Stearns SINPAC Switches Installation Instructions

Installation Instructions for SINPAC Switches

BACK TO TABLE OF CONTENTS

UL Recognition

Most SINPAC Switches are recognized

under the component program of

Underwriters Laboratories E-71115. In

addition, all switches have an internal

surge protection which meets UL-244A

Specification and are tested to the

requirement of IEEE C62.41-1991,

Category A3.

Construction

SINPAC Switches are potted and

completely sealed making them

impervious to dust, dirt and moisture. It

can be

immersed in electric grade

oil as used in submersible pumps. The

unique speed sensing circuit provides

a universal design which allows a few

switches to work in most standard

single-phase motor applications

regardless of nature.

Operation

The Stearns SINPAC Switch samples

the voltage across the motor start

winding (terminals 1 and 4) then it is

fed into a comparator. The SINPAC

Switch interrupts the start capacitor

current (between terminals 2 and 3)

after the motor has accelerated to a

speed in which the cut out voltage

has been reached, generally 75% to

80% of synchronous motor speed. A

triac or inverse parallel SCRs provides

the function referred to as cut out.

Once the start circuit is cut out the

main winding accelerates the motor

rotor up to its running speed. When

an overload drops the motor speed

to approximately 50% of synchronous

speed the switch automatically

reconnects the motor start circuit. The

SINPAC Switch constantly monitors

the start or auxiliary winding for cut

in voltage and will reconnect the start

circuit once cut in voltage is reached.

Selection Procedure

CAUTION: SINPAC Switches are line

voltage compensated. Changes in the

line voltage within ±10% of nominal

115 or 230 Vac will not affect system

operation. Operation of the motor at

line voltages less than -10% of nominal

can result in reduced motor running

speeds and failure of the SINPAC

Switch to disconnect the start circuit.

1. Be sure switch series matches

motor type.

2. Be sure switch voltage rating

matches the motor start circuit

voltage.

3. Selection should be based on actual

measurement of start circuit current.

4. SINPAC Switch current rating must

meet or exceed the motor start

circuit current requirement. Always

select a SINPAC Switch with the

next higher current rating for:

a) High cycling applications: Stop

and start rates greater than 4

times/minute.

b) Long acceleration times: Greater

than 2 seconds.

c) High ambients: Ambients greater

than 55°C.

Note: Higher rated current switches

can be used in place of lower rated

switches within the same series.

5. The motor must generate a voltage

across the start or auxiliary winding

that is 20% greater than the SINPAC

Switch cut out/cut in voltage rating.

Capacitor Start and Capacitor

Start/Capacitor Run Motors

To determine the most appropriate

SINPAC Switch cut out voltage rating

for the particular motor application,

the voltage across the motor start or

auxiliary winding must be measured.

This may be accomplished in the

following manner:

1. Prepare the motor wiring for

connection of the SINPAC Switch

as shown in the Wiring Diagrams

for SINPAC Switches section of this

publication. Secure the motor to a

firm mounting surface.

2. Connect the lead wire that is to

be connected to SINPAC Switch

terminal #2 securely to the lead wire

that is to be connected to SINPAC

Switch terminal #3.

3. Connect an AC voltmeter across the

lead wires that are to be connected

to SINPAC Switch terminals #1 & #4.

4. Apply power to the motor. Observe

and record the voltage across the

motor start or auxiliary winding,

as indicated by the AC voltmeter,

with the motor operating near

synchronous speed.

CAUTION: Measurement of the start

or auxiliary winding voltage must be

done quickly to prevent damage to

the start capacitor, motor winding or

SINPAC Switch!

5. Multiply the measured voltage by

0.8 (80%). Select a SINPAC Switch

having a cut out voltage rating equal

to or less than this number.

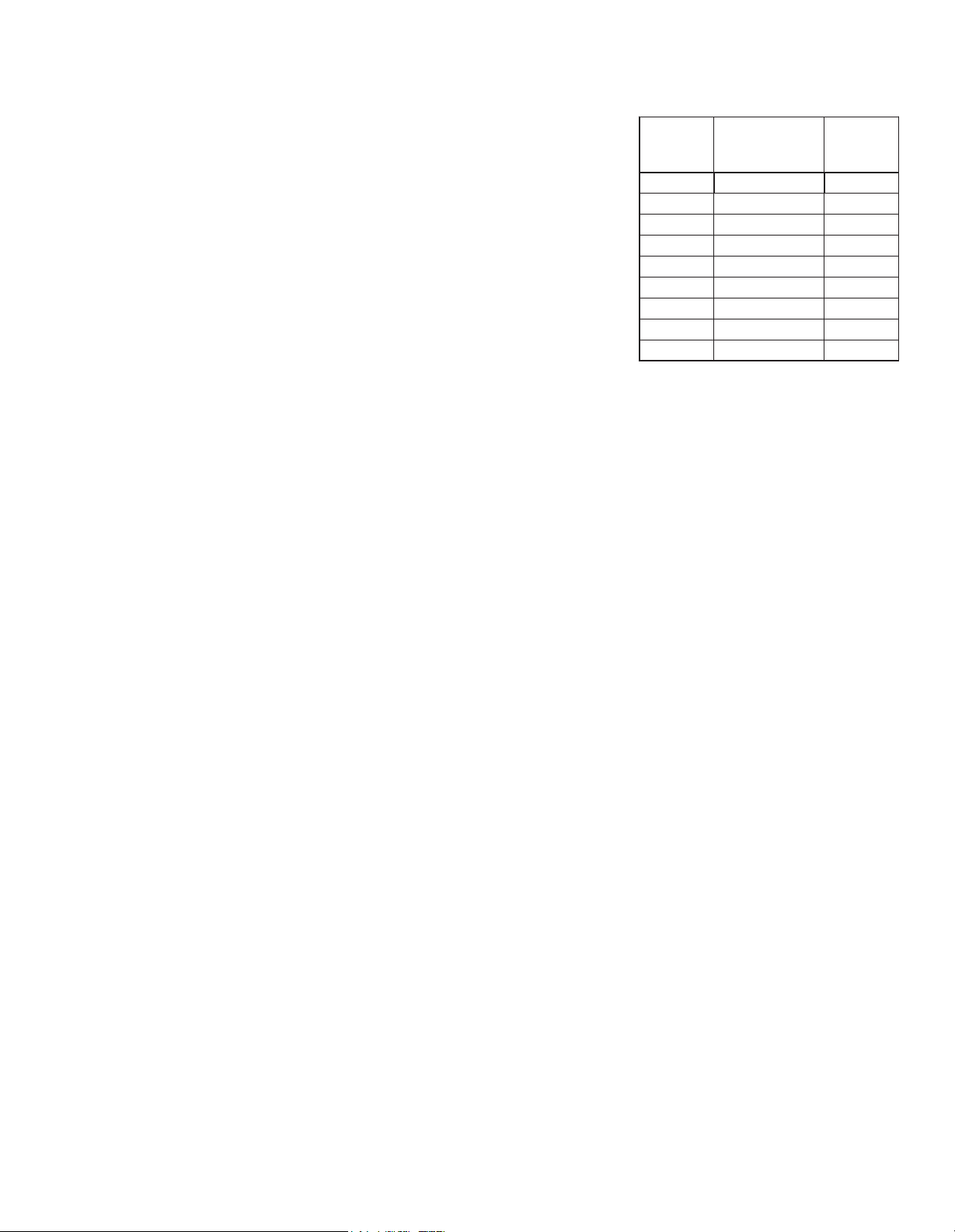

Capacitor Start and Capacitor Start/

Capacitor Run Motors

Measured

Voltage

226V

200V-225V

*Consult factory

Voltage Across

SINPAC Switch

Terminals 1 & 2

115V

115V

115V<150V

230V<300V

Cut Out

Voltage

Rating

180V

165V

147V115V176-200V

130V115V150-175V

*

410V230V>492V

310V230V370-492V

260V230V300-369V

*

Caution: Application of 230 Vac to the

line input terminals (1 and 2) of a 115

Vac rated SINPAC Switch will result in

immediate switch failure. The switch

may rupture and emit smoke.

Important

Please read these instructions carefully

before installing, operating, or servicing

your SINPAC Switch. Failure to comply

with these instructions could cause

injury to personnel and/or damage

to property if the switch is installed

or operated incorrectly. For definition

of limited warranty/liability, contact

Rexnord Industries, Inc, Stearns

Division, 5150 S International Drive,

Cudahy, Wisconsin 53110,

(414) 272-1100.

Initial Inspection and Handling

Upon receipt, check for package

damage. Note any signs of damage

on appropriate shipper forms. Upon

opening package, if concealed damage

is found, immediately file a claim with

carrier.

Check the label to verify that data

conforms to specifications of ordered

switch and the connection diagram

agrees with labeling.

Caution

1. Installation and servicing must

be made in compliance with

all local safety codes including

Occupational safety and Health Act

(OSHA). All wiring and electrical

connections must comply with the

National Electric Code (NEC) and

local electric codes in effect.

2. To prevent an electrical hazard,

disconnect power source before

working on the motor. If power

disconnect point is out of sight, lock

16

BACK TO TABLE OF CONTENTS

Installation Instructions for SINPAC Switches Continued

disconnect in the off position and

tag to prevent accidental application

of power.

3. Make certain power source

conforms to the requirements

specified on the SINPAC Switch

nameplate.

4. Installation and servicing should

be performed only by qualified

personnel familiar with the

operation of the SINPAC Switch.

5. Determine what type of start switch

the motor presently has:

a) Externally mounted electronic

switch – go to Step 6.

b) Internally mounted electronic

switch – go to Step 6.

c) Externally or internally mounted

mechanical switch – it is not

necessary to remove the

existing centrifugal switch

actuating mechanism, but if

feasible, it should be removed

as it is no longer needed, and

can cause future mechanical

problems in the motor should

the mechanism fail. Follow the

manufacturers recommendation

when removing the shaft end

bearing, if necessary, to take off

the centrifugal actuator.

6. Remove the existing electronic

switch. Determine the existing

wiring diagram. Mark the existing

wires and determine which wires

can be reused for installation of

the SINPAC Switch. Select a

location in the motor conduit box or

endbell for mounting the SINPAC

Switch.

If a metal enclosure version of

SINPAC Switch is being used, the

switch with SINPAC Switch gasket

may be mounted on an external

mounting surface such as the

exterior of the conduit box. Plastic

enclosure versions of the SINPAC

Switch should be mounted

internally, within the conduit box,

or externally, under a capacitor

housing.

IMPORTANT: SINPAC Switch

in a metal enclosure must have

the metal enclosure grounded.

The temperature at the

mounting location should not

exceed 65°C (149°F).

TEFC/TENV motors require

external mounting of SINPAC

Switch.

7. Refer to motor manufacturer’s

wiring diagram to aid in identifying

terminal locations for the start

winding switch, start winding, start

and run capacitors (if needed) and

AC line.

8 Connect the SINPAC circuit per the

connection diagram (on Pages

18-19 or 20-21) using insulated

terminals. If the connections are

made incorrectly, the result will be

no starting torque and possible

damage to the circuit and/or motor.

CAUTION: Be sure that

appropriate insulation is used

between the terminals of the switch

and the body of the motor or

conduit box.

If mounted external to motor,

always use gasket supplied with

kit.

9. DO NOT USE a Variac to gradually

increase the voltage to the motor

starting circuit when SINPAC

Switch is installed.

10. Reassemble the motor with

SINPAC Switch installed, so as to

not damage lead wires.

11. If the motor fails to start or the start

winding does not cut out properly,

see

Troubleshooting Guide (Page

29).

12. Hipot test procedures:

Motors 250 Volts or Less and

1/2 Horsepower or Less

The motor, equipped with SINPAC

Switch, shall be tested for dielectric

withstand (hipot), by the application

of a 1200 volt sinusoidal potential,

in the range of 40-70 Hz, for 1

second. During the test, each

lead of the primary motor wiring,

accessible at the connection

board or conduit box, are to be

connected together and to one

terminal of the test equipment,

and the second test equipment

terminal is to be connected to the

accessible dead metal.

Motors 250 Volts or Less and

More Than 1/2 Horsepower

The motor, equipped with SINPAC

Switch, shall be tested for dielectric

withstand (hipot), by the application

of an 1800 volt sinusoidal potential,

in the range of 40-70 Hz, for 1

second. During the test, each

lead of the primary motor wiring,

accessible at the connection

board or conduit box, are to be

connected together and to one

terminal of the test equipment,

and the second test equipment

terminal is to be connected to the

accessible dead metal.

13.

CAUTION: The terminals of the

SINPAC Switch should not be used

as the junction for this field wiring.

17

Loading...

Loading...