Sta-Rite P13316V-01 Installation Manual

Models PC13316V-01

and P13316V-01

Pedestal Sump Pump

INSTALLATION, OPERATION, & PARTS MANUAL

SAFETY INFORMATION

Carefully read and follow all safety instructions in this

manual or on pump.

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for one of the

following signal words and be alert to the potential for

personal injury!

warns about hazards that will cause serious

personal injury, death or major property damage if ignored.

warns about hazards that can cause serious

personal injury, death or major property damage if ignored.

warns about hazards that will or can cause

minor personal injury or property damage if ignored.

The word NOTICE indicates special instructions which are

important but not related to hazards.

DESCRIPTION

This Pedestal Sump Pump is designed for home sumps.

Unit is equipped with a 3-prong grounding-type power cord.

Sleeve bearings on motor shaft never need lubrication.

Motor has automatic reset thermal protection.

SPECIFICATIONS

Power supply required . . . . . . . . . . . . . . . . . . . . .115V, 60 HZ

Motor duty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Intermittent

Liquid Temp. Range . . . . . . . . . . . . . . .32° F-70° F (0°-21° C)

Individual Branch Circuit Required . . . . . . . . . . . . . .15 Amps

Discharge Adapter . . . . . . . . . . . . . . . . . . . . . . . . .1-1/4" NPT

GENERAL SAFETY INFORMATION

Electrically powered sump pumps normally give many years

of trouble-free service when correctly installed, maintained,

and used. However, unusual circumstances (interruption of

power to the pump, dirt/debris in the sump, flooding that

exceeds the pump’s capacity, electrical or mechanical failure

in the pump, etc.) may prevent your pump from functioning

normally. To prevent possible water damage due to flooding,

consult your dealer about installing a secondary sump

pump, a DC backup sump pump, and/or a high water alarm.

See the “Troubleshooting Chart” in this manual for information about common sump pump problems and remedies. For

more information, see your dealer or call customer service

at 1-888-782-7483.

© 2005 S499 (Rev. 2/11/09)

293 Wright Street • Delavan, WI 53115

GPM (LPM) AT TOTAL FEET (m)

5101520

Model (1.5m) (3m) (4.6m) (6.1m)

CAPACITY GALLONS(L)/MINUTE

PC13316V-01 50 40 27 12

P13316V-01 (189) (151) (102) (45)

Individual *Switch

Motor Branch Setting

Motor Full Load Circuit in inches (mm)

HP Amps Req. (Amps)

On Off

10-12" 2-1/2"

1/3 3.5 15

(254-305) (964)

No flow at 22 feet of lift.

PERFORMANCE

MOTOR, SWITCH & CORD

SPECIFICATIONS

1. Know the pump application, limitations, and potential

hazards.

Risk of fire or explosion. Do not use in

explosive atmospheres. Pump water only with this

pump.

2. Disconnect the power before servicing.

3. Release all pressure within the system before servicing

any component.

4. Drain all water from the system before servicing.

5. Secure the discharge line before starting the pump. An

unsecured discharge line will whip, possibly causing personal injury and/or property damage.

6. Check hoses for weak or worn condition before each

use, making certain all connections are secure.

7. Inspect the sump, pump and system components monthly. Keep free of debris and foreign objects. Perform routine maintenance as required.

Fire hazard. Do not store or rest objects

on or near motor or switch linkage. Keep all flammable objects or liquids away from motor.

8. Provide a means of pressure relief for pumps whose discharge line can be shut-off or obstructed.

9. Personal Safety:

a. Wear safety glasses at all times when working with

pumps.

b. Keep work area clean, uncluttered and properly light-

ed – replace all unused tools and equipment.

c. Keep visitors at a safe distance from the work area.

d. Make workshop child-proof – with padlocks, master

switches, and by removing starter keys.

10. When wiring an electrically driven pump, follow all electrical and safety codes, as well as most recent National

Electrical Code (NEC) and Occupational Safety and

Health Act (OSHA).

11. This equipment is only for use on 115 volt (single phase)

current and is equipped with an approved 3-conductor

cord and 3-prong, grounding-type plug.

To reduce risk of electric shock, be certain that it is connected to properly grounded,

grounding-type receptacle. Never connect green (or

green and yellow) wire in cord to a live terminal!

Where a 2-prong wall receptacle is encountered, it must

be replaced with a properly grounded 3-prong receptacle

installed in accordance with the National Electrical Code

and local codes and ordinances.

12. All wiring should be performed by a qualified electrician.

13. Make certain that power source conforms to requirements of your equipment.

14. Protect the electrical cord from sharp objects, hot surfaces, oil, and chemicals.Avoid kinking the cord.Replace

or repair damaged or worn cords immediately.

15. Do not touch an operating motor.Modern motors are

designed to operate at high temperatures.

16. Do not handle pump or pump motor with wet hands or

when standing on wet or damp surface, or in water.

Risk of electrical shock. If your basement has water or moisture on floor, do not walk on

wet area until all power has been turned off. If shutoff box is in basement, call electric company to shutoff service to house, or call local fire department for

instructions. Remove pump and repair or replace.

Failure to follow this warning can result in fatal

electrical shock.

INSTALLATION

1. This unit can be installed in a sump pit with a minimum

diameter of 12"(30cm) and a depth of 12"(30cm).The

sump pit may be constructed of tile, concrete, steel or

plastic. Check the local codes for approved materials.

2. Install the pump on a solid, level foundation, as near as

possible to the center of the sump pit. Do not hang the

pump from the discharge pipe or power cord.

Fire hazard. Pump must be level (column must be vertical) when operating. If motor is tilted, internal start/run switch may overheat and damage motor.

3. The pump should not be installed on clay, ear th or sand

surfaces.Clean the sump pit of small stones and gravel

which could clog the pump. Keep the pump inlet screen

clear.

4. Thread the outlet pipe into the pump body carefully to

avoid stripping or crossing threads.

NOTICE: Do not use ordinar y pipe joint compound on

plastic pipe or pump. Pipe joint compound can attack

plastics and damage the pump.

5. To reduce motor noise and vibrations, a short length of

rubber hose (e.g. radiator hose) can be connected into

the discharge line near the pump using suitable clamps.

Risk of electric shock. Pump is supplied

with a 3-wire cord set with grounding-type plug for

use in a 3-wire, grounded outlet. Do not modify cord

or plug or cut off the round grounding prong. For

safety, outlet must always be electrically grounded to

a suitable electrical ground such as a grounded

water pipe or a properly grounded metallic raceway

or ground wire system.

2

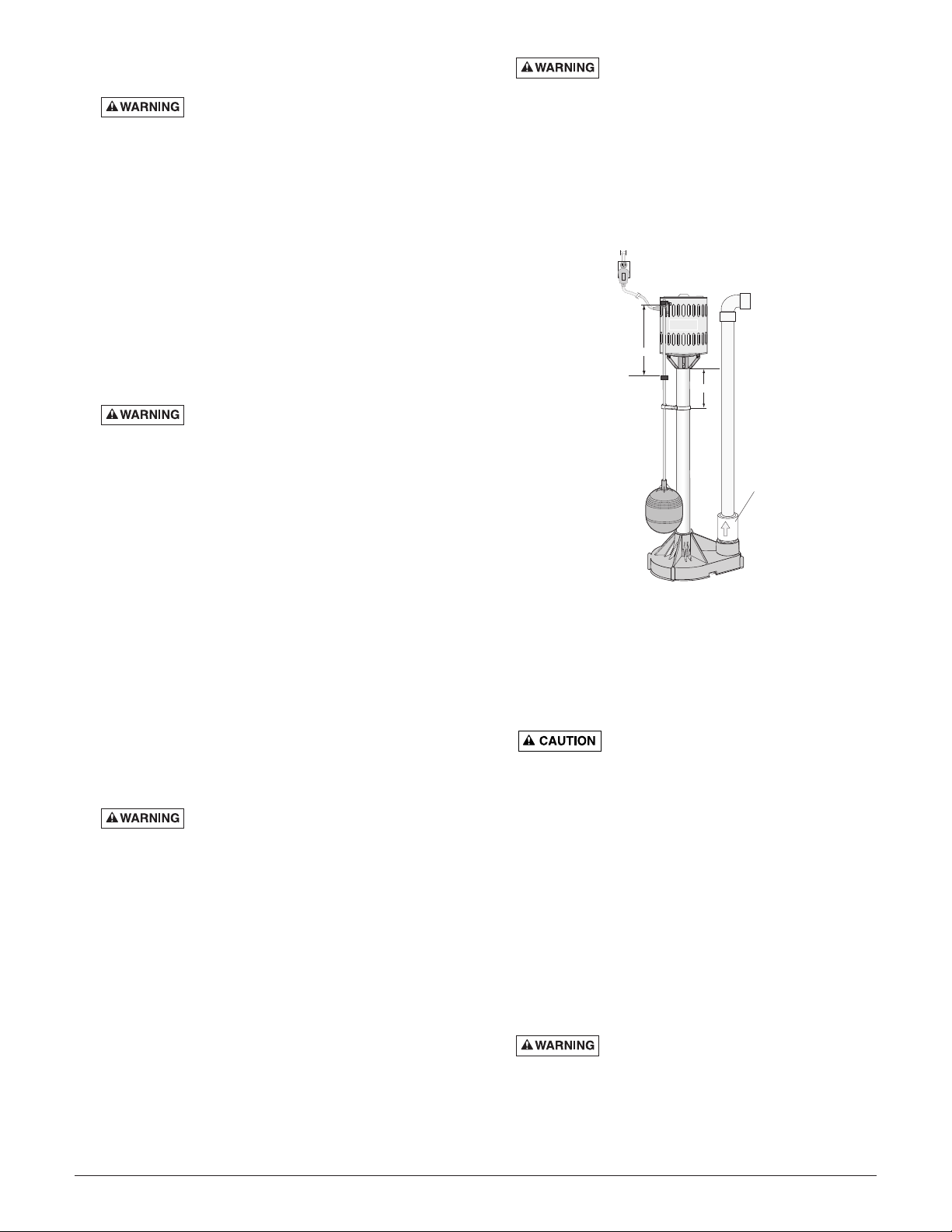

Discharge

About 6"

About 8"

Check

Valve

(Purchase

Separately)

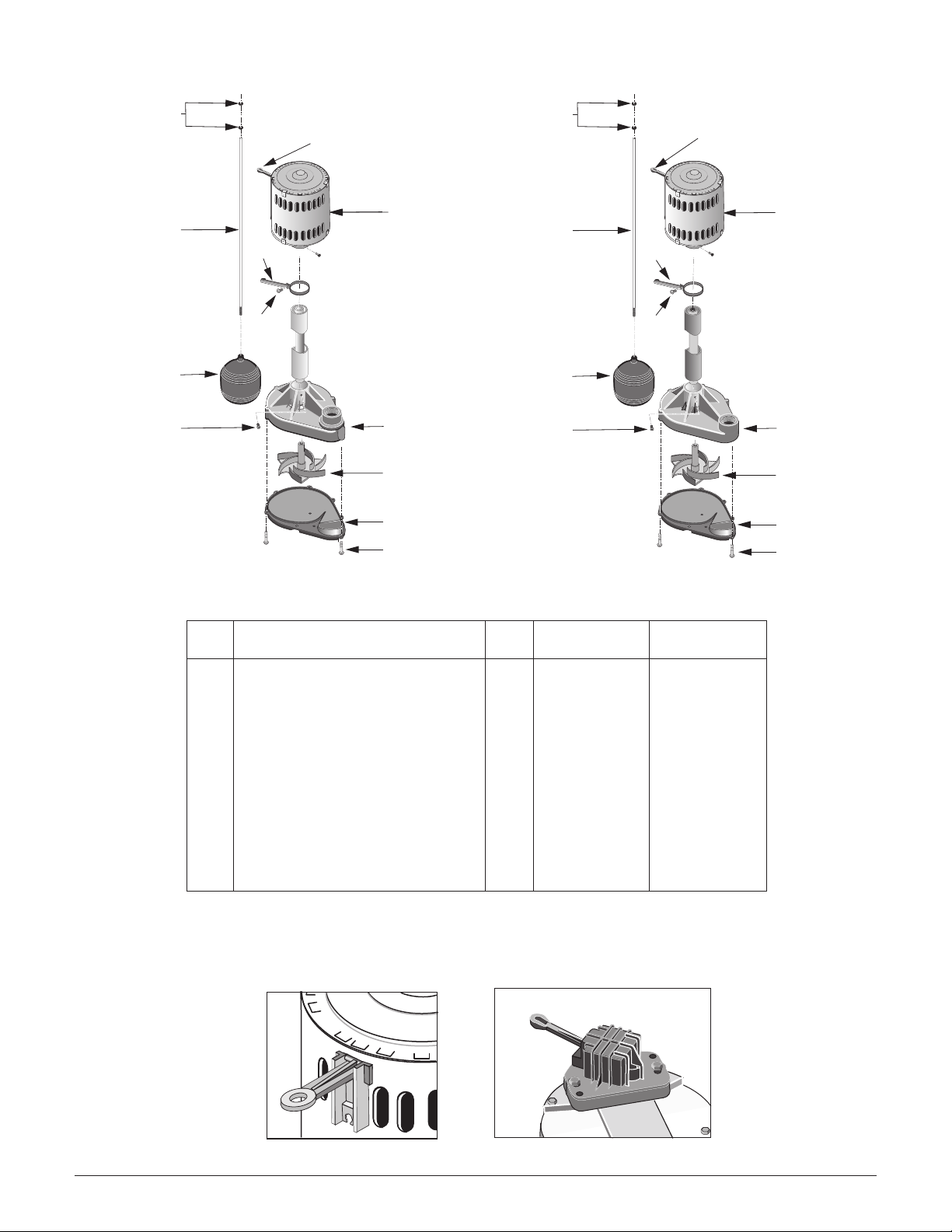

6. Locate the float rod guide (Key No. 10) about 6" (16cm)

below the motor.Clamp the guide to the column with the

screw (Key No. 11).

Risk of flooding. Be sure that guide is

securely clamped so that float rod is vertical and can

move up and down freely. If float is angled or binds,

pump may not start, allowing flooding to occur.

7. Screw the float onto the threaded end of the rod.The

threads on the rod will cut threads into the corrosion

resistant float.

8. Insert the plain end of float rod up through eye of rod

guide.

9. Slide one rod stop on the float rod before passing the rod

through the eye of the pump switch.Slide the second rod

stop on the rod after passing through the eye of switch.

Position the second rod stop flush with top of the pump.

See the Exploded View on Page 3.

10. Position the lower rod stop to within 8"(20cm) of switch

lever arm.With the lower rod stop in this position, the

pump will automatically cycle at approximately 2-1/2"

(6cm) off and 10-12" (25-30cm) on. For faster cycling,

move the lower rod stop closer to switch lever arm.

11. If the pump discharge line is exposed to an outside subfreezing atmosphere, then the portion of the line exposed

must be installed so any water remaining in the pipe will

drain to the outfall by gravity. Failure to do this can cause

water trapped in the discharge to freeze which could

result in damage to pump.

12. Install an in-line check valve to prevent backward flow

through the pump after it shuts off.

NOTICE: If using a check valve, drill a 1/8" (3.2mm) hole

in the discharge pipe just above pump body to prevent

air locks.

13. After all the piping and controls have been installed, the

unit is ready for operation.

Risk of flooding. If a flexible discharge

hose is used, pump may move when motor starts. If it

moves far enough so that switch hits side of the sump,

the switch may stick and prevent the pump from starting.

Make sure the pump is secured so it cannot move

around in the sump.

14. Run the pump through one cycle to check the float switch

operation.

Sudden starts.The pump motor is

equipped with automatic resetting thermal protector

and may restart unexpectedly. Protector tripping is an

indication of motor overloading as a result of operating

the pump at low heads (low discharge restriction), excessively high or low voltage, inadequate wiring, incorrect

motor connections, or a defective motor.

OPERATION / MAINTENANCE

Risk of electrical shock. Do not touch sump

pump, pump motor, water, or discharge piping when

pump is connected to electrical power. Always disconnect pump cord (power) before handling. Before attempting to service, always disconnect power from unit.

1. Plug this unit into a 115V outlet, on an individual branch

circuit, with a Class A, 15 amp GFCI (Ground Fault

Circuit Interrupter). Consult an electrician for information

and availability.

2. Fill the sump pit with water.The pump will star t automati-

cally when the lower rod stop actuates the switch lever

arm. When the upper rod stop actuates the switch lever

arm, the pump will stop.

NOTICE: Do not allow the pump to run dr y.

3. The motor is equipped with an automatic reset thermal

protector to protect the unit from overheating.When the

motor has cooled sufficiently, the switch will reset automatically and restart the motor. Repeated tr ipping could

be caused by low voltage, long extension cords, a

clogged impeller, or very low head or lift, etc. Cycling of

the protector will cause an eventual motor burnout.

3

4

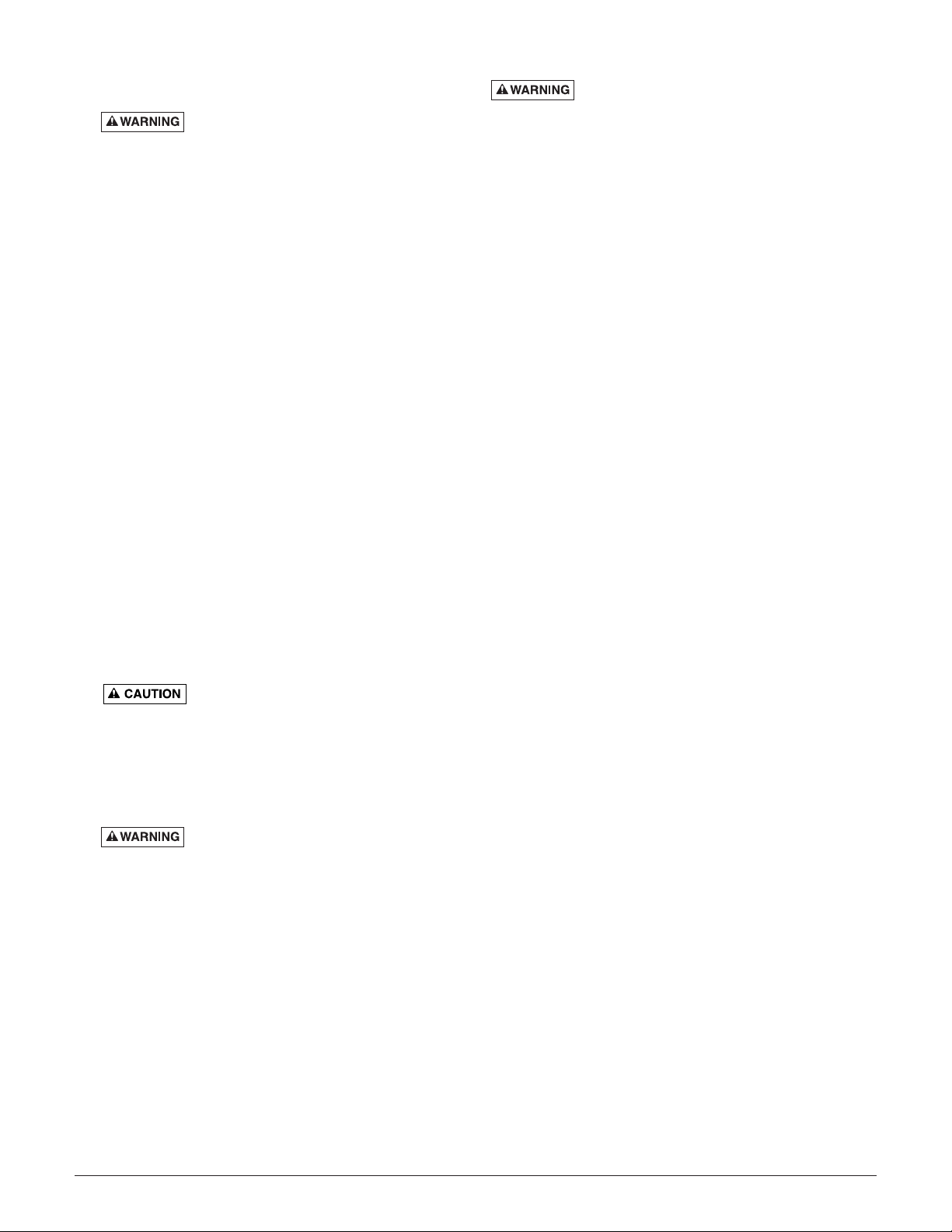

REPLACEMENT PARTS

1

2

3

4

5

6

7

8

9

10

11

12

1

2

3

4

5

6

7

8

9

10

11

12

Key

No. Description Qty. PC13316V-01 P13316V-01

1 Motor 1 * *

2 Switch 1 † †

3 Volute (Pump Body) 1 S1-31B PS1-25P

4 Impeller 1 PS5-269P PS5-269P

5 Base Plate 1 PS4-17P PS4-17P

6 Screws (Base Plate) 8 U30-571BT U30-934ZP

7 Float Rod Guide 1 RP0005249 RP0005249

8 Screw (Guide Rod) 1 U30-929ZP U30-929ZP

9 Screw (Base) 1 U30-946PH SC004-116

10 Float 1 FT0013-63 FT0013-63

11 Float Rod 1 RP005168S RP005168S

12 Float Stop 2 RP0005248 RP0005248

Switch FP0020

Switch FP0018-7D

* If the motor fails, replace the entire pump.

† Select switch model number below.

MODEL PC13316V-01 MODEL P13316V-01

Loading...

Loading...