Steca coolcept-x StecaGrid 1500x, coolcept StecaGrid 1500, coolcept StecaGrid 3010, coolcept StecaGrid 2000, coolcept StecaGrid 2500 Installation And Operating Instruction

...Page 1

coolcept coolcept-x

Installation and operating instructions

EN

747.431 | Z09.2 | 2016-02-18

Page 2

EN

Table of contents

1 Preface................................................................................. 4

2 General information........................................................... 5

3 Structure and function..................................................... 12

4 Installation........................................................................ 31

5 Operation.......................................................................... 49

6 Self test.............................................................................. 60

7

8 Maintenance and disposal............................................... 69

9 Technical data................................................................... 70

2.1 General safety instructions........................................... 5

2.2 Identification................................................................ 6

2.3 Scope of delivery.......................................................... 8

2.4 Intended use................................................................ 8

2.5 About this manual....................................................... 9

3.1 Housing...................................................................... 12

3.2 Operating buttons..................................................... 14

3.3 Display....................................................................... 14

3.4 Cooling...................................................................... 21

3.5 Grid monitoring......................................................... 22

3.6 Data communication.................................................. 22

4.1 Safety measures during installation........................... 31

4.2 Mounting the inverter................................................ 33

4.3 Prepare AC connection............................................... 35

4.4 Prepare DC connections............................................. 37

4.5 Preparing the data connection cable.......................... 38

4.6 Connecting the inverter inverter and switching the

AC on......................................................................... 38

4.7 Initial commissioning of the inverter.......................... 39

4.8 Feed-in management................................................. 46

4.9 Switch on DC............................................................. 47

4.10 Deinstalling the inverter........................................... 47

5.1 Overview of operating functions................................ 49

5.2 General operating functions...................................... 50

5.3 Important operating functions................................... 50

5.4 Internet portal............................................................ 53

Fault rectification.............................................................. 63

8.1 Maintenance.............................................................. 69

8.2 Disposal..................................................................... 69

9.1 Inverter...................................................................... 70

9.2 AC cables and line circuit breakers............................. 81

9.3 Country table............................................................. 82

2

747,431 | Z09.2 | 18/02/2016

Page 3

EN

10 Liability, commercial guarantee, legal guarantee.......... 83

Contact.............................................................................. 84

11

Appendix........................................................................... 85

A Assembly...................................................................... 86

A.A Bore dimension drawing for coolcept devices........... 86

A.B Bore dimension drawing for coolcept-x devices......... 87

A.C AC plug...................................................................... 88

A.D Phoenix Contact SUNCLIX (DC connector)................. 91

747,431 | Z09.2 | 18/02/2016

3

Page 4

EN

1 Preface

Thank you for choosing inverters from the coolceptproduct line of

Steca Elektronik GmbH . By using solar energy, you are making a

significant contribution to environmental protection; by reducing the

amount of carbon dioxide (CO2) and other harmful gases that

burden the earth's atmosphere.

Maximum efficiency with a long service life

The innovative inverter topology is based on a single-stage

transformer-less circuit concept and is integrated into all devices in

the coolcept series. This unique technology allows peak efficiencies

of 98,0 %

or 98,6 % to be achieved. Depending on the type, the

European efficiency of the devices is also significantly greater than

98 % and sets new standards in photovoltaic grid-feed systems.

A new and unique cooling concept inside the inverter ensures an

even distribution of heat and a long service life.

Designer casing and easy installation

For the first time, the very high efficiency allows the use of a

designer casing made of plastic for the coolcept inverters. This offers

many advantages. The surface temperatures of the devices overall

remains extremely low. In addition, there are clear benefits for the

installation. The coolcept-x inverters have a sturdy metal casing that

allows them to be also used outdoors.

The lightweight devices weigh only 9 or 12 kg and can be easily and

safely mounted on a wall. The supplied wall bracket and practical

recessed grips for right and left handed installers make mounting of

the device simple and convenient. All connections and the DC circuit

breaker are externally accessible.

Visualization and accessories

The devices have a graphic display, with which the energy load

values, actual capacities, and operating parameters of the

photovoltaic system can be visualized. The innovative menu offers

the possibility of individual selection of the different measured

values.

www.stecasolar.com for further information on accessories.

See

Your installer can, of course, also give you more information about

the options and accessories that are available.

4

747,431 | Z09.2 | 18/02/2016

Page 5

2 General information

2.1

General safety instructions

n This document is part of the product.

n Install and use the device only after reading and understanding

this document.

n Always perform the measures described in this document in the

sequence specified.

n Keep this document in a safe place for the entire service life of

the device. Pass the document on to subsequent owners and

operators of the device.

n The yield of the system can be reduced through improper

operation

n If the housing is damaged, do not connect the device to the DC

or AC lines

n If one of the following components is damaged, immediately

take the device out of operation and disconnect it from the

mains grid and PV generators.

– Device (not functioning, visible damage, smoke,

– Lines

– PV generators

Do not switch the system on again before

– the device has been repaired by a dealer or the

– Damaged cables or PV generators have been repaired by a

n Never cover the device

n Do not open the casing: Risk of death. Invalidation of the

guarantee.

n Factory labels and markings must never be altered, removed or

rendered unreadable.

n Comply with the instructions of the respective manufacturer

when you connect an external component that is not described

in this document (e.g. external data loggers). Components that

are incorrectly connected can damage the device.

EN

:

penetration of liquid etc.)

manufacturer,

technical specialist.

747,431 | Z09.2 | 18/02/2016

5

Page 6

EN

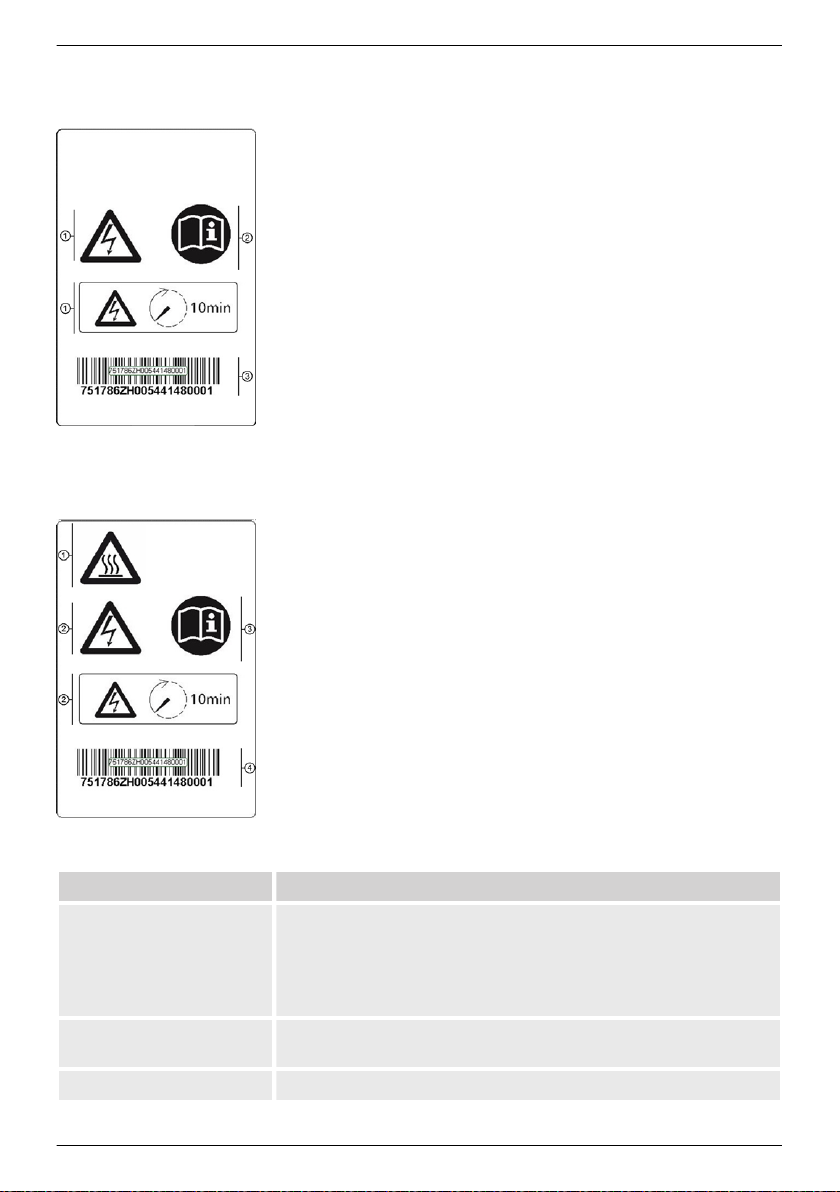

Safety information on

the device (coolcept

Indoor)

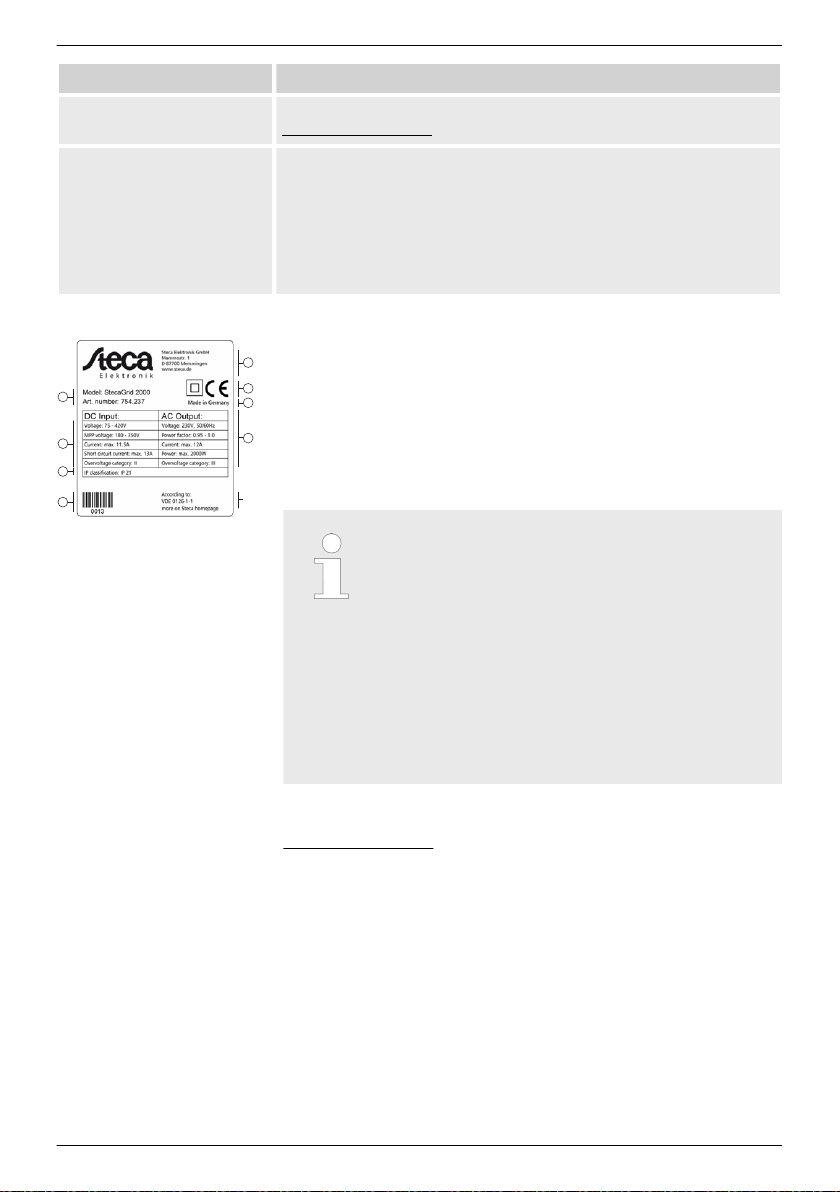

Safety information on

the device (coolcept

Indoor)

①

Dangerous voltages can remain present on the components up

to 10minutes after switching off the DC circuit breaker and the

line circuit breaker.

②

Read and follow the manual!

③

Serial number as a bar code and in plain text

①

Caution: Surface may be hot

②

Dangerous voltages can remain present on the components up

to 10minutes after switching off the DC circuit breaker and the

line circuit breaker.

③

Read and follow the manual!

④

Serial number as a bar code and in plain text

2.2 Identification

Feature Description

Types coolcept (plastic housing): StecaGrid 1500,

Version status of the

manual

Manufacturer's address

6

StecaGrid 2500, StecaGrid 3010, StecaGrid 3600, StecaGrid 4200

coolcept-x (stainless steel housing): StecaGrid 1500x,

StecaGrid 2000x, StecaGrid 2500x, StecaGrid 3010x,

StecaGrid 3600x, StecaGrid 4200x

Z09

Ä

Chapter 11 ‘Contact’ on page 84

See

StecaGrid 2000,

747,431 | Z09.2 | 18/02/2016

Page 7

Feature Description

1

7

2

3

4

5

6

8

⑨

Certificates See Appendix ⇒ Certificates and

www.stecasolar.com ⇒ coolcept – coolcept-x

Optional accessories

n External data loggers:

– WEB‘log from Meteocontrol

– Solar-Log from Solare Datensysteme

n Termination plug for RS485 bus

–

IP21: 752,856

– IP65: 740,864

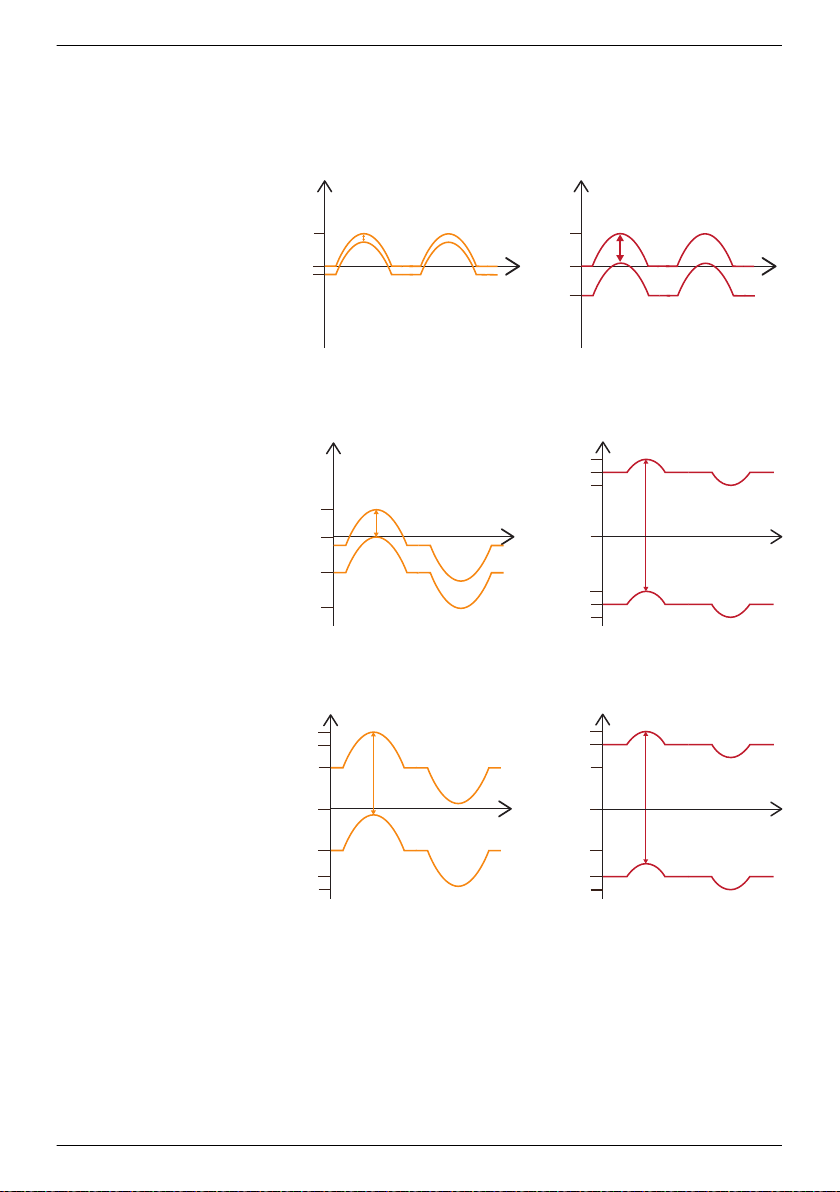

Rating plate

①

Bar code for internal use

②

Protection class

③

Technical data of the DC input

④

Article number and product designation

⑤

Manufacturer's address

⑥

Cover the Protection class II and CE mark

⑦

Country of manufacture

⑧

Technical data of the AC output

⑨

Standard for grid monitoring

Notice

– For Australia only: Cover the

Protection class II

described on

Protection class II symbol on the type plate. ’

on page 33.

– For the serial number, see

on the device (coolcept Indoor)’ on page 6 and

Ä

‘Safety information on the device (coolcept

Indoor)’ on page 6

– For the position of the type plate, see

3.1 ‘Housing’ on page 12.

symbol on the type plate, as

Ä

‘ For Australia only: Cover the

Ä

‘Safety information

Ä

EN

Chapter

EU Declaration of

Conformity

747,431 | Z09.2 | 18/02/2016

The products described in this document comply with the applicable

European directives. Certificates for the products are provided at

www.stecasolar.com ⇒ PV GRID CONNECTED ⇒ Grid inverters

7

Page 8

EN

2.3 Scope of delivery

n Inverter ①, type coolcept (plastic housing) or coolcept-x

(stainless steel housing, IP65)

n Mounting plate ② for type coolcept or coolcept-x

n AC plug ③

n 1 pair SUNCLIX plug-in connectors ④

n 3 sealing caps (for RJ45 socket; only coolcept-x) ⑤

n Brief installation and operating instructions ⑥

①

②

2.4 Intended use

⑥

③

n The inverter must only be used in grid-coupled photovoltaic

systems. The inverter is suitable for all PV generator with

connections that do not need to be grounded.

n PV generator must be used that have an IEC 61730 class A

rating because the inverter does not have electrical isolation.

n If the maximum AC operating voltage is higher than the

maximum system voltage of the photovoltaic generator, then

PV generator must be used that have a maximum system

voltage that is higher than the AC grid voltage.

Notice

An overview of suitable PV generators is available at

www.stecasolar.com

Service and support.

④

Þ

⑤

PV GRID CONNECTED

Þ

8

747,431 | Z09.2 | 18/02/2016

Page 9

375 V

−350 V

DC (+)

DC (−)

U

t

0 V

U

P

V

= 350 V

375 V

−75 V

DC (+)

DC (−)

U

t

0 V

U

P

V

= 75 V

125 V

−160 V

DC (+)

DC (−)

U

t

0 V

−320 V

UPV = 125 V

180 V

−180 V

−250 V

250 V

320 V

0 V

−320 V

U

t

UPV = 500 V

DC (+)

DC (−)

175 V

−175 V

−275 V

275 V

320 V

U

t

0 V

−320 V

U

PV

= 350 V

DC (+)

DC (−)

175 V

−175 V

−275 V

275 V

320 V

0 V

−320 V

U

t

UPV = 550 V

DC (+)

DC (−)

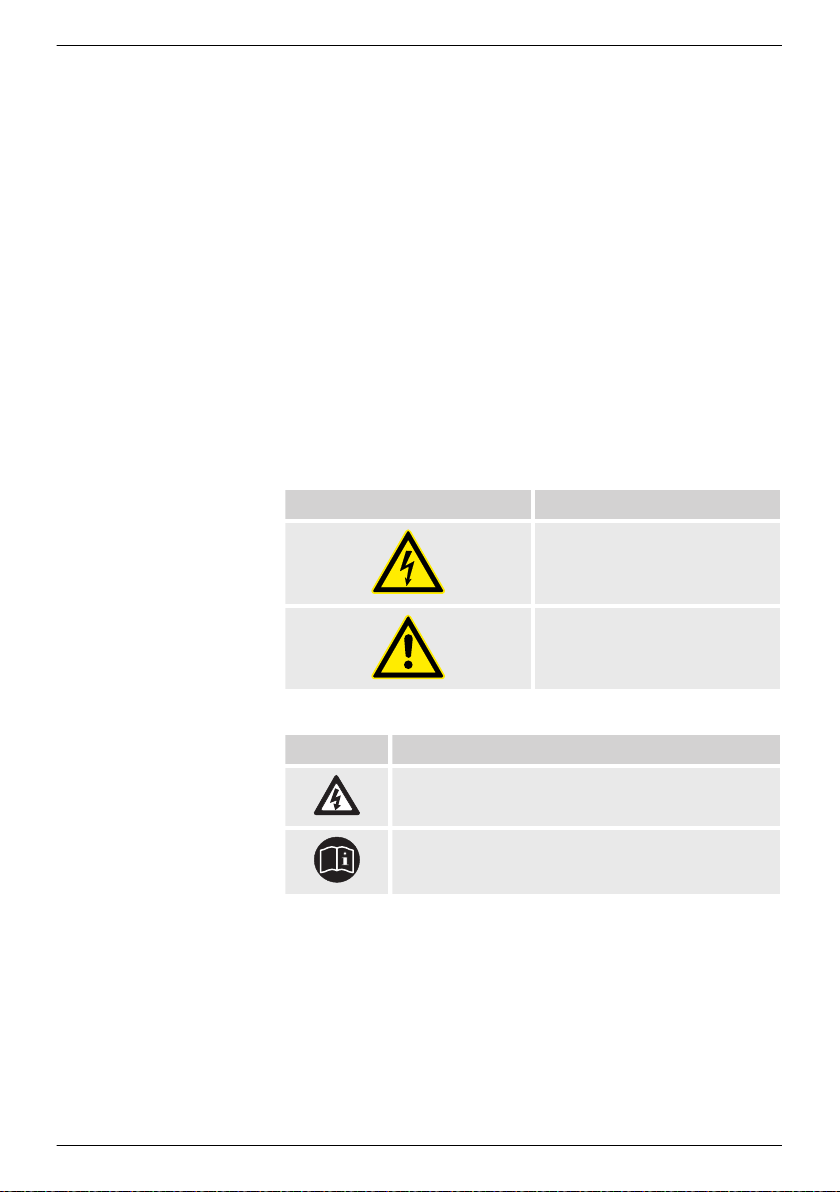

Potential curves of the

plus (+) and minus (–) DC

connections with respect

to PE

UPV = Potential between the

plus (+) and minus (–) DC‑connections

StecaGrid 1500/2000 and 1500x/2000x

Fig. 1: Potential curves of UPV at 75 V (left) and 350 V (right)

StecaGrid 2500/3010 and 2500x/3010x

EN

2.5 About this manual

Contents

2.5.1

747,431 | Z09.2 | 18/02/2016

Fig. 2: Potential curves of UPV at 125 V (left) and 500 V

StecaGrid 3600/4200 and 3600x/4200x

Fig. 3: Potential curves of UPV at 350 V (left) and 550 V

This manual describes the inverters of the types coolcept and

coolcept-x. The points at which the types differ are marked in the

text.

(right)

(right)

9

Page 10

EN

2.5.2

Target group

2.5.3 Designations

Symbols

This manual contains all information that a specialist needs to set up

and operate the inverters. Follow the instructions of the respective

manufacturers when installing other components (e.g. PV generator,

cables).

Unless otherwise indicated, the target audiences of this manual are

technical professionals and system operators. Technical professionals

are, for example:

n Persons who have the knowledge of terminology and the skills

necessary for setting up and operating photovoltaic systems.

n Persons who have the necessary training, knowledge and

experience, and knowledge of the applicable regulations in

order to evaluate and recognise the dangers inherent in the

following work:

–

Installation of electrical equipment

– Production and connection of data communication cables

– Production and connection of mains grid power supply

cables

The following table contains the symbols used in this manual

Warning signs Type of danger

Warning – high-voltage.

Symbols used on the

device

10

Warning – danger zone.

The following table contains the symbols used on the device.

Cover the Description

Danger from electricity.

Read the manual before using the product.

747,431 | Z09.2 | 18/02/2016

Page 11

Signal words

Keywords used in conjunction with the symbols described:

Signal word Meaning

DANGER! This combination of symbol and

signal word indicates an

immediate dangerous situation

that will result in death or

serious injury if it is not

avoided.

WARNING! This combination of symbol and

signal word indicates a possible

dangerous situation that can

result in death or serious injury

if it is not avoided.

NOTICE! This combination of symbol and

signal word indicates a possible

dangerous situation that can

result in material and

environmental damage if it is

not avoided.

Abbreviations

Abbreviation Description

Derating Power reduction

DHCP DHCP automatically integrates the device in an existing network

(acronym: Dynamic Host Configuration Protocol)

MSD Internal grid monitoring of the inverter (English: Mains monitoring with

allocated Switching Devices).

MPP Working point producing the most power (English: maximum power

point)

MPP tracker Controls the power of the connected module strings to match the MPP

SELV, TBTS, MBTS Schutzkleinspannung (EN: Safety Extra Low Voltage; FR: Très Basse

Tension de Sécurité; ES: Muy Baja Tensión de Seguridad)

V

PV

The PV generator voltage present at the DC connection (photovoltaic

voltage)

EN

747,431 | Z09.2 | 18/02/2016

11

Page 12

11

2

3

14

16

8 7 15

11

10

9

EN

3 Structure and function

3.1

Housing

3.1.1 coolcept

①

Hood

②

Display (monochrome, 128 x 64 pixels)

③

Rating plate, serial number, warnings

④

Operating buttons: ESC, r, s, SET (from left to right)

⑤

1x AC connection

⑥

1x DC connection Minus (−) for PV generator (Phoenix Contact

SUNCLIX, touch protection)

⑦

1x DC connection Plus (+) for PV generator (Phoenix Contact

SUNCLIX, touch protection)

⑧

DC load-break switch (disconnects plus and minus input

simultaneously)

⑨

2 x RJ45 sockets (RS485 bus)

⑩

1x RJ45 socket (Ethernet)

⑪

1x RJ10 socket (Modbus RTU)

The housing components are described in detail below.

12

747,431 | Z09.2 | 18/02/2016

Page 13

3.1.2 coolcept-x

11

2

3

14

89 6711151

10

1213

①

Hood

②

Display (monochrome, 128 x 64 pixels)

③

Rating plate, serial number, warnings

④

Operating buttons: ESC, r, s, SET (from left to right)

⑤

1x AC connection

⑥

Pressure equalization membrane

⑦

1x RJ45 socket (RS485 bus)

⑧

1x DC connection Minus(−) for PV generator (Phoenix Contact

SUNCLIX, touch protection)

⑨

1x RJ45 socket (RS485 bus)

⑩

1x DC connection Plus(+) for PV generator (Phoenix Contact

SUNCLIX, touch protection)

⑪

1x RJ45 socket (Ethernet)

⑫

DC load-break switch (disconnects plus and minus input

simultaneously, can be safeguarded with a padlock)

⑬

Bore for optional attachment of a grounding element or

mechanical fastening element (securing chain)

The housing components are described in detail below.

EN

747,431 | Z09.2 | 18/02/2016

13

Page 14

EN

3.2 Operating buttons

The operating buttons ④ in Ä Chapter 3.1.1 ‘coolcept’ on page 12

and in

functions:

Ä

Chapter 3.1.2 ‘coolcept-x’ on page 13 have the following

Button Action

ESC

r

s

SET

Press briefly Goes to the next higher menu

Press longer

(≥ 1 second)

Press briefly

Press briefly

Press briefly Goes to the next lower menu

Press longer

(≥ 1 second)

Function

General guided operation

level

Discards any changes

Goes to the status display Jumps to the start of the

n Moves the marking bar or the display content upward

n In a numeric setting, moves the marking 1 position to the

left

n Increases an adjustment value by 1 increment

n Moves the marking bar or the display content downward

n In a numeric setting, moves the marking 1 position to the

left

n Increases an adjustment value by 1 increment

level

n a selected numerical value starts flashing and can be

changed

n adopts a change

n changes the state of a control element (check box/radio

button)

Answers a query dialog with

Yes

Navigates 1 step back

guided configuration process

—

Goes 1 step back

3.3 Display

3.3.1

14

General information

Ä

For the presentation on the display (② in

on page 12 and

n Symbol

data, it cannot process any user inputs. The resulting waiting

time is indicated by the animated sun symbol.

n Errors are indicated by a red flashing backlighting. An event

message is also displayed at the same time.

Ä

Chapter 3.1.2 ‘coolcept-x’ on page 13)

: While the inverter is processing large volumes of

Chapter 3.1.1 ‘coolcept’

747,431 | Z09.2 | 18/02/2016

Page 15

Notice

3

4

2

2

7 8

9

5 6

1

F

The display reacts slower at very low temperatures. In

particular, this can apply for coolcept-xdevices if they

are used outdoors.

EN

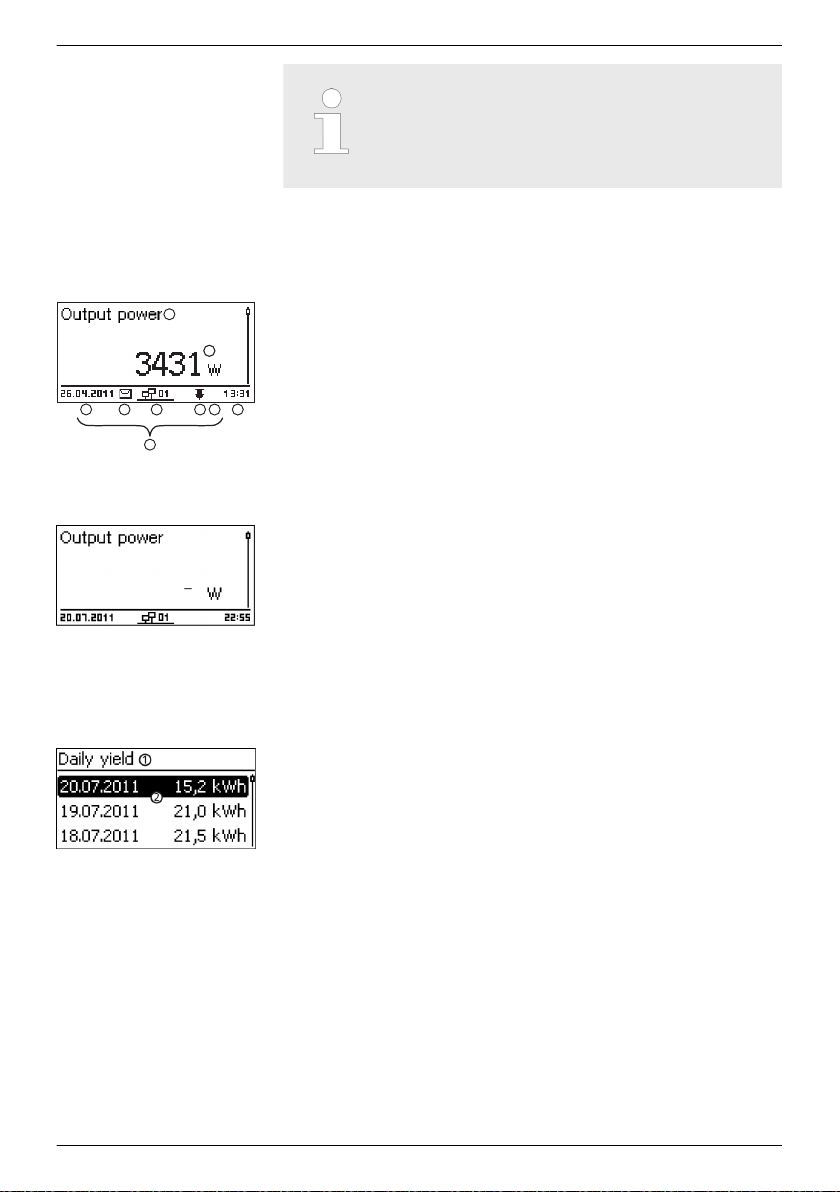

3.3.2 Information

Status display

Numeric yield (day,

month, year)

The information shown on the display is described below using

illustrative examples.

The status display shows the following values:

①

Measurement name

②

Measurement with units

③

Date is displayed alternatingly with IP address

④

Cover the Non-confirmed event messages; more information on

this is provided in Section

⑤

Animated symbol Connect symbol with 2‑digit inverter address;

Ä

‘Event messages’ on page 64

indicates data traffic on the RS485 bus.

⑥

Cover the Power reduction (Derating)

⑦

Cover the Fixed voltage mode activated

⑧

Time

⑨

IP address of the device when a network connection has been

established, display alternates with ③ – ⑦

The following applies to the status display:

n The measurements shown in the status display are defined

under Settings ▶ Meas. values. Some measurements are

always displayed (default setting).

n Current values are not displayed at night (solar irradiation too

low; example in Fig. left).

n The CO2 saving shown in the status display are calculated

using the savings factor 508 g/kWh .

Daily, monthly and annual yields can be displayed numerically in a

list.

①

Yield period (day/month/year)

②

Individual yields with period and value (1 per row)

The yield periods contain the following numbers of individual

entries:

n Day yield: last 31 days

n Monthly yield: last 13 months

n Annual yield: last 30 years

1)

A yield value of 0 is shown when the inverter was not yet installed

1)

1)

1)

at that time.

747,431 | Z09.2 | 18/02/2016

15

Page 16

EN

Graphical yield (day,

month, year)

Event messages

PV generator

characteristic curve

Information

Daily, monthly and annual yields can be displayed graphically in a

chart.

①

Period on an individual yield (here: day yield)

②

Y axis 1) 2)

③

X axis: Time in hours/days/months/years

④

Total of all individual yields shown in the diagram, in kWh

3)

The graphical representation can show annual yields for the last 20

years.

1)

Yield in kWh

2)

With addition of ‘M’ : : yield in MWh

3)

The scaling changes depending on the maximum value.

Ä

Chapter 7 ‘Fault rectification’ on page 63

①

X axis: input voltage in V

②

Y axis: power in kW

③

Peak = MPP

If the ‘Ch. Curve’ menu item is called, the inverter records the PV

generator characteristic curve and then displays it (Fig. upper left).

The following applies:

n The inverter traverses the input voltage range and records the

power generated over this range. Duration: a few seconds;

is

displayed.

n The MPP is at the peak of the PV generator characteristic curve.

n This peak and the PV generator characteristic curve change with

the level of solar irradiation.

The menu item Information contains the following sub-menu

items.

n Contact info

n System info (see Fig. left):

–

Product designation

– Serial number of the inverter

– Information concerning the software and hardware version

of the inverter (see sample ① in Fig. left)

– Inverter address

– Version of the manual that belongs with the inverter

n Country setting: country that is currently set and country-

specific grid parameters; see also

Ä

Chapter 9.3 ‘Country table’

on page 82.

n Reactive power characteristic curve: Diagram of the

reactive power characteristic curve (only if prescribed for the set

country)

16

747,431 | Z09.2 | 18/02/2016

Page 17

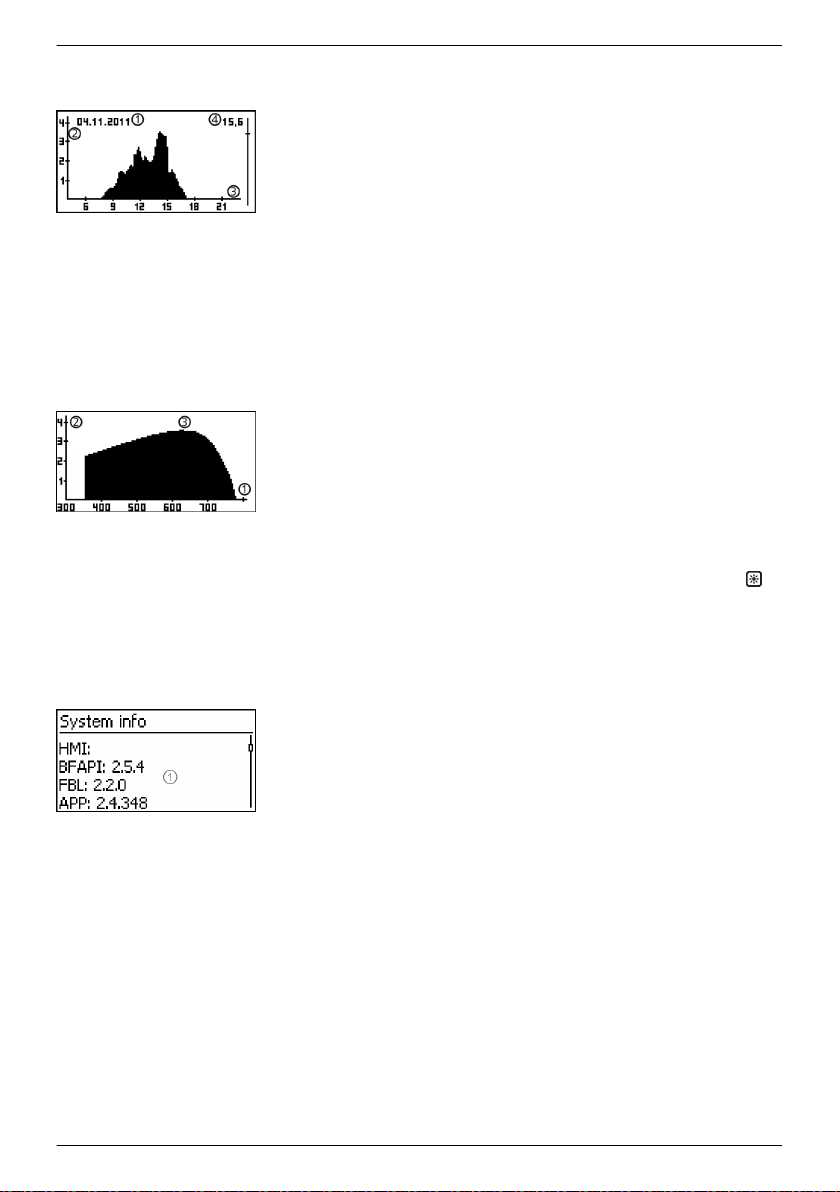

3.3.3

Settings

Numerical settings

Selection of the

measurements

n Network: Network parameters, partially configurable under

Settings ▶ Network

– Host name: Unique name in the network

– DHCP status: DHCP on/off

– Link status: Status of the network connection

– IP address: IP address of the inverter

– Subnet mask: Subnet mask of the inverter

– Gateway: IP address of the network gateway

– DNS address: IP address of the DNS server

– MAC address: Hardware address of the inverter

n Results of the last self-test (only if in the country setting Italy is

set)

When performing numerical settings of remuneration and dates, the

following applies:

Remuneration

n Possible currencies: £ (Pounds), € (Euros), kr (Krones), none.

n The maximum value that can be set for remuneration is limited

for technical reasons. The remuneration must be set using

different units as required. Example: Dollars instead of Cents

(set currency to none ).

①

Designation of the numerical setting

②

Value to be set; the selected value to be set is highlighted in

black.

Date

When setting the month/year, a check is performed to ensure that

the selected day is valid. If not, then the day is automatically

corrected.

Example: 31.02.2011 is corrected to 28.02.2011.

Selection of the measurements to be shown in the status display.

The following measurements can be selected:

n Output power: Inverter output power

1)

n Current day yield: Day yield since 0:00

n PV voltage: The voltage supplied by the PV generators

n PV current: The current supplied by the PV generators

n Grid voltage: Voltage at the inverter connection

1)

n Grid current: The current fed into the mains grid

n Grid frequency: The frequency of the public grid

n Internal temperature: Internal temperature of the inverter

n Derating Reason for derating

n Max. daily power: The maximum power supplied in the

current day

n Abs. max. power: The maximum power ever fed into the

grid

3)

3)

2)

EN

747,431 | Z09.2 | 18/02/2016

17

Page 18

EN

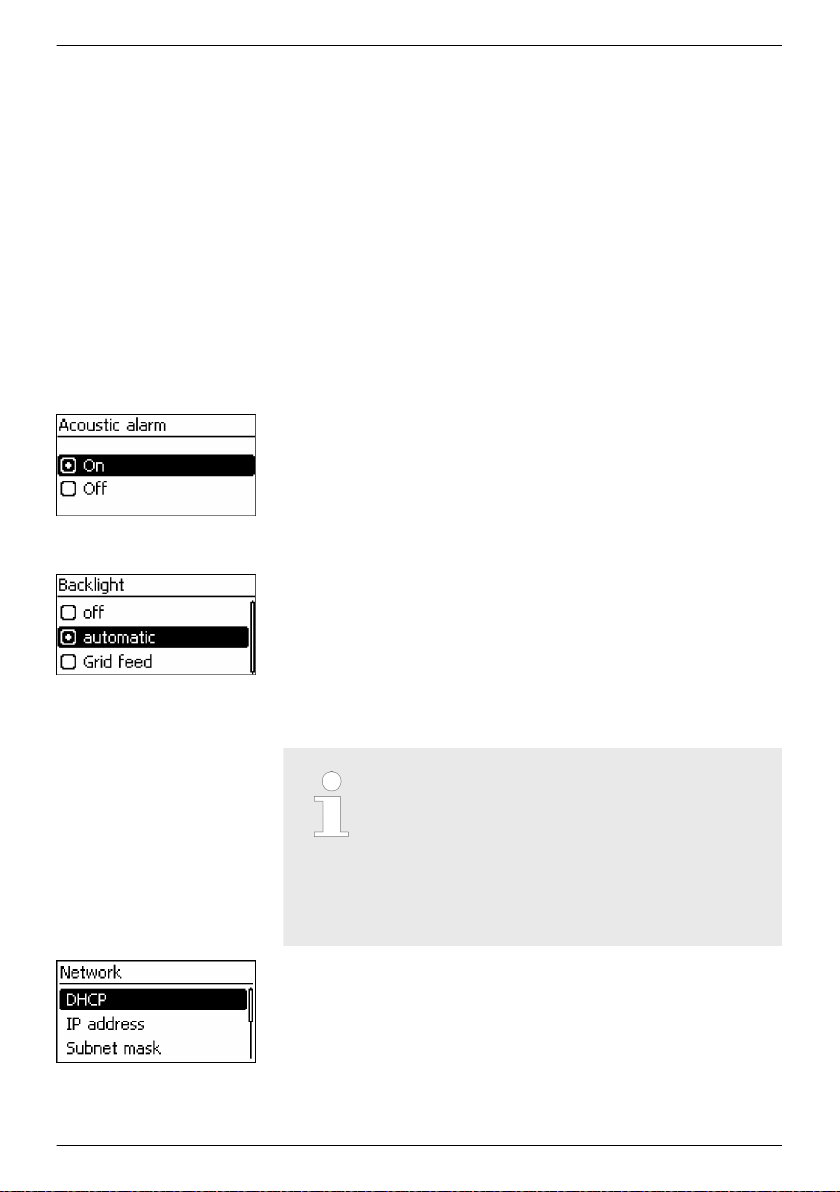

Acoustic alarm

Backlight

TCP/IP network

n Max. daily yield: The maximum daily yield achieved

3)

n Operating hours: The operating hours during which the

device has been connected to the grid (including night-time

hours).

n Total yield: Yield since commissioning

n CO2 savings: CO2 savings achieved since commissioning

1)

Measurement is always displayed (cannot be switched off)

2)

Possible causes:

– Internal temperature too high

– User default Power limiter

– Frequency too high

– Controlled by grid operator (feed-in management)

– Delayed increase in power after starting

3)

Can be reset to 0 via Settings ▶ Reset max. vals.

An acoustic alarm sounds (approx. 4.5 kHz) when an event message

is displayed.

n 2 Sounds: Warning

n 3 Sounds: Error

The acoustic alarm is switched off with the factory default settings.

n off

n automatic: Switches on for 30 seconds when a button is

pushed

n Grid feed: (factory setting)

– Not feeding: Switches on for 30 seconds when a button is

pushed; then switches off

– Feeding: Switches on for 30 seconds when a button is

pushed; then dims

Notice

– A prerequisite for this is that you know the

parameters required for setting up the TCP/IP

network connection. Consult (further) technical

professionals if required.

– DHCP is activated in the device ex-works. This

allows automatic integration of the device in

most networks.

18

Network settings, required for network communication, e. g. with an

Internet portal:

n DHCP: Switch DHCP on/off

n IP address: IP address of the inverter

n Subnet mask: Subnet mask of the inverter

n Gateway: IP address of the network gateway

747,431 | Z09.2 | 18/02/2016

Page 19

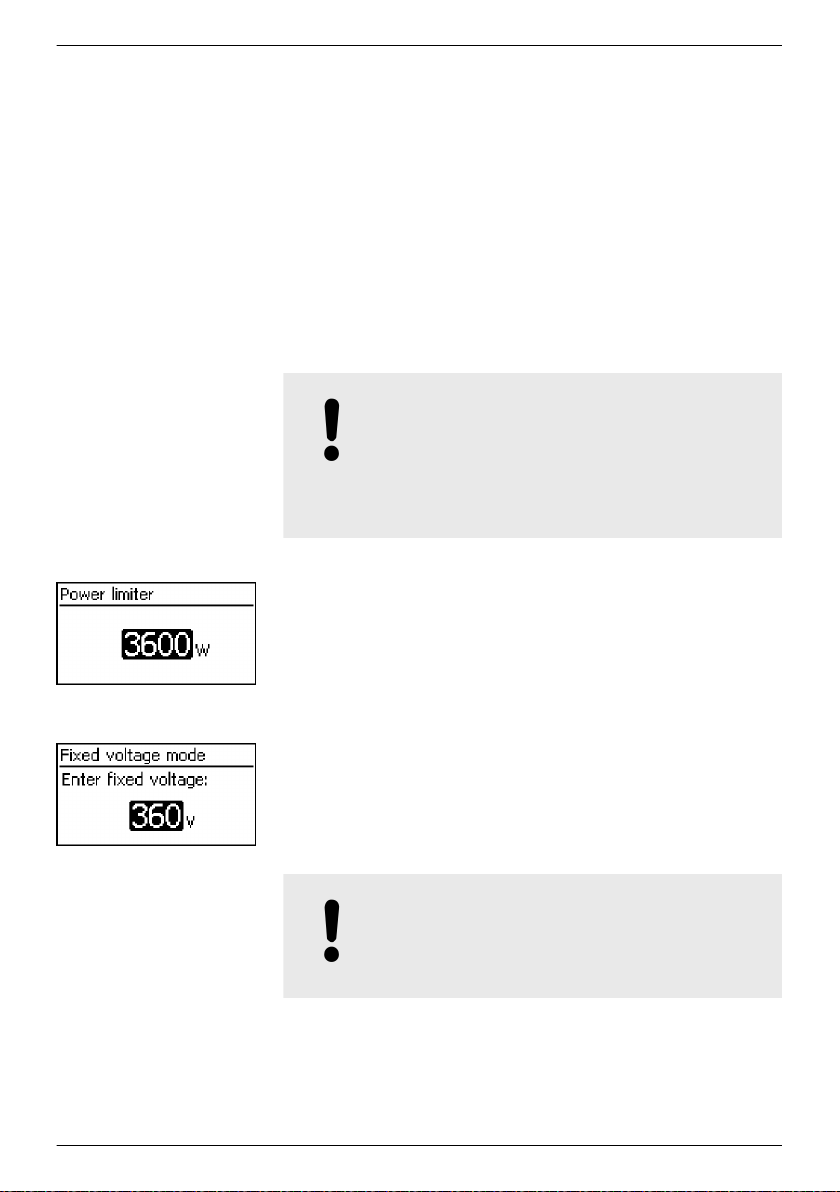

3.3.4

Service menu

Power limiter

n DNS address: IP address of the DNS server

n web-portal: Settings at the web portal

– Web portal setting: Disabling of data transmission

and selection of a web portal

– Re-transmission: Data in the inverter is transmitted a

second time

– Connection check: Checks the internet connection and

indicates the result

The service menu items are described below. Some items are

Ä

password protected; see

further information on page 49 (menu

structure)

You can obtain the password from technical support; see

Ä

Chapter

11 ‘Contact’ on page 84.

NOTICE!

Risk of reduced yields. In the service menu, inverter

and grid parameters can be changed. The service

menu must only be operated by a specialist, who

ensures that the change does not violate applicable

regulations and standards!

The inverter output power can be manually limited to a minimum of

500 W. When the power is manually limited, the Power reduction

symbol is shown in the status display and the ‘Derating’ / ‘Cause:

User default’ measurement is displayed.

EN

Fixed voltage

747,431 | Z09.2 | 18/02/2016

The device can regulate the input voltage to a manually adjustable

value. This switches off the automatic setting of the MPP (MPP

tracking). The input voltage can be adjusted over a range between

the maximum and minimum input voltage and the minimum input

voltage in 1V steps.

Exemplary application: Hydroelectric installation

NOTICE!

Before setting a fixed input voltage, make sure that

the PV generator is suitable for this. Otherwise, this

may result in yield losses or damage to the system.

19

Page 20

EN

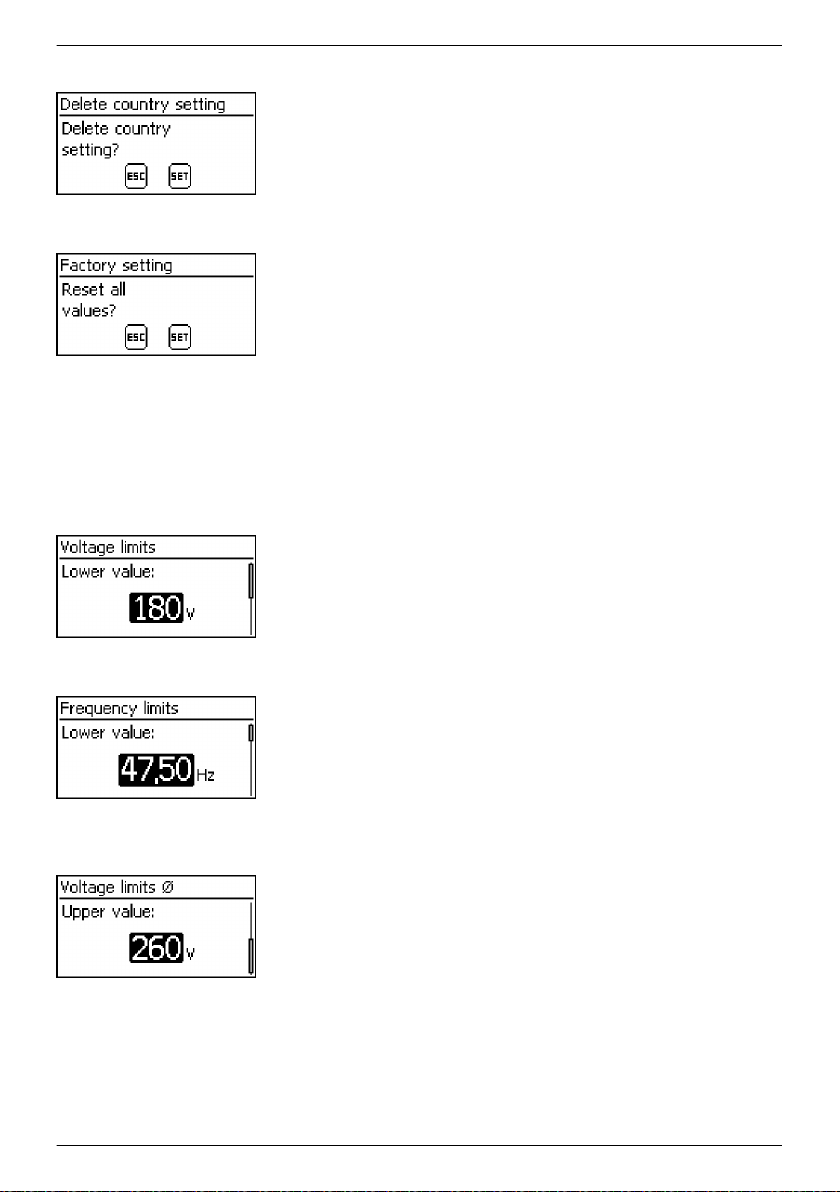

Delete country setting

Factory setting

Voltage limits (peak

value)

After the country setting has been deleted the device restarts anew

and displays the guided 1st commissioning menu.

Resetting the device to the factory setting deletes the following

data:

n Yield data

n Event messages

n Date and time

n Country setting

n Display language

n Network settings

After the factory setting has been deleted, the device restarts anew

and displays the guided 1st commissioning menu.

The following voltage limits can be changed:

n Upper disconnection value

1)

n Lower disconnection value1) (Fig. left)

1)

The disconnection value relates to the peak value of the voltage.

Frequency limits

Voltage limits ø (average

value)

Reactive power

characteristic curve

20

The following frequency limits can be changed:

n Upper disconnection value

n Lower disconnection value (Fig. left)

n Derating switch-on threshold (because frequency is too high)

n Frequency threshold when switching on again

The following voltage limits can be changed:

n Upper disconnection value1) (Fig. left)

n Lower disconnection value

1)

The disconnection value relates to the average value of the

1)

voltage.

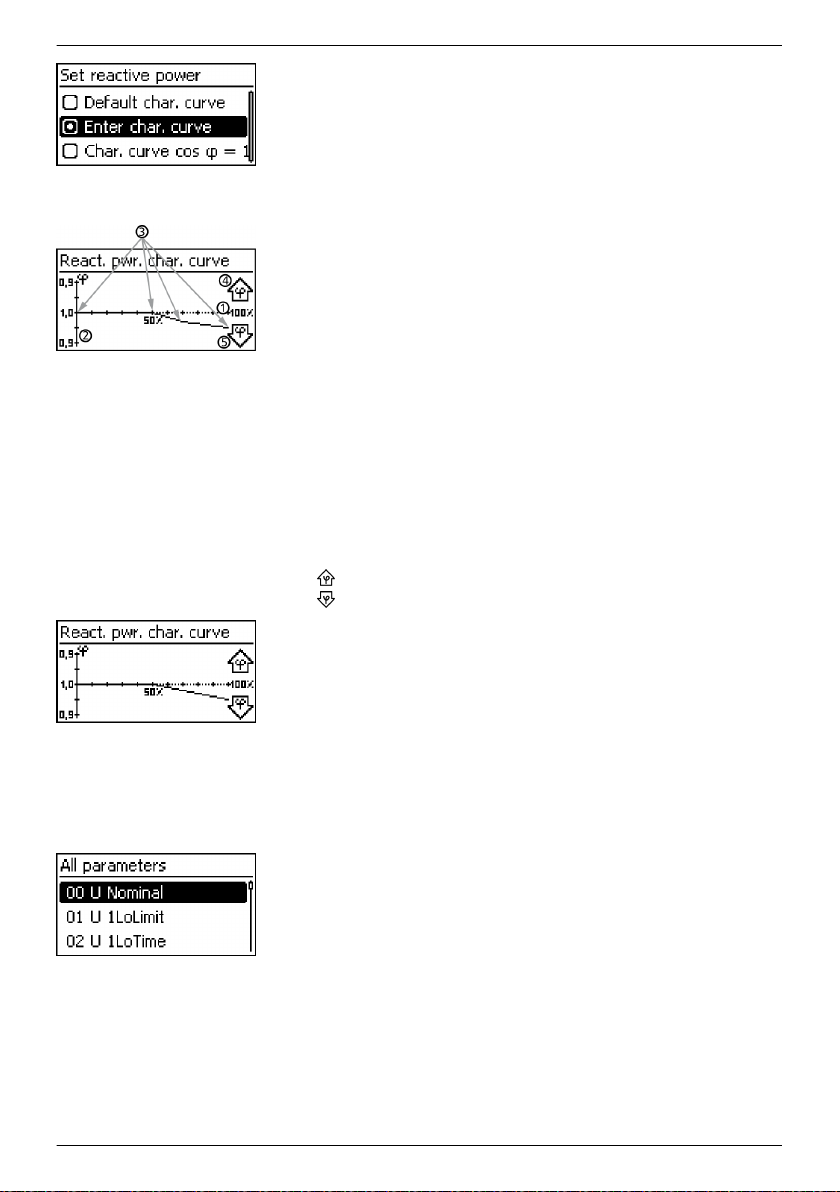

Overview:

747,431 | Z09.2 | 18/02/2016

Page 21

All parameters

The reactive power characteristic curve must be set during 1st

commissioning if this is prescribed for the previously selected

country. The following applies:

n 3 characteristic curves are available for selection (Fig. left):

– Default. char. curve (pre-defined)

– Enter char. curve (manually adjustable)

– Char. curve cos φ = 1 (pre-defined)

n After configuration, the characteristic curve is displayed as a

graph (example in Fig. left).

① x-axis, output power P in %

② y-axis, phase shift cos φ

③ Nodes (in example: 4 nodes)

④ Arrow symbol Overexcitation

⑤ Arrow symbol Underexcitation

Technical details

n Each characteristic curve is defined by 2 to 8 nodes.

n A node is defined by the output power P of the inverter (x-axis)

and the associated phase shift (y-axis).

n The phase shift can be set over a range of 0.95 (overexcitation)

through 1.00 (no phase shift) to 0.95 (underexcitation).

n The type of phase shift is shown in the graph using arrow

symbols defined as follows (defined from the point of view of

the inverter):

Overexcitation, inductive

Underexcitation, capacitive

n The 3 characteristic curves available for selection have the

following properties:

Default char. curve: pre-defined according to the selected

country (example in Fig. left).

Char. curve

φ = 1: pre-defined with cos φ =

constantly 1.00. This characteristic curve must be selected if no

reactive power control is to be performed on the device.

Enter char. curve: The number of nodes and their x/y

values can be configured. Exceptions: The first node is always at

x (P %) = 0 %, the last always at x (P %) = 100 %.

Service technicians can use this menu item for changing additional

MSD parameters.

EN

3.4 Cooling

747,431 | Z09.2 | 18/02/2016

The internal temperature control system prevents excessive

operating temperatures. When the internal temperature is too high,

the inverter adjusts the power consumption from the PV generators

to reduce the heat dissipation and operating temperature.

21

Page 22

EN

Grid monitoring

3.5

The inverter is convection cooled via fins on the front and rear side.

A maintenance-free fan circulates the heat within the closed housing

evenly over the entire surface of the housing.

The inverter constantly monitors the mains grid parameters while

feeding the grid. If the grid deviates from the legally prescribed

specifications then the inverter automatically switches off. When the

grid conforms to the legally prescribed specifications then the

inverter automatically switches on again.

3.6 Data communication

The device has the following communication interfaces:

n 1x RJ45 socket (Ethernet for TCP/IP network) for

communication, e. g. with a central data server

n 2x RJ45 sockets (RS485 bus) for communication with external

devices, e. g. a data logger

n 1x RJ10 socket (Modbus RTU) for communication e. g. with an

external energy counter

3.6.1 Data

Displayed data

Logged data (EEPROM)

The inverter can transmit a wide range of data to other devices.

Some of this data is shown on the display and certain data is stored

in the internal memory (EEPROM) as described below.

n Voltage and current of the PV generator

n Power and current fed into the grid

n Voltage and frequency of the power grid

n Energy yields on a daily, monthly and annual basis

n Error conditions, notes

n Version information

n Event messages with date

n Energy yields on a daily, monthly and annual basis

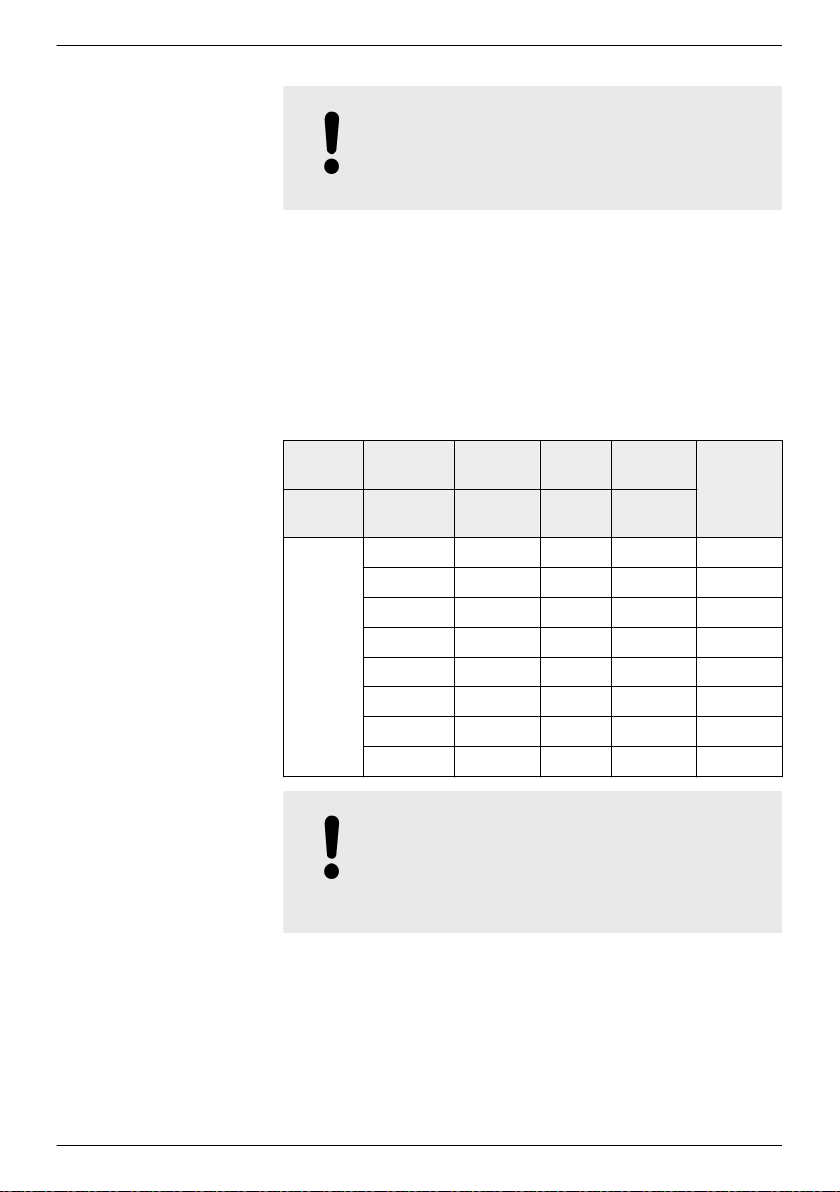

The storage resolution of the energy yield data is as follows:

Energy yield data Storage resolution/period

10-minute values 31 days

Daily values 13 months

Monthly values 30 years

Annual values 30 years

Total yield permanent

22

747,431 | Z09.2 | 18/02/2016

Page 23

3.6.2 Network (TCP/IP)

EN

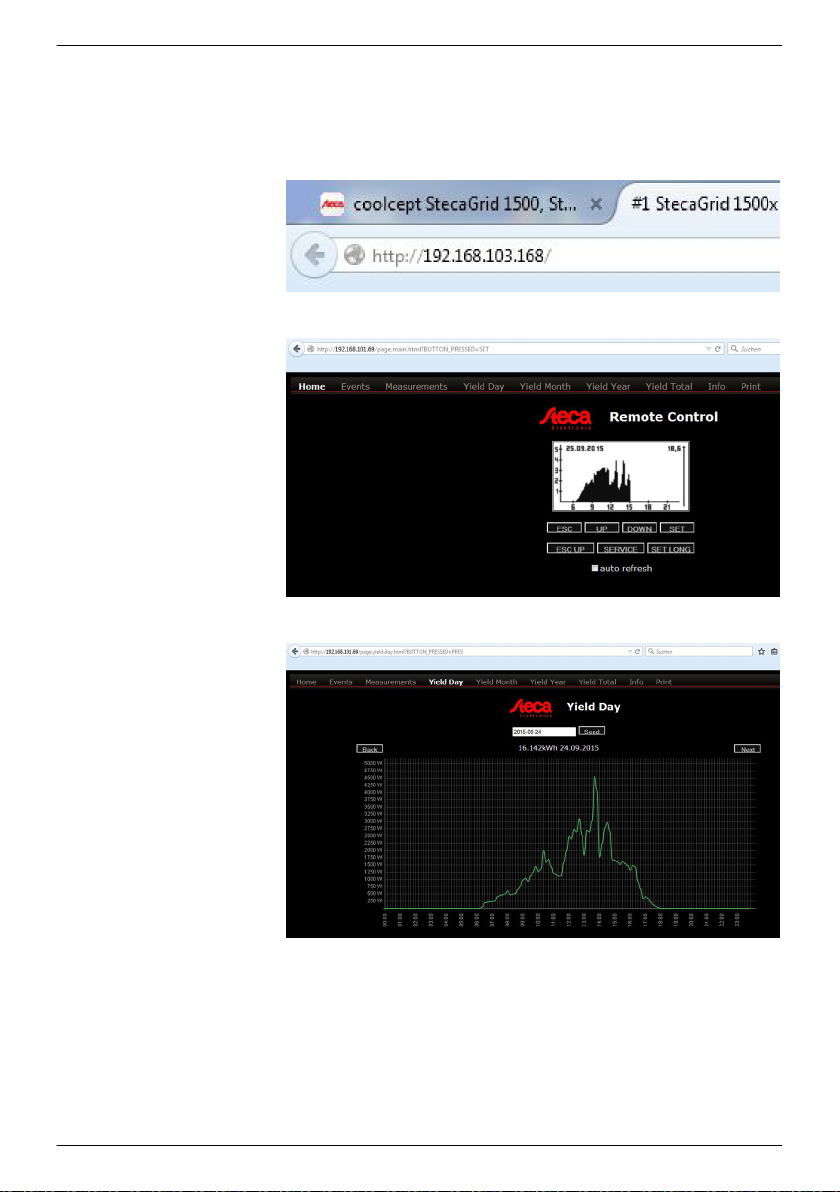

The device can transfer yield data and event messages via the TCP/IP

interface to the Internet portal http://www.solare-energiewende.de

server. The yield data can be displayed graphically in the Internet

portal as illustrated below. This service is free of charge for a period

of 2 years from the time of registration. The following applies:

n Before the Internet portal can be used, the user must go to

www.steca.com/portal to register. See more

Ä

Chapter 5.4

‘Internet portal’ on page 53

n The local network settings must be set at the inverter in order to

establish a connection to the Internet portal server. This can be

performed automatically or manually:

Automatically: If IP addresses are automatically assigned in

your network (DHCP), then no settings need to be made at the

inverter.

Manually: If IP addresses are not automatically assigned in your

network, then you must manually set the inverter network

settings via Settings ▶ Network; see

Ä

‘TCP/IP network’

on page 18

n The address of the Internet portal server is permanently stored

in the inverter and cannot be changed.

n Once the network connection is established, the inverter

automatically starts non-encrypted transmission of data to the

server.

Notice

The network cable must be disconnected in order to

prevent transmission of the data, or data transmission

must be disabled according to

Ä

‘TCP/IP network’

on page 18.

747,431 | Z09.2 | 18/02/2016

Fig. 4: Graphical representation of the yield data in the Internet

portal

23

Page 24

EN

Furthermore, you can use the TCP/IP interface to display yield data

and other information as HTML pages. You need a PC connection to

indicate the data. The HTML pages can be displays by means of a

browser, such as Mozilla Firefox. To enable the connection, enter the

IP address of the inverter (see inverter status indication) in the

browser.

Fig. 5: Example for an IP address

3.6.3 RS485 bus

24

Fig. 6: Example 1 of an HTML page

Fig. 7: Example 2 of an HTML page

The inverter communicates with other devices via an RS485 bus. The

following applies: The following applies:

747,431 | Z09.2 | 18/02/2016

Page 25

n The inverter has two RS485 interfaces (RJ45 sockets) on the

lower side of the casing.

n The beginning and end of the RS485 bus must be terminated;

see

Ä

Chapter 3.6.5 ‘RS485 termination’ on page 28.

n Standard RJ45 cables can be used as bus cables (Cat-5 patch

cables, not supplied). Use an alternative data connection cable

for longer connections; see

Ä

Chapter 3.6.4 ‘Alternative RS485

data connection cable’ on page 28.

n The inverters connected to the RS485 bus operate as slaves.

Notice

The following inverters have compatible data

interfaces and can be connected to the RS485 bus as

slaves:

– StecaGrid 2020

– StecaGrid 1500, 1800, 2000, 2300, 2500, 3010,

3000, 3600, 4200 and StecaGrid 1500, 1800x,

2000x, 2300x, 2500x, 3010x, 3000x, 3600x,

4200x

– StecaGrid 8000 3ph

, StecaGrid 10000 3ph

– StecaGrid 8000+ 3ph, StecaGrid 10000+ 3ph

Comply with the instructions in the manuals of these

devices relative to addressing, termination, and

approved data cables.

EN

747,431 | Z09.2 | 18/02/2016

25

Page 26

81

EN

Notice

If in the country setting Italy is set, then the RS485

bus must be connected as follows to enable control

through an external device in accordance with

CEI 0-21.

– External fast switch-off (ital.: Teledistacco): If the

lines 31) and 81) of the RS485 bus2) are

connected, e. g. via an external relay, the

following applies:

Relay closes: The inverters on the bus

disconnect themselves from the network.

Relay opens: The inverters connected on the

network connect themselves to the network

(regular operation).

– Switch-over of the grid frequency disconnection

thresholds (Ital.: Modalità definitiva di

funzionamento del sistema di protezione di

interfaccia (impiego del SPI sulla base di letture

locali e di informazioni/comandi esterni)): If the

lines 51) and 81) of the RS485 bus2) are

connected, e. g. via an external relay, the

following applies:

Relay closes: The inverters connected on the bus

set the switch-off thresholds in accordance with

CEI 0-21 to 47.5 Hz and 51.5 Hz.

Relay opens: The inverters connected on the

bus set the switch-off thresholds in accordance

with the country setting Italy ;

Ä

Chapter 9

‘Technical data’ on page 70

We recommend that you integrate the wiring of lines

3, 5, and 8 in the bus termination.

1)

Contact assignment of the RJ45 plug for the RS485

bus: See

2)

‘Housing’ on page 12 and

Fig. 8.

In this regard, see

⑥

under Ä Chapter 3.1

⑦

and ⑨ under Ä Chapter

3.1 ‘Housing’ on page 12.

Fig. 8: Contact assignment (= line number) of the RJ45 plug

Optionally one (!) of the following masterdevices can be connected

to the RS485 bus. The devices support the transfer protocol used by

the inverter.

26

747,431 | Z09.2 | 18/02/2016

Page 27

n Energy management unit StecaGrid SEM: Interface to a ripple

1

2

3

4

5

5

5

RS485

RS485 RS485

control receiver for EEC-compliant feed-in management

n PC or notebook (with suitable software):

– Read inverter information using the "StecaGrid User" read

out software. This is available on our homepage see http://

www.steca.com/index.php?StecaGrid_User_de

– Connection to the inverter via optional adapter

RS485⇔USB is possible; the adapter is available from Steca

under Article Number 746.610 (IP21) or 737.707 (IP65).

– Load firmware updates (for technical professionals only)

n External data loggers, recommended by Steca for professional

system monitoring:

– WEB‘log (Meteocontrol)

– Solar-Log (Solare Datensysteme)

– Energy-Manager (Kiwigrid GmbH)

Note

The settings must be made on the external data

loggers as specified by the manufacturer, before

connecting.

The wiring diagram of the RS485 bus is shown below.

EN

Fig. 9: Wiring diagram

①

External data logger

②

First inverter

③

Inverter

④

Last inverter, terminated

⑤

RJ45 standard cable (patch cable)

747,431 | Z09.2 | 18/02/2016

27

Page 28

EN

3.6.4 Alternative RS485 data connection cable

NOTICE!

Material damage caused by electrical voltage! The

alternative data connection cable may only be

manufactured by professional personnel.

The alternative data connection cable is a Cat-5 cable for long data

connections. The following applies to the alternative data

connection cable:

n The total length of the RS485 bus must not exceed 1,000 m

(Master/first inverter to last inverter).

n Use the pin assignment according to the table below if the

alternative data connection cable is connected to the RJ45

socket of the first inverter or to the connector of an external

data logger.

Pin assignment of the alternative RS485 data cable

Device Inverter Solar-Log

Connect

ion

3.6.5 RS485 termination

To prevent data transmission errors, the start and end of the RS485

bus should be terminated:

Contact

RJ45

Terminal

strip

WEB‘

log

RJ12

1)

Kiwigrid

Terminal

strip

Signal

¤

1 1 2 A Data A

2 4 4 B Data B

3 — — — —

4 — — — —

5 — — — —

6 — — — —

7 — — — —

8 3 6 GND Ground

NOTICE!

1

Danger of destroying the inverter's RS485 input.

Pin 1 of the RJ12 socket of the Web‘log data logger

carries 24 V DC. Never connect the alternative data

connection cable to pin 1!

28

747,431 | Z09.2 | 18/02/2016

Page 29

n The external data logger (at the start of the data connection)

must be terminated according to the manufacturer's

specifications.

n The last inverter (at the end of the data connection) is

terminated by plugging the optionally available termination

plug into the free RJ45 socket (for RS485 bus) (see table in

Ä

Chapter 2.2 ‘Identification’ on page 6 under 'Optional

accessories').

3.6.6 RS485 addressing

Every inverter must be assigned its own unique address for

communication between the bus master and the slaves.

Every inverter is set with an address of 1 at the factory. This means

that the addresses must be adjusted in systems having more than 1

inverter. The following applies:

n The address is changed at the inverter via the menu items

‘Settings’ ▶ ‘Address’ .

n Only addresses ranging from 1 – 99 may be set.

n The bus master devices usually support less than 99 addresses.

Consult the respective operating instructions for these devices

before setting the addresses of the inverters.

n We recommend starting with address 1 for the first inverter on

the bus and then incrementing the address by 1 for each

subsequent inverter on the bus, in the same order as they are

physically installed. This makes it easier to identify the relevant

inverters when their address is displayed in messages shown on

the remote display.

3.6.7 Modbus RTU

The inverter communicates via Modbus RTU with energy meters. The

following applies:

n Only energy meter pre-programmed in the inverter can be used.

n The energy meter must measure the supply from the grid in

positive direction. Follow the manufacturer's instructions.

3.6.8 Modbus RTU data connection cable

EN

747,431 | Z09.2 | 18/02/2016

NOTICE!

Material damage from electrical current! The

alternative data connection cable may only be

manufactured by technical professionals.

On the inverter side, a 4-pole telephone cable with RJ10 connector

may be used as data connection cable.

29

Page 30

41

EN

Fig. 10: Contact assignment (= line number) of the RJ10 plug

Device

Connection

Inverter

RJ10

Signal

Contact 1 Data A

2 Data B

3 Ground

4 —

NOTICE!

Danger of destroying the Modbus RTU input of the

inverter. Contact 4 of the RJ10 socket of the inverter

carries voltage <20V. Do not use this contact.

30

747,431 | Z09.2 | 18/02/2016

Page 31

4 Installation

4.1

Safety measures during installation

Observe the following safety notes when performing the work

described in Section Installation .

DANGER!

Risk of death by electrocution!

– Only technical professionals may perform the

work described in Section Installation

– Do not connect cables to the inverter until

explicitly asked to do so in the manual.

– Do not open the housing of the inverter.

– Connect only SELV circuits to the RJ45 sockets.

– Lay the cables such that the connection cannot

come loose accidentally.

– When laying cables, ensure that no damage

occurs to any of the constructional fire safety

measures in the building.

– Make sure that no inflammable gases are

present.

– Observe all applicable installation regulations

and standards, national laws and connection

values specified by the regional power supply

company.

.

EN

747,431 | Z09.2 | 18/02/2016

DANGER!

Danger from electrical current

ELECTRICAL SHOCK AND DISCHARGE!

The PV generators/lines may be energised as soon as

the PV generators are exposed to light.

Always disconnect all DC and AC cables as follows before starting

work on the inverter:

1. Turn the AC circuit breaker to off. Take measures to prevent

the system from being unintentionally switched on again.

2. Set the DC circuit breaker on the inverter to position 0. Take

measures to prevent the system from being unintentionally

switched on again.

3. Disconnect the DC cable plug connectors according to the

manufacturer's instructions.

4. Disconnecting the AC plug from the inverter ⇒ Release safety

clip at the front of the AC plug by depressing it with a

suitable object, then pull the plug out.

31

Page 32

EN

5. Check that all pins of the AC plug are free of voltage. Use a

suitable voltmeter for this (do not use a simple neon phase

checker).

NOTICE!

Risk of damage to the inverter or derating!

– The mounting location must satisfy the following

conditions:

– The mounting location and immediate

environment are permanently fixed, vertical,

flat, non-inflammable and not subject to

constant vibration.

– The permissible ambient conditions are

conformed to; see Technical data

Ä

Chapter

9 ‘Technical data’ on page 70

– The following free spaces must be present

around the inverter:

Above/below: at least 200 mm

At the sides/in front: at least 60 mm

– Do not install the inverter in areas where animals

are kept.

– Observe the connection ratings specified on the

type plate.

– The DC cables must not be connected to an earth

potential (DC inputs and AC output are not

galvanically isolated).

32

NOTICE!

When transmitting data over a public network:

– Transmitting data over a public network may

result in additional costs.

Data transmitted over a public network is not

–

protected from unauthorised access by thirdparties.

Note

– Avoid exposing the inverter to direct sunlight.

– The display must be readable on the installed

device.

747,431 | Z09.2 | 18/02/2016

Page 33

4.2 Mounting the inverter

Fastening the mounting

plate

u Screw the mounting plate to the mounting surface using 4

screws:

n Use screws (and dowels etc.) appropriate for the weight of the

inverter.

n The mounting plate must lie flat on the mounting surface and

the metal strips at the sides must point forwards (Fig. left).

n Install the mounting plate vertically with the retaining plate ①

at the top (example in Fig. left).

EN

NOTICE!

With coolcept-x, you can secure the inverter with a

padlock against theft or unauthorized removal. The

padlock is inserted in a shackle which will lock into

the retaining plate during mounting. Now, it is no

longer possible to unlock the retaining plate.

NOTICE!

For more information on determining the optimum

position for the mounting plate, refer to the Brief

Installation Instructions comprised in the delivery, and

to the Appendix under Mounting.

For Australia only: Cover

the Protection class II

symbol on the type plate.

747,431 | Z09.2 | 18/02/2016

Notice

When the inverter is used in Australia, the national

regulations do not permit the

Protection class II

symbol to be displayed on the type plate.

33

Page 34

①

②

EN

Fig. 11: Position of the sticker for covering the Protection Class II

symbol

Completely cover the Protection class II symbol using the

small sticker provided, as shown in Fig. 11

.

Attaching the inverter on

the mounting plate

34

NOTICE!

How to remove the inverter from the mounting plate

Ä

is described under

Chapter 4.9 ‘Switch on DC’

on page 47.

1. Grasp inverter on the grip recesses ①

(coolcept) or on the

perimeter edge (coolcept-x), fit it onto the mounting plate ➊

so that it is centred ② and lightly press it on (see the example

in the fig. on the left).

2. Lower the inverter ③ until the securing sheet metal element

of the mounting plate audibly locks in place. In this process,

the hooks on the rear of the inverter must be guided above

the catches on the mounting plate.

3. The inverter must now be firmly seated on the mounting

plate and it can no longer be lifted (upwards).

747,431 | Z09.2 | 18/02/2016

Page 35

4.3 Prepare AC connection

4.3.1

4.3.2 Fault current circuit breaker

4.3.3 Assemble AC plug

Grid voltage 220 V ...

240 V

Grid voltage 100 V ...

127 V

Miniature circuit breaker

Information on the required line circuit breaker and the cables to be

used between the inverter and the line circuit breaker is provided in

Ä

Chapter 9.2 ‘AC cables and line circuit breakers’ on page 81.

If the local installation regulations require the installation of an

external residual current circuit breaker, then a Type A residual

current circuit breaker as per IEC 62109-1, § 7.3.8. is sufficient.

Wire the AC plug supplied as described in the Appendix under

Mounting ⇒ AC plugs.

DANGER!

Risk of death by electrocution! Observe the hazard

warnings under

during installation’ on page 31.

DANGER!

Risk of death by electrocution! Never connect one of

the phases L1, L2 or L3 to PE or N on the mains grid

side.

Ä

Chapter 4.1 ‘Safety measures

EN

747,431 | Z09.2 | 18/02/2016

35

Page 36

EN

Notice

With a mains grid voltage of 100 V ... 127 V, the

inverter can be connected between the L1, L2 and L3

external conductors as follows:

2-phase mains grids

– N and L are connected between the L1 – L2

external conductors at the inverter side. See

②

and ③ in Fig. 12.

– One of the two connected external conductors is

connected to PE at the inverter side. This

connection can be made within the AC plug or in

an external junction box.

Fig. 12 shows an example of an inverter-side

connection between L1 and PE:

Top: Connection ① in the AC plug

⑤

Bottom: Connection ④ in an external junction

box ⑥)

3-phase mains grids

– N and L are connected between the L1 – L2 or

L1 – L3 or L2 – L3 external conductors at the

inverter side.

– One of the two connected external conductors is

connected to PE at the inverter side. This

connection can be made within the AC plug or in

an external junction box.

Fig. 12 shows an example of an inverter-side

connection between L1 and PE:

Top: Connection ① in the AC plug

⑤

Bottom: Connection ④ in an external junction

box ⑥)

The external conductor voltages are shown in Fig. 13.

36

1. Wire the AC plug supplied for the selected external

conductors as described in the Appendix

Ä

Appendix

‘Assembly’ on page 86.

2. Connect one of the two connected phases to PE at the

inverter side. Make this connection inside the AC plug or use

an external junction box, as shown in Fig. 12.

3. Close the AC plug.

747,431 | Z09.2 | 18/02/2016

Page 37

Fig. 12: Connection of N and PE in the AC plug (above) or junction

box (below)

①

Connection cable between N and PE with the connection point

inside the AC plug

②

External conductor L1

③

External conductor L2

④

Connection cable between N and PE with the connection point

inside the junction box

⑤

Casing of the AC plug

⑥

Junction box

EN

Fig. 13: External conductor voltages in 2- and 3-phase grids with

100 V ... 127 V

4.4 Prepare DC connections

747,431 | Z09.2 | 18/02/2016

DANGER!

Risk of death by electrocution!

– Observe the hazard warnings under

Ä

Chapter

4.1 ‘Safety measures during installation’

on page 31.

– Use the provided SUNCLIX plugs so that the

specified protection class is maintained.

37

Page 38

EN

NOTICE!

Risk of damage to the inverter and the modules.

Connect the opposing connectors for the DC

connections to the DC cable, observing the correct

polarity.

Attach the connector plug counterparts to the DC cable

according to the manufacturer's instructions; see Appendix.

4.5

Preparing the data connection cable

If a data connection is required, use a standard RJ45 cable

(patch cable, Cat5) or construct an alternative data

connection cable(see

Ä

further information on page 28).

4.6 Connecting the inverter inverter and switching the AC on

DANGER!

Risk of death by electrocution! Observe the hazard

warnings under

during installation’ on page 31.

Ä

Chapter 4.1 ‘Safety measures

38

NOTICE!

– Between the data connection cables (RS485/

Ethernet) and the DC/AC lines, maintain a

distance of 200 mm, to avoid interference in the

data transmission.

– The protection class IP65 for type coolcept-x is

only ensured if the AC and DC plugs are plugged

in and the RJ45 sockets are sealed with sealing

caps.

1. If necessary, establish the data connection:

n Connect the inverters and the master with data

connection cables.

n On the last inverter, switch on the termination (slide

switch).

2. Seal open RJ45 sockets with sealing caps.

3. Forcefully press the plug connector mating piece (DC cable)

into the DC connection on the inverter until it audibly locks in

place.

4. Plug the AC connector onto the coupling on the inverter, until

the plug audibly locks in place.

747,431 | Z09.2 | 18/02/2016

Page 39

5. Switch on the AC miniature circuit breaker. The start page for

1st commissioning is shown on the display.

6. Perform 1st commissioning and switch on the DC supply, as

described in

Initial commissioning of the inverter

4.7

4.7.1 Function

Conditions for starting

initial commissioning

Guided initial

commissioning

Setting the country

Initial commissioning starts automatically when at least the AC

connector has been installed and switched on as described

previously. If initial commissioning is not fully completed then it

starts again anew the next time the device is switched on.

Initial commissioning is a guided procedure that sets the following

information:

n Display language

n Date / Time

n Country

n Reactive power characteristic curve (if prescribed for the

selected country)

The following applies when setting the country:

n The country set must always be the same as the country where

the inverter is installed. This ensures that the inverter will load

the specified net parameters of the respective country; for more

information, refer to the Countries table on the Steca

homepage,

n The country can only be set once!

Contact the Steca Technical Support if you have set the wrong

country.

n If the Countries table does not list your country, select a country

with stricter specifications.

n The country setting does not affect the language used on the

display. The display language is set separately.

4.7.2 Operation

Starting 1st

commissioning

The check list for 1st commissioning is displayed:

n The default display language is English.

n The Language entry is selected.

n The check boxes are not selected.

EN

www.steca.com/Wechselrichter-Wohnsiedlung.

747,431 | Z09.2 | 18/02/2016

39

Page 40

EN

Language

NOTICE!

– When a check list item is called up, the

corresponding check box is automatically

selected.

– Initial commissioning is completed by calling up

the Finish item.

– Finish can only be performed when all other

check boxes are selected.

1.

Press rs to select a check list item.

2. Press SET to call up the item.

The items are described in detail below.

1.

Press rs to select a display language.

2. Press SET.

The language is adopted.

ð

3. Press ESC.

✓ The check list is shown.

Date format

Date

40

1.

Press rs to select a date format.

2. Press SET.

The date format is adopted.

ð

3. Press ESC.

✓ The check list is shown.

1. Press SET.

The day flashes.

ð

2.

Press rs to change the day.

3. Press SET.

The change is adopted.

ð

747,431 | Z09.2 | 18/02/2016

Page 41

Time format

Time

4.

Press s.

The month is selected.

ð

5. Repeat steps 1 to 3 for the month.

6.

Press s.

The year is selected.

ð

7. Repeat steps 1 to 3 for the year.

8. Press ESC.

✓ The check list is shown.

1.

Press rs to select a time format.

2. Press SET.

The time format is adopted.

ð

3. Press ESC.

✓ The check list is shown.

1. Press SET.

The hours display flashes.

ð

2.

Press rs to change the hour.

3. Press SET.

The change is adopted.

ð

4.

Press s.

The minutes are selected.

ð

5. Repeat steps 1 to 3 for the minutes.

6. Press ESC.

✓ The check list is shown.

EN

747,431 | Z09.2 | 18/02/2016

41

Page 42

EN

Country selection

NOTICE!

The country can only be set once!

1.

Press rs to select a country.

2. Press SET.

3. Press ESC.

the dialog shown at the left is displayed.

ð

4. Press ESC to select a different country by performing step 1

and step 2, or

Press SET for a longer period of time (> 1 s) to confirm the

currently selected country.

✓ The check list is shown.

42

747,431 | Z09.2 | 18/02/2016

Page 43

Reactive power

NOTICE!

The following items are only displayed when the use

of a reactive power characteristic curve is prescribed

for the country currently selected in the Country item:

– Mode: Type of characteristic curve

Select one of the following types:

- cos phi = 1

- Q(P)

- Q(U) linear

- Q(U) hysteresis

– Loading defaults1): A default characteristic

curve can be selected here.

– Node 1

1)

No. of nodes1)

The nodes provide for free

programming of a characteristic curve.

– Node 2

– Node n1)

1)

2)

– Display char. curve

1)

: Not indicated with mode cos phi = 1.

2)

: Is only displayed when no. of nodes has been

set to a value > 2.

EN

747,431 | Z09.2 | 18/02/2016

1. Press SET to call up the item.

2.

Press rs to select a type of reactive power characteristic

curve.

3. Press SET.

The reactive power characteristic curve type is adopted.

ð

4. Press ESC.

✓ The check list is shown.

43

Page 44

EN

Loading defaults

Number of nodes

NOTICE!

If cosPhi = 1 was not selected, an additional menu

item Load defaults is indicated.

1.

Press s to select "Load defaults".

2. Press SET.

3.

Press rs to select a default characteristic line.

4. Press SET.

The default characteristic line is adopted.

ð

5. Press ESC.

✓ The check list is shown.

1. Press SET.

The value flashes.

ð

2.

Press rs to change the number of nodes.

3. Press SET.

The value is adopted.

ð

4. Press ESC.

✓ The check list is shown.

44

747,431 | Z09.2 | 18/02/2016

Page 45

Node n

Display char. curve

NOTICE!

P % cannot be changed at the first and last nodes

(000 %, 100 %).

1.

Press rs to select a parameter for the node.

2. Press SET.

The parameter value flashes.

ð

3.

Press rs to change the value.

4. Press SET.

The change is adopted.

ð

5. Repeat steps 1 to 4 for the other parameters.

6. Press ESC.

✓ The check list is shown.

1. The previously set reactive power characteristic curve is

displayed graphically (example in Fig. left).

2. Press ESC

✓ The check list is shown.

EN

Finish

747,431 | Z09.2 | 18/02/2016

✔ Finish has been selected in the check list and SET has been

pressed. One of 2 possible dialogues is displayed.

1. Proceed as follows, depending on the respective dialogue:

n Dialogue Settings are incomplete: Press SET and

work through the open items in the check list.

n Dialogue Are all settings correct?:

Press ESC to correct settings or

2. Press and hold SET (> 1 s) to finish 1st commissioning.

✓ If SET was pressed for a longer time then the inverter

starts anew and synchronises itself with the grid (Fig. left).

45

Page 46

EN

4.8 Feed-in management

Depending on the country, photovoltaic systems must have the

possibility of being reduced in the fed-in effective power by the

network operator. The following products are recommended for

implementing this legally prescribed specification:

n StecaGrid SEM

n WEB'log from Meteocontrol

n Solar-Log from Solare Datensysteme

n Energy-Manager from Kiwigrid

Furthermore, an energy meter can be used for feed-in management.

It must be connected to the Modbus RTU interface and meet the

preconditions specified in

on page 29 and

cable’ on page 29.

Mode

1. Press SET to call up the item.

2.

3. Press SET.

4. Press ESC to go one level higher to Energy management.

Ä

Ä

Chapter 3.6.8 ‘Modbus RTU data connection

Chapter 3.6.7 ‘Modbus RTU’

NOTICE!

The settings for feed-in management must be made

in the sub-menu 'Energy management'.

Press s to select "Energy meter".

Dynamic feed-in

regulation

Configuration of the

energy meter

46

NOTICE!

The power fed into the grid is adjusted in 10 W steps.

It can be limited to a minimum of 0 W.

NOTICE!

The inverter can only work with energy meters that

have been pre-programmed in the inverter. The preprogrammed energy meters are listed under Meter

type.

747,431 | Z09.2 | 18/02/2016

Page 47

1. Press SET to call up the item.

2.

Press rs to select a meter type.

3. Press SET.

4. Press ESC to quit the sub-menu.

4.9 Switch on DC

Place DC load-break switch on the inverter on position I (Fig.

left). After testing via the internal MSD (approx. 2 minutes),

the power fed into the grid can be shown on the display

(assuming that sunlight is present).

4.10 Deinstalling the inverter

NOTICE!

On the coolcept-x-devices the DC load-break switch

can be safeguarded against being switched on

unintentionally with a padlock (shackle thickness max.

7 mm).

DANGER!

Risk of death by electrocution! Only technical

professionals may perform the work described in this

section. Follow the safety instructions at the

beginning of the Section "Installation"

.

EN

Switching off the AC and

DC supplies

747,431 | Z09.2 | 18/02/2016

1. Set the DC circuit breaker on the inverter to position 0 (Fig.

left).

2. Turn the AC circuit breaker to off.

3. Wait for at least 10 minutes before disconnecting the plug-in

connectors of the DC cable.

47

Page 48

EN

Disconnecting the DC

connections from the

inverter

Disconnecting the AC

plug from the inverter

Opening the AC plug

(only if required)

Disconnect the DC cable plug connectors according to the

manufacturer's instructions; see appendix.

WARNING!

DC cables carry voltage when the PV generators are

subjected to sunlight.

1. Disconnecting the AC plug from the inverter

Release the safety clip at the front of the AC plug by

depressing it with a suitable object, then pull the plug out.

2. Check that all pins of the AC plug are free of voltage:

Use a suitable voltmeter for this (do not use a simple neon

phase checker).

Opening the AC plug:

First, unscrew the rear cable connection. Next, release the

safety clips at the left and right of the plug housing by

depressing them simultaneously with a suitable object. Now,

pull the top part of the housing off the contact element.

Removing the inverter

from the mounting

surface

48

1. Use one hand to press the retaining plate on the mounting

plate approx. 5 mm towards the mounting surface ① (Fig.

left).

2. Use the other hand to push the inverter upwards, far enough

so that the retaining plate no longer latches ②. Release the

retaining plate.

3. Lift the inverter with both hands until the hooks on the rear

side of the inverter are free ③.

4. Remove the inverter from the mounting surface ④.

747,431 | Z09.2 | 18/02/2016

Page 49

5 Operation

TESTES SET

SET

TESTESTES

SET

SET

SET

SET

SET

All parameters

Network

Reactive

power *)

*) Dieser Menüpunkt wird nicht immer angezeigt. Ob er vorhanden ist, hängt von den

Einstellungen am Wechselrichter und der Fimware-Version ab.

CO

2

saving *)

Total yield

*)

Frequency

li

mits

Voltage

limits Ø

Power limiter

Fixed voltage

Factory

setting

off *)

Energy

meter *)

Meter type *)

Configuration

*)

Dyn. feedin

control *)

Mode *)

Submenus

Information

DNS

Web portal

Subnet

mask

Gateway

Meas. values

Reset max.

vals.

DHCP

IP addressLanguage

Clear

event log

Status

d

isplay

Main menu

Grid voltage

Gener. ch.

curve

Output power

Current day

yield *)

Grid current *)

Grid

frequency

*)

PV voltage *)

PV current *)

Operating

h

ours *)

Internal

tem

p.

*)

Derating *)

Abs. max.

p

ower *)

Day max.

yield

*)

Max. daily

power *)

Event log

Total

Contact info

System info

Country

setting

React. pwr.

char. curve *)

Autarky level *)

Settings

Self test *)

Self

consumption *)

Time/date

Remuneration

*)

Energy

management *)

Daily

Monthly

Annual

Yield

Remuneration

*)

Del. country

settting

Contrast

RS485

address *)

Network

Alarm

Self test *)

Backlight

Service

Voltage limits

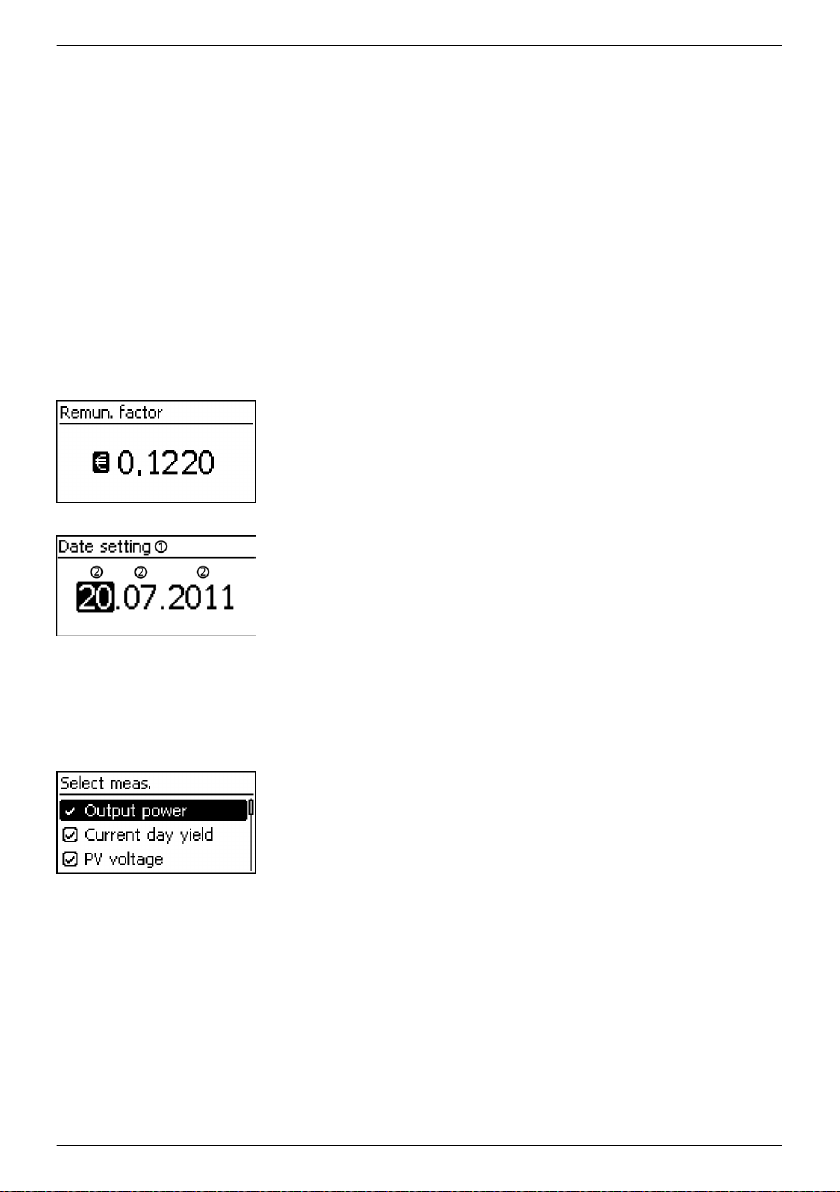

5.1

Overview of operating functions

EN

747,431 | Z09.2 | 18/02/2016

Only the s

of clarity).

and SET operating buttons are illustrated (for the sake

49

Page 50

EN

5.2 General operating functions

n Hidden content is shown using the r and s buttons.

n Repeated button presses: If rs need to be pressed repeatedly,

you can alternatively hold these buttons pressed for a long

time. The rate of repetition increases the longer the button is

held.

n Pressing any button switches on the display backlighting

5.3 Important operating functions

The figures in this section show examples.

Status display

1. If necessary, press ESC for 1 second to call up the status

display (Fig. left).

2.

Press rs to display a different parameter.

Menu navigation

1. Press ESC for 1 second to call up the status display as

required.

2. Press SET.

The main menu is displayed with the top item selected.

ð

3.

Press rs to select a menu item.

4. Press SET to call up the submenu (Fig. left).

5. Repeat steps 3 and 4 for further submenus as required.

Event messages

Displaying entries

numerically (list) and

graphically (diagram)

50

Ä

‘Event messages’ on page 64

See .

The status display is shown.

1. Press SET.

The main menu is displayed with Yield selected.

ð

2. Press SET.

The list with yield time periods is shown.

ð

3.

Press rs to select a yield time period.

4. Press SET.

The individual yields for the yield time period are shown

ð

in a list (Fig. left).

5.

Press rs to select an individual yield value.

747,431 | Z09.2 | 18/02/2016

Page 51

Editing selection lists

containing check boxes

Editing selection lists

containing radio buttons

6. Press SET.

The selected individual yield is shown in a chart (Fig.

ð

left).

7.

Press rs to page through the charts.

8. Press SET to return to the list.

A selection list with check boxes is displayed (Fig. left).

1.

Press rs to select a check box.

2. Press SET.

The state of the check box changes from onto offand

ð

vice-versa (preset check boxes cannot be changed).

3. Repeat steps 1 and 2 for further check boxes as required.

4. Press ESC.

✓ The changes are adopted and the next higher menu level

is displayed.

A selection list with radio buttons is displayed (Fig. left).

1.

Press rs to select a radio button that is currently switched

off.

2. Press SET.

The selected radio button is switched on and the

ð

previously switched on radio button is switched off.

3. Press ESC.

✓ The changes are adopted and the next higher menu level

is displayed.

EN

Changing numeric

settings

747,431 | Z09.2 | 18/02/2016

A numeric setting is displayed (example Date in Fig. left).

1. Press SET.

The selected value flashes (Day in Fig. left).

ð

2.

Press rs to change the value.

51

Page 52

EN

Calling up the service

menu and editing the

values

3. Press SET.

The change is adopted (value no longer flashes) or

ð

4. Press ESC to cancel the change (value no longer flashes).

5.

Press s.

The next value is selected.

ð

6. Repeat steps 1 to 4 for the remaining values.

7. Press ESC.

✓ The next higher menu level is displayed.

NOTICE!

Risk of yield losses and contravention of regulations

and standards. Inverter and grid parameters can be

changed in the service menu. The service menu must

therefore only be used by technical professionals who

know the applicable regulations and standards.

1. Select the Service

menu item.

2. Press SET.

The fig. shown at the left appears.

ð

3.

Press rs simultaneously for 3 seconds.

The service menu is displayed (Fig. left).

ð

4.

Press rs to select a menu item.

5. Press SET to edit the menu item. The following applies:

n Enter the password if required (Fig. left); see

Ä

Chapter

3.3.4 ‘Service menu’ on page 19.

n If necessary, press rs within a menu item to display

and edit other settings (e.g. Voltage limits).

n The menu items are described in

Ä

Chapter 3.3.4

‘Service menu’ on page 19.

52

747,431 | Z09.2 | 18/02/2016

Page 53

5.4 Internet portal

1

2

3