Page 1

MULTI-PORT FILTER VALVE

O W N E R’ S M A N U A L

INSTALLATION, OPERATION & PARTS

MODELS

SIDE MOUNT – 1-1/2" SIDE MOUNT – 2"

18202-0150 18201-0200

18202-0150H 18201-0200H

18201-0110 18201-0300

18202-0250

Sta-Rite Pool/Spa Group

293 Wright Street, Delavan, WI 53115

International: 262-728-5551, FAX: 262-728-7550

www.starite.com

Union City, TN • Delavan, WI • Mississauga, ON • Murrieta, CA

© 2005, Sta-Rite Industries S532 (Rev. 6/24/05)

This manual should be furnished to

the end user of this valve; its use will

reduce service calls and chance of

injury and will lengthen valve life.

RECIRC.

R

W

AS

TE

IN

S

E

FILTER

3587 1099

BACKWASH

D

C

L

O

S

E

Page 2

2

MULTI-PORT FILTER

VA LV E

To avoid unneeded service calls, prevent possible injuries,

and get the most out of your filter, READ THIS MANUAL

CAREFULLY!

Table of Contents

Safety Instructions ............................................................2

General Information.........................................................3

Functions .........................................................................4

Maintenance.................................................................4-5

Repair Parts List ............................................................6,7

Performance Curves.........................................................7

Warranty..........................................................................8

READ AND FOLLOW ALL

INSTRUCTIONS!

This is the safety alert symbol. When you see this

symbol on your system or in this manual, look for

one of the following signal words and be alert to the

potential for personal injury.

warns about hazards that will cause death,

serious personal injury, or major property damage if

ignored.

warns about hazards that can cause death,

serious personal injury, or major property damage if

ignored.

warns about hazards that will or can cause

minor personal injury or property damage if ignored.

NOTICE indicates special instructions not related to hazards.

Carefully read and follow all safety instructions in this

manual and on equipment. Keep safety labels in good con-

dition; replace if missing or damaged.

Incorrectly installed or tested equipment may

fail, causing severe injury or property damage.

Read and follow instructions in owner's manual

when installing and operating equipment. Have

a trained pool professional perform all pressure tests.

1. Do not connect system to a high pressure or city water

system.

2. Use equipment only in a pool or spa installation.

3. Trapped air in system can cause explosion. BE SURE all air

is out of system before operating or testing equipment.

Before pressure testing, make the following safety checks:

• Check all clamps, bolts, lids, and system accessories

before testing.

• Release all air in system before testing.

• Tighten Sta-Rite trap lids to 30 ft. lbs. (4.1 kg-cm) torque

for testing.

• Water pressure for test must be less than 25 PSI (172 kPa).

• Water Temperature for test must be less than 100

o

F.

(38oC).

• Limit test to 24 hours. After test, visually check system to

be sure it is ready for operation. Remove trap lid and

retighten hand tight only.

NOTICE: These parameters apply to Sta-Rite equipment

only. For non-Sta-Rite equipment, consult manufacturer.

Page 3

3

GENERAL

Inspect valve upon receipt and file claim with carrier if

parts are damaged or missing.

Valve may be used with Sta-Rite DE or sand filters, except

Model HRP36.

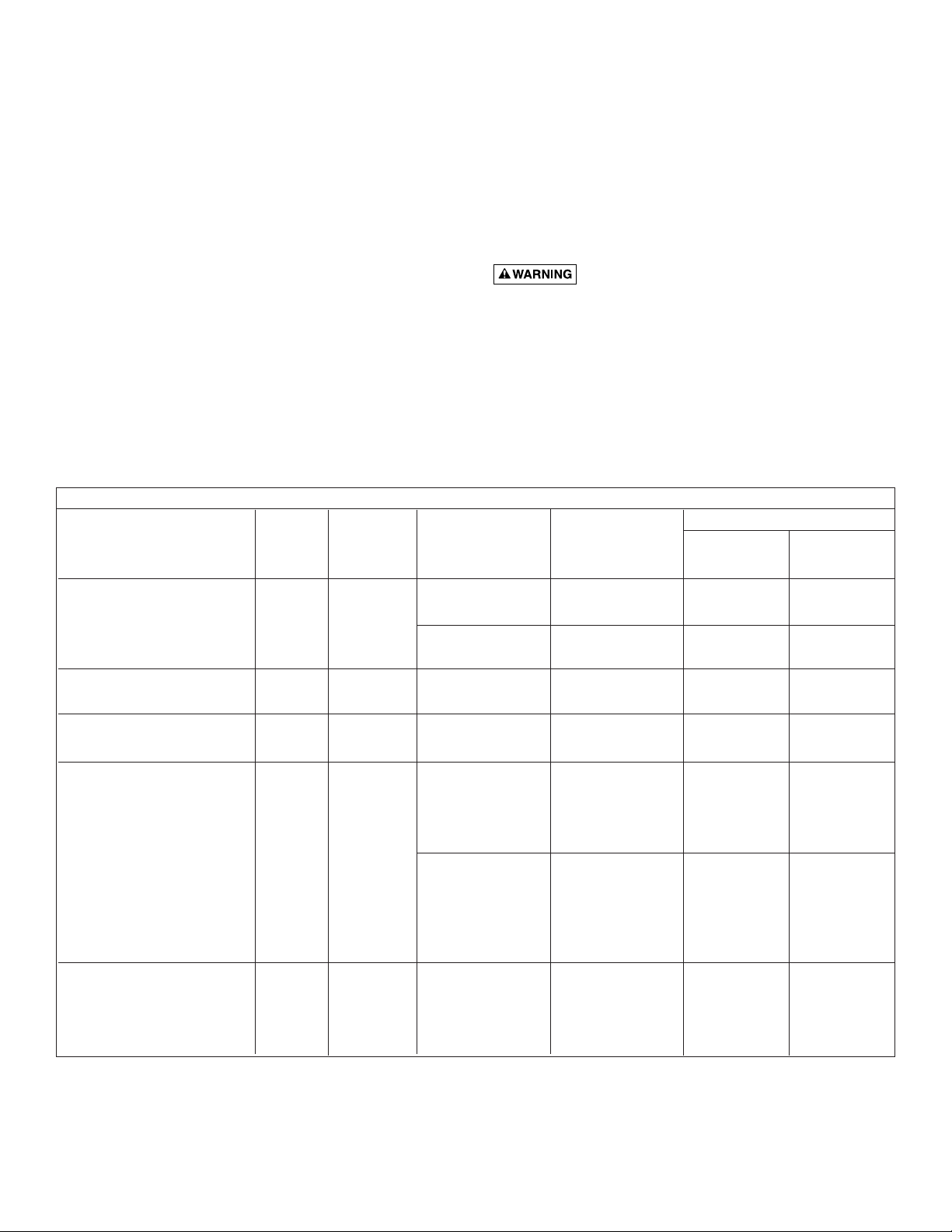

Mating half of unions are on filters shown on Table I.

Connecting Multi-Port Valve To Filter System

For filters listed below, select correct valve clamp connector kit from the chart.

Use care before assembly not to damage union sealing surfaces or O-Ring. Install union O-Rings in groove; tighten

union collar hand tight.

FOR SLIP FITTINGS: Use correct solvent/cement when fitting

piping or adapters to slide valve. The valve body is ABS

plastic, thus any good quality ABS to PVC solvent can be

used, such as Weld-On #793 or #710. Use P70 (purple)

primer on PVC components only. Allow a minimum of four

hours drying time prior to pressure testing or operation. If

ABS adapters are glued into valve ports in lieu of PVC fittings, use Weld-On Solvent #771, #1707 or #773.

To avoid serious personal injury or property

damage, follow cement manufacturer’s instructions exactly.

NOTICE: FOR THREADED FITTINGS: Use Plasto-Joint Stik

1

,

teflon tape or RTV. Other substances may degrade plastic

and create poor joints and leaks. Do not overtighten.

1

Lake Chemical Co., Chicago, IL

TABLE I – Filters and connector kits to use with valves.

Filter Connection Chart

18201 and

Use Hose Kit No.

Port Valve Use With 18202 Series with with

Valve No. Size Outflow* Filter model Valves Replace 2" Pipe 1-1/2" Pipe

18202-0150 DES25 WC212-143P

––

for Union Connections

1-1/2"

Bottom

DES36 (Unions)

or 18202-0150H, HRS16 14964-0014 24750-0624 24750-0331

for Hose Connections HRS20 (Hoses) 2"x1-1/2" 1-1/2"x1-1/2"

18202-0250

1-1/2"

Top

PLDE36

–––

for Union Connections PLDE48

18201-0110 1-1/2"

Top

S200BP-1M

–––

S240BP-1M

DEP36, DEPB36 WC212-144PN

DEP51, DEPB51 WC212-150PN – –

18201-0200 DEP83, DEPB83 (Unions)

for Union Connections DES51, DES60

or 2" Bottom HRP20, HRP24

18201-0200H HRP30 WC212-150PA 24750-0341 –

for Hose Connections HRS24 14971-0000 2"x2"

S7M120, S8M150 (Hoses)

S7D75, S8D110

S7MD60

18201-0300 2"

Top

S7MD72 – – –

SR-300-2U

SR-360-2U – – –

* When the multiport valve handle is in filter position, flow to filter will be from this port.

Page 4

4

FUNCTIONS OF THE

MULTI-PORT VALVE

To avoid severe injury

and major property damage, stop pump before changing handle positions.

To avoid major property

damage due to flooding,

make sure pointer is accurately positioned and down all the

way before restarting pump.

Press down on handle to

release pressure before turning.

1. FILTER – Normal position during operation of system.

2. BACKWASH – Position when operating system to

purge filter of accumulated debris. This normally is

necessary when filter pressure gauge reads 10 PSI

higher than starting pressure on a clean filter. Consult

your filter operating instructions.

3. RINSE – This position is only used with sand filters

and is designed to flush stray sand from system before

returning to filter operation after backwashing.

Consult your filter operating instructions.

4. CLOSED – Valve may be set in closed position when

servicing filter tanks located below water level.

5. RECIRCULATE – This position permits pump to continue recirculating water (chemicals, heat, etc.) without flow through filter. This is advantageous when filter or its components are being repaired or replaced.

6. WASTE – This position permits draining or lowering

of pool water level. When pump is stopped with

valve in this position, quickly move handle to another

position to avoid air getting into piping.

VALVE MAINTENANCE

To avoid severe personal injury and major property

damage, stop pump and release all pressure from

system before servicing valve.

No regular maintenance is required for proper operation

of multi-port valve.

Winterizing For Freezing Climates:

Place valve handle in an intermediate position, between

regular setting positions.

Part Replacement:

To prevent flooding, make sure that system is drained or

isolation valves are closed before opening multi-port

valve.

Replacing Handle:

1. STOP PUMP and release all pressure from system.

2. Place handle in “FILTER” position.

3. Remove all bolts and nuts holding cover to valve

body.

4. Remove cover, handle, and plug as a unit from valve

body.

5. Compress plug as shown in Figures 1 and 2.

6. Remove handle pin from handle; remove handle

and replace with new one, making sure pointer

is in “FILTER” position.

7. Replace pin by tapping lightly into place with

hammer and punch.

8. Remove fixture, align cover pin (See Figure 3), and

reinstall cover and plug. Tighten all bolts securely.

Hazardous pressure.

Can cause severe

injury or major

property damage

from valve blow up.

Release all pressure

and read instructions

before working on

system.

Figure 2 – Tighten wingnuts to compress spring

Pull top of valve

down 1/2-5/8";

Tap pin out

of shaft.

3586 1099

Figure 1 – Fixture dimensions for valve spring compressor

8" (For 2" Valve)

6" (For 1-1/2" Valve)

Scrap 1x2,

1x4 or 3/4"

Ply 10" Long

1/4 x 6"

Carriage

Bolts (2)

Wing Nut

1/4" holes through (3 Places)

Flat Washer

3585 1099

Page 5

5

To prevent flooding, make sure that system is drained or

isolation valves are closed before opening multi-port valve.

Replacing Cover and Plug Assembly (as a unit):

1. STOP PUMP and release all pressure from system.

2. Remove all bolts and nuts around perimeter of cover.

3. Remove assembly by lifting straight up.

4. Align cover pin (see Figure 3) and install new cover

and plug. Press down on cover to allow bolts to

engage nuts; tighten each bolt securely.

Replacing Internal Valve Parts:

1. STOP PUMP and release all pressure from system.

2. Place handle in “FILTER” position.

3. Remove all bolts and nuts.

4. Remove cover by lifting straight up.

5. Remove handle pin and handle (See procedure on

Page 4).

6. Remove washer.

7. While disassembled, check condition of plug, rubber

gasket, spring,

O-Ring, and internal plastic washer. If any of these

parts appear worn, replace them.

8. Reassemble plug, cover, and handle by compressing

spring (See Figures 1 and 2) and reversing procedure

on Page 4.

9. Before reinstalling cover, be sure plug and handle are

in same position as when cover was removed.

10. Make sure tab on valve cover aligns with pin on top of

pump port (see Figure 3). Press down on cover or set

handle to “WINTERIZE” to allow bolts to engage nuts.

Tighten each bolt securely.

Spider Gasket Replacement:

NOTICE: Read instructions completely before starting.

Once Step 6 is started, continue through Step 10 without

interruption.

1. STOP PUMP and release all pressure from system.

2. Place the selector handle at the ‘Winterize’ position

(this lifts the plug off the seat).

3. Remove the bolts and nuts holding the cover to the

valve body. Remove the cover assembly.

4. Remove the old gasket from the valve body.

5. Make sure that the gasket groove is free of water,

grease, oils, debris and parts of the old gasket. Use

alcohol to degrease.

6. NOTICE:

Once this step is started, continue through

Step 10 without interruption.

Using Loctite®401 or 416, apply glue sparingly (a bead

about 1/16” wide) to the bottom only (not the sides) of

the spider groove in the valve body. The glue lines

must be continuous and intersect at the intersections of

the grooves.

7. Insert the new gasket into the groove with the rounded

bead up. Press the gasket firmly into all groove areas to

seat the new gasket evenly.

8. Align the tab on the cover assembly with the pin on

the valve body (See Figure 3) and insert the cover

assembly into the body, fastening it with the bolts and

nuts removed in Step 3. Tighten all bolts securely.

9. Depress the valve handle and rotate it to the closest

standard position (FILTER or RINSE), being careful not

to rub the plug on the new gasket. Release the handle,

allowing the plug to hold the gasket in place while curing.

10. Minimum cure time is 2 hours. Curing for 24 hours is

recommended for full strength.

Figure 3 – Cover alignment

BACKWASH

RECIRC.

RINSE

FILTER

WASTE

CLOSED

W

I

N

T

E

R

I

Z

E

Align

Tabs

3611 1099

Page 6

6

Side Mount Multiport Valve Assembly

REPAIR PARTS LIST

B

A

C

K

W

A

S

H

RECIRC.

R

I

N

S

E

F

I

L

T

E

R

WASTE

CLOSED

1

2

3

4

5

6

7

8

8

11

12

12A

13

14

Valve Body

Not Available

Separately

9

10

15

18201-0110

18202-0150 18201-0300

18202-0150H 18201-0200

Key 18202-0250 18201-0200H

No. Description Qty. 1-1/2" Valve 2" Valve

1 Handle 1 14971-SM10E1 14971-SM10E1

2 Label Decal 1 32155-4133 32155-4136

3 Washer 1 14971-SM10E3 14971-SM10E3

4 Valve Cover 1 14971-SM10E6 14971-SM20E6

5 Cover O-Ring 1 14971-SM10E7 14971-SM20E7

6 Washer 1 14971-SM10E8 14971-SM10E8

7 Spring 1 14971-SM10E9 14971-SM10E9

8 O-Ring 2 14971-SM10E10 14971-SM10E10

9 Plug 1 14971-SM10E11 14971-SM20E11

10 Spider Gasket 1 14971-SM10E12 14971-SM20E12

11 1/4" NPT Plug w/O-Ring 1 U178-920P U178-920P

12 Sight Glass w/O-Ring 1 14971-SM10E17 14971-SM10E17

13 Nut () 14971-SM10E14(6) 14971-SM10E14(10)

14 Bolt () 14971-SM10E4(6) 14971-SM10E4(10)

15 Handle Pin 1 14971-SM10E2 14971-SM10E2

16 O-Ring (-0150, -0200 only) 2 U9-362 U9-362

• Key Assembly (Includes 1-11,13) 1 14971-SM10E50 14971-SM20E50

Models 18202-0150, 18201-0200, 18201-0110,

18202-0250 and 18201-0300 include union

halves as shown. Table 1, Page 3 gives filter

models and correct valves to use with filters.

Models 18202-0150H and 18201-0200H

require hose connector kits (sold separately –

See Table 1, Page 4 for kit and filter numbers).

• Not illustrated.

16

Page 7

7

Sight Glass Adaptor – 11⁄2" NPT & Hose ..............................Order #14962-0012

Sight Glass Adaptor – 11⁄2" NPT...........................................Order #14962-0013

• Male Adaptor – 11⁄2" NPT to 11⁄2" ID Hose............................Order #U78-767P

• Not illustrated.

Performance Curves – Multi-Port Valves

11⁄2" and 2" Side Mount Valves with Piping

Sight Glass, Sight Glass Adaptors

0

40

60 80 100 120 140 160

2

4

6

8

10

12

14

16

Capacity (GPM)

P.S.I. Loss

2" Valve

1-1/2"

Valve

Backwash Position

Filter Position

3588 1099

2840 0597

2841 0597

Page 8

CREATE A RECORD OF YOUR WARRANTY AT STA-RITE:

• Complete a warranty registration at www.staritepool.com by clicking on “Register Products” and selecting Sta-Rite Pool

OR

• Complete bottom portion completely and mail within 10 days of installation to Sta-Rite, Attn.: Pool Warranty Dept., 293 Wright St., Delavan , WI 53115

Warranty Registration Card

Name

Address

City State Zip

Installation (or Purchase) Date

Product Purchased

Model Number

■■ New installation ■■ Replacement

Years pool has been in service ■■ less than 1 ■■ 1-3 ■■ 3-5 ■■ 5-10

This product was purchased from:

Company name

Address

City State Zip

STA-RITE LIMITED WARRANTY

For technical information about this product, contact the installer or call Sta-Rite at 262-728-9181.

Visit www.staritepool.com

• for more information about Sta-Rite products listed above

• to locate a Sta-Rite dealer near you

Product Specific Warranties (from date of installation)

Product Limited

Family Warranty Exceptions

Filters 1 Year System 3 Tank Bodies - 10 Yrs

Filter Valves 1 Year

Pumps 1 Year

Heaters 2 Years *Commercial Application - 1 Yr

Controls 1 Year

Above Ground Systems 1 Year

Lights and Niches 1 Year Lamps and Bulbs - 90 Days

White Goods 1 Year

Maintenance Equipment 90 Days

Drainer/Utility Pumps 90 Days

Replacement Parts 90 Days

Cleaners: Lil Shark 1 Year

Cleaners: Calypso 1 Year

Cleaners: Pool Shark 2 Years Footpad and Seal Flaps - 1 Yr

Cleaners: Great White 2 Years

* Commercial and multi-family application.

Retain this warranty certificate in a

safe and convenient location for your records.

Pumps, filters, skimmers, underwater lights (excluding bulbs),

accessories and fittings manufactured by Sta-Rite are warranted

to be free of defects in material and/or workmanship for one (1)

year from the original date of installation.

The foregoing warranties relate to the original consumer purchaser (“Purchaser”) only. Sta-Rite Industries shall have the option to

repair or replace the defective product, at its sole discretion.

Purchasers must pay all labor and shipping charges necessary to

replace the product covered by this warranty. Requests for warranty service must be made through the installing dealer. This

warranty shall not apply to any product that has been subject to

negligence, misapplication, improper installation or maintenance,

or other circumstances which are not in Sta-Rite’s direct control.

Failure to have product installed by a professional in compliance

with local codes will void any and all manufacturers warranty.

This warranty sets forth Sta-Rite’s obligation and Purchaser’s

exclusive remedy for defective products.

STA-RITE SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL,

INCIDENTAL OR CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN

LIEU OF ALL OTHER EXPRESS WARRANTIES. IMPLIED

WARRANTIES, INCLUDING BUT NOT LIMITED TO THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE, SHALL NOT EXTEND

BEYOND THE DURATION OF THE APPLICABLE EXPRESS

WARRANTIES PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental

or consequential damages or limitations on how long an implied

warranty lasts, so the above limitations or exclusion may not

apply to you. This warranty gives you specific legal rights and you

may also have other rights which vary from state to state.

Supersedes all previous publications.

S4877PS (Rev. 7/21/04)

Loading...

Loading...