights

Connections

Electrical Power kW 34.0 2.0 2.0 34.0 34.0

Electrical Current A 50.0 5.0 5.0 50.0 50.0

Steam Consumption

* Upon the client’s request, it is possible to have the same models with power supply at 480V 3~ +T 60 Hz

Depth

Sterilization Unit N° 3 3 3 3 3

Usable Volume

Total Volume

Width

Height

Depth

Net Weight

Hydraulic Test Weight

A-General Drain / 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32

B-Safety Valve Drain / n°3 Ø 18 n°3 Ø 18 n°3 Ø 18 n°3 Ø 18 n°3 Ø 18

C-Condensation Discharge / - - ½” male DN 15 - ½” male DN15

D-Steam Input / - ½” male DN 15 - ½” male DN15 -

E-Softened Water Input

Demi Water Input

F-Compressed Air Input / ¼” male ¼” male ¼” male ¼” male ¼” male

G-Power Supply / 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz*

H-City Water Input / ¾” male DN 20 ¾” male DN 20 ¾” male DN 20 ¾” male DN 20 ¾” male DN 20

I-Steam Input / - - ½” male DN 15 - ½” male DN15

U.M. VS3/2E VS3/2V VS3/2I VS3/2EV VS3/2EI

mm

inch

mm

inch

mm

inch

litres

Cft

litres

Cft

mm

inch

mm

inch

mm

inch

kg

lb

kg

lb

/ ¾” male DN20 - ¾” male DN 20 ¾” male DN 20 ¾” male DN 20

kg/h

lb/h

-

440.0

17.3

700.0

27.6

970.0

38.2

295.0

10.4

300.0

10.6

1000.0

39.4

1900.0

74.8

1292.0

50.9

815.0

1796.8

1115.0

2458.2

440.0

17.3

700.0

27.6

970.0

38.2

295.0

10.4

300.0

10.6

1000.0

39.4

1900.0

74.8

1292.0

50.9

772.0

1702.0

1073.0

2365.6

45.0

99.2

440.0

17.3

700.0

27.6

970.0

38.2

295.0

10.4

300.0

10.6

1000.0

39.4

1900.0

74.8

1292.0

50.9

815.0

1796.8

1115.0

2458.2

60.0

132.3

440.0

17.3

700.0

27.6

970.0

38.2

295.0

10.4

300.0

10.6

1000.0

39.4

1900.0

74.8

1292.0

50.9

815.0

1796.8

1115.0

2458.2

45.0

99.2

440.0

17.3

700.0

27.6

970.0

38.2

295.0

10.4

300.0

10.6

1000.0

39.4

1900.0

74.8

1292.0

50.9

815.0

1796.8

1115.0

2458.2

60.0

132.3

25

Technical characteristics of VS 4 VERSIONS

Chamber

dimensions

Footprint

dimensions

Weights

Connections

Electrical Power kW 34.0 2.0 2.0 34.0 34.0

Electrical Current A 50.0 5.0 5.0 50.0 50.0

Steam Consumption

* Upon the client’s request, it is possible to have the same models with power supply at 480V 3~ +T 60 Hz

MODEL

Width

Height

Depth

Sterilization Unit N° 4 4 4 4 4

Usable Volume

Total Volume

Width

Height

Depth

Net Weight

Hydraulic Test Weight

A-General Drain / 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32

B-Safety Valve Drain / n°3 Ø 18 n°3 Ø 18 n°3 Ø 18 n°3 Ø 18 n°3 Ø 18

C-Condensation Discharge / - - ½” male DN 15 - ½” male DN15

D-Steam Input / - ½” male DN 15 - ½” male DN15 -

E-Softened Water Input

Demi Water Input

F-Compressed Air Input / ¼” male ¼” male ¼” male ¼” male ¼” male

G-Power Supply / 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz*

H-City Water Input / ¾” male DN 20 ¾” male DN 20 ¾” male DN 20 ¾” male DN 20 ¾” male DN 20

I-Steam Input / - - ½” male DN 15 - ½” male DN15

U.M. VS4/1E VS4/1V VS4/1I VS4/1EV VS4/1EI

mm

inch

mm

inch

mm

inch

litres

Cft

litres

Cft

mm

inch

mm

inch

mm

inch

kg

lb

kg

lb

/ ¾” male DN20 - ¾” male DN 20 ¾” male DN 20 ¾” male DN 20

kg/h

lb/h

-

670.0

26.4

700.0

27.6

686.0

27.0

319.0

11.3

322.0

11.4

1250.0

49.2

1900.0

74.8

992.0

39.1

675.0

1488.1

995.0

2193.6

670.0

26.4

700.0

27.6

686.0

27.0

319.0

11.3

322.0

11.4

1250.0

49.2

1900.0

74.8

992.0

39.1

630.0

1388.9

955.0

2105.4

45.0

99.2

670.0

26.4

700.0

27.6

686.0

27.0

319.0

11.3

322.0

11.4

1250.0

49.2

1900.0

74.8

992.0

39.1

675.0

1488.1

995.0

2193.6

60.0

132.3

670.0

26.4

700.0

27.6

686.0

27.0

319.0

11.3

322.0

11.4

1250.0

49.2

1900.0

74.8

992.0

39.1

675.0

1488.1

995.0

2193.6

45.0

99.2

670.0

26.4

700.0

27.6

686.0

27.0

319.0

11.3

322.0

11.4

1250.0

49.2

1900.0

74.8

992.0

39.1

675.0

1488.1

995.0

2193.6

60.0

132.3

26

MODEL

Width

Height

Chamber

dimensions

Footprint

dimensions

Weights

Connections

Electrical Power kW 34.0 2.0 2.0 34.0 34.0

Electrical Current A 50.0 5.0 5.0 50.0 50.0

Steam Consumption

* Upon the client’s request, it is possible to have the same models with power supply at 480V 3~ +T 60 Hz

Depth

Sterilization Unit N° 4 4 4 4 4

Usable Volume

Total Volume

Width

Height

Depth

Net Weight

Hydraulic Test Weight

A-General Drain / 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32

B-Safety Valve Drain / n°3 Ø 18 n°3 Ø 18 n°3 Ø 18 n°3 Ø 18 n°3 Ø 18

C-Condensation Discharge / - - ½” male DN 15 - ½” male DN15

D-Steam Input / - ½” male DN 15 - ½” male DN15 -

E-Softened Water Input

Demi Water Input

F-Compressed Air Input / ¼” male ¼” male ¼” male ¼” male ¼” male

G-Power Supply / 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz*

H-City Water Input / ¾” male DN 20 ¾” male DN 20 ¾” male DN 20 ¾” male DN 20 ¾” male DN 20

I-Steam Input / - - ½” male DN 15 - ½” male DN15

U.M. VS4/2E VS4/2V VS4/2I VS4/2EV VS4/2EI

mm

inch

mm

inch

mm

inch

litres

Cft

litres

Cft

mm

inch

mm

inch

mm

inch

kg

lb

kg

lb

/ ¾” male DN20 - ¾” male DN 20 ¾” male DN 20 ¾” male DN 20

kg/h

lb/h

-

670.0

26.4

700.0

27.6

710.0

28.0

330.0

11.7

333.0

11.8

1250.0

49.2

1900.0

74.8

992.0

39.1

750.0

1653.5

1085.0

2392.0

670.0

26.4

700.0

27.6

710.0

28.0

330.0

11.7

333.0

11.8

1250.0

49.2

1900.0

74.8

992.0

39.1

705.0

1554.3

1040.0

2292.8

45.0

99.2

670.0

26.4

700.0

27.6

710.0

28.0

330.0

11.7

333.0

11.8

1250.0

49.2

1900.0

74.8

992.0

39.1

750.0

1653.5

1085.0

2392.0

60.0

132.3

670.0

26.4

700.0

27.6

710.0

28.0

330.0

11.7

333.0

11.8

1250.0

49.2

1900.0

74.8

992.0

39.1

750.0

1653.5

1085.0

2392.0

45.0

99.2

670.0

26.4

700.0

27.6

710.0

28.0

330.0

11.7

333.0

11.8

1250.0

49.2

1900.0

74.8

992.0

39.1

750.0

1653.5

1085.0

2392.0

60.0

132.3

27

Technical characteristics of VS 6 VERSIONS

Chamber

dimensions

Footprint

dimensions

Weights

Connections

Electrical Power kW 50.5 2.5 2.5 50.5 50.5

Electrical Current A 75.0 5.0 5.0 75.0 75.0

Steam Consumption

* Upon the client’s request, it is possible to have the same models with power supply at 480V 3~ +T 60 Hz

MODEL

Width

Height

Depth

Sterilization Unit N° 6 6 6 6 6

Usable Volume

Total Volume

Width

Height

Depth

Net Weight

Hydraulic Test Weight

A-General Drain / 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32

B-Safety Valve Drain / n°3 Ø 18 n°3 Ø 18 n°3 Ø 18 n°3 Ø 18 n°3 Ø 18

C-Condensation Discharge / - - ½” male DN 15 - ½” male DN15

D-Steam Input / - ½” male DN 15 - ½” male DN15 -

E-Softened Water Input

Demi Water Input

F-Compressed Air Input / ¼” male ¼” male ¼” male ¼” male ¼” male

G-Power Supply / 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz*

H-City Water Input / ¾” male DN 20 ¾” male DN 20 ¾” male DN 20 ¾” male DN 20 ¾” male DN 20

I-Steam Input / - - ½” male DN 15 - ½” male DN15

U.M. VS6/1E VS6/1V VS6/1I VS6/1EV VS6/1EI

mm

inch

mm

inch

mm

inch

litres

Cft

litres

Cft

mm

inch

mm

inch

mm

inch

kg

lb

kg

lb

/ ¾” male DN20 - ¾” male DN 20 ¾” male DN 20 ¾” male DN 20

kg/h

lb/h

-

670.0

26.4

700.0

27.6

986.0

38.8

458.0

16.2

462.0

16.3

1100.0

43.3

1900.0

74.8

1292.0

50.9

835.0

1840.9

1300.0

2866.0

670.0

26.4

700.0

27.6

986.0

38.8

458.0

16.2

462.0

16.3

1100.0

43.3

1900.0

74.8

1292.0

50.9

780.0

1719.6

1180.0

2601.5

60.0

132.3

670.0

26.4

700.0

27.6

986.0

38.8

458.0

16.2

462.0

16.3

1100.0

43.3

1900.0

74.8

1292.0

50.9

835.0

1840.9

1300.0

2866.0

75.0

165.4

670.0

26.4

700.0

27.6

986.0

38.8

458.0

16.2

462.0

16.3

1100.0

43.3

1900.0

74.8

1292.0

50.9

835.0

1840.9

1300.0

2866.0

60.0

132.3

670.0

26.4

700.0

27.6

986.0

38.8

458.0

16.2

462.0

16.3

1100.0

43.3

1900.0

74.8

1292.0

50.9

835.0

1840.9

1300.0

2866.0

75.0

165.4

28

MODEL

Width

Height

Chamber

dimensions

Footprint

dimensions

Weights

Connections

Electrical Power kW 50.5 2.5 2.5 50.5 50.5

Electrical Current A 75.0 5.0 5.0 75.0 75.0

Steam Consumption

* Upon the client’s request, it is possible to have the same models with power supply at 480V 3~ +T 60 Hz

Depth

Sterilization Unit N° 6 6 6 6 6

Usable Volume

Total Volume

Width

Height

Depth

Net Weight

Hydraulic Test Weight

A-General Drain / 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32

B-Safety Valve Drain / n°3 Ø 18 n°3 Ø 18 n°3 Ø 18 n°3 Ø 18 n°3 Ø 18

C-Condensation Discharge / - - ½” male DN 15 - ½” male DN15

D-Steam Input / - ½” male DN 15 - ½” male DN15 -

E-Softened Water Input

Demi Water Input

F-Compressed Air Input / ¼” male ¼” male ¼” male ¼” male ¼” male

G-Power Supply / 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz*

H-City Water Input / ¾” male DN 20 ¾” male DN 20 ¾” male DN 20 ¾” male DN 20 ¾” male DN 20

I-Steam Input / - - ½” male DN 15 - ½” male DN15

U.M. VS6/2E VS6/2V VS6/2I VS6/2EV VS6/2EI

mm

inch

mm

inch

mm

inch

litres

Cft

litres

Cft

mm

inch

mm

inch

mm

inch

kg

lb

kg

lb

/ ¾” male DN20 - ¾” male DN 20 ¾” male DN 20 ¾” male DN 20

kg/h

lb/h

-

670.0

26.4

700.0

27.6

1010.0

39.8

470.0

16.6

474.0

16.7

1100.0

43.3

1900.0

74.8

1292.0

50.9

910.0

2006.2

1385.0

3053.4

670.0

26.4

700.0

27.6

1010.0

39.8

470.0

16.6

474.0

16.7

1100.0

43.3

1900.0

74.8

1292.0

50.9

855.0

1885.0

1330.0

2932.1

60.0

132.3

670.0

26.4

700.0

27.6

1010.0

39.8

470.0

16.6

474.0

16.7

1100.0

43.3

1900.0

74.8

1292.0

50.9

910.0

2006.2

1385.0

3053.4

75.0

165.4

670.0

26.4

700.0

27.6

1010.0

39.8

470.0

16.6

474.0

16.7

1100.0

43.3

1900.0

74.8

1292.0

50.9

910.0

2006.2

1385.0

3053.4

60.0

132.3

670.0

26.4

700.0

27.6

1010.0

39.8

470.0

16.6

474.0

16.7

1100.0

43.3

1900.0

74.8

1292.0

50.9

910.0

2006.2

1385.0

3053.4

75.0

165.4

29

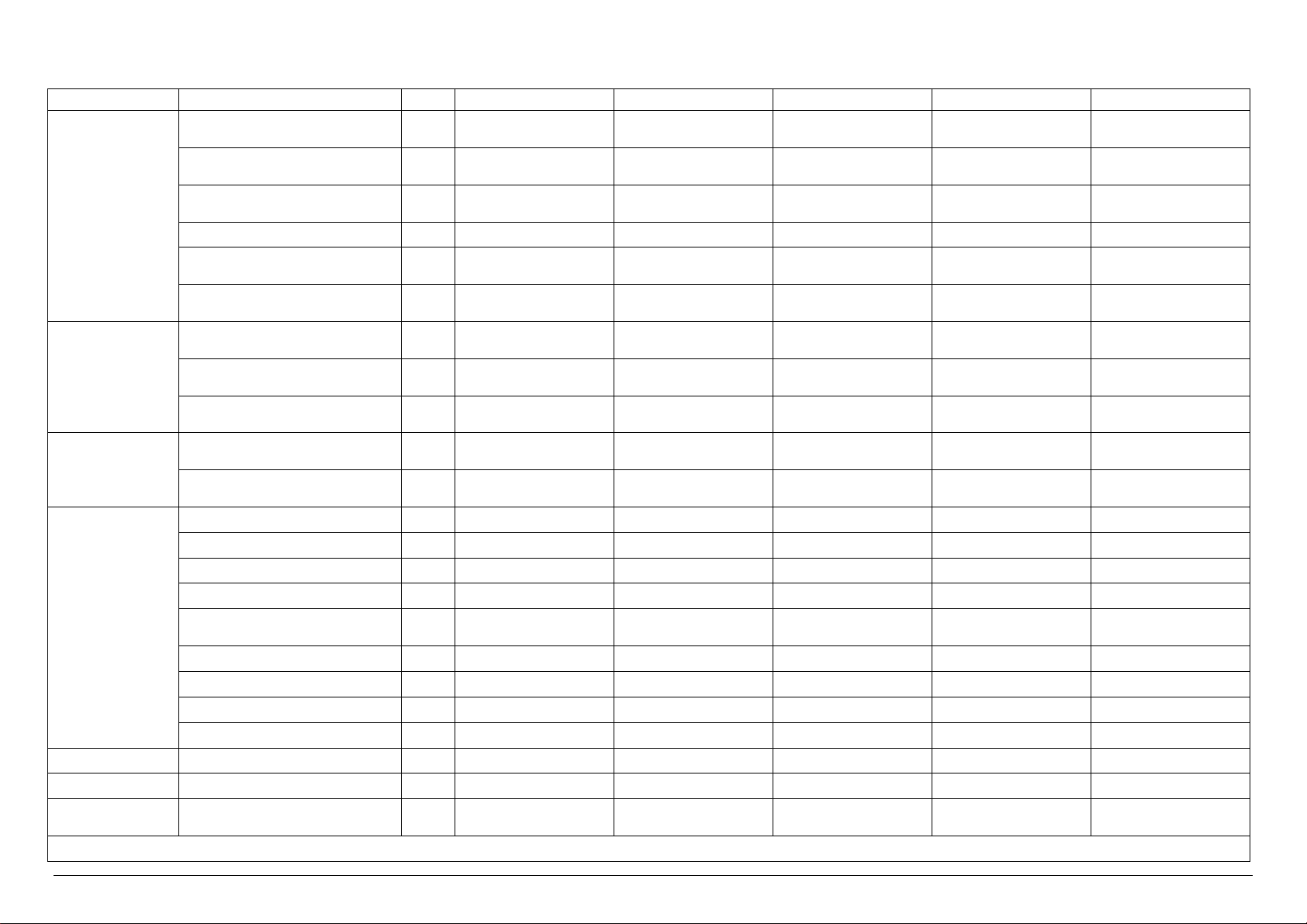

Technical characteristics of VS 8 VERSIONS

Chamber

dimensions

Footprint

dimensions

Weights

Connections

Electrical Power kW 50.5 2.5 2.5 50.5 50.5

Electrical Current A 75.0 5.0 5.0 75.0 75.0

Steam Consumption

* Upon the client’s request, it is possible to have the same models with power supply at 480V 3~ +T 60 Hz

MODEL

Width

Height

Depth

Sterilization Unit N° 8 8 8 8 8

Usable Volume

Total Volume

Width

Height

Depth

Net Weight

Hydraulic Test Weight

A-General Drain / 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32 1 ¼” Female DN32

B-Safety Valve Drain / n°3 Ø 18 n°3 Ø 18 n°3 Ø 18 n°3 Ø 18 n°3 Ø 18

C-Condensation Discharge / - - ½” male DN 15 - ½” male DN15

D-Steam Input / - ½” male DN 15 - ½” male DN15 -

E-Softened Water Input

Demi Water Input

F-Compressed Air Input / ¼” male ¼” male ¼” male ¼” male ¼” male

G-Power Supply / 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz* 400V 3~ + T50Hz*

H-City Water Input / ¾” male DN 20 ¾” male DN 20 ¾” male DN 20 ¾” male DN 20 ¾” male DN 20

I-Steam Input / - - ½” male DN 15 - ½” male DN15

U.M. VS8/1E VS8/1V VS8/1I VS8/1EV VS8/1EI

mm

inch

mm

inch

mm

inch

litres

Cft

litres

Cft

mm

inch

mm

inch

mm

inch

kg

lb

kg

lb

/ ¾” male DN20 - ¾” male DN 20 ¾” male DN 20 ¾” male DN 20

kg/h

lb/h

-

670.0

26.4

700.0

27.6

1286.0

50.6

598.0

21.1

603.0

21.3

1100.0

43.3

1900.0

74.8

1592.0

62.7

1045.0

2303.8

1650.0

3637.6

670.0

26.4

700.0

27.6

1286.0

50.6

598.0

21.1

603.0

21.3

1100.0

43.3

1900.0

74.8

1592.0

62.7

990.0

2182.6

1590.0

3505.3

70.0

154.3

670.0

26.4

700.0

27.6

1286.0

50.6

598.0

21.1

603.0

21.3

1100.0

43.3

1900.0

74.8

1592.0

62.7

1045.0

2303.8

1650.0

3637.6

90.0

198.4

670.0

26.4

700.0

27.6

1286.0

50.6

598.0

21.1

603.0

21.3

1100.0

43.3

1900.0

74.8

1592.0

62.7

1045.0

2303.8

1650.0

3637.6

70.0

154.3

670.0

26.4

700.0

27.6

1286.0

50.6

598.0

21.1

603.0

21.3

1100.0

43.3

1900.0

74.8

1592.0

62.7

1045.0

2303.8

1650.0

3637.6

90.0

198.4

30

Loading...

Loading...