Page 1

C O M M E R C I A L

OPTIONAL

CRN

U

ASME

FACTORY JACKETED AND INSULATED

SOLAR COMMERCIAL STORAGE TANKS

These storage tanks are eligible

for a 30% federal tax credit

when installed as part of a

complete commercial solar

thermal hot water system.

Large volume solar storage

tanks from State are designed

for storing potable water. These

storage tanks are fitted with

additional openings to suit the

specific needs of solar thermal,

commercial heat pump, and

other renewable energy

heat sources.

These tanks are available as

pre-configured Specialty Solar

Tanks and as Custom Solar

Tanks built to specified

application requirements. See

the Custom Solar Tank options

on page 4 and consult your

factory representative for

more information.

FEATURES

Specialty Solar Tanks

Vertical tanks from 140 to 2,000

gallons, horizontal tanks from 200 to

1,000 gallons. State commercial solar

storage tanks are constructed with

openings for potable water and solar

thermal/renewable energy applications as

shown in the drawings that follow.

These heavy duty storage tanks have

been designed for new construction and

retrofit applications.

ASME Construction

• All tanks are ASME constructed at

160 psi working pressure. Consult

your factory representative for tanks

with greater or lesser working pressures

Glasslined

• Specialty Solar Tanks feature State's

commercial grade glasslining that

provides superior protection against

corrosion and is fused to all inner

tank surfaces at 1600°F

Insulation

• All tanks are surrounded with 3

inches of high density fiberglass

insulation to reduce costly heat loss;

insulation is non-sagging and

verminproof.To meet ASHRAE 90.1

(current edition) depth of insulation

cavity requires use of remote bulbtype tank temperature control and

thermometer. Storage tanks meet

R12.5 minimum thermal insulation

requirements of the U.S. Department

of Energy and current edition of

ASHRAE/IESNA 90.1

Jacket/Cabinet

• All tanks feature heavy gauge steel

with high quality powder coat paint

that provides additional insulating

qualities for greater energy savings

Cathodic Protection

• All tanks are furnished with factory

installed magnesium anodes designed

for maximum protection

Connections

• Tanks will be supplied with the fittings

located as indicated on the drawings

unless specified otherwise. Manhole or

handholes are optional on glasslined

tanks but are included on cement

lined tanks

Temperature Sensors

• Factory installed upper and lower

temperature sensor wells with

Pt1000 type sensors and internal

wiring pre-installed

Custom Solar Tanks

• See options and suggested

specification on page 4

For more information on Solar Storage Tanks, contact:

State Water Heaters

500 Tennessee Waltz Parkway

Ashland City, TN 37015

800-365-0024 Toll-free USA

www.statewaterheaters.com

SCESS00811

Page 2

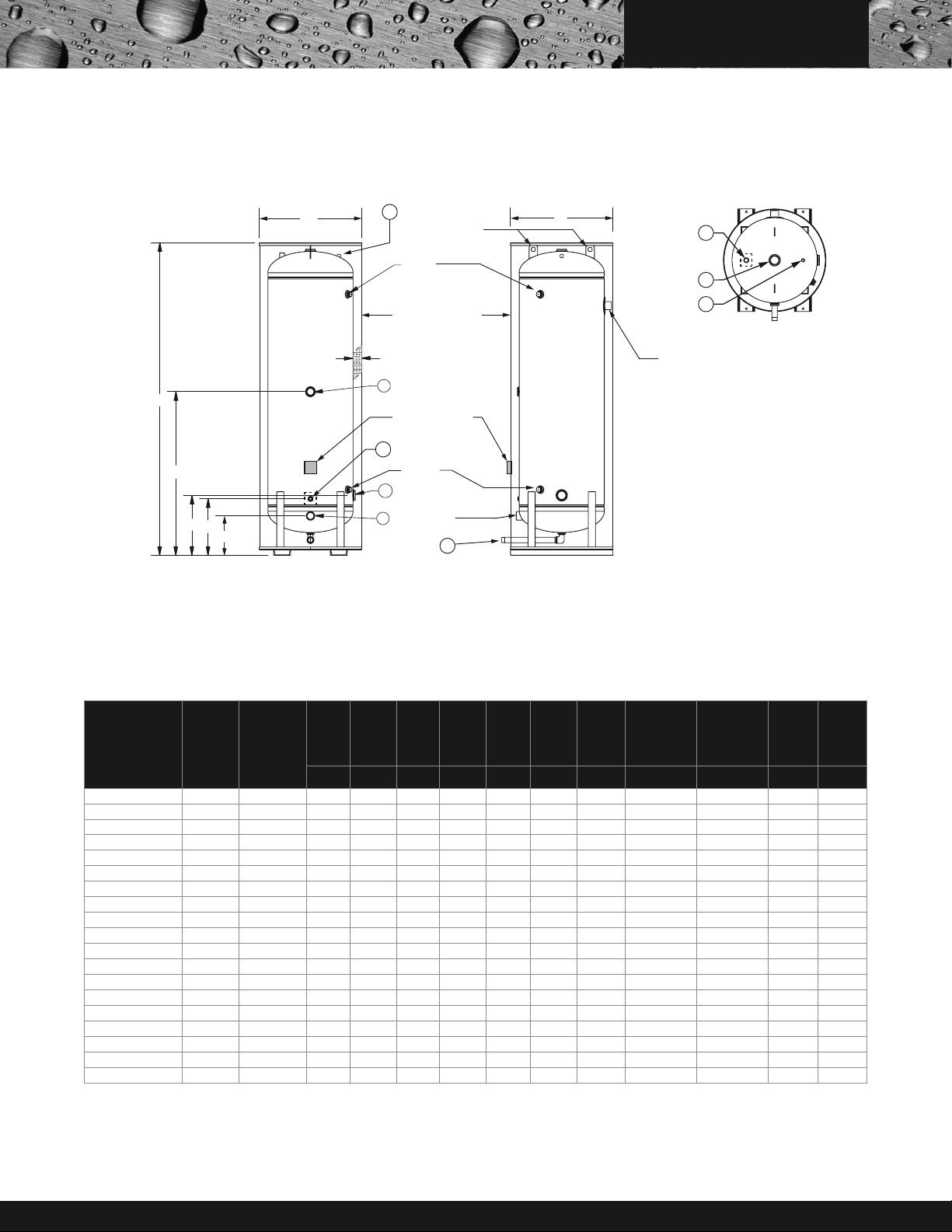

C O M M E R C I A L

B

C

D

F

E

A

ANODE

ANODE

I

I

H

FOR SHIPPING

ONLY

LIFTING LUGS

JACKET (CABINET)

SOLAR RETURN

SOLAR DRAW

DRAIN

(MALE NPT)

COLD INLET

HOT OUTLET

SENSOR WELL

T&P VALVE

OPENING

SENSOR WELL

SENSOR WELL

G

FRONT VIEW SIDE VIEW TOP VIEW

A

K

H

J

J

J

SENSOR WIRING

3" INSULATION

SOLAR COMMERCIAL STORAGE TANKS

VERTICAL STORAGE TANKS

DRAWING NOTES:

• Inspection openings, IE: handholes and manholes, are optional with glasslined or stainless steel tanks and will only be included when specified.Tanks so equipped

are FOB Seattle.

• All openings female pipe thread except as noted.

• Number of factory installed anode rods will vary with tank size.

SVG-01400 OVTA125 THROUGH SVG-20000 OVTA125

SOLAR

MODEL

SVG 01400 OVTA125 140 613 30 86 13 18-1/2 19 49-1/2 1-1/2 2-1/2 1-1/2 1/2 1

SVG 02000 OVTA125 200 749 36 82 14 20 20 48 1-1/2 2-1/2 1-1/2 1/2 1

SVG 02500 OVTA125 250 811 36 95 14 20 20 54 1-1/2 2-1/2 1-1/2 1/2 1

SVG 03000 OVTA125 300 898 36 110 14 20 20 62 1-1/2 2-1/2 1-1/2 1/2 1

SVG 03000 OVSA125 300 857 42 82 15-1/2 21-1/2 22 48 1-1/2 2-1/2 2 1/2 1

SVG 03500 OVTA125 350 942 42 97 15-1/2 21-1/2 22 56 1-1/2 2-1/2 1-1/2 1/2 1

SVG 04000 OVTA125 400 1436 42 104 15-1/2 21-1/2 22 59 1-1/2 2-1/2 2 1/2 1

SVG 04500 OVTA125 450 1565 42 118 15-1/2 21-1/2 22 66-1/2 1-1/2 2-1/2 2 1/2 1

SVG 05000 OVTA125 500 1682 42 133 15-1/2 21-1/2 22 74 1-1/2 2-1/2 2 1/2 1

SVG 05000 OVSA125 500 1714 48 99 17 23 23-1/2 57 1-1/2 3 2-1/2 1/2 1

SVG 06000 OVTA125 600 1820 48 114 17 23 23-1/2 65 1-1/2 3 2 1/2 1

SVG 07000 OVTA125 700 1911 48 130 17 23 23-1/2 73 1-1/2 3 2 1/2 1

SVG 08000 OVTA125 800 2974 54 120 18 24-1/2 25 68 1-1/2 3 2-1/2 1/2 1

SVG 09000 OVTA125 900 3208 54 128 18 24-1/2 25 72 1-1/2 3 2-1/2 1/2 1

SVG 10000 OVTA125 1000 3697 54 148 18 24-1/2 25 82 1-1/2 3 2-1/2 1/2 1-1/2

SVG 10000 OVSA125 1000 3947 **66 99 21 27-1/2 28 58 1-1/2 3 3 1/2 1-1/2

SVG 15000 OVTA125 1500 4456 **60 164 19-1/2 26 26-1/2 90-1/2 1-1/2 3 3 1/2 1-1/2

SVG 20000 OVTA125 2000 6035 **66 176 21 27-1/2 28 97 1-1/2 3 3 1/2 1-1/2

SVG 20000 OVSA125 2000 5952 **78 131 24 30-1/2 31 75 1-1/2 3 3 1/2 1-1/2

All dimensions are in inches.

Four vertical tanks are available in short and tall models. The S and T designators at the end of the model numbers are used to identify these models.

* Sensor well openings are 1/2" NPT female. All models have factory installed Pt1000 temperature sensors and wiring to an external junction box. Access covers are provided for field

supplied temperature sensors and servicing.

** These models will have rectangular jackets when manufactured for indoor use. All other models will have round jackets.

NOMINAL

VOLUME

(gallons)

GLASSLINED

DRY WEIGHT

(lbs.)

WIDTH HEIGHT

A

B C D E F G H I J K

DRAW

HEIGHT

LOWER

SENSOR

HEIGHT

COLD

INLET

HEIGHT

SOLAR

RETURN

HEIGHT

DRAIN

(in. NPT)

INLET/OUTLET

CONNECTIONS

(in. NPT)

SOLAR LOOP

CONNECTIONS

(in. NPT)

*SENSOR

WELLS

(in. NPT)

T&P

VALVE

OPENING

(in. NPT)

SCESS00811 Page 2 of 4

Page 3

C O M M E R C I A L

SOLAR RETURN

SOLAR DRAW

(MALE NPT)

DRAIN

(MALE NPT)

COLD INLET

HOT OUTLET

ANODEANODE

FRONT VIEW SIDE VIEW

SENSOR WELL

SENSOR

WELL

SENSOR WIRING

T&P VALVE

OPENING

H

E

H

F

A

B

C

I

K

K

L

L

M

J

J

D

G

CABINET

3" INSULATION

SOLAR COMMERCIAL STORAGE TANKS

HORIZONTAL STORAGE TANKS

DRAWING NOTES:

• Inspection openings, IE: handholes and manholes, are optional with glasslined or stainless steel tanks and will only be included when specified.Tanks so equipped are FOB Seattle

• All openings female pipe thread except as noted

• Number of factory installed anode rods will vary with tank size

SHG-02000 OHTA125 THROUGH SHG-10000 OHTA125

HOT

COLD

SOLAR

SOLAR

MODEL

NOMINAL

VOLUME

(GALLONS)

GLASSLINED

DRY

WEIGHT

(LBS.)

HEIGHT DEPTH LENGTH

OUTLET

CENTER

INLET

HEIGHT

RETURN

HEIGHT

DRAW

HEIGHT

TANK

SADDLE

CENTERS

A B C D E F G H I J K L M

DRAIN

(IN. NPT)

INLET/OUTLET

CONNECTIONS

(IN. NPT)

SOLAR LOOP

CONNECTIONS

(IN. NPT)

*SENSOR

WELLS

(IN. NPT)

SHG 02000 OHTA125 200 1020 41 36 77 16 13 23 4 16 1-1/2 2-1/2 1-1/2 1/2 1

SHG 02500 OHTA125 250 1082 41 36 90 16 13 23 4 22-1/2 1-1/2 2-1/2 1-1/2 1/2 1

SHG 03500 OHTA125 350 1232 47 42 93 17-1/2 12 26 4 22-1/2 1-1/2 2-1/2 1-1/2 1/2 1

SHG 04000 OHTA125 400 1402 47 42 99 17-1/2 12 26 4 26 1-1/2 2-1/2 2 1/2 1

SHG 05000 OHTA125 500 2270 59 54 79 23 14 32 4 11 1-1/2 3 2 1/2 1

SHG 07500 OHTA125 750 2970 59 54 111 23 14 32 4 1/2 27 1-1/2 3 2-1/2 1/2 1

SHG 10000 OHTA125 1000 3751 59 54 143 23 13 32 5 43 1-1/2 3 3 1/2 1-1/2

All dimensions are in inches.

* Sensor well openings are 1/2" NPT female. All models have factory installed Pt1000 temperature sensors and wiring to an external junction box. Access covers are provided for field

supplied temperature sensors and servicing.

T&P

VALVE

OPENING

(IN. NPT)

SCESS00811 Page 3 of 4

Page 4

C O M M E R C I A L

CUSTOM SOLAR TANKS: Customized solar tanks with specified construction materials and configurations are also available; consult your factory sales

representative for more information.

CUSTOM OPTIONS INCLUDE:

• Glasslined tanks

• Cement lined tanks

• Stainless steel tank construction

• Specified gallon capacities up to 12,500 gallons

• Specified tank dimensions

• Specified tank openings

• Specified tank opening locations

• Outdoor models - entire tank is sprayed with minimum of 2 inch high-density polyurethane foam insulation that forms a watertight jacket that is approved for

outdoor use. Meets or exceeds the thermal efficiency and standby loss requirements of the U.S. Department of Energy and Current Edition of the

ASHRAE/IESNA 90.1

Note: Minimum foam insulation thickness is 2 inches; however, since tank is hand sprayed, insulation thicknesses may be greater in some areas giving the finished

tank an uneven but watertight surface

• Additional insulation - provides R16 insulation value - adds 8” to tank jacket diameter/cabinet dimensions

• Supplemental/backup heat sources

– Electric heating element packages - standard voltages 208/240 VAC (single/three phase), 480 three phase. Advanced electronic controller, modulating step

control, low water cutoffs. Contact your factory sales representative for available kW input configurations

– Tank heaters - flange mounted removable single/double wall copper tube heat exchangers for backup heating from low pressure steam or boiler water

– Tank heaters - flange mounted removable single/double wall copper tube heat exchangers for supplemental heat from alternate heat sources such as

geo-thermal, air or water source heat pumps

LIMITED WARRANTY OUTLINES

GLASSLINED and CEMENT: If the tank should leak anytime during the first five years, under the terms of the warranty, State will repair or replace the tank;

installation, labor and handling extra.

NOTE: THIS OUTLINE IS NOT A WARRANTY. For complete information, consult the written warranty or State Water Heaters. Warranty does not apply to

product installed outside of the United States of America or its territorial possessions and Canada.

SAMPLE SPECIFICATION FOR CUSTOM-LINE STORAGE TANKS

Jacketed or insulated models meet R12.5 minimum thermal insulation requirements of the U.S. Department of Energy and current edition of ASHRAE/IESNA 90.1.

ASME storage tank to be State Custom-Line model ___________________. Capacity to be ___________ gallons with a diameter of _________ inches. Tank(s) shall be constructed

and stamped according to ASME specifications for __________ psi working pressure. Manhole (11 x 15),handhole (4x6) or inspection openings (2-2˝) shall be installed in accordance

with ASME code requirements and manufacturer(s) standard practice. Tank to be constructed of (carbon steel)_________.Lining shall be (glass or cement) ______________. Tank(s)

linedwith (glass or cement) _____________lining shall be equipped with the number and size of magnesium anode rod(s) sufficient to provide adequate protection for the tank lining.

Tank shallbe(vertical,horizontal)____________ design and provided with (four) ___________(angleiron legs,threaded leg socket(s)) _____________ ringbase, ___________saddles.

Tankshall be equipped with two (one upper and one lower) factory-installedPt1000 temperature sensors for renewable energycontrol devices such as those used on solar thermal control

systems. Sensor wells shall be installed in 1/2 inch female NPT openings to accommodate Pt1000 sensors. These wells shall be removable to accommodate field supplied temperature

sensing devices. Wiring for temperature sensors will be factory installed and terminate in a junction box affixed to the outside jacket. On outdoor models this wiring shall terminate in a

weather proof wiring box.

SAMPLE SPECIFICATION FOR TANK HEATERS (Tube Bundle Heat Exchangers)

Tank heaters shall be Model No. ____________ 3/4˝ OD 20 gauge copper “U” tubes. The tank heater shall be a (single, double) __________ wall heat exchanger construction.Tank

heater to have ________ square feet of heating surface to heat ____________ gallons per hour from _____________ degrees F to ____________ degrees F with heating media of

____________ psi steam (or _________degrees F boiler, heat pump, geothermal,or other heat sourcewater).The tank heaterelement shall be constructed so that the entire section can

be removed from the tank for cleaning and inspection.

For complete information on limited warranties, consult written warranty or contact

the State Customer Care Center at 1-800-365-0024.

State Industries, Inc., reserves the right to make product changes or improvements without prior notice.

For more information on Solar Storage Tanks, contact:

State Water Heaters

500 Tennessee Waltz Parkway

Ashland City, TN 37015

800-365-0024 Toll-free USA

www.statewaterheaters.com

SCESS00811 Page 4 of 4 © 2011 State Industries, Inc. Printed in U.S.A

Loading...

Loading...