Page 1

Compool

Cp3000 POOL-SPA CONTROL SYSTEM

Installation & Operating Instructions

01/01/95

941-0881

Page 2

Page 3

Table of Contents

SAFETY NOTIC E .............. ... ................ ... ................. .. ................. .. .... 1

INSTALLATION ................................................................................. 2

PLUMBING REQUIREMENTS .................................................................. 3

EQUIPMENT LOCATION.......................................................................... 4

HIGH VOLTAGE WIRING............................................ ..... ..... .... ................ 5

LOW VOLTAGE WIRING........................................................................... 9

SYSTEM OPTIONS................................................................................. 14

SYSTEM START-UP ............................................................................... 19

CALIBRATING TEMPERATURE SENSORS.......................................... 20

OPERATING INSTRUCTIONS........................................................ 21

INTRODUCTION...................................................................................... 21

SAFETY FEATURES................................................... ..... ..... .... .............. 21

Cp3000 CONTROLLER........................................................................... 22

PROGRAMMING..................................................................................... 27

Lx3000 POWER CENTER....................................................................... 30

VALVE ACTUATORS.............................................................................. 32

SPA-SIDE REMOTE................................................................................ 32

SYSTEM OPTIONS................................................................................. 34

MAINTENANCE............................................................................... 35

PROBLEM SOLVING ...................................................................... 37

WARRANTY .................................................................................... 39

INDEX.............................................................................................. 40

Page 4

Compool Cp3000

Safety Notice

SAFETY NOTICE

IMPORTANT SAFETY INSTRUCTIONS

WHEN INSTALLING AND USING THIS ELECTRICAL EQUIPMENT, BASIC SAFETY PRECAUTIONS

SHOULD ALWAYS BE FOLLOWED, INCLUDING THE FOLLOWING:

• READ AND FOLLOW ALL INSTRUCTIONS.

• WARNING: TO REDUCE THE RISK OF INJUR Y, DO NO T PER MIT CHILDREN TO USE THIS PR ODUCT

UNLESS THEY ARE CLOSELY SUPERVISED AT ALL TIMES.

• WARNING: WATER IN EXCESS OF 100° FAHRENHEIT MAY BE HAZARDOUS TO YOUR HEALTH.

• A TERMINAL BAR (MARKED FOR EQUIPMENT GROUND ONLY) IS LOCATED INSIDE THE HIGH

VOLTAGE COMPAR TMENT OF THE PO WER CENTE R. TO REDUCE THE RISK OF ELECTRIC SHOCK,

THIS TERMINAL MUST BE CONNECTED TO THE GROUNDING MEANS PROVIDED IN THE

ELECTRICAL SUPPLY PANEL WITH A CONTINUOUS C OPPER WIR E EQUIVALENT IN SIZE TO THE

CIRCUIT CONDUCTORS SUPPLYING THIS EQUIPMENT.

• SAVE THESE INSTRUCTIONS .

1

Page 5

Compool Cp3000

Installation

INSTALLATION

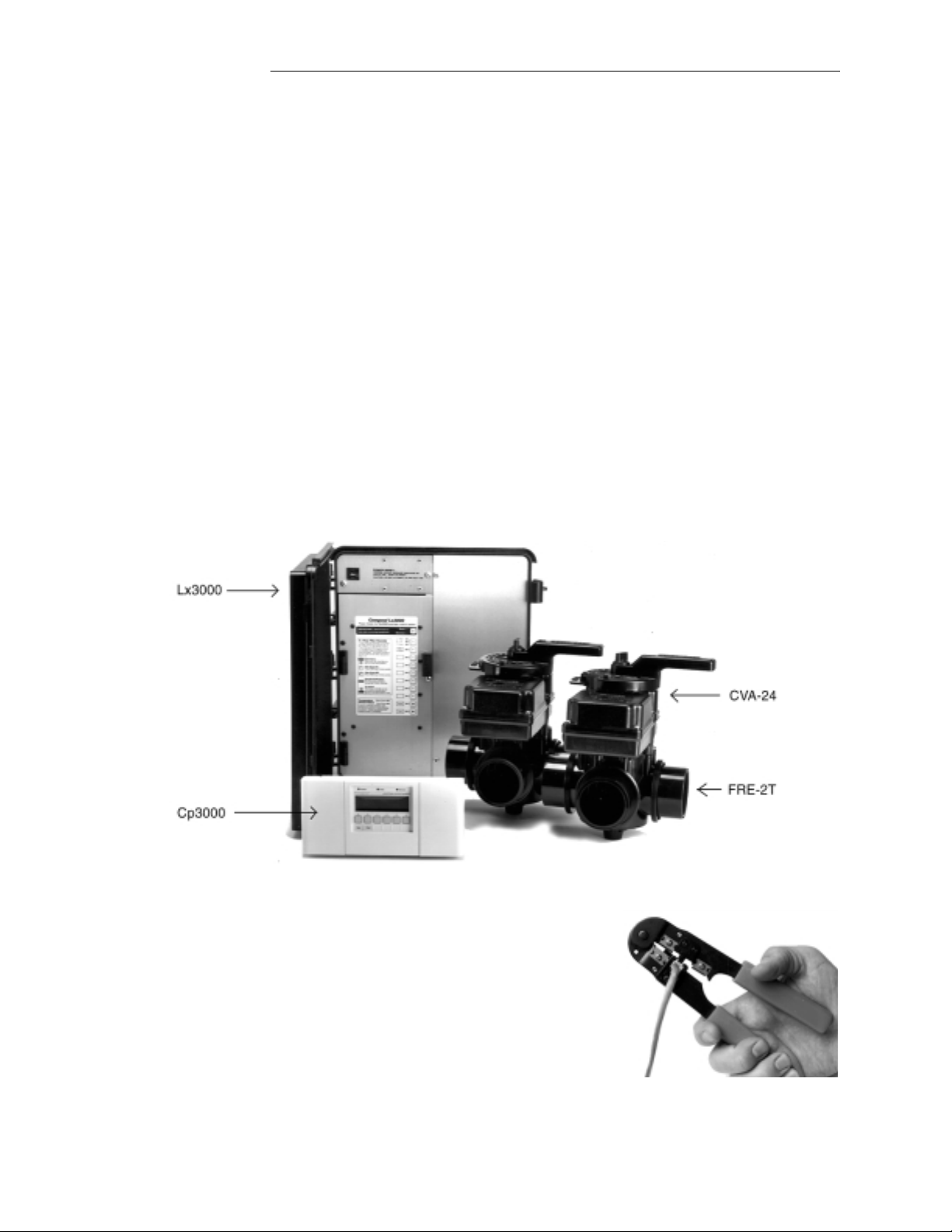

PRODUCT PACKAGE

Open the shipping carton and check the contents. If any items are missing or damaged, contact your dealer

immediately.

The package should include the following items:

• CP-3000 Controller.

• LX-3000 Power C enter.

• CVA-24 Valve Actuators (2 qty).

• FRE-2T 3-Port Freedom Valves (2 qty).

• 6COND Hookup Cable (150 ft.).

• Installation Hardware Kit:

½

” Encloser Screws (4 qty)

”

¼

1

Mounting Screws (3 qty)

Plastic Mounting Anchors (3 qty)

Water Temperature Sensor (w/ Hardware)

2-conduct or Hook-up Cable (25 ft.)

Modular Plugs for Communication Cabl e (3 qty)

Test Cable with Modular Plugs (4 ft.)

SPECIAL TOOLS REQUIRED

1. 3/16” dia. Drill (for mounting Cp3000 Controller).

2. 5/16” dia. Drill (for mounting Water Temperature Sensor).

3. Crimping Tool (model TOOL-6) for mounting Connectors to Hookup Cable.

TOOL-6

2

Page 6

Compool Cp3000

CP-3000

CONTROLLER

INTAE

BLOWER

AIR

SPA

ET

PUMP

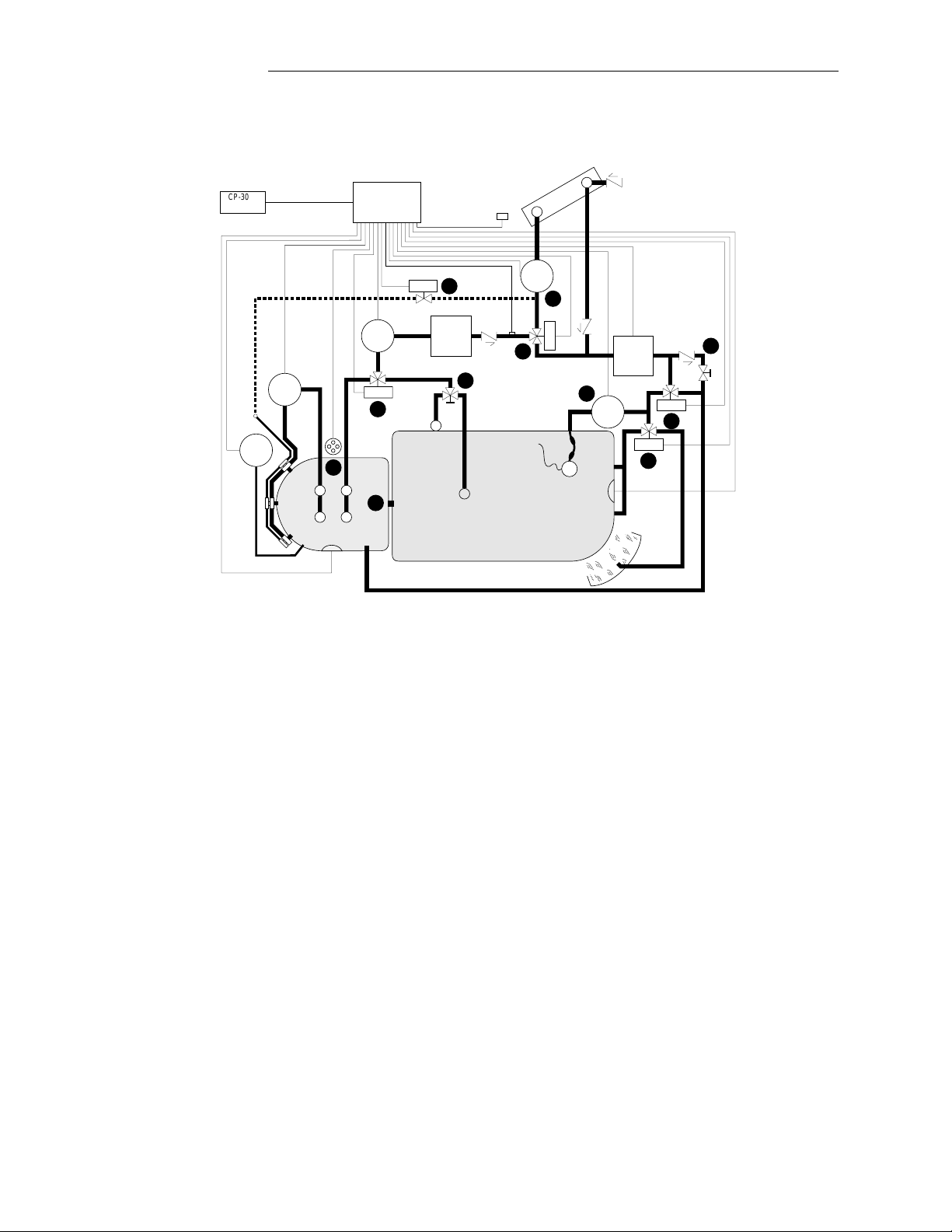

PLUMBING REQUIREMENTS

LX-3000

SERVICE CENTER

HW-5B

REMOTE

SPA-SIDE

FILTER

PUMP

CVA-24

FILTER

SIMMER

SPA POOL

SPA

LIGHT

MAIN

DRAIN

SOLAR

SENSOR

WATER

SOLAR

PUMP

SENSOR

CVA-24

POOL

CLEANER

PUMP

POOL

LIGHT

VACUUM

RELIEF

HEATER

CVA-24

WATERFALL

Installation

CVA-24

Recommended Hydraulic Schematic

Plumb system in accordance with recommended hydraulic schematic, local codes and the following gu idelines.

Bring all lines back to the equipment pad:

1. Spa should be at or above the lev e l of the pool. If spa is attached to pool, provide a dam between the two bodies

of water and allow spa overflow into pool. If spa is not attached to pool, an overflow, sufficient in size to carry

full pump-flow, must be installed between spa and pool.

2. Plumb a 3-port Freedom Valve on the suction-side of the filter pump, so that center port of valve is connected to

the pump inlet. Connect spa suction to one side of Intake Valve, and pool suction to the other side.

3. Plumb a 3-port Freedom Valve on the output-side of the heater, so that return water will enter valve through the

center port. Connect spa retu rn to one port, and pool return to the other.

4. A ¾” spa makeup line (incorporating a ¾” manual gate or ball valve and, for elevated spas, a ¾” check valve)

may be provided to bypass the pool return line. This will enable some of the pool water to cycle through the spa,

thus keeping it chemically balanced with the pool. The manual valve will allow the amount of by pas s to be

adjusted.

5. If an optional Spa-Side Remot e is to be used, install a 6” t o 12” leng th of 1½” Sc h. 40 p vc pipe abo v e w ater le vel

in the spa wall so that the Spa-Side Remote will not be submerged. This can be done by positioning the top of

the 1 ½” pipe ½” below the coping. The pipe should be perpendicular to the spa wall and protrude beyond the

finished surface of the spa. It will be cut back at a later date. Outside the spa, reduce the pipe size down to ½” or

¾” conduit, and run to proposed Lx3000 Power Center l ocation at equipment pad. Use sweep elbows for turns.

The Spa-Side Remote should not be installed until spa constructio n is complete.

3

Page 7

Compool Cp3000

6. For systems which incorporate a skimmer, it is possible to balance the amount of suction between the skimmer

and main drain for maintenance purposes. This is easily accomplished by installing a manual 3-port Freedom

Valve at the suction line. Plumb one port to the skimmer and the other to the main drain.

7. If a “booster pump” type pool cleaner is being used, plumb the pump so that its suction-side is connected to the

pool return, after the heater and as close to t he ground as practical.

8. A motorized 3-port Freedom Valve can be installed to create a waterfall from the return line. This enables a

waterfall effect to occur whenever the filter pump is running, and eliminates the need for a separate pump.

9. For systems which utilize solar panels, plumb the solar feed and return lines between the filter and heater, and

install a motorized 3-port Compool Solar Valve at the solar feed line. Provide a vacuum relief valve at the

highest point of the solar panel array, and a ½ lb. spring check valve at the solar return line. Use Compool Solar

Valve (model SOL-2T), to allow the panels to automatically drain whenever the filter pump is not running.

10. For solar systems with very long plumbing runs, or where panels are i nstalled at a very high elevation (higher

than reasonable head pressure of filter pump), a solar booster pump should be installed at the solar feed line. The

motorized Solar Valve should always be used in conjunction with this pump, except where the vertical elevation

of panels above pool water level exceeds 25 feet.

11. For solar systems with glazed panels, plumb a ½” motorized Solar Drain Valve (model HW-5B) from the solar

feed line, through a check valve, to a zero psi point (such as a jet air intake or pool fill line). Do not connect it to

pump suction. This will enable the panels to automatically drain whenever the solar turns off, even if the filter

pump is still running. This prevents possible scaling of panels and damage from overheating. The Solar Drain

Valve (model HW-5B) should also be used for solar systems which do not facilitate gravity drainage of panels

(i.e.: where solar plumbing crosses the ridge of the roof).

Installation

EQUIPMENT LOCATION

With the exception of the Spa-Side Remote (which is UL Listed for installation right at the tile-line of the spa), all

equipment must be located five feet or more from the water’s edge.

1. Lx3000 Power Center at the equipment site.

2. Cp3000 Controller inside th e house or other weathe r-protected area.

3. CVA-24 Valve Actuator(s) at valve(s) to be motorized.

4. TS-5L Water Temperature Sensor at the filter pump.

5. TS-5L Solar Temperature Sensor at solar panels (where applicable).

6. Spa-Side Remote (optional) at spa wall or decking.

4

Page 8

Compool Cp3000

Installation

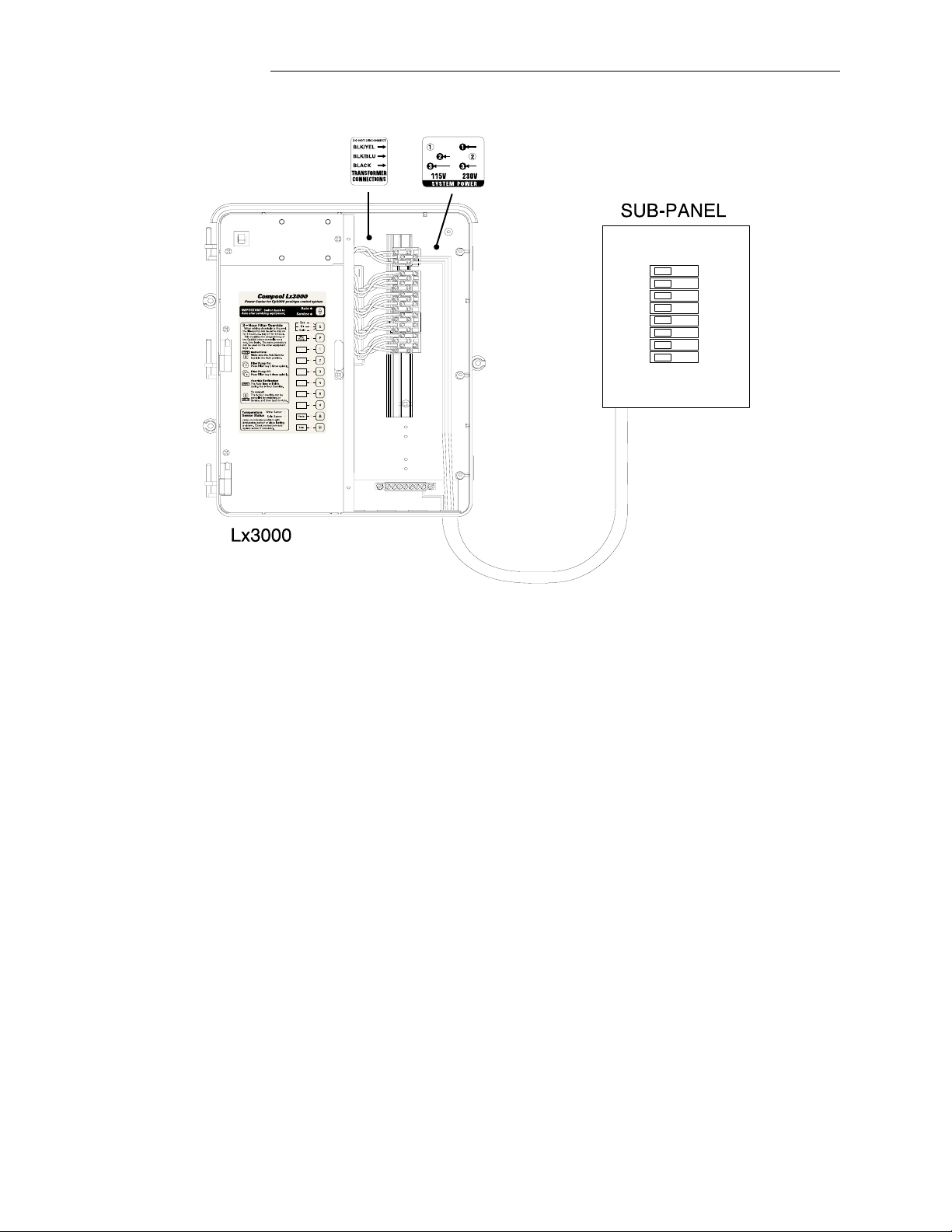

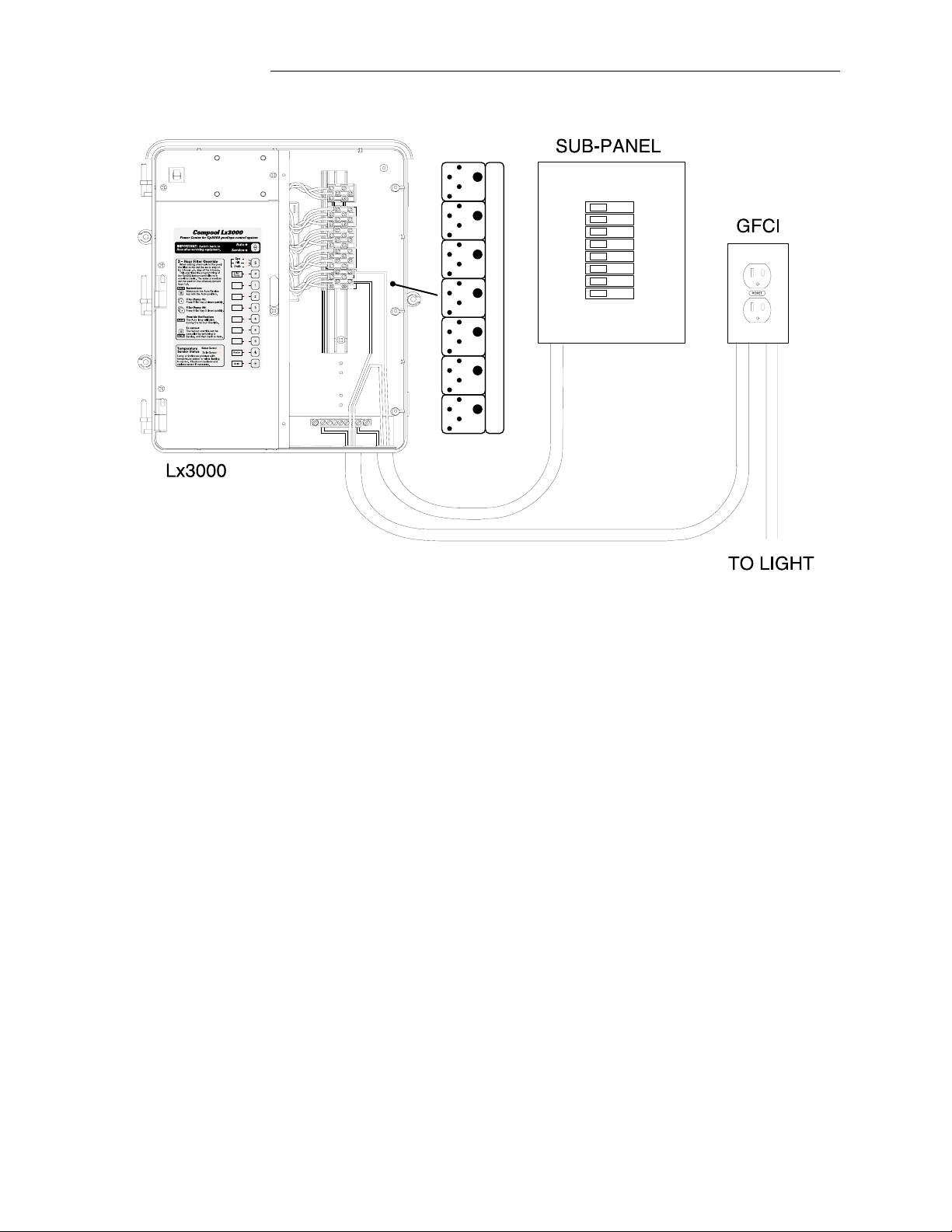

HIGH VOLTAGE WIRING

SUB-PANEL

At the equipment site, install an electrical sub-panel with separate breakers for each load. Circuit breakers should be

readily accessible to the pool/spa user, but installed at least 5 feet from the water’s edge.

Note: It is possible to install system without a sub -pa nel.

Lx3000 POWER CENTER

Lx3000

1. Select a convenient location to mount the Lx3000 Power Center. Ensure that the location is greater than 5 feet

from the water’s edge and no further than 15 feet from any motorized valves (otherwise Valve Actuator cables

will need to be extended).

2. Mount the Lx3000 on a flat surface using appropriate screws through the three external mounting points located

on the side of the enclosure.

Caution: Do not drill and mount from inside the enclosure

3. Remove the three service panel screws in right-side of Lx3000 to expose the high voltage compartment.

4. Knock-out the appropriate holes at bottom of enclosure to facilitate conduit mounting. Screw terminals are

provided for high voltage connections.

.

5

Page 9

Compool Cp3000

SYSTEM POWER

Installation

1. Provide a separate circuit breaker to power the system. Either 115 or 230 VAC can be used (115 VAC is

preferable). The Cp3000 system draws less than 1 amp.

Caution: Incorrect system wiring will cause permanent damage to the transformer.

2. Verify that the breaker will open all ungrounded supply conductors to comply with section 422-20 of the

Nationa l E lectrical Code, ANSI / NF PA 70-1987.

3. Run appropriate wires from circuit breaker to high voltage compartment of Lx3000, and connect to top terminal

block in accordance with wiring label, which is mark ed “SYSTEM POWER”. The diagram above shows system

wired for 115 volts.

4. For 115 VAC, connect to Screw Terminals #2 and #3.

5. For 230 VAC, connect to Screw Terminals #1 and #3.

6

Page 10

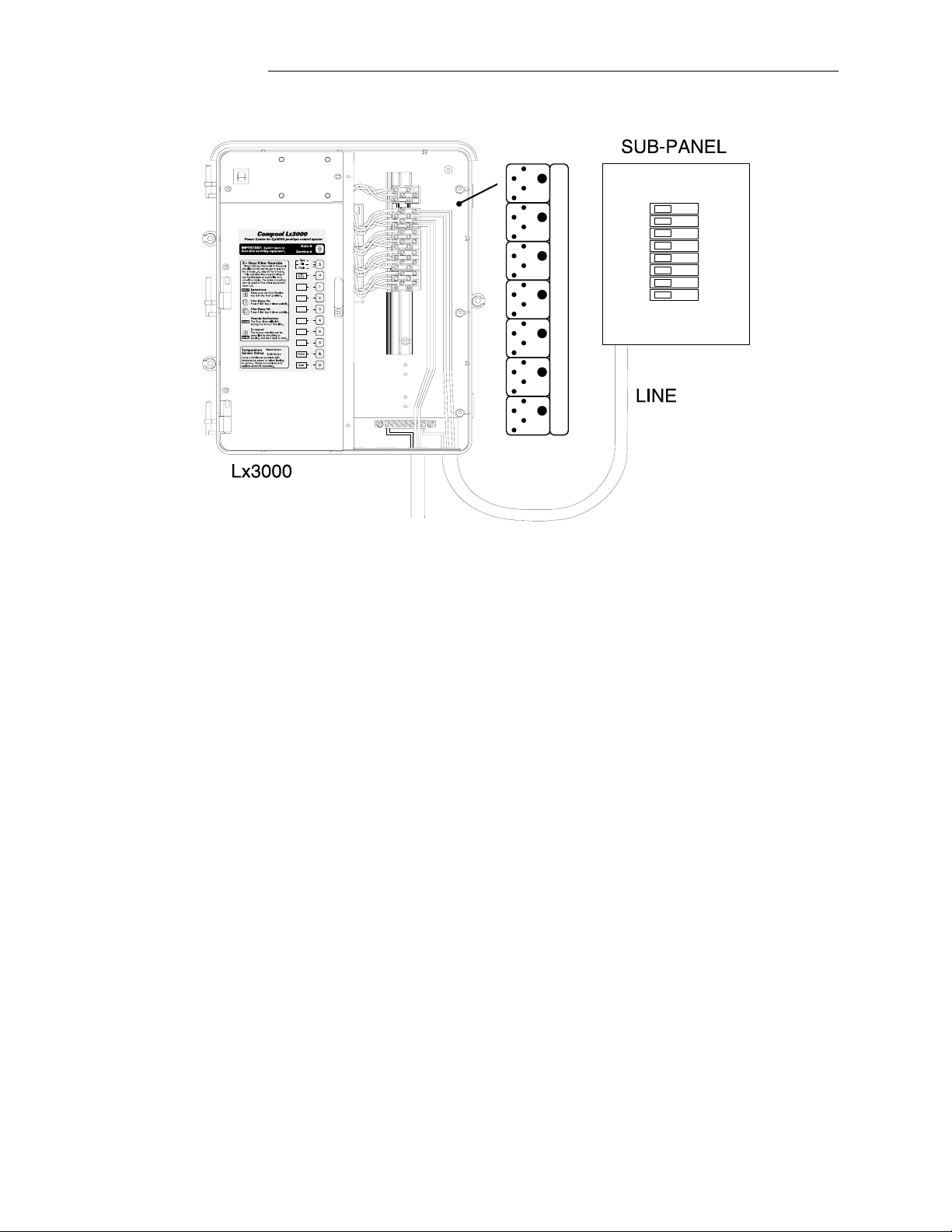

Compool Cp3000

EQUIPMENT POWER

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

R

R

R3

R

R

R

R

Installation

FULL LOAD 0AMP

LOCKED ROTOR 0AMP

HIGH VOLTAGE RELAYS

1. Install circuit breakers to provide voltage for power relays at R1 through R4. Run appropriate wires from

breakers to high voltage compartment of Lx3000, and connect to LINE 1 and LINE 2 Screw Terminals at each

terminal block.

2. Pumps and other high voltage equipment are connected to LOAD 1 and LOAD 2 terminals. Each individual

terminal block can be wired to operate either 115 or 230 VAC.

3. Connect the high voltage equipment to LOAD 1 and LOAD 2 terminals at each terminal block. The diagram

above shows the high voltage wiring of a 230 VAC filter pump.

4. If the system is to control a pool cleaner pump, it should be connected to the R2 terminal block.

Note: For 115 VAC equipment, only half of the terminal block needs to be used (i.e.: LINE 1 and LOAD 1). The

neutral wire connects directly from the sub panel to the equipment.

ADDING RELAYS

The Cp3000 system comes standard with 4 power relays for activating the Filter Pump, Aux1, Aux2 and Aux3 circuits.

It is possible to install additional Relay Kits (model RLY-LX) to the Lx3000, in order to activate additional equipment.

Install RLY-LX in accordance with instructions provided, and plug relay control wire into Lx3000 circuit board at

appropriate Relay Socket. The Lx3000 Power Center will accommodate a maximum of 7 power relays.

7

Page 11

Compool Cp3000

UNDERWATER LIGHTS

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

R

R

R3

R

R

R

R

Installation

FULL LOAD 0AMP

LOCKED ROTOR 0AMP

HIGH VOLTAGE RELAYS

If the system incorporates 115 Volt Underwater Light(s), you should provide GFCI protection on the load side of the

relay (not the line side) as shown above.

Note: Low voltage lights and fiber optic lights do not require GFCI protection.

1. Run appropriate wire from circuit breaker to LINE 1 of terminal block.

2. Run wire from LOAD 1 and neutral wire from circuit breaker to GFCI.

3. Connect underwater lights to GFCI.

Note: If total load exceeds 500 watts (i.e.: two 400 watt pool lights), provide a jumper wire between LINE 1 and LINE

2 at the terminal block.

8

Page 12

Compool Cp3000

Installation

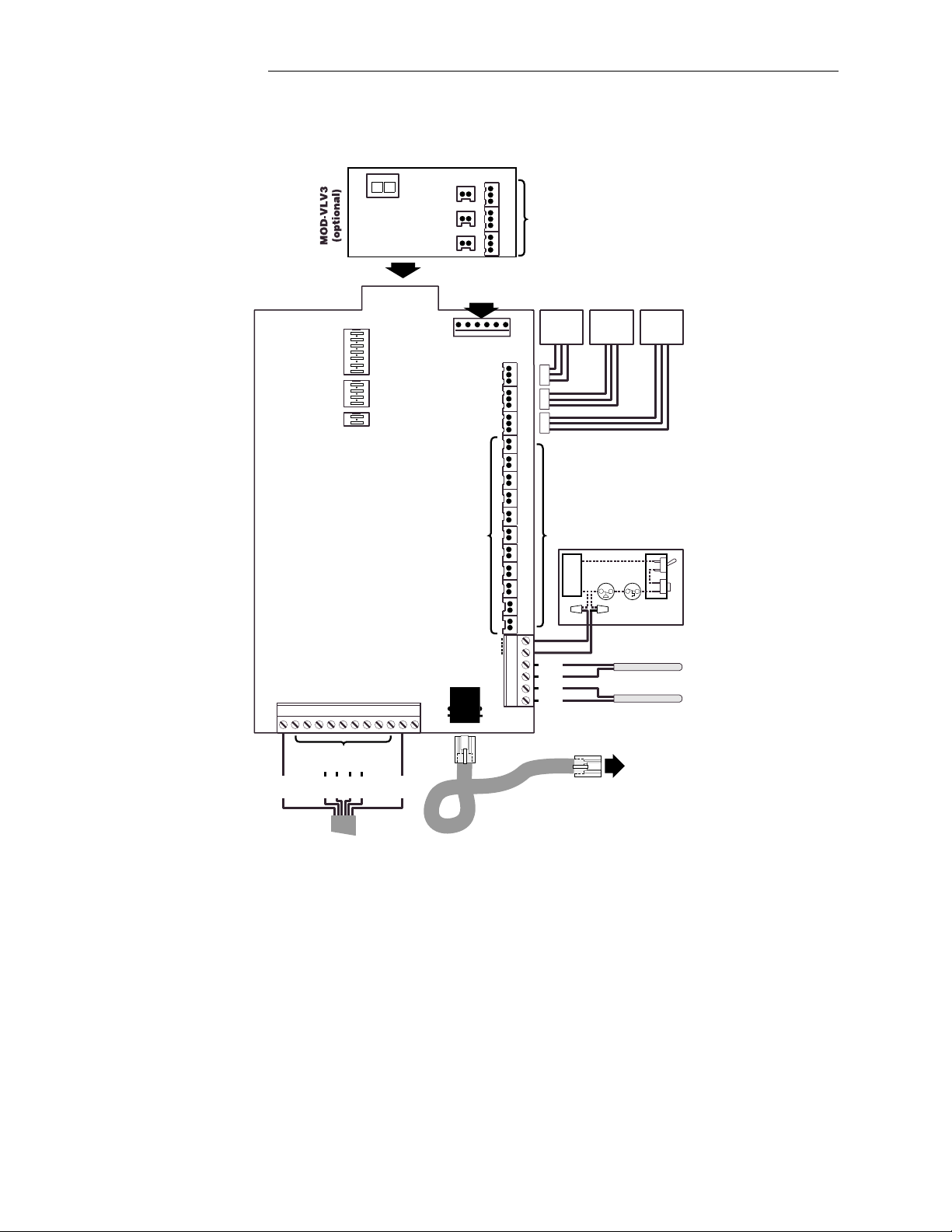

LOW VOLTAGE WIRING

PC-LX3000

COMPOOL 10890D

GND

SPA

VLV1

WITH

VLV2

ON

FLTR

AUX1

3

AUX2

AUX3

AUX4

AUX5

AUX6

FREEZ PORTHI SPD

ON

SPA

FLTR

3

SOLR

AUX1

ON

SOLAR

MANHT

FEATURES

REM1

REMF

SELECT 4 CIRCUITS

REM3

REM2

S S S 3

REM4

S

VLV2

O

WITH

N

VLV3

COMPOOL 11040A

MOD-VLV3

HLMP

REM5

HBST

REM6

VLV1

VLV2

ACTUATORS

VLV3

AUXILIARY VALVE

TRANSFORMER

CONNECTIONS

INTAKE

VALVE

18

10 24

CAUTION: DO NOT SHORT PINS OF RELAY SOCKETS

HTR

STSSTS+

WTS-

+10

WTS+

TO CP-3000

ACTUATOR ACTUATOR

INT

VLV

RET

VLV

SOL

VLV

SPA

FLTR

AUX1

AUX2

AUX3

AUX4

AUX5

AUX6

EHTR

SOL

PMP

2SPD

GRN

RED

GRN

RED

BLU

RETURN SOLAR

VALVE

RELAY CONNECTIONS

PRESSURE

CONTROL

GAS VALVE

BLU

VALVE

ACTUATOR

HEATER

LIMIT

THERMOSTAT

SOLAR SENSOR

WATER SENSOR

to CP-3000

ON

OFF

RED

YEL

GRN

BLU

ORG

BLK

to SPA-SIDE REMOTE

Lx3000 Circuit Board

LOW VOLTAGE CABLES

All low voltage connections are made to the circuit board which is located behind the hinged faceplate in left-side

compartment of Lx3000 Power Center.

150 feet of 6-conductor communication cable (model 6COND), and 25 feet of 2-conductor cable (model 2COND) is

provided with the system. Additional cable is available from your distributor.

Determine lengths of hookup cable required to run from the low voltage compartment of the Lx3000 Power Center to

the various pieces of equipment:

9

Page 13

Compool Cp3000

1. 6-conductor 26 AWG communication cable to the Cp3000 Con troll er. Note: 300’ run maximum. Ca ll Co mpool

for instruction for longer run s. Caution: Always lubricate cable with cable lubricant when pulling through

conduit.

2. 2-conductor 22 AWG cable to the gas heater.

3. 2-conductor 22 AWG cable to the Water Temperature Sensor.

4. 2-conductor 22 AWG cable to optional Solar Temperature Sensor.

5. CVA-24 Valve Actuators are provided with 15 feet of 3-conductor cable. Note: May be extended to a max.

length of 150’ w/ 18 gauge cable (model 3COND/VOR).

6. Optional Spa-Side Remote is provided with necessary cable attached (50’, 100’, 150’, 200’, or 250’ length).

Note: Do not install low voltage and high voltage wires in the same conduit.

Do not install temperature sensor and gas heater wires in the same conduit.

Install cables, using plastic or metallic conduit where cables run underground, through concrete, etc.

MOUNTING THE Cp3000 CONTROLLER

Installation

1. Select a convenient location inside the house or other weather-protected area to mount the Cp3000 Controller.

The overall width of the Controller (with doors open) is 11½”. The location of the 6-conductor communication

cable (on the centerline of the enclosure) should therefore be at least 5¾” from any door jamb, wall corner or

other obstacle. Install the Cp3000 Cont roller at eye level for best viewing of the L CD display.

2. Remove backplate from Controller. Temporarily pull cable through large hole in backplate, and position

backplate on surface of wall. Ensure that backplate is level, and that “TOP” nomenclature is oriented correctly.

Level the backplate and mark the three mounting points on the surface of the wall.

3. With the back plate remov ed from the wall, drill 3/16” d iameter holes at the three points. Insert mo unting anchors

(included) into the three holes.

4. Pull cable through large hole in backplate, and use the three 1¼” screws to mount backplate to wall. Cut off

excess cable, and use crimping tool (m odel TOOL-6) to connect modular plug at each end of cable. See USING

THE CRIMPING TOOL for details.

5. At the Cp3000, insert cable (with modular plug attached) into circuit board at “LINE TO LX” Socket.

10

Page 14

Compool Cp3000

6. Use the four ½” screws (included) to mount Controller to the backplate.

7. At the Lx3000, insert cable (with modular plug attached) into circuit board at “to CP-3000” Socket.

USING THE CRIMPING TOOL

TOOL-6

1. Use Cutter to prepare cable end. Make sure that cable is cut squarely (not diagonally).

Installation

2. Insert the cable between the Stripper blades of the tool until it touches the stop. Squeeze the handles and pull the

tool, making sure that the cable stays perpendicular to it. If this is done correctly, the outer jacket of the cable

will be removed without damaging the insulation on the individual conductors.

3. Plug a modular connector into the holder so that the gold contacts face the Crimper.

4. Orient the prepared cable so that the blue conductor is closest to the tool handles, and insert cable into connecto r.

Make sure the wires go all the way to the back of the connector.

5. Squeeze the handles firmly

Note: It is important that the orientation (blue conductor closest to tool handles) is identical at each end of the cable.

CVA-24 VALVE ACTUATORS

to set the contacts and secure the cable.

CVA-24

1. Remove knob, handle and four screws from cap of valve(s) to be motorized, and use the four mounting screws

provided to mount Valve Actuator(s) to valve(s).

2. Run cable(s) to low voltage compartment of Lx3000 Power Center.

3. At the Lx3000, plug cable(s) into appropriate Valve Socket on circuit board:

11

Page 15

Compool Cp3000

• Plug Intake (suction) Valve to INT VLV Socket.

• Plug Return Valve to RET VLV Socket.

• Plug Optional Solar Valve (if applicable) to SOL VLV Socket.

Note: To control additional valve actuators, see AUXILIARY VALVE ACTUATORS for details.

GAS HEATER CONNECTIONS

Installation

Follow these instructions to connect a gas heater (millivolt or electronic-ignition) or propane heater:

1. Cut sufficient 2-conductor cable (25 ft. is included with Accessory Kit) to run between the heater and the

Lx3000.

2. Inside the heater, interrupt wire between thermostat and pressure switch (where fireman’s switch is typically

connected), and interconnect with 2-conductor cable us ing wire nuts. Do not discon nect or by pass the thermostat

or any safety switches.

3. Run cable to low voltage compartment of Lx3000. At the Lx3000, strip insulation ¼” and connect to circuit

board at the two HTR Screw Terminals.

4. Turn the heater switch to ON (or High) and set thermostat(s ) to maximum.

WATER TEMPERATURE SENSOR

1. Select a convenient location to mount the Temperature Sensor (model TS-5L) between the pump and filter.

2. Drill a 5/16” diameter hole in the pipe, and insert the Sensor. Position the hose clamp over the Sensor, and gently

tighten around pipe. Caution: Overtightening of clamp can cause deformation of O-ring seal.

3. Use the remainder of the 2-conductor cable (provided with Accessory Kit) to run between Sensor location and

low voltage compartment of Lx3000 Power Center.

4. At the Sensor, p ay attention to color -coding of wire s (green wire connects to green; red wire connects to red), an d

use crimp connectors (included) to provide waterproof connections. Before making connections, shorten sens or

12

Page 16

Compool Cp3000

leads to about 6”. Do not strip wires. Push the 2 wires to be connected into the small holes at one end of the

connector, and squeeze the connector with a pair of pliers. 2 extra connectors are included.

5. At the Lx3000, connect Sensor cable to circuit board at WTS- and WTS+ Screw Terminals in accordance with

wiring diagram located inside Lx3000 door. Pay attention to color-coding of wires (green wire connects to

WTS- and red wire connects to WTS+).

Note: Infield calibration of temperature sensor(s) is required. See CALIBRATING TEMPERATURE SENSORS for

details.

Installation

13

Page 17

Compool Cp3000

Installation

SYSTEM OPTIONS

SPA-SIDE REMOTE

SS4-100W

The optional Spa-Side Remote (model SS4-100W) is a double-insulated device which is UL Listed for installation

within 5 feet of the water’s edge. It is typically installed at the tile- line on th e spa wall (abov e water level), or i n the

deck within arm’s reach of the spa. If the Spa-Side Remote is to be installed into the wall of a gunite spa, provision

must be made while the spa is being plumbed (See PLUMBING REQUIREMENTS for details):

1. When the spa construction is completed, cut back the 1½” dia. pvc pipe receptacle flush with the spa wall finish

or surface of deck.

2. Screw Mounting Adapter onto Spa-Side Remot e, and finger-tighten. Caution: Do not use wrench.

3. Thread Spa-Side Remote cable through conduit to low-voltage compartment of Lx3000.

4. Carefully glue Mounting Adapter into 1½” pvc receptacle using pvc cement. For aesthetic purposes, it is

suggested that the Spa-Side Remote be installed with Red button in the 12 o’clock position.

5. At the Lx3000, identify the 6-conductor cable from the Spa-Side Remote, and cutoff excess cable as necessary.

Strip insulation of each conductor ¼" and connect to appropriate Screw Terminals at bottom of circuit board in

accordance with wiring diagram:

6. Connect Black wire (Switch Common) to GND Screw Terminal.

7. Connect Orange (Status Lamp) to HLMP Screw Terminal.

8. Determine which 4 of the following circuits you wish to control from within the spa, and connect Red (Red

button), Yellow (Yellow button), Green (Green button) and Blue (Blue button) wires to the appropriate Screw

Terminals (see LX3000 CIRCUIT BOARD for details):

• SPA Rotates intake and return valves, and activates filter pump and heater.

• REMF Activates filter pump (normally not used).

• REM1 Activates auxiliary 1 equipment (such as pool cleaner).

• REM2 Activates auxiliary 2 equipment (such as pool light).

• REM3 Activates auxiliary 3 equipment (such as spa light).

• REM4 Activates auxiliary 4 equipment (such as fountain or waterfall).

• REM5 Activates auxiliary 5 equipment (such as jet pump).

• REM6 Activates auxiliary 6 equipment (such as air blower).

• HBST Enables spa heating for a five minute period.

For Spa-Side control of more than 4 pieces of equipment, a second Spa-Side Remote may be installed.

14

Page 18

Compool Cp3000

Installation

A set of adhesive labels is provided for custom identification of individual Spa-Side Remote buttons. Use a pair of

fine-tip tweezers to carefully adhere the appropriate label at each button.

2-SPEED FILTER PUMP CONTROL

If the system is equipped with a 2-Speed Filter Pump, a 2-Speed Filter Pump Relay Kit (model RLY-LXD) s hou ld be

installed at the Power Center in accordance with instructions provided.

There are three ways to configure the 2-Speed Filter Pump control:

1. Automatic configuration:

The system will run the filter pump in “low sp eed” durin g norm al operati on, but will au tomati cally sw itch th e pump

to “high speed” for 5 minutes whenever the filter pump turns on.

It is additionally possible to activate the pump in “high speed” whenever the spa, heater, solar and/or Aux1 (pool

cleaner) is running. To enable the pump to run in “high speed” during these conditions, it is necessary to adjust the 4position HI SPD Program Switch, which is located at top center of Lx3000 circuit board. Use the corner of a small

screwdriver or other blunt instrument to slide the appropr iate Switch(es) to the ON position:

Switch #1: Enables high speed when spa is running.

Switch #2: Enables high speed when heater is running.

Switch #3: Enables high speed when solar system is running.

Switch #4: Enables high speed when Aux1 (pool cleaner) is running.

Connect RLY-LXD relay control wire into 2SPD Relay Socket.

2. Manual configuration:

The system will run the filter pump in “low speed” during normal operation, but will switch the pump to “high speed”

when an Auxiliary Circuit is activated.

Select an Auxiliary Circuit (Aux1 - Aux6), and connect RLY-LXD control wire into the appropriate Relay Socket.

3. Combined configuration:

The “high speed” is controlled by an Auxiliary Circuit an d the HI-SPD Program Switch. Use Dual Circuit Relay

Adapter (model CRA-LX) to connect RLY- LXD relay control wire into an Auxiliary Relay Socket and into 2SPD

Relay Socket.

AUXILIARY VALVE ACTUATORS

VLV1

WITH

VLV2

VLV2

12

O

WITH

N

VLV3

COMPOOL 11040A

MOD-VLV3

CONTROL JUMPER

SOCKETS

VLV1

VLV2

VLV3

ACTUATORS

AUXILIARY VALVE

MOD-VLV3

It is possible to add Valve Actuators ( model CVA-24) to the system to motorize two-port or three-port valves for

custom hydraulic features (such as a pool cleaner, fountain, waterfall, etc.). A total of three Valve Actuators may be

added. Valve Actuators can be activated from any Circuit.

1. Install Auxiliary Valve Module (model MOD-VLV3) at the Lx3000 low voltage compartment in accordance with

instructions provided.

15

Page 19

Compool Cp3000

2. Remove knob, handle and four screws from cap of valve(s) to be motorized, and use the four mounting screws

provided to mount Valve Actuator(s) to valve(s).

3. Run cable from Valve Actuator to Lx3000 low voltage compartment.

4. Plug end of Valve Actuator cable(s) into appropriate Valve Socket(s) on the MOD-VLV3 circuit board (VLV1,

VLV2, or VLV3).

5. Locate Wiring Harnesses, which are provided with the Valve Module.

6. Select which Circuit(s) you wish to use for activating Valve Actuator(s). Each Circuit will require a Wiring

Harness.

7. Plug one end of Wiring Harness into Lx3000 circuit board at the appropriate Relay Socket.

8. Plug other end of Wiring Harness into MOD-VLV3 at appropriate CONTROL JUMPERS Socket.

9. To combine the operation of VLV1 with VLV2 and/or VLV 2 with VLV3, adjust the COMBINED VALVES

Program Switch (at upper left-side of MOD-VLV3) accordingly.

HIGH VOLTAGE THERMOSTAT HEATER

For systems which utilize a high voltage thermostat, such as an oil fired heater, electric heater, or heat pump, a Relay

Kit (model RLY-LX) should be added.

Installation

1. Install RLY-LX at the Lx3000 in accordance with instructions provided, and plug relay control wire onto circuit

board at EHTR Relay Socket. The relay will close whenever the Cp3000 is calling for heat.

2. Splice thermostat wiring inside heater and run wires of sufficient gauge to Line 1 and Load 1 of RLY-LX relay

terminal block.

FREEZE PROTECTION SETTINGS

It is possible to automatically circulate water through the equipment whenever the temperature drops to 35° F. This

will protect the equipment against possible freeze damage.

The Control System uses the Water Temperature Sensor to detect freezing conditions, so a separate Freeze Sensor is

not required.

It is, however, necessary to adjust the 7-position FREEZ PROT Program Switch, which is located at top center of

Lx3000 circuit board. Determine which e quipm ent yo u wou ld like to activate during freezing conditions, and us e the

corner of a small screwdriver or other blunt instrument to slide the appropriate Switch (es) to the ON position:

Switch #1: Activates FLTR (filter pump) during freezing conditions.

Switch #2: Activates AUX1 during freezing conditions.

Switch #3: Activates AUX2 during freezing conditions.

Switch #4: Activates AUX3 during freezing conditions.

Switch #5: Activates AUX4 during freezing conditions.

Switch #6: Activates AUX5 during freezing conditions.

Switch #7: Activates AUX6 during freezing conditions.

When Freeze Mode starts, the Cp3000 display will indicate “FRZ” and turn on any circuit that has been selected by

the FREEZ PROT Program Switch. Equipment key icons will not show “ON” if activated by the Freeze Mode.

Switch #1 additionally cycles the pool and spa for 15 minutes each. The Freeze Mode lasts for 30 minutes. Pressing

16

Page 20

Compool Cp3000

any of the equipment keys on the Cp3000 controller will deactivate the Freeze Mode.

SOLAR TEMPERATURE SENSOR

If the system incorporates solar, install an optional Temperature Sensor (model TS-5L) at the solar panel array.

1. Adjust the 2-position Program Switch, which is located at top center of Lx3000 circuit board. Use the corner of

a small screwdriver or other blunt instrument to slide Switch #1 (SOLAR) to the ON position.

2. Discard clamp (included with TS-5L). Do not drill hole and clamp sensor into solar pipe. For unglazed

panels, fasten Sensor to surface next to solar panels. Do not bolt directly to panel. For glazed panels, suspend

Sensor between collector and glazing.

3. Provide 2-conductor cable between Solar Sensor and low voltage compartment of Lx3000 Power Center.

4. At the Sensor, p ay attention to color -coding of wire s (green wire connects to green; red wire connects to red), an d

use crimp connectors (included) to provide waterproof connections. Before making connections, shorten sens or

leads to about 6”. Do not strip wires. Push the 2 wires to be connected into the small holes at one end of the

connector, and squeeze the cylinder with a pair of pliers. 2 additional connectors are included. It is

recommended to tape connections and wiring to prevent possible damage from UV radiation. Be sure to keep

wires separated.

Installation

5. At the Lx3000, connect cable from Solar Sensor to circuit board at STS- and STS+ Screw Terminals. Pay

attention to color-coding of wires (green wire connects to STS- and red wire connects to STS+).

Note: Infield calibration of temperature sensors is required. See CALIBRATING TEMPERATURE SENSORS for

details.

SOLAR BOOSTER PUMP CONTROL

If a solar booster pump is being used, install a Relay Kit (model RLY-LX) at the Lx3000 in accordance with

instructions provided, and plug onto circuit board at SOL PMP Relay Socket.

17

Page 21

Compool Cp3000

Cp3000 CIRCUIT BOARD

COMPOOL 10881A

PART No PC-CP3000

Installation

S1

3

2

1

LINE

TO LX

S2

CS

FS

FC

CD

FD

ON

RESET

NORMAL

To enable the following options, refer to the Cp3000 circuit board diagram shown above.

SPA WATERFALL CONTROL SWITCH

For systems where spa water level is higher than that of the pool, it is possible to use Circuit #2 to rotate the return

valve to spa return position, thus creating an overflow (waterfall effect) from the spa into the pool. This effect will

cease during spa circulation or pool cleaner operation.

To enable this feature, it is necessary to adjust the 3-position S1 Program Switch, which is located at top right-side of

Cp3000 circuit board. Using the corner of a small screwdriver or other blunt instrument, slide Switch #3 to the ON

position.

CUSTOM CLOCK OPTIONS

The standard Cp3000 Controller is provided with the appropriate equipment interlock and safety delays, assuming that

Aux1 Circuit is being used to activate a pool cleaner pump. It is, however, possible to eliminate the interlocks and

delays for custom applications (such as where there is no pool cleaner).

To achieve this, it is necessary to modify the 5-position S2 Program Switch which is located at center right-side of the

Cp3000 circuit board. Use the corner of a small screwdriver or other blunt instrument to slide the appropriate

Switch(es) to the OFF position:

Switch #1: Filter Pump Off Delay (fireman’s switch).

Switch #2: Aux1 (Pool Cleaner) On Delay.

Switch #3: Aux1 Pool Cleaner/Filter Interlock.

Switch #4: Spa/Filter Interlock.

Switch #5: Spa/Aux1 (Pool Cleaner) Interlock.

If the control system does not incorporate a pool cleaner pump, Switches #2, #3 and #5 can be turned OFF, and the

Aux1 Circuit can be used for another auxiliary function.

SPA-SIDE COUNTDOWN TIMER

A built in 30 minute countdown timer is set at the factory for Auxiliary Circuits 5 and 6. These circuits usually operate

a jet pump and blower, and are controlled by the Spa-Side Remote.

To disable this feature, it is necessary to modify the 3-position S1 Program Switch which is located at center right-side

of the Cp3000 circuit board. Use the corner of a small screwdriver or other blunt instrument to slide the appropriate

Switch(es) to the OFF position. Switch #1 will actuate Aux6; and Switch #2 will actuate Aux5.

18

Page 22

Compool Cp3000

Installation

SYSTEM START-UP

1. Turn system power on.

2. At the heater, m ake sure that the switch is tur ned to the ON, High or Spa position, and that the temperature dial is

turned to the highest setting.

3. At the Lx3000 Power Center, press the Auto/Service Key to switch the System to “Service” mode. Press the #S

Key to Spa mode, and check that Valve Actuators have rotated to spa positions. If either valve is 180° out of

phase, flip toggle switch on rear of Valve Actuator from ON1 to ON2 position.

4. Press the remaining Equipment Service Keys (#P, #1, #2, #3, #4, #5 and #6) to verify that corresponding

equipment is being activated.

5. Press the Heater Key, and verify that the heater is firing (filter pump must be on and pumping).

6. If solar system is installed, verify program switch on the Lx3000 circuit board SOLAR is in the ON position.

The Cp3000 system will only recognize the solar installation if this switch is ON (see SOLAR SENSOR for

details).

7. Press the Solar Key , and check that the Solar Valve (if applicable) has rotated to solar position. If it is 180° out of

phase, flip toggle switch on rear of Valve Actuator from ON1 to ON2 position.

8. Check that neither Temperature Sensor Status lamps are illuminated. If a lamp has turned on, check wiring

connections to the appropriate Sensor.

9. After the equipment operation has been tested from the Lx3000, press Auto/Service Key to return System to

“Auto” mode.

10. At the Cp3000 Controller, press each Equipment Key (#S, #P, #1, #2, #3 and #4), and check that appropriate

equipment is being activated. Note: If the Auto/Service Key at the Lx3000 has inadvertently been left in the

“Service” mode, the Service status lamp will illuminate at the Cp3000 Controller.

11. A set of adhesive labels is provided for custom identification of individual circuits. Use a pair of fine-tip

tweezers to adhere the appropriate label adjacent to the Equipm ent Key at the Cp3000 Controller and Lx3000

Power Center. A set of labels is also provided for custom identification of the buttons at the optional Spa-Side

Remote.

19

Page 23

Compool Cp3000

CALIBRATING TEMPERATURE SENSORS

The following infield calibration is required for the Temperature Sensor(s):

Installation

1. Use a thermometer to verify pool temperature.

2. Use a thermometer to verify solar temperature if applicable.

3. At the Cp3000 Controller, turn on the Pool and let it run for a few minutes.

4. Press the Program Key.

5. Press the Pool Heat Source Key. ADJ 1 will appear on the Display.

6. Use the Pool Temperature Keys to enter the temperature verified in Step 1.

7. Press the Pool Heat Source Key again. If the system incorporates a Solar Temperature Sensor, ADJ 2 will now

appear on the Display. Use the Pool Temperature Keys to enter the temperature verified in step 2.

8. Press the Pool Heat Source Key once more to return the Display to the normal operating mode.

20

Page 24

Compool Cp3000

Operating Instructions

OPERATING INSTRUCTION S

INTRODUCTION

The Cp3000 is an electronic control system which is designed to coordinate and oper ate all of the equipment associated

with your swimming pool and spa. The system is comprised of three principal components:

• Cp3000 Controller.

• Two CVA-24 Valve Actuators.

• Lx3000 Power Center.

The Controller automatically controls and monitors the timing of all your pool and spa equipment, and the temper ature

of your pool and spa; the Valve Actuators switch the filter and heater from pool to spa; and the Power Center provides

easy maintenance for your Pool Serv iceperson.

Additionally, the Control System incorporates important safety features which protect your pool equipment from

accidental damage. Your system may also include a Spa-Side Remote and other options which further add to the

convenience, safety, and economy of operating your pool and spa equipment.

Note: It is not recommended to use the Cp3000 system to control a pool cover.

SAFETY FEATURES

HEATER PROTECTION

A built-in electronic delay circuit automatically runs the filter pump for an additional 5 minutes whenever the system

is turned off. This feature enables the heater to cool down, so that the heat exchanger and plumbing are not damaged

from overheating.

If the filter pump is being turned off after using the spa and the pool was not previously on, the motorized valves will

remain in the “spa circulation” position during t his 5 m inute “heater cool down” cycle. Th is prevents the poss ibility

of any cold water being cycled from the pool into the spa during this period of time.

21

Page 25

Compool Cp3000

POOL CLEANER PROTECTION

If your system incorporates a pool cleaner, it may have been plumbed in conjunction with the filter pump so that it

must have water circulation in order to operate. The Cp3000 incorporates the following protection features against

accidental pump damage, which can occur if there is no water circulation:

1. The filter pump will automatically switch to pool circulation whenever the pool cleaner is running.

2. Whenever the pool cleaner is turned on, a built-in electronic delay circuit will prevent it from running until 5

minutes of filtration have passed. This protects the cleaner pump from possible damage caused by air which may

have entered the plumbing since the system was last used.

3. Your pool cleaner will automatically be switched off whenever water is being circulated to the spa.

4. If your system incorporates solar, the pool cleaner will automatically be disabled for a period of 5 minutes

whenever the solar system turns on. This protects the pool cleaner from possible damage caused by residual air

within the solar panels.

Note: If your system incorporates a pool cleaner, your Pool Builder will have labeled Equipment Key #1 (Aux1

circuit) at the Cp3000 Controller for switching this equipment.

OVERRIDING THE SAFETY DELAY CIRCUITS

For testing and servicing purposes only, it is possible to override any of the safety delay circuits by pushing the

CANCEL Key, which is located behind the right-side door of the Cp3000 Controller.

Operating Instructions

BATTERY BACK-UP

In case of a power failure, a long-life battery automatically maintains the program and clock functions of your Control

System. This safeguards against the equipm ent operating erratically once power has b een restored, and also eliminates

the need to reprogram whenever there is a power failure.

Cp3000 CONTROLLER

Installed in a convenient location inside your house, the Cp3000 Controller gives you fingertip control of all the

equipment associated with your swimming pool and spa.

EQUIPMENT STATUS LAMPS

There are three Equipment Status Lamps located above the Display:

22

Page 26

Compool Cp3000

Heater:

Indicates whenever the heater is on.

Solar:

Indicates whenever the solar system (if applicable) is running.

Service:

Indicates whenever the equipment is being op erated from the equipment site (i.e. the Auto/Service Key at the Lx3000

Power Center is in the Service position).

DISPLAY

When the system is in the “normal operating mode”, the TIME O F DAY and the ON/OFF Equipment Status of each

of the six Equipment Keys will be displayed. If the pool or spa is running, the actual POOL or SPA temperature will

be displayed.

Operating Instructions

EQUIPMENT KEYS

Six Equipment Keys are provided for activating the various pieces of equipment. Your Pool Builder should have

custom-labeled each Key for your specific application. To switch equipment ON or OFF, simply press the appropriate

Equipment Key once. An audible beep will sound indicating the Equipment Key has been pressed.

Equipment Status is indicated on the Display immediately above each Equipment Key:

• A solid ON indicates that the equipment has been activated.

• A solid OFF indicates that the equipment is switched off.

• A blinking ON indicates that the equipment will activate after its 5 minute safety delay has expired.

• A blinking OFF indicates that the equipment will turn off after its 5 minute safety delay has expired.

Key #S:

Rotates valves to spa circulation and activates filter pump. Activates spa heating. Disables pool cleaner (if applicable).

Key #P:

Activates filter pump and circulates water for pool filtration. Enables pool heating.

Key #1:

Activates pool cleaner (if applicable) after 5 minute safety delay. Automatically activates pool filtration if Key #P is

not already turned ON.

Note: If system does not incorporate a pool cleaner, Key #1 will activate auxiliary equipment (such as lighting).

23

Page 27

Compool Cp3000

Key #2:

Activates auxiliary equipment (such as a pool light).

Key #3:

Activates auxiliary equipment (such as a spa light).

Key #4:

Activates auxiliary equipment (such as a fountain).

USING YOUR SPA

To turn your Spa ON, simply press Key #S. The motorized valves will rotate to “spa circulation” position, the filter

pump will turn on, and the heater will heat the spa to the pre-selected spa temperature. The Display will indicate the

precise spa temperature, and the Heater Status Lamp will indicate whether the spa is heating or not.

To turn your Spa OFF, press Key #S. The heater will automatically shut- off. Provided the sy st em is not resum ing a

preset pool circulation cycle, the filter pump will continue to circulate the spa water for its 5 minutes safety d elay in

order to cool down the system. After 5 minutes, the filter pum p will shut- off and the mot orized valves will r eturn to

pool circula t ion position.

Note: Some heaters do not require a cool down cycle, so this safety feature may be turned off. See CUSTOM CLOCK

OPTIONS for details.

Operating Instructions

It is possible to program the Spa, so it will automatically shut-off after a predetermined length of time. See

COUNTDOWN TIMER PROGRAM for details.

POOL AND SPA HEATING

Concealed behind the left-side door are separate Temperature Controls for the Pool and Spa. Each control incorporates

a Heat Source Key, two Temperature Keys, and four Heat Source Lamps.

HEAT SOURCE KEY

It is possible to heat your pool and spa us ing con ventional heat, s olar energ y ( if app licable), o r a co mbin ation of bo th.

Pressing the Heat Source Key will toggle through the different heating options, as follows:

• Off: Allows no heating.

24

Page 28

Compool Cp3000

• Heater: Allows heating with gas or electric heater only.

• Solar Priority: Allows heating with solar, but automatically switches to conventional heating when solar energy

is unavailable. If your system does not incorporate solar, the Solar Priority and Solar Only options will not be

available.

• Solar Only: Allows heating with solar only when solar heat is available. If your system does not incorporate

solar, the Solar Priority and Solar Only options will not be available.

Note1: Pressing the Heat Source Keys(s) does not activate the heater and solar system. Heating can only occur when

the pool or spa is being circulated and desired temperature settings have not yet been satisfied.

Note2: For added convenience, whenever the spa is manually activated (from either th e Cp3000 Controller or the SpaSide Remote), the Spa Heat Source Lamp will automatically switch to “Heat er” and heating will begin. Tur ning the

spa off will return Spa Heat Source Lamp to its previous position.

TEMPERATURE KEYS

The UP and DOWN Temperature Keys are used to prese t your d esired water temperature. As long as the Heat Sou rce

Key(s) are not in the OFF position, the pool and spa will heat up to the preset temperature(s) whenever pool or spa is

being circulated.

Operating Instructions

CHECKING DESIRED WATER TEMPERATURE SETTING

To check the pool and spa temperature settings, press the appropriate (Pool or Spa) Temperature Key once. The preset

temperature will blink on the Display for 5 seconds.

SETTING DESIRED WATER TEMPERATURE

To adjust the pool and spa temperature settings, press the appropriate (Pool or Spa) Temperature Key until the Display

indicates your desired water temperature. After 5 seconds, the Display will automatically return to its original

condition. Temperature settings can be adjusted in the normal operating mode only.

FAHRENHEIT/CELSIUS TEMPERATURE DISPLAY

The “Temp. Display” Key (located behind right-side door) will enable you to display temperatures in either Fahr enheit

or Celsius.

25

Page 29

Compool Cp3000

SETTING THE CLOCK

To set the Display to the correct TIME OF DAY, press the Hours and Minutes Keys (located behind the right-side door

of the Cp3000 Controller). Pay attention to the AM/PM symbols on the Display.

Operating Instructions

26

Page 30

Compool Cp3000

Operating Instructions

PROGRAMMING

DAILY EQUIPMENT OPERATING CYCLES

Behind the right-side door are Keys for programming the daily operating cycles of the equipment. Programming is a

“set and forget” procedure, which is normally implemented by your Pool Builder at the completion of the installation.

Most systems only require that you program the pool filtration cycles (Key #P) and, in some cases, pool cleaning cycles

(Key #1). However, it is possible to program equipment connected to any of the six Equipment Keys at the Cp3000

Controller.

Before commencing programming, you will need to determine at what time yo u would like t he equipment to turn on

(START TIME), and for how long you would like each piece of equipment to run (RUN TIME). Your Pool Builder

will be able to recommend the appropriate filtration and cleaning cycles for your pool and spa.

BASIC PROGRAM

The following example programs the Pool Filter Pump to run eight hours every day:

1. Press the Program Key to start the program.

2. Press the Equipment Key “P” to program the pool.

3. Press the Hours Key to set the START TIME (example 8:00 A.M.)

4. Press the Enter Key to save the STA RT TIME.

5. Press the Hours Key to set the RUN TIME (example 8 Hours).

6. Press the Enter Key to save the RUN TIME.

7. Press the Program Key to return to the normal operating mode.

➥

➥

27

Page 31

Compool Cp3000

MULTIPLE PROGRAMS

A total of four operating cycles may be programmed each piece of equipment. To program multiple operating cycles,

follow steps 1 to 6 on the BASIC PROGRAM, and then press the Equipment Key a second time. The display will

indicate PROG 2, plus a blinking START TIME. Repeat steps 3 to 6 to program a second START TIME and RUN

TIME. If additional cycles are desired, repeat this procedure for PROG 3 and PROG 4.

Note: If only one operating cycle is programmed, PROG will be displayed. PROG 1 indicates that multiple operating

cycles have been programmed for that equipment.

COUNTDOWN TIMER PRO GRAM

It is possible to program a “COUNTDOWN TIMER” for any piece of equipment, so that, whenever that equipment is

activated manually it will run for its predetermined length of time and then automatically shut-off. This energy saving

program is particularly useful for programming the Spa to shut-off after a few hours.

The COUNTDOWN TIMER is programmed by setting the START TIME to 0:00 hours and setting the RUN TIME

to the desired time you wish the equipment to run. The RUN TIME can be set (in 10 minute increments) for any length

of time fr om 10 mi nutes (0 :10) t o 23 ho urs and 50 minu tes (23 :50). T his fea ture may be com bined with an y other

program (i.e. if PROG 1 is already used, use PROG 2, PROG 3, or PROG 4).

Note: If there is no COUNTDOWN TIMER program, the equipment will automatically shut-off after 12 hours.

Operating Instructions

The following example programs the Spa to shut-off after two hours:

➥

➥

1. Press the Program Key to start the program.

2. Press the Equipment Key “S” to program the spa.

3. Press the Enter Key to save the START TIME at 0:00.

4. Press the Hours Key to set the RUN TIME (example 2 hours) .

5. Press the Enter Key to save the RUN TIME.

6. Press the Program Key to return to the normal operating mode.

28

Page 32

Compool Cp3000

ONCE ONLY PROGRAM

It is possible to program a “ONCE ONLY” program for any of the Equipment Keys on the Cp3000. When a ONCE

ONLY program is executed, it is erased automatically. This feature is useful to program the Spa in advance so it will

be ready for use within a 24 hour period. With this convenient feature, there is no need to “de-program” the spa after

use. The ONCE ONLY program simply erases itself.

Follow the standard programming procedure to Step 3, enter a START TIME only. Do not enter a RUN TIME (RUN

TIME should indicate 0:00). Press Program Key to return to the normal operating mode.

This feature may be combined with any program (i.e. if PROG 1 is already u sed, us e PROG 2, PROG 3, or PROG 4).

REVIEWING THE PROGRAM(S)

To review the programmed operating cycle(s) of any piece of equipment:

1. Press the Program Key. The Display will indicate PROG (to show that Clock is in programming mode), plus a

row of blinking icons located immediately above the six Equipment Keys.

2. Press the appropriate Equipment Key (either #S, #P, #1, #2, #3 or #4). The icon above the Equipment Key will

stop blinking, the remaining icons will disappear, and the programmed START TIME (blinking) and R UN TIME

will be displayed.

Operating Instructions

3. The appearance of PR OG 1 on the Display indicates that there is more th an one o perating c ycle pr ogr ammed f or

this equipment. To review additional program(s), press Equipment Key again.

4. If you wish to review the operating cycle(s) of another piece of equipment, return to Step 2 (i.e. press the

appropriate Equipment Key).

5. When you hav e f inished r e viewing the various pieces of equipment, press the Program K e y to return the Clock to

normal operating mode.

CANCELING PROGRAM(S)

It is possible to cancel one or more of the programmed operating cycles:

1. Press the Program Key. The Display will indicate PROG (to show that Clock is in programming mode), plus a

row of blinking icons located immediately above the six Equipment Keys.

2. Press the appropriate Equipment Key (either #S, #P, #1, #2, #3 or #4). The icon above the Equipment Key will

stop blinking, the remaining icons will disappear, and the programmed START TIME (blinking) and R UN TIME

will be displayed.

3. Press the Cancel Key. The Display will indicate a START TIME (blinking) of 0:00 and a RUN TIME of 0:00.

4. If you wish to cancel additional program(s), return to Step 2 (i.e. press the appropriate Equipment Key).

5. If you wish to cancel all of the programs, press and hold down the Cancel Key for 5 seconds. After 5 seconds, a

continuous alarm will sound (until you release the Cancel Key), indicating that all of the programming has been

erased.

29

Page 33

Compool Cp3000

Operating Instructions

Lx3000 POWER CENTER

Lx3000 Equipment Service Keys

Located in close proximity to your pool and spa equipment, the Lx3000 Power Center provides your Pool

Serviceperson with manual control of the system without having to gain access to the Cp3000 Controller.

Caution: To prevent possible water damage, the door of the Lx3000 must be kept closed at all times.

There are no user-serviceable components located behind se rvice panel in the right-side comp artment. Do not remove

service panel. Refer service to qualified personnel only.

Equipment Service Keys and Status Lamps for all of the equipment are located in the left-side compartment.

A UTO/SERVICE KEY

Pressing this Key will toggle the Control System between “Auto” and “Service” modes:

• Auto: Keep the System in this mode during normal equipment operation. In “ Auto” mode, it will not be possible

to manually activate any of the Equipment Service Keys at the Lx3000.

30

Page 34

Compool Cp3000

Note: A blinking “Auto” Status Lamp indicates that the equipment is undergoing a 3-Hour pro gram overr ide. Se e 3HOUR FILTER OVERRIDE for details.

• Service: This mode disables the Cp3000 Controller and provides your Pool Serviceperson with complete

manual-override capability, using the various Equipment Service Keys at the Lx3000.

Note: Manual-activation of equipment from the Lx3000, will override any of the built-in equipment interlocks and

safety delay circuits.

EQUIPMENT SERVICE KEYS

Key #S:

Pressing this Key will manually toggle the Intake and Return Valve Actuators through the following options:

• Spa: Rotates both Valves to spa circulation.

• Fill: Rotates Intake Valve to pool suction and Return Valve to spa return positio ns .

• Drain: Rotates Intake Valve to spa suction and Return Valve to pool return positions.

Note: If there is no Status Lamp, both Valves will rotate to pool circulation.

Operating Instructions

Key #P:

Manually activates the filter pump.

Key #1:

Manually activates equipment connected to Aux1 circuit. Overrides Equipment Key #1 at the Cp3000 Controller.

Note: If the system incorporates an automatic pool cleaner, it is controlled by this circuit.

Keys #2 - #4:

Manually activates equipment connected to Aux2 through Aux4 circuits. Overrides Equipment Keys #2 through #4

at the Cp3000 Controller.

Keys #5 - #6:

Manually activates equipment connected to Aux5 and Aux6 circuits. Overrides Equipment Keys at Spa-Side Remote.

Heater Key:

Manually activates the heater (filter pump must also be on).

Solar Key:

Manually activates the solar valve and/or solar booster pump (if applicable).

TEMPERATURE SENSOR STATUS LAMPS

If the Control System is not receiving accurate information from a Temperature Sensor, the appropriate Status Lamp

will illuminate. Check cable and connections to appropriate Sensor. If necessary, replace Sensor (model TS-5L).

3-HOUR FILTER OVERRIDE

It is possible for the Pool Serviceperson to override t he daily equipment operating cycles, and manually activate (or

deactivate) any piece of equipment for a 3-Hour period. This is particularly u seful when adding chemicals to the pool.

31

Page 35

Compool Cp3000

Note: The Control System must be in “Auto” mode to enable this feature.

To turn the filter pump on, press Key #P (Filter Pump) 2 times quickly. The “Auto” mode Status Lamp will begin to

blink, and the Filter Pump Status Lamp will illuminate for the 3-Hour cycle.

To turn the filter pump off, press Key #P (Filter Pump) 3 times quickly. The “Auto” mode Status Lamp will begin to

blink, and the Filter Pump Status Lamp will not be illuminated during the 3-Hour cycle.

To cancel this 3-Hour cycle fro m the Lx3000 Power Center, pre ss Auto/Service Key to “Service” mode, and then b ack

to “Auto” mode.

Operating Instructions

VALVE ACTUATORS

Your control system is designed to actuate two motorized valves, which automatically rotate between pool and spa

circulation whenever the Spa is activated. A motorized valve may also be used to automatically divert the flow of

water through your solar panels (if applicable) when ever solar energy is available.

These Valve Actuators are also activated by the Spa/Fill/Drain and Solar Equipment Service Keys at the Lx3000

Power Center. Your system may also include additional motorized valves for hydraulic applications, such as a

fountain, waterfall, or pool cleaner.

SPA-SIDE REMOTE

One or more 4-button waterproof Remote Controls may be located at your spa. This will enable you to override the

Cp3000 Controller, and manually activate your spa equipment from the convenience of the spa.

32

Page 36

Compool Cp3000

Your Pool Builder will have connected this Remo te to the appropriate circuits, and labeled each push-button to suit

your particular applicatio n.

The Status Lamp (located in the center of the Spa-Side Remote) will i lluminate whenever the spa is being circulated.

Whenever the spa is being heated, the Status Lamp will blink.

SPA-SIDE HEAT BOOST OPTION

If your Spa-Side Remote incorporates a HEAT BOOST push-button, it is possible to manually activate the spa heater,

and boost the spa temperature for a five minute period after the Control System has turned the spa heater off.

This feature can only be activated if the Status Lamp at the Spa-Side Remote is on, and not blinking (i.e. the spa is

being circulated and the heater is not on).

To activate this feature, press the HEAT BOOST push-button. The Status Lamp will blink (during the 5-minute cycle)

to indicate that the spa is being heated. If you wish to turn the heater off at any time dur ing this 5-min ute cycle, press

the HEAT BOOST push-button. The Status Lamp will stop blinking to indicate that the spa is no longer being heated.

DISABLING THE SPA-SIDE REMOTE

Operating Instructions

It is possible to disable the Spa-Side Remote(s) from your Control System. This feature is convenient, if you do not

wish children to play with the Spa-Side Remote or you wish to prevent the un authorized u se of your s pa while you are

away from home.

To achieve this, press the “Remote Control at Spa” Key, which is located behind the right-side door of the Cp3000

Controller. If the status lamp is illumin a ted, the Remote Control is operational. If the status lamp is not illuminated,

the Remote Control is disabled.

33

Page 37

Compool Cp3000

Operating Instructions

SYSTEM OPTIONS

2-SPEED FILTER PUMP CONTROL

If your system incorporates a 2-Speed Filter Pump, the Cp3000 has been designed to provide you with the maximum

energy- efficient usage of this feature. See 2-SPEED FILTER PUMP CONTROL in the Installation section for details.

Although your Pool Builder may have adjusted the two speed control circuitry to your specific requirements, the

Cp3000 typically switches the pump to high speed under any of the following conditions:

1. For five minutes when the pump is first turned on. This features establishes proper flow through the system, and

packs the filter grids. After five minutes, the pump will automatically switch to low speed.

2. Whenever the poo l cleaner (if applicable) is running. This pro vides suf ficient flo w for the p ool cleaner to operate

effectively.

3. During spa circulation to increase the jet action.

4. Whenever the heater is on. Larger heaters may require high speed circulation for proper operation.

5. Whenever your solar system (if applicable) is operating. This provides high flow rate through your solar panels,

which ensures the most efficient usage of the available solar energy.

6. Whenever a dedicated Equipment Key is pressed.

SPA WATERFALL CONTROL

If your spa water level is elevated above that of the pool, it is possibl e to circulate the pool water back to the spa, thus

creating an overflow (waterfall effect) from the spa to the pool. This effect will cease during spa circulation or you

turn on your “booster pump” pool cleaner (if applicable).

This feature can be activated from Equipment Key #2 (Aux2 circuit) at the Cp3000 Controller. See SPA

WATERFALL CONTROL SWITCH for details.

FREEZE PROTECTION

It is possible to protect the plumbing and equipment from possible freeze damage by activating the filter pump and

other pumps whenever the temperature falls to 35° F ahrenheit. Your Pool builder may have already activated this

feature. See FREEZE PROTECTION SETTINGS for details.

Note: This type of freeze protection will not provide circulation of water through your solar panels. Solar freeze

protection must be accomplished by other methods. See Plumbing Requirements for details.

34

Page 38

Compool Cp3000

Maintenance

MAINTENANCE

CLEANING THE SPA

For cleaning or maintenance purposes, it is possible to use the Control System to automat ically empty your spa and

then to refill with clean water from your pool.

At the Lx3000 Power Center:

1. Press Auto/Service Key to switch the system to “Service” mode.

2. Press Key #S until “Drain” Status Lamp is illuminated.

3. Press Key #P (Filter Pump) to turn the filter pump on. The spa will begin to drain into the pool.

Caution: Do not leave equipment unattended when draining or filling the spa.

4. Before the spa has drained completely, press Key #P (Filter Pump) to turn the filter pump off. The spa will stop

draining, and cleaning can now commence.

Note: The spa should not be drained completely, or prime will be lost.

5. When cleaning is complete, press Key #S until “Fill” Status Lamp is illuminated.

6. Press Key #P (Filter Pump) to turn the filter pump on. The spa will begin to fill with clean water from the pool.

7. When the spa water level has returned to normal, press the Auto/Service Key to switch the system back to “Auto”

mode.

ADDING CHEMICALS

When adding chemicals to the water it is possible to override the daily equipment operation cycles, and activate (or

shut-off) the filter pump for a 3-Hour period. See 3-HOUR FILTER OVERRIDE for details.

WINTERIZING THE SYSTEM

During the winter season, it is possible t o disable the pool from your control system, but still be able to use your spa.

Consult a qualified service company to winterize your pool and protect the plumbing from freeze damage.

The following procedure will disable the pool equipment:

1. At the Lx3000 Power C enter, press the Auto/Service Key to switch the system to “Serv ice” mod e, an d p res s Key

#S until “Spa” Status Lamp is illuminated.

2. Flip toggle switch on back of Intake and Return Valve Actuators to OFF.

3. At the Lx3000 Power Center, press Auto/Service Key to return system to “Auto” mode.

4. At the electrical supply panel, turn off the pool cleaner circuit breaker (if applicable).

5. At the Cp3000 Controller, press the Pool Heat Source Key until “Off” Status Lamp is illuminated.

6. If your control system incorporates solar, ensure that the panels are completely drained. To inactivate the Solar

T emperature Sensor, it is necessary to adjust the “FEA TURES” Program Switch, which is located at top center of

Lx3000 circuit board. Use the corner of a small screwdriver or other blunt instrument to slide Switch #1

(SOLAR) to the OFF position.

35

Page 39

Compool Cp3000

If recirculating freeze protection has been set on your system, it may no t be necessary to winterize the pool. However,

it is recommended that the Water Temperature Sensor be calibrated accurately before the onset of the winter season.

REPLA CING THE BACK-UP BATTERY

There is a small 3-Volt lithium battery located inside the Cp3000 Controller. In the absence of power, this battery will

keep the clock running and retain the programming in memory for approximately 2 years. The display will be blank

during power failure.

While power is connected to the system, the battery will not be drained. However, it is not rechargeable. It is

recommended that the battery be replaced every 5 years.

The replacement battery is available from your pool dealer (Compool model BAT-3), or can be purchas ed at Radio

Shack or your local drug store (Type CR2032, or equivalent).

To replace the battery:

1. Do not turn the power off.

2. Open Cp3000 doors and remove the four mounting screws.

Maintenance

3. Close Cp3000 doors and pull enclosure away from wall.

4. Pry-out battery from battery clip, and replace it with a new one. Pay special attention to the polarity (+ sign faces

up).

36

Page 40

Compool Cp3000

Problem Solving

PROBLEM SOLVING

DISPLAY READS “Err"

1. At the Lx3000 Power Center, check the Water Temperature Sensor Status lamp.

2. If lamp is illuminated, check cable and connections to Sensor.

3. If necessary, replace Sensor (model TS-5L).

INCORRECT TEMPERATURE READING

Calibrate temperature sensor. See CALIBRATING TEMPERATURE SENSORS.

HEATER DOES NOT OPERATE

1. At the Cp3000 Controller, press Key #S (turn on the spa).

2. Make sure that preset temperature setting for the spa is higher than the current water temperature.

3. At the heater, make sure that the ON-OFF switch is “ON” position and temperature dial is set to highest setting.

CANNOT SELECT SOLAR HEATING

At the Lx3000 circuit board, locate “FEATURES” Program Switch, and make sure that (SOLAR) is in the “ON”

position.

SOLAR HEATING NOT ON WHEN IT SHOULD BE

1. At the Cp3000 Controller, make sure that either the pool or spa is being circulated.

2. The Cp3000 system has a 10° Fahrenheit solar differential. This means that if the pool temperature is 80°

Fahrenheit, the solar temperature must be 90° Fahrenheit or higher before the solar system is activated.

3. Check calibration of Solar Temperature Sensor. ADJ 2 will indicate the current solar temperature. If

temperature display is not correct, then adjust calibration as necessary.

EQUIPMENT DOES NOT TURN OFF AT EXPECTED TIME

1. Manual activation of equipment will o v erride an y daily operating c ycle which may be in effect. If the equipment

was turned on manually, it will run for 12 hours and automatically turn off.

2. At Cp3000 Controller, verify that the problem is not program-related. If you see PROG 1 while reviewing

programs, then that equipment has more than o ne progr am. Press same Equipmen t K e y again to vie w ad ditional

programs. Cancel programs as needed. See Programming for details

3. It is normal for the freeze protection circuitry to tu rn equip ment on when th e temperature falls to 35° Fahr enheit.

At the Lx3000 circuit board, locate 7-position “FREEZ PROT” Program Switch, and determine which circuits

have been selected for freeze protection.

EQUIPMENT TURNS OFF AFTER 12 HOURS

1. This is normal if equipment is turned on manually. A built-in 12 hour shut-off will always turn your equipment

off.

2. This function overrides programs that have both a START TIME and a RUN TIME.

37

Page 41

Compool Cp3000

EQUIPMENT TURNS ON AT AN UNEXPECTED TIME

1. At the Cp3000 Controller, verify that the problem is not program-related. If you see PROG 1 while reviewing

programs, then that equipment has more th an on e program. Press same Equipment Key again to view additional

programs. Cancel programs as needed.

2. It is normal for the freeze protection circuitry to tu rn equip ment on when th e temperature falls to 35° Fahr enheit.

At the Lx3000 circuit board, locate 7-position “FREEZ PROT” Program Switch, and determine which circuits

have been selected for freeze protection.

SPA-SIDE REMOTE NOT WORKING

At the Cp3000 Controller, locate the “Remote Con trol at Spa” Key (behind right-side d oor), and verify that status lamp

is on.

SPA-SIDE EQUIPMENT TURNS OFF AFTER 30 MINUTES

This is a normal function for Aux5 and Aux6 circuits. If you would like to disabl e thi s funct i on , adjus t the 3- pos i t ion

S1 Program Switch which is located at center right-side of the Cp3000 circuit board (see SPA-SIDE COUNTDOWN

TIMER for details).

NO DISPLAY AT Cp3000

1. At the Lx3000 Powe r Center, verify Auto/Service Status Lamp is illuminated (t his conf i rms there is power to the

system).

Problem Solving

2. Unplug communication cable from Cp3000 and Lx30 00 circuit boards. Temporarily transfer Cp3000 Controller

to equipment site, and use 4’ test cable (included with system) to interconnect Cp3000 with Lx3000.

3. If the test cable activates the Cp3000 display, repair or replace communication cable.

ABNORMAL OPERATION

Re-setting the Cp3000:

1. Remove Cp3000 control pane l from wall.

2. Disconnect 6-conductor communication cable.

3. Locate resetting pins on lower right hand corner of circuit board.

4. Unplug shorting plug from “NORMAL” position, and insert into “RESET” position.

5. Return shorting plug to “NORMAL” position.

6. Reconnect 6-conductor communication cable.

7. Re-install Cp3000 control panel.

This has reset the Cp3000 circuit board. Be sure to reset the Clock Time, Programs, and Sensor Calibration.

Re-setting the Lx3000

Turn system power off (moment arily trip system circuit breaker at sub-panel ). This will reset the Lx 3000 circuit board.

38

Page 42

Compool Cp3000

Warranty

WARRANTY

Compool Corporation warrants to the purchaser of this electronic control system, for the period of one year from the

date of original purchase for use, that any defective product proved to be caused by faulty workmanship or faulty

material, will be repaired or replaced at Compool’s o ption at no charg e, providing the product is returned to Compool

with all transportation charges prepaid.

This warranty covers the Cp3000 Controller, Lx3000 Power Center, CVA-24 Valve Actuators, and optional Remote

Controls including all component s and parts . It extends to the fir st ret ail purch aser and any s ubs equ ent owners of the

system.

This limited warranty applies only to controls which have been installed and maintained in strict accordance with

installation and operat i ng i nstructions provided by Compool Corporation , us ing i nst all at i on hard wa re s upp lied and/or

recommended in writing by Compool, and to controls which have been connected to the correct supply voltage.

This limited warranty does not apply to any controls which have been repaired or altered by anyone other than

Compool or a person authorized by it; or which have been subject to misuse, neglect or accident; or which have been

damaged by wind, rain, lightning, freezing or other cause, thing, person, or act of God; or which have been subject to

damage in transit, during installation, or by someone other than Compool Corporation; or which have been damaged

because of a defect in a component or p art which is n ot part of the C omp ool C ontrol Sys tem; or upo n wh ich the s erial

number or manufacture date has been altered, effaced or removed.

This warranty gives you specific legal rights and you may also have other rights which vary from State to State.

Compool Corporation does not authorize any person to create any other obligation o r liability in connection with

Compool controls.

Compool Corporation makes no warranty of merchantability or fitness for any use. Any implied warranty applicable

to Compool controls is limited in duration to the duration of this written warranty. Unless state law provides otherwise,

Compool Corporation shall not be liable for consequential or incidental damages resulting from breach of this written

warranty or any implied warranty, or any inconvenience, loss of time, or incidental expenses such as telephone calls.

Compool Corporation shall not be liable for any labor charges associated with the removal or reinstallation of any soclaimed defective products.

To exercise this warranty, send defective parts*, with copy of dated receipt and a brief description of the problems

encountered, postage prepaid, to:

COMPOOL CORPORATION

599 Fairchild Drive

Mountain View, California 94043

For questions, repairs, replacement parts, or information on possible Authorized Service Centers within your vicinity

call:

Compool Customer Service

1-800-458-2201

Monday - Friday

8:00 a.m. - 5:00 P.M.

Pacific Standard Time

*For your protection, you should always insure your package when shipping or mailing.

39

Page 43

Compool Cp3000

Index

INDEX

NUMERICS

2-SPEED FILTER PUMP CONTROL 15, 34

3-HOUR FILTER OVERRIDE

A

ADDING CHEMICALS 35

23

7

ADDING RELAYS

AUTO/SERVICE KEY

AUXILIARY VALVE ACTUATORS

B

BASIC PROGRAM 27

BATTERY BACK-UP

C

CALIBRATING TEMPERATURE SENSORS 20

CANCELING PROGRAM(S)

CHECKING DESIRED WATER TEMPERATURE SETTING

CLEANING THE SPA

COUNTDOWN TIMER PROGRAM

CP3000 CIRCUIT BOARD

CUSTOM CLOCK OPTIONS

CVA-24 VALVE ACTUATORS

D

DAILY EQUIPMENT OPERATING CYCLES 27

DISABLING TH E SPA-SIDE REMOTE

DISPLAY

E

EQUIPMENT KEYS 23