Steca 746785, Solarix PI 500-12, Solarix PI 500-60, Solarix PI 500-L60, PI 550-24 Installation and operating instructions

...Page 1

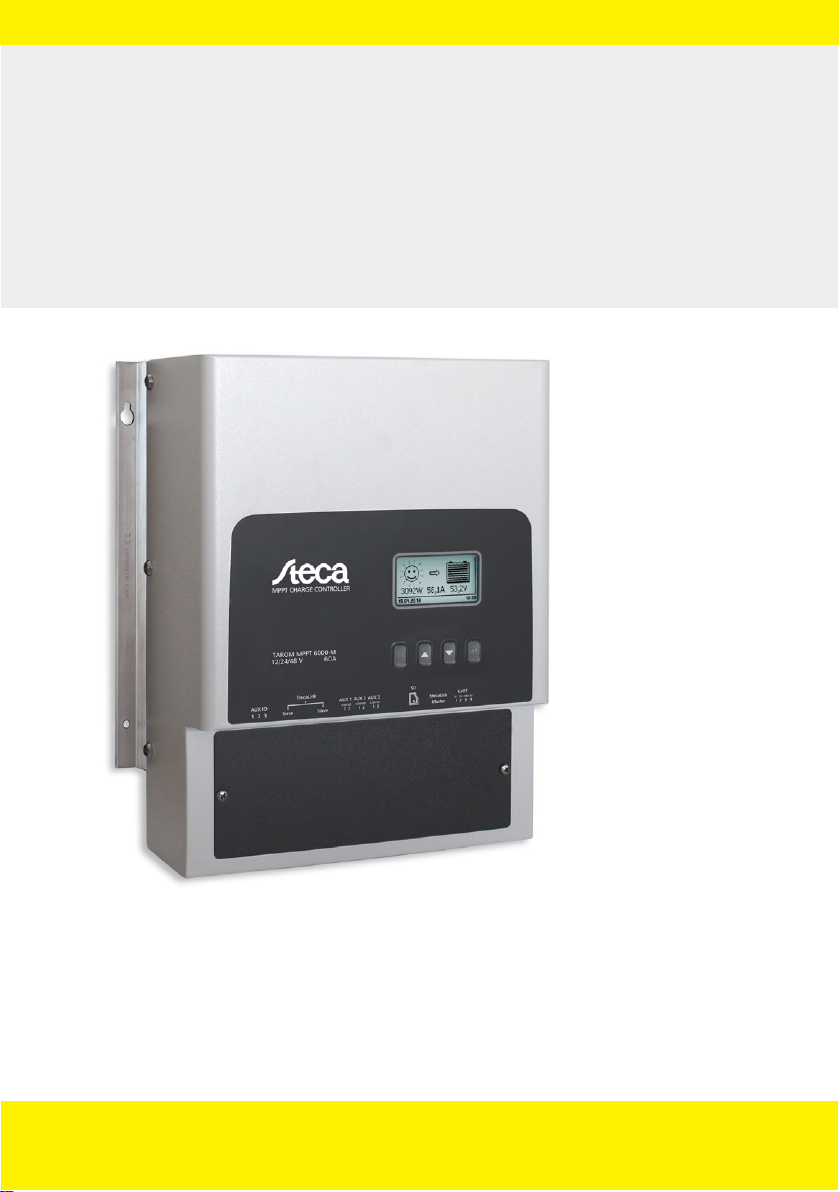

Solar charge controller

Installation and User Instructions

Tarom MPPT 6000-M

Tarom MPPT 6000-S

EN

756.404 | Z01 | 16.06

For further languages please visit: www.stecasolar.com

Page 2

Table of contents

1 General information............................................................................................................. 6

1.1 General safety instructions............................................................................................ 6

1.2 Identification................................................................................................................. 6

1.3 Scope of delivery........................................................................................................... 7

1.4 Proper usage................................................................................................................. 7

1.5 Markings....................................................................................................................... 8

1.5.1 Symbols for warnings and notices.............................................................................. 8

1.5.2 Keywords.................................................................................................................... 9

1.5.3 Terms and abbreviations used.................................................................................... 9

2 Quick guide......................................................................................................................... 10

Overview............................................................................................................................. 11

3

3.1 Controller power unit.................................................................................................. 11

3.2 Additional connections on the MPPT 6000-M............................................................. 13

3.3 Additional connections on the MPPT 6000-S............................................................... 15

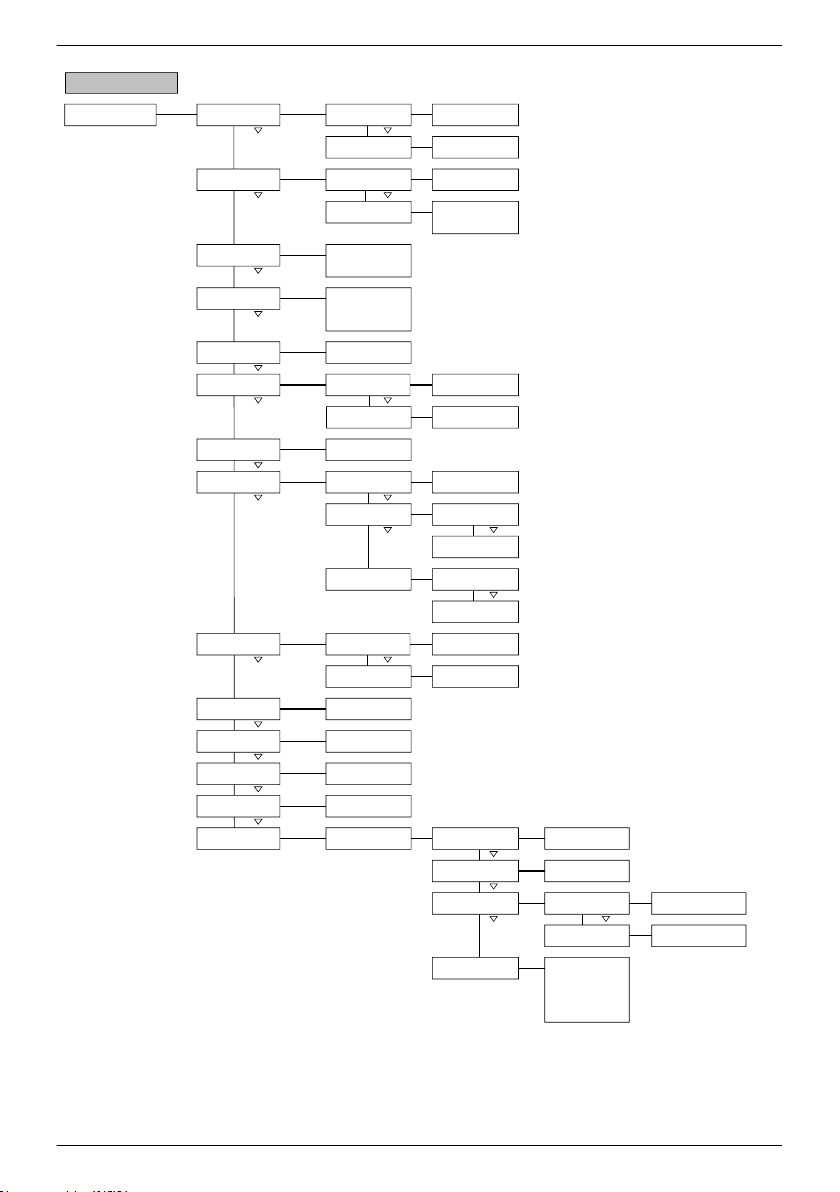

3.4 Menu structure............................................................................................................ 17

4 Installation of the base system......................................................................................... 23

4.1 Safety instructions....................................................................................................... 23

4.2 Installing the device..................................................................................................... 26

4.3 Establishing the electrical connections........................................................................ 27

4.3.1 Preparing the cables................................................................................................. 28

4.3.2 Connecting the battery............................................................................................. 28

4.3.3 Connecting the battery voltage sensor..................................................................... 29

4.3.4 Connect the ground (PE).......................................................................................... 29

4.3.5 Connecting the solar module................................................................................... 30

4.3.6 Install lightning protection....................................................................................... 30

4.4 Supplying the controller with voltage.......................................................................... 31

5 Initial commissioning of the base system........................................................................ 33

Installation and initial commissioning of optional components.................................... 40

6

6.1 Commissioning the SD card (MPPT 6000-M only)........................................................ 40

6.2 AUX 1,2,3 relay output connection (MPPT 6000-M only)............................................ 41

6.3 AUX IO remote control input connection (MPPT 6000-M only)................................... 41

6.4 PA TS-S external temperature sensor connection......................................................... 43

6.5 StecaLink slave connection.......................................................................................... 45

6.6 StecaLink master connection (MPPT 6000-M only)...................................................... 48

6.7 UART/RS-232 interface connection (MPPT 6000-M only)............................................. 50

6.8 Redundancy function (MPPT 6000-S only)................................................................... 51

6.9 Install cable strain relief............................................................................................... 51

7 Display (layout, function, operation)................................................................................ 52

7.1 Operating buttons....................................................................................................... 52

7.2 Overview/Menu structure............................................................................................ 52

2

756.404 | Z01 | 16.06

Page 3

7.3 Status display.............................................................................................................. 53

7.4 Display of special states............................................................................................... 56

7.5 General operation....................................................................................................... 56

7.6 Advanced operation.................................................................................................... 56

7.7 Display settings........................................................................................................... 58

8 System functions................................................................................................................ 59

8.1 Protection functions.................................................................................................... 59

8.1.1 Controller overload................................................................................................... 59

8.1.2 Overheating of the controller................................................................................... 60

8.1.3 Deep discharging of the battery (MPPT 6000-M only).............................................. 60

8.2 Battery type setting..................................................................................................... 60

8.3 Current limit system setting (MPPT 6000-M only)........................................................ 60

8.4 Current limit device setting......................................................................................... 61

8.5 Lead-acid battery system functions............................................................................. 62

8.5.1 Equalisation cycle mode........................................................................................... 62

8.5.2 Battery control mode (MPPT 6000-M only)............................................................... 63

8.5.3 Battery capacity test (MPPT 6000-M only)................................................................ 65

8.5.4 Battery type.............................................................................................................. 66

8.5.5 Battery capacity........................................................................................................ 66

8.5.6 Current limit system (MPPT 6000-M only)................................................................ 66

8.5.7 Current limit device.................................................................................................. 66

8.5.8 Charge voltages........................................................................................................ 66

8.5.9 IUIA charge mode (MPPT 6000-M only).................................................................... 69

8.5.10 Start boost charge.................................................................................................. 70

8.5.11 Battery temperature sensor.................................................................................... 71

8.5.12 Cable compensation............................................................................................... 71

8.5.13 PV string connection.............................................................................................. 71

8.5.14 Expert menu........................................................................................................... 72

8.6 Li-Ion battery system functions (MPPT 6000-M only)................................................... 74

8.6.1 Battery control mode................................................................................................ 74

8.6.2 Battery type.............................................................................................................. 74

8.6.3 Battery capacity........................................................................................................ 74

8.6.4 Current limit system................................................................................................. 74

8.6.5 Current limit device.................................................................................................. 75

8.6.6 Li-Ion battery settings............................................................................................... 75

8.6.7 Battery temperature sensor...................................................................................... 77

8.6.8 Cable compensation................................................................................................. 77

8.6.9 PV string connection................................................................................................ 77

8.7 NiCd battery system functions (MPPT 6000-M only).................................................... 77

8.7.1 Battery control mode................................................................................................ 78

8.7.2 Battery type.............................................................................................................. 78

8.7.3 Battery capacity........................................................................................................ 78

8.7.4 Current limit system................................................................................................. 78

8.7.5 Current limit device.................................................................................................. 78

756.404 | Z01 | 16.06

3

Page 4

8.7.6 NiCd battery settings................................................................................................ 79

8.7.7 Battery temperature sensor...................................................................................... 85

8.7.8 Cable compensation................................................................................................. 85

8.7.9 PV string connection................................................................................................ 85

8.7.10 Expert menu........................................................................................................... 85

8.8 StecaLink bus............................................................................................................... 85

8.8.1 StecaLink slave address setting................................................................................. 86

8.8.2 StecaLink master setting (MPPT 6000-M only).......................................................... 86

8.8.3 Changing the MPPT 6000-S slave settings (MPPT 6000-M only)............................... 87

8.9 Internal data logger..................................................................................................... 91

8.9.1 Energy input............................................................................................................. 92

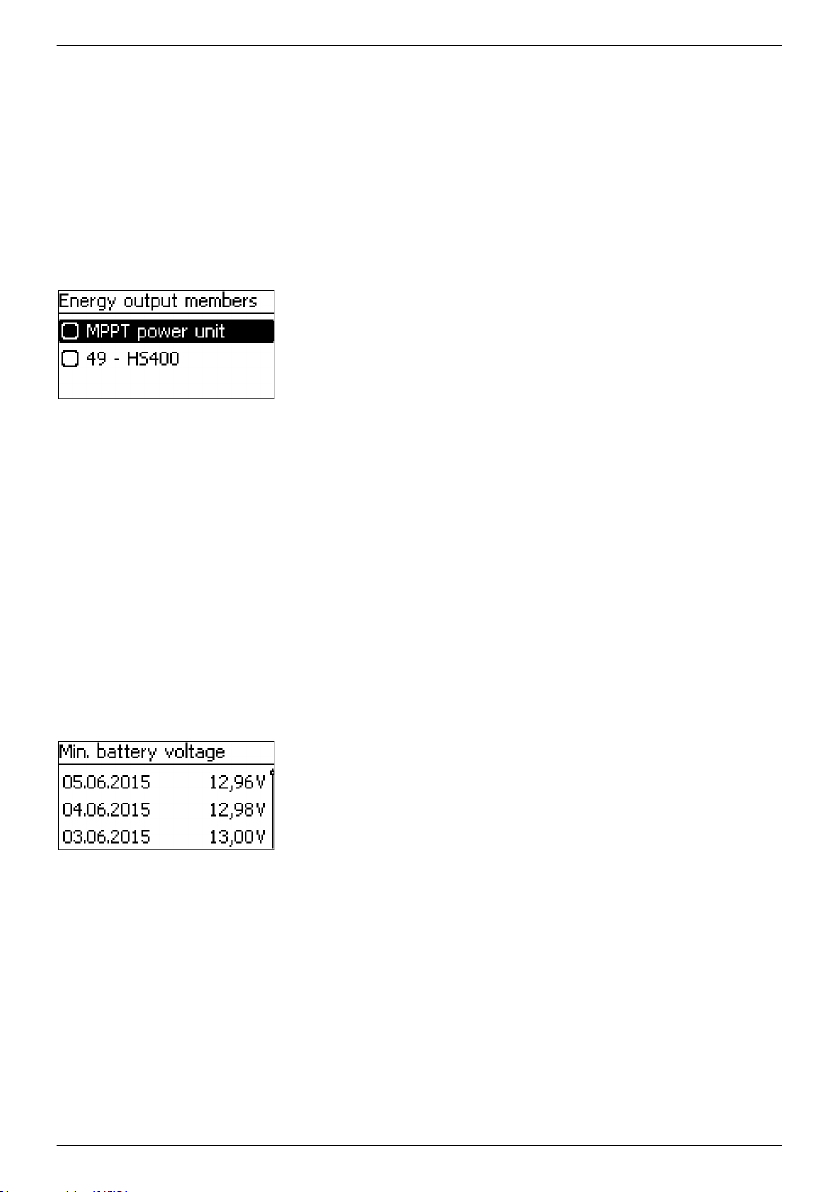

8.9.2 Energy output (MPPT 6000-M only).......................................................................... 94

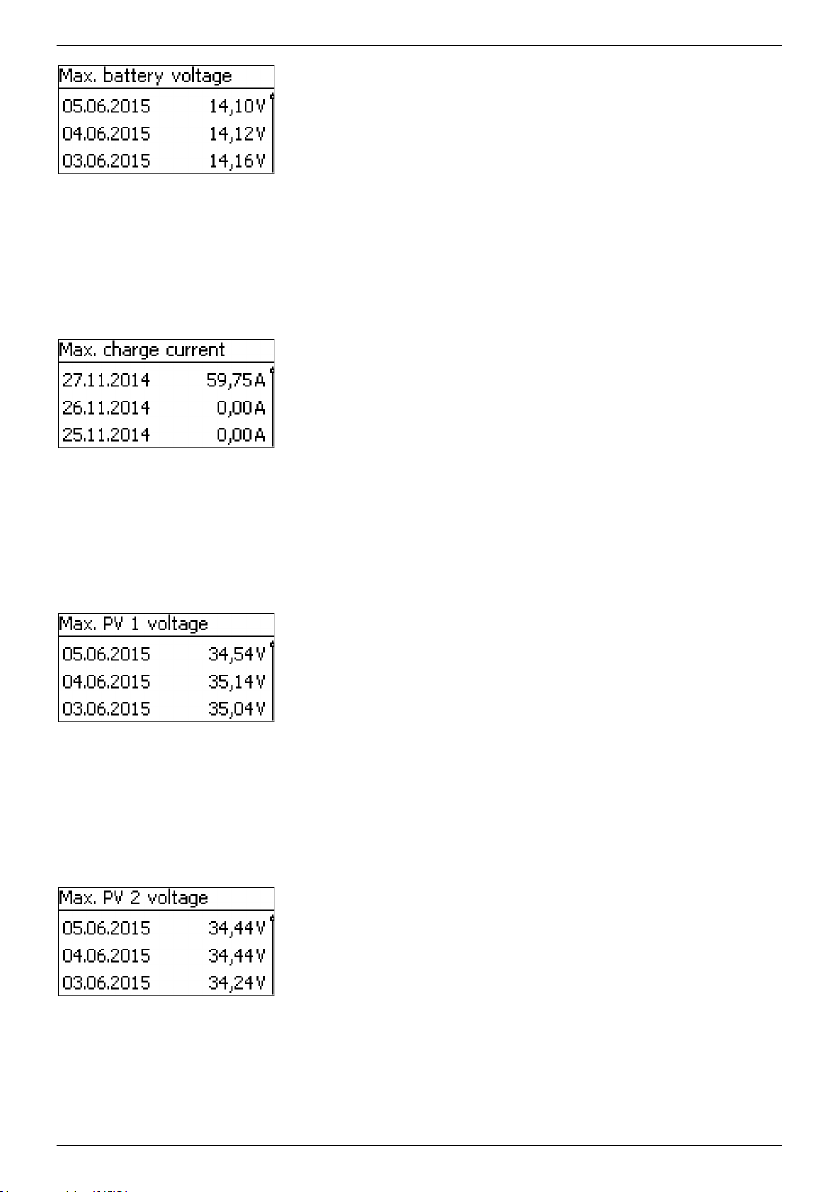

8.9.3 Min./Max. values...................................................................................................... 97

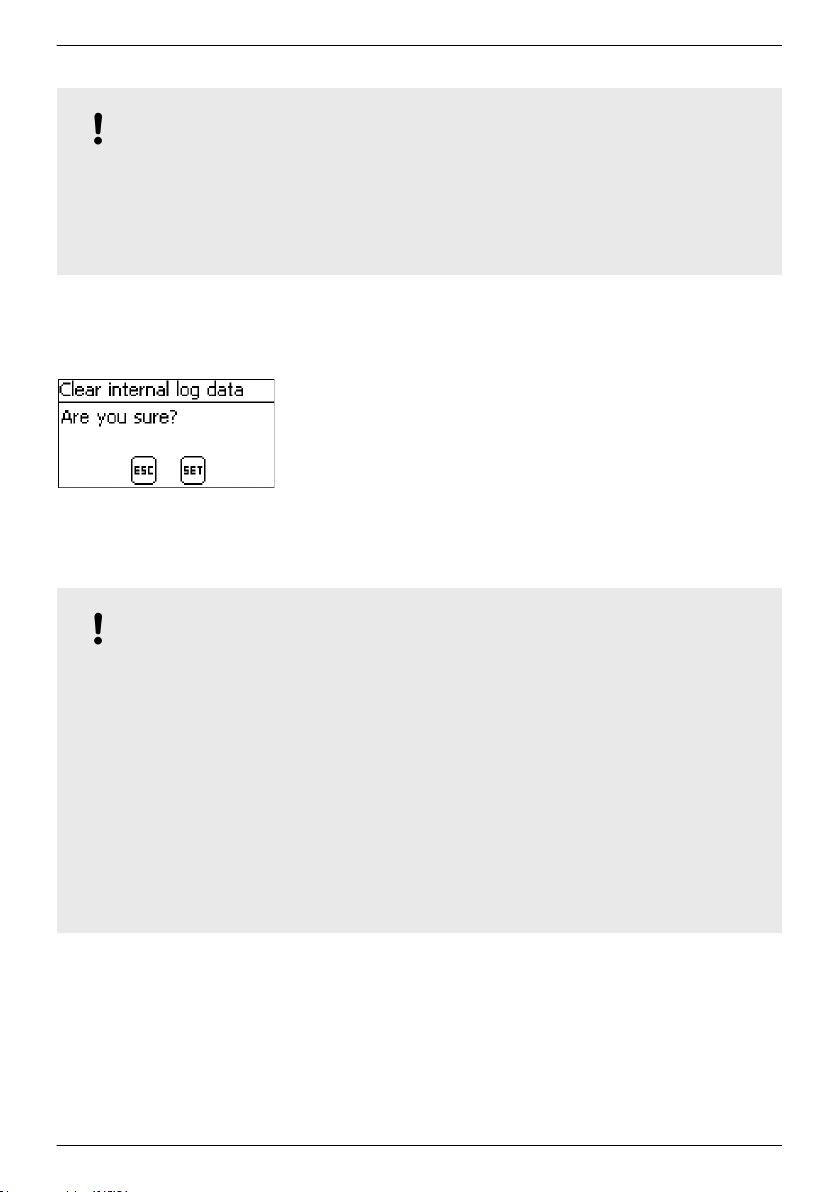

8.10 Clear log data............................................................................................................ 99

8.11 Clear event log.......................................................................................................... 99

8.12 Factory settings......................................................................................................... 99

8.13 UART/RS-232 interface (MPPT 6000-M only)............................................................ 100

8.14 Acoustic alarm......................................................................................................... 100

8.15 SD card (MPPT 6000-M only)................................................................................... 101

9 Control functions via AUX 1/2/3 (MPPT 6000-M only).................................................... 103

9.1 Overview................................................................................................................... 103

9.2 Operation.................................................................................................................. 103

9.3 Functionality.............................................................................................................. 106

9.3.1 Deep discharge protection..................................................................................... 107

9.3.2 Evening light function ........................................................................................... 107

9.3.3 Night light function ............................................................................................... 107

9.3.4 Morning light function........................................................................................... 108

9.3.5 Excess energy control............................................................................................. 108

9.3.6 Generator control................................................................................................... 109

9.3.7 Timer 1 to 4............................................................................................................ 109

10 Troubleshooting............................................................................................................... 111

10.1 Factory settings....................................................................................................... 111

10.2 Event messages....................................................................................................... 111

10.2.1 Indicator on the display........................................................................................ 111

10.2.2 Function............................................................................................................... 111

10.2.3 Operation............................................................................................................. 111

10.2.4 List of event messages.......................................................................................... 112

10.3 Errors without event messages................................................................................ 118

11 Maintenance, dismounting and disposal....................................................................... 121

11.1 Maintenance of the controller................................................................................. 121

11.1.1 Removing dust..................................................................................................... 121

11.1.2 Removing heavy soiling........................................................................................ 121

11.2 System maintenance............................................................................................... 121

4

756.404 | Z01 | 16.06

Page 5

11.3 Dismounting the controller..................................................................................... 122

11.4 Disposal of the controller........................................................................................ 123

12 Technical data.................................................................................................................. 124

12.1 Controller................................................................................................................ 124

12.2 Connection cable..................................................................................................... 138

12.3 UART/RS-232 interface protocol (MPPT 6000-M only).............................................. 142

12.3.1 Settings................................................................................................................ 142

12.3.2 UART/RS-232........................................................................................................ 143

12.4 Recording data on an SD card (MPPT 6000-M only)................................................ 145

12.4.1 MPPT 6000-M data file......................................................................................... 146

12.4.2 TIMECHG data file................................................................................................ 148

12.4.3 PA HS400 data file................................................................................................ 148

12.4.4 MPPT 6000-S data file.......................................................................................... 149

13 Guarantee conditions, exclusion of liability, contacts, notes........................................ 151

13.1 Guarantee conditions.............................................................................................. 151

13.2 Exclusion of liability................................................................................................. 151

13.3 Contact.................................................................................................................... 151

13.4 Notes....................................................................................................................... 151

756.404 | Z01 | 16.06

5

Page 6

1 General information

1.1

General safety instructions

n This document is part of the product.

n Only technical professionals may perform the work described in this manual.

n Install and use the device only after reading and understanding this document.

n Always perform the measures described in this document in the sequence specified.

n Keep this document in a safe place for the entire service life of the device. Pass the document

on to subsequent owners and operators of the device.

n Incorrect operation can reduce solar system yields or damage system components.

n The device must not be connected to the DC cables if it has a damaged casing.

n Immediately take the device out of operation and disconnect it from the battery and modules if

any of the following components is damaged:

–

device (not functioning, visible damage, smoke, penetration of liquid etc.),

– connected cables,

– solar module,

– battery.

Do not switch the system on again before the following requirements are satisfied:

– The device has been repaired by a dealer or the manufacturer.

– Damaged cables or solar modules have been repaired by a technical specialist.

n Battery acid splashes on skin or clothing should be immediately treated with soap suds and

rinsed with plenty of water. Immediately seek medical advice in the case of injuries.

n If battery acid splashes into the eyes, immediately rinse with plenty of water and seek medical

advice.

n Never cover the device.

n Do not open the casing: Risk of death! Invalidation of the guarantee! Only the terminal cover

may be removed by a technical professional for installation or repair purposes.

n Do not operate the device without the terminal cover installed. Risk of death!

n Factory labels and markings must never be altered, removed or rendered unreadable.

n Observe the manufacturer's manual when connecting an external device that is not described in

this document. Incorrectly connected devices can damage the controller.

n This device is not intended for:

– children,

– persons with physical, sensory or mental impairment,

– persons without sufficient experience or knowledge, unless they are instructed in the use

of the device, and initially supervised, by a person responsible for their safety.

1.2 Identification

General information

Feature Description

Types MPPT 6000-M; MPPT 6000-S

Issue version of the manual Z01

6

756.404 | Z01 | 16.06

Page 7

Feature Description

Certificates

See www.steca.com ‘Solar Electronics è PV Off Grid

è Solar Charge Controllers è Steca Tarom MPPT’.

Optional accessories

n Steca PA TS-S external temperature sensor

n StecaLink-compatible Steca PA HS400 current sensor

n RJ45 termination plug for the StecaLink bus

n RJ45 cable for connecting the MPPT 6000-M and

1)

Included in the scope of delivery with the 6000-M.

2)

Can only be used with the MPPT 6000-M.

Scope of delivery

1.3

1)

2)

1)

MPPT 6000-S

MPPT 6000-S:

n MPPT 6000-S device

n Fastening set (screws, dowels)

n Socket, 2-pin, green, for connecting the battery voltage sensor cable

n Operating instructions

MPPT 6000-M:

n MPPT 6000-M device

n Fastening set (screws, dowels), socket, 2-pin, green, for connecting the battery voltage sensor

cable

n Steca PA TS-S external temperature sensor, with socket,

2-pin, green

n Socket, 3-pin, green, for AUX IO connection

n Socket, 3-pin, green, for RS-232 connection

n 3 sockets, 2-pin, green, for the AUX1/2/3 connections

n Termination plug (RJ45)

n Operating instructions

1.4 Proper usage

The solar charge controller, hereinafter named as the controller or device, may only be used in

stand-alone photovoltaic systems for charging and controlling the following types of battery.

n MPPT 6000-S: lead acid batteries

n MPPT 6000-M: lead acid batteries, lithium-ion batteries (Li-Ion), nickel-cadmium batteries (NiCd)

When the device is used with lithium-ion systems, an external battery management system (BMS)

must be present to provide the protection and safety functions necessary for such systems (e.g.

temperature monitoring, safety switch-off, equalisation of cell voltages). These functions are not

provided by the MPPT 6000-M/S.

NOTICE!

MPPT 6000-M: In a networked system with MPPT 6000-M and MPPT 6000-S devices, the

charging of Li-Ion and NiCd batteries is only possible using a Master/Slave system controlled by

the MPPT 6000-M. The charging of Li-Ion and NiCd batteries via the MPPT 6000-S is deactivated

as soon as the MPPT 6000-M is no longer active in the network.

756.404 | Z01 | 16.06

7

Page 8

The following also applies:

n The controller must not be connected to the public electricity grid.

n Only solar modules may be connected to the solar module connections.

n Possible system voltages for the MPPT 6000-M/-S (nominal battery voltages): 12 V, 24 V, 36 V,

48 V, 60 V; (12 V, 24 V and 48 V: automatic detection; 36 V, 60 V: manually set via the Expert

menu).

n The controller performs, in particular, the following tasks:

–

Maximisation of power extraction from the modules via an integrated MPP tracker.

– Controlling of the charging process.

– Recording of yield and system data.

– Recording of data on a microSD card (MPPT 6000-M only).

– Integration of StecaLink-compatible devices (MPPT 6000-M only).

– Charging control via the AUX IO input (MPPT 6000-M only).

– Programmable AUX1/2/3 outputs (MPPT 6000-M only).

– UART/RS-232 data output (MPPT 6000-M only).

1.5 Markings

1.5.1 Symbols for warnings and notices

Symbol Description Location

General danger warning. Instructions

Danger from electricity. Instructions

Danger from hot surfaces. Instructions

Danger from battery acid. Instructions

Read the manual before using the product. Device

General information. Instructions

✔

8

The following information describes prerequisites

for further operation.

Instructions

756.404 | Z01 | 16.06

Page 9

1.5.2 Keywords

The following keywords are used together with corresponding symbols for warnings and

notices.

Keyword Description

Danger Immediate danger of death or serious bodily injury.

Warning Possible danger of death or serious bodily injury.

Caution Possible danger of light or medium bodily injury.

Attention Possible damage to property.

Notice Note on operation of the device or use of the manual.

1.5.3 Terms and abbreviations used

Term, abbreviation Description

Battery This manual uses the singular term ‘battery’ . The battery can

Module

Solar module This manual uses the singular term ‘solar module’ . The solar

String Multiple solar modules connected in series or parallel.

Lead-acid battery Collective term for batteries using lead technology. Includes variants

Li-Ion battery Collective term for batteries using lithium ion technology.

NiCd battery Collective term for batteries using nickel-cadmium technology.

however consist of multiple batteries connected together (battery

bank).

Ä

Chapter 4.3.5 ‘Connecting the solar module’ on page 30.

See

module can however consist of multiple solar modules connected

together (string, solar module array).

such as lead-acid batteries with liquid electrolyte, gel batteries and

AGM batteries.

756.404 | Z01 | 16.06

9

Page 10

1.

2.

3.

4.

5.

6.

+

4x

-

+

+

B

A

+

-

C

M1+

M1-

+

-

D

M2+ M2-

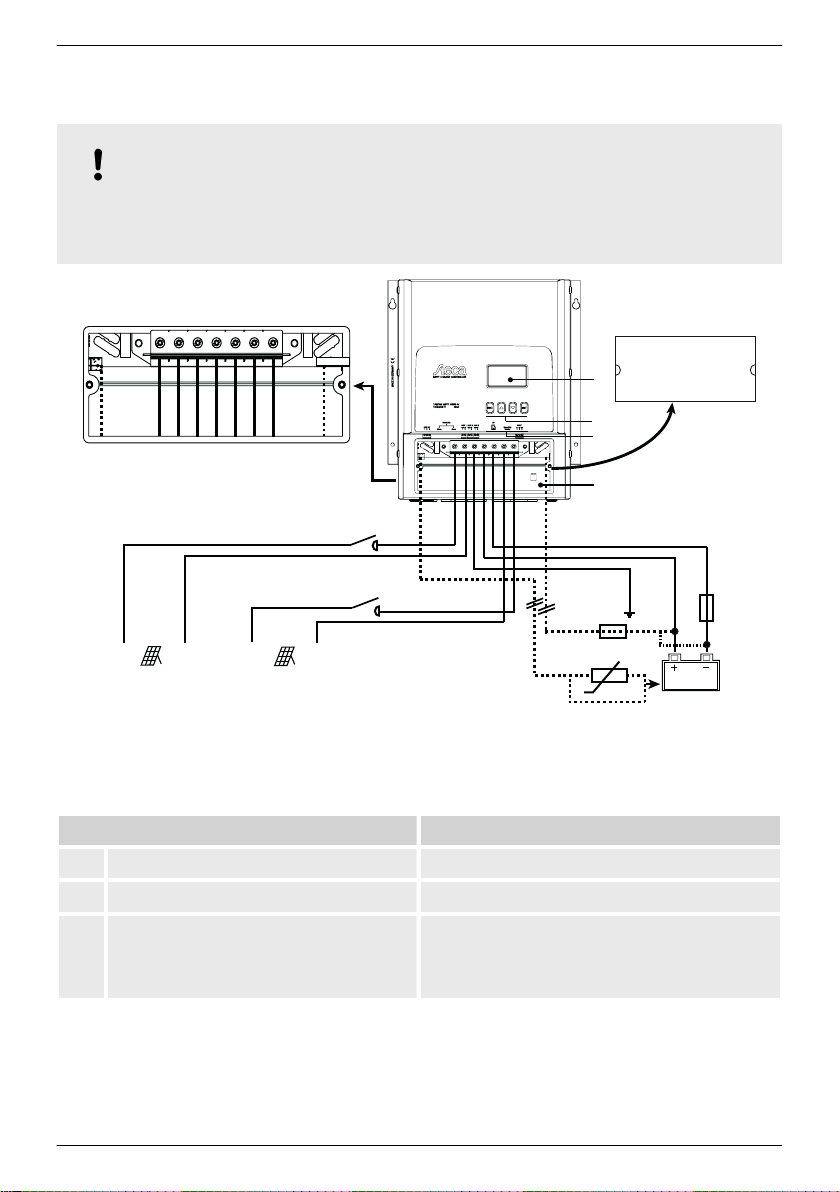

2 Quick guide

DANGER!

Risk of death by electrocution. Observe the safety notice at the start of the section ‘Installation

Ä

of the base system’ (

‘Installation of the base system’ on page 23)!

Fig. 1: Quick guide

A Installation

B Removal

10

= Mandatory!

C Module 1

D Module 2

756.404 | Z01 | 16.06

Page 11

3 Overview

+

+

-

-

M1+

M1-

M2+

M2-

M1+

M1-

PEB+B-

M2-

M2+

TEMP

BAT+/-

+/-

TEMP

TEMP

M1+

M1-

M2-

M2+

B-

B+

B

AT+/-

B-

B+

PE

BAT+/-

ཱི

ཱི

ཱི

ཱ

ི

ུ

ཱུྲྀ

ླྀ

ཹ

ཽ

ེ

ོ

ཻ

ཷ

ཾ

3.1

Controller power unit

NOTICE!

The power unit connector assignments of the MPPT 6000-M and MPPT 6000-S are identical.

The MPPT 6000-M and MPPT 6000-S differ in the additional components that can be

connected.

Fig. 2: Overview of the casing and connections on the power units for the MPPT 6000-M and MPPT

6000-S

Component Description

1 Display

2 Operating buttons

3 2 x RJ45 sockets for StecaLink slave

(MPPT 6000-S)

756.404 | Z01 | 16.06

ESC, D, Ñ, SET

Service interface for technical professionals,

connection to an MPPT 6000-M and connection

to additional StecaLink expansion devices such

as (e.g.) the PA HS400.

11

Page 12

Component Description

4 Terminal area

n "M1+"/"M1−" (solar module 1)

n "M1+"/"M1−" (solar module 2)

n "B+"/"B−" (battery)

n "PE" (ground)

n "BAT+/−" (battery voltage sensor cable)

n "TEMP" (ext. battery temperature sensor)

5 Terminal cover The terminal cover is fastened with 2 Phillips

screws.

External components Description

6 Solar module 1 Connect to terminals "M1+" and "M1−".

7 Solar module 2 Connect to terminals "M2+" and "M2−".

8 Battery Connect to terminals "B+" and "B−".

9,

DC load circuit breaker 4) for solar

10

module1/2

Danger

Danger from electrical voltage. Installation is

legally prescribed!

11 External battery temperature sensor

PA TS-S

3)

2)

3)

12 Battery voltage sensor cable connection

2)

13 External battery fuse (safety fuse or DC

circuit breaker

12

1) 4)

Attention

Use only an original Steca PA TS-S sensor. The

connection polarity is unimportant.

n Connect the cable directly to the battery.

n Observe the polarity specified in the

drawing.

Caution

Danger from high currents. Installation is legally

prescribed!

756.404 | Z01 | 16.06

Page 13

External components Description

11

1

9

15 20 17 16

18

12

14 Central grounding point If a grounding point is not already present then

this must be created, e.g. by hammering in a

grounding spike! Using the PE connection on

the MPPT 6000-M and MPPT 6000-S is legally

prescribed.

15 Fuse for battery voltage sensor cable The installation is mandatory if the optional

battery voltage sensor cable is used!

1)

For technical data see

2)

Optional, connector included in the scope of delivery. Connecting cable not included in the scope

Ä

Chapter 12 ‘Technical data’ on page 124.

of delivery.

3)

Included in the scope of delivery with the 6000-M.

4)

Not included in the scope of delivery.

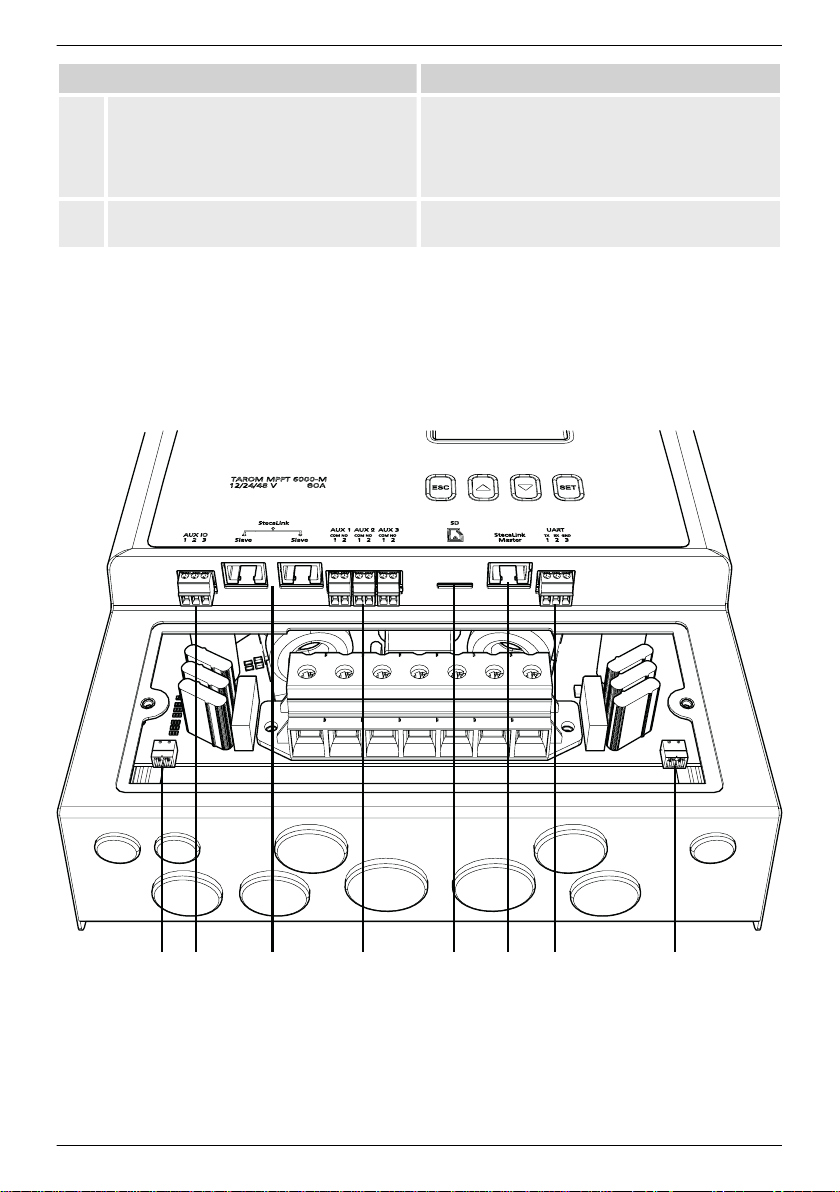

3.2 Additional connections on the MPPT 6000-M

Fig. 3: Overview of additional connections on the MPPT 6000-M

756.404 | Z01 | 16.06

13

Page 14

Component Description

15 2 x RJ45 sockets for StecaLink Slave

(MPPT 6000-M)

16 1 x RJ45 socket for StecaLink Master

(MPPT 6000-M)

17

Slot for microSD card 4) (MPPT 6000-M)

Service interface for technicians and connection

for superordinate StecaLink systems.

Connection for subordinate StecaLink

extensions such as e.g. PA HS400, MPPT 6000-S.

MicroSD card for data logging and storing

parameters.

18

Open UART interface

+5 V/0 V/-5 V (MPPT 6000-M)

19

AUX IO input 2) (MPPT 6000-M)

1) 2)

, RS-232 levels of

RS-232 data output, with Tx, Rx, GND

connections.

Remote control input for activating/deactivating

charging of the battery.

20

AUX 1/2/3 outputs 2) (MPPT 6000-M)

Programmable, potential-free relay outputs for

various control functions.

External components Description

11 External battery temperature sensor

PA TS-S

3)

Attention

Use only an original Steca PA TS-S sensor. The

connection polarity is unimportant.

12 Battery voltage sensor cable connection

2)

n Connect the cable directly to the battery.

n Take care to ensure the correct polarity, as

shown in Fig. 2, terminal area

enlargement.

1)

For technical data see

2)

Optional, connector included in the scope of delivery. Connecting cable not included in the scope

Ä

Chapter 12 ‘Technical data’ on page 124.

of delivery.

3)

Included in the scope of delivery with the 6000-M.

4)

Not included in the scope of delivery.

14

756.404 | Z01 | 16.06

Page 15

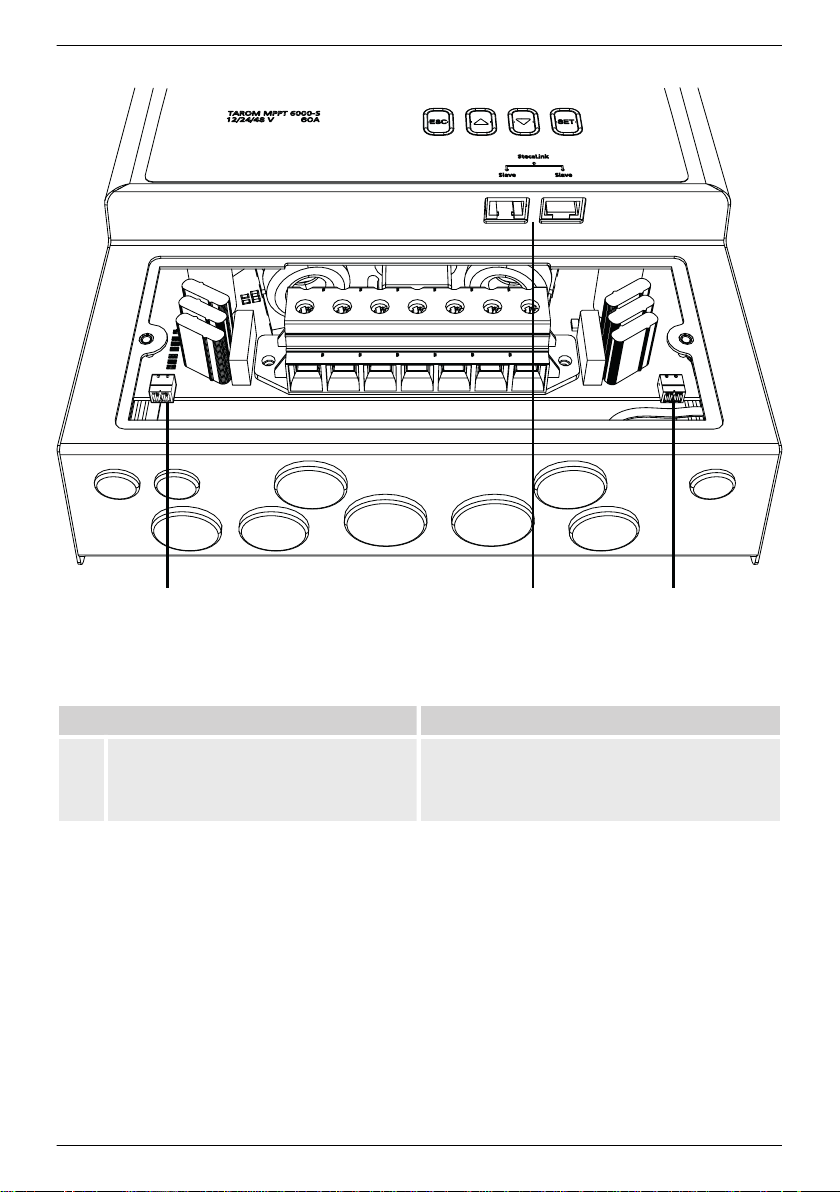

3.3 Additional connections on the MPPT 6000-S

11

12

3

Fig. 4: Overview of additional connections on the MPPT 6000-S

Component Description

3 2 x RJ45 sockets for StecaLink Slave

(MPPT 6000-S)

Service interface for technical professionals and

connection to an MPPT 6000-M and connection

to additional StecaLink expansion devices such

as (e.g.) the PA HS400.

756.404 | Z01 | 16.06

15

Page 16

External components Description

11 External battery temperature sensor

PA TS-S

3)

Attention

Use only an original Steca PA TS-S sensor. The

connection polarity is unimportant.

12 Battery voltage sensor cable connection

2)

n Connect the cable directly to the battery.

n Observe the polarity specified in the

drawing.

13 External battery fuse (fuse or DC circuit

breaker)

1) 4)

Caution

Danger from high currents. Installation is legally

prescribed!

14 Central grounding point If a grounding point is not already present then

this must be created, e.g. by hammering in a

grounding spike! Using the PE connection on

the MPPT 6000-M and MPPT 6000-S is legally

prescribed.

1)

For technical data see

2)

Optional, connector included in the scope of delivery. Connecting cable not included in the scope

Ä

Chapter 12 ‘Technical data’ on page 124.

of delivery.

3)

Included in the scope of delivery with the MPPT 6000-M.

4)

Not included in the scope of delivery.

16

756.404 | Z01 | 16.06

Page 17

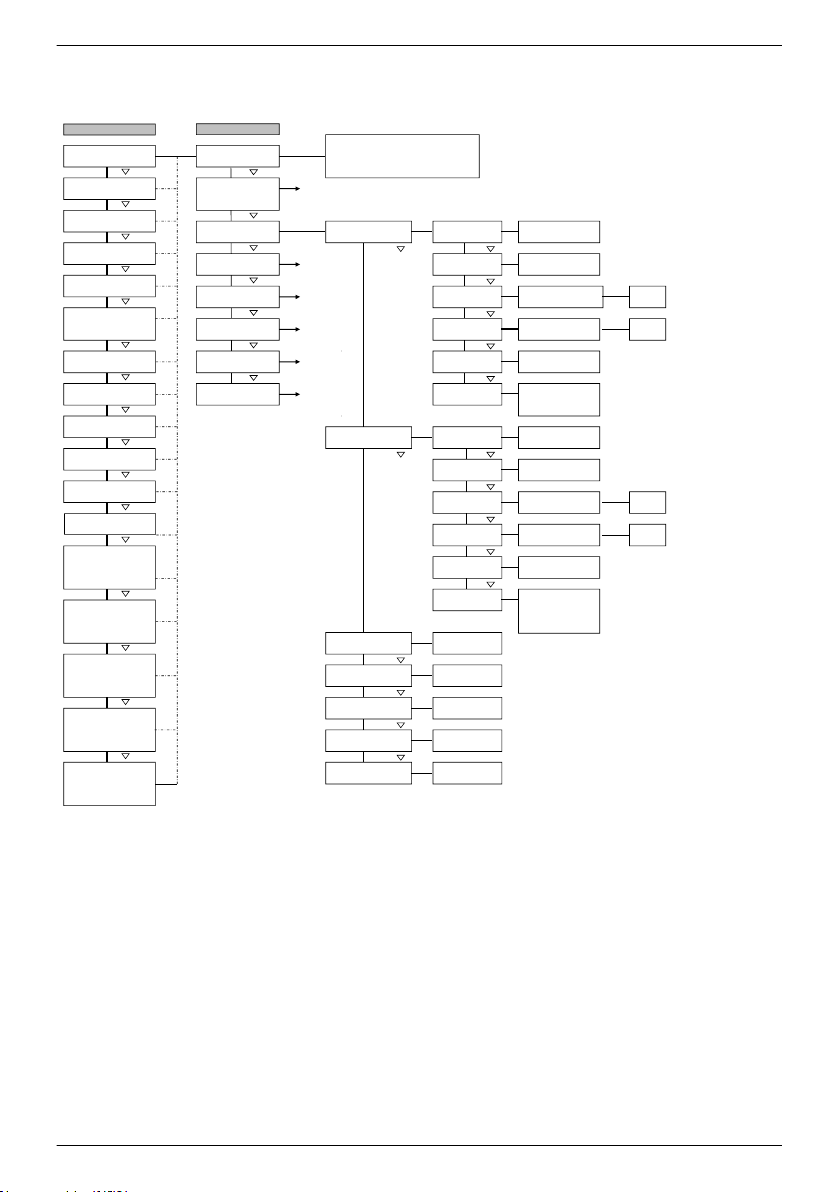

3.4 Menu structure

Set Set

Set Set

A)

Set

Set Set Set

Set

Set Set

B)

Set

Set Set Set

C)

Set

Set Set Set

D)

Set Set Set

E)

Set Set Set

F)

Set

Set Set

Set

Set

Set

Set Set

Set Set Set

Set

Set

Set

Set

Set

Set Set

Set

Set

Set

Set

Set

*1) MPPT 6000-M only

*3) SOC Control mode only

*2) MPPT 6000-S only

Status display

Basic position

Main window

Charge current M PPT

Battery voltage

Voltage ext. bat. sens e

SOC

*1, *3

Result of capacity test

*1

PV 1 voltage

PV 2 voltage

PV power tot al

PV 1 power

PV 2 power

Operating hours

Total charge/discharge

current of battery

*1

Total discharge current of

battery

*1

Total charge/discharge

power of battery

*1

Total charge c urrent of

battery

*1

Device On/Off

Settings AUX 1/2/3

*1

Intern al dat a logg er

SD card

*1

System sett ings

Battery settings

Event log

Information

Energy input

Main menu

Device On/Off

[ ] On

[ ] Off

[ ] Remote *1 / [ ] Redundanc y *2

Energy output

*1

Min. battery voltage

Max. battery voltage

Max. charge current

Max. PV 1 voltage

Max. PV 2 voltage

Last 18 hours

Day

Month

Year

Total

Configuration

*1

Graphic

List for last 30 days

Ah

List for last 12 months

Ah

Total yield info

Ah

List for last 20 years

Ah

Energy input members

[ ] MPPT power unit

[ ] …..

Graphic

Graphic

Last 18 hours

Day

Month

Year

Total

Configuration

*1

Graphic

List for last 30 days

Ah

List for last 12 months

Ah

Total yield info

Ah

List for last 20 years

Ah

Energy output members

[ ] MPPT power unit

[ ] …..

Graphic

Graphic

List for last 30 days

V

List for last 30 days

V

List for last 30 days

A

List for last 30 days

V

List for last 30 days

V

Power information from

StecaLi nk s lave

participants

*1

For the sake of clarity, only the Ñ

and SET operating buttons are illustrated.

756.404 | Z01 | 16.06

17

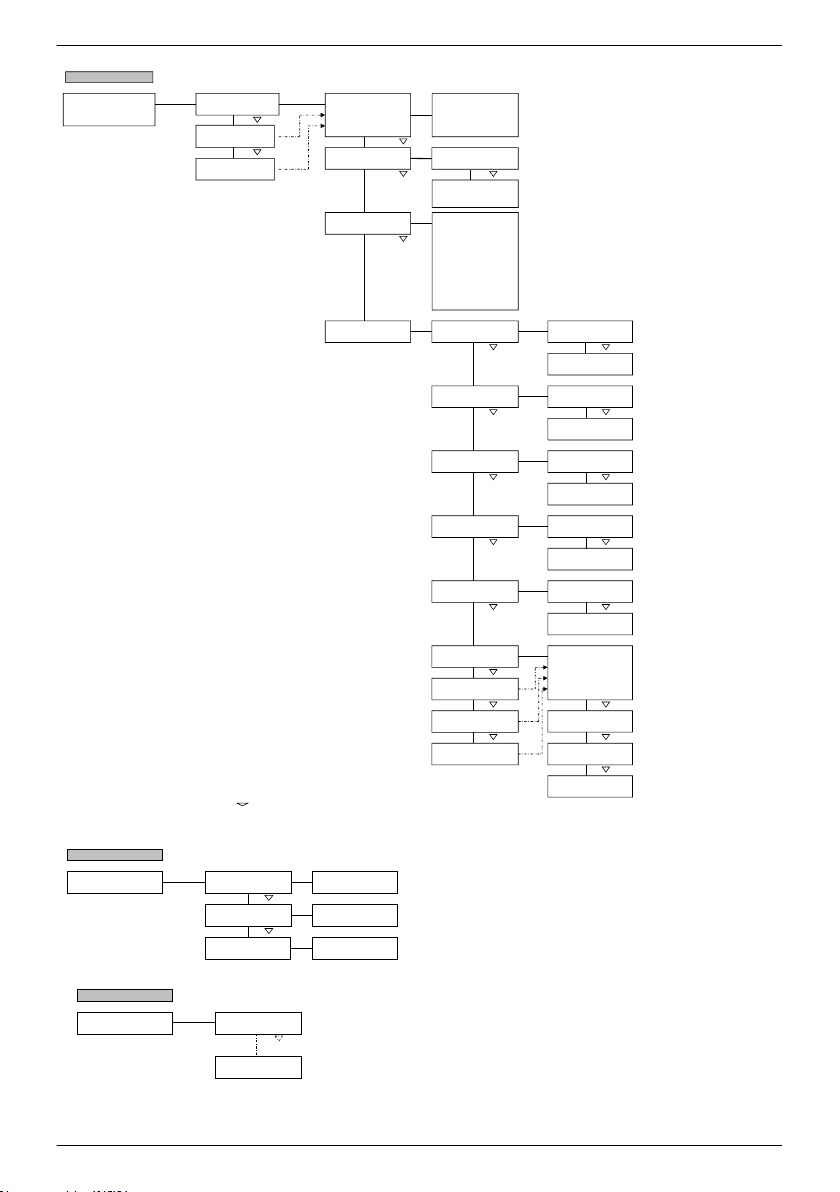

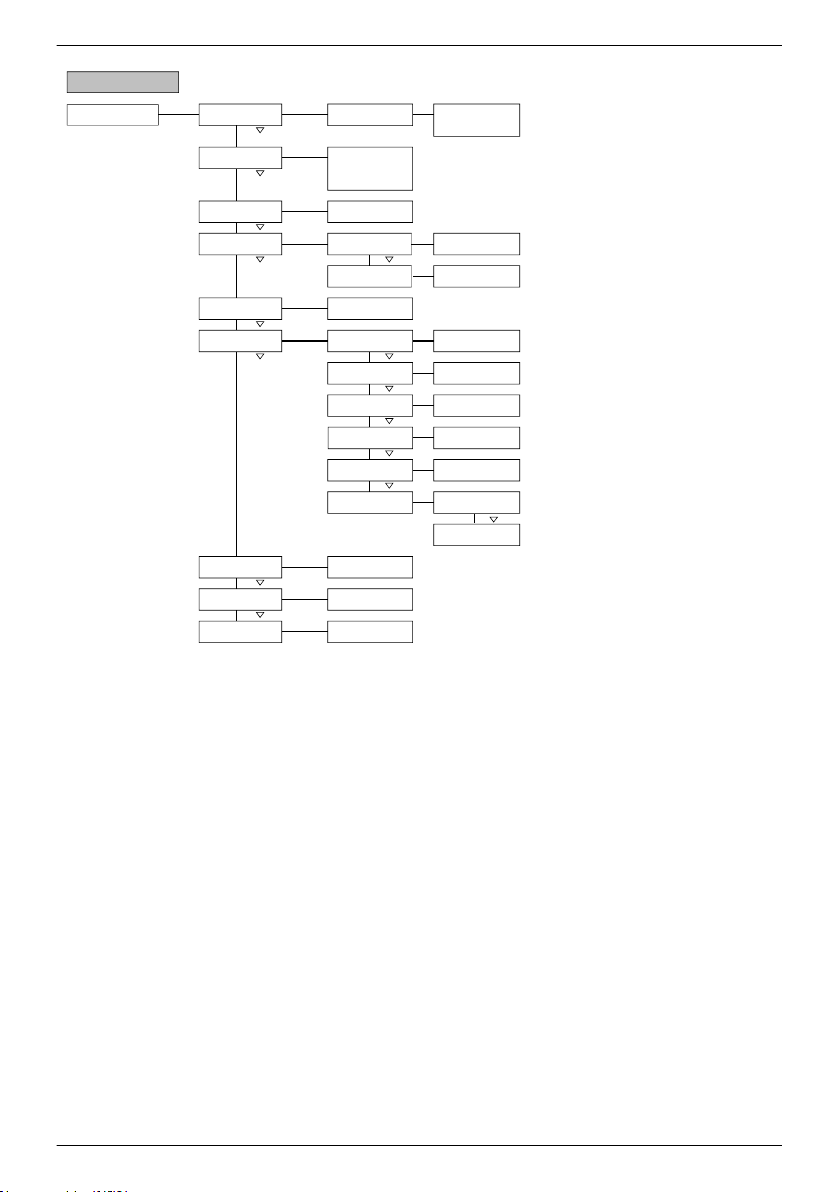

Page 18

Set Set

Set

Set

Set

Set

Same scope of settings for AUX1/2/3

Set

Set Set

*5

Set

*5

Set

*5

Set

Set

Set

Set

Set

Set

*1) MPPT 6000-M only

*3) SOC Control mode only

*5) Separate entry of hh and mm, therefore press multiple times to change to the next window

Same scope of

settings for timer 1/2/3/4

*4) Voltage control mode only

Settings AUX 1/2/3

*1

AUX 1

AUX 2

AUX 3

Operation mode

Deep dischar ge p rot.

Select function

Function settings

AUX op eration mode

[ ] On

[ ] Off

[ ] Function

Disconnection threshold

SOC *3 / V *4

Reconnection hys teresis

SOC *3 / V *4

Select AUX func tion

[ ] Evening light

[ ] Night light

[ ] Morning light

[ ] G enerator con trol

[ ] E xcess energy contr ol

[ ] Timer 1

[ ] Timer 2

[ ] Timer 3

[ ] Timer 4

Evening light

Night light

Morning light

Generator control

Excess energ y con trol

Timer 1

Timer 2

Timer 3

Timer 4

Switch-on delay

00:00

Switch-on duration

00:00

Switch-on delay

00:00

Switch-off delay

00:00

Switch-off delay

00:00

Switch-on duration

00:00

Starting threshold

SOC *3 / V *4

Hyster esis

SOC *3 / V *4

Starting threshold

SOC *3 / V *4

Hyster esis

SOC *3 / V *4

Switch-on day

MON_TUE_WED_THU_FRI_SAT_SUN

Switch-on time

00:00

Switch-off day

MON_TUE_WED_THU_FRI_SAT_SUN

Switch-off time

00:00

A)

Set Set

Set

Set

Set

Set

Same scope of settings for AUX1/2/3

Set

Set

Set

*5

Set

*5

Set

*5

Set

Set

Set

Set

Set

Set

*1) MPPT 6000-M only

*3) SOC Control mode only

*5) Separate entry of hh and mm, therefore press multiple times to change to the next window

Set Set

Set

Set

*1) MPPT 6000-M only

Same scope of

settings for timer 1/2/3/4

*4) Voltage control mode only

Settings AUX 1/2/3

*1

AUX 1

AUX 2

AUX 3

Operation mode

Deep discharge prot.

Select function

Function settings

AUX operation mode

[ ] On

[ ] Off

[ ] Function

Disconnection threshold

SOC *3 / V *4

Reconnection hysteresis

SOC *3 / V *4

Select AUX function

[ ] Evening light

[ ] Night light

[ ] Morning light

[ ] Generator control

[ ] Excess energy control

[ ] Timer 1

[ ] Timer 2

[ ] Timer 3

[ ] Timer 4

Evening light

Night light

Morning light

Generator control

Excess energy control

Timer 1

Timer 2

Timer 3

Timer 4

Switch-on delay

00:00

Switch-on duration

00:00

Switch-on delay

00:00

Switch-off delay

00:00

Switch-off delay

00:00

Switch-on duration

00:00

Starting threshold

SOC *3 / V *4

Hysteresis

SOC *3 / V *4

Starting threshold

SOC *3 / V *4

Hysteresis

SOC *3 / V *4

Switch-on day

MON_TUE_WED_THU_FRI_SAT_SUN

Switch-on time

00:00

SD card

*1

Datalogger On/Off

Load parameter

Store parameter

[ ] On

[ ] Off

Load parameter

[ ESC ] [ 1s ]

Switch-off day

MON_TUE_WED_THU_FRI_SAT_SUN

Switch-off time

00:00

A)

B)

Store parameter

[ ESC ] [ 1s ]

Set

Event log

E)

01/30 Event message

30/30 Event message

18

756.404 | Z01 | 16.06

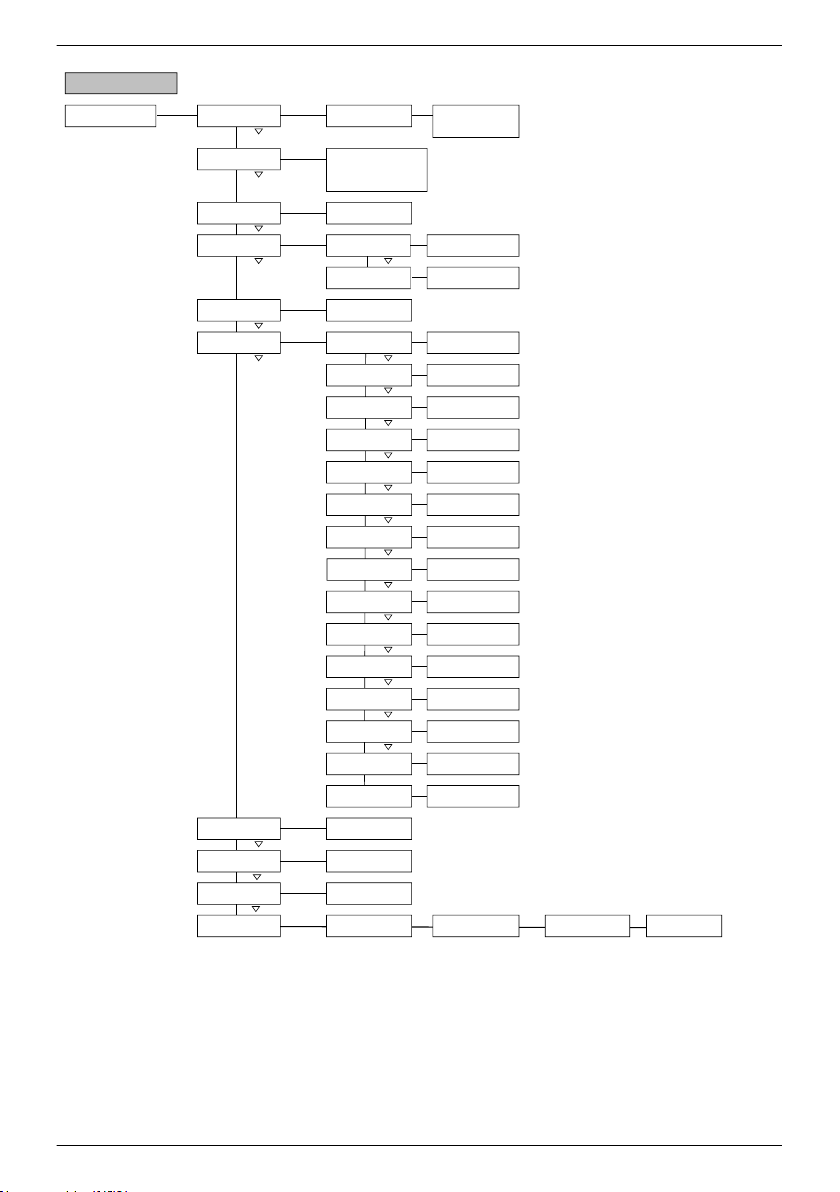

Page 19

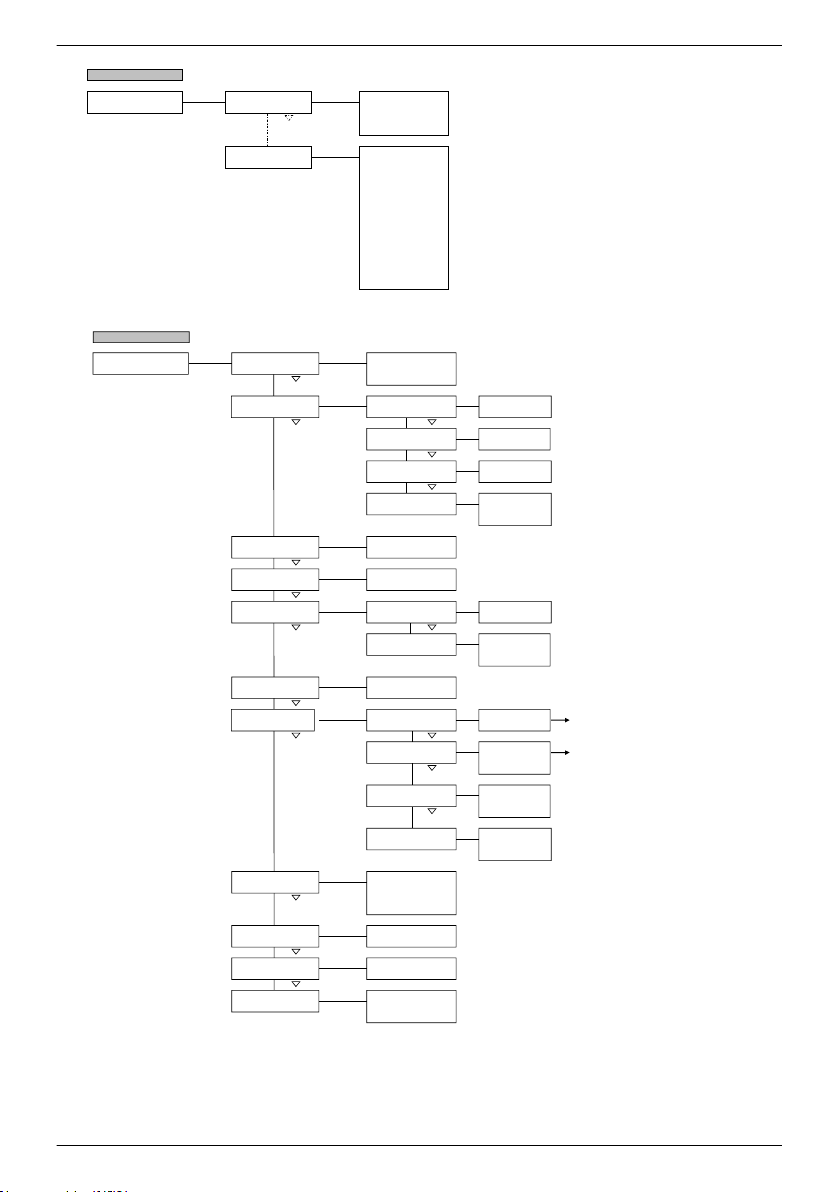

Set

Set Set

Set

Event log

E)

01/30 Event message

30/30 Event message

F)

Information

Contact info

System info

Manufacturer

Address

Email

QR code

Platform name

Serial num.

PU version

- APP

- FBL

- BFAPI

- HW

SYS version

- BFAPI

- FBL

- APP

- PAR

- HW

MPPT slave address

Manual

Set Set

Set Set

Set

Set

Set

Set

Set

Set Set

Set

Set

Set Set

Set

Set

Set

Set

Set

Set

Set

*1) MPPT 6000-M only

… further menu entries

depending on the Slave properties

… further menu entries

depending on the Slave properties

System settings Language

Time / date

Clear log data

Clear event log

Display settings

StecaLink slave addr.

StecaLink master menu

*1

Mode AUX IO

*1

RS-232 port

*1

Acoustic alarm

Factory reset

[ ] english

[ ] deutsch

[ ] ….

Time

Date

Time format

Date format

Time

00:00

Date

11.12.2015

[ ] yyyy-mm-d d

[ ] dd.mm.yyyy

[ ] mm/dd/yyyy

[ ] 12h

[ ] 24h

Are you sure?

[ ESC ] [ 1s ]

Contrast

Backlight

Value

50%

[ ] Off

[ ] Automatic

[ ] Power mode

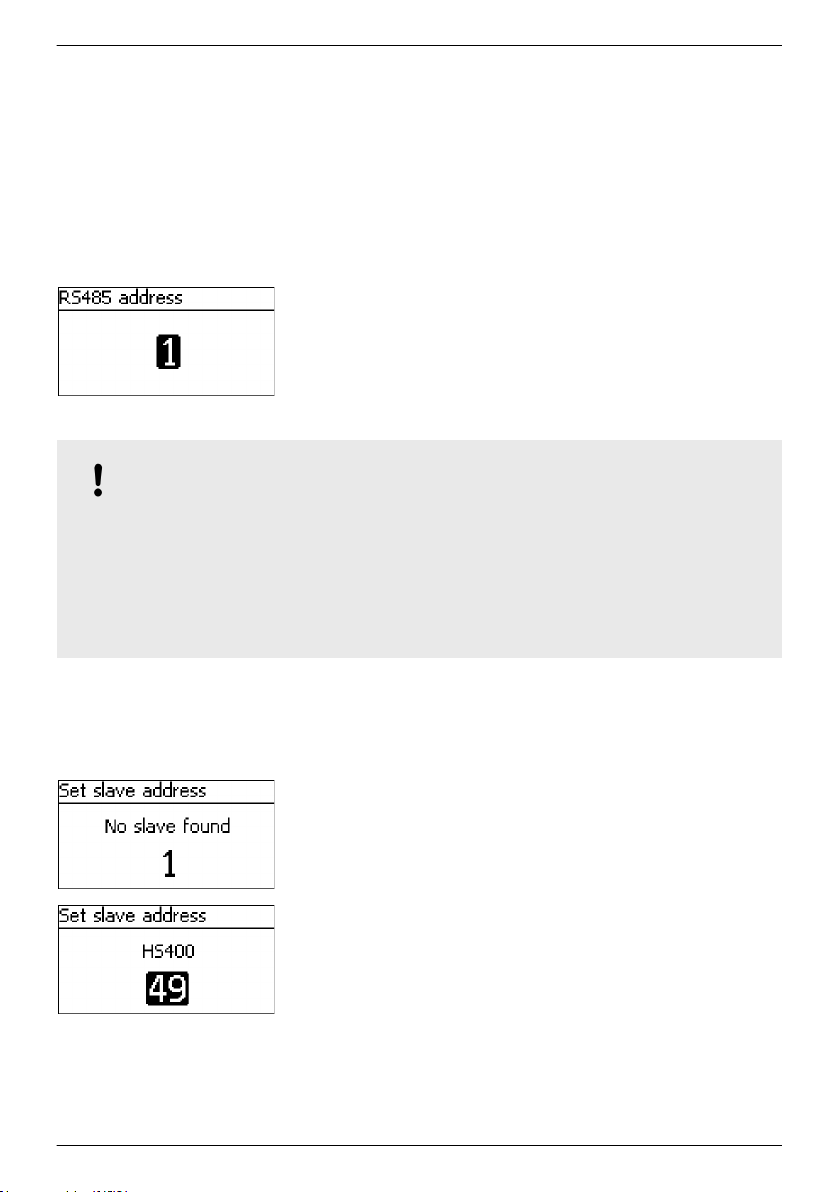

RS485 address

1 - 99

Add slave device

Change slave settings

Delete slave

Synchronise

Set slave address 1

-99

[ ] MPPT 6000

[ ] HS400

[ ] ….

Synchronise all

slaves

[ ESC ] [ 1s ]

[ ] Ext. voltage on

[ ] Ext. voltage off

[ ] Ext. switch on

[ ] Ext. switch off

C)

Are you sure?

[ ESC ] [ 1s ]

[ ] MPPT 6000

[ ] HS400

[ ] ….

[ ] On

[ ] Off

[ ] On

[ ] Off

Reset a ll values

[ ESC ] [ 1s ]

756.404 | Z01 | 16.06

19

Page 20

Set Set Set

Set

Set Set

Set

Set

Set

Set

Set Set

Set

Set

Set Set

Set

Set

Set Set

Set

Set

Set

Set

Set

Set Set Set

[1s]

Set

Set Set

*1) MPPT 6000-M only

*3) SOC Control mode only

Set

*5) Lead acid battery only

Set

*4) Voltage control mode only

Battery settings Equalisation cycle *5

Batter y con trol mode

*1

Battery capac ity test

*1

Battery type

Batter y cap acity

Charge voltag es

IUIA charge mode

*1

Start boost charg e

Bat. temperat ure sensor

Cable compens ation

PV string connection

Expert menu

On/Off

Cycle Duration

30 days

SOC control mode

Sensor member lis t

Capacity

100 Ah

Float charg ing

Boost chargi ng

Equalisation c harging

*5

Cycle

Code

17038

Equal. charge duration

*5

Boost charge dur ation

Temp. compensation

System voltag e

Duration

240 min

Temperat ure coeff icient

-4 mV/K/cell

D)

Leadacid/LeadGel/AGM

[ ] On

[ ] Off

[ ] State of charge (SOC)

[ ] Voltage control

[ ] MPPT 6000

[ ] HS400

[ ] ….

Charging deactivated !

Are you sure?

[ ESC ] [ 1s ]

[ ] Lead acid battery

[ ] Lead Gel/AGM

[ ] Li-Ion battery *1

[ ] NiCd battery *1

Current limit system *1

Current lim it device

On/Off [ ] On

[ ] Off

Value Limit

1605.0 A

Limit

60.0 A

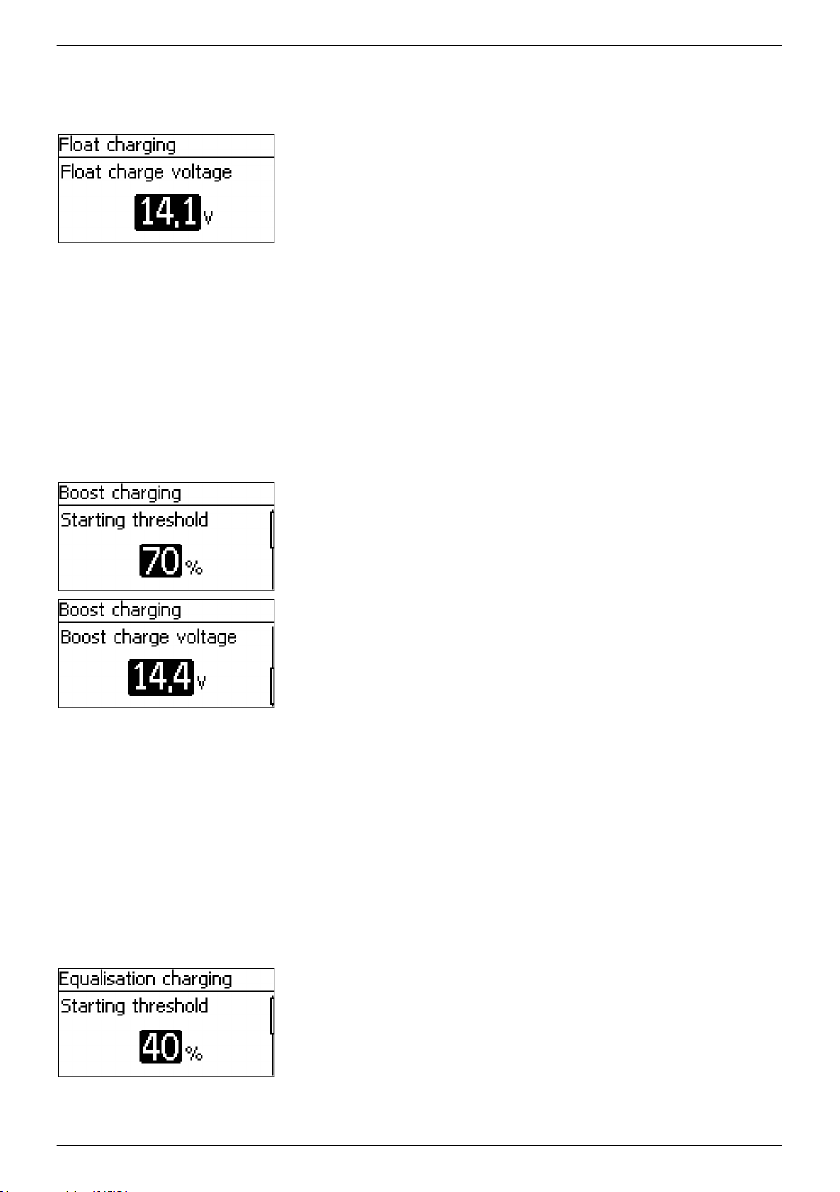

Float charg e voltag e

56.4 V

Starting threshold

SOC *3 / V *4

Boost charge voltag e

57.6 V

Starting threshold

SOC *3 / V *4

Equal. charge voltage

60.0 V

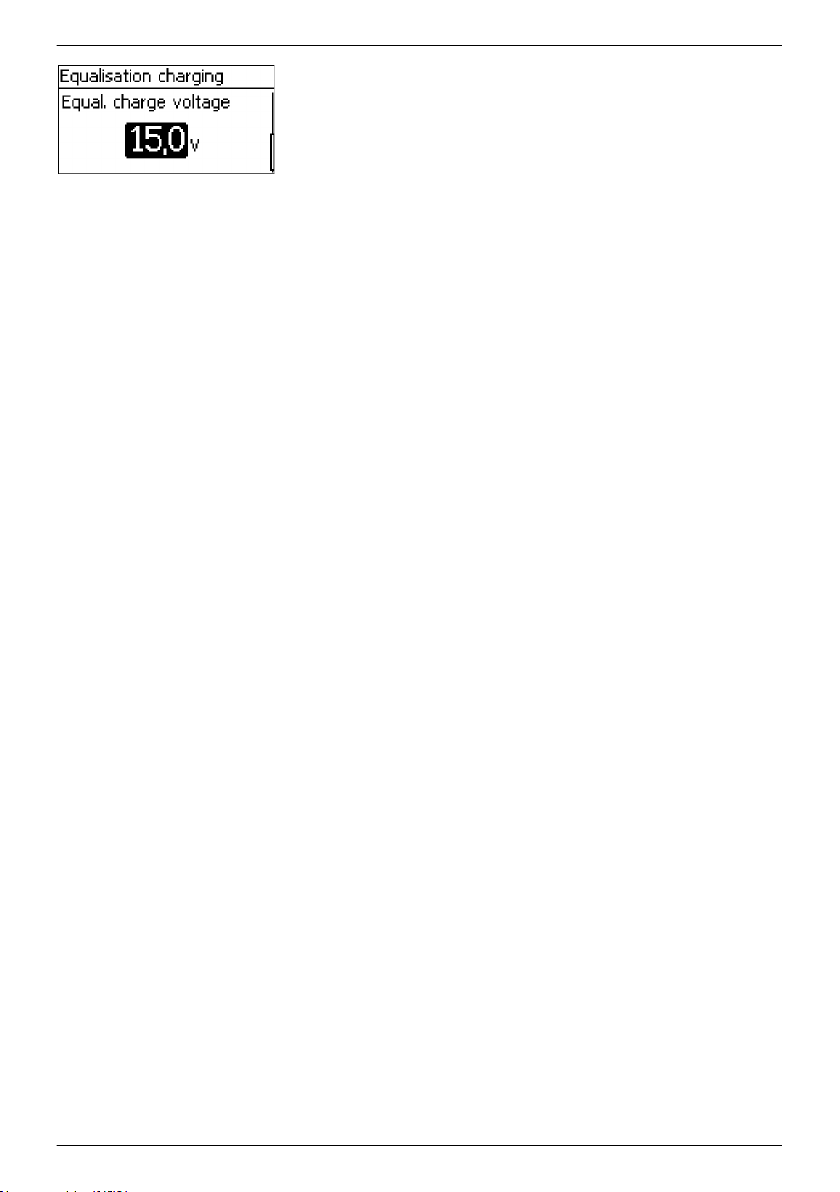

On/Off [ ] On

[ ] Off

Cycle

6 month

Are you sure?

[ ESC ] [ 1s ]

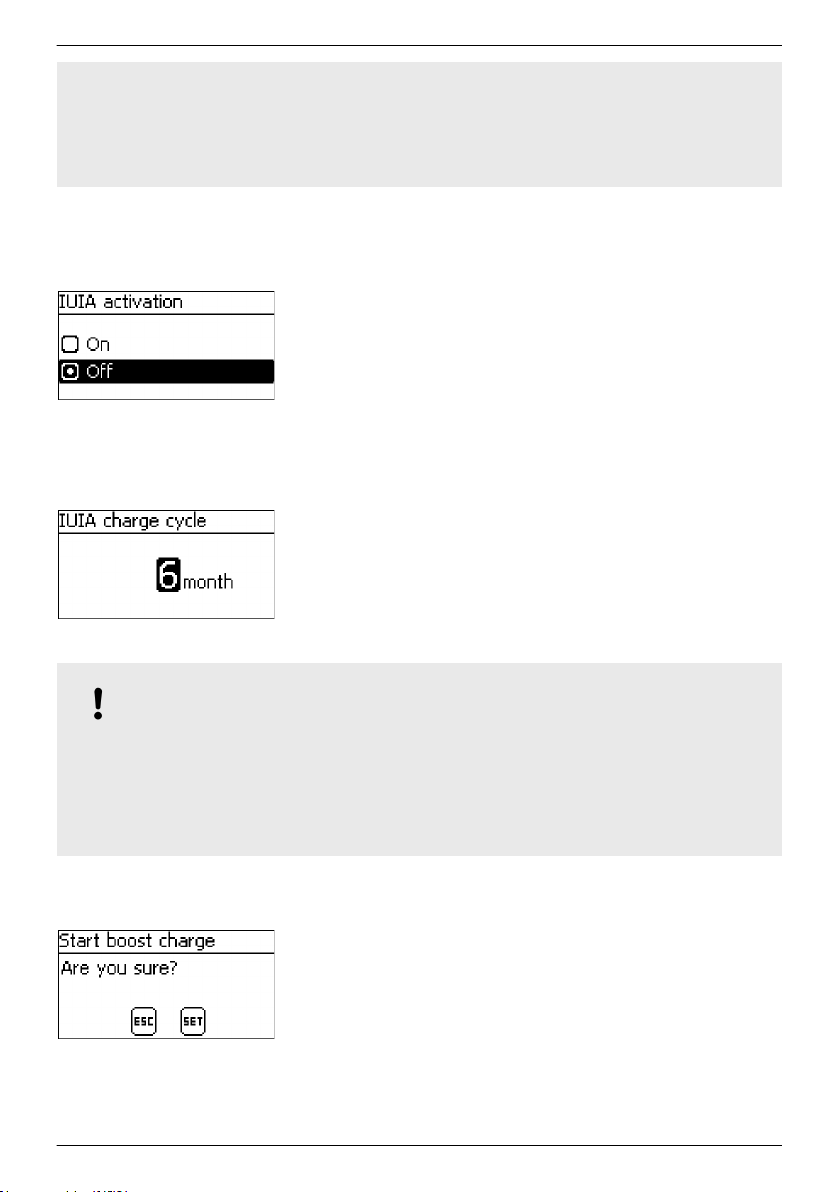

[ ] Internal

[ ] External

[ ] On

[ ] Off

[ ] s eparated

[ ] parallel

Duration

120 min

On/Off

Temp. coefficient

[ ] On

[ ] Off

[ ] Automatic

[ ] 12V

[ ] 24V

[ ] 36V

[ ] 48V

[ ] 60V

20

756.404 | Z01 | 16.06

Page 21

Set Set Set

Set

Set

Set Set

Set

Set

Set Set

Set

Set

Set

Set

Set

Set

Set

Set

*1) MPPT 6000-M only

Battery settings

Batter y con trol mode

*1

Battery type

Batter y cap acity

Li-Ion battery settings

*1

Bat. temperat ure sensor

PV string connection

Sensor member lis t

Capacity

100 Ah

Number of cells

Cell voltage

Charge voltag e

Charge timer

D)

Li-Ion battery *1

[ ] MPPT 6000

[ ] HS400

[ ] ….

[ ] Lead acid battery

[ ] Lead Gel/AGM

[ ] Li-Ion battery *1

[ ] NiCd battery *1

Current lim it system *1

Current lim it device

On/Off [ ] On

[ ] Off

Value Limit

1605.0 A

Limit

60.0 A

Number of cells

7

Voltage per cell

3.7V

Min. temperature

0°C

Charge activ ation

Temperat ure range

[ ] Internal

[ ] External

[ ] s eparated

[ ] parallel

Voltage per cell

4.20V

Voltage per cell

4.00V

Charge timer

60min

Max. temperature

60°C

Cable compens ation [ ] On

[ ] Off

756.404 | Z01 | 16.06

21

Page 22

Set Set Set

Set

Set

Set Set

Set

Set

Set Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set Set Set Set

[1s]

*1) MPPT 6000-M only

Battery settings B attery contr ol mode

*1

Battery type

Batter y cap acity

NiCd battery settings *1

Bat. temperat ure sensor

Sensor member lis t

Capacity

100 Ah

Upper charge voltage

U1

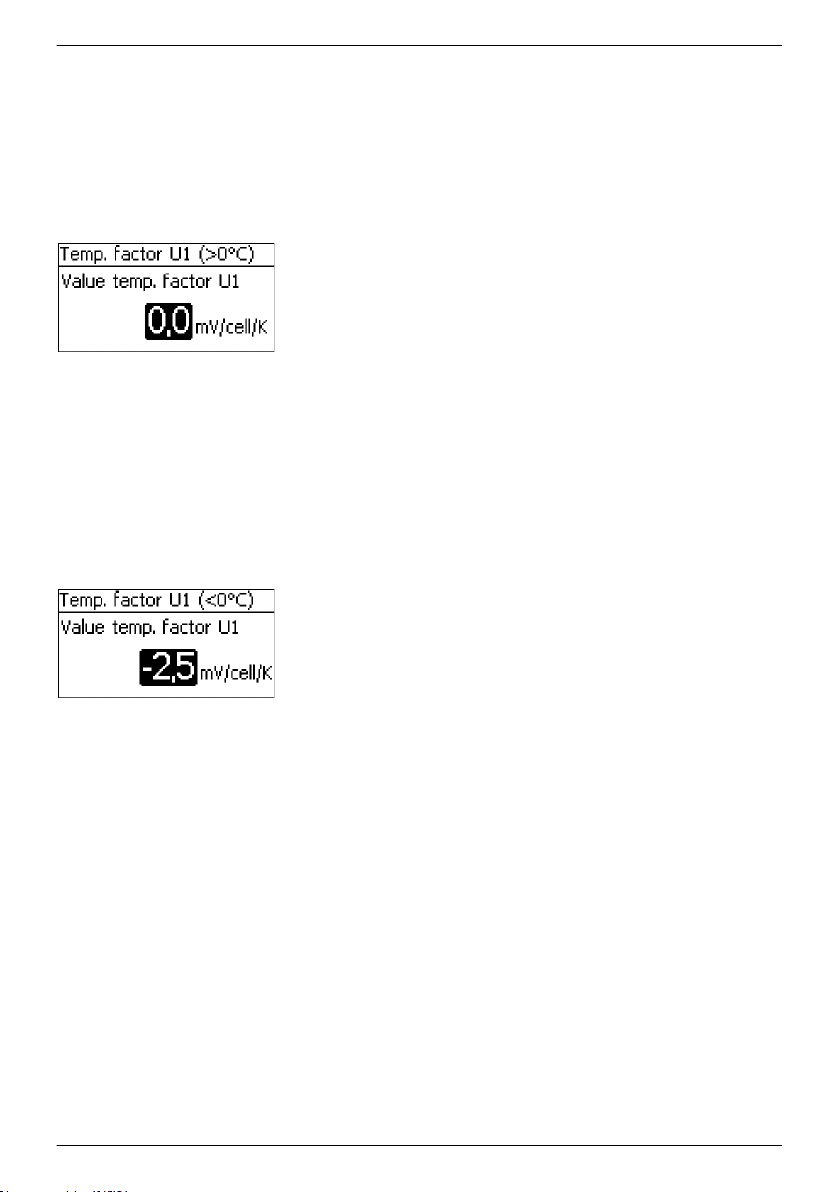

Temp. factor U1 (>0°C)

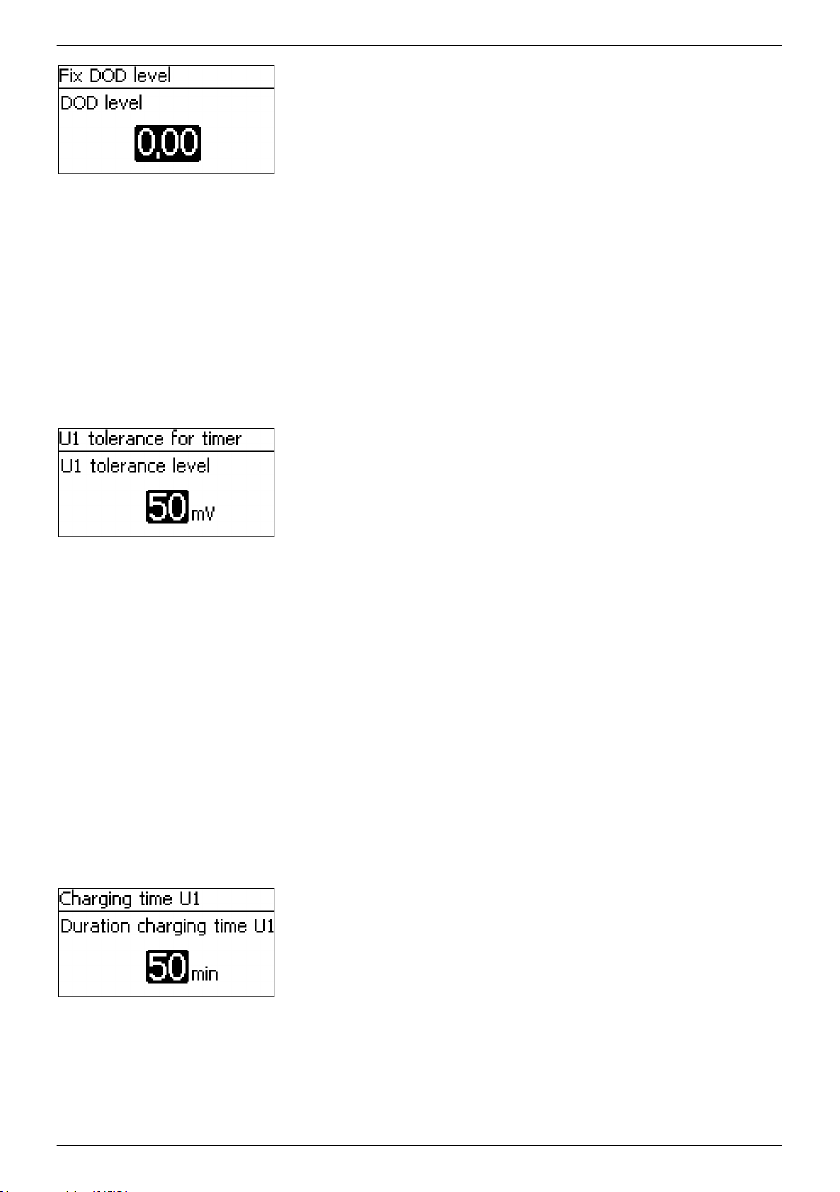

Fix DOD level

Charging time U1

D)

NiCd battery *1

[ ] MPPT 6000

[ ] HS400

[ ] ….

[ ] Lead acid battery

[ ] Lead Gel/AGM

[ ] Li-Ion battery *1

[ ] NiCd battery *1

Current lim it system *1

Current lim it device

On/Off [ ] On

[ ] Off

Value Limit

1605.0 A

Limit

60.0 A

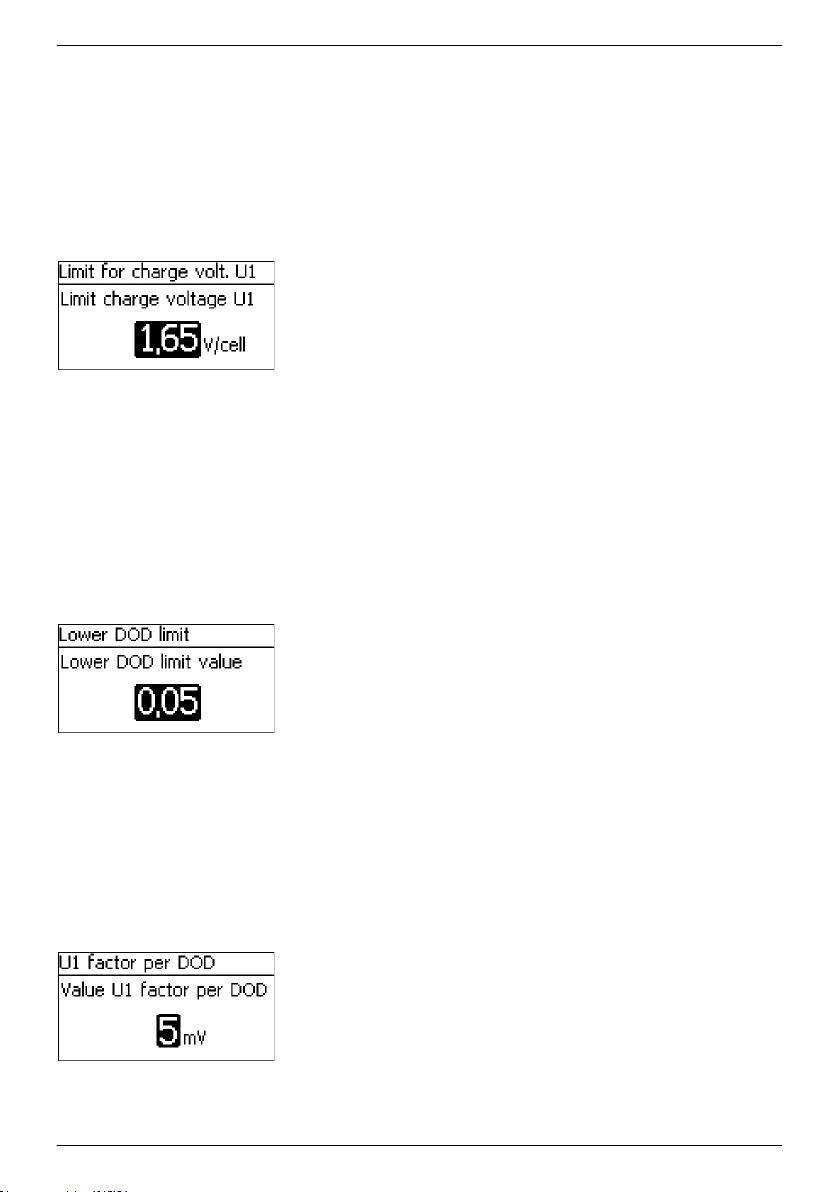

Level charge voltage U1

1.50 V/cell

U1 tolerance for timer

DOD lev el c harge reset

[ ] Internal

[ ] External

Limit for charge volt.

U1

Lower DOD limit

U1 fac tor per DO D

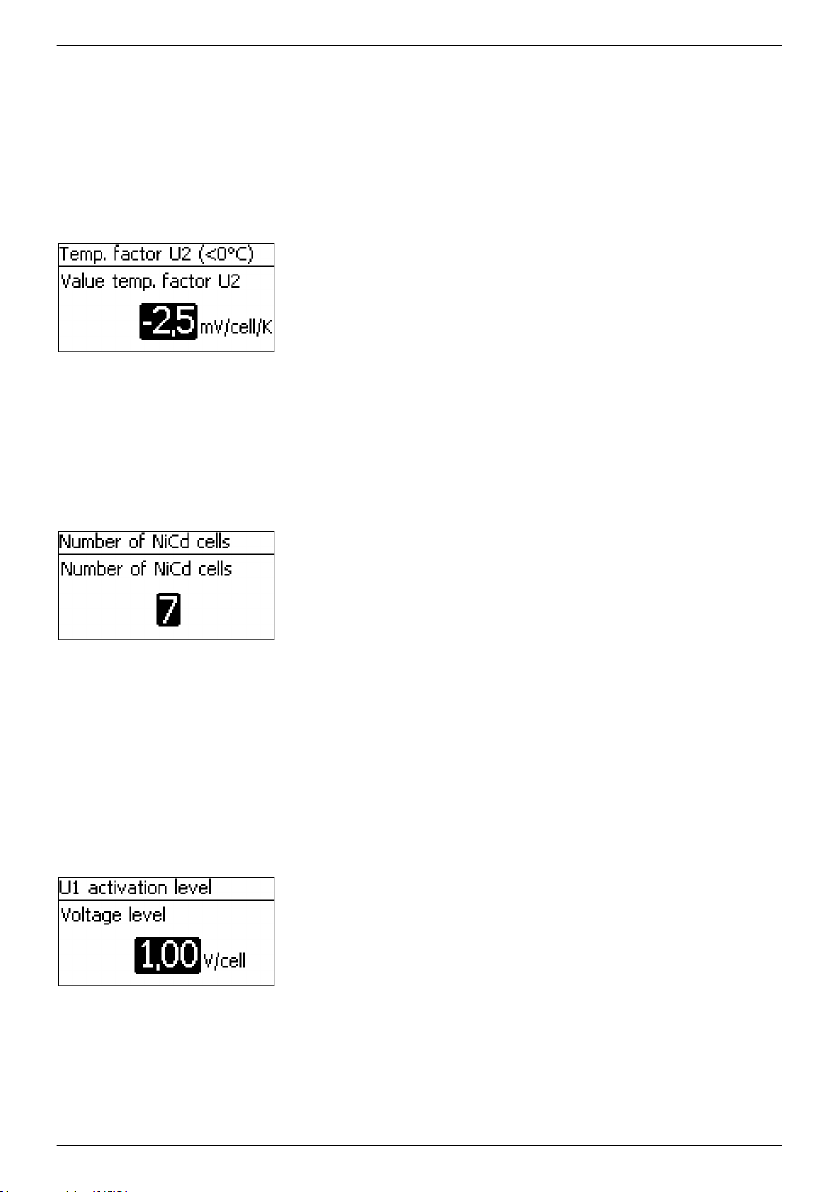

Temp. factor U1 (<0°C)

Lower charge voltage

U2

Temp. factor U2 (>0°C)

Temp. factor U2 (<0°C)

Number of NiCd cells

U2 U1 switch

Limit charge volt. U1

1.65 V/cell

Lower DOD limit value

0.05

Value U1 f actor per DO D

5 mV

Value temp. factor U1

0.0 mV/K

Value temp. factor U1

-2.5 mV/K

DOD level

0.00

U1 tolerance level

50 mV

Duration charging time U1

50 min

DOD lev el c harge reset

0.02

Level charge voltage U2

1.50 V/cell

Value temp. factor U2

0.0 mV/K

Value temp. factor U2

-2.5 mV/K

Number of NiCd cells

7

Voltage level

1.00 V/cell

Cable compens ation [ ] On

[ ] Off

PV string connection

Expert menu Code

17038

Temp. compensation

[ ] s eparated

[ ] parallel

On/Off [ ] On

[ ] Off

22

756.404 | Z01 | 16.06

Page 23

4 Installation of the base system

Topics

1.

Ä

Chapter 4.1 ‘Safety instructions’ on page 23

2.

Ä

Chapter 4.2 ‘Installing the device’ on page 26

3.

Ä

Chapter 4.3 ‘Establishing the electrical connections’ on page 27

4.

Ä

Chapter 4.4 ‘Supplying the controller with voltage’ on page 31

4.1 Safety instructions

DANGER!

Risk of death by electrocution! Observe the following safety instructions when performing the

measures described in section

General information

n Only technical professionals may perform the work described in the section ‘Installation of the

base system’ .

n The PE connection must be connected to the system ground (grounding spike).

– If the system is to be positively grounded then "PE" must be additionally connected to

battery terminal "B+". The external battery fuse must then be installed in the "B−" cable!

With this grounding method, the module relay and battery relay provide safe isolation

from the PV module.

– This safe isolation from the PV module is disabled when the system is negatively grounded

via "B−" or "B−" and "PE". In the case of a simple fault (module relay does not open),

grounding of "B−" results in the "M−" potential being present on the casing of the MPPT

via the "PE" – ground connection. Only implement this grounding method when the system

has additional protection against touching live and electrically conductive system

components.

– Common grounding of "M1−/M2−" with "B−", "M1+/M2+" with "B+", "M1−/M2−" with "B

+" or "M1+/M2+" with "B−" is generally not permitted.

– The solar module frames can always be grounded.

n The solar module installation branch, including the DC load circuit breaker up to the controller

terminal area, must be implemented to protection class II.

n The battery installation branch must be implemented to protection class II.

n The following components must be installed:

– battery,

– at least 1 solar module,

– external battery fuse (safety fuse or DC circuit breaker) and

– a DC load circuit breaker for solar modules 1 and 2.

n Do not open the controller casing. Only the terminal cover may be removed by a technical

professional for installation.

Ä

‘Installation of the base system’ on page 23.

756.404 | Z01 | 16.06

23

Page 24

Always take the following measures before working on the controller:

1. Switch off all loads.

2. Switch off the DC load circuit breaker (solar module) and secure it against being switched on

again or safely cover the solar module (ensure that wind cannot blow off the covering!).

3. Switch off the external battery fuse: Remove the fuse insert from the fuse holder (safety fuse)

or switch off the DC line circuit breaker and secure it against being switched on again.

4. Disconnect the battery cable from both battery terminals.

Cable connections

n The module cables carry voltage when the solar module is illuminated.

n Insulate exposed cable ends with insulation tape or wire connector blocks.

n Connect the cables for the battery and solar module to the controller in the described sequence

( Fig. 1

).

n Secure the cables with a strain relief clamp. Clearance of strain-relief to controller: 200 mm.

n Connect only 1 cable to each connection terminal.

n Cable to be used: Observe the specifications in section

Ä

‘Technical data’ on page 124.

n Lay the cables so that:

– connections cannot accidentally come loose,

– persons cannot tread on or trip over these and

– fire protection devices are not impaired or obstructed.

n The entire installation must be designed with protection class II if the open-circuit module

voltage exceeds 60 V DC at least once anywhere over the entire temperature range.

n Observe all applicable installation regulations and standards, national laws and connection

values specified by the regional power supply company.

Fuses and switching devices

Installation of an external battery fuse (safety fuse or DC line circuit breaker) is mandatory! Observe

the following:

n Mount the external battery fuse directly next to the battery.

n The external battery fuse must conform to the specifications described in section

Ä

‘Technical

data’ on page 124.

n The external battery fuse is not included in the scope of delivery.

WARNING!

Danger of acid injuries

– Do not subject the battery to open flames or sparks.

Provide adequate ventilation in the installation location of the battery. Inflammable gases

–

can escape from the battery.

– Follow the charging instructions of the battery manufacturer.

24

756.404 | Z01 | 16.06

Page 25

CAUTION!

Danger of bodily injury. The device weighs over 6 kg. If in doubt, install the device with two

persons.

CAUTION!

Danger of destroying the device through overloading

– Conform to the technical specifications, especially the connection values. See type plate

Ä

and section

‘Technical data’ on page 124.

– When selecting the solar module, note that the open-circuit module voltage is higher than

the value specified on the type plate at temperatures below 25 °C.

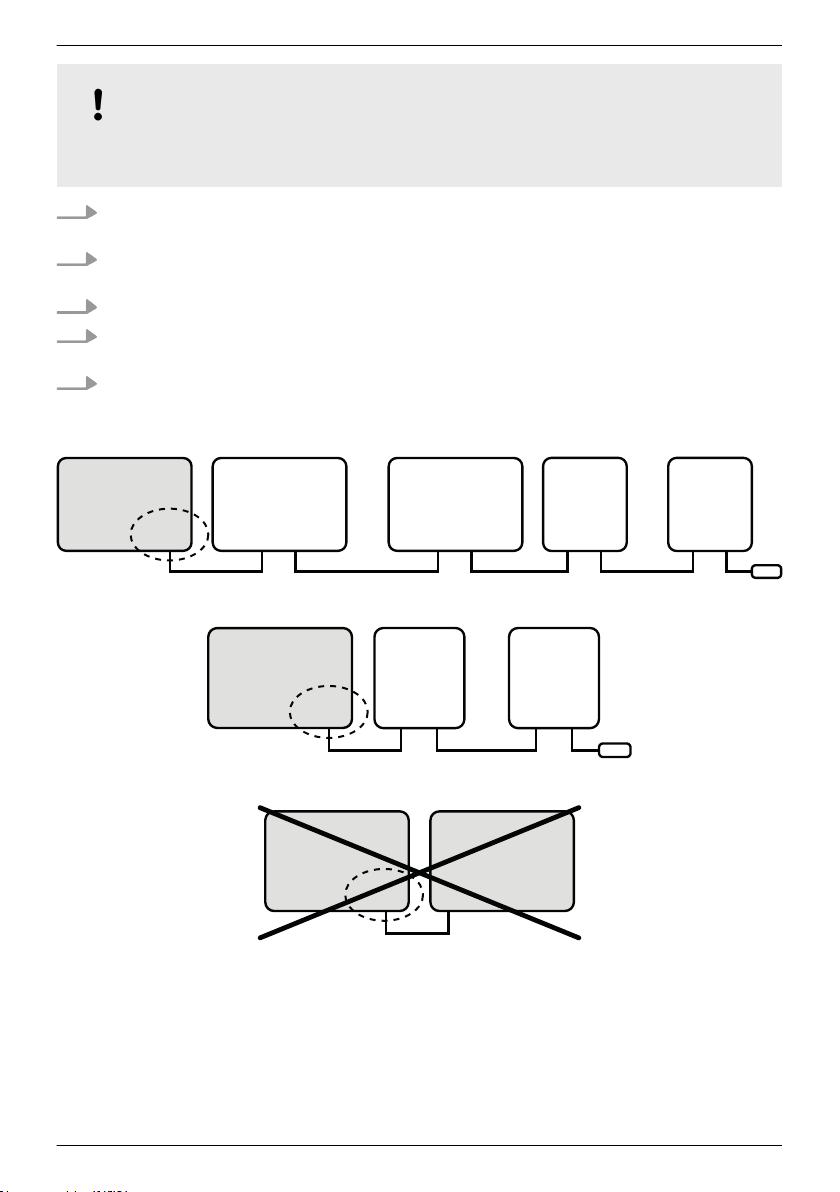

– Do not connect the solar module to 2 controllers in parallel. The solar module can however

be connected in parallel to both solar module inputs of one controller. Make the

appropriate settings under Battery settings è PV string connection!

– Installation of a fuse in the battery voltage sensor cable is prescribed by law.

NOTICE!

The following section describes only the installation of the controller. Observe the instructions

in the manual from the respective manufacturer when installing the external components.

756.404 | Z01 | 16.06

25

Page 26

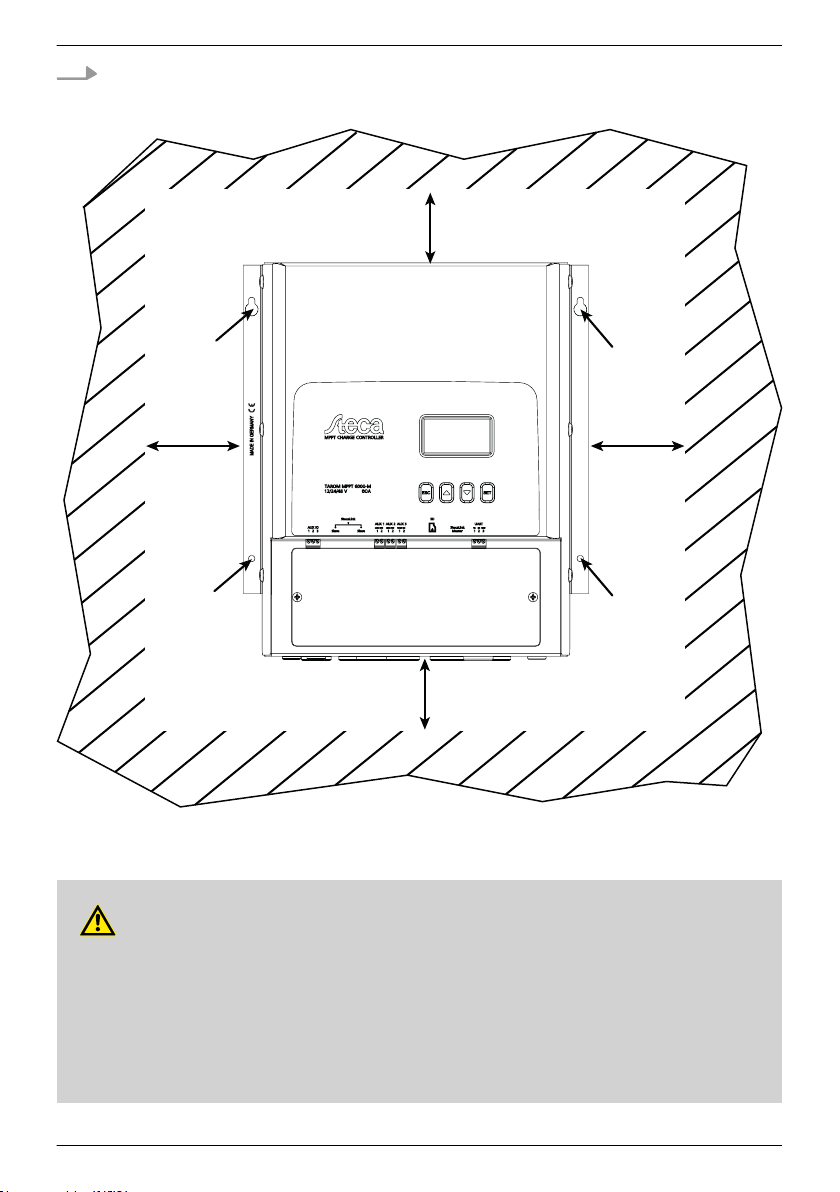

4.2 Installing the device

CAUTION!

Danger of damage to the inverter and reduction of power. Observe the following safety

requirements during installation:

– The mounting location and immediate environment are permanently fixed, vertical, flat,

non-inflammable and not subject to constant vibration.

A free space of at least 60 mm must be present on all sides of the controller (③ in Fig. 5).

–

– The controller must be easily accessible and the display easily readable.

– The controller is mounted as close as possible to the battery; the prescribed minimum

safety clearance of 0.5 m between the controller and battery is adhered to.

– The controller must not be located

– outdoors or in a location subject to rain or splashing water,

– in dusty environments,

– in stalls with active animal husbandry or

– in direct sunlight.

– The battery cable is no longer than 2 m (recommended), to keep cable losses and the

compensation voltage as low as possible.

– Do not drill through the fastening openings ①/② (Fig. 5).

1. Select the mounting location under consideration of the previously mentioned safety

requirements.

2. Position the controller level on the mounting surface and mark the mounting holes through

the fastening openings ①/② shown in Fig. 5.

NOTICE!

The keyhole form of the two upper fastening holes makes it possible to first install the

screws for ① and then mark the holes to be drilled for ② with the device hung in place

(lower risk of incorrectly positioned drilled holes).

3. Remove the controller and drill the mounting holes.

26

756.404 | Z01 | 16.06

Page 27

4. Use the screws/dowels supplied to fasten the controller to the mounting surface.

60 mm

60 mm

60 mm

60 mm

ི

ི

ི

ི

ཱ

ཱ

Fig. 5: Fastening openings

① /②

and free space

③

4.3 Establishing the electrical connections

CAUTION!

Always make connections in the following sequence:

1. First connect the load and then the source.

Example: First connect the cable to the controller and then to the battery.

2. First connect the positive pole then connect the negative pole.

Example: First connect "B+" then connect "B–".

756.404 | Z01 | 16.06

27

Page 28

NOTICE!

Use the cable pass-through holes plugged with rubber stops on the bottom of the casing as

follows:

– 2 large cable pass-through holes for the battery cables;

5 medium-sized cable pass-through holes for the module and "PE" cables;

3 small cable pass-through holes for the sensor cables (1 as a reserve).

Feed each cable through the corresponding cable pass-through hole lying opposite to the

–

cable connection, see Fig. 2.

– Use a screwdriver to punch a hole in the rubber stop of the respective cable pass-through

hole.

4.3.1 Preparing the cables

1. Label the cable ends according to

2. Lay the battery and module cables directly next to each other. Do not yet connect the cables!

3. Connect the external battery fuse to the "B–" battery cable, in an easily accessible position

close to the battery (

4. Switch off the external battery fuse: Remove the fuse insert from the fuse holder (safety fuse)

or switch off the DC line circuit breaker and secure it against being switched on again.

5. Connect the DC load circuit breaker to the module cables "M1+" and "M2+" (

an easily accessible position close to the controller.

6. Switch off the DC load circuit breaker and secure it against being switched on again.

7. Remove the terminal cover (release the 2 fastening screws with a Phillips screwdriver).

4.3.2

Connect the battery cable and external battery fuse to the battery connection of the controller and

to the battery.

Connecting the battery

✔

No devices are connected to the battery.

CAUTION!

Danger of damage to the controller. Observe the maximum battery voltage as per

data’ on page 124.

Fig. 2 ⑬).

Fig. 2 ("M1+", "M1–", "M2+", "M2–", "B+", ...).

Fig. 2 ⑨/⑩), in

Ä

‘Technical

NOTICE!

We recommend installing the external battery fuse in the "B–" cable.

28

756.404 | Z01 | 16.06

Page 29

4.3.3 Connecting the battery voltage sensor

NOTICE!

The external battery voltage sensor cable allows the controller to directly measure the voltage

at the battery. This voltage value can be used for compensation of voltage drops across the

battery cables. This means that the voltage measurement is not affected by (e.g.) powerdependent voltage drops across the battery cables.

A 2-pin plug with screw terminals for connecting the sensor cable is supplied with the device.

-

A cable with a cross-section of 0.14-1.5 mm2 (AWG 28-16) can be used.

The necessary sensor cable is not supplied with the device.

-

✔

A sufficiently long battery voltage sensor cable conforming to the technical data is available.

DANGER!

Install a fuse in the connection between the battery voltage sensor cable and the battery. The

fuse rating must match the cross-section of the cable used. This protects the cable from

burning in the case of a short-circuit in the battery voltage sensor cable.

1. Fit the green 2-pin socket (supplied) to the other end of the cable.

2. Plug the 2-pin socket into the"BAT+/–" connection so that the "+" conductor is at the left and

the "–" conductor is at the right; see the enlarged view of the terminal area in

3. Install an external fuse for protecting the battery voltage sensor cable.

4. Connect the battery voltage sensor cable directly to the battery; see ⑫ in Fig. 2.

5. Activate usage of the battery voltage sensor cable in the cable compensation settings.

‘Battery settings è Cable compensation

’.

Fig. 2.

4.3.4 Connect the ground (PE)

DANGER!

Risk of death by electrocution. The controller must be grounded via PE (controller has

protection class I).

756.404 | Z01 | 16.06

29

Page 30

CAUTION!

Danger of damaging the devices (e.g. computer) connected to the StecaLink master bus,

StecaLink slave bus or the UART interface. The galvanic isolation normally present at the AUX

IO, StecaLink master/slave bus and UART connections is disabled if the connected peripheral

devices are connected to the "PE" connection of the controller via a common ground/

equipotential bonding cable.

If the entire system is commonly grounded then all StecaLink bus connections, UART connections

and AUX IO connections must be additionally externally galvanically isolated!

è Connect the ground cable to the "PE" terminal.

4.3.5

1. Safely cover the module (ensure that wind cannot blow off the covering!).

2. Connect the module cable with the (open) DC load circuit breaker to the solar module

3. Remove the covering from the solar module.

Connecting the solar module

connection of the controller and the solar module as follows:

n A common DC load circuit breaker (in the common part of the module cable), when 1

solar module is connected in parallel to solar module inputs "M1" and "M2".

n Two separate DC load circuit breakers, when 2 solar modules are each separately

connected to solar module inputs M1 and M2; see Fig. 2.

4.3.6

è Install suitable lightning protection.

30

Install lightning protection

756.404 | Z01 | 16.06

Page 31

4.4 Supplying the controller with voltage

✔ At least the battery and the solar module have been connected as described previously.

1. Fit the terminal cover so that the danger notice is legible (and not upside-down).

2. Fit the fastening screws.

3. Switch on the external battery fuse: Insert the fuse insert into the fuse holder (safety fuse) or

switch on the DC line circuit breaker. The controller automatically starts operating, displays

the company logo after a few seconds and then displays the detected system voltage in an

event message (System voltage xx V) or RTC not set ( Fig. 6).

NOTICE!

English is set as the default menu language at the factory.

4.

Press D, Ñ to display the System voltage xx V. Note the displayed system voltage.

5. If additional event messages are displayed, or no messages are displayed (display dark), then

check the installation and if necessary correct the error using

on page 111.

6. Press ESC to acknowledge the event message. The standard status display appears (

7. Check that the noted system voltage corresponds to the actual battery voltage. If not, then

set the correct system voltage via the expert menu (‘Main menu è Battery settings

è Expert menu è System voltage

’;

Ä

Chapter 8.5.14 ‘Expert menu’ on page 72).

Ä

Chapter 10 ‘Troubleshooting’

Fig. 7).

NOTICE!

When commissioning an MPPT 6000-S slave in a master/slave system via the StecaLink bus, the

system voltage used locally at the device is specified by the MPPT 6000-M master, without

changing the information message at the MPPT 6000-S. In a master/slave system the system

voltage detection must always be checked, and corrected if necessary, at the master device.

When operating the MPPT 6000-S in single mode the system voltage detected at the device

must be checked as described. In systems with lead-acid batteries the detected system voltage

is used for defining the charge voltage and deep-discharge protection ranges. The detected

system voltage is only displayed for information when using Li-Ion or NiCd battery types. The

charging range is determined based on the configured number of battery cells.

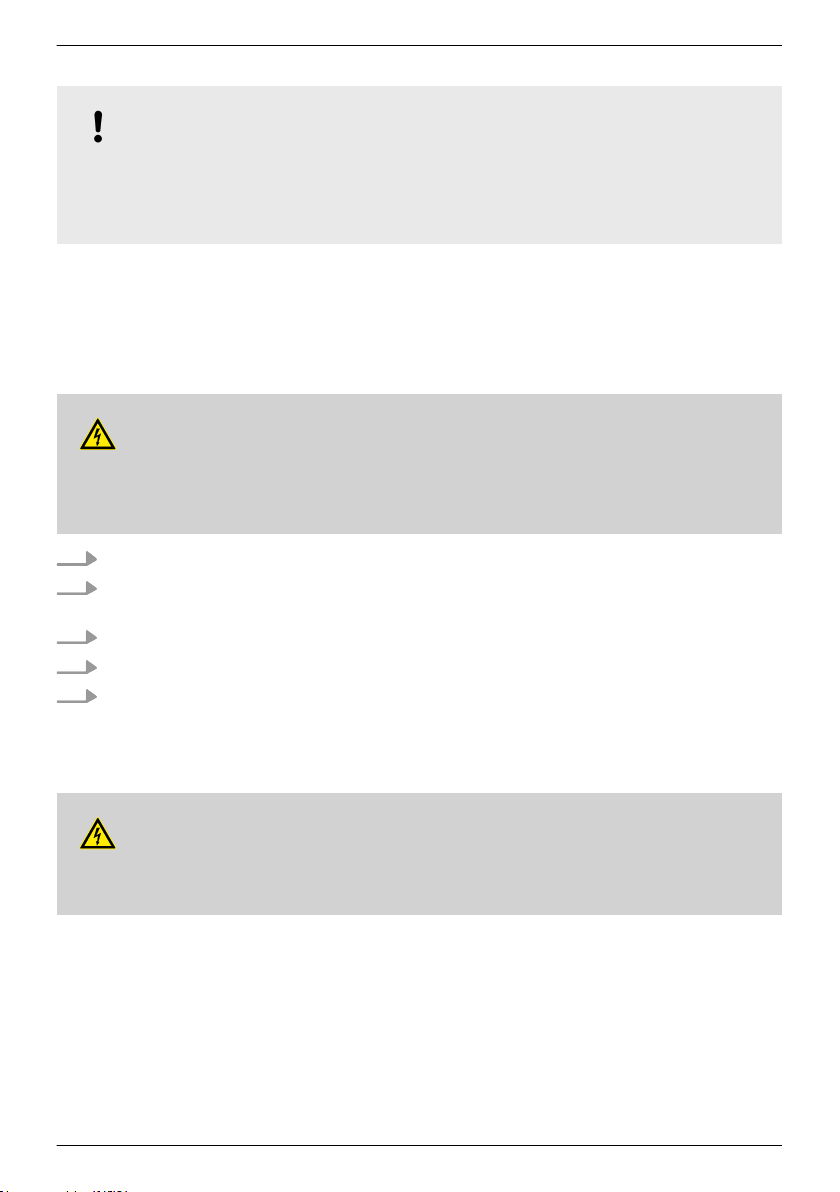

Fig. 6: Event message with the detected system voltage (in the example: 48 V)

756.404 | Z01 | 16.06

31

Page 32

Fig. 7: Display after switching on the external battery fuse

NOTICE!

The battery can be charged from multiple sources. The following applies:

– The battery can be charged by multiple controllers connected to the battery in parallel. The

MPPT 6000-M can assume control of other MPPT 6000-S devices. In this type of master/

slave system, a single MPPT 6000-M

can control up to 22 MPPT 6000-S devices.

– MPPT 6000-M only: Other suitable charging sources can also be connected to the battery

in addition to the controller. These charging sources can be switched on and off by the

controller via relay outputs AUX 1–3.

– MPPT 6000-M only: The controller can only perform sensible calculation of the state of

charge (SOC) when it is able to measure the charge and discharge currents of additional

sources and loads via additional PA HS400 current sensors.

– We recommend having the connection of additional controllers and other charging

sources planned by a technical expert.

32

756.404 | Z01 | 16.06

Page 33

5 Initial commissioning of the base system

CAUTION!

Danger of damage to the device and reduction of power. Only technical professionals may

perform the work described in this section.

NOTICE!

A basic system consists of only a single MPPT 6000-M or a single MPPT 6000-S. The description

of the initial commissioning process only covers the absolute minimum settings necessary.

Please consult the relevant sections below for information on further configuration possibilities.

To install and commission a master/slave system the individual units are installed as specified

according to the respective initial commissioning procedure but remain in the OFF

cabling is completed and all StecaLink bus settings in the master device have been completed.

Topics

1.

Ä

‘Show the basic setting of the status display’ on page 33

2.

Ä

‘Set the language’ on page 34

3.

Ä

‘Set the time’ on page 34

4.

Ä

‘Set the date’ on page 34

5.

Ä

‘Set the battery type’ on page 35

6.

Ä

‘Set the battery capacity’ on page 36

7.

Ä

‘Setting the charge parameters’ on page 36

8.

Ä

‘Switching on the cable compensation’ on page 37

9.

Ä

‘Configuring the temperature sensor’ on page 38

10.

Ä

‘Setting the PV string connection’ on page 38

11.

Ä

‘Finishing initial commissioning’ on page 39

state until all

✔All the measures described in

full.

Show the basic setting of the status display

756.404 | Z01 | 16.06

Ä

‘Installation of the base system’ on page 23 have been taken in

If necessary, press ESC for 1 s to show the basic setting of the

u

status display.

33

Page 34

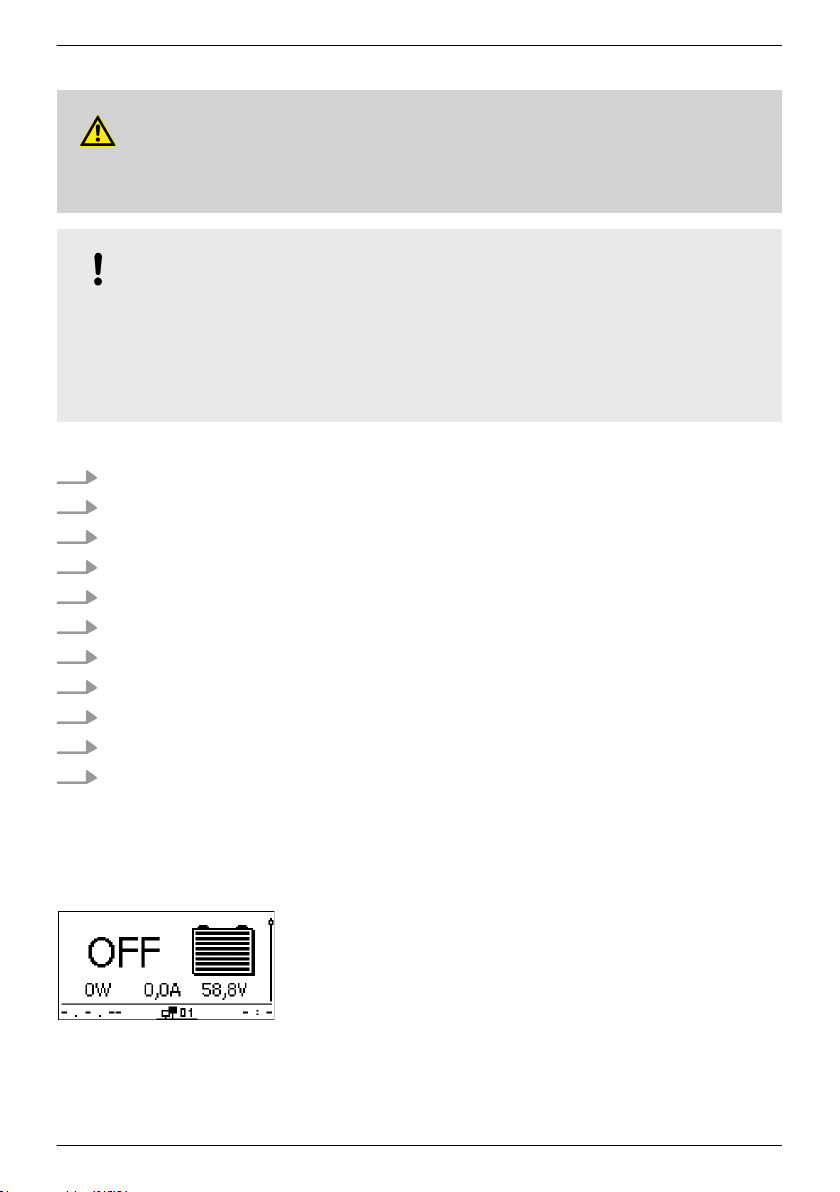

Set the language

Set the time

1. Press SET. The main menu appears and the Device On/Off

entry is selected (Fig. left).

NOTICE

English is set as the default menu language at the factory. In a

master/slave system, enabling the Save setting

parameter

for the slave allows the language setting of the master to be

transferred to the slave, see

Ä

Chapter 8.8.3 ‘Changing the

MPPT 6000-S slave settings (MPPT 6000-M only)’ on page 87.

2.

Press Ñ until System settings is selected.

3. Press SET. The System settings menu appears and

Language is selected (Fig. left).

4. Press SET. The Language menu appears (Fig. left).

5.

Press D, Ñ to select another language as required.

6. Press SET.

7. PressESC, the System settings menu appears and the

selected language is active.

1. The System settings menu appears after completing the

language selection (Fig. left).

2.

Press Ñ to select Time/date.

3. Press SET. The Time and date menu appears and Time is

selected.

4. Press SET. The

Time setting dialogue appears (Fig. left).

5. Press SET. The hours display flashes.

6.

Press D, Ñ to change the hour.

7. Press SET. The hour stops blinking.

8.

Press Ñ. The minutes are selected.

9. Repeat steps 5 to 7 for the minutes.

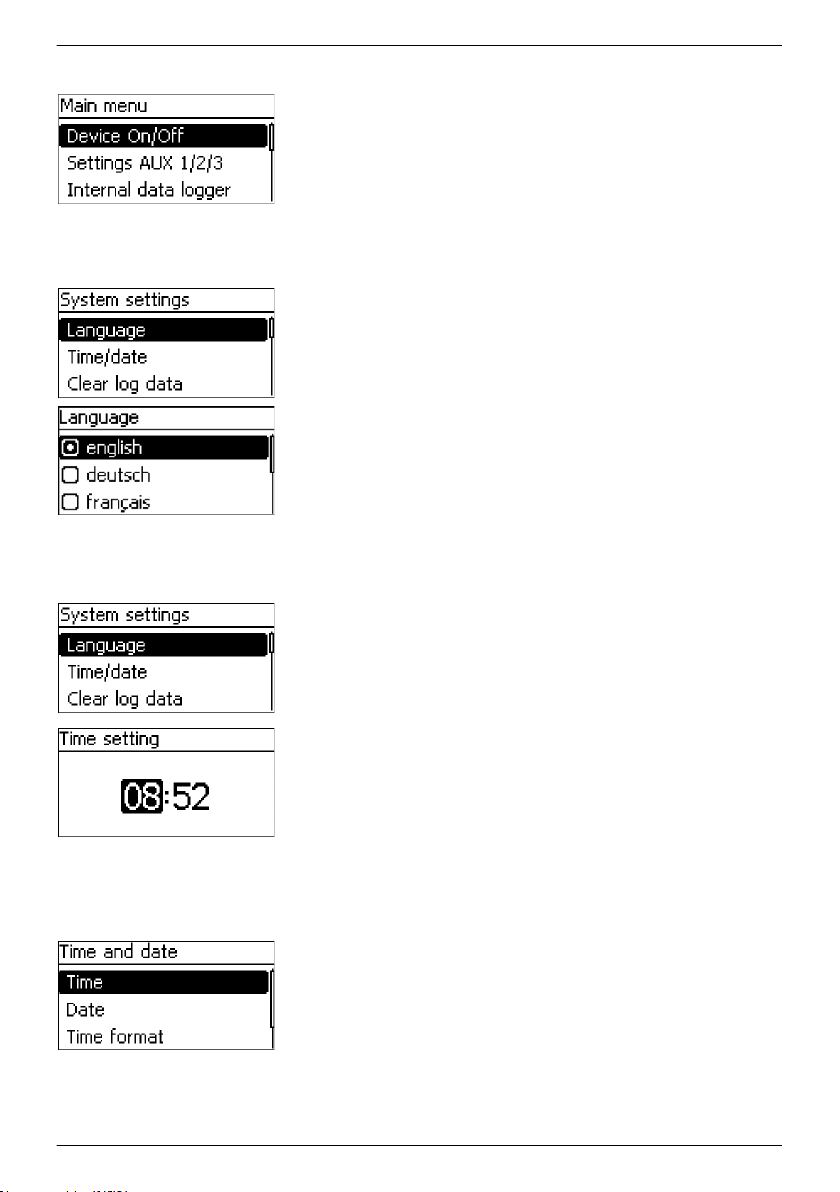

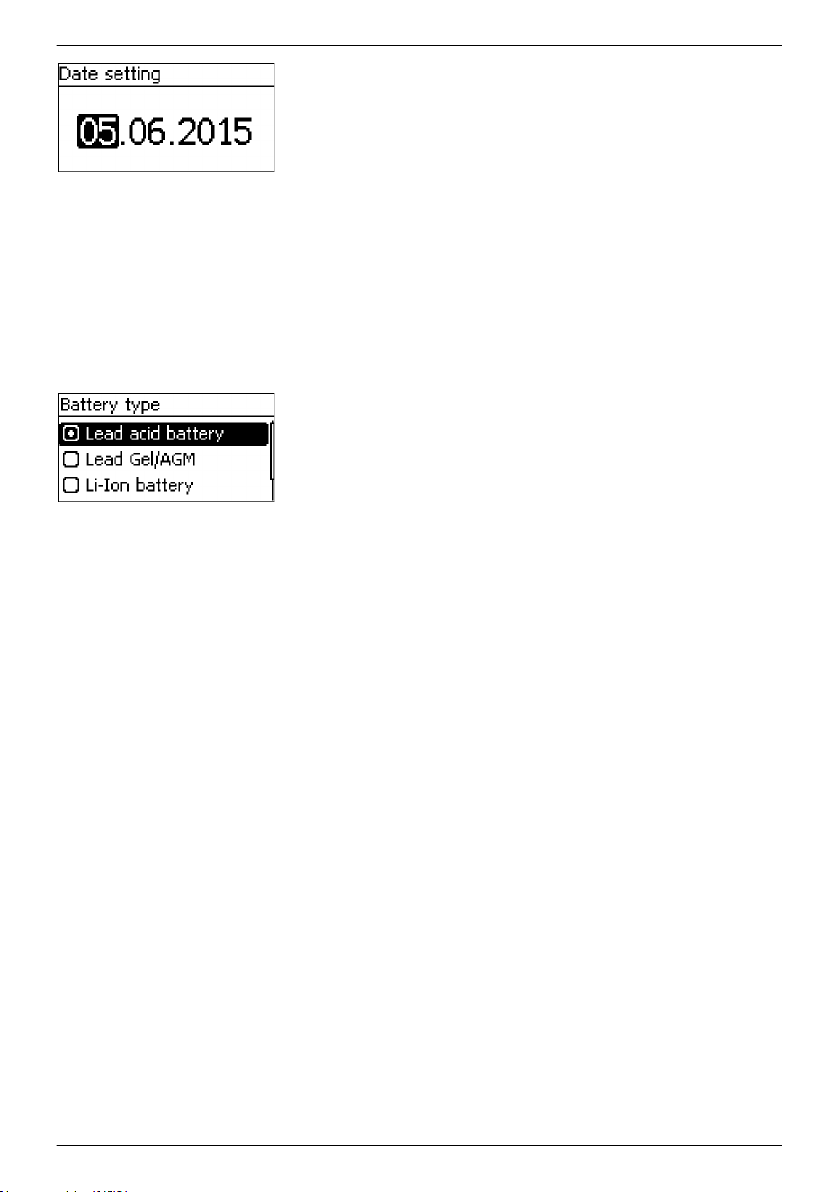

Set the date

34

1. Press ESC. The Time and date menu appears (Fig. left).

2.

Press Ñ to select Date.

3. Press SET. The Date setting dialogue appears (Fig. left).

4. Press SET. The day flashes.

5.

Press D, Ñ to change the day.

6. Press SET. The day stops blinking.

7.

Press Ñ to select the month.

756.404 | Z01 | 16.06

Page 35

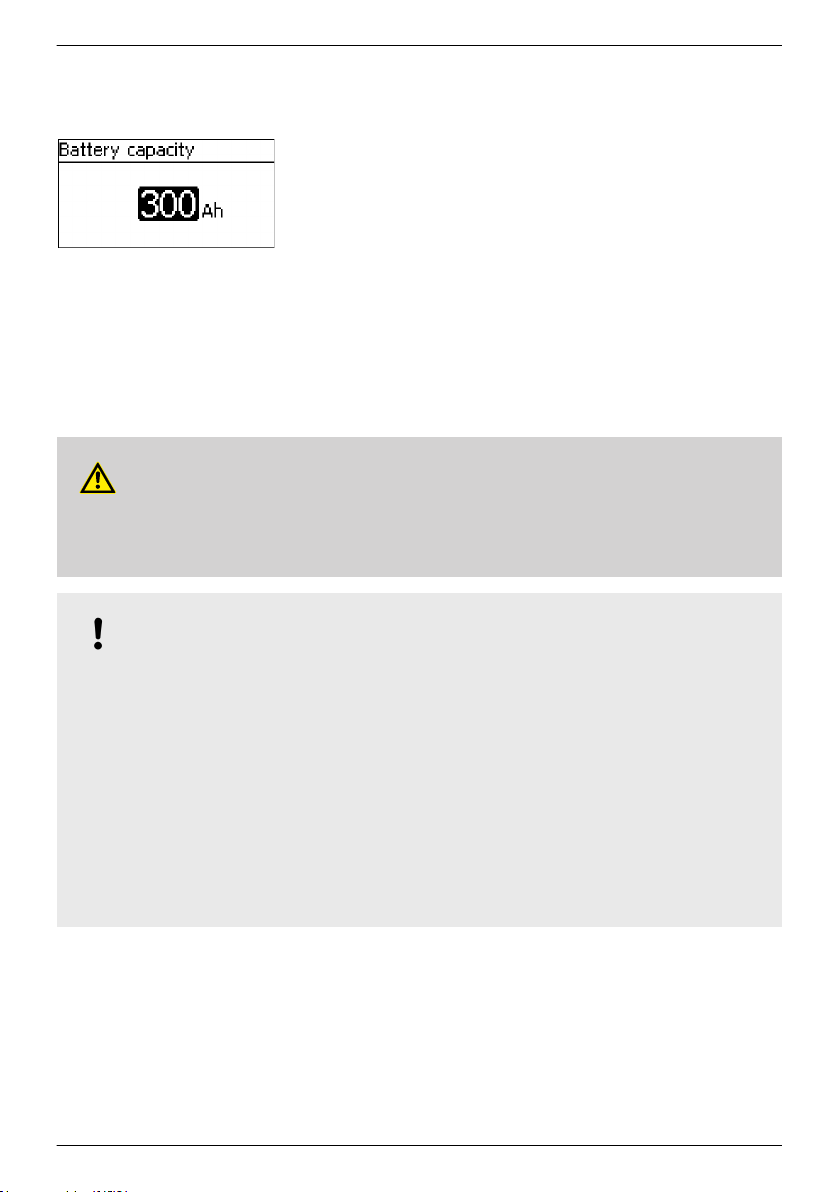

Set the battery type

8. Repeat steps 4 to 6 for the month.

9.

Press Ñ to select the year.

10. Repeat steps 4 to 6 for the year.

NOTICE

Correctly setting the time and date is essential for correct

operation of the device. In a master/slave system, enabling the

Save setting parameter for the slave allows the language

and time settings of the master to be transferred to the slave,

Ä

Chapter 8.8.3 ‘Changing the MPPT 6000-S slave settings

see

(MPPT 6000-M only)’ on page 87. In the case of a power

failure, the time and date settings are retained for approx. 4

days.

1. Press ESC for 1 s. The standard status display appears.

2. Press SET. The main menu appears.

3.

Press Ñ to select Battery settings.

4. Press SET. The Battery settings menu appears.

5.

Press Ñ to select Battery type.

6. Press SET. The Battery type dialogue appears (Fig. left).

7.

Press D, Ñ to select a different battery type.

8. Press SET. The selected battery type is set.

NOTICE

MPPT 6000-M: The following battery types can be selected:

n Lead acid battery

n Lead Gel/AGM battery

n Li-Ion battery

n NiCd battery

MPPT 6000-S: The following battery types can be selected:

n Lead acid battery

n Lead Gel/AGM battery battery

In a master/slave system, enabling the Save setting

parameter for the slave allows the Lead acid and Lead Gel/AGM

battery type settings of the master to be transferred to the

slave. Settings for the Li-Ion and NiCd battery types cannot be

stored in the

MPPT 6000-S. The MPPT 6000-M can however

function as the master and control the charge function of the

slaves for all battery types when the Master mode

configuration for the slave is active, see

Ä

Chapter 8.8.3

‘Changing the MPPT 6000-S slave settings (MPPT 6000-M only)’

on page 87.

756.404 | Z01 | 16.06

35

Page 36

Set the battery capacity

1. Press ESC. The Battery settings menu appears.

2.

Press Ñ to select Battery capacity.

3. Press SET. The Battery capacity dialogue appears (Fig.

left).

4. Press SET. The value flashes.

5.

Press D, Ñ to change the value.

6. Press SET. The value stops blinking.

NOTICE

Enter the specified nominal capacity of the battery here. This

value is required by functions such as the state of charge

calculation (SOC), IUIA charging and the capacity test. In a

master/slave system, enabling the Save setting

parameter

for the slave allows the battery capacity setting of the master

to be transferred to the slave.

Setting the charge parameters

WARNING!

Charging the battery with incorrect parameters can damage the battery. This can result in

conditions that are a danger to persons. Ensure that the correct charging parameters for the

selected battery type are used. Consult the battery manufacturer if necessary.

NOTICE!

Newly delivered

MPPT 6000-M and MPPT 6000-S devices are configured with the lead-acid

battery type. Always check the charge parameters.

– For the charge parameter settings applying to the lead-acid and lead-gel/AGM battery

Ä

types, see

– For the charge parameter settings applying to the Li-Ion battery type, see

Chapter 8.5 ‘Lead-acid battery system functions’ on page 62.

Ä

Chapter 8.6

‘Li-Ion battery system functions (MPPT 6000-M only)’ on page 74.

– For the charge parameter settings applying to the NiCd battery type, see

Ä

Chapter 8.7

‘NiCd battery system functions (MPPT 6000-M only)’ on page 77.

In a master/slave system, enabling the Save setting parameter for the slave allows the leadacid and lead-gel/AGM battery type settings of the master to be transferred to the slave. When

the slave has been configured with the Master mode operating mode then the slave is

controlled using the charge parameters configured in the master for all battery types.

36

756.404 | Z01 | 16.06

Page 37

Switching on the cable compensation

The cable compensation corrects the deviation of the measured

battery voltage resulting from the voltage drop across the

battery cable.

NOTICES

n The unit is supplied with cable compensation switched off.

n The battery voltage sensor cable must be connected in

order to use cable compensation, see

Ä

Chapter 4.3.3

‘Connecting the battery voltage sensor’ on page 29.

n The voltage measured via the battery voltage sensor cable

is displayed in the measurements shown on the status

display of the device.

n Measuring the actual voltage at the battery allows the

device to compensate for voltage drops across the battery

cables. This can result in higher voltages at the battery

connection terminals on the controller.

n An Error event message is displayed if the battery voltage

sensor cable is not connected when the cable

compensation is switched on.

n If cable compensation is to be used in every member of a

master/slave system then this must be individually

installed and activated at each device.

1. Press ESC. The Battery settings menu appears.

2.

756.404 | Z01 | 16.06

Press D, Ñ to select Cable compensation (Fig. left).

3. Press SET. The Cable compensation dialogue appears (Fig.

left).

4.

Press D, Ñ to select On.

5. Press SET. The line compensation is switched on.

37

Page 38

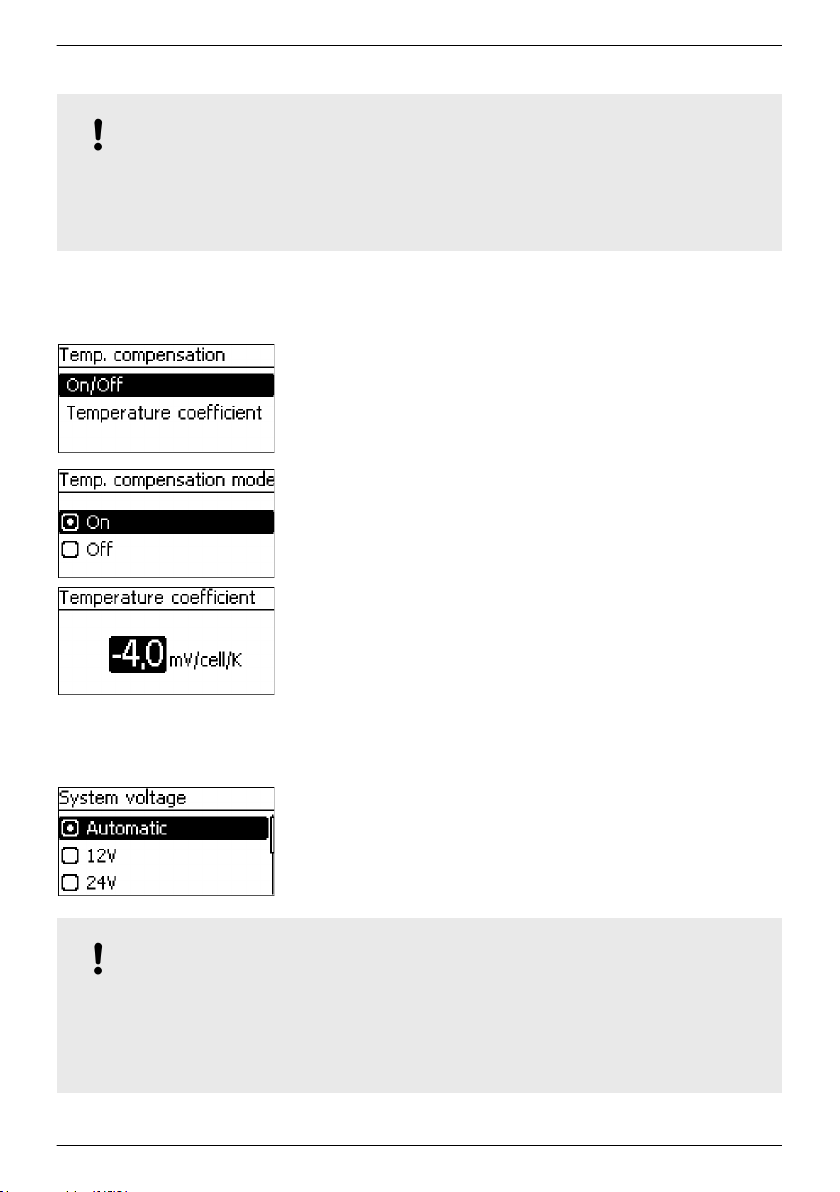

Configuring the temperature sensor

The end-of-charge voltage can be adjusted according to the

measured ambient temperature of the battery. If an external

temperature sensor is used then this must be activated in the

corresponding menu.

NOTICES

n The external temperature sensor is switched off in newly

delivered devices. The internal sensor is used.

n We recommend connecting and using the external

temperature sensor supplied with the device

(MPPT 6000-M

only).

n In a master/slave system the master device performs the

central temperature compensation and controls the slaves

accordingly if these are configured for master-controlled

operation.

n MPPT 6000-M: An external temperature sensor must be

installed and activated for the battery capacity test

function.

See

Ä

Chapter 8.5.11 ‘Battery temperature sensor’ on page 71

for information on activating the PA TS-S external temperature

sensor.

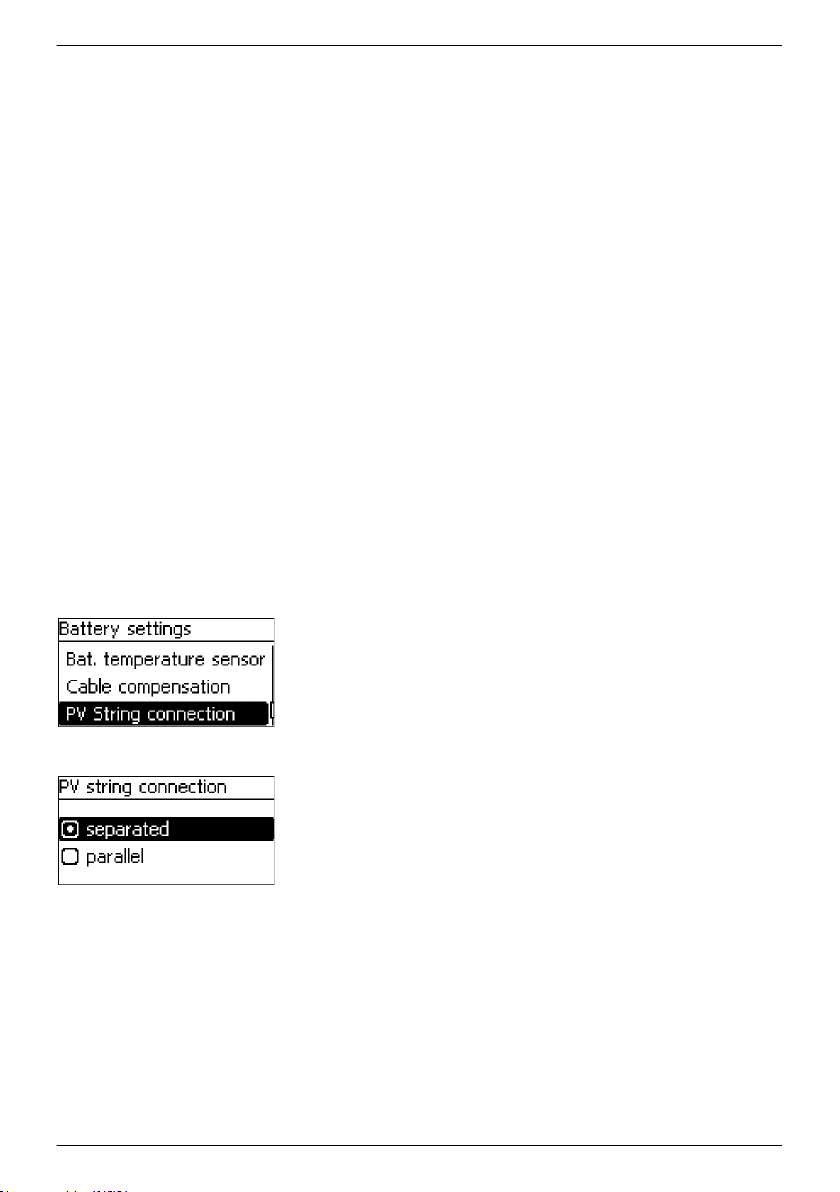

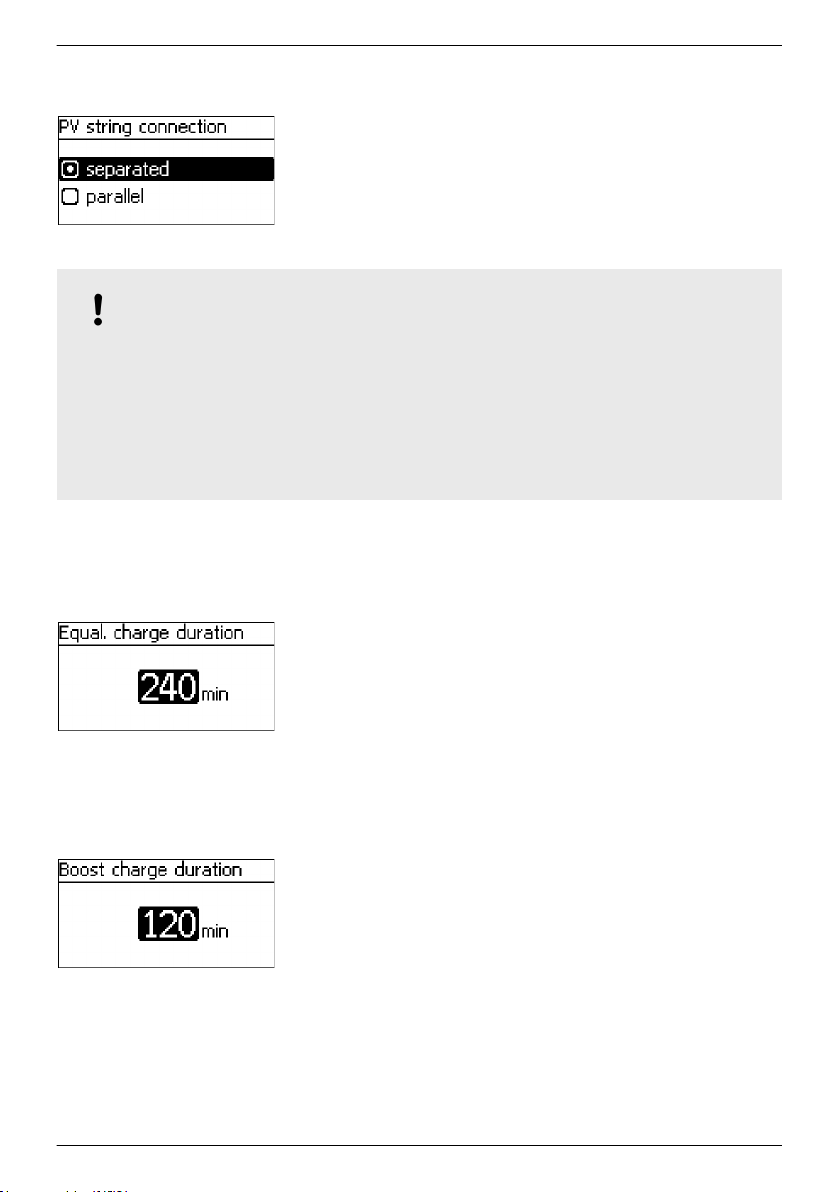

Setting the PV string connection

Newly delivered devices are configured for separate use of the

two module inputs "M1+/M1–" and "M2+/M2–". The PV string

connection parameter must be changed to "parallel" if both

module connections are wired in parallel.

1. Press ESC. The Battery settings menu appears.

2.

38

Press D, Ñ as required to select PV string connection (Fig.

left).

3. Press SET. The PV string connection dialogue appears

(Fig. left).

4.

Press D, Ñ to select parallel.

5. Press SET. The string connection is now changed to parallel

connection of the modules.

756.404 | Z01 | 16.06

Page 39

Finishing initial commissioning

NOTICE!

After completing basic installation of a master/slave system the devices must then be connected

via the StecaLink bus. Finish the installation of all devices before switching on any devices.

Ä

MPPT 6000-M, MPPT 6000-S: If further optional components,

Chapter 6 ‘Installation and

initial commissioning of optional components’ on page 40, are to be installed and configured,

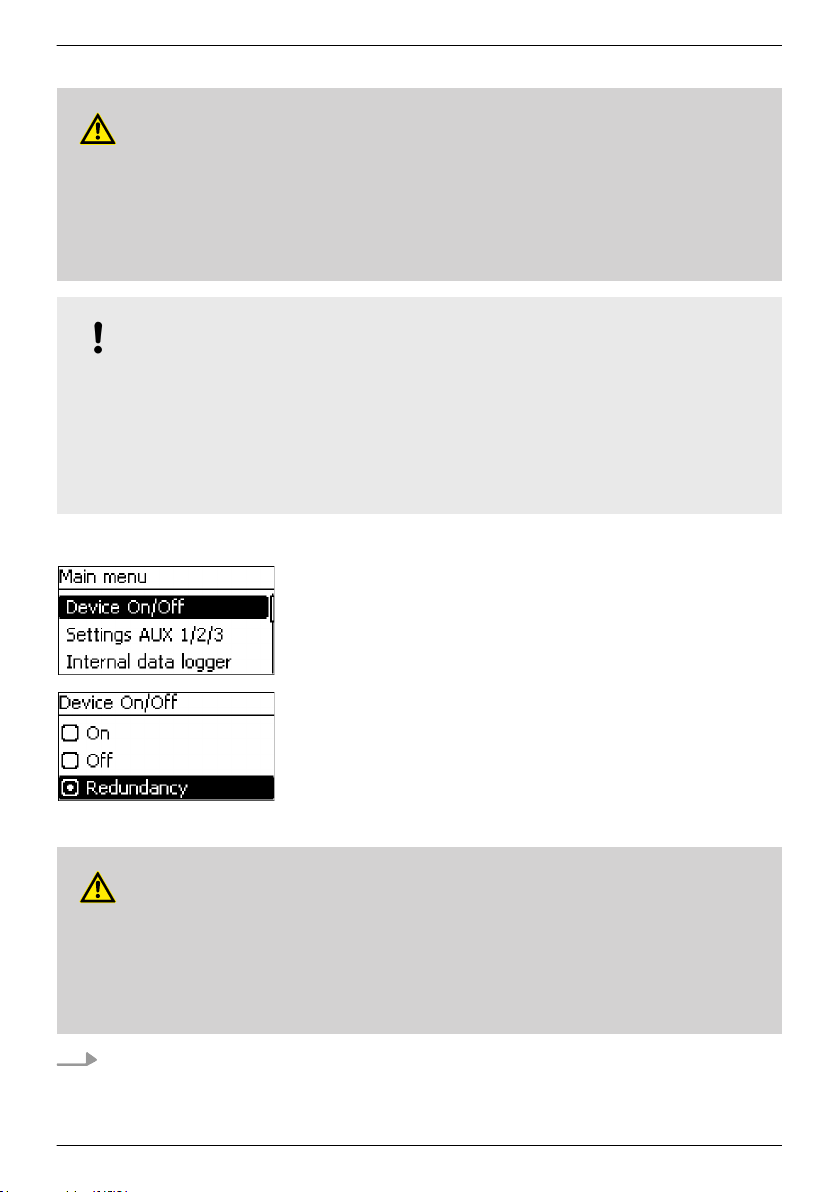

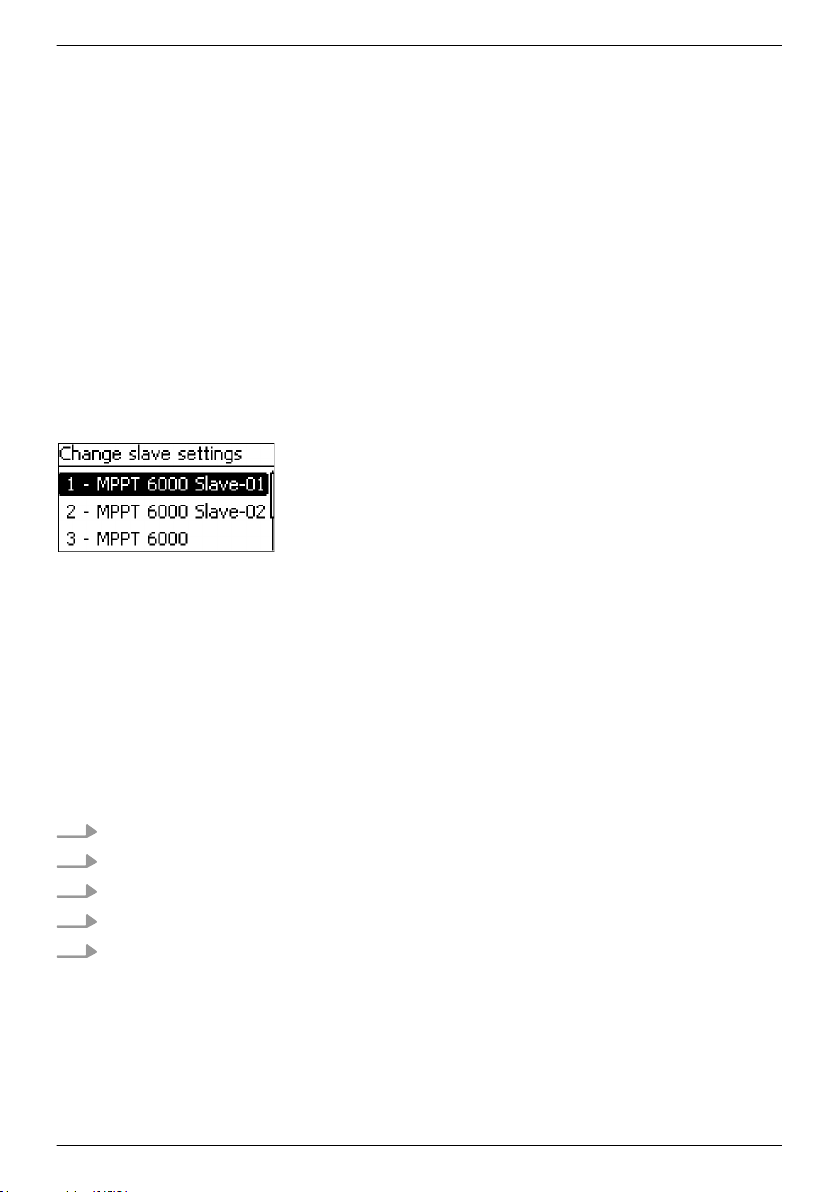

finish the installation of all devices before switching on the unit.