Star Manufacturing 1000BW Installation Manual

OPERATORS MANUAL

HOLMAN WALL MOUNTED CONVEYOR TOASTERS

(MODELS 1000BW, 1100TW)

(For Service Information Call: 800-225-3958)

TABLE OF CONTENTS

UNCRATING AND INSPECTION PAGE 1

ASSEMBLY PAGE 1, 2

ELECTRICAL INSTALLATION PAGE 2

OPERATION PAGE 3

CLEANING (DAILY) PAGE 3

TROUBLE SHOOTING GUIDE PAGE 4

MAINTENANCE PROCEDURES PAGE 4, 5, 6

PARTS LIST PAGE 7

DRAWINGS

EXPLODED VIEW PAGE 8

WIRING DIAGRAM, MODEL 1100TW

(208V, 220V, 240V) PAGE 9

WIRING DIAGRAM, MODEL 1100TW,

(120/208V, 120/240V) PAGE 10

WIRING DIAGRAM, MODEL 1000BW

(120V & 208V) PAGE 11

WIRING DIAGRAM, MODEL 1000BW, (240V) PAGE 12

WIRING DIAGRAM, MODEL 1000BW, (120/208V) PAGE 13

WIRING DIAGRAM, MODEL 1000BW, (120/240V) PAGE 14

F:/MICHAEL/VAMANUALS/1000WMAN.DOC

HGO156

REV. 5/28/96 MJC

OPERATORS MANUAL

D

HOLMAN WALL MOUNTED CONVEYOR TOASTERS

(MODELS 1000BW, 1100TW)

(For Service Information Call: 800-225-3958)

UNCRATING AND INSPECTION

Unpack unit and components from container. Remove all visible packing tapes

and inspect unit for damage. If damage is discovered, file a claim immediately

with the carrier that handled the shipment.

ASSEMBLY

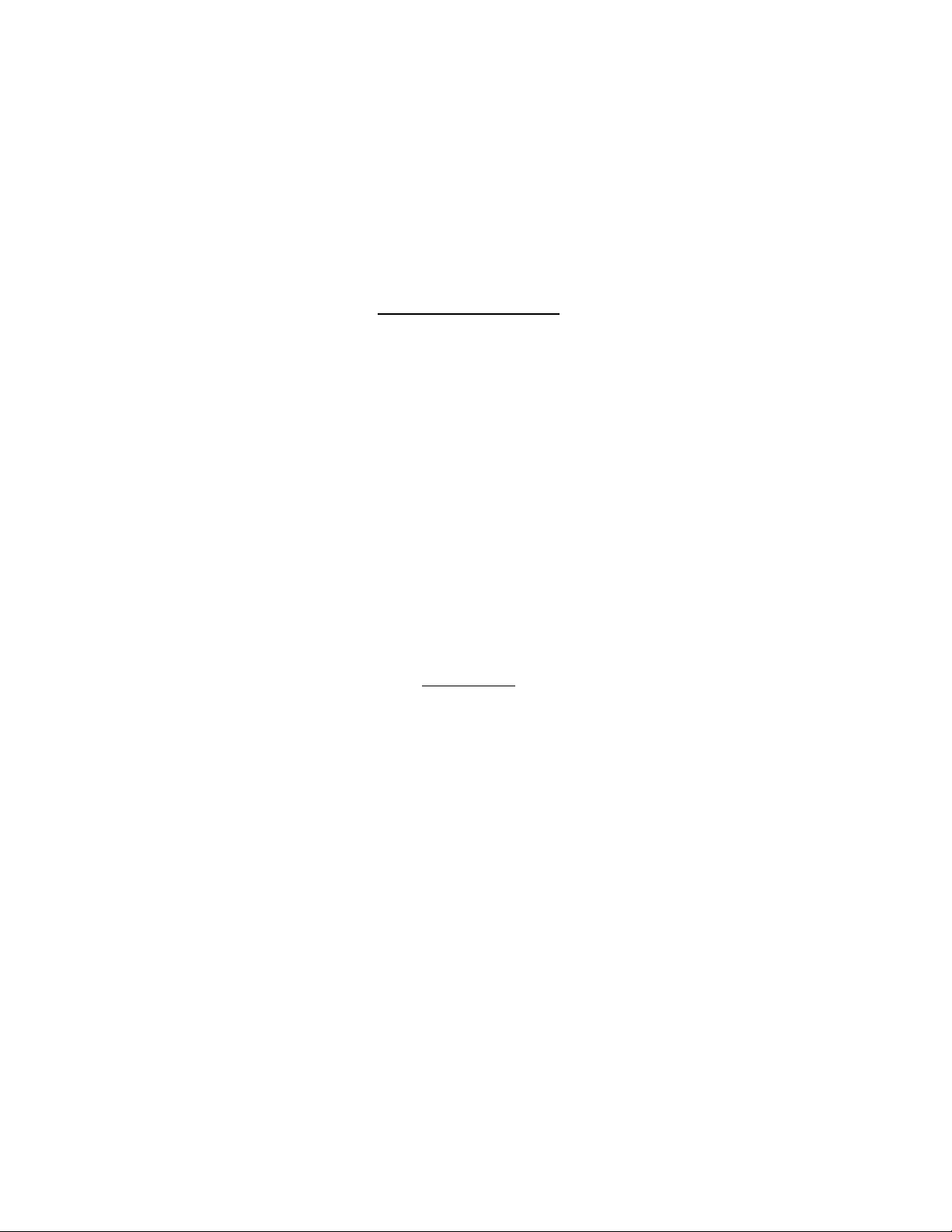

1. Wall mounted units :

a. Measure and mark mounting location on wall where toaster is to be

mounted. NOTE: Mounting bolts must be screwed into wall studs to

properly secure toaster to wall.

b. Insert the four lag bolts (provided) through the mounting holes in the top and

bottom rear of the toaster.

c. Place 1 each aluminum spacer (provided) over the threaded end of

each lag bolt.

d. Mount toaster to wall by screwing lag bolts into wall stud as shown below.

WALL

STU

PAGE 1

TOAST CHUTE

BRACKET

SPACERS

1100WALL.DS4

e. Attach the unload slide brackets to the bottom of the control box through

the pre-drilled holes using the 1/4-20 X 1/2 slotted head machine screws and the

two 1/2 inch flat washers (provided).

f. Attach the unload slide to the unload slide brackets using the 8-32 X 1/2

machine screws, the two 8-32 knurled nuts and the two #8 lock washers

(provided).

CAUTION- LOCATE UNIT SO THAT THERE IS AT LEAST 6 INCHES ON

EITHER THE LEFT OR THE RIGHT SIDE FROM ANY SURFACE.

Assembly continued on page 2

REV. 5/28/96 MJC

OPERATORS MANUAL

HOLMAN WALL MOUNTED CONVEYOR TOASTERS

(MODELS 1000BW, 1100TW)

(For Service Information Call: 800-225-3958)

Assembly Con't.

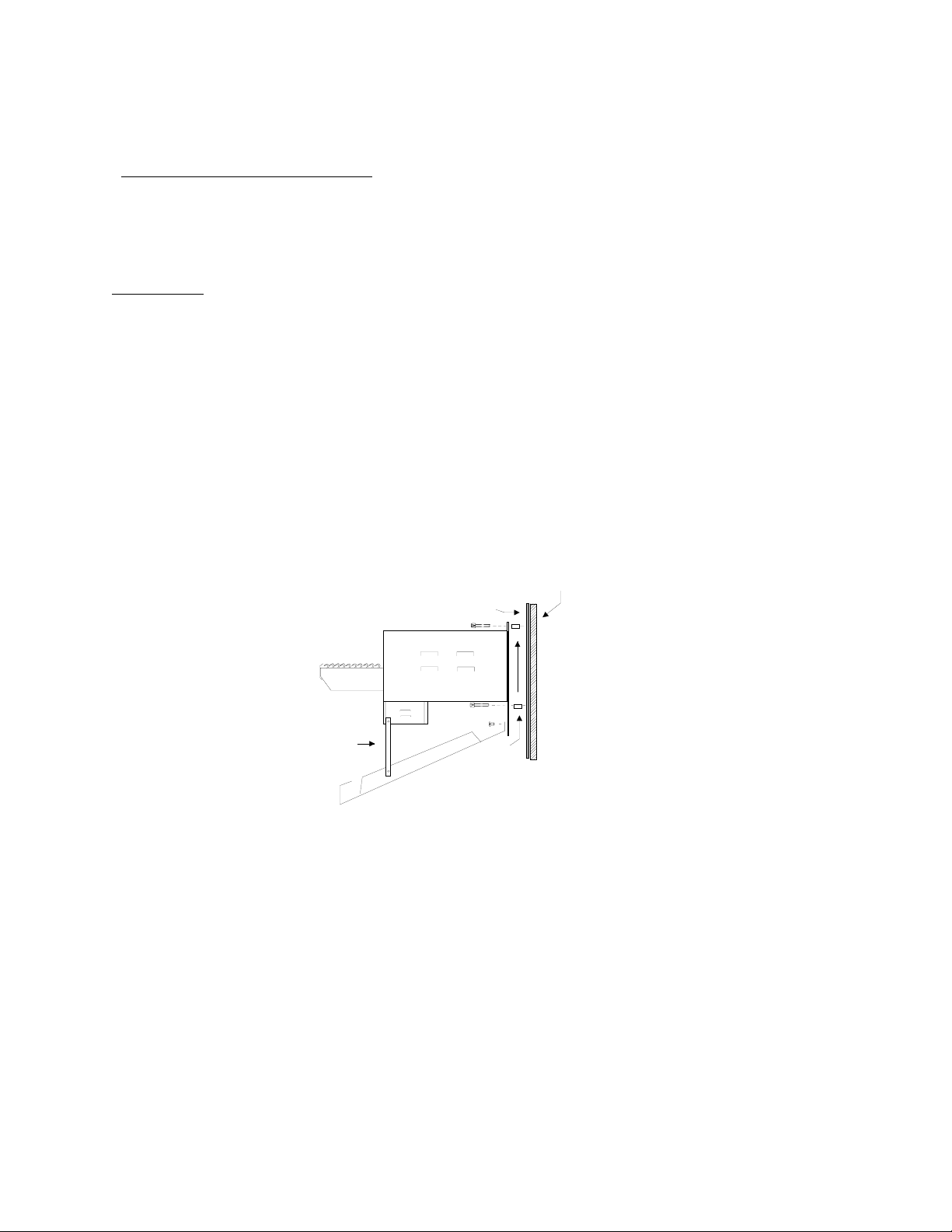

2. Conveyor Belt Installation

a. The conveyor belt should always be positioned so that the open position of

the links are facing up towards the operator as the conveyor enters the

toasting chamber.

DIRECTION OF TRAVEL

PAGE 2

1100BELT

ELECTRICAL INSTALLATION

WARNING: NEVER PLUG A 120 VOLT UNIT INTO 208 VOLTS OR 240 VOLTS.

NEVER PLUG A 208 VOLT UNIT INTO 240 VOLTS OR A 240 VOLT UNIT INTO 208

VOLTS. CHECK WITH POWER COMPANY TO DETERMINE ACTUAL VOLTAGE AT

THE JOB SITE BEFORE INSTALLING UNIT.

WARNING:

RECEPTACLE IS PROPERLY WIRED. NEVER CONNECT UNIT TO POWER

WITHOUT PROPER GROUND CONNECTIONS. IMPROPER GROUND

CONNECTION MAY RESULT IN SEVERE INJURY OR FATALITY.

1. The electrical potential between the white lead and the black lead on units rated

120/208 or 120/240 must not exceed 127 volts or damage will occur to the drive

motor.

The models 1000BW and 1100TW, are furnished with a 18" cord and standard NEMA 6-20 plug for

plug in installation in a grounded 208 or 240 volt outlet. Your HOLMAN oven should be the only

appliance connected to the electrical line and should have its own fuse or breaker in the electrical box.

120V 1000BW is furnished with a 18" cord and a NEMA 5-20 plug for plug in installation in a grounded

120 volt, 20 amp outlet.

REV. 5/28/96 MJC

BE ABSOLUTELY SURE THE GROUND CONNECTION FOR THE

PAGE 3

OPERATORS MANUAL

HOLMAN WALL MOUNTED CONVEYOR TOASTERS

(MODELS 1000BW, 1100TW)

(For Service Information Call: 800-225-3958)

OPERATION

1. Bread Toasting, Model 1100TW.

a. Switch the top and bottom heat switches to the ON position.

b. Allow warm up time of about 5 to 10 minutes.

c. Test with a slice of bread.

1. If toast is too light, turn the conveyor speed control counterclockwise.

2. If toast is too dark, turn the conveyor speed control clockwise.

2. Bun Toasting, Model 1000BW.

a. Buns should be placed on the belt with the side to be toasted facing up.

b. Allow 5 to 10 minutes warm up time.

c. Test as in step "C" above.

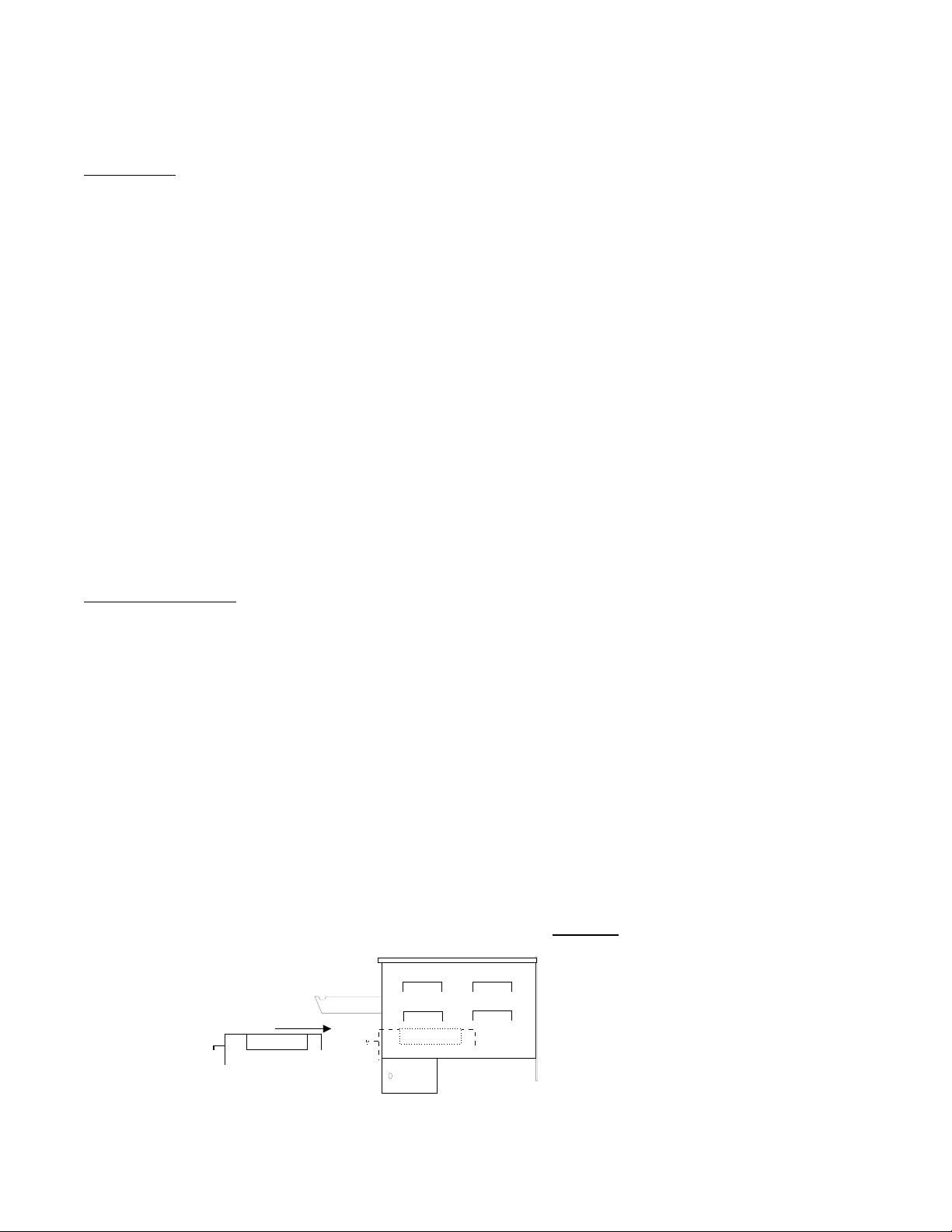

CLEANING (DAILY)

1. Move heat switches to the OFF position.

2. Turn conveyor speed control to the fastest setting (100) and wipe the

conveyor belt with a damp cloth as it moves across the load up area.

3. Turn the conveyor speed control to the off position.

4. After the unit cools, remove the interior crumb tray and wipe clean. Slide the

crumb tray back into position. DO NOT OPERATE THIS UNIT WITHOUT THE

CRUMB TRAY PROPERLY IN POSITION. (THIS CAUSES EXTREME HEAT

IN THE CONTROL BOX AND WILL REDUCE THE LIFE OF THE

COMPONENTS).

5. Wipe exterior of unit.

NOTE- THE CONVEYOR BELT AND DRIVE MOTOR DO NOT

REQUIRE LUBRICATION.

CRUMB TRAY

1100CTRY.DS4

REV. 5/28/96 MJC

OPERATORS MANUAL

HOLMAN WALL MOUNTED CONVEYOR TOASTERS

(MODELS 1000BW, 1100TW)

TROUBLE SHOOTING GUIDE

1. UNIT WILL NOT HEAT, CONVEYOR WILL NOT TURN.

a. Check to see if unit is connected to power source and switches are in the "ON"

position.

b. Check main panel circuit breaker or fuse.

2. UNIT WILL NOT HEAT UP BUT CONVEYOR TURNS.

a. Check to see if heaters are switched on.

b. *Check for defective heat switch.

c. *Check heaters for continuity.

Note: *It is suggested that a service technician perform the function noted.

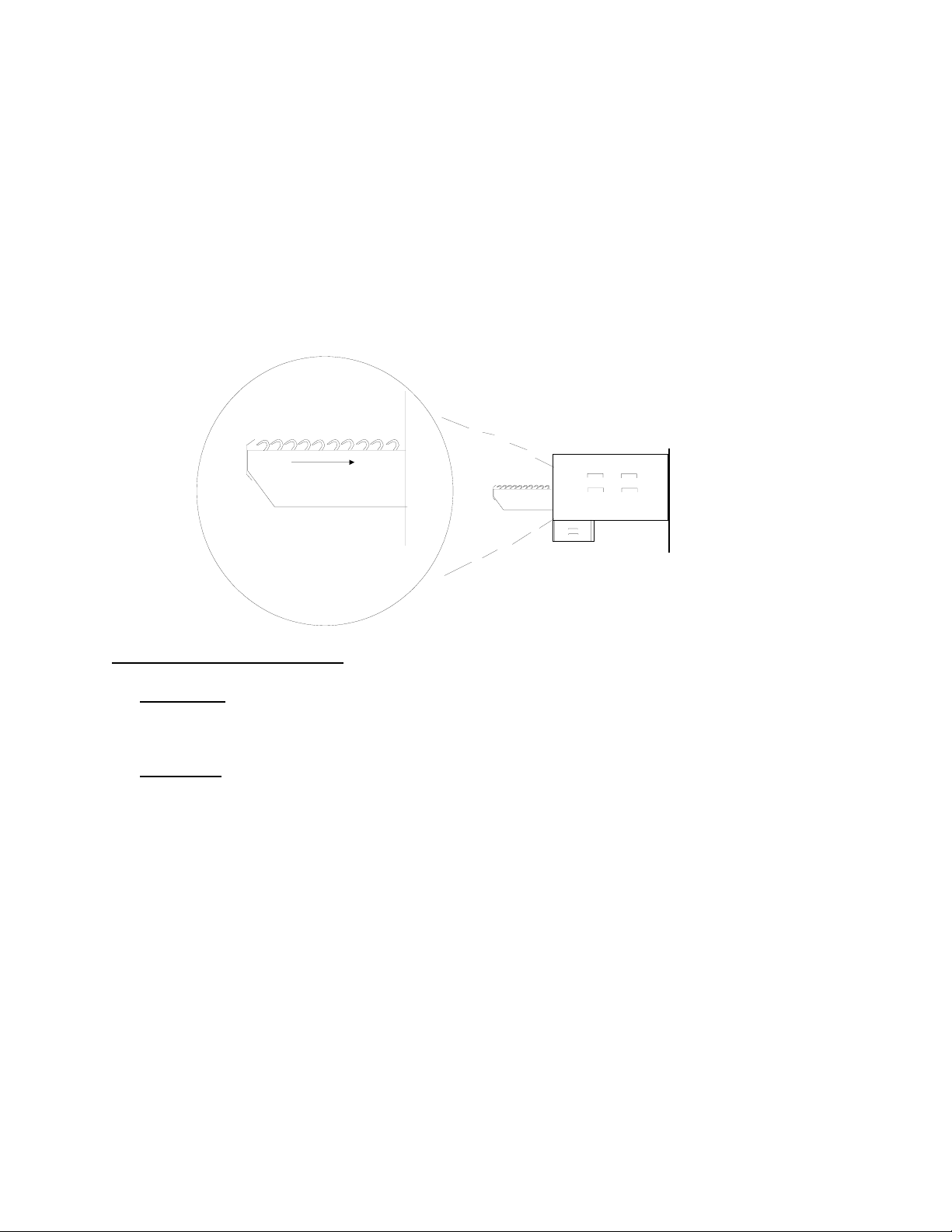

3. CONVEYOR WILL NOT TURN, UNIT HEATS PROPERLY.

a. Remove lower right hand side panel and motor sprocket. Recheck to see if the

motor will run. If motor runs, check the conveyor chain and the bearings for

binding; if the motor does not run, disconnect unit from power and remove front control

panel. Find the small fan blade attached to the rotor on the drive motor. The rotor

should spin freely when the fan blade is turned. If it does not turn freely, tap the

black portion (stack) of the drive motor with the handle of a screw driver and spin the

rotor again. If motor will not work when power is applied, call the Holman Factory Service

Department at 1-800-225-3958 for service assistance.

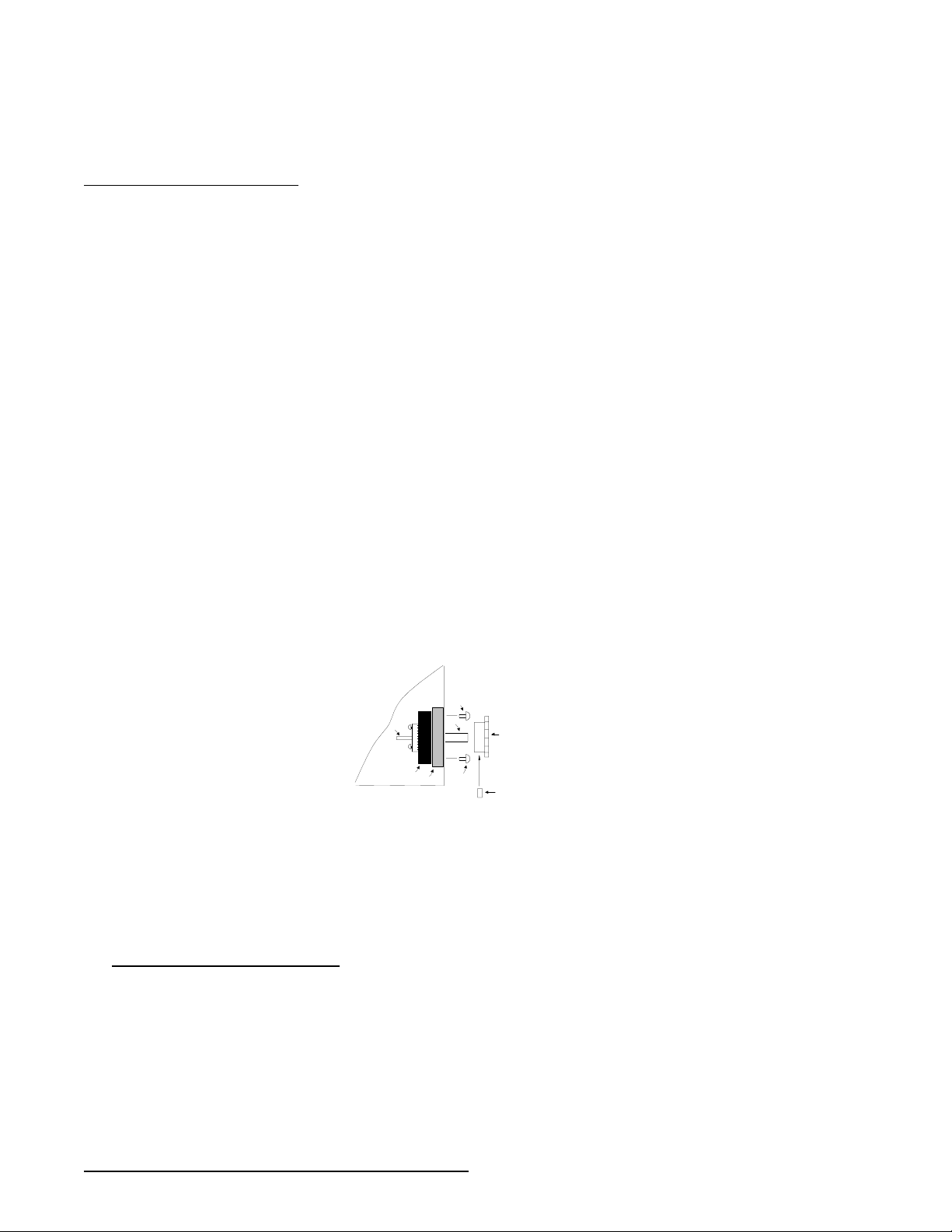

CUT AWAY VIEW OF CONTROL BOX

1- ROTOR

2- FIELD/STACK

3- GEAR BOX

4- MOUNTING SCREW

5- DRIVE SPROCKET

6- MOTOR SHAFT

7- SET SCREW

(For Service Information Call: 800-225-3958)

4

1

6

5

PAGE 4

2

DRVMTR.WMF

4

3

7

4. DRIVE MOTOR RUNS AT ONE SPEED REGARDLESS OF THE SPEED CONTROL

SETTINGS.

a. Call Holman Cooking Equipment's Service Department as the speed control

should be replaced.

MAINTENANCE PROCEDURES

1. REPLACING HEATER TUBES

CAUTION : DISCONNECT UNIT FROM POWER.

a. Remove right and left side panels by removing top cover then sliding both

panels to the front of the unit.

b. Disconnect heater tube wires which require replacement from terminal

block connections.

MAINTENANCE PROCEDURES CONTINUED PAGE 5 REV. 5/28/96 MJC

Loading...

Loading...