Page 1

OWNER’S MANUAL

PENTEK INTELLIDRIVE

™

293 Wright Street, Delavan, WI 53115

Phone: 866-9 PENTEK (866-973-6835)

Fax: 800-426-9446

www.pumps.com

PID10, PID20, PID50

Installation/Operation/Parts

For further operating, installation,

or maintenance assistance call:

©2012 PN957 (08/14/12)

866-9PENTEK

(866-973-6835)

Page 2

Safety 2

Important Safety

Instructions

SAVE THESE INSTRUCTIONS - This manual

contains important instructions that should be

followed during installation, operation, and

maintenance of the PENTEK INTELLIDRIVE Variable

Frequency Drive (VFD).

This is the safety alert symbol. When you see

this symbol on your PENTEK INTELLIDRIVE or in

this manual, look for one of the following signal

words and be alert to the potential for personal

injury!

avoided, will result in death or serious injury.

avoided, could result in death or serious injury.

avoided, could result in minor or moderate injury.

NOTICE addresses practices not related to

personalinjury.

Carefully read and follow all safety instructions in

this manual and on the PENTEK INTELLIDRIVE.

Keep safety labels in good condition. Replace

missing or damaged safety labels.

from EMI/RFI filter inside drive. Can shock,

burn or kill if the front cover of the PENTEK

INTELLIDRIVE is open or removed while power

is connected to the Drive or the Drive is running.

The front cover of the Drive must be closed during

operation.

• Makeallwiringconnections,thencloseand

• NEVER open the box when power is connected to

• Beforedoinganyserviceormaintenanceinside

• Beforestartinganywiringorinspection

• NEVER connect power wiring to

• NEVER handle or service

• NEVER reach into or change the cooling fan while

• NEVER touch the printed circuit board when

indicates a hazard which, if not

indicates a hazard which, if not

indicates a hazard which, if not

Risk of high-voltage electrical shock

fasten the cover before turning on power to drive.

Drive.

Drive or when connecting or disconnecting any

wires inside Drive:

1. DISCONNECT power.

2. WAIT 5 minutes for retained voltage

todischarge.

3. Open box.

procedures, check for residual voltage with a

voltage tester.

Drive

mounting the box.

hands. Always make sure hands are dry before

working on

power is applied to Drive.

power is applied to Drive.

Drive

Drive

.

before

with wet or damp

property damage or death if installed with incorrect

or inadequate circuit breaker protection. To ensure

protection in the event of an internal fault in the

PENTEK INTELLIDRIVE, install the Drive on an

independent branch circuit protected by a circuit

breaker (see Table 2 for circuit-breaker sizing), with

no other appliances on the circuit.

hot during normal operation. Allow it to cool for

5minutes after shut-down and before handling it to

avoid burns.

NOTICE To avoid damage to Drive or problems

with Drive:

• Connectoutputcablesto3-wire and 3-phase

RedtoR,YellowtoY,BlacktoB.

Any other order will reverse the motor rotation

• Connectoutputcablesto2-wire 1-phase

ConnecttoYandBonly.

Connect Ground to green screw.

• Aboveground3-phasemotorsmayhavedifferent

RtoL1,YtoL2,BtoL3.

Verify rotation after startup.

• Donotmodifyequipment.

• Donotusepowerfactorcorrectioncapacitors

• Donotremoveanypartsunlessinstructedtodo

• DonotuseamagneticcontactoronDrivefor

• DonotinstalloroperateDriveifitisdamagedor

• BeforestartingDrivethathasbeeninstorage,

• Donotcarryoutamegger(insulationresistance)

• Donotallowlooseforeignobjectswhichcan

• GroundDriveaccordingtotherequirementsof

• Allinstallation,servicework,andinspections

Risk of fire. Can cause severe injury,

Risk of burns. The Drive can become

submersible motors as follows:

and may damage the motor.

submersible motors as follows:

lead colors. Generally connect output leads

asfollows:

Drive

PENTEK

.

as they will damage both motor and

INTELLIDRIVE

so in Owner’s Manual.

frequent starting/stopping.

parts are missing.

always inspect it and test operation.

test on the control circuit of the

conduct electricity (such as screws and metal

fragments) inside Drive box at any time. Do not

allow flammable substances (such as oil) inside

Drive box at any time.

the National Electrical Code Section 250, IEC536

Class 1, or the Canadian Electrical Code (as

applicable) , and any other codes and ordinances

that apply.

must be done by qualified electrician.

.

Page 3

Table of Contents 3

Safety .............................................................2

Owner’s Information .................................................3

Description ...................................................... 4-5

Installation ...................................................... 6-10

In itial Startup ................................................... 11-12

Programming ................................................... 13-16

I/O Connections ................................................ 17-18

Additional Information ..............................................19

Troubleshooting ................................................ 20-22

Warranty .........................................................23

Owner’s Information

PENTEK INTELLIDRIVE Model No. _________________________

EMI/RFI Filter

PENTEK INTELLIDRIVE Serial No. _________________________

Pump Model No. _________________________

Pump Serial No. _________________________

Motor Model No. _________________________

Motor Service Factor Amps _________________________

Risk of electric shock. Can

shock, burn or kill.

• Drive’sinternal

components retain

high voltage for up to

5minutes after input

power is disconnected.

• EMI/RFIFiltercarries

high voltage when pump

is running.

• Disconnectpowerand

wait 5 minutes before

opening

PENTEK

INTELLIDRIVE

cover.

Pressure Tank Model No. _________________________

Pressure Tank Serial No. _________________________

Dealer/Installer: _____________________________________________

_____________________________________________

Installer Phone No. _________________________

Date of Installation _________________________

Wire Lengths in Feet (Meters):

CircuitBreakertoDrive _________________________

PENTEK INTELLIDRIVE to Motor _________________________

Supply Voltage _________________________

Note to Installer: Record the data listed above for future reference. Give manual to

end user or attach to

PENTEK INTELLIDRIVE

when installation is complete.

Page 4

Description 4

Specifications/Ratings

Input Voltage ........... 1-Phase 230VAC Nominal (190–265VAC)

Input Frequency .........................................................50/60Hz

Ambient Tempature Range ............ -4 to 122 °F (-20° to 50 °C)

Output Connections ..................3-Phase, 3-Wire/1-Phase or

Max Motor Cable Length .......................................... 1,000 feet

Enclosure ....................................................................... Type 1

Table 1 - Specifications

Model

PID10 1.0

PID20 2.0 13.5

Max HPInput

Phase

1

Operation

2-wire, 3-wire,

PID50 5.0 1 3-phase 18.0

The PENTEK INTELLIDRIVE is specifically designed

to operate 4” submersible pumps and 3-phase

above ground pumps in water well and residential

booster applications. Each Drive is rated for

maximum output amp rating. Any use of Drive

outside of intended design parameters will void

warranty. If Drive is used with above ground motors

not rated for a Variable Frequency Drive, maximize

motor life by limiting lead length to 25 ft. Refer to

pump Owner’s Manual and the National Electrical

Code for proper wire size.

Motor

3-phase

1-Phase/2-Wire

Max

Amps

10.5

Each carton contains:

• PENTEK INTELLIDRIVE Variable Frequency Drive

•PressureTransducer

•10’PressureTransducerCable

•QuickStartGuide

•Owner’sManual

PENTEK INTELLIDRIVE Model Number Structure

PIDXX

Product Family

PID - PENTEK INTELLIDRIVE

HP Range

10 = up to 1.0 HP

20 = up to 2.0 HP

50 = up to 5.0 HP

The PID10 and PID20

will operate a 1-phase

2-wire, 1-phase 3-wire, and 3-phase motor up to the

HP range of the Drive. The

PID50 only operates a

3-phase motor up to 5 HP.

Gnd

(3 phase only)

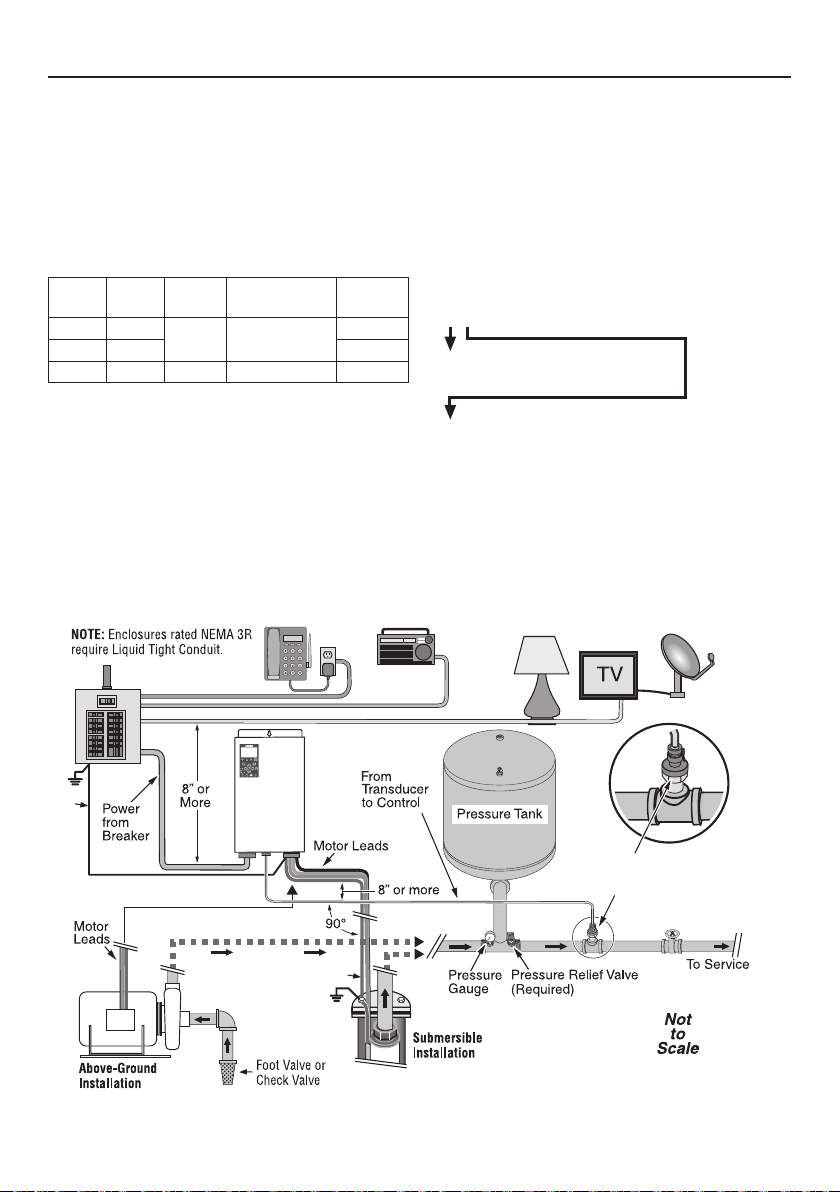

Figure 1 -

PENTEK

INTELLIDRIVE™

Gnd

A typical residential installation layout

Transducer; install in straight

pipe downstream of tank, at

least one foot away from

pipe fittings on each side.

Page 5

Description 5

Transducer

The PENTEK INTELLIDRIVE uses a 4-20mA,

0-100PSI pressure transducer to control motor

speed (max is 300 PSI transducer).

The transducer (see Figure 1) senses pressure in

the pipe and converts it to an electrical signal.

The Drive senses and processes the signal in the

PID (Proportional, Integration, Derivative) control.

When operating in AUTOSTART mode, the Drive

increases and decreases the speed of the pump

motor as needed to maintain constant pressure in

the piping system.

Changes internal pressure setpoint from

15 PSI to transducer max -3PSI

Runs the Drive at 45Hz (with no

pressure control) to allow installer to

Changes display to previous screen.

Selects menu items and confirms

Drive is in Warning Mode (TPM); refer to

Displays Drive’s current operating

condition and changes display

Figure 2 - PENTEK INTELLIDRIVE keypad functions

(default is 60 PSI).

pump out well.*

numeric value changes.

Power is ON to Drive.

Troubleshooting section.

A fault has occurred.

parameters.

Stops the motor.

Keypad

The keypad programs the Drive, monitors the status

of the pump, and displays faults if they occur.

Each button has a unique function, as described in

Figure 2. The LCD display shows a text display of

the status of the Drive’s operation. Other LEDs light

up to indicate when certain buttons are pressed or

certain events occur.

Fan

The Drive uses a thermostatically controlled

internal fan which operates automatically when

necessary to cool the Drive components.

Views and changes parameters.

Shows last 15 faults.

With code, locks and unlocks password

protected keys.

Toggles between English, Spanish, and

French (default is English).

Left and right arrows move cursor.

Up and down arrows scroll through

menus and change numeric values.

Resets fault that stopped Drive/pump.

Checks for line fill, then starts pump in

constant pressure mode.

Page 6

Installation 6

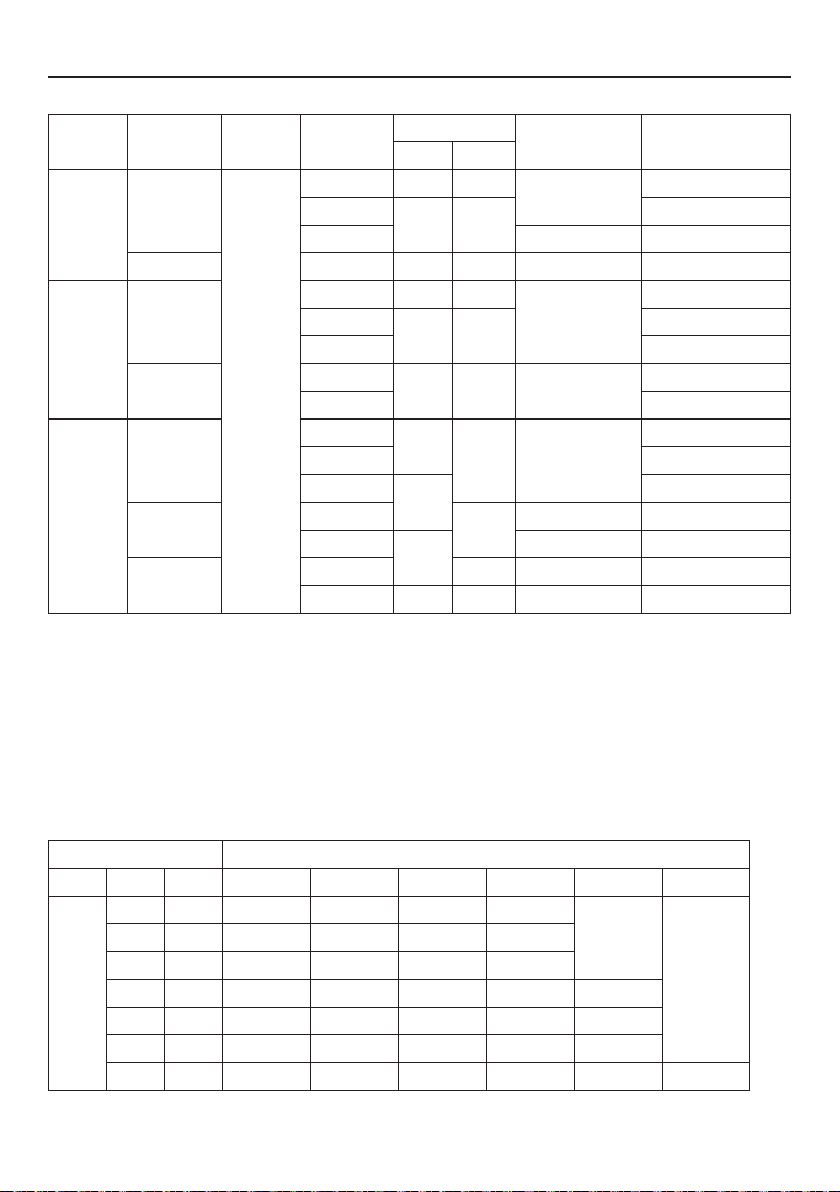

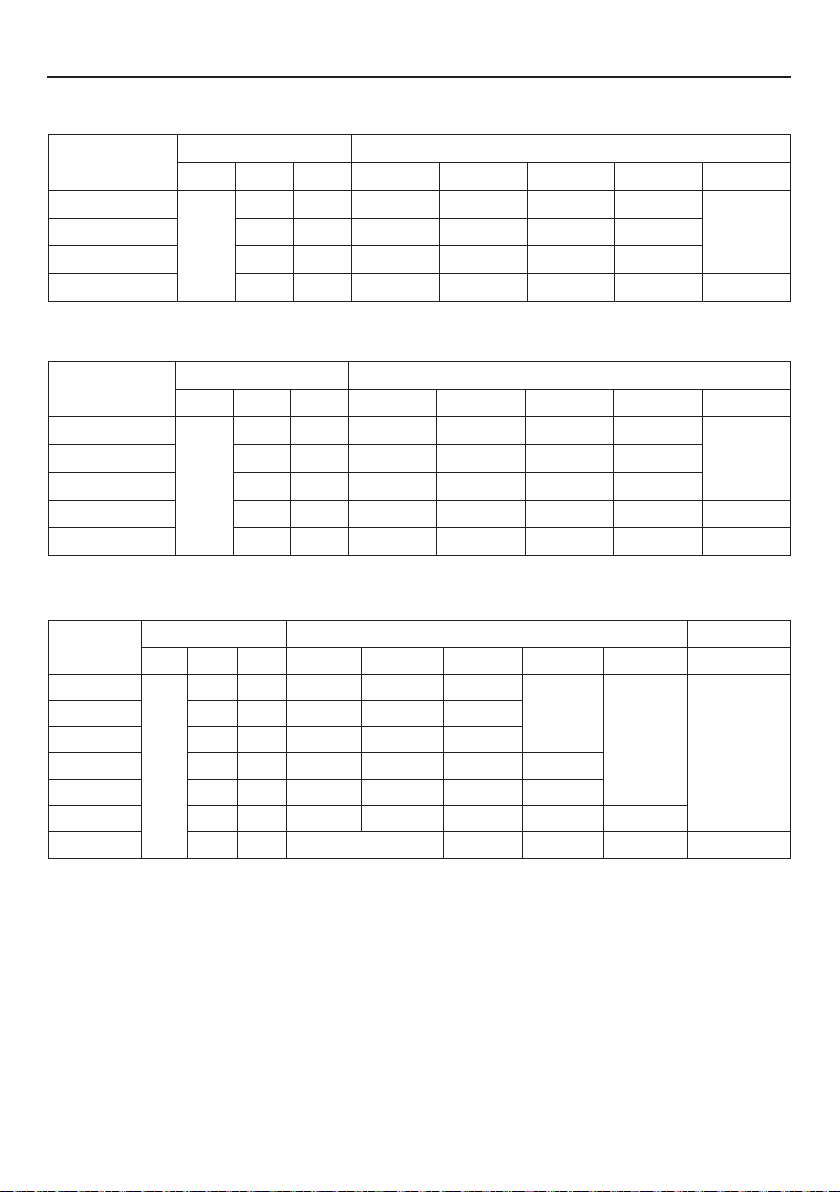

Table 2 - Circuit Breaker and Wire Sizes.

Motor

2-wire

3-wire

3 phase

* AWG will change depending on the length of wire. See Tables 3-6.

** With properly-sized circuit breakers, the Drive is protected from short circuit on the input and the

output. There is no risk of fire or electrical shock due to a short circuit. The Drive has NEC Class 10

overload protection.

*** Minimum 240V generator size.

NOTICE Information in Tables 3-6 applies ONLY to PENTEK® motors. For other motors, refer to motor

manufacturer specifications for wire sizing.

Drive

Model

PID10

PID20 1-1/2 10 10 25 5.3

PID10

PID20

PID10

PID20

PID50

Volts Motor HP

1/2 14 14

3/4

1 20 4.4

1/2 14 14

3/4

1 3.5

230

1-1/2

2 5.8

1/2

3/4 2.8

1

1-1/2

2

3 10 30 7.3

5 6 8 50 12.6

Wire Size*

Input Output

12 12

12 12

10 10 25

14

12

10

Circuit Breaker** Generator (kVA)***

14 15

12

15

15

20 4.4

25 5.5

2.2

3.1

2.3

3.0

5.3

2.1

3.4

Table 3 - Service Entrance to Drive - 1 Phase, 2-Wire 40°C Ambient, and 5 percent Voltage Drop,

60C and 75C Insulation (copper only).

Motor Rating Maximum Cable Length in feet (M)

Volts HP SFA 14 AWG 12 AWG 10 AWG 8 AWG 6 AWG 4AWG

1/2 4.7 447 (136) 712 (217) 1000 (305) –

3/4 6.2 341(104) 542 (165) 864 (263) 1000 (305)

1 8.1 261(79) 415 (126) 661 (202) 1000 (305)

230

1 1/2 10.4 203 (62) 323 (98) 515 (157) 816 (249) 1000 (305)

2 12.2 173 (53) 275 (84) 439 (134) 696 (212) 1000 (305)

3 10.1 209 (64) 333 (101) 530 (162) 840 (256) 1000 (305)

5 17.5 121(37) 192 (59) 306 (93) 485 (148) 754 (230) 1000 (305)

–

–

Page 7

Installation 7

Table 4 - AWG Wire Sizing, Drive to 1-Phase, 2-Wire Motor, 40°C Ambient, and 5 percent Voltage Drop,

60C and 75C Insulation (copper only).

Motor P/N

P42B0005A2-01

P42B0010A2-01 1 8.1 261 (80) 415 (126) 661 (201) 1000 (305)

Motor Rating Maximum Cable Length in feet (M)

Volts HP SFA 14 AWG 12 AWG 10 AWG 8 AWG 6 AWG

1/2 4.7 447 (136) 712 217) 1000 (305) –

230

–P42B0007A2-01 3/4 6.2 341 (104) 542 (165) 864 (263) 1000 (305)

P42B0015A2-01 1 1/2 10.4 203 (62) 323 (98) 515 (157) 816 (249) 1000 (305)

Table 5 - AWG Wire Sizing, Drive to 3-Wire, 1-Phase Motor, 40°C Ambient, and 5 percent Voltage Drop,

60C and 75C Insulation (copper only).

Motor P/N

P43B0005A2-01

Motor Rating Maximum Cable Length in feet (M)

Volts HP SFA 14 AWG 12 AWG 10 AWG 8 AWG 6 AWG

1/2 4.8 440 (134) 700 (213) 1000 (305) –

–P43B0007A2-01 3/4 6 352 (107) 560 (171) 893 (272) 1000 (305)

P43B0010A2-01 1 7.3 289 (88) 460 (140) 734 (224) 1000 (305)

230

P43B0015A2-01 1 1/2 10.9 194 (59) 308 (94) 492 (150) 778 (237) 1000 (305)

P43B0020A2-01 2 12.2 173 (53) 275 (84) 439 (134) 696 (212) 1000 (305)

Table 6 - AWG Wire Sizing, Drive to 3-Phase Motor, 40°C Ambient, and 5 percent Voltage Drop,

60C and 75C Insulation (copper only).

Motor P/N

P43B0005A3

P43B0007A3 3/4 3.9 541 (165) 861 (262) 1000 (305)

P43B0010A3 1 4.7 449 (137) 715 (218) 1000 (305)

P43B0015A3 1 1/2 6.1 346 (105) 551 (168) 878 (268) 1000 (305)

P43B0020A3 2 7.6 278 (85) 442 (135) 705 (215) 1000 (305)

P43B0030A3 3 10.1 209 64) 333 (101) 530 (162) 840 (256) 1000 (305)

P43B0050A3 5 17.5 306 (93) 485 (148) 754 (230) 1000 (305)

Motor Rating Maximum Cable Length in feet (M)

Volts HP SFA 14 AWG 12 AWG 10 AWG 8 AWG 6 AWG 4 AWG*

1/2 2.9 728 (222) 1000 (305) –

–

_

230

_

*Installations that require wire gauge larger than 6AWG will require an external junction box. Run 6AWG

wire from the Drive into the junction box, then make external connections with wire nuts to appropriately

sized wire.

Page 8

8Installation 8

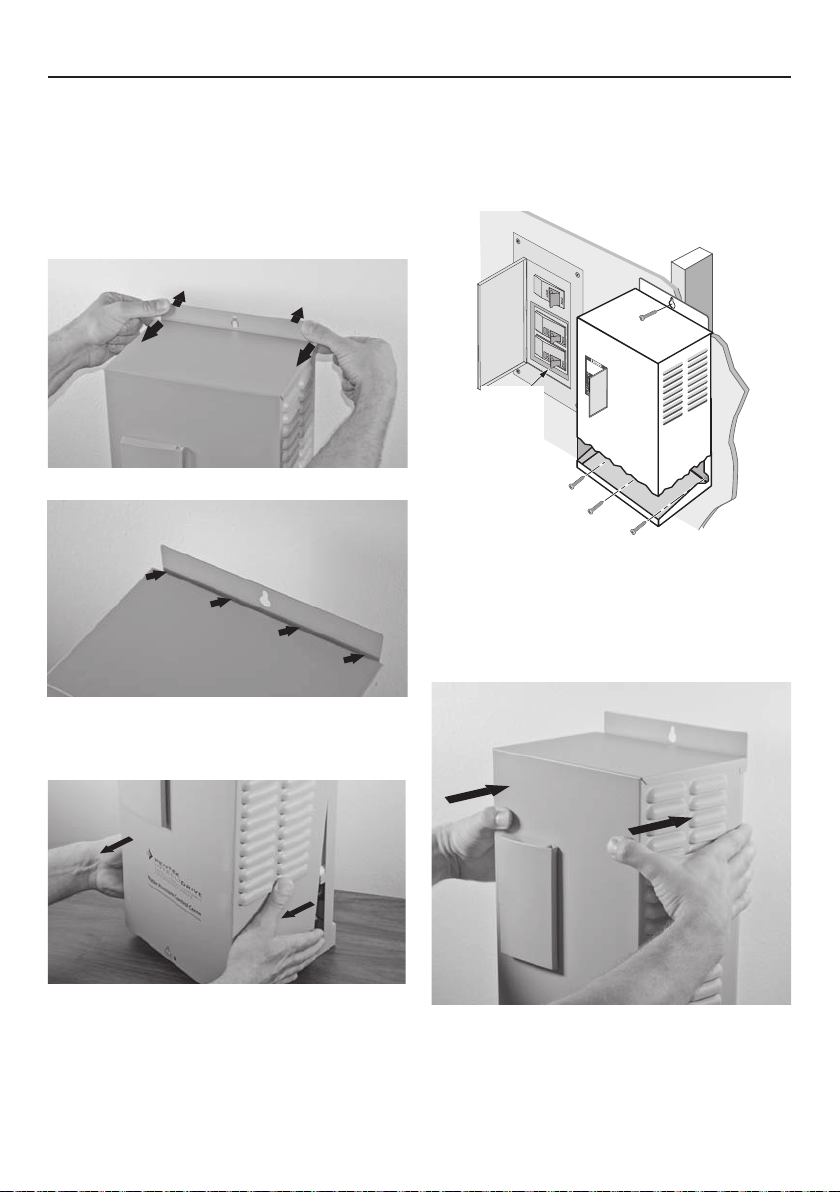

Mounting the Drive

To mount the Drive as shown in Figure 6, follow

this procedure:

1. First, remove the cover by backing out screw

at bottom of front cover.

2. Push on backplate with thumbs while pulling

the cover toward you with index fingers,

creating a gap. See Figures 3 and 4.

Figure 3 - Seperate cover and backplate

Gap

5. Ensure the Drive’s ventilation holes are not

blocked and there is enough space around it

to allow free air flow (minimum 3” clearance

on top, bottom, and sides). See Figure 6. Once

the Drive is mounted, electrical wiring can be

connected.

Typical

230VAC

Circuit

Breaker

(Double

Width)

Figure 6 - Attaching Drive to wall

6. To reattach the Drive cover, hook the top of it

on backplate (be sure to leave a gap). Lower

bottom of cover into place. Push cover evenly

against backplate, eliminating the gap. See

Figure 7.

Figure 4 - Gap between cover and backplate

3. Pull bottom of cover towards you; liftup on

cover and remove. See Figure 5.

Figure 5 - Pull out bottom of cover

4. With the cover removed, permanently mount

the Drive using the top slotted hole, plus

either the three bottom holes (for flat surface

mounting) or the center bottom hole (for

attaching to a post or stud). See Figure 6.

Figure 7 - Reattaching Drive cover

7. Replace screw at bottom of front cover.

Page 9

9Installation 9

Wiring

To allow for ease of wiring, the enclosure wiring

area is free of electronics other than the terminals.

Conduit holes and knockouts are located so

that the wire can be fed straight through to the

connectors, with minimal bending. The terminals

accept 6-14 AWG wire.

Installations that require larger wire gauge than

6AWG will require an external junction box. Run

6AWG wire from the Drive into the junction box,

then make external connections with wire nuts to

appropriately sized wire.

NOTICE For convenience in wiring, the input and

motor terminals unplug from the box. Pull them

down to remove them for ease of access, as shown

in Figure 9.

Verify that the terminal connectors are completely

seated when you replace them. It is best practice

Figure 8 - Pull input and motor terminals down to

remove, making wiring easier.

to connect all output wires (larger wire gauge) first,

then all input wires.

Pump Connections

If the PENTEK INTELLIDRIVE is used with above

ground motors not rated for Variable Frequency

Drive use, maximize motor life by limiting lead

length to 25 ft. Refer to the pump owner’s manual,

the National Electrical Code, and local codes for

proper wire size.

The output of the Drive is single phase (2-wire or

3-wire) or 3-phase, depending on motor selection

during startup.

The output power terminals (motor wire

connections) are located on the lower right side

of the Drive and are labeled R (Red), Y (Yellow),

andB(Black).SeeTables2through6forsuggested

wiresizes.

Feed the motor cable through the 3/4” conduit hole

on the bottom right side and into the appropriate

terminals. If the wire is large enough to require a

larger conduit hole, remove the 1-1/4” knockout

and use the appropriate conduit connections.

Attach the motor ground wire to the grounding

screw, located to the upper right of the terminal

block. Attach the motor power wires to the

terminals as shown in Figure 9.

01+ 01+ I1+ I1- I2+ I2- V+ V- AI+ AI- P N SD CARD

Green Cable Shield/Screw

Input Power

Connections

Input

Ground Screws

Green/Yellow

(Ground)

Figure 9 - Basic Wiring Connections for Startup

Red to AI+

Black to AI–

Transducer Cable

Connections

Red

Yellow

Black

Output

Ground Screw

Submersible Motor: 3-Ph./ 3-W. 1-Ph., follow colors as above.

Submersible Motor: 1-Ph./ 2-W., connect to Y and B, any order.

Above-Ground Motors: L1 to R, L2 to Y, L3 to B; verify rotation.

Motor Connections

Green/Yellow (Ground)

Page 10

10Installation 10

Pressure Tank Recommendations

Minimum tank size is two gallons. Use a precharged pressure tank with Drive, as shown in

Table6. The tank size must equal at least 20

percent of the pump’s rated flow in gallons per

minute (GPM), but cannot be less than two gallons

capacity. For example, a pump rated at 7GPM

would require a tank of two gallons capacity or

larger. A pump rated at 50 GPM would require a 10

gallon tank or larger. Tanks larger than 10gallons

can be used, but may require adjustment of Wake

Delayparameter.

Table 7 - Control Pressure Set Point and Tank

Pre-Charge Pressure Values (PSI).

Pressure

Point

Setting

(PSI)

25 18 65 46

30 21 70 49

35 25 75 53

40 28 80 56

45 32 85 60

50 35 90 63

55 39 95 67

60

(Default)

NOTICE Set pressure tank’s pre-charge to 70

percent of the system operating pressure. When

using an external set point as well as an internal

set point, pre-charge tank to 70 percent of the

lower setpoint of the two. Some applications may

require a different percentage when determining

the setpoint.

Precharge

Pressure

(PSI)

42 –

Pressure

Point

Setting

(PSI)

Precharge

Pressure

(PSI)

Transducer Connections

A 0-100 PSI 4-20 mA transducer is provided with

Drive. Install the transducer downstream of tank,

as shown in Figure 1. Install transducer in a tee

in a straight section of pipe with at least 1 foot of

straight pipe on each side of the tee (i.e., all fittings

must be at least 1 foot away from transducer).

Feed transducer cable through the open 1/2”

conduit hole on bottom of the Drive enclosure.

As shown in Figure 5, connect the red wire of the

transducer cable to AI+, connect black wire to AI–,

and connect the green cable shield to the metal

cable shield screw.

To connect the transducer wires:

1. Strip wire ½ inch

2. Push spring terminal up with finger or slotted

screwdriver

3. Insert wires from bottom

4. Release spring terminal

Input Power Connections

The input power terminals are located on the

lower left side and are marked L1 and L2 (see

Figure 9). There is a ground screw for the input

ground wire to the right of the connector (torque

to 10 lbs in). Feed wire through the 3/4” conduit

hole on the bottom left side and into appropriate

terminals. If wire is large enough to require a larger

conduit hole, remove the 1-1/4” knockout and use

appropriate conduitconnections.

To determine the correct wire sizes for installation,

see Tables 2 through 6.

NOTICE The PENTEK INTELLIDRIVE only accepts

230V single phase input power. If incoming power

does not match this, have a qualified electrician

alter supply voltage to 230V/1Ph before connecting

it to the Drive.

Page 11

11Initial Startup 11

Press Enter

Press Enter

Press Enter

Apply 230V to Drive

Set Time

Set Date

Setup Complete

1 Phase

Connection Type

(2 Wire or 3 Wire)

3 Phase

Motor Type

Subm or Above Gnd

Enter Service

Factor Amps

Enter Motor Phase

(1 Phase or 3 Phase)

Press Enter

Use arrows to

scroll to Motor

Press Enter

Use arrows to

select 80 Hz

Press Enter

to save

Press MAIN MENU

button

Press Enter

Use arrows to select

Max Frequency

Initial Startup and

Programming Procedures

Ensure that the cover is installed before operating

the

PENTEK INTELLIDRIVE.

Most installations will only require the initial

startup settings. However, the installer may need

to set additional parameters. Information about

accessing all parameters, explanations of their

functions, and procedures for changing parameter

values, will be found later in this section.

1. Program the Drive: Apply power to the

PENTEK INTELLIDRIVE. Setup Guide will appear

in the display. Follow keypress sequence shown in

Figure 10.

NOTICE If Setup Guide does not appear, refer to

Drive Reset Procedure, Figure 20.

Service Factor Amps

To maximize pump performance, be sure to

enter the correct Service Factor Amps (SF Amps)

in the

PENTEK INTELLIDRIVE

• EnteringSFAmpshigher than the motor rating

lets the Drive supply more amps to the motor

than the motor is designed for and may allow

the motor to overheat (see Table 8).

• EnteringSFAmpslower than the motor rating

limits the output amps to less than the motor is

designed for and will reduce the performance

of the pump.

• Forany1-Phase3-Wiremotor,thecorrect

Service Factor Amp rating for the Drive is Cap

Start/Cap Run amps (see Table 8). This may

not match the motor nameplate, which (for a

Single Phase, 3-Wire motor) will generally be

Cap Start/ Induction Run Amps.

• Forany3-Phaseor1Phase,2-Wiremotor,

use the motor nameplate Service Factor

Amprating.

NOTICE

PENTEK®

submersible motors may differ

from motors of the same horsepower from other

manufacturers. For 1-Phase, 3-Wire motors from

all other submersible motor manufacturers,

enter the motor manufacturer’s CS/CR service

factor amps for your motor. For 3-Phase or

2-Wire 1-Phase motors, use the motor nameplate

amp value. Also see Retro Fit Applications.

2. Select 80 Hz Operation, if necessary (See 60 Hz

to 80Hz Operation for more information):

A. Press MAINMENU button.

B. Followthekeypresssequenceshownin

Figure11.

.

Figure 10 - Drive Setup Guide.

Figure 11 - Select 80 Hz (3-phase operation only).

Page 12

12

Initial Start-up 12

3. Pump out well (if necessary):

Direct pump’s discharge to appropriate location

not connected to system and press Pump Out.

The pump will run at 45 Hz.

Adjust frequency as appropriate:

A. Press ENTER

B. Changefrequencyvalue

Table 8 - PENTEK Motor Service Factor Amps

Motor

Type

2-Wire

CS/CR

3-Wire

3-Phase

PENTEK Part

Number

P42B0005A2-01 1/2 4.7

P42B0007A2-01 3/4 6.2

P42B0010A2-01 1 8.1

P42B0015A2-01 1-1/2 10.4

P42B0005A2 1/2 4.7

P42B0007A2 3/4 6.4

P42B0010A2 1 9.1

P42B0015A2 1-1/2 11.0

P43B0005A2-01 1/2 4.8

P43B0007A2-01 3/4 6.0

P43B0010A2-01 1 7.3

P43B0015A2-01 1-1/2 10.9

P43B0005A2 1/2 4.9

P43B0007A2 3/4 6.3

P43B0010A2 1 7.2

P43B0015A2 1-1/2 11.1

P43B0020A2 2 12.2

P43B0005A3 1/2 2.9

P43B0007A3 3/4 3.9

P43B0010A3 1 4.7

P43B0015A3 1-1/2 6.1

P43B0020A3 2 7.6

P43B0030A3 3 10.1

P43B0050A3 5 17.5

Rating @

230V

HP

Service

Factor

Amps

4. Verify installation: Make sure that the system has

properly-sized, pressure-relief valve and pressure

tank.

Make sure pressure tank’s precharge is correct.

See Table 7.

Make sure pump discharge is connected to

system.

5. System Start:

A. Open valves at the ends of lines so that air

will escape during pressurization.

B. PressAuto Start; close valves at the ends of

lines after all air has escaped.

C. The system goes into Constant Pressure

Operation as soon as the transducer registers

the Dry Run Sensitivity parameter (default

is 10 PSI). If system pressure does not reach

thatPSI value within 3 minutes, the Drive will

stop. Press Auto Start again to restart line fill.

If longer priming or line fill time is required,

adjust Fill Time parameter. See Table 9.

Changing a Parameter Value

This procedure works for ANY parameter.

A. Press MAINMENU button.

B. Followthekeypresssequenceshownin

Figure12:

A shorthand way to remember this is:

• PressENTER to change a value

• PressENTER again to save it

• Ifnewvalueisnotsaved,anyscreenchangewill

result in the loss of the new value.

Use arrows to

find a parameter

Press Enter

Use arrows to

change the value

NOTICE Above ground pumps should run at 60

Hz for this step (until pump is primed). Then

adjust frequency as necessary.

C. Press ENTER again.

Run the Drive in this mode until the well

discharge runs clear, then press STOP button to

stop Drive.

Risk of explosion. In Pump Out

mode, pump runs at a constant speed, which

can cause very high pressure if flow is restricted.

Press Enter to Save

Figure 12 - Changing parameter value.

Table 9 lists all available commands and

parameters for the PENTEK INTELLIDRIVE.

Page 13

13Programming 13

Press PSI Preset

Use arrows to

change the value

Press Enter to Save

Press Enter

60 Hz to 80 Hz Operation

When installing the PENTEK INTELLIDRIVE with

a motor and liquid end of the same HP rating,

operate it at 60 Hz (the default value). The Drive

can be operated at frequencies of up to 80 Hz

when the installation uses a 3-phase motor 2 times

the size of the pump. For example, a 1 HP pump

with a 2 HP 3-phase motor. This combination

will equal the performance of a conventional

2HPpump.

Press Main Menu and

shown in Figure7

follow the keypress sequence

.BesuretopressENTER to save

the new Max Frequency selected. The Drive will

now use the new value selected.

NOTICE The Drive will not allow the output amps

to go above the Service Factor Amps selected on

thekeypad.Becauseofthis,some80Hzoperations

may be limited. This protects the motor and may be

a commonoccurrence in a 80Hz operation.

Keypad Lock - Password

The password locks or unlocks the blue buttons

on keypad. All PENTEK

INTELLIDRIVE

units are

shipped from factory with the default password

7777. It can be changed to any other 1 to 4 digit

number. To reset password to a unique password

for unit, unlock keypad (see below) and follow the

keypress sequence shown in Figure 8 to make the

change.

If installer does not press the password button, then

the keypad will automatically lock 60 minutes after

the Drive is powered up. The time out period is

adjustable (see Table 9).

To unlock keypad press Password, use directional

arrows to select numeric code and press ENTER.

NOTICE For more detailed information on keypad

functions, see Figure 2.

Pump Out Operation

Press Pump Out. The Drive will start pump in a

constant speed mode (default 45 Hz). The pump

will run until STOP or Auto Start are pushed.

If speed change is necessary, follow keypress

sequence shown in Figure 8 to change parameter

as desired.

Setting the Pressure

NOTICE Default pressure setting is 60 PSI. If this

value is changed, adjust tank pressure accordingly

(see Table 7).

There are three ways to change the pressure

setpoint:

1. While running the pump

• Follow keypress sequence shown in Figure

13 to make desiredchange. This parameter

allows either Internal or External Setpoint

to be changed, depending on which one is

referenced at the time the change is made.

Press Auto Start

Verify

“Running Fixed Press”

displayed on screen

Press Enter

Use arrows to

change the value

Press Enter to Save

Figure 13 - Change PSI Setpoint while running

pump.

2. Via the PSI Preset

Figure 14 - Change PSI Setpoint using PSIPreset.

3. Via the Main Menu (Main Menu/Settings/

Setpoint/Internal Setpoint)

Page 14

14Programming 14

Table 9 lists all available commands and parameters for the PENTEKINTELLIDRIVE.

Table 9 - Main Menu and Parameters

Menu

Settings

Time/Date

PID Control

Sleep

Password

Parameter

Hour Format Hours 12Hr 12Hr 24Hr Selects 12 or 24 hour time scale.

Time mm:ss 1:00 AM 1 24

Date MM/DD/YYYY 1/1/12 – –

Proportional

Gain

Integration

Time

Derivation

Time

Derivative

Limit

Boost

Differential

BoostDelay MM:SS 1 Min 30 Sec 5 Min

Wake Up

Differential

Wake Delay MM:SS 15 Sec 3 Sec 2 Min

Password Time

Out

Password – 7777 0000 9999

Unit of

Measure

– 2500 0 10000

Milliseconds 500 ms 20 ms

Milliseconds 60 ms 0 ms

– 120 0 2000

PSI 3 PSI 3 PSI 10 PSI

PSI 5 PSI 5 PSI 15 PSI

HrHr:mm 1 Hr 1 Min 6 Hr

Default Min. Max.

Value

Description

Sets current time. Used for time

stamp in fault log.

Sets current date. Used for date

stamp in fault log.

Sets the PID controller gain. Used

in conjunction with all PID Control

parameters to control how fast or

slow the Drive reacts to pressure

changes.

Sets the PID controller integration

time. Used in conjunction with all

65000

PID Control parameters to control

ms

how fast or slow Drive reacts to

pressure changes.

Sets PID controller derivation time.

Used in conjunction with all PID

10000

Control parameters to control how

ms

fast or slow Drive reacts to pressure

changes.

Sets derivative filter time constant

for PID controller.

First part of Boost Process. Pressure

boost that happens before it goes to

Wake Delay.

The time Drive takes to start Boost

Process after system has stabilized.

Pressure amount below setpoint that

wakes up Drive.

Second part of the Boost Process.

The time it takes to ramp down

pressure during the Boost Process.

Amount of time it takes to lock

keypad (after last button is pressed).

Password used to unlock keypad.

Page 15

15

Programming 15

Table 9 - Continued

Menu

Settings

Setpoints

Sub Menu Parameter

Motor

Sensor

Parameter

Internal

Setpoint

External

Setpoint

Motor Phase _ 1 1 3

Connection

Type

Motor Type – Subm Subm

Service Factor

Amps

Min Frequency Hz 30 Hz 30 Hz

Max

Frequency

Max Sensor

Value

Unit of

Measure

PSI 60 PSI 15 PSI

PSI 40 PSI 15 PSI

Unit of

Measure

– 3 wire 3 wire 2 wire

A 00.0 A 00.0 A

Hz 60 Hz

PSI 100 PSI 10 PSI 300 PSI

Default Min Max

Default Max Min Description

Value

Sensor

minus 3

Sensor

minus 3

Above

1 below

1 above

Min Hz80 Hz

Description

Main pressure setpoint used. Sets

Max

main system operational pressure.

This parameter is accessed here,

Value

through PSI Preset button, or by

pressing Enter button while in

PSI.

Constant Pressure operation.

Second pressure setpoint. When

another pressure setting is desired

Max

other than Internal Setpoint.

Additional programming needed in

Value

I/O section. Requires an external

switch or timer to wired to I1or

PSI.

I2 terminals. It is only active when

there is voltage present I1terminals

(see Figure 11)

Selects phase of motor to be

operated. An additional sub menu

will appear, based on phase

selection, to select proper motor

type.

Wire type for 1 phase motor

operation only. Can only access by

first setting Motor Phase parameter

to 1 Phase.

Motor type for 3 phase motor

operation only. Can only access by

Gnd

first setting Motor Phase parameter

to 3 Phase.

Per

Service factor amps (max. load) of

drive

motor the Drive is operating. Sets

and

maximum allowed amps at output

motor

of Drive. See Table 7 for values.

Minimum frequency (speed) motor

Max

will run.

Hz

Maximum frequency (speed)

motor will run. Up to 80Hz is only

available on only when Motor

Phase is set to 3.

Maximum pressure value of

transducer sensor used with Drive.

Only change if different transducer

is used with Drive, other than 100

PSI max scale.

Page 16

16

Programming 16

Table 9 - Continued

Menu or

Sub Menu

Ex Runtime

Dry Run

I/O

Over Press Over Pressure PSI 80 PSI 15 PSI 97 PSI

No Ground

Reset Factory Reset – No No Yes

SW Update Software Update – Disabled Disabled Enabled Used to update software, if necessary.

Parameter Unit of Measure

Excessive

Runtime

Detection

Excessive

Runtime Hours

Auto Restart

Delay

Number of

Resets

Detection Time M:SS 15 Sec 5 Sec 10 Min

Sensitivity PSI 10 0 300

Fill Time M:SS 1 M 15 S 10 M

Digital Input 1

Digital Input 2

Relay Output – Unused – –

No Ground

Detection

_ Enabled

Hours 24 1 100

Minutes 10 Min 3 Min 60 Min

– 3 0 5

– Unused – –

– Enabled

Value

Default Min Max

Disabled

Disabled

Enabled

Enabled

Description

Enables or disables Excessive Runtime

Detection.

Number of hours Drive can run before it

faults on Excessive Runtime.

Time Drive waits to restart pump when

Dry Run is detected.

Number of tries Drive attempts to restart

pump when Dry Run condition is

detected.

Time the Drive takes to recognize Dry

Run condition.

Pressure value that Dry Run condition

is detected at. Dry Run fault will occur

if this pressure cannot be met within

Detection Time window. Lower pressure

= less sensitivity.

Time allowed to fill (prime) pipes during

Auto Line Fill process. Relates to Dry

Run Sensitivity value. (Time starts after 55

Hz is reached).

Selects operation of Drive when terminal

I1 is used. Select between Unused, Run

Enabled, Ext Fault, and Setpoint. The

Drive will respond to selected command

when voltage is present at I1 terminal.

Selects the operation of Drive when

terminal O1 is used. Select between

Unused, Run, and Fault. The Drive closes

the Relay when Run or Fault is selected.

Sets Over Pressure Warning value.

Change if higher than 80 PSI system

pressure is needed.

Selects whether Ground Detection

parameter is Enabled or Disabled. If

Disabled is selected, it will revert back to

Enabled after 72 hours. Warning LED will

flash entire time it is Disabled.

Resets all parameters to factory defaults.

Displays Setup Guide after it is complete.

Software version displayed here. Does

not clear fault log.

Page 17

17I/O Connections 17

The I/O terminals are located in the center of

the wiring compartment, as shown previously in

Figure9.

The Digital Input connections (I1 and I2) are used to

control the Drive based on the state of an external

device, such as a flow switch, moisture sensor,

alternator, or other device. Programming is needed

to activate any of these functions (see Table 9).

The Output Relay (O1) is used to control an external

device based on two states of Drive; either Running

the pump or Faulted. Programming is needed to

activate any of these functions (see Table 9).

Cable Installation

Three 1/2” conduit knockouts are provided on the

bottom of the Drive enclosure for the I/O wires.

Breakouttheclosest1/2”knockoutandroutethe

wires through. Use a cord grip to prevent the wire

from rubbing and causing a short.

NOTICE Never run low voltage I/O wire through

the same conduit hole as the 230V input wires or

motor wires.

To connect the external wires to the terminals:

1. Strip wire ½ inch

2. Push spring terminal up with finger or slotted

screwdriver

3. Insert wires from bottom

4. Release spring terminal

Connection Examples

Figures 15-18 show various connection schemes for

typical applications. Table 10 describes each I/O

terminal, including purpose and rating.

115 VAC

or

230 VAC

Figure 16 - Example external Input with

externalsupply

Figure 17 - Example Output relay with internal

24 volt supply

+

-

Figure 15 - Example Input with internal 24 volt

supply

+

115 VAC

or

230 VAC

-

Figure 18 - Example Output with externalsupply

Page 18

18I/O Connections 18

Table 10 - I/O Function, Connections, Ratings

Label Function Connection Rating

Positive connection for transducer Red transducer wire

AI+

Negative connection for transducer Blacktransducerwire

AI-

Positive side of 24 volt power supply.

V+

Used to power external devices.

Negative side of 24 volt power supply.

V-

Used to power external devices.

Positive (dry contacts) connection of

Digital Input 1. Connect when using an

I1+

external device to control Drive.

Negative (dry contacts) connection of

Digital Input 1. Connect when using an

I1-

external device to control Drive.

Positive (dry contacts) connection of

Digital Input 2. Connect when using an

I2+

external device to control Drive.

Negative (dry contacts) connection of

Digital Input 2. Connect when using an

I2-

external device to control Drive.

Output relay (dry contacts) connection.

Programmed to close when pump is

O1+

Running or Faulted.

Output relay (dry contacts) connection.

Programmed to close when pump is

O1+

Running or Faulted.

Positive connection of an RS-485

P

communication device (see Figure 15).

Negative connection of an RS-485

N

communication device (see Figure 15).

Positive side of 24V external device, i.e.,

flow switch, moisture sensor, alternator,

etc. Need to complete the circuit with V-.

See Figures 11 and 13.

Typically to I1-, I2-, or O1-. Used with a

flow switch, moisture sensor, alternator,

etc. Need to complete the circuit with V+.

See Figures ll and 13.

From an external device i.e., flow switch,

moisture sensor, alternator, etc. Requires

complete circuit connection with I1-. See

Figures 11 and 12.

Can be from V- or from the negative side

of an external power supply. Requires

complete circuit connection with I1+. See

Figures 11 and 12.

From an external device, i.e., flow switch,

moisture sensor, alternator, etc. Requires

complete circuit connection with I2-. See

Figure 11 and 12.

Can be from V- or from the negative side

of an external power supply. Requires

complete circuit connection with I2+. See

Figure11 and 12.

Positive wires of an external device. See

Figures 13 and 14.

Positive wires of an external device. See

Figures 13 and 14.

Positive wire from RS-485 device.

Negative wire from RS-485 device.

24 Volt

(supplied)

40mA maximum

output

Accepts 24VDC

and up to

230VAC

Accepts up

to 5Amps at

24VDC and

8Amps at up to

230VAC

Per RS-485

Standard

Page 19

19

Additional Information 19

RS-485 Communications

RS-485 is a US-based telecommunications

standard for binary serial communications between

devices. It is the protocol, or set of specifications,

that needs to be followed to allow devices that

implement the standard to speak to each other.

A fully compliant RS-485 port is included in the

PENTEK INTELLIDRIVE system to permit serial

connections among more than two devices on an

RS-485 compliant network. Figure 15 shows twowire connection to the Drive.

Figure 19 - Example RS-485 Connection

Lightning/Surge Protection

Lightning arrestors or other surge suppressing

devices can be used with this product. MOV(Metal

Oxide Varistor), SOV(Silicon Oxide Varistor).

Accessories

Part Descrption Qty Part Number

Alternating Control Panel 1 VFD-ALT

Moisture Sensor 1 VFD-WS

Surge Protection Kits 1 VFD-SGA

300 PSI Transducer 1 U17-2000

Flow Switch 1 U17-1999

Retrofit Applications

When retrofitting an installation with the

PENTEK INTELLIDRIVE, most of the preceding

text can be applied. As a convenience, the

recommended Service Factor Amps for nonPENTEK motors is provided in Table 11. Always

verify Service Factor Amp values from current

manufacturer literature.

Table 11 - Service Factor Amps @ 230V

Service Factor Rating,

Motor Type HP

1/2 4.7

2-Wire

CS/CR

3-Wire

3-Phase

¹CentriProSFAdatawastakenfromtheMarch2012BMAID

manual on 4/2012.

² Franklin Electric SFA data was taken from the 7/2011 Franklin

Electric AIM manual on 4/2012.

NOTICE The PENTEK INTELLIDRIVE will not

operate Franklin Electric 2-wire motors.

3/4 6.4

1 9.1

1-1/2 11.0

1/2 4.9 4.3

3/4 6.3 5.7

1 7.2 7.1

1-1/2 11.1 11.5

2 12.2 13.2

1/2 2.9 2.9

3/4 3.9 3.8

1 4.7 4.7

1-1/2 6.1 5.9

2 7.6 8.1

3 10.1 10.9

5 17.5 17.8

in Amps

CentriPro¹ Franklin²

N/A

Repair Parts

Part Description Qty Part Number

InputTerminalBlock

Connector

OutputTerminalBlock

Connector

Cooling Fan 1 PID-FAN-R

Pressure Transducer 1 U17-1561-R

10’ Transducer Cable 1 U18-1593

25’ Transducer Cable* 1 U18-1594

50’ Transducer Cable* 1 U18-1595

100’ Transducer Cable* 1 U18-1596

150’ Transducer Cable* 1 U18-1597

200’ Transducer Cable* 1 U18-1598

Keypad 1 PID-HMI-R

* Purchase Separately

1 PID-CON2

1 PID-CON3

Page 20

20Troubleshooting* 20

Fault Possible Causes Solution

Shorted output Check for any shorts in motor cables.

Over Current

Over Voltage

Under Voltage

Cannot Start Motor

Dry Run

Ground Fault

System Not Grounded Ungrounded Drive

Locked rotor Check for debris in pump.

Damaged wire insulation Check motor wire insulation with a megger.

Internal Drive short

Power cycling on and off

High line voltage

Low line voltage

Temporary loss of power Check for local power outage.

Excessive load current

Loss of a motor phase

Power was removed from

Drive

Exceeding Service Factor Amps

No Service Factor Amps value

entered

There is an open (connection)

in motor wires

Locked rotor Pull pump check for debris in pump.

Operation at open discharge

Drive cannot read transducer

signal

Possible leak Check for pipe break or large leak.

Dry running pump Check water level in well.

Ground wire shorted to motor

phase

Long motor cable length

With power to Drive off, measure outputs

with ohmmeter to detect short.

Check for a generator or switching on input

line.

Measure incoming line voltage to Drive;

should be between 190V and 265V.

Check motor is correctly sized for the

application.

Check correct voltage is present on all motor

leads.

Check correct voltage is present on all input

lines.

Check Service Factor Amps entered are

correct.

Check pump and motor are correct.

Check Service Factor Amps entered and are

correct.

Check resistance of all motor wires is

correct.

May need to reduce Dry Run Sensitivity

pressure or apply back pressure on

transducer.

Check linearity of transducer, as it may be

damaged. See Troubleshooting Guide for

more information.

Check the ground wire for short to motor

phase wire or check insulation integrity with

a megger.

If motor cable length is more than 1000 ft

a reactor or filter may be needed to limit

capacitance between motor wires.

Ground Detect parameter can be disabled,

but will reactivate after 72 hours.

*For additional Troubleshooting information, please visit www.sta-rite.com/resources/images/16455.pdf for

a downloadable guide.

Page 21

21Troubleshooting 21

Troubleshooting, Continued

Fault Possible Causes Solution

Intermittent connection

Open Connection

Open Transducer

Shorted Transducer

Over Temperature Excessive heating in drive

Excessive Runtime

Internal Fault

Hardware Fault Internal hardware failure

External Fault

Low Amps

Drive cannot read transducer

signal

Transducer wires crossed

Possible failed transducer

Short in transducer wires

Possible failed transducer

Leak detected Check for leaks in pipe system.

Application calls for long run

times

Internal voltages are out of

range

The external device detected

fault condition and closed the

I1 or I2 input

Under-sized pump

Low current draw from pump

Thermal protector open in

motor (3 wire)

Missing motor phase Check all motor connections at the Drive.

Check all transducer wires are securely

connected or for damaged cable insulation.

Check for proper wiring of all transducer

wires and verify cable connector securely

attached to transducer.

Check electrical system for ground loops or

no ground connection.

Check red is in AI+ and black is in AI-.

Check linearity of transducer; see

Troubleshooting Guide for more information.

Check for shorted transducer wire or

damaged insulation.

Check linearity of transducer; see

Troubleshooting Guide for more information.

Check ambient temperature is not above

50°C (122°F).

Check for inoperable or unobstructed fan.

Check vents are not obstructed.

Extend Excessive Runtime Hours limitation.

Disable Excessive Runtime Fault.

Drive will auto reset and attempt to clear

fault. Fault Reset can be pressed to clear

fault as well. Then try to operate pump. If

fault continues Drive may need replacement.

Fault Reset can be pressed to clear fault.

Then try to operate pump. If fault continues

Drive may need replacement.

Check external device.

Increase Minimum Speed to 35 Hz.

Wait 20 minutes then restart pump.

Page 22

22Troubleshooting 22

Troubleshooting, Continued

Warning Possible Causes Solution

Verify ground wire is connected on both

incoming voltage side and motor side of

Drive.

With power disconnected, use ohmmeter to

verify the pipe the transducer is connected

to and that input ground wire are at same

potential (approx 0 ohms).

Verify the input ground is connected all the

way back to electrical panel.

Drive tries to free debris in pump by

reversing or pulsing motor.

Drive stops and waits 1 minute, then checks

that pressure is below the Setpoint pressure.

Belowitrestarts,ifnotchecksagainin

another minute. Can increase over-pressure

value.

Warning LED flashing

Jam Warning

Over Pressure Warning

Ungrounded Drive, with

ground detection parameter

disabled (will operate for 72

hours and then fault).

Debris in pump stopping motor

from turning (locked rotor).

Pressure rising above Over

Pressure setting.

Drive Reset Procedure

Follow the keypress sequence

shown at right to test the Drive.

Press Password

button

Enter Passwword

(Default is 7777)

Press Enter

Press Main Menu

button

Press up or down arrow

until Reset appears

Press Enter to Edit

Change “No” to “Yes”

Press Enter

Confirm Reset

Figure 20 - Drive Reset Procedure

NOTICE In a domestic environment, this product may cause radio interference which may require

supplementary mitigation measures.

Page 23

23Warranty 23

Limited Warranty

PENTAIR warrants to the original consumer purchaser (“Purchaser” or “You”) of the products listed below, that they will be free from

defects in material and workmanship for the Warranty Period shown below.

Product Warranty Period

Water Systems Products — jet pumps, small centrifugal pumps,

submersible pumps and related accessories

PENTEK INTELLIDRIVE™

Pro-Source™ Composite Tanks 5 years from date of original installation

Pro-Source™ Steel Pressure Tanks 5 years from date of original installation

Pro-Source™ Epoxy-Line Tanks 3 years from date of original installation

Sump/Sewage/Effluent Products

Our warranty will not apply to any product that, in our sole judgment, has been subject to negligence, misapplication, improper

installation, or improper maintenance. Without limiting the foregoing, operating a three phase motor with single phase power through a

phase converter will void the warranty. Note also that three phase motors must be protected by three-leg, ambient compensated, extraquick trip overload relays of the recommended size or the warranty is void.

Your only remedy, and PENTAIR’s only duty, is that PENTAIR repair or replace defective products (at PENTAIR’s choice). You must pay

all labor and shipping charges associated with this warranty and must request warranty service through the installing dealer as soon

as a problem is discovered. No request for service will be accepted if received after the Warranty Period has expired. This warranty is

nottransferable.

PENTAIRISNOTLIABLEFORANYCONSEQUENTIAL,INCIDENTAL,ORCONTINGENTDAMAGESWHATSOEVER.

THE FOREGOING LIMITED WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS AND IMPLIED WARRANTIES,

INCLUDINGBUTNOTLIMITEDTOIMPLIEDWARRANTIESOFMERCHANTABILITYANDFITNESSFORAPARTICULARPURPOSE.THE

FOREGOINGLIMITEDWARRANTIESSHALLNOTEXTENDBEYONDTHEDURATIONPROVIDEDHEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on how long an implied warranty

lasts, so the above limitations or exclusions may not apply to You. This warranty gives You specific legal rights and You may also have

other rights which vary from state to state.

This Limited Warranty is effective June 1, 2011 and replaces all undated warranties and warranties dated before June 1, 2011.

293 Wright Street • Delavan, WI 53115

Phone (262) 728-5551 • Fax (262) 728-7323

whichever occurs first:

12 months from date of original installation,

18 months from date of manufacture

12 months from date of original installation, or

18 months from date of manufacture

12 months from date of original installation, or

18 months from date of manufacture

PENTAIR

Page 24

Loading...

Loading...