Sta-Rite 184941 Installation Manual

Nautilus® Plus NSP Stainless Steel D.E. Filter

Installation, Operation & Service Manual

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

Table of Contents

SECTION I. FILTER OPERATION. ............................................................................................... 1

SECTION II. FILTER INSTALLATION. ......................................................................................... 3

SECTION III. TROUBLE SHOOTING. .......................................................................................... 10

SECTION IV. TECHNICAL DATA ................................................................................................. 11

A. REPLACEMENT PARTS ......................................................................................... 11

WARNING

Before installing this product, read and follow all warning notices and instructions accompanying this filter. Failure to

follow safety warnings and instructions can result in severe injury, death, or property damage. Call (800) 831-7133 for

additional free copies of these instructions.

Important Notice

Attention Installer.

This manual contains important information about the installation, operation and safe use of this product.

This information should be given to the owner/operator of this equipment.

SECTION I. FILTER OPERATION.

A. GENERAL INFORMATION.

1. This filter operates under pressure. When closed properly and operated without air in the water system, this

filter will operate in a safe manner.

2. Warning labels should be affixed to the top of the filter and on the clamp bands at all times. Keep safety

labels in good condition. Replace missing or damaged safety labels. {For free labels call (805) 523-2400

or (919) 774-4151}.

Pentair Pool Products

1620 Hawkins Ave., Sanford, NC 27330 • (919) 774-4151

10951 West Los Angeles Ave., Moorpark, CA 93021 • (805) 523-2400

Rev. C 12-30-03 1 P/N 191807

MEMBER

NATIONAL

SPA & POOL

INSTITUTE

R

CAUTION

The following information should be read carefully. It outlines the proper manner of care and operation for your filter system. You

can expect maximum efficiency and life from your filtration system by following these instructions and taking the necessary

preventative care.

3. Your vertical grid diatomaceous earth (D.E.) filter is designed to operate for years with proper maintenance. This

filter housing is made of corrosion resistant materials and when installed, operated and maintained in accordance

with these instructions, your filter will provide years of service.

4. An External Air Relief Valve has been factory installed for your safety.

5. Your filter must be charged with D.E. at initial start-up before operating filter. This D.E. will cover the vertical

filter grid cloth within the filter with a thin coating. Dirty water flows from the pool through the control valve on

the side of the filter and into the lower side connection of the filter (part 24). The dirty water flows through the

vertical grid elements (part 16) where dirt is filtered out by the D.E. Coating. All grid elements channel cleaned

water into a manifold system (part 13) which exits at the upper side connection (part 17) and through the control

valve to return back to the pool. By diluting the dirty pool water with clean water, the entire pool becomes

gradually cleaned. Your filter and pump should be sized to circulate from 2 to 4 times the volume of water in the

entire pool through the filter every day to accomplish the cleaning.

6. As dirt is collected in the coating of D.E. in the filter, the pressure will rise and the flow of water to the pool will

be reduced. See other sections in the manual to determine when to clean the filter and how to choose the

appropriate cleaning method. This filter will only remove suspended matter and does not sanitize the pool. The

pool must be sanitized and pH balanced for sparkling clear water. Your filtration system must be configured and

sized to meet you local health codes.

NOTE

Part no.'s in parenthesis refer to the replacement parts as shown in the exploded drawing at the end of the manual.

WARNING

Failure to run your filter or inadequate filtration can result in pool water clarity that could obstruct visibility and allow diving

into or on top of obscured objects which can cause serious personal injury or drowning.

7. Clear water is the result of proper filtration as well as proper water chemistry. Pool chemistry is a specialized

area and you should consult your local pool service specialist for specific help or instructions. In general proper

pool sanitation requires a free chlorine level of 1 to 2 PPM and a pH range of 7.2 to 7.6.

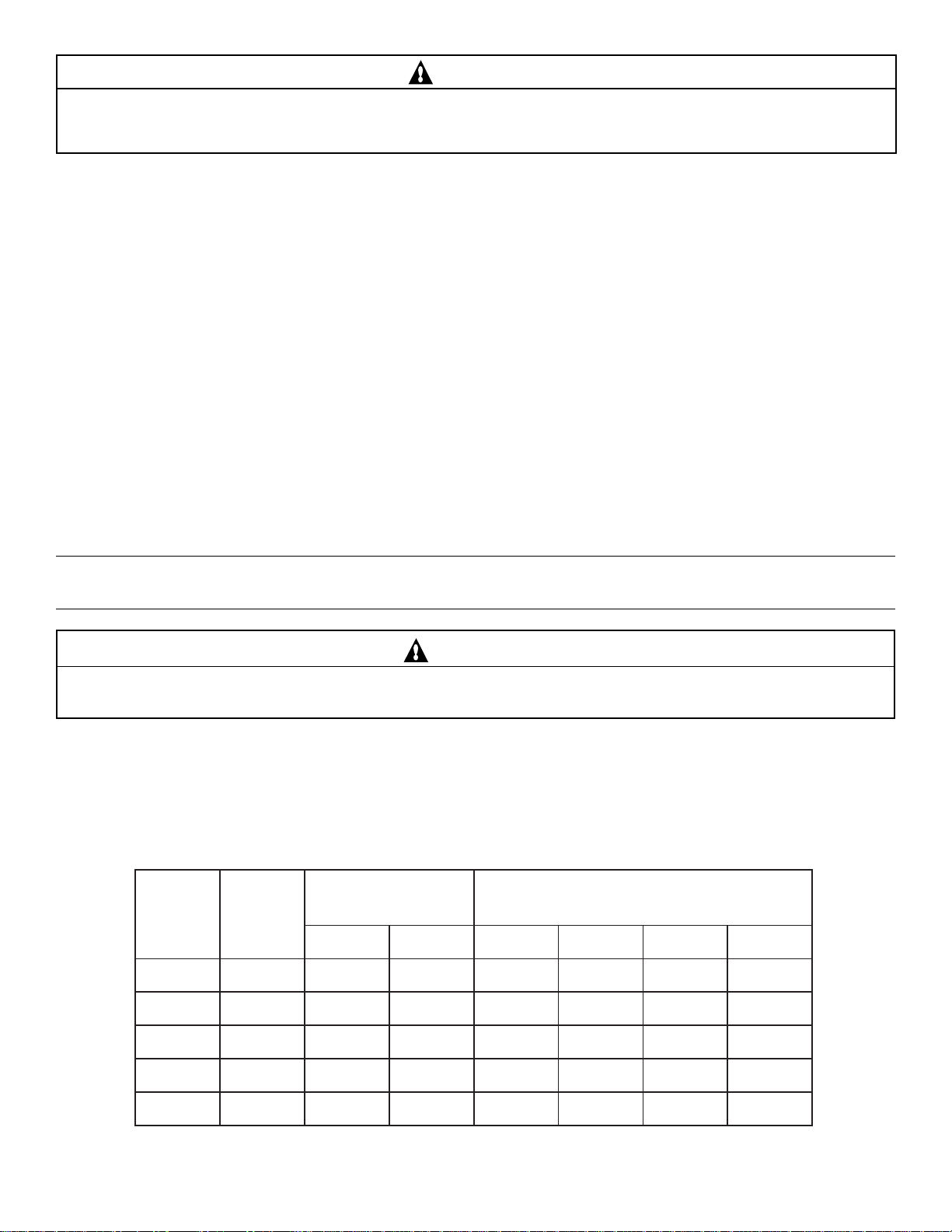

FILTER OPERATIONAL DATA

RETLIF

LEDOM

REBMUN

RETLIF

LEDOM

).tF.qS(

laitnediseR

ETARWOLF

)MPG(

.tF.qS/MPG5.2

cilbuP

.tF.qS/MPG0.2

.srH6.srH8.srH01.srH21

G( )snolla

42-PSN420684082,71040,32008,82065,43

63-PSN630927029,52065,43002,34048,15

YTICAPACREVONRUT

).tF.qS/MPG0.2nodesaB(

84-PSN8402169065,43080,64006,75021,96

06-PSN06051021002,34006,75000,27004,68

27-PSN27051441048,15021,96004,68086,301

P/N 191807 2 Rev. C 12-30-03

SECTION II. FILTER INSTALLATION.

THIS FILTER OPERATES UNDER HIGH PRESSURE. WHEN ANY PART OF THE CIRCULATING

SYSTEM, e.g., CLAMP, PUMP, FILTER, VALVE(S), ETC. IS SERVICED, AIR CAN ENTER THE SYSTEM

AND BECOME PRESSURIZED. PRESSURIZED AIR CAN CAUSE THE LID TO BE BLOWN OFF

WHICH CAN RESULT IN SEVERE INJURY, DEATH, OR PROPERTY DAMAGE. TO AVOID THIS

POTENTIAL HAZARD, FOLLOW THESE INSTRUCTIONS.

1. BEFORE REPOSITIONING VALVE(S) AND BEFORE BEGINNING THE ASSEMBLY, DISASSEMBLY,

OR ADJUSTMENT OF THE CLAMP OR ANY OTHER SERVICE OF THE CIRCULATING SYSTEM: (A)

TURN THE PUMP OFF AND SHUT OFF ANY AUTOMATIC CONTROLS TO ENSURE THE SYSTEM

IS NOT INADVERTENTLY STARTED DURING THE SERVICING; (B) OPEN THE AIR RELIEF VALVE;

(C) WAIT UNTIL ALL PRESSURE IS RELIEVED.

2. WHENEVER INSTALLING THE FILTER CLAMP FOLLOW THE FILTER CLAMP INSTALLATION

INSTRUCTIONS EXACTLY.

3. ONCE SERVICE ON THE CIRCULATING SYSTEM IS COMPLETE FOLLOW SYSTEM RESTART

INSTRUCTIONS EXACTLY.

4. MAINTAIN CIRCULATION SYSTEM PROPERLY. REPLACE WORN OR DAMAGED PARTS

IMMEDIATELY, e.g., clamp, pressure gauge, valve(s), O-rings, etc.

5. BE SURE THAT THE FILTER IS PROPERLY MOUNTED AND POSITIONED ACCORDING TO

INSTRUCTIONS PROVIDED.

WARNING

A. GENERAL INFORMATION.

1. Check carton for any evidence of damage due to rough

handling in shipment. If carton or any filter components are

damaged, notify freight carrier immediately.

2. After inspection, carefully remove filter components from

carton.

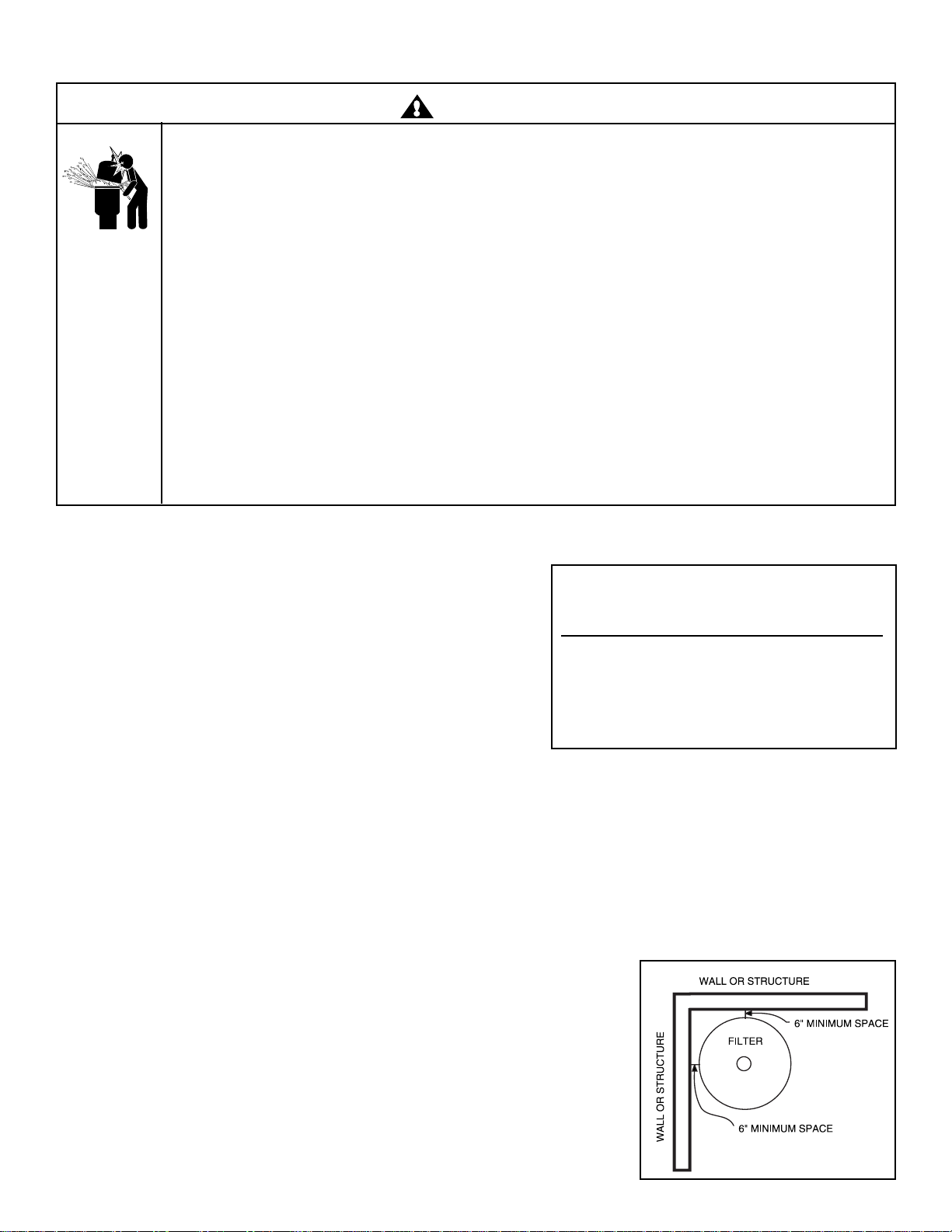

3. The filter should be mounted on a level concrete slab. Position

the filter so that instructions, warnings and the pressure gauge

are visible to the operator. It also should be positioned so that

Model Size Clearance Req. NSF

184941 24 sq. ft. 61 in. yes

184942 36 sq. ft. 67 in. yes

184943 48 sq. ft. 73 in. yes

184944 60 sq. ft. 79 in. yes

184945 72 sq. ft. 85 in. yes

Table 1.

Vertical

the piping connections, control valve and drain port are

convenient and accessible for servicing and winterizing.

4. Provide space and lighting for routine maintenance access. Do not mount electrical controls over filter. Install

electrical controls (e.g., on/off switches, timers, control systems, etc.) at least five (5) feet from the filter. This

will allow you enough room to stand clear of the filter during system start up.

5. Allow sufficient clearance around the filter to permit visual verification that the clamp is properly installed around

the tank flanges, see Figure 1.

6. Allow sufficient space above the filter to remove the filter lid for cleaning and servicing. This distance will vary

with the model of filter you are using. See Table 1. for the required vertical clearance.

7. Filter plumbing connections are provided with an O-ring seal. If you have a

Multi-port Valve, assemble the valve to tank, being sure O-rings on valve

fittings are in place and are clean. To avoid damage to the O-rings, use

only a silicone base lubricant, applied lightly, such as silicone grease,

Mytilube or similar product on O-rings and O-ring grooves prior to

assemble. Do not use pipe joint compound, glue or solvent on the bulkhead

connections.

8. If you have a two position slide valve, align the valve with tank so that the

handle is toward the top of the tank, push valve into ports and turn the

valve nuts snugly on tank fittings. It is not necessary to cinch valve nuts to

tank fitting beyond hand tightness.

Rev. C 12-30-03 3 P/N 191807

Figure 1.

9. Assemble piping and pipe fittings to pump and valve. All piping must conform to local and state plumbing and

sanitary codes.

10. Use Teflon tape or Plastojoint stick on all male connections of pipe and fittings. Use only pipe compounds suited

for plastic pipe. Support pipe to prevent strains on filter, pump or valve.

11. Long piping runs and elbows restrict flow. For best efficiency use the fewest possible fittings, large diameter pipe

(at least 1½", preferably 2") and locate equipment as close to the pool as possible.

12. A check valve is recommended between the filter and heater to prevent hot water "back up" which will damage

the filter and valve. Another check valve is recommended between the filter and the pump to prevent D.E. from

migrating back to the pool when the filter is off.

13. The maximum operating pressure of this unit is 50 pounds per square inch. Never operate this filter above this

pressure or attach a pump to this filter that has more than 50 psi shut off pressure.

14. Never install a chlorinator upstream of the filter - always downstream and with a check valve in between the

chlorinator and filter.

15. A positive shut off valve is not recommended at the outlet of the filtering system. If the system is ever run with

such a valve closed, the internal air relief system becomes inoperative and an explosive situation could exist.

Additionally, running the system with no flow will seriously damage the equipment.

16. A positive shut off valve is also not recommended at the waste port of the valve. If the system is ever run with

such a valve closed, the filter pressure will go abnormally high and increase the risk of vessel separation.

Additionally, running the system with no flow will seriously damage the equipment.

17. Never store pool chemicals within 10 ft. of your pool filter and pump. Pool chemicals are corrosive and should

always be stored in a cool, dry and well ventilated area.

WARNING

Chemical fumes and/or spills can cause sever corrosive attack to the filter and pump structural metallic components.

Structurally weakened filter components can cause filter or valve attachments to blow off and could cause severe

bodily injury or property damage.

B. INITIAL START-UP.

1. On a new pool, clean the pool before filling with water. Excess dirt and large particles can cause damage to pump

and filter.

2. Check clamp assembly for tightness. See Filter Disassembly and Assembly procedures.

3. Move valve handle to filter position. Open air bleeder screw (Item 1) on the filter top. Check pump strainer

pot to be sure it is full of water. Replace pump lid.

WARNING

Conditions where air enters the filter and the tank lid is not installed properly can cause the lid to separate and could

cause serious bodily injury and/or major property damage. Always stand clear of the filter when it is in operation or

when power to the pump is turned on.

4. Open all suction and return line valves. Stand clear of filter during the following operations.

5. Start pump. The tank will fill with water and expel air from air bleeder.

6. Remove the skimmer lid, put the recommended amount of diatomaceous earth (D.E.) into the skimmer. The D.E.

will be drawn into the filter and deposited evenly upon the grid elements. Now the filter is providing the pool with

bright, clean water.

NOTE

Do not operate filter without D.E. charge for more than two minutes. Do not use more than the recommended amount of D.E. in your filter.

P/N 191807 4 Rev. C 12-30-03

Loading...

Loading...