Sta-Rite 188549 Installation Manual

Titan RPM™ Ver tical Grid D.E. Filter Owner's Manual

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

Table of Contents

SECTION I. FILTER INSTALLATION. ............................................................................................... 1

SECTION II. FILTER OPERATION. .................................................................................................... 2

SECTION III. TROUBLE SHOOTING. ................................................................................................. 8

SECTION IV. TECHNICAL DATA. ..................................................................................................... 10

WARNING

Before installing this product, read and follow all warning notices and instructions accompanying this filter. Failure to follow

safety warnings and instructions can result in severe injury, death, or property damage. Call (800) 831-7133 for additional free

copies of these instructions.

Important Notice

Attention Installer.

This manual contains important information about the installation, operation and safe use of this product.

This information should be given to the owner/operator of this equipment.

SECTION I. FILTER INSTALLATION.

A. GENERAL INFORMATION.

1. The filter should be mounted on a level concrete slab. Position the filter

so that instructions, warnings and the pressure gauge are visible to the

operator. It also should be positioned so that the piping connections,

control valve and drain port are convenient and accessible for servicing

and winterizing.

2. Install electrical controls (e.g., on/off switches, timers, control systems,

etc.) at least five (5) feet from the filter. This will allow you enough

room to stand clear of the filter during system start up.

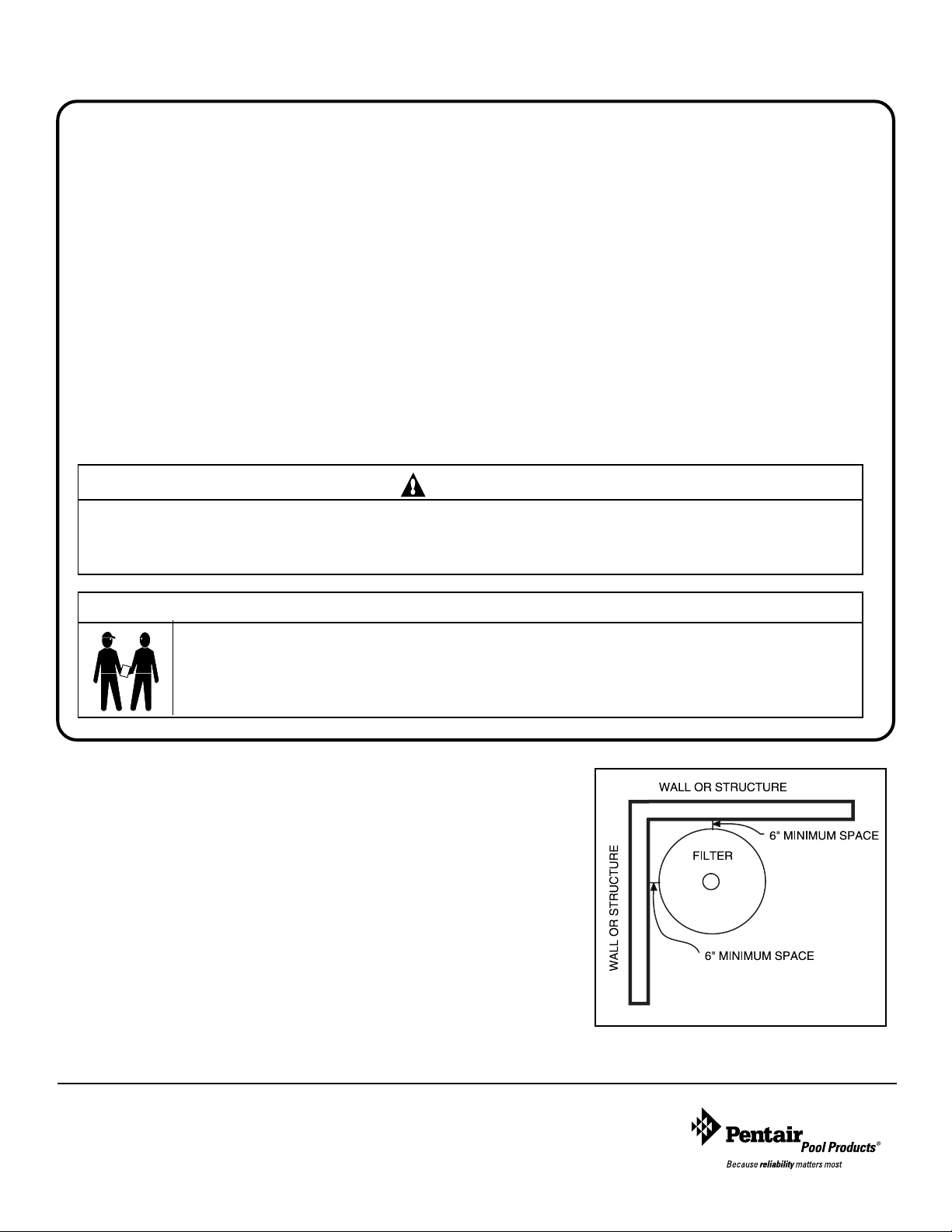

3. Allow sufficient clearance around the filter to permit visual verification

that the clamp is properly installed around the tank flanges, see Figure 1.

a. Tap the clamp with a mallet or similar tool to ensure uniform

loading during clamp tightening.

Figure 1.

Pentair Pool Products

1620 Hawkins Ave., Sanford, NC 27330 • (919) 774-4151

10951 West Los Angeles Ave., Moorpark, CA 93021 • (805) 523-2400

Rev. E 4-3-00 1 P/N 99100900

4. Allow sufficient space above the filter to remove the filter lid for cleaning and servicing. This distance will vary with the model of

filter you are using. See Table 1 for the required vertical clearance.

5. Position the filter to safely direct water drainage. Rotate the High Flow™ manual air relief valve to safely direct purged air or

water. Water discharged from an improperly positioned filter or valve can create an electrical hazard as well as damage

property.

WARNING

Risk of electrical shock or electrocution. Position the filter and High Flow™ manual air relief valve to safely direct water drainage

and purged air or water. Water discharged from an improperly positioned filter or valve can create an electrical hazard that can

cause severe personal injury as well as damage property.

6. Install the drain hose on your High Flow™ manual air relief valve.

Determine drainage area for the water purged from the filter. The

filter base has four (4) drainage holes. Place the end of the drain

hose into one of these holes if you wish to drain into the base.

a. The drain hose holders can be mounted on the side of the filter

tank with the self-adhesive backing provided. Be sure the area

where the hose holders are mounted is free of dirt, grease, or

water.

b. Insert the drain hose through the hose holders and clamp the end of the hose to the High Flow™ manual air relief valve

with the plastic clamp provided.

c. Place the open end of the drain hose into one of the holes in the filter base or in the direction of the water to be drained.

7. Your filter requires one of the following PurexTriton accessories which must be purchased separately.

a. Push-Pull valve

b. Multiport valve

c. Bulkhead union set

8. Make all plumbing connections in accordance with local plumbing and building codes. Filter plumbing connections are

provided with an O-ring seal. To avoid damage to the O-rings, use only a silicone base lubricant on the O-rings. Do not use

pipe joint compound, glue or solvent on the bulkhead connections.

9. The maximum working pressure of this filter is 50 psi. Never subject this filter to pressure in excess of this amount - even when

conducting hydrostatic pressure tests. Pressures above 50 psi can cause the lid to be blown off, which can result in severe injury,

death or property damage.

Model Size Clearance Req.

188549 24 sq. ft. 48 in.

188550 36 sq. ft. 62 in.

188551 48 sq. ft. 74 in.

188552 60 sq. ft. 86 in.

Table 1.

Vertical

When performing hydrostatic pressure tests or when testing for external leaks of the completed filtration and plumbing

system, ensure that the maximum pressure that the filtration system will be subjected to DOES NOT EXCEED THE

MAXIMUM WORKING PRESSURE OF ANY OF THE COMPONENTS CONTAINED WITHIN THE SYSTEM. In

most cases, the maximum working pressure will be stated on each component of the system.

If doubt exists as to the pressure to which the system will be subjected, install an ASME approved automatic Pressure Relief or

Pressure Regulator in the circulation system for the lowest working pressure of any of the components in the system.

SECTION II. FILTER OPERATION.

A. GENERAL INFORMATION.

1. This filter operates under pressure. When clamped properly and operated without air in the water system, this filter will

operate in a safe manner.

2. The maximum working pressure of this filter is 50 psi. Never subject this filter to pressure in excess of this amount - even

when conducting hydrostatic pressure tests. Pressures above 50 psi can cause the lid to be blown off, which can result in

severe injury, death or property damage.

When performing hydrostatic pressure tests or when testing for external leaks of the completed filtration and plumbing

system, ensure that the Maximum Pressure that the filtration system will be subjected to DOES NOT EXCEED THE

MAXIMUM WORKING PRESSURE OF ANY OF THE COMPONENTS CONTAINED WITHIN THE SYSTEM. In

most cases, the maximum working pressure will be stated on each component of the system.

P/N 99100900 2 Rev. E 4-3-00

WARNING

THIS FILTER OPERATES UNDER HIGH PRESSURE. WHEN ANY PART OF THE CIRCULATING SYSTEM, e.g.,

CLAMP, PUMP, FILTER, VALVE(S), ETC. IS SERVICED, AIR CAN ENTER THE SYSTEM AND BECOME

PRESSURIZED. PRESSURIZED AIR CAN CAUSE THE LID TO BE BLOWN OFF WHICH CAN RESULT IN

SEVERE INJURY, DEATH, OR PROPERTY DAMAGE. TO AVOID THIS POTENTIAL HAZARD, FOLLOW THESE

INSTRUCTIONS.

1. BEFORE REPOSITIONING VALVE(S) AND BEFORE BEGINNING THE ASSEMBLY, DISASSEMBLY, OR

ADJUSTMENT OF THE CLAMP OR ANY OTHER SERVICE OF THE CIRCULATING SYSTEM: (A) TURN THE

PUMP OFF AND SHUT OFF ANY AUTOMATIC CONTROLS TO ENSURE THE SYSTEM IS NOT

INADVERTENTLY STARTED DURING THE SERVICING; (B) OPEN HIGH FLOW™ MANUAL AIR RELIEF

VALVE; (C) WAIT UNTIL ALL PRESSURE IS RELIEVED.

2. WHENEVER INSTALLING THE FILTER CLAMP FOLLOW THE FILTER CLAMP INSTALLATION

INSTRUCTIONS EXACTLY.

3. ONCE SERVICE ON THE CIRCULATING SYSTEM IS COMPLETE FOLLOW SYSTEM RESTART

INSTRUCTIONS EXACTLY.

4. MAINTAIN CIRCULATION SYSTEM PROPERLY. REPLACE WORN OR DAMAGED PARTS IMMEDIATELY,

e.g., clamp, pressure gauge, valve(s), O-rings, etc.

5. BE SURE THAT THE FILTER IS PROPERLY MOUNTED AND POSITIONED ACCORDING TO

INSTRUCTIONS PROVIDED.

If doubt exists as to the pressure to which the system will be subjected, install an ASME approved automatic Pressure

Relief or Pressure Regulator in the circulation system for the lowest working pressure of any of the components in the

system.

3. The pressure gauge is the primary indicator of how the filter is operating. Maintain your pressure gauge in good working order.

4. Never operate filter in excess of three (3) minutes without use of diatomaceous earth. Diatomaceous earth is the substance that

filters the water, the filter cloth merely supports the diatomaceous earth. Operating without diatomaceous earth will damage

filter elements and shorten filtering cycles.

B. CLAMP INSTALLATION INSTRUCTIONS.

These instructions MUST BE FOLLOWED EXACTLY to prevent the lid from blowing off during system restart or later

operation.

1. Perform the following steps before working on any part of the circulating system, e.g., clamp, pump, filter, valve(s), etc.

a. Turn the pump off and shut off any automatic controls to ensure that the system is not inadvertently started during

servicing.

b. Open the High Flow™ manual air relief valve.

c. Wait until all pressure is relieved. Never attempt to assemble, disassemble or adjust the filter clamp while there is

any pressure in the filter.

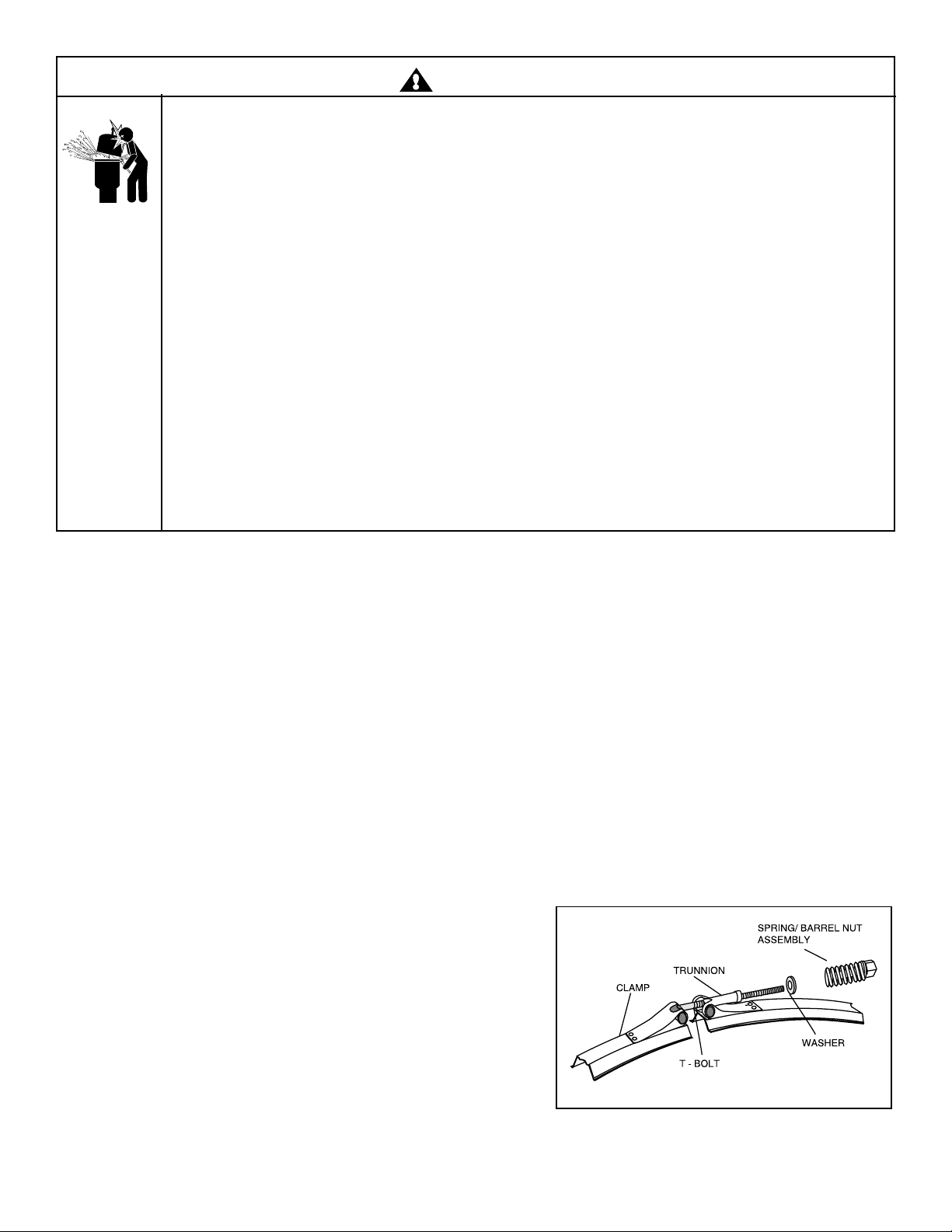

2. Be certain the O-ring is in position in the lower tank half. Press the

filter lid over the lower tank half sandwiching the O-ring in between.

3. Holding the ends of the filter clamp apart, position the center

segment of the filter clamp over both upper and lower tank flanges.

Bring the ends of the filter clamp together, while inserting the T-Bolt

into the trunnion; see Figure 2.

4. Using Figure 2 as a guide - place washer and the tension-indicating

spring/barrel nut assembly on T-Bolt. Hand-tighten nut. Recheck

filter clamp for proper seating on tank flanges.

Rev. E 4-3-00 3 P/N 99100900

Figure 2.

5. Begin to tighten nut using a 7/8 in. wrench. Then tap around the outside of the filter clamp with a mallet (or similar tool) to

ensure uniform loading and proper seating of the clamp. Continue tapping and tightening until the spring coils touch each

other. Do not tighten beyond this point.

6. Follow the instructions in Section C, SYSTEM RESTART INSTRUCTIONS, which follows.

7. The spring coils should be checked at least once per month to ensure that they continue to touch each other, indicating that

the clamp is under sufficient tension. If coils fail to touch repeat step B.5 above.

C. SYSTEM RESTART INSTRUCTIONS.

W ARNING

THIS FILTER OPERATES UNDER HIGH PRESSURE. WHEN ANY PART OF THE CIRCULATING SYSTEM, e.g.,

CLAMP, PUMP, FILTER, VALVE(S), ETC. IS SERVICED, AIR CAN ENTER THE SYSTEM AND BECOME

PRESSURIZED. PRESSURIZED AIR CAN CAUSE THE LID TO BE BLOWN OFF WHICH CAN RESULT IN SEVERE

INJURY, DEATH, OR PROPERTY DAMAGE. TO AVOID THIS POTENTIAL HAZARD, FOLLOW THESE

INSTRUCTIONS.

1. Open the High Flow™ manual air relief valve until it snaps into the full open position (this only requires a quarter turn

counter clockwise. Opening this valve rapidly releases air trapped in the filter.

2. Stand clear of the filter tank, then start the pump.

3. Close the High Flow™ manual air relief valve after a steady stream of water appears.

4. The system is not working properly if:

a. A solid stream of water does not appear within 30 seconds after the pump's inlet basket fills with water.

b. The pressure gauge indicates pressure before water out-flow appears.

If either condition exists, shut off the pump immediately, open valves in the water return line to relieve pressure, and clean the

air relief valve; see Section I, FILTER INSTALLATION. If the problem persists, call Customer Service at (800) 831-7133.

D. COATING THE FILTER ELEMENTS WITH DIATOMACEOUS EARTH.

CAUTION

The following information should be read carefully since it outlines the proper manner of care and operation for your filter system. You can

expect maximum efficiency and life from your filtration system by following these instructions and taking the necessary preventative care.

1. Push-Pull Valve.

a. Push handle on valve down with slight twisting motion as far as it will go.

b. Lock upper pin in cap. Open High Flow™ manual air relief valve on the filter.

c. Proceed with steps 2.b to 2.g, below.

2. Multiport Rotary Valve.

a. Position valve to FILTER OR VACUUM TO POOL setting. This is your normal flow from the pump through the filter to

the pool. Open the High Flow™ manual air relief valve on the filter. Proceed with steps 2.b to 2.g, below.

b. Prepare recommended amount of diatomaceous earth by mixing it with water in a bucket until it is the consistency of

milk; see Section E, PREPARING DIATOMITE.

c. On initial start-up the pump must be primed by filling the hair and lint strainer pot with water. You may have to do this

several times.

d. Follow the steps outlined in Section C, SYSTEM RESTART INSTRUCTIONS for system start-up.

e. Introduce the slurry of diatomite from the bucket directly into the top of the skimmer. With the pump running and the

pool skimmer valve open, pour the mixture directly into the skimmer. The slurry will be drawn into the filter.

f. Your filter is now operational. Note the original starting pressure on the gauge and record it below.

P/N 99100900 4 Rev. E 4-3-00

Loading...

Loading...