Page 1

Commercial Electric Xi Control Instruction Manual

COMMERCIAL ELECTRIC WATER HEATER

MODELS SEV-150 THRU SEV-10000

SEH-200 THRU SEH-10000

UP TO 150KW

500 Tennessee Waltz Parkway

Ashland City, TN 37015

PLACE THESE INSTRUCTIONS ADJACENT TO HEATER AND NOTIFY OWNER TO KEEP FOR FUTURE REFERENCE.

PRINTED 0910 318579-000

Page 2

SAFE INSTALLATION, USE AND SERVICE

Your safety and the safety of others is extremely important in the installation, use, and servicing of this water heater.

Many safety-related messages and instructions have been provided in this manual and on your own water heater to warn you and

others of a potential injury hazard. Read and obey all safety messages and instructions throughout this manual. It is very important

that the meaning of each safety message is understood by you and others who install, use, or service this water heater.

This is the safety alert symbol. It is used to alert

you to potential personal injury hazards. Obey all

safety messages that follow this symbol to avoid

possible injury or death.

DANGER indicates an imminently hazardous

DANGER

WARNING

CAUTION

situation which, if not avoided, will result in

death or injury.

WARNING indicates a potentially hazardous

situation which, if not avoided, could result

in death or injury.

CAUTION indicates a potentially hazardous

situation which, if not avoided, could result

in minor or moderate injury.

CAUTION used without the safety alert

CAUTION

All safety messages will generally tell you about the type of hazard, what can happen if you do not follow the safety

message, and how to avoid the risk of injury.

The California Safe Drinking Water and Toxic Enforcement Act requires the Governor of California to publish a list of

substances known to the State of California to cause cancer, birth defects, or other reproductive harm, and requires

businesses to warn of potential exposure to such substances.

This product contains a chemical known to the State of California to cause cancer, birth defects, or other reproductive

harm. This appliance can cause low level exposure to some of the substances listed.

• QualiedInstallerorServiceAgency:

Installation and service of this water heater requires ability equivalent to that of a Qualied Agency (as dened by ANSI below) in

the eld involved. Installation skills such as plumbing and electrical supply are required in addition to electrical testing skills when

performing service.

symbol indicates a potentially hazardous

situation which, if not avoided, could result

in property damage.

IMPORTANT DEFINITIONS

• ANSIZ223.12006Sec.3.3.83:

“Qualied Agency” - “Any individual, rm, corporation or company that either in person or through a representative is engaged in and is

responsible for (a) the installation, testing or replacement of gas piping or (b) the connection, installation, testing, repair or servicing of

appliances and equipment; that is experienced in such work; that is familiar with all precautions required; and that has complied with all

the requirements of the authority having jurisdiction.”

2

Page 3

GENERAL SAFETY INFORMATION

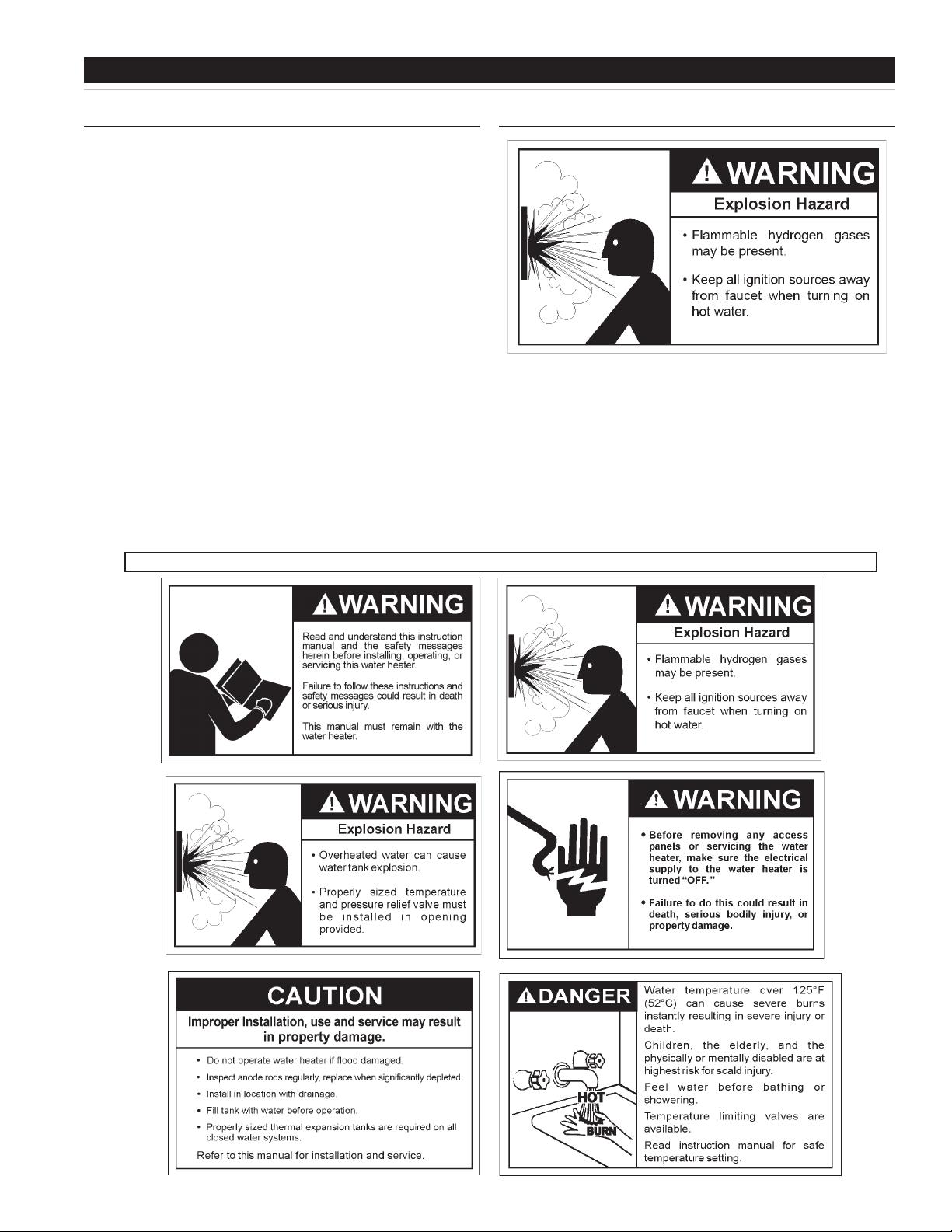

PRECAUTIONS

DO NOT USE THIS APPLIANCE IF ANY PART HAS BEEN UNDER

WATER. Immediately call a qualied service technician to inspect

the appliance and to replace any part of the control system which

has been under water.

If the unit is exposed to the following, do not operate heater until all

corrective steps have been made by a qualied service agency.

1. External re.

2. Damage.

3. Firing without water.

GROUNDING INSTRUCTIONS

This water heater must be grounded in accordance with the National

Electrical Code and/or local codes. These must be followed in all cases.

Failure to ground this water heater properly may also cause erratic

control system operation on ELECTRONIC CONTROL models.

This water heater must be connected to a grounded metal, permanent

wiring system, or an equipment grounding conductor must be run with

the circuit conductors and connected to the equipment grounding

terminal or lead on the water heater.

When servicing this unit, verify the power to the unit is turned off prior to opening the control cabinet door.

HYDROGEN GAS (FLAMMABLE)

Hydrogen gas can be produced in a hot water system served by this heater

that has not been used for a long period of time (generally two weeks or

more). Hydrogen gas is extremely ammable. To reduce the risk of injury

under these conditions, it is recommended that the hot water faucet be

opened for several minutes at the kitchen sink before using any electrical

appliance connected to the hot water system. If hydrogen is present there

will probably be an unusual sound such as air escaping through the pipe

as the water begins to ow. THERE SHOULD BE NO SMOKING OR

OPEN FLAME NEAR THE FAUCET AT THE TIME IT IS OPEN.

3

Page 4

TABLE OF CONTENTS

This manual contains the operating instructions for the commercial electric Xi control. It is intended to be used in conjunction with

the water heater instruction manual.

SAFE INSTALLATION, USE AND SERVICE........................ 2

GENERAL SAFETY INFORMATION .................................... 3

Precautions ...................................................................... 3

Hydrogen Gas (Flammable) ............................................. 3

INTRODUCTION ..................................................................4

Preparing for the Installation ............................................ 4

ELECTRICAL DATA .............................................................. 5

General ............................................................................ 5

Branch Circuit .................................................................. 5

Heater Circuits ................................................................. 5

Control Circuits ................................................................ 5

Power Circuit .................................................................... 5

WIRING DIAGRAMS ............................................................ 6

TEMPERATURE REGULATION .......................................... 7

High Temperature Limit Controls (ECO) .......................... 7

Thermostat Controls ........................................................ 7

Mixing Valves ................................................................ 7-8

Temperature Adjustment .................................................. 8

CONTROL SYSTEM OPERATION ...................................... 9

INTRODUCTION

Heating Element Operation .............................................. 9

Control System Features ................................................. 9

Control System Navigation .............................................. 9

The Desktop Screen ........................................................ 9

Temperatures Menu ....................................................... 12

Water Heater Status Menu............................................. 14

Economy Mode Settings ...........................................16-18

Alarm Output Setup Menu ............................................. 19

Heater Information Menu ............................................... 19

Current Fault / Alert Menu .............................................. 20

Fault History Menu ......................................................... 20

Fault Occurence Menu ................................................... 20

Restore Factory Defaults Menu ..................................... 21

TROUBLESHOOTING CHECKLIST .................................. 22

Not Enough or No Hot Water ......................................... 22

Water Is Too Hot ............................................................ 22

Water Heater Makes Strange Sounds ........................... 22

Notes .................................................................................. 23

Thank You for purchasing this water heater. Properly installed and

maintained, it should give you years of trouble free service.

Abbreviations Found In This Instruction Manual:

• ANSI - American National Standards Institute

• ASME - American Society of Mechanical Engineers

• NEC - National Electrical Code

• NFPA - National Fire Protection Association

PREPARING FOR THE INSTALLATION

1. Read the “General Safety” section of this manual first

and then the entire manual carefully. If you don’t follow

the safety ru les, the wate r heater may not oper ate safely.

It could cause DEATH, SERIOUS BODILY INJURY AND/

OR PROPE RTY DAMAGE.

Th is manu al cont ai ns in st ructi ons f or the in st all at ion,

ope r a tio n , an d ma i n ten a n ce o f th e wa t er h eate r. It

also co ntains wa rnings throughou t the manu al that you

must read and be aware of. All warnings and all instructions

are e s sent i a l to t he pr o p er op e rati o n of t h e wa t e r

heater and your safety. READ THE ENTIRE MANUAL

BEFORE ATTEMPTIN G TO INSTAL L O R OPERATE THE

WATER HEATER.

Gen era l outl i ne dia gra ms are in th i s m anu a l. Th e se

diagrams will serve to provide the installer with a reference

for basic installation of this product. IT IS NECESSARY

TH AT A LL THE ELECTRICAL WIR IN G BE I NS TAL LE D

AND CONNECTED AS SHOWN IN THE DIAGRAMS.

Be sur e to tu rn off po w er whe n wo rki ng o n or ne ar

the electrical system of the water heater. Never touch

electrica l c omponents wi th we t hands or when standing

in water. When replacing fuses always use the correct

size for the circuit. Use same size and type of fuse

when replacing.

2. T he in st all at ion must con for m with th ese instru ction s

and t he lo cal c od e authorit y having jurisd ic tion and t he

requirements of the power company. In the absence of

code requiremen ts, foll ow NFPA-70 (curre nt edition). The

National Electrical Code may be ordered from: National

Fire Protection Association, 1 Batterymarch Park, Quincy,

MA 02269.

3. If a fter readi ng th is manual you have any que stions or do

not underst and an y portion of the i nstructi ons, call the toll

free num be r on th e back co ver for further a ssistance .

4. Installation and service of this water heater requires ability

equivalent to that of a lic en sed trade sm an or quali fi ed

age ncy (pag e 2) i n t he fie ld in v ol v ed . Plum bin g a nd

electrical work are required.

5. Massachusetts Code requires this water heater to be

in stall ed in a cc ordan ce with M assac hu setts 248 -CMR

2.00: State Plumbing Code and 248-CMR 5.00.

4

Page 5

ELECTRICAL DATA

GENERAL

Check the water heater model and rating plate information against

the characteristics of the branch circuit electrical supply. Do not

connect the heater to an improper source of electricity.

Voltage applied to the water heater should not vary more than +5% to

-10% of the model and rating plate marking for satisfactory operation.

Do NOT energize the branch circuit for any reason before the water

heater tank is lled with water. Doing so may cause the heating

elements to fail.

The installation must conform to these instructions and the local

code authority having jurisdiction. Grounding and electrical wiring

connected to the water heater must also conform to the National

Electrical Code, NFPA 70. This publication is available from The

National Fire Protection Association, 1 Batterymarch Park, Quincy,

MA 02269.

BRANCH CIRCUIT

The branch circuit wire size should be established through reference

to the NEC (National Electrical Code) or other locally approved

sources in conjunction with the water heater amperage rating.. Wire

rated at 75°C should be used. For convenience, portions of the wire

size tables from the Code are reproduced in Table 1 on page 9. It

is suggested the electrician size the branch circuit at 125 percent

of the heater rating and further increase wire size as necessary to

compensate for voltage drop in long runs. Voltage drop should not

exceed 3% at the water heater.

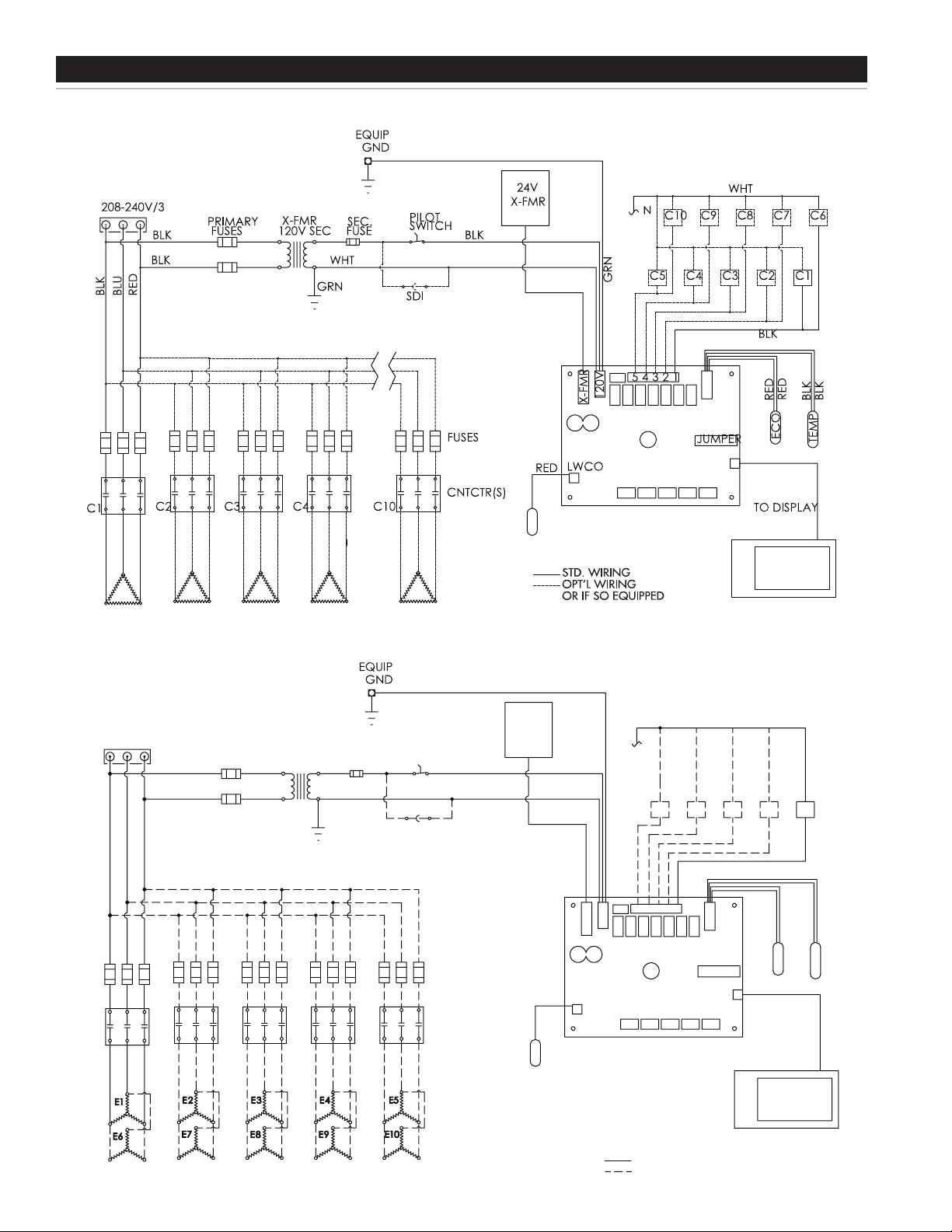

HEATER CIRCUITS

The water heater’s electrical components are pictured and identied

in the Features and Components illustrations in Diagrams 1 and 2.

The model and rating plate provides heater circuit ratings. There are

two main electrical circuits:

Control Circuit: Power supply for the electromagnetic

contactor co ils. 12 0V powe r is supplied to the contac tor coi ls

by the CCB (Central Control Board) see wiring diagrams in

this manual.

Power Circuit: High voltage, single or three phase, circuit that

carries the heating element load.

The following section and pages describe the water heater circuits

and includes wiring diagrams.

CONTROL CIRCUITS

The water heater is equipped with an electronic control system. The

system includes a CCB (Central Control Board) circuit board, an

immersion temperature probe with ECO for temperature sensing and

limiting, a UIM (User Interface Module) for user interface & information

display and element current sensors for monitoring the power circuits.

Refer to the control circuit label on the water heater for details. The

CCB is powered by a small 120V/24V transformer. The control circuit

operates on 120V supplied by a larger 100VA transformer.

Sequence of Operation

1. When the control is powered, the UIM should display model

information, water temperature, operating setpoint, heating

status and operating mode.

2. If the control determines that the actual water temperature inside

the tank is below the programmed operating setpoint minus the

(1st) differential setpoint, a call for heat is activated.

3. After all safety checks are veried the CCB will energize the

contactor coil(s). On models with more than one heating

element the upper most heating elements are energized rst.

Successive heating elements are energized according to

programmed differential setpoints for each heating element.

4. The control remains in the heating mode until the water

temperature reaches the programmed operating setpoint. At

this point the contactors will be de-energized.

5. The control system now enters the standby operating mode

while continuing to monitor the water temperature and the state

of other system devices. If the water temperature drops below

the programmed Operating Setpoint minus the (1st) differential

setpoint, the control will automatically return to step 2 and repeat

the heating cycle.

POWER CIRCUIT

Power circuit wiring is type THHN (or equivalent) rated 600 volts,

105°C, sized as necessary.

The following wiring diagrams on page 6 are included in this manual

to show typical arrangements of electrical components in the control

and power circuits by voltage and phase characteristics. They are to

be used as a reference by the installer or servicer in performing their

work. An actual diagram of the water heater wiring is furnished with

the water heater.

5

Page 6

WIRING DIAGRAMSWIRING DIAGRAMS

300-600V/3

BLK

BLK WHT

WHT

C5 C4 C3 C2 C1

C5C4C3C2C1

N

GRN

GRN

BLK

BLK

X-FMR

ECO

TEMP

120V

BLK

BLU

RED

RED

RED

RED

SDI

24V

X-FMR

PRIMARY

FUSES

X-FMR

12 0V SEC

SEC.

FUSE

PILOT

SWITCH

BLK

BLK

JUMPER

TO DISPLAY

LWCO

54321

FUSES

CNTCTR(S)

ELEMENT ORDER = E1 THROUGH E10

STD. WIRING

OPT’L WIRING

OR IF SO EQUIPPED

DIAGRAM 1. LARGE COMMERCIAL WIRE DIAGRAM 208-240V / 3PH

DIAGRAM 2. LARGE COMMERCIAL WIRE DIAGRAM 300-600V/3PH

6

Page 7

DANGER

Water temperature over 125°F (52°C)

can cause severe burns instantly

resulting in severe injury or death.

Children, the elderly and the physically

or mentally disabled are at highest risk

for scald injury.

Feel water before bathing or showering.

Te mperature limiting devices such as

mixing valves must be installed when

required by codes and to ensure safe

temperatures at fixtures.

Water Te mperature

Time to Produce 2nd & 3rd

Degree Burns on Adult Skin

180°F (82°C) Nearly instantaneous

170°F (77°C) Nearly instantaneous

160°F (71°C) About 1/2 second

150°F (66°C) About 1-1/2 seconds

140°F (60°C) Less than 5 seconds

130°F (54°C) About 30 seconds

120°F (49°C) More than 5 minutes

TEMPERATURE REGULATION

HIGH TEMPERATURE LIMIT CONTROLS (ECO)

This water heater is equipped with an ECO (energy cut off). This

switch is adjustable, up to 190 degree F. An ECO is a normally

closed switch that opens (activates) on a rise in temperature. If the

ECO switch contacts open (activate) due to abnormally high water

temperatures the control system will lock-out and disable further

heating element operation. It is important that a qualied service

agent be contacted to determine the reason for the ECO activation

before resetting the ECO. Once the reason has been determined

and corrected the ECO can be reset as follows:

When the ECO switch contacts open (activate) the electronic control

system locks out and displays a Fault message. Voltage to the

contactor coils and heating elements is terminated to prevent further

heating operation. Should the ECO activate, the water temperature

must drop below 120°F/49°C before the control system can be reset.

Once the water temperature has cooled below this point the power

supply to the water heater must be turned off and on again to reset

the control system.

MIXING VALVES

Water heated to a temperature which will satisfy clothes washing,

dish washing, and other sanitizing needs can scald and cause

permanent injury upon contact. Short repeated heating cycles

caused by small hot water uses can cause temperatures at the

point of use to exceed the water heater’s temperature setting by

up to 20°F (11°C).

Some people are more likely to be permanently injured by hot water

than others. These include the elderly, children, the infirm and the

physically/mentally disabled. Figure 1 shows the approximate time-

to-burn relationship for normal adult skin. If anyone using hot water

provided by the water heater being installed fits into one of these

groups or if there is a local code or state law requiring a certain

water temperature at the point of use, then special precautions

must be taken.

THERMOSTAT CONTROLS

The water heaters covered in this instruction manual are equipped

with adjustable thermostat controls to control water temperature. Hot

water temperatures required for automatic dishwasher and laundry

use can cause scald burns resulting in serious personal injury and/

or death. The temperature at which injury occurs varies with the

person’s age and duration of exposure. The slower response time

of children, the elderly or disabled persons increases the hazards to

them. Never allow small children to use a hot water tap or draw their

own bath water. Never leave a child or disabled person unattended in

a bathtub or shower. The water heater should be located in an area

where the general public does not have access to set temperatures.

Setting the water heater temperatures at 120°F will reduce the

risk of scalds. Some States require settings at specic lower

temperatures.

See Figure 1 which shows the approximate time-to-burn relationship

for normal adult skin.

In addition to using the lowest possible temperature setting that

satises the demand of the application a Mixing Valve should be

installed at the water heater (see Figure 2) or at the hot water taps

to further reduce system water temperature.

Mixing valves are available at plumbing supply stores. Consult a

Qualied Installer or Service Agency. Follow mixing valve manufacturer’s

instructions for installation of the valves.

FIGURE 1.

7

Page 8

HOT WATER

OUTLET

TO TANK

INLET

CHECK

VALV E

MIXING

VALV E

COLD

WATER

INLET

TEMPERED WATER

OUTLET

12” TO 15”

(30-38 cm)

CHECK

VALV E

FIGURE 1.

TEMPERATURE ADJUSTMENT

TEMPERATURE REGULATION

temperature from a factory installed immersion temperature

probe. The “Operating Set Point” is adjusted to control water

temperature. This is an adjustable user setting in the control

system’s “Temperatures Menu.” This and all control system

menus are accessed through the UIM (User Interface Module

located on the front panel of the water heater.

The Operating Set Point is adjustable from 90°F/42 °C to

190°F/88°C. The factory setting is 120°F/49°C. See the Control

System Operation sec tion of this manual for instructions on how

to adjust the Operating Set Point and other user settings.

Set the Operating Set Point at the lowest setting which produces

an acceptable hot water supply. This will always give the most

energy efficient operation.

The water heaters covered in this instruction manual are equipped

with an electronic control system. The control system senses

8

Page 9

CONTROL SYSTEM OPERATION

HEATING ELEMENT OPERATION

ProgressiveSequencing: Elements are energized and de-energized

according to adjustable (1 to 20°F) Differential set points for each element.

Element Rotation - rst element on is rotated with each successive call

for heat. First On/First Off - the rst heating element energized at the

beginning of a heating cycle is the rst element de-energized at the

end of the heating cycle. Successive heating cycles would progress as

follows on a model equipped with 3 heating elements:

• First heating cycle: Elements come on [1, 2, 3] and cycle off [1, 2, 3].

• Second heating cycle: Elements come on [2, 3, 1] and cycle off [2, 3, 1].

• Third heating cycle: Elements come on: [3, 1, 2] and cycle off [3, 1, 2].

• Fourth heating cycle: pattern repeats - same as rst.

CONTROL SYSTEM FEATURES

Advanced Diagnostics

Plain English text and animated icons display detailed operational

and diagnostic information. LCD screen on the front of the water

heater displays the Sequence of Operation in real time. Fault or

Alert messages are displayed when operational problems occur.

Advanced Service menu displays a list of possible causes for current

Fault and Alert conditions to aid in servicing.

Economy Mode Operation

Control system automatically lowers the Operating Set Point by a

programmed value during user dened time periods. Helps reduce

operating costs during unoccupied or peak demand periods.

appears on the LCD screen above an Operational Button there is no

function assigned.

THE DESKTOP SCREEN

The illustration below shows the control system “Desktop Screen.”

This is the default screen. If there are no active Fault or Alert

conditions and no user input for approximately 10 minutes the control

system will return to this screen automatically.

ModelInformation: Model information and menu titles are shown in

the black bar at the top of the Desktop Screen.

TankTemperature: Current water temperature as sensed from the

immersion Temperature Probe.

OperatingSetPoint: Temperature at which the control system will

maintain tank (water) temperature in the Normal Mode. This line of

text will read Economy Set Point whenever the control system is

operating in the Economy Mode.

Status: The Operating State of the control system is displayed

beneath the Operating Set Point.

CONTROL SYSTEM NAVIGATION

The UIM (User Interface Module) is located on the front cabinet of the water

heater. All operational information and user settings are displayed and

accessed using the UIM. The UIM includes ve snap acting (momentary)

user input buttons; an Up, Down and 3 Operational Buttons.

Up & Down Buttons

Used to navigate (up and down) and to select (highlight) menu items.

Also used to adjust or change (increase/decrease, on/off, set time)

various user settings.

Operational Buttons

The 3 Operational Buttons are multifunctional. Their current function

is dened by the text that appears directly above each button on

the LCD screen. The function will change depending on what menu

is currently displayed or what menu item is selected. When no text

Menu: The left Operational Button is pressed to enter the Main Menu

where all control system menus are accessed. See Table 3 on page

10 for a list of control system menus.

Help: The right Operational Button is pressed to access instructions

and explanations for user settings, Operating States, Status Icons,

manufacturer’s web address, technical support phone number and

service agent contact information.

Day/Time/Operating Mode: The current time and day are also

displayed on the Desktop Screen. “Clock Not Set” will be displayed

until the time clock has been initially set. Day and Time are adjusted

in the Economy Mode Setup menu. The current Operating Mode,

either Normal Mode or Economy Mode, is displayed beneath the

day and time.

Discreet Menu Contact Information: From the Desktop Screen

press and hold down the middle (unmarked) Operational Button for

30 seconds and then release it. This will launch a discreet menu

where personalized contact information can be entered. Installing

contractors and/or service agents can enter their company name

and telephone number. This contact information will be displayed

with all Fault and Alert messages.

9

Page 10

TABLE 1 - STATUS ICONS

ICON DESCRIPTION

Water temperature in the tank has fallen. Shaded area of the animated thermometer icon will rise and fall in response to

water temperature in the storage tank as sensed from the immersion Temperature Probe.

Water temperature in the tank has reached the Operating Set Point. Shaded area of the animated thermometer icon will rise

and fall in response to water temperature in the storage tank as sensed from the immersion Temperature Probe.

The control is unable to initiate a heating cycle. This will happen whenever a Fault condition is detected by the control system

or when either of the two Enable/Disable circuits are open circuits.

The control system is in Heating Mode and has energized the electromagnetic contactor coils for at least one heating

element. This animated icon DOES NOT indicate current has been sensed from the heating elements, only that there is a

call for heat present and the control system has initiated heating element operation.

The control has detected/declared a Fault Condition. Fault message details can be viewed in the Current Fault menu.

Heating operation is discontinued (locked out) until the condition that caused the fault is corrected. Power to the water heater

must be cycled off and on to reset the control system. Note; cycling power will not reset the control system if the condition

that caused the fault has not been corrected.

The control has detected/declared an Alert Condition. The water heater will continue to operate during an Alert Condition but

there is an operational condition that requires the attention of a Qualied Service Agent. Alert message details can be viewed

in the Current Alert menu.

TABLE 2 - OPERATING STATES

STATE DESCRIPTION

Standby

Heating The control system is in the Heating Mode. At least one heating element has been energized.

Alert

Fault

The water heater is not in an active heating cycle. This usually indicates the temperature in the tank has reached the

Operating Set Point and the control system has terminated the heating cycle.

The control system has detected/declared an Alert Condition. The controls system will continue heating operation.

However, a Qualied Service Agent should be contacted to check/service the water heater.

The control system has detected/declared a Fault Condition. The control system will discontinue heating operation and

“lock out.” Power to the water heater must be cycled off and on to reset the control system. Note; cycling power will not

reset the control system until the condition that caused the fault has been corrected.

10

Page 11

TABLE 3 - CONTROL SYSTEM MENUS

MENUS DESCRIPTION

Temperatures

Heater Status

Economy Mode Setup

Alarm Output Setup

Display Settings

Heater Information

Current Fault/Alert

Most commonly accessed menu. Operating Set Point, Differential settings, Tank Temperature and Tank Probe

Offset are located in this menu.

Current Operating State/Mode (heating/standby etc) and status (open/closed - on/off - yes/no) of monitored

water heater functions and components are displayed in this menu.

Seven day 24 hour time clock with temperature set back capability to reduce operating costs during unoccupied

or reduced demand periods.

The control system’s CCB (Central Control Board - see wiring diagrams) features on board SPDT (single pole

double throw) relay contacts for building EMS (Energy Management System) notication of operational conditions

such as Fault Conditions and heating mode status. This menu features a list of user denable conditions for

relay activation.

Temperature units (°F or °C), appearance (brightness contrast) and backlight delay user adjustable settings are

located in this menu.

Elapsed time of operation, total heating cycle time, heating cycle count, heating element(s) cycle count and on

time along with UIM and CCB software revisions can be viewed in this menu.

Displays any current Alert or Fault messages.

Fault History

Fault Occurrence

Restore Factory Defaults

Help Menu

Retains 9 event history of Fault/Alert messages with time stamp. The Fault History is useful when dealing with

intermittent operational problems or when the customer has reset the control system prior to a service agent’s

arrival.

Total accumulated number each individual Fault condition has occurred is displayed in this menu. This

running total of Fault Occurrences can be useful in determining which (if any) operational problems have been

persistent.

This control system feature allows the user to restore control system user settings to their factory default settings.

Alarm Output Setup and Display Settings menu items ARE NOT changed when factory defaults are restored.

Accessible by pressing the corresponding Operational Button from most menus and screen displays. This menu

provides access to instructions and explanations for user settings, Operating States, Status Icons, manufacturer’s

web address, technical support phone number and service agent contact information.

11

Page 12

TEMPERATURES MENU

Operating Sequence

Operating Set Point

User adjustable setting 90°F to 190°F range; factory default is

120°F. When the water temperature sensed by the control system

from the immersion Temperature Probe reaches the Operating Set

Point the control system will end the heating cycle. A call for heat

will be activated again when the water temperature drops below the

Operating Set Point minus the 1st Differential Setting.

Example: Operating Set Point is 120°F, the 1st Differential Setting is

2°F (factory default). A call for heat will be activated when the sensed

water temperature drops to 118°F.

Differential Settings

On a water heater equipped with 3 heating elements, with an

Operating Set Point of 120°F and all Differential settings at 2°F the

On/Off sequencing of heating elements would be as follows:

ELEMENT

NUMBER

Element 1 2°F 118°F 120°F

Element 2 2°F 116°F 118°F

Element 3 2°F 114°F 116°F

DIFFERENTIAL

SETTING

TURN ON TEMP TURN OFF TEMP

TABLE 4.

Tank Temperature

Non adjustable information display. Current water temperature as

sensed by the control system from immersion Temperature Probe.

Tank Probe Offset

User adjustable setting -5°F to +5°F range; factory default is 0°F.

If the current Tank Temperature is sensed (from the immersion

Temperature Probe) at 120°F and the offset is adjusted to -5°F the

control system would calibrate or “offset” the Tank Temperature to

115°F. Heating cycles would then start/stop based on the calibrated

Tank Temperature.

Adjustable user setting(s) 1°F to 20° range; factory default is 2°F.

The water heaters covered in this manual will have between 1

and 5 heating elements. There is at least one Differential Setting

on all models. There will be additional Differential Settings for each

additional heating element installed.

Used to calibrate for slight differences in control system temperature

sensing. This can improve the precision of temperature control in storage

tank and at points of use. This feature can also be used to compensate

for building recirculation loops (hot water returning to storage tank) that

may cause the heating cycle to terminate prematurely.

12

Page 13

Temperature Settings

The Operating Set Point and the Differential Settings are adjusted in the Temperatures Menu. The following instructions explain how to adjust

these user settings and navigate the control system menus.

ACTION DISPLAY

From the Desktop Screen, press the Operational Button underneath

“MENU” to enter the Main Menu.

Notice how the text above the Operational Buttons on the display

changes as you navigate through the various menus and screens.

With Temperatures selected (highlight in black) in the Main Menu,

press the Operational Button underneath “SELECT” to enter the

Temperature Menu.

If Temperatures is not selected use the Up and Down buttons to select

this menu item.

With the Operating Set Point selected (highlighted in black) in the

Temperatures Menu, press the Operational Button underneath

“CHANGE” to activate the adjustment mode for this menu item.

Press the Up and Down buttons to adjust the Operating Set Point to

the desired setting.

Press the Operational Button underneath “UPDATE” to conrm the new

setting. Press the Operational Button underneath “CANCEL” to discard

the new setting and retain the previous setting.

The new Operating Set Point value should now be displayed as the

current value.

NOTE: Use this same procedure to adjust the Differential settings and

the Tank Probe Offset in the Temperatures Menu.

This same procedure is used to change user settings in other control

system menus.

13

Page 14

WATER HEATER STATUS MENU

Element # On

This menu displays non adjustable operational information. Use the

Up & Down Buttons to navigate to the bottom of this menu.

Top of Menu

Bottom of Menu

Displays the on/off status of each heating element. Yes = On, No =

Off.

Tank Full

Displays the status of the optional LWCO (Low Water Cut Off) device.

Yes = water level is acceptable, No = water level is low.

Alarm Condition

Displays the status of the user denable Alarm Output function - see

Alarm Output Setup Menu. Yes = alarm condition has been met, No

= alarm condition has not been met.

Alarm Relay Output

Displays the state of the normally open contacts of the Alarm

Output relay. This relay (J3 contacts on the CCB - see wiring

diagrams) is used for building EMS (Energy Management

System) notification of operational conditions such as Fault

conditions.

ECONOMY MODE SETUP MENU

This menu contains settings used to establish an “Economy Set

Point” and “Economy Mode” operating periods. This control system

feature can help reduce operating costs during unoccupied, low load,

or peak demand periods.

Status

Displays the current Operating State of the control system. IE:

Heating, Standby, Fault.

Elements On #

Displays the number of heating elements the control system has

energized.

ECO Contact

Displays the current state of the ECO high temperature limit switch

contacts.

Enable / Disable 1 & 2

Displays the current state, open or closed, of the two Enable/Disable

circuits (J7 socket on the CCB - see wiring diagrams on page 6)

provided for external supervisory controls such as building EMS

(Energy Management System). Both of these Enable/Disable circuits

must be closed to “enable” heating operation. If either Enable/Disable

circuit is open for any reason heating operation will be “disabled.”

There is a plug with two jumper wires installed from the factory in the

CCB J7 socket to enable heating operation when external controls

are not in use.

Desktop Screen During Economy Mode

Economy Mode Setup Menu

ServiceNote: If a supervisory control(s) is used to enable/disable

heating operation, install eld wiring between the J7 socket on

the CCB and a set of “dry contacts” on the external control per all

applicable building codes. This is a switching circuit only: DO NOT

apply any external voltage or connect any load (IE: relay coil) to

either circuit.

Setpoint Adjustment

Adjustable user setting (2°F to 50°F - factory default is

20°F) the control system uses to calculate the “Economy

Se t Poi nt .” The Economy Set Point = no rm al Op er at in g S et

Po in t minus t he p ro gr ammed Setpoin t A djustment value .

14

Page 15

The Economy Set Point is the water temperature the control

sy st em ma in ta ins d ur ing p ro grammed Economy Mode

time periods. “Economy Set Point” is displayed instead of

“Operating Set Point” and “Economy Mode” appears beneath

th e c urrent time on t he De sktop Screen du ri ng Economy

Mode time periods.

Current Time

Seven Day 24 hr clock. Use this menu item to set the current time

and day of the week. Current day and time are not set from the

factory. “Clock Not Set” will be displayed on the Desktop until the

time/day has been initially set. Note: the time will not self adjust for

Daylight Savings time.

Heater In Economy Mode

Displays whether the control system is currently operating in

Economy Mode or not.

Daily Operating Mode (Sun - Mon - Tue - Wed - Thu - Fri - Sat)

Seven daily sub menus are listed at the bottom of the Economy

Mode Setup menu. There are 3 Operating Modes in each sub menu;

“Normal Operation All Day” - “Economy Mode All Day” and “Normal

Operation Between.” Only one Operating Mode can be active, the

factory default is Normal Operation All Day.

NormalOperationAllDay: When this operating mode is active the

normal Operating Set Point is used for the entire day.

EconomyModeAll Day: When this operating mode is active the

Economy Set Point is used for the entire day.

Normal Operation Between: When this operating mode is active

there will also be start and stop times to program. The normal

Operating Set Point is used between the programmed start and stop

times and the Economy Set Point will be in effect during the rest of

the day. There is one start time and one stop time event per day.

15

Page 16

ECONOMY MODE SETTINGS

Setpoint Adjustment Value

ACTION DISPLAY

From the Desktop screen, press the Operational Button underneath

“MENU” to enter the Main Menu.

Notice how the text above the Operational Buttons on the display

changes as you navigate through the various menus and screens.

Use the Up/Down buttons to select (highlight in black) the Economy

Mode Setup menu from the Main Menu. Press the Operational Button

underneath “SELECT” to enter the Economy Mode Setup menu.

Use the Up/Down buttons to select (highlight in black) Setpoint

Adjustment. Press the Operational Button underneath “CHANGE” to

activate the adjustment mode for the Setpoint Adjustment value.

Use the Up/Down buttons to change the Setpoint Adjustment to the

desired value. The Setpoint Adjustment value is adjustable from 2°F to

50°F. The factory default is 20°F.

Notice how the text above the Operational Buttons on the display changes

to “UPDATE” & “CANCEL” when the adjustment mode is activated and

how the current value is outlined rather than highlighted in black.

Press the Operational Button underneath “UPDATE” to enter and conrm

the new value. Pressing the Operational Button underneath “CANCEL”

would discard the new value and retain the previous value.

The new Setpoint Adjustment value should now be displayed as the

current value.

16

Page 17

ECONOMY MODE SETTINGS

Time Clock Settings

ACTION DISPLAY

From the Desktop Screen navigate to the Economy Mode Setup menu.

Use the Up/Down buttons to select (highlight in black) Current Time sub

menu. Press the Operational Button underneath “CHANGE” to enter the

Current Time sub menu.

Use the Up/Down buttons to select the “Weekday” setting.

Press the Operational Button underneath “CHANGE” to activate the

adjustment mode for this setting.

Press the Up/Down buttons to adjust the Weekday setting to the current

day.

Notice how the text above the Operational Buttons on the display changes

to “ACCEPT” & “CANCEL” when the adjustment mode is activated and

how the current setting is outlined rather than highlighted in black.

Press the Operational Button underneath “ACCEPT” to enter and conrm

the new setting. Pressing the Operational Button underneath “CANCEL”

would discard the new setting and retain the previous setting.

Use the Up/Down and the CHANGE/ACCEPT Operational Buttons to

individually select and change the remaining time settings (Hour, Minutes,

AM/PM) to the current time in the same way as outlined above.

When nished making changes press the Operational Button underneath

“BACK” to conrm all new settings and update the control system. The

display will automatically return to the Economy Mode Setup menu.

The new settings should be displayed as the Current Time.

17

Page 18

ECONOMY MODE SETTINGS

Daily Operating Mode Settings

ACTION DISPLAY

Economy Mode All Day:

From the Economy Mode Setup menu use the Up/Down buttons to

select (highlight in black) the Daily sub menu for “Sun.” Press the

Operational Button underneath “CHANGE” to enter this menu.

Use the Up/Down buttons to select (highlight in black) the “Economy

Mode All Day” setting.

Press the Operational Button underneath “SELECT” to change from

the factory default Normal Operation All Day setting to the Economy

Mode All Day setting.

Press the Operational Button underneath “BACK” to conrm the

new setting and update the control system. You will be returned to

the Economy Mode Setup menu. The new setting should now be

displayed for Sun.

Normal Operation Between:

From the Economy Mode Setup menu Use the Up/Down and

CHANGE buttons to enter the Mon sub menu as described above.

Use the Up/Down buttons to select (highlight in black) the “Normal

Operation Between” setting. Press the Operational Button

underneath “SELECT” to change the operating mode for Monday to

Normal Operation Between. Note that when this setting is selected

Start and Stop time user settings appear on the display.

Use the Up/Down buttons to navigate between the Start and Stop

time Hour, Minutes and AM/PM settings.

With each item selected press the Operational Button underneath

“CHANGE” to activate the adjustment mode for each setting. Use

the Up/Down buttons to change the value to the desired setting.

Press the Operational Button underneath “ACCEPT” to enter the

new setting or “CANCEL” to discard the new setting and retain the

previous setting.

Press the Operational Button underneath “BACK” when nished to

conrm the new settings and update the control system. The display

will return to the Economy Mode Setup menu with the new settings

shown for Mon.

18

Page 19

ALARM OUTPUT SETUP MENU

Alarm Output Settings

Permits user to set the condition (from a list of options) for when

the CCB’s integral alarm output relay will be energized. Alarm relay

connections (common, normally open, normally closed) are located on

the J3 terminal strip on the CCB - see wiring diagrams. Alarm output

relay contacts are capable of switching 1 amp maximum at 120 VAC.

Changing the user settings in this menu is done using the same

methods for changing the Operating Set Point.

ServiceNote: Adjustable user settings in the Alarm Output Setup

menu are unaffected by Restore Factory Defaults.

DISPLAY SETTINGS MENU

Permits user to set display options for viewing information on the

UIM’s LCD screen.

Temperature Units

Adjustable user setting that changes temperature units display to

Celsius °C or Fahrenheit °F.

The alarm relay operates in the background according to the settings

in this menu and is not capable of disabling water heater operation.

The alarm relay is used for external notication/verication of

various operational conditions such as fault conditions and heating

mode status. This relay can be used with building EMS (Energy

Management System) and other external supervisory controls.

Output Function

Adjustable user setting. Available options for the Alarm Output

Function setting are:

HeatingMode: Used for heating mode on/off status notication.

Enable/DisableClosed: Used for notication and/or verication of

the enable/disable circuits open/closed status. There are two enable/

disable circuits available for external supervisory control(s) at the J7

socket on the CCB - see wiring diagrams on page 6. Enable/disable

circuit(s) status can be viewed in the Heater Status Menu.

Temp<HeaterSP: Used for external notication when current tank

temperature drops below Operating Set Point.

Temp<AlarmSP: Used for external notication when current tank

temperature drops below programmable Alarm SP.

Fault or Alert: Used for external notication whenever a Fault or

Alert condition is active.

Backlight Delay

Adjustable user setting that determines how long the UIM’s LCD

backlight remains illuminated after a key has been pressed. Available

settings are; Always Off, 10, 30 or 60 seconds and Always On.

Contrast

Adjustable user setting to adjust the UIM’s LCD screen contrast

between text and background.

Display Settings

Changing the user settings in this menu is done using the same

methods for changing the Operating Set Point.

ServiceNote: Adjustable user settings in the Display Settings menu

are unaffected by Restore Factory Defaults.

HEATER INFORMATION MENU

This menu displays non adjustable operational information.

Top of Menu

Fault: Used for notication whenever a Fault condition is active.

Disabled: Disables the Alarm Relay Output Function.

Alarm SP

Adjustable user setting (90°F to 190°F) the control system uses for

the “Temp < Alarm SP” function described above. This setting has no

effect with any other Alarm Output functions.

19

Page 20

Bottom of Menu

messages in chronological order in this menu. The most recent

will be at the top of the list. A time stamp is displayed below each

listed Fault and Alert message showing when the Fault or Alert

condition occurred.

The Fault History is useful when dealing with intermittent operational

problems or when the customer has reset the control system prior to

a service agent’s arrival.

With a Fault or Alert item selected press the Operational Button

underneath “VIEW” to display the details for the Fault or Alert

message. The Fault/Alert message screen displays a brief description

of the condition, contact information and access to the Advanced

service information sub menu.

Elapsed Time

Total accumulated time the control system (water heater) has been

energized.

Total Heating Time

Total accumulated time the control system has been in the heating

mode. IE: any heating elements have been energized.

Element # Cycles

Total accumulated count of heating cycles for each heating

element.

Element # On Time

Total accumulated heating on time for each heating element.

CCB Version

Software version for Central Control Board.

UIM Version

Software version for User Interface Module

CURRENT FAULT / ALERT MENU

Fault History Menu

Current/History Fault Message

This menu displays non adjustable operational information. With the

Fault History sub menu selected in Main Menu; press the Operational

Button underneath “SELECT” to display the current Fault or Alert

message. If there is not a Fault or Alert condition currently active

“(none)” is displayed to the right of this menu.

Main Menu - Current Fault Selected

FAULT HISTORY MENU

This menu displays non adjustable operational information. The

control system records and stores the last 9 Fault and Alert

FAULT OCCURRENCE MENU

Total accumulated number each individual Fault condition has

occurred is displayed in this menu. This running total of Fault

Occurrences can be useful in determining which (if any) operational

problems have been persistent.

Fault Occurrence Menu

20

Page 21

RESTORE FACTORY DEFAULTS MENU

Th is con tr ol sys te m menu all ows the use r to resto re m os t of the c on trol sys tem’s user settings to their factory default

settings. Us er s et tings in th e Alarm Ou tp ut S etup and Di sp lay Setting s me nus are una ff ec ted by exec ut ing Restore

Factory Defaults.

Restore Factory Defaults

ACTION DISPLAY

From the Main Menu use the Up/Down buttons to select (highlight in

black) the “Restore Factory Defaults” menu.

Press the Operational Button underneath “SELECT.” The Restore

Factory Defaults menu will be displayed.

From the Restore Factory Defaults menu press the Operational Button

underneath “YES.” The display will show text conrming the factory

default settings have been restored.

Press the Operational Button underneath “BACK” to exit the Restore

Factory Defaults menu.

21

Page 22

TROUBLESHOOTING CHECKLIST

Before cal lin g for service, check the followin g points to see if

the cause of trouble can be identified and corrected. Reviewing

th is checklist ma y elimi na te the need o f a s er vi ce call and

quickly restore hot water service.

BE SURE TO TURN OFF THE ELECTRICITY (ELECTRICAL

DISCONNECT SWITCH) WHEN CHECKING EQUIPMENT.

NOT ENOUGH OR NO HOT WATER

1. Be certain the electrical disconnect switch serving the water

heater is in the ON position. The pilot toggle switch on the

cabinet should be ON.

In some areas water heater electrical service may be limited

by the power company. If the heater operates on a controlled

circuit, heater recovery may be affected.

The optional manual override switches on the cabinet front may

be turned off, de-energizing the elements.

2. Check the fuses.

The electrical disconnect switch usually contains fuses.

The water heater has fuses located behind the cabinet front door.

3. If the water was excessively hot, and is now cold, the ECO

high limit switch may have activated.

• See the Temperature Regulation section of this manual

for more information on how to reset the ECO high limit

controls.

Repeated activation of the ECO high limit switch should be

investigated by a Qualified Service Agent.

4. The storage capacity and/or recovery rate of the water heater

may have been exceeded by a large demand for hot water.

Large demands require a recovery period to restore water

temperature.

5. Cold incoming water temperature will lengthen the time required

to heat water to the desired temperature.

If the heater was installed when incoming water temperature was

warm, colder water creates the effect of less hot water.

7. Se dim en t or lim e sc ale may be a ff ectin g wa ter he ate r

operation.

WATER IS TOO HOT

Refer to the TEMPERATURE REGULATION section of this

manual.

WATER HEATER MAKES STRANGE SOUNDS

1. Sediment or lime scale accumulations on the elements causes

sizzling and hissing noises when the heater is operating.

The sounds are normal, however, the tank bottom and elements

should be cleaned.

2. Some of the electrical components of the water heater make

sounds which are normal ie. contactors will “Click” or snap

as the heater starts and stops.

22

Page 23

NOTES

Page 24

500 Tennessee Waltz Parkway, Ashland City, TN 37015

Phone: 800-365-0024 • Parts: 800-433-2545 • Fax: 800-644-9306

www.statewaterheaters.com

Copyright © 2010 A.O. Smith Corporation, All rights reserved.

Loading...

Loading...