Sta-Rite 100 MV Installation Manual

Warning:

MiniMax 100 ( Marked)

ABOVE GROUND POOL & SPA HEATER

USERS & INSTALLATION MANUAL

IMPORT ANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

SA VE THESE INSTRUCTIONS

WARNING

FOR YOUR SAFETY - READ BEFORE OPERATING

If you do not follow these instructions exactly, a fire or explosion may

result, causing property damage, personal injury or loss of life.

Consumer

Retain For

Future

Reference

U.S. Patent Numbers

5,318,007 - 5,228,618

5,201,307 - 4,595,825

WARNING

Warning: Improper installation, adjustment, alteration, service or maintenance can cause

property damage, personal injury or death. Installation and service must be performed by a

qualified installer , service agency or the gas supplier.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

For Your

Safety

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone.

Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

To

Do not store or use gasoline or other flammable vapors and liquids in

the vicinity of this or other appliances.

PacFab, Inc.

Corporate Headquarters: 1620 Hawkins Ave., Sanford, NC 27330 • (919) 774-4151

Western Operations: 10951 West Los Angeles Ave., Moorpark, CA 93021 • (805) 523-2400

Rev . A 2-4-2000 P/N 471438

TABLE OF CONTENTS:

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Important Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii - iii

Users Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Operating (Controls) / Heater Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Maintenance Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chemical Balance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Outdoor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Indoor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Flue Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Plumbing Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Water Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Gas Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Service Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Burner Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Soot Formation on the Heat Exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Removing the Heat Exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Reinstalling the Heat Exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Trouble Shooting (General). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Exploded View & Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

P/N 471438 Rev. A 2-4-2000

Introduction

MiniMax 100 ( Marked)

ABOVE GROUND POOL AND SPA HEATERS

Congratulations on your purchase of a MiniMax 100 high performance heating system. Proper installation and

service of your new heating system and correct chemical maintenance of the water will ensure years of enjoyment.

The MiniMax 100 is a compact, lightweight and efficient gas fired high performance above ground pool and spa

heater that can be connected to schedule 40 PVC pipe and has a built-in top. The heater includes the following

features:

• Reliable direct-spark ignition (DSI) system available in propane or natural gas versions.

• Millivolt standing pilot versions in propane and natural gas, when no convenient line power is present.

• Fuel gas input of 100,000 btu/hr.

• Quiet and dependable operation from packaged burner system proven reliable in worldwide usage.

• Heat exchanger constructed of premium non-corroding materials including bronze headers standard.

• The controls have been designed to be very easy to troubleshoot and very easy to access and replace in the

rare event of a malfunction-making the MiniMax 100 user friendly .

i

IMPORTANCE NOTICES FOR THE INSTALLER AND OPERATOR

Gas Safety (Installation and Use) Regulations, 1994 (as amended)

It is the law that all gas appliances are installed by competent persons in accordance with the above regulations.

Failure to install appliances correctly could lead to prosecution. It is in your own interest, and that of safety , to

ensure that the law is complied with.

General Requirements

This appliance must be installed be a competent person, i.e. CORGI registered in accordance with the relevant

requirements of the Gas Safety Regulations, current I.E.E. Regulations, Model Water Byelaws, Local Water Authority

Byelaws and any relevant requirements of the local gas supplier, local authority and the relevant British Standard

Codes of practice and Building Regulations. Manufacturers notes must not be taken in any way as overriding statutory

obligations. T ypical documents include:

• BS. 6891; Installation of low pressure pipework.

• BS. 6644; Installation of Gas Fired Hot W ater Boilers 60kW to 2MW .

• CP341; W ater Supply .

• British Gas Publications:

• IM2; Purging Procedures of Non-domestic Gas Installations.

• IM5; Soundness T esting Procedures for Industrial and Commercial Gas Installations.

• IM11; Flues for Commercial and Industrial Gas Fired Boilers and Air Heaters.

• Model W ater Byelaws.

Rev . A 2-4-2000 P/N 471438

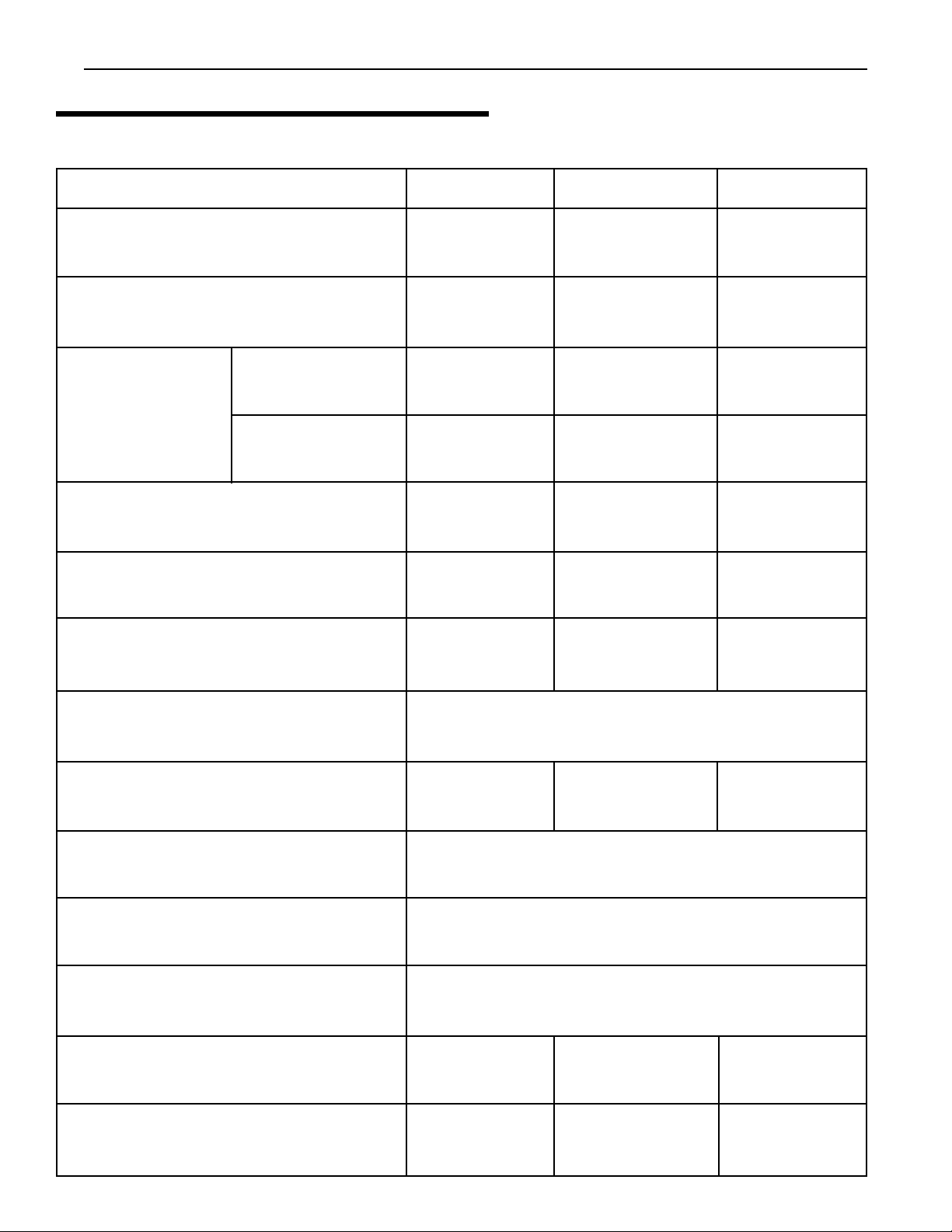

SPECIFICATIONS - TECHNICAL D AT A

(NATURAL GAS MODELS ONLY)

ii

CATEGORY

I

2H

I

2E

I

2E+

GAS AND G20 @ 20mb. G20 @ 20mb. G20 @ 20mb.

SUPPLY PRESSURE G25 @ 25mb.

BURNER PRESSURE mbar 9.3 9.3 9.3 (3.7)

(in.wg) (3.7) (3.7) 13.8 (5.5)

HEAT INPUT GROSS kW 29.3 29.3 29.3

(Btu/h) (100,000) (100,000) (100,000)

NET kW 26.4 26.4 26.4

(Btu/h) (90,077) (90,007) (90,007)

HEAT OUTPUT kW 23.4 23.4 23.4

(Btu/h) (79,841) (79,841) (79,841)

GAS RA TE m

3

/h 2.8 2.8 G20 - 2.8

G25 - 3.2

FLUE GAS VOLUME m

3

/h 88 88 88

(4.5% CO

, 100°C)

2

INJECTOR DIAMETER mm 1.25

& (MARKING) (125)

NUMBER OF INJECTORS 14 14 14

(BURNERS)

MAXIMUM WATER PRESSURE 8

bar (psi) (125)

MAXIMUM WATER FLOW 45

TEMP °C

ELECTRICAL SUPPLY 230V - 50Hz

FUSED AT 5A. POWER 35W

WEIGHT (EMPTY) kg 38 38 38.25

(lbs)

NOMINAL FLUE DIAMETER mm 125 125 125

(INDOOR INSTALLATION) (in.) (5) (5) (5)

P/N 471438 Rev. A 2-4-2000

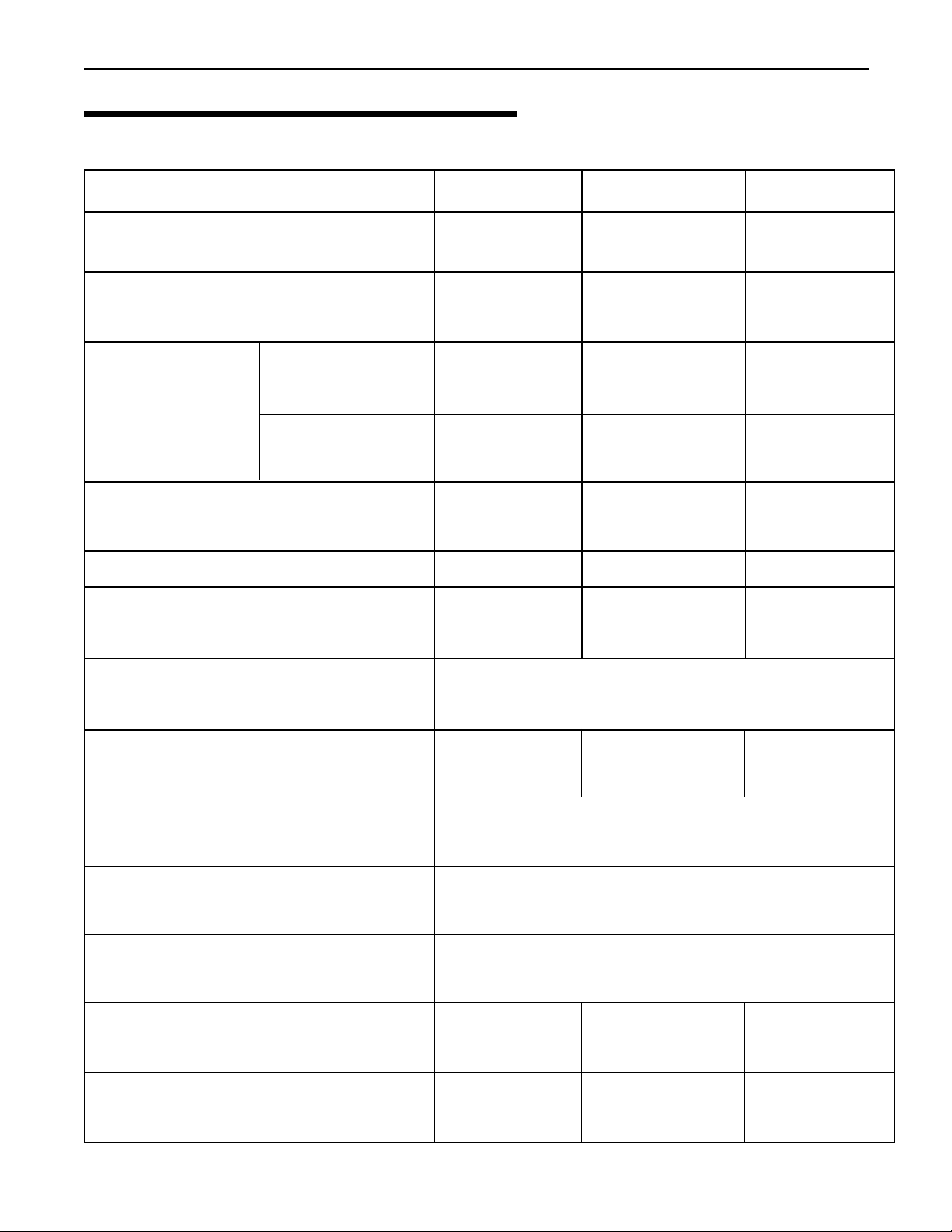

SPECIFICATIONS - TECHNICAL D AT A

(LPG MODELS ONLY)

iii

CATEGORY

I

3P

I

3P

I

3B/P

GAS AND G31 @ 37mb. G31 @ 50mb. G30 @ 29mb.

SUPPLY PRESSURE

BURNER PRESSURE mbar 21.0 21.0 21.0

(in.wg) (8.4) (8.4) (8.4)

HEAT INPUT GROSS kW 29.3 29.3 34.3

(Btu/h) (100,000) (100,000) (117,000)

NET kW 26.96 26.96 31.6

(Btu/h) (91,988) (91,988) (107,819)

HEAT OUTPUT kW 23.4 23.4 27.4

(Btu/h) (79,841) (79,841) (93,625)

GAS RATE m

FLUE GAS VOLUME m

(4.5% CO

, 100°C)

2

3

/h 1.1 1.1 0.98

3

/h 101 101 119

INJECTOR DIAMETER mm 0.85

& (MARKING) (085)

NUMBER OF INJECTORS 14 14 14

(BURNERS)

MAXIMUM WATER PRESSURE 8

bar (psi) (125)

MAXIMUM WATER FLOW 45

TEMP °C

ELECTRICAL SUPPLY 230V - 50Hz

FUSED AT 5A. POWER 35W

WEIGHT (EMPTY) kg 38 38 38

(lbs)

NOMINAL FLUE DIAMETER mm 125 125 125

(INDOOR INSTALLATION) (in.) (5) (5) (5)

Rev . A 2-4-2000 P/N 471438

Users Section

1

This instruction manual provides operating instructions, installation, and service information for the MiniMax 100

high performance heater . The information in this manual applies to the MiniMax 100 natural gas and L.P .G., DBI

and millivolt standing pilot heater models.

This heater is designed for the heating of fresh water swimming pools and spas, and should not be used for any

other purpose.

The heater must only be installed in the open air or in a room separated from living rooms and

provided with appropriate ventilation directly to the outside.

The heater must be used only in accordance with these instructions. Incorrect use is dangerous and invalidates

all warranties and certification.

W ARRANTY INFORMA TION

The MiniMax 100 pool heater is sold with a limited factory warranty . Specific details are described on the

back cover of this manual and a copy of the warranty and warranty registration card are included with

the product. Return the warranty registration card after filling in the serial number from the rating plate inside the

heater . For ordering parts, you should indicate model and serial numbers of the heater. If the parts are

requested for warranty , you must also indicate the date of installation.

PacFab's high standards of excellence include a policy of continuous product improvement resulting

in your state-of-the-art heater . W e reserve the right to make improvements which change the

specifications of the heater without incurring an obligation to update current heater equipment.

Operation

SAFETY RULES

1. Spa or hot tub water temperatures should never

exceed 40° C (104° F). A temperature of 38° C

(100° F) is considered safe for a healthy adult.

Special caution is suggested for young children.

2. Drinking of alcoholic beverages before or

during spa or hot tub use can cause drowsiness

which could lead to unconsciousness and

subsequently result in drowning.

3. Pregnant women beware! Soaking in water

above 39° C. (102° F.) can cause fetal damage

during the first three months of pregnancy

(resulting in the birth of a brain-damaged or

deformed child). Pregnant women should stick

to the 38° C. (100° F.) maximum rule.

4. Before entering the spa or hot tub, the user should

check the water temperature with an accurate

thermometer. Spa or hot tub thermostats may err

in regulating water temperatures by as much as

2.2° C. (4° F.).

5. Persons with medical history of heart disease,

circulatory problems, diabetes or blood pressure

problems should obtain their physician's advice

before using spas or hot tubs.

6. Persons taking medication which induce

drowsiness, such as tranquilizers, antihistamines or

anticoagulants should not use spas or hot tubs.

WARNING

Should overheating occur or the gas supply fail to shut off, turn off the manual gas control valve to the

appliance. Do not use this heater if any part has been under water. Immediately call a qualified service

technician to inspect the heater and to replace any part of control system and gas control which has

been under water.

P/N 471438 Rev. A 2-4-2000

Users Section

MINIMAX 100 DIRECT-SPARK IGNITION LIGHTING/OPERA TIONNATURAL GAS & PROPANE

FOR YOUR SAFETY: READ BEFORE LIGHTING

WARNING

If you do not follow these instructions exactly, a fire or explosion may result causing property damage, personal

injury or loss of life.

2

A. This appliance is equipped with an ignition device

which automatically lights the burner. Do not try to

light the burner by hand.

B. BEFORE OPERATING smell all around the

appliance area for gas. Be sure to smell next to the

floor because some gas is heavier than air and will

settle on the floor.

SAFETY INFORMATION - IF YOU SMELL GAS, FOLLOW THESE RULES

1. Shut off gas line or propane tank.

2. Immediately call your gas supplier from a

neighbour's phone.

3. Follow the gas supplier's instructions.

4. If you cannot reach your gas supplier, call the fire

brigade.

STOP! HAVE YOU READ THE SAFETY INFORMATION?

C. Do not use this appliance if any part has been

under water. Immediately call a qualified

service technician to inspect the appliance and

to replace any part of the control system and

any gas control which has been under water.

D. Never store any materials within the vicinity of

the appliance or ventilation openings.

5. Do not light matches or lighter .

6. Do not try to light any appliance.

7. Do not touch any electric switch; do not use any

phone in your building.

8. Open all doors and windows. (Indoor)

OPERA TING INSTR UCTIONS

TO LIGHT THE APPLIANCE

1. Make sure pump is running and primed.

2. Push power switch on.

3. Set thermostat to desired setting.

4. The unit should spark and the burner should ignite.

5. In new installations where the gas line hasn't been

bled, the ignition sequence may require resetting by

interrupting the electrical supply following each

failed ignition.

6. If the heater does not operate as it should, in a

reasonable amount of time, read the

Troubleshooting Guide portion of this manual or

isolate gas supply and call a service technician at

your gas supplier .

TO TURN THE APPLIANCE OFF

1. Set the thermostat to lowest setting and turn off

power switch.

2. Turn off all electric power to the appliance if

service is to be performed, (if applicable).

Rev . A 2-4-2000 P/N 471438

3. If the appliance is to be turned off during a period

when frost is likely , consult your service

engineer/gas supplier to take the appropriate

action. (Drain the system.)

Users Section

MILLIV OL T LIGHTING/OPERATION- NA TURAL GAS & PROPANE

FOR YOUR SAFETY: READ BEFORE LIGHTING

WARNING

If you do not follow these instructions exactly, a fire or explosion may result causing property damage, personal

injury or loss of life.

BEFORE OPERA TING: Smell all around the appliance area for gas. Be sure to smell next to the floor because some gas is

heavier than air and will settle on the floor.

Do not use this appliance if any part has been under water. Immediately call a qualified service technician to inspect the

appliance and to replace any part of the control system and any gas control which has been under water.

NEVER store any materials within the vicinity of the appliance or ventilation openings.

SAFETY INFORMATION - IF YOU SMELL GAS, FOLLOW THESE RULES

1. Shut off gas line or propane tank.

5. Do not light matches or lighter .

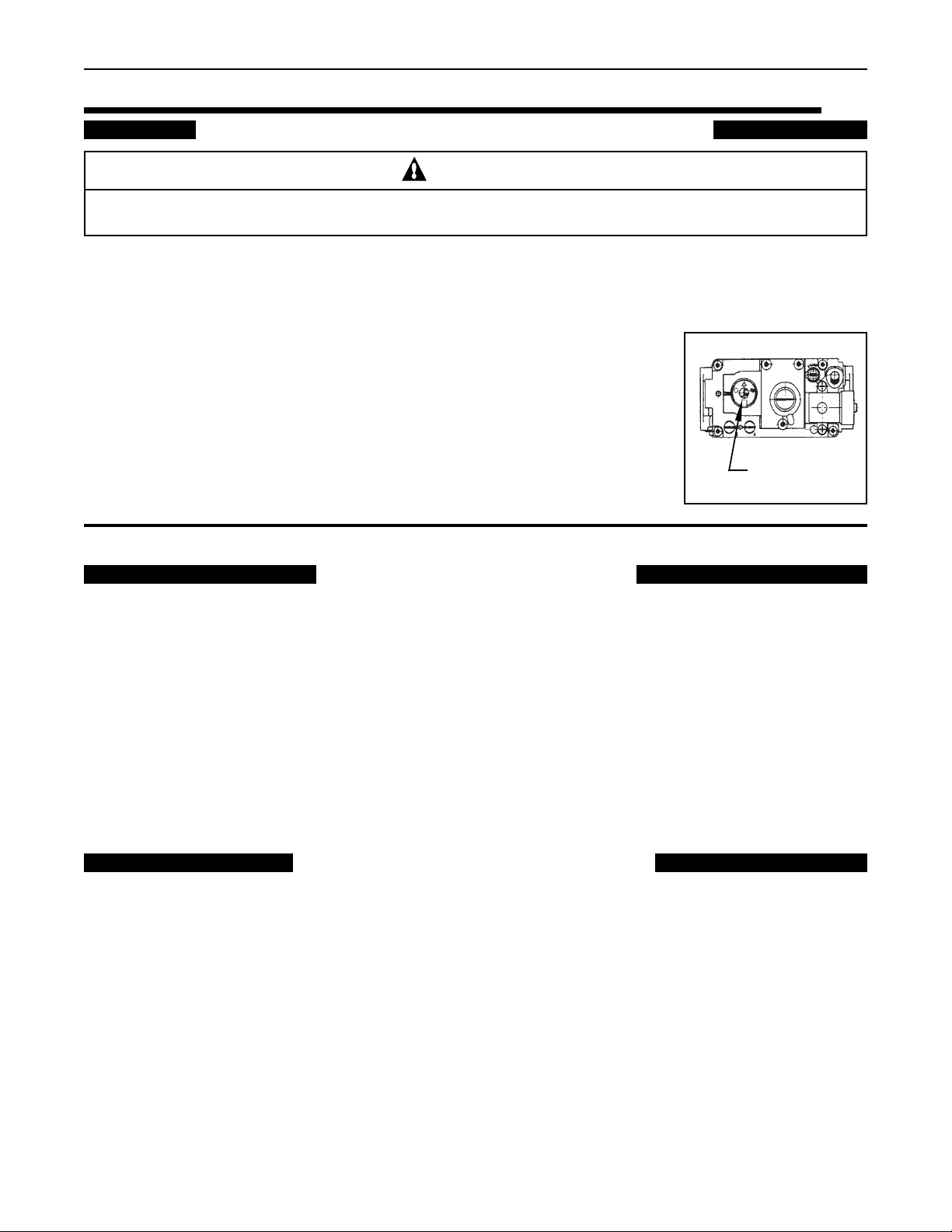

SIT V alv e

3

2. Immediately call your gas supplier

from a neighbour's phone.

3. Follow the gas supplier's instructions.

4. If you cannot reach your gas supplier,

call the fire brigade.

STOP! HAVE YOU READ THE SAFETY INFORMATION?

6. Do not try to light any appliance.

7. Do not touch any electric switch;

do not use any phone in your building.

8. Open all doors and windows. (Indoor)

On - Off Knob

Figure 1.

TO LIGHT THE APPLIANCE

1. Push power switch off. Remove the front casing door. Twist the black knob on the gas valve anti-clockwise to

the pilot position and release it.

2. Make sure pump is running and primed.

3. Push in and retain fully depressed the black knob on the gas control. At the same time, repeatedly operate the

piezo spark generator to produce a spark at the pilot burner. When the pilot has been lit, keep the black knob

depressed for a further 20 seconds. If the pilot does not remain alight when the black knob is released, twist

the knob clockwise then release it. Wait at least three minutes then repeat the procedure from step 5.

4. In new installations where the gas line hasn't been bled, the pilot may be slow to light.

5. When this pilot flame is established, turn knob anti-clockwise and turn the power on. Set the thermostat to the

desired setting and the main burner should light. Refit casing door.

6. If the heater does not operate satisfactorily, consult the T roubleshooting Guide portion of this manual.

TO TURN THE APPLIANCE OFF

FOR SHORT PERIODS

Set the thermostat to its lowest setting, wait two minutes, then turn the power off. (Turn off all electric power to

the appliance if a service is to be performed.)

NOTE: The appliance is fitted with a thermo-electric flame failure device therefore the pilot and gas cock

must not be turned off except for long term shut-down, emergencies, or servicing.

If the appliance is to be turned off during a period when frost is likely, consult your service engineer/gas

supplier to take the appropriate action. (Drain the system.)

FOR LONG PERIODS

Set the thermostat to it's lowest setting, wait two minutes, then turn the power off. Twist the black button on the

gas valve clockwise then release it. Turn off the gas cock.

NOTE: If severe weather (frost) conditions are anticipated during a period, shutdown the heater and

system must be completely drained. Consult your service engineer/gas supplier to take the appropriate

action. (Drain the system.)

P/N 471438 Rev. A 2-4-2000

Users Section

4

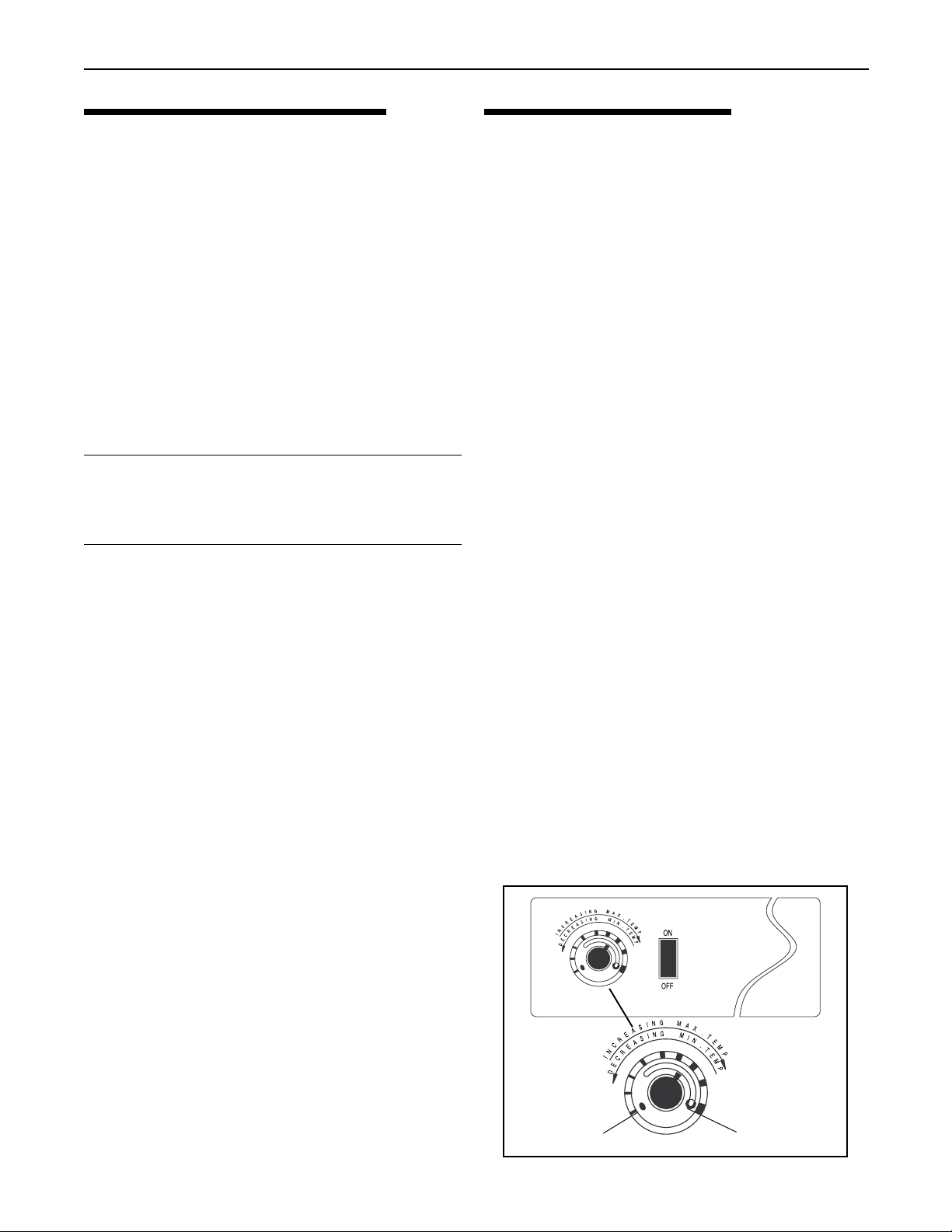

OPERA TING (CONTR OLS)

DIRECT SPARK ELECTRONIC AND

MILLIVOLT MODELS

For convenience and economy all MiniMax 100

heaters are equipped with a thermostat on the front of

the heater control panel; see Figure 2.

The Pool/Off/Spa switch allows the heater to be turned

off when heating is not desired.

1. "ON" position - Maintains selected pool temperature.

2. "OFF" position - Heater will not come on regardless

of drop in pool temperature.

SELECTOR DIALS

The selector dial (knob) eliminates constant thermostat

adjustments. Set the spa dial at the desired spa

temperature.

NOTE

To eliminate error due to piping heat losses,

measure pool temperature with an accurate

thermometer directly at the pool or spa.

If further adjustment is needed rotate the knob until the

desired temperature is obtained. This knob position

corresponding to your desired maximum pool or spa

temperature may now be preset (locked) by the knob

stopper which prevents the knob from being turned

beyond the maximum temperature you set.

THERMOSTAT KNOB STOPPER

Each thermostat is equipped with a mechanical stop

that can be locked or unlocked with use of a screwdriver to prevent temperatures in excess of that

desired by the user; see Figure 2.

The maximum setting can be adjusted by loosening

the screw "A" and turning the stopper dial to desired

maximum setting. Lock the setting by tightening the

screw . The Mechanical stop is under the knob.

Ensure that the knob is stopping at the correct

position when the knob is rotated clockwise from a

lower temperature position.

HEA TER OPERATION

GENERAL

The MiniMax 100 DBI employs a microprocessor

based Direct Spark Ignition (DSI) system to light the

main burner and therefore has no pilot. The ignition

circuit operates at 24 VAC and requires that a 230

VAC (50Hz) line voltage be supplied to the heater.

The MiniMax 100 MV (Millivolt) requires no external

power source and the control circuit derives all its

power from the energy generated from the standing

pilot/thermopile generator combination.

The MiniMax 100 DSI Control utilizes a

microprocessor to continually and safely monitor,

analyze, and control the proper operation of the gas

burner. The DSI Control features LED diagnostics,

automatic one hour reset, and flame current test pins.

The LED is located on the DSI.

CONTROLS OPERATION

Heat Mode

1. When a call for heat is received from the

thermostat supplying 24 volts to TH/W , the control

will reset, perform a self check routine, and flash

the diagnostic LED for up to four seconds. After a

brief delay the gas valve is energized and the

ignition electrode begins to spark for the four (4)

second trial for ignition period.

2. When flame is detected during the trial for ignition,

sparking is shut-off immediately and the gas valve

remains energized. The thermostat and main burner

flame are constantly monitored to assure the system

continues to operate properly .

a.When the thermostat is satisfied and the demand

for heat ends, the main valve is de-energized

immediately.

(DBI SYSTEM)

OVERHEAT THERMOSTAT

A manual reset overheat thermostat is fitted on the

RHS of the unit adjacent to the flow header .

Figure 2.

If the appliance will not light, press the overheat reset

button before contacting a service engineer.

If the overheat condition persists, contact a service

engineer or your gas supplier.

Rev . A 2-4-2000 P/N 471438

Knob Stopper

Screw A

Users Section

5

Failure to Light- Lockout (DBI Models Only)

1. Should the main burner fail to light, or flame is not

detected during the trial for ignition period the

control will go into lockout and the valve will be

turned off immediately .

2. Recovery from lockout requires a manual reset by

resetting the thermostat or turning off the ON/OFF

switch for a minimum period of 5 seconds.

IMPORTANT!

IT IS RECOMMENDED THAT NO MORE THAN

TWO IGNITION ATTEMPTS IN SUCCESSION

BE PERFORMED FOR NATURAL GAS

SYSTEMS . BEFORE FURTHER IGNITION

ATTEMPTS, WAIT AT LEAST FIVE MINUTES

FOR GAS TO CLEAR.

FOR PROPANE (LPG) SYSTEMS ALLOW AT

LEAST FIVE (5) MINUTES BETWEEN IGNITION

ATTEMPTS FOR THIS HEAVIER-THAN-AIR

GAS TO SAFELY DISSIPATE. AFTER TWO

UNSUCCESSFUL IGNITION ATTEMPTS WITH

PROPANE, OPEN THE BURNER ACCESS

DOOR AND WAIT AT LEAST THIRTY (30)

MINUTES BEFORE REPLACING DOOR TO

ATTEMPT FURTHER IGNITION ATTEMPTS.

Control Fault -Diagnostic LED Conditions

Error Mode LED Indication

Internal Control Failure Steady on

Flame Sense Fault 2 flashes

Ignition Lockout 3 flashes

The DBI Ignition Control can be accessed after

removing the heater’s front control panel. The

diagnostic LED located on the top of the DBI control

will flash on for 1/4 second, then off for 1/4 second

during a fault condition. The pause between fault codes

is 3 seconds.

NOTE

Normally the heater will light in the first or

second attempt. And with the exception of

a new installation or one that has been shut

down for an extended period, where there

is considerable air trapped in the gas

supply line, unsuccessful ignition indicates

other problems with the ignition system such as an unclean ignition electrode

impeding flame sensing.

3. If the thermostat is still calling for heat one hour

after a lockout the control will automatically reset

and attempt to ignite the burner again.

Flame Failure-Re-Ignition

1. If the established flame signal is lost while the

burner is operating, the control will respond within

0.8 seconds. The H.V. spark will be energized for a

trial for ignition period in an attempt to relight the

burner.

a.If the burner does not light, the control will

de-energize the gas valve, shutting off the gas

flow , and the control will go into lockout as

described above in “Failure to Light-Lockout." If

flame is re-established, normal operation resumes.

P/N 471438 Rev. A 2-4-2000

Loading...

Loading...