Page 1

DOT MATRIX PRINTER

SP2000 SERIES

USER’S MANUAL

MODE D’EMPLOI

BEDIENUNGSANLEITUNG

MANUALE DI ISTRUZIONI

Page 2

Federal Communications Commission

Radio Frequency Interference

Statement

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to correct

the interference at his own expense.

For compliance with the Federal Noise Interference Standard, this equipment requires a

shielded cable.

This statement will be applied only for the printers marketed in U.S.A.

Statement of

The Canadian Department of Communications

Radio Interference Regulations

This digital apparatus does not exceed the Class A limits for radio noise emissions from

digital apparatus set out in the Radio Interference Regulations of the Canadian Department

of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites

applicables aux appareils numériques de la classe A prescrites dans le Règlement sur le

brouillage radioélectrique édicté par le ministère des Communications du Canada.

The above statement applies only to printers marketed in Canada.

Manufacturer’s Declaration of Conformity

CE

EC Council Directive 89/336/EEC of 3 May 1989

This product, has been designed and manufactured in accordance with the International

Standards EN 50081-1/01.92 and EN 50082-1/01.92, following the provisions of the

Electro Magnetic Compatibility Directive of the European Communities as of May 1989.

EC Council Directive 73/23/EEC and 93/68/EEC of 22 July 1993

This product, has been designed and manufactured in accordance with the International

Standards EN 60950, following the provisions of the Low Voltage Directive of the

European Communities as of July 1993.

The above statement applies only to printers marketed in EU.

Trademark acknowledgments

SP2000 Series: Star Micronics Co. Ltd.

ESC/POS: Seiko Epson Corporation

Notice

• All rights reserved. Reproduction of any part of this manual in any form whatsoever,

without STAR’s express permission is forbidden.

• The contents of this manual are subject to change without notice.

• All efforts have been made to ensure the accuracy of the contents of this manual at the

time of going to press. However, should any errors be detected, STAR would greatly

appreciate being informed of them.

• The above notwithstanding, STAR can assume no responsibility for any errors in this

manual.

©

Copyright 2000 Star Micronics Co., Ltd.

Page 3

TABLE OF CONTENTS

1. Outline ...............................................................................................................1

2. Unpacking and Installation................................................................................2

2-1. Unpacking ..............................................................................................2

2-2. Locating the Printer................................................................................3

2-3. Handling Care ........................................................................................3

2-4. Maintenance ...........................................................................................3

3. Parts Identification and Nomenclature ..............................................................4

4. Optional AC Adapter.........................................................................................6

5. Connecting.........................................................................................................8

5-1. Ferrite Core Installation .........................................................................8

5-2. Connecting to Host Computer (Serial Interface) ...................................9

5-3. Connecting to Host Computer (Parallel Interface) ..............................10

5-4. Connecting to a Peripheral Unit...........................................................10

6. Loading the Ribbon Cartridge and Paper ........................................................12

6-1. SP2300 Type ........................................................................................12

6-2. SP2500 Type ........................................................................................15

6-3. Removing the Paper .............................................................................23

7. Control Panel ...................................................................................................24

7-1. Basic Operation....................................................................................24

7-2. Errors ...................................................................................................25

7-3. Switch Operation (Combined Switch Operation) ................................26

8. Optional Near-end Sensor ...............................................................................30

8-1. Adjusting the Near-end Sensor ............................................................30

Appendix A: General Specifications .................................................................128

Power Supply Specifications......................................................................131

Appendix B: Serial Interface .............................................................................132

B-1. Pins and Signal Names ......................................................................132

B-2. Interface Connections (Serial Interface) ............................................133

Appendix C: Parallel Interface ..........................................................................134

C-1. Table of Connection Signals for Each Mode .....................................134

Appendix D: DIP Switch Setting ......................................................................136

D-1. Parallel Interface ................................................................................136

D-2. Serial Interface ...................................................................................138

Appendix E: Memory Switch Settings ..............................................................141

Appendix F: Peripheral Unit Driver Circuit .....................................................142

Page 4

1. Outline

ENGLISH

The SP2000 Series Serial Impact Dot Matrix Printer is designed for use with

electronic instruments such as POS, banking equipment, computer peripheral

equipment, etc.

The major features of the SP2000 series are as follows:

1. Bi-directional printing at approx. 3.1 lines/sec.

2. Serial interface or parallel interface.

3. The data buffer allows the unit to receive print data even during printing.

4. Peripheral unit drive circuit enables control of external devices such as cash

drawers.

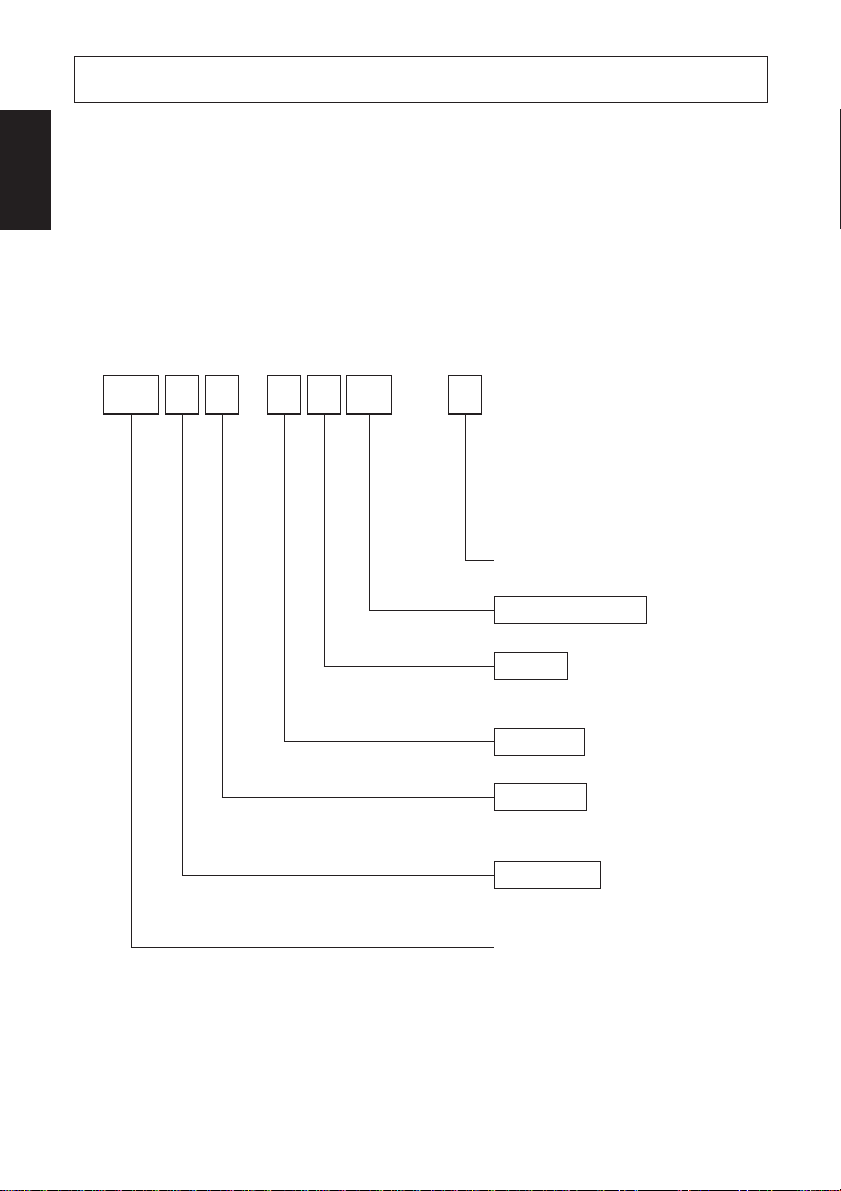

SP2 3 2 0 M D 42 – 24 R

R : With Rewinder

None: Without Rewinder

No. of print columns

42 : 42 columns (16 CPI)

Interface

D : Serial interface (RS-232C)

C : Parallel interface

Paper feed

M : Friction paper feed method

Mechanism

2 : Single color, 42 columns (16 CPI)

6 : Two color, 42 columns (16 CPI)

MPrinter type

3 : Standard type

5 : Auto cutter equipped type

SP2000 series printer

– 1 –

Page 5

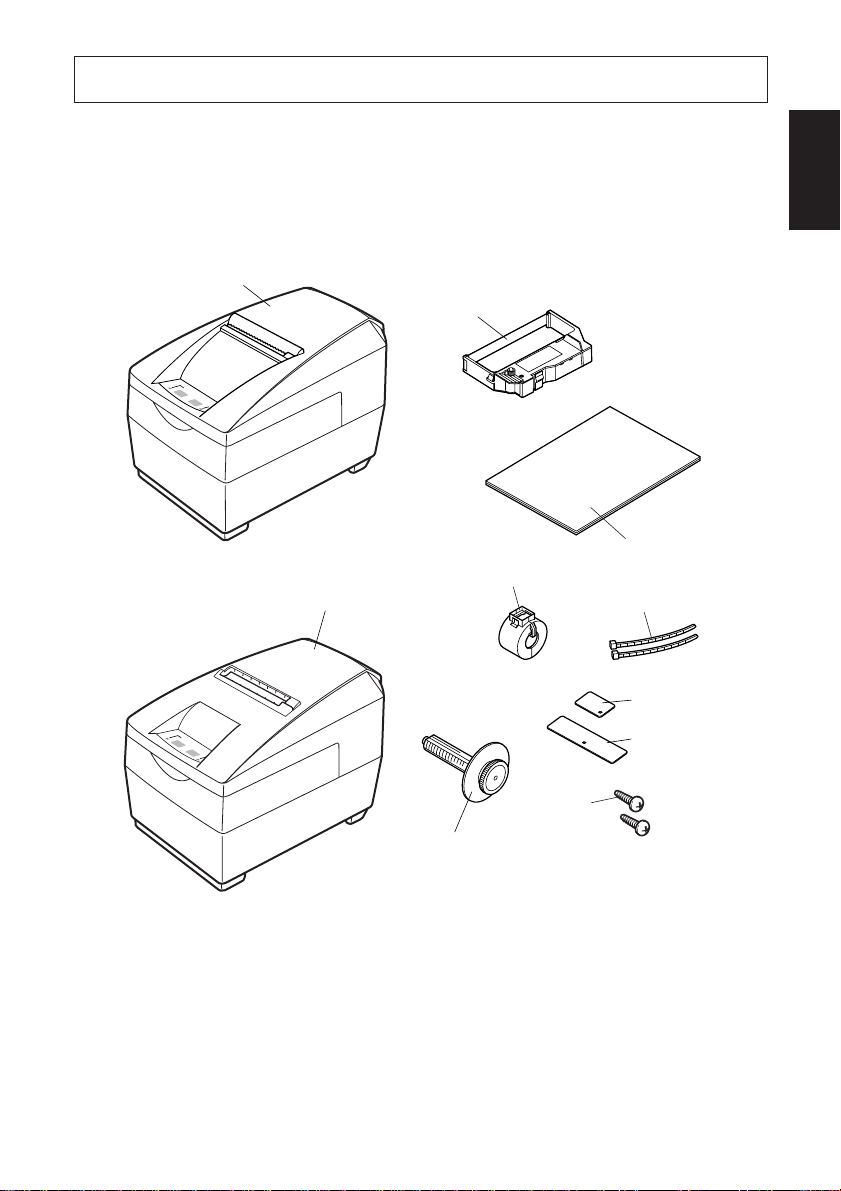

2. Unpacking and Installation

2-1. Unpacking

After unpacking the unit, check that all the necessary accessories are included in

the package.

SP2300 type

Printer

Ribbon cartridge

User’s manual

SP2500 type

Printer

Ferrite core

Fasteners

ENGLISH

Adaptor holder

Cord holder

Screws

Spool (R series only)

Note: The spool is only included with the R series (rewinder model).

The spool is under the printer cover.

Fig. 2-1 Unpacking

If anything is missing, contact the dealer where you bought the printer and ask

them to supply the missing part. Note that it is a good idea to keep the original box

and all the packing materials just in case you need to pack the printer up again and

send it somewhere at a later date.

– 2 –

Page 6

2-2. Locating the Printer

When you locate your printer, keep the following tips in mind:

ENGLISH

1. Protect your printer from excessive heat such as direct sunlight or heaters, and

keep it away from moisture and dust.

2. Place the printer on a firm, level surface which is fairly vibration-free.

3. A steady power supply that is not subject to power surges should be connected

to the printer.

For example, do not connect it to the same circuit as a large, noise-producing

appliance such as a refrigerator or an air conditioner.

4. Make sure the line voltage is the voltage specified on the printer’s identification plate.

5. To disconnect the printer, the plug has to be disconnected from the wall socket,

which has to be located close to the printer, and easy to access.

2-3. Handling Care

1. Be careful not to drop paper clips, pins or other foreign matter into the unit as

these cause the printer to malfunction.

2. Do not attempt to print when either paper or ribbon cartridge is not located in

the printer, otherwise the print head can be damaged.

3. Do not open the cover while printing.

4. Do not touch the print head immediately after printing as it gets very hot.

5. Use only roll paper that is not glued to the core.

6. When the paper end mark appears on the paper, replace the roll paper before

it runs out.

2-4. Maintenance

Essentially, your printer is a robust piece of equipment, but should be treated with

a modicum of care in order to avoid malfunctions. For example:

1. Keep your printer in a “comfortable” environment. Roughly speaking, if you

feel comfortable, then the environment is suitable for your printer.

2. Do not subject the printer to physical shocks or excessive vibration.

3. Avoid over-dusty environments. Dust is the enemy of all precision mechanical devices.

4. To clean the exterior of the printer, use a cloth barely dampened with either

water with a little detergent or a little alcohol, but do not allow any liquid to

fall inside the printer.

5. The interior of the printer may be cleaned with a small cleaner or a compressed-air aerosol (sold for this purpose). When performing this operation,

be sure not to bend or damage any cable connections or electronic components.

– 3 –

Page 7

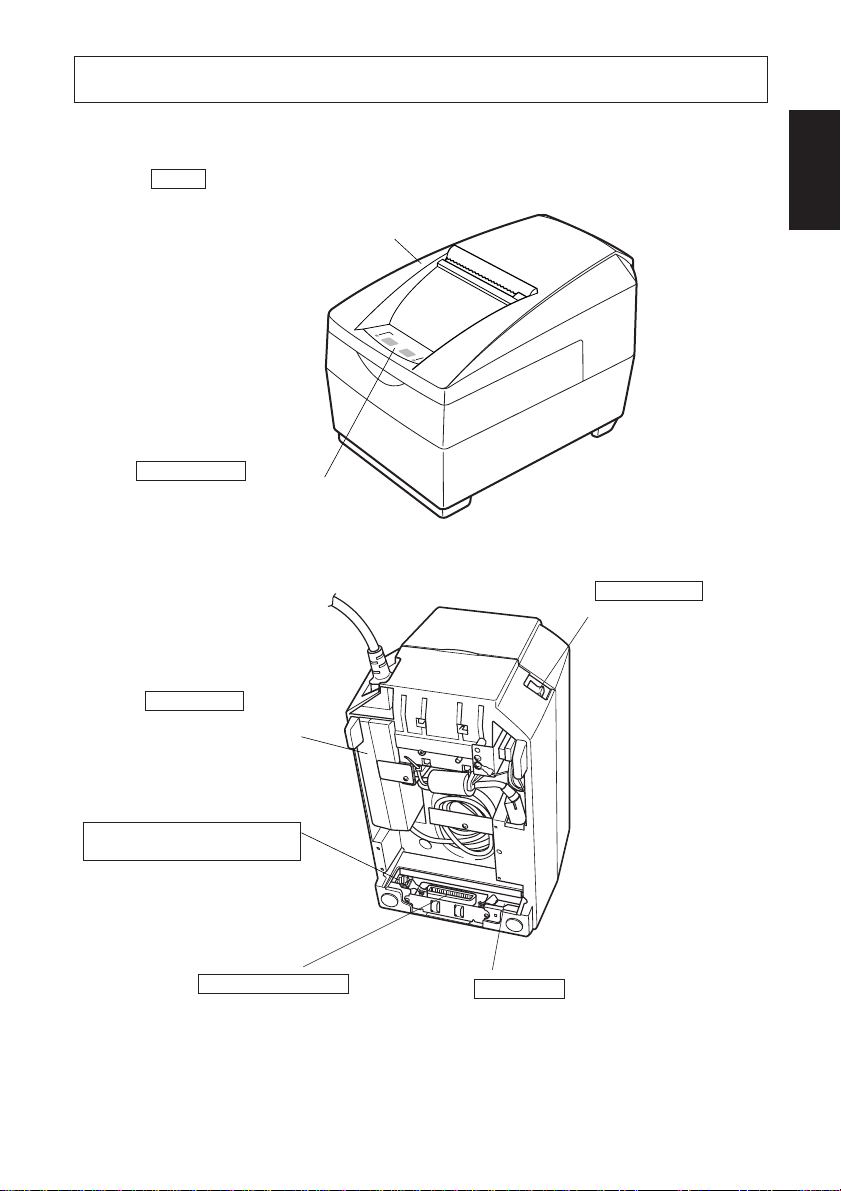

SP2300 type

Cover

Protects the printer from dust and reduces noise.

Do not open the cover while printing.

Control panel

Features two control switches and

two indicators to indicate printer

status.

3. Parts Identification and Nomenclature

ENGLISH

Power switch

Turns printer power on

and off.

AC adapter

Refer to the following

section for installation

instructions.

Peripheral unit drive circuit

connector

Connects to peripheral units

such as cash drawers, etc.

Do not connect this to a

telephone.

Interface connector

Connects the printer with

host computer.

Fig. 3-1 External view of the printer (SP2300 type)

DIP switch

Use to make various

settings.

– 4 –

Page 8

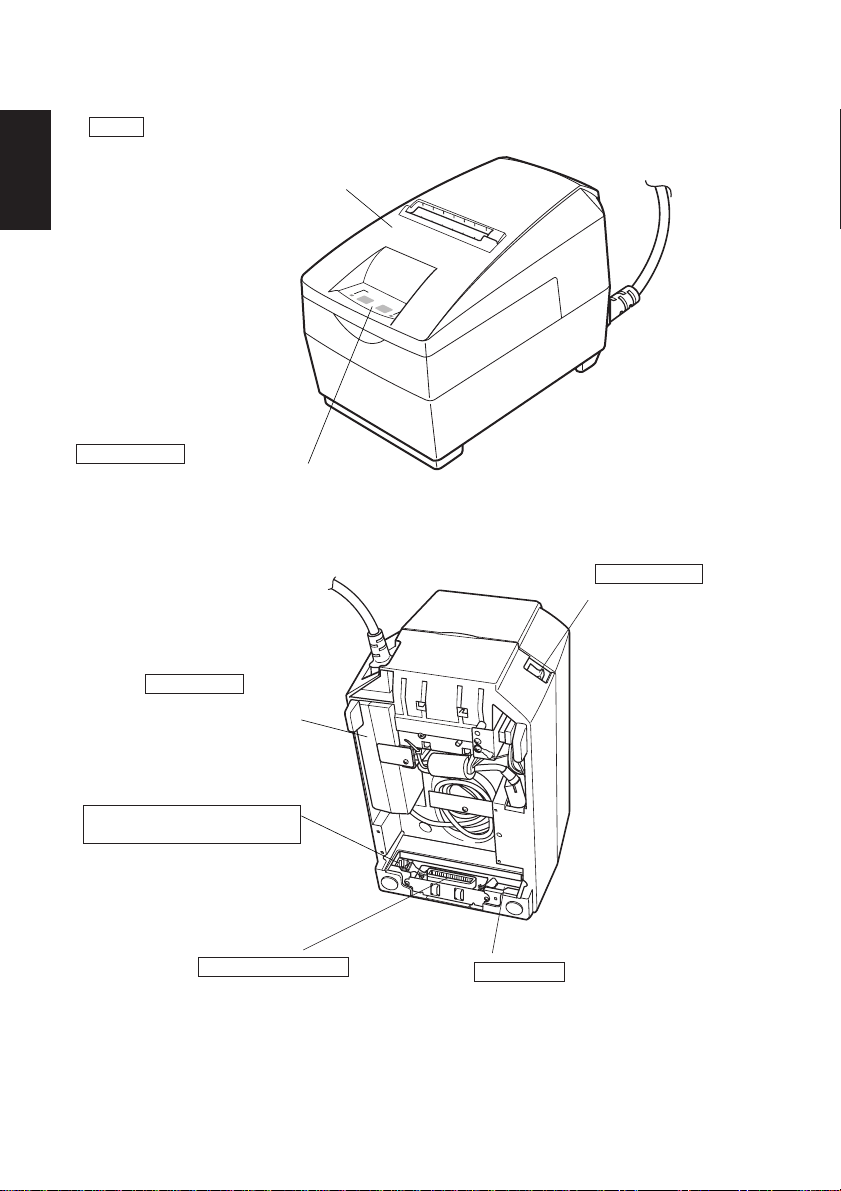

SP2500 type

ENGLISH

Cover

Protects the printer from dust and reduces noise.

Do not open the cover while printing.

Control panel

Features two control switches and two

indicators to indicate printer status.

AC adapter

Refer to the following

section for installation

instructions.

Power switch

Turns printer power on

and off.

Peripheral unit drive circuit

connector

Connects to peripheral units

such as cash drawers, etc.

Do not connect this to a

telephone.

Interface connector

Connects the printer with

host computer.

Fig. 3-2 External view of the printer (SP2500 type)

DIP switch

Use to make various

settings.

– 5 –

Page 9

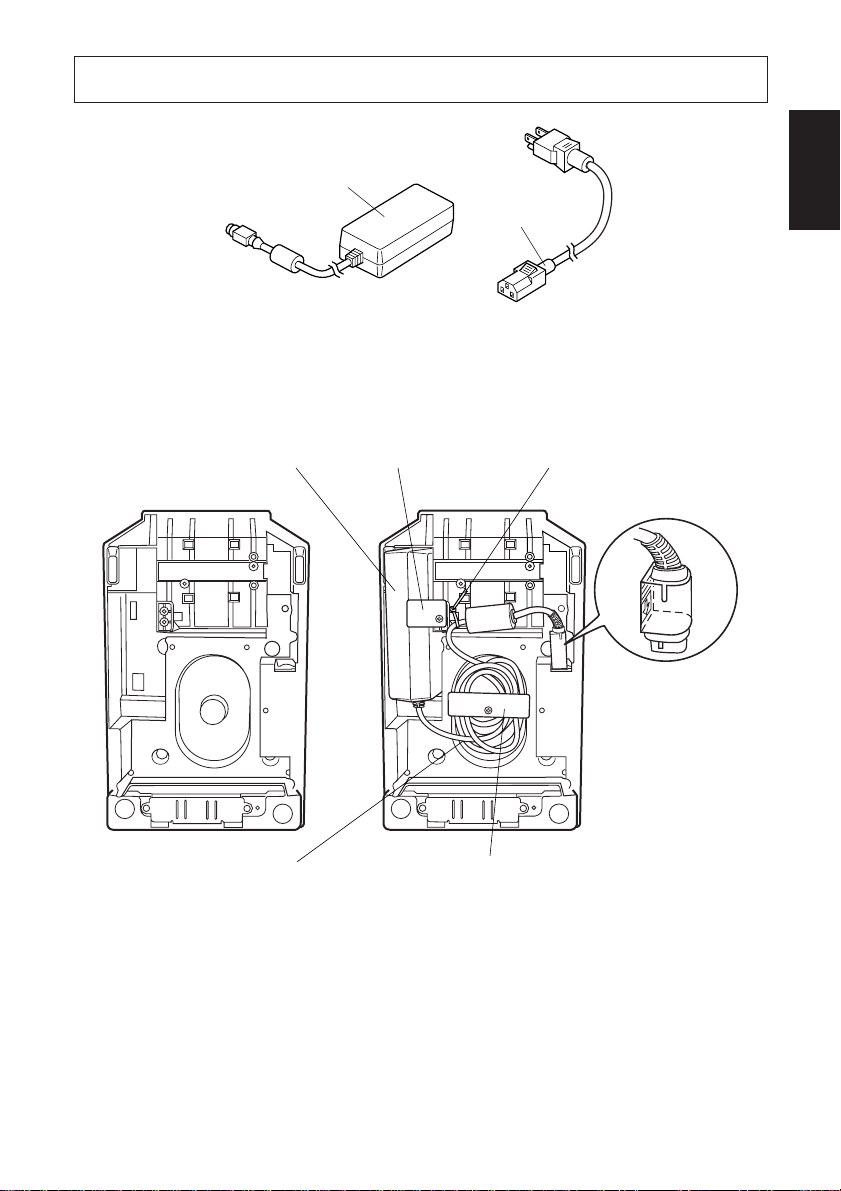

4. Optional AC Adapter

AC adaptor

Power code

Fig. 4-1

Use the following procedure to install the optional AC adapter.

AC adapter Adapter holder Fasteners

ENGLISH

AC adapter cord

[Before AC adaptor installed] [After AC adaptor installed]

Fig. 4-2 Flat side faces this way

Cord holder

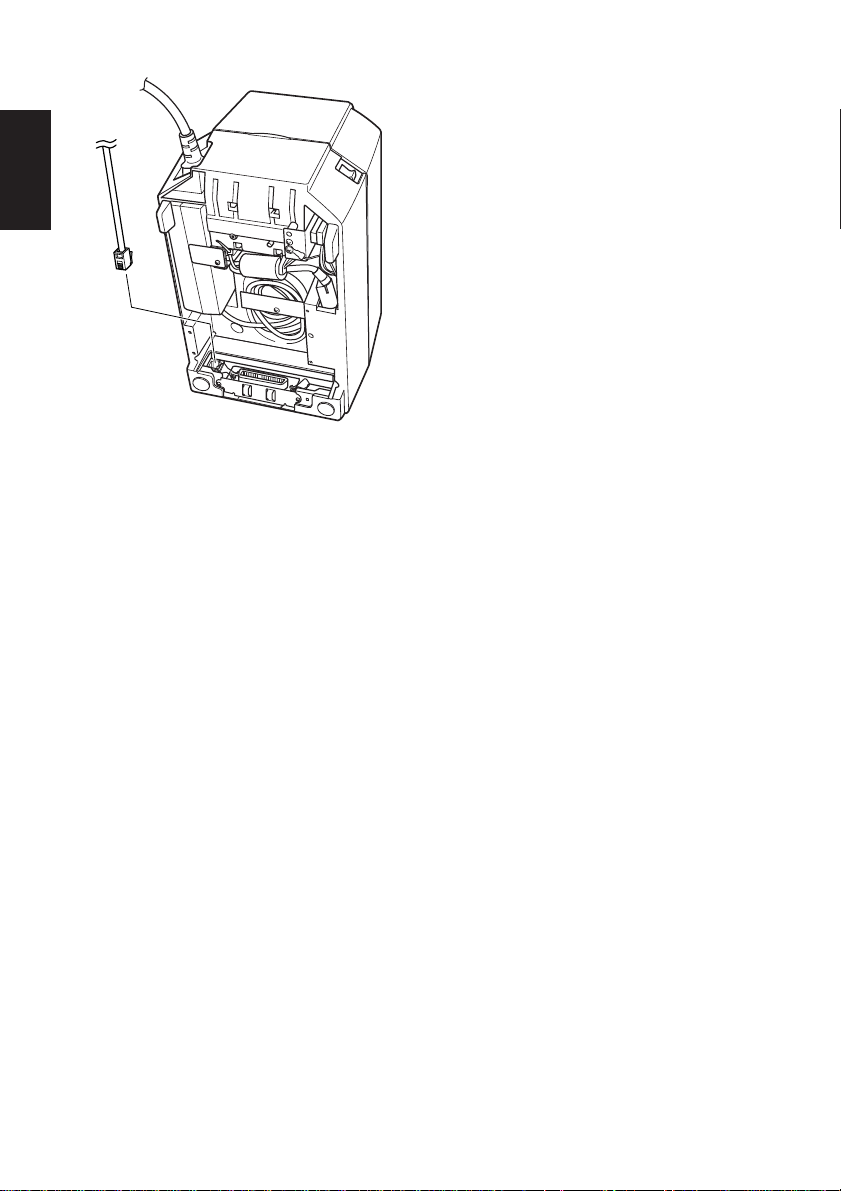

1 Turn the printer over.

2 Plug the AC adapter’s cord into the socket as shown in the above illustration.

Make sure the flat side of the plug is facing towards the inside of the printer.

3 Use one of the nylon fasteners that comes with the printer to fasten the cord

at the point indicated in the illustration.

– 6 –

Page 10

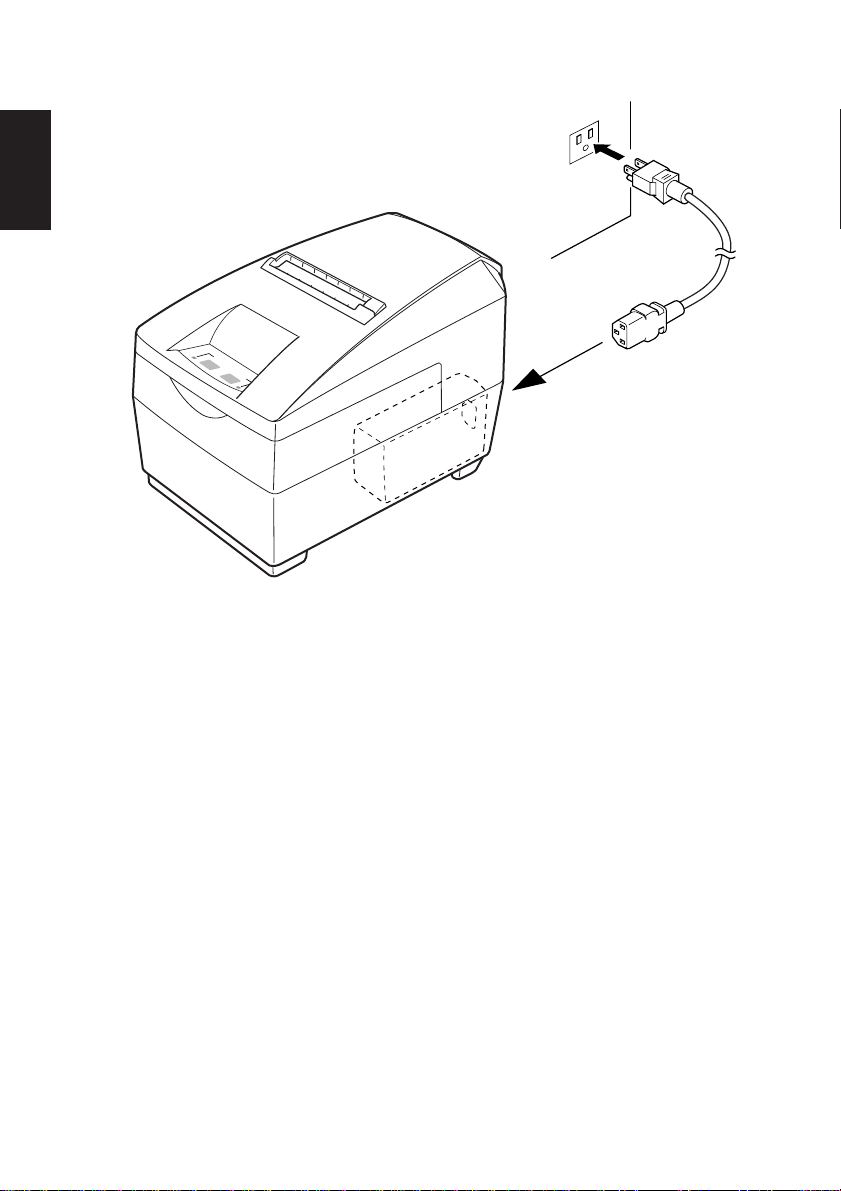

ENGLISH

Fig. 4-3 Fasten cord here

4 Coil the AC adapter cord into the space provided, and insert the AC adapter

into its space.

5 Use the adapter holder and screw to secure the AC adapter and the cord holder

and screw to secure the cord.

6 Turn the printer back right side up.

7 Plug the female end of the power cord into the AC adapter, and plug the other

end into a power outlet.

– 7 –

Page 11

5. Connecting

The computer sends data to the printer through a cable to the printer’s interface

(Serial Interface Connector Type: D-sub 25-pin or Parallel Interface Connector

Type: 36-pin Centronics compatible). This printer does not come with a cable, so

it is up to you to obtain one that suits your needs.

Important!

• The following instructions apply to the cable that is used with an IBM-

compatible personal computer. Note that they do not apply to all types of

computers and cables. If you are unsure about what type of cable you should use

to connect with your computer, consult your dealer.

• Make sure that the printer is turned off and unplugged from the AC outlet and

that the computer is turned off before connecting them.

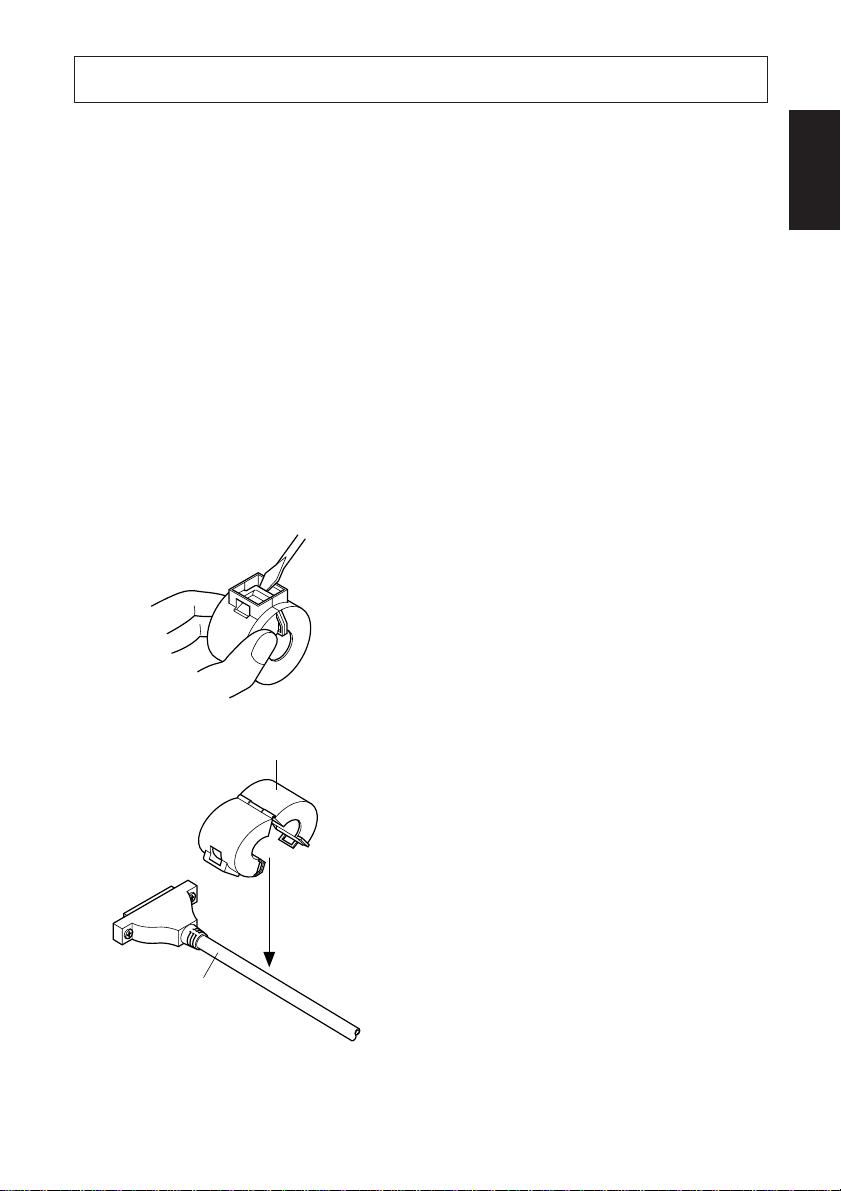

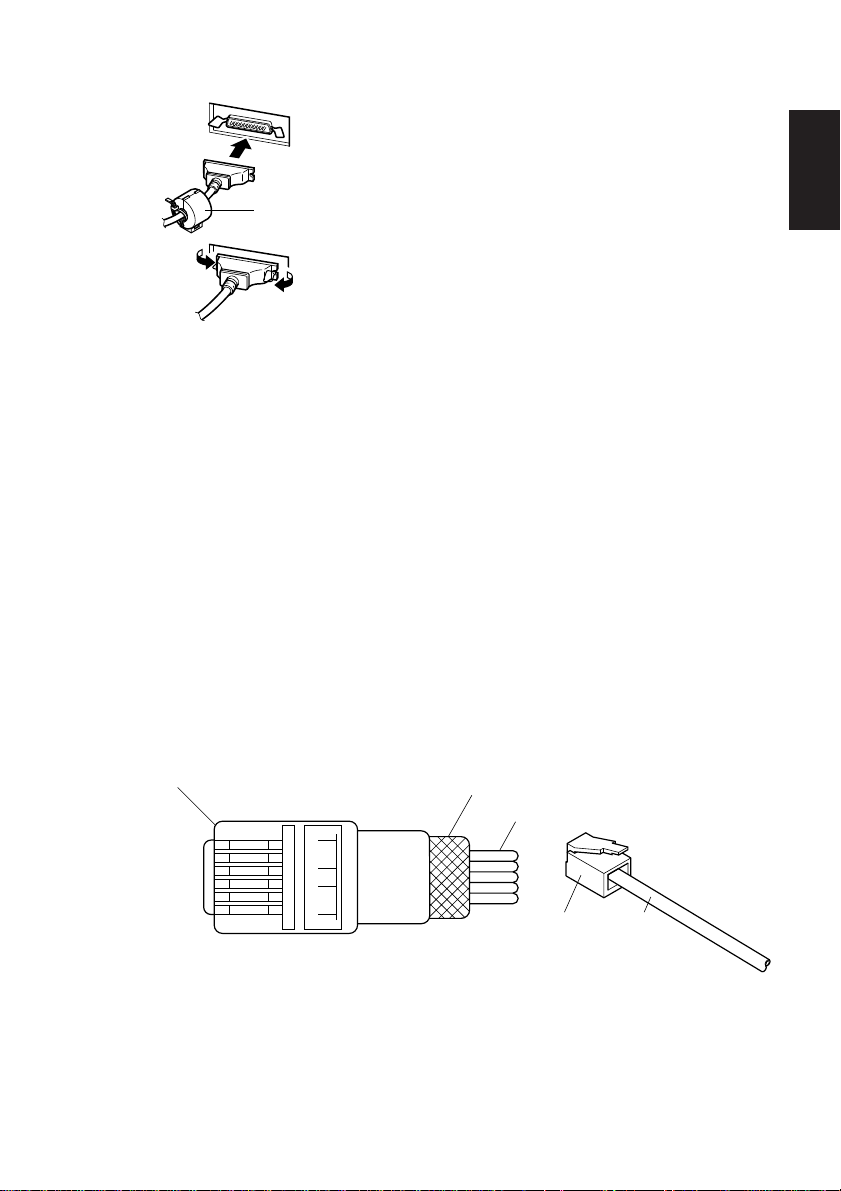

5-1. Ferrite Core Installation

1 Affix the ferrite core onto the cable

as shown in the illustration below.

ENGLISH

Interface cable

Ferrite core

Fig. 5-1

– 8 –

Page 12

ENGLISH

5 cm

maximum

Fig. 5-2

Fig. 5-3

2 Pass the fastener through the ferrite

core.

Fastener

3 Loop the fastener around the cable

and lock it. Use scissors to cut off

any excess.

Pull and cut

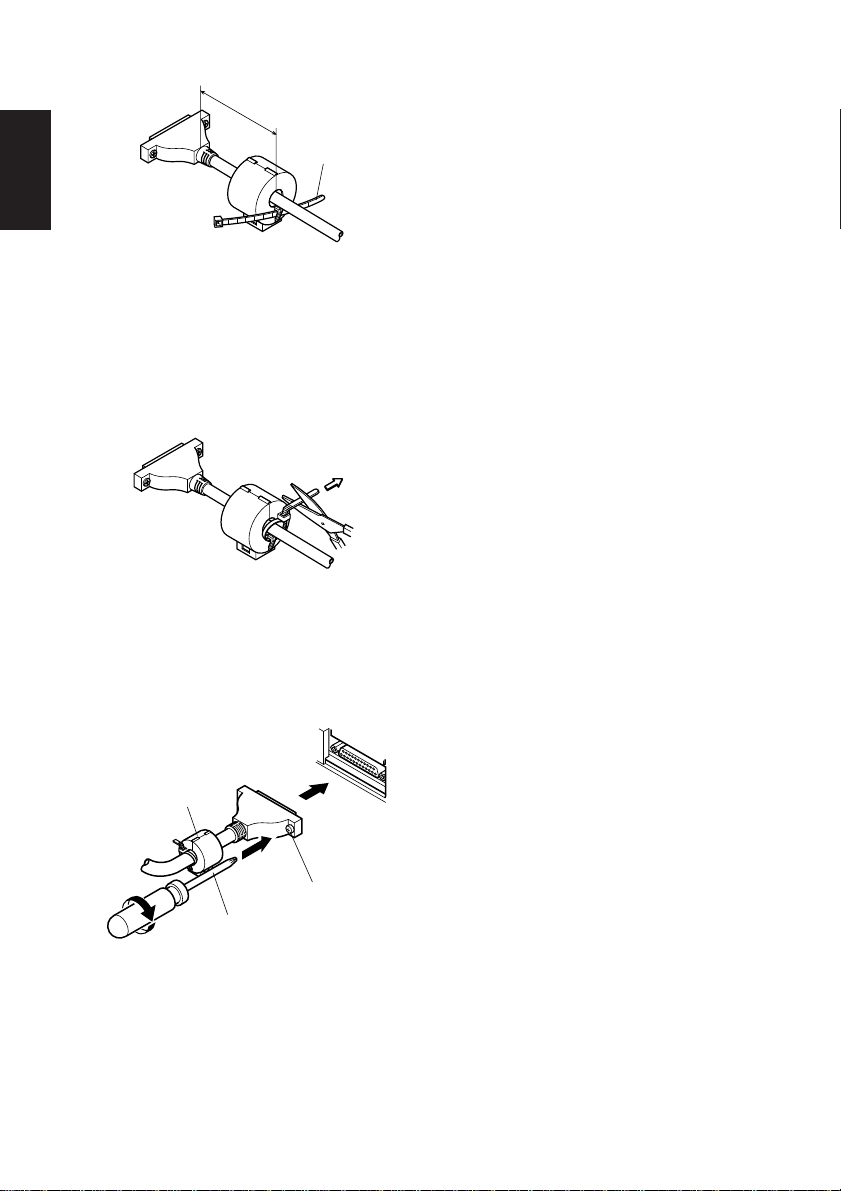

5-2. Connecting to Host Computer (Serial Interface)

1 Turn off power to both the host

computer and the printer.

Ferrite core

Screws

Screwdriver

Fig. 5-4 Connecting the serial

interface cable

2 Insert the connector at one end of

the interface cable into the connector on the printer and the other connector into the connector for the

host computer.

3 Next, fasten the right and left screws

for the respective interface connectors to fix them in place on the

connectors.

– 9 –

Page 13

5-3. Connecting to Host Computer (Parallel Interface)

1 Turn off power to both the host

computer and the printer.

2 Insert one terminal of the interface

cable into the printer’s connector,

Ferrite core

as shown in the diagram, and fasten

it there with the clasp.

3 Insert the other terminal of interface

cable into the host computer’s connector, and again fasten it with the

clasp.

Fig.5-5 Connecting the parallel

interface cable

5-4. Connecting to a Peripheral Unit

You can connect a peripheral unit to the printer using a modular plug. See

“Modular plug” on page 142 for details about the type of modular plug that is

required. Note that this printer does not come with a modular plug or wire, so it

is up to you to obtain one that suits your needs.

Important!

Make sure that the printer is turned off and unplugged from the AC outlet and

that the computer is turned off before making connections.

ENGLISH

Modular plug: MOLEX 90075-0007,

AMP641337, or JAPAN BURNDY B-66-4

16

Fig. 5-6

– 10 –

Shield

Wire lead

Modular

plug

Cable

Fig. 5-7

Page 14

ENGLISH

Important!

1 Plug one end of the modular cable

into the modular jack of the peripheral.

2 Remove the modular jack cover

from the back of the printer and plug

the other end of the modular cable

into the jack of the printer.

Fig. 5-8

Do not connect a telephone line to the peripheral unit drive circuit connector;

otherwise the printer and the telephone line may be damaged.

– 11 –

Page 15

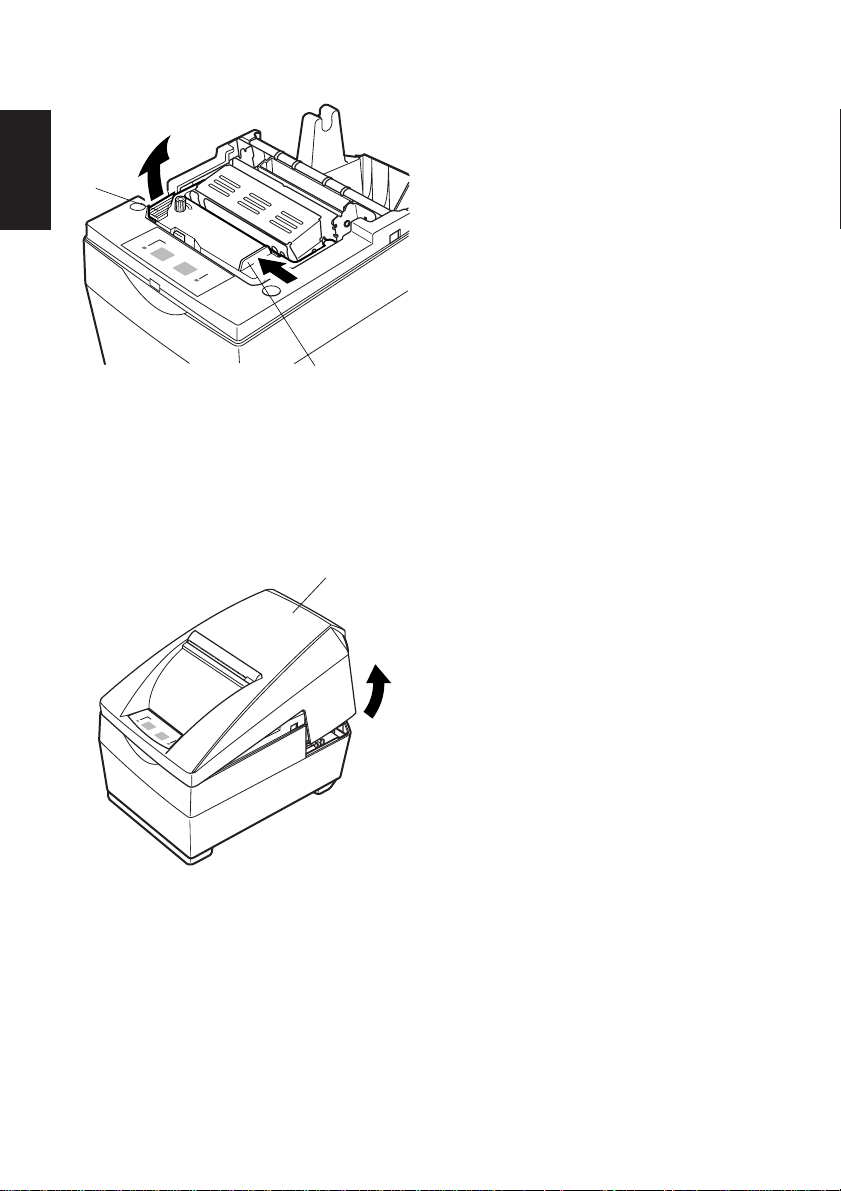

6. Loading the Ribbon Cartridge and Paper

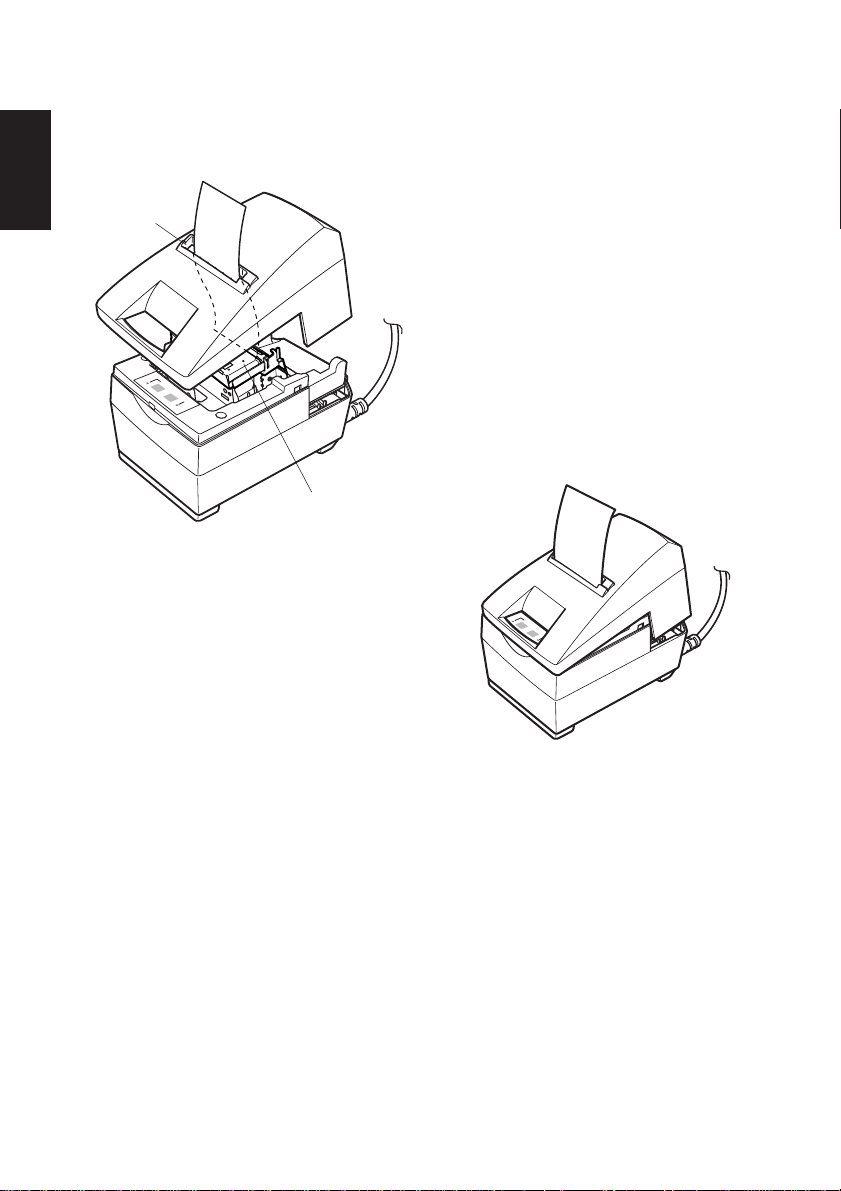

6-1. SP2300 T ype

6-1-1.Loading the Ribbon Cartridge

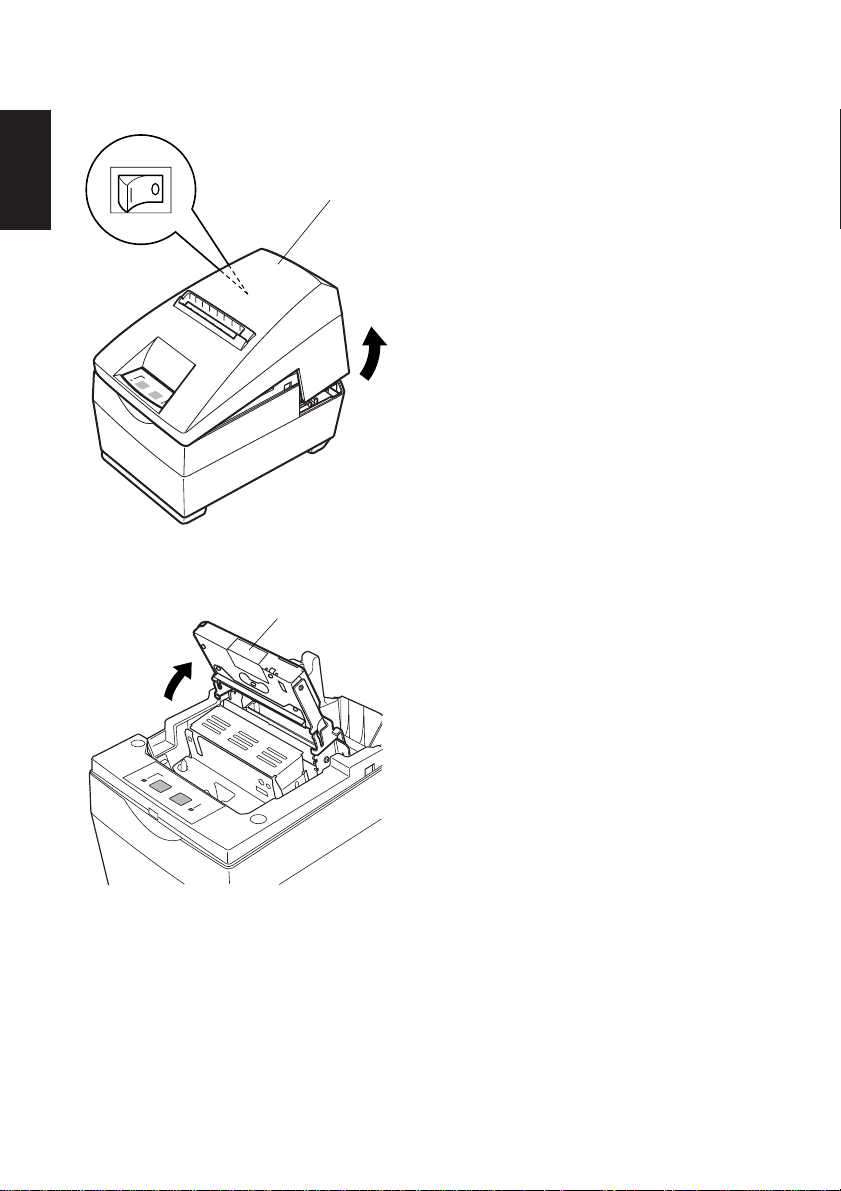

Cover

Power off

Fig. 6-1 Removing the cover

1 Turn off power to the printer.

2 Lift the cover up approx. 3 cm. Hold

the cover tilted at this angle, then

pull it toward you to remove it.

3 Place the ribbon cartridge in the

direction shown in Fig. 6-2 and press

it down to load it. If loading of the

ribbon cartridge is not satisfactory,

press down the cartridge while rotating the ribbon feed knob in the

direction of the arrow.

4 Turn the ribbon feed knob of the

ribbon cartridge in the direction of

the arrow to remove slack in the

ribbon.

5 Mount the cover by reversing the

procedure outlined in step 2 above.

ENGLISH

Ribbon separater

Print head

Ink ribbon

Ribbon

feed knob

Notched part

Fig. 6-2 Loading the ribbon cartridge

Ribbon

cartridge

– 12 –

Page 16

ENGLISH

A

Fig. 6-3 Removing the ribbon cartridge

6-1-2.Loading the paper

Note: When removing the ribbon

cartridge, raise the A section

and then remove it by holding the B section as shown in

Fig. 6-3.

B

Cover

Fig. 6-4 Removing the cover

1 Lift the cover up approx. 3cm. Hold

the cover tilted at this angle, then

pull it toward you to remove it.

2 Cut off the front edge of the roll

paper perpendicularly.

3 Confirm that the power of the printer

is turned on.

– 13 –

Page 17

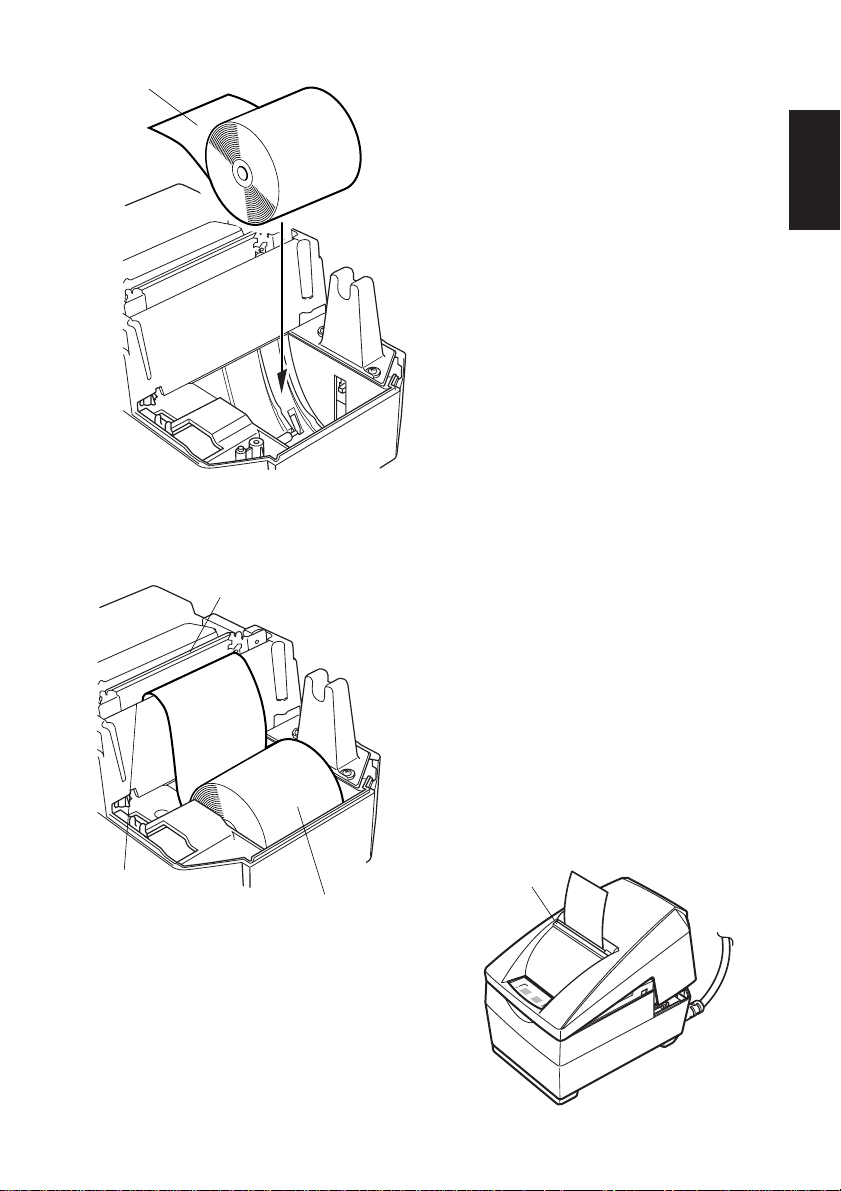

Roll paper

Fig. 6-5 Setting the paper

4 While observing the direction of the

roll, set the paper roll into the hollow as shown in Fig. 6-5.

ENGLISH

Paper exit

Paper feeder

Fig. 6-6 Loading the paper

Roll paper

5 Insert the edge of the paper into the

paper feeder. If inserted correctly,

the edge of the paper will pass

through the paper exit.

6 Insert the top edge of the paper into

the tear bar slot, then mount the cover

by reversing the procedure for removing the cover in step 1 above.

Note: When the paper end mark ap-

pears on the paper, replace the

roll paper before it runs out.

Tear bar

– 14 –

Fig. 6-7

Page 18

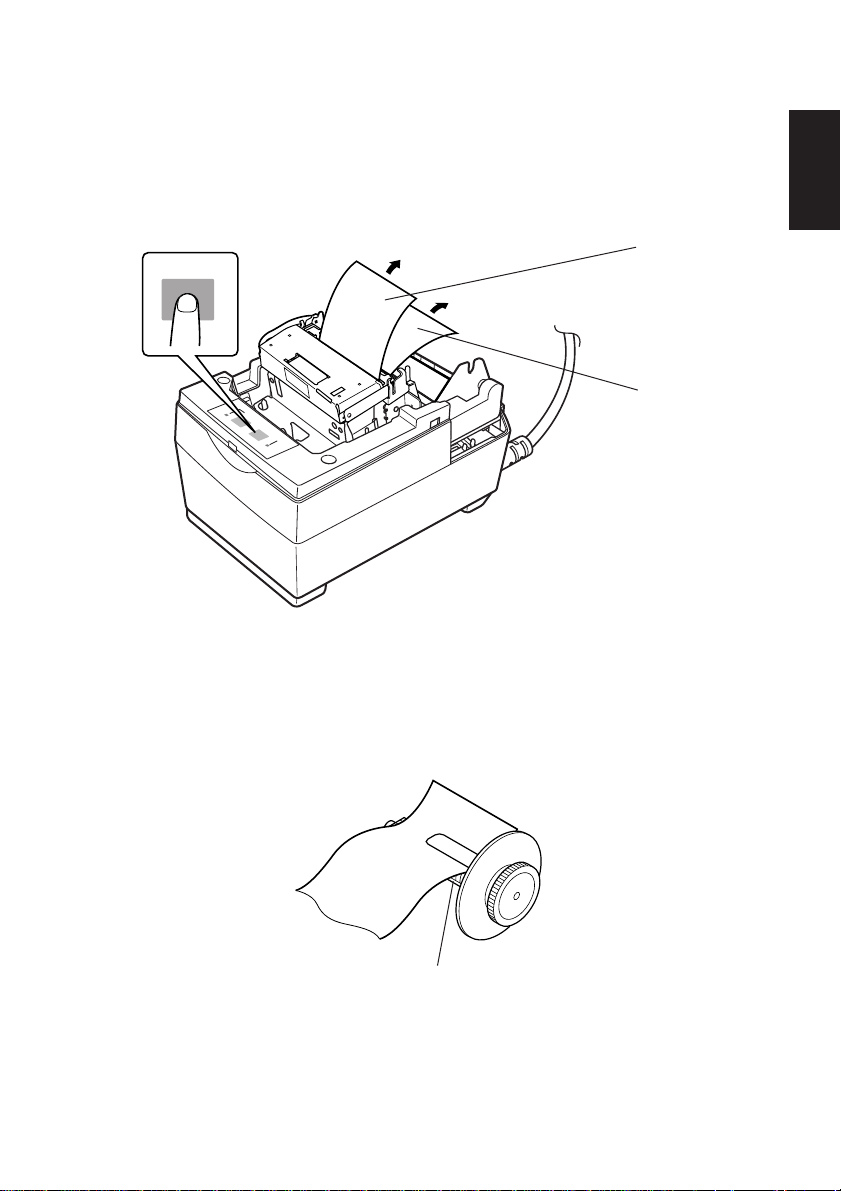

6-2. SP2500 T ype

6-2-1.Loading the Ribbon Cartridge

ENGLISH

Power off

Fig. 6-8 Removing the cover

Auto cutter

Cover

1 Turn off power to the printer.

2 Lift the cover up approx. 3 cm. Hold

the cover tilted at this angle, then

pull it toward you to remove it.

3 Lift up the auto cutter and put it in a

vertical position, as shown in Fig. 6-

9.

Fig. 6-9 Raise the auto cutter

– 15 –

Page 19

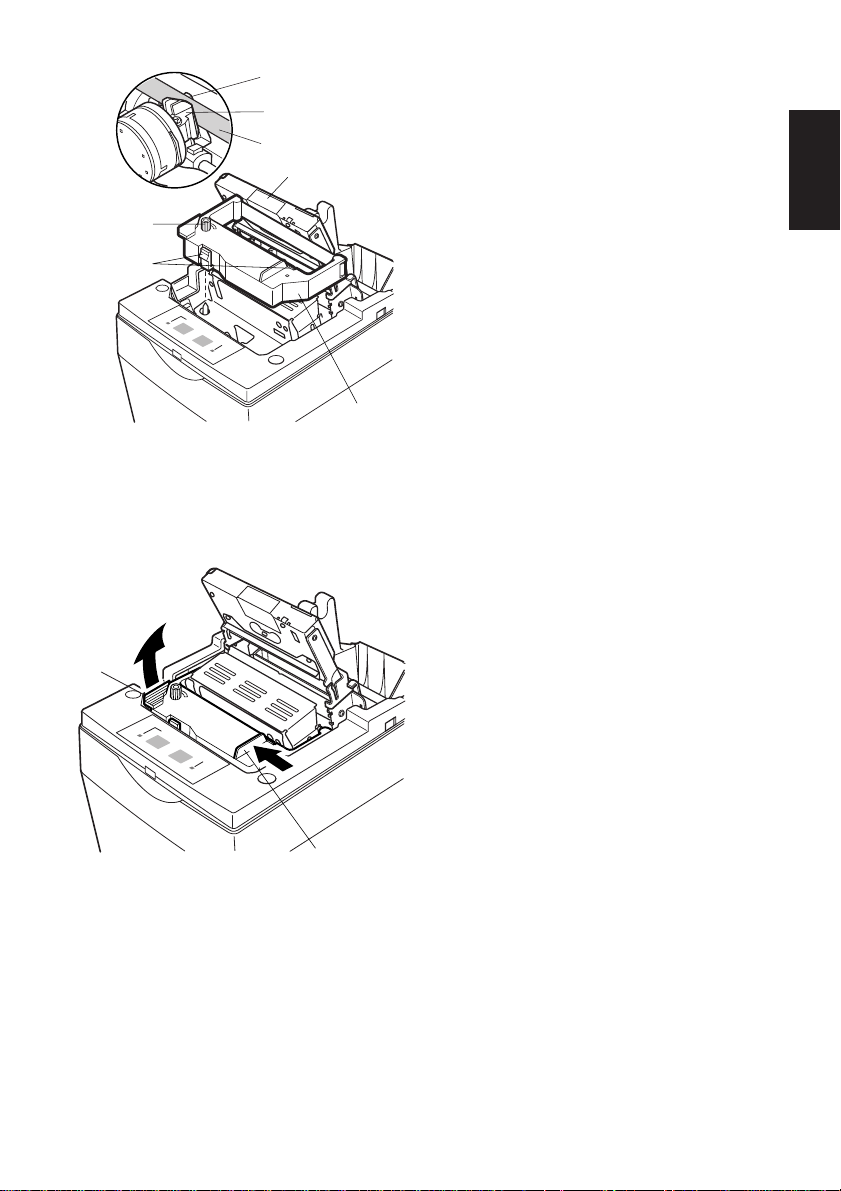

Ribbon separater

Print head

Ink ribbon

Auto cutter

Ribbon

feed knob

Notched

part

Ribbon

cartridge

Fig. 6-10 Loading the ribbon cartridge

4 Place the ribbon cartridge in the

direction shown in Fig. 6-10 and

press it down to load it. If loading of

the ribbon cartridge is not satisfactory, press down the cartridge while

rotating the ribbon feed knob in the

direction of the arrow.

5 Turn the ribbon feed knob of the

ribbon cartridge in the direction of

the arrow to remove slack in the

ribbon.

6 Close the Auto Cutter.

7 Mount the cover by reversing the

procedure outlined in step 2 above.

8 When removing the ribbon cartridge,

raise the A section and then remove

it by holding the B section as shown

in Fig. 6-11.

ENGLISH

A

B

Fig. 6-11 Removing the ribbon cartridge

– 16 –

Page 20

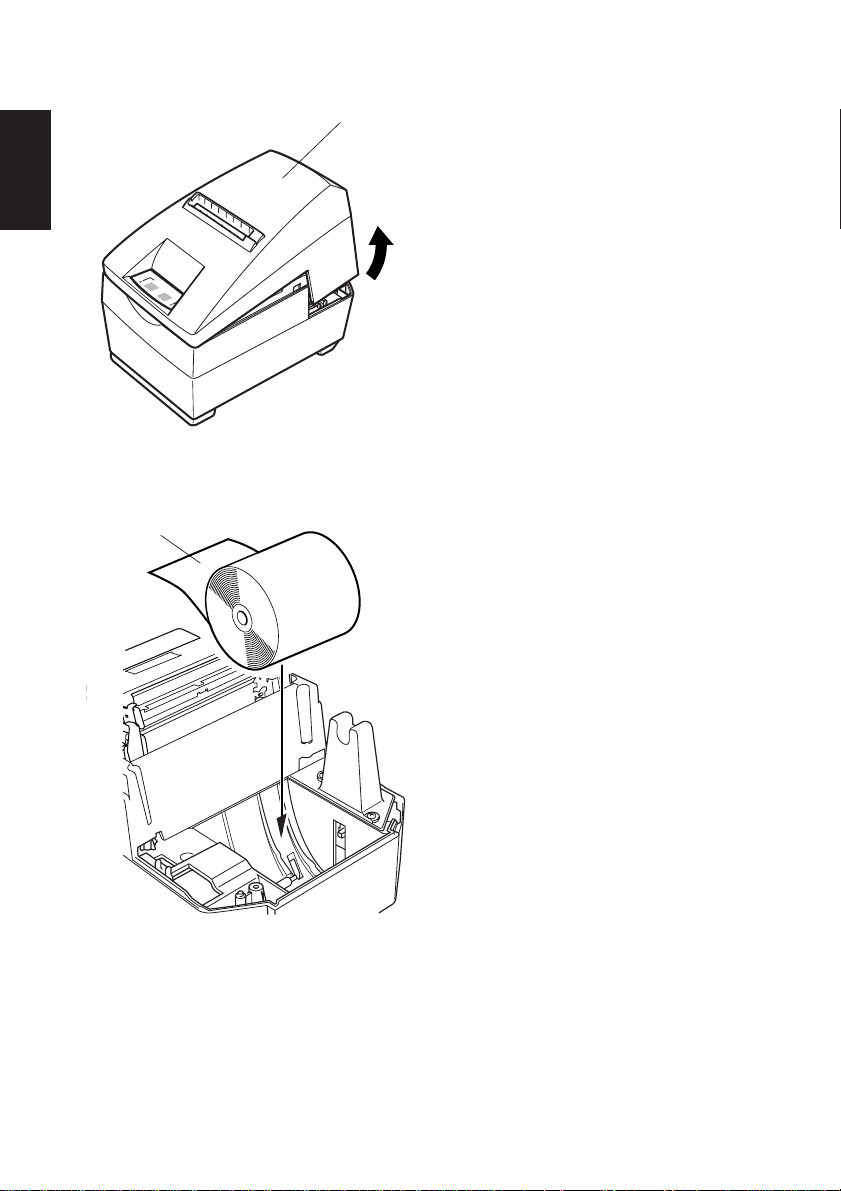

6-2-2.Loading the Paper

ENGLISH

Roll paper

Cover

Fig. 6-12 Removing the cover

1 Lift the cover up approx. 3 cm. Hold

the cover tilted at this angle, then

pull it toward you to remove it.

2 Cut off the front edge of the roll

paper perpendicularly.

3 Confirm that the power of the printer

is turned on.

4 While observing the direction of the

roll, set the paper roll into the hollow as shown in Fig. 6-13.

Fig. 6-13 Setting the paper

– 17 –

Page 21

[When using single-ply paper]

Auto cutter paper

slit

Paper feeder

Roll paper

Fig. 6-14 Loading the paper

[When using multi-ply paper]

5 Inset the edge of the paper into the

paper feeder. If inserted correctly,

the edge of the paper will pass

through the auto cutter paper slit.

The paper will be cut once.

6 Remove the cut tip, and mount the

cover by reversing the procedure

outlined in step 1.

Note: When the paper end mark

appears on the paper, replace

the paper roll before it runs

out.

ENGLISH

Upper

paper

Print head

Lower paper

Paper

insertion

slit

Platen

Print head

Fig. 6-15 Insertion of the paper into the auto cutter

(When using copying paper)

5 Lift up the auto cutter and place it in

a vertical position.

6 Insert the edge of the paper into the

paper feeder. If inserted correctly,

the edge of the paper will pass

through the paper exit.

– 18 –

Auto cutter

Upper paper

Lower paper

Platen

Page 22

ENGLISH

Paper

outlet

Auto cutter

Fig. 6-16 Paper outlet of the front

cover

7 Insert only the original (the upper

paper) into the slit of the auto cutter.

Insert the paper onto which you

wish to copy (the lower paper) between the platen and the auto cutter.

8 Pull on the edge of the paper to

remove any slack and then lower the

auto cutter.

9 Insert the paper through the paper

outlet and then replace the cover by

reversing the removal steps.

Note: When the paper end mark

appears on the paper, replace

the roll paper before it runs

out.

– 19 –

Fig. 6-17 Mounting the cover

Page 23

6-2-3. Rewinder

When using the rewinder, follow steps 1 through 8 of section 6-2-2, and then

continue with the procedure described below.

9 Feed approximately 20 cm of roll paper from the paper exit by pressing the

[FEED] button.

ENGLISH

FEED

Upper paper

Lower paper

Fig. 6-18 Loading the paper

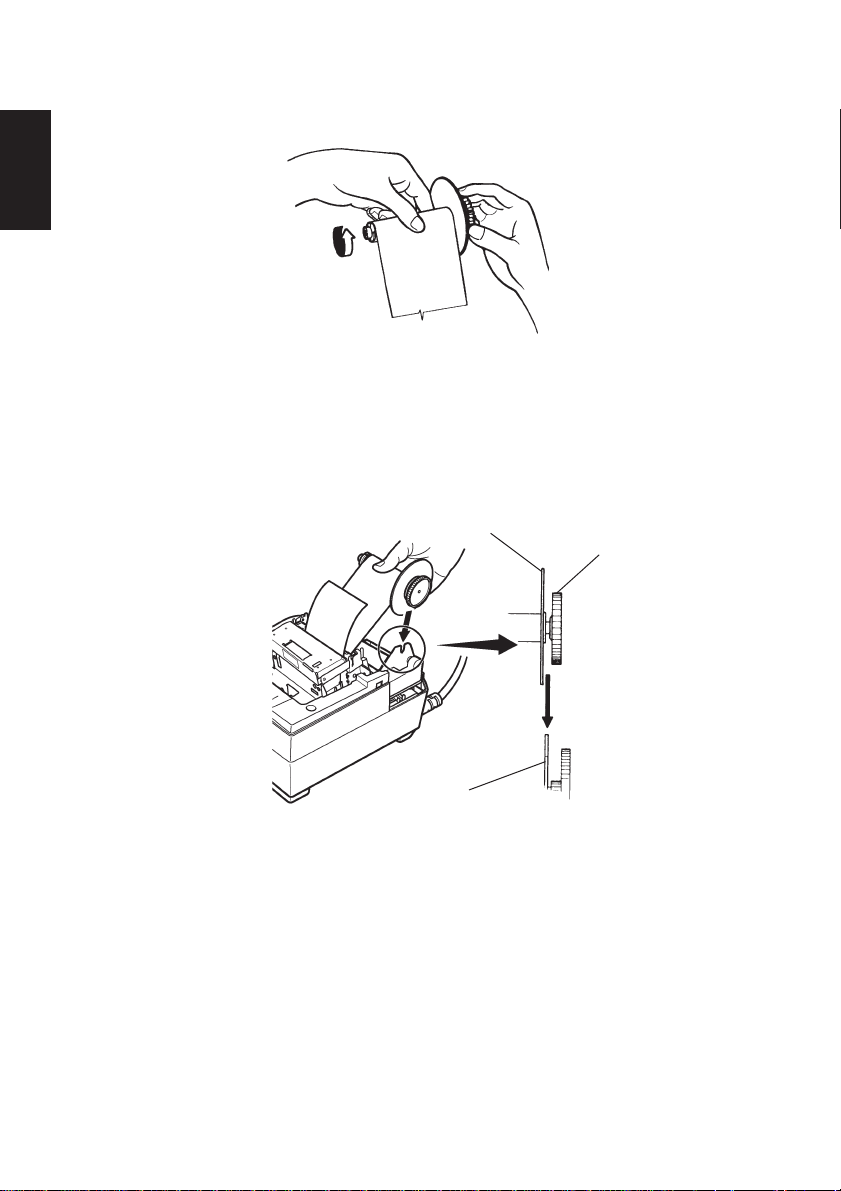

0 Insert the end of the journal paper through the slit in the take-up spool as shown

below. Be sure that the right side of the paper is against the reel.

Spool

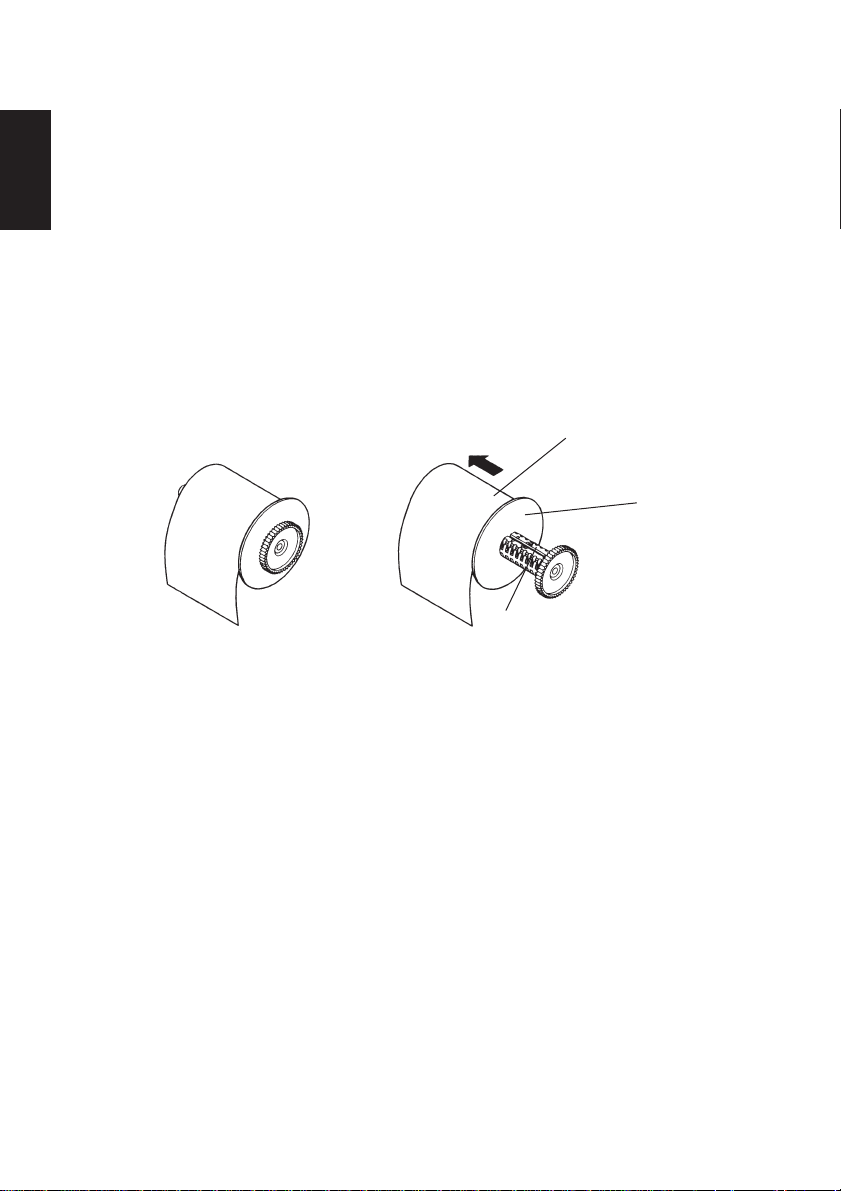

Fig. 6-19 Spool

– 20 –

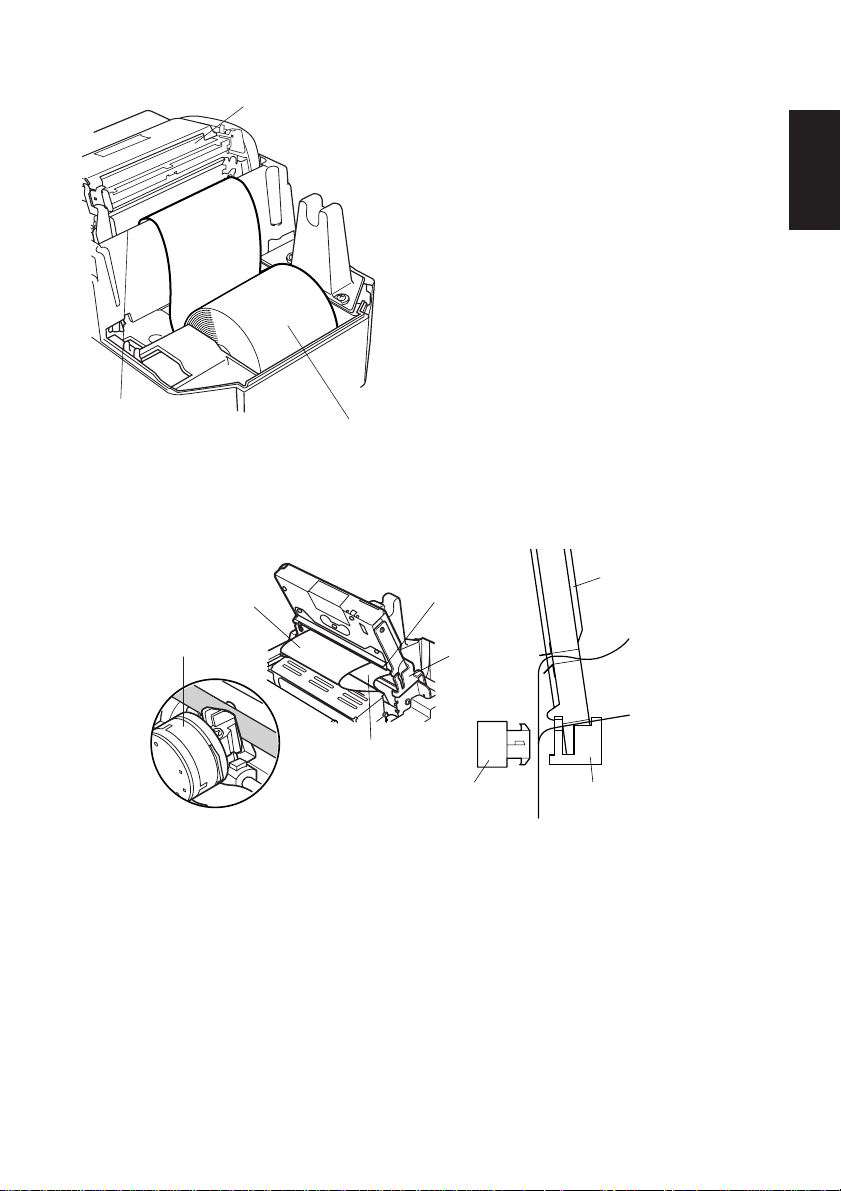

Page 24

A Wind the paper onto the spool about three turns.

ENGLISH

Fig. 6-20

B While holding the paper down so that there is no slack, set the spool into place

so the gear on the spool engages with the gear inside the printer.

Reel

Gear

Fig. 6-21

– 21 –

Frame

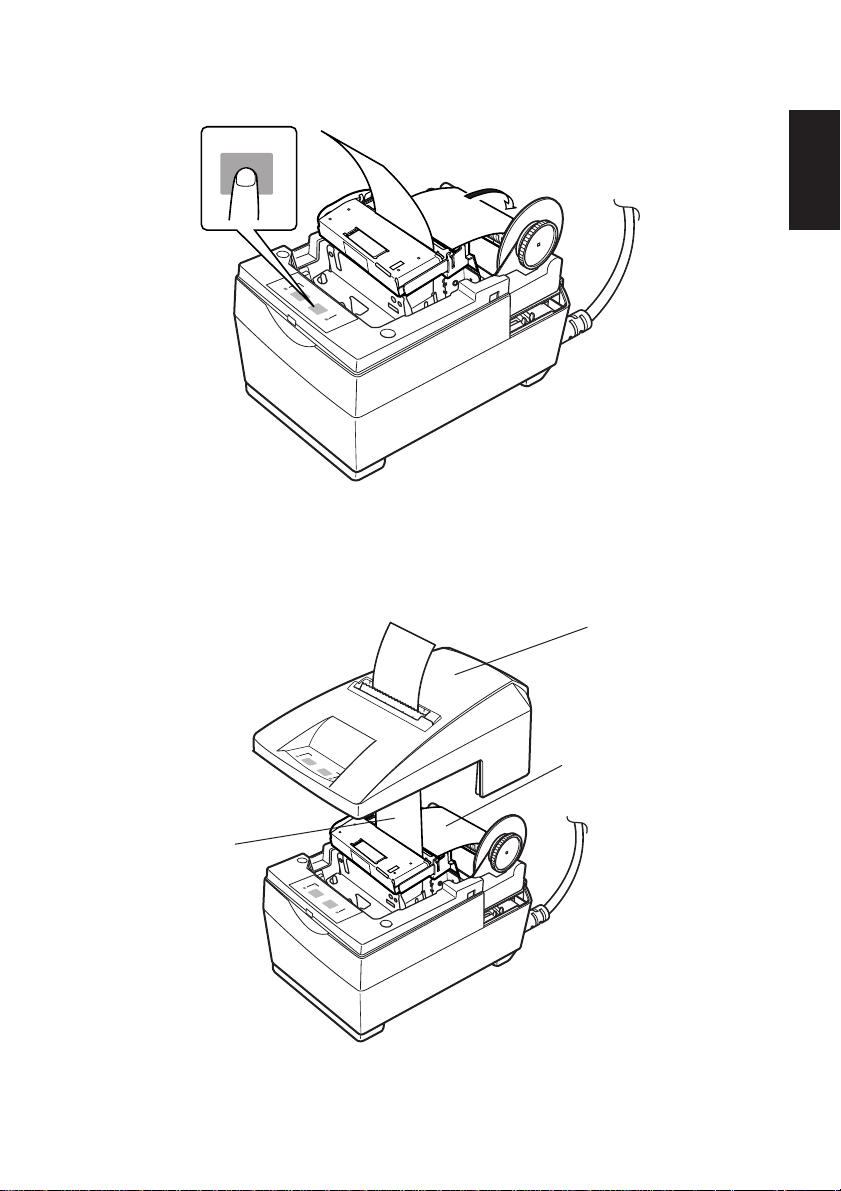

Page 25

C Press the [FEED] button to wind the paper a round the take-up spool. Hold

down the [FEED] button until there is no slack in the paper.

FEED

Fig. 6-22

D After installation is complete, replace the printer cover while passing the

leading edge of the upper paper through the slit in the cover.

Cover

ENGLISH

Upper paper

Lower paper

Fig. 6-23

– 22 –

Page 26

6-3. Removing the Paper

Remove the cover, then cut off the paper near the rear of the paper guide and press

ENGLISH

the FEED switch to feed out the paper remaining in the unit.

When the paper runs out, the POWER lamp will blink.

Note: 1. Remove the paper remaining in the printer by pressing the FEED

switch.

2. When the paper end mark appears on the paper, replace the roll

paper before it runs out.

[When the rewinder is used]

Remove the reel together with the paper rolled up on it.

Paper

Reel

Spool

Fig. 6-24

– 23 –

Page 27

7. Control Panel

7-1. Basic Operation

FEED POWERON LINE

4

1 2

Fig. 7-1 Control panel

3 POWER lamp (green LED)

LED lit : Power to the printer is ON.

LED off : Power to the printer is OFF.

4 ON LINE lamp (green LED)

LED lit : Printer is ON LINE

LED off : Printer is OFF LINE

3

1 ON LINE switch

Switches the printer between ON

LINE and OFF LINE. ON LINE

and OFF LINE switching is possible only when paper is loaded in the

printer.

2 FEED switch

• When this switch is pressed and

then released within 0.5 sec., the

paper feeds on line.

• When this switch is held depressed

for more than 0.5 sec., the paper

feeds continuously.

(The above paper feed operation is

possible for both ON LINE and OFF

LINE modes.)

ENGLISH

– 24 –

Page 28

7-2. Errors

Determine the nature of the error by the flashing of the lamp or the sound of the

ENGLISH

buzzer.

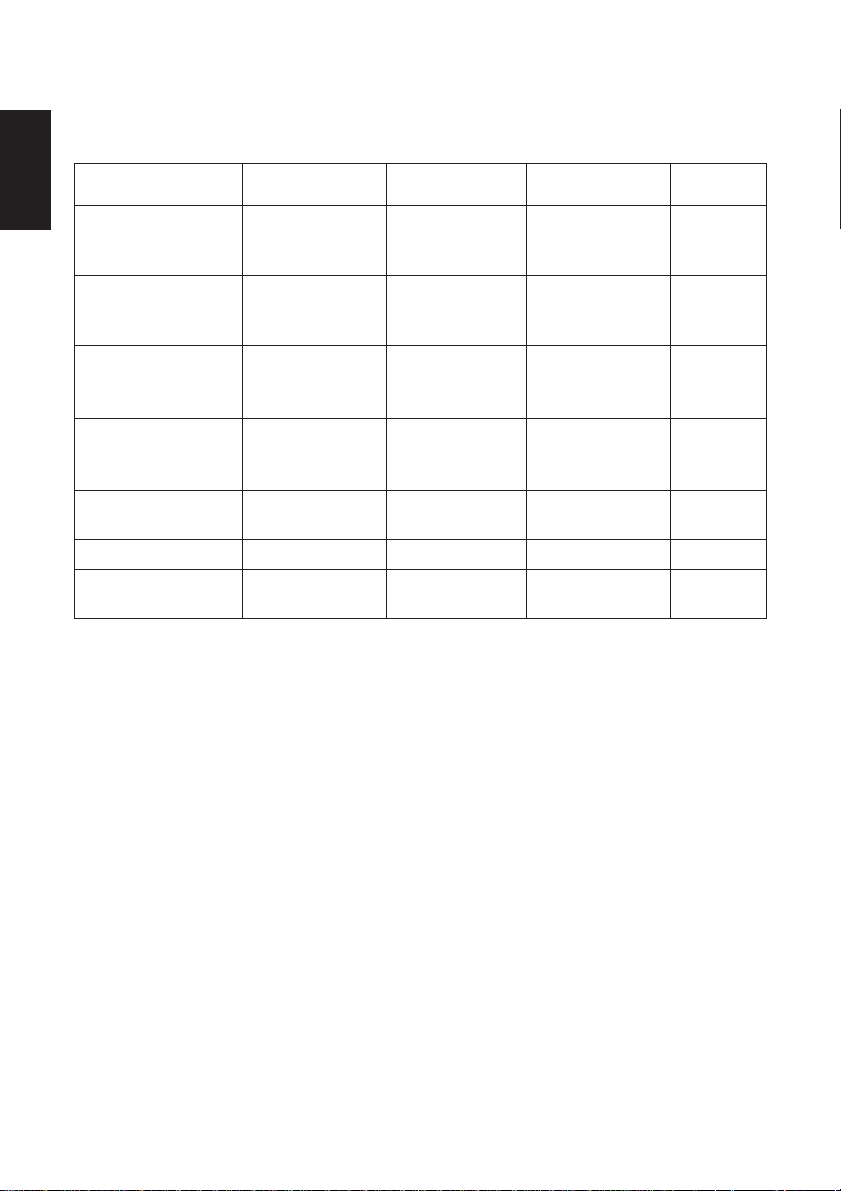

Error Description Power lamp On-line lamp Buzzer

No paper

Paper near end of

roll (when Near End

Stop is operative)

Mechanical error

(other than cutter

error)

Cutter error (on

models with cutter

only)

Print-order overload

error

RAM R/W error

CPU error

Flashes at 1second intervals

Flashes at 2second intervals

Flashes at 0.25second intervals

Flashes at 0.125second intervals

Flashes at 0.5second intervals

Off

Off

Off

Off

On (after on-line

switch pushed)

Off

Off

On

On

On

4 short beeps

(0.13 seconds)

repeated twice

None

One short (0.13

sec.) and one long

(0.5 sec.) beep

Two short (0.13

sec.) and one long

(0.5 sec.) beep

None

None

Sounds for 2

seconds

Recovery

Conditions

*1

*2

*3

*3

*4

*5

*5

*1 After changing the paper, press the On-line switch.

*2 Press the On-line switch to continue printing; or change the paper and press

the On-line switch.

*3 After clearing the paper jam or remedying another problem, press the On-line

switch.

*4 Printing will resume automatically after some time has elapsed. (Recovery is

automatic after the print head has cooled.)

*5 This is not a recoverable error. Consult dealer for repairs.

– 25 –

Page 29

7-3. Switch Operation (Combined Switch Operation)

7-3-1.Self Printing

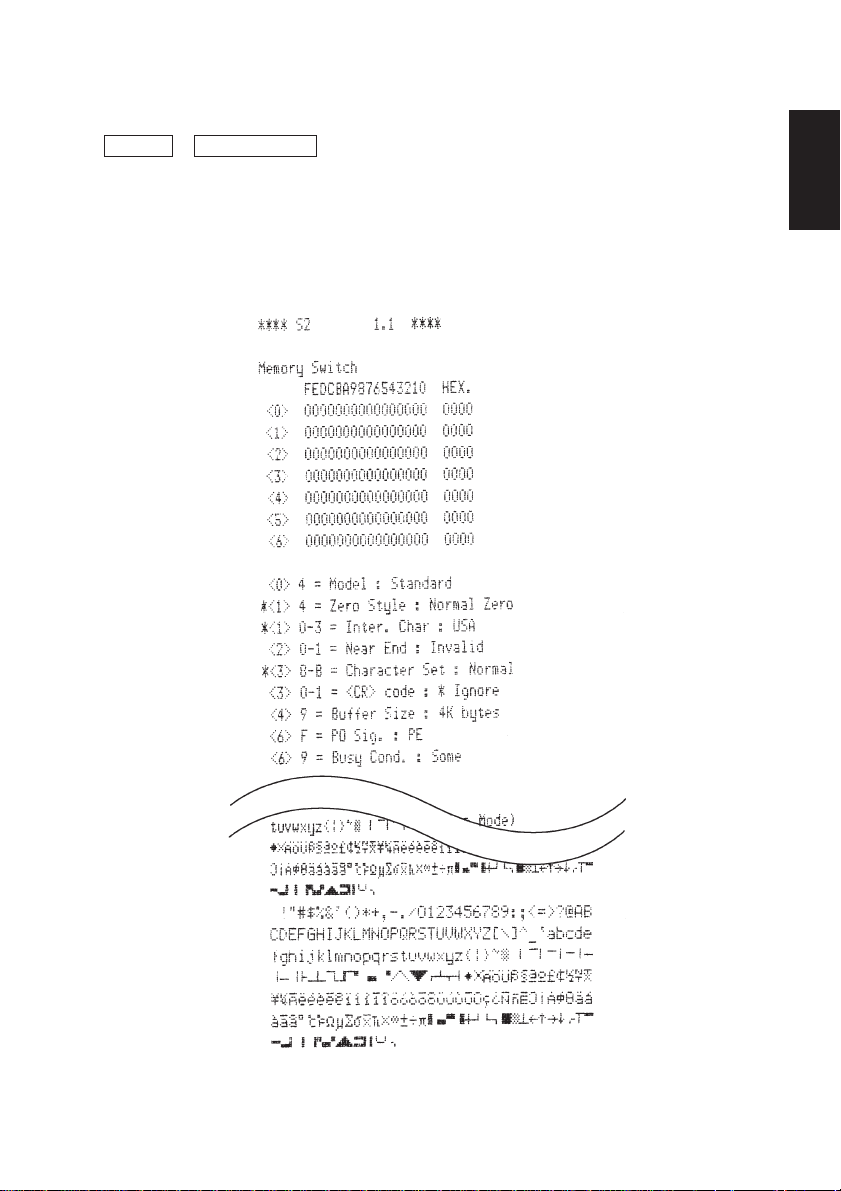

FEED + POWER ON (Turn the power on while holding the FEED switch

depressed.)

Self-printing will be performed according to the VER. NO., DIP switch

settings and character order. When the FEED switch is held continuously or

when the FEED switch is depressed at the time of the end of self-printing, only

the characters will be printed out repeatedly.

ENGLISH

Fig. 7-2 Self printing sample (when using serial interface printer)

– 26 –

Page 30

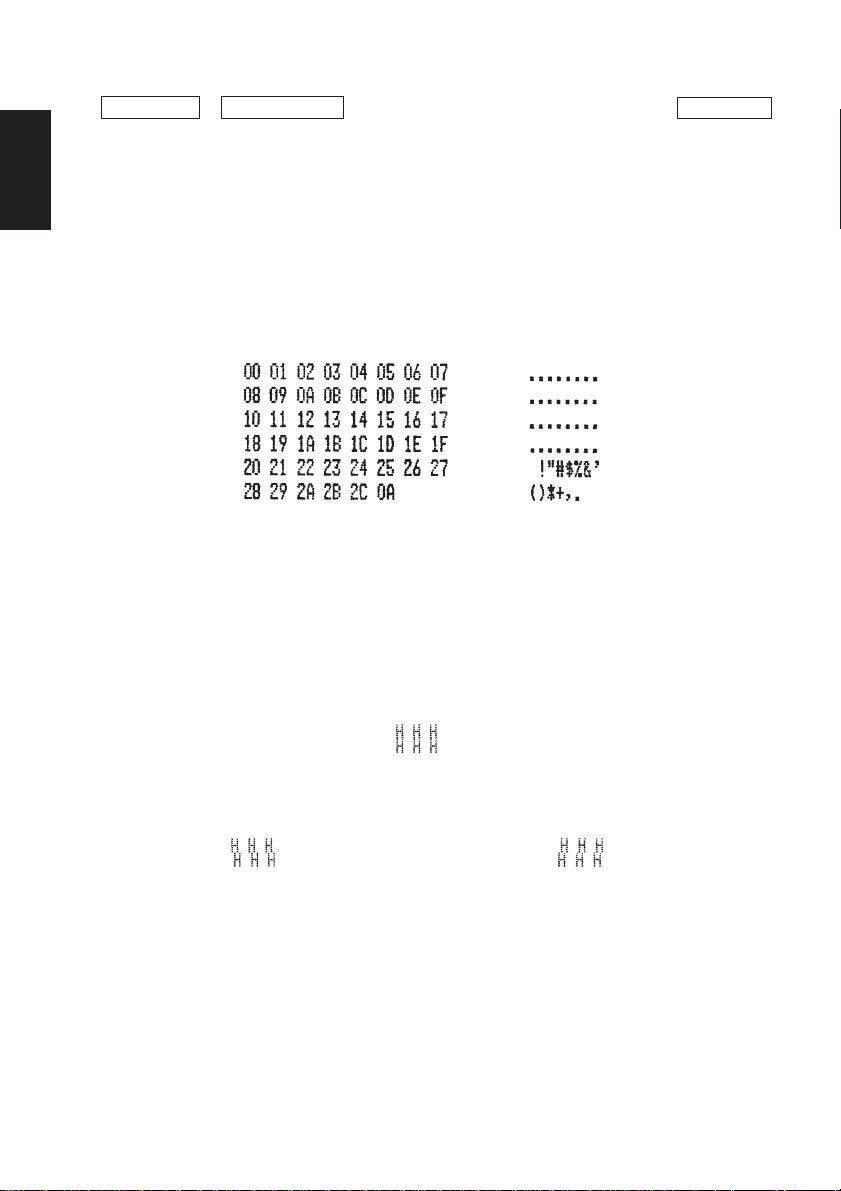

7-3-2.Hexadecimal Dump Mode

ENGLISH

ON LINE + POWER ON (Turn the power on while holding the ON LINE

switch depressed.)

Each of the signals sent from the computer to the printer will be printed out in

hexadecimal code.

This function allows you to check if a control code sent to the printer by the

program being used is correct or not. The last line is not printed if its data is

less than one full line. However, if the ON LINE switch is pressed to set the

off line mode, the last line will be printed. To turn off the mode, it is necessary

to turn off the printer completely.

Fig. 7-3 Hexadecimal dump printing sample

7-3-3.Adjusting the Dot Alignment

You may never have to use the procedure described in this section, but after

you have been using your printer for some time you may find that the dots of

some graphics do not align correctly. For example, what should look like:

may come out looking like one of the following:

or like this

– 27 –

Page 31

This is caused when mechanical parts of the printer get out of alignment. This

happens only rarely and you may never experience it at all throughout the life

of the printer. If you do have problems, use the following procedure to correct

it.

• Turn on the printer and insert a piece of paper.

• Turn off printer power.

• While holding down the control panel’s ON LINE and FEED switches,

turn the printer back on to enter the Dot Alignment Adjust Mode, which is

indicator by a flashing POWER indicator flashes.

Entering the Dot Alignment Adjust Mode causes seven blocks to be

printed, each of which indicates a dot alignment setting, as shown below.

An asterisk to the left of the blocks indicates which block is currently

selected.

ENGLISH

• Use FEED to specify the block that appears to have the best aligned

characters. Press FEED once to specify the first block, twice to specify the

second block, and so on up to seven times to specify the seventh block.

Warning beep will sound if you press FEED more than seven times.

• After specifying a block, press ON LINE to register your selection and exit

the Dot Alignment Adjust Mode.

– 28 –

Page 32

ENGLISH

The dots alignment adjustment setting you selected is stored in printer

memory and a pattern is printed using the selected setting followed by the

message “Adjust Complete!” The printer ejects the paper after printing is

complete.

Note: You setting is not registered if you turn off printer power before

pressing ON LINE to exit the Dot Alignment Adjust Mode.

If a paper feed error occurs during this mode, the printer ejects the

paper and this mode is cancelled.

– 29 –

Page 33

8. Optional Near-end Sensor

The near-end sensor detects when the roll of paper loaded in it is reaching the end.

The near-end sensor is normally disabled when the printer is shipped from the

factory, but it can be enabled by your dealer using the memory switch. The

information in this chapter applies only to printers whose near-end sensor is

enabled.

Important!

Installation of the near-end sensor should normally be left to your dealer.

8-1. Adjusting the Near-end Sensor

Use the following procedure to adjust the near-end sensor so it is compatible with

the size of roll paper you are using.

Important!

Regardless of the overall diameter of the paper roll, the heavy paper core at the

center off the roll must have an inside diameter of 12 mm and an outside

diameter of 18 mm for proper detection.

1 Make sure that the printer is turned

off and unplugged from its power

outlet.

2 Remove the printer cover.

3 Remove the roll paper.

ENGLISH

Fig. 8-1

– 30 –

Page 34

ENGLISH

ø18 mm

ø12 mm

Roll paper core

Level 3

Level 2

Level 1

…

……

………

Fig. 8-2

Fig. 8-3

4 Determine the diameter of the roll

paper you are using and find the

required setting in the table below.

Distance A Setting Indicator

Approximate 9 mm

Approximate 7 mm

Approximate 5 mm

*1 Cannot be used with 2 and 3 ply.

Level 3 ooo

Level 2 oo

*1

Level 1

o

Note:

1. Since the distance A corresponding to the adjustment position on

the chart is a calculated value,

there may variations due to the

actual mechanism.

2. If there is an end mark at the end

of a roll of paper, that end mark

is an adhesive that may lift the

A

entire roll of paper. In such a

case, the remaining roll paper

amount (Distance A) shown in

the chart above will not apply.

3. The quality of some paper may

cause it to become jammed. This

can result in erroneous detection.

5 Insert the tip of a ballpoint pen or

similar pointer object into the hole

of the adjuster. While pressing the

adjuster, slide it up or down to the

A

setting you that matches the roll

paper you are using.

6 Make sure the tab indicated by the

arrow in the illustration is inside

one of the grooves.

– 31 –

Page 35

TABLE DES MATIERES

1. Introduction .....................................................................................................33

2. Déballage et inspection....................................................................................34

2-1. Déballage .............................................................................................34

2-2. Emplacement de l’imprimante .............................................................35

2-3. Précautions de manipulation ................................................................35

2-4. Entretien ...............................................................................................35

3. Identification des pièces et nomenclature........................................................36

4. Adaptateur secteur en option ...........................................................................38

5. Raccordement ..................................................................................................40

5-1. Installation du tore de ferrite ................................................................40

5-2. Raccordement à l’ordinateur hôte (interface série)..............................41

5-3. Raccordement à l’ordinateur hôte (interface parallèle) .......................42

5-4. Raccordement d’un appareil périphérique ...........................................42

6. Installation d’une cartouche à ruban et chargement du papier ........................44

6-1. Modèle SP2300 ....................................................................................44

6-2. Modèle SP2500 ....................................................................................47

6-3. Enlèvement d’un rouleau de papier .....................................................55

7. Panneau de commande ....................................................................................56

7-1. Fonctionnement de base.......................................................................56

7-2. Erreurs ..................................................................................................57

7-3. Utilisation des touches (Utilisation combinée des touches) ................58

8. Capteur de fin de papier en option ..................................................................62

8-1. Réglage du capteur de fin de papier.....................................................62

APPENDICE .....................................................................................................128

FRANÇAIS

L’appendice n’est pas traduit.

– 32 –

Page 36

1. Introduction

L’imprimante série à impact et matrice de points est conçue pour une utilisation

avec des instruments électroniques tels que des terminaux points de vente, du

matériel bancaire, du matériel périphérique pour ordinateurs, etc.

Les caractéristiques principales des modèles de la série SP2000 sont les suivan-

FRANÇAIS

tes:

1. Impression bi-directionnelle à 3,1 lignes/sec. environ.

2. Interface série ou parallèle.

3. Tampon de données permettant à l’appareil de recevoir des données d’impression même pendant le travail d’impression.

4. Circuit de contrôle d’appareils périphériques permettant la commande de

dispositifs extérieurs tels que des tiroirs-caisses.

SP2 3 2 0 M D 42 – 24 R

R : Avec rembobineur

Sans: Sans rembobineur

Nombre de colonnes d’impression

42 : 42 colonnes (16 ccp)

Interface

D : Interface série (RS-232C)

C : Interface parallèle

Alimentation de papier

M : Alimentation de papier par friction

Mécanisme

2 : Une couleur, 42 colonnes (16 ccp)

6:

Deux couleurs, 42 colonnes (16 ccp)

Type d’imprimante

3 : Type standard

5 : Type avec unité de découpage

automatique

Imprimante de la série SP2000

– 33 –

Page 37

2. Déballage et inspection

2-1. Déballage

Après avoir déballé l’appareil, vérifiez si tous les accessoires nécessaires se

trouvent dans la boîte.

Modèle SP2300

Imprimante

Cartouche à ruban

FRANÇAIS

Mode d’emploi

Attache

Plaque de fixation

de l’adaptateur

Plaque de fixation

du cordon

Vis

Modèle SP2500

Tore de ferrite

Imprimante

Bobine (Série R uniquement)

Remarque: La bobine est fournie uniquement avec les modèles de la série R (avec

rembobineur). La bobine se trouve sous le capot de l’imprimante.

Fig. 2-1 Déballage

Si l’un des éléments mentionnés ci-dessus ne se trouve pas dans la caisse,

adressez-vous au magasin où vous avez acheté l’imprimante et demandez que la

pièce manquante vous soit fournie. Il est préférable de conserver la caisse

d’origine ainsi que tous les emballages. Ceux-ci vous seront utiles s’il vous faut

emballer l’imprimante ou la transporter.

– 34 –

Page 38

2-2. Emplacement de l’imprimante

Pour installer correctement l’imprimante, gardez à l’esprit les conseils suivants:

1. Mettez l’imprimante à l’abri de températures excessivement élevées comme en plein

soleil ou à proximité d’un appareil de chauffage, et à l’abri de l’humidité et de la

poussière.

2. Installez l’imprimante sur une surface stable et de niveau sur laquelle l’imprimante

FRANÇAIS

ne sera pas soumise à des vibrations.

3. Veillez à ce que l’imprimante soit branchée sur une source secteur stable.

Par exemple, ne pas brancher l’imprimante sur la prise secteur d’un circuit alimentant

déjà un appareil électroménager gros consommateur de courant et producteur de

parasites, tel qu’un réfrigérateur ou un climatiseur.

4. Veillez à ce que la tension du secteur corresponde bien à la tension spécifiée sur la

plaque d’identification de l’imprimante.

5. Pour débrancher l’imprimante, la fiche doit être débranchée de la prise murale, et

celle-ci doit être située à proximité de l’imprimante et facile d’accès.

2-3. Précautions de manipulation

1. Faites attention à ne pas laisser tomber de trombones, punaises ou autres objets dans

l’imprimante. Un dysfonctionnement pourrait en résulter.

2. Ne pas essayer d’imprimer quand il n’y a pas de papier ou de cartouche à ruban dans

l’imprimante. La tête d’impression pourrait être endommagée.

3. Ne pas ouvrir le capot pendant l’impression.

4. Ne pas toucher la tête d’impression immédiatement après un travail d’impression car

elle devient très chaude.

5. Utilisez seulement un rouleau de papier dont l’extrémité n’est pas collée au tube

central.

6. Quand le repère de fin de papier apparaît sur le papier, remplacez le rouleau de papier

avant qu’il soit terminé.

2-4. Entretien

Avant tout, cette imprimante est un appareil robuste, mais un minimum de précautions

sont à prendre pour éviter les dysfonctionnements. Par exemple:

1. Laissez l’imprimante dans un environnement “confortable”. En gros, si vous êtes à

l’aise, l’environnement sera acceptable pour l’imprimante.

2. Ne pas soumettre l’imprimante à des chocs ou à des vibrations excessives.

3. Évitez les environnements excessivement poussiéreux. La poussière est l’ennemi de

tous les appareils mécaniques de précision.

4. Pour nettoyer l’extérieur de l’imprimante, utilisez un chiffon légèrement imbibé

d’eau ou d’alcool, mais ne laissez aucun liquide pénétrer à l’intérieur de l’imprimante.

5. L’intérieur de l’imprimante peut être nettoyé avec une petite brosse de nettoyage ou

un aérosol à air comprimé (vendu à cet effet). Pendant cette opération, veillez à ne pas

plier ni endommager les connexions ou les composants électroniques.

– 35 –

Page 39

3. Identification des pièces et nomenclature

Modèle SP2300

Capot

Protège l’imprimante de la poussière et réduit le bruit.

Ne pas ouvrir le capot pendant l’impression.

Panneau de commande

Comprend deux commutateurs de

commande et trois témoins indiquant

le statut de l’imprimante.

Adaptateur secteur

Consulter la section suivante

pour les instructions concernant

son installation

FRANÇAIS

Interrupteur d’alimentation

Cet interrupteur vous

permet de mettre

l’imprimante sous

tension et hors tension.

Connecteur de pilotage

d’appareils périphériques

Ce connecteur vous permet

de raccorder l’imprimante à

des appareils périphériques

tels que des tiroirs-caisses,

etc.Ne pas raccorder à un

téléphone.

Connecteur d’interface

Ce connecteur vous permet de

raccorder l’imprimante à

l’ordinateur hôte.

Fig. 3-1 Vue externe de l’imprimante (Modèle SP2300)

Commutateurs DIP

Ces commutateurs permettent d’effectuer divers

réglages.

– 36 –

Page 40

Modèle SP2500

Capot

Protège l’imprimante de la poussière et réduit le bruit.

Ne pas ouvrir le capot pendant l’impression.

FRANÇAIS

Panneau de commande

Comprend deux commutateurs de commande et

deux témoins indiquant le statut de l’imprimante.

Adaptateur secteur

Consulter la section suivante

pour les instructions concernant

son installation

Interrupteur d’alimentation

Cet interrupteur vous

permet de mettre

l’imprimante sous

tension et hors tension.

Connecteur de pilotage

d’appareils périphériques

Ce connecteur vous permet

de raccorder l’imprimante à

des appareils périphériques

tels que des tiroirs-caisses,

etc.Ne pas raccorder à un

téléphone.

Connecteur d’interface

Ce connecteur vous permet de

raccorder l’imprimante à

l’ordinateur hôte.

Fig. 3-2 Vue externe de l’imprimante (Modèle SP2500)

Commutateurs DIP

Ces commutateurs permettent d’effectuer divers

réglages.

– 37 –

Page 41

4. Adaptateur secteur en option

Adaptateur secteur

Câble

d’alimentation

Fig. 4-1

Procéder de la manière suivante pour installer l’adaptateur secteur en option.

Adaptateur secteur

Cordon de l’adaptateur secteur

[Avant l’installation de l’adaptateur secteur] [Après l’installation de l’adaptateur secteur]

Plaque de fixation

de l’adaptateur Attache

Plaque de fixation du cordon

FRANÇAIS

Fig. 4-2 Vue côté plat

1 Retourner l’imprimante.

2 Brancher le cordon de l’adaptateur secteur dans la prise comme illustré ci-

dessous. Vérifier que le côté plat de la fiche soit tourné vers l’intérieur de

l’imprimante.

3 Utiliser une des attaches en nylon livrées avec l’imprimante pour fixer le

cordon au point marqué sur l’illustration.

– 38 –

Page 42

FRANÇAIS

Fig. 4-3 Fixer le cordon ici

4 Enrouler le cordon de l’adaptateur secteur dans l’espace prévu et insérer

l’adaptateur secteur dans son logement.

5 Utiliser la plaque de fixation de l’adaptateur et la visser pour caler l’adapta-

teur ; utiliser la plaque de fixation du cordon et la visser pour caler le cordon.

6 Retourner l’imprimante et la mettre à l’endroit.

7 Brancher la fiche femelle du cordon d’alimentation dans l’adaptateur secteur

et brancher l’autre extrémité du cordon dans une prise de courant.

– 39 –

Page 43

5. Raccordement

L’ordinateur communique les données à l’imprimante via le câble connecté à

l’interface de l’imprimante (type de connecteur d’interface série : D-Sub à 25

broches ou type de connecteur d’interface parallèle : compatible Centronics à 36

broches). Ce câble n’est pas fourni avec l’imprimante. Vous devrez donc vous en

procurer un.

Attention!

• Les instructions suivantes concernent le câble de connexion employé sur un

ordinateur personnel compatible IBM. Notez que ces instructions ne s’appliquent pas à tous les types d’ordinateurs et de câbles. Si vous n’êtes pas sûr du

type de câble adapté à votre ordinateur, demandez conseil à votre revendeur.

• Assurez-vous que l’imprimante est hors tension, qu’elle est débranchée de la

prise secteur et que l’ordinateur est hors tension avant de les connecter.

5-1. Installation du tore de ferrite

1 Fixez le tore de ferrite sur le câble

comme illustré.

FRANÇAIS

Interface câble

Tore de ferrite

Fig. 5-1

– 40 –

Page 44

FRANÇAIS

5 cm

maximum

Fig. 5-2

Fig. 5-3

2 Passez l’attache dans le tore de fer-

rite.

Attache

3 Passez l’attache autour du tore de

ferrite et serrez-la. Coupez l’extrémité de l’attache à l’aide de ciseaux.

Tirez et coupez

5-2. Raccordement à l’ordinateur hôte (interface série)

1 Mettez l’ordinateur hôte et l’impri-

mante hors tension.

Tore de ferrite

Vis

Toumevis

Fig. 5-4 Connexion du câble

d’interface série

2 Insérez un des connecteurs du câble

d’interface dans la prise de l’imprimante et l’autre dans la prise de

l’ordinateur hôte.

3 Serrez ensuite les vis droite et gau-

che des connecteurs pour les fixer

aux prises.

– 41 –

Page 45

5-3. Raccordement à l’ordinateur hôte (interface parallèle)

1 Mettez l’ordinateur hôte et l’impri-

mante hors tension.

2 Insérez un des connecteurs du câble

d’interface dans la prise de l’impri-

Tore de ferrite

mante comme indiqué dans le

schéma, et fixez-le avec les fermoirs

3 Insérez l’autre connecteur du câble

d’interface dans la prise de l’ordinateur hôte, puis fixez-le également

avec les fermoirs.

Fig.5-5 Connexion du câble

d’interface parallèle

5-4. Raccordement d’un appareil périphérique

Vous pouvez raccorder un appareil périphérique à l’imprimante à l’aide d’une

fiche modulaire. Pour les détails sur le type de fiche modulaire à utiliser, reportezvous à la page 142. Notez que le fil ou la fiche modulaires ne sont pas fournis avec

l’imprimante. Vous devrez donc vous les procurer.

Attention!

Assurez-vous que l’imprimante est hors tension, qu’elle est débranchée de la

prise secteur et que l’ordinateur est hors tension avant d’effectuer les connexions.

FRANÇAIS

Modular plug: MOLEX 90075-0007,

Fiche modulaire: MOLEX 90075-0007,

AMP641337, or JAPAN BURNDY B-66-4

AMP641337 ou JAPAN BURNDY B-66-4

16

Fig. 5-6

– 42 –

Shield

Blindage

Wire lead

Fil

Fiche

modulaire

Câble

Fig. 5-7

Page 46

FRANÇAIS

Attention!

Ne connectez pas une ligne de téléphone au connecteur de pilotage d’appareils

périphériques, sous peine de risquer d’endommager l’imprimante et la ligne de

téléphone.

1 Raccordez une extrémité du câble

modulaire à la prise modulaire du

périphérique.

2 Retirez le cache de prise modulaire

au dos de l’imprimante, et raccordez l’autre extrémité du câble modulaire dans la prise de l’imprimante.

Fig. 5-8

– 43 –

Page 47

6. Installation d’une cartouche à ruban et chargement du papier

6-1. Modèle SP2300

6-1-1. Installation d’une cartouche à ruban

1 Mettez l’imprimante hors tension.

2 Soulevez le capot d’environ 3 cm.

Capot

Hors tension

Fig. 6-1. Dépose du capot

Séparateur de ruban

Tête d’impression

Ruban encreur

Bouton

d’alimentation du ruban

Parties avec

encoches

Tout en tenant le couvercle incliné à

cet angle, tirez-le vers vous pour

l’enlever.

3 Mettez la cartouche à ruban en place

dans le sens indiqué dans la figure

6-2 et appuyez légèrement sur la

cartouche afin qu’elle se mette en

place. Si la mise en place de la

cartouche n’est pas satisfaisante,

appuyez sur la cartouche tout en

faisant tourner le bouton d’alimentation du ruban de la cartouche dans

le sens de la flèche.

4 Pour tendre le ruban, faites tourner

le bouton d’alimentation du ruban

de la cartouche dans le sens de la

flèche.

5 Pour remettre en place le capot, sui-

vant la procédure décrite à l’étape

2 dans le sens inverse.

FRANÇAIS

Fig. 6-2 Mise en place de la

cartouche à ruban

Cartouche à ruban

– 44 –

Page 48

A

FRANÇAIS

Fig. 6-3 Dégagement de la

cartouche du ruban

6-1-2.Ehargement du papier

Remarque: Pour enlever la cartouche à

ruban, soulevez la partie A,

puis enlevez la cartouche en la

tenant par la partie B comme

indiqué dans la figure 6-3.

B

Capot

Fig. 6-4 Dépose du capot

1 Soulevez le capot d’environ 3 cm.

Tout en tenant le couvercle incliné à

cet angle, tirez-le vers vous pour

l’enlever.

2 Coupez l’extrémité du papier per-

pendiculairement.

3 Vérifiez si l’imprimante est bien

sous tension.

– 45 –

Page 49

Rouleau de papier

Fig. 6-5 Chargement du papier

Mécanisme d’avance

de papier

4 En faisant attention au sens du rou-

leau, mettez le rouleau de papier en

place dans le creux, comme indiqué

dans la figure 6-5.

FRANÇAIS

5 Insérer le bord du papier dans le

mécanisme d’avance de papier. S’il

est inséré correctement, le bord du

papier ressortira par la fente de sortie de papier.

6 Insérez l’extrémité du papier dans

la fente de sortie où se trouve la

barre de découpage, puis remettez

le capot en place en suivant la procédure de dépose du capot décrite à

l’étape 1 ci-dessus dans le sens

inverse.

Remarque:Quand le repère de fin

de papier apparaît sur

le papier, remplacez le

rouleau de papier avant

qu’il soit terminé.

Fente de sortie

de papier

Fig. 6-6 Chargement du papier

Rouleau de papier

– 46 –

Barre de

découpage

Fig. 6-7

Page 50

6-2. Modèle SP2500

6-2-1.Installation d’une cartouche à ruban

Capot

FRANÇAIS

Hors tension

Fig. 6-8 Dépose du capot

Unité de découpage

automatique

1 Mettez l’imprimante hors tension.

2 Soulevez le capot d’environ 3 cm.

Tout en tenant le couvercle incliné à

cet angle, tirez-le vers vous pour

l’enlever.

3 Soulevez l’unité de découpage auto-

matique pour la mettre en position

verticale, comme indiqué dans la

figure 6-9.

Fig. 6-9 Redressement de l’unité

de découpage automatique

– 47 –

Page 51

Bouton

d’alimentation

du ruban

Parties avec

encoches

Fig. 6-10 Mise en place de la

cartouche à ruban

A

Séparateur de ruban

Téte d’impression

Ruban encreur

Unité de découpage automatique

Cartouche à

ruban

4 Mettez la cartouche à ruban en place

dans le sens indiqué dans la figure

6-10 et appuyez légèrement sur la

cartouche afin qu’elle se mette en

place. Si la mise en place de la

cartouche n’est pas satisfaisante, appuyez sur la cartouche tout en faisant tourner le bouton d’alimentation du ruban de la cartouche dans le

sens de la flèche.

5 Pour tendre le ruban, faites tourner

le bouton d’alimentation du ruban

de la cartouche dans le sens de la

flèche.

6 Refermez l’unité de découpage auto-

matique.

7 Pour remettre en place le capot, sui-

vez la procédure décrite à l’étape 2

dans le sens inverse.

8 Pour enlever la cartouche à ruban,

soulevez la partie A, puis enlevez la

cartouche en la tenant par la partie B

comme indiqué dans la figure 6-11.

FRANÇAIS

B

Fig. 6-11 Dégagement de la

cartouche du ruban

– 48 –

Page 52

6-2-2.Chargement du papier

FRANÇAIS

Rouleau de papier

Capot

Fig. 6-12 Dépose du capot

1 Soulevez le capot d’environ 3 cm.

Tout en tenant le couvercle incliné à

cet angle, tirez-le vers vous pour

l’enlever.

2 Coupez l’extrémité du papier per-

pendiculairement.

3 Vérifiez si l’imprimante est bien

sous tension.

4 En faisant attention au sens du rou-

leau, mettez le rouleau de papier en

place dans le creux, comme indiqué

dans la figure 6-13.

Fig. 6-13 Chargement du papier

– 49 –

Page 53

[Avec une feuille de papier simple]

Mécanisme

d’avance de papier

Fente de sortie

de papier

Rouleau de papier

Fig. 6-14 Chargement du papier

[Avec du papier pour copie]

5 Insérez l’extrémité du papier dans

le mécanisme d’avance de papier.

S’il est inséré correctement, le bord

du papier passera par la fente de

l’unité de découpage automatique.

Le papier sera coupé une fois.

6 Enlevez le bout coupé et remettez le

capot en place en suivant la procédure inverse de celle décrite à l’étape

1.

Remarque: Quand la marque de fin

de papier apparaît sur

le papier, remplacez le

rouleau avant qu’il soit

épuisé.

FRANÇAIS

Feuille

supérieure

Tête d’impression

Fig. 6-15 Insertion du papier dans l’unité de découpage

Fente

d’insertion

du papier

Cylindre

Feuille inférieure

Tête d’impression

Unité de découpage

automatique

Feuille supérieure

Feuille inférieure

Cylindre

automatique (avec utilisation de papier pour copie)

5 Soulevez l’unité de découpage auto-

matique pour la mettre en position

verticale.

6 Insérez le bord du papier dans le

mécanisme d’avance de papier. S’il

est inséré correctement, le bord du

papier ressortira par la fente de sortie de papier.

– 50 –

Page 54

FRANÇAIS

Sortie de

papier

Fig. 6-16 Fente de sortie du cache

avant

Unité de

découpage

automatique

7 Insérez seulement l’original (feuille

supérieure) dans la fente de l’unité

de découpage automatique. Insérez

le papier sur lequel vous souhaitez

effectuer la copie (feuille inférieure)

entre le cylindre et l’unité de découpage automatique.

8 Tirez sur l’extrémité du papier afin

de tendre le papier, puis rabaissez

l’unité de découpage automatique.

9 Insérez le papier dans la sortie de

papier, puis remettez le capot en

place en suivant la procédure de

dépose du capot dans le sens inverse.

Remarque:

Quand le repère de fin de papier

apparaît sur le papier, remplacez

le rouleau de papier avant qu’il

soit terminé.

Fig. 6-17 Remise en place du capot

– 51 –

Page 55

6-2-3.Rembobineur

Pour utiliser le rembobineur, procédez aux étapes 1 à 8 de la section 6-2-2, puis

poursuivez comme suit.

9 Faites sortir environ 20 cm de papier de la sortie de papier en appuyant sur la

touche FEED.

FEED

Feuille supérieure

Feuille inférieure

Fig. 6-18 Chargement du papier

0 Insérez l’extrémité du papier dans la fente de la bobine réceptrice et le rouleau

de la façon indiquée ci-dessous. Faites attention à ce que le bord droit du papier

soit bien contre le bord de la collerette.

FRANÇAIS

Bobine

Fig. 6-19 Bobine

– 52 –

Page 56

A Enrouler le papier sur la bobine sur environ trois tours.

FRANÇAIS

Fig. 6-20

B Tenir le papier de sorte qu’il reste tendu et mettre la bobine en place de manière

que le mécanisme de la bobine s’emboîte dans le mécanisme de l’imprimante.

Collerette

Mécanisme

Fig. 6-21

– 53 –

Cadre

Page 57

C Appuyez sur la touche [FEED] pour rembobiner le papier sur la bobine

réceptrice.

Maintenez la touche [FEED] enfoncée jusqu’à ce le papier soit tendu.

FEED

Fig. 6-22

D Lorsque le rouleau est en place, remettre le couvercle de l’imprimante en

faisant passer le bord de l’amorce de la feuille supérieure dans la fente du

couvercle.

Capot

FRANÇAIS

Feuille supérieure

Feuille inférieure

Fig. 6-23

– 54 –

Page 58

6-3. Enlèvement d’un rouleau de papier

Retirez le capot, puis coupez le papier juste derrière le guide de papier et appuyez

sur la touche d’avance FEED afin de faire sortir le reste du papier qui se trouve

toujours dans l’imprimante.

Quand tout le papier est sorti, le témoin POWER clignote.

FRANÇAIS

Remarques: 1. Enfoncez la touche d’avance FEED pour retirer le reste du

papier qui se trouve dans l’imprimante.

2. N’attendez pas que le rouleau de papier soit épuisé avant de

le remplacer. Remplacez-le dès que le repère de fin de

rouleau apparaît.

[Lorsque le rembobineur est utilisé]

Retirer la collerette ainsi que le rouleau de papier.

Fig. 6-24

Papier

Collerette

Bobine

– 55 –

Page 59

7. Panneau de commande

7-1. Fonctionnement de base

1 Touche ON LINE

FEED POWERON LINE

4

1 2

Fig. 7-1 Panneau de commande

3

3 Témoin d’alimentation POWER (DEL verte)

LED allumée : L’imprimante est sous tension.

LED éteinte : L’imprimante est hors tension.

4 Témoin ON LINE (DEL verte)

DEL allumée : L’imprimante est en ligne

DEL éteinte : L’imprimante est hors ligne

Cette touche permet de mettre l’imprimante en ligne ou hors ligne.

Vous ne pouvez effectuer cette commutation que si du papier est chargé

dans l’imprimante.

2 Touche d’avance FEED

• Si vous appuyez sur cette touche,

puis la relâchez moins de 0,5 seconde après, le papier avancera

d’une ligne à la fois.

• Si vous maintenez la pression sur

cette touche pendant plus de 0,5

seconde, le papier avancera de façon continue.

(Cela est valable que l’imprimante

soit en ligne ou hors ligne.)

FRANÇAIS

– 56 –

Page 60

7-2. Erreurs

Déterminez la nature de l’erreur en fonction du clignotement du témoin ou du son

de la sonnerie.

FRANÇAIS

Pas de papier

Le rouleau de papier

est presque épuisé

(quand la fonction

d’arrêt automatique

en fin de rouleau est

en service)

Erreur mécanique

(autre qu’une erreur

de l’unité de

découpage)

Erreur de l’unité de

découpage (sur les

modèles avec unité de

découpage seulement)

Erreur de surcharge

de commandes

d’impression

Erreur de lecture/

écriture de la

mémoire vive

Erreur du processeur

Description Témoin

de l’erreur d’alimentation de reprise

Clignote à des

intervalles d’une

seconde

Clignote à des

intervalles de 2

secondes

Clignote à des

intervalles de

0,25 seconde

Clignote à des

intervalles de

0,125 seconde

Clignote à des

intervalles de 0,5

seconde

Éteint

Éteint

Témoin en ligne Sonnerie

Éteint

Éteint

Allumé (après

une pression sur

le commutateur

en ligne)

Éteint

Éteint

Allumé

Allumé

Allumé

4 bips courts

(0,13 seconde)

répétés deux fois

Rien

Un bip court

(0,13 seconde) et

un bip long (0,5

seconde)

Deux bip courts

(0,13 seconde) et

un bip long (0,5

seconde)

Rien

Rien

Retentit pendant

2 secondes

Conditions

*1

*2

*3

*3

*4

*5

*5

*1 Après avoir changé le papier, appuyez sur le commutateur en ligne.

*2 Appuyez sur le commutateur en ligne pour continuer l’impression; ou

changez le papier et appuyez sur le commutateur en ligne.

*3 Après avoir remédié au bourrage de papier ou à un autre problème, appuyez

sur le commutateur en ligne.

*4 L’impression reprendra automatiquement après un certain temps. (La reprise

est automatique après le refroidissement de la tête d’impression).

*5 La reprise n’est pas possible avec cette erreur. Consultez un revendeur pour

les réparations.

– 57 –

Page 61

7-3. Utilisation des touches (Utilisation combinée des touches)

7-3-1.Test d’impression

FEED + POWER ON (Mettez l’imprimante sous tension tout en maintenant

la touche FEED enfoncée.)

Le test d’impression sera effectué conformément au réglage du numéro de

vérification, des commutateurs DIP et de l’ordre des caractères. Si vous

maintenez la pression sur la touche FEED ou si vous appuyez sur la touche

FEED à la fin du test d’impression, seuls les caractères seront imprimés à

plusieurs reprises.

FRANÇAIS

Fig. 7-2 Exemple d’impression d’essai

(quand l’imprimante est utilisée avec l’interface série)

– 58 –

Page 62

7-3-2.Vidage hexadécimal

ON LINE + POWER ON (Mettez l’imprimante sous tension tout en

maintenant la touche ON LINE enfoncée.)

Chacun des signaux envoyés de l’ordinateur à l’imprimante sera imprimé en

code hexadécimal.

Cette fonction vous permet de vérifier si un code de contrôle envoyé à

FRANÇAIS

l’imprimante par le programme utilisé est correct ou non. La dernière ligne

n’est pas imprimée si les données correspondantes ne remplissent pas une

ligne complète. Néanmoins, si vous appuyez sur la touche ON LINE pour

mettre l’imprimante hors ligne, la dernière ligne sera imprimée. Pour sortir de

ce mode, il est nécessaire de mettre l’imprimante hors tension.

Fig. 7-3 Exemple d’impression d’essai avec vidage hexadécimal

7-3-3.Réglage de l’alignement des points

Vous n’aurez peut-être jamais besoin d’effectuer les réglages décrits dans

cette section, mais près avoir utilisé l’imprimante pendant un certain temps,

vous remarquerez peut-être que les points de certains graphiques ne sont pas

alignés correctement. Ainsi par exemple, ce qui devrait être imprimé comme

ceci :

pourrait être imprimé comme cela :

ou encore comme cela

– 59 –

Page 63

Ce problème est causé par un décalage des pièces mécaniques de l’imprimante. Ce problème est relativement rare et il est possible que vous ne le

rencontriez jamais. Si toutefois vous rencontrez ce problème, suivez les

instructions ci-dessous afin de le corriger.

• Mettez l’imprimante sous tension et introduisez un morceau de papier.

• Mettez l’imprimante hors tension.

• Tout en maintenant les touches ON LINE et FEED du tableau de commande enfoncées, remettez l’imprimante sous tension afin d’activer le

mode de réglage d’alignement des points, qui est signalé par le clignotement du témoin POWER.

Une fois le mode de réglage d’alignement des points activé, l’imprimante

imprime sept blocs de caractères de la manière indiquée ci-dessous,

chacun représentant un réglage d’alignement des points. Un astérisque (*)

à gauche des blocs vous indique le réglage sélectionné.

FRANÇAIS

• Utilisez la touche FEED pour spécifier le bloc dont l’alignement des

caractères semble optimal. Appuyez une fois sur FEED pour spécifier le

premier bloc, deux fois pour spécifier le deuxième bloc, et ainsi de suite

jusqu’à sept fois pour spécifier le septième bloc.

Un avertisseur sonore fait entendre si vous appuyez plus de sept fois sur la

touche FEED.

• Après avoir spécifié un bloc, appuyez sur ON LINE pour sauvegarder

votre sélection et quitter le mode de réglage d’alignement des points.

– 60 –

Page 64

Le réglage d’alignement des points que vous avez sélectionné est sauvegardé

dans la mémoire, et l’imprimante imprime une série de lignes graduées

correspondant à l’état d’impression sélectionné, suivie du message “Adjust

Completed!”, vous indiquant que le réglage est terminé. L’imprimante éjecte

ensuite le morceau de papier fort.

FRANÇAIS

Remarque: Votre réglage ne sera pas sauvegardé si vous mettez l’impri-

mante hors tension avant d’appuyer sur ON LINE pour quitter le

mode de réglage d’alignement des points. En cas d’erreur

d’alimentation de papier dans ce mode, l’imprimante éjecte le

papier et le mode est annulé.

– 61 –

Page 65

8. Capteur de fin de papier en option

Le capteur détecte lorsque le rouleau chargé arrive presque à la fin du papier. Ce

capteur est normalement désactivé à la sortie d’usine mais on peut l’activer à

l’aide de l’interrupteur de mémoire (ou s’adresses à son revendeur). Les informations contenues dans le présent chapitre concernent uniquement les imprimantes

dont le capteur de détection de fin de papier est activé.

Attention!

L’installation du capteur de fin de papier doit normalement être effectuée par

le revendeur.

8-1. Réglage du capteur de fin de papier

Procéder de la manière suivante pour régler le capteur de fin de papier de sorte

qu’il soit compatible avec les dimensions du rouleau de papier utilisé.

Attention!

Quel que soit le diamètre global du rouleau de papier, le rouleau intérieur (en

carton) se trouvant au centre doit avoir un diamètre intérieur de 12 mm et un

diamètre extérieur de 18 mm pour permettre une détection adéquate.

1 Vérifier si l’imprimante est hors ten-

sion et débranchée de la prise secteur.

2 Retirer le couvercle de l’imprimante

3 Retirer le rouleau de papier.

FRANÇAIS

Fig. 8-1

– 62 –

Page 66

Niveau 3

FRANÇAIS

Niveau 2

Niveau 1

…

……

………

4 Définir le diamètre du rouleau de

papier utilisé et situer le réglage

correspondant dans le tableau cidessous.

Distance A Réglage Indicateur

Environ 9 mm Niveau 3 ooo

Environ 7 mm Niveau 2 oo

Environ 5 mm Niveau 1

*1 Ne pas utiliser avec des papiers à 2 ou 3 exemplai-

res.

*1

o

Fig. 8-2

ø18 mm

ø12 mm

Mandrin du rouleau de

papier

Fig. 8-3

Remarque:

1. Etant donné que la distance A

correspondant à la position de

réglage sur le tableau est une

valeur calculée, certaines variations dues au mécanisme peuvent se produire.

A

2. Lorsqu’il y a une marque finale

à la fin du rouleau de papier,

cette marque est adhésive et peut

soulever tout le rouleau de papier. Dans ce cas, la quantité

restante du rouleau de papier

(Distance A) indiquée dans le

tableau ci-dessus n’est pas d’application.

3. La qualité de certains papiers

peut provoquer des bourrages et

causer une détection d’erreur.

A

5 Insérer la pointe d’un stylo à bille ou

d’un objet pointu similaire dans l’orifice du curseur de réglage. Appuyer

sur le curseur et le faire glisser vers

le haut ou vers le bas jusqu’au réglage correspondant au rouleau de

papier utilisé.

6 Vérifier si le taquet indiqué par la

flèche sur l’illustration se trouve

inséré dans une des rainures.

– 63 –

Page 67

INHALTSVERZEICHNIS

1. Kurzbeschreibung............................................................................................65

2. Auspacken und Aufstellen...............................................................................66

2-1. Überprüfen ...........................................................................................66

2-2. Wahl eines Aufstellungsorts für den Drucker......................................67

2-3. Hinweise zum Umgang........................................................................67

2-4. Wartung ...............................................................................................67

3. Beschreibung und Bezeichnung der Geräteteile..............................................68

4. Als Sonderzubehör erhältlicher Netzadapter...................................................70

5. Anschließen .....................................................................................................72

5-1. Anbringen des Ferritkerns....................................................................72

5-2. Anschließen an den Hostcomputer (serielle Schnittstelle) ..................73

5-3. Anschließen an den Hostcomputer (parallele Schnittstelle) ................74

5-4. Anschluß an ein Peripheriegerät ..........................................................74

6. Einlegen von Farbbandkassette und Papier .....................................................76

6-1. Typ SP2300..........................................................................................76

6-2. Typ SP2500..........................................................................................79

6-3. Entfernen des Rollenpapiers ................................................................87

7. Bedienfeld........................................................................................................88

7-1. Grundlegender Betrieb.........................................................................88

7-2. Fehler ...................................................................................................89

7-3. Tastenbedienung (kombinierte Tastenbedienung) ...............................90

8. Als Sonderzubehör erhältlicher Papierende-Sensor ........................................94

8-1. Den Papierende-Sensor einstellen........................................................94

ANHANG..........................................................................................................128

DEUTSCH

Der Anhang dieser Bedienungsanleitung ist nur in englischer Sprache.

– 64 –

Page 68

1. Kurzbeschreibung

Der serielle Nadeldrucker der Serie SP2000 ist zur Verwendung mit elektronischen Instrumenten wie POS, Bankgeräte, Computerzubehör, etc. gedacht.

Die wichtigsten Merkmale der Serie SP2000 sind:

1. Bidirektioneller Druck mit ca. 3,1 Zeilen/s

2. Serielle oder parallele Schnittstelle

3. Pufferspeicher erlaubt, Druckdaten auch während des Druckvorgangs zu

empfangen.

4. Peripherie-Steuerschaltung zur Steuerung von externen Geräten wie Registrier-

DEUTSCH

kassen:

SP2 3 2 0 M D 42 – 24 R

R : Mit Rückspulvorrichtung

Ohne: Ohne Rückspulvorrichtung

Anzahl der Druckspalten

42 : 42 Spalten (16 cpi)

Schnittstelle

D : Serielle Schnittstelle (RS-232C)

C : Parallele Schnittstelle

Papiervorschub

M : Walzenvorschub

Mechanismus

2 : Einfarbig, 42 Spalten (16 cpi)

6 : Zweifarbig, 42 Spalten (16 cpi)

Druckertyp

3 : Standardtyp

5 : Mit automatischem Schneidwerk

Drucker Serie SP2000

– 65 –

Page 69

2. Auspacken und Aufstellen

2-1. Überprüfen

Sie den Kartoninhalt, und vergewissern Sie sich, daß alle unten abgebildeten

Teile vorhanden sind.

Typ SP2300

Drucker

Farbbandkassette

DEUTSCH

Bedienungsanleitung

Befestigungsband

Adapterhalter

Kabelhalter

Schrauben

Typ SP2500

Ferritkern

Drucker

Bobine

(Nur Modelle der R-Serie)

Hinweis: Die Bobine gehört nur zum Lieferumfang der Modelle der R-Serie (mit

Rückspulvorrichtung) und befindet sich unterhalb der Drucker-Abdekkung.

Abb. 2-1 Auspacken

Falls Teile fehlen, wenden Sie sich zwecks Nachlieferung bitte an den Fachhandel, bei dem das Gerät gekauft wurde. Im Hinblick auf einen eventuellen

zukünftigen Transport des Druckers empfiehlt es sich, den Lieferkarton und das

gesamte Verpackungsmaterial aufzubewahren.

– 66 –

Page 70

2-2. Wahl eines Aufstellungsorts für den Drucker

Bevor Sie den Drucker auspacken, sollten Sie einige Minuten damit verbringen,

einen geeigneten Aufstellungsort auszusuchen. Denken Sie dabei an die folgenden

Punkte:

1. Den Drucker vor Hitzequellen wie direktem Sonnenlicht oder Heizkörpern

schützen und von Feuchtigkeit und Staub fernhalten.

2. Den Drucker auf einem flachen, aber festen Untergrund aufstellen, wo keine

Vibrationen vorhanden sind.

3. Sicherstellen, daß der Drucker an eine einwandfreie Stromzufuhr angeschlossen ist.

Er sollte nicht an Steckdosen angeschlossen werden, an denen bereits Geräte mit

möglichen Netzstörungen wie Kopierer, Kühlschränke u.a. angeschlossen sind.

4. Die Versorgungsspannung muß dem Spannungswert auf dem Typenschild an der

DEUTSCH

Unterseite des Druckers entsprechen.

5. Die verwendete Steckdose soll in der Nähe und frei zugänglich sein.

2-3. Hinweise zum Umgang

1. Achten Sie darauf, keine Papierclips oder anderen Fremdkörper in den Drucker

fallen zu lassen. Diese können Betriebsstörungen oder Schäden am Gerät hervorrufen.

2. Versuchen Sie nicht zu drucken, wenn kein Papier oder keine Farbbandkassette

eingelegt ist, da sonst der Druckkopf beschädigt werden kann.

3. Öffnen Sie nicht die Frontabdeckung während des Druckens.

4. Berühren Sie nicht den Druckkopf sofort nach dem Druckvorgang, da dieser sehr

heiß wird.

5. Verwenden Sie nur Rollenpapier, das nicht am Rollenkern festgeklebt ist.

6. Wenn die Papierende-Markierung erscheint, tauschen Sie die Papierrolle aus,

bevor sie ganz verbraucht ist.

2-4. Wartung

Ihr Drucker ist ein robust gebautes Gerät, sollte aber trotzdem mit einem gewissen

Maß an Vorsicht behandelt werden, um Fehlfunktionen zu vermeiden. Zum Beispiel:

1. Stellen Sie den Drucker in einer “komfortablen” Betriebsumgebung auf. Als

Faustregel gilt: Wo Sie sich wohlfühlen, fühlt sich der Drucker ebenfalls wohl.

2. Setzen Sie den Drucker keinen Erschütterungen oder starken Vibrationen aus.

3. Vermeiden Sie sehr staubige Umgebungen. Staub ist der Erzfeind aller Präzisionsgeräte.

4. Zum Reinigen des Gehäuses verwenden Sie einen nur leicht mit Wasser, sehr

milder wässriger Seifenlösung oder ein wenig Alkohol angefeuchteten Lappen.

Lassen Sie auf keinen Fall Flüssigkeiten in das Innere des Druckers geraten.

5. Das Innere des Druckers kann mit einem kleinen Reiniger oder einem Luftspray

(in Fachgeschäften erhältlich) gereinigt werden. Bei dieser Arbeit darauf achten,

keine Kabelverbindungen oder elektronische Bauteile zu verbiegen oder zu

beschädigen.

– 67 –

Page 71

3. Beschreibung und Bezeichnung der Geräteteile

Typ SP2300

Abdeckung

Schüzt den Drucker vor Staub, und reduziert das

Betriebsgeräsch. Nicht die Frontabdeckung

würend des Druckens öfnen.

Bedienfeld

Hat zwei Bedienungstasten und zwei

Anzeigen zur Anzeige des

Druckerzustands.

Netzadapter