Page 1

Solar Charge Controllers

Steca Elektronik GmbH | 87700 Memmingen | Germany | Fon +49 (0) 8331 8558-0 | Fax +49 (0) 8331 8558-132 | www.steca.com

128

187

4985

177

20

5

4x ø5

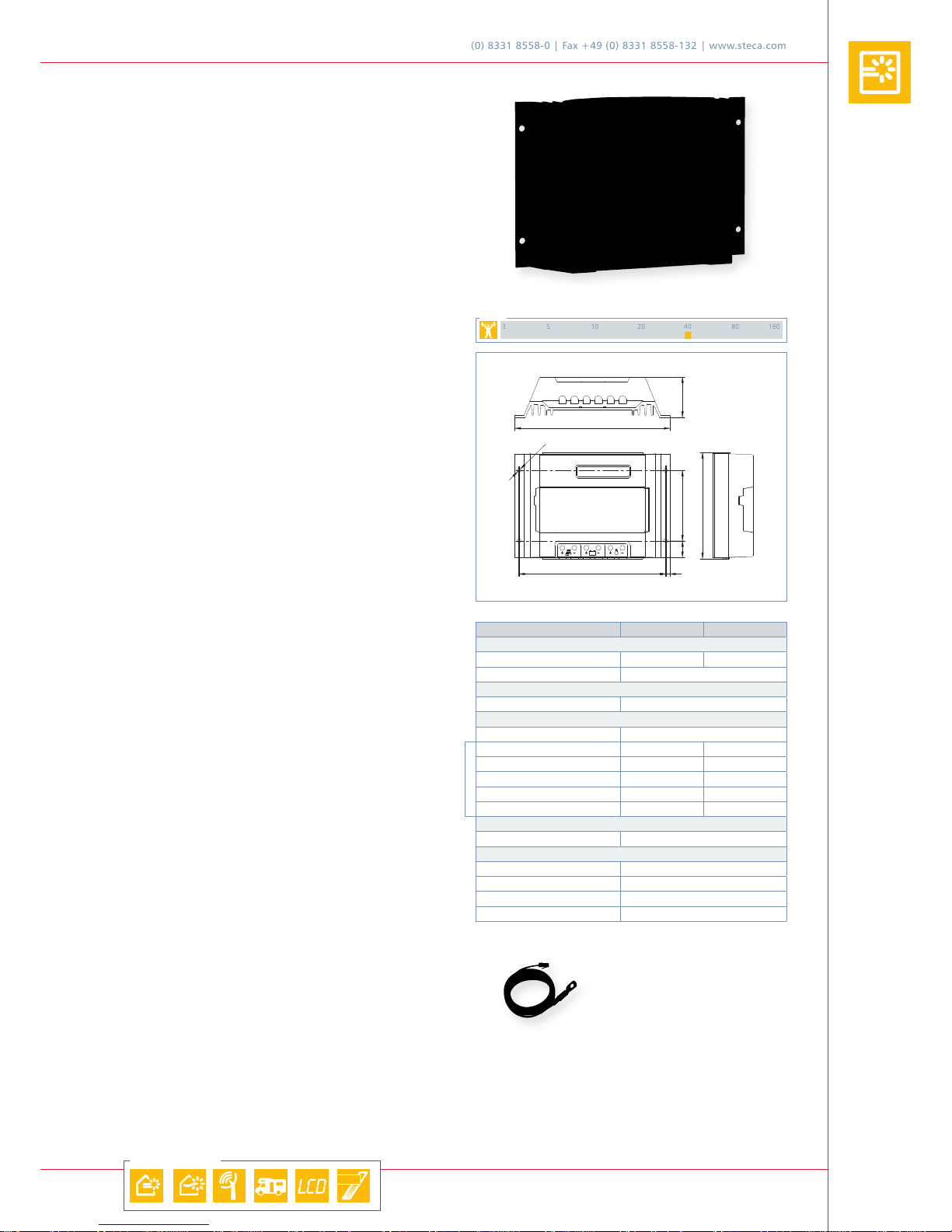

Steca Solarix

2401, 4401

The solar charge controllers Steca Solarix 2401 and 4401 are

optimally suited for inverter systems. The controller combines

basic solar charger functions with a 40 A high-performance

charge controller. It is available as 12 V / 24 V and 48 V system.

This makes the solar charge controller very cost effective.

The load current is limited to 10 A. The charging processes

are based on the voltage level, which can be individually set

with the help of four buttons behind the front casing.

Product features

Hybrid controller

Voltage regulation

Automatic detection of voltage

PWM control

Multistage charging technology

Load disconnection depending on voltage

Automatic load reconnection

Temperature compensation

Common positive grounding or negative grounding on

one terminal

Integrated self test

Monthly maintenance charge

Electronic protection functions

Overcharge protection

Deep discharge protection

Reverse polarity protection of load, module and battery

Reverse polarity protection by internal fuse

Automatic electronic fuse

Short circuit protection of load and module

Overvoltage protection at module input

Open circuit protection without battery

Reverse current protection at night

Overtemperature and overload protection

Battery overvoltage shutdown

Displays

Text LCD display

— for operating parameters, fault messages, self test

Operation

Simple menu-driven operation

Programming by buttons

Manual load switch

Interfaces

RJ45 interface

Options

External temperature sensor

Alarm contact

Certificates

Compliant with European Standards (CE)

Made in Germany

Developed in Germany

Manufactured according to ISO 9001 and ISO 14001

[40 A]

[areas of application]

1920 W

2401 4401

Characterisation of the operating performance

System voltage 12 V (24 V) 48 V

Own consumption 14 mA

DC input side

Module current 40 A

DC output side

Load current 10 A

End of charge voltage 13.7 V (27.4 V) 54.8 V

Boost charge voltage 14.4 V (28.8 V) 57.6 V

Equalisation charge 14.7 V (29.4 V) 58.8 V

Reconnection voltage (LVR) 12.6 V (25.2 V) 50.4 V

Deep discharge protection (LVD) 11.1 V (22.2 V) 44.4 V

Operating conditions

Ambient temperature -10 °C … +60 °C

Fitting and construction

Terminal (fine / single wire) 16 mm

2

/ 25 mm2 - AWG 6 / 4

Degree of protection IP 32

Dimensions (X x Y x Z) 187 x 128 x 49 mm

Weight 550 g

Technical data at 25 °C / 77 °F

programmable

Steca PA TSK10

External temperature sensor

Page 2

User- and Operation manual

Specially designed for hybrid systems and telecommunications

Steca Solarix 2401 - 4401

716.148 | Z02 | 09_45

PHOTOVOLTAIK - PHOTOVOLTAIC - PHOTOVOLTAIQUE - FOTOVOLTAICA

EN

Page 3

System-Manager TAROM | 716148 page 2 V09_45A

1

Safety Instructions And Waiver of Liability.........................................................................................................3

1.1 Symbol of Safety Instructions..................................................................................................................................3

1.2 How To Use This Manual ........................................................................................................................................3

1.3 General Safety Instructions .....................................................................................................................................3

1.4 Waiver Of Liability....................................................................................................................................................4

2 Range of Applications...........................................................................................................................................4

2.1 Performance............................................................................................................................................................5

3 Functioning ............................................................................................................................................................5

3.1 Description...............................................................................................................................................................5

3.1.1 Overcharge Protection..............................................................................................................................................................5

3.1.2 Temperature Compensation Of Final Charge Voltage...............................................................................................................6

3.1.3 Boost Charging (Lead&Sealed) And Equalisation Charging (Only Lead)..................................................................................6

3.1.4 Automatic Monthly Mixture Of Electrolyte..................................................................................................................................6

3.1.5 Display......................................................................................................................................................................................6

3.1.6 Overdischarge Protection..........................................................................................................................................................6

3.1.7 Control Keyboard......................................................................................................................................................................7

3.1.8 System Voltage.........................................................................................................................................................................7

4 Indication Of Status...............................................................................................................................................7

5 Operating The System-Manager...........................................................................................................................8

5.1 Safety Cover............................................................................................................................................................8

5.2 Main Menu...............................................................................................................................................................8

5.3 Sub Menu ................................................................................................................................................................8

6 Installation............................................................................................................................................................10

6.1 Precautions............................................................................................................................................................10

6.2 Location Of Installation..........................................................................................................................................10

6.2.1 Installation On Walls ...............................................................................................................................................................11

6 2.2 Rules for mounting the System-Manager................................................................................................................................11 .

6.3 Preparations ..........................................................................................................................................................11

6.3.1 Assemblies..............................................................................................................................................................................11

6.3.2 Preparation Of Wiring..............................................................................................................................................................11

6 3.3 Cabling.................................................................................................................................................................................... 11 .

6.4 Installation And Operation .....................................................................................................................................12

6.4.1 Connecting The Battery Bank To The System-Manager.........................................................................................................12

6.4.2 Connecting The Solar PV Module Array To The System-Manager .........................................................................................12

6 4.3 Connecting The Loads............................................................................................................................................................ 12 .

6.5 Uninstalling............................................................................................................................................................13

6.6 Safety Measures....................................................................................................................................................13

6.6.1 Electronic Short Circuit Safety.................................................................................................................................................13

6.6.2 Hardware Safety.....................................................................................................................................................................13

6.6.3 Flammability............................................................................................................................................................................13

6.6.4 Overvoltage Protection............................................................................................................................................................13

6 6.5 Simple And Double Errors.......................................................................................................................................................13 .

6.7 Grounding..............................................................................................................................................................14

6.7.1 Positive Grounding..................................................................................................................................................................14

6.7.2 Negative Grounding................................................................................................................................................................14

7 Maintenance.........................................................................................................................................................14

8 Technical Data .....................................................................................................................................................14

8.1 Performance Data..................................................................................................................................................14

8.2 Controlling Data at 25°C........................................................................................................................................15

9 Malfunctions And Errors.....................................................................................................................................15

10 Legal Guarantee...................................................................................................................................................16

© Steca GmbH; Version 09_45; S.Nr. 716.148

Page 4

1 Safety Instructions And Waiver of Liability

1.1 Symbol of Safety Instructions

Safety instructions for personal protection and instructions that refer to the safety functions of the

system are marked with this sign and are printed in bold letters.

For safe installation of other components which are not mentioned in the PV System-Manager instructions, please see

the corresponding safety manual of the component manufacturer.

1.2 How To Use This Manual

This manual describes the functions and installation of a PV System-Manager - a solar charge/load controller in a PV

system with a battery as storage.

For safe installation of other components, e.g. solar modules, electrical accessories and battery, please see the

corresponding manual of the manufacturer.

Hint: Before you start your work, read the instructions for Installation (chapter 6; page 10). Make sure that all

preparatory measures are taken.

Only start to install the System-Manager when you are sure that you have understood all the technical details of this

manual. Please make sure that all steps are done in the sequence that is described in this manual.

These instructions must be handed out to all persons that work with this system. These instructions are part of the

System-Manager and must be handed over in case the System-Manager is sold.

This manual has to be made accessible for any third party or parties working on the PV system.

Before you start work:

• Read the chapter Installation (chapter 6; page 10)

• Make sure that all Precautions (chapter 6.1; page 10) are taken.

• Only start to install your System-Manager when you are sure that you have understood all technical

instructions.

• Only proceed in the order started in this manual!

1.3 General Safety Instructions

For your own safety, please note the following for installation:

Avoid generating sparks!

Solar modules produce current whenever light strikes them. Even at a small light level, the full voltage can be present.

Therefore, work carefully and pay attention to the corresponding safety precautions. Cover the modules with something

to block the light while connecting the system.

During installation and wiring of the photovoltaic system, the system voltage may double (with the 12 V system up to 24

V, with the 24 V system up to 48 V, and within the 48 V system up to 96 V)

Therefore: Do not ever touch bare wire ends even in DC Systems! This habit can cause

injury or even death!

Only use well insulated tools!

Do not use technical tools that are defective or broken!

The safety features of the System-Manager can be defeated when it is operated in a way not specified by the

manufacturer.

Restriction of ventilation can lead to overheating of the System-Manager and thus failure. Do not cover any ventilating

slots or cooling ribs.

The System-Manager must not be installed and used in moist damp areas (e. g. bathrooms) or in rooms in which there

are flammable gas mixtures (from gas bottles, paint, solvents etc.)!

System-Manager TAROM | 716148 page 3 V09_45A

Page 5

Do not allow anyone to store any of the above-mentioned hazardous items, or similar items in rooms where the SystemManager is installed!

The pre-set signs and marks must not be changed, removed, or made illegible.

All operations must be conducted in accordance with your national electricity regulations and local rules!

For installation in your country, please see your corresponding institutions for information on regulations and safety

measures.

Keep children away from any and all electronics! Fatal accidents can occur!

1.4 Waiver Of Liability

The manufacturer (STECA and its assigned representatives) cannot check that this manual is strictly followed, nor the

conditions and methods for installation, operation, use and maintenance of the System-Manager.

Improper installation can lead to physical damage to the System-Manager and its safety features, and thus can endanger

persons.

Therefore, we the manufacturer do not take any liability and responsibility for losses, damages and costs which are due

to an improper installation, operation, use and maintenance or any other consequences resulting from such damage.

Furthermore, we do not take any liability for infringements of patent rights, or rights of third persons, which result from the

use of this System-Manager.

The manufacturer reserves the right to make alterations, without prior notice, to the product itself, technical data or the

installation and instruction manual.

If other components, which are not prescribed by manufacturer are connected to this System-Manager, the user has to

accept the consequences.

CAUTION: Opening the System-Manager (connecting cover excluded) as well as use other than

prescribed by the manufacturer, will cause the warranty to be voided.

2 Range of Applications

The System-Manager is designed for a wide range of applications from private use to professional use: private homes or

leisure market (like recreational vehicles or weekend/seasonal cottages, etc.) or in locations where trade, business or

commerce is done (like workshops, stores, offices etc.) or industrial applications or telecom systems.

The System-Manager can NOT be used outdoors, where it would not be protected against rain or sun.

Unless external temperature sensor the System-Manager must be installed in the same room as the battery due to the

following reasons:

• an integrated temperature sensor registers the ambient temperature of the room, which is almost identical to

the battery temperature.

• In order to keep the voltage drop between System-Manager and battery to a minimum, please only use the

shortest possible battery cables.

The System-Manager’s PV input should only be connected to solar modules. However, the battery can also be charged

in parallel by other sources with appropriate battery charge functions.

Hint: The System-Manager is able to adapt to customised applications. We will optimise your product concerning your

special requirements. With these modifications the System-Manager will withstand strong ambient conditions like

advanced temperature range, mechanical and climatic ambient conditions or advanced interference resistance.

System-Manager TAROM | 716148 page 4 V09_45A

Page 6

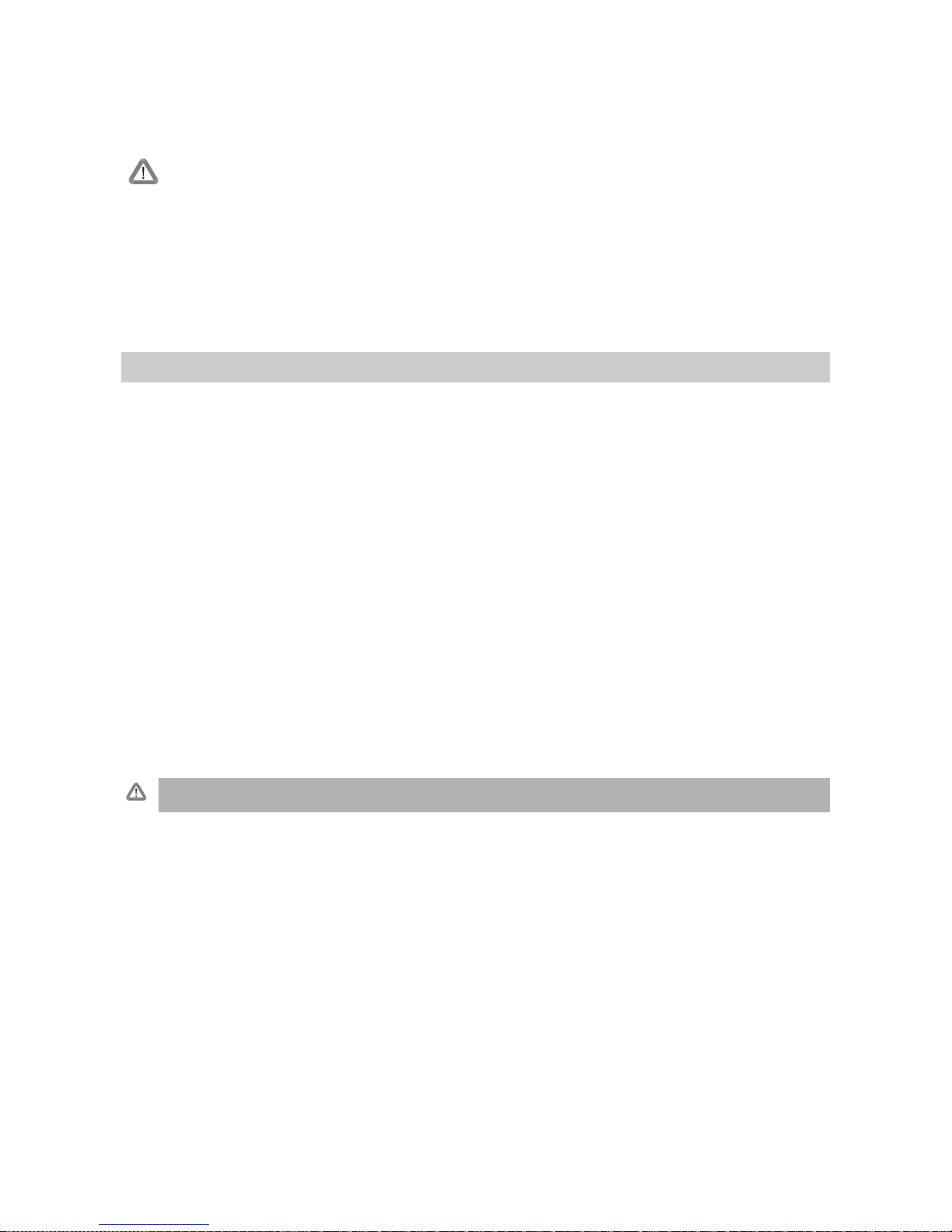

2.1 Performance

The System-Manager uses a heat sink (the black

aluminium back plate) to dissipate heat produced by

the electronics during high amperage charging. The SystemManager can be used in a wide range of conditions

and temperatures. It automatically detects the maximum

permissible temperature of the heat sink and disconnects

the loads in the case that temperature is exceeded.

Therefore, the heat sink can be shared for the heat

produced during charging and powering the loads.

However, it is necessary to stay within the “Safe Operating

ARea“ (SOAR) for sizing the system in order to avoid

undesired switch-off of the loads in the case the temperature

is exceeded.

You must size the PV system in a way that the ambient

temperature line is not exceeded in the case of maximal

charge and discharge currents. With an ambient temperature

of 20 °C and correct installation, the System- Manager

can handle both 100% module and 100% load nominal

currents (see graph at right). These nominal currents

correspond to 100 % in the diagram

nominal load current / A

nominal module current / A

Hint: If you install the System-Manager into an electrical box or cabinet enclosure, please assume the maximum

temperatures inside this box. These are higher than the ambient temperatures, since the System-Manager and

other devices may well increase the temperature.

3 Functioning

The System-Manager monitors the charge status of the battery, regulates the charge process as well as it switches the

loads on -off in order to make full use of the battery and to extend its life.

On delivery, the system is set for use with lead accumulators (batteries) with liquid electrolyte and can be set for

accumulators with fixed electrolyte like gel batteries. The System-Manager can be used for all types of solar modules.

3.1 Description

3.1.1 Overcharge Protection

The overcharge protection prevents uncontrolled gassing within the battery cells. The gas development is depending on

the acid temperature and cell voltage. So the System-Manager monitors the ambient temperatures and adjusts the

battery’s maximum allowed charge voltage. The overcharge protection and voltage limitation is independent on the

battery’s state of charge, since the decomposition of electrolyte is exclusively depending on the voltage and the

temperature. This means that charging is already limited even though the battery is not completely charged.

Overcharging the battery leads to uncontrolled gassing. Here the electrolyte is decomposed into oxygen and hydrogen.

The consequences are harmful oxidation processes and mechanical damages since the gas blisters may knock out

active lead material from the lead plates.

What is even worse is that the uncontrolled gassing in closed batteries e. g. sealed or fluid batteries where the gas

pressure can even burst or crack the battery case. Frequent overcharging damages the battery casing. The charging

process and the overcharge protection are thus regulated by a new hybrid System-Manager utilising pulse width

modulation in order to insure smooth battery charging. The user in particular should not choose a float voltage too high

via user settings. If you want to program this value individually from the System-Manager’s factory setting, please take

note of the battery manufacturers' recommendations.

System-Manager TAROM | 716148 page 5 V09_45A

Page 7

3.1.2 Temperature Compensation Of Final Charge Voltage

As the battery temperature increases, the acid/lead

battery’s optimal final load voltage decreases. A constant

final charge voltage leads to uncontrolled gassing in

the case of higher battery temperatures, and

undercharging in case of low temperatures. The

temperature compensation software algorithm automatically

decreases the final charge voltage at higher temperatures

and increases them at lower ones. The temperature

compensation system with the sensor integrated in

the System-Manager influences all three overcharge

thresholds.

The integrated sensor makes maintenance and

installation easier and can be properly used under the

following circumstances:

• System-Manager and battery must be

in the same room

-20

-40

-10

-14-0321050206830864010450122

13,2

13,5

13,8

14,1

14,4

14,7

15,0

[°C]

[°F]

2,20

2,25

2,30

2,35

2,40

2,45

2,50

[°C]

[°F]

2,35

2,40

2,45

2,55

• the System-Manager’s own

warming-up is compensated by substantial calculations. However, even if the sensor was outside the SystemManager, the room temperature itself only corresponds to the battery pole temperature, so actual electrolyte

temperature inside the battery may be actually different by a bigger margin of error.

• However, an external sensor can be installed if the most accurate sensing is desired.

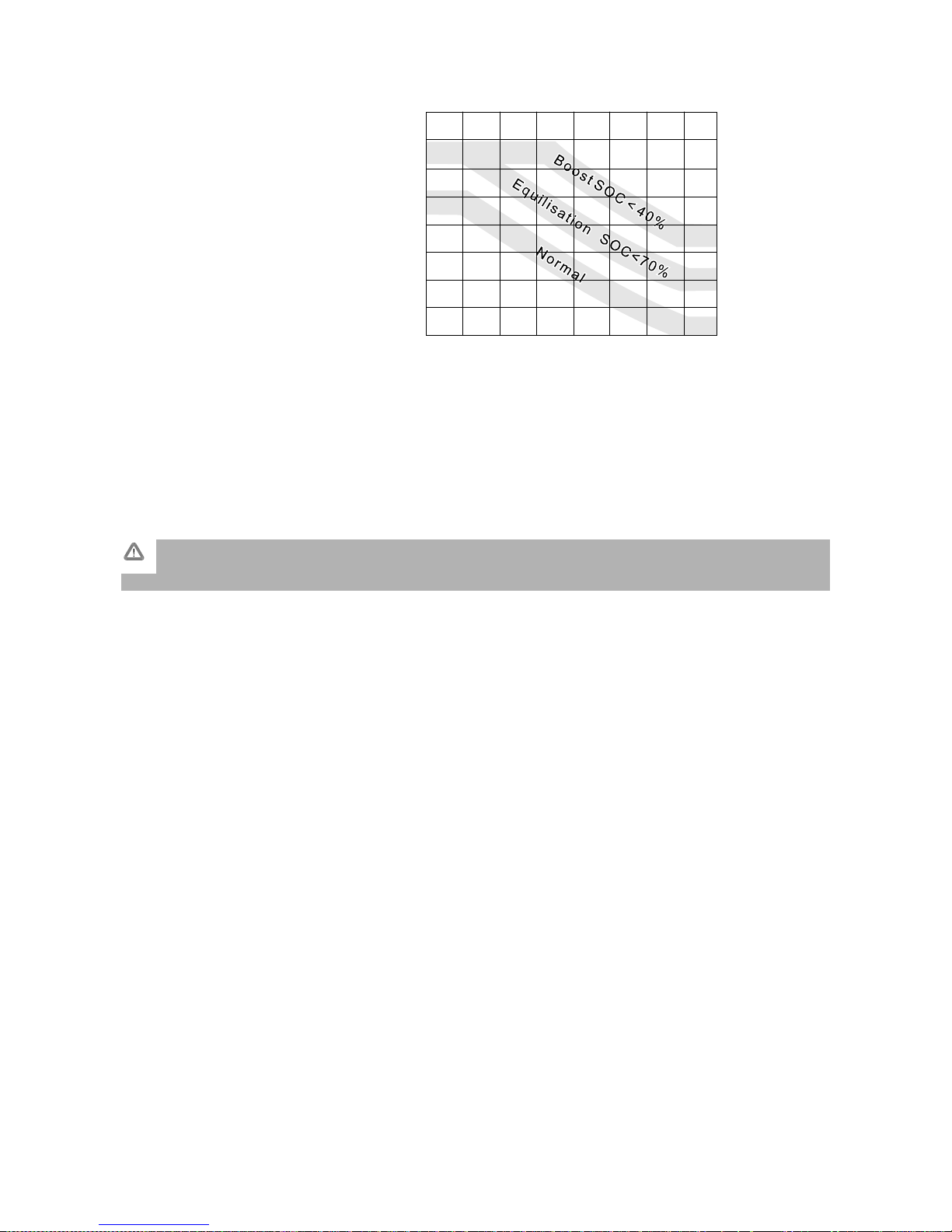

3.1.3 Boost Charging (Lead&Sealed) And Equalisation Charging (Only Lead)

For this charging cycle, the System-Manager increases the battery charge voltage for a certain period of time after the

battery has fallen below a certain voltage. The Boost Charge countdown is only activated when the desired battery

voltage has been reached. This is the reason why it is important to pay attention to the fact that the solar module will be

able give out sufficient charge energy with the corresponding final voltages.

If the Boost Charge voltage level is too high in comparison with the module voltage (reduced by

wire losses) the countdown may never be started and your battery is therefore charged at a

higher voltage with no time control.

Equalising charge works similar to the above Boost Charging but is at an even higher voltage. Using equalisation

charging is only possible and can only then be programmed if the battery has been configured to be of liquid electrolyte

type. It is activated when the battery falls below a certain voltage

3.1.4 Automatic Monthly Mixture Of Electrolyte

Batteries that are shallow cycled will never trigger the equalisation cycle, so an automatic function has been added so the

final charge voltage is increased for a limited time every month. In this case, either Boost or Equalise charging is

activated depending on the electrolyte configuration. This function prevents harmful acid layering which occurs especially

after remaining a long time at a certain charge status.

3.1.5 Display

The display scrolls every 3

rd

second. Pressing once the OK button stops the scrolling at the actuell window. Pressing

this key will start the scrolling again.

The LCD works correctly only within the operating temperature range specified by the manufacturer. When this

temperature range is exceeded, disturbances may occur which prevent reading the display. The display will return to

normal when the operating temperature range is again reached. The storing temperature range, however, must not be

exceeded or permanent damage may occur.

3.1.6 Overdischarge Protection

Overdischarging leads to sulphation and as result a loss of your battery’s capacity. The overdischarge protection feature

disconnects the loads if the battery is becoming too discharged and re-connects them after sufficient re-charging. The

loads can also be manually switched on/off, so the System-Manager can be used as a main DC load disconnect switch.

System-Manager TAROM | 716148 page 6 V09_45A

Page 8

3.1.7 Control Keyboard

By using the tact switches underneath the LCD screen, the factory set values can be configured to the user’s custom

requirement. Freely programmable values can only be changed within a pre-set window. These minimum-maximum

values are selected in a way that even extreme adjustments do not lead to severe damage to the lead batteries.

However, the operating elements are not protected or locked with a child-proof lock (code). For this and many other

safety reasons, we would highly recommend that you make the System-Manager as well as the battery room inaccessible

to children

3.1.8 System Voltage

The System-Manager adjusts itself automatically to 12 or 24 V system. For this it is necessary that the battery of the

proper voltage is connected to the System-Manager first.

There are two variants of the System-Manager: one for the system voltages of 12/24V and another 48V version. The

12/24V System-Manager only adjusts itself for system voltages below 30 V. For 48 V systems you will need another

model with more voltage-stable components. Please have a look at the marks on the case for information if your SystemManager fits the desired system voltage.

4 Indication Of Status

The display constantly changes its information. All values and system information are indicated alpha-numerically. The

following displays can only be seen during regular operation (not while programming). You can stop the scrolling in one of

the following windows while pressing once the right Menu key.

”U Bat”: Since the voltage drop between controller and battery can be calculated without sensor

wires, this display shows the battery’s actual voltage at the battery poles, and not the voltage at the controller’s

connection terminals.

”I_in” is the charging currents flowing into the battery. Whenever the battery is full and not able to

consume any charge current „I_in“ could be zero even the sun is shining with high intensity.

”I_out” is the discharge currents flowing out of the battery and is composed of the load current

running through the controller.

I_mod is the charging current produced by the solar modules. When the voltage of the battery is

getting near the final charge voltage, the module current „I_mod“ is substantially higher than the charge current (I_in).

”I_in” will be regulated by the controller in order to protect the battery from being overcharged.

The controller can determine night time from the solar module current. The condition ”night” is shown instead of the

actual module current. Another feature of the controller recognises whether a solar module has been connected or not

(I_mod = no modul).

I_accu is the balance of the charging and discharging currents. As long as the charging current is

higher than the discharging current, the value is positive, in the opposite case, it is negative.

Messages such as ”over-temperature”, ”load current”, ”low voltage” and ”high voltage” are warning

.The controller automatically takes steps in order to protect itself, the battery and the loads. After the error condition

ceases to exist, the controller resumes normal function. See Malfunctions And Errors(chapter 9, page 15)

Charge regulator status such as ”float charge”, ”boost charge” and ”equal charge” indicate which

stage of charging is in process. After a certain period of time of operating in the ”boost” and ”equal” charging modes, the

float charge mode is resumed. ”Deep protection” (meaning the controller has decided to disconnect the loads to protect

the battery from deep discharge) is also indicated on the display, even when automatic load disconnection has been deactivated.

System configuration settings such as the selection of the electrolyte ” electrolyte liqui” for liquid

batteries or ” electrolyte fixed” for sealed batteries as well as manual load disconnection ”manu discon auto”, ”manu

discon off” or ”manu discon on” are indicated.

Some windows are monitoring several values. You can stop scrolling and fix your display in one of the following windows

to get an overview of your system.

This window monitors the battery voltage (13,7V) as well as the INput charge current (IN04) and the

OUTput discharge current (OUT12). The explanation of tension (voltage [V]), IN and OUT waste too much space to

allows a accurate current monitoring.

System-Manager TAROM | 716148 page 7 V09_45A

Page 9

This window monitors also battery voltage (13,7) as well as charge current (+04.3) and the discharge

current (-12.4) with more accurate values.

5 Operating The System-Manager

5.1 Safety Cover

The safety cover is a plastic lid covering the programming keys and safety fuses. The lid can be removed if desired. In

order to avoid undesired modification of important settings, however, it is recommended that the lid be left on the SystemManager. Intentionally, the lid is designed to be difficult to open. This is to prevent unwanted changes from being easily

made. The lid can be easily opened with following trick.

Hint: To open the cover, using your left-hand, stick your fingernail into the slot, move it along the slot and pull open the

cover.

When putting the lid on the case again, please make sure to put the turning joint into the case first and then into the

snap-in hole.

Using one of the option you can break the rated point on the left side.

5.2 Main Menu

Pressing the MENU button you will enter into

the menu. With the arrow keys ▲▼ you

can scroll through the menu items, but no

values appear and no parameters can be

changed by this scrolling action. To enter into a

selected window press OK.

System-Manager TAROM | 716148 page 8 V09_45A

⇒ With the arrow keys ▲▼ you can

scroll through the menu items, but no

values appear and no

parameters can be changed by this

scrolling action.

⇒ By pressing OK the displayed menu

window is activated, and the value is

indicated. Pressing OK once again leads to a closure of the window without adjustment.

⇒ After a menu window is activated and its value is displayed, use the arrow keys ▲▼ to can change the value. When

the maximum value has been reached, the parameter starts at the lowest value again. By constantly pressing the key,

the value starts to scroll in small steps.

⇒ Confirmation and storage of the new value is done by pressing OK

⇒ if no selection of another menu is made within 5 seconds after OK is pressed, the System-Manager will automatically

exit from all menus and the normal indication of running status appears .

⇒ If there are no adjustments for 2 minutes on an activated submenu value being changed, the display indication jumps

to the main menu and the adjustment in the open window is not stored or applicable.

⇒ The MENU key will bring the display back to the status indicator display.

5.3 Sub Menu

Here you have the possibility to directly influence the System-Manager’s behaviour

Within this window, the load can manually be connected or disconnected. By pressing OK you enter

this window and you may then switch ▲▼ from “load on“ to “load off“ or ”auto“. However, the battery will still be

protected from the worst discharge by an emergency cut-off that cannot be overridden by the manual control function.

“load off“ switches off all loads and may be used as main switch if you leave your solar system for a longer period of

Page 10

time. “auto“ automatically protects the battery from being deep discharged.

possibilities for programming: load on, load off, auto

Before this menu function is activated, it is necessary to disconnect the solar PV modules and all

loads. Before Uninstalling (chapter 6.5, page 13) please refer to the related information. After having scrolled to this

window, a self test can be started by pressing OK. The System-Manager examines its performance components:

software and parts of the hardware. When the window appears ”TEST: SUN+ LOAD+”, the operation and hardware

have been verified to be in good condition. If ”TEST: SUN− LOAD+” or TEST: SUN+ LOAD−” appears, re-start the Test

again after you have verified that the modules and loads were properly disconnected. If the failure message appears

again, disconnect all connections and please return the System-Manager to your authorised dealer.

Within this menu, the battery electrolyte type can be set. After having entered this menu, by pressing

OK you may toggle between ▲▼ fixed to liquid electrolyte. Setting this to fixed deactivates the window for

programming the acid density as well as disabling the equal charging mode since gassing must be prevented where

sealed batteries are used.

possibilities for programming: liquid, fixed

The end of charge “float” voltage serves for maintaining the charge in the battery for long periods

and preventing self-discharge. This voltage should not be too high, since this may lead to permanent gassing, which

damages the battery. Maximum values are stated on the battery data sheet of your battery

possibilities for programming: 13,0V...14,5V

26,0V...29,0V

52,0V...58,0V

Increasing the charge voltage over a limited period of time (boost or “bulk” charging) is not harmful

for lead battery types, if within certain parameters. Maximum values are stated on the battery data sheet. After having

entered the window by pressing OK, you can change the voltage values by pressing the arrow keys ▲▼. This setting

can be confirmed and stored by OK.

Possibilities for programming: 13,5V...15,0V 27,0V...30,0V

54,0V...60,0V

The equalisation charging can be programmed similar to adjusting the boost charging. Press OK to

enter, edit the equalisation charge voltage by pressing the arrow keys ▲▼ and confirm setting by pressing OK. The

equalisation charging can only be adjusted for batteries with liquid electrolyte, since high equalising voltages are harmful

for sealed batteries. The maximum equalising voltage value should be stated on the battery manufacturers’ data sheet.

This window is deactivated if you have selected “electrolyte fixed“Fehler! Verweisquelle konnte nicht gefunden werden.

presumes liquid electrolyte batteries.

Possibilities for programming: in the period from 14,0V...15,5V

28,0V...31,0V 56,0V...62,0V

Battery charging voltage is passed on directly to the loads by the System-Manager! Therefore,

during equalise charging, high charging voltages can be programmed that may damage some

loads. Please select this equalise charge voltage very carefully and compare the desired value to the

battery and load (appliance) manufacturers' data sheets.

The discharge threshold at which the loads are automatically disconnected can be programmed by

the user. When you have reached this window by pressing the arrow keys ▲▼, you may open it for editing by pressing

OK. Afterwards you may alter the disconnect threshold by pressing the arrow keys ▲▼ within given values. Press OK to

store the setting. NOTE: the difference between disconnect and reconnect threshold must be at least 0,13V/cell. If you

wish disconnect at higher state of charge you have to first adjust the reconnect threshold (as per below) to 0,13V/cell

above the desired disconnect threshold.

Possibilities for programming by voltage regulation: 11,0V...12,5V

22,0V...25,0V

44,0V...50,0V

The charge threshold at which the loads are automatically reconnected, can also be programmed by

the user. The reconnect setting window is reached by pressing the arrow keys ▲▼. Enter the window by pressing OK,

and alter the values within the window. Press OK to store the setting. The reconnect level can only be reduced to

0,13V/cell above disconnect threshold (see above).

Possibilities for programming: by voltage regulation: 11,8V...13,3V

23,6V...26,6V

47,2V...53,2V

System-Manager TAROM | 716148 page 9 V09_45A

Page 11

6 Installation

6.1 Precautions

Do not install any PV or electronic components in rooms where flammable gas mixtures may occur!

Within the battery’s immediate surroundings, explosive gases may be generated. So please see that the battery room is

adequately ventilated and avoid generating sparks.

The following instructions for batteries must be adhered. We recommend these basic

precautions for any country. Check your local electric and safety codes for all applicable

precautions in dealing with DC wiring and battery installations.

⇒ DIN (German) VDE 0510 part 2, sections:

• 7. Precautions against explosion danger

• 8. Precautions against risks occurring by electrolyte gas (hydrogen sulphide)

• 9. Location

⇒ National Electric Code including article No. 690. The unit shall be installed according to this regulation

6.2 Location Of Installation

The System-Manager must be connected to the solar PV array, the battery and the loads. The line loss and drops in

voltage should be kept to a minimum, so the System-Manager must be installed in a way that the shortest cable possible

and the most direct access can be used. This is a major decisive factor for the battery’s location as well as for the solar

PV array’s location. The cable lengths to the loads have a lesser effect on System-Manager site selection since

distribution throughout the building or site is necessary.

The ideal location for the battery is a well-ventilated battery room (keeping a minimum safety distance of 30 cm from the

System-Manager) inside the building but nearest to the solar PV array. Since both charging and discharging currents are

running via the battery cable connections, close proximity and short thick cables to the battery are recommended. This

battery cable connection is the point where the losses have the worst effect on the PV system’s efficiency and

performance.

The solar PV array should be installed in a way that – in the most unfavourable case – the voltage drop is not so high that

the battery can not be charged completely again. Within the limited period of time for equalise charging, the battery is

charged at a high voltage level. However, if the drop in voltage along the PV array cables is too high, this equalizing

charge voltage cannot be reached. The timer for the equalize charge stage will not start running until the equalise voltage

is reached, so the timer will be “stuck” and the System-Manager will stay in equalise mode permanently until the situation

is corrected. For example, if the MPP voltage at the PV array connection is 16.5V, minus 1.0V drop in voltage on the PV

array-to-System-Manager wiring, minus 0.3V drop in voltage at the System-Manager and the safety fuses, the maximum

voltage reaching the battery is only 15.2V.

The System-Manager must not be installed in locations with easily flammable liquids or mixtures such as gas bottles,

paint, varnish, solvents etc.. Installation is only permitted in areas where the System-Manager’s environmental

specifications are not exceeded (see technical data) . Furthermore, the System-Manager must not be installed and

operated in very humid rooms e. g. bathrooms.

The System-Manager must be protected from direct exposure to weather. Sun and external warming from nearby devices

should also be avoided.

The battery and the System-Manager must be installed in a place out of reach of children’s and

unauthorised persons. Therefore, we have not taken any precautions on the System-Manager

itself in order to prevent unauthorised use.

The surface on which the System-Manager is to be installed should not be easily flammable.

During operation, the backside of the System-Manager heats up. So the materials at the

location for installation should be able to withstand a constant temperature of 85°C without damage

or risk of fire.

System-Manager TAROM | 716148 page 10 V09_45A

Page 12

6.2.1 Installation On Walls

The System-Manager has to be mounted on fire-proof surface. Furthermore, no flammable material should be allowed

under the place where the System-Manager is mounted.

The System-Manager is to be installed on vertical walls. This is the only way that the

System-Manager can be cooled by naturally rising air (chimney effect) and work

correctly.

The System-Manager is screwed to the wall with the four holes drilled into the heat sink

flanges. The System-Manager is designed without an integrated strain relief, so that the unit

can be adapted to the prevailing conditions of various types of installations. For this reason,

you must install a strain relief (e. g. cable clips) approx. 200 mm below the SystemManager before the cables spread out to the individual components.

When the System-Manager is in operation, the high currents being regulated by the SystemManager warm up the heat sink and air naturally rising past the heat sink fins extracts the

heat. This chimney effect is necessary for proper cooling and System-Manager operation.

Do not confine the System-Manager in a closed space, since this would make

ventilation and cooling impossible. Adhere to a safety distance of min. 200 mm

below and above the unit.

After screwing the System-Manager to the wall, you can start wiring.

6.2.2 Rules for mounting the System-Manager

The System-Manager must be installed with cable openings down.

For marking the mounting holes use the System-Manager as a stencil, but never as a stencil for

drilling!

Make sure that the heat sink is well ventilated when mounting.

6.3 Preparations

6.3.1 Assemblies

Before installation, lay out all cables, junction boxes and safety fuses:

• cut into sections

• isolate on both sides and press on end sleeves for strands

• prepare junction boxes

6.3.2 Preparation Of Wiring

Wires that are not permanently connected to the building must be strain-relieved outside the

System-Manager!

Please make sure that the wire diameter is in accordance with the System-Manager’s expected currents. The following

table states the minimum cross sections that are necessary for constant currents that may occur during a period of time

of approx. 30 min. This chart will allow the maximum distance from System-Manager to PV array junction box of approx.

10m; to battery approx. 2m; and to load distribution box approx. 5m.

Before wiring, please check if the batteries are the right type

and size, and always double check if they are connected to the

System-Manager in the right polarity with a voltmeter, and it is

a good idea to check battery bank voltage with voltmeter! Also

make sure that the solar PV array’s maximum solar PV array

current does not exceed the specifications of the SystemManager.

Current diameter AWG Isolation

20A 10mm² 8 85°C

30A 16mm² 6 85°C

40A 16mm² 6 85°C

50A 25mm² 4 85°C

6.3.3 Cabling

Solar PV modules create current whenever light strikes them. The current created varies with the light intensity, but even

in the case of low levels of light, full voltage is given by the modules. Always cover the solar modules with an opaque lid

that is fixed with tape while working on the PV array wiring or joining to the System-Manager. Due to this cover, the

System-Manager TAROM | 716148 page 11 V09_45A

Page 13

System-Manager TAROM | 716148 page 12 V09_45A

modules will be free of voltage and current so the chances of damage to the System-Manager or injury to the installer is

greatly reduced.

• Solar modules must in no case be short circuited to zero out the voltage from the PV array! Spark

development can damage wiring, connections, cause fire, or even damage electronics due to the high spikes

of current!

• Only use well-isolated tools!

• Never touch bare cable ends! High DC voltage can be present and is dangerous!

• Insulate each bare cable end with tape or other non-conducting material if it is not to be connected

immediately!

• Work only on dry ground! Components (solar module, cables etc.) must not be wet or moist during installation!

• Pay attention to the right polarisation during cabling! Double check with volt meter in case something was

labelled wrong or connected backwards by someone else.

The battery stores a substantial quantity of energy that may be set free in a dramatic and dangerous way during a short

circuit, and the resulting heat and sparks may evoke fire. Therefore, it is indispensable to install a safety fuse directly on

the battery pole. This fuse insures the safety of the cables between System-Manager and battery.

Hint: For isolated systems, it is not necessary, common or even permitted by some countries’ laws to ground-connect

the components (e. g. DIN 57100 part 410). For further instructions, please see Safety Measures (chapter 6.6,

page 13)

6.4 Installation And Operation

It is absolutely necessary to adhere to all our General Safety Instructions (chapter 1.3, page 3 ). To guarantee a

faultless working of the System-Manager, it is necessary to follow the chronological sequence described in the following

chapters.

6.4.1 Connecting The Battery Bank To The System-Manager

• open the safety lid of the System-Manager and remove both safety fuses .

• Lay both battery cables (B+, B-) between the System-Manager and battery bank in parallel.

• Insert the battery cable bare ends to the System-Manager’s battery connection terminals (the symbol shows a

rectangular battery with + and – indicators) and tighten securely with a proper slot screwdriver.

• Pay attention to the right polarity and make sure the battery cables have been labelled and connected

correctly.

• Fix a fuseholder block for an external safety fuse ( not included ) for the battery cable near the battery’s pole

with a short length of battery cable: DO NOT INSTALL THE SAFETY FUSE YET!

• Connect battery cable B+ to the battery’s positive pole.

• Connect battery connecting cable B- to the fuseholder block at the battery’s negative pole

⇒ Install external safety fuse on the battery pole, and double verify that the battery voltage now appears at the System-

Manager’s battery connection terminals, in the right polarity.

⇒ Install either one of the two safety fuses in the System-Manager. Now the System-Manager should start operation.

6.4.2 Connecting The Solar PV Module Array To The System-Manager

• Insert the module array’s M+ and M- bare wires into the System-Manager’s PV terminals (labelled with a

symbol of a slanted PV module) and tighten the screws securely. Pay attention to the right polarity.

• Remember the + and – terminals are shorted to each other internally by the System-Manager to regulate

current. Therefore, it is IMPORTANT to connect ONLY solar PV modules as charging energy source. NO

grid-operated battery charging or DC power devices, diesel sets, or wind generators should be connected, as

these will be shorted out and severe damage to these devices and the System-Manager can result.

6.4.3 Connecting The Loads

• Protect each load circuit by a safety fuse

• Disconnect all loads before joining the load cables in order to prevent spark development which may damage

sensitive loads.

• Connect the main load cables to the System-Manager’s Load terminals (labelled with a round light bulb) and

securely tighten the screws. Pay attention to the right polarity!

Connect any vital urgent loads that must never be disconnected by the System-Manager (e.g. emergency light, radio link)

directly to the battery! Note that there is increased risk of damaging discharge to the battery since the System-Manager

Page 14

System-Manager TAROM | 716148 page 13 V09_45A

no longer controls these loads! Here user training and awareness is vital to protect the customer’s batteries from

damage. Protect these direct loads by installation of safety fuses.

Finally, secure all cables within the System-Manager’s immediate surrounding by strain reliefs. All other components

must also have their wiring be strain-relieved.

6.5 Uninstalling

Uninstall the System-Manager in the opposite way like installing. Firstly all consumer appliances and loads must be

switched off by hand and then the L+/L- main load cables disconnected from the System-Manager. Secondly, the PV

modules’ M+/M- cable must be disconnected. To avoid any sparking, the modules must be disconnected at night or

covered with opaque material before disconnecting the wires. Now, the safety fuses can be removed and the SystemManager's display should go blank.

In order to avoid short circuits while removing the B+/B- cables, you have to remove the safety fuse from the block

installed at the – battery pole, and also it is a good idea to remove the B+/B- cables from the battery poles before you

disconnect the cables from the System-Manager. Before reinstalling the System-Manager, it should be reset to the

factory pre-set adjustments and reprogrammed for the site.

6.6 Safety Measures

All safety measures we have designed into the System-Manager for its protection cannot prevent damage caused by

wrong installation outside the System-Manager. This is the reason why we urgently recommend the installation of a

safety device on the battery pole in order to prevent damage from short circuits between battery and System-Manager.

6.6.1 Electronic Short Circuit Safety

An electronic short circuit safety device is built into the System-Manager and prevents both destruction of the System-

Manager and the blowing of the safety fuse in case of short circuits on the load terminals. The display indicates this error

as “load current“. After elimination of this fault, the System-Manager automatically switches back to normal operation

after about 30 seconds.

6.6.2 Hardware Safety

In addition to the electronic fuse device mentioned above, the System-Manager has also been protected by regular fuses

which have been rated far beyond nominal currents to prevent false blowing of the fuses during surges. The SystemManager’s nominal current must not be mistaken from the safety fuses values. The Performance (chapter 2.1, page 5)

must be taken from the SOAR diagram.

The safety fuses are wired in parallel. In order to prevent fuses from blowing in the case of high currents over a short

period of time, a high value has been selected. Before the fuses blow, the electronic safety fuse should prevent any

excessive current flow.

The safety fuses are only for the System-Manager’s protection from being connected in reverse polarity to the battery.

After reverse connection, both fuses have to be exchanged. Moreover, the system’s safety is considerably increased by

the fact that even in the rare case of an electronic breakdown of the System-Manager (and thereby its internal electronic

safety fuse) there is no danger at all to the site, as the 2 safety hardware fuses will still be operational.

6.6.3 Flammability

The System-Manager is solely made of non-flammable and self-dissolving material. Even in unpredictable error

situations, there is no risk of fire if there is no flammable material within the ambient surrounding of the System-Manager

mounting site, and if the System-Manager has been installed above a fire-proof flooring material.

6.6.4 Overvoltage Protection

Due to cost and space, it has not been possible to integrate a full high-voltage protection system in a System-Manager of

this size. High-voltage protection must be installed within the framework of the system’s installation and must be adjusted

to local circumstances. However, some measures have been taken to compensate atmospheric static high voltage. In

most applications, this protection is sufficient. Nevertheless, for fully professional installations with expensive emergency

communications or life-saving equipment being powered, you should consider additional protection.

6.6.5 Simple And Double Errors

The System-Manager is protected from simple errors ( e.g. load short circuit, battery reverse polarity connection, module

reverse polarity connection etc.) by appropriate measures, mainly electronic or by fuses.

Page 15

However, there are some double errors that may lead to the destruction of the System-Manager or components

(consumer components, modules ), such as:

• reverse polarity battery connection on the solar PV terminals

• One battery wire on the module terminal, the other on the load terminal.

• A wrong voltage source (grid current with 230VAC ) on the solar PV terminals

6.7 Grounding

By grounding the negative poles of the loads, battery and modules together, the electronic components that are

necessary for the regulation and the safety fuse are bypassed. In this way, internal protection components are also

deactivated and the System-Manager can be destroyed, as well as damage to the PV system may occur.

6.7.1 Positive Grounding

The following passages describe some of the technical possibilities of

a positive + grounding scheme. The aim is to always maintain the

System-Manager's proper functions and still achieve grounding to

all the main components. National regulations of the operational

area must be adhered to by the installing electrician. Loss of the “safety

low voltage status” arising from grounding has to be compensated

by corresponding insulation methods of active parts (protection

against direct contact).

A+

A-

L-

L+

M+

M-

When grounding at the plus-side is done, it can also be considered as common ground for all system components. All

plus connections are internally connected anyway in the System-Manager.

6.7.2 Negative Grounding

If Negative Grounding is used, only one minus connection from any

one the components, i.e. module, battery or load can be grounded.

When your solar system requires a minus ground (e. g. battery

minus), only this component can be connected to ground. A connection

with further minus poles (module or load) bypasses the control

elements and the fuse. This can lead to a malfunction and destruction

of the System-Manager.

A+

A-

L-

L+

M+

M-

In systems with required load-minus-grounding (e.g. grounding

of aerials), all further components have to be connected with the grounds floating.

7 Maintenance

The System-Manager depends on its heat sink’s cooling area to meet its technical specifications. Therefore, the heat sink

must be kept clean of dust and debris that hampers cooling efficiency.

As far as the fuse and the cables are concerned, they must be checked for corrosion periodically. Due to corrosion, the

transfer resistance increases and the contacts could become so hot that damage occurs.

8 Technical Data

8.1 Performance Data

Reglertyp

2401 4401

System voltage 12V 24V 48V

Max. input voltage 48V 90V

Nominal load current at 20°C 40A 40A

Nominal discharge current at 20°C 10A 10A

max. current for 10s 55A 55A

Surge current for 0,5s 60A 60A

max. pulse current (200ms) 180A 180A

Own consumption 14 mA

Temp. range during operation -25°C...50°C

System-Manager TAROM | 716148 page 14 V09_45A

Page 16

System-Manager TAROM | 716148 page 15 V09_45A

storage temperature -25°C...80°C

Connecting screws 16/25mm²

Weight 400g

Dimensions 188x128x49mm

Type of protection IP22

8.2 Controlling Data at 25°C

2401 4401

programmable

13,0V...14,5V 26;0V...29,0V 52,0V...58,0V

end of charge (float) voltage

Factory adjustment

13,7V 27,4V 54,8V

programmable

13,5V...15,0V 27;0V...30,0V 54,0V...60,0V

Factory adjustment

14,4V 28,8V 57,6V

Quick charging

boost charging

activation

< 12,7V <25,4V < 50,8V

programmable

14,0V...15,0V 27;0V...30,0V 56,0V...62,0V

Factory adjustment

14,7V 29,4V 58,8V

equal charging

activation

< 12,4V <24,8V < 49,6V

programmable

11,0V...12,5V Deepcharging protection

Factory adjustment

11,4V

programmable

11,8V...13,3V

Load reconnection

Factory adjustment

12,6V

Charging process

IU-characteristic with PWM at 20Hz

low voltage < 10,5V <21,0V < 44,0V

high voltage

increasing the programmed value by 0,3V

high temperature

75°C inside, reset occurs automatically at 50°C

Voltage tolerance

+/- 50mV +/- 100mV +/-200mV

Current tolerance

<40% nominal current

Nominal current

5%

10%

5%

10%

5%

10%

9 Malfunctions And Errors

The System-Manager is designed for many years of constant use. Nevertheless, there may be faults. It is very often,

however, that the causes for these faults and errors do not occur in the System-Manager itself, but in the peripheral

system components. The following description should be used as a helpful guide to find the sources of malfunctions and

to put the device into operation as soon as possible so that unnecessary costs can be avoided. Certainly not all errors

are listed below. You will find the most common errors and symptoms covering the major part of all possible errors. Send

in the System-Manager only when you are sure that none of the below-described errors has occurred.

The System-Manager is protected against damage by various measures. Nevertheless, always take utmost care in the

proper operation of the System-Manager. Short hints of the malfunctions are indicated with the help of the LCD display.

However, errors are only properly indicated in which the system has been properly installed. If there are other

malfunctions than the ones described below, please check first of all if the System-Manager has been connected to the

battery, the module and the loads correctly in the right polarity. Afterwards, check the safety fuses. In each case of

malfunction, the System-Manager automatically switches off the load.

Error

message /

Symptoms

Meaning Remedy

Defective

fuses

Usually caused by wrong polarity at the battery connections

• Check the proper polarity of the

connections and after having fixed the

error, install the spare fuses

The indication

on the LCD

display went

out

• There is no current or voltage feed from the battery, the

reason could be a defective fuse

• current operating temperature is too high or too low

above/below the operating temperature, causing LCD

not to function

• Check the battery connections and

fuses

• Check the working temperature

• Reinstall the System-Manager

disconnect everything and connect it

again in the right order

“module The PV module current exceeds the max. currents allowed.

• The solar PV array exceeds the

Page 17

System-Manager TAROM | 716148 page 16 V09_45A

current” Although this will not cause an immediate defect, the heat

sink will become very hot and could cause injury. The load

is disconnected in order to avoid further self-heating. After

the current has decreased, the load will be reconnected

automatically and the error message disappears.

nominal currents. The system must

be split into smaller PV arrays units

on separate System-Managers.

“load current”

• The load current is too high and the output is

disconnected. Either the whole consumption exceeds

the max. discharge currents or the max. pulse currents

were exceeded by using high surge appliances.

• A short circuit has been caused. After the problem has

been solved, the System-Manager reconnects the load

about 30 seconds later.

• Switch off some loads by hand

• Clear the short circuit

“over

temperature”

The maximum allowable temperature has been exceeded.

In order to reduce further heat generation the loads are

disconnected automatically. As soon as the SystemManager has cooled down, normal operation will resume.

• Check the ventilation at the back heat

sink and clean it if necessary

• Protect the System-Manager from

direct sunshine

• Reduce warming caused by

appliances near the System-Manager

• Reduce the loads or PV modules.

“over voltage” In particular, the recharge process through back-up

generators or chargers tied directly to the battery causes

voltages which are harmful for some appliances. Therefore

these loads are disconnected when high battery voltages

are present.

• Disconnect external chargers

• adjust external chargers for less

voltage

“low voltage” To protect the battery, all loads powered by the System-

Manager will be disconnected. They will be reconnected

automatically after the battery voltage has reached the load

reconnecting level.

• Reduce loads or hours of operation of

loads to keep the battery from being

discharged deeply, or increase solar

array to add energy to the system

• Connect all loads through the

System-Manager to avoid strong

discharge of the battery

No module is connected, otherwise module, module internal

blocking diodes, or array is defective.

• Check contacts and junctions

“no module”

no module is connected but there is no detection of “no

modul”

• disconnect both wire (M+ and M-) at

the terminal of the regulator

• wait up to 1 hour

“EEProm

defect”

The EEPROM memory chip inside of the System-Manager

cannot be read or accessed any longer by the SystemManager’s circuitry.

• Disconnect the System-Manager and

reconnect it in the order described. If

the indication remains, the SystemManager must return to the dealer for

repair.

“self test

failure”

The self-test could not be carried out correctly, since the

solar PV array or the load was not disconnected, or one of

the components in the System-Manager is defective

• Disconnect all components, except

the battery and try again.

• If the self-test still failed, the SystemManager should be sent to the dealer

for service.

night "Night" appears at daytime

• wrong polarity module

"Night" appears not at night only "no module"

• string diodes block measurement

• 20kΩ parallel to string diode

10 Legal Guarantee

In accordance with German statutory regulations, there is a 2-year legal guarantee on this product for the customer.

The seller will remove all manufacturing and material faults that occur in the product during the legal guarantee period

and affect the correct functioning of the product. Natural wear and tear does not constitute a malfunction. Legal

guarantee does not apply if the fault can be attributed to third parties, unprofessional installation or commissioning,

incorrect or negligent handling, improper transport, excessive loading, use of improper equipment, faulty construction

work, unsuitable construction location or improper operation or use. Legal guarantee claims shall only be accepted if

notification of the fault is provided immediately after it is discovered. Legal guarantee claims are to be directed to the

seller.

Page 18

System-Manager TAROM | 716148 page 17 V09_45A

The seller must be informed before legal guarantee claims are processed. For processing a leg al g uarantee

claim an exact fault description and the invoice / delivery note must be provided.

The seller can choose to fulfil the legal guarantee either by repair or replacement. If the product can neither be repaired

nor replaced, or if this does not occur within a suitable period in spite of the specification of an extension period in writing

by the customer, the reduction in value caused by the fault shall be replaced, or, if this is not sufficient taking the interests

of the end customer into consideration, the contract is cancelled.

Any further claims against the seller based on this legal guarantee obligation, in particular claims for damages due to lost

profit, loss-of-use or indirect damages are excluded, unless liability is obligatory by German law.

Page 19

Page 20

Page 21

716148

Loading...

Loading...