Page 1

MS series

Vertical Multi-Stage Deep Well Jet Pumps

FEATURES

Automatic Pressure Regulator –

Faster-acting and quieter, design

eliminates “hunting” for correct drive

pressure. New improved stem

and guide are precisely molded to

assure efficient, trouble-free performance on all deep wells.

Quality Construction – Precisionmachined, close-grained cast iron

pump body and base are specially

treated to resist corrosion.

Noryl Impellers – Precision

molded for perfect balance, and

ultra-smooth for highest performance and efficiency.

Pressure Switch – High quality.

Differential and cut-in/cut-out

pressure settings are adjustable.

The MS Series Vertical Jet Pumps

are the industry standard deep

well jet pumps for over-the-well

APPLICATIONS

■

Water systems and sprinkling…

for homes, farms and cottages.

“bolt-on” installations.

The MS Series Jet Pumps include

the pre-plumbed external automatic regulator, pressure gauge,

pressure switch, and a complete

line of casing adapters to drive

the 4" double pipe or 2" and 3"

single pipe jet packages.

SPECIFICATIONS

Body – Rugged cast iron

Pump and Motor Shaft – 416

stainless steel

Impellers – Noryl®

Diffuser – Close-grained cast iron

ORDERING INFORMATION

Cat.

No. HP Description Reg. Setting Suct. Drive Disch. Voltage Wt. Lbs.

MSD 3/4 Deep Well Jet 40 PSI 1-1/4" 1" 1" 115/230 67

MSE 1 Deep Well Jet 60 PSI 1-1/4" 1-1/4" 1" 115/230 73

MSF 1-1/2 Deep Well Jet 85 PSI 1-1/4" 1-1/4" 1" 230 120

MSG 2 Deep Well Jet 95 PSI 1-1/4" 1-1/4" 1" 230 125

ADAPTER FLANGE

Catalog Number Description Used With

J216-26 1-1/4" x 1" Offset single pipe, 4" double pipe through 3/4 HP

J216-27 1-1/4" x 1-1/4" 4" double pipe 1, 1-1/2 and 2 HP

Order pump from ordering information table above. A Jet Package should be ordered

with every MS Series Pump. All installations require an appropriate size adapter flange

or casing adapter if bolt-on feature is desired.

Noryl® is registered trademark of General Electric Co. PRO-Source™ is a trademark of

Pentair Water.

In order to provide the best products possible, specifications are subject to change.

Max. Press.

Pipe Tapping Sizes

Motor Approx.

Motor Windings – Superior

insu lation materials protect against

excessive moisture and contaminants to ensure prolonged motor life.

Mechanical Shaft Seal – Precision

lapped and highly polished

carbon-ceramic, stainless steel

construc tion. Internal design

guarantees continuous water

lubrication for maximum protection.

Dustproof Cover – All electrical

components are protected from

dirt, dust and insects by a dustproof

canopy. Ventilating air cannot

contaminate vital switching components. This eliminates the most

common cause of motor failure.

Balanced Rotor – Rotor is die cast

under high pressures for uniform

performance and greater efficiency;

dynamically balanced.

Heavy-duty Ball Bearings –

Permanently lubricated sealed

bearings are extensively tested to

ensure extended life and smooth,

quiet operation.

Pump and Motor Shaft – One

piece threaded shaft for positive

impeller drive and alignment. Shaft

is stainless steel for maximum

corrosion resistance.

Customer Service: (888) 782-7483

Fax Orders: (800) 426-9446 www.sta-rite.com

•

1

Pentair Water

•

Delavan, WI 53115 USA

•

S4513WS (5/11)

•

Page 2

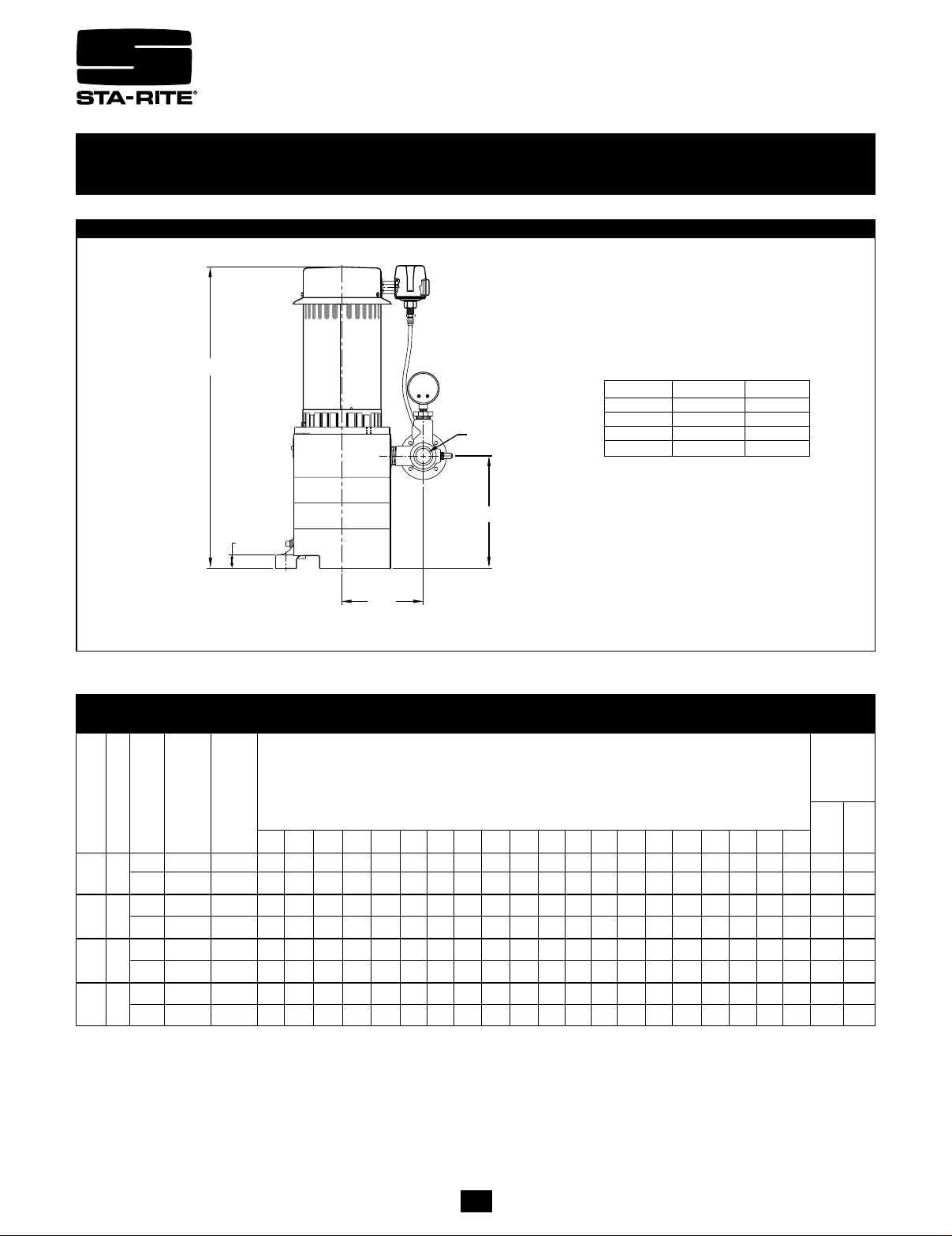

5.75

.96

A

B

1'' NPT

MS series

Vertical Multi-Stage Deep Well Jet Pumps

OUTLINE DIMENSION

Cat. No. A B

MSD 17-5/16 5-5/8

MSE 18-3/8 5-5/8

MSF 20-7/16 7-1/2

MSG 20-15/16 7-1/2

Dimensions (in inches) are for estimating purposes only.

PUMP PERFORMANCE

DEEP WELL (40 PSI) 4" DOUBLE PIPE

Max. Pump

Shut-Off

Press.

(PSI)

Jet at Jet at

Cat. Jet Uses Uses Min. Max.

No. HP No. Venturi Nozzle 30' 40' 50' 60' 70' 80' 90' 100' 110' 120' 130' 140' 180' 200' 220' 240' 260' 280' 300' 320' Depth Depth

15SD J32P-18 J34P-42 5.5 5.4 5.3 5.2 4.7 4.3 4.1 3.7 3.1 2.7 2.3 1.9 137 75

15SD J32P-18 J34P-42 5.5 5.5 5.5 5.4 5.3 5.3 5.2 5.1 5.1 5.0 4.8 4.5 3.3 2.7 2.0 1.3 1.0 200 97

15SD J32P-18 J34P-42 5.5 5.5 5.5 5.5 5.5 5.5 5.3 5.3 5.2 5.1 5.1 5.0 4.8 4.7 4.5 4.3 4.0 3.3 2.7 314 172

15SD J32P-18 J34P-42 5.5 5.5 5.5 5.5 5.5 5.5 5.3 5.3 5.2 5.1 5.1 5.0 5.0 4.8 4.8 4.5 4.3 4.0 3.3 2.7 314 172

Tested and rated in accordance with Water Systems Council Standards.

NOTE: Pumps installed with a PRO-Source™ tank require a 100 PSI relief valve. Pumps installed with a conventional tank require

23SD J32P-24 J34P-42 10.2 8.4 6.8 5.8 4.5 3.1 2.1 1.1 80 46

MSD 3/4

23SD J32P-24 J34P-42 12.1 11.7 11.6 11.1 10.2 9.2 7.8 6.4 5.0 4.0 3.0 120 76

MSE 1

MSF 1-1/2

MSG 2

23SD J32P-24 J34P-42 12.2 12.2 12.2 12.2 11.7 11.3 10.7 9.9 9.0 8.3 7.0 4.0 1.3 164 95

23SD J32P-24 J34P-42 12.2 12.2 12.2 12.2 11.8 11.3 11.2 11.1 11.0 10.0 8.7 7.0 4.0 2.0 195 110

a 75 PSI relief valve. Relief valve must be capable of relieving entire flow of pump at relief pressure.

(Capacity in Gallons Per Minute)

Pumping Depth in Feet

Customer Service: (888) 782-7483

Fax Orders: (800) 426-9446 www.sta-rite.com

•

2

Pentair Water

•

Delavan, WI 53115 USA

•

S4513WS (5/11)

•

Page 3

MS series

Vertical Multi-Stage Deep Well Jet Pumps

PUMP PERFORMANCE

DEEP WELL (40 PSI) 2" SINGLE PIPE

Cat. Jet Uses Uses

No. HP No. Venturi Nozzle

MSD 3/4

8AP J32P-18 J34P-42 5.5 5.4 5.2 5.0 4.4 4.3 4.1 3.7 3.1 2.4 2.1 1.4 135 73

MSE 1

8AP J32P-18 J34P-42 5.5 5.5 5.3 5.3 5.2 5.1 5.0 5.0 5.0 5.0 4.5 4.2 2.0 198 126

MSF 1-1/2

8AP J32P-18 J34P-42 5.5 5.5 5.5 5.5 5.5 5.3 5.2 5.1 5.0 5.0 5.0 4.8 4.3 3.5 2.7 1.7 266 158

MSG 2

8AP J32P-18 J34P-42 5.5 5.5 5.5 5.5 5.5 5.3 5.2 5.2 5.1 5.1 5.0 4.8 4.7 4.3 3.7 3.2 2.5 312 192

12AP J32P-24 J34P-42 10.0 8.3 6.1 4.7 3.8 2.0 1.4 79 50

12AP J32P-24 J34P-42 12.1 11.3 11.2 10.0 8.8 7.6 6.5 5.6 3.3 1.8 118 80

12AP J32P-24 J34P-42 12.2 12.0 12.0 12.0 11.5 11.2 9.7 8.3 6.8 5.5 4.2 3.3 162 110

12AP J32P-24 J34P-42 12.2 12.0 12.0 12.0 11.7 11.2 11.0 10.3 8.3 7.5 6.3 5.3 193 139

PUMP PERFORMANCE

DEEP WELL (40 PSI) 3" SINGLE PIPE

Max. Pump

Shut-Off

Press.

(PSI)

Jet at Jet at

Cat. Jet Uses Uses Min. Max.

No. HP No. Venturi Nozzle 30' 40' 50' 60' 70' 80' 90' 100' 110' 120' 130' 140' 180' 200' 220' 240' 260' 280' 300' 320' Depth Depth

23CP J32P-24 J34P-42 10.2 8.4 6.8 5.8 4.5 3.1 2.1 1.1 80 46

MSD 3/4 17CP J32P-29 J34P-44 12.0 10.4 8.5 6.6 4.3 2.1 77 50

16CP J32P-18 J34P-42 5.5 5.4 5.3 5.2 4.7 4.3 4.1 3.7 3.1 2.7 2.3 1.9 137 75

23CP J32P-24 J34P-42 12.1 11.7 11.6 11.1 10.2 9.2 7.8 6.4 5.0 4.0 3.0 120 76

MSE 1

16CP J32P-18 J34P-42 5.5 5.5 5.5 5.4 5.3 5.3 5.2 5.1 5.1 5.0 4.8 4.5 3.3 2.7 2.0 1.3 1.0 200 97

23CP J32P-24 J34P-42 12.2 12.2 12.2 12.2 11.7 11.3 10.7 9.9 9.0 8.3 7.0 4.0 1.3 164 95

MSF 1-1/2 22CP J32P-20 J34P-42 7.7 7.7 7.7 7.5 7.5 7.4 7.3 7.3 7.2 7.2 7.0 7.0 4.3 4.0 3.2 2.2 210 110

16CP J32P-18 J34P-42 5.5 5.5 5.5 5.5 5.5 5.5 5.3 5.2 5.2 5.1 5.0 5.0 4.9 4.7 4.0 3.8 3.0 2.3 1.7 268 132

23CP J32P-24 J34P-42 12.2 12.2 12.2 12.2 11.8 11.3 11.2 11.1 11.0 10.0 8.7 7.0 4.0 2.0 195 110

MSG 2 22CP J32P-20 J34P-42 7.7 7.7 7.7 7.5 7.5 7.4 7.3 7.3 7.2 7.2 7.0 7.0 5.3 5.0 4.7 4.0 3.0 2.2 250 128

16CP J32P-18 J34P-42 5.5 5.5 5.5 5.5 5.5 5.5 5.3 5.3 5.2 5.1 5.1 5.0 5.0 4.8 4.7 4.5 4.3 4.0 3.3 2.7 314 172

(Capacity in Gallons Per Minute)

30' 40' 50' 60' 70' 80' 90' 100' 110' 120' 130' 140' 180' 200' 220' 240' 260'

(Capacity in Gallons Per Minute)

Pumping Depth in Feet

Pumping Depth in Feet

Max. Pump

Shut-Off

Press.

(PSI)

Jet at Jet at

Min. Max.

Depth Depth

Tested and rated in accordance with Water Systems Council Standards.

NOTE: Pumps installed with a PRO-Source™ tank require a 100 PSI relief valve. Pumps installed with a conventional tank require

a 75 PSI relief valve. Relief valve must be capable of relieving entire flow of pump at relief pressure.

Customer Service: (888) 782-7483

Fax Orders: (800) 426-9446 www.sta-rite.com

•

3

Pentair Water

•

Delavan, WI 53115 USA

•

S4513WS (5/11)

•

Loading...

Loading...