Sta-Rite 14971-TM-22-L Installation Manual

CRISTAL-FLO

R

E

C

I

R

C

U

L

A

T

E

B

A

C

K

W

A

S

H

E

W

A

S

T

E

F

I

L

T

E

R

Aquatools

.

WATERFORD, WI.

53185

USA

729 0294

TM

HIGH RATE SAND FILTERS

O W N E R’ S M A N U A L

INSTALLATION, OPERATION & PARTS

MODELS

T-150BP-1 T-170BP-1 T-200BP-1 T-240BP-1 T-300BP-2

This manual should be furnished to

the end user of this filter; its use will

reduce service calls and chance of

injury and will lengthen filter life.

Pentair Water Pool and Spa, Inc.

1620 Hawkins Ave., Sanford, NC 27330 • (800) 831-7133 • (919) 566-8000

10951 West Los Angeles Ave., Moorpark, CA 93021 • (800) 831-7133 • (805) 553-5000

Visit us on the Internet @ www.pentairpool.com or www.staritepool.com

© 2009 Pentair Water Pool and Spa, Inc. S242 (Rev. D 4/16/09)

HIGH RATE SAND FILTERS

o avoid unneeded service calls, prevent possible injuries, and get the most

T

out of your filter, READ THIS MANUAL CAREFULLY!

The Sta-Rite Top Mounted Series High Rate Sand Filter:

• Is designed to filter water for swimming pools.

• Is an excellent performer; durable, reliable.

Table of Contents

Safety Instructions .....................................................................................2-3

Dimensions/Specifications ............................................................................4

General Information .....................................................................................5

Installation ................................................................................................5-7

Filter Mount/Piping....................................................................................5

Filter Set-up...............................................................................................6

Loading Sand Media ..................................................................................6

Valve Installation.......................................................................................6

Startup/Operation ......................................................................................7

Maintenance ................................................................................................8

Water Maintenance ...................................................................................8

Storage/Winterizing.................................................................................8-10

Mult-Port Valve Service .............................................................................9

Drain Fitting Installation/Removal ............................................................10

Troubleshooting Guide................................................................................11

Repair Parts List .....................................................................................12-13

Pressure Drop Curve...................................................................................14

READ AND FOLLOW SAFETY

INSTRUCTIONS!

This is the safety-alert symbol. When you see this symbol on your valve

or in this manual, look for one of the following signal words and be alert to the

potential for personal injury

warns about hazards that

death or major property damage if ignored.

warns about hazards that

death or major property damage if ignored.

warns about hazards that

jury or property damage if ignored.

The label NO

related to hazards.

Carefully read and follow all safety instructions in this manual and on filter.

Keep safety labels in good condition.

Replace missing or damaged safety labels.

TICE

indicates special instructions which are important but not

2

.

will cause serious personal injury,

can cause serious personal injury,

will or can cause minor personal in-

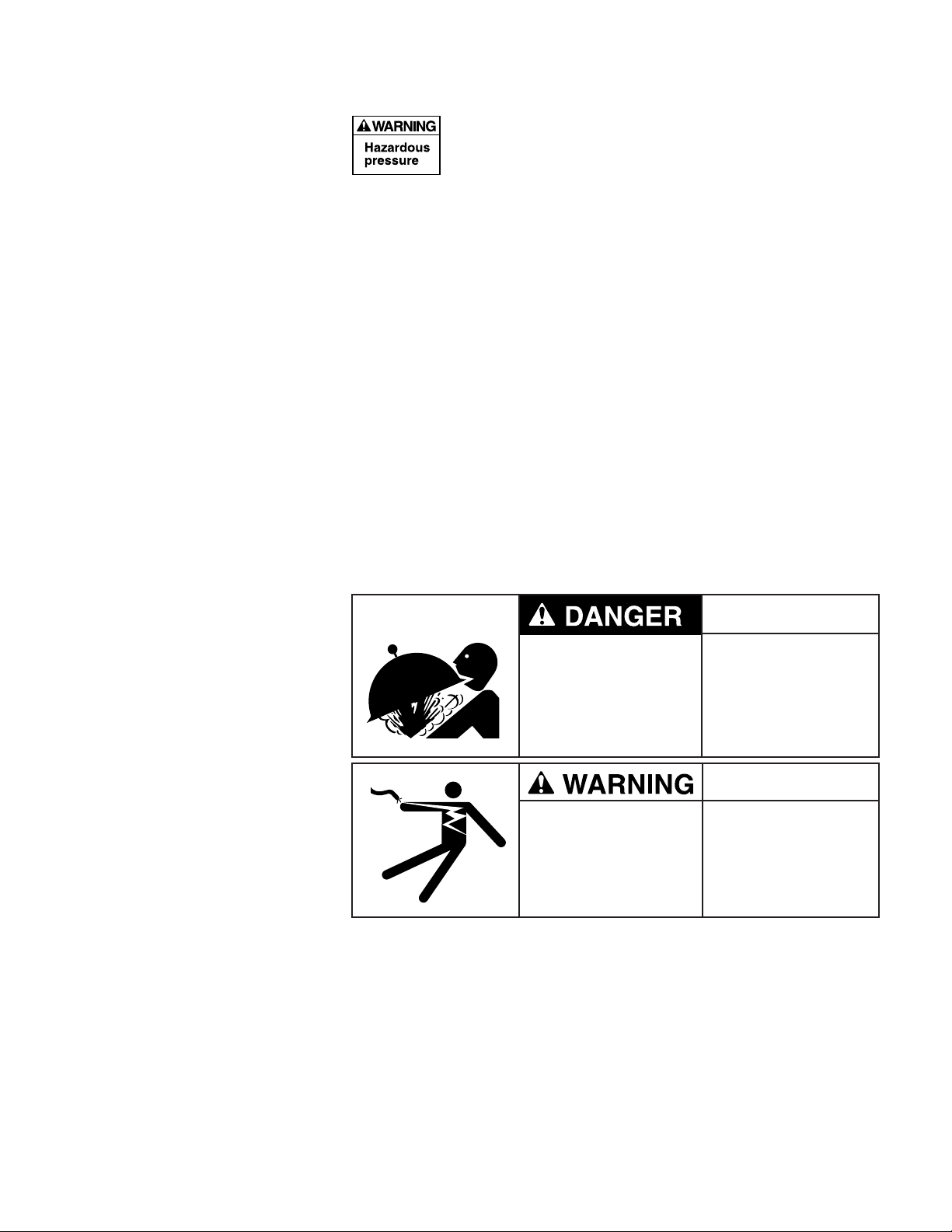

Incorrectly installed or tested equipment may fail, causing severe injury or property damage. Read and follow instructions

n owner's manual when installing and operating equipment.

i

Have a trained pool professional perform all pressure tests.

1. Do not connect system to a high pressure or city water system.

2. Use equipment only in a swimming pool installation.

3. Trapped air in system can cause explosion. BE SURE all air is out of system

before operating or testing equipment.

Before pressure testing, make the following safety checks:

• Check all clamps, bolts, lids, and system accessories before testing.

• BE SURE all air is out of system before testing.

• Tighten Sta-Rite trap lids to 30 ft. lbs. (4.1 kg-cm) torque for testing.

• Water pressure for test must be less than 25 PSI (172 kPa).

• Water temperature for test must be less than 95˚ F. (35˚ C).

• Limit test to 24 hours. After test, visually check system to be sure it is ready

for operation. Remove trap lid and retighten hand tight only.

NOTICE: These parameters apply to Sta-Rite equipment only. For

non-Sta-Rite equipment, consult manufacturer.

Hazardous Pressure!

Can cause severe

injury or major

property damage from

tank explosion.

Filter pumps require

hazardous voltage

which can shock,

burn, or cause death.

BEFORE WORKING

ON FILTER:

1. Stop pump.

2. Open air release

valve.

3. Release all pressure

from system.

BEFORE WORKING

ON PUMP OR MOT

Disconnect power to

motor.

OR

3

C

Dia.

B

A

D

2.88 (73)

Pump Inlet 1-1/2"

W

aste Outlet 1-1/2"

U

nion connection

Return Outlet

1

-1/2" Slip

E,F

1355 1094

C

D

A

B

9.25 (235)

2" NPT Outlet

(Waste)

2

" NPT Inlet

(Pump)

2" NPT

Outlet

(Return)

E,F

8.00(203)

1356 1094

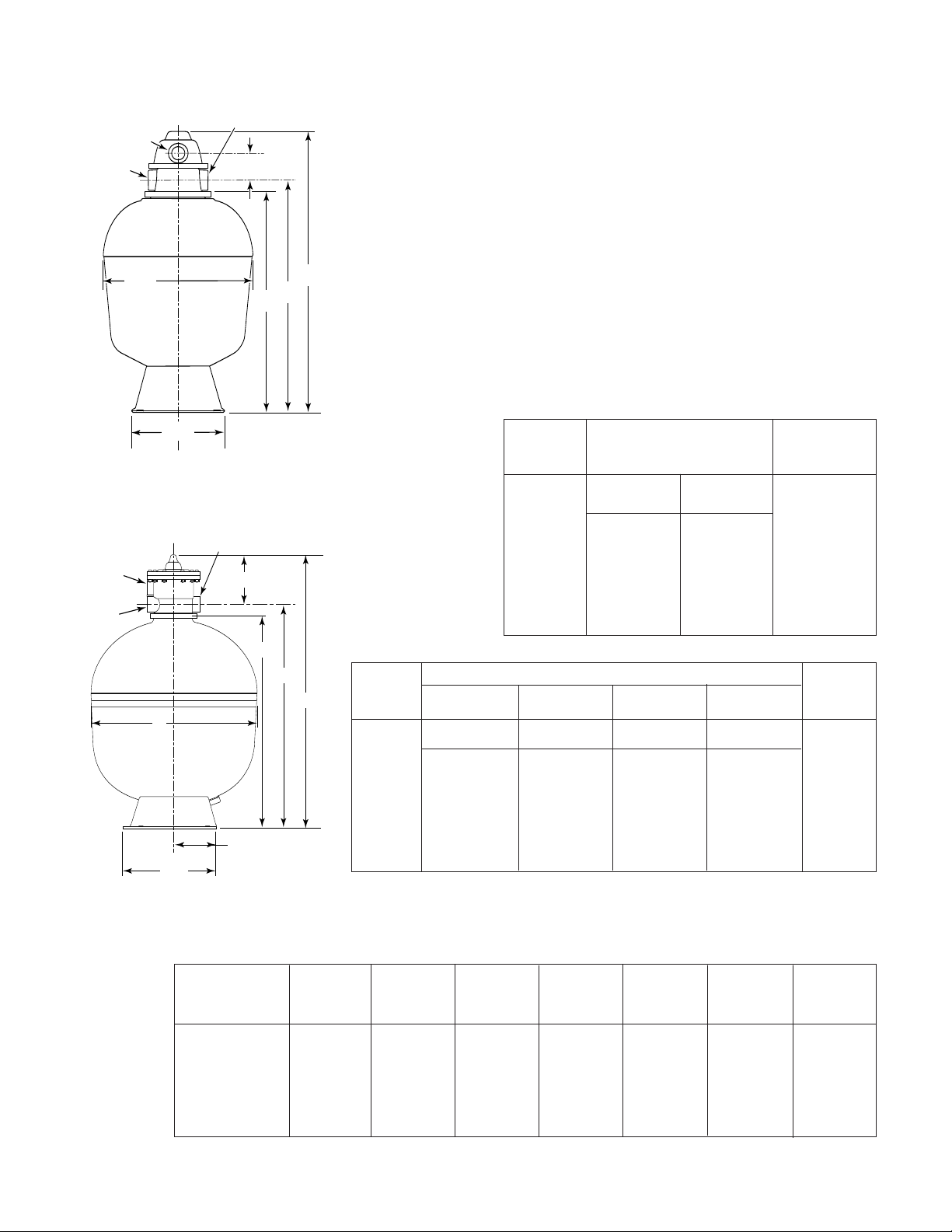

Fig. 1: Dimensions, T-150BP-1,

T-170BP-1 T-200BP-1, T240BP-1

See Page 14 for Pressure Drop Curve.

RECOMMENDED SAND GRADES:

se only: #20 Silica Sand, Size Range .40-.55mm., Uniformity Coefficient less

U

han 1.75.

t

NOTICE: Use of other sands will reduce filter performance, may damage

pump, and will void warranty.

Recommended:

1. Wedron Silica/Best Sand Co., Sand Grade: Wedron .45-.55mm., Effective

Size .46mm, Uniformity Coefficient 1.22.

2. U.S. Silica - Silurian Filter Sand, Sand Grade.45-.55 mm., Effective Size

.48mm, Uniformity Coefficient 1.18.

TABLE I - FILTER OPERATIONAL DATA

Max.

Filter Filter Flow Rate

Model Size in GPM (L/M)

Dia. in Area in Ft

Inches (mm) (M2)

T-150BP-1

15 (381) 1.26 (.117) 25.2 (95)

T-170BP-1 17 (432) 1.57 (.146) 31.5 (123)

T-200BP-1 20 (508) 2.18 (.203) 43.6 (165)

T-240BP-1 24 (610) 3.10 (.288) 62.0 (234.7)

T-240BP-2 24 (610) 3.10 (.288) 62.0 (234.7)

T-300BP-2 30 (762) 4.90 (.455) 98 (371)

2

Fig. 2: Dimensions, T-300BP-2,

T240BP-2

Filter Model No.

T-150BP-1 27 (686) 33-13/16 (859) 15-3/4 (400) 24-11/16 (627) 13 (330) 16-1/4 (413) 1-1/2” SLIP

T-170BP-1 29-9/16 (751) 36-3/8 (924) 17-3/4 (451) 27-1/4 (692) 13 (330) 16-1/4 (413) 1-1/2” SLIP

T-200BP-1 31-5/8 (803) 38-1/2 (978) 20-3/4 (527) 29-3/8 (746) 13 (330) 16-1/4 (413) 1-1/2” SLIP

T-240BP-1 35-3/16 (897)

T-240BP-2 35-1/4 (895)

T-300BP-2 42 (1067) 51-1/4 (1302) 31 (787) 39-5/8 (1008) 16-7/8 (429) 21 (533) 2” (NPT)

Filter Volume

Turnover in Hours Sand

Model 6 8 10 12 in lbs. (kg.)

gal. (L) gal. (L) gal. (L) gal. (L)

T-150BP-1 9,070(34 330) 12,100(45 799) 15,120(57 229) 18,144(68 675) 100 (45.4)

T-170BP-1 11,340(42 922) 15,120(57 229) 18,900(71 536) 22,680(85 844) 150 (68)

T-200BP-1 15,700(59 424)

T-240BP-1 22,230(84 481)

T-240BP-2 22,230(84 481) 29,760(112 642) 37,200(140 802) 44,640(168 962) 300 (136)

T-300BP-2 35,280(133 535)

20,930(79 220)

29,760(112 642)

47,040(178 046) 58,800(222 558) 70,560(267 070) 600 (272)

26,160(99 016) 31,390(118 811) 200 (90.7)

37,200(140 802)

44,640(168 962)

300 (136)

*NOTE: 1 cubic foot of sand weighs approx. 100 lbs. (45.4 kg). Do not use finer or

coarser grade than recommended for best performance.

TABLE II - DIMENSIONAL DATA In Inches (mm)

Base Base Piping

Width Length Port

A B C D (E) (F) Size

42 (1067) 24-3/4 (629) 32-7/8 (835) 16-7/8 (429) 21 (533) 1-1/2” SLIP

44-1/2 (1130)

24-3/4 (629)

32-7/8 (835)

16-7/8 (429)

21 (533)

2” (NPT)

4

GENERAL INFORMATION

Clean a new pool as well as possible before filling pool and operating filter.

•

xcess dirt and large particles of foreign matter in the system can cause serious

E

damage to the filter and pump.

NEVER test this filter with compressed air.

Do not operate filter at water temperatures above 95°F (35°C).

NEVER operate this filter system at more than the stated pressure on

the filter tank.

INSTALLATION

Installation of filter should only be done by qualified, licensed personnel.

For assembly and filling instructions, see page 6.

Filter mount must:

• Provide weather and freezing protection.

• Provide space and lighting for easy access for routine maintenance.

(See Figures 1 and 2, Table II, Page 4, for space requirements.)

• Be on a reasonably level surface and provide adequate drainage.

•

Be as close to pool as possible to reduce line loss from pipe friction.

Piping:

•

Piping must conform to local/state plumbing and sanitary codes.

• Use pipe joint sealing compound or Teflon®tape on all male connections of

metal pipe and fittings (except unions). Use Teflon®tape or Plasto-Joint Stik®on

all male connections of plastic pipe and fittings. DO NOT use pipe dope on

plastic pipe; it will cause the pipe to crack. Do not use sealant or tape on

unions – assemble them dry and hand tight.

• Do not damage union sealing surfaces and “O” Rings.

•

Support pipe independently to prevent strains on filter or valve.

• Use 1-1/2 or 2” pipe to reduce pressure losses as much as possible.

NOTICE: Filter may be located away from pool, but for adequate flow larger

pipe may be needed. Check local codes when considering remote installation.

•

Fittings restrict flow; for best efficiency use fewest possible fittings

• Keep piping tight and free of leaks: pump suction line leaks may cause trapped

air in filter tank or loss of prime at pump; pump discharge line leaks may show

up as dampness or jets of water.

• When unions are provided, use as follows for leak free connections:

1. O-Ring and sealing surfaces must be clean.

2. Assemble hand tight only (

3. No pipe compound or T

no wrenches).

®

tape on unions.

eflon

Valves:

• A check valve installed between filter and heater will prevent hot water from

backing up into filter and deforming internal components.

• Use care before assembly not to damage union sealing surfaces or O Ring.

.

Wastewater:

• Be sure all provisions for waste water disposal meet applicable local, state or

national codes. 100 gallons (379 liters) or more of pool water will be discharged during filter backwashing. Do not discharge where water will cause

flooding or damage.

5

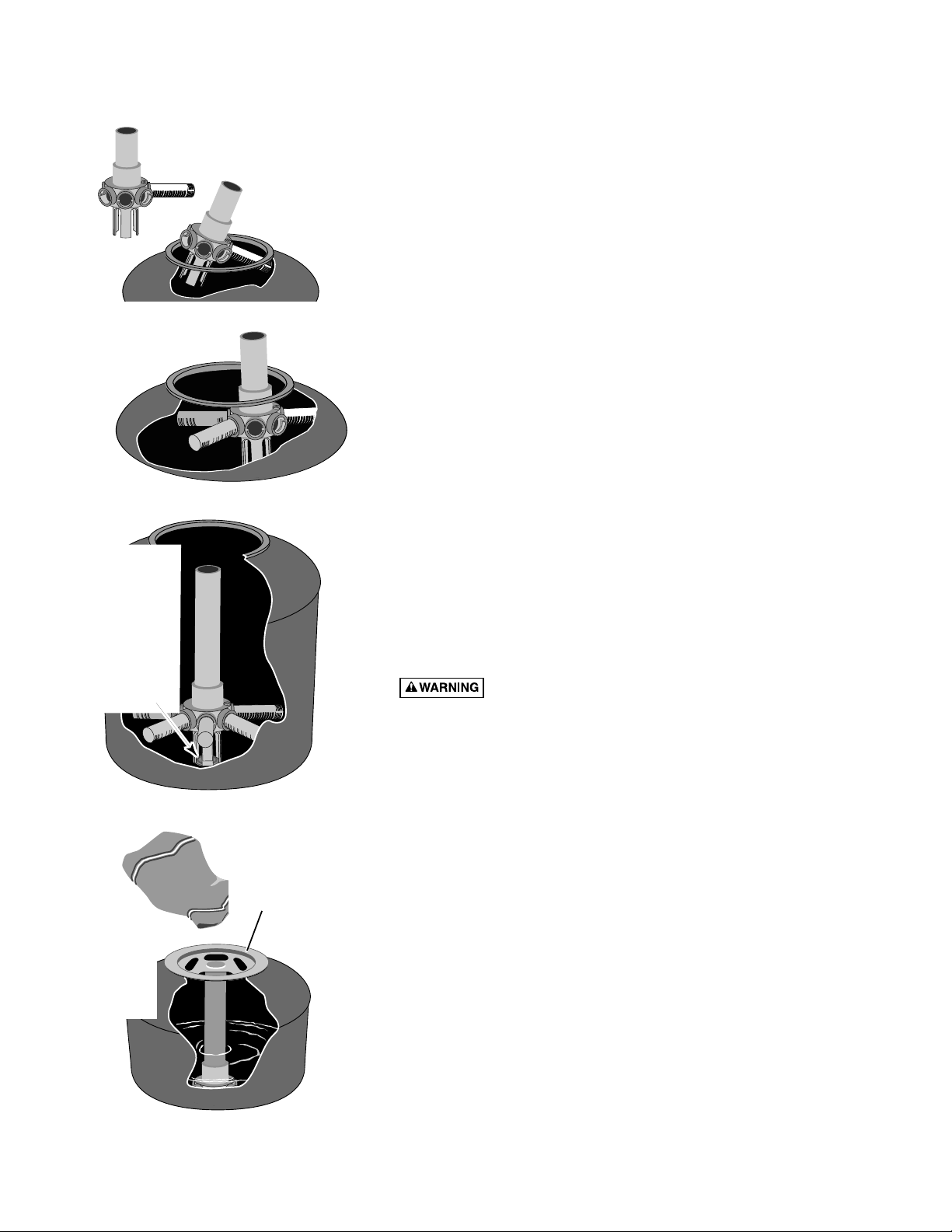

B. Insert assembly

into top of

filter tank.

A. Insert first lateral into socket;

twist clockwise 1/4 turn

to lock lateral into hub.

Lateral is correctly installed

when slots face down.

7

31 0294

C

. Hold assembly up

near top of tank and

add remaining

laterals.

732 0294

D. After all

laterals are

securely in

sockets,

position

assembly on

centering

boss in

bottom of

tank.

733 0294

S

A

N

D

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

::::

Fill tank

about

half full

of water

before

adding

sand.

Sand Shield

keeps collector

hub assembly

clean when

loading filter.

734 0294

Fig. 2

Filter Setup

Assembly: See Figures 2 through 5 for filter assembly.

Loading Sand Media

.To keep sand out of collector assembly, place plastic sand shield over top

1

of collector tube before pouring sand into filter (See Figure 5).

2.To support laterals and prevent lateral breakage during loading, fill tank

about half full of water before loading sand.

3.Pour sand into filter tank. See Page 4, for correct type and quantity of sand

to use.

NOTICE: Make sure gasket area on top of tank is free of sand before

installing valve and clamp.

4.Before installing valve, double-check that correct quantity of sand has

been loaded (see Page 4).

5.Remove plastic sand loading shield and keep for future use.

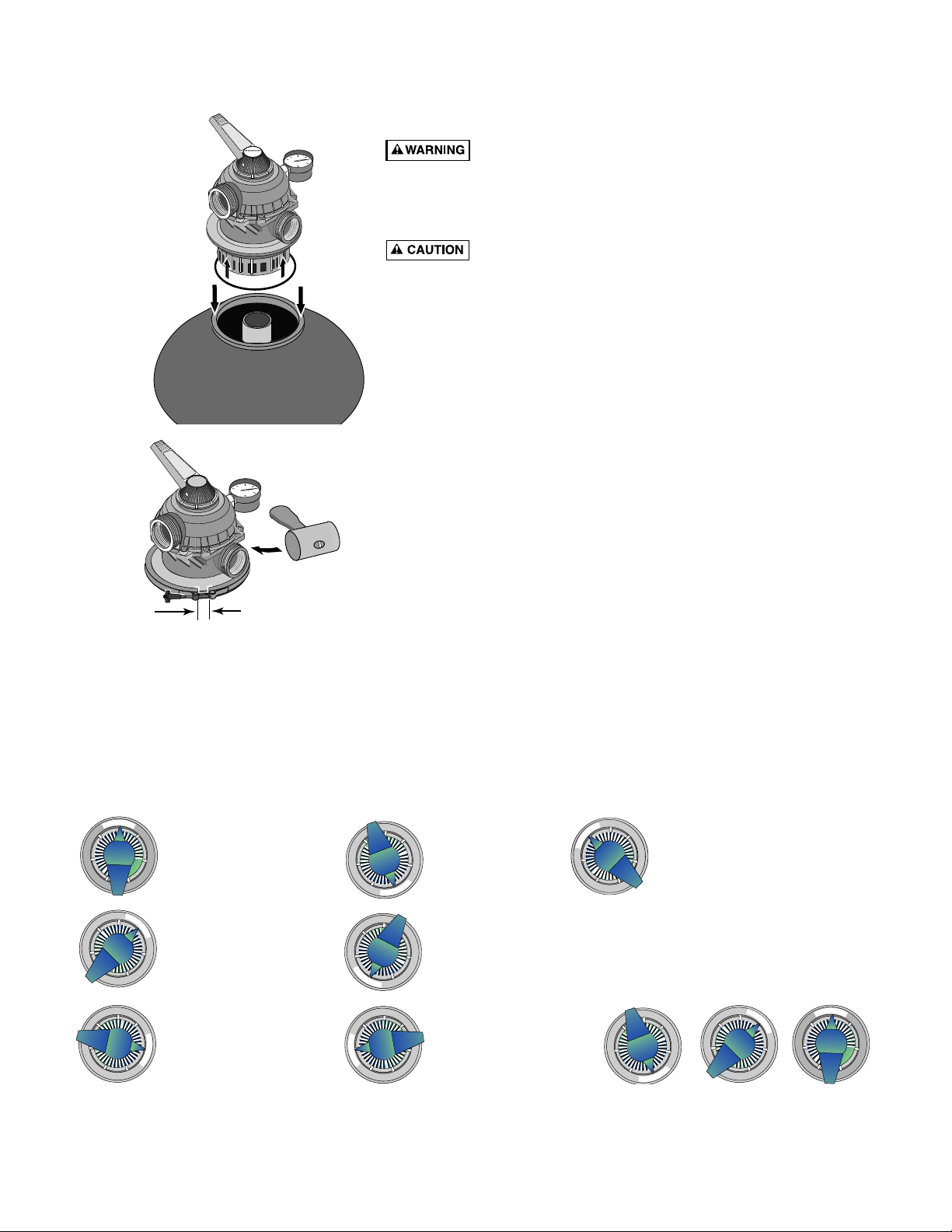

Valve Installation:

Fig. 3

ig. 4

F

Fig. 5

See Figures 6, 7, and 8

1. Install O-Ring on valve flange; make sure O-Ring is clean, dry, and has

no nicks, tears, or scrapes.

2. Make sure tank and valve flanges are clean and free of sand; put valve

on top of tank. Vertical pipe of collector assembly inserts into base of

valve.

3.Install clamp; make sure knob is positioned for easy access for filter

maintenance. Valve port labeled “PUMP” should point toward pump.

4.Tighten clamp knob until clamp ends (under bolt) are 1/4” (6mm) apart.

Tap around outside of clamp with a mallet to help seat clamp.

Hazardous pressure. Clamp will not hold unless it is

seated properly! DO NOT START PUMP until clamp ends are 1/4”

(6mm) apart or less.

5.If clamp will not pull up to 1/4” (6mm) gap, wait 15-30 minutes and

retighten. Tap clamp gently with mallet to help seat clamp.

6.Connect pipe from pump discharge to valve port labeled “PUMP”; use

union half provided. Assemble union as follows for leakfree operation:

A. O-Ring and sealing surfaces must be clean.

B. Assemble hand tight only (no wrenches).

C. NO pipe compound or Teflon®tape on unions.

7.Complete all plumbing connections (see Page 5 for piping

requirements).

A. Pipe from valve RETURN port to pool return.

B. Pipe from valve WASTE port to waste.

C. Suction piping from pool to trap inlet on pump.

8.System is ready for startup.

NOTICE: If there are leaks from beneath valve/clamp area, STOP

PUMP, release all pressure, remove clamp and valve and clean sealing

surfaces.

6

RR

EE

C

C

I

I

R

R

CC

U

U

LL

AA

T

T

EE

B

B

A

A

C

C

KK

W

W

AA

SS

HH

EE

WW

A

A

S

S

TT

EE

FF

I

I

L

L

TT

EE

R

R

1. Install O-Ring

on valve flange.

2. Install valve on tank.

Tank flange must

be clean; insert

collector pipe

into bottom

of valve.

Delavan, WI.

53115

USA

1/4" Max.

Port labeled

"PUMP" should

point toward

pump.

Install clamp

and tighten

until clamp

ends (under

bolt) are 1/4"

apart.

If unable to

close gap

to 1/4" or less,

wait 15-30

minutes and

retighten.

Tap around

clamp while

tightening to

help seat

clamp.

.WATERFORD, WI.

53185

USA

736 0294

RR

EE

CC

I

I

R

R

C

C

U

U

LL

A

A

T

T

E

E

BB

AA

C

C

K

K

W

W

A

A

SS

H

H

E

E

WW

AA

S

S

TT

EE

FF

I

I

L

L

TT

EE

RR

Fig. 6

R

E

C

I

R

C

U

L

A

T

E

B

A

C

K

W

A

S

H

C

L

O

S

E

D

W

I

N

T

E

R

I

Z

E

W

A

S

T

E

F

I

L

T

E

R

R

I

N

S

E

Valve Setting

Purpose/Flow

FILTER

Normal filtration and

vacuuming; water goes

through filter to pool.

RINSE

For initial startup cleaning

and sand bed leveling

after backwash; water goes

through filter to waste.

RECIRCULATE

Circulates pool water;

bypasses filter.

R

E

C

I

R

C

U

L

A

T

E

B

A

C

K

W

A

S

H

C

L

O

S

E

D

W

I

N

T

E

R

I

Z

E

W

A

S

T

E

F

I

L

T

E

R

R

I

N

S

E

R

E

C

I

R

C

U

L

A

T

E

B

A

C

K

W

A

S

H

C

L

O

S

E

D

W

I

N

T

E

R

I

Z

E

W

A

S

T

E

F

I

L

T

E

R

R

I

N

S

E

737 0294

BACKWASH

Reverses flow for

cleaning; water

goes through filter

to waste.

CLOSED

Shuts off all flow to

filter and pool.

WINTERIZE

Leaves all valve ports

partially open for

winter storage.

R

E

C

I

R

C

U

L

A

T

E

B

A

C

K

W

A

S

H

C

L

O

S

E

D

W

I

N

T

E

R

I

Z

E

W

A

S

T

E

F

I

L

T

E

R

R

I

N

S

E

Valve Setting

Purpose/Flow

R

E

C

I

R

C

U

L

A

T

E

B

A

C

K

W

A

S

H

C

L

O

S

E

D

W

I

N

T

E

R

I

Z

E

W

A

S

T

E

F

I

L

T

E

R

R

I

N

S

E

R

E

C

I

R

C

U

L

A

T

E

B

A

C

K

W

A

S

H

C

L

O

S

E

D

W

I

N

T

E

R

I

Z

E

W

A

S

T

E

F

I

L

T

E

R

R

I

N

S

E

738 0294

WASTE

Lowers pool level or

drains pool; water

bypasses filter,

goes to waste.

Valve Setting

Purpose/Flow

R

E

C

I

R

C

U

L

A

T

E

B

A

C

K

W

A

S

H

C

L

O

S

E

D

W

I

N

T

E

R

I

Z

E

W

A

S

T

E

F

I

L

T

E

R

R

I

N

S

E

743 0294

BACKWASH

Reverses flow for

cleaning; water

goes through filter

to waste.

R

E

C

I

R

C

U

L

A

T

E

B

A

C

K

W

A

S

H

C

L

O

S

E

D

W

I

N

T

E

R

I

Z

E

W

A

S

T

E

F

I

L

T

E

R

R

I

N

S

E

Valve Setting

Purpose/Flow

R

E

C

I

R

C

U

L

A

T

E

B

A

C

K

W

A

S

H

C

L

O

S

E

D

W

I

N

T

E

R

I

Z

E

W

A

S

T

E

F

I

L

T

E

R

R

I

N

S

E

Valve Setting

Purpose/Flow

FILTER

Normal filtration and

vacuuming; water goes

through filter to pool.

RINSE

For initial startup cleaning

and sand bed leveling

after backwash; water goes

through filter to waste.

R

E

C

I

R

C

U

L

A

T

E

B

A

C

K

W

A

S

H

C

L

O

S

E

D

W

I

N

T

E

R

I

Z

E

W

A

S

T

E

F

I

L

T

E

R

R

I

N

S

E

R

E

C

I

R

C

U

L

A

T

E

B

A

C

K

W

A

S

H

C

L

O

S

E

D

W

I

N

T

E

R

I

Z

E

W

A

S

T

E

F

I

L

T

E

R

R

I

N

S

E

Valve Setting

Purpose/Flow

FILTER

Normal filtration and

vacuuming; water goes

through filter to pool.

Fig. 7

Startup/Operation (See Figure 9)

azardous pressure. To avoid explosion and possible

H

severe or fatal injury, filter system pressure must not exceed the stated

pressure in the filter tank under any circumstances. NEVER test this filter

system with compressed air; never operate system with water

temperature above 95° F (35° C).

To prevent equipment damage and possible injury, turn

pump OFF before changing valve position.

NOTICE: Do not add chemicals directly into the pool skimmer. Adding

undiluted chemicals may damage equipment and void warranty.

1. Open system valves and make sure pump is filled with water. Make

sure pool water level is 2” (51mm) above bottom of skimmer

opening.

2. With pump OFF, set valve to ‘BACKWASH’ position.

3. Start pump, circulating water backwards through filter to waste. Do

not install pressure gauge until a steady stream of water runs out of

gauge port; then stop pump and install gauge.

NOTICE: To prevent pump from running dry, be sure water level

never drops below bottom of skimmer inlet. Add water to pool if

necessary to keep skimmer flooded while backwashing and rinsing.

4. Backwash until water runs clear (3-5 minutes).

5. Stop pump; set valve to ‘RINSE’ position.

6. Start pump; run pump for one minute.

7. Stop pump; set valve to ‘FILTER’ position.

8. Filter is now ready for service.

9. Record clean starting filter pressure gauge reading as a reference.

10. When pool is first filled, backwash once a day until pool water is

sparkling clear. After that, backwash when pressure gauge shows 5 to

7 PSI (34.5 to 48 kPa) higher than starting pressure.

Fig. 8

Fig. 9: Valve settings for startup. Stop

e position.

pump befor

hanging v

e c

alv

7

MAINTENANCE

WASTE

Lowers pool level or

drains pool; water

bypasses filter,

goes to waste.

Valve Setting

Purpose/Flow

R

E

C

I

R

C

U

L

A

T

E

B

A

C

K

W

A

S

H

C

L

O

S

E

D

W

I

N

T

E

R

I

Z

E

W

A

S

T

E

F

I

L

T

E

R

R

I

N

S

E

R

E

C

I

R

C

U

L

A

T

E

B

A

C

K

W

A

S

H

C

L

O

S

E

D

W

I

N

T

E

R

I

Z

E

W

A

S

T

E

F

I

L

T

E

R

R

I

N

S

E

Valve Setting

Purpose/Flow

FILTER

Normal filtration and

vacuuming; water goes

through filter to pool.

BACKWASH

Reverses flow for

cleaning; water

goes through filter

to waste.

CLOSED

Shuts off all flow to

filter and pool.

WINTERIZE

Leaves all valve ports

partially open for

winter storage.

R

E

C

I

R

C

U

L

A

T

E

B

A

C

K

W

A

S

H

C

L

O

S

E

D

W

I

N

T

E

R

I

Z

E

W

A

S

T

E

F

I

L

T

E

R

R

I

N

S

E

Valve Setting

Purpose/Flow

R

E

C

I

R

C

U

L

A

T

E

B

A

C

K

W

A

S

H

C

L

O

S

E

D

W

I

N

T

E

R

I

Z

E

W

A

S

T

E

F

I

L

T

E

R

R

I

N

S

E

R

E

C

I

R

C

U

L

A

T

E

B

A

C

K

W

A

S

H

C

L

O

S

E

D

W

I

N

T

E

R

I

Z

E

W

A

S

T

E

F

I

L

T

E

R

R

I

N

S

E

General:

• Wash outside of filter with a mild detergent and water. Rinse off with hose.

NOTICE: DO NOT use solvents to clean filter; solvents may damage plastic

components in system.

• Inspect sand bed at least once a year to remove foreign material which has not

been backwashed out of system.

NOTICE: When the sand bed gets hard and crusty on top, remove all the old

sand and replace it with new sand.

Weekly Pool Equipment Inspection:

1. Check pressure during operation. When pressure is 5 to 7 PSI (34.5 to

48 kPa) higher than initial operating pressure, backwash filter (see

instructions under “Startup/Operation”, Page 7).

2. Except during hot weather with heavy swimmer loads, operating filter 6 to

12 hours per day should be sufficient. Carefully monitor water chemical

balance and follow recommendations of your local pool professional.

Water Maintenance

• Keep water level at least 2” (51mm) above bottom of skimmer opening.

Failure to do so can allow air to enter system, causing pump to lose prime

and air to enter filter.

• Maintain pH at 7.2 to 7.6 in pool.

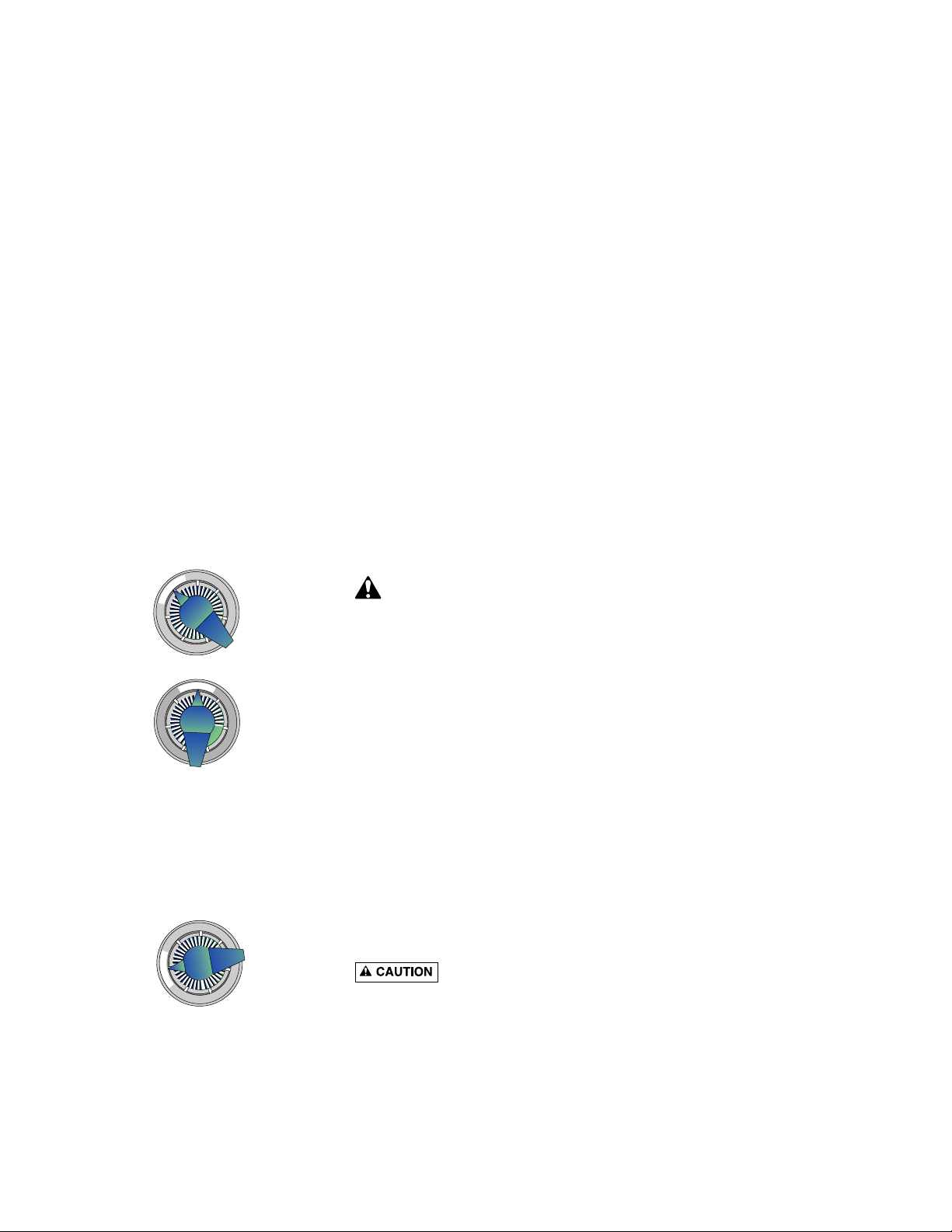

Fig. 10: Valve settings to lower

pool water level. Stop pump

before changing valve position.

ig. 11: Valve setting for winter

F

storage. Stop pump befor

changing valve position.

To prevent damage to system components, keep water temperature below

95° F. (35° C) at all times.

Vacuum Pool:

1. Fill vacuum hose by submerging in water from one end to the other.

2. To vacuum, insert hose into skimmer suction manifold or into vacuum

line in pool wall. See instructions provided by pool builder or pool

manufacturer. Start pump, making sure it is primed and pumping.

3. After vacuuming, clean pump trap to remove accumulated debris, then

check filter pressure gage. If reading is 5 to 7 PSI (34.5 to 48 kPa) higher

than initial operating pressure, backwash filter.

Lower or Drain Pool

1. Turn pump ‘OFF’; set valve handle to ‘WASTE’.

2. Use vacuum cleaner hose and head.

3. Start pump; run until pool is lowered to desired level.

4. Turn pump ‘OFF’; set valve handle to ‘FILTER’.

5. Start pump.

STORAGE/WINTERIZING

Pool chemicals may give off corrosive fumes. Store chemicals

way from system in a well ventilated area.

a

NOTICE: Allowing water to freeze will damage filter and void warranty. If

antifreeze is needed, use propylene glycol; it’s plastic compatible and

e

non-toxic. Follow manufacturers instructions. Do not use ethylene glycol

based anti-freeze – it’

s toxic and it may damage plastic components.

1. Open all system valves. Set multiport valve at ‘WINTERIZE’ to allow air

passage to all ports.

8

2. Remove drain plug from filter.

R

E

C

I

R

C

U

L

A

T

E

B

A

C

K

W

A

S

H

C

L

O

S

E

D

W

I

N

T

E

R

I

Z

E

W

A

S

T

E

F

I

L

T

E

R

R

I

N

S

E

1

1

A

2

3

4

5

6

Aquatools

.

WATERFORD, WI.

5

3185

USA

744 0294

1344 1094

1

1A

2

3

5

6

4

3. Drain filter tank completely and replace drain cap (Figure 13, Page 10).

. Cover with plastic or tarpaulin to protect from weather, but do not seal from

4

air circulation.

. Protect from freezing.

5

Startup for Winterized Equipment:

1. Remove any temporary weather protection placed around system for

shutdown.

2. See “Startup”, Page 7, for reactivation of the filter.

3. Inspect all electrical wiring to pump for damage or deterioration over the

shutdown period. Have a qualified serviceman repair/replace wiring as

needed. Inspect and tighten all watertight connections.

4. Open all valves in suction and return piping.

5. Remove any winterizing plugs in system.

6. Drain all winterizing chemicals (if used) from system; flush system.

7. Close all drain valves and replace all drain plugs in system (see Page 10).

8. Fill pool with water to proper level (see pool manufacturer’s instructions).

MULTI-PORT VALVE SERVICE

Hazardous pressure. Stop pump and release all pressure from

system before working on filter, valve, or clamp. Filter and valve design allows

air to bleed off automatically in normal service. However, always be sure

pressure is off system before working on filter, valve or clamp.

NOTICE: if Multi-Port valve is below pool water level, close suction and

discharge valves before disassembly to prevent draining pool.

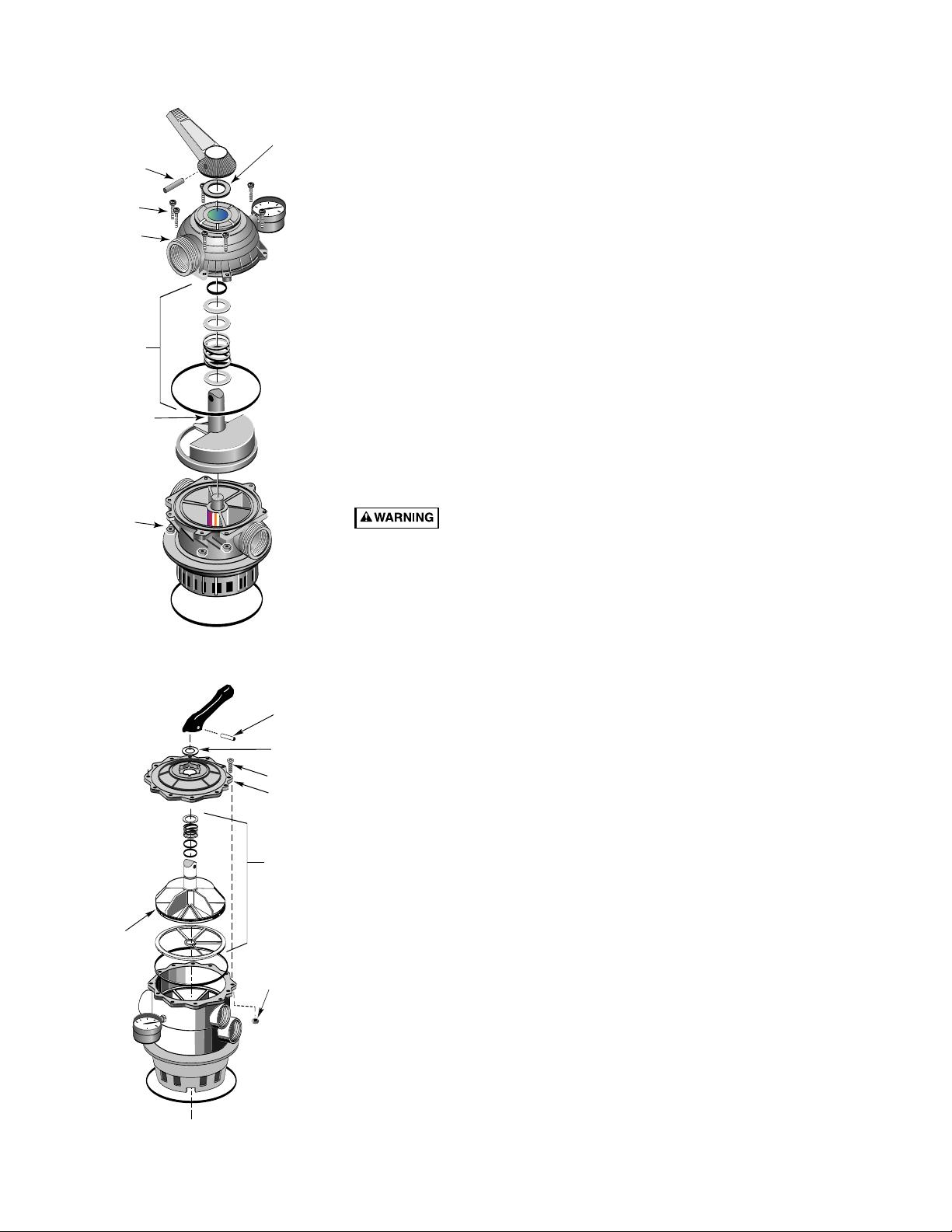

Fig. 12A: Valve Disassembly

(1-1/2” Multiport Valve)

Handle Replacement:

1. Stop pump.

2. Place handle in ‘FILTER’ position.

3. Remove pin (Key 1, Figures 12A and 12B) to disconnect handle. If it cannot

be removed by hand, use a hammer and center punch and lightly tap it out.

4. Remove handle; replace with a new one. Be sure new handle is in ‘FILTER’

position.

Replace pin.

5.

Lid and Plug replacement:

1. Remov

e Handle (see ‘Handle Replacement’ abo

2. Remove plug:

A. Remove all screws and nuts (Key Nos. 2 and 6, Figures 12A and 12B).

Remove lid (Key No. 3) by pulling straight up while holding plug shaft

B.

(Key No. 5) down with thumb.

3. Inspect Internal Parts:

Inspect plug and gasket spring, O-Rings, and internal washers (Key No. 4).

Replace if necessary.

e).

v

Fig. 12B: Valve Disassembly

(2” Multiport Valve)

9

About 1"

Small

O-Ring

Open end

of lateral

Seat small

O-Ring

Large

O-Ring

End of lateral is

flush with end of

drain fitting

746 0294

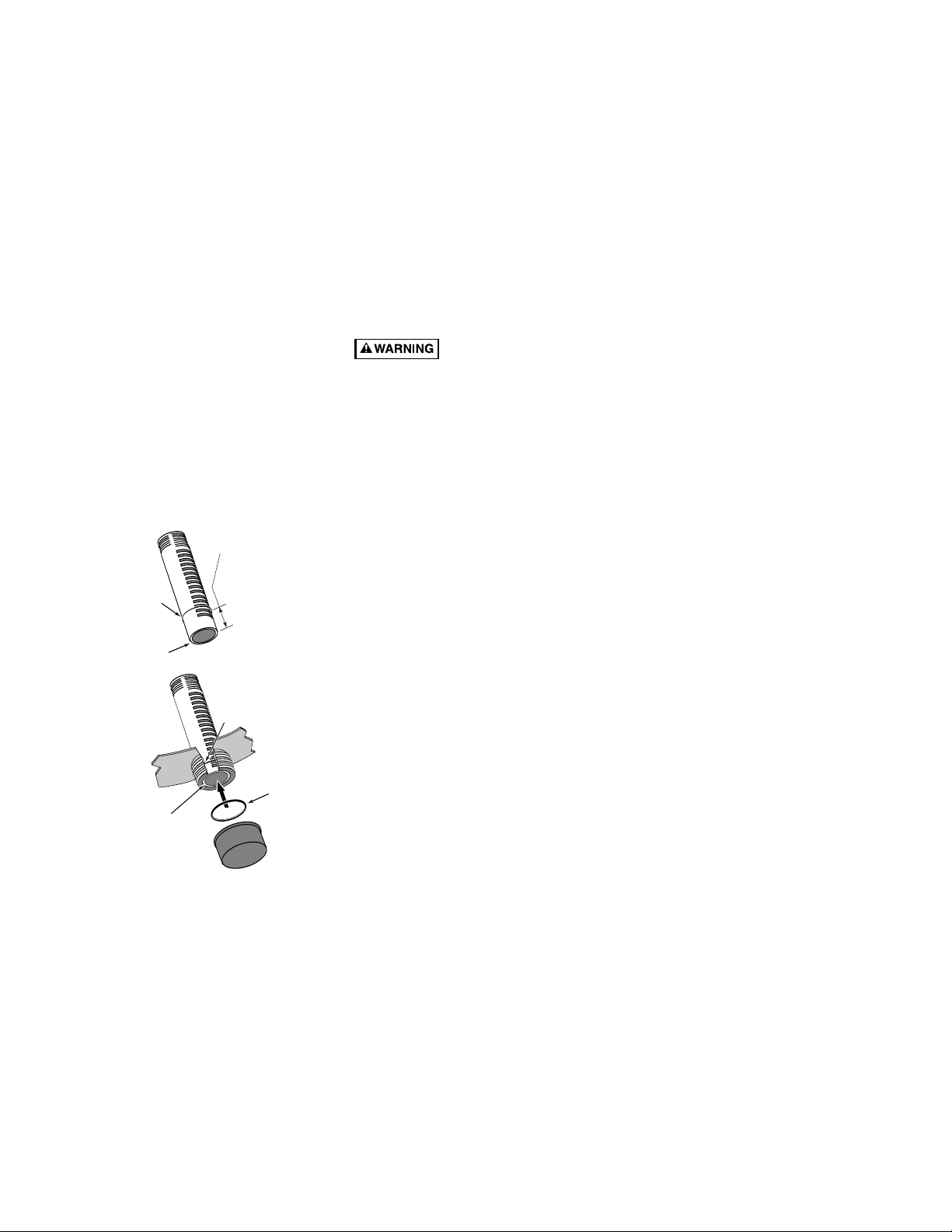

Figure 13: Drain Fitting Assembly.

This assembly allows water to drain

without losing the sand out of the

filter tank.

Make sure all surfaces are clean and

free of sand. Don’t cross thread cap;

don’t overtighten cap.

4. Reassemble Valve:

A. Replace plug gasket and shaft, mounting spring, washers, and O-Ring on

plug shaft. Lubricate O-Ring with Amojel.

B. Replace lid; match screw holes in lid and body.

. Press down on lid to allow screws to engage nuts; tighten each nut

C

securely.

D. Replace top washer (Key No. 1A) and handle, making sure indexing pin

on plug shaft points in same direction as pointer on handle. Replace

handle pin.

E. Tighten all lid screws to 55 inch-lbs. (63.4 kg-cm) torque.

Valve Removal

Hazardous pressure. Stop pump and release all pressure from

system before working on filter, valve, or clamp.

NOTICE: If Multi-Port Valve is below pool water level, close suction and

discharge valves before disassembly to prevent draining pool.

1. Disconnect piping from pump and pool.

2. Remove clamp.

3. Remove valve from filter top.

4. To reinstall valve, follow instructions, Figures 6 and 7, Page 7. BE SURE to

follow clamp tightening instructions.

Drain Fitting Installation/Removal

NOTICE: If pool is above height of filter, first close valves in pump suction and

return lines to prevent draining pool. If there are no shutoff valves installed,

disconnect suction and return lines and raise ends above pool water level.

1. Installation: See Figure 13.

2. To Drain Filter:

A. Remove drain cap. Lateral tube should remain in place inside drain

opening to prevent sand from draining out.

B. Open union coupling on backwash port of Multi-Port valve. This will

allow air into filter and allow water to drain from filter tank.

C. Replace cap when tank is empty.

om Filter:

Removing Sand F

3.

A. Remove both drain cap and slotted lateral tube (see Figure 13). Sand and

water will drain from tank.

B. To completely flush filter tank of sand, remove top clamp and multiport

valve and flush the inside of the tank with a hose.

C. Thoroughly clean sand from all parts and from tank drain opening

before reassembling drain fitting.

r

10

Loading...

Loading...