PENTAIR POOL PRODUCTS

THS SERIES FILTER

DIAPHRAGM VALVE STYLE

FACE PIPING INSTALLATION

INSTRUCTIONS

This manual covers installation and operating instructions for the optional diaphragm valve style

face piping kits for use with the THS series filter vessels.

WARNING: This manual contains critical safety information that must be furnished to the end

user. Failure to read and follow the instructions could result in serious personal injury and/or

major property damage.

Pentair Pool Products

1620 Hawkins Ave.

Sanford, NC 27330

Phone: 919-774-4151

Fax: 919-774-4841

TABLE OF CONTENTS

PRINCIPALS OF OPERATION 2

1.0

1.1 DIAPHRAGM VALVE OPERATION 2

1.2 SINGLE TANK NORMAL OPERATION 2

1.3 SINGLE TANK DURING BACKWASH 3

1.4 DUAL TANK NORMAL FILTRATION 3

1.5 DUAL TANK DURING BACKWASH 3

2.0 FACE PIPING INSTALLATION 4

2.1 SINGLE TANK FACE PIPING INSTALLATION – THS 3461 (4” GROOVED CONNECTIONS) 4

2.2 SINGLE TANK FACE PIPING INSTALLATION – THS 3484, THS4272, THS 4284 AND THS

4296 (6” FLANGE CONNECTIONS) 9

2.3 DUAL TANK FACE PIPING INSTALLATION – THS 3461 (4” GROOVED TANK

CONNECTIONS) 12

2.4 DUAL TANK FACE PIPING INSTALLATION – THS 3484, THS4272, THS 4284 AND THS

4296 (6” FLANGE CONNECTIONS) 15

3.0 BACKWASH CONTROLLER INSTALLATION 19

3.1 SINGLE TANK SEMI-AUTOMATIC CONTROLLER INSTALLATION 19

3.2 DUAL TANK SEMI-AUTOMATIC CONTROLLER INSTALLATION 23

3.3 SINGLE TANK AUTOMATIC CONTROLLER INSTALLATION 27

3.4 DUAL TANK AUTOMATIC CONTROLLER INSTALLATION 30

4.0 OPERATION 33

4.1 SETTING THE MULTIPORT PRESSURE 33

4.2 WHEN TO BACKWASH 33

4.3 SEMI-AUTOMATIC CONTROLLER OPERATION 33

4.3.1 Controller Overview 33

4.3.2 Switching to Backwash Mode 34

4.4 AUTOMATIC CONTROLLER 36

APPENDIX 37

APPENDIX A 38

APPENDIX B 39

APPENDIX C 40

APPENDIX D 41

Diaphragm Valve Face Piping Kit Installation Manual Pg. 1 of 47

1/16/05 Rev. D

Thank you for purchasing the diaphragm valve style face piping kit for your THS series filter

vessel. They include features such as pneumatically actuated diaphragm valves, semi-automatic or

automatic backwash controller options, and pre-glued construction for ease of assembly.

This manual covers the installation of face piping for both one and two tank filter systems,

as well as installation of the semi-automatic and automatic controllers for the same. This manual

also covers operation of the semi-automatic controller, as well as a trouble-shooting guide to assist

with any problems which may occur during installation and operation. If you should have any

questions pertaining to the filter tank itself, please refer to the separate manual provided for the

tanks.

Please remember to use proper safety equipment and techniques when installing this

filtration system.

1.0 Principals of Operation

This section will familiarize you with how the face piping kit and valves work in order to

provide a means of backwashing the filter. It will cover how the diaphragm valves operate, the flow

of water in a single tank system in normal filtration and backwash modes, and a dual tank system in

normal filtration and backwash modes. Please note that the diagrams are for reference only,

and may not be representative of the actual face piping kit.

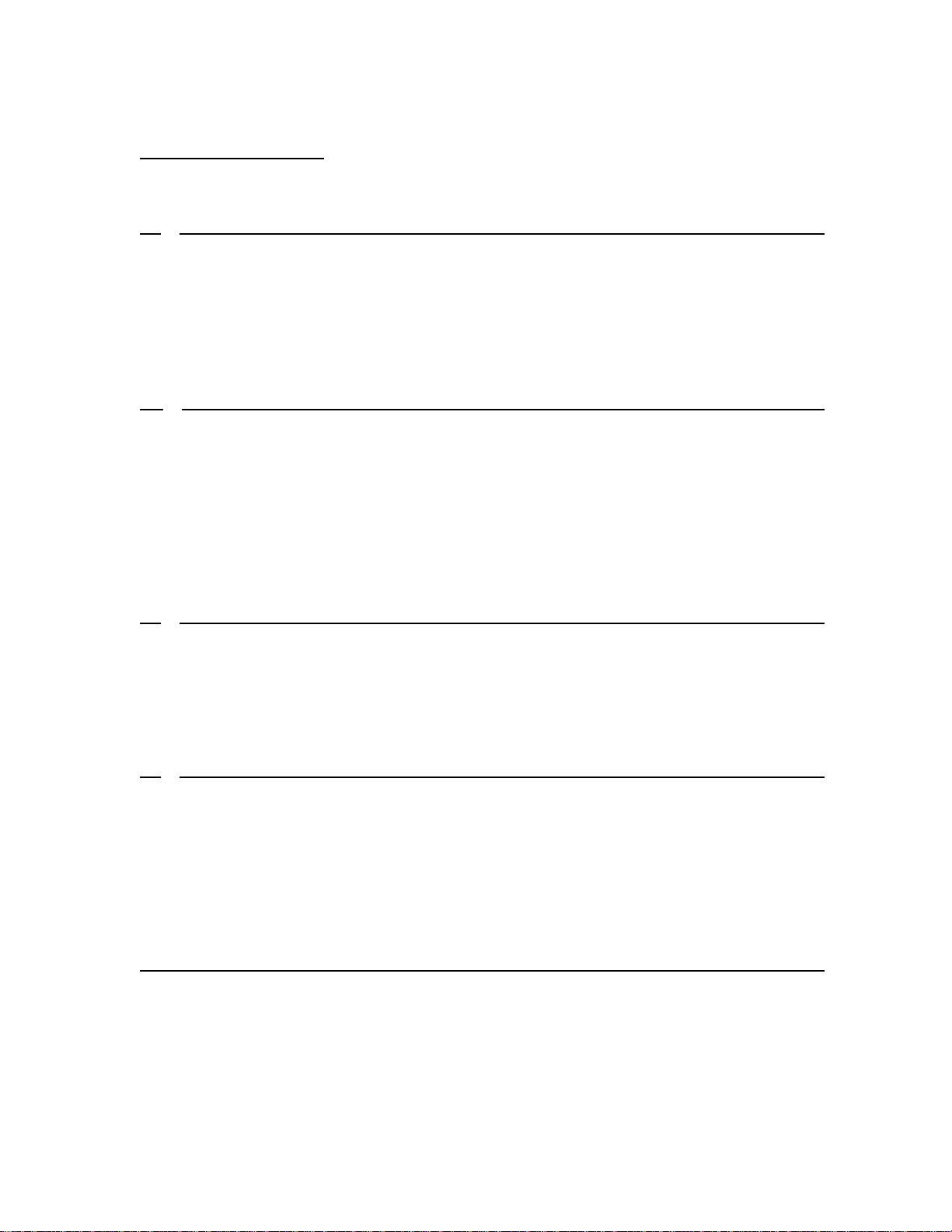

1.1 Diaphragm Valve Operation

During normal operation water enters one side of

the valve and exits the other. A shaft, which is

attached to a diaphragm at one end, and a throttling

cone and seal at the other, prevents water from

flowing out of the sideport. When the valve is

actuated, water is pumped into the top of the valve

from the controller. This water and pressure causes

the diaphragm to collapse onto the sealing surface

of the valve body. This moves the cone portion of

the shaft allowing water to exit out of the sideport,

while sealing off flow from the influent side of the

valve.

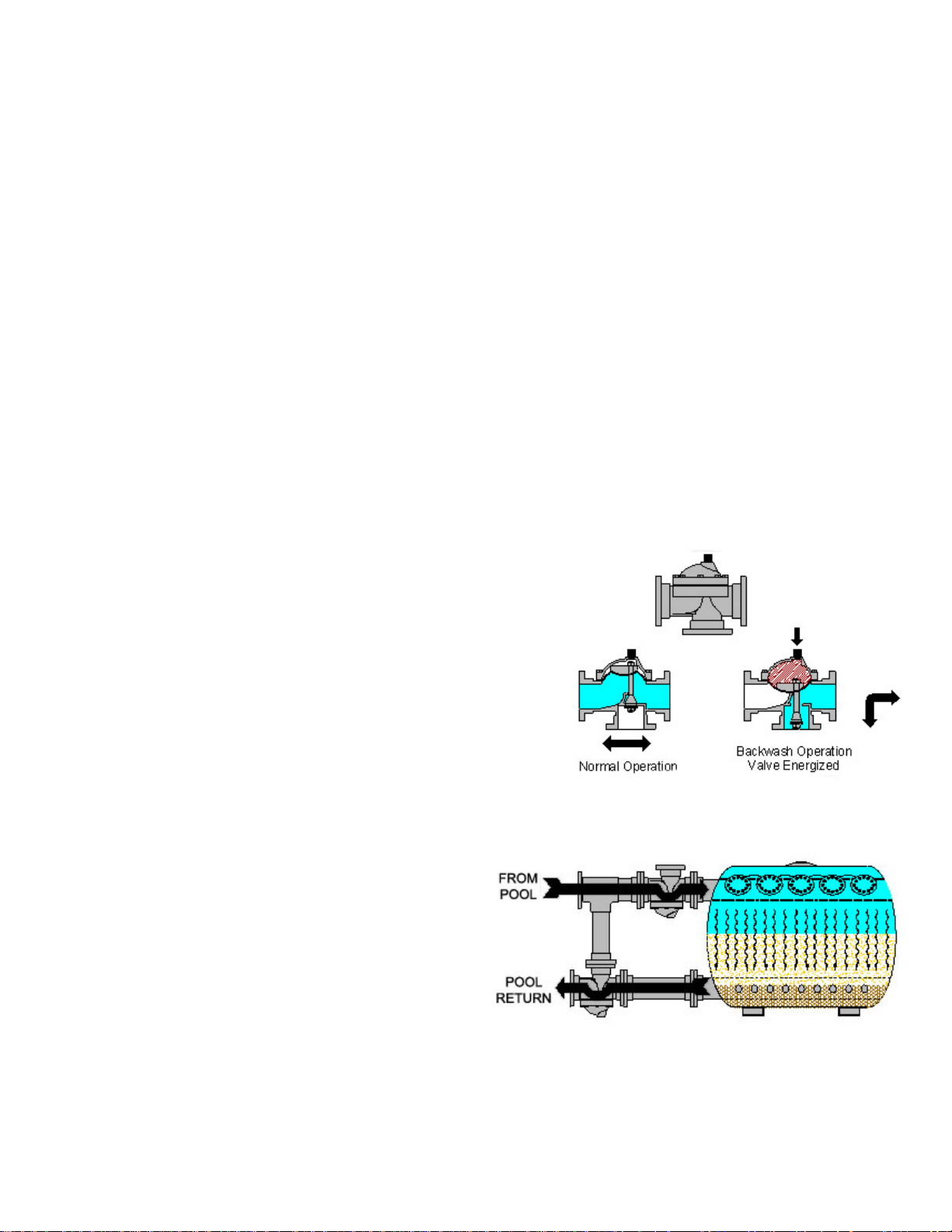

1.2 Single Tank Normal Operation

During normal filtration mode, water

is passed through the influent piping

and into the tank. Water is then

passed through the sand, which is

what actually filters the water. It is

then passed through the collection

laterals at the bottom of the tank. It

then passes out of the effluent pipe

and continues on through the rest of

the filtration system.

Diaphragm Valve Face Piping Kit Installation Manual Pg. 2 of 47

1/16/05 Rev. D

1.3 Single Tank During Backwash

During backwash mode, both of the

diaphragm valves are actuated. Since

water cannot enter the tank through

the influent piping, it enters through the

effluent piping. The water is pushed

up through the sand bed, which is

called “Fluidizing” the sand bed. This

loosens dirt and debris trapped by the

sand. This debris is then passed

through the influent piping and exits

through a waste pipe connected to the

valve.

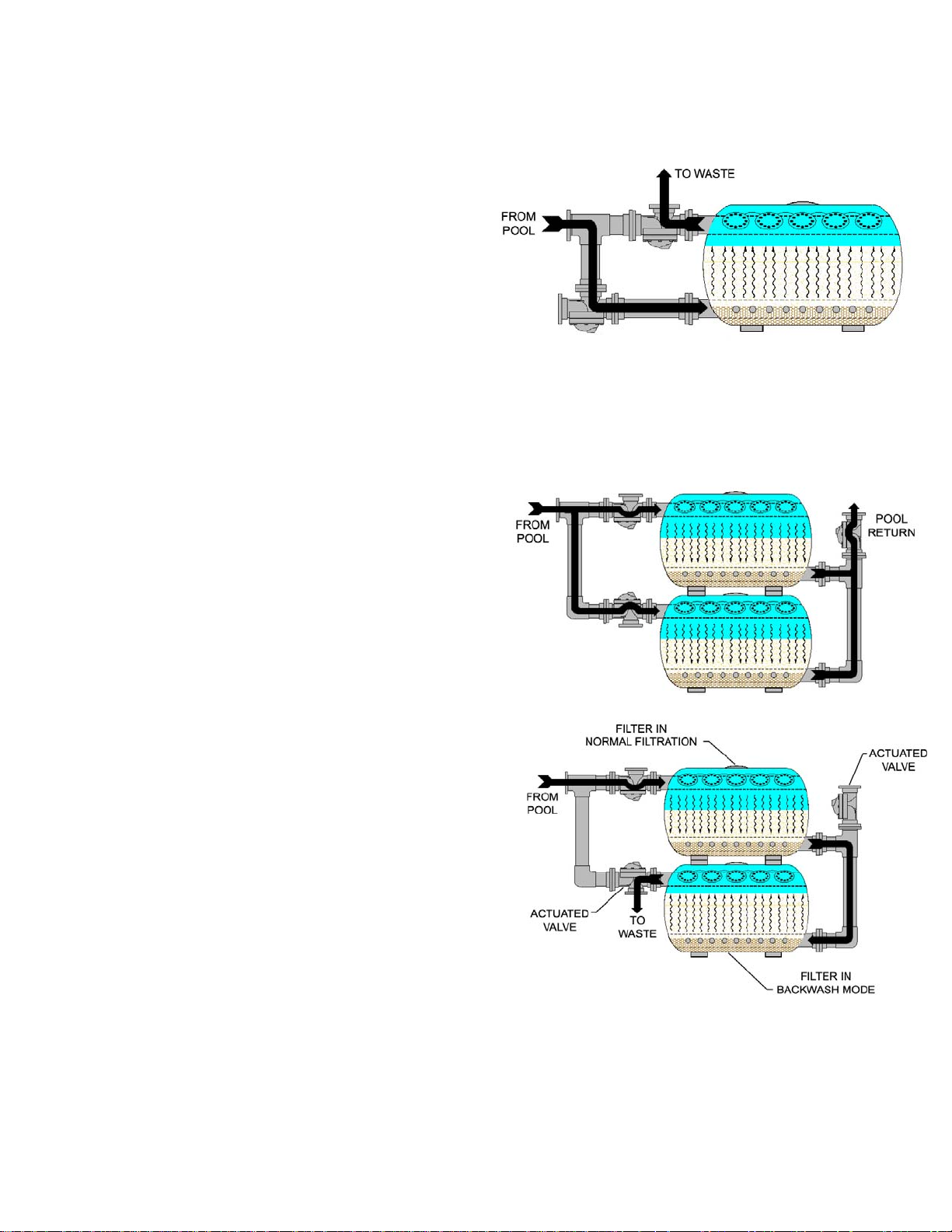

1.4 Dual Tank Normal Filtration

During normal filtration in a dual tank

system, water is split between the two

tanks. It passes through the influent

piping and then through the sand beds.

It is then passed through the collection

laterals at the bottom of the tanks and

passed out of the effluent piping and

returned to the pool.

1.5 Dual Tank During Backwash

During backwash mode in a dual tank

system, one of the three way valves and

the two-way valve are actuated

simultaneously. This allows water to pass

through one of the filters as if it were

filtering normally. When the water exits

that tank, it is forced to enter the second

tank through the effluent pipe. This water

then backwashes the second tank. The

dirt and debris is then passed through the

influent pipe of tank two and out of a waste

pipe connected to the valve.

Diaphragm Valve Face Piping Kit Installation Manual Pg. 3 of 47

1/16/05 Rev. D

2.0 Face piping installation

IMPORTANT: Installation of the face piping should occur after the filter vessels have been

positioned in their permanent location. Please refer to the Tank Owner’s/Operator’s Manual

section on locating the filter vessels. For dual tank systems, it is very important that the “CC” dimension listed in Figure 1 on page 5 of that manual is followed. Please refer to the

Tank Owner/Operators Manual for more information.

Diaphra gm valve style face piping kits come in either one or two tank kits. All piping is pre-

glued, which means the only connections that need to be made are flanged connections between

mating sections. Please refer to the appropriate drawings in the Appendix section at the end of this

manual for aid in assembly.

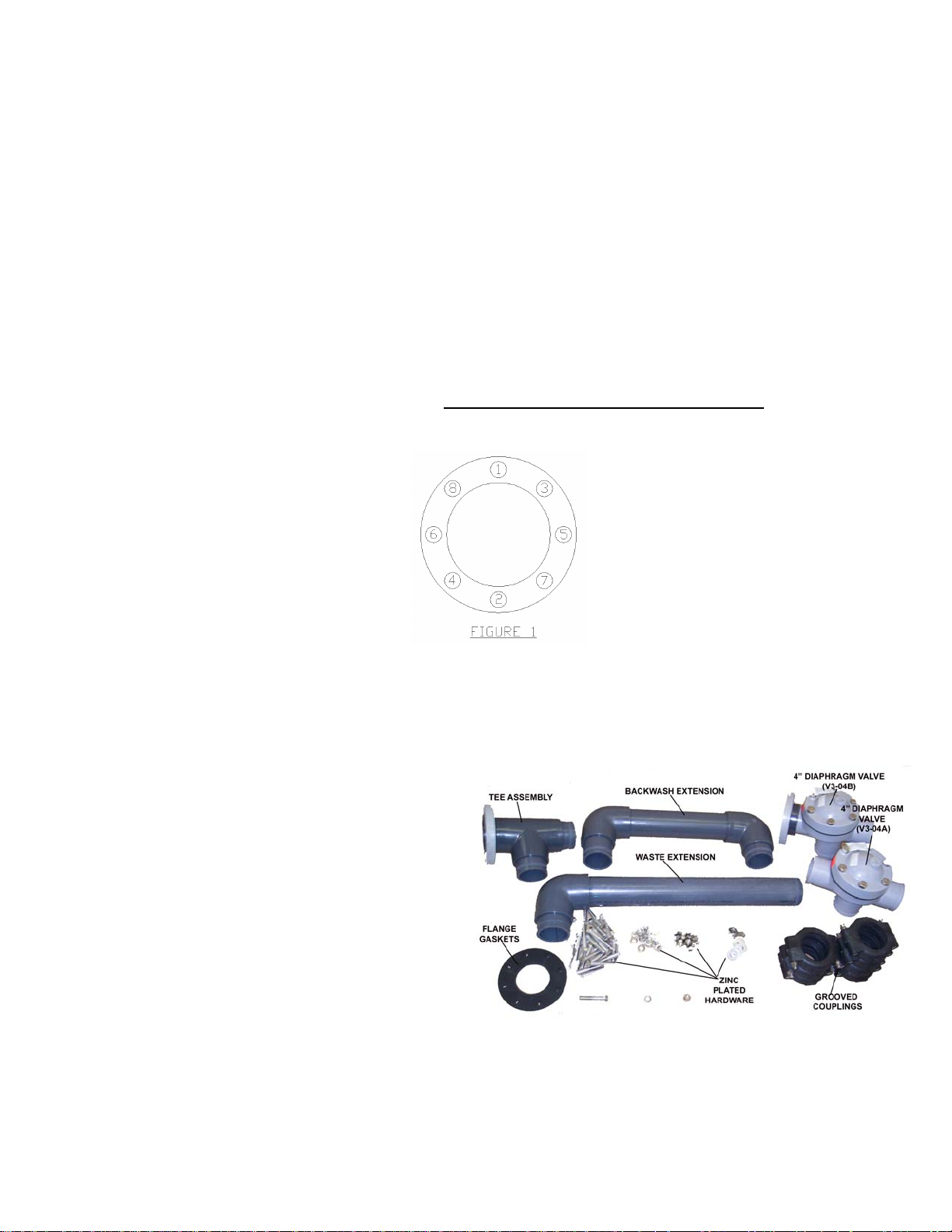

IMPORTANT: When tightening flange bolts, it is important to follow a diametrically opposed

pattern. This will ensure that a proper seal between the flanges is obtained. Refer to Figure

1 below for proper tightening sequence. Torque all bolts to a maximum of 25 ft-lbs.

may be beneficial to apply a teflon based lubricant to each bolt or nut to help relieve stress

due to friction.

Prior to Installation see “Grooved Coupling Assembly Instruction” found on page 6.

Also, it

2.1 Single Tank Face Piping Installation – THS 3461 (4” Grooved

Connections)

The single tank face piping kit consists of:

(1) V3-04A, 4” 3-way diaphragm valve

without Flanges

(1) V3-04B, 4” 3-way diaphragm valve

with Flange, Thru port only.

(1) Tee Assembly

(1) Waste pipe extension

(1) Backwash extension

(1) Sightglass assembly (not shown)

(7) 4” Grooved Coupling Assembly

(3) 4” Flange gaskets

(24) 4” ¾-10 x 3 1/2” Zinc Plated Bolts

(48) Flat Washer, Zinc Plated

(24) Lock Washer, Zinc Plated

(24) Hex Nut, ¾-10, Zinc Plated

(1) Semi-automatic backwash controller

(See Controller Installation Section)

Verify that all parts listed above were supplied before beginning installation. Replacement parts

can be ordered through your local distributor.

Diaphragm Valve Face Piping Kit Installation Manual Pg. 4 of 47

1/16/05 Rev. D

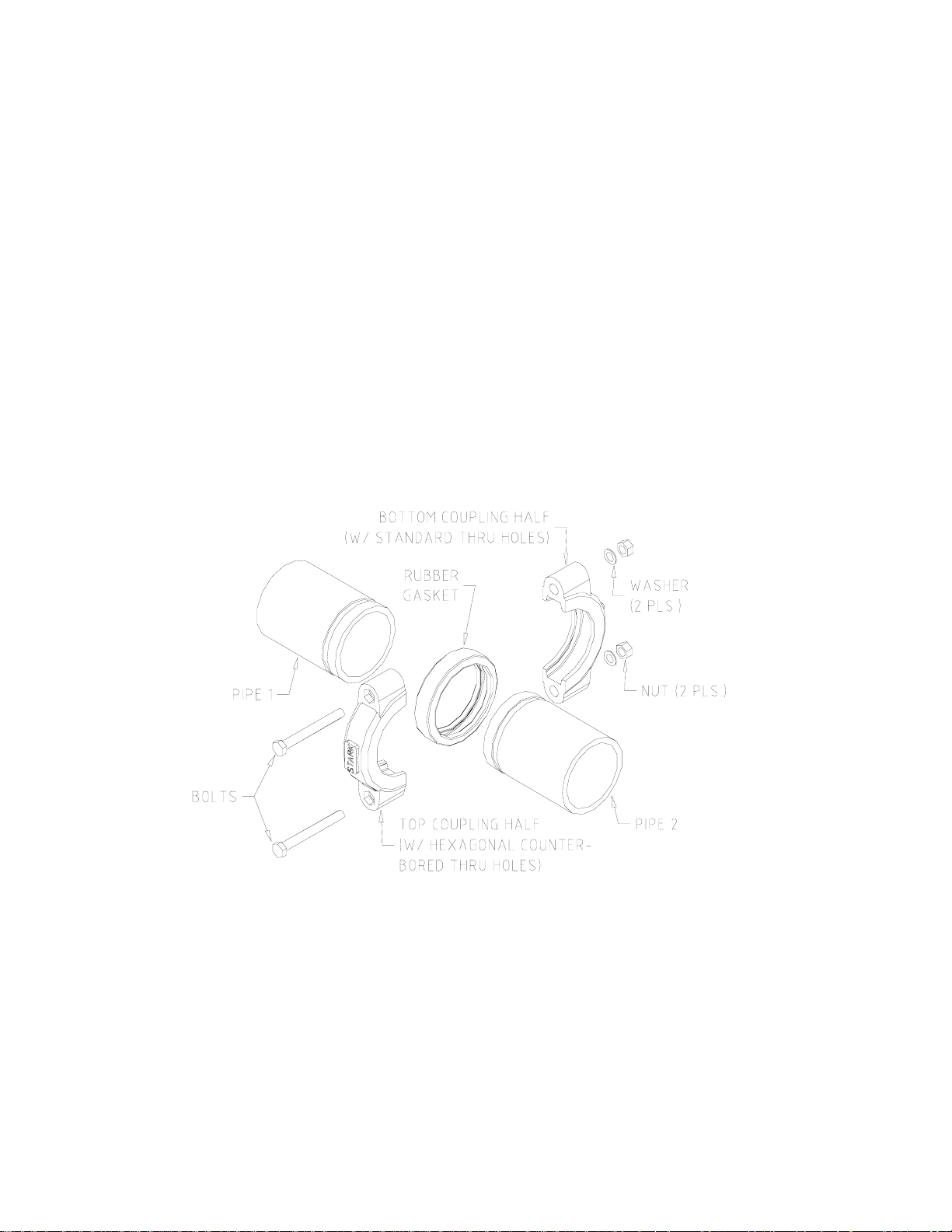

Grooved Coupling Assembly Instruction

1) Seat rubber gasket over end of pipe 1, making sure that the gasket does not cover the groove

cut in the pipe.

2) Insert end of pipe 2 into rubber gasket, again making sure that the gasket does not cover the

groove in the pipe.

3) Fit coupling halves over rubber gasket making sure that coupling halves are seated into the

grooves of the (2) pipes. Make sure one coupling half has standard thru bolt holes and the

other has hexagonal counter-bored thru bolt holes.

Apply an anti-seize lubricant to the threads of the coupling bolts. Insert bolts into the holes in the

coupling, making sure that the bolt heads fit inside the hexagonal counter-bored holes on one side

of the coupling. Place one washer and nut on each bolt and tighten.

Diaphragm Valve Face Piping Kit Installation Manual Pg. 5 of 47

1/16/05 Rev. D

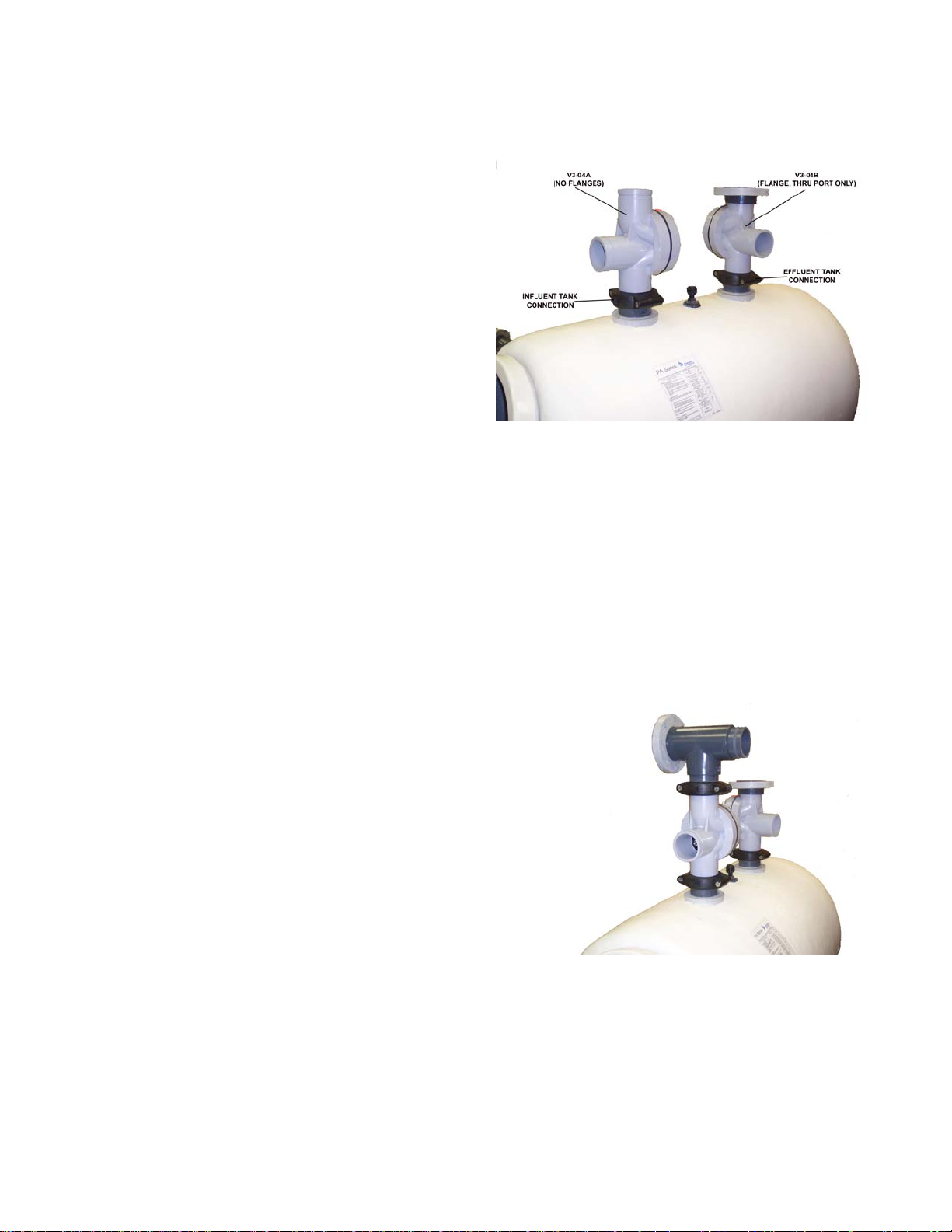

STEP 1: 4” Valve Installation

Place a gasket of grooved coupling

assembly on the influent and effluent tank

grooved pipe connections. Place valve (V3-

04A) with no flanges on influent grooved

pipe connection, install groove coupling

assembly (Refer to page 5). Place valve

(V3-04B) with flange on thru port on effluent

grooved pipe connection, install groove

coupling assembly. See picture at right for

proper orientation. Snug the nuts to “hand

tight”, but do not fully tighten. This will allow

for adjustments during the remainder of the

installation. Please note the orientation of

the valves. The arrows on the valve

covers should be pointing toward the

STEP 2: Tee Assembly Installation

Place gasket of grooved coupling assembly on top

grooved connection of the influent valve. Install the

Tee assembly on the top of the influent valve, and

orient it as shown in picture, install groove coupling

assembly. Snug the nuts to “hand tight”, but do not

fully tighten.

tank.

Diaphragm Valve Face Piping Kit Installation Manual Pg. 6 of 47

1/16/05 Rev. D

STEP 3: Backwash Extension Installation

Place gasket of grooved coupling assembly on grooved

connection of the Tee assembly along with the effluent

valve. Install the backwash extension on to the system

as shown in picture. It may be necessary to turn the

valves or tee assembly slightly to ensure a proper fit.

Install groove coupling assembly. Snug the nuts to “hand

tight”, but do not fully tighten.

STEP 4: Waste Extension Installation

Place gasket of grooved coupling assembly on grooved

connection of influent valve. Install the waste extension

on to the system as shown in picture. Install groove

coupling assembly. Snug the nuts to “hand tight”, but do

not fully tighten.

Diaphragm Valve Face Piping Kit Installation Manual Pg. 7 of 47

1/16/05 Rev. D

STEP 5: Sightglass Installation

Assemble the sightglass by threading the glass

portion into the threaded saddle on the spool. Be

sure to use pipe thread sealant tape on the threads.

Place gasket of grooved coupling assembly on to the

waste extension Install the sightglass assembly on to

the waste flange. Orient the glass portion so it will be

visible during operation. Install groove coupling

assembly. Snug the nuts to “hand tight”, but do not

fully tighten.

STEP 6: Final Adjustments

Once all piping is in place make any necessary adjustments and fully tighten all flange bolts.

Be sure to follow the bolt tightening pattern explained at the beginning of Section 2.0. Tighten

all bolts to a maximum of 40 ft-lbs.

Note: All piping should be fully supported with adequate bracing and hangers

to prevent damage from weight and vibration.

STEP 7: Backwash Controller Installation

If a semi-automatic backwash controller was purchased, please refer to Section 3.1 of this

manual. If an automatic backwash controller was purchased, please refer to Section 3.3.

NOTE: There will be extra gaskets and isoplast hardware. This is to join the remaining

flanged connections of the filter system to any existing or new plumbing.

Diaphragm Valve Face Piping Kit Installation Manual Pg. 8 of 47

1/16/05 Rev. D

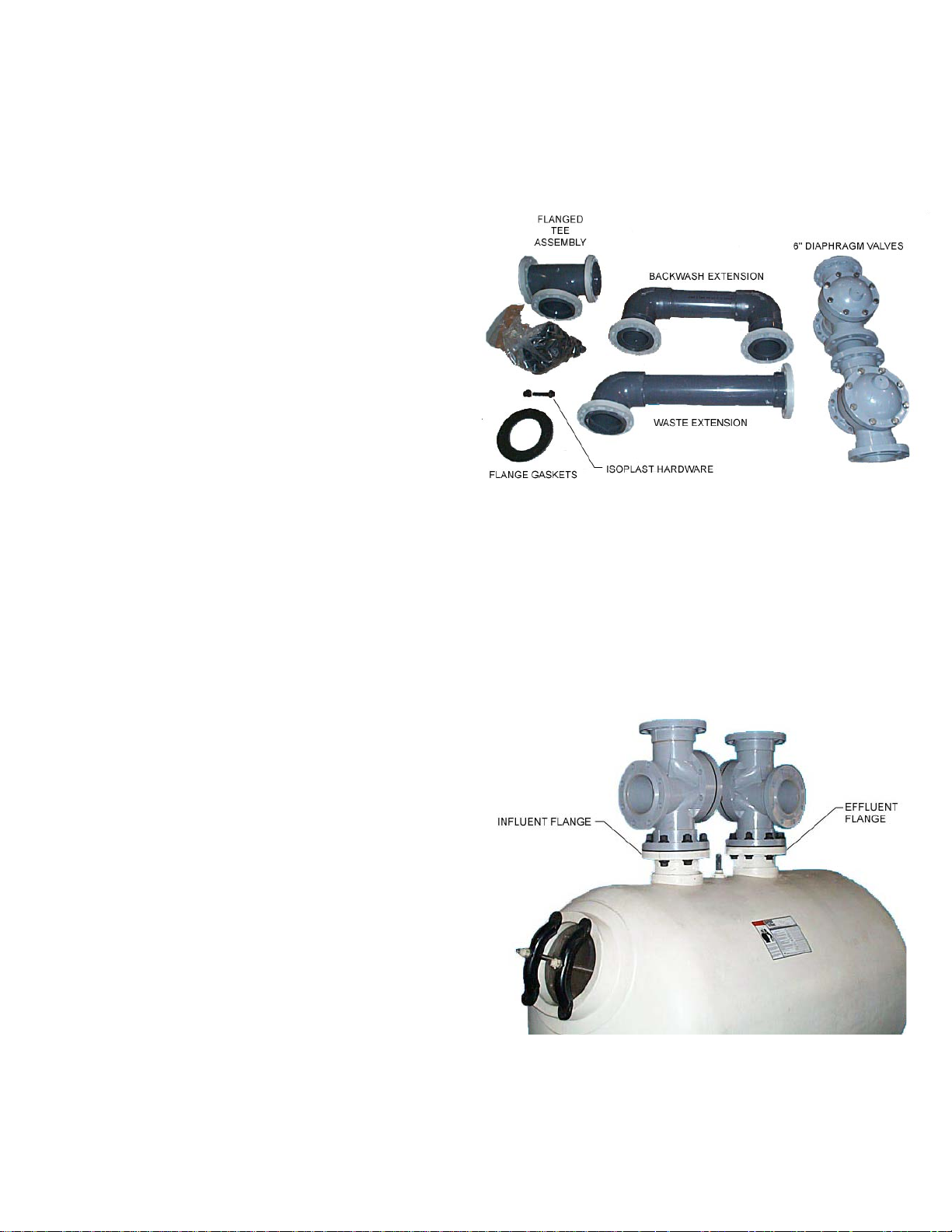

2.2 Single Tank Face Piping Installation – THS 3484, THS4272, THS

4284 and THS 4296 (6” Flange Connections)

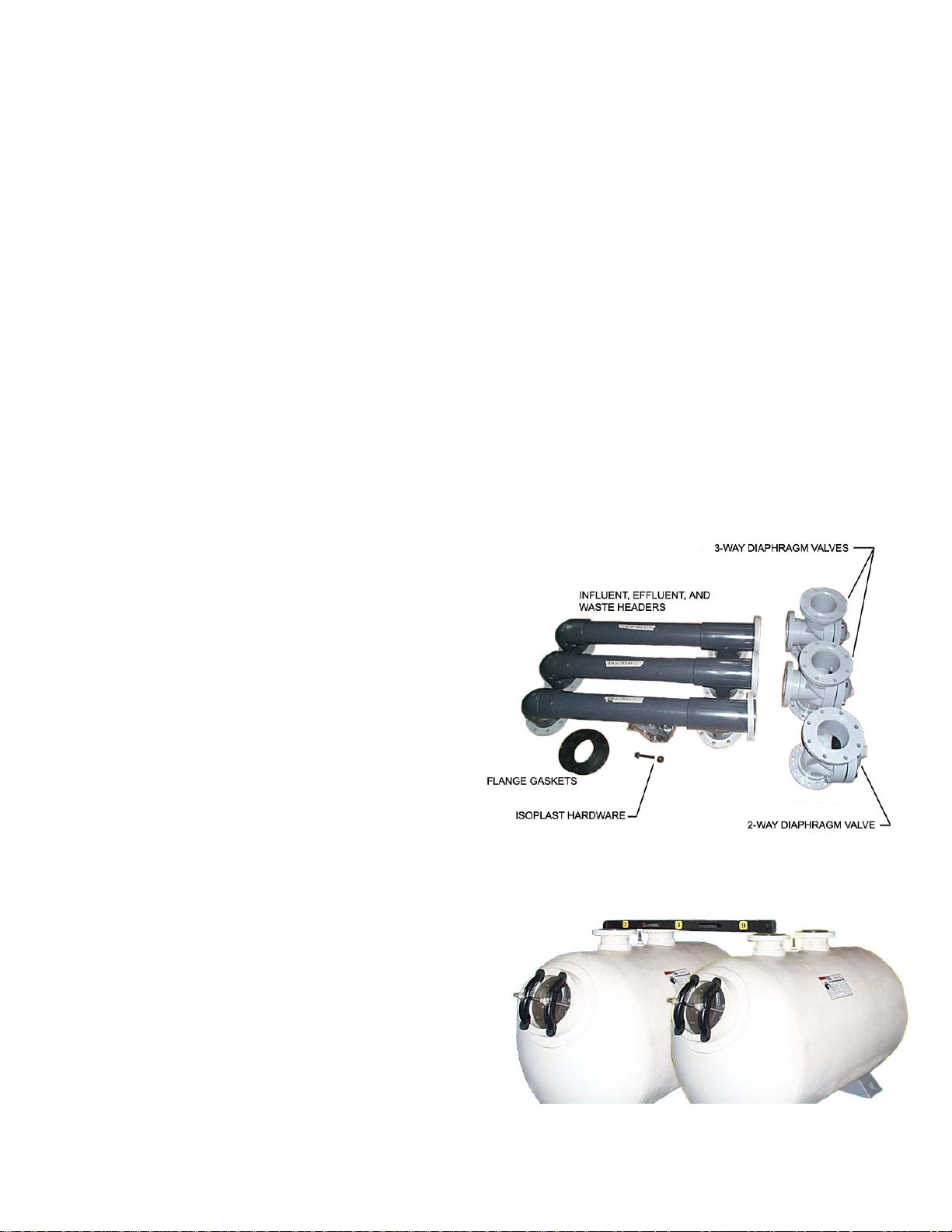

The single tank face piping kit consists of:

(2) 6” 3-way diaphragm valves

(1) Waste pipe extension

(2) Backwash extension

(1) Sightglass assembly (not shown)

(3) 6” Flange

gaskets

(80) Isoplast bolts

(80) Isoplast nuts

(2) Semi-automatic backwash controller

(See Controller Installation Section)

Verify that all parts listed above were supplied before beginning installation. Replacement

parts can be ordered through your local distributor.

STEP 1: 6” Valve Installation

Place a flange gasket on the influent and

effluent tank flanges. Align the holes in the

gasket with the holes in the flange ring on

the tank. Place valves on the flanges

aligning the holes on the valve flange with

the tank flange ring. Please note the

orientation of the valves. The arrows on

the valve covers should be pointing

toward the tank. Install isoplast bolts and

nuts on the influent and effluent flanges.

Snug the nuts to “hand tight”, but do not

fully tighten. This will allow for adjustments

during the remainder of the installation.

Diaphragm Valve Face Piping Kit Installation Manual Pg. 9 of 47

1/16/05 Rev. D

STEP 2: Flanged Tee Assembly Installation

Place gasket on top flange of the influent valve.

Install the flanged tee assembly on the top of the

influent valve, and orient it as shown in picture.

Install isoplast bolts and nuts. Snug the nuts to

“hand tight”, but do not fully tighten.

STEP 3: Backwash Extension Installation

Place isoplast bolts through the bolt holes on

the backwash extension flanges, then place

flange gaskets on to the flanges with the bolts.

Install the backwash extension on to the

system as shown in picture. It may be

necessary to turn the valves or flanged tee

assembly slightly to ensure a proper fit. Install

isoplast nuts. Snug the nuts to “hand tight”,

but do not fully tighten.

Diaphragm Valve Face Piping Kit Installation Manual Pg. 10 of 47

1/16/05 Rev. D

STEP 4: Waste Extension Installation

Place isoplast bolts through bolt holes

on the waste extension flange (elbow

side), then place a flange gasket onto

the flange. Install waste extension onto

valve making sure it is oriented properly

with the flange on the elbow connecting

to the valve (see picture). Install

isoplast nuts. Snug the nuts to “hand

tight”, but do not fully tighten.

STEP 5: Sightglass Installation

Assemble the sightglass by threading the glass portion into

the threaded saddle on the spool. Be sure to use pipe

thread sealant tape on the threads. Place isoplast bolts

through flange on the waste header, then place a flange

gasket on to the flange. Install the sightglass assembly on to

the waste flange. Orient the glass portion so it will be visible

during operation. Install isoplast nuts and snug them to

“hand tight”, but do not fully tighten.

STEP 6: Final Adjustments

Once all piping is in place make any necessary adjustments and fully tighten all flange bolts.

Be sure to follow the bolt tightening pattern explained at the beginning of Section 2.0. Tighten

all bolts to a maximum of 40 ft-lbs.

Note: All piping should be fully supported with adequate bracing and hangers

to prevent damage from weight and vibration.

STEP 7: Backwash Controller Installation

If a semi-automatic backwash controller was purchased, please refer to Section 3.1 of this

manual. If an automatic backwash controller was purchased, please refer to Section 3.3.

NOTE: There will be extra gaskets and isoplast hardware. This is to join the remaining

flanged connections of the filter system to any existing or new plumbing.

Diaphragm Valve Face Piping Kit Installation Manual Pg. 11 of 47

1/16/05 Rev. D

2.3 Dual Tank Face Piping Installation – THS 3461 (4” Grooved Tank

Connections)

The two tank face piping kit consists of:

(2) 4” 3-way diaphragm valves

(1) 6” 2-way diaphragm valve

(2) Influent/effluent headers

(1) Waste header

(1) Sightglass assembly (not shown)

(4) 4” Grooved Coupling Assembly

(2) 4” Flange gaskets

(2) 6” Flange gaskets

(24) Isoplast bolts

(24) Isoplast nuts

(16) 4” ¾-10 x 3 1/2” Zinc Plated Bolts

(32) Flat Washer, Zinc Plated

(16) Lock Washer, Zinc Plated

(16) Hex Nut, ¾-10, Zinc Plated

(1) Semi-automatic backwash

controller (See Controller

Installation Section)

Verify that all parts listed above were supplied before beginning installation. Replacement

parts can be ordered through your local distributor.

Prior to Installation see “Grooved Coupling Assembly Instruction” found on page 5.

IMPORTANT: Verify that the center to center dimension between the two tanks is correct.

Refer to Figure 1 on page 5 of the Tank Owner’s/Operator’s Manual for more information.

STEP 1: Level the tanks

Make sure influent and effluent flanges on each

tank are level. Shimming may be required to bring

the tanks to level with each other. Use a noncompressible material placed under the tank

saddles. Further leveling may require the saddles

to be adjusted. Please refer to page 5 of the Tank

Owner’s/Operator’s Manual for more information.

Diaphragm Valve Face Piping Kit Installation Manual Pg. 12 of 47

1/16/05 Rev. D

STEP 2: 4” 3-way Valve Installation

Place a gasket of grooved coupling assembly on

the influent grooved pipe connection of each tank.

Place valves on influent grooved pipe

connections, install groove coupling

assembly(Refer to page 5). See picture at right for

proper orientation. Snug the nuts to “hand tight”,

but do not fully tighten. This will allow for

adjustments during the remainder of the

installation. Please note the orientation of the

valves. The arrows on the valve covers should

be pointing toward the tank.

STEP 3: Influent/Effluent Header Installation

Place a gasket of grooved coupling assembly on

top grooved connection of each valve and the

effluent grooved pipe connection of each tank.

Install headers on to the valve/tank connections

(see pictures). Install groove coupling assembly.

The headers can be installed with the terminating

flange facing either left or right depending on what

is needed for the application. Snug the nuts to

“hand tight”, but do not fully tighten. This will allow

for adjustments during the remainder of the

installation.

Diaphragm Valve Face Piping Kit Installation Manual Pg. 13 of 47

1/16/05 Rev. D

STEP 4: Waste Header Installation

Place gasket of grooved coupling assembly on

grooved connection of influent valves. Install the waste

extension on to the system as shown in picture. Install

groove coupling assembly. Snug the nuts to “hand

tight”, but do not fully tighten.

STEP 5: 6” 2-way Valve Installation

Place isoplast bolts through the flange on the

effluent header, then place a flange gasket on to the

flange. Install the valve on to the flanges making

sure to align the flange holes with the bolts. The

arrow on the valve cover should be pointing

away from the tank, in the direction of the

effluent flow. Install isoplast nuts. Snug the nuts to

“hand tight”, but do not fully tighten.

STEP 6: Sightglass Installation

Assemble the sightglass by threading the glass portion into

the threaded saddle on the spool. Be sure to use pipe

thread sealant tape on the threads. Place isoplast bolts

through flange on the waste header, then place a flange

gasket on to the flange. Install the sightglass assembly on

to the waste flange. Orient the glass portion so it will be

visible during operation. Install isoplast nuts and snug

them to “hand tight”, but do not fully tighten.

Diaphragm Valve Face Piping Kit Installation Manual Pg. 14 of 47

1/16/05 Rev. D

STEP 7: Final Adjustments

Once all piping is in place make any necessary adjustments and fully tighten all flange bolts.

Be sure to follow the bolt tightening pattern explained at the beginning of Section 2.0. Tighten

all bolts to a maximum of 25 ft-lbs.

Note: All piping should be fully supported with adequate bracing and hangers

to prevent damage from weight and vibration.

STEP 8: Backwash Controller Installation

If a semi-automatic backwash controller was purchased, please refer to Section 3.2 of this

manual. If an automatic backwash controller was purchased, please refer to Section 3.4.

NOTE: There will be extra gaskets and isoplast hardware. This is to join the remaining

flanged connections of the filter system to any existing or new plumbing.

2.4 Dual Tank Face Piping Installation – THS 3484, THS4272, THS 4284 and

THS 4296 (6” Flange Connections)

The two tank face piping kit consists of:

(2) 6” 3-way diaphragm valves

(1) 6” 2-way diaphragm valve

(2) Influent/effluent headers

(1) Waste header

(1) Sightglass assembly (not shown)

(13) 6” Flange gaskets

(104) Isoplast bolts

(104) Isoplast nuts

(2) Semi-automatic backwash controller

(See Controller Installation Section)

Verify that all parts listed above were

supplied before beginning installation.

Replacement parts can be ordered

through your local distributor.

IMPORTANT: Verify that the center to center dimension between the two tanks is correct.

Refer to Figure 1 on page 5 of the Tank Owner’s/Operator’s Manual for more information.

STEP 1: Level the tanks

Make sure influent and effluent flanges on

each tank are level. Shimming may be

required to bring the tanks to level with each

other. Use a non-compressible material

placed under the tank saddles. Further

leveling may require the saddles to be

adjusted. Please refer to page 5 of the Tank

Owner’s/Operator’s Manual for more

information.

Diaphragm Valve Face Piping Kit Installation Manual Pg. 15 of 47

1/16/05 Rev. D

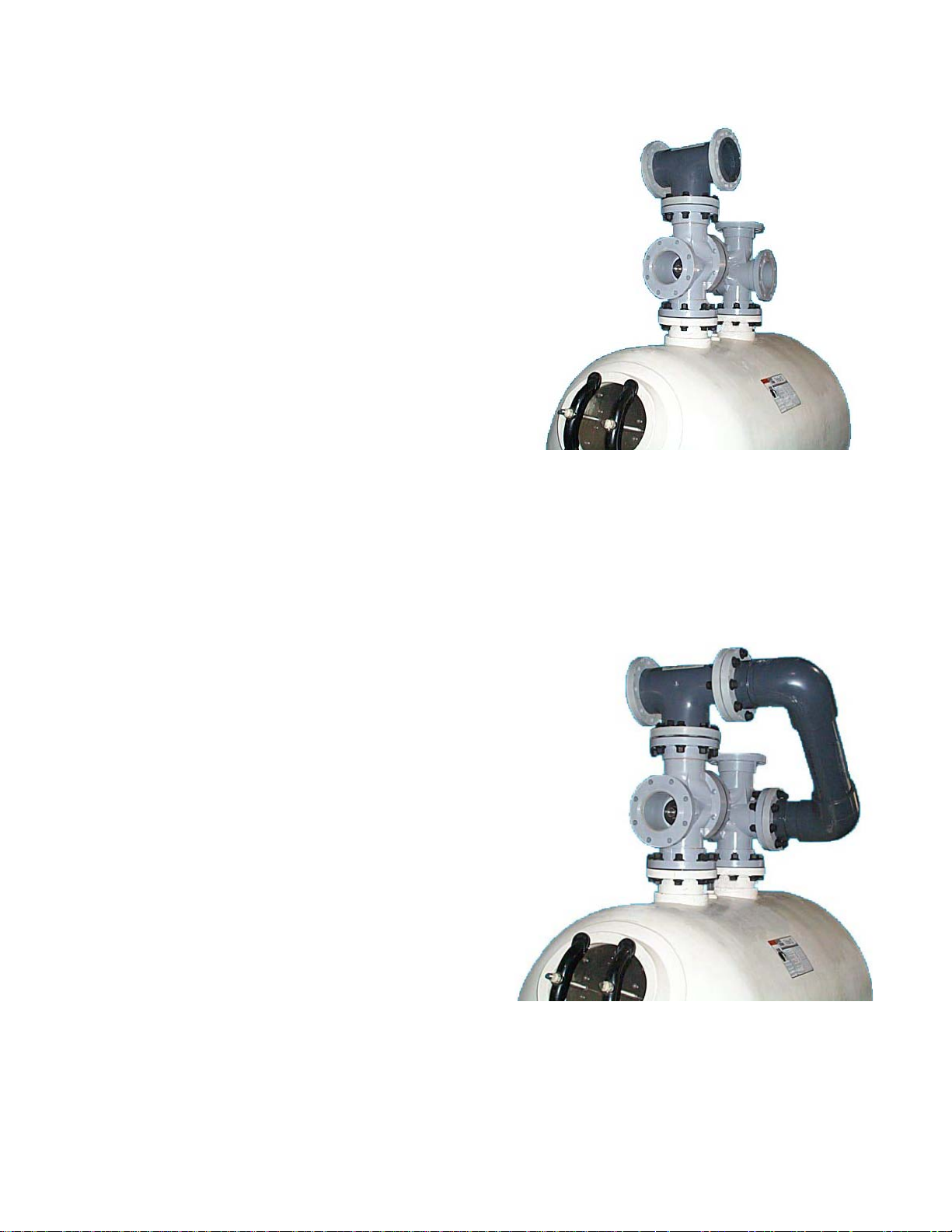

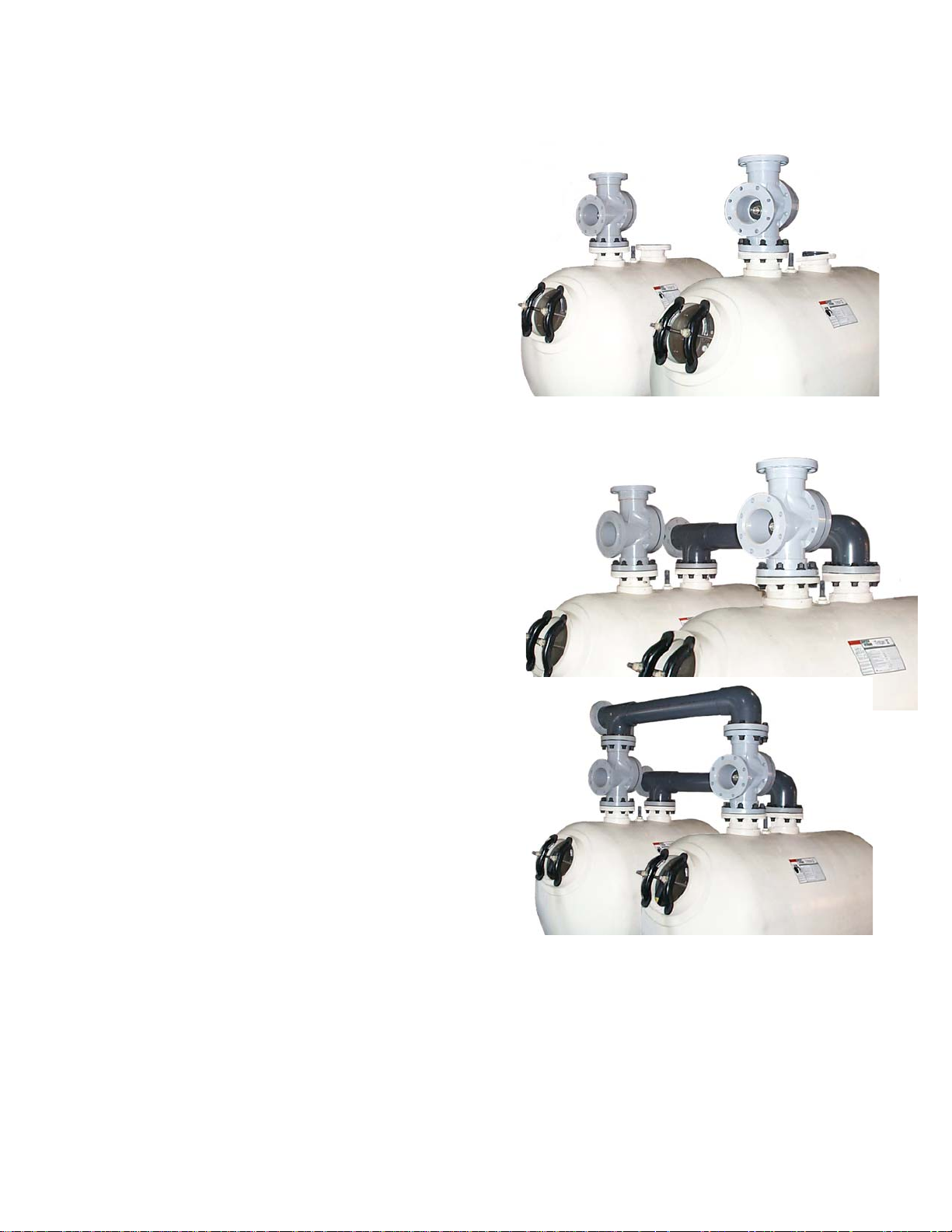

STEP 2: 6” 3-way Valve Installation

Place a flange gasket on the influent flange

of each tank. Align the holes in the gasket

with the holes in the flange on the tank.

Place valves on the influent flanges aligning

the holes on the valve flange with the tank

flange. Please note the orientation of the

valves. The arrows on the valve covers

should be pointing toward the tank. Install

isoplast bolts and nuts on the influent flanges

of each tank. Snug the nuts to “hand tight”,

but do not fully tighten. This will allow for

adjustments during the remainder of the

installation

STEP 3: Influent/Effluent Header Installation

Place flange gaskets on the top flanges of the

valves and on the effluent flanges of the tanks.

Align the holes in the gaskets with the holes in

the flanges. Install headers on to the valve/tank

flanges (see picture). The headers can be

installed with the terminating flange facing either

left or right depending on what is needed for the

application. Install isoplast bolts and nuts on the

flanges of the headers. Snug the nuts to “hand

tight”, but do not fully tighten.

Diaphragm Valve Face Piping Kit Installation Manual Pg. 16 of 47

1/16/05 Rev. D

STEP 4: Waste Header Installation

Place isoplast bolts through the flanges on the waste

header, then place flange gaskets on to the flanges

with the bolts. Install the waste header on to the

remaining valve flanges making sure to align the

flange holes with the bolts. It may be necessary to

turn the valves slightly to ensure a proper fit. Install

isoplast nuts. Snug the nuts to “hand tight”, but do not

fully tighten.

STEP 5: 6” 2-way Valve Installation

Place isoplast bolts through the flange on the effluent

header, then place a flange gasket on to the flange.

Install the valve on to the flanges making sure to align

the flange holes with the bolts. The arrow on the

valve cover should be pointing away from the tank,

in the direction of the effluent flow. Install isoplast

nuts. Snug the nuts to “hand tight”, but do not fully

tighten.

STEP 6: Sightglass Installation

Assemble the sightglass by threading the glass portion into

the threaded saddle on the spool. Be sure to use pipe

thread sealant tape on the threads. Place isoplast bolts

through flange on the waste header, then place a flange

gasket on to the flange. Install the sightglass assembly on

to the waste flange. Orient the glass portion so it will be

visible during operation. Install isoplast nuts and snug

them to “hand tight”, but do not fully tighten.

STEP 7: Final Adjustments

Once all piping is in place make any necessary adjustments and fully tighten all flange bolts.

Be sure to follow the bolt tightening pattern explained at the beginning of Section 2.0. Tighten

all bolts to a maximum of 25 ft-lbs.

Diaphragm Valve Face Piping Kit Installation Manual Pg. 17 of 47

1/16/05 Rev. D

STEP 8: Backwash Controller Installation

If a semi-automatic backwash controller was purchased, please refer to Section 3.2 of this

manual. If an automatic backwash controller was purchased, please refer to Section 3.4.

NOTE: There will be extra gaskets and isoplast hardware. This is to join the remaining

flanged connections of the filter system to any existing or new plumbing.

Diaphragm Valve Face Piping Kit Installation Manual Pg. 18 of 47

1/16/05 Rev. D

3.0 Backwash Controller Installation

NOTE: This section covers the installation of semi-automatic and automatic backwash

controllers for single and dual tank systems.

3.1 Single Tank Semi-automatic Controller Installation

The single tank semi-automatic backwash

controller consists of:

(1) Controller gauge panel

(2) 3/8” OD tube quick connect tees

(3) 3/8” OD x ¼” MNPT quick connect

fittings

(1) Check valve w/ fittings

(1) Adjustable pressure regulator

(100 ft) 3/8” OD polyethylene tube

(2 pr.) Mounting brackets and hardware

(2) Controller supports

(2) Isoplast bolts

(2) Isoplast nuts

Verify that all parts listed above were supplied

before beginning installation. Replacement parts

can be ordered through the manufacturer.

Diaphragm Valve Face Piping Kit Installation Manual Pg. 19 of 47

1/16/05 Rev. D

STEP 1: Controller Support Assembly

Attach controller supports t o the gauge panel assembly

using the ¾” isoplast nuts and bolts. Attach so the

channel side of the supports is away from the gauge

panel. Tighten bolts, but do not over tighten, this may

crack the face of the gauge panel.

Diaphragm Valve Face Piping Kit Installation Manual Pg. 20 of 47

1/16/05 Rev. D

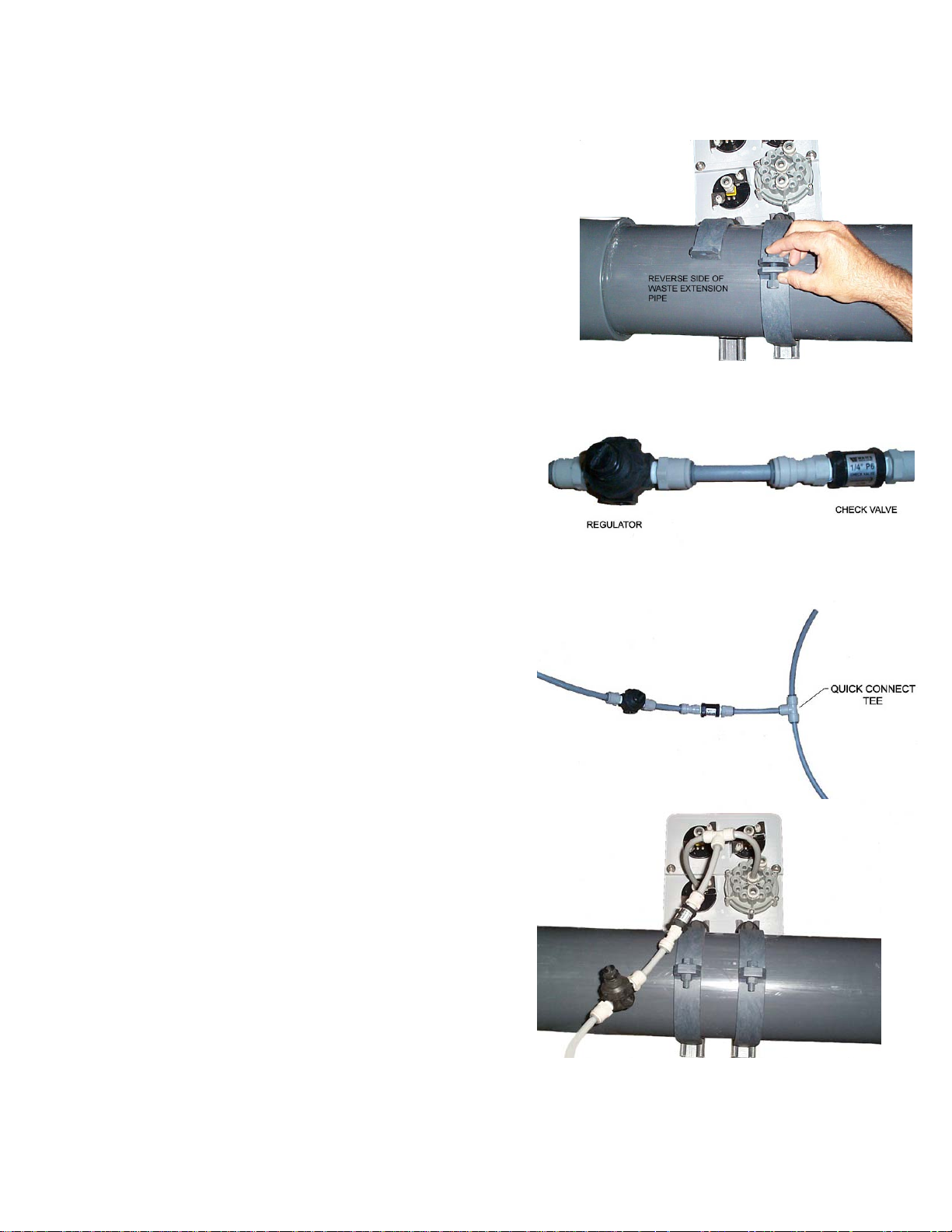

STEP 2: Attach Gauge Panel to System

Insert notched end of pipe clamps into the channel of

the controller supports. Attach the gauge panel

assembly to the waste extension (see picture). Slide

remaining pipe clamps into the channels of the controller

supports. Use the nuts and bolts supplied to tighten the

clamps on to the pipe.

STEP 3: Installation of Controller Tubing

Connect the regulator with the check valve

assembly with a section of 3/8” OD tube. Please

note the direction of the flow arrow on the check

valve. It should be pointing away from the

regulator.

Connect length of tubing to open end of the

check valve. Connect quick connect tee to end

of tube. On both open ends of the quick connect

tee connect tubing as shown in picture.

Connect tubes from the quick connect tee to back

of gauge panel assembly as shown in picture.

One end should be connected to the center fitting

on the multiport valve, the other should be

connected to the multiport pressure gauge.

Connect open end of tubing from the regulator to

your city water supply, or other water source. An

extra 3/8" x 1/4" MNPT fitting has been provided

for connection. Please note, the water source

must be able to supply water at a pressure of

35 psi minimum.

Diaphragm Valve Face Piping Kit Installation Manual Pg. 21 of 47

1/16/05 Rev. D

Drill and tap for ¼” NPT hole on the influent and

effluent pipes from the filter system (see

schematic diagram in Appendix B). Install quick

connect fittings into pipe. Be sure to use pipe

thread sealant tape on threads. Install 3/8” OD

tube from fittings to rear of gauge panel assembly.

Connect tubes into correct gauge on rear of panel

(see picture).

Connect lengths of tubing into the quick connect

fittings on top of the valve cover. Join these two

tubes with a quick connect tee as shown in the

picture.

Connect a length of tube from open end of quick

connect tee from the valves to the fitting on the

back of the gauge panel assembly as shown in

the picture. Connect tube from remaining quick

connect fitting and connect to drain.

Diaphragm Valve Face Piping Kit Installation Manual Pg. 22 of 47

1/16/05 Rev. D

This completes the installation of the semi-automatic backwash controller for single tank

systems. Please proceed to Section 4.0 for operating instructions.

3.2 Dual Tank Semi-Automatic

Controller Installation

The dual tank semi-automatic controller kit

consists of the following:

(1) Controller gauge panel

(3) 3/8” OD tube quick connect tees

(3) 3/8” OD x ¼” MNPT quick connect

fittings

(1) Check valve w/ fittings

(1) Adjustable pressure regulator

(1) And/Or Valve

(100 ft) 3/8” OD polyethylene tube

(2pr.) Mounting brackets and hardware

(2) Controller supports

(2) Isoplast bolts

(2) Isoplast nuts

Verify that all parts listed above were

supplied before beginning installation.

Replacement parts can be ordered through

the manufacturer.

Diaphragm Valve Face Piping Kit Installation Manual Pg. 23 of 47

1/16/05 Rev. D

STEP 1: Controller Support Assembly

Attach controller supports to the gauge panel

assembly using the ¾” isoplast nuts and bolts. Attach

so the channel side of the supports is away from the

gauge panel. Tighten bolts, but do not over tighten,

this may crack the face of the gauge panel.

Diaphragm Valve Face Piping Kit Installation Manual Pg. 24 of 47

1/16/05 Rev. D

STEP 2: Attach Gauge Panel to System

Insert notched end of pipe clamps into the channel of

the controller supports. Attach the gauge panel

assembly to the waste extension (see picture). Slide

remaining pipe clamps into the channels of the controller

supports. Use the nuts and bolts supplied to tighten the

clamps on to the pipe.

STEP 3: Installation of Controller Tubing

Connect the regulator with the check valve

assembly with a section of 3/8” OD tube. Please

note the direction of the flow arrow on the check

valve. It should be pointing away from the

regulator.

Connect length of tubing to open end of the

check valve. Connect quick connect tee to end of

tube. On both open ends of the quick connect tee

connect tubing as shown in picture.

Connect tubes from the quick connect tee to back

of gauge panel assembly as shown in picture.

One end should be connected to the center fitting

on the multiport valve, the other should be

connected to the multiport pressure gauge.

Connect open end of tubing from the regulator to

your city water supply, or other water source. An

extra 3/8" x 1/4" MNPT fitting has been provided

for connection. Please note, the water source

must be able to supply water at a pressure of

35 psi minimum.

Diaphragm Valve Face Piping Kit Installation Manual Pg. 25 of 47

1/16/05 Rev. D

Drill and tap for ¼” NPT hole on the influent and

effluent pipes from the filter system (see

schematic diagram in Appendix B). Install quick

connect fittings into pipe. Be sure to use pipe

thread sealant tape on the threads. Install 3/8”

OD tube from fittings to rear of gauge panel

assembly. Connect tubes in to correct gauge on

rear of panel (see picture).

Assemble the And/Or assembly shown

in the picture (above right). Be sure to

leave enough tubing to reach all of the

necessary connections. Connect all tubes to

their appropriate locations as explained in the

picture.

Diaphragm Valve Face Piping Kit Installation Manual Pg. 26 of 47

1/16/05 Rev. D

Connect length of tube into remaining fitting on gauge panel assembly. Connect this to the

drain. Please note, And/Or assembly note shown for clarity.

This completes the installation of the semi-automatic backwash controller for single tank

systems. Please proceed to Section 4.0

for operating instructions.

3.3 Single Tank Automatic

Controller Installation

The single tank automatic backwash

controller consists of:

(1) Automatic controller enclosure

(1) Multiport valve enclosure

(4) 3/8” OD tube quick connect tees

(3) 3/8” OD x ¼” MNPT quick connect

fittings

(1) Check valve w/ fittings

(100 ft) 3/8” OD polyethylene tube

(4pr.) Mounting brackets and hardware

(1) Owner’s/Operator’s manual for

automatic controller

Verify that all parts listed above were supplied before beginning installation. Replacement

parts can be ordered through the manufacturer.

Diaphragm Valve Face Piping Kit Installation Manual Pg. 27 of 47

1/16/05 Rev. D

STEP 1: Attach Controller/Multiport Enclosures to Piping

Insert notched end of pipe clamps

into the channel of the enclosure

supports. Attach the enclosure

assemblies to the waste extension

(see picture). Slide remaining pipe

clamps into the channels of the

enclosure supports. Use the nuts and

bolts supplied to tighten the clamps on

to the pipe.

STEP 2: Installation of Controller Tubing

Insert length of 3/8” tube into top fitting on

the regulator (see picture). Connect other

end of this tube to your city water supply, or

other water source. An extra 3/8" x 1/4"

MNPT fitting has been provided for

connection. Please note, the water source

must be able to supply water at a

pressure of 35 psi minimum. Connect the

check valve to the other fitting from the

regulator with a small length of tubing. Make

sure that the arrow on the check valve is

pointed away from the regulator. From the

other end of the check valve connect a length

of tube and attach a quick connect tee fitting

(see picture).

Connect tubes to each side of the quick

connect tee. Connect one tube to the

multiport pressure gauge and the other to the

center fitting on the multiport valve (see

picture).

Diaphragm Valve Face Piping Kit Installation Manual Pg. 28 of 47

1/16/05 Rev. D

Drill and tap for ¼” NPT hole on the influent

and effluent pipes from the filter system (see

schematic diagram in Appendix B). Install

quick connect fittings in to holes. Be sure to

use pipe thread sealant tape on the

threads. Install into each fitting a length of

3/8” OD tubing. Connect a quick connect tee

on to the other end of each tube. Connect

two smaller pieces of tubing into each tee

and connect to the rear of the automatic

controller enclosure as shown.

Connect lengths of tubing into the quick connect

fittings on top of the valve cover. Join the two

tubes with a quick connect tee as shown in the

picture.

Connect a length of tube from open end of quick

connect tee from the valves to the fitting on the

back of the gauge panel assembly as shown in

the picture. Connect tube from remaining quick

connect fitting and connect to drain.

Diaphragm Valve Face Piping Kit Installation Manual Pg. 29 of 47

1/16/05 Rev. D

Connect the four wires from the rear of the multiport valve enclosure to the rear of the

automatic controller enclosure. Each wire has a different style pin connector and can only

connect to one of the sockets on the back of the automatic controller enclosure.

This completes the installation of the automatic backwash controller for single tank systems.

Please see Owner’s/Operater’s Manual for automatic controller set up and operation.

3.4 Dual Tank Automatic

Controller Installation

The dual tank automatic controller kit

consists of the following:

(1) Automatic controller enclosure

(1) Multiport valve enclosure

(5) 3/8” OD tube quick connect tees

(3) 3/8” OD x ¼” MNPT quick connect

fittings

(1) Check valve w/ fittings

(1) And/Or Valve

(100 ft) 3/8” OD polyethylene tube

(4pr.) Mounting brackets and hardware

(1) Owner’s/Operators manual for

automatic backwash controller

Verify that all parts listed above were supplied before beginning installation. Replacement

parts can be ordered through the manufacturer.

STEP 1: Attach Controller/Multiport Enclosures to Piping

Insert notched end of pipe clamps

into the channel of the enclosure

supports. Attach the enclosure

assemblies to the waste extension

(see picture). Slide remaining pipe

clamps into the channels of the

enclosure supports. Use the nuts and

bolts supplied to tighten the clamps on

to the pipe.

Diaphragm Valve Face Piping Kit Installation Manual Pg. 30 of 47

1/16/05 Rev. D

STEP 2: Installation of Controller Tubing

Insert length of 3/8” tube into top fitting on

the regulator (see picture). Connect other end

of this tube to your city water supply, or other

water source. An extra 3/8" x 1/4" MNPT

fitting has been provided for connection.

Please note, the water source must be able

to supply water at a pressure of 35 psi

minimum. Connect the check valve to the

other fitting from the regulator with a small

length of tubing. Make sure that the arrow on

the check valve is pointed away from the

regulator. From the other end of the check

valve connect a length of tube and attach a

quick connect tee fitting (see picture).

Connect tubes to each side of the quick

connect tee. Connect one tube to the

multiport pressure gauge and the other to the

center fitting on the multiport valve (see

picture).

Drill and tap for ¼” NPT hole on the influent

and effluent pipes from the filter system (see

schematic diagram in Appendix B). Install

quick connect fittings in to holes. Be sure to

use pipe thread sealant tape on the

threads. Install into each fitting a length of

3/8” OD tubing. Connect a quick connect tee

on to the other end of each tube. Connect

two smaller pieces of tubing into each tee

and connect to the rear of the automatic

controller enclosure as shown.

Diaphragm Valve Face Piping Kit Installation Manual Pg. 31 of 47

1/16/05 Rev. D

Assemble the And/Or assembly shown in

the picture (above right). Be sure to leave

enough tubing to reach all of the

necessary connections. Connect all tubes

to their appropriate locations as explained

in the picture. Connect tube from

remaining quick connect fitting and

connect to drain.

Connect the four wires from the rear of the

multiport valve enclosure to the rear of the

automatic controller enclosure. Each wire has a

different style pin connector and can only

connect to one of the sockets on the back of the

automatic controller enclosure.

This completes the installation of the automatic backwash controller for dual tank systems.

Please see Owner’s/Operater’s Manual for automatic controller set up and operation.

Diaphragm Valve Face Piping Kit Installation Manual Pg. 32 of 47

1/16/05 Rev. D

4.0 Operation

The diaphragm valve style face piping kits are designed for simple operation and

maintenance. Backwashing is accomplished by turning a single knob to actuate the

diaphragm valves. The automatic controller can be set up to backwash automatically

dependant on certain chosen parameters, as well manually if required (refer to automatic

controller manual for more information). The systems backwash one tank at a time, and in

the case of the dual tank systems, each tank is backwashed with clean, filtered water.

The following section will explain briefly how to set the multiport pressure, when to

backwash the tanks, how the controllers work, how to initiate a backwash cycle, and how to

address maintenance issues.

4.1 Setting the Multiport Pressure

The multiport pressure is crucial to the operation of both the automatic and semiautomatic controllers. The pressure of the water supplied is what actuates the

valves in the system. For the valves to actuate properly there must be 35-40 psi of

water pressure supplied to the controller. Both controller kits come with a regulator

to adjust the pressure of the supplied water. For the semi-automatic controller kit,

the regulator can be located by following the tube from the back of the multiport

pressure gauge. For the automatic controller kit, the regulator is located on the top

right side of the multiport valve enclosure, next to the multiport pressure gauge.

The regulator can be adjusted by turning the top knob (with the slot) with a flathead

screw driver. Turning the knob clockwise increases the pressure and counter

clockwise decreases pressure. A d just t he regulator until the multiport pressure

gauge reads between 35 psi and 40 psi.

4.2 When to Backwash

Backwashing is the process which is used to clean the filter tanks. There are many

ways to determine when to backwash the filters as explained in the Tank

Owner’s/Operator’s Manual, however, the method that is most commonly used with

the semi-automatic and automatic controllers offered is the pressure differential

method (see Section 4.1 of the tank manual). Both types of controllers offer

gauges to monitor influent and effluent pressures to make determining when to

backwash easy.

4.3 Semi-Automatic Controller Operation

4.3.1 Controller Overview

The

semi-

Diaphragm Valve Face Piping Kit Installation Manual Pg. 33 of 47

1/16/05 Rev. D

automatic controller consists of a single gauge panel with gauges to measure

influent and effluent pressures, water pressure supplied to the multiport valve, and

the multiport valve knob, which is used to actuate the valves.

The influent and effluent pressure gauges show the water pressure coming into

and out of the filter system. This information will be useful in determining when the

tanks need to be backwashed. The influent pressure should always be higher than

the effluent. If it is not, please refer to the troubleshooting section of this manual

for assistance.

The multiport pressure gauge shows the water pressure supplied to the multiport

valve. This gauge should read at least 35 psi for proper valve operation. The

water supplied to the multiport valve is what actuates the diaphragm valves. If

insufficient water pressure is supplied, the valves may not actuate fully. This can

lead to insufficient backwashing of the sand bed, which will diminish the

effectiveness of the filters.

The multiport valve knob is what is used to initiate the backwash cycle. On it there

will be numbers, which correspond to the tanks, and the word home. When turned

to position 1 it will backwash tank one. If there are 2 tanks in the system then

position 2 will be used to backwash tank two. The home position is for use in

normal filtration mode.

4.3.2 Switching to Backwash Mode

The following are the steps to follow to initiate a backwash cycle with a semiautomatic controller. This can be used for both single and dual tank systems.

NOTE: Before actuating the multiport valve, it is recommended that the filter

feed pump be turned off. Make sure all isolation valves to the feed pump are

in their open position.

STEP 1: Rotate the multiport valve to

position 1. This actuates the diaphragm

valves. The pressure reading on the

multiport pressure gauge will drop as

water is allowed to flow into the tops of the

valves via the 3/8” polyethylene tubing.

Diaphragm Valve Face Piping Kit Installation Manual Pg. 34 of 47

1/16/05 Rev. D

STEP 2: Verify that multiport pressure gauge returns to normal pressure.

When actuating the valves the pressure to the multiport valve drops. When the

valves become actuated the pressure gauge will begin to rise, and should return to

its preset value (35 psi minimum). At this point, the valves are fully actuated. If the

pressure does not return to its initial value, please consult the troubleshooting

section of this manual. After the pressure has returned to normal, proceed to step

3.

STEP 3: Backwash the tank for 3-5 minutes. After the valves actuate, the filer

is now running in backwash mode. Water should be coming out of the waste pipe

and going to the drain. The filter tank should be backwashed 3-5 minutes, or until

the water in the sightglass runs clear. When the water runs clear, the tank is

cleaned. If there is more than one tank in the system proceed to step 4. If the

system consists of only one tank, proceed to step 6.

STEP 4: Rotate the multiport valve to

position 2. This will actuate the valves to

backwash tank 2.

STEP 5: Follow steps 2 and 3 as explained above.

STEP 6: Return the multiport valve to the

“Home” position. This will set system back

into normal filtration mode.

Diaphragm Valve Face Piping Kit Installation Manual Pg. 35 of 47

1/16/05 Rev. D

4.4 Automatic Controller

STEP 7: Verify that the influent and effluent pressures return to the clean

pressure values. The system should now be filtering water in normal filtration

mode. Take note of the influent and effluent pressures on the pressure gauges.

They should return to the values of a clean filter system. If not, repeat the

backwash process.

If the automatic controller option was purchased, there will be a separate manual

which will cover set-up options, operation, and maintenance. Please be aware that

what is supplied with the automatic controller kit is a basic system for use with the

pressure differential method of determining backwash. Options discussed in the

automatic controller manual may require additional parts which are not supplied

with the kit (i.e. relays and transformers to control pumps, heaters, etc. with the

controller).

Diaphragm Valve Face Piping Kit Installation Manual Pg. 36 of 47

1/16/05 Rev. D

APPENDIX

APPENDIX A TROUBLESHOOTING

APPENDIX B CONTROLLER INSTALLATION SCHEMATICS

APPENDIX C FILTER SYSTEM SPECIFICATION SHEETS

APPENDIX D VALVE ASSEMBLY DRAWINGS

Diaphragm Valve Face Piping Kit Installation Manual Pg. 37 of 47

1/16/05 Rev. D

Problem Possible Cause Solution

Slow activation of valves

APPENDIX A

1. Faulty or improperly installed check valve

2. Faulty or improperly installed regulator

3. Not enough pressure to the multiport valve

4. Kinked or obstructed controller tubing

5. Failing seals in the multiport valve

Verify that valve was installed correctly, making sure

the arrow points in the proper direction. Refer to

installation instructions for more information. Retry

valve actuation.

Verify that regulator was installed correctly. Refer to

installation instructions for more information. Retry

valve actuation.

Verify that the multiport pressure gauge reads between

35 psi and 40 psi. If not, readjust pressure using

regulator.

Check to see if and controller tubing is kinked or

pinched. If no pinching is present, disconnect the

tubing to the valve not actuating and visually inspect for

debris which may be blocking the tube.

Over time the o-ring seals in the muliport valve can

become worn and brittle. Eventually these seals will

need to be replaced. A good sign of this is water

constantly leaking from the multiport valve drain hose.

A multiport valve rebuild kit is available from the

manufacturer which offers replacement seals.

Inconsistend multiport

valve pressure

Leaking through waste

pipe in normal filtration

mode

Valves not actuating/

Can't intitate backwash

cycle

1. Faulty or improperly installed/adjusted regulator

2. Failing seals in the multiport valve

1. Debris preventing full closure of sideport seal

1. Not enough pressure to the multiport valve

2. Faulty or improperly installed and/or valve

Verify that regulator was installed correctly. Refer to

installation instructions for more information. Adjust

regulator, refer to Section 4.1. If regulator adjustment

does not fix problem, regulator may need to be

replaced.

Over time the o-ring seals in the muliport valve can

become worn and brittle. Eventually these seals will

need to be replaced. A good sign of this is water

constantly leaking from the multiport valve drain hose.

A multiport valve rebuild kit is available from the

manufacturer which offers replacement seals.

Inspect the valve and clear any debris which may be

preventing the side port seal from seating correctly.

Refer to drawing in Appendix for parts reference.

Verify that the multiport pressure gauge reads between

35 psi and 40 psi. If not, readjust pressure using

regulator, refer to Section 4.1.

Verify that the And/Or valve was installed properly.

Refer to installation instructions for more information.

Diaphragm Valve Face Piping Kit Installation Manual Pg. 38 of 47

1/16/05 Rev. D

APPENDIX B

Diaphragm Valve Face Piping Kit Installation Manual Pg. 39 of 47

1/16/05 Rev. D

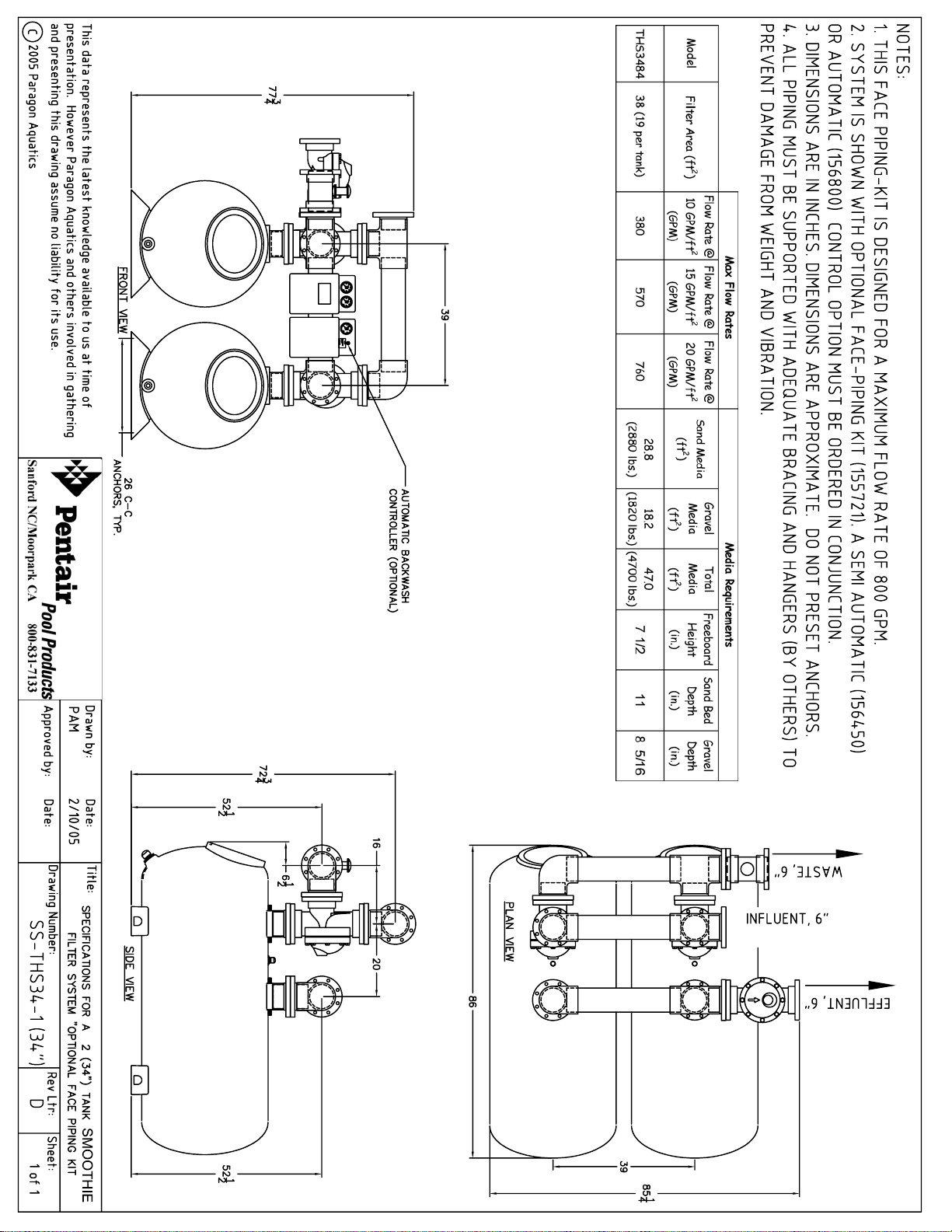

APPENDIX C

APPENDIX D

Loading...

Loading...