Page 1

C O M M E R C I A L

SOLAR GAS BACKUP

INT EGRATED SOLAR & HIG H EFFICIENCY GAS BACKUP

WATER HEATERS

The Solar Gas Backup blends all of the features of the Ultra Force™high

efficiency gas water heater with a storage tank optimized for solar thermal

applications. The integrated space-saving design provides a single tank

solution combining storage for heat captured by solar thermal collectors

with 96% thermally efficient gas backup. This innovative hybrid

technology takes efficiency and performance to their highest levels.

SSF100 120NE and SSX100 120NE

These models are eligible for a 30%

federal tax credit for the total installed

costs (no cap) when installed as part of a

complete commercial or residential solar

thermal hot water system. State and local

incentives may also apply.

SOLAR FEATURES

• Designed for commercial or large

residential with 200-500 gallons daily

hot water usage

• Solar loop side connections - supply and

return from collectors

• Direct and Indirect models

• SSF direct models have open tank

solar loop connections and are

suitable for open loop systems or

closed loop systems using an

external heat exchanger

• SSX indirect models have an integrated

single wall heat exchanger coil and are

suitable for closed loop systems using

Propylene Glycol and distilled water

mixture as the heat transfer fluid

• Combine with our new two, three and

four collector solar package systems that

are SRCC certified OG-300 for a

complete solar hot water system

(package systems available

October 2012)

• Compatible with our integrated

standard and double wall solar

pump stations

• Recirculation loop side connection

• Factory-installed lower tank

temperature sensor for field supplied

solar controls

TANK FEATURES

• 100-gallon storage

• Powered anode rod - maintenance free

protection against corrosion permanent design that does not require

replacement unless damaged

• Commercial grade glasslined tank

provides superior protection

against corrosion.

GAS BACKUP

FEATURES

• Maximum operating set point for the gas

backup burner is 140°F – allows for

optimum solar contribution

• Exclusive State designed control system

provides detailed operational

information, precise temperature control

and built-in diagnostics.

• 96% thermally efficient 120,000 Btu/hr

gas backup burner - available in natural

gas and propane

• Top mounted, down-fired pre-mix

burner provides optimum efficiency and

quiet operation

• Complies with SCAQMD Rule 1146.2

and other Air Quality Management

Districts with similar requirements for

low NOx emissions

• Meets the thermal efficiency and standby

loss requirements of the U.S.

Department of Energy and current

edition of ASHRAE/IESNA 90.1

• Design-certified by CSA International

• iComm

• Conventional power venting or power

• Vents vertically or through sidewall

• Direct vent intake and exhaust pipe can

• Uses inexpensive PVC, CPVC, pipe for

• Flexible venting – uses 3” or 4” pipe –

™

remote monitoring of

the gas heat section.

Call 1.888.WATER02

for more information.

direct venting

terminate separately outside building, or

through single opening, using concentric

vent assembly

intake and exhaust

up to 120 equivalent feet

compatible for

For more information on Solar Gas Backup, contact:

State Water Heaters

500 Tennessee Waltz Parkway

Ashland City, TN 37015

800-365-0024 Toll-free USA

www.statewaterheaters.com

JULY 2012 SCQSS00212

Page 2

SOLAR GAS BACKUP

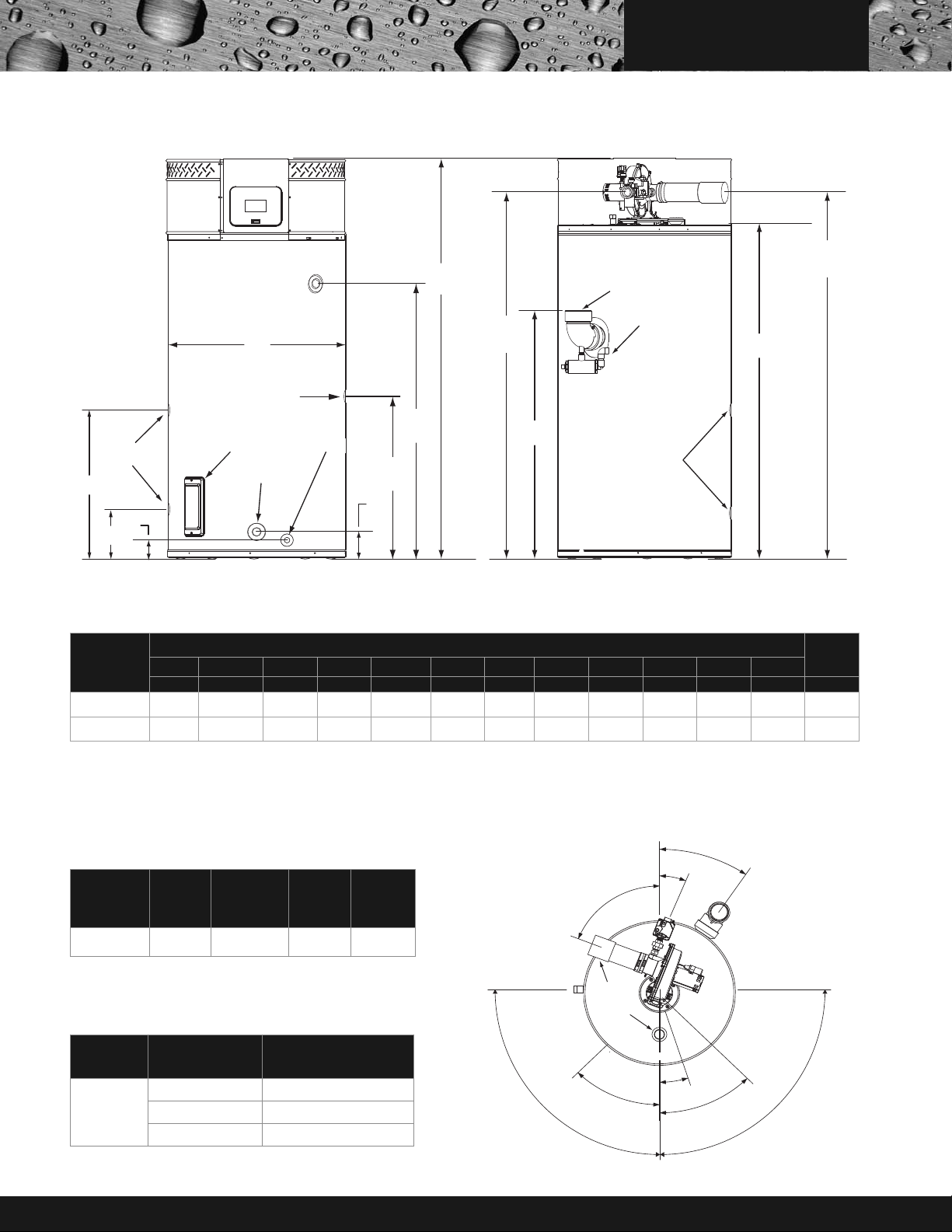

FRONT

BACK

CLEANOUT

*SOLAR

LOOP

T & P VALVE

3/4” NPT DRAIN

1 1/2” NPT

WATER INLET

VENT CONNECTION

3 INCH PVC

(exhaust elbow)

CONDENSATE

DRAIN CONNECTION

1/2 INCH PVC

INTAKE AIR CONNECTION

3 INCH PVC

SUPPLY GAS

CONNECTION

*SOLAR

LOOP

E

H

D

L

C

A

J

K

I

G

F

B

WATER OUTLET

HEIGHT

3/4” NPT

RECIRCULATION

LOOP RETURN

* Center line of water outlet on top of the water heaters is approximately 7 inches from the front edge of the water heater.

TOP VIEW

RECIRCULATION LOOP RETURN

90°

90°

SOLAR LOOP

35°

22°

68°

45°

18°

45°

*1 1/2” NPT

WATER

OUTLET

FRONT

INTAKEAIR

3 INCH PVC

GAS

CLEANOUT

DRAIN VALVE

T & P VALVE

VENT

3 INCH

PVC

C O M M E R C I A L

*Solar loop connections are 1 1/2” NPT female on SSF 100 120NE models and 1” NPT female on SSX 100 120NE models.

These designs comply with the current edition of the American National Standard for Gas Water Heaters, Volume III, ANSI Z21.10.3 / CSA 4.3 as an automatic circulating tank water

heater, and automatic storage water heaters.

SHIP

WEIGHT

STD

MODEL

DIMENSIONS

A B C D E F G H I J K L

INCHES/CM INCHES/CM INCHES/CM INCHES/CM INCHES/CM INCHES/CM INCHES/CM INCHES/CM INCHES/CM INCHES/CM INCHES/CM INCHES/CM LBS/KG

SSF100 120NE 3 / 7.62 27.75 / 70.5 6.3 / 16 55.5 / 141 75.5 / 191.8 68.5 / 174 32 / 81.3 63 / 160 69 / 175.3 5.5 / 14 26.5 / 67.3 31.8 / 80.7 535 / 245

SSX100 120NE 3 / 7.62 27.75 / 70.5 6.3 / 16 55.5 / 141 75.5 / 191.8 68.5 / 174 32 / 81.3 63 / 160 69 / 175.3 5.5 / 14 26.5 / 67.3 31.8 / 80.7 568 / 258

Change "N" to "P" in model number for propane.

SSF models have open tank solar loop connections and are suitable for use in open systems or closed systems using an external heat exchanger.

SSX models have an integrated single wall heat exchanger coil in the bottom of the tank and are suitable for closed loop active systems using non-toxic Propylene Glycol and distilled

water mixture as the heat transfer fluid. Glycol used must contain corrosion inhibitors.

SSX MODEL HEAT EXCHANGER COIL DATA

MODEL

NUMBER

TUBE SIZE

I.D.

(inches)

SSX100 120NE 1.63 18.8 4 43.5

Heat exchanger must only be used with a propylene glycol heat transfer fluid

containing corrosion inhibitors such as Dowfrost

Working pressure of the internal heat exchanger coil is 150 PSI.

SURFACE

AREA

(square feet)

CAPACITY

(gallons)

™

.

COIL

TUBE

LENGTH

(feet)

MODEL

NUMBER

SSX100 120NE

SCQSS00212 Page 2 of 6

(gallons per minute)

FLOW RATE

2 0.05

4 0.15

6 0.25

PRESSURE DROP THROUGH COIL

(feet of H2O)

Page 3

SINGLE WALL

HEAT EXCHANGER

COIL - SOLAR LOOP

SOLAR CONTROL TANK

TEMP SENSOR

STANDARD

INTEGRATED SOLAR

PUMP STATION

GAS FIRED BURNER

HEAT EXCHANGER

FINISHED FLOOR

ROOF

COLD WATER

SUPPLY

RECIRCULATION

RETURN OPTIONAL

COLLECTOR TEMP SENSOR

COLLECTORS

SOLAR LOOP

EXPANSION TANK

DOMESTIC WATER

EXPANSION TANK

T

TEMPERED

WATER OUTLET

MIXING VALVE

LEGEND

TEMPERATURE & PRESSURE

RELIEF VALVE

PRESSURE RELIEF VALVE

CIRCULATING PUMP

DRAIN

FULL PORT BALL VALVE

TEMPERATURE GAUGEEXPANSION TANK

CHECK VALVE

MIXING VA LVE

TANK OR LINE TEMPERATURE

CONTROL

T

(NORMALY OPEN

UNLESS OTHERWISE STATED)

TYPICAL APPLICATION SSX-100

C O M M E R C I A L

SCQSS00212 Page 3 of 6

SOLAR SYSTEM PACKAGES

SOLAR SYSTEM

PACKAGE

MODEL

SOLAR GAS

BACKUP

MODEL

NUMBER OF

COLLECTORS

COLLECTOR

SIZE

(FT)

HEAT

EXCHANGER

TYPE

SSC 02ACI202 LC SSX100 120NE 2 3.5' x 7' Single Wall Internal Coil

SSC 03ACI203 LC SSX100 120NE 3 3.5' x 7' Single Wall Internal Coil

SSC 04ACI204 LC SSX100 120NE 4 3.5' x 7' Single Wall Internal Coil

Solar system packages available October 2012

Page 4

FINISHED FLOOR

ROOF

COLD WATER

SUPPLY

COLLECTOR TEMP SENSOR

COLLECTORS

OPEN TANK

SOLAR LOOP

DOUBLE WALL HX

INTEGRATED SOLAR

PUMP STATION

SOLAR CONTROL TANK

TEMP SENSOR

T

SOLAR LOOP

EXPANSION TANK

DOMESTIC WATER

EXPANSION TANK

RECIRCULATION

RETURN OPTIONAL

TEMPERED

WATER OUTLET

GAS FIRED BURNER

HEAT EXCHANGER

MIXING VALVE

TYPICAL APPLICATION SSF-100

LEGEND

TEMPERATURE & PRESSURE

RELIEF VALVE

PRESSURE RELIEF VALVE

CIRCULATING PUMP

DRAIN

FULL PORT BALL VALVE

TEMPERATURE GAUGEEXPANSION TANK

CHECK VALVE

MIXING VA LVE

TANK OR LINE TEMPERATURE

CONTROL

T

(NORMALY OPEN

UNLESS OTHERWISE STATED)

C O M M E R C I A L

SCQSS00212 Page 4 of 6

SOLAR SYSTEM PACKAGES

SOLAR SYSTEM

PACKAGE

MODEL

SSE 02ACE202 LC SSF100 120NE 2 3.5' x 7' Double Wall External Plate

SSE 03ACE203 LC SSF100 120NE 3 3.5' x 7' Double Wall External Plate

SSE 04ACE204 LC SSF100 120NE 4 3.5' x 7' Double Wall External Plate

Solar system packages available October 2012

SOLAR GAS

BACKUP

MODEL

NUMBER OF

COLLECTORS

COLLECTOR

SIZE

(FT)

HEAT

EXCHANGER

TYPE

Page 5

C O M M E R C I A L

INSTALLATION CLEARANCES

REAR WALL

0

0

0

CEILING

FRONT VIEW

TOP VIEW

*Minim um clear ance to r emove t op cover

WATER

HEATER

LEFT

WALL

LEFT

WALL

RIGHT

WALL

RIGHT

WALL

*

1” (2.5 cm)

TOP COVER

SOLAR GAS BACKUP

HEAT INPUT SOLAR LOOP - SOLAR THERMAL COLLECTORS

COLLECTOR MODEL/SIZE

CR-110-AP FLAT PLATE

COLLECTOR (3.5’ X 7’)

Notes: CR-110-AP collector model specification sheet available for download on company website. Contact your local distributor or sales representative

for more information. If other collectors are used in place of CR-110-AP do not exceed maximum Btu/day input above.

COLLECTOR

APERTURE AREA

Square

Feet

Square

Meters

25.5 2.37 25.1 kBtu/day 15.5 kBtu/day 4 100.4 kBtu/day

THERMAL PERFORMANCE

(per collector)

SRCC Data Warm

Climate Clear Day

SRCC Data Cool

ClimateClear Day

MAXIMUM SOLAR THERMAL INPUT

Maximum Number

CR-110-AP Collectors

GAS BACKUP RECOVERY CAPACITY

U.S. GALLONS/HR AND LITRES/HR AT TEMPERATURE RISE INDICATED

MODEL

SSF100 120NE /

SSX100 120NE

Change "N" to "P" in model number for propane.

Recovery capacities are based on heater performance at 96% thermal efficiency.

Maximum gas supply pressure: 10.5” W.C. natural gas 14” W.C. propane.

Electrical requirements: 120 VAC/60Hz, Blower 2.2 Amps FL, Igniter 4.0 Amps.

TYPE OF

GAS

NATURAL/

PROPANE

INPUT

BTUH kW C° 17C° 22C° 28C° 33C° 39C° 44C° 50C° 56C° 61C° 67C° 72C° 78C°

120,000 35 96%

THERMAL

EFFICIENCY

APPROX.

CAPACITY

60 U.S. Gal GPH 461 345 276 230 197 173 154 138 126 115 106 99

227 Litres LPH 1744 1308 1046 872 747 654 581 523 476 436 402 374

Maximum Equivalent Vent Lengths

SSF100 120NE / SSX100 120NE

*NUMBER OF 90°

ELBOWS INSTALLED

One (1) 45 feet (13.7 meters) 115 feet (35.0 meters)

Two (2) 40 feet (12.2 meters) 110 feet (33.5 meters)

Three (3) 35 feet (10.7 meters) 105 feet (32.0 meters)

Four (4) 30 feet (9.1 meters) 100 feet (30.5 meters)

Five (5) ------- 95 feet (29.0 meters)

Six (6) ------- 90 feet (27.4 meters)

3 INCH PIPE 4 INCH PIPE

MAXIMUM FEET (METERS) MAXIMUM FEET (METERS)

F° 30F° 40F° 50F° 60F° 70F° 80F° 90F° 100F° 110F° 120F° 130F° 140F°

MINIMUM SUPPLY GAS LINE SIZE

MODEL NATURAL GAS PROPANE GAS

SSF100 120NE /SSX100 120NE 3/4” NPT 3/4” NPT

Change "N" to "P" in model number for propane.

Maximum

kBtu/day

* Maximum number of 90° elbows allowed for the vent (exhaust) pipe is four (4) when

installing 3 inch pipe and six (6) when installing 4 inch pipe. Maximum number of 90°

elbows allowed for intake air pipe is four (4) when installing 3 inch pipe and six (6) when

installing 4 inch pipe. Two (2) 45° elbows equal one (1) 90° elbow.

SCQSS00212 Page 5 of 6

Page 6

C O M M E R C I A L

OTHER FEATURES

SPACE-SAVING DESIGN FOR INSTALLATION FLEXIBILITY

• Reduced footprint, ease of service, protection from water damage in case of flooding

• Easy to remove top cover for convenient access to serviceable parts

• 0˝ installation clearances on sides and rear, 1-1/2˝ installation clearance on top, 4˝ alcove installation clearance in front Handhole Cleanout of unit

• Handhole cleanout allows easy access to tank interior for cleaning

• 0˝ clearance to combustibles, approved for installation on combustible floors

LIMITED WARRANTY

• Three year tank warranty standard (5 year tank warranty optional)

• One year parts warranty

• For complete warranty details, consult written warranty shipped with heater

INSTALLATION CONSIDERATIONS

1. Condensate Drain – This is a condensing water heater and should be located near a drain to permit proper disposal of condensate.

2. Vent Termination – Exhaust gases of this water heater are less than 140°F. In cold climates water vapor in flue gases will condense into a cloud of vapor where the

vent exits the building.This vapor can gradually discolor exterior building surfaces when terminated through a side wall. The vent termination should be located

where this is not a concern or through the roof to avoid the potential problem. Always locate vent termination above the maximum snowline, and do not locate

vent termination above a walkway.

3. Air Intake – In cold climates, air intake should be located at least four feet from the vent termination of the water heater and any other appliance vents that discharge

moisture-laden air (such as clothes dryers). This will help prevent freeze-over of the intake screen. Air intake should be located above the maximum snowline.

4. Noise – Vent terminal should be located away from bedroom windows or other areas where blower noise will be objectionable.

5. Optional Concentric Vent Kit - Helps to minimize unsightly wall/roof penetrations. Vent kit p/n 9006328005

SAMPLE SPECIFICATION

Water heater shall be State Water Heater model # __________ or equal and shall be an integrated solar thermal __________ (direct/indirect) water heater with a gas fired backup

burner to maintain system temperature during periods when solar energy is not available. The water heater shall have a water storage capacity of 100 gallons. The water heater shall

be fitted with a dedicated recirculation loop connection in the mid portion of the storage tank for applications with hot water building recirculation to maximize solar energy gain

in the lower portion of the tank.

Direct models shall have two open tank solar loop connections in the lower portion of the tank for connection to a solar thermal collector array. Direct models will be compatible

with open loop solar thermal water heating systems or closed loop solar thermal systems with external heat exchangers.

Indirect models shall have an integrated single wall coil type heat exchanger with two solar loop connectionsin the lower portion ofthe tank for connection to a solar thermal collector

array. Indirect models will be compatible with closed loop solar thermal systems using heat transfer fluid containing a mixture of distilled/demineralized water and propylene glycol

with corrosion inhibitors.

The gas fired backup burner shall be fueled by ___________ (Natural/Propane) gas and be 96% thermally efficient with an input rating of 120,000 BTUs per hour, a recovery

rating of 138 gallons per hour (gph) at 100°F rise and a maximum hydrostatic working pressure of 160 PSI. Water heater(s) shall: 1. Have seamlessglasslined steel tank construction,

with glasslining applied to all domestic water-side surfaces after the tank has been assembled and welded; 2. Meets the thermal efficiency and standby loss requirements of the

U. S. Department of Energy and current edition of ASHRAE/IESNA 90.1 3. Have foam insulation and a CSA Certified and ASME rated T&P relief valve; 4. Have a down-fired

power burner designed for precise mixing of air and gas for optimum efficiency, requiring no special calibration on start-up; 5. Be approved for 0˝ clearance to combustibles.

Heater shall be supplied with maintenance-free powered anode.

The control shall be an integrated solid-state temperature and ignition control device with integral diagnostics, graphic user interface, fault history display, and shall have digital

temperature readout.

The water heater(s) shall be: 1. Design certified by CSA; 2. Meets the thermal efficiency and standby loss requirements of the U. S. Department of Energy and current edition

ASHRAE/IESNA 90.1.; 3. Comply with SCAQMD Rule 1146.2 and other air quality management districts with similar requirements for low NOx emissions.

For conventional-vent specification: The water heater(s) shall be suitable for venting in 3˝ PVC pipe for a total equivalent distance of 50 ft and 4˝ PVC pipe for a total equivalent

distance of 120 ft.

For sealed-combustion direct vent specification: The water heater(s) shall be suitable for venting with (3˝ or 4˝) _______ diameter PVC pipe for a total equivalent distance of

(50 ft or 120 ft) ________ feet. [Alternative venting: the heater(s) shall be suitable for sealed combustion direct venting using a (3˝ or 4˝) ________ diameter PVC exhaust pipe

for a total distance of (50 ft or 120 ft) ________ equivalent feet of vent and (50 ft or 120 ft) _______ equivalent feet of intake.]

Operation of the water heater(s) in a closed system where thermal expansion has not been compensated for (with a properly sized thermal expansion tank) will void the warranty.

Water heater should incorporate the iCOMM™ system for remote monitoring of the gas fired backup burner, leak detection and fault alert.

For complete information on limited warranties, consult written warranty or contact

the State Customer Care Center at 1-800-365-0024.

State Industries, Inc., reserves the right to make product changes or improvements without prior notice.

For more information on Solar Gas Backup, contact:

State Water Heaters

500 Tennessee Waltz Parkway

Ashland City, TN 37015

800-365-0024 Toll-free USA

www.statewaterheaters.com

SCQSS00212 Page 6 of 6 © 2012 State Industries, Inc. Printed in U.S.A

Loading...

Loading...