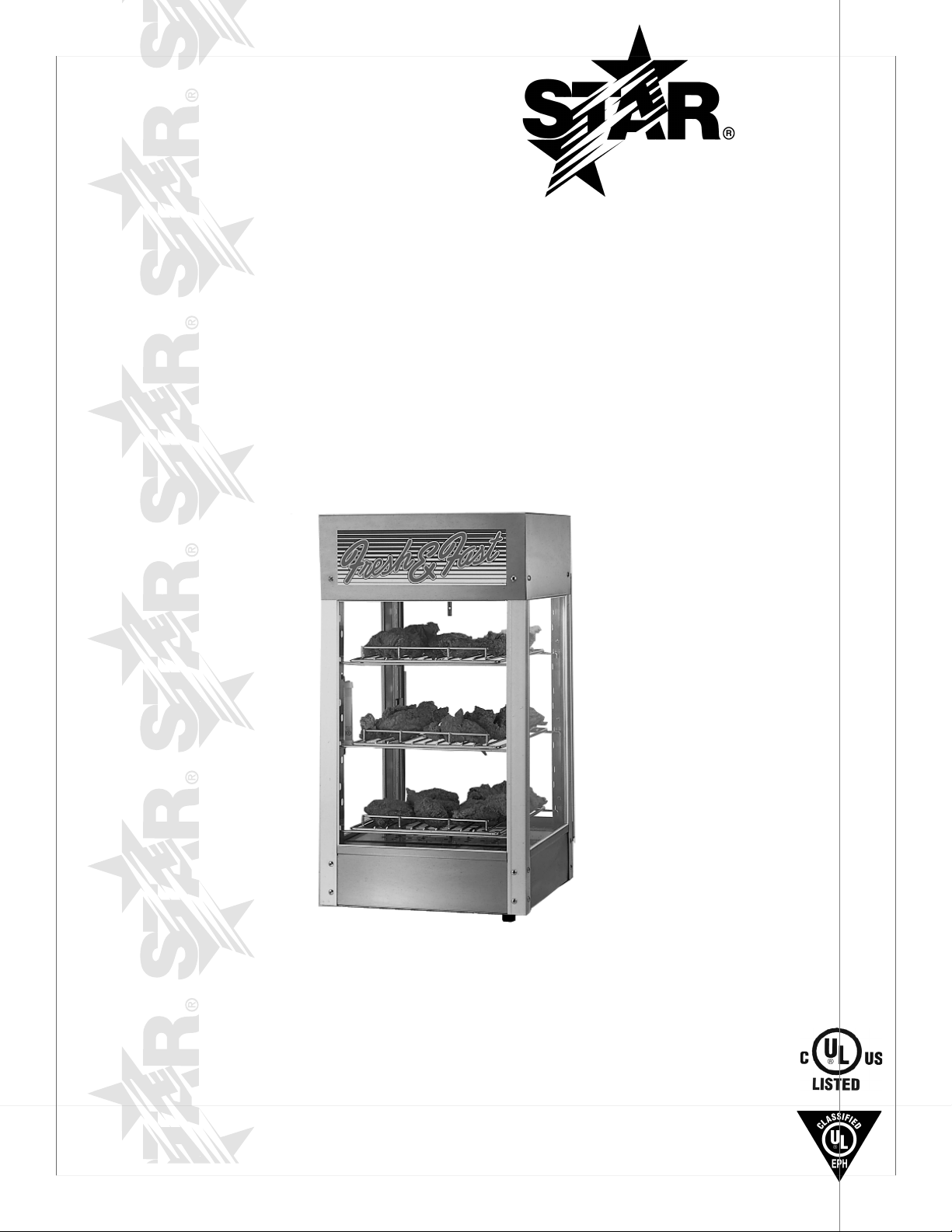

Star Manufacturing HFD-1, HFD-1-CR Parts List

HOT FOOD

HUMIDITY CABINET

MODEL

HFD-1

Installation and

Operation

Instructions

2M-Z0662 Rev. J 10/4/07

HFD-1

1

SAFETY SYMBOL

Using any part other than genuine Star factory supplied parts relieves the

manufacturer of all liability.

Star reserves the right to change specifi cations and product design without

notice. Such revisions do not entitle the buyer to corresponding changes,

improvements, additions or replacements for previously purchased

equipment.

Due to periodic changes in designs, methods, procedures, policies and

regulations, the specifi cations contained in this sheet are subject to change

without notice. While Star Manufacturing exercises good faith efforts to provide

information that is accurate, we are not responsible for errors or omissions

in information provided or conclusions reached as a result of using the

specifi cations. By using the information provided, the user assumes all risks in

connection with such use.

These symbols are intended to alert the user to the presence of

important operating and maintenance instructions in the manual

accompanying the appliance.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

NOTICE

MAINTENANCE AND REPAIRS

Contact your local authorized service agent for service or required maintenance. Please record the model

number, serial number, voltage and purchase date in the area below and have it ready when you call to

ensure faster service.

Model No.

Serial No.

Voltage

Purchase Date

Authorized Service Agent

Reference the listing provided with the unit

or

for an updated listing go to:

Website: www.star-mfg.com

E-mail Service@star-mfg.com

Telephone: (800) 807-9054 Local (314) 781-2777

The Star Service Help Desk

Business 8:00 am to 4:30 p.m. Central Standard Time

Hours:

Telephone: (800) 807-9054 Local (314) 781-2777

Fax: (800) 396-2677 Local (314) 781-2714

E-mail Parts@star-mfg.com

Service@star-mfg.com

Warranty@star-mfg.com

Website: www.star-mfg.com

Mailing Address: Star Manufacturing International Inc.

10 Sunnen Drive

St. Louis, MO 63143

U.S.A

2

2

PRODUCT IDENTIFICATION

Star Manufacturing International, Inc. Humidifi ed Cabinet

Models: HFD-1 120V, HFD-1-P 120V, HFD-1-CR 120V,

HFD-1 240V*, HFD-1-P 240V, HFD-1-CR 240V

* These models are equipped with European cord set and 240V elements.

Note: -1 = Multipurpose Shelving; -1-P = Pretzel Rack; -1-CR = Pizza Rack

All models were designed and tested to the guidelines set forth by the National Sanitation Foundation

(NSF), Standard Number 4.

SPECIFICATIONS

Capacity: 48 large pretzels/bagels (P models), three 12" (30 cm) pizzas (CR models)

3 multi-purpose shelves

Electrical: 120 volt, 50/60 hertz, single phase, 1280 watts, 10.6 amps

240 volt, 50/60 hertz, single phase, 1280 watts, 5.3 amps

Dimensions: 15"W x 15"D x 28-1/4"H

(38.1 cm W x 38.1 cm D x 71.7 cm H)

Weight: Approximately 60 lbs. (27.2 Kg)

3

OPERATING CONTROLS

4.

D

o

no

t

ru

n

dr

y

dia

l

to

d

es

ir

e

d h

u

m

idi

ty

The temperature controls are located at the top of the unit above the door and the humidity controls are

located on the bottom of the unit below the door (see Figures 1 and 2).

OPE

RAT

1.

ING I

Ad

d w

ater

NSTRUCTIONS

to

2.

pan

Ad

an

just t

3.

d ad

dia

Dr

op

jus

ain

l t

d

ial

t bo

o

and cle

to desi

des

ttom

5.

ire

an

red

4. Do not r

Co

d hu

wat

nsu

temp

er

midi

lt

pan

er

Operat

Info

atur

ty

dai

rma

e

ly

or'

u

tion on

n

s

ma

dry

nua

op

l f

erat

or

com

ing

an

plete

d cl

eani

ng.

Temperature Dial - Adjusts cabinet temperature

CAUT

ION: HOT RACKS

Do NOT Rotate Manually

1

2

3

0

4

6

5

TEMPERATURE

CONTROL

Figure 1

STAR

MA

P.O. BOX

NUFACTURING

ST. LOU

430129

63143

IS, M

INT'L INC

O

HUMI

DIT

Y CONTR

1

2

OL

0

3

LOW

4

WATER

6

5

POW

ER

Figure 2

ON/OFF Switch - Activates cabinet light, and air circulation system.

Humidity Dial - Adjusts cabinet humidity.

Low Water Indicator - Illuminates when water needs to be added.

Drain Tube - Allows the water reservoir to be emptied during cleaning.

Door Switch - Allows the rotisserie motor to rotate when the door is closed.

4

CAUTION

This equipment is designed and sold for commercial use only by personnel trained and

experienced in its operation and is not sold for consumer use in and around the home nor for

use directly by the general public in food service locations.

All shipping containers should be checked for freight damage both visible and concealed. This

unit has been tested and carefully packaged to insure delivery of your unit in perfect condition.

If equipment is received in damaged condition, either apparent or concealed, a claim must be

made with the delivering carrier.

Concealed damage or loss - if damage or loss is not apparent until after equipment is unpacked, a

request for inspection of concealed damage must be made with carrier within 15 days. Be certain

to retain all contents plus external and internal packaging materials for inspection. The carrier will

make an inspection and will supply necessary claim forms..

INSTALLATION

Each machine has been properly wired and inspected at the factory for operation on the voltage

and type of current specifi ed on the nameplate. Machines with a nameplate stamped 120V,

are equipped for operation on 120 volt 50/60 hertz AC single phase service. Machines with a

nameplate stamped 240V, are equipped for operation on 240 volt 50/60 hertz AC single phase

service. Each condition must be connected to a separate 15 amp circuit with a 3 wire grounded,

polarized receptacle.

WARNING

DO NOT CONNECT TO ANY OTHER TYPE OF CURRENT OR THE MACHINE WILL

BE SERIOUSLY DAMAGED.

The guarantee of this machine as covered by the warranty card does not apply if an improper

installation has been made.

GENERAL OPERATING INSTRUCTIONS

CAUTION

DO NOT BLOCK VENT HOLES ON TOP OF THE CABINET

1. Ensure cabinet is plugged into the proper voltage receptacle prior to turning on.

2. Fill reservoir with water (distilled preferred) such that the water is approximately

level with the top of the water reservoir (low water indicator should extinguish).

Capacity is 3/4 gallon (2.8 L).

CAUTION: DO NOT OVERFILL !

3. Follow preheat instructions on the following page. Allow approximately 15 minutes for the

machine to reach the proper temperature.

4. Monitor product temperature via the thermometer (see Figure 3).

5. Load product into the racking system. For maximum product freshness, adjust the settings as

specifi ed. Pizza and pretzel racks are adjustable for different applications using the screws

provided.

6. Periodically monitor the water level by the red indicator light on the lower

20

0

control panel. If the light is illuminated, add water (distilled preferred)

until the indicator light is no longer illuminated or to the maximum

recommended water level (see Figure 4).

°

90°

180

°

80°

160

°

70°

140°

60°

120

°

50°

100°

40°

F°

C°

CAUTION: DO NOT OVERFILL !

7. See attached sketch for instructions on reversing the door.

5

Figure 3

Loading...

Loading...