Page 1

500 Tennessee Waltz Parkway

Ashland City, TN 37015

Service Handbook

COMMERCIAL GAS WATER HEATERS

FOR MODELS:

SBL95 199NE, SBL85 275NE(A),

SBL85 390NE(A)

ULTRA LOW NOx SERIES 100

INSTALLATION CONSIDERATIONS - PRE SERVICE CHECKS -

CONSTRUCTION - OPERATION & SERVICE - TROUBLESHOOTING

SERVICING SHOULD ONLY BE PERFORMED BY A QUALIFIED SERVICE TECHNICIAN

PRINTED IN THE U.S.A. 0413 324659-001

Page 2

Page 3

TABLE OF CONTENTS

INTRODUCTION ......................................................................2

QUALIFICATIONS .....................................................................2

TOOLS REQUIRED ....................................................................3

INSTALLATION CONSIDERATIONS .......................................................4

GAS AND ELECTRICAL CHARACTERISTICS ...............................................4

GAS PRESSURE – REQUIREMENTS .....................................................4

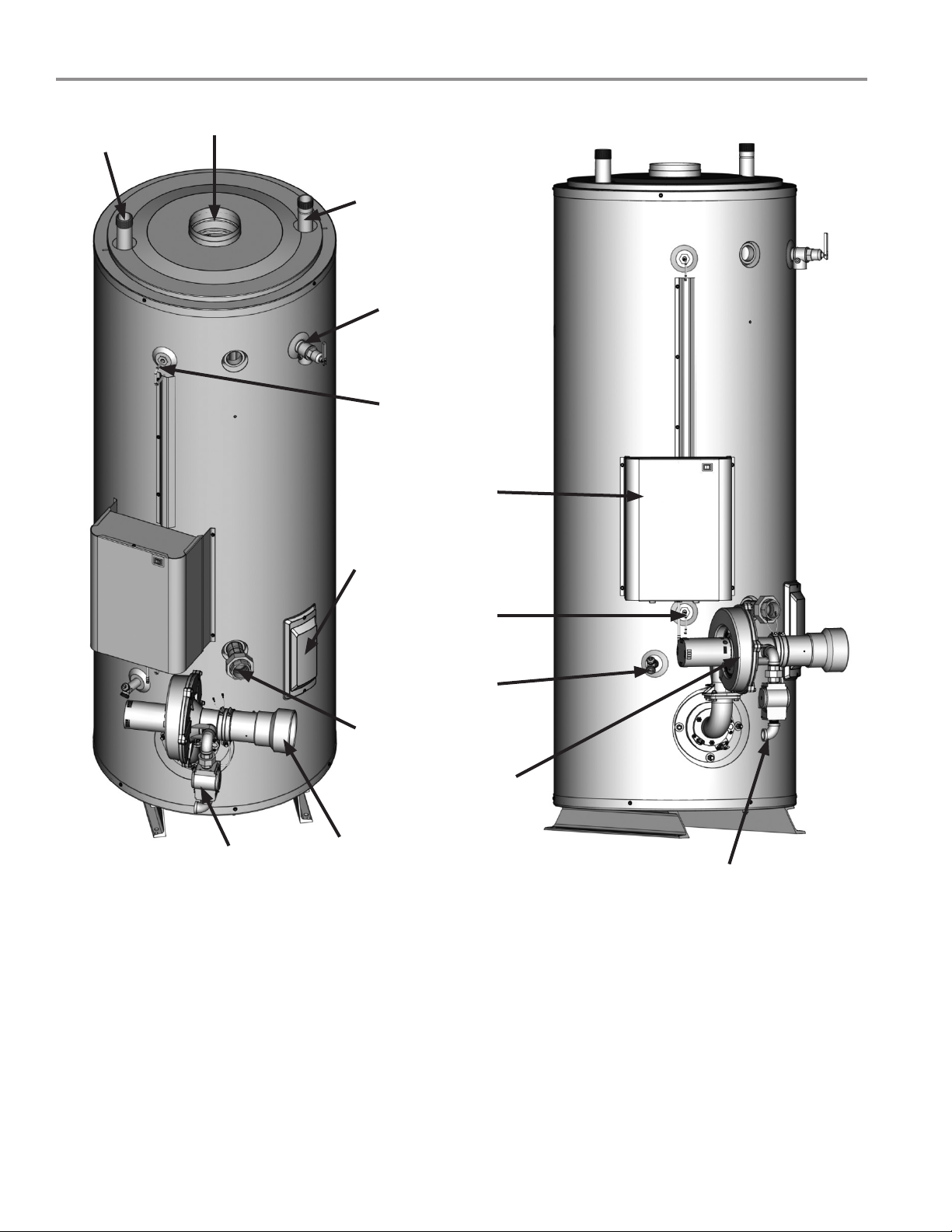

FEATURES AND COMPONENTS – ALL MODELS ............................................8

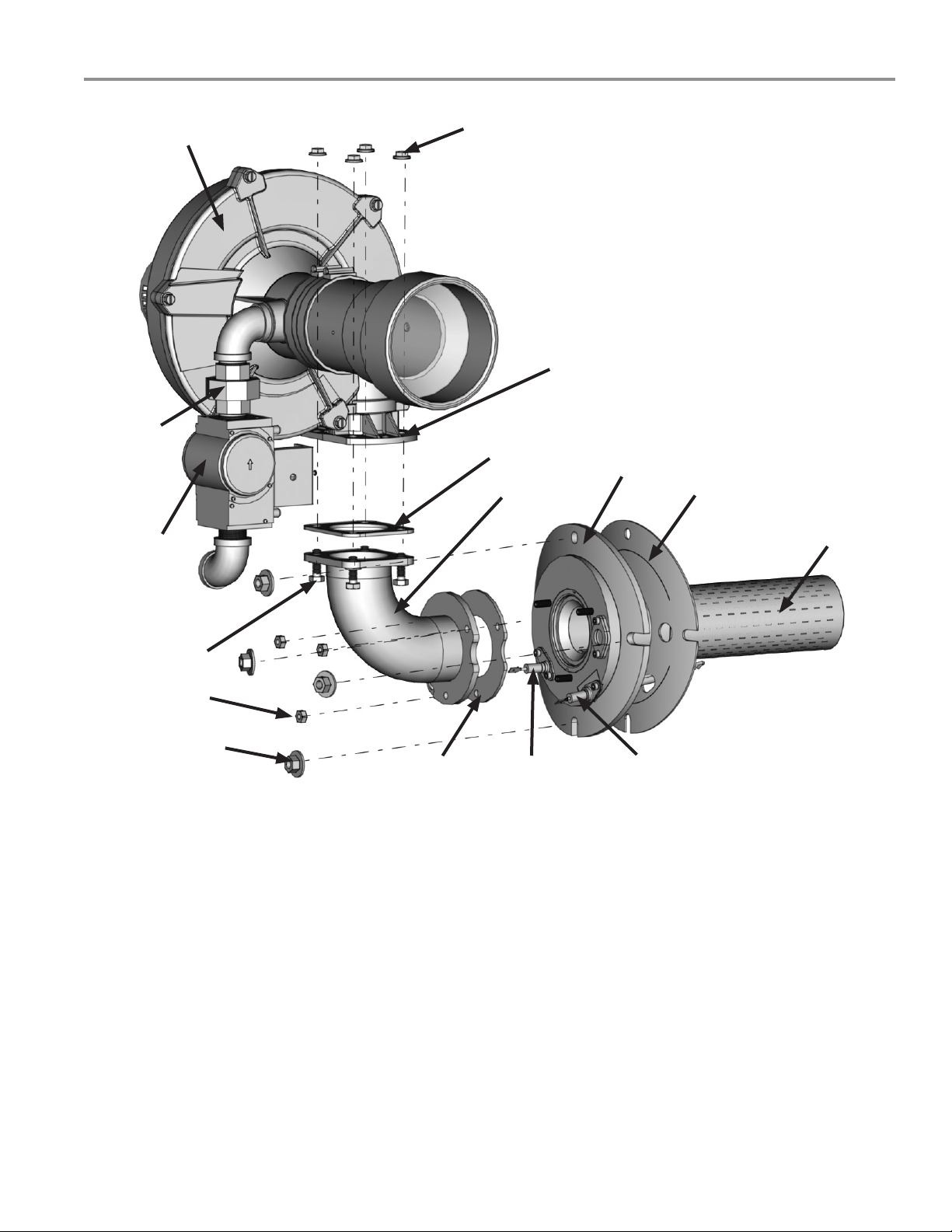

BLOWER AND BURNER ASSEMBLY ......................................................9

SPARK IGNITER, FLAME SENSOR, SIGHT GLASS .........................................11

VENTING ...........................................................................12

VENTING TABLES – TECHNICAL VENTING DATA ..........................................14

OPERATION AND SERVICE ............................................................16

DIAGNOSTIC SEQUENCE OF OPERATION – FLOW CHART .................................17

SEQUENCE OF OPERATION – FLOW CHART .............................................18

LIGHTING AND OPERATING LABEL .....................................................19

TROUBLESHOOTING .................................................................20

CONTROLS OVERVIEW - CONTROL BOX ASSEMBLY ......................................21

PRESSURE SWITCHES – ALL MODELS ..................................................22

HIGH LIMIT SWITCH/ DIGITAL THERMOSTAT .............................................23

CONTINUITY CHECK OF HIGH LIMIT (ECO)...............................................25

UPPER TEMPERATURE PROBE CONTINUITY CHECK ......................................26

LOWER TEMPERATURE PROBE CONTINUITY CHECK .....................................27

IGNITION CONTROL..................................................................28

START UP/ FLAME RECOVERY/ SAFETY LOCKOUT........................................29

VARIABLE FREQUENCY DRIVE – ALL MODELS ...........................................31

CHARACTERISTICS AND FUNCTIONS OF THE CONTROL TERMINALS........................32

VFD – BLOWER SPEED AND FREQUENCY READINGS .....................................32

WIRING DIAGRAM – ALL MODELS.......................................................33

Servicing should only be performed by a Qualied Service Technician

1

Page 4

INTRODUCTION

The service handbook is designed to aid in servicing and troubleshooting State Water Heaters SBL commercial

water heaters in the field. No duplication or reproduction of this book may be made without the express

written authorization of the State Water Heaters.

The following text and illustrations will provide you with a step by step procedure to verify proper installation,

operation, and troubleshooting procedures. Additional quick reference data is included to assist you in

servicing these products.

The information contained in this handbook is designed to answer commonly faced situations encountered

in the operation of this product line and is not meant to be all inclusive. If you are experiencing a problem not

covered in this handbook, please contact State Water Heaters Technical Information at 1-800-365-0024, by

email at help@statewaterheaters.com or your local State Water Heaters representative for further assistance.

Our website at: www.statewaterheaters.com is also a resource for installation and service information. This

handbook is intended for use by licensed plumbing professionals and reference should be made to the

installation manual accompanying the product. This handbook contains supplemental information to the

product’s installation and operation manual.

QUALIFICATIONS

“Qualified Service Technician" or "Qualified Agency”

Installation and service of this water heater requires ability equivalent to that of a Qualified Agency (as defined

by ANSI below) in the field involved. Installation skills such as plumbing, air supply, venting, gas supply and

electrical supply are required in addition to electrical testing skills when performing service.

ANSI Z223.1 Sec. 3.3.85: “Qualified Agency” - “Any individual, firm, corporation or company that either

in person or through a representative is engaged in and is responsible for (1) the installation, testing or

replacement of gas piping or (2) the connection, installation, testing, repair or servicing of appliances and

equipment; that is experienced in such work; that is familiar with all precautions required; and that has

complied with all the requirements of the authority having jurisdiction.”

Service of this water heater requires ability equivalent to that of a Qualified Service Technician in the field

involved. Installation skills such as plumbing, air supply, venting, gas supply, electrical supply are required in

addition to electrical testing skills. Some products may require combustion testing equipment and certification.

If you do not possess these skills or do not have the proper tools you should not attempt to service this water

heater.

SERVICE WARNING

If you are not qualified (as defined by ANSI above) and licensed or certified as required by the authority

having jurisdiction to perform a given task do not attempt to perform any of the procedures described in

this manual. If you do not understand the instructions given in this manual do not attempt to perform any

procedures outlined in this manual.

SERVICE REMINDER

When performing any troubleshooting step outlined in this manual always consider the wiring and connectors

between components. Perform a close visual inspection of all wiring and connectors to and from a given

component before replacement. Ensure wires were stripped before being crimped in a wire connector, ensure

wires are crimped tightly in their connectors, ensure connection pins in sockets and plugs are not damaged

or worn, ensure plugs and sockets are mating properly and providing good contact.

Failure to perform this critical step or failing to perform this step thoroughly often results in needless down

time, unnecessary parts replacement, and customer dissatisfaction.

2

Servicing should only be performed by a Qualied Service Technician

Page 5

TOOLS REQUIRED

• Electrical multimeter capable of measuring continuity/ ohms, ac & dc volts, amperes, microamperes,

millivolts, and frequency (hz)

• UEi Model DL289 or equivalent

• Digital manometer + 60" w. c., resolution 0.01" increments

Note: A digital manometer is required for testing pressure switches and can replace a gas pressure

gauge, draft gauge or slack tube manometer for checking gas pressure.

• UEi model EM200 or equivalent

• Water pressure gauge w/lazy hand and hose bibb connection

• Thermometer

• 1-1/16 Inch socket with extension for anode replacement

• Phillips head screwdriver

• Set of numbered drill bits

• Standard screwdrivers

• 3/8, 7/16, 1/2 and 9/16 inch open end wrench

DIGITAL MANOMETER DIGITAL MULTIMETER

Servicing should only be performed by a Qualied Service Technician

WATER PRESSURE

TEST GAUGE W/LAZY

HAND AND HOSE BIBB

CONNECTION

3

Page 6

INSTALLATION CONSIDERATIONS

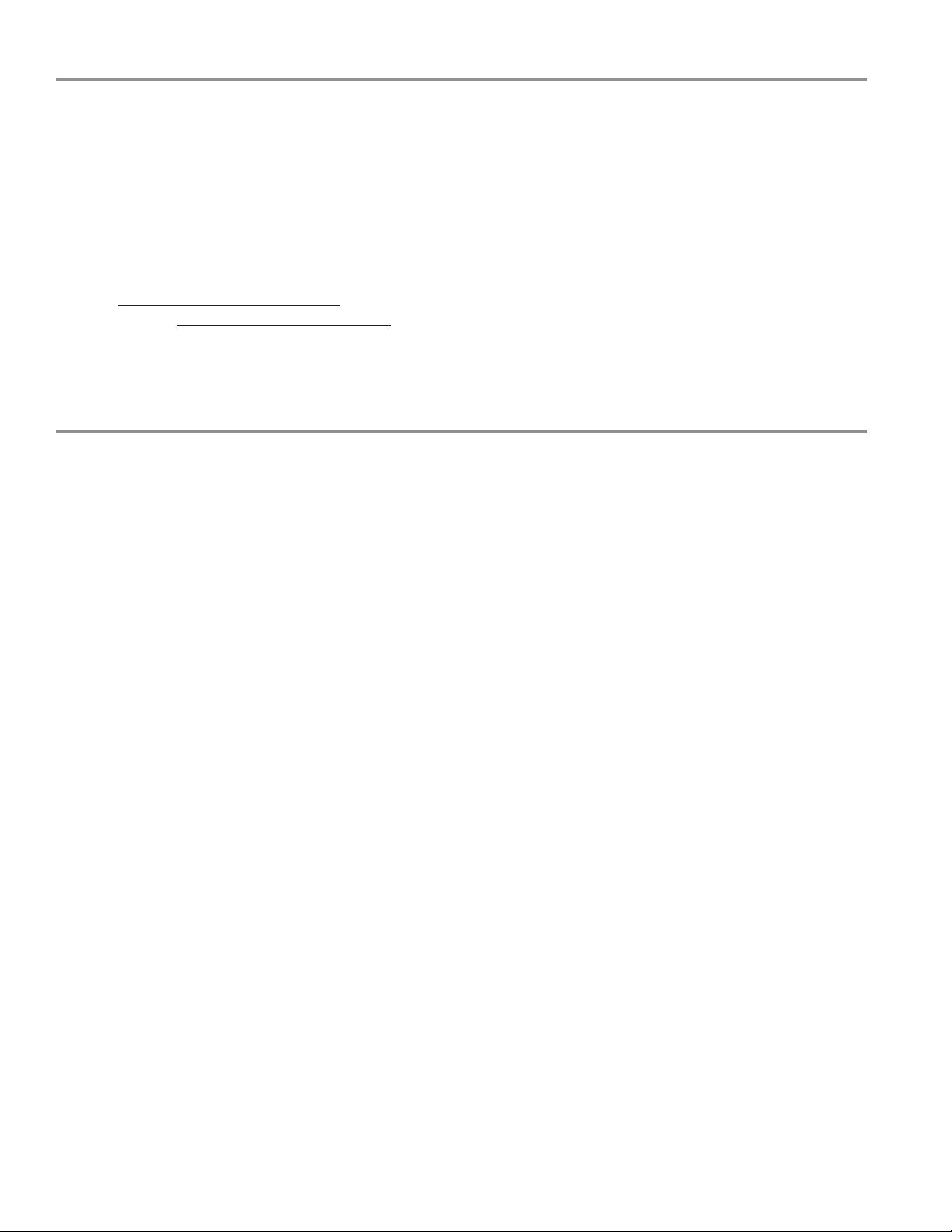

GAS AND ELECTRICAL CHARACTERISTICS

MODELS GAS TYPE

All Models Natural 3.5" WC (0.87 kPa) 14.0" WC (3.45 kPa) 120/60 < 5

All models require a minimum gas supply pressure of 3.5” W.C. The minimum supply pressure is measured

while gas is flowing (dynamic pressure). The supply pressure (dynamic) should never fall below 3.5” W.C.

The supply pressure should be measured with all gas fired appliances connected to the common main firing

at full capacity. If the supply pressure drops more than 1.5” W.C. as gas begins to flow to the water heater

then the supply gas system including the gas line and/or the gas regulator may be restricted or undersized.

The gas valve on all models has a maximum gas supply pressure limit of 14" W.C. The maximum supply

pressure is measured while gas is not flowing (static pressure).

GAS SUPPLY PRESSURE

VOLTS/HZ AMPERES

MINIMUM MAXIMUM

GAS PRESSURE – REQUIREMENTS

Main line gas pressure to the water heater for natural gas should be between a maximum of 14" w.c. (3.45

kPa) static pressure and a minimum of 3.5" w.c. (0.87 kPa) dynamic pressure for Natural Gas.

A supply gas pressure regulator (service regulator) must be installed no closer than 3 feet (1 meter)

and no farther than 8 feet (2.4 meters) of equivalent length from the water heater's inlet gas connection.

1. Check gas line pressure with a manometer.

2. Cycle the burner on and off several times to check its operation.

3. Check the operation of the limit and operating controls.

4. Check the vent system seams and joints and ensure that there is no discharge of flue products into

the room.

5. Check the input rate.

Supply gas pressure shall be measured while the water heater is not firing (static pressure) and while the

water heater is firing at full capacity (dynamic pressure). If the supply gas pressure to the water heater is not

between the required minimum and maximum values given in table above, adjust the supply gas regulator

as necessary. Adjust the supply gas regulator(s) per the regulator manufacturer’s instructions to achieve the

required “static” and “dynamic” supply gas pressure.

MULTIPLE APPLIANCE INSTALLATIONS:

In multiple water heater installations or in installations where the installed water heater(s) share a common

gas supply main with other gas fired appliances; the supply gas pressures shall be measured at each water

heater with all gas fired appliances connected to a common main firing at full capacity.

In multiple water heater installations the supply gas line regulators shall be adjusted to provide gas pressure

to each water heater within the minimum and maximum supply pressure requirements listed in table above

with all gas fired appliances connected to a common gas main firing at full capacity.

Note: A pressure drop of more than 1.5” W. C. (0.37 kPa) when the main burner ignites is an indication of

an inadequate supply of gas and can lead to ignition failure, rough starts and/or rough operation. If a

drop of more than 1.5” W. C. (0.37 kPa) in supply gas pressure occurs when the main burner ignites,

ensure the supply gas lines and regulator(s) are properly sized and installed.

4

Servicing should only be performed by a Qualied Service Technician

Page 7

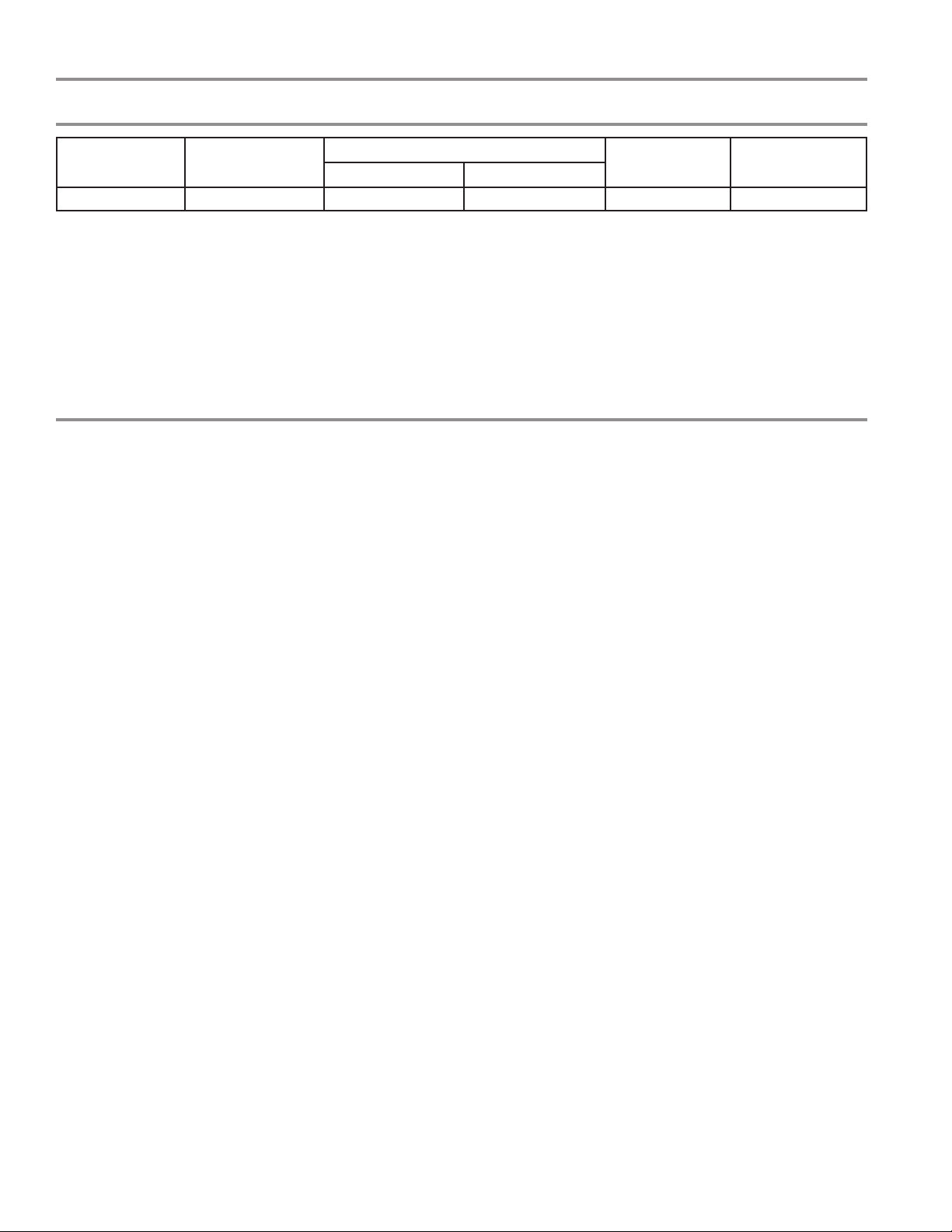

AIR SUPPLY:

Stoichiometric or theoretical complete combustion requires 10 cubic feet of air per 1,000 BTU of gas supplied.

The National Fuel Gas Code also recommends an additional 2.5 cubic feet of “excess” air. For information

on minimum make-up air opening sizes for various building installations, refer to the National Fuel Gas Code

NFPA 54/ANSI Z223.1.

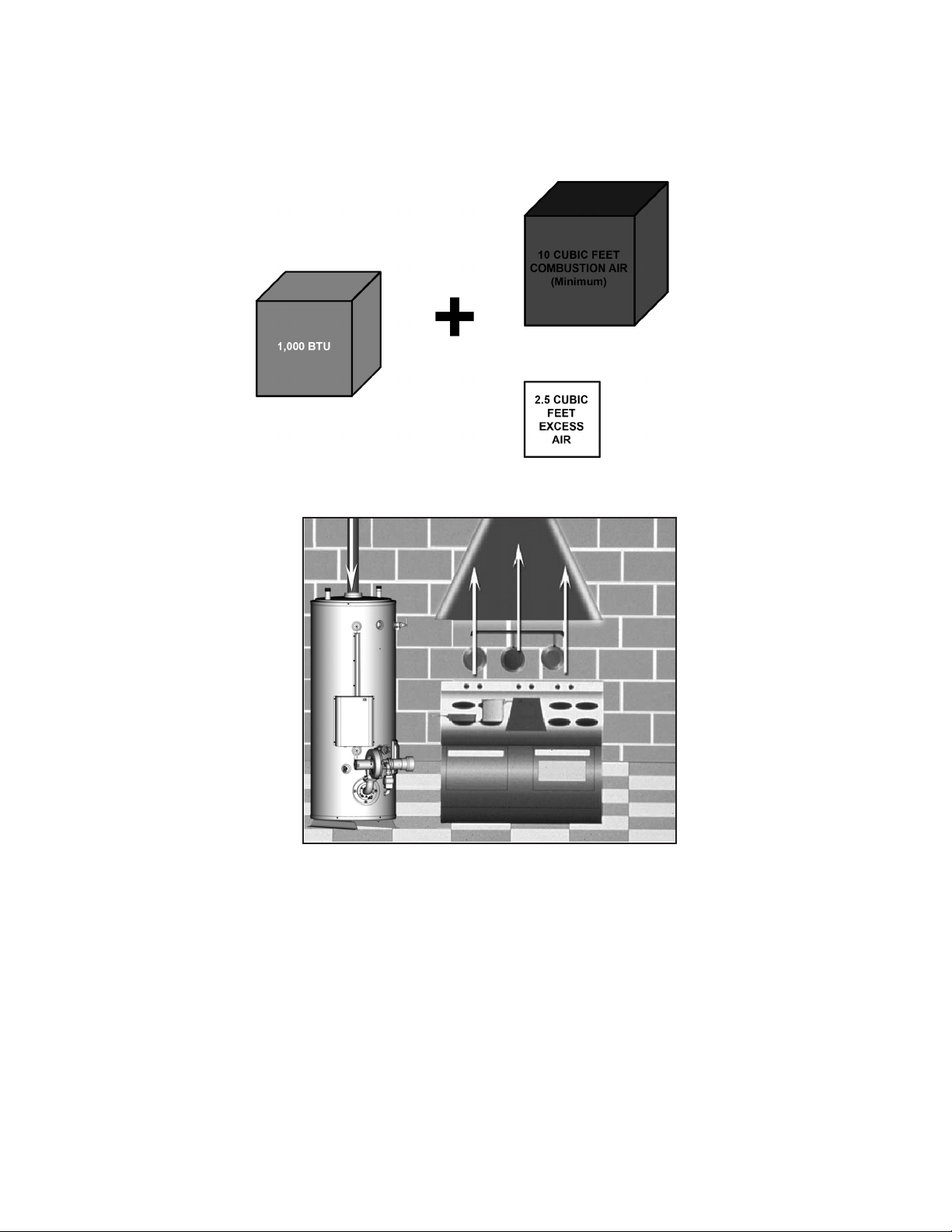

INSUFFICIENT MAKE-UP AIR, NEGATIVE AIR PRESSURE AND DOWNDRAFTS:

Downdraft Caused by Kitchen Vent Hood

A lack of combustion and ventilation air can create a negative ambient air pressure in the installed space. The

vent system on one or more gas fired appliances can experience down drafts due to the outdoor air pressure

being greater than the ambient air pressure in the installed space. Where multiple gas fired appliances are

installed, one or more gas fired appliances can “pull air” through the vent system(s) of other appliances

installed nearby.

One common example is in a restaurant installation where exhaust vent equipment was not considered in

sizing make-up requirements. This condition may result in air being back drafted by the restaurant exhaust

equipment through the heater causing the draft proving switch to open and/or erratic heater shutdown.

• Down drafts can cause flue gases to spill into the installed space.

Servicing should only be performed by a Qualied Service Technician

5

Page 8

MAKE-UP AIR – DIRECT COMMUNICATION WITH OUTDOORS:

A fresh supply of make-up air for combustion can be supplied to the water heater through make-up air ducts,

which directly communicate with the outdoors. (Not Direct Vent.)

Two openings are required: one within 12 inches of the top of the enclosure and one within 12 inches

of the bottom of the enclosure. Each opening must have a free area of not less than 1 square inch per

4,000 BTU/Hr of the total input of all appliances within the enclosure. The lower opening primarily provides

combustion air. The upper opening provides vent dilution air and acts as a relief opening for flue gases

should the vent become obstructed or a downdraft condition occur.

Additionally, when the water heater is installed in a confined space and communicating with the outdoor air,

one permanent opening, beginning within 12 inches (30 cm) of the top of the enclosure, must be permitted

where the equipment has clearances of at least 1 inch (2.5 cm) from the sides and back, and 6 inches

(16 cm) from the front of the appliance. The opening must directly communicate with the outdoors and

must communicate through a vertical or horizontal duct to the outdoors or spaces (crawl or attic) that freely

communicate with the outdoors, and must have a minimum free area of a) 1 square inch per 3,000 BTU/Hr

(7cm2 per kW) of the total input of all equipment located in the enclosure and b) not less than the sum of the

areas of all vent connectors in the confined space.

CONTAMINATED AIR:

Corrosion of the flue ways and vent system may occur if air for combustion contains certain chemical vapors.

Such corrosion may result in failure and risk of asphyxiation.

Combustion air that is contaminated can greatly diminish the life span of the water heater and water heater

components such as hot surface igniters and burners. Propellants of aerosol sprays, beauty shop supplies,

water softener chemicals and chemicals used in dry cleaning processes that are present in the combustion,

ventilation or ambient air can cause such damage.

Do not store products of this sort near the water heater. Air which is brought in contact with the water

heater should not contain any of these chemicals. If necessary, uncontaminated air should be obtained from

remote or outdoor sources. The limited warranty is voided when failure of water heater is due to a corrosive

atmosphere. (See limited warranty for complete terms and conditions).

6

Servicing should only be performed by a Qualied Service Technician

Page 9

AIR REQUIREMENTS:

For safe operation an adequate supply of fresh uncontaminated air for combustion and ventilation must be

provided. An insufficient supply of air can cause recirculation of combustion products resulting in contamination

that may be hazardous to life. Such a condition often will result in a yellow, luminous burner flame, causing

sooting of the combustion chamber, burners and flue tubes and creates a risk of asphyxiation.

Do not install the water heater in a confined space unless an adequate supply of air for combustion and

ventilation is brought in to that space using the methods described in the Confined Space section of the

Instruction Manual.

Never obstruct the flow of ventilation air. If you have any doubts or questions at all, call your gas supplier.

Failure to provide the proper amount of combustion air can result in a fire or explosion and cause property

damage, serious bodily injury or death.

CLOSED WATER SYSTEMS:

Water supply systems may, because of code requirements or such conditions as high line pressure, among

others, have installed devices such as pressure reducing valves, check valves, and back flow preventers.

Devices such as these cause the water system to be a closed system.

THERMAL EXPANSION:

As water is heated, it expands (thermal expansion). In a closed system the volume of water will grow when

it is heated. As the volume of water grows there will be a corresponding increase in water pressure due to

thermal expansion. Thermal expansion can cause premature tank failure (leakage). This type of failure is not

covered under the limited warranty. Thermal expansion can also cause intermittent Temperature-Pressure

Relief Valve operation: water discharged from the valve due to excessive pressure build up. This condition

is not covered under the limited warranty. The Temperature-Pressure Relief Valve is not intended for the

constant relief of thermal expansion.

CONTAMINATED AIR:

Corrosion of the flue ways and vent system may occur if air for combustion contains certain chemical vapors.

Such corrosion may result in failure and risk of asphyxiation.

Combustion air that is contaminated can greatly diminish the life span of the water heater and water heater

components such as hot surface igniters and burners. Propellants of aerosol sprays, beauty shop supplies,

water softener chemicals and chemicals used in dry cleaning processes that are present in the combustion,

ventilation or ambient air can cause such damage.

Do not store products of this sort near the water heater. Air which is brought in contact with the water

heater should not contain any of these chemicals. If necessary, uncontaminated air should be obtained from

remote or outdoor sources. The limited warranty is voided when failure of water heater is due to a corrosive

atmosphere. (See limited warranty for complete terms and conditions).

POWER SUPPLY:

The water heaters covered in this manual require a 120 VAC, 1Ø (single phase), 60Hz, 15 amp power

supply and must also be electrically grounded in accordance with local codes or, in the absence of local

codes, with the National Electrical Code, ANSI/ NFPA 70 or the Canadian Electrical Code, CSA C22.1.

Servicing should only be performed by a Qualied Service Technician

7

Page 10

FEATURES AND COMPONENTS – ALL MODELS

Outlet Tube

Exhaust/Vent

Inlet Tube

T & P

Relief

Valve

Upper

Thermostat

Probe/ECO

Control Box

Assembly

Clean Out

Cover

Gas Control

Valve

Lower

Thermostat

Probe

The Hydrocannon

Combustion

Blower & Burner

Assembly

Combustion

Air Intake

Drain

Valve

Gas Supply Piping:

3/4" NPT Connection

Gas Supply Pressure:

Natural Gas - Min 3.5" WC,

Max 14.0" WC

8

Servicing should only be performed by a Qualied Service Technician

Page 11

BLOWER AND BURNER ASSEMBLY

Blower

Union

Gas Control

Valve

Fasteners (4)

Blower

Flange

Silicone

Gasket

Adapter

Tube

Flange

Plate

Skirt Ring

Flange Gasket

Burner

Fasteners (4)

Brass Locknuts (3)

Brass Nuts/

Lock Washers (4)

Burner

Gasket

Flame

Sensor

Spark Igniter

BURNER REPLACEMENT:

1. Turn off the gas supply and electricity to the water heater.

2. Disconnect the spark ignition cable and ground wire plus the flame sensor wire at their connection points

on the flange plate.

3. Disconnect the hose tubes at the gas valve connection, blower outlet connection and fresh air intake

connection if necessary.

4. Disconnect the gas line at the union above the gas valve.

5. Remove the 4 fasteners joining the blower flange to the adapter tube. Save the silicone gasket between

the blower flange and the adapter tube.

6. Move the blower aside and support it so that it will not hang from the power connection wires.

Servicing should only be performed by a Qualied Service Technician

9

Page 12

7. Remove the 4 brass nuts and 4 lock washers holding the flange plate to the skirt ring flange.

8. Pull the adapter tube/flange plate/burner assembly out of the combustion chamber. Take care not to

damage the spark igniter or flame sensor during the removal process.

9. Clean the flange plate and skirt ring flange surfaces to remove any portions of the old skirt ring flange

gasket.

10. Support the adapter tube/flange plate/burner assembly in a vertical position with the burner extending

downward.

11. Remove the 3 brass locknuts holding the adapter tube to the flange plate.

12. Separate the adapter tube from the flange plate.

13. Clean the adapter tube and flange plate surfaces removing any portions of the old burner gasket.

14. Remove the burner from the flange plate.

15. Insert the new burner into the flange plate and align the notch in the burner flange with the tab in the

flange plate.

16. Install the new burner gasket over the three studs extending from the flange plate.

17. Install the adapter tube on the flange plate with the 3 brass locknuts. Torque the nuts to 60 in.lb.

18. Install the new skirt ring flange gasket on the flange plate.

19. Insert the adapter tube/flange plate/burner assembly into the combustion chamber and engage the 4

studs through the mounting holes/slots in the flange plate. Install 4 lock washers and 4 brass nuts on

the studs and torque to 16 ft.lb.

20. Reinstall the blower and silicone gasket on the adapter tube flange using the 4 fasteners. Torque the

fasteners to 20 ft.lb.

21. Reconnect the gas line at the union above the gas valve.

22. Reconnect the spark ignition cable and ground wire plus the flame sensor wire at their connection

points on the flange plate.

23. Reconnect the hose tubes if removed in step 3.

24. Check that all gas connections and fasteners are tight.

25. Turn on the gas supply and electricity to water heater.

10

Servicing should only be performed by a Qualied Service Technician

Page 13

SPARK IGNITER, FLAME SENSOR, SIGHT GLASS

The spark igniter and the flame sense rod are shown below. Also shown is the burner sight glass. These

features are typical for all models.

Burner

Flame Sensor

Sightglass

Spark Igniter

SPARK IGNITER / FLAME SENSOR / CONTROL TIMING

SPARK IGNITER

This water heater is equipped with a spark igniter. Do not damage the ceramic insulator. Inspect the igniter

ceramic insulator for any cracks. The spark gap between the spark rod and grounding rod is 1/8".

FLAME SENSOR

This water heater is equipped with a flame sensor. The flame sensor senses flame by passing a small

electric current through the flame. This type of flame sensing is also known as flame rectification. The

Ignition Control is looking for a minimum current of 0.7 micro amperes for the water heater to operate.

CONTROL TIMING

Pre-purge 30 seconds

Inter Purge 30 seconds

Trial for ignition 4 seconds

Tries 3

Flame Sensing Remote

Loss of Flame Recycle

Reset 15 minutes auto reset

Note: 5 seconds delay between low and high fire rate.

Servicing should only be performed by a Qualied Service Technician

11

Page 14

VENTING

INSTALLATION – VENTING CATEGORY AND MATERIALS

SBL MODELS VENTING

Category I • Non-condensing, negative pressure in vent, below atmospheric.

Type venting • Must be installed Conventional Vent; uses room air for combustion and discharges flue

gases to the outdoor atmosphere through one pipe.

Vent materials • B Vent.

MINIMUM CLEARANCES

This water heater is approved for installation on combustible flooring in an alcove with minimum clearance

from combustion construction as indicated in below Figure and Table.

In all installations the minimum combustible clearances from vent piping shall be 6” (15.2 cm). Vent piping

passing through a combustible wall or ceiling must be a continuous run (no joints) and retain 6” (15.2 cm)

clearance unless an approved reducing thimble is used.

A service clearance of 24” (61 cm) should be maintained from serviceable parts, such as Temperaturepressure relief valves, baffles, digital thermostats, cleanout openings or drain valves.

The units are approved for installation with side, rear and ceiling clearances as indicated below:

MINIMUM CLEARANCES TO COMBUSTIBLE OR NON-COMBUSTIBLE CONSTRUCTION:

MODELS "A" RIGHT SIDE "B" LEFT SIDE "C" BACK "D" CEILING

SBL95 199NE

SBL85 275NE(A)

SBL85 390NE(A)

0" 0" 0" 12"

0 cm 0 cm 0 cm 30.5 cm

0" 0" 0" 12"

0 cm 0 cm 0 cm 30.5 cm

0" 0" 0" 12"

0 cm 0 cm 0 cm 30.5 cm

12

Servicing should only be performed by a Qualied Service Technician

Page 15

EXTERIOR CLEARANCES

The illustration below shows the required clearances for venting units using natural draft venting.

The vent must extend at least 3 feet above the highest point where it passes through a roof of a building

and at least 2 feet higher than any portion of a building within a horizontal distance of 10 feet (for vents of 12

inches in diameter or less).

References: NFPA 54/ ANSI Z223.1 may allow reduction to 8 feet with a “listed vent cap.”

Servicing should only be performed by a Qualied Service Technician

13

Page 16

VENTING TABLES – TECHNICAL VENTING DATA

TYPE B GAS VENT

Multiple Gas Fired Tank-Type Heaters

When venting multiple tank type heaters

using Type B vent pipe, follow the installation

diagram and tables below which give sizing

and data based upon NFPA 54 ANSI Z223.1.

MODEL SBL95 199NE

Input: 199,000 Btu/hr Total Vent Height (Feet)

Vent Connector Size: 6 inches

Input Btuh/hr

199,000

199,000

199,000

Number of 199

MODEL SBL85 275NE(A)

Input: 275,000 Btu/hr Total Vent Height (Feet)

Vent Connector Size: 6 inches

Number of 275

MODEL SBL85 390NE(A)

Input: 390,000 Btu/hr

Vent Connector Size: 6 inches

Number of 400 Heaters

2

3

4

2

3

4

2

3

4

Heaters

Heaters

Combined Input (Btu/hr) Manifold and Common Vent Diameters (Inches)

398,000

597,000

796,000

Input Btu/hr

275,000

275,000

275,000

Combined Input (Btu/hr) Manifold and Common Vent Diameters (Inches)

550,000

825,000

1,100,000

Input Btu/hr

390,000

390,000

390,000

Combined Input (Btu/hr) Manifold and Common Vent Diameters (Inches)

780,000

1,170,000

1,560,000

Rise

1 Ft. 7 7 7 6 6 6 6 6

2 Ft. 7 7 6 6 6 6 6 6

3 Ft. 6 6 6 6 6 6 6 6

Rise

1 Ft. 8 8 8 7 7 6 6 6

2 Ft. 8 8 7 7 7 6 6 6

3 Ft. 7 7 7 7 7 6 6 6

Rise

1 Ft. - - - - 8 7 7 6

2 Ft. - - - 8 8 7 7 6

3 Ft. - - 8 8 8 7 7 6

6 8 10 15 20 30 50 100

Vent Connector Diameter (Inches)

9 8 8 8 7 7 7 6

10 10 10 9 9 8 8 7

12 12 12 10 10 9 9 8

6 8 10 15 20 30 50 100

Vent Connector Diameter (Inches)

10 10 9 9 8 8 7 7

14 12 12 10 10 9 9 8

14 14 14 12 12 12 10 9

Total Vent Height (Feet)

6 8 10 15 20 30 50 100

Vent Connector Diameter (Inches)

12 12 12 10 10 9 9 8

16 14 14 14 12 12 10 9

16 16 16 14 14 14 12 10

14

Servicing should only be performed by a Qualied Service Technician

Page 17

TYPE B GAS VENT

Single Gas Fired Tank-Type Heater

When venting single tank type water heater using Type B vent pipe, follow the tables below which give sizing

and data based upon NFPA 54 ANSI Z223.1.

Total Vent Height (Feet)

6 8 10 15 20 30 50 100

Lateral (Feet) Minimum Vent Diameter (Inches)

MODEL SBL95 199NE

Input: 199,000 Btu/hr

Vent Connector Diameter: 6 inches

Vent Type: Type B Double-Wall Gas Vent

Vent Connection: Connected directly to Vent

Number of Appliances: Single

Appliance Venting: Fan assist

Note: Refer to NFPA 54/ ANSI Z223.1 for

maximum vent diameter.

MODEL SBL85 275NE(A)

Input: 275,000 Btu/hr

Vent Connector Diameter: 6 inches

Vent Type: Type B Double-Wall Gas Vent

Vent Connection: Connected directly to Vent

Number of Appliances: Single

Appliance Venting: Fan assist

Note: Refer to NFPA 54/ ANSI Z223.1 for

maximum vent diameter.

0 6 6 5 5 5 5 5 5

2 6 6 6 5 5 5 5 5

4 6 NA NA NA NA NA NA NA

5 NA 6 6 6 5 5 5 5

6 6 NA NA NA NA NA NA NA

8 NA 6 NA NA NA NA NA NA

10 NA NA 6 6 5 5 5 5

15 NA NA NA 6 6 5 5 5

20 NA NA NA NA 6 5 5 5

30 NA NA NA NA NA 6 5 5

Total Vent Height (Feet)

6 8 10 15 20 30 50 100

Lateral (Feet) Minimum Vent Diameter (Inches)

0 6 6 6 5 5 5 5 5

2 7 7 7 6 6 6 5 5

4 7 NA NA NA NA NA NA NA

5 NA 7 7 6 6 6 5 5

6 7 NA NA NA NA NA NA NA

8 NA 7 NA NA NA NA NA NA

10 NA NA 7 6 6 6 6 5

15 NA NA NA 6 6 6 6 5

20 NA NA NA NA 6 6 6 5

30 NA NA NA NA NA 6 6 6

MODEL SBL85 390NE(A)

Input: 390,000 Btu/hr

Vent Connector Diameter: 6 inches

Vent Type: Type B Double-Wall Gas Vent

Vent Connection: Connected directly to Vent

Number of Appliances: Single

Appliance Venting: Fan assist

Note: Refer to NFPA 54/ ANSI Z223.1 for

maximum vent diameter.

Total Vent Height (Feet)

6 8 10 15 20 30 50 100

Lateral (Feet) Minimum Vent Diameter (Inches)

0 7 6 6 6 6 6 6 6

2 8 8 7 7 7 6 6 6

4 8 NA NA NA NA NA NA NA

5 NA 8 7 7 7 6 6 6

6 8 NA NA NA NA NA NA NA

8 NA 8 NA NA NA NA NA NA

10 NA NA 8 7 7 6 6 6

15 NA NA NA 7 7 7 6 6

20 NA NA NA NA 7 7 6 6

30 NA NA NA NA NA 7 6 6

Servicing should only be performed by a Qualied Service Technician

15

Page 18

OPERATION AND SERVICE

SEQUENCE OF OPERATION:

1. Switch power on to unit.

2. Thermostat calls for heat.

3. VFD sends power to Blower.

4. Blower runs at low speed.

5. Combustion Blower initiates air flow through water heater closing the Prover Switch.

6. After 30 seconds, the Ignition Control provides power to the Spark Igniter and Gas Valve.

7. Ignition Control maintains spark for up to 4 seconds and monitors Flame Sensor to determine if

Burner is lit.

8. If the Flame Sensor does not detect proper flame, the Ignition Control shuts off the Gas Valve and

allows the Blower to purge the unit. At that time, the Ignition Control restarts with step 6. It will try and

ignite the main burners 2 more times. If the unit does not light, the Ignition Control will wait 15 minutes

and then restart at step 6. This cycle will continue until the unit lights or the power is shut off to the

unit.

9. If the Flame Sensor detects proper flame, the Ignition Control will allow the unit to operate until the

thermostat is satisfied.

10. Once the unit is satisfied, the Thermostat will shut off the Blower, Gas Valve and Ignition Control and

the unit will be in standby mode until another call for heat is initiated by the thermostat.

16

Servicing should only be performed by a Qualied Service Technician

Page 19

DIAGNOSTIC SEQUENCE OF OPERATION – FLOW CHART

Servicing should only be performed by a Qualied Service Technician

17

Page 20

SEQUENCE OF OPERATION – FLOW CHART

18

Servicing should only be performed by a Qualied Service Technician

Page 21

LIGHTING AND OPERATING LABEL

GNITAREPO EROFEB DAER YTEFAS RUOY ROF

WARNING:

If you do not follow these instructions exactly, a fire or

explosion may result causing property damage, personal injury

or loss of life.

BEFORE OPERATING: ENTIRE SYSTEM MUST BE FILLED WITH WATER AND AIR PURGED FROM ALL LINES.

This appliance does not have a pilot. It is equipped with

A.

an ignition device which automatically lights the burner.

Do not try to light the burner by hand.

B.

BEFORE OPERATING smell all aroung the

Be sure to smell next to the floor

heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

Do not touch any electric switch;

do not use any phone in your building.

Immediately call your gas supplier from a

phone. Follow the gas suppliers

1.

STOP! Read the safety information

because some gas is

instructions.

area for gas.

neighbor's

above on this label.

2.

Set the ON/OFF switch on the control box to

the “OFF” position.

3.

Set the thermostat to the lowest setting.

4.

This appliance is equipped with a device which

automatically lights the burner.

DO NOT TRY TO LIGHT THE BUNER BY HAND.

Wait five (5) minutes to clear out any gas.

5.

you then smell gas,

If

STOP! Follow “B”

in the safety information above on this label. If

you don’t smell gas, go to the next step.

6.

Turn on all electrical power to the appliance.

FLAMMABLE

If you cannot reach your gas supplier, call the fire

department.

Use only your hand to push the control buttons.

C.

tools. If the control buttons will not

repair them, call a qualified

attempted repair

Do not use this appliance if any part has been under water.

D.

Immediately contact a qualified installer or service agency

to replace a flooded water heater. Do not attempt to repair

the unit. It must be replaced!

may result in a fire or explosion.

service technician. Force or

push in, don’t try to

Never use

SNOITCURTSNI GNITAREPO

8.

Set the thermostat to the desired setting.

CAUTION: Hotter water increases the risk

of scald injury. Consult the instruction

manual before changing temperature.

9.

If the appliance will not operate, follow the

instructions “TO TURN OFF GAS TO

APPLIANCE” and call your technician or gas

supplier.

WARNING: TURN OFF ALL ELECTRIC

POWER BEFORE SERVICING.

7.

Set the ON/OFF switch on the control box to

the “ON” position.

TO TURN OFF GAS TO APPLIANCE

1.

Set the thermostat to the lowest setting.

2.

Set the ON/OFF switch on the control box to

the “OFF” position.

Servicing should only be performed by a Qualied Service Technician

ON

3.

Turn off all electrical power to the appliance

if service is to be performed.

OFF

19

Page 22

TROUBLESHOOTING

COMPLAINT CAUSE

*Water not hot enough. Thermostat set too low. Set thermostat dial to a

higher temperature

Upper and/or lower

temperature probe out of

calibration.

*Insufcient hot water.

*See WATER TEMPERATURE

CONTROL WARNING on page

12 of Instruction Manual.

Water temperature too hot. Thermostat set too high. Set thermostat to a lower

Rumbling. Sediment accumulation on

Ticking or metallic sounds. Expansion and contraction -

Pounding or water hammer. Air chambers in piping

Water leaks. Drain valve not closed tightly. If drain valve cannot be

Gas odors. Possible gas leaks. Shut off gas supply to heater

Thermostat set too low. Set thermostat dial to a

Upper and/or lower

temperature probe out of

calibration.

Main manual gas shutoff

valve partially closed.

Heater too small for demand. Space usage to give heater

Heater recovery is slower. Call qualied agency. Check gas input. If incorrect, check

bottom of tank.

normal.

have become waterlogged.

Thermal expansion tank

damaged, improperly

charged, or improperly sized.

If leakage source cannot be

corrected or identied, call

qualied agency.

Call qualied agency. Check continuity and resistance

higher temperature

Call qualied agency. Check continuity and resistance

Open main manual gas

shutoff valve to fullest extent.

time to restore water

temperature.

setting.

Drain a quantity of water

through drain valve. If

rumbling persists, call

qualied agency.

Drain piping system and

rell. Heater must be off

while this is being done.

Check thermal expansion

tank charge pressure when

the water system pressure

is zero.

closed tightly, replace.

Shut off gas supply to heater

and close cold water inlet

valve to heater.

and call gas company at

once.

USER QUALIFIED AGENCY

REMEDY

(Ohms) of upper and lower

temperature probes. Replace

probes if out of specication.

(Ohms) of upper and lower

temperature probes. Replace

probes if out of specication.

for inlet air blockage and/or ue

gas exhaust blockage.

Delime heater.

Follow the manufacturer's

instructions for proper charging of

the thermal expansion tank.

Repair or in case of suspected

tank leakage, be certain to conrm

before replacing heater.

20

Servicing should only be performed by a Qualied Service Technician

Page 23

CONTROLS OVERVIEW - CONTROL BOX ASSEMBLY

Variable

Frequency

Drive

ON/OFF

Switch

Digital

Thermostat

Blocked

Inlet Switch

Blocked

Outlet

Switch

Blower

Prover

Switch

Low Speed

I/O Module

High Speed

I/O Module

Ignition

Control

Servicing should only be performed by a Qualied Service Technician

21

Page 24

PRESSURE SWITCHES – ALL MODELS

All SBL models are provided with three pressure switches. These switches are essential to the safe and proper

operation of the unit. The switches are wired to the Ignition control in series. It is important to understand the

purpose of each switch.

Blocked Inlet Switch

Blocked Outlet Switch

Blower Prover Switch

SBL MODELS PRESSURE SWITCHES

PRESSURE SWITCHES Model Setpoint (WC) Tolerance (WC)

Blocked Inlet Switch SBL95 199NE -0.67" +0.03"/-0.05"

SBL85 275NE(A) -0.59" +0.03"/-0.05"

SBL85 390NE(A) -1.00" +0.03"/-0.05"

Blocked Outlet Switch SBL95 199NE +4.80" +/-0.10"

SBL85 275NE(A) +2.65" +/-0.10"

SBL85 390NE(A) +5.35" +/-0.10"

Blower Prover Switch SBL95 199NE +0.38" +0.01"/-0.07"

SBL85 275NE(A)/

SBL85 390NE(A)

+0.46" +0.02"/-0.06"

22

Servicing should only be performed by a Qualied Service Technician

Page 25

BLOWER PROVER SWITCH

The blower prover switch is provided on the heater to verify that the fan is operating. It is a positive pressure

switch whose electrical contacts are normally open. The blower prover switch electrical contacts will close

on a rise in pressure as the blower increases the pressure in the burner. This switch is connected to the

blower outlet pressure tap by a piece of silicone tubing. This tubing must be connected in order for the switch

to close the electrical contacts.

BLOCKED OUTLET SWITCH

The blocked outlet switch electrical contacts are normally closed. The blocked outlet switch electrical

contacts will open on a rise in pressure.

BLOCKED INLET SWITCH

The blocked inlet switch electrical contacts are normally closed. The blocked inlet switch electrical contacts

will open when an increase in negative pressure (vacuum) occurs in the intake vent pipe. The switch

is connected to the pressure tap on the PVC pipe connected to the inlet of the blower. When this switch

prevents the unit from igniting, most likely the intake is blocked by some means. Verify that the air intake pipe

is free of obstructions that may prevent air from entering the unit.

HIGH LIMIT SWITCH/ DIGITAL THERMOSTAT

The digital thermostat contains the high limit (energy cut out) switch. The high limit switch interrupts burner

gas flow should the water temperature reach 203°F (95°C).

In the event of high limit switch operation, the water heater cannot be restarted unless the water temperature

is reduced to approximately 120°F (49°C). The manual reset button on the front of the control then needs to

be depressed.

Continued manual resetting of high limit control, preceded by higher than usual water temperature is evidence

of high limit switch operation.

Contact your dealer or qualified service technician if continued high limit switch operation occurs.

Manual

Reset

Temperature

Adjustment

Dial

Display

LED Label

To 120V

supply

(E2)

Fuse

To Lower (E4)

Temperature

Probe

Display LED's

To Pressure Switches, I/O Modules & Ignition Control (E1)

Servicing should only be performed by a Qualied Service Technician

To Upper (E3)Temperature Probe

23

Page 26

DISPLAY LIGHTS – DIGITAL THERMOSTAT

LED

STATUS

INDICATION ACTION

Calling for heat Normal status. No action required.

• Check for excessively hot water (203° F or

The ECO (Energy Cut-Out) has

opened.

No power Check the breaker.

Tank is at a set temperature ± 2° F. No action required.

higher).

• Check the resistance of the temperature

probes and continuity of the high limit (ECO).

24

Tank has cooled below 120° F.

Preceded by “ECO Open” indication.

Servicing should only be performed by a Qualied Service Technician

• Push the manual reset button.

• Check the resistance of the temperature

probes and continuity of the high limit (ECO).

Page 27

CONTINUITY CHECK OF HIGH LIMIT (ECO)

CONDITIONS:

• Power On – No Hot Water.

• Red, digital thermostat “Call for Heat” LED – On.

• Turn Power OFF.

Continuity check of ECO (energy cut-out, high limit)

Black to Black wires of upper probe. Power is off.

IF......... THEN............

Continuity is indicated

(ZERO “0.0” Resistance)

Continuity is not present

(meter reads “0.L”)

Water is less than 120° F • Reset status LED should be on.

Opens at 203° F; closes at 193° F. If water is below 193° F,

continuity is correct.

Replace ECO sensor, if water temperature is below 193° F.

• Replace digital thermostat if control will not manually reset.

Servicing should only be performed by a Qualied Service Technician

25

Page 28

UPPER TEMPERATURE PROBE CONTINUITY CHECK

CONDITIONS:

• Power On – Water below temperature set point.

• Red, digital thermostat “Reset Status” LED – OFF.

• "Call for Heat" LED Off.

OHMS RESISTANCE TABLE

° F

70° 11,884

120° 3,759

140° 2,488

180° 1,169

Upper Temperature Probe continuity check

Red wire to red wire – Turn supply power "Off" for this test.

OHMS

IF......... THEN............

Test indicates no continuity. Replace probe.

Continuity is indicated. Probe should be okay (also verify Ohms resistance for water

temperature). (Reading will be approximate.)

26

Servicing should only be performed by a Qualied Service Technician

Page 29

LOWER TEMPERATURE PROBE CONTINUITY CHECK

CONDITIONS:

• Main burner ignited.

• Stored water is below temperature setting more than 5° F (Tank Average).

• Power Off.

• Plug disconnected from digital thermostat receptacle E4.

OHMS RESISTANCE TABLE

° F

70° 11,884

120° 3,759

140° 2, 488

180° 1, 169

Lower Temperature Probe continuity check

Red wire to red wire – Turn supply power "Off" for this test.

OHMS

IF......... THEN............

Test indicates no continuity. Replace probe.

Continuity is indicated. Probe should be okay (also verify Ohms resistance for water

temperature). (Reading will be approximate.)

Servicing should only be performed by a Qualied Service Technician

27

Page 30

IGNITION CONTROL

Each heater is equipped with an ignition control. The solid state ignition control, ignites the burner by utilizing a

spark igniter. The spark igniter shuts off during the heating cycle and the burner flame is sensed through a remote

flame sensor.

The ignition control will try to ignite the burner three times before lockout. The control waits 15 minutes before

trying again to ignite the burner. This is a continuous cycle.

This is a 24 VAC ignition control. The microprocessor circuit design provides precise, repeatable timing and

operating sequences. The on-board diagnostics with LED output make troubleshooting easy and ensures

safe and efficient operation.

WIRING TERMINALS

TERMINAL DESCRIPTION

TH/W Thermostat Input

PV1 Gas Valve Power

MV1 VFD High Speed Signal

V2 Valve Ground

GND System Ground

S1 Remote Flame Sensor

HV High Voltage Output

28

Servicing should only be performed by a Qualied Service Technician

Page 31

START UP/ FLAME RECOVERY/ SAFETY LOCKOUT

START UP - HEAT MODE

When a call for heat is received from the thermostat supplying 24 volts to TH/W, the control will reset, perform

a self check routine, flash the diagnostic LED once in the first two seconds, and a pre-purge delay begins.

Following the pre-purge period, the gas valve is energized and sparks commence for the trial for ignition

period. The VFD high speed signal remains de-energized until flame is detected.

When flame is detected during the trial for ignition, the sparking process is terminated and the VFD high

speed signal is energized after a 5 second dwell period. The thermostat and burner flame are constantly

monitored to assure the system continues to operate properly. When the thermostat is satisfied and the

demand for heat ends, the gas valve and VFD speed signals are de-energized immediately.

FAILURE TO LIGHT - LOCKOUT

MULTI TRIAL CONTROL

Should the burner fail to light, or if flame is not detected during the first trial for ignition period, the gas valve is

de-energized. The control then goes through an interpurge delay before another ignition attempt. The control

will attempt two additional ignition trials before going into lockout and the valve relay will be de-energized

immediately. This ignition control has an automatic reset. If the thermostat is still calling for heat after 15

minutes the control will automatically reset and attempt to ignite the burner.

FLAME FAILURE- RECYCLE MODE

This control has the "recycle after loss of flame" function, upon loss of an established burner flame, the gas

valve is de-energized and the control proceeds to interpurge before attempting to relight the burner. The

ignition control will allow three tries for ignition including inter-purges. If the burner relights, normal operation

resumes. If the burner does not relight, the control will go into lockout as described in "failure to light".

Servicing should only be performed by a Qualied Service Technician

29

Page 32

FAULT CONDITIONS

The water heater is equipped with an ignition control that incorporates a diagnostic system to assist in

troubleshooting the appliance. The indicator codes on the ignition module are as follows:

LED INDICATION FAULT MODE

2 Flashes Flame sensed without call for heat.

3 Flashes Ignition Lockout.

Steady On Internal Control Failure

The LED will flash on for 1/4 second, then off for 1/4 second during a fault condition. The pause between

fault codes is 3 seconds.

INTERNAL CONTROL FAILURE

If the ignition control detects an error in its software or hardware, all outputs are turned off and the LED

displays a steady ON condition. If an internal control failure is indicated, replace the ignition control.

TROUBLESHOOTING GUIDE FOR IGNITION CONTROL

SYMPTOMS CAUSES

1. Control does not start a. Miswired.

b. No 24V AC power supply at TH/W terminal.

c. Bad control, check LED for steady on or flashing

code (see above Table).

2. Thermostat on -no spark a. Miswired.

b. No 24V AC power supply at TH/W terminal.

c. Bad control, check LED for steady on or flashing

codes.

3. Valve on - no spark during TFI a. Shorted electrode -establish 1/8 inch gap.

b. Check high voltage cable.

c. Miswired.

4. Spark on - valve off a. Valve coil open.

b. Valve wire disconnected.

c. Bad control, check voltage at gas valve terminals

PV1 and V2.

5. Flame okay during TFI - no flame sense after TFI a. Poor ground at burner.

b. Poor flame, check flame current.

c. Check flame rod position.

FLAME SENSOR CURRENT CHECK

Flame current is the current that passes through the flame from the sensor to ground. The minimum

flame current necessary to keep the system from lockout is 0.7 micro amps. To measure flame current,

connect analog DC microammeter to the FC-, FC+ terminals on the Ignition Control. Meter should read 0.7

microamps or higher. If the meter reads below "0" on scale, meter leads are reversed; disconnect power

and reconnect meter leads for proper polarity.

30

Servicing should only be performed by a Qualied Service Technician

Page 33

VARIABLE FREQUENCY DRIVE – ALL MODELS

The SBL95 199NE, SBL85 275NE(A) and SBL85 390NE(A) models have a variable frequency drive (VFD)

that controls the speed of the blower motor. The VFD receives a signal from the thermostat and ignition

control that instructs the VFD to transmit the proper frequency to the blower to produce the proper blower

speed and proper input rate.

Two conditions must be met for the variable frequency drive to start the blower at low speed:

1. 100 - 120VAC must be supplied to the VFD input.

2. The thermostat closes a contact through the low speed I/O module – VFD terminals LI1 and +24V.

Servicing should only be performed by a Qualied Service Technician

31

Page 34

Two conditions must be met for the variable frequency drive to switch the blower from low speed to high

speed:

1. 100 - 120VAC must be supplied to the VFD input.

2. The ignition control closes a contact through the high speed I/O module – VFD terminals LI2 and

+24V.

CHARACTERISTICS AND FUNCTIONS OF THE CONTROL TERMINALS

Display:

•4 - digit display

•Display of numeric values and codes

TERMINALS FUNCTIONS

COM Common of analog and logic I/Os

LI1 Logic input for low speed

LI2 Logic input for high speed

+24V + 24 VDC supply provided by the drive

Line supply is at the top of the drive, the motor power supply is at the bottom of the drive.

VFD – BLOWER SPEED AND FREQUENCY READINGS

The logic inputs for the VFD are sent from the thermostat and ignition control through the low and high

speed I/O modules in the form of a contact closure. The chart below lists the nominal speed of the blower

and the frequency signal displayed by the VFD for low and high speed blower operation. If the water heater

exhibits poor run characteristics check the frequency display.

Nominal RPM – Frequency – VFD

Model SBL95 199NE SBL85 275NE(A) SBL85 390NE(A)

Nominal RPM Frequency Nominal RPM Frequency Nominal RPM Frequency

Low Speed 1550 53 Hz 1475 50 Hz 1475 50 Hz

High speed 4050 138 Hz 2550 101 Hz 4250 144 Hz

32

Servicing should only be performed by a Qualied Service Technician

Page 35

WIRING DIAGRAM – ALL MODELS

WIRING DIAGRAM FOR SBL95 199NE, 85 275NE(A), AND 85 390NE(A) WHEN EQUIPPED WITH FENWAL IGNITION

CONTROL, WHITE-RODGERS THERMOSTAT, FASCO BLOWER AND ATV12 VARIABLE FREQUENCY DRIVE.

Servicing should only be performed by a Qualied Service Technician

33

Page 36

NOTES

34

Servicing should only be performed by a Qualied Service Technician

Page 37

NOTES

Servicing should only be performed by a Qualied Service Technician

35

Page 38

COMMERCIAL GAS WATER HEATERS

Visit the "Information Central" link of

www.statewaterheaters.com for a listing of available Service Handbooks.

For additional information contact:

State Water Heaters

500 Tennessee Waltz Parkway

Ashland City, TN 37015

1-800-365-8170

www.statewaterheaters.com

©2013 State Industries, Inc.

36

324659-001

Loading...

Loading...