Sta-Rite THS 4272 Installation Manual

PENTAIR POOL PRODUCTS

THS SERIES FILTER

BUTTERFLY VALVE STYLE

FACE PIPING INSTALLATION

INSTRUCTIONS

This manual covers installation and operating instructions for the optional butterfly valve style

face piping kits for use with the THS series filter vessels.

WARNING: This manual contains critical safety information that must be furnished to the end

user. Failure to read and follow the instructions could result in serious personal injury and/or

major property damage.

Pentair Pool Products

1620 Hawkins Ave.

Sanford, NC 27330

Phone: 919-774-4151

Fax: 919-774-4841

TABLE OF CONTENTS

1.0 PRINCIPALS OF OPERATION 2

1.1 SINGLE TANK NORMAL OPERATION 2

1.2 SINGLE TANK DURING BACKWASH 2

1.3 DUAL TANK NORMAL OPERATION 3

1.4 DUAL TANK DURING BACKWASH 3

2.0 FACE PIPING INSTALLATION 3

2.1 SINGLE TANK FACE PIPING INSTALLATION – THS 3461 (4”- GROOVED TANK

CONNECTIONS) 4

2.2 SINGLE TANK FACE PIPING INSTALLATION – THS 3484, THS 4272, THS 4284 AND THS

4296 (6” FLANGE TANK CONNECTIONS) 8

2.3 DUAL TANK FACE PIPING INSTALLATION -THS 3461 (4”- GROOVED TANK

CONNECTIONS) 11

2.4 DUAL TANK FACE PIPING INSTALLATION – THS 3484, THS 4272, THS 4284 AND THS

4296 (6” FLANGE TANK CONNECTIONS) 15

2.5 INFLUENT/EFFLUENT GAUGE PANEL INSTALLATION 19

3.0 OPERATION INSTRUCTIONS 20

3.1 NORMAL FILTRATION MODE 21

3.2 SWITCHING SYSTEM TO BACKWASH MODE 22

3.2.1 Single Tank System With Influent Piping on Right of Tank 22

3.2.2 Single Tank System With Influent Piping on Left of Tank 23

3.2.3 Dual Tank System With Influent Piping on Right of Tank 24

3.2.4 Dual Tank System With Influent Piping on Left of Tank

25

APPENDIX 26

APPENDIX A 27

APPENDIX B 28

Butterfly Valve Face Piping Kit Installation Manual Pg. 1 of 28

1/9/06 Rev. D

Thank you for purchasing the butterfly valve style face piping kit for your THS series filter

vessel. This kit includes features such as pre-glued subassemblies for ease of assembly and

simple operation of valves for switching to backwash mode.

This manual covers the installation and operation of face piping kits for both one and two

tank filter systems. This manual also includes a trouble-shooting guide to assist with some

typical problems which may occur during operation. If you should have any questions pertaining

to the filter tank itself, please refer to the separate manual provided for the tanks.

Please remember to use proper safety equipment and techniques when installing this

filtration system.

1.0 Principals of Operation

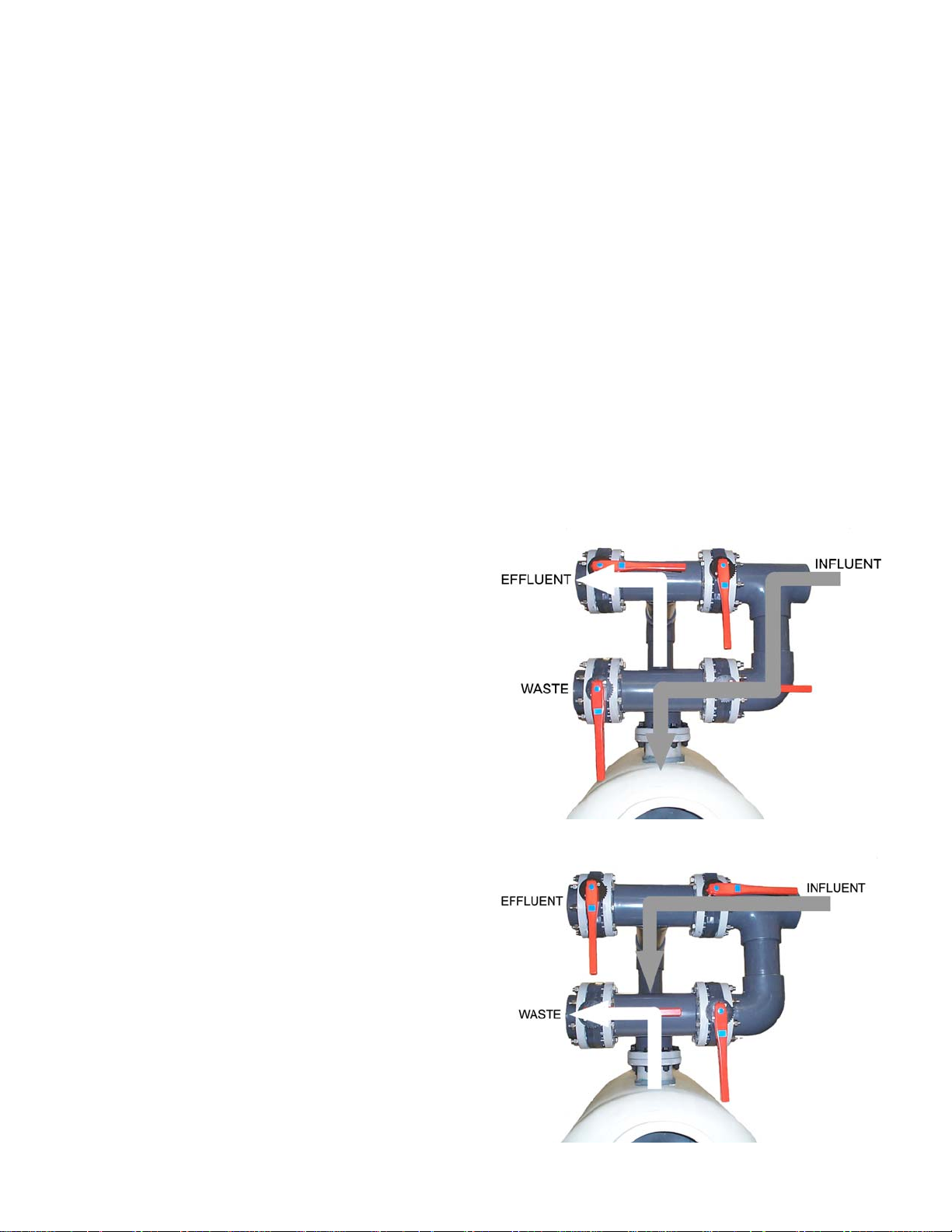

This section will familiarize you with how the face piping kit and valves work in order to

provide a means of backwashing the filter. It will cover the flow of water in a single tank system in

normal filtration and backwash modes, and a dual tank system in normal filtration and backwash

modes. Please note that the gray arrows represent influent water flow and white arrows

represent effluent/waste water flow.

1.1 Single Tank Normal Operation

During normal filtration mode, water is

passed through the influent piping and into

the tank. Water is then passed through the

sand, where the filtration process occurs. It is

then passed through the collection laterals at

the bottom of the tank. It then passes out of

the effluent pipe and continues through the

rest of the system.

1.2 Single Tank During Backwash

During backwash mode, the butterfly valves are

actuated so that a backwash cycle can be run.

Since water cannot enter the tank through the

influent piping, it enters through the effluent

piping. The water is pushed up through the sand

bed, which causes the sand bed to fluidize. This

loosens dirt and debris trapped by the sand.

This debris is then passed through the influent

piping and exits through a waste pipe.

Butterfly Valve Face Piping Kit Installation Manual Pg. 2 of 28

1/9/06 Rev. D

1.3 Dual Tank Normal Operation

During normal operation in a dual tank

system, water is split between the two

tanks. It passes through the influent piping

and then through the sand beds. It is then

passed through the collection laterals at

the bottom of the tanks and passed out of

the effluent piping and returned to the pool.

1.4 Dual Tank During Backwash

During backwash mode in a dual tank

system, the butterfly valves are actuated

so that a backwash cycle can be run.

Since water cannot enter the tanks

through the influent piping, it enters

through the effluent piping. The water is

pushed up through the sand beds, which

is called “Fluidizing” the sand beds. This

loosens dirt and debris trapped by the

sand. This debris is then passed through

the influent piping and exits through a

waste pipe. On a dual tank system, both

tanks backwash simultaneously.

2.0 Face Piping Installation

IMPORTANT: Installation of the face piping should occur after the filter vessels have been

positioned in their permanent location. Please refer to the Tank Owner’s/Operator’s

Manual section on locating the filter vessels. For dual tank systems, it is very important

that the “C-C” dimension listed in Figure 1 on page 5 of that manual is followed. Please

refer to the Tank Owner/Operators Manual for more information.

Butterfly valve face piping kits come in either one or two tank kits. The piping kits come

with pre-glued subassemblies. This means that some sections of the kit will require gluing by the

installer. For single tank systems there will be 2 glue joints required, dual tank systems will

require 8 glue joints. All other connections that need to be made are flanged or grooved coupli ng

connections between mating sections. Please refer to the appropriate drawings in the Appendix

section at the end of this manual for aid in assembly.

IMPORTANT: When tightening flange bolts, it is important to follow a diametrically

opposed pattern. This will ensure that a proper seal between the flanges is obtained.

Refer to Figure 1 (next page) for proper tightening sequence. Torque all bolts to a

Butterfly Valve Face Piping Kit Installation Manual Pg. 3 of 28

1/9/06 Rev. D

maximum of 40 ft-lbs. Also, it may be beneficial to apply a teflon based lubricant to each

bolt or nut to help relieve stress due to friction.

2.1 Single Tank Face Piping Installation – THS 3461 (4”- Grooved Tank

Connections)

The single tank face piping kit consists of:

(4) Butterfly valves (1) Set of Mounting Brackets and Hardware

(1) Subassembly “A” (32) Zinc plated nuts

(1) Subassembly “B1” (2) 4” Groove Coupling Assembly

(1) Subassembly “B2” (32) 6” Zinc plated bolts

(1) Subassembly “C” (64) Zinc plated washers

(1) 90° Elbow Fitting (32) Lock washers

(2) Socket flange (2) 3/8” OD x ¼” MNPT quick connect fitting

(1) Gauge panel assembly 3/8” OD tubing (not shown)

Prior to installation see “Grooved Coupling Assembly instruction” found on page 5.

Butterfly Valve Face Piping Kit Installation Manual Pg. 4 of 28

1/9/06 Rev. D

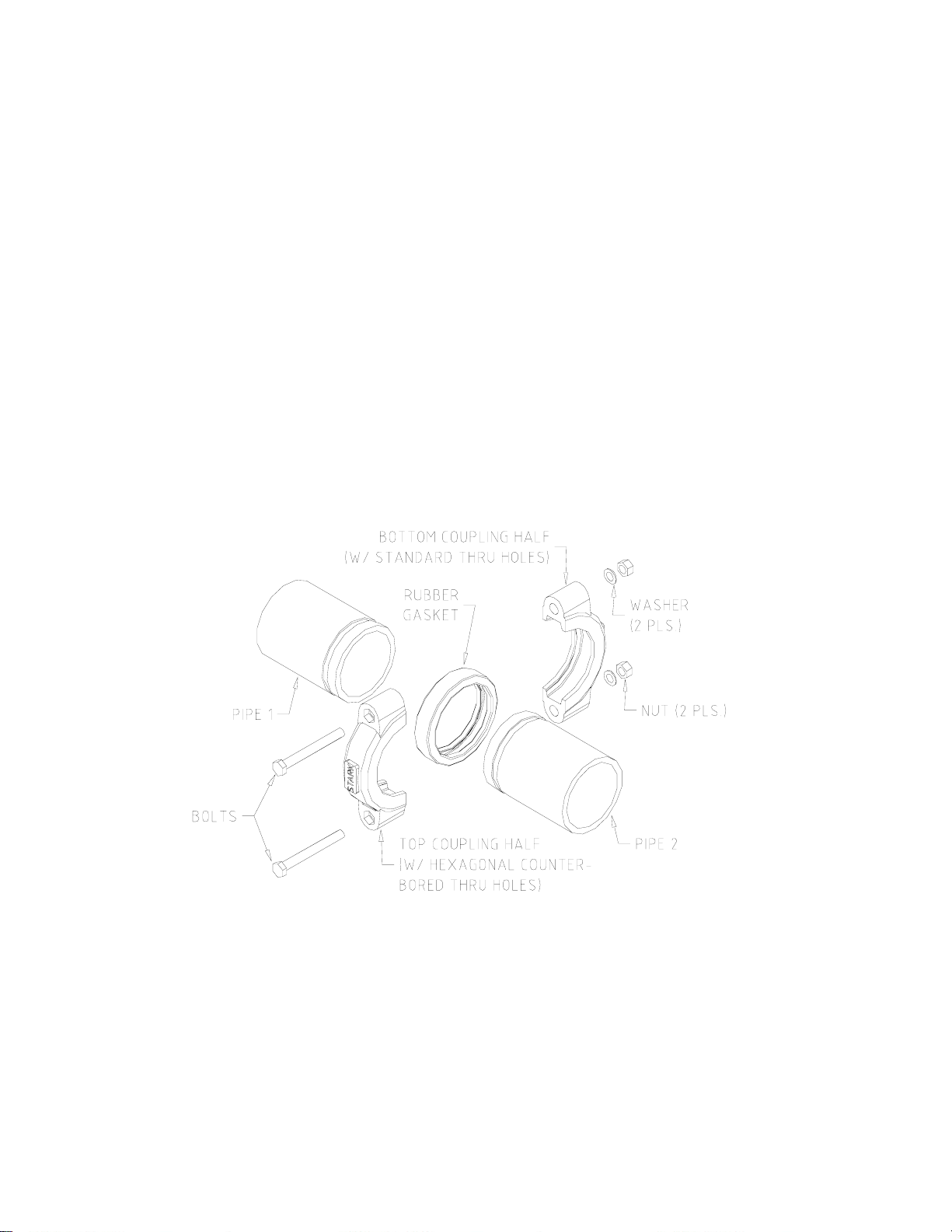

Grooved Coupling Assembly Instruction

1) Seat rubber gasket over end of pipe 1, making sure that the gasket does not cover the

groove cut in the pipe.

2) Insert end of pipe 2 into rubber gasket, again making sure that the gasket does not cover the

groove in the pipe.

3) Fit coupling halves over rubber gasket making sure that coupling halves are seated into the

grooves of the (2) pipes. Make sure one coupling half has standard thru bolt holes and the

other has hexagonal counter-bored thru bolt holes.

Apply an anti-seize lubricant to the threads of the coupling bolts. Insert bolts into the holes in th e coupling,

making sure that the bolt heads fit inside the hexagonal counter-bored holes on one side of the coupling.

Place one washer and nut on each bolt and tighten.

Butterfly Valve Face Piping Kit Installation Manual Pg. 5 of 28

1/9/06 Rev. D

STEP 1: Influent Subassembly Installation

With gasket of Groove coupling assembly installed on influent

tank grooved pipe connection, Place Subassembly “C” on to

pipe connection, install groove coupling assembly. See

picture at right for proper orientation. Snug the nuts to “hand

tight”, but do not fully tighten. This will allow for adjustments

during the remainder of the installation.

STEP 2: Effluent piping installation

With gasket of Groove coupling assembly installed on effluent tank

pipe connection, Place Subassembly “B1” on to pipe connection,

install groove coupling assembly. See picture at right for proper

orientation. Snug the nuts to “hand tight”, but do not fully tighten.

This will allow for adjustments during the remainder of the

installation.

Place 90° elbow on top of effluent pipe, but DO NOT GLUE. Next

place Subassembly “B2” into elbow, again DO NOT GLUE. Level

the front faces of both tees on the influent and effluent assemblies.

Also ensure that the tee on the effluent piping is level horizontally.

Next, verify that the vertical dimension between the centerlines of

both tees is 17 ¼”. In some cases adjustments or trimming of pipes

may be needed. Once the piping is in its correct position, mark all

of the piping as needed for trimming and gluing. Remove all

components of the effluent assembly from the tank. Make any

necessary trims at this time if needed. Glue all of the pieces

together making sure to align all marks made previously. Use

PVC cement for use with schedule 80 pipe. Please follow the

cement manufacturer’s directions. Once assembly is glued and

allowed ample time to cure, refit the effluent assembly on to the

tank. Re-Install groove coupling assembly on the effluent flange.

Snug the nuts to “hand tight”, but do not fully tighten. This will

allow for adjustments during the remainder of the installation.

Butterfly Valve Face Piping Kit Installation Manual Pg. 6 of 28

1/9/06 Rev. D

STEP 3: Influent Extension Installation

Install valves on the two flanges on the side of the tank

that the influent piping will be coming from. Orient them

so that when the valves are in the closed position, the

handles are pointing down towards the ground. This

means that the valve handles will rotate counter

clockwise to open. Install the Subassembly “A” on to

the appropriate side of the tank, depending on where

the influent piping is coming from. It may be necessary

to rotate the influent and effluent subassemblies slightly

to properly align Subassembly “A”. Install the 6” zinc

plated bolts, washers, and lock washers on to the two

flanges. Snug the nuts to “hand tight”, but do not fully

tighten.

STEP 4: Effluent/Waste Flange Installation

On the remaining two flanges install the remaining two

valves. Again, orient them so that when the valves are in

the closed position, the handles are pointing down

towards the ground. The means that all of the valve

handles will rotate counter clockwise to open. Install the

socket flanges provided on to each valve. Install the 6”

zinc plated bolts, washers, and lock washers on to the

two flanges. Snug the nuts to “hand tight”, but do not fully

tighten.

STEP 5: Final Adjustments

Once all piping is in place, make necessary adjustments and fully tighten all flange bolts and

groove coupling assemblies. For flange connection be sure to follow the tightening pattern

explained at the beginning of Section 2.0. Tighten all bolts to a maximum of 40 ft-lbs.

Note: All piping should be fully supported with adequate bracing and hangers to

prevent damage from weight and vibration.

Butterfly Valve Face Piping Kit Installation Manual Pg. 7 of 28

1/9/06 Rev. D

2.2 Single Tank Face Piping Installation – THS 3484, THS 4272, THS 4284

and THS 4296 (6” Flange Tank Connections)

The single tank face piping kit consists of:

(4) Butterfly valves (1) Set of Mounting Brackets and Hardware

(1) Subassembly “A” (48) zinc plated nuts

(1) Subassembly “B1” (16) 4” zinc plated bolts

(1) Subassembly “B2” (32) 7” zinc plated bolts

(1) Subassembly “C” (96) zinc plated washers

(2) 90° Elbow Fitting (48) lockwashers

(3) Flange gaskets (2) 3/8” OD x ¼” MNPT quick connect fitting

(2) Socket flange 3/8” OD tubing (not shown)

(1) Gauge panel assembly

Butterfly Valve Face Piping Kit Installation Manual Pg. 8 of 28

1/9/06 Rev. D

STEP 1: Influent Subassembly Installation

Place a flange gasket on the influent tank

flange. Align the holes in the gasket with the

holes of the flange ring on the tank. Place

Subassembly “C” on to flange, making sure to

align the bolt holes on the tank flange and the

subassembly. See picture at right for proper

orientation. Install 4” zinc plated bolts, nuts,

washers, and lockwashers on the influent

flange. Snug the nuts to “hand tight”, but do

not fully tighten. This will allow for adjustments

during the remainder of the installation.

STEP 2: Effluent piping installation

Place a flange gasket on the effluent tank flange.

Align the holes in the gasket with the holes of the

flange ring on the tank. Place subassembly “B1” on

to the effluent tank flange, making sure to align the

bolt holes of the tank flange and the subassembly.

Install 4” zinc plated bolts, nuts, washers, and

lockwashers on the efffluent flange. Snug the nuts to

“hand tight”, but do not fully tighten.

Place 90° elbow on top of effluent pipe, but DO

NOT GLUE. Next place Subassembly “B2” into

elbow, again DO NOT GLUE. Level the front faces

of both tees on the influent and effluent assemblies.

Also ensure that the tee on the effluent piping is

level horizontally. Next, verify that the vertical

dimension between the centerlines of both tees is

19 ¾”. In some cases adjustments or trimming of

pipes may be needed. Once the piping is in its

correct position, mark all of the piping as needed

Butterfly Valve Face Piping Kit Installation Manual Pg. 9 of 28

1/9/06 Rev. D

for trimming and gluing. Remove all components of the effluent assembly from the tank. Make

any necessary trims at this time if needed. Glue all of the pieces together making sure to align all

marks made previously. Use PVC cement for use with schedule 80 pipe. Please follow the

cement manufacturer’s directions. Once assembly is glued and allowed ample time to cure, refit

the effluent assembly on to the tank. Make sure that the flange gasket is placed back between

the flange connection on the effluent pipe from the tank. Re-Install zinc plated hardware on the

effluent flange. Snug the nuts to “hand tight”, but do not fully tighten. This will allow for

adjustments during the remainder of the installation.

STEP 3: Influent Extension Installation

Install valves on the two flanges on the side of the tank that the

influent piping will be coming from. Orient them so that when the

valves are in the closed position, the handles are pointing down

towards the ground. This means that the valve handles will rotate

counter clockwise to open. Install the Subassembly “A” on to the

appropriate side of the tank, depending on where the influent

piping is coming from. It may be necessary to rotate the influent

and effluent subassemblies slightly to properly align Subassembly

“A”. Install the 7” zinc plated bolts, washers, and lock washers

on to the two flanges. Snug the nuts to “hand tight”, but do not

fully tighten.

STEP 4: Effluent/Waste Flange Installation

On the remaining two flanges install the remaining two valves.

Again, orient them so that when the valves are in the closed

position, the handles are pointing down towards the ground.

The means that all of the valve handles will rotate counter

clockwise to open. Install the socket flanges provided on to

each valve. Install the 7” zinc plated bolts, washers, and lock

washers on to the two flanges. Snug the nuts to “hand tight”,

but do not fully tighten.

STEP 5: Final Adjustments

Once all piping is in place, make necessary adjustments and

fully tighten all flange bolts. Be sure to follow the tightening

pattern explained at the beginning of Section 2.0.

Tighten all bolts to a maximum of 40 ft-lbs.

Note: All piping should be fully supported with

adequate bracing and hangers to prevent damage

from weight and vibration.

Butterfly Valve Face Piping Kit Installation Manual Pg. 10 of 28

1/9/06 Rev. D

Loading...

Loading...