Page 1

Nautilus® FNS & Nautilus® NS Filters

Replacement Kit Installation Instructions

Clamp Kit Installation

Filter operates under high pressure. When any part of the circulating system (e.g., Lock Ring,

Pump, Fliter, Valves, etc.) is serviced, air can enter the system and become pressurized.

Pressurized air can cause the fi lter lid to separate which can result in severe injury, death, or

property damage. To avoid this potential hazard, follow these instructions.

Follow these instructions and your fi lter installation and user’s guide exactly. If you do not have

a fi lter installation and user’s guide, STOP. Do not install clamp. Call (800) 831-7133 for a free

installation and user’s guide.

1. Remove contents of kit and check against parts list to be sure all components are present.

2. Backwash fi lter according to instructions under “Filter Backwash Procedure” in your fi lter Installation,

Operation & Service Manual. Stop after instruction #8. Do not precoat with new D.E.

3. Be sure pump is turned off and all pressure has been released from system

4. Remove the fi lter drain plug and drain all water from tank.

5. Loosen the clamp nuts alternately until one is removed. Lift clamp assembly off of fi lter.

6. Remove second nut from clamp assembly. If replacing entire band assembly, (Kit P/N 181011), discard the

old band. The following instructions apply to installation of the new band assembly. The threaded end of

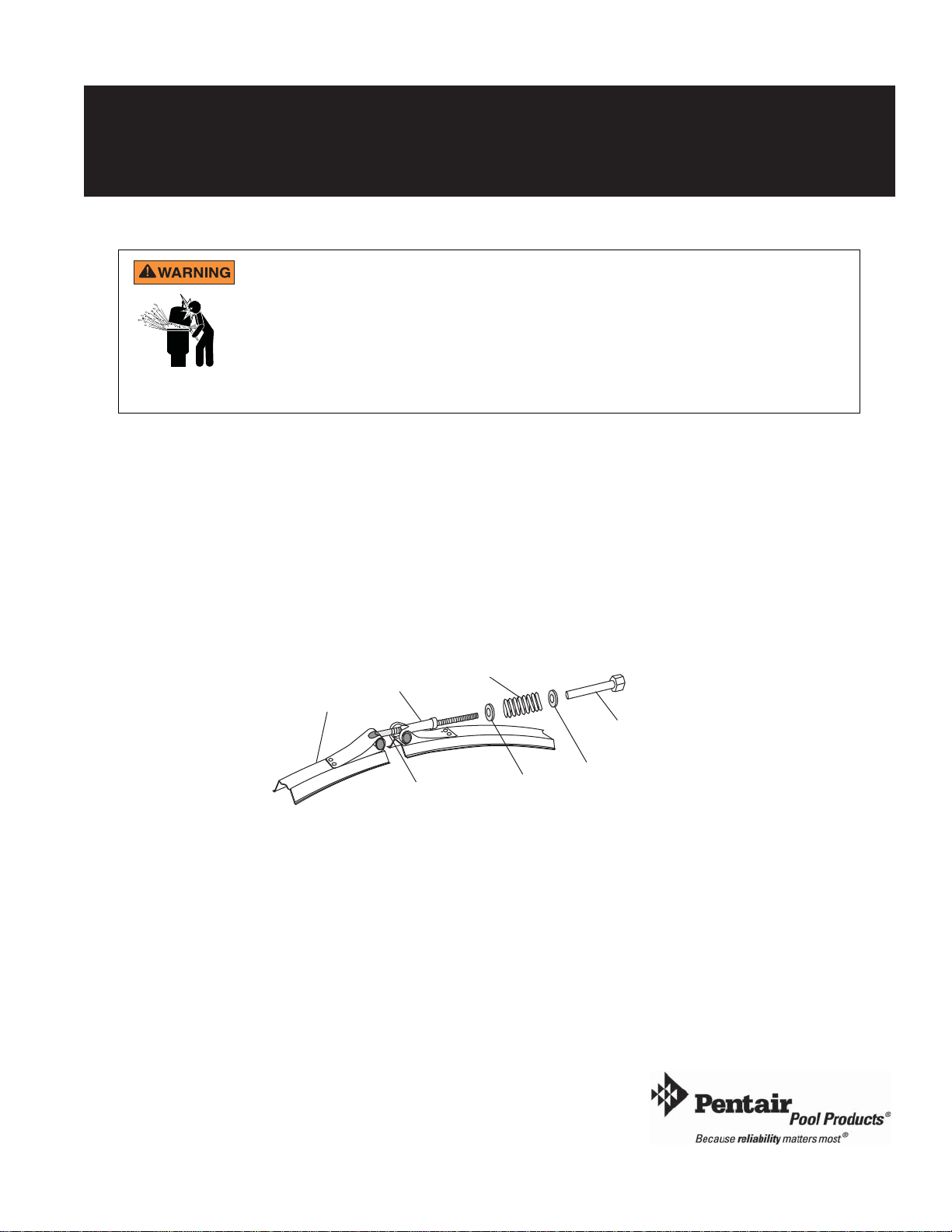

the T-bolt should protrude through the trunnion, see Figure 1 below.

Spring

Trunnion

Clamp

Barrel

Nut

T-Bolt

7. Place one of the washers (with the small hole- 5/16” inside diameter) on the threaded end of the T-bolt and

slide washer down bolt until it is against the trunnion. See Figure 1 above.

8. Place one of the washers (with the large hole-7/16” inside diameter for NS and 17/32” inside diameter for

FNS) over the shank of the brass nut. Place one of the springs over the shank of the brass nut so that the

washer with the large hole is captured between the end of the spring and the head of the brass nut. See Figure

2 on page 2.

Washer

(small)

Washer

(large)

Figure 1.

Technical Support

Sanford, North Carolina (8 A.M. to 5 P.M. - ET)

Moorpark, California (8 A.M. to 5 P.M. - PT)

Phone: (800) 831-7133

Fax: (800) 284-4151

Web sites: www.pentairpool.com - www.staritepool.com

P/N 195627 Rev. C 6/9/11

1

Page 2

Clamp Kit Installation, (Continued).

*195627*

Filter operates under high pressure. When any part of the circulating system (e.g., Lock Ring,

Pump, Fliter, Valves, etc.) is serviced, air can enter the system and become pressurized.

Pressurized air can cause the fi lter lid to separate which can result in severe injury, death, or

property damage. To avoid this potential hazard, follow these instructions.

Do not over tighten the clamp band. Tightening the clamp band beyond recommended procedures

may damage the clamp band and cause unexpected failure, sudden release of pressure and

injury or damage. Clamp hardware and fi lter surface could have sharp edges which can cause

bodily injury if improperly handled. Please use caution when performing the following procedures.

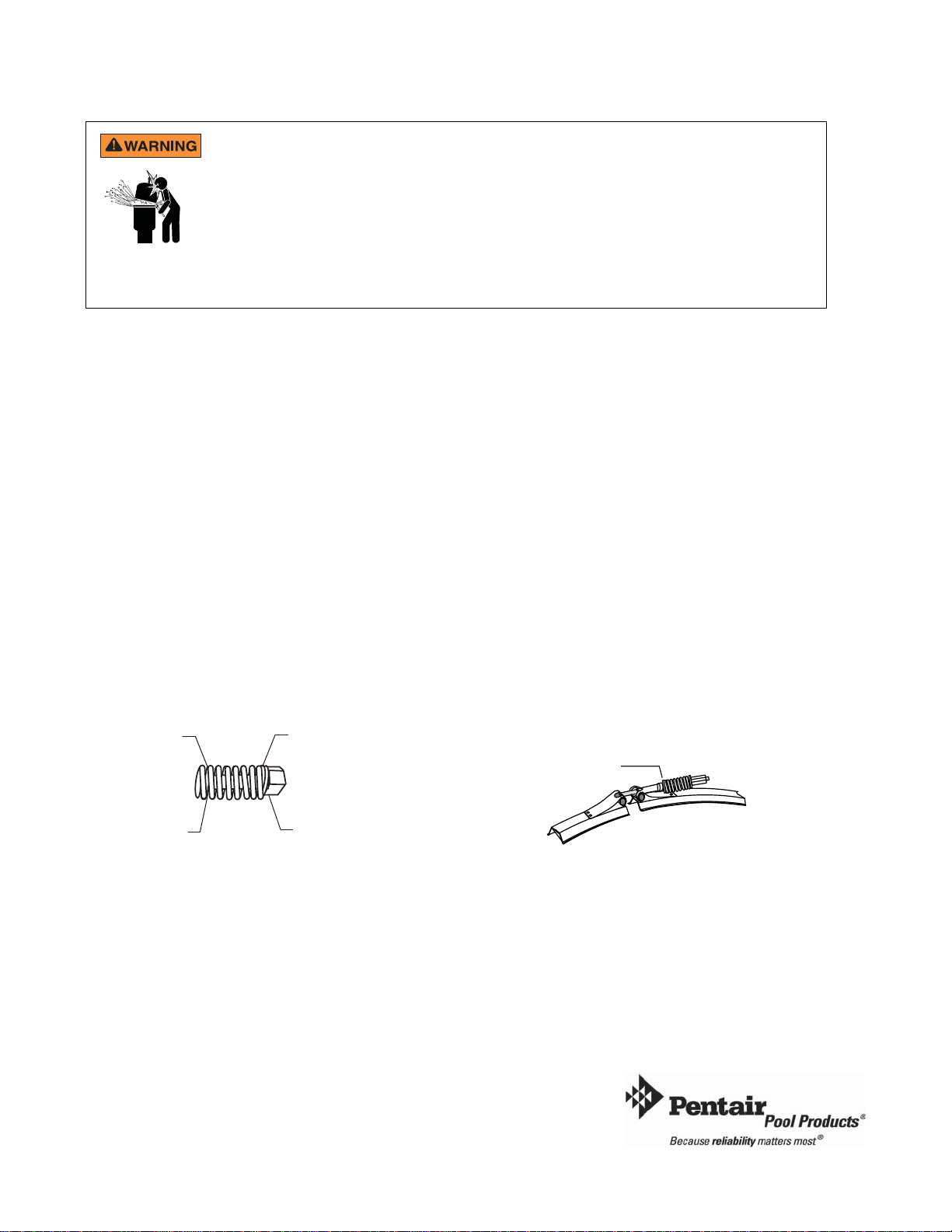

9. Thread shank of nut onto T-bolt 2 turns maximum.

10. Pre- assemble second washer with large hole, nut and spring for opposite side of band clamp assembly.

11. Insure fl anges on tank halves are free of dirt and or D.E.

12. Place clamp around tank fl ange making sure threaded end of T -bolt protrudes through trunnion as shown in

Figure 1.

13. Place remaining washer (with the small hole- 5/16” inside diameter) on the threaded end of the T-bolt and

slide washer down bolt until it is against the trunnion. See Figure 1.

14. Thread shank of nut onto T-bolt - 2 turns minimum. If end of T-bolt does not protrude through trunnion far

enough to engage shank of nut, make sure that fi rst spring assembly is tight against trunnion per Figure 3,

and band is tight against tank.

15. Tighten nuts evenly and alternately until spring coils touch each other. Tap clamp around tank with rubber

hammer to assist seating of clamp.

16. Use only those components supplied in this kit or Pentair Water Pool and Spa replacement parts when dealing

with the bands and spring tensioning devices.

17. Follow instructions under “Initial Start-UP” section of your fi lter Installation, Operation & Service Manual

to return your fi lter to operation.

Spring

Shank

© 2011 Pentair Water Pool and Spa, Inc. All rights reserved

1620 Hawkins Ave., Sanford, NC 27330 (919) 566-8000

10951 West Los Angeles Ave., Moorpark, CA 93021 (805) 553-5000

Nautilus® , Because reliability matters most®, and Pentair Pool Products® are trademarks and/or registered trademarks of

Pentair Water Pool and Spa, Inc. and/or its affi liated companies in the United States and/or other countries. Unless noted,

names and brands of others that may be used in this document are not used to indicate an affi liation or endorsement between

the proprietors of these names and brands and Pentair Water Pool and Spa, Inc. Those names and brands may be the

trademarks or registered trademarks of those parties or others.

P/N 195627 Rev. C 6/9/11

Washer

Nut

Figure 2.

PULL BAND HALVES

APART UNTIL NO GAP

EXISTS AT “A” OR

BETWEEN SPRING

AND WASHERS.

A

Figure 3.

2

Loading...

Loading...