Stearns Series 350 Catalog Page

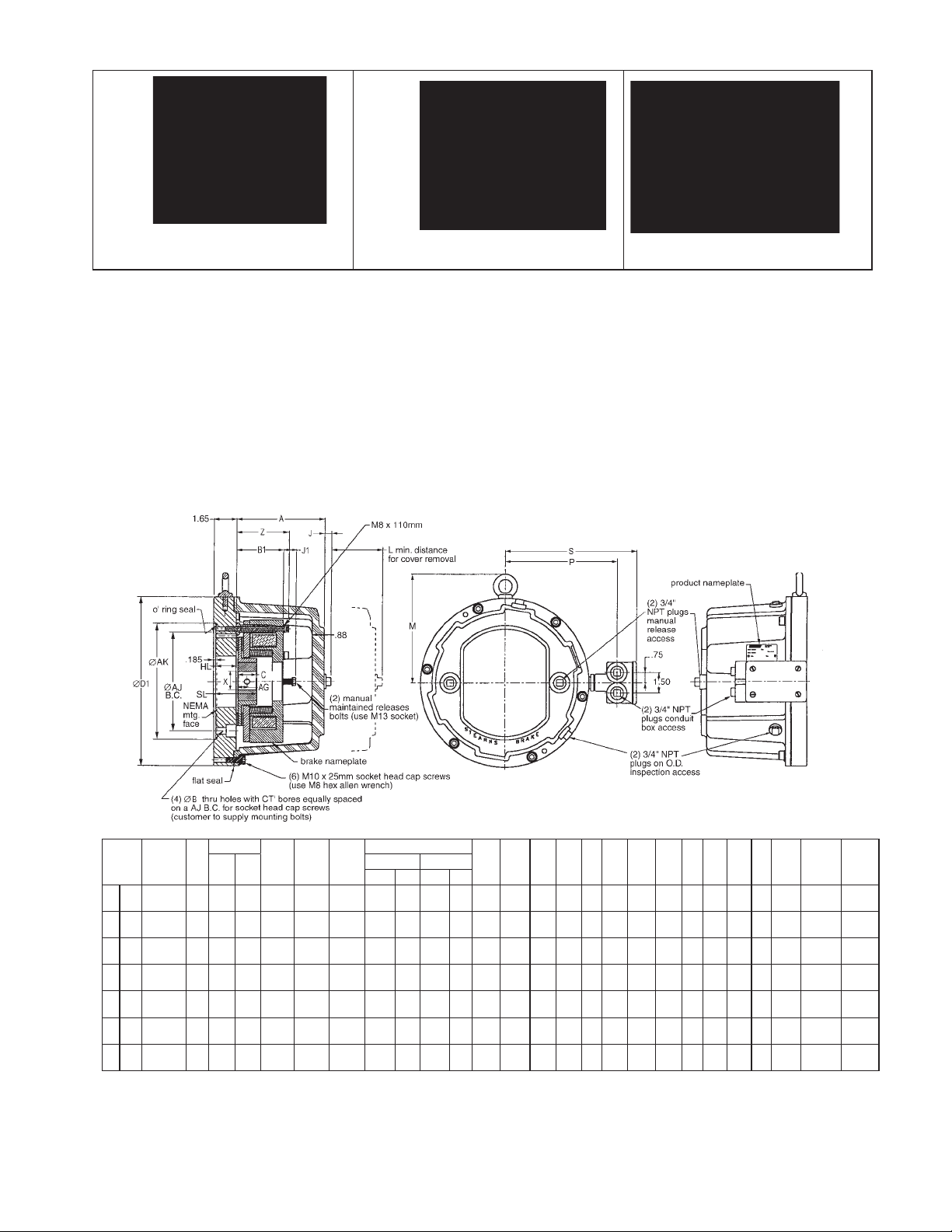

Series 350 Armature Actuated Brakes

BACK TO T ABLE OF CONTENTS

Brake with IP56 Aluminum Cover Brake showing space heater

and release indicator location

Features

• Torque rating 102 - 400 Nm,

75 - 300 lb-ft

• Universal mounting

• Class H insulation

• Maintained manual release

• Corrosion resistance

(stainless steel external hardware)

• IP56 enclosure protection (available

in ductile cast iron or aluminum cover)

• ABS, CSA and CE certification

• Simple wear adjustment with access

hole for air gap inspection

• Metric and US Customary bore sizes

• C-Face mounting - various adapter

plates available for 182TC through

405TSC frame mounting

• Splined hub for quiet dependable

operation

• Installation Instructions/Parts List:

P/N 8-078-895-00

Reverse view showing adapter

mounting plate orientation

Standard Options

• AC rectifier (see pages 86-89)

• Tach/encoder mounting

• Space Heater 115, 230 or

460 Vac

• Thru-shaft

• IEC D and C Flange

• Conduit Box- specify F1 or F2

location (F1 location shown)

F1 Conduit Box location shown.

F2 location on left side facing brake housing.

NEMA

Size

Frame

182TC-

7

196

256TSC

182TC-

7

196

256TSC

284TC-

7

196

286TSC

324TC-

7

196

405TSC

284TC-

8

230

286TSC

324TC-

8

230

405TSC

324TC-

9

278

405TSC

*Key to DIN 6885/3p9-Standard Metric Keyway DIN 6885/1p9

D1** & A** for Aluminum Cover

D1*** & A*** for Ductile Iron Cover

Component Materials:

• Adapter plate - steel (zinc plate)

• Splined hub - steel (zinc plate)

• Splined carrier - aluminum

Torque

B

lb-ft Nm

.53 75 102 7.250 8.500 1/2”-13 1.375 20 1.625 48* 12.38 15.75 3.57 3.97 4.6 8.00 9.68 8.25 .93 6.47 6.73 .50 1.378 1.63

.53 110 150 7.250 8.500 1/2”-13 1.375 20 1.625 48* 12.38 15.75 3.57 3.97 4.6 8.00 9.68 8.25 .93 6.47 6.73 .50 1.378 1.63

.53 110 150 9.000 10.500 1/2”-13 1.375 20 1.625 48* 12.38 15.75 3.57 3.97 4.6 8.00 9.68 8.25 .93 6.47 6.73 .50 1.378 1.63

.66 110 150 11.000 12.500 5/8”-18 1.375 20 1.625 48* 15.75 15.75 3.57 3.97 4.6 9.63 11.38 9.94 .93 6.73 6.73 .50 1.378 1.63

.53 180 240 9.000 10.500 1/2”-13 1.625 25 1.875 50* 15.75 15.75 4.00 4.46 5.0 9.63 11.38 9.94 .93 6.73 6.73 .25 1.575 1.63

.66 180 240 11.000 12.500 5/8”-11 1.625 25 1.875 50* 15.75 15.75 4.00 4.46 5.0 9.63 11.38 9.94 .93 6.73 6.73 .25 1.575 1.63

.66 300 400 11.000 12.500 5/8”-11 1.875 25 2.125 70 15.75 15.75 4.00 5.08 5.0 9.63 11.38 9.94 .97 6.73 6.73 .25 1.969 1.63

AJ AK

Mount

Bolt

• Armature - steel (zinc plate)

• Magnet body - steel (zinc plate)

• Hardware - steel (corrosion resistant

plating or stainless)

X

Min. Bore Max. Bore

in mm in mm

D1** D1*** B1 Z L M S P J1 A** A*** J

• Cover: Size 196 - 182T thru 286TS

NEMA - Aluminum (anodized) (additional

paint optional) Size 196 - 324T thru 405TS

NEMA - Cast Iron (primed) (additional

paint optional)

• Size 230 - 284T thru 405TS NEMA - Cast

Iron (primed ) (additional paint optional)

• Size 278 - 324T thru 405TS NEMA - Cast

Iron (primed) (additional paint optional)

C

Hub

length

HL Hub

Location

AG set

screw

location

.689

17.50

.689

17.50

.689

17.50

.689

17.50

.790

20.07

.790

20.07

.985

25.02

85

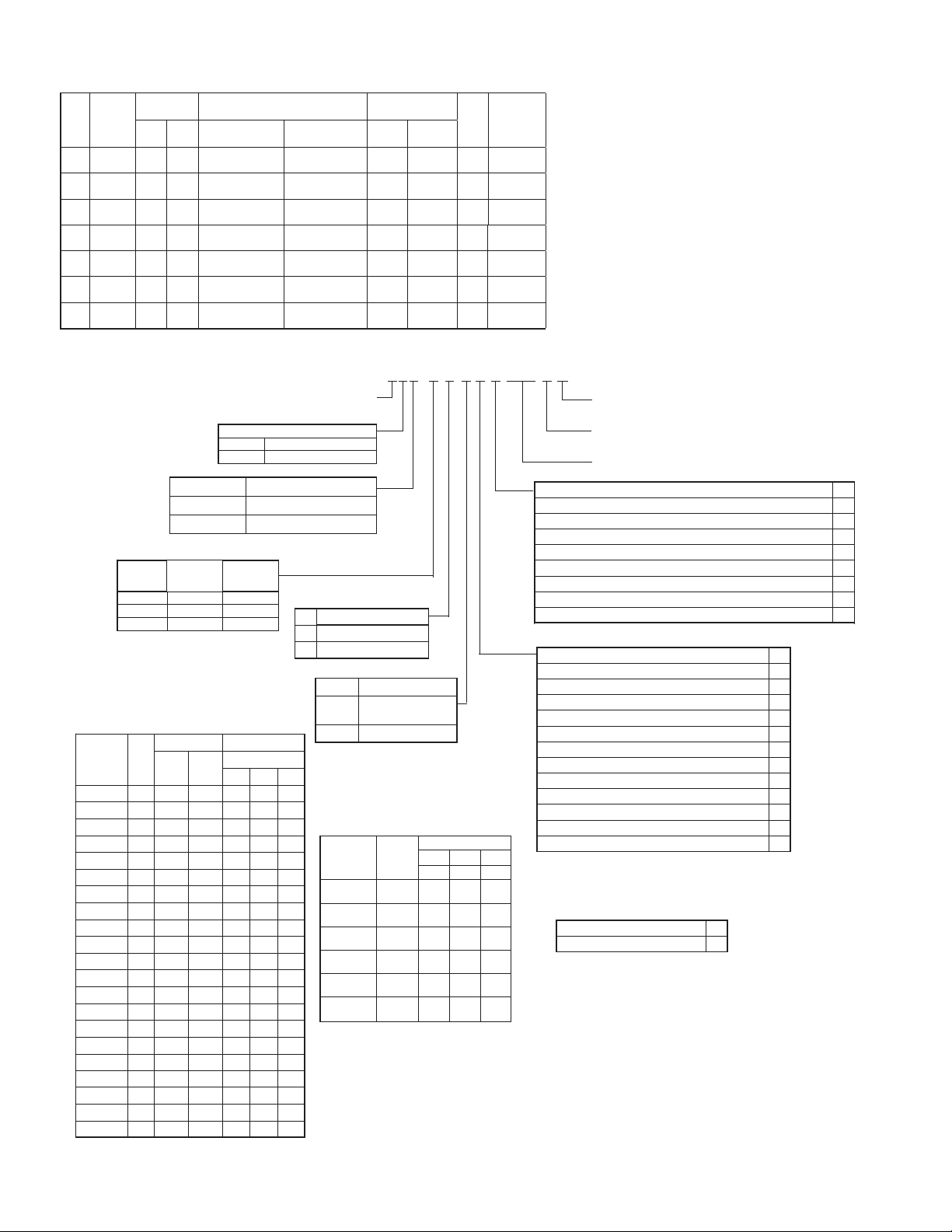

Series 350 Continued

Unit Specifications

Size

196

196

196

196

230

230

278

NEMA

Frame

182TC-

256TSC

182TC-

256TSC

284TC-

286TSC

324TC-

405TSC

284TC-

286TSC

324TC-

405TSC

324TC-

405TSC

Nominal

Static Torque

lb-ft Nm Ductile Cast Iron Aluminum Cover

75 102 351-734HX-XX-XX 355-734HX-XX-XX – 103 1800 22

110 150 351-744HX-XX-XX 355-744HX-XX-XX – 103 1800 22

110 150 351-744JX-XX-XX 355-744JX-XX-XX – 103 1800 22

110 150 351-744KX-XX-XX 355-744KX-XX-XX 134 128 1800 22

180 240 351-844JX-XX-XX 355-844JX-XX-XX 208 178 1800 28

180 240 351-844KX-XX-XX 355-844KX-XX-XX 208 178 1800 28

300 400 351-944KX-XX-XX 355-944KX-XX-XX 219 189 1800 30

Part Number Weight/lbs

Ductile

Iron

Aluminum

Max

RPM

BACK TO T ABLE OF CONTENTS

Thermal

Capacity

Hp-Sec/Min

Ordering Information

355-74 4JCOMEA

Part number example:

Group “3” Armature Acting Brake

(Direct acting with a DC Coil)

Mounting Design

Numeral Design

5 Pressure Plate Mount

Brake Cover TypeNumeral

Ductile Iron

1

Aluminum

5

Numeral/

Alpha

7

8

9

Magnet

Body Size

196

230

278

Torque

lb-ft

110

180

300

Torque/Modification

Reduced Torque

43Standard Torque

Table 1 - Hub Bores

NOTE: See page 100 for recommended

minimum bore sizes by torque

Character

to insert

0M

0I

0L

30

38

42

45

48

50

50

55

60

70

* Standard U.S. keyseats made to ANSI B17.1 standard.

Standard metric keyseat DIN 6885/1 p9.

**Keyseat to DIN 6885/3 p9.

86

Keyway Size*

Bore

1.500

1.750

30

38

42

45

48

50**

50

55

60

70

Width

(in.)

5/161.3750G

3/81.6250H

3/8

1/21.8750J

1/22.000

1/22.1250N

—2020

103535

124040

12

14

14

14

14

16

18

20

Depth

(in.)

5/32

3/16

3/16

3/16

1/4

1/4

1/4

Depth

—

3.3

3.3

3.3

3.3

3.3

3.8

3.8

3.8**

3.8

4.3

4.4

4.9

Bores Available

Unit Size

278230196

X

X3/8

X

X

X

X

X

X

X

278230196Metric Bore Width

X

XX8

X

X

X

X10

X

X

X

X

X

X

X

X

X

X

X

X

X

X

Numeral

H

M IP66 conduit box*

*Specify F1 or F2 location

for conduit box modification

Table 2 - Coil Voltage

Character

Insert

Other voltages available - consult factory

For AC rectifiers see pages 86-89

Enclosure

IP66 conduit box*

with terminal strip

Current Rating

Coil

to

Voltage

7 8 9

196 230 278

E 24 Vdc 3.30 4.27 3.85

J 90 Vdc .82 1.05 1.19

K 103 Vdc .75 .96 1.08

L 180 Vdc .42 .54 .61

M 205 Vdc .38 .49 .56

414/432

B

Vdc

.24 .26 .28

Options Table 3

Voltages - Table 2

Hub bore and keyset - Table 1

Additional Options

Standard Brake

Space Heater 115

Space Heater 230 2

Space Heater 460 3

Brake release indicator NO/NC 4

Brake release indicator NO/NC Space Heater 115 5

Brake release indicator NO/NC Space Heater 230 6

Brake release indicator NO/NC Space Heater 460 7

Mounting

HNEMA 180/210/250 C-face

JNEMA 280 C-face

KNEMA 320/400 C-face

NEMA 440 C-face Mt*

NEMA 500 C-face Mt*

IEC 132 C-face Mt*

IEC 160 C-face Mt*

IEC 132 D-face Mt*

IEC 160 D-face Mt*

IEC 180 D-face Mt*

IEC 200 D-face Mt*

IEC 225 D-face Mt*

L

M

S

T

U

V

W

X

Y

*Contact factory for pricing on these mounting options

Table 3 - Additional Options

ANo manual release

RMaintained release (standard)

NOTE: Final part number may change due to

specifications or options selected or other product

design considerations. A number such as a 2, 3, 4 etc.,

in the 12

th

position is used to designate a unique brake

(custom) and can only be assigned by Stearns Design

Engineering Department.

Modifications are available - see AAB Modification

Section.

0

1

Loading...

Loading...