Star Manufacturing 175 Installation Manual

FOR YOUR SAFETY

Modular

In-Direct Fired

Heater

s and Inserts

Installation, Operation, and Maintenance Manual

Modular

In-

Direct

Fired

Heater

In-Direct Fired Module

Save the

se instructions

RECEIVING AND INSPECTION

WARNING!!

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. Don’t touch electrical switches.

3. Extinguish any open flames.

In-Direct Fired Furnace

4. Immediately call your gas supplier.

The use and storage of gasoline or other flammable vapors and liquids in open containers in the

vicinity of this appliance is hazardous.

Upon receiving unit, check for any interior and exterior damage, and if found, report it

immediately to the carrier. Also check that all accessory items are accounted for and are

damage free. Turn the blower wheel by hand to verify free rotation and check the damper (if

supplied) for free operation.

Improper installation, adjustment, alteration, service or maintenance can cause property

damage, injury or death. Read the installation, operating and maintenance instructions

thoroughly before installing or servicing this equipment. ALWAYS disconnect power and gas

prior to working on heater.

. This document is the property of the owner of this equipment and is

required for future maintenance. Leave this document with the owner when installation or

service is complete.

August 2009 Rev. 15

TABLE OF CONTENTS

WARRANTY ............................................................................................................................................ 3

INSTALLATION ....................................................................................................................................... 4

Mechanical .......................................................................................................................................... 4

Site Preparation .............................................................................................................................. 4

Assembly ........................................................................................................................................ 4

Curb and Ductwork ......................................................................................................................... 4

Roof Mount Installation .................................................................................................................... 5

Installation with Exhaust Fan ........................................................................................................... 5

In-Direct Fired Module Installation ................................................................................................... 6

Indoor (INLINE) Installation ............................................................................................................. 6

Indoor Flue Venting ......................................................................................................................... 7

Gas ..................................................................................................................................................... 8

Electrical ............................................................................................................................................. 9

Motorized Intake Damper ................................................................................................................ 9

Remote Control Panel ................................................................................................................... 10

Fan to Building Wiring Connection ................................................................................................. 10

OPERATION ......................................................................................................................................... 11

Start Up ............................................................................................................................................. 11

Special Tools Required ................................................................................................................. 11

Start Up Procedure ....................................................................................................................... 11

Pilot Adjustment ............................................................................................................................ 11

Main Burner Adjustment ................................................................................................................ 12

Furnace Start Up Summary ........................................................................................................... 13

Final Start Up Procedure ............................................................................................................... 14

Pulley Adjustment ......................................................................................................................... 15

Pulley Alignment ........................................................................................................................... 15

Proper Belt Tension ...................................................................................................................... 15

Pulley Combination Chart .............................................................................................................. 16

Sequence of Operation ...................................................................................................................... 16

Modulating Gas System ................................................................................................................ 16

Flame Safety Control ..................................................................................................................... 17

Operation Summary ...................................................................................................................... 17

Optional Remote Panel Circuit ...................................................................................................... 18

Components ...................................................................................................................................... 19

Remote Panel Option .................................................................................................................... 20

Troubleshooting ................................................................................................................................ 21

Airflow Troubleshooting Chart ....................................................................................................... 21

Furnace Troubleshooting Chart ..................................................................................................... 22

Remote Panel Troubleshooting Chart ............................................................................................ 23

Troubleshooting Flowcharts........................................................................................................... 24

MAINTENANCE .................................................................................................................................... 25

General Maintenance ........................................................................................................................ 25

2 weeks after startup ......................................................................................................................... 26

Every 3 months ................................................................................................................................. 26

Filter Quantity Chart ...................................................................................................................... 26

Yearly................................................................................................................................................ 26

Orifice and Gas Consumption Chart .............................................................................................. 27

Start-Up and Maintenance Documentation ........................................................................................ 28

Job Information ............................................................................................................................. 28

Heater Information ........................................................................................................................ 28

Maintenance Record ..................................................................................................................... 28

Factory Service Department .......................................................................................................... 28

3

WARRANTY

This equipment is warranted to be free from defects in materials and workmanship, under normal use and

service, for a period of 12 months from date of shipment. This warranty shall not apply if:

1. The equipment is not installed by a qualified installer per the MANUFACTURER’S installation

instructions shipped with the product,

2. The equipment is not installed in accordance with federal, state and local codes and regulations,

3. The equipment is misused or neglected,

4. The equipment is not operated within its published capacity,

5. The invoice is not paid within the terms of the sales agreement.

The MANUFACTURER shall not be liable for incidental and consequential losses and damages

potentially attributable to malfunctioning equipment. Should any part of the equipment prove to be

defective in material or workmanship within the 12-month warranty period, upon examination by the

MANUFACTURER, such part will be repaired or replaced by MANUFACTURER at no charge. The

BUYER shall pay all labor costs incurred in connection with such repair or replacement. Equipment shall

not be returned without MANUFACTURER’S prior authorization and all returned equipment shall be

shipped by the BUYER, freight prepaid to a destination determined by the MANUFACTURER.

4

INSTALLATION

CLEARANCES

IMPORTANT

It is imperative that this unit is installed and operated with the designed airflow, gas, and electrical supply

in accordance with this manual. If there are any questions about any items, please call the service

department at 1-866-784-6900 for warranty and technical support issues.

Mechanical

WARNING: DO NOT RAISE VENTILATOR BY THE INTAKE HOOD, BLOWER OR

MOTOR SHAFT, OR BEARINGS – USE LIFTING LUGS PROVIDED OR A SLING

Site Preparation

1. Provide clearance around installation site to safely rig and

lift equipment into its final position. Supports must

adequately support equipment. Refer to manufacturer’s

estimated weights.

2. Consider general service and installation space when

locating unit.

3. Locate unit close to the space it will serve to reduce long,

twisted duct runs.

4. Do not allow air intake to face prevailing winds. Support

unit above ground or at roof level high enough to prevent

precipitation from being drawn into its inlet. The inlet must

also be located at least 10 feet away from any exhaust

vents. The heater inlet shall be located in accordance

with the applicable building code provisions for ventilation

air.

Assembly

Intakes, curbs and downturn plenums are shipped unassembled.

Upon unit arrival, follow the following procedure to assemble the

intake and downturn plenum (if down discharge) to the heater.

1. Apply silicone or weather-proof gasket on the back side of

the flanges of the intake hood or v-bank intake.

2. Screw the flanges of the intake hood or v-bank to the unit with the supplied sheet metal screws.

If the unit is a modular unit with a v-bank or evaporative cooler section, the v-bank or evaporative

cooler will bolt to the heater with the bolts provided. Place caulk on the outside of the screws to

prevent water leaks.

3. If the unit is a down discharge unit, bolt

the downturn plenum to the indirect

fired module with the provided bolts.

The doors of the indirect fired module

provide access to install the bolts into

the downturn plenum. Ensure that seal

closes properly.

The top, back, and front

surfaces of this heater may not

be installed less than 6” from

combustible materials. The

heater base may be installed

on combustible surfaces.

Allow 24” minimum service

clearance on both sides of this

heater.

To prevent premature heat

exchanger failure, do not

locate any gas fired unit in

areas where chlorinated,

halogenated, or acid vapors

are present in the atmosphere.

Curb and Ductwork

This fan was specified for a specific CFM and

static pressure. The ductwork attached to this

unit will significantly affect the airflow performance. Flexible ductwork and square elbows should not be

used. Also, transitions and turns in ductwork near the fan outlet will cause system effect and will

5

Blower Size

Straight Duct Length

15 72 in.

18 86 in.

drastically increase the static pressure and

reduce airflow. The chart below shows the

minimum fan outlet duct sizes and straight

lengths recommended for optimal fan

performance. Follow SMACNA guides and

recommendations for the remaining duct

run. Fans designed for rooftop installation

should be installed on a prefabricated or factory built roof curb. Follow curb manufacturer’s instructions

for proper curb installation. The unit should be installed on a curb and/or rail elevated not less than 20”

above any surface. Be sure duct connection and fan outlet are properly aligned and sealed. Secure fan

to curb through vertical portion of the ventilator base assembly flange using a minimum of eight (8) lug

screws, anchor bolts, or other suitable fasteners (not furnished). Shims may be required depending upon

curb installation and roofing material. Check all fasteners for tightness. The diagrams below show

different mechanical installation configurations.

Recommended Supply Ductwork Sizes

10 48 in.

Roof Mount Installation

Installation with Exhaust Fan

6

In-Direct Fired Module Installation

Indoor (INLINE) Installation

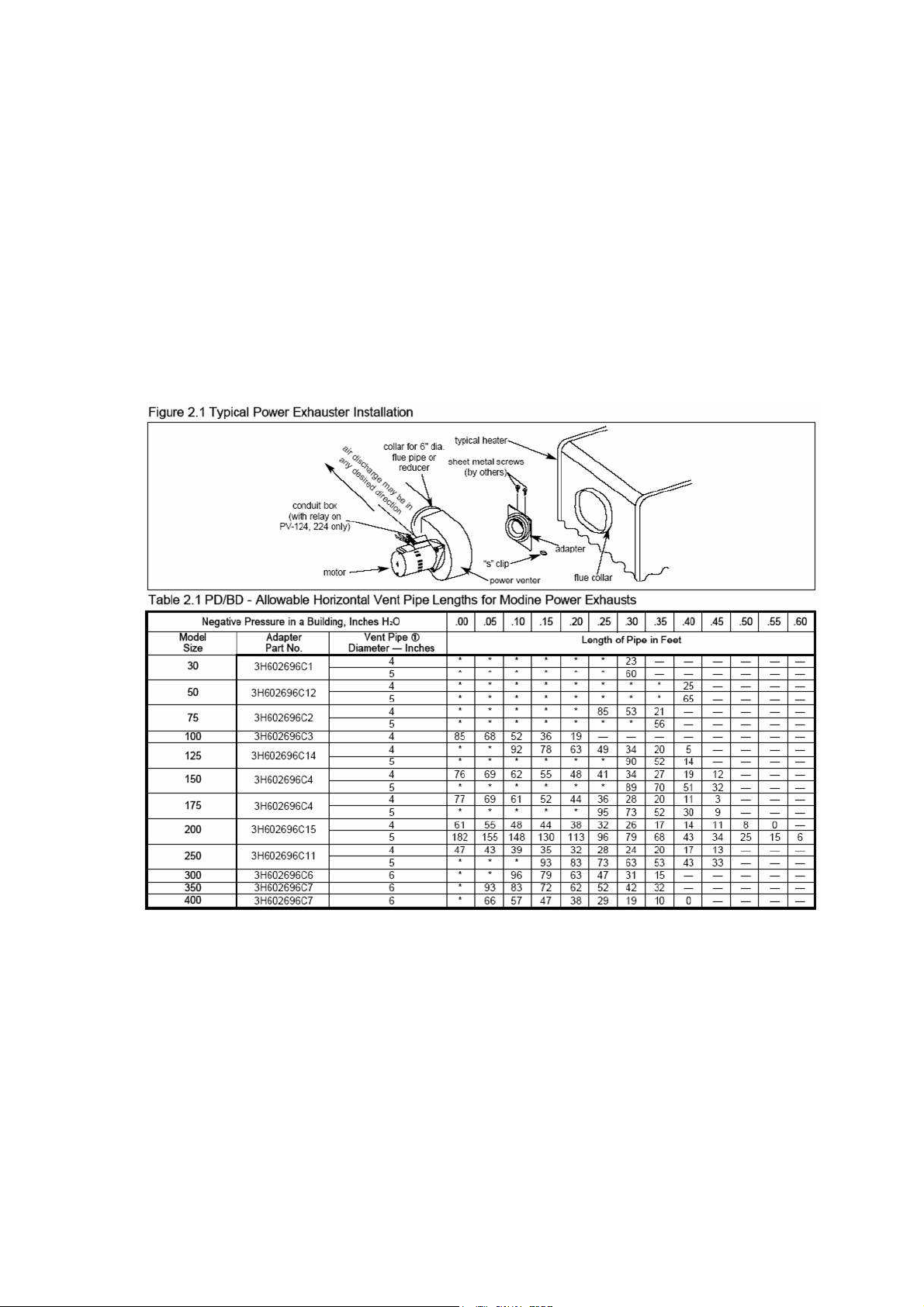

Indoor Flue Venting

Indoor gas fired heating equipment must be vented. Do not operate un-vented. Gas fired heating

equipment which has been improperly vented, or which experiences a blocked vent condition may emit

flue gases into heated spaces.

1. Installation of venting must conform with local building codes, or in the absence of local codes,

with the National Fuel Gas Code.

2. Do not use a vent pipe smaller than the size of the outlet on the heater.

3. Reference Table 2.1. Length of horizontal vent pipe should not exceed the values given in this

chart based on Model size. Install with a minimum upward slope from unit of ¼ inch per foot and

suspend from overhead structure at points no greater than 3 feet apart. For best venting, put as

much vertical vent as close to the unit as possible.

4. Fasten individual lengths of vent together with at least three corrosion resistant sheet metal

screws.

5. Vent pipes should be fitted with a tee with a drip leg and clean out tap at the low point in the vent

run. This should be inspected and cleaned out periodically during the heating season.

6. Do NOT use dampers or other devices in the vent or combustion air pipes.

7. Use a vent terminal to reduce downdrafts and moisture in the vent line.

8. When venting into a common vent, the individual vents should enter at different levels. The area

of the common vent should be equal to or greater than the area of the largest vent plus 50% of

the area of all additional vents.

August 2009 Rev. 15

8

Gas

NOTICE

Installation of gas piping must conform with local building codes, or in the absence of local codes, with the

National Fuel Gas Code, ANSI Z223.1 (NFPA 54) – latest edition. In Canada, installation must be in

accordance with CAN/CGA-B149.1 for natural gas units and CAN/CGA-B149.2 for propane units.

WARNING: INLET GAS PRESSURE MUST NOT EXCEED 14 IN. W.C. SEE UNIT

RATING PLATE FOR PROPER GAS SUPPLY PRESSURE AND GAS TYPE.

1. Always disconnect power before working on or near a heater. Lock and tag the disconnect

switch or breaker to prevent accidental power up.

2. Piping to the unit should conform with local and national requirements for type and volume of gas

handled, and pressure drop allowed in the line. Refer to the Gas Engineer’s Handbook for gas

line capacities.

3. The incoming pipe near the heater should be sized to

match the connection on the outside of the unit. Unit

inlet sizes are shown in the table to the right. Avoid

multiple taps in the gas supply so the unit has a steady

supply of gas at all times.

4. Install a ground joint union with brass seat and a

manual shut-off valve external to the unit casing, as

shown below, adjacent to the unit for emergency shut-off and easy servicing of controls.

5. Provide a sediment trap, as shown below, before each unit and where low spots in the pipe line

cannot be avoided.

6. Blow out the gas line to remove debris before making connections. Purge line to remove air

before attempting to start unit. Purging of air from gas lines should be performed as described in

ANSI Z223.1-latest edition “National Fuel Gas Code”, or in Canada in CAN/CGA-B149.

7. All field gas piping must be pressure/leak tested prior to unit operation. Use a non-corrosive

bubble forming solution or equivalent

for leak testing. The heater and its

individual shut-off valve must be

disconnected from the gas supply

piping system during any pressure

testing of that system at test

pressures in excess of ½ psi. The

heater must be isolated from the gas

supply piping system by closing its

individual manual shutoff valve

during any pressure testing of the

gas supply piping system at test pressures equal to or less than ½ psi. This must be performed

on an annual basis.

8. This unit requires a constant 7 in. w.c. minimum natural gas supply, (LP should be 11 in. w.c.

minimum) when the unit is operating at maximum gas flow. If the gas supply exceeds 14 in.

w.c. it will damage the internal valve components, and if it is below 7 in. w.c., the heater may not

perform to specifications.

Refer to the heater rating

plate for determining the

minimum gas supply

pressure for obtaining the

maximum gas capacity for

which this heater is specified.

Max. Manifold Pressure - Natural Gas 3.5 in. w.c. maximum

Max. Manifold Pressure - Propane 10 in. w.c. maximum

Min. Manifold Pressure - Natural Gas 0.56 in. w.c. maximum

Min. Manifold Pressure - Propane 1.6 in. w.c. maximum

Gas Pressure Type Gas Pressure

Inlet Pressure - Natural Gas 7 in. w.c. – 14 in. w.c.

Inlet Pressure - Propane 11 in. w.c. – 14 in. w.c.

Gas Connection Sizes

Unit Size Gas Pipe Size (NPT)

Size 1 ¾”

Size 2 1”

Size 3 1”

Gas Pressure Table

Gas Connection Diagram

9

Wire Size AWG

Maximum Amps

14 15

10 30

8 50

Electrical

WARNING!!

Before connecting power to the heater, read and understand this

entire section of this document. As-built wiring diagrams are

furnished with each fan by the factory, and are attached to the

door of the unit.

Electrical wiring and connections should be done in accordance

with local ordnances and the National Electric Code,

ANSI/NFPA70. Be sure the voltage and phase of the power

supply and the wire amperage capacity is in accordance with the

motor nameplate. For additional safety information refer to AMCA publication 410-96, Recommended

Safety Practices for Users and Installers of Industrial and Commercial Fans.

Disconnect power before

installing or servicing fan. High

voltage electrical input is

needed for this equipment. This

work should be performed by a

qualified electrician.

1. Always disconnect power before working on or near a

heater. Lock and tag the disconnect switch or breaker

to prevent accidental power up.

2. An electrical drop containing the motor power wiring is

shipped with every fan. The electrical drop should be

brought through one of the conduit openings located in

the base of the unit, run through the curb, and

connected to a junction box inside the building.

3. A dedicated branch circuit should supply the motor

circuit with short circuit protection according to the National Electric Code. This dedicated branch

should be run to the junction box mentioned above and connected as shown in a following

illustration labeled “Fan to Building Wiring Connection”.

4. Make certain that the power source is compatible with the requirements of your equipment. The

heater nameplate identifies the proper phase and voltage of the motor.

5. Units shipped with an optional remote

panel have two electrical circuit drops.

It is important to run the motor wires in

a separate conduit from the remote

control wiring. The DC wires from the

unit temperature controller, located in

the control drop, should either be

shielded cable or be run in a separate

conduit.

6. Before connecting heater to the

building power source, verify power

line wiring is de-energized.

7. Secure the power cables to prevent

contact with sharp objects.

8. Do not kink power cable and never allow the cable to come in contact with oil, grease, hot

surfaces or chemicals.

9. Before powering up the heater, check fan wheel for free rotation and make sure that the interior of

the heater is free of loose debris or shipping materials.

10. If any of the original wire supplied with the heater must be replaced, it must be replaced with type

THHN wire or equivalent.

Copper Wire Ampacity

12 20

6 65

Motorized Intake Damper

On units shipped with the optional motorized intake damper, a power transformer is supplied with the unit

if the main incoming voltage is greater than 120V. The damper motor is automatically energized when

the main disconnect switch is in the ON position. No external wiring to the damper motor is required.

Loading...

Loading...