Sta-Rite 175K BTU-HR Installation Manual

Attention Installer

Please give this manual to the owner and/or operator once installation is complete.

À l'intention de l'installateur

Veuillez remettre ce manuel au propriétaire et/ou à l'opérateur de cet équipement après l'installation.

Atención instalador

Por favor, entréguele este manual al dueño y/o operador una vez la instalación haya sido

completada.

Attention User

Please retain this manual for future reference, it contains important information that will help you

in operating and maintaining this heater.

À l'intention de l'utilisateur

Veuillez conserver ce manuel d'utilisation pour consultation ultérieure, il contient d'importantes

informations concernant le fonctionnement et l'entretien de ce chauffe eau.

Atención usuario

Por favor, conserve este manual para consultas en el futuro, el mismo contiene información

importante que lo ayudará en la operación y mantenimiento de este calentador.

Call (800) 831-7133 for additional free copies of these instructions.

Pour des copies supplémentaires gratuites de ce guide, veuillez appeler au (800) 831-7133.

Llame al (800) 831-7133 para obtener gratuitamente copias adicionales de estas instrucciones.

© 2011 Pentair Water Pool and Spa, Inc.

This document is subject to change without notice.

1620 Hawkins Ave., Sanford, NC 27330 • (800) 831-7133 • (919) 566-8000

10951 West Los Angeles Ave., Moorpark, CA 93021 • (800) 831-7133 • (805) 553-5000

All rights reserved.

1

1

1

MasterTemp

Pool and Spa Heater

OPERATION AND INSTALLATION MANUAL

WARNING

FOR YOUR SAFETY - READ BEFORE OPERATING

Warning:

120/240 VAC NATURAL GAS/LP GAS

MODELS Natural Propane

175K BTU/HR 460792 460793

200K BTU/HR 460730 460731

250K BTU/HR 460732 460733

250K BTU/HR (HD) 460806 –

300K BTU/HR 460734 460735

400K BTU/HR 460736 460737

400K BTU/HR (HD) 460805 –

400K BTU/HR

FOR YOUR SAFETY - This product must be

installed and serviced by authorized personnel,

qualified inpool/spa heater installation. Improper

installation and/or operation can create carbon

monoxide gas and flue gases which can cause

serious injury, property damage, or death. For

indoor installations, as an additional measure of

safety, Pentair Water Pool and Spa, Inc. strongly

recommends installation of suitable Carbon

Monoxide detectors in the vicinity of this appliance

and in any adjacent occupied spaces. Improper

installation and/or operation will void the warranty.

If you do not follow these instructions exactly, a fire or explosion may result, causing

property damage, personal injury or loss of life.

For additional free copies of this manual; call (800) 831-7133.

(ASME)

460775 460776

®

OWNER:

Retain For

Future

Reference

WARNING

Warning: Improper installation, adjustment, alteration, service or maintenance can cause property

damage, personal injury or death. Installation and service must be performed by a qualified installer,

service agency or the gas supplier.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

For Your

Safety

Rev. D 03-09-11 P/N 472592

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone.

Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

DO NOT store or use gasoline or other flammable vapors and liquids in the vicinity

of this or other appliances.

Pentair Water Pool and Spa, Inc.

1620 Hawkins Ave., Sanford, NC 27330 • (800) 831-7133 or (919) 566-8000

10951 W. Los Angeles Ave., Moorpark, CA 93021 • (800) 831-7133 or (805) 553-5000

2

Customer Service

If you have questions about ordering Pentair Pool and Spa® replacement parts, and pool

products, please call:

Customer Service and Technical Support (8 A.M. to 5 P.M. Eastern Time/Pacific Time)

Phone: (800) 831-7133

Fax: (800) 284-4151

Web sites

www.pentairpool.com - www.staritepool.com

© 2011 Pentair Water Pool and Spa, Inc. All rights reserved.

1620 Hawkins Ave., Sanford, NC 27330 • (800) 831-7133 or (919) 566-8000

10951 West Los Angeles Ave., Moorpark, CA 93021 • (800) 831-7133 or (805) 553-5000

MasterTemp®, IntelliTouch®, EasyTouch®, Pentair Pool Products® , and Because reliability matters most® are registered

trademarks of Pentair Water Pool and Spa, Inc. and/or its affiliated companies in the United States and/or other countries.

Unless noted, names and brands of others that may be used in this document are not used to indicate an affiliation or

endorsement between the proprietors of these names and brands and Pentair Water Pool and Spa, Inc. Those names and

brands may be the trademarks or registered trademarks of those parties or others.

P/N 472592 Rev. D 03-09-11

Table of Contents

Section 1. Heater Identification Information ....................................................................... 4

Section 2. Warning and Safety Information ......................................................................... 5

Important Notices................................................................................................................................................................................. 5

Warranty Information ............................................................................................................................................................................ 5

Code Requirements .............................................................................................................................................................................. 6

Consumer Information and Safety Information ...................................................................................................................................... 6 - 9

General Specifications ......................................................................................................................................................................... 9

Section 3. Installation ............................................................................................................. 10

Heater Description................................................................................................................................................................................ 10

Putting the Heater into Service ............................................................................................................................................................ 10

Specifications ...................................................................................................................................................................................... 11

Plumbing Connections .......................................................................................................................................................................... 12

Valves .................................................................................................................................................................................................. 12

Manual By-Pass .................................................................................................................................................................................. 12

Water Connections ............................................................................................................................................................................... 13

Below Pool Installation ......................................................................................................................................................................... 13

Gas Connections ................................................................................................................................................................................. 14

Sediment Traps .................................................................................................................................................................................... 14

Gas Pipe Sizing ................................................................................................................................................................................... 15

Testing Gas Pressure/Gas Pressure Requirements ............................................................................................................................. 16

Outdoor Installation .............................................................................................................................................................................. 17

Outdoor Installation Venting Guidelines ................................................................................................................................................ 18

Indoor Venting—General Requirements (Category I & Category III – clarification) ............................................................................... 19

Heater Clearances................................................................................................................................................................................ 19

Outside Vent Removal ......................................................................................................................................................................... 19

Combustion Air Supply ......................................................................................................................................................................... 20

Corrosive Vapors and Possible Causes ................................................................................................................................................ 20

Vent Installation (Indoor Installation for U.S. or Outdoor Shelter for Canada) ........................................................................................ 21

Vertical Venting - Negative Pressure ................................................................................................................................................... 21 - 23

Horizontal or Vertical Venting - Positive Pressure ................................................................................................................................ 24

Connecting Special Gas Venting .......................................................................................................................................................... 24 - 26

Outdoor Shelter Vent Installation .......................................................................................................................................................... 27

Garage or Utility Room Installation ....................................................................................................................................................... 27

Control Panel Indexing ......................................................................................................................................................................... 28

Final Installation Check ........................................................................................................................................................................ 28

Electrical Connections .......................................................................................................................................................................... 29

Fireman’s Switch Connection/Remote Control Connections .................................................................................................................. 30

MasterTemp Wiring Diagram................................................................................................................................................................. 31

Electrical Schematic Ladder Diagram ............................................................................................................................................

Section 4. Operation............................................................................................................... 33

Basic System Operation ...................................................................................................................................................................... 33

HSI (Hot-Surface Ignition) Lighting/Operation ....................................................................................................................................... 33

Operating ............................................................................................................................................................................................. 34

To Turn Off Gas to Appliance ............................................................................................................................................................... 34

Safety Controls .................................................................................................................................................................................... 35 - 37

Section 5. Troubleshooting ................................................................................................... 38

Initial Troubleshooting and Troubleshooting Chart ................................................................................................................................. 38

Heater Will Not Fire Troubleshooting .................................................................................................................................................... 39 - 42

LED Diagnostics .................................................................................................................................................................................. 43 - 44

Burner / Heat Exchanger Troubleshooting ............................................................................................................................................ 45

Section 6. Maintenance .......................................................................................................... 46

Care and Maintenance .......................................................................................................................................................................... 46

Pressure Relief Valve ........................................................................................................................................................................... 46

After Start-Up ...................................................................................................................................................................................... 47

Spring, Fall and Winter Operation ......................................................................................................................................................... 47

Maintaining Pool Temperature............................................................................................................................................................... 48

Energy Saving Tips .............................................................................................................................................................................. 49

Chemical Balance ................................................................................................................................................................................ 48 - 49

Replacement Parts .............................................................................................................................................................................. 50 - 54

3

....... 32

Rev. D 03-09-11 P/N 472592

4

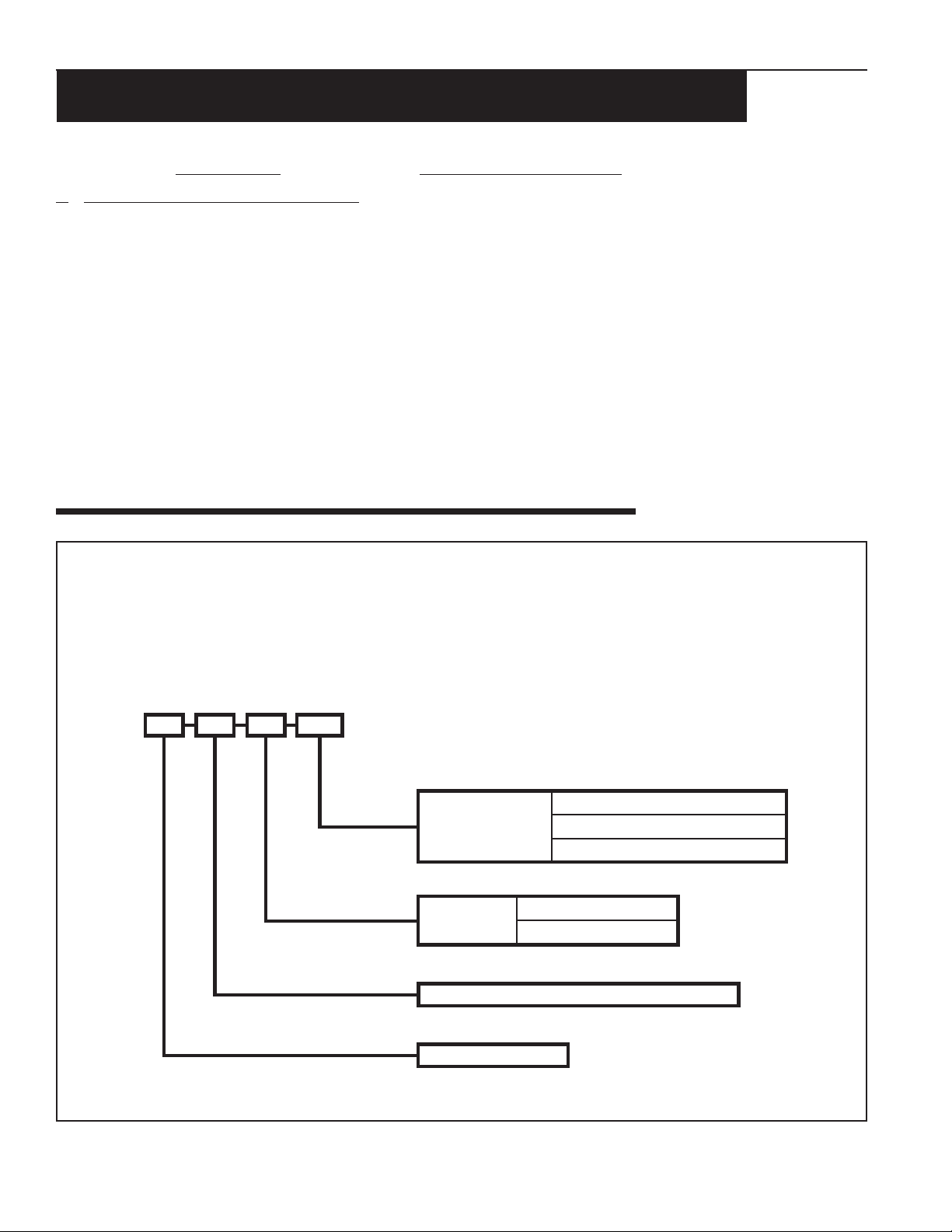

Section 1. Heater Identification Information

Section 1: Heater Identification Information

To identify the heater, see rating plate on the inner front panel of the heater. There are two designators for each

heater, one is the Model Number and the other is the Heater Identification Number (HIN).

a. Heater Identification Number (HIN)

The following example simplifies the identification system:

1) MT : MasterTemp

2) Model Size : (175, 200, 250, 300 or 400) : Input rating (Btu/hr) X 1000

3) Fuel Type : (LP = Propane gas or NA = Natural gas)

4) Construction : (STD = Standard Model)

(HD = Heavy Duty Model)

(ASME = ASME Certified Model)

HEATER IDENTIFICATION INFORMATION — (HIN)

H. I. N.

HEATER IDENTIFICATION NUMBER

ID DESIGNATOR FOR PENTAIR WATER POOL & SPA MASTERTEMP HEATERS

Example:

1 2 3 4

MT 250 NA ASME

STD = STANDARD MODEL

CONSTRUCTION =

FUEL TYPE =

MODEL SIZE = BTU INPUT in 1000 of BTU / HR

HD = HEAVY DUTY MODEL

ASME = ASME CERTIFIED MODEL

NA = NATURAL GAS

LP = PROPANE GAS

MT = MASTERTEMP

P/N 472592 Rev. D 03-09-11

Section 2. Warning and Safety Instructions

Section 2: Warning and Safety Instructions

5

MasterTemp

®

Pool and Spa Heater

Congratulations on your purchase of a MasterTemp high performance heating system. Proper installation and service of

your new heating system and correct chemical maintenance of the water will ensure years of enjoyment. The MasterTemp

is a compact, lightweight, efficient, induced-draft, gas fired high performance pool and spa heater that can be directly

connected to schedule 40 PVC pipe. The MasterTemp also comes equipped with the Pentair multifunction temperature

controller which shows, at a glance, the proper functioning of the heater. All MasterTemp heaters are designed with a

direct ignition device, HSI (hot-surface ignition), which eliminates the need for a standing pilot. The MasterTemp requires

an external power source (120/240 VAC 60 Hz) to operate.

SPECIAL INSTRUCTIONS TO OWNER: Retain this manual for future reference. This instruction manual provides

operating instructions, installation and service information for the MasterTemp high performance heater. The information

in this manual applies to all MasterTemp models. READ AND REVIEW THIS MANUAL COMPLETELY, it is very

important that the owner/installer read and understand the section covering installation instructions, and recognize the

local and state codes before installing the MasterTemp. Its use will reduce service calls and chance of injury and will

lengthen product life. History and experience has shown that most heater damage is caused by improper installation

practices.

IMPORTANT NOTICES

...For the installer and operator of the MasterTemp pool and spa heater. The manufacturer’s warranty may be void if, for

any reason, the heater is improperly installed and/or operated. Be sure to follow the instructions set forth in this manual.

If you need any more information, or if you have any questions regarding to this pool heater, please contact Pentair Water

Pool and Spa, Inc. at (800) 831-7133.

WARRANTY INFORMATION

The MasterTemp pool heater is sold with a limited factory warranty. Specific details are described on the warranty

registration card which is included with the product. Return the warranty registration card after filling in the serial

number from the rating plate inside the heater.

Pentair Water Pool and Spa’s high standards of excellence include a policy of continuous product improvement

resulting in your state-of-the-art heater. We reserve the right to make improvements which change the specifications

of the heater without incurring an obligation to update the current heater equipment.

These heaters are designed for the heating of chlorine, bromine or salt system swimming pools and spas or

in non-stationary installations, and should never be employed for use as space heating boilers or general

purpose water heaters. The manufacturer’s warranty may be void if, for any reason, the heater is improperly

installed and/or operated. Be sure to follow the instructions set forth in this manual.

CAUTION

OPERATING THIS HEATER CONTINUOUSLY AT WATER TEMPERATURE BELOW 68° F. WILL CAUSE HARMFUL

CONDENSATION AND WILL DAMAGE THE HEATER AND VOID THE WARRANTY. Do not use the heater to protect

pools or spas from freezing if the final maintenance temperature desired is below 68° F., as this will cause condensation

related problems.

Rev. D 03-09-11 P/N 472592

6

Section 2. Warning and Safety Instructions

CODE REQUIREMENTS

Installation must be in accordance with all local codes and/or the latest edition of the National Fuel Gas Code,

ANSI Z223.1 and the latest edition of the National Electrical Code, NFPA 70 (US).

Installation in Canada must be in accordance with the latest CAN/CGA-B149.1 or .2 and CSA C22.1 Canadian

Electric Code, part 1.

The heater, when installed, must be electrically grounded and bonded in accordance with local codes, or, in absence of

local codes, with the National Electrical Code, ANSI/NFPA70 (US) or in Canada in accordance with the Canadian

Electric Code, part 1.as applicable.

DANGER

CARBON MONOXIDE GAS IS DEADLY – Exhaust from this pool heater contains toxic levels of carbon monoxide, a dangerous,

poisonous gas you cannot see or smell.

CONSUMER INFORMATION AND SAFETY

WARNING

The U.S. Consumer Product Safety Commission warns that elevated water temperature can be hazardous.

See below for water temperature guidelines before setting temperature.

1. Spa or hot tub water temperatures should never exceed 104° F (40° C). A temperature of 100° F (38° C) is considered safe for a

healthy adult. Special caution is suggested for young children.

2. Drinking of alcoholic beverages before or during spa or hot tub use can cause drowsiness which could lead to unconsciousness

and subsequently result in drowning.

3. Pregnant women beware! Soaking in water above 102° F (39° C) can cause fetal damage during the first three months of pregnancy

(resulting in the birth of a brain-damaged or deformed child). Pregnant women should stick to the 100° F (38° C) maximum rule.

4. Before entering the spa or hot tub, the user should check the water temperature with an accurate thermometer. Spa or hot tub

thermostats may err in regulating water temperatures by as much as 4° F (2.2° C).

5. Persons with a medical history of heart disease, circulatory problems, diabetes or blood pressure problems should obtain their

physician's advice before using spas or hot tubs.

6. Persons taking medication which induce drowsiness, such as tranquilizers, antihistamines or anticoagulants should not use spas

or hot tubs.

WARNING

Should overheating occur or the gas supply fail to shut off, turn off the manual gas control valve to the heater.

Do not use this heater if any part has been under water. Immediately call a qualified service technician to

inspect the heater and to replace any part of control system and gas control which has been under water.

P/N 472592 Rev. D 03-09-11

Section 2. Warning and Safety Instructions

SAFETY INFORMATION

The MasterTemp® pool heaters are designed and manufactured to provide many years of safe and reliable service when

installed, operated and maintained according to the information in this manual. Throughout the manual, safety warnings and

cautions are identified by the “ “ symbol. Be sure to read and comply with all of the warnings and cautions.

7

DANGER —

CARBON MONOXIDE GAS IS DEADLY

READ OWNERS MANUAL COMPLETELY BEFORE OPERATING

THIS PRODUCT MUST BE INSTALLED AND SERVICED BY A PROFESSIONAL SERVICE

TECHNICIAN, QUALIFIED IN POOL HEATER INSTALLATION. Some jurisdictions require that

installers be licensed. Check with your local building authority about contractor licensing requirements.

Improper installation and/or operation could create carbon monoxide gas and flue gases which could cause

serious injury or death. Improper installation and/or operation will void the warranty.

Exhaust from this pool heater contains toxic levels of carbon monoxide, a dangerous, poisonous gas

you cannot see or smell. Symptoms of carbon monoxide exposure or poisoning include dizziness,

headache, nausea, weakness, sleepiness, muscular twitching, vomiting and inability to think clearly.

IF YOU EXPERIENCE ANY OF THE ABOVE SYMPTOMS, IMMEDIATELY TURN OFF THE POOL

HEATER, LEAVE THE VICINITY OF THE POOL OR SPA AND GET INTO FRESH AIR IMMEDIATELY.

THE POOL HEATER MUST BE THOROUGHLY TESTED BY A GAS PROFESSIONAL BEFORE

RESUMING OPERATION.

EXCESSIVE CARBON MONOXIDE EXPOSURE CAN CAUSE BRAIN DAMAGE OR DEATH.

NEVER use this pool heater indoors without specified ventilation system (and properly installed vent pipe).

NEVER use this pool heater in the home or in partly enclosed areas (such as garages), unless

the specified ventilation system is used. If used outdoors, install far from open windows, doors,

vents and other openings.

Pentair strongly recommends that all vents, pipes and exhaust systems be initially and periodically

tested for proper operation. This testing can be accomplished by using a hand-held carbon monoxide

meter and/or by consulting with a gas professional.

Pool heaters must be used in conjunction with carbon monoxide detectors installed near the pool heater.

The carbon monoxide detectors must be periodically inspected for proper operation so as to insure

continued safety. Broken or malfunctioning carbon monoxide detectors must be replaced immediately.

WARNING — FOR YOUR SAFETY

This product must be installed and serviced by a professional service technician, qualified in pool

heater installation. Some jurisdictions require that installers be licensed. Check with your local

building authority about contractor licensing requirements. Improper installation and/or operation

could create carbon monoxide gas and flue gases which could cause serious injury or death. Improper

installation and/or operation will void the warranty.

WARNING —

Rev. D 03-09-11 P/N 472592

This heater is equipped with an unconventional gas control valve that is factory set with a

manifold pressure of -.2 inches wc. Improper installation, adjustment, alteration, service or

maintenance can cause property damage, personal injury or loss of life. Installation or service must

be performed by a qualified installer, service agency or the gas supplier. If this control is replaced, it

must be replaced with an identical control.

Do not attempt to adjust the gas flow by adjusting the regulator setting.

8

SAFETY INFORMATION, (cont’d.)

WARNING —

WARNING —

Risk of fire or explosion from incorrect fuel use or faulty fuel conversion. Do not try to run a

heater set up for natural gas on propane gas or vice versa. Only qualified service technicians should

attempt to convert heater from one fuel to the other. Do not attempt to alter the rated input or type of

gas by changing the orifice. If it is necessary to convert to a different type of gas, consult your Pentair

dealer. Serious malfunction of the burner can occur which may result in loss of life. Any additions,

changes, or conversions required in order for the appliance to satisfactorily meet the application

needs must be made by a Pentair dealer or other qualified agency using factory specified and

approved parts. The heater is available for use with natural gas or LP (propane) gas only. It is not

designed to operate with any other fuels. Refer to the nameplate for the type of gas the heater is

equipped to use.

• Use heater only with the fuel for which it is designed.

• If a fuel conversion is necessary, refer this work to a qualified service technician or gas supplier

before putting the heater into operation.

Risk of fire or explosion from flammable vapors. Do not store gasoline, cleaning fluids, varnishes,

paints, or other volatile flammable liquids near heater or in the same room with heater.

Section 2. Warning and Safety Instructions

WARNING —

WARNING —

WARNING —

CAUTION —

Risk of explosion if unit is installed near propane gas storage. Propane (LP) gas is heavier

than air. Consult local codes and fire protection authorities about specific installation requirements

and restrictions. Locate the heater away from propane gas storage and filling equipment as specified

by the Standard for the Storage and Handling of Liquefied Petroleum Gases, CAN/CSA B149.2

(latest edition) or ANSI/NFPA 58 (latest edition).

Risk of fire, carbon monoxide poisoning, or asphyxiation if exhaust venting system leaks.

Only qualified service technicians should attempt to service the heater, as leakage of exhaust

products or flammable gas may result from incorrect servicing.

Risk of asphyxiation if exhaust is not correctly vented. Follow venting instructions exactly

when installing heater. Do not use a drafthood with this heater, as the exhaust is under

pressure from the burner blower and a draft hood will allow exhaust fumes to blow into the room

housing the heater. The heater is supplied with an integral venting system for outdoor installation.

A vent conversion kit (See Page 24 for Part Numbers for Conversion Kits) is available for installations

in enclosures (Canada) or indoors (U.S.). Use the specified venting, and only the specified venting,

when heater is installed in an enclosure or indoors. In Canada, this pool heater can only be installed

outdoors or in an enclosure that is not normally occupied and has no openings directly into occupied

areas. See Page 20 for enclosure venting requirements.

Label all wires prior to disconnection when servicing controls. Wiring errors can cause

improper and dangerous operation. Wiring errors can also destroy the control board.

• Connect heater to 120 or 240 Volt, 60 Hz., Single Phase power only.

• Verify proper operation after servicing.

• Do not allow children to play on or around heater or associated equipment.

• Never allow children to use the pool or spa without adult supervision.

• Read and follow other safety information contained in this manual prior to operating this pool

heater.

P/N 472592 Rev. D 03-09-11

Section 2. Warning and Safety Instructions

CONSUMER INFORMATION AND SAFETY

WARNING

The U.S. Consumer Product Safety Commission warns that carbon monoxide is an "invisible killer". Carbon monoxide

is a colorless and odorless gas.

1. Carbon monoxide is produced by burning fuel, including natural gas and propane.

2. Proper installation, operation and maintenance of fuel-burning appliances in the home is the most important

factor in reducing carbon monoxide poisoning.

3. Be sure that fuel burning appliances such as heaters are installed by professionals according to manufacturer's

instructions and codes.

4. Always follow the manufacturer's directions for safe operation.

5. Have the heating system (including vents) inspected and serviced annually by a trained service technician.

6. Examine vents regularly for improper connections, visible cracks, rust or stains.

7. Install battery-operated carbon monoxide alarms. The alarms should be certified to the requirements of the

most recent UL, IAS, CSA and IAPMO standard for carbon monoxide alarms. Test carbon monoxide alarms

regularly and replace dead batteries.

9

GENERAL SPECIFICATIONS

NOTICE:

• Combustion air contaminated by corrosive chemical fumes can damage the heater and will void the warranty.

• The Combination Gas Control Valve on this heater differs from most appliance gas controls. If it must be replaced,

for safety reasons replace it only with an identical gas control.

• The access door panels must be in place to provide proper ventilation. Do not operate the heater for more than five (5)

minutes with the access door panels removed.

• This heater is design certified by CSA International as complying with the Standard for Gas Fired Pool Heaters,

ANSI Z21.56/CSA 4.7, and is intended for use in heating fresh water swimming pools or spas.

• The heater is designed for the heating of chlorine, bromine or salt system swimming pools and spas. It should NOT be

used as a space heating boiler, or general purpose water heater.

• The heater is design certified by CSA International for installation on combustible flooring. Specified minimum

clearances must be maintained to combustible surfaces (see “Heater Clearances”,

• The heater should be located in an area where leakage of the heater or connections will not result in damage to the

area adjacent to the heater or to the structure. When such locations cannot be avoided, it is recommended that a

suitable drain pan, adequately drained, be installed under the heater. The pan must not restrict air flow.

• The heater may not be installed within 5 ft. (1.5M ) of the inside surface of a pool or spa unless it is separated by a solid

fence, wall or other permanent barrier.

page 19).

Rev. D 03-09-11 P/N 472592

10

Section 3: Installation Instructions

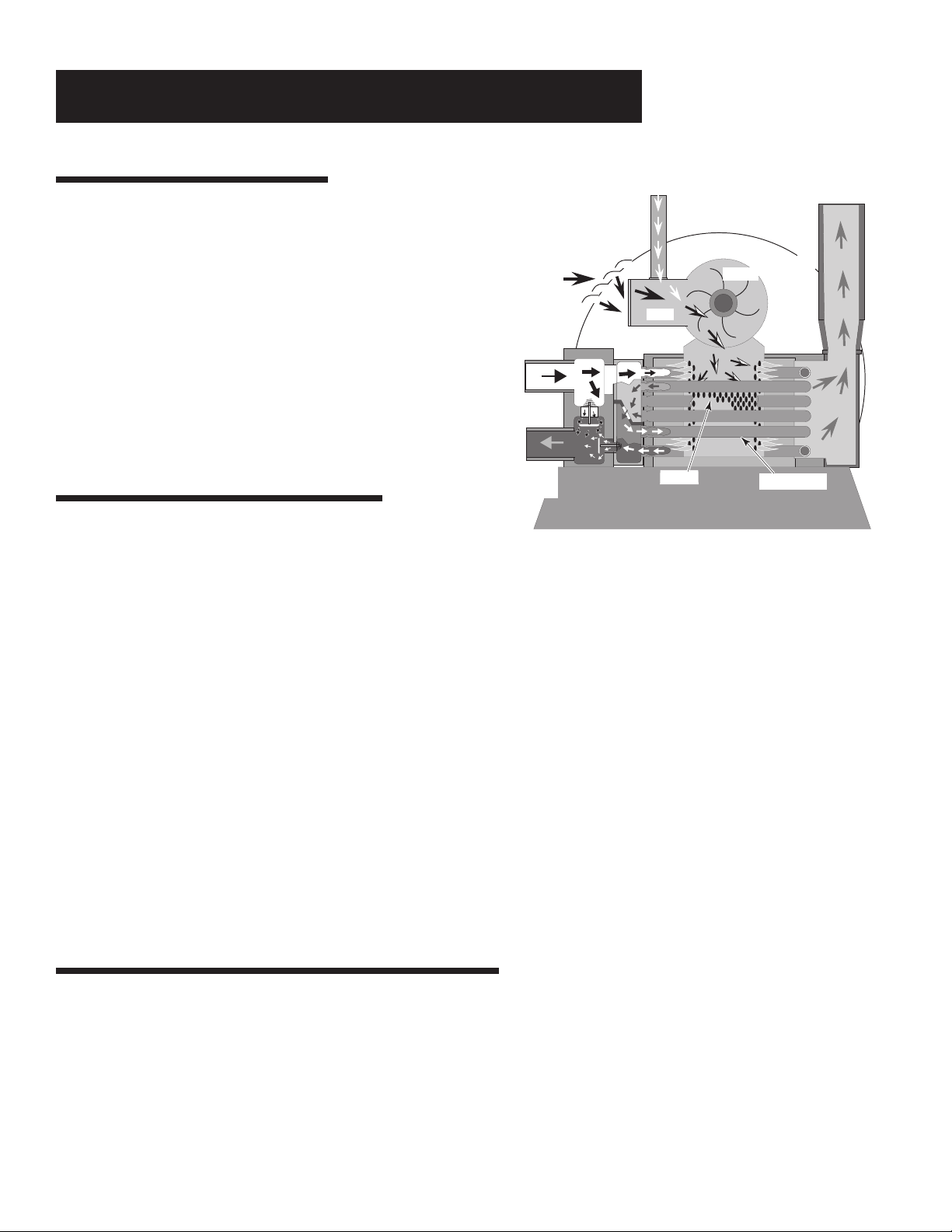

HEATER DESCRIPTION

Section 3. Installation Instructions

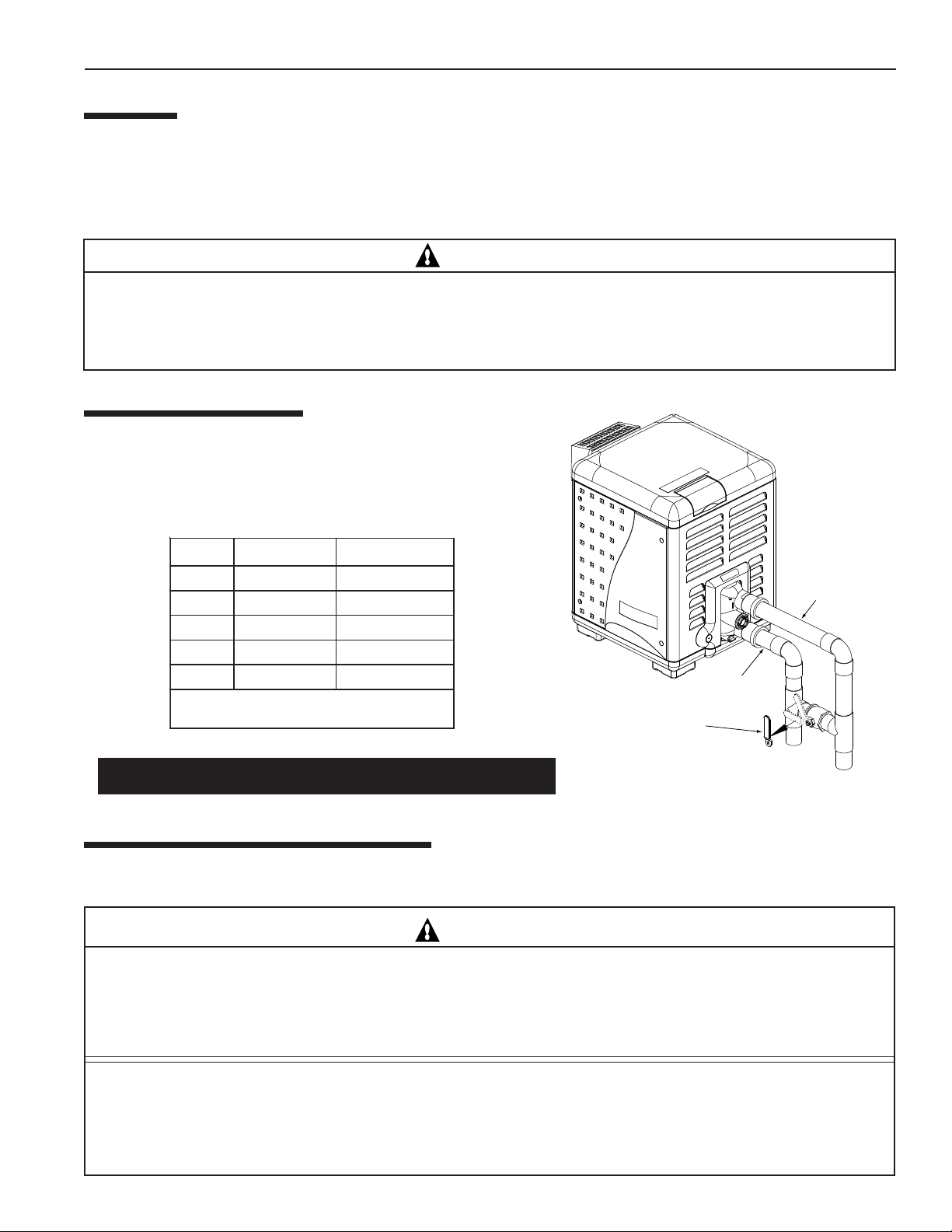

Figure 1 is a diagram of the heater showing how it operates. Precisely

Gas

matched orifice plates meter the air and gas into the mixer. The

blower draws the air and gas through the mixer and forces it into

the burner’s flame holder. A sealed heat exchanger surrounds the

flame holder, discharging exhaust gases out the flue.

Two inch PVC water piping connects directly to the manifold/header

on the heat exchanger using 2" PVC slip unions provided with the

heater. The outer manifold remains cool; no heat sinks are required.

Inlet

(Cold

Water)

Air

Mixer

Blower

Exhaust

A thermal regulator and an internal bypass regulate the water flow

through the heat exchanger to maintain the correct outlet

temperature. The heater operator control panel board assembly is

located on top of the heater.

SEQUENCE OF OPERATION

Outlet

(Mixed

Water)

Burner

Heating Coils

An electronic temperature sensing thermistor in the manifold

adapter inlet controls the heater operation. When the inlet water

Figure 1.

temperature drops below the temperature set on the operating

control, the burner controller supplies power to the combustion

air blower through a series of safety interlocks. The interlocks consist of:

• the pressure switch (PS), which senses that the pump is running,

• the high limit switch (HLS), which opens if the heat exchanger outlet temperature goes above 135° F (57° C), and

• the air flow switch (AFS), which senses the pressure drop across the air metering orifice,

• the automatic gas shut-off (AGS) switch, which opens if the heat exchanger outlet temperature goes above 140° F

(60° C).

• the stack flue sensor (SFS), which shuts down the heater if the flue gas temperature reaches 480° F (249° C).

The air flow switch (AFS) senses the pressure drop across the air metering orifice. As soon as there is sufficient air flow,

the AFS closes, closing the circuit to the hot surface igniter (HSI), which ignites the fuel mixture. On a call for heat, the

blower and HSI are energized. In about 20 seconds, the gas valve opens and ignition occurs. The HSI then switches to a

sensing mode and monitors the flame.

The heater is equipped with a digital operating control that enables the user to pre-set the desired pool and spa water

temperatures. The control enables the user to select between pool and spa heating, and features a digital display that

indicates the water temperature.

PUTTING THE HEATER INTO SERVICE

If the heater is installed below the level of the pool, or more than two feet above pool level, the pressure switch setting

should be adjusted. See WATER PRESSURE SWITCH, in the SAFETY CONTROLS Section.

Before putting the heater into service for the first time, follow the instructions under “BEFORE START-UP” (

the front of this manual. Check for proper operation of the heater by following the steps under “OPERATION

INSTRUCTIONS.”

Damage to equipment caused by improper installation or repair will void the warranty.

P/N 472592 Rev. D 03-09-11

page 33) in

Section 3. Installation Instructions

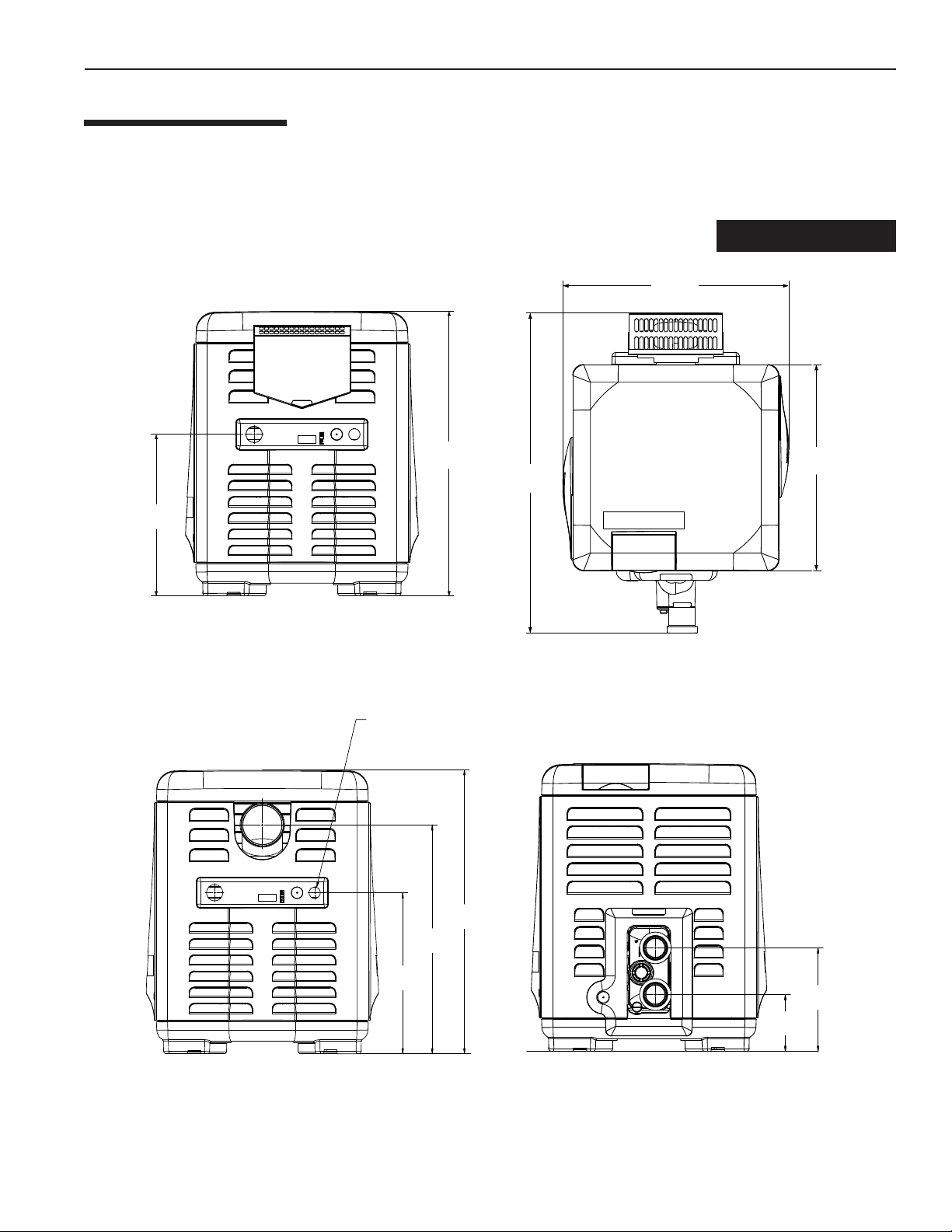

SPECIFICATIONS

These installation instructions are designed for use by qualified personnel only, trained especially for installation of this

type of heating equipment and related components. Some states require installation and repair by licensed personnel. If

this applies in your state, be sure your contractor bears the appropriate license. See Figure 2 for Outdoor and Indoor

Installations.

DIMENSIONS IN INCHES

23.02"

(58.5 cm)

11

16"

(40.6 cm)

28.15"

(71.5 cm)

ELECTRICAL

CONDUIT PORT

32.61"

(82.8 cm)

21.0"

(53.3 cm)

TOPFRONT

28.2"

(71.6 cm)

22.7"

(57.7 cm)

16.0"

(40.6 cm)

5.6"

(14.2 cm)

10.13"

(25.7 cm)

EXHAUST SIDE PLUMBING SIDE

Figure 2.

Rev. D 03-09-11 P/N 472592

12

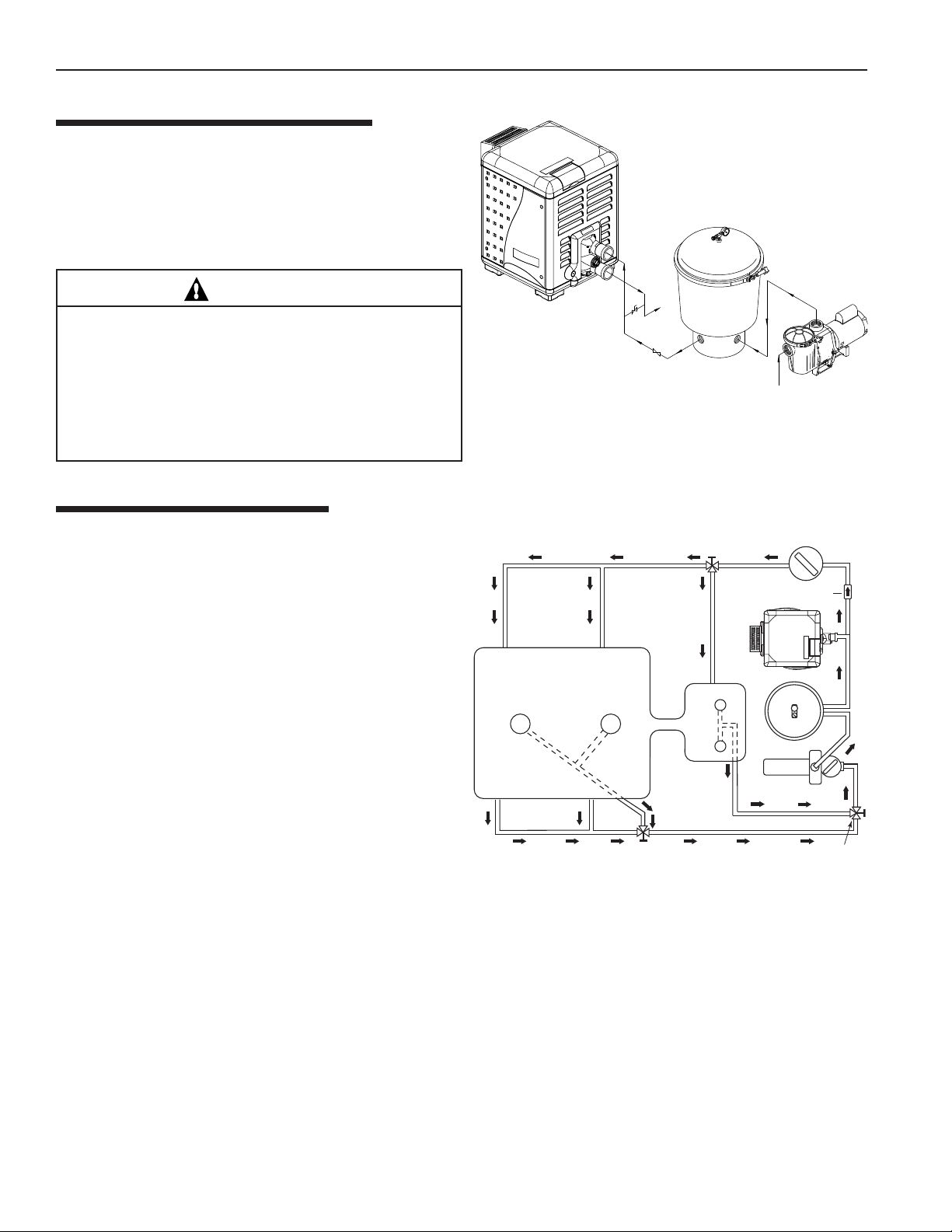

PLUMBING CONNECTIONS

The MasterTemp heater has the unique capability of direct

schedule 40 PVC plumbing connections. A set of bulkhead

fittings is included with the MasterTemp to insure conformity

with Pentair’s recommended PVC plumbing procedure. Other

plumbing connections can be used. See Figure 3 for plumbing

connections.

Section 3. Installation Instructions

CAUTION

Before operating the heater on a new installation, turn

on the circulation pump and bleed all the air from the

POOL

HEATER

MANUAL

BY-PASS

TO

POOL

GATE

VALVE

FILTER

PUMP

filter using the air relief valve on top of the filter. Water

should flow freely through the heater. Do not operate

the heater unless water in the pool/spa is at the proper

Figure 3.

FROM

POOL

level. If a manual by-pass is installed, temporarily close it

to insure that all air is purged from the heater.

WATER CONNECTIONS

The heater requires proper water flow and pressure for its

operation. See Figure 5 for the recommended installation.

The filter pump discharges to the filter, the filter discharges

to the heater, and the heater discharges directly to the pool

or spa.

A manual bypass valve should be installed across the heater

when the pump flow exceeds 120 GPM (454 LPM). See

“WATER FLOW RATE” on page 7- Table 1 for setting of

the manual by-pass valve.

Make sure that the outlet plumbing from the heater contains

Main

Drain

Pool

no shut-off valves or other flow restrictions that could prevent

flow through the heater (except for pool installations as noted

below, or winterizing valves where needed). To switch flow

between the pool and spa, use a diverter valve. Do not use

any valve that can shut off the flow.

Install the chemical feeder downstream of the heater. Install

a chemical resistant one-way check valve between the heater

From Pool

3-Way

Valve

and the chemical feeder to prevent back-siphoning through

the heater when the pump is off.

NOTICE: If the heater is plumbed in backwards, it will cycle continuously. Make sure piping from filter is not reversed

when installing heater.

Connect the heater directly to 2" PVC pipe, using the integral unions provided. Heat sinks are not required. The low

thermal mass of the heater will prevent overheating of the piping connected to the pump even if the heater shuts down

unexpectedly.

Occasionally a two-speed pump will not develop enough pressure on the low speed to operate the heater. In this case, run

the pump at high speed only to operate the heater. If this does not solve the problem, do not try to run the heater. Instead,

correct the installation.

Do not operate the heater while an automatic pool cleaner is also operating. If the circulation pump suction is plugged (for

example by leaves), there may not be adequate flow to the heater. Do not rely on the pressure switch in this case.

3-Way

Valve

Heater

Spa

Figure 5.

Chlorinator

Check Valve

Filter

Pump

3-Way

Valve

P/N 472592 Rev. D 03-09-11

Section 3. Installation Instructions

VALVES

When any equipment is located below the surface of the pool or spa, valves should be placed in the circulation piping

system to isolate the equipment from the pool or spa. Check valves are recommended to prevent back-siphoning. Backsiphoning is most likely to occur when the pump stops, creating a pressure-suction differential. Do NOT sanitize the pool

by putting chlorine tablets or sticks into the skimmer(s). When the pump is off, this will cause a high concentration of

chlorine to enter the heater, which could cause corrosion damage to the heat exchanger.

CAUTION

Exercise care when installing chemical feeders so as to not allow back siphoning of chemical into the heater, filters

or pump. When chemical feeders are installed in the circulation of the piping system, make sure the feeder outlet line

is down stream of the heater, and is equipped with a positive seal noncorrosive “Check Valve”, (P/N R172288),

between the feeder and heater.

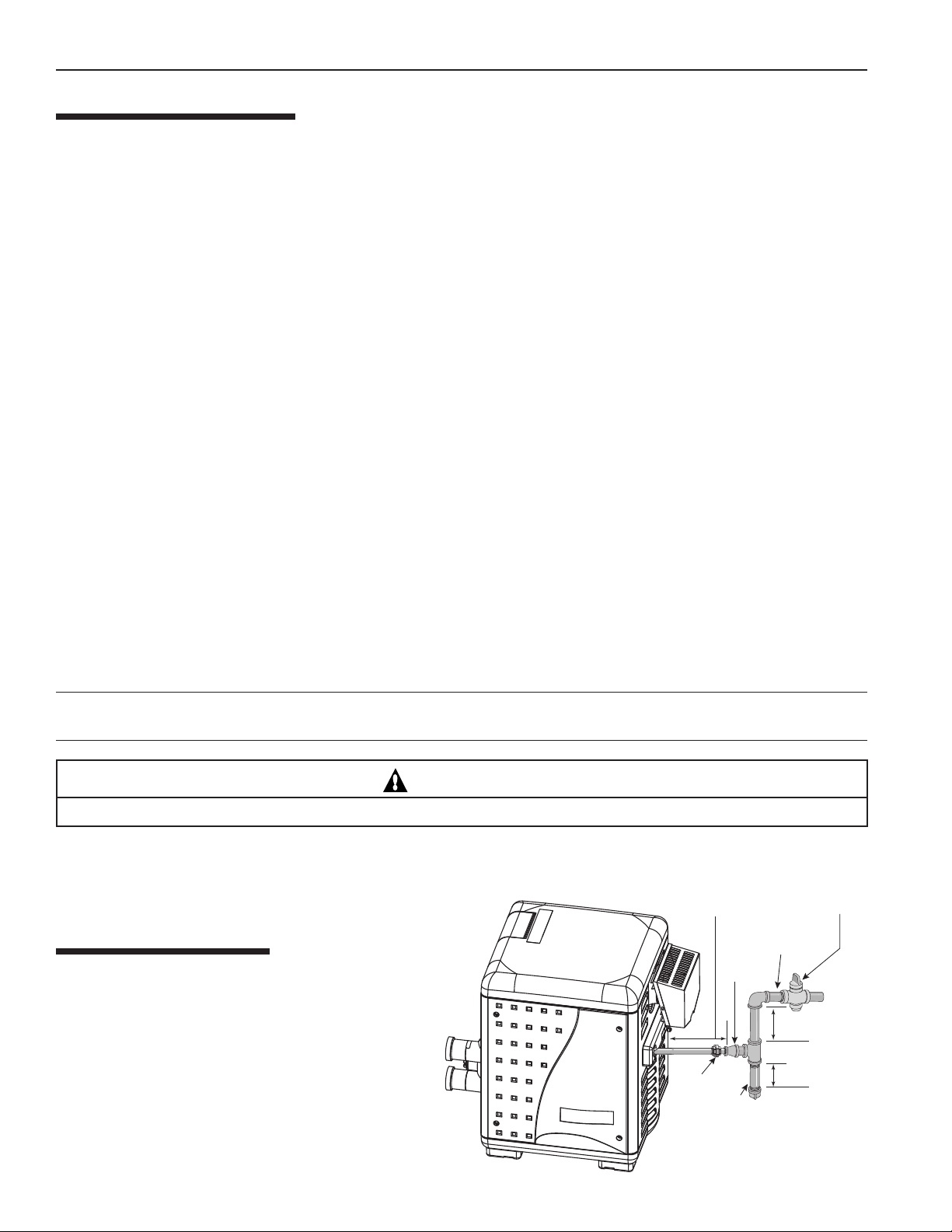

MANUAL BY-PASS

13

Where the water flow rate exceeds the maximum 120 GPM, a manual

Figure 4.

bypass should be installed and adjusted. After installing the valve,

adjust the valve to bring the flow rate within the acceptable range.

Then remove the valve handle or lock it in place to avoid tampering.

See Figure 4.

ledoM )MPL()MPG(.niM *)MPL()MPG(.xaM

571 )67(02 )454(021

002 )67(02 )454(021

052 )59(52 )454(021

003 )411(03 )454(021

004 )251(04 )454(021

wolfdednemmocermumixamehtdeecxetonoD*

.gnipipgnitcennocehtrofetar

Table 1.

See page 46 for Pressure Relief Valve Installations.

Warm water out

1. Set Manual By-Pass Valve.

2. Remove Handle.

Cool water

Outlet to pool

Inlet to heater

BELOW POOL INSTALLATION

If the heater is below water level, the pressure switch must be adjusted. This adjustment must be done by a qualified

service technician. See following CAUTION before installation.

CAUTION

BELOW OR ABOVE POOL INSTALLATION

The water pressure switch is set in the factory at 3.00 PSI (± 0.75 PSI). This setting is for a heater installed at pool level.

If the heater is to be installed more than 1’ above or below, the water pressure switch must be adjusted by a qualified

service technician. See page 35, Figure 29.

FLOW SWITCH

If the heater is installed more than 5’ above the pool or more than 4’ below the pool level, you will be beyond the limits

of the pressure switch and a flow switch must be installed. Locate and install the flow switch externally on the outlet

piping from the heater, as close as possible to the heater. Connect the flow switch wires in place of the water

pressure switch wires.

Rev. D 03-09-11 P/N 472592

14

Section 3. Installation Instructions

GAS CONNECTIONS

GAS LINE INSTALLATIONS

Before installing the gas line, be sure to check which gas the heater has been designed to burn. This is important because

different types of gas require different gas pipe sizes. The rating plate on the heater will indicate which gas the heater is

designed to burn. The tables, shown on page 14, show which size pipe is required for the distance from the gas meter to

the heater. The table is for natural gas at a specific gravity of .65 and propane at a specific gravity of 1.55.

When sizing gas lines, calculate three (3) additional feet of straight pipe for every elbow used. When installing the gas line,

avoid getting dirt, grease or other foreign material in the pipe as this may cause damage to the gas valve, which may result

in heater failure.

The gas meter should be checked to make sure that it will supply enough gas to the heater and any other appliances

that may be used on the same meter. The gas line from the meter will usually be of a larger size than the gas valve

supplied with the heater. Therefore a reduction of the connecting gas pipe will be necessary. Make this reduction

as close to the heater as possible.

The heater requires a gas supply of not less than 4" (10.2 cm) wc and not more than 14" (35.6 cm) wc. Gas supply

pressures outside of this range may result in improper burner operation. A minimum flowing or dynamic inlet pressure

(while the heater is running) of 4" (10.2cm) wc is required to maintain input rating with no more than a 2” pressure drop

between static and dynamic. The gas supply must be installed in accordance with the National Fuel Gas Code,

ANSIZ223.1, or standard CSA B149.1, Natural Gas and Propane Installation Codes, as applicable and all applicable

local codes. Install a manual shut-off valve and a sediment trap and union located outside the heater panels, see Figure 6.

Do not use a restrictive gas cock. The following minimum gas pipe sizes are recommended for natural gas supply piping,

see Table 2 on page 14. For low pressure LP gas, pipe size may be reduced by 1/4", with a minimum pipe size of 1/2".

Check for compliance with local codes.

The heater and any other gas appliances must be disconnected from the gas supply piping system during any pressure

testing on that system, (greater than ½ PSI). The heater and its gas connection must be leak tested before placing the

heater in operation. Do not use flame to test the gas line. Use soapy water or another nonflammable method.

NOTE

A manual main shut-off valve must be installed externally to the heater.

WARNING

DO NOT INSTALL THE GAS LINE UNION INSIDE THE HEATER CABINET. THIS WILL VOID YOUR WARRANTY.

SEDIMENT TRAPS

Install a sediment trap and union located outside the

heater panels in accordance with National code

requirements. Do not use a restrictive gas cock. The

sediment trap shall be either a tee fitting with a capped

nipple in the bottom outlet which can be removed for

cleaning, as illustrated in Figure 6, or an other device

recognized as an effective sediment trap. All gas piping

should be tested after installation in accordance with

local codes.

18–24" of 3/4"

Gas line from

Valve

Union

Sediment

Trap

1" Dia. or larger

(See "Recommended

Pipe Sizes" Chart)

Bell

Reducer

Figure 6.

At least 9"

At least 3"

Manual

Shut-off

Valve

P/N 472592 Rev. D 03-09-11

Section 3. Installation

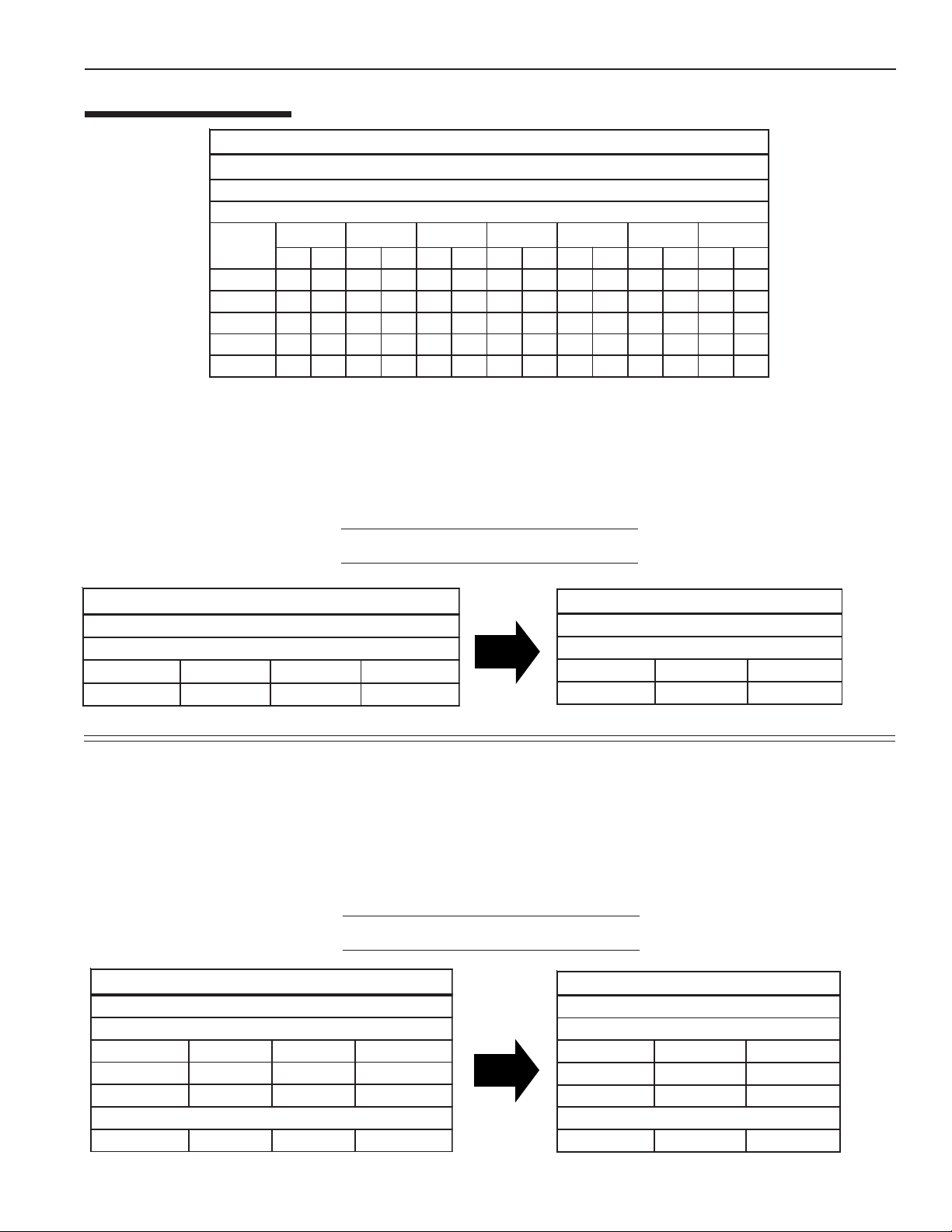

GAS PIPE SIZING

LEDOM

571 - ’02 ’03 ’08 ’521 ’052 ’054 ’006 - - - - - -

002 - ’02 ’03 ’08 ’521 ’052 ’054 ’006 - - - - - -

052 - ’01 ’02 ’05 ’07 ’051 ’052 ’005 ’006 - - - - -

003 - - ’01 ’03 ’

004 - - - ’01 ’02 ’06 ’001 ’051 ’002 ’054 ’004 - - -

Table 2.

SNOITCENNOCENILSAGROFGNIZISEPIP

HTGNELEPIPTNELAVIUQEMUMIXAM

).tF(

tooFcibuCrep.U.T.B0001tasaGlarutaN

tooFcibuCrep.U.T.B0052tasaGenaporP

”2/1 ”4/3 ”1 ”4/1-1 ”2/1-1 ”2 ”2/1-2

TAN ORP TAN ORP TAN ORP TAN ORP TAN ORP TAN ORP TAN ORP

05 ’001 ’002 ’053 ’004 ’006 - - - -

15

“RESIDENTIAL”

PROPANE

GAS 2 STAGE REGULATION

In many Propane gas line installations, the gas supplier and/or installer will utilize a two stage regulation process

where by at the supply tank they will install the first stage gas regulator, which would be at a higher pressure, usually

10 psi. This higher pressure allows for a much longer distance and in a much smaller pipe size. Then within a short

distance of the pool heater, usually around 24 inches, they will install a second regulator, which is the second stage,

and this would be set at the required inlet pressure of the heater.

See “Gas Pressure Requirement Charts”

gniziSepiPsaG"erusserPwoL"owTegatS

HTGNELEPIPTNELAVIUQEMUMIXAM

Table 4.

ledoM .tF05ot0 .tF001ot05 .tF051ot001

004hguorht571 .ni2/1 .ni2/1 .ni2/1

“RESIDENTIAL”

gniziSepiPsaG"erusserPhgiH"enOegatS

.TF.UCreP.U.T.B0052@ISP01

HTGNELEPIPTNELAVIUQEMUMIXAM

Table 3.

NATURAL

.C.W.ni41tates2egatS

ledoM .tF01ot0 .tF02ot01

004hguorht571 .ni4/3 .ni4/3

GAS 2 STAGE REGULATION

In many Natural gas line installations, the gas supplier and/or installer may utilize a two stage regulation process

where by at the streets main gas supply they will install the first stage gas regulator, which would be at a higher

pressure. This higher pressure is usually set at 2 psi or 5 psi and can be for long distances and in a much smaller pipe

size. Then within a short distance of the pool heater, generally around 24 inches, they will install a second regulator,

which is the second stage. This second stage regulator would be set at the minimum operating pressure for the heater.

For “Natural Gas Pentair Pool Heaters” the minimum is 7 inches W.C.

See “Gas Pressure Requirement Charts”

gniziSepiPsaG"erusserPhgiH"enOegatS

.TF.UCreP.U.T.B0001@ISP2

HTGNELEPIPTNELAVIUQEMUMIXAM

ledoM .tF05ot0 .tF001ot05 .tF051ot001

003hguorht571 .ni2/1 .ni2/1 .ni2/1

004 .ni4/3 .ni4/3 .ni4/3

.TF.UCreP.U.T.B0001@ISP5

004hguorht571 .ni2/1 .ni2/1 .ni2/1

Table 5.

Rev. D 03-09-11 P/N 472592

ledoM .tF01ot0 .tF02ot01

003hguorht571 .ni4/3 .ni4/3

004 .ni4/3 .ni1

004hguorht571 .ni4/3 .ni1

.C.W.ni7tates2egatS

.C.W.ni7tates2egatS

gniziSepiPsaG"erusserPwoL"owTegatS

HTGNELEPIPTNELAVIUQEMUMIXAM

Table 6.

16

Section 3. Installation Instructions

TESTING GAS PRESSURE

Before operating the heater, the heater and its gas connections must be leak tested. Do NOT use an open flame to test

for leaks. Test all gas connections for leaks with soapy water or another non-flammable method (see page 14).

The heater and its individual shut-off valve must be disconnected from the gas supply piping system during any pressure

testing of that system at test pressures in excess of 1/2 psig (3.5 kPa).

The heater must be isolated from the gas supply system by closing its individual manual shut-off valve during any pressure

testing of the gas supply at test pressures equal to or less than 1/2 psig (3.5 kPa).

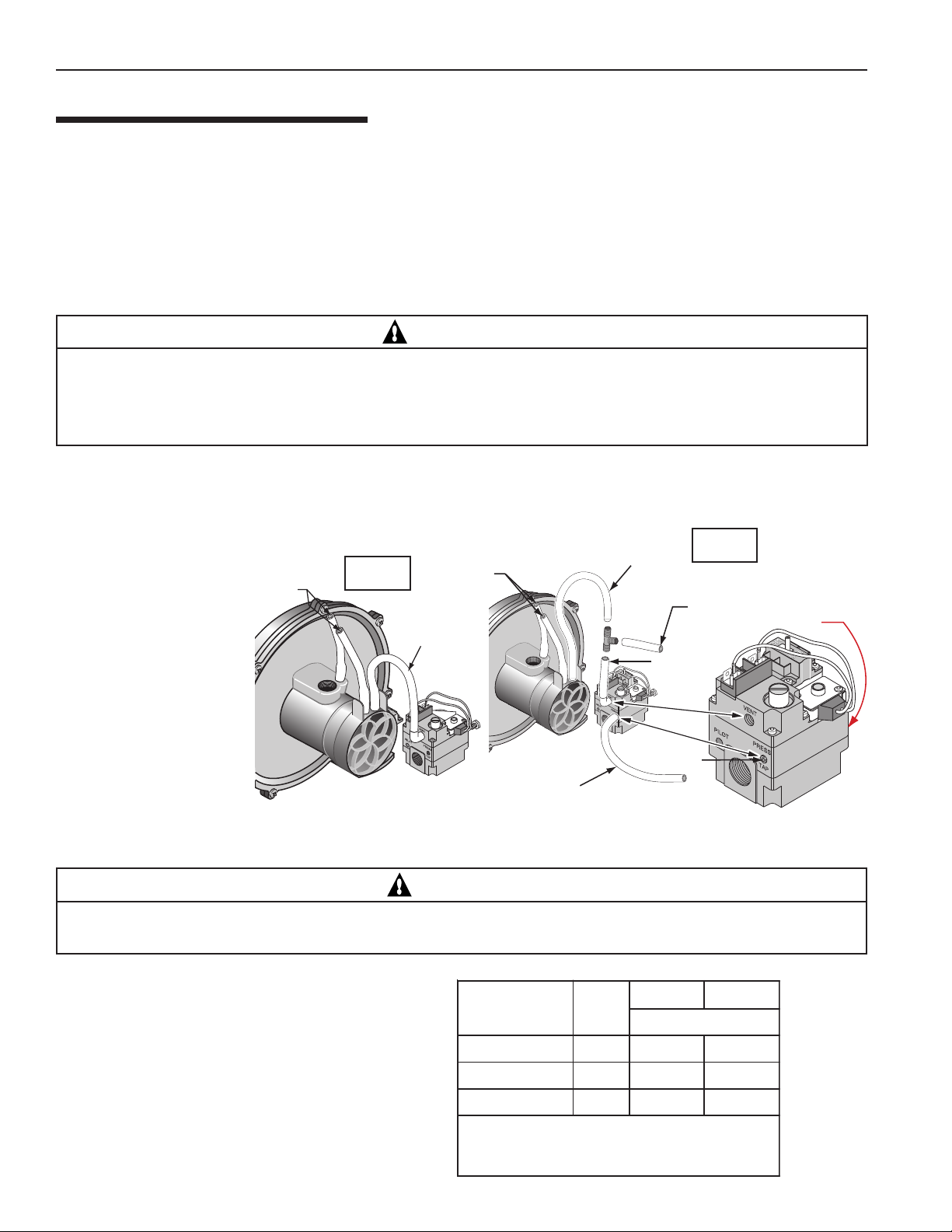

CHECKING THE GAS PRESSURE THROUGH THE COMBINATION GAS CONTROL VALVE

WARNING

Risk of fire and explosion. Improper installation, incorrect adjustment, alteration, service, or maintenance of the Combination

Gas Control Valve can lead to fire or explosion, causing loss of life, personal injury, and/or property damage. If it is necessary

to adjust the gas valve, this must be done by only by a qualified service agency. These instructions are for the use of

qualified service technicians only!

This appliance is equipped with an unconventional gas control valve that is factory set with a manifold pressure of –.2"

(–0.5cm) wc. Installation or service must be performed by a qualified installer, service agency, or the gas supplier. If this

control valve is replaced, it must be replaced with an identical control.

The combination ga s

valve i ncorporates d ual

shut- off valves a nd a

negative-pressure regulator.

For proper operation, the

regulated pressure at the

To Air Flow

Switch

Connection

for Service

To Air Flow

Switch

To Gas

Valve Vent

To Gas

Valve Vent

outlet manifold of the valve

must be –0.2" (–0.5cm) wc

below the reference pressure

at the blower mixer inlet,

and the gas valve ‘VENT’

tap must be connected to the

end cap air orifice as shown

in

Figure 7.

To Low Side of

Differential Pressure Gauge

Pressure Tap

Do not attempt to adjust the gas input by adjusting the regulator setting. The correct gas regulator setting is

required to maintain proper combustion and must NOT be altered.

Vent

Connection

for Test

To High Side

of Differential

Pressure Gauge

Figure 7.

Pressure Tap

Inlet

CAUTION

The use of Flexible Connectors (FLEX) is NOT recommended unless they are properly sized according to the

supplier recommendations for the heater rating.

GAS PRESSURE REQUIREMENTS

erusserPsaG ledoM

telnImumixaM

telnImuminiM

dlofinaM

:ETON

P/N 472592 Rev. D 03-09-11

TM 41 41

TM 4 4

TM 1.0±2.0- 1.0±2.0-

.smelborpecnamrofrepnitluser

larutaN enaporP

.C.WsehcnI

.gnitareposiretaehelihwnekatebtsumsgnidaerllA

lliwffosiretaehelihwedamsgnidaerrostnemtsujdaynA

Table 7.

Section 3. Installation Instructions

17

OUTDOOR INSTALLATION

(U.S. and Canada)

For heaters located outdoors, using the built-in stackless venting system.

WARNING

Risk of explosion if a unit burning propane gas is installed in a pit or other low spot. Propane is heavier than air. Do not

install the heater using propane in pits or other locations where gas might collect. Consult your local building code officials to

determine installation requirements and specific installation restrictions of the heater relative to propane storage tanks and

filling equipment. Installation must meet the requirements for the Standard for the Storage and Handling of Liquid Petroleum

Gases, ANSI/NFPA 58 (latest edition) in the U.S., or CAN/CSA B149.2 (latest edition) in Canada. Consult local codes and fire

protection authorities about specific installation restrictions.

Locate the heater on a level surface in an open area that is protected from drainage or run-off.

Install the heater in an area where leaves or other debris will not collect on or around the heater.

To avoid damage to the electronic components in the heater, take care to prevent prolonged exposure

to driving sources of water (such as lawn sprinklers, heavy roof runoff, hoses, etc.). Avoid operation

in persistent, extreme, moist or salty environments.

In extreme weather, shut down the heater and disconnect the power to it until the weather has

moderated. In areas subject to hurricanes or very high winds, purchase the Bolt Down Bracket Kit,

P/N 460738.

HEATER CLEARANCES – OUTDOOR

For Heater mounting

bolts and clamps,

purchase separately

Bolt Down Bracket Kit,

Part No.

460738.

Lead

Anchor

IMPORTANT!

• In an outdoor installation it is important to ensure water is diverted

from overhanging eves with a proper gutter/drainage system. The heater

must be set on a level foundation for proper drainage.

• This unit shall not be operated outdoors at temperatures below -20o F.

If the heater is located under a roof or deck overhang, there must be at least

three (3) feet (1m) of clearance between the bottom of the overhang and the

top of the heater exhaust vent, see Figure 8. If the heater is under a roof or deck

overhang, the space around the heater must be open on three sides.

For minimum exhaust vent clearances for building openings, see Figure 9,

page 18.

In Canada, the heater must be installed with the top of the vent at least 10 feet

(3m) below, or to either side of, any opening into a building.

Orient the heater for convenient access to the water connections and the gas

and electrical connections.

Note: Check local building codes for installing the heater from any property

line set back requirements (see page 18 for installtion illustration).

CAUTION

3 ft. (1 M) or more

Figure 8.

If installing the heater next to or near an air conditioning unit or a heat

pump, allow a minimum of 36 in. (91.4 cm) between the air conditioning

unit and the heater.

Rev. D 03-09-11 P/N 472592

Loading...

Loading...