Page 1

SLIP PRINTER

SP298 SERIES

Programmer’s Manual

Page 2

Trademark acknowledgments

SP298 : Star Micronics Co. Ltd.

ESC/POS, TM-295, TM-290 : Seiko Epson Corporation

Notice

• All rights reserved. Reproduction of any part of this manual in any form whatsoever, without STAR’s express permission, is strictly forbidden.

• The contents of this manual are subject to change without notice.

• All efforts have been made to ensure the accuracy of the contents of this manual at the time of printing. However,

should any errors be found, STAR would greatly appreciate being informed of them.

• The above notwithstanding, STAR can assume no responsibility for any errors in this manual.

Copyright 1998 Star Micronics Co., Ltd.

Page 3

TABLE OF CONTENTS

Chapter 1: DIP Switch Settings ................................................................. 1

Accessing the DIP switches ....................................................... 1

Available DIP switch settings (Serial Interface) ........................ 3

Available DIP switch settings (Parallel Interface) ..................... 4

Chapter 2: Memory Switch Settings.......................................................... 5

Chapter 3: Control Panel Operations ....................................................... 6

Indicator lights ........................................................................... 6

Buttons ....................................................................................... 7

Producing a test print ................................................................. 7

Adjusting the dot alignment ....................................................... 7

Hexadecimal dump .................................................................... 9

Errors ....................................................................................... 10

Chapter 4: Interface .................................................................................. 11

Serial Interface ......................................................................... 11

Serial interface pins and signal names ..................................... 12

Pins and Signal Names ............................................................ 12

Interface connections ............................................................... 13

Data protocol ............................................................................ 14

Parallel Interface ...................................................................... 17

Connectors and Signals ............................................................ 17

Chapter 5: Peripheral Unit Driver Circuit ............................................. 19

Modular plug ............................................................................ 19

Drive circuit ............................................................................. 20

Chapter 6: Control Codes ......................................................................... 21

Star Mode Commands ............................................................. 21

ESC/POS Mode Commands (TM-295 emulation) .................. 26

ESC/POS Mode Commands (TM-290 emulation) .................. 28

TM-295 mode emulation cautionary items .............................. 60

Appendix: Character Code Tables ............................................................ 62

Please access the following URL

http://www.star-micronics.co.jp/service/sp_sup_e.htm

for the lastest revision of the manual.

Page 4

Chapter 1: DIP Switch Settings

The printer’s DIP switches let you change communications parameters, input

buffer size, and emulation. This chapter explains the settings you can make and

tells you how to actually change DIP switch settings.

Accessing the DIP switches

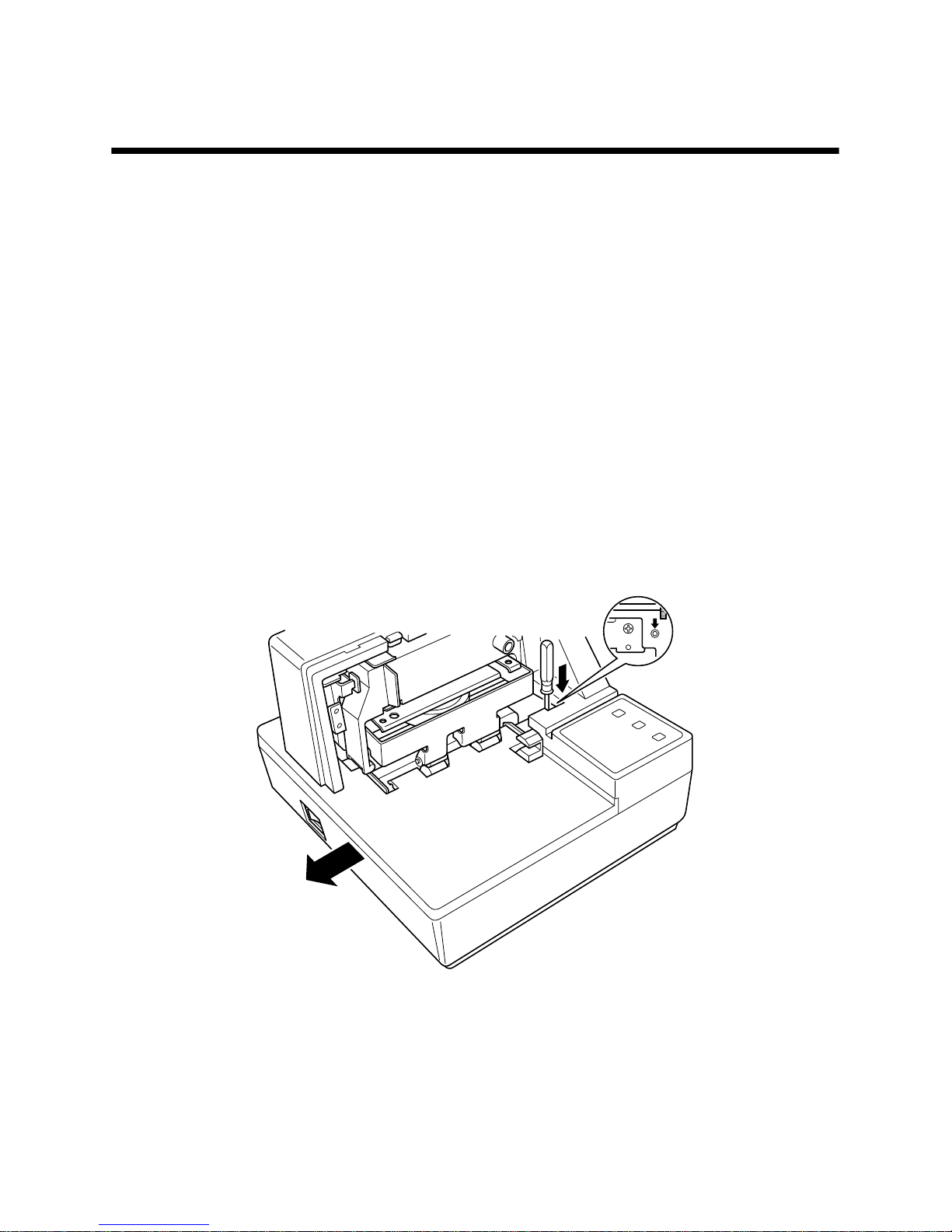

The DIP switches are located inside the printer, underneath the document table.

Use the following procedure to remove the document table so you can operate

the DIP switches.

❏

Make sure that the printer is turned off and unplugged from its wall outlet.

❏

Remove the printer cover.

❏

While using a screwdriver or other similar instrument to press down at the

location marked (a) in the illustration below, carefully slide the document

table in the direction indicated by the arrow until it is out of the way.

a

Page 5

2

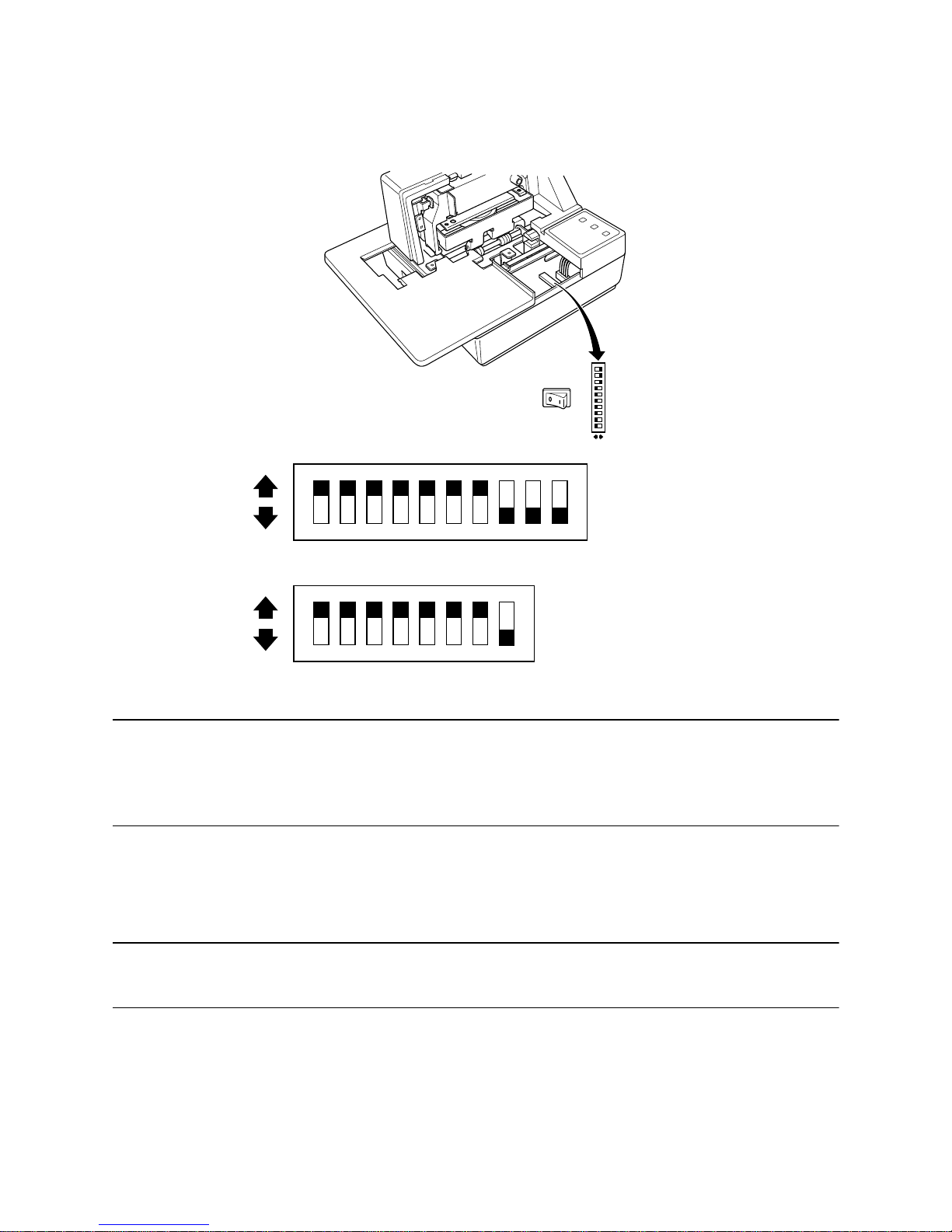

It is not necessary to remove the document table completely, just move it

enough so you can get at the DIP switches inside.

Note:

If the document table seems to be getting caught on the rollers, it means that

you are not pressing down at point (a) enough. Pressing at point (a) should

separate the rollers to the document table can slide freely.

❏

After the document table is opened sufficiently, use a thin flat-blade

screwdriver or some other similar object to change DIP switch settings.

Note:

See the following section for details on available DIP switch settings.

❏

After making the settings you want, slide the document table back into

place while pressing down at point (a). Make sure that the document table

is correctly seated in place before releasing point (a).

❏

Replace the printer cover.

ON

OFF

ON

OFF

12345678

(For Serial Interface)

(For Parallel Interface)

ON

OFF

12345678910

Page 6

3

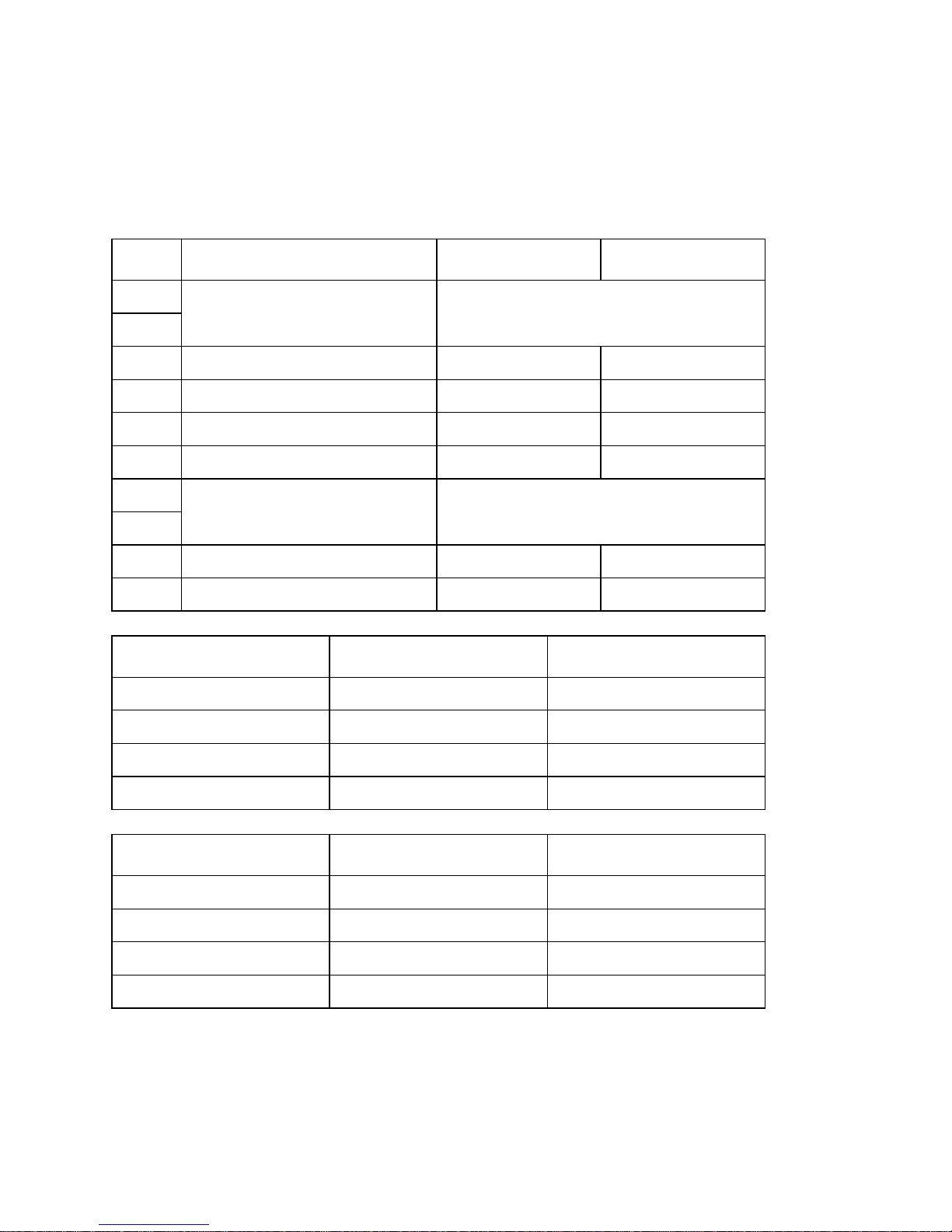

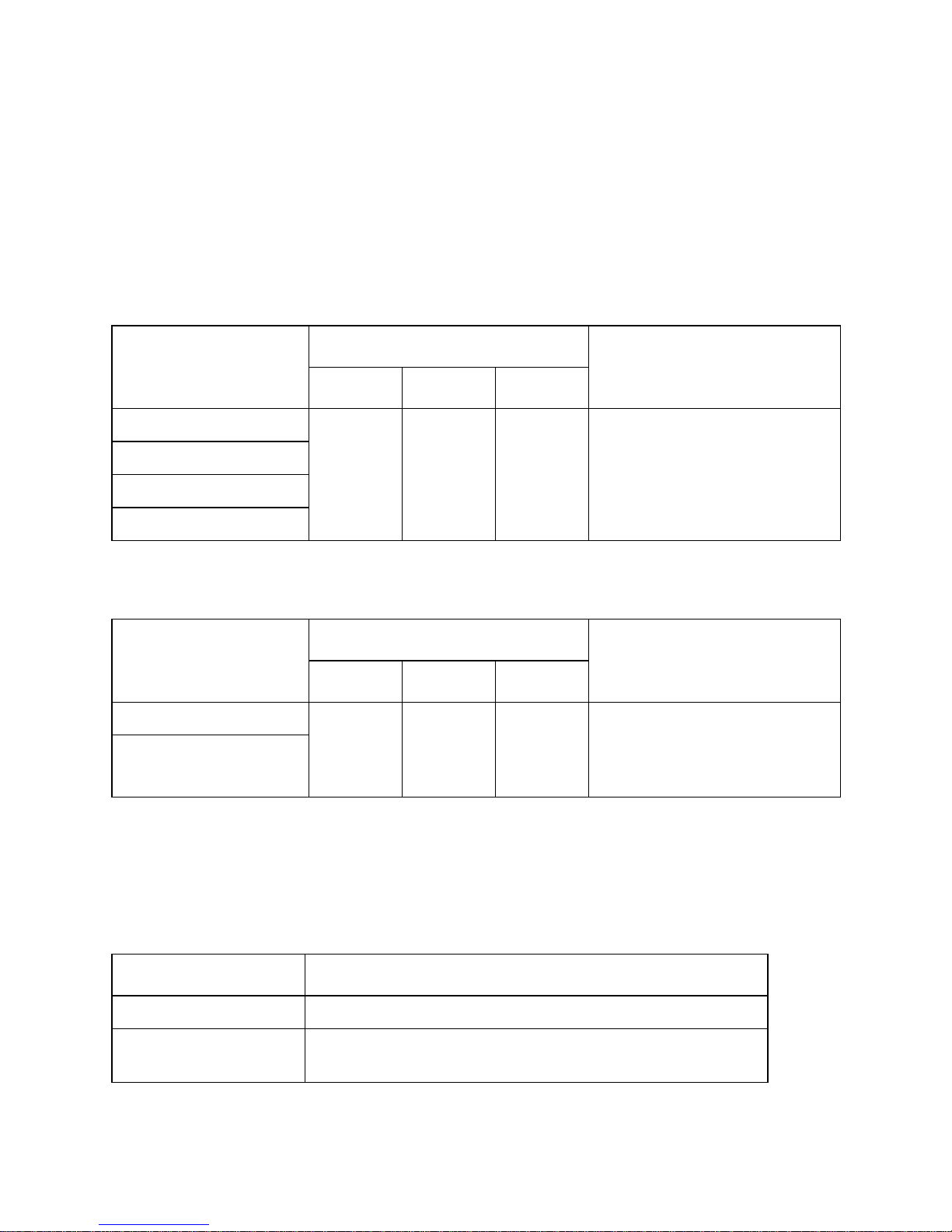

Available DIP switch settings (Serial Interface)

The following table shows all the possible settings for the DIP switch. The

factory default settings are ON for switches 1 through 7 and OFF for switches

8 through 10.

*1: Never set switch 7 to OFF at the same time that switch 8 is set to ON.

Switch Parameter ON OFF

1

Baud Rate See table below.

2

3 Data Length 8 bits 7 bits

4 Parity Check Disabled Enabled

5 Parity Odd Even

6 Handshake DTR/DSR XON/XOFF

7

Command Emulation See table below.

8

9 Pin 6 (DSR) Reset Signal Enabled Disabled

10 Pin 25 (INIT) Reset Signal Enabled Disabled

Baud Rate Switch 1 Switch 2

1200BPS OFF OFF

2400BPS ON OFF

4800BPS OFF ON

9600BPS ON ON

Command Emulation Switch 7 Switch 8

Star mode ON ON

ESC/POS (TM-295) ON OFF

ESC/POS (TM-290) OFF OFF

Not used (*1) OFF ON

Page 7

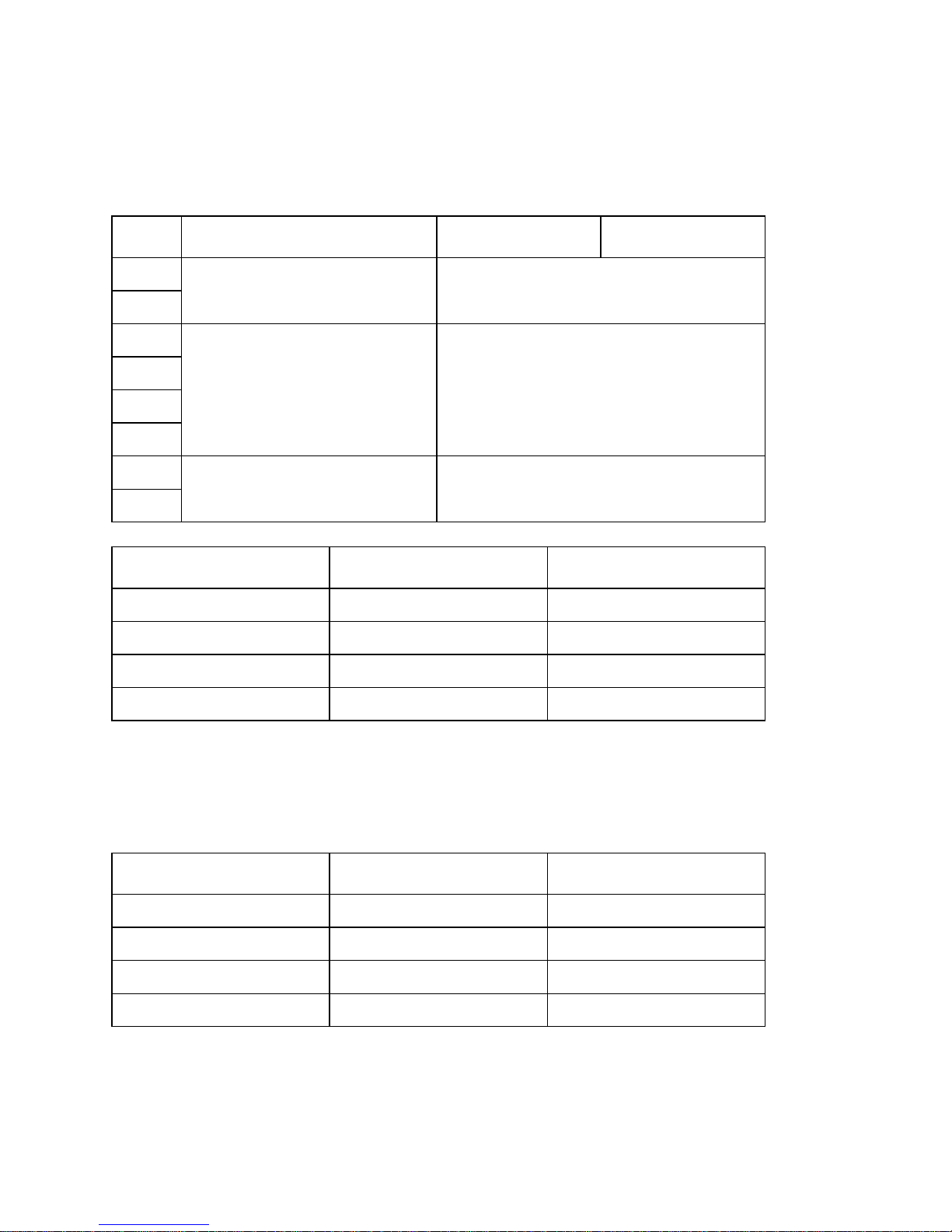

4

Available DIP switch settings (Parallel Interface)

The following table shows all the possible settings for the DIP switch. The

factory default settings are ON for switches 1 through 7 and OFF for switch 8.

A reset can be performed with pin 31 on the interface by setting DIP switch 1 to

ON (the factory default setting).

In addition, when a reset can be performed with pin 31, setting DIP switch 2 to

OFF sets up the unit to perform a reset when pin 31 and pin 36 are “LOW”.

*1: Never set switch 7 to OFF at the same time that switch 8 is set to ON.

Switch Parameter ON OFF

1

Pin 31 / Pin 36 Reset Signal See table below.

2

3

Not used (Always ON)

4

5

6

7

Command Emulation See table below.

8

Reset Signal Switch 1 Switch 2

Pin 31 is enabled. ON ON

Pin 31/Pin 36 are enabled. ON OFF

Disabled OFF ON

Disabled OFF OFF

Command Emulation Switch 7 Switch 8

Star mode ON ON

ESC/POS (TM-295) ON OFF

ESC/POS (TM-290) OFF OFF

Not used (*1) OFF ON

Page 8

5

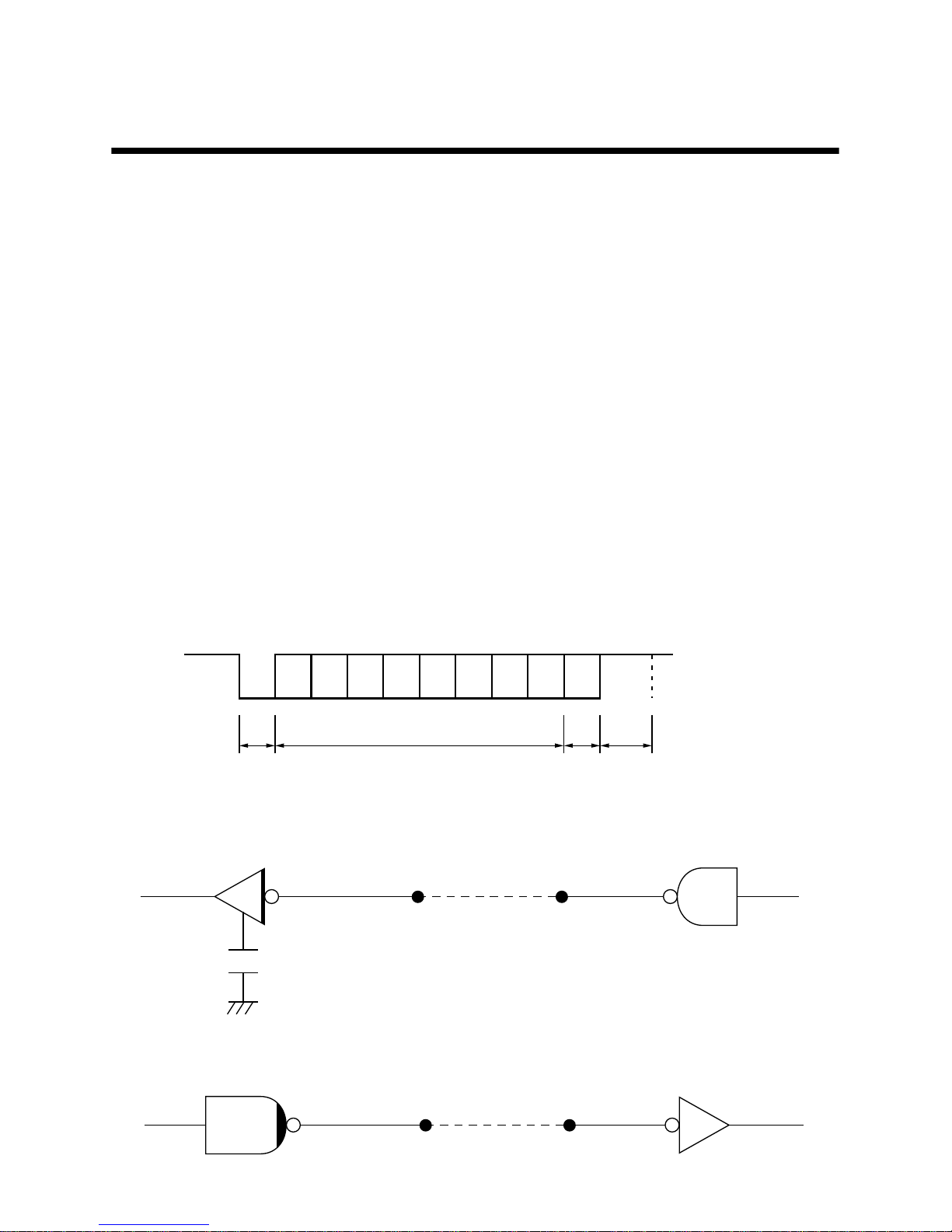

Chapter 2: Memory Switch Settings

Each memory switch is a 16-bit word store in EEPROM. For details on the

functions and settings of memory switches, refer to “Chapter 6”.

The table below shows the factory settings for the memory switches.

Warning!

Changing the memory switch settings can cause the printer to fail to operate

correctly.

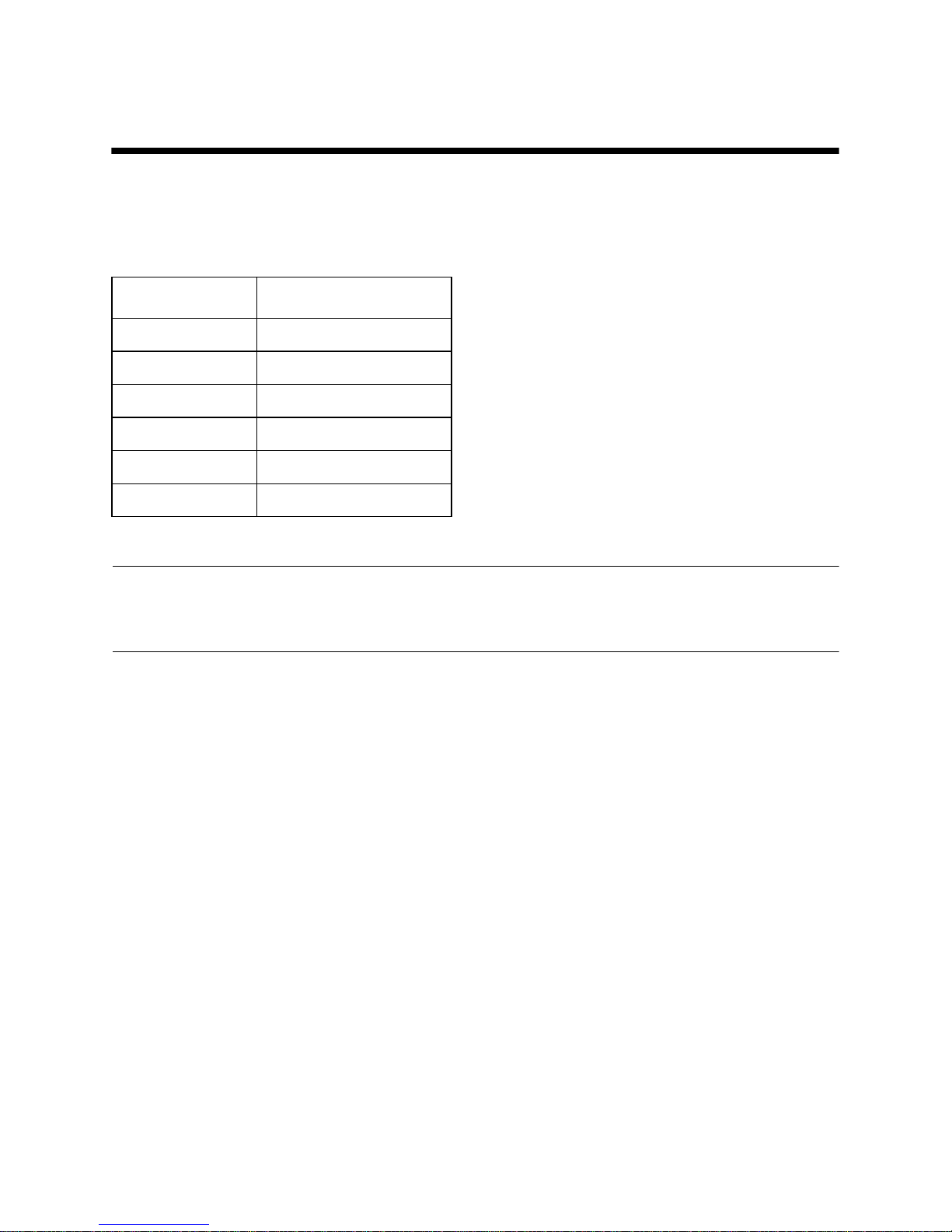

Memory Switch Hexadecimal Code

0 0000

1 0000

2 0000

3 0000

4 0000

5 0000

Page 9

6

Chapter 3: Control Panel Operations

The control panel gives you some push-button control over the slip printer

operation. It also includes indicator lights, which tell you the current status of

the printer at a glance.

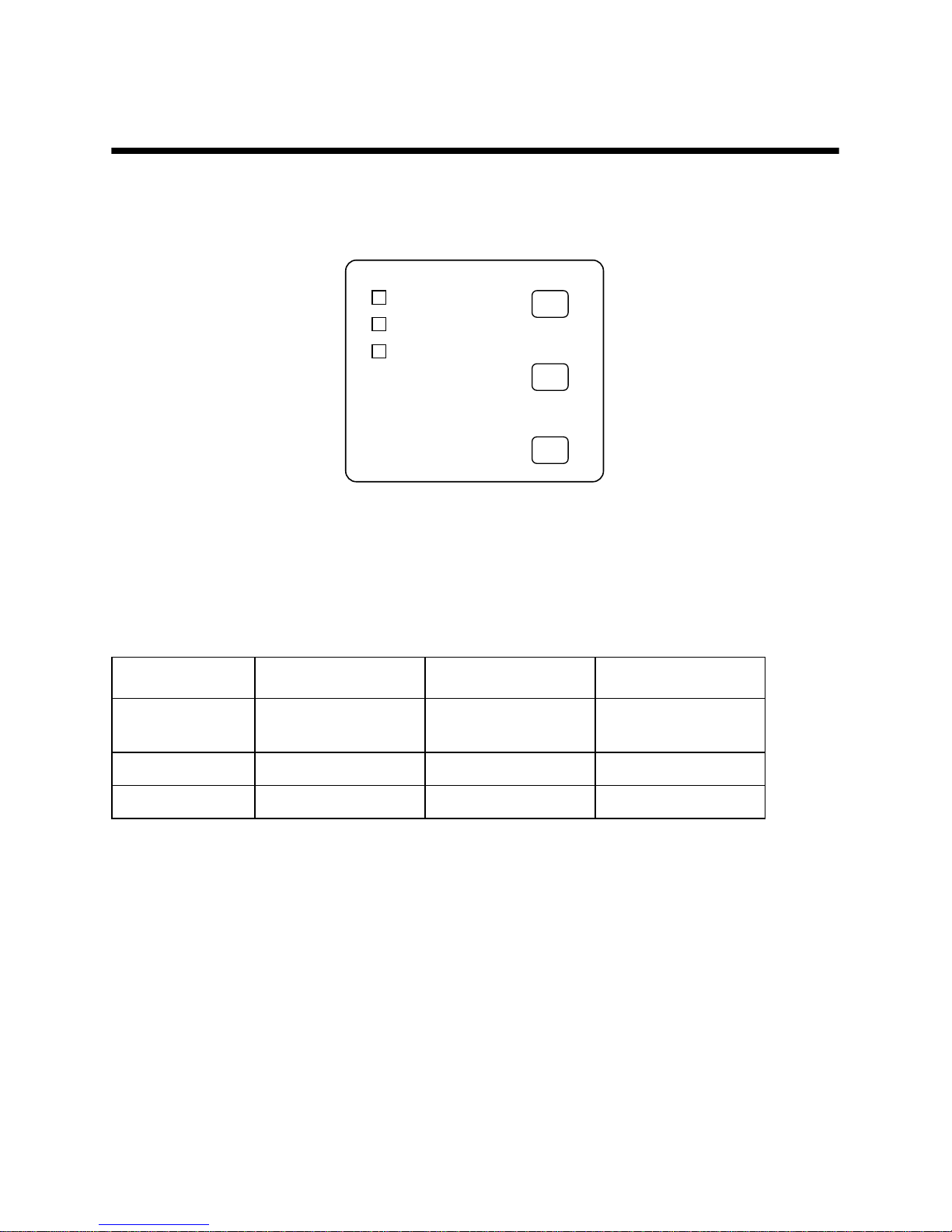

Indicator lights

The following table describes the meaning of indicator lights when it is on, off,

or flashing.

Indicator Light Off On Flashing

POWER

Power off Power on

Dot Alignment Adjust

Mode

PAPER OUT

Paper inserted No paper Insert paper prompt

RELEASE

Slip paper engaged Slip paper released Mechanical error

FORWARD

POWER

RELEASE

PAPER

OUT

REVERSE

RELEASE

Page 10

7

Buttons

The following table describes the function of the three control buttons of the

control panel.

Producing a test print

The following procedure can be used at any time to test the printer.

❏

Turn on the printer and insert a piece of paper (page 6, 11).

❏

Turn off printer power.

❏

While holding down RELEASE , turn printer back on. Keep RELEASE

depressed for a few moments until the printer beeps and the printer test

print starts.

The printer test will continue until it reaches the end of the paper.

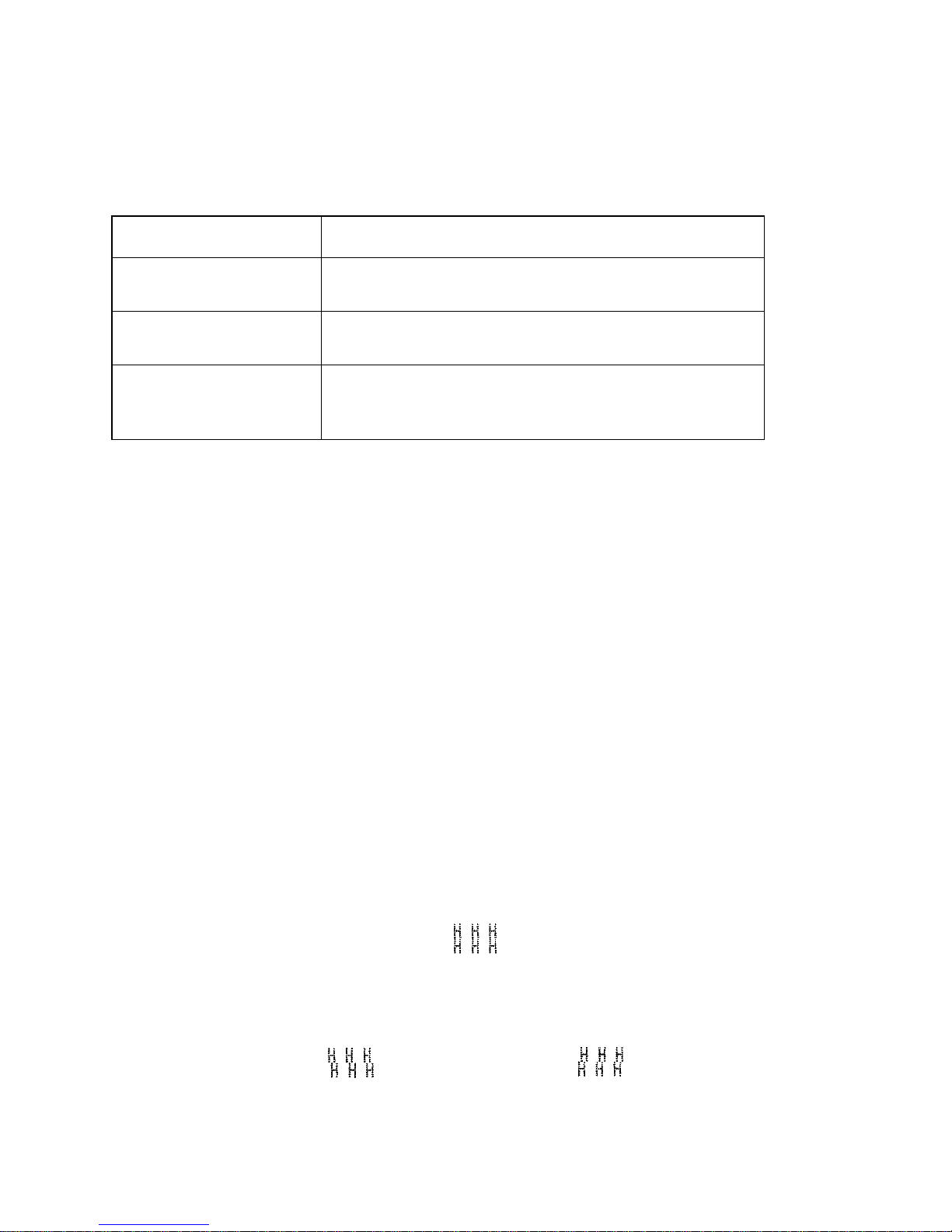

Adjusting the dot alignment

You may never have to use the procedure described in this section, but after you

have been using your printer for some time you may find that the dots of some

graphics do not align correctly. For example, what should look like:

may come out looking like one of the following:

Button Description

FORWARD

Feeds the slip paper forward, toward the back of the printer. One press

feeds one line, holding down performs continuous feed.

REVERSE

Feeds the slip paper back, toward the front of the printer. One press

feeds one line, holding down performs continuous feed.

RELEASE

Activates the printer's paper release (the paper is not held in place by

the paper feed roller).

Clears recoverable errors.

or like this

Page 11

8

This is caused when mechanical parts of the printer get out of alignment. This

happens only rarely and you may never experience it at all throughout the life

of the printer. If you do have problems, use the following procedure to correct it.

❏

Turn on the printer and insert a piece of paper.

❏

Turn off printer power.

❏

While holding down the control panel’s FORWARD and REVERSE

buttons, turn the printer back on to enter the Dot Alignment Adjust Mode,

which is indicator by a flashing POWER indicator flashes.

Entering the Dot Alignment Adjust Mode causes seven blocks to be printed,

each of which indicates a dot alignment setting, as shown below. An asterisk

to the left of the blocks indicates which block is currently selected.

❏

Use FORWARD to specify the block that appears to have the best aligned

characters. Press FORWARD once to specify the first block, twice to

specify the second block, and so on up to seven times to specify the se v enth

block.

Warning beep will sound if you press FORWARD more than seven times.

❏

After specifying a block, press REVERSE to register your selection and

exit the Dot Alignment Adjust Mode.

Page 12

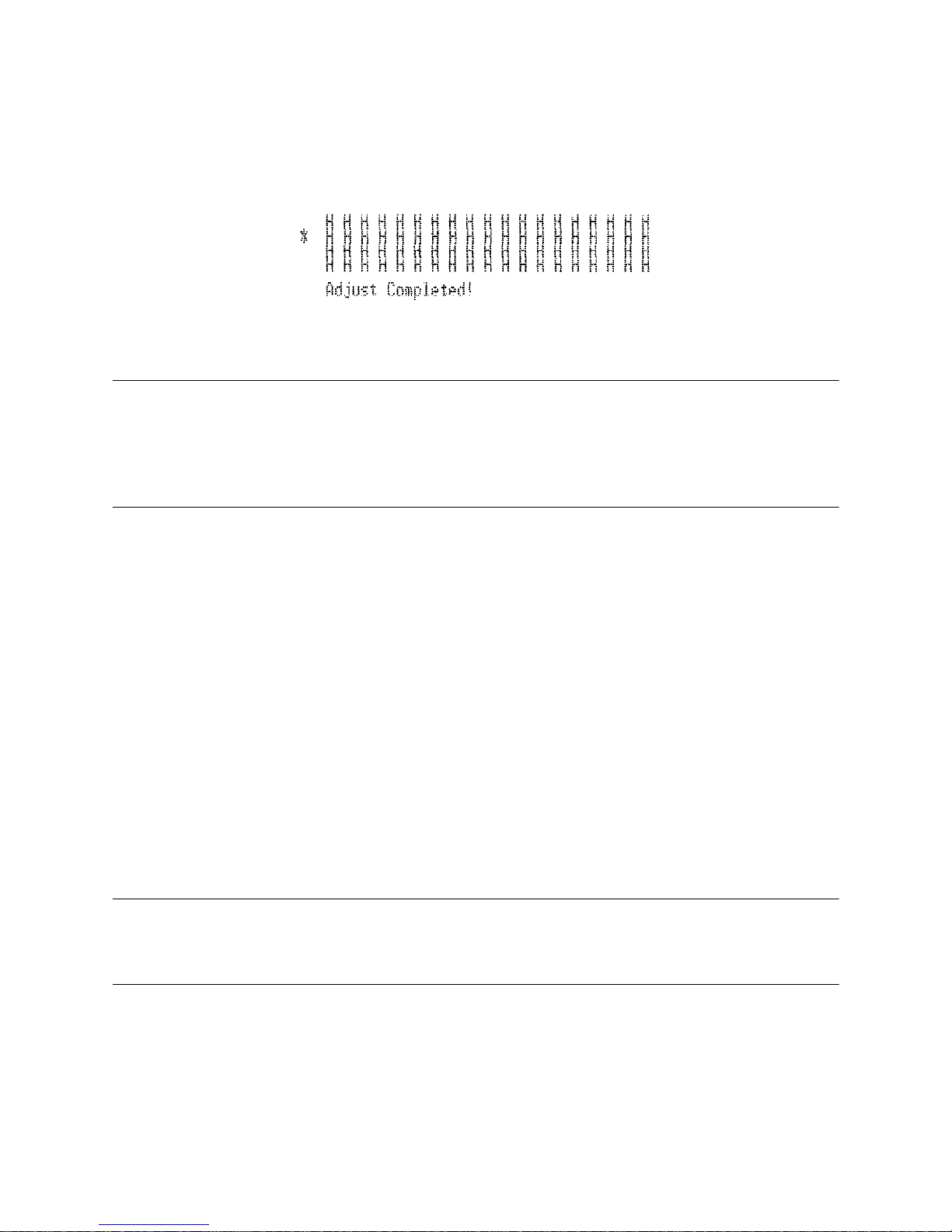

9

The dots alignment adjustment setting you selected is stored in printer memory

and a pattern is printed using the selected setting followed by the message

“Adjust Complete!” The printer ejects the paper after printing is complete.

Note:

You setting is not registered if you turn off printer power before pressing

REVERSE to exit the Dot Alignment Adjust Mode.

If a paper feed error occurs during this mode, the printer ejects the paper and

this mode is cancelled.

Hexadecimal dump

This procedure prints in hexadecimal format all codes (character codes and

control codes) that are sent to the printer by the computer. The printer does not

execute any control codes (such as 0A - linefeed), it just prints them out. The

hexadecimal dump is useful when you are writing programs for printer control.

❏

Turn on the printer and insert a piece of paper.

❏

Turn off printer power.

❏

While holding down the control panel’s FORWARD buttons, turn the

printer back on to enter the Hex Dump Mode.

❏

To exit the Hex Dump Mode, turn the printer off.

Note:

The printer will not responde to any commands you send it while it is in the

Hex Dump Mode.

Page 13

10

Errors

There are three types of errors: recoverable errors that require some action by

you before they clear, non-recoverable errors that require servicing by an

authorized service provider, and a data receive error. Errors are indicated by and

audible buzzer and the indicators.

Recoverable Errors

Non-recoverable Errors

Data Receive Error

This type of error is caused whenever a problem is encountered during data

receipt. The method used by the printer to recover from a data receive error

depends on the current command mode.

Error Type

Indicators

Recovery

POWER RELEASE PAPER OUT

Paper jam

Flashing

Correct the cause of the problem and

then press RELEASE.

Carriage motor lockup

Abnormal home position signal

Abnormal timing signal

Error Type

Indicators

Recovery

POWER RELEASE PAPER OUT

RAM read/write

Off On On

Turn off the printer, then after waiting a

few minutes, turn the printer back on. If

the printer does not recover, contact

your nearest service provider.

CPU lockup

Command mode Data Receive Error Recover Procedure

Star mode The printer prints a question mark.

ESC/POS mode

Memory switch 4-0=0 : The printer prints a question mark.

Memory switch 4-0=1 : The printer discards the received data.

Page 14

11

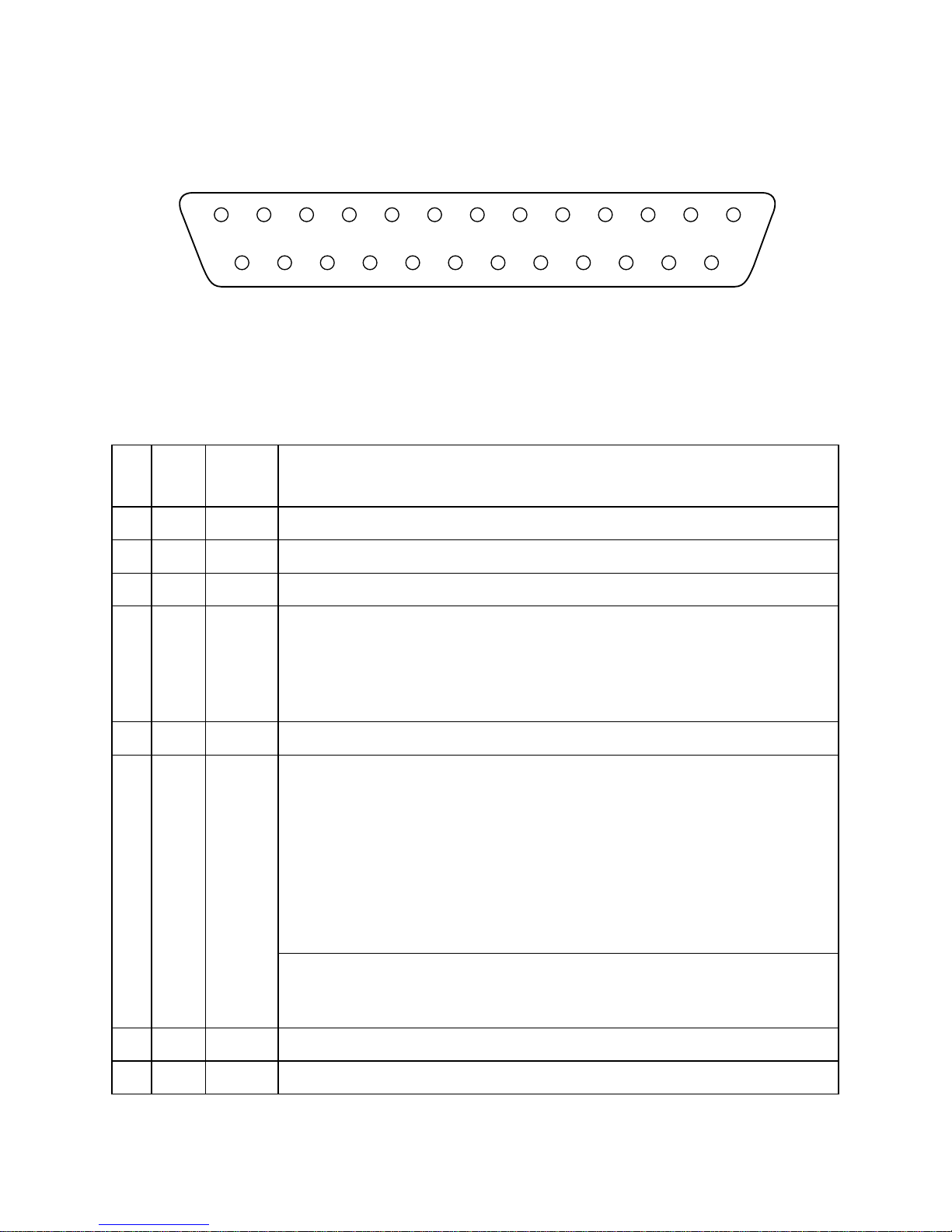

Chapter 4: Interface0

Serial Interface

❏

This chapter provides detailed specifications for the printer’ s standard serial

interface (Connector Type: D-sub 25-pin).

Set the transmission parameters with DIP Switch.

Transmission type............Asynchronous serial interface

Baud rate (bps).................1200, 2400, 4800 or 9600

(Selected by DIP switch)

Word format

Start bit:................1

Data bits: ..............7 or 8 (Selected by DIP switch)

Parity:...................Odd, Even, or None

(Selected by DIP switch)

Stop bit:................1

Signal polarities

RS-232C...............Mark = Logic “1” (–3V to –15V)

Space = Logic “0” (+3V to +15V)

Handshaking ....................DTR/DSR or XON/XOFF mode (Selected by DIP

switch)

Input (RXD, DSR, INIT)

Output (DTR, TXD, RTS)

b0 b1 b2 b3 b4 b5 b6 (b7)

ABCD

Mark [1]

Space [0]

A: Start bit

B: Data bits

C: Vertical parity bit

D: Stop bit

Printer Host computer

75188 or equivalent

Printer Host computer

Page 15

12

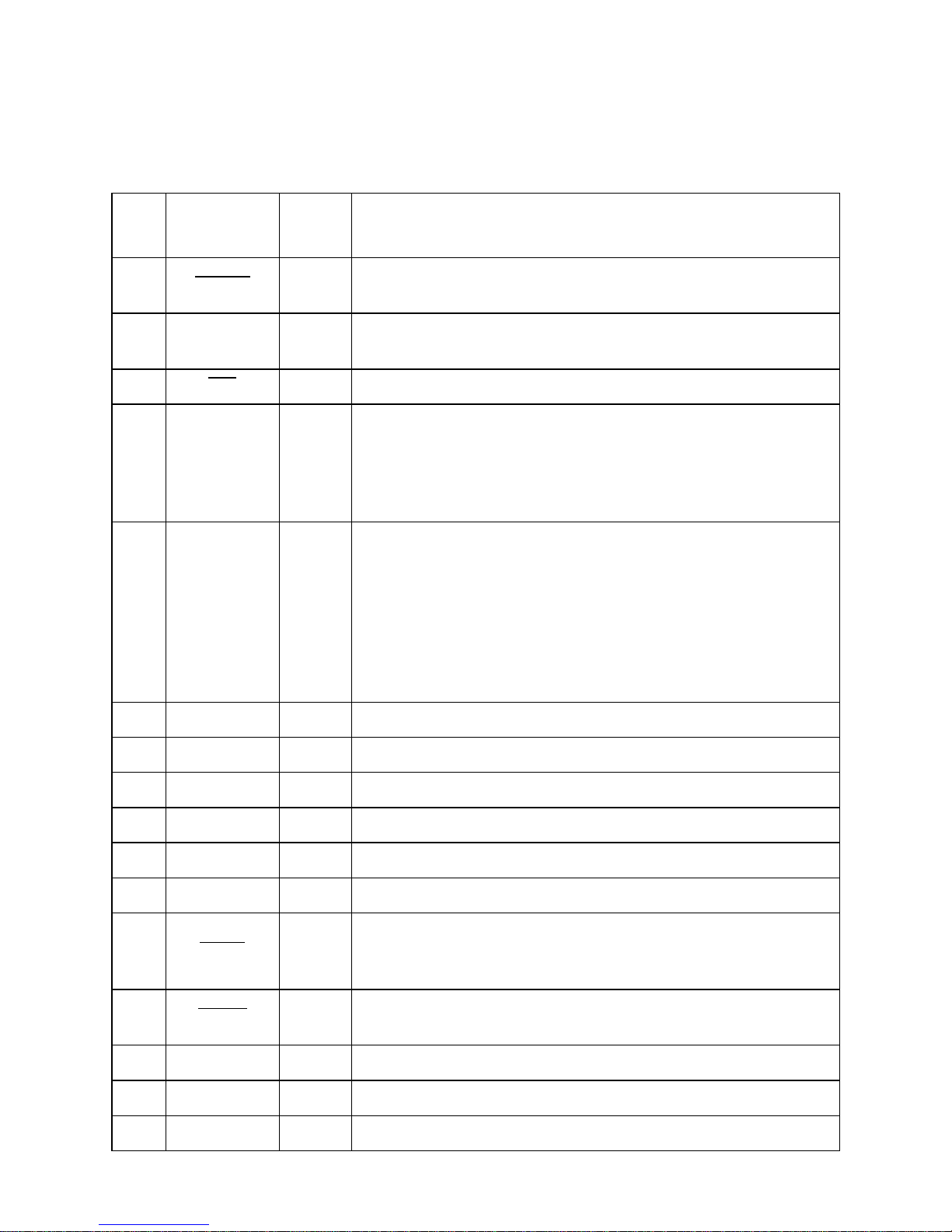

Serial interface pins and signal names

Pins and Signal Names

Pin

No.

Signal

Name

Direction Function

1 FG — Frame ground

2 TXD OUT Transmission data

3 RXD IN Receive data

4 RTS OUT

STAR Mode

When Memory Switch 4-D = 0: Same as DTR signal

When Memory Switch 4-D = 1: Always SPACE

ESC/POS Mode

Same as DTR signal

5 N.C. Not connected

6 DSR IN • DIP Switch 9 = OFF

STAR Mode

Status of this signal is not checked.

ESC/POS Mode

In DTR/DSR communication mode when Memory Switch4-5 = 0, indicates whether data

receive from host is enabled or disabled.

Space: Receive enabled

Mark: Receive disabled

This signal is not checked in the X-ON/X-OFF communication mode.

• DIP Switch 9 = ON

This signal used for external reset. Printer is reset whenever signal is in mark state with

pulse width of 1mS or more.

7 SG Signal ground

8 - 1 9 N.C. Not connected

13

25

1

14

Page 16

13

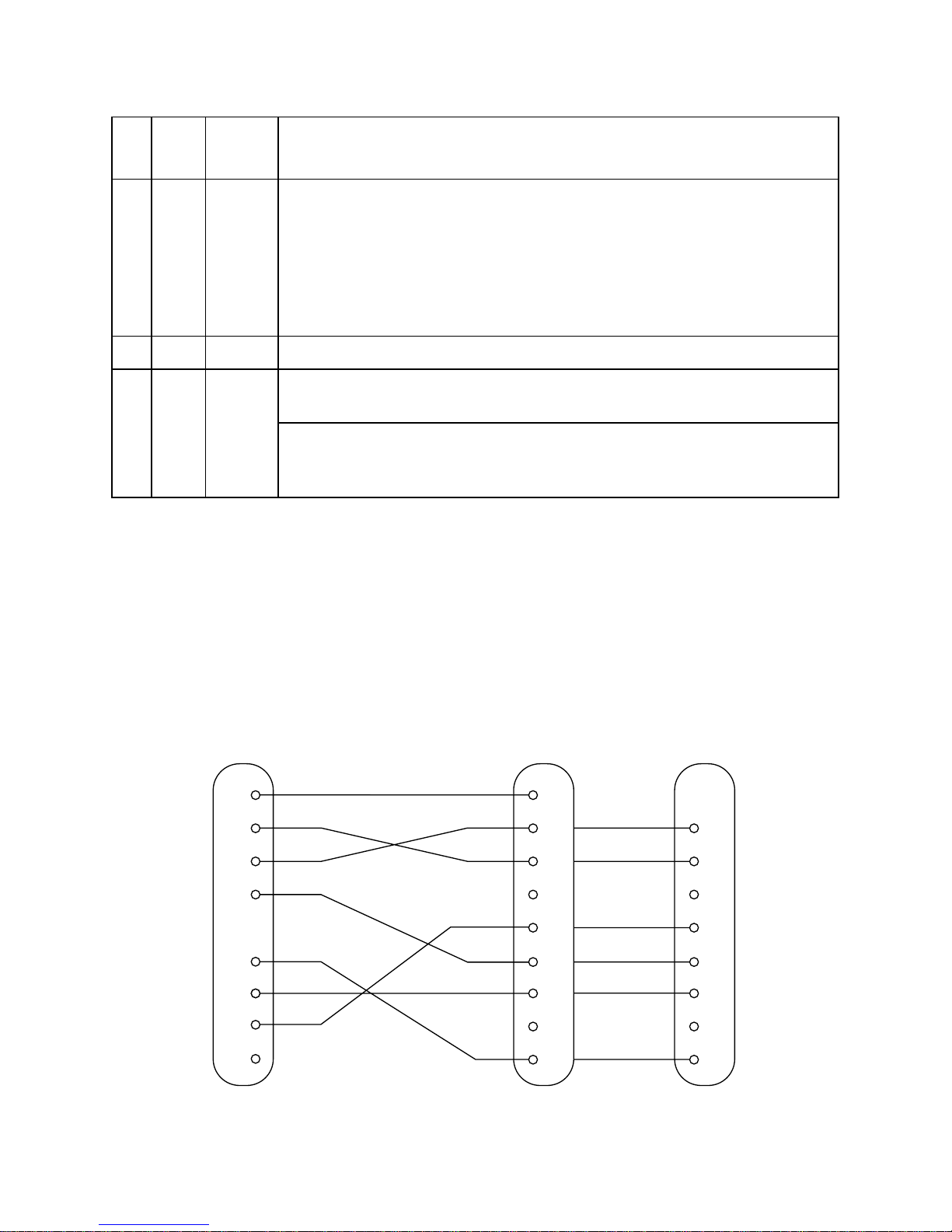

Interface connections

❏

Refer to the interface specifications for the host computer for details on

connecting to its interface connector. The following illustration shows a

typical connection configuration.

20 DTR OUT Indicates whether data receive from host is enabled or disabled.

DTR/DSR Communication Mode

Space when receive is enabled.

X-On/X-Off Communication Mode

Always space, except during following conditions:

• Period between reset and communication enabled

• During self-test printing and dot alignment adjustment

2 1 - 2 4 N.C. Not connected

25 INIT IN • DIP Switch 10 = OFF

This signal not used.

• DIP Switch 10 = ON

This signal becomes reset signal. Printer is reset whenever signal is in mark state with pulse

width of 1mS or more.

Pin

No.

Signal

Name

Direction Function

1

2

3

4

6

1

2

3

4

5

6

7

8

20

F-GND

TXD

RXD

RTS

DSR

20

25

7

S-GND

DTR

INIT

Printer side

(D-sub 25 pin)

IBM PC side

3

2

7

8

6

5

1

4

F-GND

TXD

RXD

RTS

CTS

DSR

S-GND

DCD

DTR

9 pin25 pin

Page 17

14

Data protocol

❏

Outline of DTR/DSR mode operations

This communication mode is set when dip switches 1 to 6 are set at ON.

The DTR signal shakes hands with the DSR signal (DSR signal: ESC/POS

mode only) and performs communications. The DTR signal is assumed as the

BUSY signal and then the control for the printer’s data receiving operations

are carreied out, and a “space” means that the printer is to receive the data, and

a “mark” means that the printer is not to receive the data.

The DTR signal line is set a “space” when the power supply is switched on and

no error occurs with the printer. The host confirms that the DTR signal line is

set at “space”, and then transmits the text data to the RXD signal line.

The printer sets the DTR signal line at “mark” when the empty area in the data

buffer is less that the prescribed number of bytes (*1: nearly full buffer

condition.) The host confirms that the DTR signal line is set at “mark” and

suspends text data transmission, but it is possible for the printer to continue

receiving data for the amount of space remaining in the data buffer’s empty area

at this point. If the DTR signal is ignored and data transmitted, the data that

exceeds the amount of space available in the empty area will be discarded. The

empty area in the data buffer will increase as printing is carried out, and the

DTR signal line will be set at “space” if the amount of empty space in the data

buffer is more than the prescribed number of bytes (*2: near empty condition.)

In addition to this, the host will confirm that receiving is possible (DSR signal

= “space”) and transmit the data only when memory switches 4 and 5 are set

at 0 during printer status transmission in the ESC/POS mode’s DTR/DSR

communication mode. (With the exception of certain status transmission

commands. Also, dip switches 1 to 9 must be at OFF when the DSR signal is

confirmed.)

*1 Refer to the nearly full buffer conditions for details on nearly full buffer conditions.

*2 Refer to the nearly empty buffer conditions for details on nearly empty buffer

conditions.

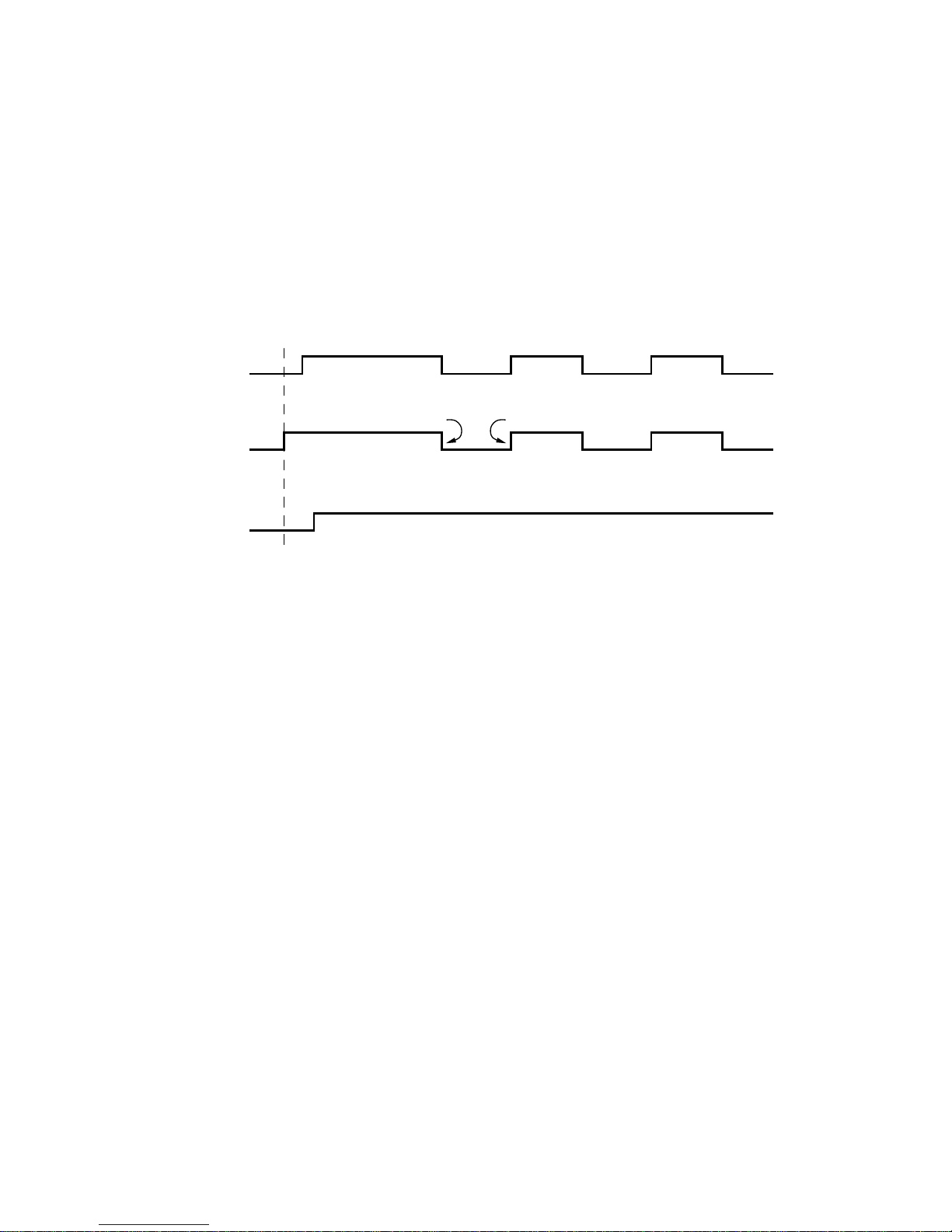

RXD

DTR

Data Data Data

Buffer full Buffer empty

Printing

Power ON

Page 18

15

❏ Outline of X-ON/X-OFF mode operations

This communication mode is set when dip switches 1 to 6 are set at OFF.

This mode notifies the host of X-0N (DC1) data when receiving is possible

and X-OFF (DC3) data when printing is not possible with the TXD signal.

The timing conditions for the output of X-ON and X-ON in the STAR mode

are set with the 4-C memory switch. When memory switch 4-C = 0 (set when

the unit is shipped from the factory,) only one byte is output by X-ON during

fluctuations from on-line (printer BUSY) to on-line (printer READY), and

only one byte is output by X-OFF during fluctuations from on-line (printer

READY) to on-line (printer BUSY). The same functions as above occur when

in the ESC/POS mode regardless of the 4-C memory switch setting.

When memory switch 4-C = 1, X-ON is output at regular three-second

intervals.

X-ON (DC1 with the control code name and 11H with hexadecimal display)

is output by the TXD signal line when the power supply is switched on and no

error occurs with the printer. The text data is transmitted to the RSD signal line

after the host has received X-ON.

X-OFF (DC3, 13H) is output when the empty area in the data buffer is less that

the prescribed number of bytes (*1: nearly full buffer condition.) Also, if

memory switch 4-C = 1, X-OFF is output for every byte of data received. The

host that receives X-OFF suspends text data transmission, but it is possible for

the printer to continue receiving data for the amount of space remaining in the

data buffer’s empty area at this point. If data that exceeds the amount of space

available in the empty area is transmitted, it will be discarded.

The empty area in the data buffer will increase as printing is carried out, and X-

ON is output if the amount of empty space in the data buffer is more than the

prescribed number of bytes (*2: near empty condition.)

*1 Refer to the nearly full buffer conditions for details on nearly full buffer conditions.

*2 Refer to the nearly empty buffer conditions for details on nearly empty buffer

conditions.

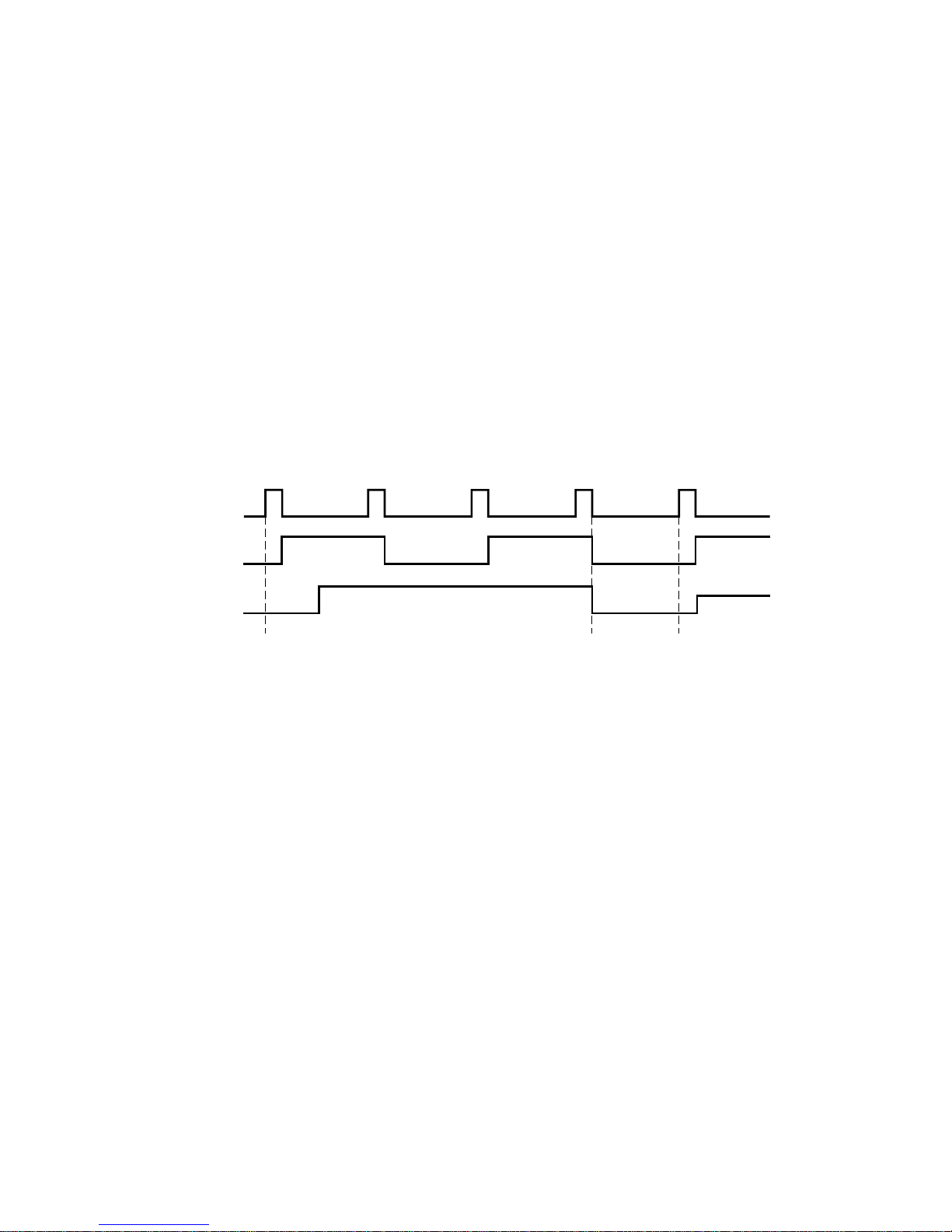

TXD

RXD

X–ON X–OFF X–ON X–OFF X–ON

Printing

Data Data Data

Page 19

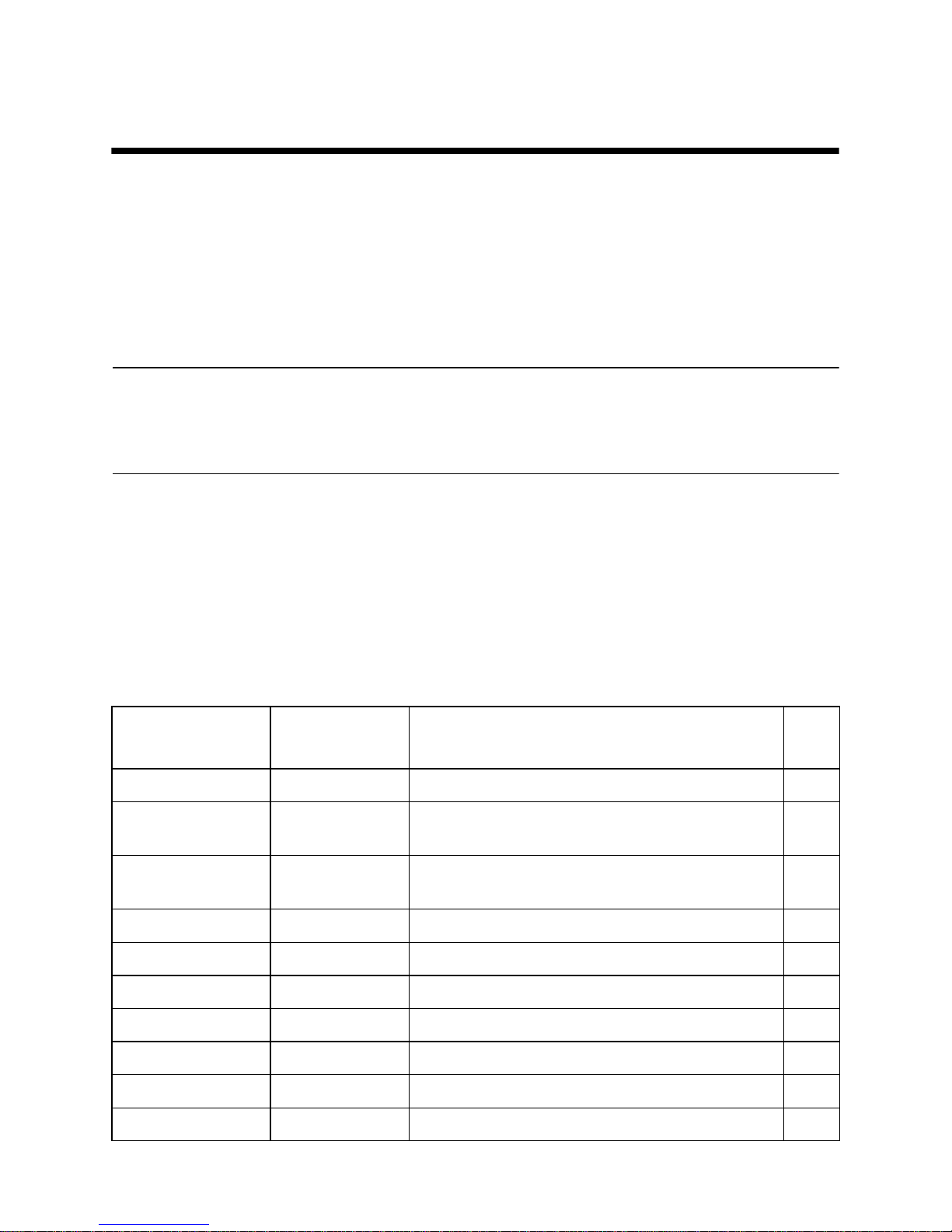

16

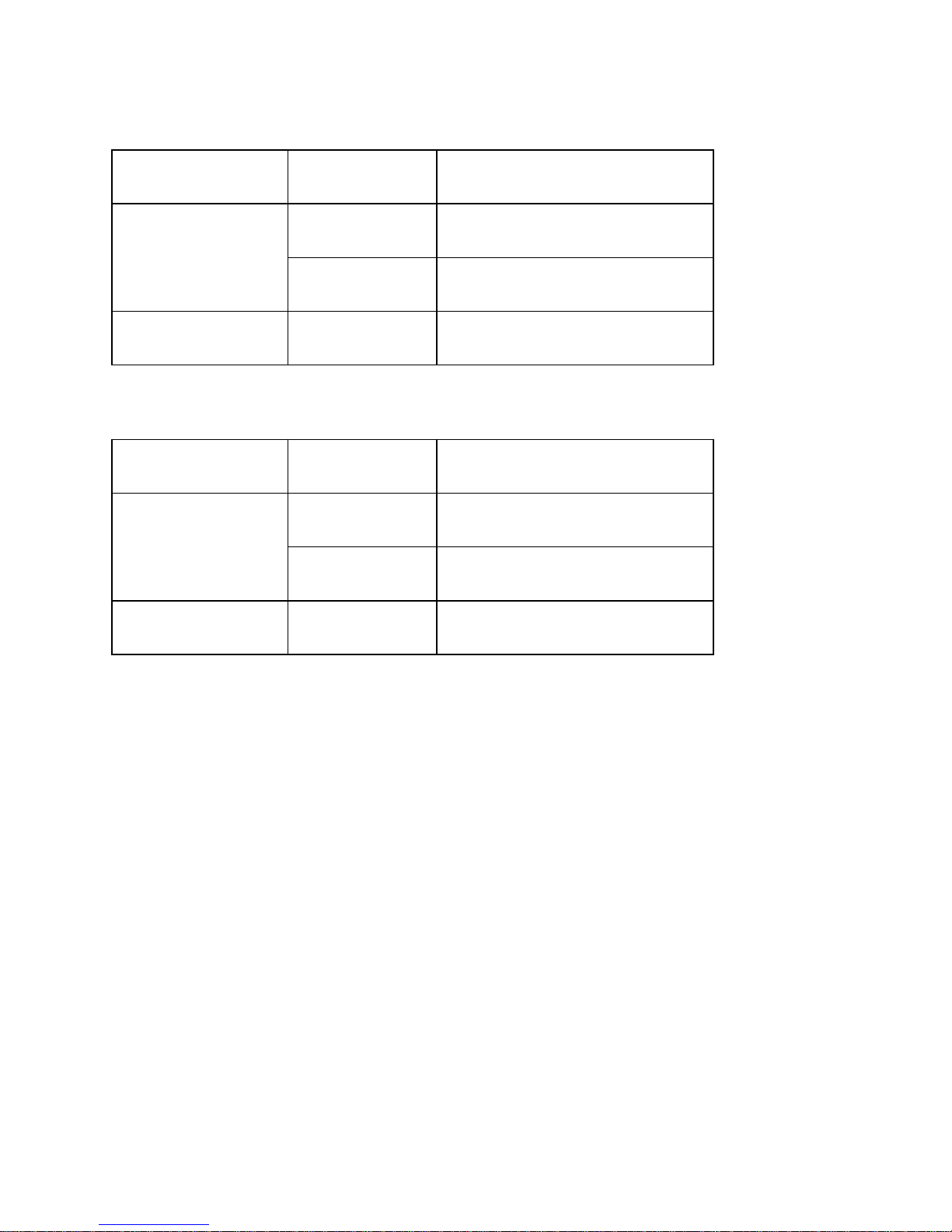

Nearly full buffer conditions

Nearly empty buffer conditions

Emulation

(DSW8)

Buffer size

(DSW7)

Available area

(during fluctuations)

STAR mode

2K byte

When 256 bytes or less are

available

35 byte

When 16 bytes or less are

available

ESC/POS mode 512/35 bytes

When 10 bytes or more are

available

Emulation

(DSW8)

Buffer size

(DSW7)

Available area

(during fluctuations)

STAR mode

2K byte

When 1792 bytes or less are

available

35 byte

When 20 bytes or less are

available

ESC/POS mode 512/35 bytes

When 20 bytes or more are

available

Page 20

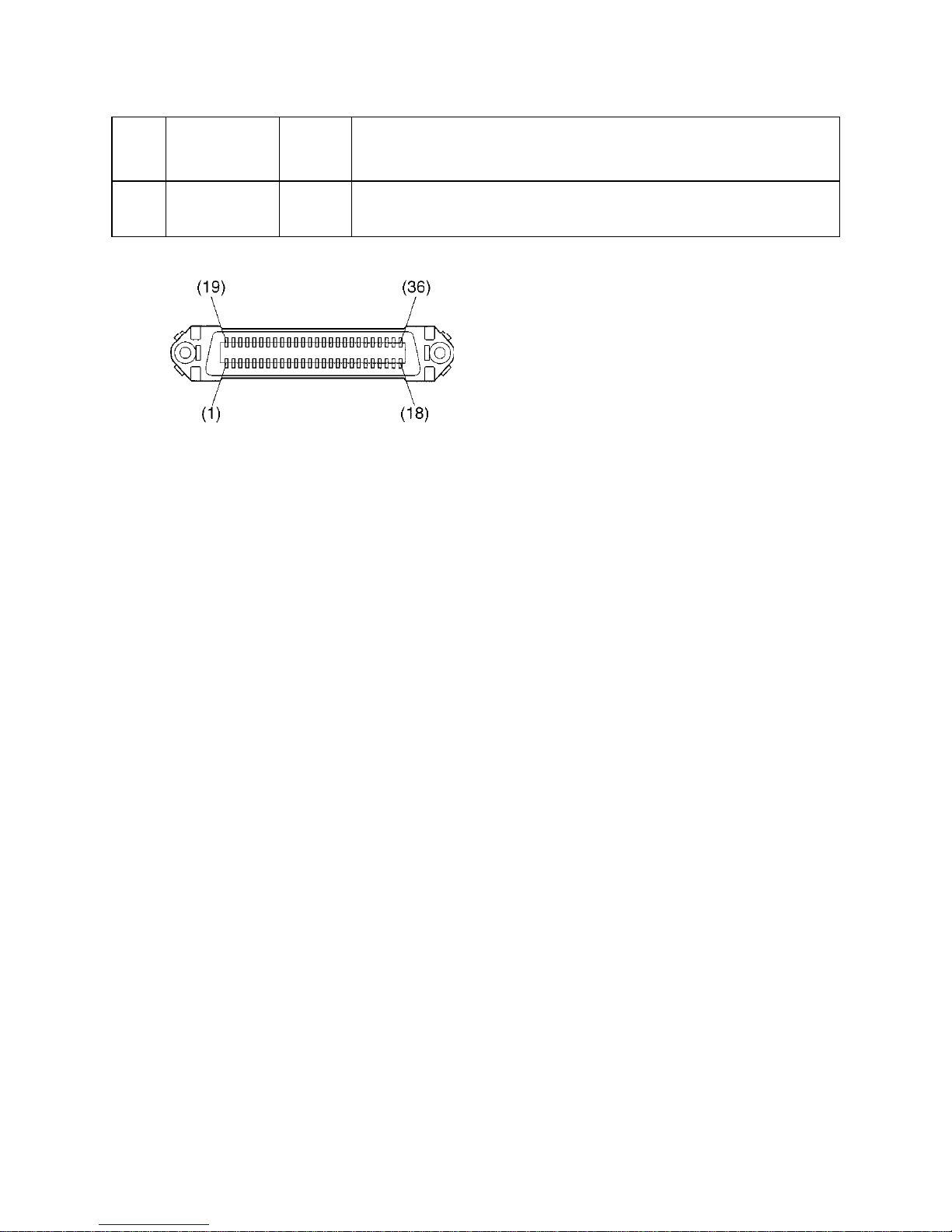

17

Parallel Interface

Connectors and Signals

Pin

No.

Signal Name IN/OUT Function

1 STROBE IN

Signals when data is ready to be read. Signal goes from HIGH to LOW (for at

least 0.5 microsec.) when the data is available.

2-9 DATA1-8 IN

These signals provide the information of the first to eighth bits of parallel data.

Each signal is at HIGH level for a logical 1 and at a LOW level for a logical 0.

10 ACK OUT A 9 microsecond LOW pulse acknowledges receipt of the data.

11 BUSY OUT

When this signal goes to LOW, the printer is ready to accept data. When the

printer is in one of the conditions below, “HIGH” is set.

1. Data is being entered

2. Off line

3. Error condition

12 PAPER OUT OUT

This signal indicates the status of the paper sensor.

[In Star mode]

This signal goes to HIGH when either the TOF or the BOF sensor detects that

there is no paper. The signal will go to LOW when both the TOF and BOF

sensor detect that there is paper installed.

[In the ESC/POS mode]

This signal outputs the status of the sensor selected using the <ESC> “c3”

command.

13 SELECTED OUT This signal is HIGH when the printer is online.

14-15 N/C Unused

16 SIGNAL GND Signal ground

17 CHASSIS GND Chassis ground, isolated from logic ground

18 LOGIC HIGH 3.9 k

Ω

pull-up

19-30 GND Twisted pair return the signal to ground level.

31 RESET IN

This becomes a reset signal when DIP switch 1 is set to ON. (See page 4 for

details.) When this signal goes to LOW (for at least 0.5 microsec.), the printer is

reset to its power-on condition.

32 ERROR OUT

This signal is normally HIGH. This signal goes to LOW to signal that the printer

cannot print due to an error condition.

33 EXT GND External ground

34 COMPULSION OUT Compulsion signal (See page 20.)

35 +5VDC 2.2 kΩ pull-up

Page 21

18

36 SELECT IN IN

Unused (However, this becomes a reset signal when DIP switch 1 is set to ON

and DIP switch 2 is set to OFF. See page 4 for details.)

Pin

No.

Signal Name IN/OUT Function

This connector mates with an Amphenol

57-30360 connector

Parallel interface connector (printer side)

Page 22

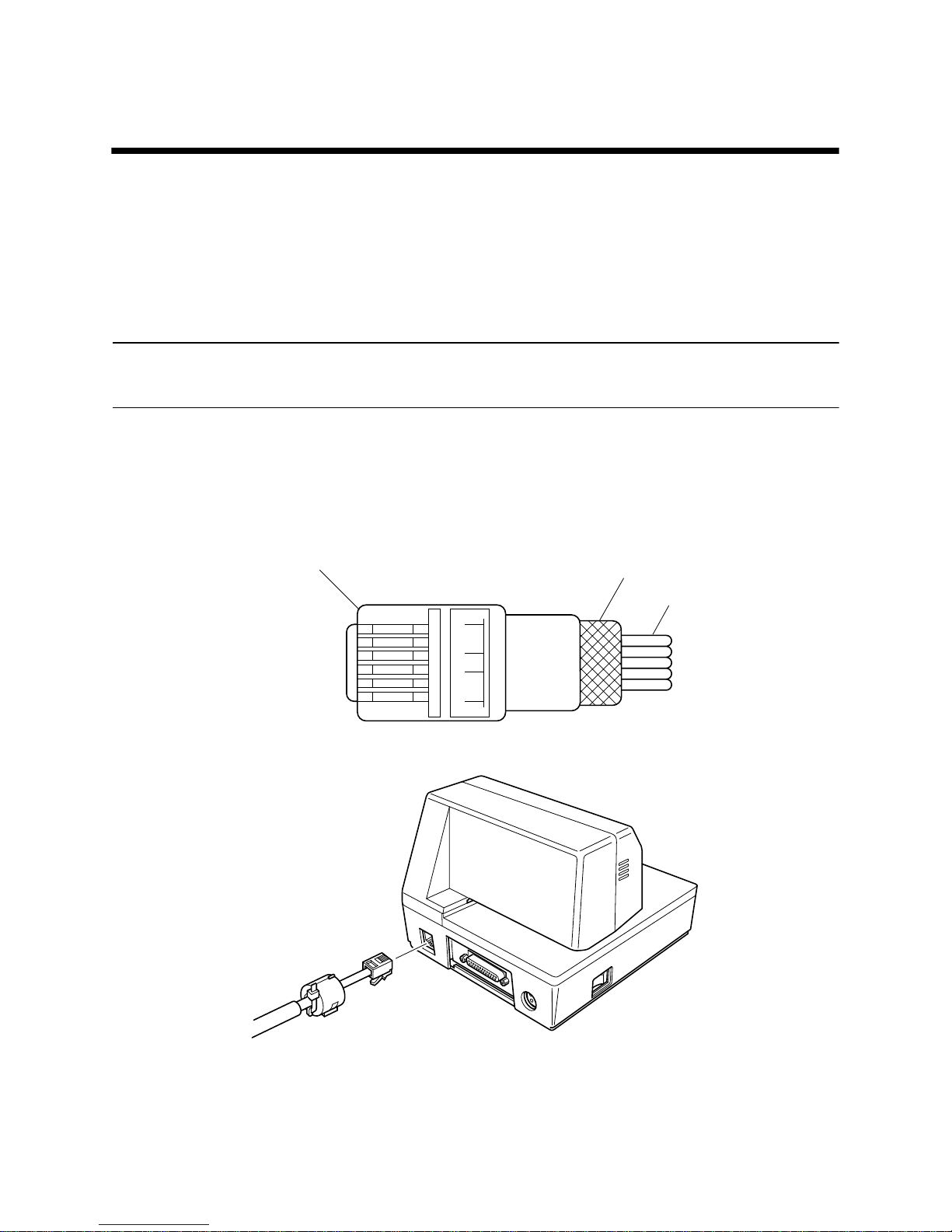

19

Chapter 5: Peripheral Unit Driver Circuit

This printer is equipped with a circuit for driving peripheral units, such as cash

drawers. A 6-pin modular connector for connection of the peripheral unit is

located on the back of the printer. To connect to the drive circuit, connect the

peripheral unit to the modular connector using a cable supplied by you like that

one shown in the figure below.

Important!

Never connect any other type of plug to the peripheral unit connector.

Modular plug

16

Modular plug: MOLEX 90075-0007,

AMP641337, or JAPAN BURNDY B-66-4

Shield

Wire lead

Page 23

20

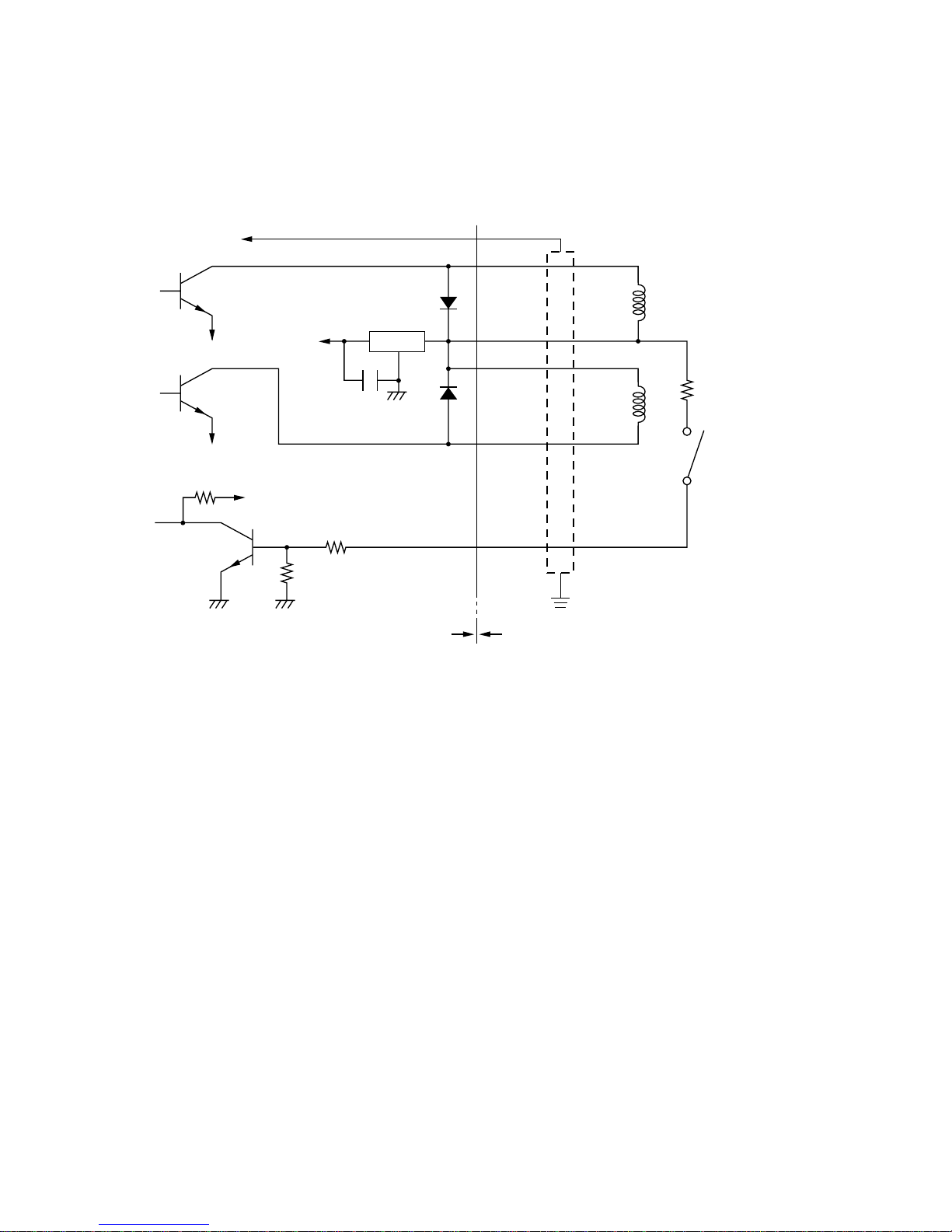

Drive circuit

The recommended drive unit is shown below.

Notes

• Peripheral Units 1 and 2 cannot be driven simultaneously.

• For continuous driving, do not use drive duty greater than 20%.

• When using a serial interface, the compulsion switch status is available

as status data. When using a parallel interface, the compulsion switch

status can be worked out from the position of the number 34 pin of the

interface connector . The switch status is ON when the number 34 pin is at

LOW level.

• Minimum resistance for coils L1 and L2 is 24Ω.

• Absolute maximum ratings for diodes D1 and D2 (Ta = 25°C) are:

Average Rectified Current Io = 1A

Maximum forward surge current (60Hz, 1-cycle sine wave) I

FSM

= 40A

• Absolute maximum rating for transistors TR1 and TR2 (Ta = 25°C) are:

Collector current Ic = 2A

Collector loss Pc = 1.2W

7824

F.G

TR1

M-GND

TR2

M-GND

TR3

+5V

+24V

R1

R2

6

5

4

3

2

1

L1

L2

R3

4.7kΩ

1/4W

Frame

ground

Printer side User side

D1

D2

Peripheral

unit 1

With shield

Peripheral

unit 2

Compulsion

switch

Drive output: 24V, 1.0A max.

Page 24

21

Chapter 6: Control Codes

This printer supports two different command modes: the Star mode and the

ESC/POS mode.

The Star mode emulates previous Star printers. The ESC/POS mode emulates

the Epson TM-295 or TM-290 slip printer.

This chapter provides you with all of the commands supported by this printer.

Important!

Access the following URL for the latest version of this manual and for updates

on supported commands: http://www.star-micronics.co.jp/service/

sp_sup_e.htm

Star Mode Commands

The following tables show the Star mode commands that are supported by this

printer.

Character Selection

Control Codes

Hexadecimal

Codes

Function Page

<ESC> “R”

n

1B 52

n

Selects the international character set 30

<ESC> “/” “1”

<ESC> “/” <1>

1B 2F 31

1B 2F 01

Selects slash zero 30

<ESC> “/” “0”

<ESC> “/” <0>

1B 2F 30

1B 2F 00

Selects normal zero 30

<ESC> <GS> “t”

n

1B 1D 74

n

Selects the character code table 30

<ESC> “M” 1B 4D Selects the 7 × 9 (half dot) font 31

<ESC> “P” 1B 50 Selects the 5 × 9 (2 pulses per dot) font 31

<ESC> “:” 1B 3A Selects the 5 × 9 (3 pulses per dot) font 31

<ESC> <SP>

n

1B 20

n

Sets character spacing 31

<SO> 0E Sets the printing magnified double in character width 31

<DC4> 14 Resets the printing magnified in character width 31

Page 25

22

<ESC> “W”

n

1B 57

n

Sets the magnification rate in character width 32

<ESC> “h”

n

1B 68

n

Sets the magnification rate in character height 32

<ESC> “–” “1”

<ESC> “–” <1>

1B 2D 31

1B 2D 01

Selects underlining 32

<ESC> “–” “0”

<ESC> “–” <0>

1B 2D 30

1B 2D 00

Cancels underlining 32

<ESC> “_” “1”

<ESC> “_” <1>

1B 5F 31

1B 5F 01

Selects upperlining 32

<ESC> “_” “0”

<ESC> “_” <0>

1B 5F 30

1B 5F 00

Cancels upperlining 32

<ESC> “4” 1B 34 Selects highlight printing 33

<ESC> “5” 1B 35 Cancels unhighlight printing 33

<SI> 0F Inverted printing 33

<DC2> 12 Cancels inverted printing 33

<ESC> <RS> “i” “0”

<ESC> <RS> “i” <0>

1B 1E 96 30

1B 1E 96 00

Cancels rotated print mode for text (Default) 33

<ESC> <RS> “i” “1”

<ESC> <RS> “i” <1>

1B 1E 96 31

1B 1E 96 01

Specifies rotated print mode for text with a 270˚ rotation. 33

<ESC> <RS> “i” “2”

<ESC> <RS> “i” <2>

1B 1E 96 32

1B 1E 96 02

Specifies rotated print mode for text with a 90˚ rotation. 33

<ESC> “E” 1B 45 Selects emphasized printing 34

<ESC> “F” 1B 46 Cancels emphasized printing 34

<ESC> “U”

n

1B 55

n

Selects print direction 34

Control Codes

Hexadecimal

Codes

Function Page

Page 26

23

Print Position Control

Control Codes

Hexadecimal

Codes

Function Page

<LF> 0A Line feed 35

<CR> 0D Carriage Return 35

<ESC> “a”

n

1B 61 n

Feeds paper n lines 35

<HT> 09 Horizontal tab 35

<ESC> “A”

n

1B 41

n

Defines n/72-inch line spacing 35

<ESC> “2” 1B 32 Sets n/72-inch line spacing 36

<ESC> “z” “0”

<ESC> “z” <0>

1B 7A 30

1B 7A 00

Sets line spacing to 1/12-inch 36

<ESC> “z” “1”

<ESC> “z” <1>

1B 7A 31

1B 7A 01

Sets line spacing to 1/6-inch 36

<ESC> “0” 1B 30 Sets line spacing to 1/8-inch 36

<ESC> “1” 1B 31 Sets line spacing to 7/72-inch 36

<ESC> “J”

n

1B 4A

n

One time n/72-inch feed 37

<ESC> “j”

n

1B 6A

n

One time n/72-inch backfeed 37

<ESC> “3”

n

1B 33

n

Sets line spacing to n/216-inch approximately 37

<ESC> “y” 1B 79

n

Sets line spacing to n/144-inch 37

<ESC> “D”

n1 n

2 ...

<0>

1B 44

n1 n

2 ...

00 Sets horizontal tab stops 38

<ESC> “l”

n

1B 6C

n

Sets left margin 38

<ESC> “Q”

n

1B 51

n

Sets right margin 38

<ESC> <GS> “a” “0”

<ESC> <GS> “a” <0>

1B 1D 61 30

1B 1D 61 00

Left justification (Default) 39

<ESC> <GS> “a” “1”

<ESC> <GS> “a” <1>

1B 1D 61 31

1B 1D 61 01

Centering 39

<ESC> <GS> “a” “2”

<ESC> <GS> “a” <2>

1B 1D 61 32

1B 1D 61 02

Right justification 39

Page 27

24

Dot Graphics Control

Download Graphics Printing

Peripheral Device Control

Control Codes

Hexadecimal

Codes

Function Page

<ESC> “K”

n <0>

m1 m2 ...

1B 4B

n 00 m1 m

2

...

Prints normal density graphics 40

<ESC> “L”

n1 n

2

m1 m2 ...

1B 4C

n1 n2

m

1

m

2 ...

Prints high density graphics 42

Control Codes

Hexadecimal

Codes

Function Page

<ESC> “&” <0>

n1 n2

.. 1B 26 00

n1 n2

.. Defines download characters 43

<ESC> “%” “1”

<ESC> “%” <1>

1B 25 31

1B 25 01

Enables download character set 44

<ESC> “%” “0”

<ESC> “%” <0>

1B 25 30

1B 25 00

Disables download character set 44

Control Codes

Hexadecimal

Codes

Function Page

<ESC> <BEL>

n1 n2 1B 07 n1 n2

Defines drive pulse width for peripheral device #1 45

<BEL> 07 Controls peripheral device #1 45

<FS> 1C Controls peripheral device #1 immediately 45

<EM> 19 Controls peripheral device #2 immediately 45

<SUB> 1A Controls peripheral device #2 immediately 45

Page 28

25

Slip Control

Page mode

Other Commands

Control Codes

Hexadecimal

Codes

Function Page

<ESC> <SI>

n

1B 0F

n

Setting slip sensor 46

<ESC> <FF>

n

1B 0C

n

Slip function 46

<ESC> <VT>

m n

1B 0B

m n

Sets the paper eject direction/length 47

<EOT> 04 Slip status enquiry 47

<ESC> <EM>

m n

<LF> <NUL>

1B 19

n m

0A 00 Sets the wait time until the automatic clamp is activated 48

Control Codes

Hexadecimal

Codes

Function Page

<ESC> “n” 1B 6E Selects page mode 48

<ESC> “!” 1B 21 Selects line mode 50

<ESC> “*” ... 1B 2A ... Setting print area in page mode 50

<ESC> “T”

n

1B 54

n

Setting print direction in page mode 51

<FF> 0C Prints in page mode 53

Control Codes

Hexadecimal

Codes

Function Page

<CAN> 18 Cancels printer buffer & Initialize printer (imimediately) 54

<DC3> 13 Deselects printer 54

<DC1> 11 Sets select mode 54

<RS> 1E Beeps the buzzer 54

<ESC> “#N,

n1 n2 n

3

n4”

<LF> <NUL>

1B 23 N 2C

n1 n

2

n3 n

4

0A 00

Sets memory switch 55

<ESC> “@” 1B 40 Initialize printer 58

<ENQ> 05 Enquiry 58

<ESC> “?” <LF>

<NUL>

1B 3F 0A 00 Resets printer hardware and produces a test print 59

Page 29

26

ESC/POS Mode Commands (TM-295 emulation)

The following table lists the TM-295 mode commands that are supported by this

printer.

*1: n/60-inch line spacing and paper feed commands:

Since the minimum paper feed pitch for this printer is 1/144 inch, n/60 inch can

considered an approximate value. However, the actual value is INT ((6n/5) +

0.5)/72 inch.

Control Codes

Hexadecimal

Codes

Function

<HT> 09 Horizontal tab

<LF> 0A Line feed

<FF> 0C

Paper eject in single sheet mode

Paper mode print and return

<DLE> <EOT> 10 04 Enables real-time status send (Serial I/F only)

<CAN> 18 Cancels print data in page mode

<ESC> SP 1B 20 Sets size of space to right of character

<ESC> ! 1B 21 Enables batch print mode

<ESC># 1B 23 Sets memory switch

<ESC> % 1B 25 Enables/disables download character set

<ESC> & 1B 26 Defines download character

<ESC> * 1B 2A Selects bit image mode

<ESC> 2 1B 32 Selects 1/6-inch line spacing

<ESC> 3 1B 33 Selects approximate

n

/60-inch line spacing *1

<ESC> = 1B 3D Selects peripheral device

<ESC> @ 1B 40 Initializes the printer

<ESC> C 1B 43 Sets the eject length for single-sheet printing

<ESC> D 1B 44 Sets horizontal tab position

<ESC> F 1B 46 Enables/disables reverse feed for single-sheet mode

<ESC> J 1B 4A Prints and n/60-inch (approximate value) paper feed *1

<ESC> K 1B 4B

Prints and n/60-inch (approximate value) reverse paper feed

*1

Page 30

27

Control Codes

Hexadecimal

Codes

Function

<ESC> L 1B 4C Selects page mode

<ESC> R 1B 52 Selects international character set

<ESC> T 1B 54 Selects direction for page mode character printing

<ESC> U 1B 55 Selects print direction

<ESC> V 1B 56 Designates/cancels 90˚ character rotation

<ESC> W 1B 57 Sets print area for page mode printing

<ESC> a 1B 61 Aligns position

<ESC> c3 1B 63 33

Selects the paper-end sensor for sending the no-paper

signal

<ESC> c4 1B 63 34 Selects the paper-end sensor for stopping printing

<ESC> c5 1B 63 35 Enables/disables control panel switches

<ESC> d 1B 64 Prints or feeds

n

lines

<ESC> e 1B 65 Prints or reverse feeds n lines

<ESC> f 1B 66 Sets single-sheet wait time

<ESC> p 1B 70 Generates specified pulse

<ESC> q 1B 71 Release

<ESC> t 1B 74 Selects character code table

<ESC> u 1B 75 Sends peripheral status (Serial I/F only)

<ESC> v 1B 76 Sends paper sensor status (Serial I/F only)

<ESC> { 1B 7B Enables/disables inverted printing

<GS> I 1D 49 Sends printer ID (Serial I/F only)

<GS> a 1D 61

Enables/disables automatic send of printer status

(Serial I/F only)

<GS> r 1D 72 Sends printer status (Serial I/F only)

Page 31

28

ESC/POS Mode Commands (TM-290 emulation)

The following table lists the TM-290 emulation commands that are supported

by this printer.

*1: n/60-inch line spacing and paper feed commands:

Since the minimum paper feed pitch for this printer is 1/144 inch, n/60 inch can

considered an approximate value. However, the actual value is INT ((6n/5) +

0.5)/72 inch.

Control Codes

Hexadecimal

Codes

Function

<HT> 09 Horizontal tab

<LF> 0A Line feed

<FF> 0C Paper eject in single sheet mode

<ESC> SP 1B 20 Sets size of space to right of character

<ESC> ! 1B 21 Enables batch print mode

<ESC># 1B 23 Sets memory switch

<ESC> * 1B 2A Selects bit image mode

<ESC> 2 1B 32 Selects 1/6-inch line spacing

<ESC> 3 1B 33 Selects approximate n/60-inch line spacing *1

<ESC> @ 1B 40 Initializes the printer

<ESC> D 1B 44 Sets horizontal tab position

<ESC> M 1B 4D Selects the 7

×

9 font

<ESC> P 1B 50 Selects the 5 × 9 font

Page 32

29

Control Codes

Hexadecimal

Codes

Function

<ESC> R 1B 52 Selects international character set

<ESC> c3 1B 63 33

Selects the paper-end sensor for sending the no-paper

signal

<ESC> c4 1B 63 34 Selects the paper-end sensor for stopping printing

<ESC> c5 1B 63 35 Enables/disables control panel switches

<ESC> d 1B 64 Prints or feeds n lines

<ESC> h 1B 68 Sets/Cancels reverse line feed

<ESC> j 1B 6A Selects character width in vertical printing mode

<ESC> q 1B 71 Release

<ESC> t 1B 74 Selects character code table

<ESC> v

n

1B 76

n

Requests paper sensor status (Serial I/F only)

<ESC> { 1B 7B Enables/disables inverted printing

<FS> J 1C 4A Sets vertical printing mode

<FS> K 1C 4B Cancels vertical printing mode

<FS> W 1C 57 Sets/Cancels double-height, double-width printing

Page 33

30

Character Selection

<ESC> “R” n

1B 52 n

Selects international character set

Selects an international character set according to the value of n, as

shown below:

0 n 12, “0” n “9”, “A” n “C”

n = 0, “0” : U.S.A. 1, “1” : France 2, “2” : Germany

3, “3” : England 4, “4” : Denmark Ι 5, “5” : Sweden

6, “6” : Italy 7, “7” : Spain Ι 8, “8” : Japan

9, “9” : Norway 10, “A” : Denmark 2 11, “B” : Spain 2

12, “C” : Latin America

Although the international character set can also be selected using a

memory switch, the control code setting is given priority.

<ESC> “/” n

1B 2F n

Selects zero style

Causes subsequent zero characters to be printed with a slash when n

is 1, and without a slash when n is 0.

The valve of n can be set to 0(00H) or “0”(30H), or 1(0H) or

“1”(31H).

The default may differ depending on the memory switch setting.

<ESC> <GS> “t” n

1B 1D 74 n

Selects the character code table

This function selects a character code table (as shown below).

The default settings follow the settings of the memory switch.

The range of n is: 0 n 10

n = (00)H : Normal (01)H : code page 437

(02)H : katakana (03)H : code page 437

(04)H : code page 858 (05)H : code page 852

(06)H : code page 860 (07)H : code page 861

(08)H : code page 863 (09)H : code page 865

(0A)H : code page 866

CODE

HEX

FUNCTION

≤ ≤ ≤ ≤ ≤ ≤

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

≤ ≤

Page 34

31

<ESC> “M”

1B 4D

Selects 7 × 9 (half dot) font

<ESC> “P”

1B 50

Selects 5 × 9 (2 pulses = 1 dot) font

<ESC> “:”

1B 3A

Selects 5 × 9 (3 pulses = 1 dot) font

<ESC> <SP> n

1B 20 n

Sets character spacing

Sets the spacing between characters according to the value of n.

The value of n can be set from 0 through 15, or from “0” through “9”

and “A” through “F”.

The default value of n is 0.

<SO>

0E

Sets the printing magnified double in character width.

Prints the subsequent data including a character spacing set by

<ESC><SP> n, magnified double in character width.

<DC4>

14

Resets the printing magnified in character width.

Resets the printing magnified in character width set by <SO>, and

<ESC> “W”n.

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

Page 35

32

<ESC> “W” n

1B 57 n

Sets the magnification rate in character width

Prints the subsequent data with a character width magnified by a rate

specified by the value of n.

n= 0, “0”: Reset magnification (same as <DC4>)

1, “1”: Double magnification (same as <SO>)

<ESC> “h” n

1B 68 n

Sets the magnification rate in character height

Prints the subsequent data with a character height magnified by a rate

specified by the value of n.

n= 0, “0”: Reset magnification

1, “1”: Double magnification

<ESC> “–” n

1B 2D n

Underlining

When the value of n is 1, underlines the subsequent data including a

character spacing set by <ESC><SP> n.

The part to be skipped by the horizontal tab setting and the block

graphic characters are not underlined.

Resets the underline mode when the value of n is 0.

The value of n can be set to 0(00H) or “0”(30H), or 1(01H) or

“1”(31H).

<ESC> “_” n

1B 5F n

Upperlining

When the value of n is 1, over lines the subsequent data including a

character spacing set by <ESC><SP> n.

The part to be skipped by the horizontal tab setting and the block

graphic characters are not upper lined.

Resets the upper line mode when the value of n is 0.

The value of n can be set to 0(00H) or “0”(30H), or 1(01H) or

“1”(31H).

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

Page 36

33

<ESC> “4”

1B 34

Selects highlight printing

Prints the subsequent data including a character spacing set by

<ESC><SP> n reversed.

The part to be skipped by the horizontal tab setting is not reversed.

<ESC> “5”

1B 35

Cancels highlight printing

<SI>

0F

Inverted printing

Causes subsequent characters to be inverted.

Enter this command at the beginning of the line. If this code is

entered at any other position, it will be invalid. Therefore, it is not

possible to mix correct and inverted printing in one line.

<DC2>

12

Cancels inverted printing

Enter this code at the beginning of the line.

<ESC> <RS> “i” n

1B IE 96 n

This function defines and cancels rotated print mode for text with a

90˚ or 270˚ rotation for the line mode.

This function is for the line mode. It rotates the following data in a

clockwise direction with a 90˚ or 270˚ rotation or cancels the rotation

and then prints the text. The n value determines whether a rotational

direction or a cancellation of the rotation is specified.

Underline or overline cannot be applied for rotated text.

The relationship of the vertical ratio and horizontal ratio for rotated

text is the reverse of when the rotation is cancelled.

n value Rotation specification

00H or “0” Cancel rotation (0˚ rotation, default)

01H or “1” 270˚ rotation

02H or “2” 90˚ rotation

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

Page 37

34

<ESC> “E”

1B 45

Selects emphasized printing

Causes subsequent characters to be emphasized.

<ESC> “F”

1B 46

Cancels emphasized printing

<ESC> “U” “1” or <ESC> “U” <1>

1B 55 31 1B 55 01

Selects uni-directional printing

After printing the data in the line buffer, the printer enters the unidirectional mode.

The subsequent data is printed when the print head moves from left

to right.

<ESC> “U” “0” or <ESC> “U” <0>

1B 55 30 1B 55 00

Selects bi-directional printing

After printing the data in the line buffer, the printer enters the bidirectional mode.

In this mode, the data is printed faster than the uni-directional mode.

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

Page 38

35

Print Position Control

<LF>

0A

Line feed

Prints the current line and feeds the paper to the next line.

<CR>

0D

Carriage return

The <CR> code is valid only if memory switch 3-1 is set to 1. (The

factory setting is 0.)

If the <CR> code is valid:

The function of the <CR> code changes according to the setting of

memory switch 5-8.

When memory switch 5-8 is set to 0 (factory setting): Functions in

the same way as an <LF> code (CRLF).

When memory switch 5-8 is set to 1: Executed only when printing.

The paper is not fed (CR).

<ESC> “a” n

1B 61 n

Feed paper n lines

Prints the current line and feeds the paper n lines (where n is between

1 and 127).

<HT>

09

Horizontal tab

Moves the print position to the next horizontal tab stop. Ignored if

there is no next horizontal tab stop on the current line.

<ESC> “A” n

1B 41 n

Defines n/72-inch line spacing

Defines the distance that the paper advances in subsequent line feed.

The line spacing defined here is set by <ESC> “2”.

0 n 85

The default value of n is 12 (1/6-inch feed)

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

≤ ≤

Page 39

36

<ESC> “2”

1B 32

Sets line spacing to n/72-inch

Sets the line spacing to n/72-inch which is defined by <ESC> “A” n.

<ESC> “z” “0” or <ESC> “z” <0>

1B 7A 30 or 1B 7A 00

Sets line spacing to 1/12 inch

Sets the distance that the paper advances in subsequent line feeds to

1/12 inch.

<ESC> “z” “1” or <ESC> “z” <1>

1B 7A 31 or 1B 7A 01

Sets line spacing to 1/6 inch

Sets the distance that the paper advances in subsequent line feeds to

1/6 inch.

<ESC> “0”

1B 30

Sets line spacing to 1/8 inch

Sets the distance that the paper advances in subsequent line feeds to

1/8 inch.

<ESC> “1”

1B 31

Sets line spacing to 7/72-inch

Sets the subsequent line spacing to 7/72-inch.

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

Page 40

37

<ESC> “J” n

1B 4A n

One time n/72-inch feed

Performs a line feed of n/72-inch only once after printing the data in

the line buffer. The space setting for lines does not change. The value

of n is between 1 and 255.

<ESC> “j” n

1B 6A n

One time n/72-inch backfeed

Performs a line feed of n/72-inch only once after printing the data in

the line buffer. The space setting for lines do not change. The value

of n is between 1 and 255.

<ESC> “3” n

1B 33 n

Sets line spacing to n/216-inch

Sets the subsequent line spacing to n/216-inch.

The value of n is between 1 and 255.

Since the min. pitch of the slip paper feed mechanism is 1/144-inch,

the set value is approximated by the following formula

INT (n × 2/3 + 0.5)/144 inch

<ESC> “y” n

1B 79 n

Sets line spacing to n/144-inch

Sets the subsequent line spacing to n/144-inch.

The value of n is between 1 and 255.

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

Page 41

38

<ESC> “D” n1 n2 ... <0>

1B 44 n1 n2 ... 00

Sets horizontal tab stops

Cancels all current horizontal tab stops and sets new tab stops at

columns n1, n2, etc. at the current character pitch, where n1, n2, etc.

are numbers between 1 and 255. A maximum of 16 horizontal tab

stops can be set.

The tab stops must be specified in ascending order; any violation of

ascending order terminates the tab stop list. Standard termination is

by the <0> control code.

With <ESC> “D” <0>, all horizontal tab stops are cancelled. The left

edge of the paper is always the reference point for the horizontal tab

positions, regardless of the left margin setting. When the power is

turned on, no horizontal tabs are set.

<ESC> “1” n

1B 6C n

Sets left margin at column n at the current character pitch.

The left margin does not move if the character pitch is changed later.

If this function is set in the middle of a line, it will become valid

starting with the following line. When the power is turned on, the left

edge is set as the left margin.

The left margin must be at least 18 dots to the left of the right margin

and within the limits below. If the size of one character and its

spacing is larger than the print area defined by the margins, printing

is not possible and “?” is printed, instead of the character.

The value of n is between 0 and the value of the right margin - 2.

<ESC> “Q” n

1B 51 n

Sets right margin

Sets right margin at column n at the current character pitch.

The right margin does not move if the character pitch is changed

later.

If this function is set in the middle of a line, it will become valid

starting with the following line. When the power is turned on, the

right edge is set as the right margin.

The right margin must be within the limits below and set so that the

allowable print area is more than 18 dots. If the size of one character

and its spacing is larger than the print area defined by the margins,

printing is not possible and “?” is printed, instead of the character.

The value of n is between 2 and the value of the maximum number

of print columns.

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

Page 42

39

<ESC> <GS> “a” n

1B 1D 61 n

This function specifies a position alignment.

This function aligns the specified position of all print data of 1 line.

The position is aligned as shown below.

n = (00)H, “0”: Left align (default)

= (01)H, “1”: Center

= (02)H, “2”: Right align

ABC

ABCD <ESC><GS> “a”0

ABCDE

ABC

<ESC><GS> “a”1 ABCD

ABCDE

ABC

<ESC><GS> “a”2 ABCD

ABCDE

Note:

• This is only valid when it is input at the start of the line.

• The position alignment is executed on the width of the specified

print area.

• The parts that are skipped because of horizontal tabs are also

included in the data for position alignment.

CODE

HEX

FUNCTION

Page 43

40

Dot Graphics Printing

<ESC> “K” n <0> m1 m2 ...

1B 4B n 00 m1 m2 ...

Prints normal density graphics

Prints a bit image of the number of dots specified by n. After printing

the bit image, the printer automatically returns to the character mode.

The relationship between the pins on the print head and the data is

shown below.

The value of n is between 1 and 210.

A maximum of 210 data bytes can printed in one line. Any data exceeding

210 bytes is ignored. Only uni-directional printing is possible.

CODE

HEX

FUNCTION

MSB LSB

Image data

D

8 D7 D6 D5 D4 D3 D2 D1

1

2

3

4

5

6

7

8

9

Dot Position

(Not Used)

Page 44

41

We will create the design below using a bit image.

First, since the volume of data is 30, n1 = (1E)

H. If the data m1 ~ m30

is converted to hexadecimal, it appears as shown below.

Data Binary

Hexa-

decimal

Data Binary

Hexa-

decimal

Data Binary

Hexa-

decimal

m1 00000001 01 m11 00111110 3E m21 00111110 3E

m2 00011110 1E m12 00000010 02 m22 00101110 2E

m3 00111110 3E m13 00000010 02 m23 00101110 2E

m4 01011111 5F m14 00111110 3E m24 00111110 3E

m5 00011111 1F m15 00111110 3E m25 00101111 2F

m6 01011110 5E m16 00101111 2F m26 00101111 2F

m7 00011110 1E m17 00101111 2F m27 00111110 3E

m8 00111111 3F m18 00111110 3E m28 00111110 3E

m9 00101111 2F m19 00101110 2E m29 00000010 02

m10 00111110 3E m20 00101110 2E m30 00000010 02

EXAMPLE

Printing Sample

Page 45

42

<ESC> “L” n1 n2 m1 m2 ...

1B 4C n1 n2 m1 m2 ...

Prints high density graphics

Prints a high density bit image of the number of dots specified by n1

and n2. The value of n1 + 256 × n2 is between 1 and 420.

A maximum of 420 data bytes can printed in one line. Any data

exceeding 420 bytes is ignored.

After printing the bit image, the printer automatically returns to the

character mode. The relationship between the pins on the print head

and the data is the same as those shown for the previous bit image

code <ESC> “K”.

While printing a high density bit image, the horizontally adjacent

dots cannot be printed.

We will create the design below using a bit image.

First, since the volume of data is 30, n1 = (1E)

H. If the data m1 ~ m30

is converted to hexadecimal, it appears as shown below.

Horizontal density is three times that of the bit image for <ESC>“k”.

(Compare the print samples.)

Data Binary

Hexa-

decimal

Data Binary

Hexa-

decimal

Data Binary

Hexa-

decimal

m1 00000001 01 m11 00111110 3E m21 00111110 3E

m2 00011110 1E m12 00000010 02 m22 00101110 2E

m3 00111110 3E m13 00000010 02 m23 00101110 2E

m4 01011111 5F m14 00111110 3E m24 00111110 3E

m5 00011111 1F m15 00111110 3E m25 00101111 2F

m6 01011110 5E m16 00101111 2F m26 00101111 2F

m7 00011110 1E m17 00101111 2F m27 00111110 3E

m8 00111111 3F m18 00111110 3E m28 00111110 3E

m9 00101111 2F m19 00101110 2E m29 00000010 02

m10 00111110 3E m20 00101110 2E m30 00000010 02

CODE

HEX

FUNCTION

EXAMPLE

Printing Sample

Page 46

43

Download Graphics Printing

When the 7 × 9 (half dot) character size (default setting) is set:

<ESC> “&” <0> n1 n2 [m0 m1 m2 m3 m4 m5 m6 m7]

n2 – n1 + 1

1B 26 00 n1 n2 [m0 m1 m2 m3 m4 m5 m6 m7] n2 – n1 + 1

When the 5 × 9 dot character size is set:

<ESC> “&” <0> n1 n2 [m0 m1 m2 m3 m4 m5] n2 – n1 + 1

1B 26 00 n1 n2 [m0 m1 m2 m3 m4 m5] n2 – n1 + 1

Defines download character (7 × 9 (half dot) font or 5 × 9 dot font)

Defines download characters

Up to 10 download characters can be defined and the defined

character patterns can be stored in the printer’s RAM.

The values of n1 and n2 are between (21)H and (7F)H with n1 less

than or equal to n2 and the value of m0 is either (00)H or (80)H.

Defining of download characters begins with character code n1 and

completes with n2. When only one character is defined, n1 = n2.

m0 indicates the relationship between the character pattern and print

head.

m1 m2.... Indicate the character pattern

CODE

HEX

CODE

HEX

FUNCTION

MSB

When m0=(00)H

LSB

D8 D7 D6 D5 D4 D3 D2 D1

1

2

3

4

5

6

7

8

9

Pin No.

(Not used)

MSB

When m0=(80)H

LSB

D

8 D7 D6 D5 D4 D3 D2 D1

1

2

3

4

5

6

7

8

9

Pin No.

(Not used)

Page 47

44

When the 7 × 9 (half dot) character size (default setting) is set, the

horizontally adjacent dots cannot be printed.

<ESC> “%” “1” or <ESC> “%” <1>

1B 25 31 or 1B 25 01

Enables download character set

Enables the download character set.

<ESC> “%” “0” or <ESC> “%” <0>

1B 25 30 or 1B 25 00

Disables download character set

Disables the selected download character set and returns to the builtin ROM character set.

EXAMPLE

m2 m4 m6

m1

D8

D7

D6

D5

D4

D3

D2

D1

m3 m5 m7

Printing possible Printing not possible

m2 m4 m6

m1

D8

D7

D6

D5

D4

D3

D2

D1

m3 m5 m7

Over lapping

horizontally

Over lapping

horizontally

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

Page 48

45

Peripheral Device Control

<ESC> <BEL> n1 n2

1B 07 n1 n2

Defines drive pulse width for peripheral device #1

Defines the drive pulse width for peripheral devices requiring other

than standard 200 ms pulse time and delay time.

n1 indicates the energizing time and n2 indicates the delay time,

using 10ms units.

<BEL>

07

Controls peripheral device #1

Executes drive pulse for peripheral device #1.

<FS>

1C

Controls peripheral device #1 immediately

Executes drive pulse for peripheral device #1 immediately.

<EM>

19

Controls peripheral device #2 immediately

Drives peripheral device #2. The drive pulse width and delay time

are fixed at 200 ms.

<SUB>

1A

Controls peripheral device #2 immediately

Drives peripheral device #2. The drive pulse width and delay time

are fixed at 200 ms.

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

Page 49

46

Slip Control

<ESC> <SI> n

1B 0F n

Setting slip sensor

Sets the slip printer TOF/BOF sensor according to the value of n.

TOF Sensor BOF Sensor

n = 00, “0” : Valid Valid

01, “1” : Valid Invalid

02, “2” : Invalid Valid

03, “3” : Invalid Invalid

The default value is n="0" when memory switch 5-2 = 0 (set when

the unit is shipped from the factory,) and n="3" when memory switch

5-2 = 1.

<ESC> <FF> n

1B 0C n

Slip function

After printing the data in the line buffer, operates the slip printer

according to the value of n.

n = 00, “0” : Operates the clamp

01, “1” : Releases the paper

02, “2” : Releases the paper and waits until it is removed

03, “3” : Feeds the paper backward (backfeed) until it

moves past the TOF sensor, then releases the

paper. (See NOTE below.)

04, “4” : Feeds the paper into the printer (operational feed)

until it moves past the BOF sensor, then releases

the paper.

05, “5” : Feeds the paper according to the direction and

length set by <ESC> <VT> m n (the paper is not

released)

(NOTE) When the slip paper is attached to duplicates, a paper jam

may occur if the paper is always fed backward. Therefore,

the paper should not be ejected with n=3. To feed slip paper

attached to duplicates backward, use <ESC> <VT> to set

the eject length to about half of the paper length, then eject

the paper using <ESC> <FF> 5.

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

Page 50

47

<ESC> <VT> mn

1B 0B mn

Sets the paper eject direction/length

Sets the length of the ejection operation performed using <ESC>

<FF> 5 in line mode.

The value of m determines the ejection direction.

When m= “+”: the ejection direction is into the printer (operational

feed), and the ejection length is n lines (at the current

carriage return)

When m= “-”: the ejection direction is backward (backfeed), and

the ejection length is n lines (at the current carriage

return)

When m= 0 : the ejection direction is backward (backfeed), and

the ejection length is n inches

The default value of n is 0.

<EOT>

04

Slip status enquiry

Sends slip printer status information to the host computer.

Status b1 and b5 is variable.

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

Status b7 b6 b5 b4 b3 b2 b1 b0

10

TOF sensor 1: No paper

BOF sensor 1: No paper

Slip printer mechanical error 1: Error

Slip release/clamp 1: Clamp

0: Release

Constantly

set at “1”

Constantly

set at “0”

Page 51

48

<ESC> <EM> nm<LF> <NUL>

1B 19 nm0A 00

Sets the wait time until the automatic clamp is activated

Sets the wait time between paper insertion (TOF/BOF sensor senses

the paper) and automatic clamp activation by n × 0.1 sec.

The default value of n is 7 (wait time is 0.7 sec.)

The value of m is fixed to 0.

Page Mode

<ESC> “n”

1B 6E

Selects page mode

Switches from line mode (default) to page mode.

This code is only valid when it is entered at the beginning of the line.

The page mode is suitable even though data is printed in the

rotational direction specified by <ESC> “T” n and in the page

coordinate range specified by <ESC> “*” •••, and though paper with

a horizontal length of a check, etc. is rotated 90 or 270 and printing

is carried out in all modes.

In page mode, since OR is applied to the data in the print area,

characters and bit images can be printed overlapping each other and

each character can be rotated and oriented independently.

In page mode, if printing data and a command such as <CR> or

<LF> are sent in the same way as in line mode, there is an automatic

rotation to the printer side.

All printing of data in the print area is performed according to <LF>.

After printing according to <FF>, the printer returns to line mode. In

addition, if <ESC> “!”, <ESC> “@” or <CAN> are specified,

printing is not performed and the printer leaves page mode and

returns to line mode.

While returning to line mode, the data in the printer buffer, the area

coordinates and the rotation directions are all cleared.

The following restrictions exist in page mode.

1) In page mode, half-dot characters cannot be printed since

printing is carried out in normal dot units.

When entering page mode, the ANK font is automatically set to

a 5 × 9 (2 pulses = 1 dot) font.

Since the 7 × 9 font and 5 × 9 (3 pulses = 1 dot) font commands

cannot be executed in page mode, they are executed after the

printer returns to line mode.

When the spacing between characters is an odd value, one halfdot is truncated.

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

Page 52

49

Also, when characters are enlarged vertically, the top of the

characters may not be printed on the first line of the page and

the characters on the second line or lower lines may overlap the

characters above them. This is because the characters are

enlarged from their baseline.

Because of this, when vertically enlarged characters are

contained in a line the print area must be secured so that the

vertically extended characters can fit. This is done by adding an

additional <LF> at the beginning of the print data line.

2) Paper feed command

In paper mode, the paper feed command and carriage return are

executed in units of dots. A 1/72-inch (0.353-mm) paper feed is

considered 1 dot. Since a 1-dot pitch in the horizontal direction

is 0.30 mm and a 1-dot pitch in the vertical direction is 0.353

mm, the paper amount that is fed while printing using a 90 or

270 rotation is less when compared with a 0 or 150 rotation.

As a result, when printing using a 90 or 270 rotation, execute a

test print, check the horizontal and vertical dot alignment, then

adjust the alignment as necessary.

3) The following commands are not executed in page mode, but

are stored and executed when the printer returns to line mode.

4) The following commands are ignored in page mode.

Select 7 × 9 (half dot) font <ESC> “M”

Select 5 × 9 (3 pulses = 1 dot) font <ESC> “:”

Inverted printing/Cancel inverted

printing

<SI>/<DC2>

Select highlight printing/Cancel

highlight printing

<ESC> “4”/<ESC> “5”

Underlining <ESC> “-” n

Upperlining <ESC> “_” n

Select print direction <ESC> “U” n

Select emphasized printing/Cancel

emphasized printing

<ESC> “E”/<ESC> “F”

Select left margin <ESC> “1” n

Select right margn <ESC> “Q” n

Specifies rotated print mode for text

with a 90˚/270˚ rotation

<ESC> <RS> “i” n

One time backfeed <ESC> “j” n

Print high density graphics <ESC> “L” •••

Slip function <ESC> <FF> n

Page 53

50

<ESC> “!”

1B 21

Select line mode (default)

If this command is specified while in page mode, printing is not

carried out and the printer returns to line mode.

<ESC> “*” X

L XH YL YH dXL dXH dYL dYH

1B 2A XL XH YL YH dXL dXH dYL dYH

Setting print area in page mode

The coordinates of the current position at the moment that page

mode is entered are (0,0). The starting point of the print area is

defined by XL, XH, YL and YH. In addition, the length DX in the X

direction is specified by dXL and dXH, and the length DY in the Y

direction is specified by dYL and dYH.

Starting point X

0 = XL + (XH × 256) dots

Starting point Y0 = YL + (YH × 256) dots

Length in horizontal direction DX = dXL + (dXH × 256) dots

Length in vertical direction DY = dYL + (dYH × 256) dots

The values of XL, YL, dXL and dYL are between 0 and 255, and the

values of XH, YH, dXH and dYH are between 0 and 1.

However, dXL = dXH = 0 and dYL = dYH = 0 are not included.

In addition, since the maximum range in the X direction (XO + DX)

is 210 dots and the maximum range in the Y direction (YO + DY) is

720 dots, each parameter should be specified to satisfy these ranges.

When the power is turned on, XL = XH = YL = YH = 0 (XO,YO =

0,0)

dXL = 210, dXH = 0 (DX = 210) and

dYL = 64, dYH = 2 (DY = 576).

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

Paper feed direction

Current position (0,0)

Print areaDY

DX

(X0,Y0)

Page 54

51

This command is stored, even in line mode, and the position at the

time that page mode is entered is used as the standard point (0,0).

Since the bottom of the character is used as the baseline, a minimum

print area of 8 dots are necessary in the character height direction to

print data in the page. (When printing a magnified character height,

the paper must be fed before printing.)

<ESC> “T” n

1B 54 n

Setting print direction in page mode

Sets the direction in which the printing will be executed in page

mode according to the value of n.

This command is only valid in line mode.

The default value of n is 0.

<Rotation direction examples>

n = 0 n = 1 or 4 n = 2 n = 3

0° rotation 270° rotation 180° rotation 90° rotation

<N=4,“4”: Check high-speed printing mode>

This parameter is only valid when no character data is expanded

into the page area, and this command is added immediately after

<ESC>“n”.

Also, once the check high-speed printing mode has been entered

with <ESC>“T”4, it is not possible to move across to a different

rotation mode (<ESC>“T”0-3) until the page mode has been exited.

Value of n Mode

0 or “0” 0 rotation mode (uni-directional printing)

1 or “1” 270 rotation mode (uni-directional printing)

2 or “2” 180 rotation mode (uni-directional printing)

3 or “3” 90 rotation mode (uni-directional printing)

4 or “4” 270 rotation mode (bi-directional printing)

CODE

HEX

FUNCTION

12345•••

ABCDE•••

12345•••

ABCDE•••

12345•••

ABCDE•••

12345•••

ABCDE•••

Page 55

52

The check high-speed printing mode provides high-speed printing

with the check at a 270 degree rotation angle and bi-directional

printing, and a wide range of limitations have been included to

enable bi-directional printing.

This mode can only be used with printing data that uses a 5 X 9 (2P-

1) font without decorations.

The limitations are listed below. The quality of the printed product

cannot be guaranteed if these limitations are removed and the unit

used.

[Limitations on the check high-speed printing mode]

• The only characters that can be printed are the 5 X 9 (2P-1) font

ANK characters.

• The double-sized width command cannot be used (the doublesized height command may be used.)

• The bit image command cannot be used.

• Horizontal tabs cannot be used.

• The space setting command for the space between characters

cannot be used.

• The following limitations apply for the Y direction in the printing

area (value set with <ESC>“*”...)

1 As To=0 has been fixed as the starting point for the printing

area, the printing area command set with <ESC>“*”....

Must be specified with Yo=YL=YH=0. (It will forcibly set

at 0 if it is at any other setting.)

2 The value of Dy must be a six-fold value.

As bi-directional printing in 6-pin units will be performed in

this mode, there are cases where the characters that have

been entered in a misaligned state will be printed in a wavelike style and will not be able to be distinguished when the

value of Dy is anything other than a six-fold value as a

joint will be established within a single character for return

printing.

Consequently, setting anything other than the six-fold value

must not be carried out. However, the printer will discard

any remainders from dividing by six and automatically

correct it into six-fold when any value other than six -fold has

been set.

Page 56

53

<FF>

0C

Print in page mode (only valid when in page mode)

In page mode, all page data in the page area is printed, then the

printer returns to line mode. After all the page data is printed, the data

in the page, the page print area and the print direction are all

initialized.

In addition, this command has no function in line mode.

CODE

HEX

FUNCTION

Page 57

54

Other Commands

<CAN>

18

Cancels printer buffer & Initialize printer

Clears the line buffer, and initializes the commands set already.

Does not affect the external equipment drive conditions set by the

code <ESC> <BEL> n1 n2. (This is the same during a mechanical

error.)

(Line buffer means the print data expansion area.)

If <CAN> is specified in page mode while printing using the slip

printer, printing is not carried out and the printer returns to line mode

from page mode.

In addition, <CAN> initializes the print station selection. If the slip

printer was selected, the receipt printer will be re-selected.

This command cannot recover from errors or return to the on-line

status from off-line.

<DC3>

13

Deselects printer

Deselects the printer. The printer disregards all subsequent

characters and commands except <DC1>, which activates the

printer.

<DC1>

11

Sets select mode

When the printer receives a <DC1> code, the deselect mode is

canceled and data following this code is input to the buffer.

<RS>

1E

Beeps the buzzer

Sounds a brief beep tone.

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

CODE

HEX

FUNCTION

Page 58

55

<ESC> “# N , n1n2n3n4” <LF> <NUL>

1B 23 N 2C n1n2n3n4 0A 00

Sets the memory switch. In order to enable changed memory switch

setting, turn the printer OFF and ON again or send printer reset

command (<ESC> “?”<LF><NUL>”) to the printer. Changed

memory switch settings are stored in EEPROM and these setting will

be stored as long as the time when they are changed again.

N :Memory switch number (“0”, “1”, “2”, “3”, “4”, “5”)

n1n2n3n4 :Mode settings (For details see below)

1) N=0

n1 :Always “0”

n2 :Always “0”

n3 :Always “0”

n4 :Always “0”

2) N=1 (Star mode only)

n1 :Always “0”

n2 :Always “0”

(Default)

Parameter Setting “0” “1”

n3 Zero style Normal zero Slashed zero

n4 International character

set

See below

n4 Country n4 Country n4 Country n4 Country

“0” USA “3” UK “6” Italy “9” Norway

“1” France “4” Denmark #1 “7” Spain #1 “A” Denmark #2

“2” Germany “5” Sweden “8” Japan “B” Spain #2

n4 Country

“C” Latin America

CODE

HEX

FUNCTION

Page 59

56

3) N=2

n1 :Always “0”

n2 :Always “0”

n3 :Always “0”

n4 :Always “0”

4) N=3 (Star mode only)

n1 :Always “0”

n3 :Always “0”

(Default)

5) N=4 (Star mode)

n3 :Always “0”

n4 :Always “0”

(Default)

N=4 (ESC/POS mode)

n1 :Always “0”

(Default)

Parameter Setting

“0”“1”“2”“3”

n2 Character table See below

n4 CR code Invalid Invalid Valid Valid

n2 Character table n2 Character table n2 Character table

“0” Normal “4” Code page 858 “8” Code page 863

“1” Katakana “5” Code page 852 “9” Code page 865

“2” IBM (Code page 437) “6” Code page 860 “A” Code page 866

“3” IBM (Code page 437) “7” Code page 861

Parameter Setting

“0”“1”“2”“3”

n1 X on/X off Timing When

Toggled

every 3

sec

When

Toggled

every 3

sec

RTS Signal Condition Save as

DTR

Save as

DTR

always

SPACE

always

SPACE

n2 Receive buffer size 2k bytes 2k bytes 35 bytes 35 bytes

Parameter Setting “0”“1”“2”“3”

n2 Receive buffer size 512 bytes

(TM-295)

2k bytes

(TM-290)

512 bytes

(TM-295)

2k bytes

(TM-290)

35 bytes 35 bytes

n3 DSR signal check

during setting status

transmission

Checked Checked

Not

checked

Not

checked