Page 1

PL series – corrosion-resistant

Convertible Deep Well Jet Pumps

UL778/CSA108

Durability and corrosion

resistance are built into every

PL Series Pump, due to the

rugged fiberglass reinforced

thermoplastic pump construction. The engineered composite

components are lightweight

yet extremely resistant to sand

and abrasive wear. The noncorrosive design and exceptional

strength assure years of troublefree operation.

APPLICATIONS

■

Water systems and sprinkling…

for homes, farms and cottages.

ORDERING INFORMATION

Catalog Pipe Tapping Sizes Motor Approx.

Number HP Description

PLC 1/2 Deep Well Jet 1-1/4" 1" 1" 115/230 27

PLD 3/4 Deep Well Jet 1-1/4" 1" 1" 115/230 28

PLE 1 Deep Well Jet 1-1/4" 1" 1" 115/230 30

PLF 1-1/2 Deep Well Jet 1-1/4" 1" 1" 115/230 36

Suction Drive Disch.

SPECIFICATIONS

Pump Body and Seal Plate –

Dura-Glas®

Impeller – Noryl®

Nozzle – Noryl

Venturi – Noryl

O-Ring – Buna-N

Clamp – Stainless steel

Shaft – Stainless steel

Diffuser – Reinforced polypropylene

with brass wear ring

Shallow Well Jet – Sold separately

Pressure Switch Pre-Set – 30-50 PSI

Suction Ports – Suction-over-Drive

Voltage Wt. Lbs.

FEATURES

Superior Rustproof

Construction – Pump body is

Dura-Glas fiberglass reinforced

thermoplastic – lightweight, rustproof and exceptionally strong. All

components in contact with water

are resistant to the corrosive and

abra sive forces found in the most

aggres sive water conditions.

Precision Diffuser – Multi-port,

reinforced polypropylene design

primes faster and handles more air.

Precision Molded Impeller –

Precision molded Noryl gives per fect

balance and ultra-smoothness for

highest performance and efficiency.

Pressure Regulator and Gauge –

Performance-proven, simple, built-in

pressure regulator is adjustable

for best performance on all deep

well installations. Pressure gauge

included.

Shaft Seal – Stainless steel heat

sink provides maximum cooling of

the mechanical shaft seal.

Heavy-duty Motor – Dustproof

canopy completely encloses electrical components and provides

dust, dirt and insect protection.

Ventilating air cannot contaminate

vital switching components.

Permanently lubricated, heavy-duty

ball bearings ensure smooth, quiet

operation and extended motor life.

Easy Serviceability – PL pumps

are disassembled by removing the

stainless steel clamp. Piping does

not have to be disturbed. Seal

replace ment takes only a few

minutes. “Control room” motor

design makes all components

easily accessible.

A Jet Package should be ordered with every PL Series pump.

Dura-Glas® is a registrered trademark of Pentair Water. Noryl® is a registered trademark

of General Electric Co. PRO-Source™ is a trademark of Pentair Water.

In order to provide the best products possible, specifications are subject to change.

Customer Service: (888) 782-7483

Fax Orders: (800) 426-9446 www.sta-rite.com

•

1

•

Pentair Water

Delavan, WI 53115 USA

•

S4510WS (5/11)

•

Page 2

PL series – corrosion-resistant

Convertible Deep Well Jet PumpsJet

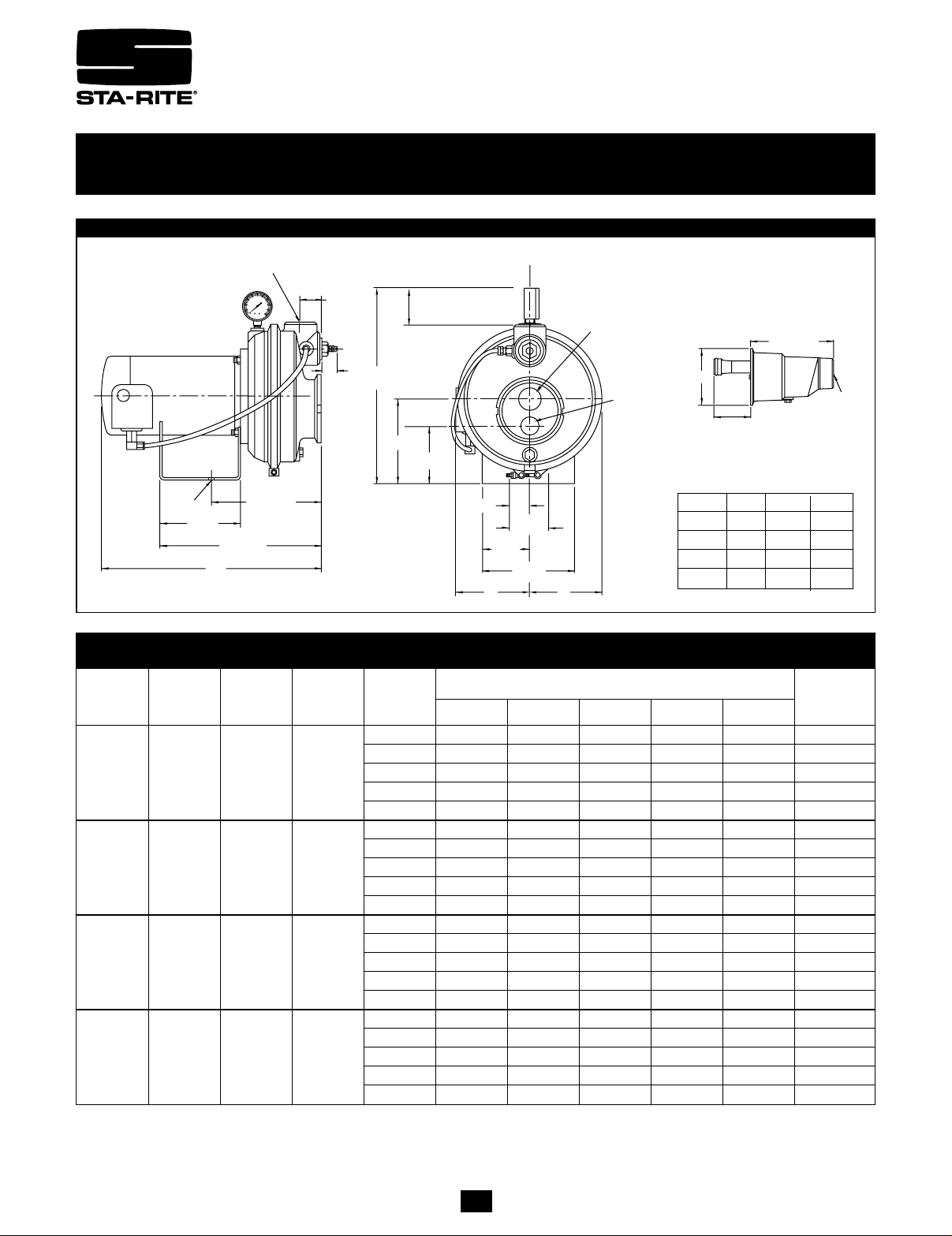

OUTLINE DIMENSIONS

1 NPT

DISCHARGE

60

0

psi

20

80

100

1-1/2

1-1/8

SUCTION

1-1/4 NPT

Shallow Well Jet

6-29/32

DRIVE

1 NPT

4-3/4 DIA.

1/4 NPT

3-1/16

(ordered separately)

Cat No. HP A B

PLC 1/2 13-7/8 4-1/8

PLD 3/4 14-5/8 4-1/8

PLE 1 15-1/8 4-1/8

PLF 1-1/2 16-1/8 4-7/16

12

1-1/2

MAX

5-13/16

1/2 DIA.

5-5/8

Dimensions (in inches) are for estimating purposes only.

PUMP PERFORMANCE

7-13/16

11-7/16

A

(Capacity in Gallons Per Minute)

3-15/16

1-3/8

3-1/4

B

2-3/4

6-1/2

5

SHALLOW WELL

Catalog Jet Switch Suct.

Number HP No. Setting Lift Ft. PSI

S.W. Press. Dynamic

Discharge Pressure — PSI

Shut-Off

20 30 40 50 60

Press.

5' 9.5 9.2 9.0 5.8 3.0 72

10' 8.2 8.0 7.8 5.2 2.3 70

PLC 1/2 PKG 1- 21N 30-50 15' 7.2 6.8 6.8 4.5 1.8 68

20' 5.7 5.7 5.7 3.8 66

25' 4.3 4.3 4.3 3.2 62

5' 16.2 15.8 15.3 8.7 1.3 62

10' 14.2 14.0 13.8 7.2 60

PLD 3/4 PKG 1- 22N 30-50 15' 12.2 12.0 11.8 5.3 58

20' 9.7 9.7 9.2 3.7 55

25' 7.2 6.8 6.8 52

5' 21.3 21.0 20.7 13.2 4.2 62

10' 18.8 18.7 18.3 11.1 1.7 60

PLE 1 PKG 1- 23N 30-50 15' 16.0 15.8 15.7 8.9 58

20' 12.8 12.7 12.3 5.7 55

25' 8.5 8.5 8.5 52

5' 26.3 26.2 26.2 21.3 7.7 64

10' 23.7 23.3 23.2 19.2 3.5 62

PLF 1-1/2 PKG 1- 24N 30-50 15' 20.3 20.2 20.0 16.3 60

20' 16.2 16.0 15.8 11.2 57

25' 11.5 11.3 11.3 54

Tested and rated in accordance with Water Systems Council standards.

NOTE: Pumps installed with a PRO-Source™ tank require a 100 PSI relief valve. Pumps installed with a conventional tank require

a 75 PSI relief valve. Relief valve must be capable of relieving entire flow of pump at relief pressure.

Customer Service: (888) 782-7483

Fax Orders: (800) 426-9446 www.sta-rite.com

•

2

Pentair Water

•

Delavan, WI 53115 USA

•

S4510WS (5/11)

•

Page 3

PL series – corrosion-resistant

Convertible Deep Well Jet Pumps

PUMP PERFORMANCE

DEEP WELL 4" DOUBLE PIPE – 40 PSI

Cat. Jet Uses Uses

No. HP No. Venturi Nozzle 20' 30' 40' 50' 60' 70' 80' 90' 100' 110' 120'

PLC 1/2

10SD N32P-67B J34P-44 9.5 7.0 4.5 2.0

PLD 3/4 4SD J32P-24 J34P-41 6.5 5.1 4.0 3.0 1.8 0.8

PLE 1 4SD J32P-24 J34P-41 8.4 7.3 6.2 5.0 4.1 2.9 2.0 1.1

PLF 1-1/2 11SD N32P-68B J34P-44 11.5 9.4 8.0 6.5 5.3 3.8 2.5 1.1

4SD J32P-24 J34P-41 4.5 3.5 2.3 1.3

PUMP PERFORMANCE

Cat. Jet Uses

No. HP No. Venturi Nozzle

DEEP WELL 2" SINGLE PIPE – 40 PSI

13AP J32P-26 J34P-44 5.8 3.8 1.0

PLC 1/2 10AP J32P-24 J34P-44 4.3 3.0 1.6

8AP J32P-18 J34P-42 3.8 3.3 2.6 2.0 1.5

14AP J32P-32 J34P-45 9.2 6.7 4.3

PLD 3/4 10AP J32P-24 J34P-44 6.2 4.8 3.7 2.3 1.2

8AP J32P-18 J34P-42 4.1 3.7 3.1 2.6 2.1 1.6 1.2 0.8

15AP J32P-33 J34P-41 12.3 9.2 5.7

PLE 1 9AP J32P-29 J34P-44 10.6 7.4 4.7 2.2

8AP J32P-18 J34P-42 5.0 4.7 4.2 3.8 3.3 2.7 2.3 1.8 1.3

16AP J32P-38 J34P-45 15.3 11.8 8.5 5.2

PLF 1-1/2 9AP J32P-29 J34P-44 12.3 9.3 6.4 4.0

8AP J32P-18 J34P-42 5.7 5.0 4.6 4.2 3.7 3.3 2.8 2.4 1.8 1.3

DEEP WELL 3" SINGLE PIPE – 40 PSI

25CP J32P-26 J34P-44 5.8 4.0 2.1

PLC 1/2

11CP J32P-32 J34P-45 9.5 7.0 4.5 2.0

PLD 3/4

26CP J32P-33 J34P-41 13.0 9.8 6.0

PLE 1 17CP J32P-29 J34P-44 11.5 8.0 5.2 2.6

19CP J32P-24 J34P-41 8.4 7.3 6.2 5.0 4.1 2.9 2.0 1.1

PLF 1-1/2

15CP J32P-22 J34P-43 8.6 7.9 6.9 6.2 5.4 4.4 3.2 2.2 1.5 0.9

Tested and rated in accordance with Water Systems Council standards.

NOTE: Pumps installed with a PRO-Source™ tank require a 100 PSI relief valve. Pumps installed with a conventional tank require

19CP J32P-24 J34P-41 4.5 3.5 2.3 1.3

19CP J32P-24 J34P-41 6.5 5.1 4.0 3.0 1.8 0.8

10CP J32P-38 J34P-45 16.6 13.3 9.5 6.0

a 75 PSI relief valve. Relief valve must be capable of relieving entire flow of pump at relief pressure.

(Capacity in Gallons Per Minute)

Pumping Depth in Feet

(Capacity in Gallons Per Minute)

Pumping Depth in Feet

20' 30' 40' 50' 60' 70' 80' 90' 100' 110' 120'

Customer Service: (888) 782-7483

Fax Orders: (800) 426-9446 www.sta-rite.com

•

3

Pentair Water

•

Delavan, WI 53115 USA

•

S4510WS (5/11)

•

Loading...

Loading...