Page 1

Instruction Manual

COMMERCIAL GAS WATER HEATERS

MODELS SBD85500NE &

SBD85500PE

SERIES 120/121

INSTALLATION - OPERATION - SERVICE

500 Tennessee Waltz Pkwy

Ashland City, TN 37015

- MAINTENANCE - LIMITED WARRANTY

ANSI / NSF 5

ASME CRN

WARNING: If the information in these

instructions is not followed exactly, a fire

or explosion may result causing property

damage, personal injury or death.

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

Do not touch any electrical switch; do

not use any phone in your building.

Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

If you cannot reach your gas supplier,

call the fire department.

Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

Thank you for buying this energy effi cient water heater.

We appreciate your confi dence in our products.

PLACE THESE INSTRUCTIONS ADJACENT TO HEATER AND NOTIFY OWNER TO KEEP FOR FUTURE REFERENCE.

PRINTED IN THE U.S.A. 0510 318298-000

Read and understand this instruction

manual and the safety messages

herein before installing, operating or

servicing this water heater.

Failure to follow these instructions and

safety messages could result in death

or serious injury.

This manual must remain with the

water heater.

Page 2

TABLE OF CONTENTS

SAFE INSTALLATION, USE AND SERVICE.......................................... 3

GENERAL SAFETY INFORMATION ................................................... 4-5

Precautions ........................................................................................ 4

INTRODUCTION .................................................................................... 6

Qualifi cations ..................................................................................... 6

FEATURES AND COMPONENTS ......................................................... 7

The Eliminator (Self Cleaning System) .............................................. 7

High Limit Switch ............................................................................... 7

Electronic Ignition Control .................................................................. 7

Exhaust Inducer (blower Assy.) ......................................................... 7

Uncrating ........................................................................................... 7

INSTALLATION CONSIDERATIONS ................................................ 8-11

Rough In Dimensions ........................................................................ 8

Recovery Capacities .......................................................................... 8

Gas and Electrical Characteristics ..................................................... 8

Locating The Water Heater ................................................................ 9

Leveling ............................................................................................. 9

Clearances ........................................................................................ 9

Installation on Combustible Flooring ............................................... 10

Insulation Blanket ............................................................................ 10

Hard Water ...................................................................................... 10

Circulation Pumps ...................................................................... 10-11

INSTALLATION REQUIREMENTS ................................................. 11-14

Supply Gas Regulator ......................................................................11

Power Supply ...................................................................................11

Mixing Valves ....................................................................................11

Dishwashing Machines .................................................................... 12

Closed Water Systems .................................................................... 12

Thermal Expansion .......................................................................... 12

Temperature-Pressure Relief Valve ............................................ 12-13

Contaminated Air ............................................................................. 13

Air Requirements ............................................................................. 13

Unconfi ned Space ...........................................................................14

Confi ned Space ............................................................................... 14

Exhaust Fans ............................................................................................ 14

Louvers and Grilles ................................................................................... 14

Vent Reducer ................................................................................... 14

VENTING INSTALLATION .............................................................. 14-18

Venting ............................................................................................. 14

Multiple Heater Manifold .................................................................. 15

Fresh Air Opening for Confi ned Spaces .......................................... 15

Outdoor Air Through Two Openings ................................................ 15

Outdoor Air Through One Opening .................................................. 15

Outdoor Air Through Two Horizontal Ducts ..................................... 15

Outdoor Air Through Two Vertical Ducts .......................................... 16

Air From Other Indoor Spaces ......................................................... 16

Technical Data Venting ............................................................... 17-18

WATER HEATER INSTALLATION ...................................................19-22

Water Line Connections .................................................................. 19

Water (Potable) Heating and Space Heating............................................19

Thermometer (Not Supplied) ....................................................................19

Water Piping Diagrams ............................................................................. 19

T&P Valve Discharge Pipe ............................................................... 19

Installation Diagrams ....................................................................... 20

Code Restrictions ............................................................................ 20

Heater Wiring ................................................................................... 21

Gas Piping ....................................................................................... 22

Purging ............................................................................................ 22

Gas Pressure Regulator .................................................................. 22

OPERATION ......................................................................................... 23

General ............................................................................................ 23

Filling ............................................................................................... 23

Adjustments ..................................................................................... 23

SEQUENCE OF OPERATION ............................................................. 23

Lighting & Operation Label .............................................................. 24

Checking Venting ............................................................................. 25

Checking the Igniter Assembly ........................................................ 25

Igniter Assembly .............................................................................. 25

Main Burner ..................................................................................... 25

Gas Valves ....................................................................................... 25

Checking the Input ........................................................................... 26

MAINTENANCE ................................................................................... 26

Venting System ................................................................................ 26

Remote Storage Tank Temperature Control .................................... 26

Temperature-Pressure Relief Valve Test ......................................... 26

Hot Water Odor ................................................................................ 27

Anode Rod Inspection ..................................................................... 27

Draining and Flushing ...................................................................... 27

To Drain the Water Heater Storage Tank ..................................................27

To Flush the Water Heater Storage Tank ..................................................27

Recommended Procedure for Periodic Removal or Lime Deposits

from the Tank Type\ Commercial Water Heaters ............................. 28

DeLiming Solvents ........................................................................... 28

Tank Cleanout Procedure ...........................................................28-29

Ignition Module System ................................................................... 29

SERVICE .............................................................................................. 29

Electrical Servicing .......................................................................... 29

FOR YOUR INFORMATION ................................................................. 30

Start up Conditions .......................................................................... 30

Operational Conditions .................................................................... 30

"Air" in the Water Faucets .........................................................................30

High Water Temperature Shut off System ................................................30

Sequence of Operation Flow Chart ................................................. 31

Operational Checklist ...................................................................... 32

WATER PIPING DIAGRAMS ........................................................... 33-47

WARRANTY ......................................................................................... 48

2

Page 3

SAFE INSTALLATION, USE AND SERVICE

The proper installation, use and servicing of this water heater is extremely important to your safety and the safety of others.

Many safety-related messages and instructions have been provided in this manual and on your own water heater to warn you and

others of a potential injury hazard. Read and obey all safety messages and instructions throughout this manual. It is very important

that the meaning of each safety message is understood by you and others who install, use, or service this water heater.

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

DANGER indicates an imminently

DANGER

WARNING

CAUTION

hazardous situation which, if not avoided,

will result in injury or death.

WARNING indicates a potentially hazardous

situation which, if not avoided, could result

in injury or death.

CAUTION indicates a potentially hazardous

situation which, if not avoided, could result in

minor or moderate injury.

CAUTION used without the safety alert

CAUTION

All safety messages will generally tell you about the type of hazard, what can happen if you do not follow the safety message, and

how to avoid the risk of injury.

The California Safe Drinking Water and Toxic Enforcement Act requires the Governor of California to publish a list of substances

known to the State of California to cause cancer, birth defects, or other reproductive harm, and requires businesses to warn of

potential exposure to such substances.

This product contains a chemical known to the State of California to cause cancer, birth defects, or other reproductive harm. This

appliance can cause low level exposure to some of the substances listed in the Act.

symbol indicates a potentially hazardous

situation which, if not avoided, could result in

property damage.

APPROVALS

ASME CRN

ANSI / NSF 5

3

Page 4

GENERAL SAFETY INFORMATION

Fire or Explosion Hazard

Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

Avoid all ignition sources if you smell gas.

Do not expose water heater controls to excessive gas

pressure.

Use only the gas shown on the water heater rating label.

Maintain required clearances to combustibles.

Keep ignition sources away from faucets after extended

periods of non-use.

Read instruction manual before

installing, using or servicing

water heater.

Breathing Hazard - Carbon Monoxide Gas

Do not obstruct water heater air intake

with insulating blanket.

Gas and carbon monoxide detectors

are available.

Install water heater in accordance with

the instruction manual.

Breathing carbon monoxide can cause brain damage or

death. Always read and understand instruction manual.

CAUTION

Property Damage Hazard

Fire Hazard

For continued protection against

risk of fire:

Do not install water heater on

carpeted floor.

Do not operate water heater if

flood damaged.

Fire and Explosion Hazard

Use joint compound or Teflon tape

compatible with propane gas.

Leak test before placing the

water heater in operation.

Disconnect gas piping and main

gas shutoff valve before leak

testing.

Install sediment trap in

accordance with NFPA 54.

Fire and Explosion Hazard

Do not use water heater with any gas

other than the gas shown on the rating

label.

Excessive gas pressure to gas valve can

cause serious injury or death.

Turn off gas lines during installation.

Contact a qualified installer or service

agency for installation and service.

All water heaters eventually leak.

•

Do not install without adequate drainage.

•

Electrical Shock Hazard

Turn off power to the water heater

•

before performing any service.

Label all wires prior to disconnecting

•

when performing service. Wiring errors

can cause improper and dangerous

operation.

Verify proper operation after servicing.

•

Failure to follow these instructions can

•

result in personal injury or death.

Jumping out control circuits or components can

result in property damage, personal injury or death.

Service should only be performed by a qualified service

•

agent using proper test equipment.

Altering the water heater controls and/or wiring in any way

•

could result in permanent damage to the controls or water

heater and is not covered under the limited warranty.

Altering the water heater controls and/or wiring in any way

•

could result in altering the ignition sequence allowing gas to

flow to the main burner before the hot surface igniter is at

ignition temperature causing delayed ignition which can

cause a fire or explosion.

Any bypass or alteration of the water

heater controls and/or wiring will result

in voiding the appliance warranty.

4

Page 5

GENERAL SAFETY INFORMATION

Read and understand this instruction

manual and the safety messages

herein before installing, operating or

servicing this water heater.

Failure to follow these instructions and

safety messages could result in death

or serious injury.

This manual must remain with the

water heater.

Water temperature over 125°F (52°C)

can cause severe burns instantly

resulting in severe injury or death.

Children, the elderly and the

physically or mentally disabled are at

highest risk for scald injury.

Feel water before bathing or

showering.

Temperature limiting devices such as

mixing valves must be installed

when required by codes and to

ensure safe temperatures at fixtures.

Explosion Hazard

Overheated water can cause

water tank explosion.

Properly sized temperature and

pressure relief valve must be

installed in the opening provided.

CAUTION

Improper installation, use and service may result

in property damage.

Do not operate water heater if flood damaged.

•

Inspect and anode rods regularly, replace if damaged.

•

Install in location with drainage.

•

Fill tank with water before operation.

•

Properly sized thermal expansion tanks are required on all

•

closed water systems.

Refer to this manual for installation and service.

Verify the power to the water heater is turned off before performing any service procedures.

GENERAL SAFETY INFORMATION

PRECAUTIONS

DO NOT USE THIS APPLIANCE IF ANY PART HAS BEEN

UNDER WATER. Immediately call a qualifi ed service agency

to inspect the appliance and to make a determination on what

steps should be taken next.

If the unit is exposed to the following, do not operate heater

until all corrective steps have been made by a qualified

service agency.

External fi re.1.

Damage.2.

Firing without water.3.

GROUNDING INSTRUCTIONS

This water heater must be grounded in accordance with the

National Electrical Code and/or local codes. These must be

followed in all cases.

This water heater must be connected to a grounded metal,

permanent wiring system; or an equipment grounding conductor

must be run with the circuit conductors and connected to the

equipment grounding terminal or lead on the water heater, see

Figure 20.

HYDROGEN GAS FLAMMABLE

Explosion Hazard

Flammable hydrogen gases

may be present.

Keep all ignition sources away

from faucet when turning on

hot water.

Hydrogen gas can be produced in a hot water system served

by this appliance that has not been used for a long period of

time (generally two weeks or more). Hydrogen gas is extremely

fl ammable. To reduce the risk of injury under these conditions, it

is recommended that a hot water faucet served by this appliance

be opened for several minutes before using any electrical

appliance connected to the hot water system. If hydrogen is

present there will probably be an unusual sound such as air

escaping through the pipe as the water begins to fl ow. THERE

SHOULD BE NO SMOKING OR OPEN FLAME NEAR THE

FAUCET AT THE TIME IT IS OPEN.

5

Page 6

INTRODUCTION

Thank You for purchasing this water heater. Properly installed

and maintained, it should give you years of trouble free service.

ABBREVIATIONS USED

Abbreviations found in this Instruction Manual include :

ANSI - American National Standards Institute•

ASME - American Society of Mechanical Engineers•

GAMA - Gas Appliance Manufacturer’s Association•

NEC - National Electrical Code•

NFPA - National Fire Protection Association•

UL - Underwriters Laboratory•

CSA - Canadian Standards Association•

QUALIFICATIONS

QUALIFIED INSTALLER OR SERVICE AGENCY

Installation and service of this water heater requires ability

equivalent to that of a Qualifi ed Agency (as defi ned by ANSI

below) in the fi eld involved. Installation skills such as plumbing,

air supply, venting, gas supply and electrical supply are required

in addition to electrical testing skills when performing service.

ANSI Z223.1 2006 Sec. 3.3.83: “Qualifi ed Agency” - “Any

individual, fi rm, corporation or company that either in person or

through a representative is engaged in and is responsible for (a)

the installation, testing or replacement of gas piping or (b) the

connection, installation, testing, repair or servicing of appliances

and equipment; that is experienced in such work; that is familiar

with all precautions required; and that has complied with all the

requirements of the authority having jurisdiction.”

If you are not qualifi ed (as defi ned by ANSI above) and licensed

or certifi ed as required by the authority having jurisdiction

to perform a given task do not attempt to perform any of the

procedures described in this manual. If you do not understand

the instructions given in this manual do not attempt to perform

any procedures outlined in this manual.

6

Page 7

FEATURES AND COMPONENTS

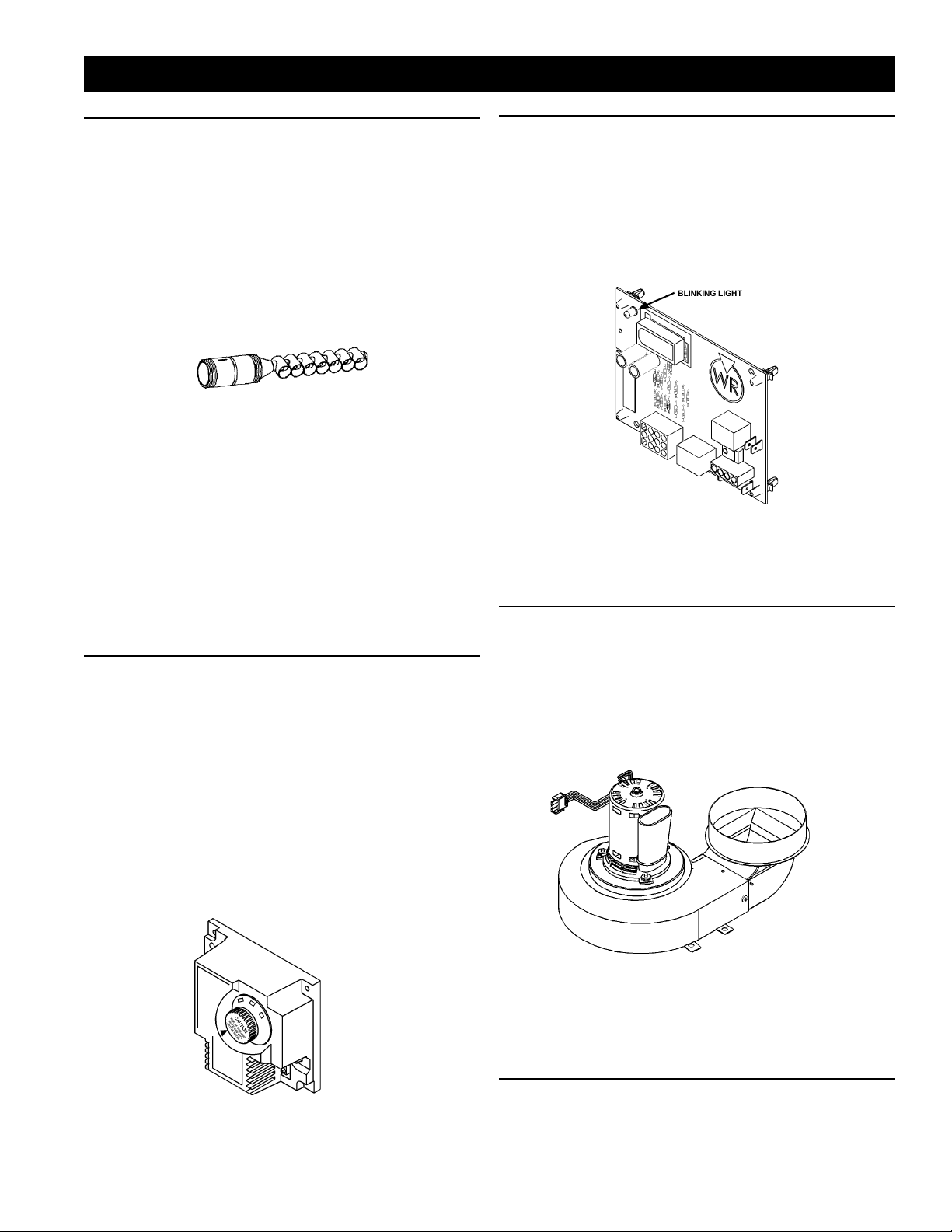

THE ELIMINATOR (SELF-CLEANING SYSTEM)

These units include The Eliminator (Self-Cleaning System)

installed in the front water inlet, See Figure 1. The Eliminator

must be oriented correctly for proper function. There is a marked

range on the pipe nipple portion of the Eliminator, that must be

aligned with the top of the inlet spud. A label above the jacket

hole has an arrow that will point to the marked portion of the pipe

nipple if the orientation is correct. If the arrow does not point

within the marked range on the pipe nipple, adjust the pipe nipple

to correct. A pipe union is supplied with the Eliminator to reduce

the probability of misaligning the Eliminator accidentally while

tightening the connection to the inlet water supply line. Improper

orientation of the Eliminator can cause poor performance of the

heater and can signifi cantly reduce outlet water temperatures

during heavy draws.

Note: The inlet tube may have 1, 3 or 7 cross tubes.

FIGURE 1

For proper function, the Eliminator must be oriented correctly.

There is a marked range on the pipe nipple that must be aligned

with the top of the inlet spud (check for label on the appliance)

to assure proper operation. Please check to confirm that

the marked range is in alignment with the top of the spud. A

pipe union is supplied with the Eliminator to help eliminate

the possibility of changing the orientation by accidentally

overtightening the inlet supply. Improper orientation of the

Eliminator may cause temperature buildup issues or spells of

colder than usual water temperatures.

HIGH LIMIT SWITCH

The digital thermostat (Figure 2) contains the high limit (energy

cutoff) sensor. The high limit switch interrupts main burner gas

fl ow should the water temperature reach 203°F (95°C).

In the event of high limit switch operation, the appliance cannot be

restarted unless the water temperature is reduced to approximately

120°F (49°C). The high limit reset button on the front of the control

then needs to be depressed.

Continued manual resetting of high limit control, preceded by

higher than usual water temperature is evidence of high limit

switch operation. The following is a possible reason for high limit

switch operation:

• A malfunction in the thermostatic controls would allow the gas

valve to remain open causing water temperature to exceed the

thermostat setting. The water temperature would continue to

rise until high limit switch operation.

Contact your dealer or service agent if continued high limit switch

operation occurs.

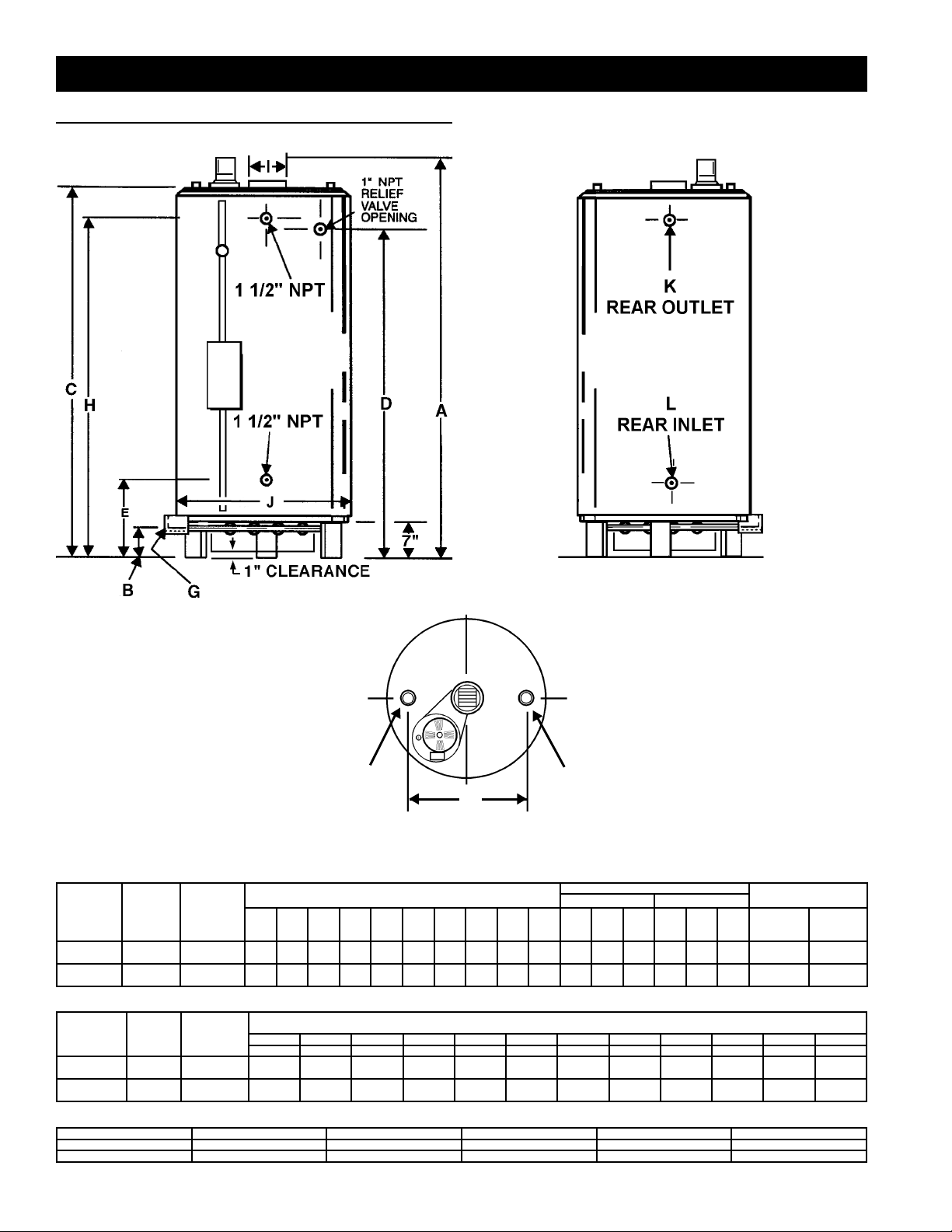

ELECTRONIC IGNITION CONTROL

Each heater is equipped with a ignition module. The solid sate

ignition control (Figure 3), ignites the main burner by utilizing a

silicone nitride ignitor. The silicone nitride ignitor shuts off during

the heating cycle and the main burner fl ame is sensed through

a remote fl ame sensor integral to the silicone nitride ignitor

assembly.

The ignition control will try to ignite the main burner three times

before lockout. Then it waits one hour before trying again to ignite

the main burners. This is a continuous cycle.

IGNITION CONTROL BOARD

FIGURE 3

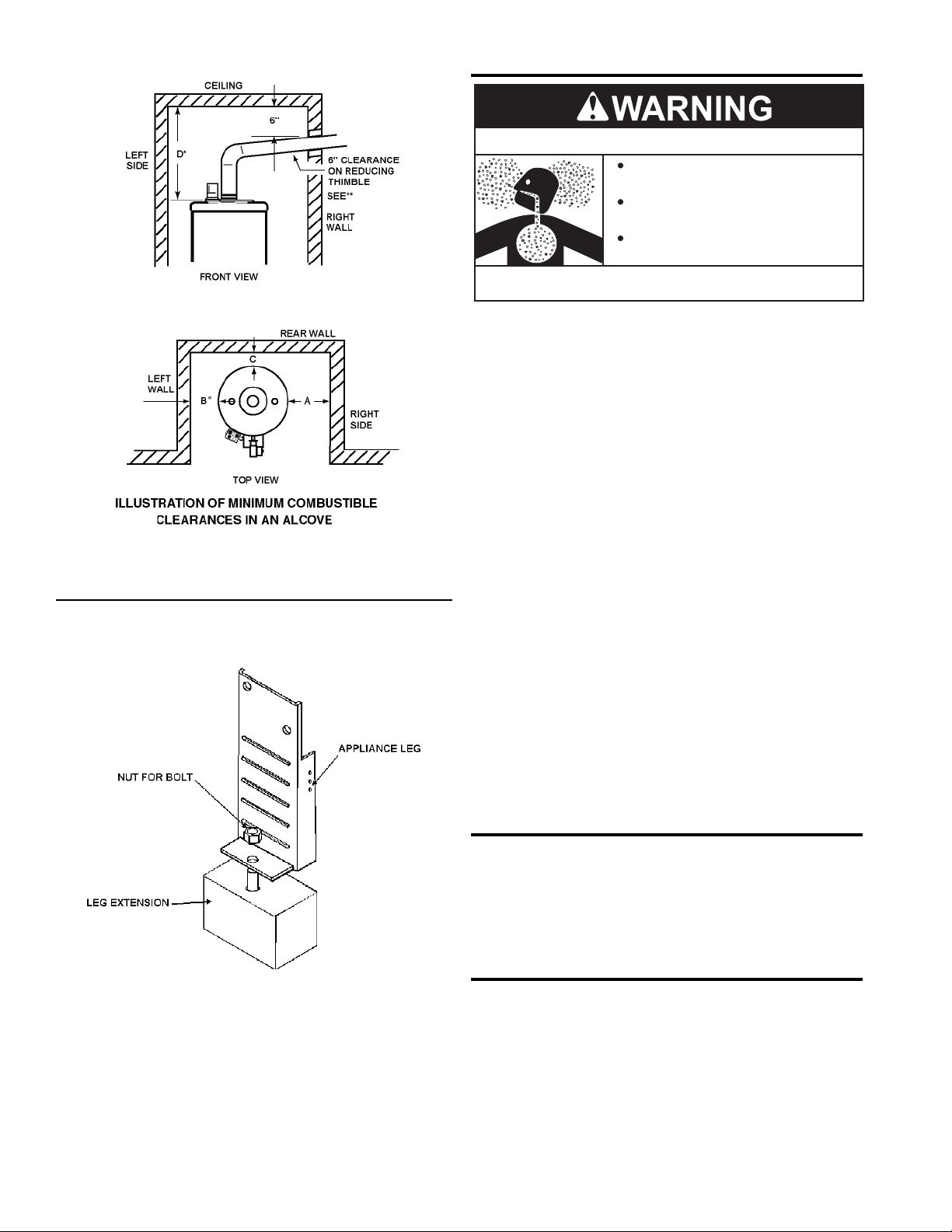

EXHAUST INDUCER (BLOWER ASSY.)

The SBD85500NE/SBD85500PE models are equipped with an

exhaust inducer. The inducer assists in drawing in fresh air to the

unit for combustion and then assists in dispensing the combustion

by-products into the venting leading outside.

The exhaust inducer is equipped with a gravity controlled damper

to reduce the amount of heat loss through the fl ue, improving

effi ciency.

DIGITAL THERMOSTAT

FIGURE 2

EXHAUST INDUCER

FIGURE 4

FAILURE TO FOLLOW THESE INSTRUCTIONS CAN RESULT IN

SERIOUS PERSONAL INJURY OR DEATH.

UNCRATING

The heater is shipped with the inducer already installed. The

wiring conduit runs from the thermostat to the inducer. Before

turning unit on, check to make sure the wiring conduit is securely

plugged into the inducer.

7

Page 8

ROUGH IN DIMENSIONS

INSTALLATION CONSIDERATIONS

FRONT VIEW

TOP

OUTLET

1 1/2” NPT

TOP

F

INLET

1 1/2” NPT

BACK VIEW

TOP VIEW

TABLE 1. ROUGH-IN-DIMENSIONS

FIGURE 5

Connections

Inlet (NPT) Outlet (NPT)

Approx. Ship Weight

Lbs/

Kgs.

745 857

338 389

Model

SBD85500NE/

SBD85500PE

SBD85500NE/

SBD85500PE

Input Rate

Btu/Hr

Kw/Hr

500,000 85

Approximate

Tank Cap

147 322

Dimensions in Inches/cm

Gas

G/L

ABCDEF

81.50 17.50 77.25 67.50 27.13 21.00 1.00 67.50 8.00 27.75

207 44 196 171 69 53 3 171 20 70

Inlet

GH

Vent

Dia

IJ

Top Front Back Top Front Back Std.

1.50 1.50 1.50 1.50 1.50 1.50

1.50 1.50 1.50 1.50 1.50 1.50

TABLE 2. RECOVERY CAPACITIES, based on 80% effi ciency

Input Rate

Model

SBD85500NE/

SBD85500PE 500,000 85 1616 1212 970 808 693 606 539 485 441 404 373 346

SBD85500NE/

SBD85500PE 147 322 6118 4588 3671 3059 2622 2294 2039 1835 1668 1529 1412 1311

Btu/Hr

Kw/Hr

Approximate

Tank Cap

G/L

30°F 40°F 50°F 60°F 70°F 80°F 90°F 100°F 110°F 120°F 130°F 140°F

(-1)°C 4°C 10°C 15°C 21°C 27°C 32°C 38°C 43°C 49°C 54°C 60°C

Recovery Rating Capacities (GPH and LPH)

TABLE 3. GAS AND ELECTRICAL CHARACTERISTICS

Model Type of Gas Inches of W.C. kPA Volts/Hz Amperes

SBD85500NE/SBD85500PE Natural 3.50" 0.87 120/60 <5

SBD85500NE/SBD85500PE Propane 10.00" 2.48 120/60 <5

ASME

Lbs/

Kgs.

8

Page 9

INSTALLATION CONSIDERATIONS

LOCATING THE WATER HEATER

CAUTION

Property Damage Hazard

All water heaters eventually leak.

•

Do not install without adequate drainage.

•

When installing the heater, consideration must be given to proper

location. Location selected should be as close to the stack or chimney

as practicable, with adequate air supply and as centralized with the piping

system as possible.

Fire or Explosion Hazard

Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

Avoid all ignition sources if you smell gas.

Do not expose water heater controls to excessive gas

pressure.

Use only the gas shown on the water heater rating label.

Maintain required clearances to combustibles.

Keep ignition sources away from faucets after extended

periods of non-use.

Read instruction manual before

installing, using or servicing

water heater.

THERE IS A RISK IN USING FUEL BURNING APPLIANCES SUCH AS

GAS WATER HEATERS IN ROOMS, GARAGES OR OTHER AREAS

WHERE GASOLINE, OTHER FLAMMABLE LIQUIDS OR ENGINE

DRIVEN EQUIPMENT OR VEHICLES ARE STORED, OPERATED OR

REPAIRED. FLAMMABLE VAPORS ARE HEAVY AND TRAVEL ALONG

THE FLOOR AND MAY BE IGNITED BY THE HEATER’S PILOT OR MAIN

BURNER FLAMES CAUSING FIRE OR EXPLOSION. SOME LOCAL

CODES PERMIT OPERATION OF GAS APPLIANCES IN SUCH AREAS

IF THEY ARE INSTALLED 18” OR MORE ABOVE THE FLOOR. THIS

MAY REDUCE THE RISK IF LOCATION IN SUCH AN AREA CANNOT

BE AVOIDED.

DO NOT INSTALL THIS WATER HEATER DIRECTLY ON A CARPETED

FLOOR. A FIRE HAZARD MAY RESULT. Instead the water heater must

be placed on a metal or wood panel extending beyond the full width and

depth by at least 3 inches in any direction. If the heater is installed in a

carpeted alcove, the entire fl oor shall be covered by the panel. Also, see

the DRAINING requirements in MAINTENANCE Section.

THE HEATER SHALL BE LOCATED OR PROTECTED SO IT IS NOT

SUBJECT TO PHYSICAL DAMAGE BY A MOVING VEHICLE.

FLAMMABLE ITEMS, PRESSURIZED CONTAINERS OR ANY

OTHER POTENTIAL FIRE HAZARDOUS ARTICLES MUST

NEVER BE PLACED ON OR ADJACENT TO THE HEATER.

OPEN CONTAINERS OR FLAMMABLE MATERIAL SHOULD

NOT BE STORED OR USED IN THE SAME ROOM WITH THE

HEATER.

THE HEATER MUST NOT BE LOCATED IN AN AREA WHERE

IT WILL BE SUBJECT TO FREEZING.

LOCATE IT NEAR A FLOOR DRAIN. THE HEATER SHOULD

BE LOCATED IN AN AREA WHERE LEAKAGE FROM THE

HEATER OR CONNECTIONS WILL NOT RESULT IN DAMAGE

TO THE ADJACENT AREA OR TO LOWER FLOORS OF THE

STRUCTURE.

WHEN SUCH LOCATIONS CANNOT BE AVOIDED, A SUITABLE

DRAIN PAN SHOULD BE INSTALLED UNDER THE HEATER.

Such pans should be fabricated with sides at least 2” deep, with

length and width at least 2” greater than the diameter of the heater

and must be piped to an adequate drain. The pan must not restrict

combustion air fl ow.

LEVELING

If the unit is not level, insert the bolts which were used in crating

into the legs to correct this condition.

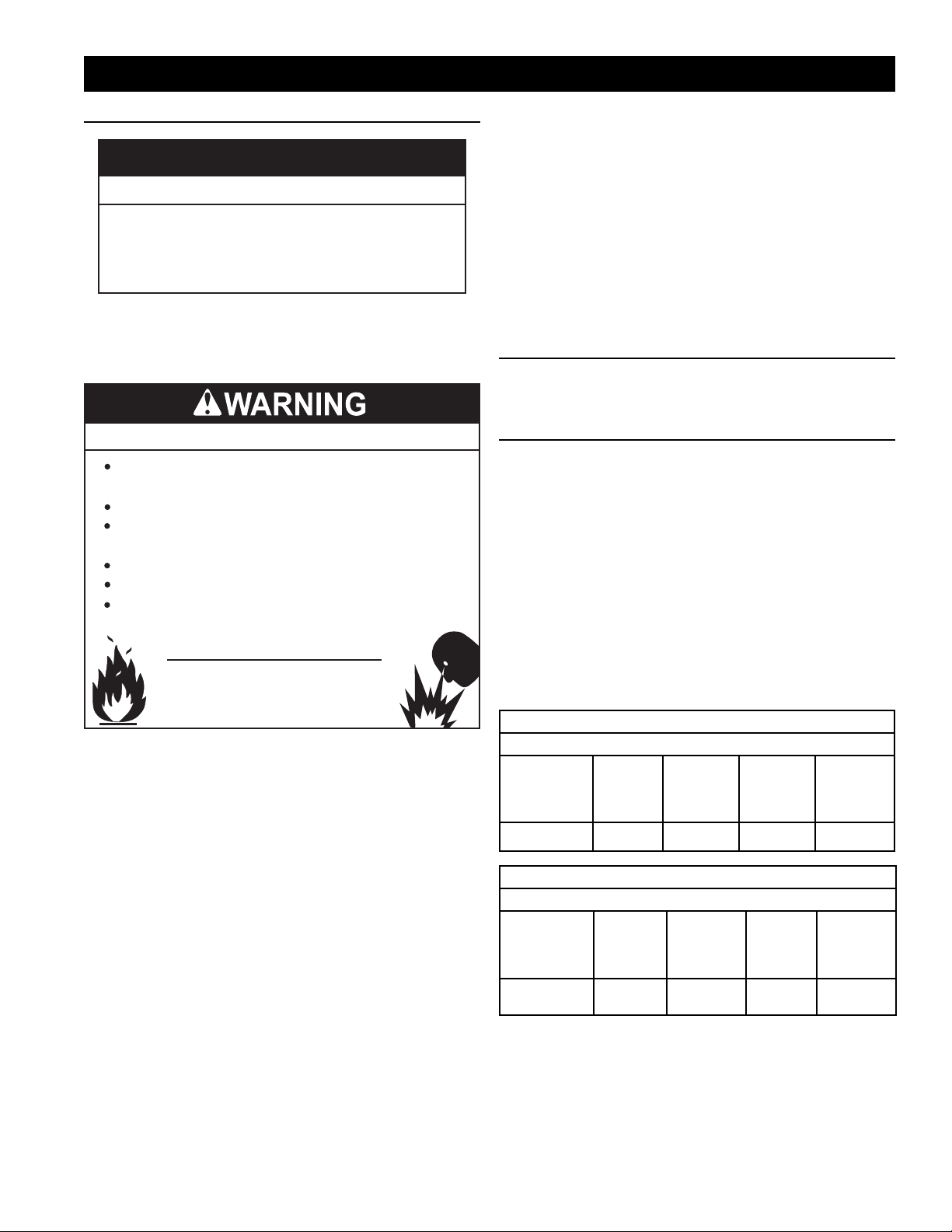

CLEARANCES

This water heater is approved for installation on combustible

fl ooring (with Installation on Combustible Flooring #9003425205)

in an alcove when the minimum clearance from any combustion

construction are followed as indicated in Figure 7 and Table 4.

In all installations the minimum combustible clearances from

vent piping shall be 6” (152mm). Vent piping passing through a

combustible wall or ceiling must be a continuous run (no joints)

and retain the 6” (152mm) clearance unless an approved reducing

thimble is used.

A service clearance of 24” (610mm) should be maintained from

serviceable parts, such as relief valves, fl ue baffl es, thermostats,

cleanout openings or drain valves.

The units are approved for installation with side, rear and ceiling

clearances as indicated below:

TABLE 4

MINIMUM CLEARANCES TO COMBUSTIBLES IN INCHES (mm)

"A"

RIGHT

MODEL

SBD85500NE/

SBD85500PE

SIDE

5"

(12.7 mm)

TABLE 5

MINIMUM CLEARANCES TO NONCOMBUSTIBLE CONSTRUCTION

"A"

RIGHT

MODEL

SBD85500NE/

SBD85500PE

SIDE

0 0 0 12"

"B"

LEFT

SIDE

5"

(12.7 mm)

"B"

LEFT

SIDE

"C"

BACK

5"

(12.7 mm)

"C"

BACK

"D"

CEILING

20"

(508mm)

"D"

CEILING

(305 mm)

9

Page 10

.

FIGURE 6

INSTALLATION ON COMBUSTIBLE FLOORING

The SBD85500NE/SBD85500PE is approved for installations

on combustible fl ooring when installed with leg kit number

9003425205.

INSULATION BLANKET

Breathing Hazard - Carbon Monoxide Gas

Do not obstruct water heater air intake

with insulating blanket.

Gas and carbon monoxide detectors

are available.

Install water heater in accordance with

the instruction manual.

Breathing carbon monoxide can cause brain damage or

death. Always read and understand instruction manual.

Insulation blankets are available to the general public for external

use on gas water heaters but are not necessary with these

products. The purpose of an insulation blanket is to reduce the

standby heat loss encountered with storage tank heaters. The

water heaters covered by this manual meet or exceed the Energy

Policy Act standards with respect to insulation and standby heat

loss requirements, making an insulation blanket unnecessary.

Should you choose to apply an insulation blanket to this

heater, you should follow these instructions. See the Features

and Components section of this manual for identifi cation of

components mentioned below. Failure to follow these instructions

can restrict the air fl ow required for proper combustion, potentially

resulting in fi re, asphyxiation, serious personal injury or death.

DO NOT• apply insulation to the top of the water heater, as

this will interfere with safe operation of the draft hood.

DO NOT• cover the gas valve, thermostat or the TemperaturePressure Relief Valve.

DO NOT• allow insulation to come within 2” (5 cm) of the

burners, to prevent blockage of combustion air fl ow to the

burners.

DO NOT• allow insulation to come within 9 inches (23 cm)

of fl oor, (within 2 inches (5 cm) of bottom cover) to prevent

blockage of combustion air fl ow to the burners..

DO NOT• cover the instruction manual. Keep it on the side of

the water heater or nearby for future reference.

DO• obtain new warning and instruction labels from the

manufacturer for placement on the blanket directly over the

existing labels.

DO• inspect the insulation blanket frequently to make certain

it does not sag, thereby obstructing combustion air fl ow.

HARD WATER

FIGURE 7

Unit needs to be lifted in a way not to damage unit or laid 1.

on it’s side to access the bottom of the legs.

Slide leg extension under leg and the bolt up through the 2.

bottom hole located in the bottom of the leg.

Once in place, screw nut down and secure.3.

Front of leg should line up with front of leg extension as 4.

shown to make sure weight of unit is distributed through the

leg extension.

Where hard water conditions exist, water softening or the

threshold type of water treatment is recommended. This will

protect the dishwashers, coffee urns, water heaters, water piping

and other equipment.

See the Maintenance Section in this manual for sediment and

lime scale removal procedures.

CIRCULATION PUMPS

A circulating pump is used when a system requires a circulating

loop or there is a storage tank used in conjunction with the water

heater. See Water Piping Diagrams in this manual for installation

location of circulating pumps.

See the Circulation Pump Wiring Diagrams in this manual for

electrical hookup information. Install in accordance with the

current edition of the National Electrical Code, NFPA 70 or the

Canadian Electrical Code, CSA C22.1.

All-bronze circulators are recommended for used with commercial

water heaters.

10

Page 11

Some circulating pumps are manufactured with sealed bearings

and do not require further lubrication. Some circulating pumps

must be periodically oiled. Refer to the pump manufacturer’s

instructions for lubrication requirements.

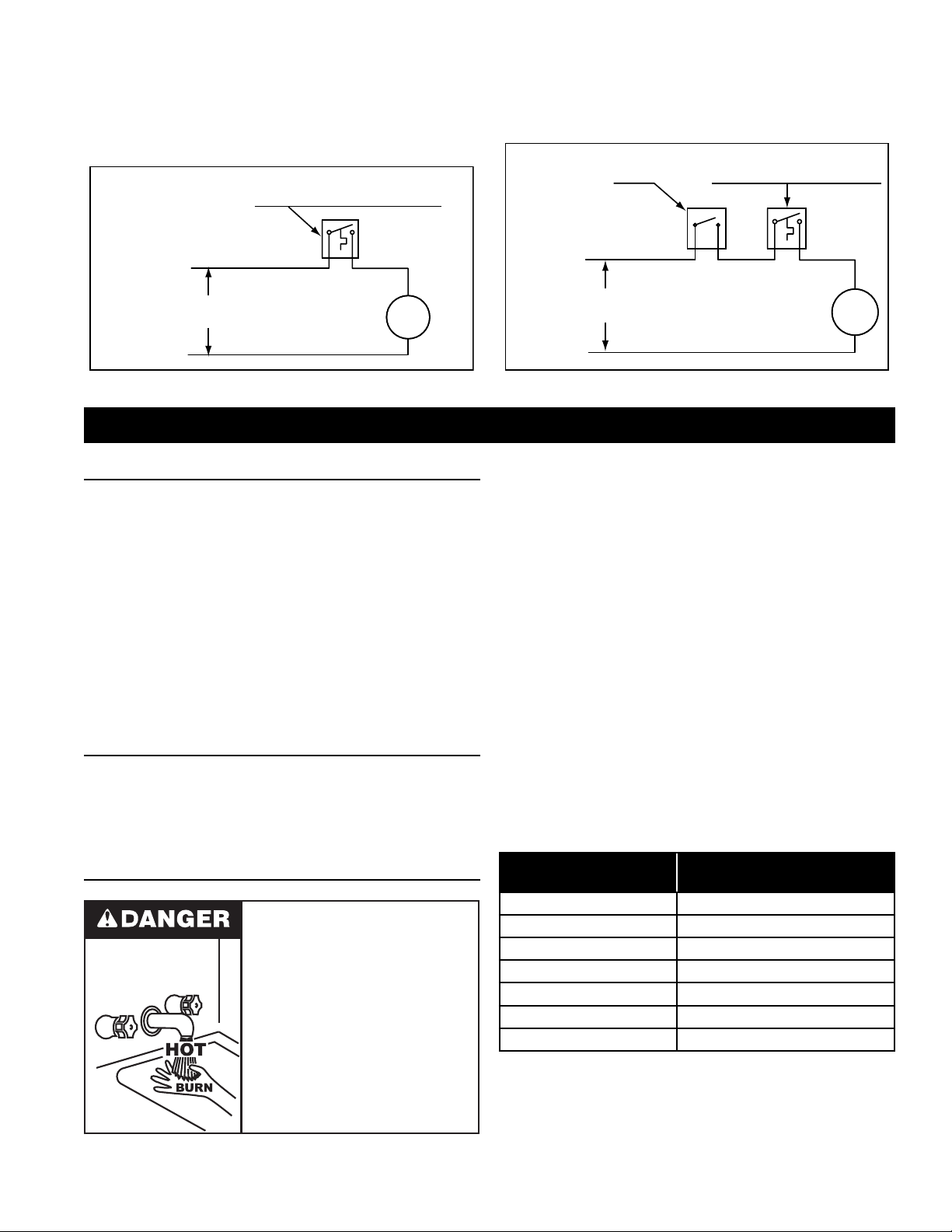

CIRCULATING PUMP WIRING DIAGRAM

STORAGE TANK OR BUILDING RECIRCULATION

FIELD SUPPLIED TEMPERATURE CONTROL

INSTALLED IN THE STORAGE TANK

NOTE: USE SEPARATE 120 VAC POWER

SUPPLY FOR PUMP CIRCUIT. DO NOT

SHARE POWER WITH APPLIANCE AS THIS

MAY CAUSE ELECTRICAL LINE NOISE AND

LEAD TO ERRATIC CONTROL SYSTEM

OPERATION.

L1 HOT

OR CIRCULATING LOOP RETURN LINE

CIRCULATING PUMP WIRING DIAGRAM

DISHWASHER LOOP WITH TOGGLE SWITCH

DISHWASHER

TOGGLE

SWITCH

NOTE: USE SEPARATE 120 VAC POWER

SUPPLY FOR PUMP CIRCUIT. DO NOT

SHARE POWER WITH APPLIANCE AS THIS

MAY CAUSE ELECTRICAL LINE NOISE AND

LEAD TO ERRATIC CONTROL SYSTEM

OPERATION.

L1 HOT

FIELD SUPPLIED TEMPERATURE

CONTROL INSTALLED IN THE

CIRCULATING LOOP RETURN LINE

L2 NEUTRAL

120 VAC

POWER

FIGURE 8

CIRC

PUMP

MOTOR

INSTALLATION REQUIREMENTS

SUPPLY GAS REGULATOR

The water heater covered by this manual requires a supply gas

regulator to be installed in the supply gas line serving the water

heater for proper operation. Supply gas regulators are required

on high and low pressure gas supply systems.

NOTE: On multiple water heater installations each water heater

shall have its own dedicated supply gas regulator installed in the

supply gas line serving the water heater.

Supply gas regulators must be rated at or above the input Btu/

hr rating of the water heater they supply. Supply gas regulators

shall have inlet and outlet connections not less than the minimum

supply gas line size for the water heater they serve as shown in

Table 5. The Maxitrol 325-7L or equivalent is recommended.

See Supply Gas Regulator Installation on page 11.

POWER SUPPLY

The water heaters covered in this manual require a 120 VAC,

1Ø (single phase), 60Hz, 15 amp power supply and must also

be electrically grounded in accordance with local codes or, in the

absence of local codes, with the National Electrical Code, ANSI/

NFPA 70 or the Canadian Electrical Code, CSA C22.1.

MIXING VALVES

Water temperature over 125°F (52°C)

can cause severe burns instantly

resulting in severe injury or death.

Children, the elderly and the

physically or mentally disabled are at

highest risk for scald injury.

Feel water before bathing or

showering.

Temperature limiting devices such as

mixing valves must be installed

when required by codes and to

ensure safe temperatures at fixtures.

L2 NEUTRAL

120 VAC

POWER

FIGURE 9

CIRC

PUMP

MOTOR

Water heated to a temperature which will satisfy clothes washing,

dish washing, and other sanitizing needs can scald and cause

permanent injury upon contact. Short repeated heating cycles

caused by small hot water uses can cause temperatures at the

point of use to exceed the water heater’s temperature setting by

up to 20°F (11°C).

Some people are more likely to be permanently injured by

hot water than others. These include the elderly, children, the

infi rm and the physically/mentally disabled. Table 6 shows the

approximate time-to-burn relationship for normal adult skin.

If anyone using hot water provided by the water heater being

installed fi ts into one of these groups or if there is a local code

or state law requiring a certain water temperature at the point of

use, then special precautions must be taken.

In addition to using the lowest possible temperature setting that

satisfi es the demand of the application a Mixing Valve should be

installed at the water heater (see Figure 10) or at the hot water

taps to further reduce system water temperature.

Mixing valves are available at plumbing supply stores. Consult

a Qualifi ed Installer or Service Agency. Follow mixing valve

manufacturer’s instructions for installation of the valves.

TABLE 6

Water Temperature

Time to Produce 2nd & 3rd

Degree Burns on Adult Skin

180°F (82°C) Nearly instantaneous

170°F (77°C) Nearly instantaneous

160°F (71°C) About 1/2 second

150°F (66°C) About 1-1/2 seconds

140°F (60°C) Less than 5 seconds

130°F (54°C) About 30 seconds

120°F (49°C) More than 5 minutes

11

Page 12

DISHWASHING MACHINES

All dishwashing machines meeting the National Sanitation

Foundation requirements are designed to operate with water fl ow

pressures between 15 and 25 pounds per square inch (103 kPa

and 173 kPa). Flow pressures above 25 pounds per square inch

(173 kPa), or below 15 pounds per square inch (103 kPa), will

result in improperly sanitized dishes. Where pressures are high,

a water pressure reducing or fl ow regulating control valve should

be used in the 180°F (82°C) line to the dishwashing machine

and should be adjusted to deliver water pressure between these

limits.

A properly sized thermal expansion tank must be installed on

all closed systems to control the harmful effects of thermal

expansion. Contact a local plumbing service agency to have a

thermal expansion tank installed.

See Water Line Connections on page 19 and the Water Piping

Diagrams beginning on page 33.

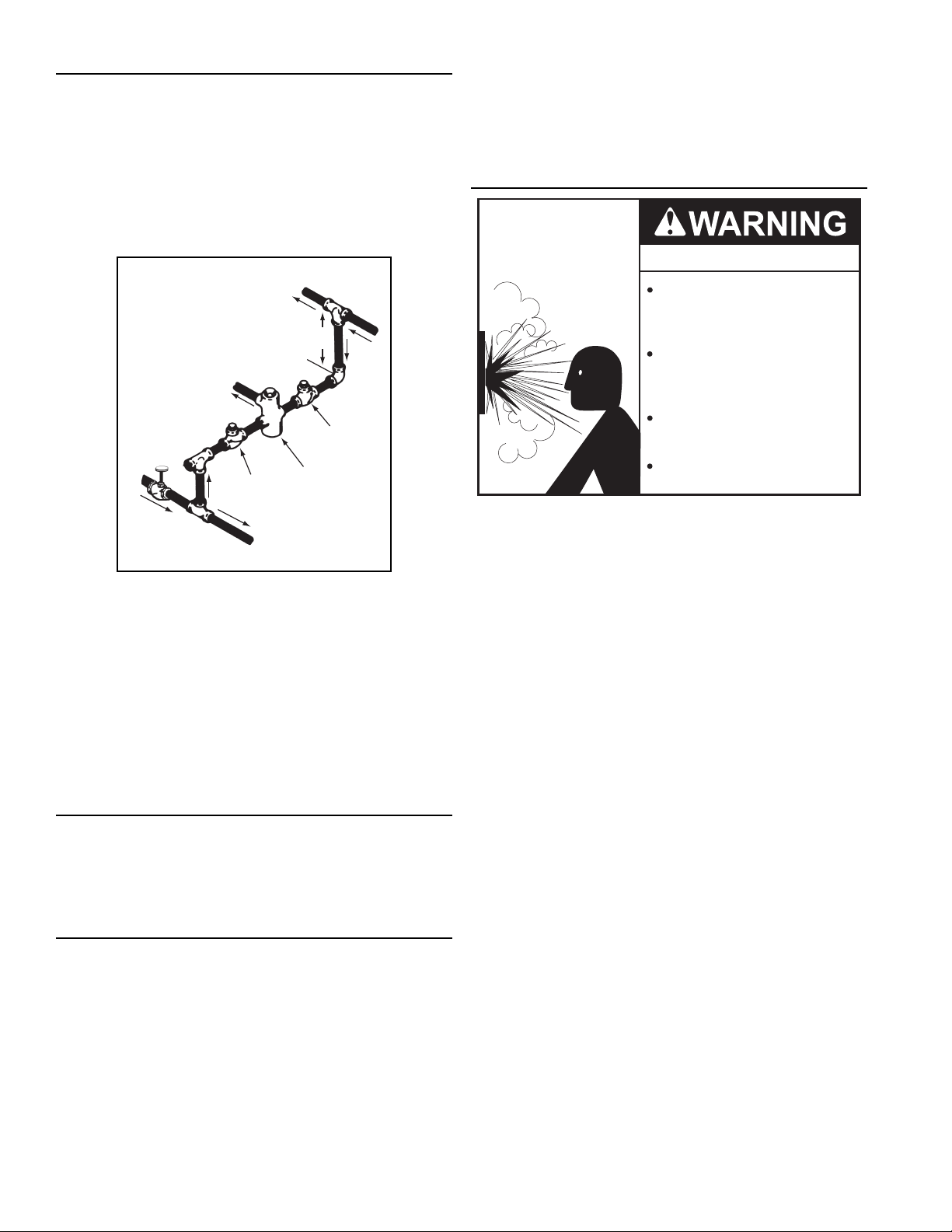

TEMPERATURE-PRESSURE RELIEF VALVE

Explosion Hazard

HOT WATER

OUTLET

12” TO 15”

(30-38 cm)

TEMPERED WATER

OUTLET

COLD

WATER

INLET

CHECK

VALV E

TO TANK

INLET

CHECK

VALV E

MIXING

VALV E

Figure 10

The National Sanitation Foundation also recommends circulation

of 180°F (82°C) water. Where this is done, the circulation should

be very gentle so that it does not cause any unnecessary

turbulence inside the water heater. The circulation should be just

enough to provide 180°F (82°C) water at the point of take-off to

the dishwashing machine.

Adjust fl ow by throttling a full port ball valve installed in the

circulating line on the outlet side of the pump. Never throttle fl ow

on the suction side of a pump. See Water Piping Diagrams in

this manual.

CLOSED WATER SYSTEMS

Water supply systems may, because of code requirements

or such conditions as high line pressure, among others, have

installed devices such as pressure reducing valves, check

valves, and back fl ow preventers. Devices such as these cause

the water system to be a closed system.

THERMAL EXPANSION

As water is heated, it expands (thermal expansion). In a closed

system the volume of water will grow when it is heated. As the

volume of water grows there will be a corresponding increase

in water pressure due to thermal expansion. Thermal expansion

can cause premature tank failure (leakage). This type of failure

is not covered under the limited warranty. Thermal expansion

can also cause intermittent Temperature-Pressure Relief Valve

operation: water discharged from the valve due to excessive

pressure build up. This condition is not covered under the limited

warranty. The Temperature-Pressure Relief Valve is not intended

for the constant relief of thermal expansion.

Temperature-Pressure Relief Valve

must comply with ANSI Z21.22CSA 4.4 and ASME code.

Properly sized temperaturepressure relief valve must be

installed in opening provided.

Can result in overheating and

excessive tank pressure.

Can cause serious injury or death.

This water heater is provided with a properly rated/sized and

certifi ed combination Temperature-Pressure Relief Valve (T&P

valve) by the manufacturer. The valve is certifi ed by a nationally

recognized testing laboratory that maintains periodic inspection

of production of listed equipment of materials as meeting the

requirements for Relief Valves for Hot Water Supply Systems,

ANSI Z21.22 • CSA 4.4, and the code requirements of ASME.

If replaced, the new T&P valve must meet the requirements

of local codes, but not less than a combination TemperaturePressure Relief Valve rated/sized and certifi ed as indicated in

the above paragraph. The new valve must be marked with a

maximum set pressure not to exceed the marked hydrostatic

working pressure of the water heater (150 psi = 1,035 kPa) and

a discharge capacity not less than the water heater Btu/hr or kW

input rate as shown on the water heater’s model rating label.

NOTE: In addition to the factory installed Temperature-Pressure

Relief Valve on the water heater, each remote storage tank that

may be installed and piped to a water heating appliance must also

have its own properly sized, rated and approved TemperaturePressure Relief Valve installed. Call the toll free technical

support phone number listed on the back cover of this manual

for technical assistance in sizing a Temperature-Pressure Relief

Valve for remote storage tanks.

For safe operation of the water heater, the Temperature-Pressure

Relief Valve must not be removed from its designated opening

nor plugged. The Temperature-Pressure Relief Valve must be

installed directly into the fi tting of the water heater designed for the

relief valve. Install discharge piping so that any discharge will exit

the pipe within 6 inches (15.2 cm) above an adequate fl oor drain,

or external to the building. In cold climates it is recommended

that it be terminated at an adequate drain inside the building. Be

certain that no contact is made with any live electrical part. The

discharge opening must not be blocked or reduced in size under

any circumstances. Excessive length, over 30 feet (9.14 m), or

use of more than four elbows can cause restriction and reduce

the discharge capacity of the valve.

12

Page 13

No valve or other obstruction is to be placed between the

Temperature-Pressure Relief Valve and the tank. Do not connect

discharge piping directly to the drain unless a 6” (15.2 cm)

air gap is provided. To prevent bodily injury, hazard to life, or

property damage, the relief valve must be allowed to discharge

water in adequate quantities should circumstances demand. If

the discharge pipe is not connected to a drain or other suitable

means, the water fl ow may cause property damage.

CAUTION

Water Damage Hazard

Temperature-Pressure Relief Valve discharge

•

pipe must terminate at adequate drain.

regarding the Temperature-Pressure Relief Valve call the toll

free number listed on the back cover of this manual for technical

assistance.

CONTAMINATED AIR

Breathing Hazard - Carbon Monoxide Gas

Install water heater in accordance with

the Instruction Manual and NFPA 54 or

CAN/CSA-B149.1.

To avoid injury, combustion and ventilation

air must be taken from outdoors.

Do not place chemical vapor emitting

products near water heater.

T&P Valve Discharge Pipe Requirements:

Shall not be smaller in size than the outlet pipe size of the •

valve, or have any reducing couplings or other restrictions.

Shall not be plugged or blocked.•

Shall not be exposed to freezing temperatures.•

Shall be of material listed for hot water distribution.•

Shall be installed so as to allow complete drainage of both •

the Temperature-Pressure Relief Valve and the discharge

pipe.

Must terminate a maximum of six inches above a fl oor •

drain or external to the building. In cold climates, it is

recommended that the discharge pipe be terminated at an

adequate drain inside the building.

Shall not have any valve or other obstruction between the •

relief valve and the drain.

Burn hazard.

Hot water discharge.

Keep clear of TemperaturePressure Relief Valve

discharge outlet.

The Temperature-Pressure Relief Valve must be manually

operated at least twice a year. Caution should be taken to ensure

that (1) no one is in front of or around the outlet of the TemperaturePressure Relief Valve discharge line, and (2) the water manually

discharged will not cause any bodily injury or property damage

because the water may be extremely hot. If after manually

operating the valve, it fails to completely reset and continues to

release water, immediately close the cold water inlet to the water

heater, follow the draining instructions in this manual, and replace

the Temperature-Pressure Relief Valve with a properly rated/sized

new one.

NOTE: The purpose of a Temperature-Pressure Relief Valve is

to prevent excessive temperatures and pressures in the storage

tank. The T&P valve is not intended for the constant relief of

thermal expansion. A properly sized thermal expansion tank must

be installed on all closed systems to control thermal expansion,

see Closed Water Systems and Thermal Expansion on page 12.

If you do not understand these instructions or have any questions

Breathing carbon monoxide can cause brain damage or

death. Always read and understand instruction manual.

Corrosion of the fl ue ways and vent system may occur if air for

combustion contains certain chemical vapors. Such corrosion

may result in failure and risk of asphyxiation.

Combustion air that is contaminated can greatly diminish the life

span of the water heater and water heater components such as

hot surface igniters and burners. Propellants of aerosol sprays,

beauty shop supplies, water softener chemicals and chemicals

used in dry cleaning processes that are present in the combustion,

ventilation or ambient air can cause such damage.

Do not store products of this sort near the water heater. Air which

is brought in contact with the water heater should not contain any

of these chemicals. If necessary, uncontaminated air should be

obtained from remote or outdoor sources. The limited warranty

is voided when failure of water heater is due to a corrosive

atmosphere. (See limited warranty for complete terms and

conditions).

AIR REQUIREMENTS

Breathing Hazard - Carbon Monoxide Gas

Install water heater in accordance with

the Instruction Manual and NFPA 54 or

CAN/CSA-B149.1.

To avoid injury, combustion and ventilation

air must be taken from outdoors.

Do not place chemical vapor emitting

products near water heater.

Breathing carbon monoxide can cause brain damage or

death. Always read and understand instruction manual.

For safe operation an adequate supply of fresh uncontaminated

air for combustion and ventilation must be provided.

An insuffi cient supply of air can cause recirculation of combustion

products resulting in contamination that may be hazardous to

life. Such a condition often will result in a yellow, luminous burner

fl ame, causing sooting of the combustion chamber, burners and

fl ue tubes and creates a risk of asphyxiation.

Do not install the water heater in a confi ned space unless an

adequate supply of air for combustion and ventilation is brought

in to that space using the methods described in the Confi ned

13

Page 14

Space section that follows.

Never obstruct the fl ow of ventilation air. If you have any doubts

or questions at all, call your gas supplier. Failure to provide the

proper amount of combustion air can result in a fi re or explosion

and cause property damage, serious bodily injury or death.

UNCONFINED SPACE

An Unconfi ned Space is one whose volume IS NOT LESS THAN

50 cubic feet per 1,000 Btu/hr (4.8 cubic meters per kW) of the

total input rating of all appliances installed in the space. Rooms

communicating directly with the space, in which the appliances

are installed, through openings not furnished with doors, are

considered a part of the unconfi ned space.

Makeup air requirements for the operation of exhaust fans,

kitchen ventilation systems, clothes dryers and fi replaces shall

also be considered in determining the adequacy of a space to

provide combustion, ventilation and dilution air.

UNUSUALLY TIGHT CONSTRUCTION

In unconfi ned spaces in buildings, infi ltration may be adequate to

provide air for combustion, ventilation and dilution of fl ue gases.

However, in buildings of unusually tight construction (for example,

weather stripping, heavily insulated, caulked, vapor barrier, etc.)

additional air must be provided using the methods described in

the Confi ned Space section that follows.

CONFINED SPACE

through the water heater’s vent system causing poor combustion.

Sooting, serious damage to the water heater and the risk of fi re

or explosion may result. It can also create a risk of asphyxiation.

LOUVERS AND GRILLES

The free areas of the fresh air openings in the instructions that

follow do not take in to account the presence of louvers, grilles or

screens in the openings.

The required size of openings for combustion, ventilation and

dilution air shall be based on the “net free area” of each opening.

Where the free area through a design of louver or grille or screen

is known, it shall be used in calculating the size of opening

required to provide the free area specifi ed. Where the louver and

grille design and free area are not known, it shall be assumed

that wood louvers will have 25% free area and metal louvers and

grilles will have 75% free area. Non motorized louvers and grilles

shall be fi xed in the open position.

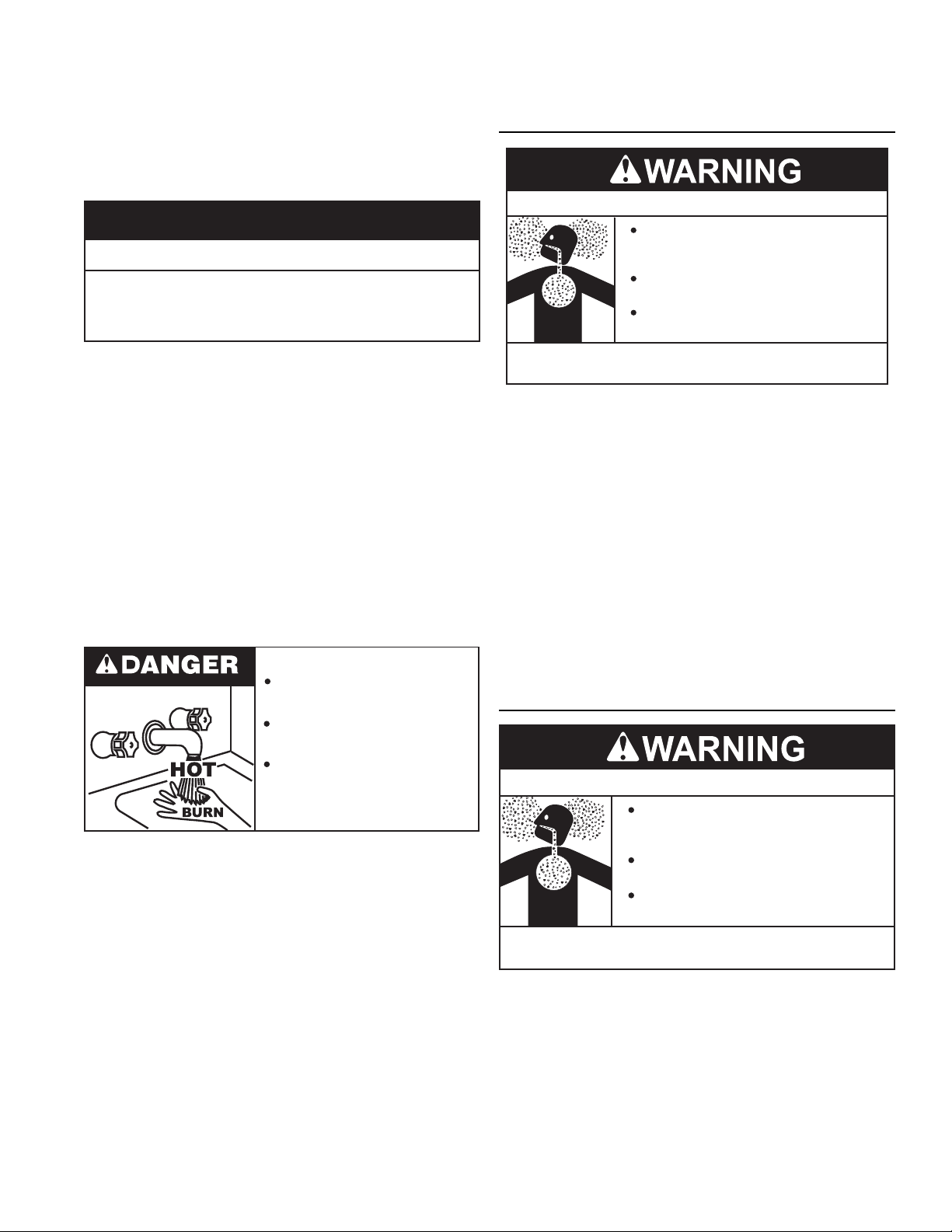

VENT REDUCER

The SBD85500NE/SBD85500PE model is shipped with a 6" to

8" diameter fl ue outlet adapter. Each adapter fi ts on top of the

installed blower exhaust. Use only vent reducers supplied with

the unit. The venting must comply with the NATIONAL FUEL GAS

CODE, ANSI Z223.1/NFPA 54 and for Canadian installations

consult the Canadian Installation Code CAN/CSA B149.1-00.

A Confi ned Space is one whose volume IS LESS THAN 50 cubic

feet per 1,000 Btu/hr (4.8 cubic meters per kW) of the total input

rating of all appliances installed in the space.

Openings must be installed to provide fresh air for combustion,

ventilation and dilution in confi ned spaces. The required size for

the openings is dependent on the method used to provide fresh

air to the confi ned space AND the total Btu/hr input rating of all

appliances installed in the space.

EXHAUST FANS

Where exhaust fans are installed, additional air shall be provided

to replace the exhausted air. When an exhaust fan is installed

in the same space with a water heater, suffi cient openings to

provide fresh air must be provided that accommodate the

requirements for all appliances in the room and the exhaust fan.

Undersized openings will cause air to be drawn into the room

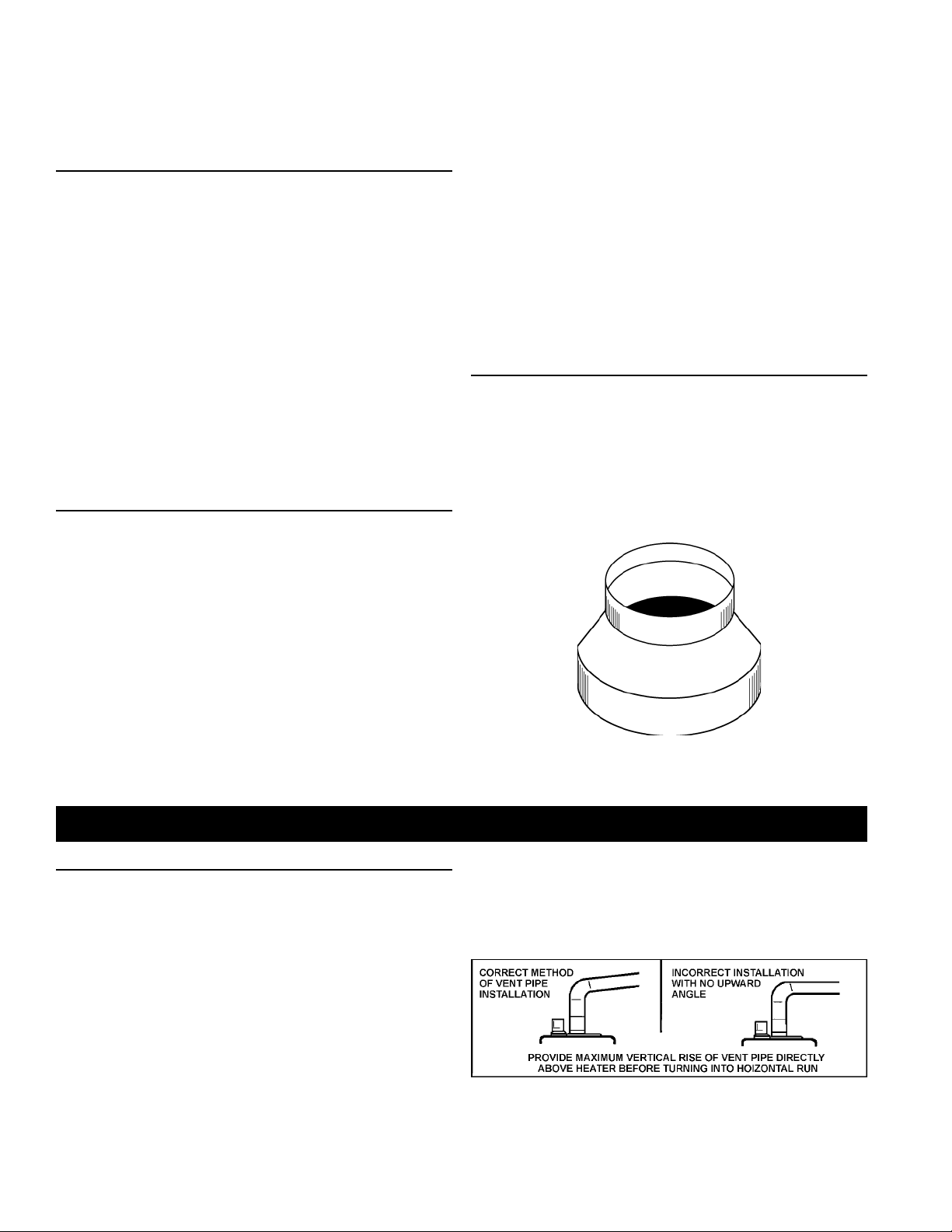

VENTING INSTALLATION

VENTING

THE INSTRUCTIONS IN THIS SECTION ON VENTING MUST

BE FOLLOWED TO AVOID CHOKED COMBUSTION OR

RECIRCULATION OF FLUE GASES. SUCH CONDITIONS

CAUSE SOOTING OR RISKS OF FIRE AND ASPHYXIATION.

Heater must be protected from freezing downdrafts.

Remove all soot or other obstructions from the chimney that will

retard a free draft.

Type B venting is recommended with these heaters. For typical

venting application see TECHNICAL DATA VENTING on pages

17 and 18.

This water heater must be vented in compliance with all local

codes, the current revision of the National Fuel Gas Code (ANSIZ223.1) and with the Category I Venting Tables.

If any part of the vent system are exposed to ambient temperatures

below 40°F it must be insulated to prevent condensation.

Figure 11

• Do not connect the heater to a common vent or chimney with

solid fuel burning equipment. This practice is prohibited by

many local building codes as is the practice of venting gas

fi red equipment to the duct work of ventilation systems.

FIGURE 12

• Where a separate vent connection is not available and the

vent pipe from the heater must be connected to a common

14

Page 15

vent with an oil burning furnace, the vent pipe should enter the

smaller common vent or chimney at a point above the large

vent pipe.

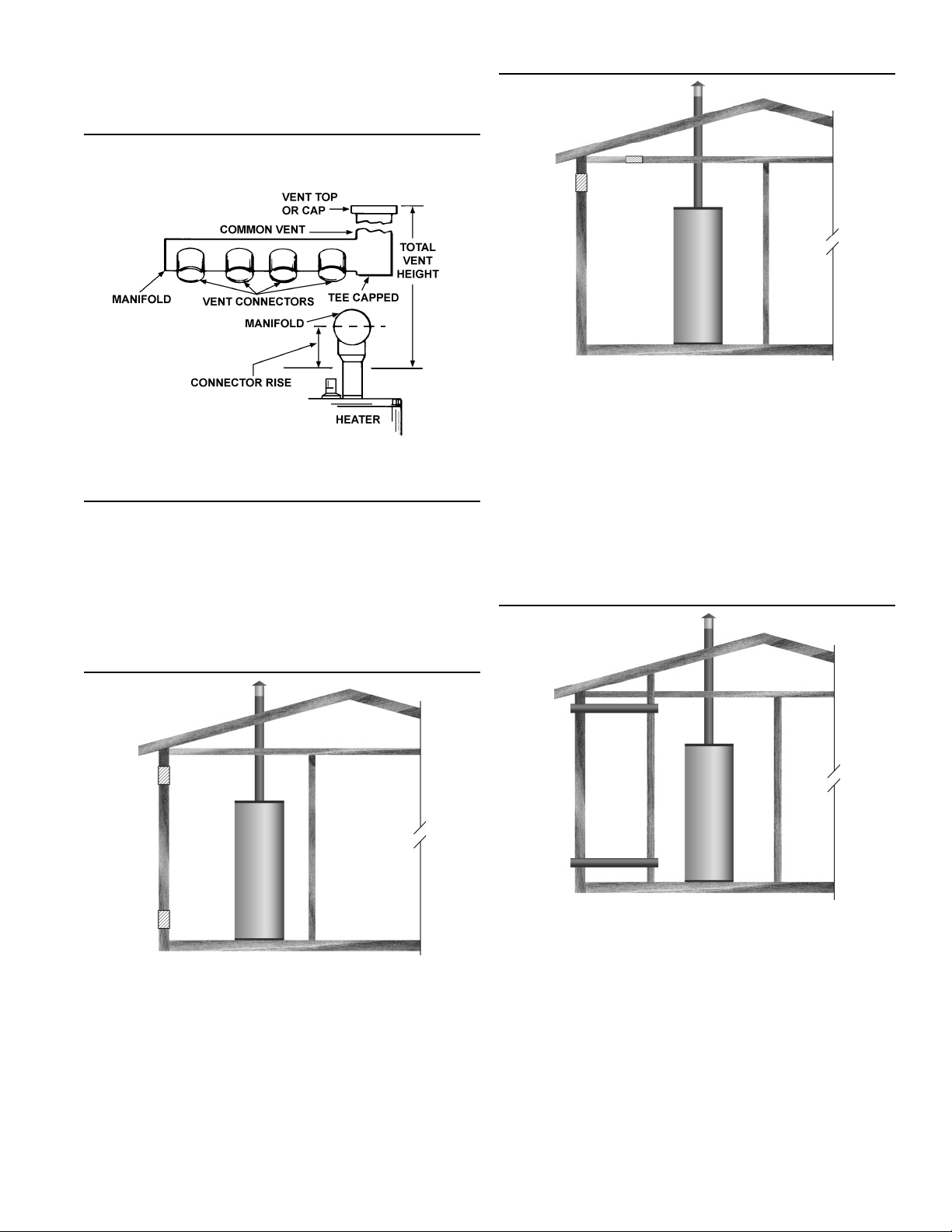

MULTIPLE HEATER MANIFOLD

Figure 13 and tables on pages 17 and 18 should be used for

horizontally manifolding two or more heaters.

FIGURE 13

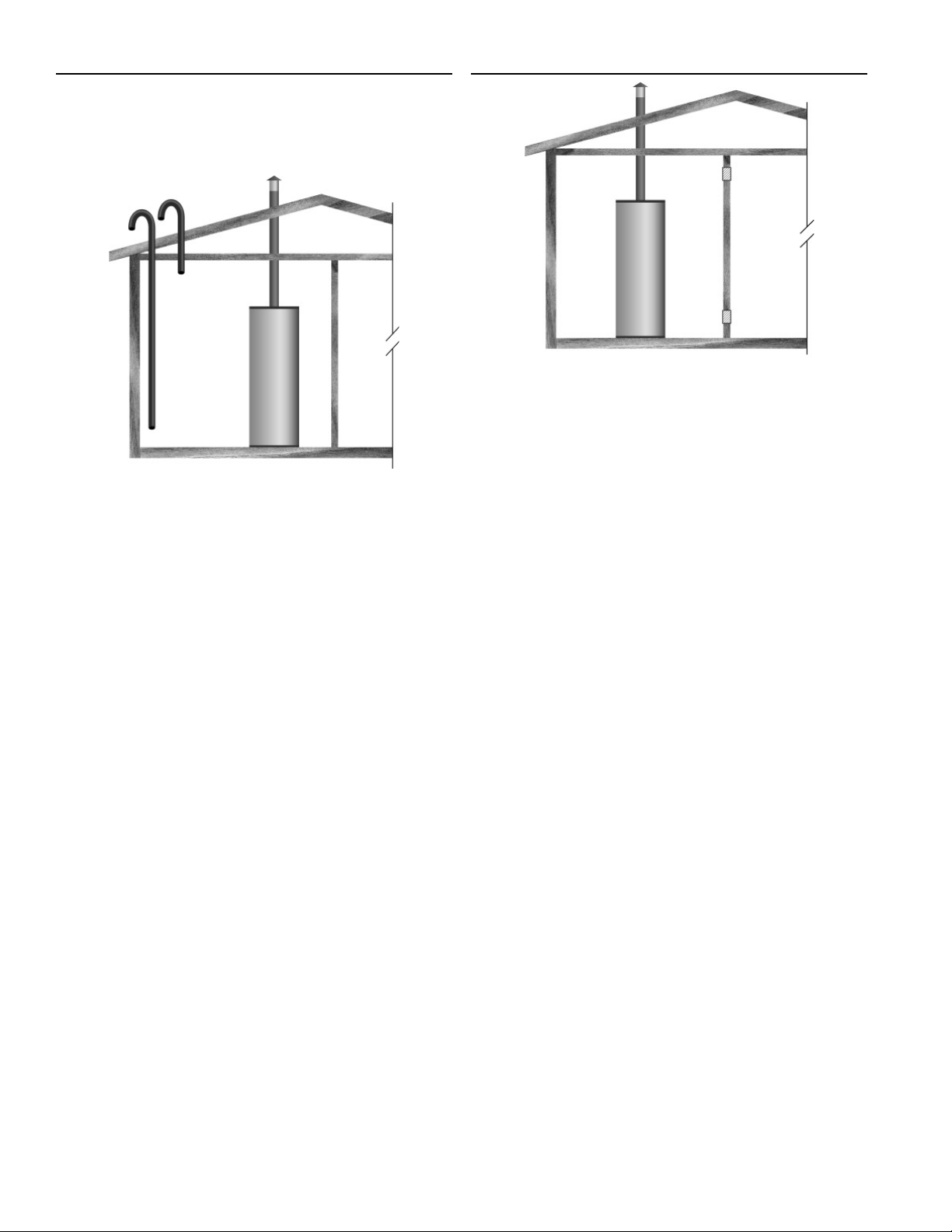

FRESH AIR OPENINGS FOR CONFINED SPACES

The following instructions shall be used to calculate the size,

number and placement of openings providing fresh air for

combustion, ventilation and dilution in confi ned spaces. The

illustrations shown in this section of the manual are a reference

for the openings that provide fresh air into confi ned spaces

only. DO NOT refer to these illustrations for the purpose of vent

installation. See Venting Installation on page 14 for complete

venting installation instructions.

OUTDOOR AIR THROUGH TWO OPENINGS

OUTDOOR AIR THROUGH ONE OPENING

Figure 15

Alternatively a single permanent opening, commencing within 12

inches (300 mm) of the top of the enclosure, shall be provided.

See Figure 15. The water heater shall have clearances of at

least 1 inch (25 mm) from the sides and back and 6 inches (l50

mm) from the front of the appliance. The opening shall directly

communicate with the outdoors or shall communicate through a

vertical or horizontal duct to the outdoors or spaces that freely

communicate with the outdoors and shall have a minimum free

area of the following:

1 square inch per 3000 Btu/hr (700 mm1.

2

per kW) of the total input

rating of all appliances located in the enclosure, and

Not less than the sum of the areas of all vent connectors in the space.2.

OUTDOOR AIR THROUGH TWO HORIZONTAL DUCTS

Figure 14

The confi ned space shall be provided with two permanent

openings, one commencing within 12 inches (300 mm) of the top

and one commencing within 12 inches (300 mm) of the bottom of

the enclosure. The openings shall communicate directly with the

outdoors. See Figure 14.

Each opening shall have a minimum free area of 1 square inch

per 4,000 Btu/hr (550 mm

of all appliances installed in the enclosure. Each opening shall

not be less than 100 square inches (645 cm

2

per kW) of the aggregate input rating

2

).

Figure 16

The confi ned space shall be provided with two permanent

horizontal ducts, one commencing within 12 inches (300 mm) of

the top and one commencing within 12 inches (300 mm) of the

bottom of the enclosure. The horizontal ducts shall communicate

directly with the outdoors. See Figure 16.

Each duct opening shall have a minimum free area of 1 square

inch per 2,000 Btu/hr (1100 mm2 per kW) of the aggregate input

rating of all appliances installed in the enclosure.

When ducts are used, they shall be of the same cross sectional

area as the free area of the openings to which they connect.

The minimum dimension of rectangular air ducts shall be not less

than 3 inches.

15

Page 16

OUTDOOR AIR THROUGH TWO VERTICAL DUCTS

The illustrations shown in this section of the manual are a

reference for the openings that provide fresh air into confi ned

spaces only.

DO NOT refer to these illustrations for the purpose of vent

installation. See Venting Installation on page 14 for complete

venting installation instructions.

Figure 17

The confi ned space shall be provided with two permanent vertical

ducts, one commencing within 12 inches (300 mm) of the top and

one commencing within 12 inches (300 mm) of the bottom of the

enclosure. The vertical ducts shall communicate directly with the

outdoors. See Figure 17.

Each duct opening shall have a minimum free area of 1 square

inch per 4,000 Btu/hr (550 mm2 per kW) of the aggregate input

rating of all appliances installed in the enclosure.

When ducts are used, they shall be of the same cross sectional

area as the free area of the openings to which they connect.

The minimum dimension of rectangular air ducts shall be not less

than 3 inches.

AIR FROM OTHER INDOOR SPACES

Figure 18

The confi ned space shall be provided with two permanent

openings, one commencing within 12 inches (300 mm) of the top

and one commencing within 12 inches (300 mm) of the bottom of

the enclosure. See Figure 18.

Each opening shall communicate directly with an additional

room(s) of suffi cient volume so that the combined volume of all

spaces meets the criteria for an Unconfi ned Space.

Each opening shall have a minimum free area of 1 square inch

per 1,000 Btu/hr (1100 mm2 per kW) of the aggregate input rating

of all appliances installed in the enclosure. Each opening shall

not be less than 100 square inches (645 cm2).

16

Page 17

TABLE 7. TECHNICAL DATA VENTING

TYPE B GAS VENT

Multiple Gas Fired Tank-Type Heaters

When venting multiple tank type heaters using Type B vent

pipe, follow the installation diagram (fi gure 13) and tables

below which give sizing and data based upon NFPA 54/ANSI

Z223. 1992.

MODEL 120

Input: 120,000 Btu/hr Total Vent Height (Feet)

Vent Connector Size: 5 inches 6 8 10 15 20 30 50 100

Input Btu/hr Rise Vent Connector Diameter (Inches)

120,000 1 Ft. 6 6 5 5 5 5 5 5

120,000 2 Ft. 5 5 5 5 5 5 5 5

120,000 3 Ft. 5 5 5 5 5 5 5 5

Number of Combined Input

Heaters in Thousands of Btu/hr Manifold and Common Vent Diameter (Inches)

2 240,000 7 7 6 6 6 6 6 6

3 360,000 8 8 7 7 7 6 6 6

4 480,000 9 9 9 8 8 7 7 6

MODEL 154

Input: 154,000 Btu/hr Total Vent Height (Feet)

Vent Connector Size: 6 inches 6 8 10 15 20 30 50 100

Input Btu/hr Rise Vent Connector Diameter (Inches)

154,000 1 Ft. 6 6 6 6 6 6 6 6

154,000 2 Ft. 6 6 6 6 6 6 6 6

154,000 3 Ft. 6 6 6 6 6 6 6 6

Number of Combined Input

Heaters in Thousands of Btu/hr Manifold and Common Vent Diameter (Inches)

2 308,000 7 7 6 6 6 6 6 6

3 462,000 8 8 7 7 7 6 6 6

4 616,000 9 9 9 8 8 7 7 6

MODEL 180,199, 200

Input: 180,000, 190,000 and 199,000 Btu/hr T otal Vent Height (Feet)

Vent Connector Size: 6 inches 6 8 10 15 20 30 50 100

Input Btuh/hr Rise Vent Connector Diameter (Inches)

180,000 1 Ft. 7 7 6 6 6 6 6 6

190,000 1 Ft. 7 7 7 6 6 6 6 6

199,000 1 Ft. 7 7 7 6 6 6 6 6

180,000 2 Ft. 6 6 6 6 6 6 6 6

190,000 2 Ft. 7 6 6 6 6 6 6 6

199,000 2 Ft. 7 7 6 6 6 6 6 6

180,000 3 Ft. 6 6 6 6 6 6 6 6

190,000 3 Ft. 6 6 6 6 6 6 6 6

199,000 3 Ft. 6 6 6 6 6 6 6 6

Number of Combined Input

Heaters in Thousands of Btu/hr Manifold & Common Vent Diameter (Inches)

360,000 7 7 6 6 6 6 6 6

2 380,000 7 7 7 6 6 6 6 6

398,000 6 7 7 6 6 6 6 6

540,000 7 6 6 6 6 6 6 6

3 570,000 7 6 6 6 6 6 6 6

597,000 6 7 6 6 6 6 6 6

720,000 6 6 6 6 6 6 6 6

4 760,000 6 6 6 6 6 6 6 6

796,000 6 6 6 6 6 6 6 6

17

Page 18

TABLE 8. TECHNICAL DATA VENTING (Continued)

MODEL 250

Input: 250,000 Btu/hr Total Vent Height (Feet)

Vent Connector Size: 6 inches 6 8 10 15 20 30 50 100

Input Btuh/hr Rise Vent Connector Diameter (Inches)

250,000 1 Ft 8 8 7 7 7 6 6 6

250,000 2 Ft 7 7 7 7 6 6 6 6

250,000 3 Ft 7 7 7 7 6 6 6 6

Number Combined Input

of Heaters in Thousands of Btu/hr Manifold and Common Vent Diameter (Inches)

2 500,000 9 9 9 8 8 7 7 7

3 750,000 12 12 10 10 10 9 8 8

4 1,000,000 14 14 12 12 10 10 9 9

MODEL 275

Input: 275,000 Btu/hr Total Vent Height (Feet)

Vent Connector Size: 6 inches 6 8 10 15 20 30 50 100

Input Btu/hr Rise Vent Connector Diameter (Inches)

275,000 1 Ft 8 8 7 7 6 6 6 6

275,000 2 Ft. 8 8 7 7 6 6 6 6

275,000 3 Ft 7 7 7 7 6 6 6 6

Number of Combined Input

Heaters in Thousands of Btu/hr Manifold and Common Vent Diameter (Inches)

2 550,000 10 9 9 8 8 8 7 7

3 825,000 12 12 12 10 9 9 8 8

4 1,100,000 14 14 14 12 12 10 9 9

MODEL 310

Input: 310,000 Btu/hr T otal Vent Height (Feet)

Vent Connector Size: 6 inches 6 8 10 15 20 30 50 100

Input Btu/hr Rise Vent Connector Diameter (Inches)

310,000 1 Ft. 9 8 8 8 7 7 6 6

310,000 2 Ft. 8 8 8 7 7 7 6 6

310,000 3 Ft. 8 8 8 7 7 7 6 6

Number of Combined Input

Heaters in Thousands of Btu/hr Manifold & Common Vent Diameter

2 620,000 10 10 9 9 8 8 7 7

3 930,000 14 12 12 12 10 9 9 8

4 1,240,000 14 14 14 12 12 12 10 9

MODEL 366, 400

Input: 366,000, 399,000 Btu/hr Total Vent Height (Feet)

Vent Connector Size: 6 inches 6 8 10 15 20 30 50 100

Input Btu/hr Rise Vent Connector Diameter (Inches)

366,000 1 Ft 9 9 9 8 8 8 8 8

399,000 1 Ft 10 9 9 9 8 8 8 8

366,000 2 Ft 9 9 8 8 8 8 8 8

399,000 2 Ft 9 9 9 8 8 8 8 8

366,000 3 Ft 9 8 8 8 8 8 8 8

399,000 3 Ft 9 9 8 8 8 8 8 8

Number of Combined Input

Heaters in Thousands of Btu/hr Manifold & Common Vent Diameter (Inches)

2 732,000 12 10 10 9 9 9 8 8

798,000 12 12 10 10 9 9 8 8

3 1,098,000 14 14 14 12 12 10 9 9

1,197,000 14 14 14 12 12 10 10 9

4 1,464,000 16 16 14 14 14 12 12 10

1,596,000 16 16 16 14 14 12 12 10

18

Page 19

WATER HEATER INSTALLATION

WATER LINE CONNECTIONS

This manual provides detailed installation diagrams (see pages

33-47 of this manual) for typical methods of application for the

water heater(s).

The water heater may be installed by itself, or with a separate

storage tank, on both single and two-temperature systems. When

used with a separate storage tank, the circulation may be either

by gravity or by means of a circulating pump. When a circulating

pump is used it is important to note that the fl ow rate should be slow

so that there will be a minimum of turbulence inside the heater.

WATER (POTABLE) HEATING AND SPACE HEATING

All piping components connected to this unit for space heating1.

applications shall be suitable for use with potable water.

Toxic chemicals, such as those used for boiler treatment,2. shall

NEVER be introduced into this system.

This unit may NEVER be connected to any existing heating3.

system or component(s) previously used with a non-potable

water heating appliance.

When the system requires water for space heating at4.

temperatures higher than required for domestic water

purposes, a tempering valve must be installed. Please refer

to installation diagrams on pages 33-47 of this manual for

suggested piping arrangements.

THERMOMETERS (NOT SUPPLIED)

Thermometers should be obtained and fi eld installed as shown in

the installation diagrams.

Thermometers are installed in the system as a means of detecting

the temperature of the outlet water supply.

WATER PIPING DIAGRAMS

This manual provides detailed water piping diagrams for typical

methods of application for the water heaters, see Water Piping

Diagrams beginning 33.

The water heater may be installed by itself, or with a separate

storage tank. When used with a separate storage tank, the

circulation may be either by gravity or by means of circulating

pump. When a circulating pump is used, it is important to note

that the fl ow rate should be slow so that there will be a minimum

of turbulence inside the water heater storage tank.

Adjust fl ow by throttling a full port ball valve installed in the

circulating line on the outlet side of the pump. Never throttle fl ow

on the suction side of a pump. See the Water Piping Diagrams

beginning on page 33.

NOTE: In addition to the factory installed Temperature-Pressure

Relief Valve (T&P valve) on the water heater, each remote

storage tank that may be installed and piped to a water heating

appliance must also have its own properly sized, rated and

approved Temperature-Pressure Relief Valve installed.

Call the toll free technical support phone number listed on the

back cover of this manual for further assistance in sizing a T&P

valve for remote storage tanks.

T&P VALVE DISCHARGE PIPE

Explosion Hazard

Temperature-Pressure Relief Valve

must comply with ANSI Z21.22CSA 4.4 and ASME code.

Properly sized temperaturepressure relief valve must be

installed in opening provided.

Can result in overheating and

excessive tank pressure.

Can cause serious injury or death.

This water heater is provided with a properly rated/sized and

certifi ed combination temperature - pressure (T&P) relief valve

by the manufacturer. See Temperature-Pressure Relief Valve

on pages 12-13 for information on replacement and other

requirements.

CAUTION

Water Damage Hazard

Temperature-Pressure Relief Valve discharge

•

pipe must terminate at adequate drain.

Install a discharge pipe between the T&P valve discharge opening

and a suitable fl oor drain. Do not connect discharge piping

directly to the drain unless a 6” (15.2 cm) air gap is provided.

To prevent bodily injury, hazard to life, or property damage, the

relief valve must be allowed to discharge water in adequate

quantities should circumstances demand. If the discharge pipe is

not connected to a drain or other suitable means, the water fl ow

may cause property damage.

T&P Valve Discharge Pipe Requirements:

Shall not be smaller in size than the outlet pipe size of the •

valve, or have any reducing couplings or other restrictions.

Shall not be plugged or blocked.•

Shall not be exposed to freezing temperatures.•

Shall be of material listed for hot water distribution.•

Shall be installed so as to allow complete drainage of both •

the Temperature-Pressure Relief Valve and the discharge

pipe.

Must terminate a maximum of six inches above a fl oor •

drain or external to the building. In cold climates, it is

recommended that the discharge pipe be terminated at an

adequate drain inside the building.

Shall not have any valve or other obstruction between the •

relief valve and the drain.

19

Page 20

INSTALLATION DIAGRAMS - TOP INLET/OUTLET USAGE

CODE RESTRICTIONS

The type, size and location of the relief valves must be in

accordance with local codes. The locations of the relief valves

shown in the installation diagrams are typical. See pages 33-47.

The heater has a factory installed high temperature limit switch

and temperature and pressure relief valve.

Cold water lines to heater should be installed as shown in order

to minimize gravity circulation of hot water to building cold water

lines.

A listed temperature and pressure relief valve of adequate capacity

is installed on the heater. The locations shown in the installation

diagrams on the following pages are typical.

The discharge opening of the temperature and pressure relief

valve, located in front of the heater must be piped to an open drain

and should not be subject to freezing temperatures.

Install in accordance with all local codes.

Use of the top inlet water connection requires installation of an inlet

dip tube (refer to fi gure 19). The tube is supplied in the heater.

Follow caution labels if applying heat to this fi tting. Do not allow

pipe dope to contact the plastic tube during installation.

TUBE INLET INSTALLATION

Use of the top inlet water connection is not permitted on

installations in the state of North Carolina, due to the material of

the tube (Polypropylene). Where such code restrictions exist, use

only lower inlet tank connection. This may also require a heat

trap - check local codes. The “Top Outlet” connection may still be

used on these applications. Plug or cap all unused openings in

the tank before fi lling with water.

TEMPERATURE SETTING SHOULD NOT EXCEED SAFE USE

TEMPERATURE AT FIXTURES. SEE WATER TEMPERATURE

CONTROL WARNING ON PAGE 11. IF HIGHER PREHEAT

TEMPERATURES ARE NECESSARY TO OBTAIN ADEQUATE

BOOSTER OUTPUT, ADD AN ANTI-SCALD VALVE FOR HOT

WATER SUPPLIED TO FIXTURES.

FIGURE 19

20

Page 21

HEATER WIRING

All electrical work must be installed in accordance with the latest version of the National Electrical Code ANSI/NFPA No. 70, must conform to all

local code authority having jurisdiction. AN ELECTRICAL GROUND IS REQUIRED TO REDUCE RISK OF ELECTRICAL SHOCK OR POSSIBLE

ELECTROCUTION.

If any of the original wire as supplied with the appliance must be replaced, use only type 105°C thermoplastic or equivalent. 250

used for the fl ame sensor leads and the spark ignition cable must be high voltage 250°C.

R

UPPER

PROBE/

ECO

BK

BK

R

BLOWER PROVER

PRESSURE SWITCH

W

BK

Y

THERMOSTAT

INDUCER

0

C type F must be

LOWER

PROBE

BK - BLACK

BR - BROWN

R - RED

Y - YELLOW

G - GREEN

BL - BLUE

W - WHITE

R

R

TO EARTH

GROUND

BL

BR

IGNITION BOARD

BK

W

R

1a 1 1b

R

HOT 120 VAC

NEUTRAL

EARTH GROUND

G

IGNITOR/FLAME

SENSOR

R

R

120 VAC CIRCUIT

FACTORY INSTALLED

W

IN

IN

PSI

PSI

Y

OFF

OFF

ON

ON

Y

WIRING DIAGRAM:

WHEN EQUIPPED WITH WHITE-RODGERS IGNITION

BOARD, DIGITAL THERMOSTAT AND CONTROLS.

IF ANY OF THE ORIGINAL WIRE AS SUPPLIED

MUST BE REPLACED USE ONLY TYPE 105 C

BY INSTALLER

THERMOPLASTIC OR EQUIVALENT.

FIGURE 20

21

Page 22

GAS PIPING

Contact your local gas service company to ensure that adequate gas

service is available and to review applicable installation codes for your

area.

Size the main gas line in accordance with Table 3. The fi gures shown

are for straight lengths of pipe at 0.5 in. W.C. pressure drop, which is

considered normal for low pressure systems. Note: Fittings such as

elbows, tees and line regulators will add to the pipe pressure drop. Also

refer to the latest version of the National Fuel Gas Code.

THE HEATER IS NOT INTENDED FOR OPERATION AT HIGHER

THAN 14.0” W.C.- NATURAL GAS, (1/2 POUND PER SQUARE INCH

GAGE) SUPPLY GAS PRESSURE. EXPOSURE TO HIGHER SUPPLY

PRESSURE MAY CAUSE DAMAGE TO THE GAS VALVE WHICH

COULD RESULT IN FIRE OR EXPLOSION. IF OVERPRESSURE HAS

OCCURRED SUCH AS THROUGH IMPROPER TESTING OF GAS LINES

OR EMERGENCY MALFUNCTION OF THE SUPPLY SYSTEM, THE GAS

VALVE MUST BE CHECKED FOR SAFE OPERATION. MAKE SURE

THAT THE OUTSIDE VENTS ON THE SUPPLY REGULATORS AND

THE SAFETY VENT VALVES ARE PROTECTED AGAINST BLOCKAGE.

THESE ARE PARTS OF THE GAS SUPPLY SYSTEM, NOT THE HEATER.

VENT BLOCKAGE MAY OCCUR DURING ICE STORMS.

TABLE 9 - GAS SUPPLY LINE SIZES (IN INCHES)*

MAXIMUM CAPACITY OF PIPE IN

CUBIC FEET PER HOUR

LENGTH

IN

FEET

100

125

150

175

200

IT IS IMPORTANT TO GUARD AGAINST GAS VALVE FOULING FROM

CONTAMINANTS IN THE GAS WAYS. SUCH FOULING MAY CAUSE

IMPROPER OPERATION, FIRE OR EXPLOSION.

IF COPPER SUPPLY LINES ARE USED THEY MUST BE INTERNALLY

TINNED AND CERTIFIED FOR GAS SERVICE. BEFORE ATTACHING

THE GAS LINE, BE SURE THAT ALL GAS PIPE IS CLEAN ON THE

INSIDE.

TO TRAP ANY DIRT OR FOREIGN MATERIAL IN THE GAS SUPPLY

LINE, A DIRT LEG (SOMETIMES CALLED SEDIMENT TRAP OR DRIP

LEG) MUST BE INCORPORATED IN THE PIPING (SEE FIG. 21). THE

DIRT LEG MUST BE READILY ACCESSIBLE AND NOT SUBJECT

TO FREEZING CONDITIONS. INSTALL IN ACCORDANCE WITH

RECOMMENDATIONS OF SERVING GAS SUPPLIERS. REFER TO

THE LATEST VERSION OF THE NATIONAL FUEL GAS CODE.

1/2" 3/4" 1" 1 1/4" 1 1/2" 2" 2 1/2" 3" 4"

175 360 680 1400 2100 3960 6300 11000 23000

10