Page 1

OPERATORS MANUAL

Standard Horizon PF-P320 Paper Folder

PF-P320/OM

Read this manual, and thoroughly

familiarize yourself with its

contents before operating or

servicing this equipment.

Page 2

Page 3

I

PAPER FOLDER

Important Information

- This manual is designed to help you to install, operate and maintain the Table Top

Folder PF-P320. Read, understand and keep this manual in a safe and convenient

place.

- Do not operate the PF-P320 until you read and understand the instructions in this

manual.

- Horizon International Inc. shall not be liable for incidental consequential damages

resulting from : improper or inadequate maintenance by customer; unauthorized modification or misuse; operation outside of the environmental specifications for the product.

- No Horizon dealer and distributor is authorized to make any modification, expression, or addition to the warranties written in contract.

- Horizon International Inc. pursues a policy of continuing improvement in design and

performance of the product. Therefore, the product design and specifications are subject to change without prior notice and without our legal obligation.

- All rights are reserved. No part of the manual may be photocopied, reproduced or

translated to another language without the prior written consent of Horizon International Inc.

010711/PFP320/02E/DV UM203004-02

PF-P320

Page 4

II

Safety Precautions

- The signal word WARNING indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

- The signal word CAUTION indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may also be used to alert against

unsafe practices.

- The signal word NOTE indicates a potentially hazardous situation which, if not

avoided, may result in damage on products.

- Read and understand all safety instructions with signal word such as WARNING,

CAUTION and NOTE. If safety instructions are ignored, personal injury will result.

- Observe the provisions of the federal, state, or local regulations, including OSHA.

- Horizon International Inc. cannot anticipate every possible situation that might involve a potential hazard. The instruction in this manual and warning labels on the

machine are therefore not all inclusive.

- All equipment shall be locked out or tagged out to protect against accidental or inadvertent operation when such operation could cause injury to personnel. Do not attempt

to operate any switch, valve, or other energy isolating device where it is locked or

tagged out.

- Do not operate the machines with any covers being removed.

- Some of the drawings in this manual shows the machine uncovered for explaining the

detail or inside of machine.

Page 5

III

Contents

Important Information .....................................................................I

Safety Precautions ...........................................................................II

1. Before You Begin

This section explains machine parts and thier functions.

1-1 Specifications ............................................................................2

1-2 Machine Parts Descriptions ...................................................... 3

1-2-1 General View ................................................................... 3

1-2-2 Operation Panel ...............................................................4

1-3 Precaution When Sheets Are Piled. ..........................................5

2. Operation Procedure

This section explains stting up each parts and operation procedure.

2-1 Operation Procedure ................................................................. 10

2-2 Irregular Size Sheet Folding. .................................................... 14

2-3 Input / Call Memory..................................................................18

2-3-1 How to input folding size into memory...........................18

2-3-2 How to call memorized folding size................................18

2-4 Pad Pressure and Tray Pressure Adjustment. ...........................19

2-5 How To Set Preset Counter.......................................................20

2-6 How to Fold Cross- Fold and 12-page Letter Fold. ..................21

2-7 When Folding Is Not Even or Square .......................................25

2-7-1 Adjustment for uneven folding. .......................................25

2-7-2 Adjustment for not square folding...................................26

3. Troubleshooting

This section shows quick reference to troubles which can resolved or

prevented by operator.

3-1 Trouble Message Is Indicated on LCD. ....................................28

3-2 Before Calling Your Local Dealer ............................................30

4. Maintenance

This section explains maintenance for PF-P310.

4-1 How to Replace Feed Roller and Double Feed Stop Pad. ........ 32

4-2 How to Replace Folding Roller. ............................................... 33

4-3 How to Remove Jammed Sheets...............................................35

4-4 How to Clean Count Sensor......................................................36

4-5 Maintenance Kit (Option) .........................................................37

4-6 Cross Folding Guide (Option) .................................................. 37

4-7 Accessories ...............................................................................37

Page 6

IV

Page 7

1. Before You Begin

1

1. Before You Begin

This section explains machine parts and thier functions.

1-1 Specifications ......................................................................................... 2

1-2 Machine Parts Descriptions.................................................................. 3

1-3 Precaution When Sheets Are Piled. ..................................................... 5

Page 8

1. Before You Begin

2

Model: PF-P320

Standard Sheet size A3, A4, B4, B5 (5.5" x 8.5", 8.5" x 11", 9" x 11", 11" x 17")

Sheet size Maximum : 297 x 420 mm (11" x 17")

Minimum : 65 x 44 mm (2.6" x 1.7")

Paper Weight Normal paper 50 to 105 gsm

Operation speed 200 sheets/min. (A4 single fold )

Maximum Pile Height 30 mm (1.2")

Power supply 100 V 50/60 Hz 115 V 60 Hz

230 V 50 Hz

Power Consumption 100/115 V- 60 Hz ; 150 W

100 V - 50 Hz : 80 W

230 V- 50 Hz : 90 W

Machine size (W x D x H) 956 x 493 x 582 mm (Operating)

677 x 493 x 357 mm (Not operating)

Weight 36 kg (79,4 lb )

1-1 Specifications

The machine design and specifications are sbject to change without any notice.

Page 9

1. Before You Begin

3

Delivery Tray

The folded sheet will

be delivered on this

tray.

Tray Pressure Adjust Knob

Used to adjust the feed tray

pressure according to weight of

sheets.

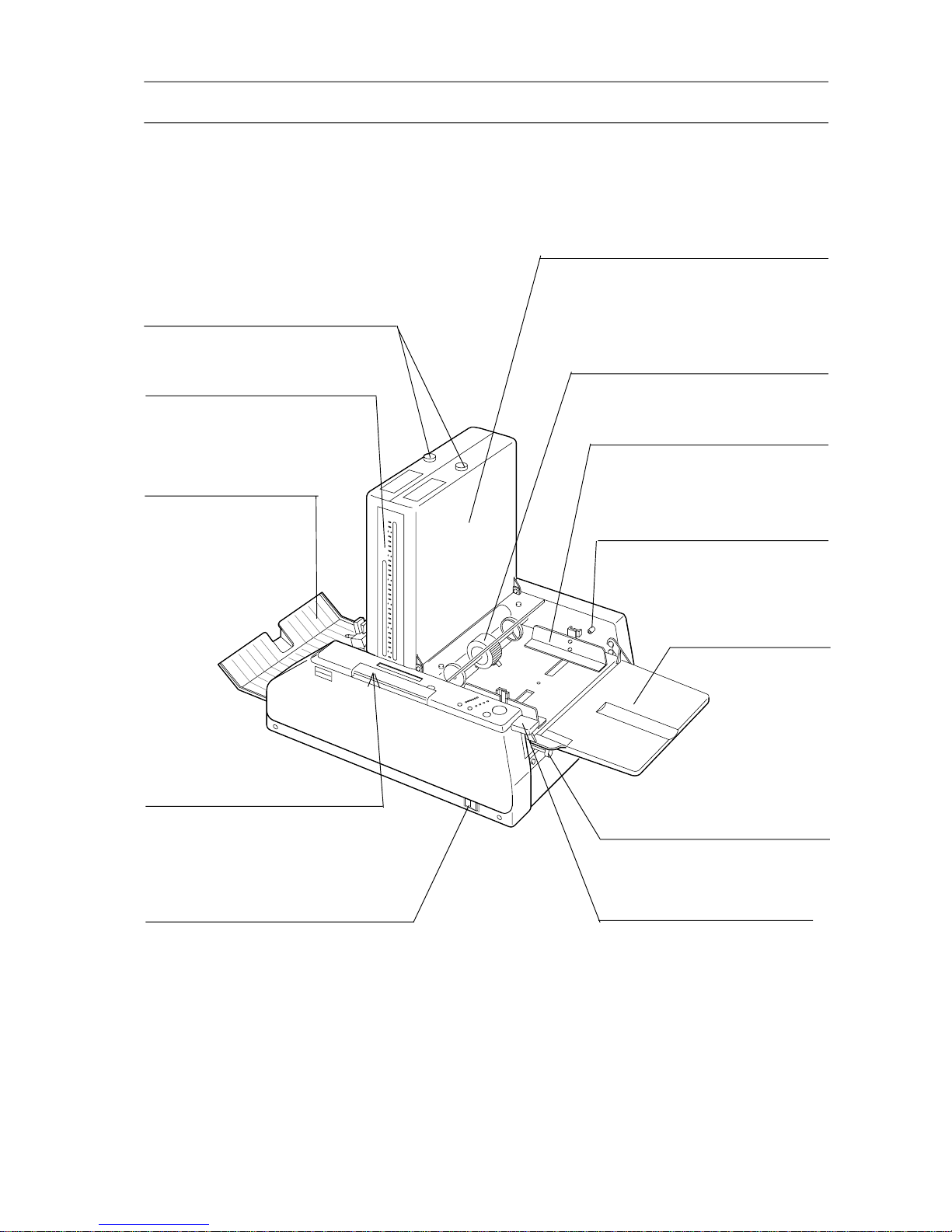

1-2 Machine Parts Descriptions

1-2-1 General View

Stopper Scale

Used as a reference of stopper

position when irregular size

sheets are folded.

Feed Roller

The Feed Roller is for feeding the

piled sheet to buckle section.

Feed Guide

Used to guide the piled sheet so

that sheets are fed straightly.

Power Switch

Used to turn on or off ( I / 0 )main

power.

Square Adjust Knob

Used to adjust square of folding sheet.

Function Switch Cover

Switches which will be used for

irregular size folding or memorizing stopper position are housed in

this position.

Feed Tray

Stocks are piled on

this tray.

Feed Tray Lever

Used to lower lever for piling,

and to raise for folding.

Buckle

Two stopper for folding are housed in

this section. ( when the jammed paper is

removed, and folding rollers are cleaned,

this part is opened )

Stopper Micro Adjust Knob

Used to adjust the stopper position.

Page 10

1. Before You Begin

4

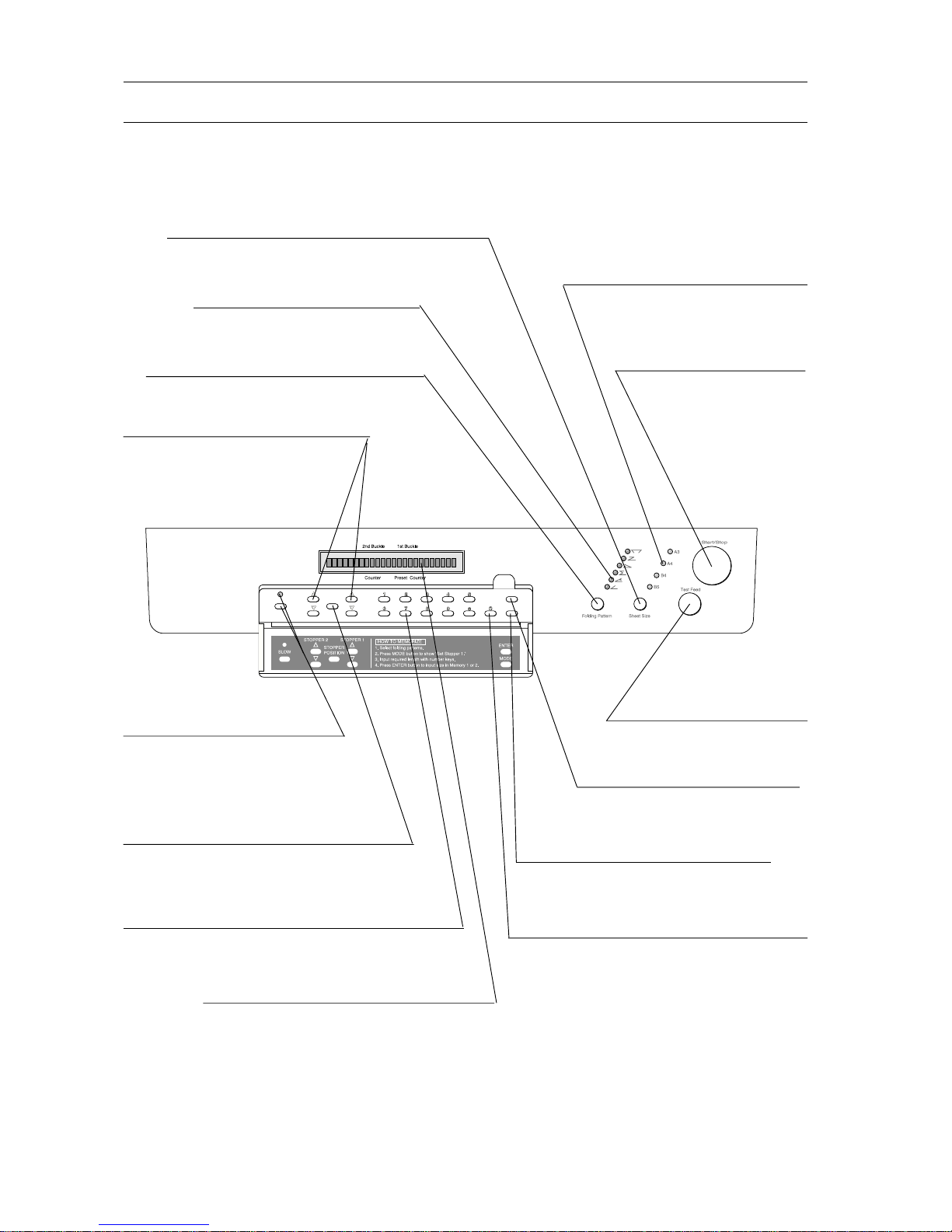

1-2 Machine Parts Descriprions

1-2-2 Operation Panel

Stopper Up / Down Button

Used to adjust stopper position

when irregular size sheet are

folded.

Memory and Access Button

Use to memory and to access

memory of the Stopper size.

Mode Select Button

Used to select memorized fold size.

Clear Button

Use to clear preset number, the number

of folding sheet, and stopper position

indication.

LCD

This is indicates the number of folded

sheets and the stopper position.

Sheet Size Lamp

Indication lamp of selected

sheet size with the Sheet Size

Select Button.

Fold Pattern Lamp

This indicates selected fold

pattern.

Folding Pattern Select Button

Used to select fold pattern.

Test Button

Used to feed one sheet

for testing.

Start and Stop Button

Used to start and stop

of folding.

Speed Select Button and

Speed Indication Lamp

When the indication lamp is

ON, folding speed is down

and the noise level will be

lower.

Sheet Size Select Button

Used to select sheet size A3, A4, B4, B5 (11 x

17, 81/2 x 11, 6 x 9, 51/2 x 81/2 ).

Stopper Location Button

When this button is depressed, current

stopper positions are indicated.

Number Entry Key

Used to input predetermined folds number or to

input required stopper position.

Page 11

1. Before You Begin

5

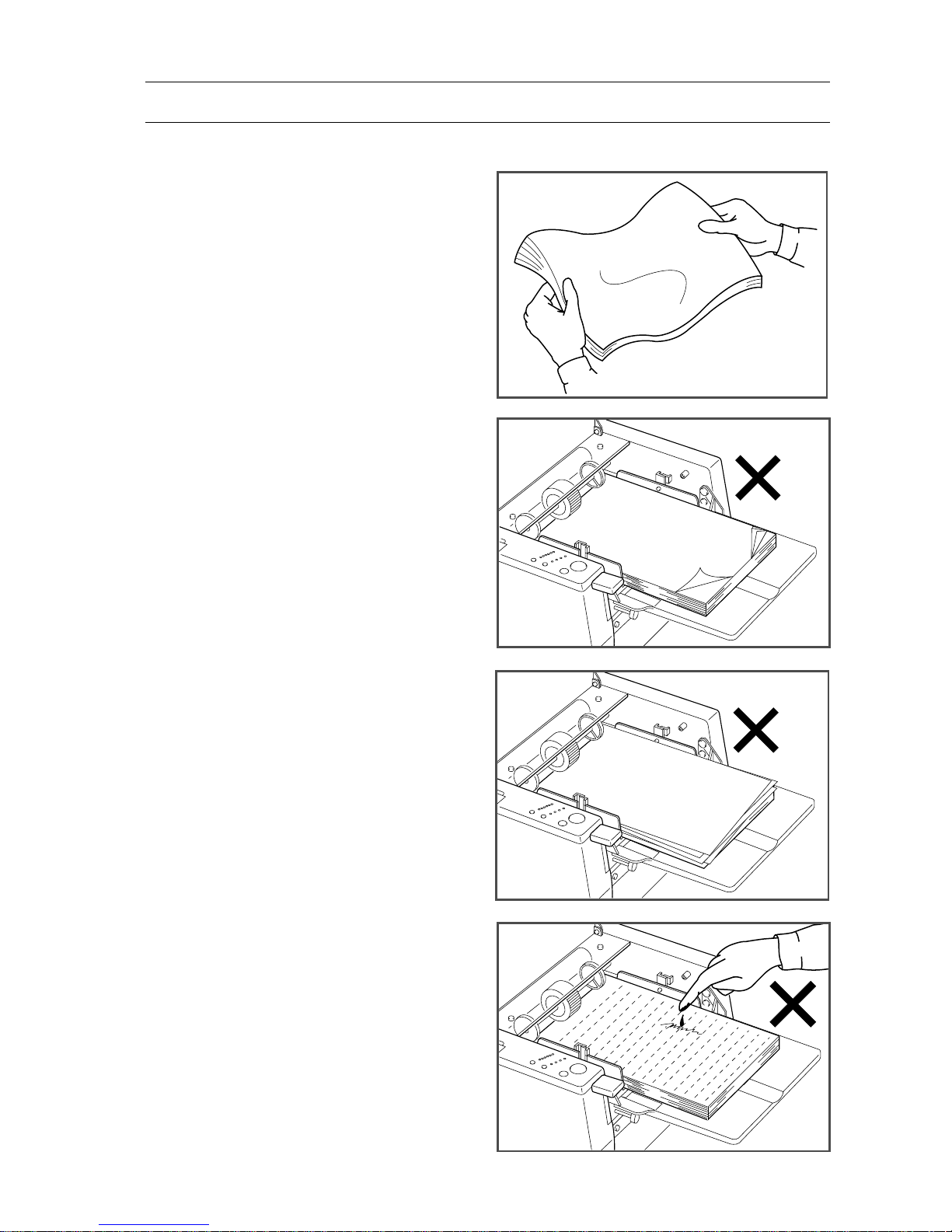

1-3 Precaution When Sheets Are Piled.

1.Fun well the sheet before piling on the

feed tray. Otherwise, double sheet feeding or miss feed will occur.

2.Straighten up the curled sheet or folded

sheet.

3.Jog well the sheet before piling on the

feed tray. Otherwise, jamming or miss

feed or fold on edge of sheet will occur.

4.Make sure that the printed ink is dry

enough. Otherwise, double sheet feed

will occur. The wet ink will not only

be stain the printed sheet but also make

lower the precision of folding of this

machine.

Page 12

1. Before You Begin

6

Page 13

2. Operation Procedure

7

2. Operation Procedure

This section explains stting up each parts and operation procedure.

2-1 Operation Procedure........................................................................... 10

2-2 Irregular Size Sheet Folding. ............................................................. 14

2-3 Input / Call Memory. .......................................................................... 18

2-4 Pad Pressure and Tray Pressure Adjustment. ................................. 19

2-5 How To Set Preset Counter ................................................................ 20

2-6 How to Fold Cross- Fold and 12-page Letter Fold. ......................... 21

2-7 When Folding Is Not Even or Square ............................................... 25

Page 14

2. Operation Procedure

8

OPEN

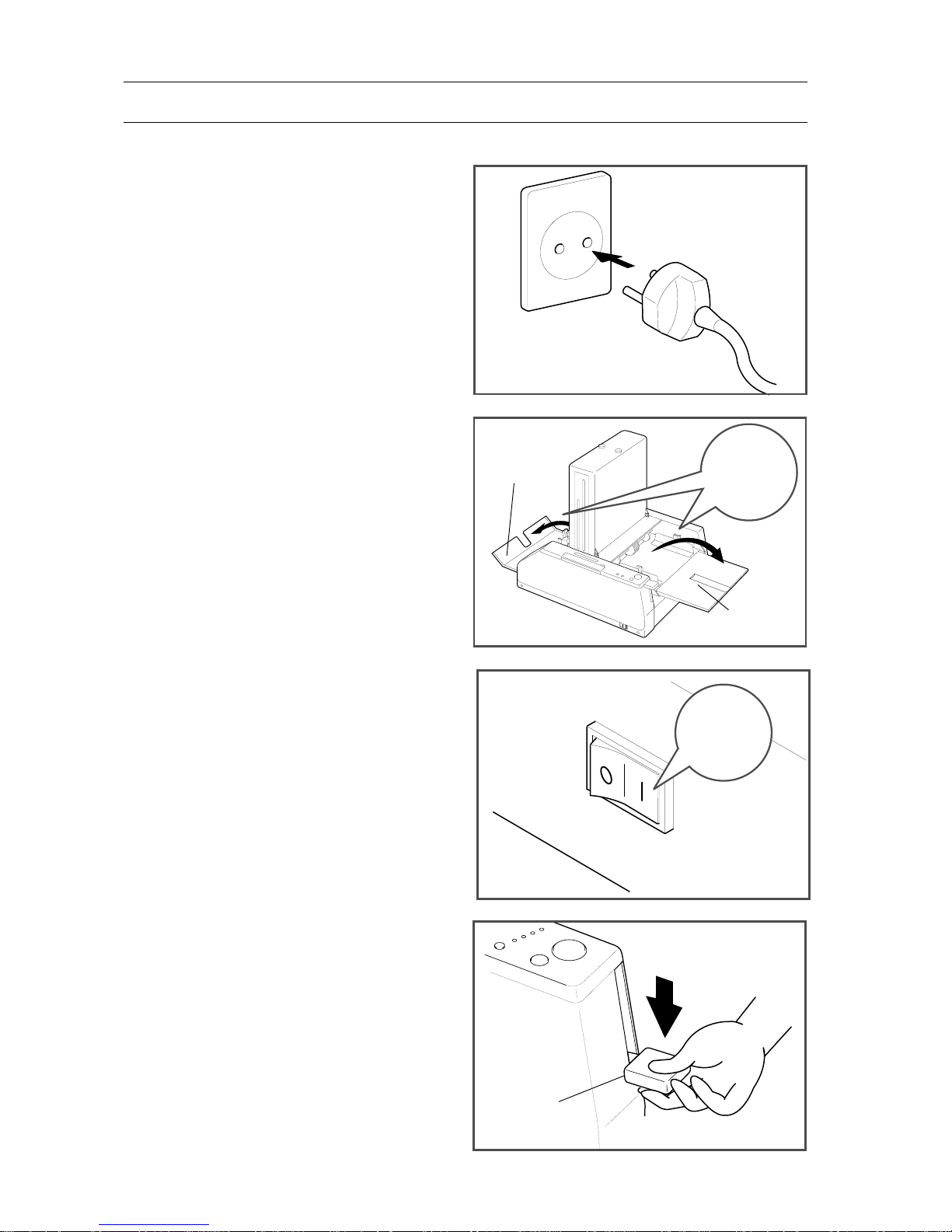

1.Plug power cord to out let.

2.Open delivery tray and feed tray.

3.Turn on power switch.

4. Lower feed tray lever.

Feed Tray

Lever

2-1 Operation Procedure

Delivery

Tray

Feed Tray

ON !

DOWN!!

Page 15

2. Operation Procedure

9

10mm

5.Jog well and true up sheets toward feed

roller.

-Sheets must be placed center of feed tray

according to sheet size indication.

6.Slide both feed guide so that they

slightly touch piled sheets.

-Place support rollers at 10 mm inside of

sheet edge.

7. Select sheet size with sheet size select

button.

NOTE:

When irregular size sheets are folded,

refer to "2-2 Irregular Size Sheet Folding"

(page 15).

8. Select folding pattern with folding

pattern select button.

Feed Guide

Support Roller

2-1 Operation Procedure

Feed Tray

A3

B4

A4

B5

Sheet SizeFolding Pattern

Select

ABC

ABC

ABC

ABC

ABC

ABC

Select

Page 16

2. Operation Procedure

10

S

S

L

L

Red

Mark

9. Align red mark (center of delivery

roller) to illuminated roller position

lamp.

10. Raise feed tray lever.

11. Depress test button (Only one sheet is

fed and folded ).

- When sheet is not fed or more than two

sheets are fed, adjust position of the tray

pressure adjust knob and pad pressure

adjust knob. Refer to "2-4 Pad Pressure

and Tray Pressure Adjustment." (page

19)

12. Check folded sheet.

NOTE:

If folding is not even, or not square, perform

buckle stopper micro adjustment. Refer to

reference guide on top of buckle, also refer

to "2-7 When Folding is Not Even or

Square." (page 25) depress test button again.

2-1 Operation Procedure

LED

Stopper Micro Adjust Knob

Reference

Guide

Delivery

Roller

UP!!

Start/Stop

Test Feed

A3

B4

A4

B5

Sheet Size

Page 17

2. Operation Procedure

11

13. Depress start / stop button (Folding is

started ).

14. When you want to stop folding, de-

press start / stop button or lower feed

tray lever.

- If require number of folding is input in

preset counter, folding will stop automatically as soon as counter reaches

preset number. Refer to "2-5 How To

Set Preset Counter" (page 20)

15. When your folding job is finished, turn

off power switch.

16. Pull out power cord after turn off

power.

- Close the delivery tray and the feed tray.

2-1 Operation Procedure

OFF!

DOWN!!

Start/Stop

or

Start/Stop

Page 18

2. Operation Procedure

12

• Single Fold

• Parallel Fold

(Stopper 2 does not require input size.)

1 = Size for Stopper 1

2 = Size for Stopper 2

printed (face) side.

2-2 Irregular Size Sheet Folding.

NOTE

Folding size can be memorized.

1. Fold sheet with your hands in your

required form.

2. Measure size of holding edge to input

size for Stopper 1 and Stopper 2 with a

scale. In this process, different edge

must be measured according to folding

pattern.

[ How to measure size of folding edge and

how to pile sheets.]

Page 19

2. Operation Procedure

13

• Short Fold

• Letter Fold

• Accordion Fold

• Gate Fold

2-2 Irregular Size Sheet Folding.

1 = Size for Stopper 1

2 = Size for Stopper 2

printed (face) side.

Page 20

2. Operation Procedure

14

3. After following "3-1 Operation Proce-

dure: steps 1 to 6 (pages 12 and 13),

select fold pattern with fold pattern

select button.

4. Open function switch cover.

5. Select set up mode "Set Stopper 1" with

mode select button.

6. Input required sizes which measure it in

step 2 (pages 14 and 15) with number

entry key.

-The size unit is "mm."

NOTE

- The stopper 1 input range is from 50 to 325

mm. If the input figure is out of the range,

the message "000.0 Set Stopper 1" will be

indicated on LCD.

- If it takes two seconds or more to input size,

the message "000.0 Set Stopper 1" will be

indicated on LCD again. Input folding size

with number entry key once again.

Function Switch Cover

2-2 Irregular Size Sheet Folding.

STOPPER

POSITION

STOPPER 1

HOW TO MEMORIZE

1. Select folding patterns.

2. Press MODE button to show "Set Stopper 1."

3. Input required length with number keys.

4. Press ENTER button to input size in Memory 1 or 2.

ENTER

MODE

Number

Entry Key

1 0 0 . 0 S e t S t o p p e r 1

ABC

ABC

ABC

ABC

ABC

ABC

Select

Page 21

2. Operation Procedure

15

0 / 0

M

e m o r y 1 P r e s s

MEMORY

7. After stopper 1 is input,indication of

LCD moves to "000,0 set stopper 2".

NOTE

- When single fold is selected, the message

"000.0 Set Stopper 2" is not indicated on

LCD.

- The stopper 2 input range is from 50 to 215

mm. If the input figure is out of the range,

the message "000.0 Set Stopper 2" will be

indicated on LCD.

- If it takes two seconds or more to input,

the message "000.0 Set Stopper 2" will be

indicated on LCD again. Input folding size

with number entry key once again.

8. After Stopper 2 is input, " Memory 1

Press MEMORY" is indicated on LCD.

Then if mode select button is depressed,

the message "Memory 2 Press Memory"

is indicated on LCD, and this button is

depressed twice, "0 / 0" (counter) is

indicated on LCD.

NOTE

When Stopper size is set with number entry

key, lamp at delivery section doesn't turn on.

When smaller sheet is used, set to right side,

and when lager sheet is used, set to left side.

If you want to input folding size to

memory, refer to "2-3 Input / Call

Memory" (page 18).

Memory Mode

Counter Mode

2-2 Irregular Size Sheet Folding.

STOPPER

POSITION

STOPPER 1

HOW TO MEMORIZE

1. Select folding patterns.

2. Press MODE button to show "Set Stopper 1."

3. Input required length with number keys.

4. Press ENTER button to input size in Memory 1 or 2.

ENTER

MODE

Number

Entry Key

1 2 0 . 0 S e t S t o p p e r 2

Left

Right

Page 22

2. Operation Procedure

16

2-3 Input / Call Memory.

2-3-1 How to input folding size into memory.

Folding size can be input the Memory upto

two different folding sizes.

1.Depress mode select button 3 times.

"Memory 1 Press MEMORY" is indicated on LCD. Depress mode select

button 4 times. "Memory 2 Press

MEMORY" is indicated on LCD.

2.When "Memory 1 Press MEMORY" or

"Memory 2 Press MEMORY" is indicated on the LCD, it is possible to input

present position of stopper with memory

button.

NOTE

- When memory button is depressed, previous memory is erased and the new memory is

stored.

- After inputting folding size, "0 / 0" is

indicated automatically on LCD.

-Memory will hold after power is OFF.

2-3-2 How to call memorized folding

size.

Depress memory button, and memorized

folding size is shown in LCD.

- Depress memory button once to call

Memory 1.

- Depress memory button twice, to call

Memory 2.

- When irregular sized sheet which is

memory is folded, follow "2-1 Operation

Procedure : step 1 ~ 6" (page 10 ~ 11 ).

After calling memory, follow "2-1 Operation Procedure" (page 12 ).

NOTE

When Stopper size is set with number entry

key, lamp at delivery section doesn't turn on.

When smaller sheet is used, set to right side,

and when lager sheet is used, set to left side.

Page 23

2. Operation Procedure

17

Normal

Weak

Strong

Normal

Weak

Paper type / Feeding condition

Normal Sheet

Thin Paper

Double Sheet Feeding Occurs

Miss Feed Occurs

Cross Folding

• Pad Pressure Knob.

• Tray Pressure Knob.

Medium

Weak

Normal or Weak

Strong

Strong

Pad Pressure adjusting

Knob position

Tray Pressure Knob Position

2-4 Pad Pressure and Tray Pressure Adjustment.

Pad pressure and tray pressure are adjusted

with each Knob.

Strong

Normal

Weak

PULL

Tray

Pressure

Weak

Strong

PULL

Medium

Page 24

2. Operation Procedure

18

2-5 How To Set Preset Counter

- When "counter" (0/0) is indicated on

LCD, it is possible to set required number

of sheet to be folded ten number entry

key.

NOTE

- Maximum number can be set is 9999.

- When you input wrong numbers,

depress clear button and input again.

- When folding started, counter is added

according to folding, and when folding

reaches to preset number, folding will stop

automatically.

Page 25

2. Operation Procedure

19

2-6 How to Fold Cross- Fold and 12-page Letter Fold.

NOTE

- In case of Cross fold or 12-page letter

folding, sheet wider than 210 mm (8.5") may

not be folded completely.

- In case of cross fold or 12-page letter

folding, to use, Cross Folding Guide

(option) is recommended.

( Meaning of cross folding )

Sheet is folded into half, and then this

single folded sheet (signature) is folded

once again in half.

When folded sheet is opened, each

creases of this signature become crisscross pattern.

( Meaning of sheet 12-page letter fold )

Sheet is folded into half, and then this

single folded sheet is folded in letter size.

In this section, procedure of folding is

explained with A3 (11" x 17") size sheet

without using cross folding guide (Option).

1.Fold A3 size sheet into half

(Please refer to “3-1 Operation Proce-

dure” in page 12.)

2. Press tightly fold edge of sheets.

NOTE

If fold edge of sheet is not pressed sufficiently, sheet (signature) will not be folded

completely.

[Crossed Letter Folding]

[Cross Fold]

A crease of sheet

Page 26

2. Operation Procedure

20

1

2

2

1

3. Set double feed stop pad knob to

“Weak” and set feed tray pressure knob

to “Strong ”.

4.After Perform “3-1 Operation Step :

Step 1~4 in page 12”, pile folded sheets

on feed tray.

- Illustration shows that sheets are piled at

non-operator side and fold edge faces

operator side.

NOTE

Pile folded sheets half depth of Feed Guide.

If too much folded sheets are piled on feed

tray at once, it is not possible to fold completely.

5.Set feed guides so that they will slightly

touch sheets.

5-1 If width of folded sheets is narrower

than 185 mm, Set feed guide at operation side to fully non-operation side,

The other feed guide must be set according to width of folded sheets.

5-2 If width of folded sheets is wider than

185 mm, set feed guide at non-operation

side. The other feed guide must be set

according to width of folded sheets.

Feed Guide

Feed Guide

2-6 How to Fold Cross- Fold and 12-page Letter Fold.

Fold

Edge

Strong

Normal

Weak

PULL

Tray

Pressure

Weak

Strong

PULL

Medium

Weak ! Strong!

Page 27

2. Operation Procedure

21

20mm

6. Set support roller.

- Support roller at operation side must be

set on fold edge.

- Support roller at non operator side must

be positioned at 20 mm inside of edge of

sheets.

7. Select sheet size.

Original sheet size : A3 Select A4

Original sheet size : B4 Select B5

Irregular size sheet :Input suitable size

with ten number

buttons. (Please refer

to "4-2 Irregular Size

Sheet Folding" in

page 14

8. Set delivery roller, raise feed tray, and

then depress Start/Stop Button.

- When folded sheet is fed, hold folded

edge slightly with your fingers.

NOTE

Cross fold guide is prepared as an option

parts for quantity folding job.

9.When you finish folding job, turn off

power, pull out power cord, and close

delivery tray and feed tray.

3-6 How to Fold Cross- Fold and 12-page Letter Fold.

Start/Stop

A3

B4

A4

B5

Sheet Size

Select

1

2

345

6

7

8 9

0

C

1

2

345

6

7

89

0

C

STOPPER

POSITION

STOPPER 1

HOW TO MEMORIZE

1. Select folding patterns.

2. Press MODE button to show "Set Stopper 1."

3. Input required length with number keys.

4. Press ENTER button to input size in Memory 1 or 2.

ENTER

MODE

Number Keys

5 . 0 0 0 S e t S t o p p e r 1

Support Rollers

Page 28

2. Operation Procedure

22

Roller

Roller

(Left)

(Right)

2-6 How to Fold Cross- Fold and 12-page Letter Fold.

How to set Cross Folding Guide (Option)

- Cross folding guide (option) is used to

hold folding edge when second folding is

performed.

- Set cross folding guide along feed guide

on feed tray.

Cross Folding Guide

Cross Folding

Guide

Page 29

2. Operation Procedure

23

S

S

L

L

Gate Fold

Letter Fold

Short Fold

Parallel Fold

03PFP320A60

is long : L

is short : S

Single Fold

is long : L

is short : S

is long : L

is short : S

is long : L

is short : S

is long : L

is short : S

is long : L

is short : S

is long : L

is short : S

is long : L

is short : S

is long : L

is short : S

is long : L

is short : S

is long : L

is short : S

Stopper (2) Micro

Adjust Knob

Appearance of

delivered sheet

Accordion Fold

Appearance of

delivered sheet

Stopper (2)

Stopper (1)

2-7 When Folding Is Not Even or Square

2-7-1 Adjustment for uneven folding.

In case that one side of fold sheet is long

or short, adjust folding with stopper

micro adjust knob on top of buckle.

NOTE

- Following chart shows style of delivered

sheet.

- Turn stopper micro adjust knob gradually,

and adjust folded position with verifying

appearance of folded sheet.

Stopper (1) Micro

Adjust Knob

Page 30

2. Operation Procedure

24

2-7 When Folding Is Not Even or Square

2-7-2 Adjustment for not square folding.

Square Adjust Knob

Square Adjust Knob

Appearance of delivered sheet

Appearance of delivered sheet

When not square folding occurs, adjust

square with square adjust knob.

Page 31

3. Troubleshooting

25

3. Troubleshooting

This section shows quick reference to troubles which can resolved or

prevented by operator.

3-1 Trouble Message Is Indicated on LCD.............................................. 28

3-2 Before Calling Your Local Dealer ..................................................... 30

Page 32

3. Troubleshooting

26

(COUNTERMEASURE)

Turn off power, remove jammed sheet

(Refer to "4-3 How to Remove Jammed

Sheets" in page 37.) Then push breaker

button and turn on power.

(COUNTERMEASURE)

Turn off power and turn stopper micro

adjust knob counterclockwise (3 turns).

Then push breaker button. In case stopper

will be locked as soon as power is ON, call

your local dealer.

(COUNTERMEASURE)

Turn off power and turn stopper micro

adjust knob so that stopper moves up about

20 mm. Then push breaker button. When

power is turned on, depress and hold clear

button.

In case Stopper will be locked as soon as

power is on, call your local dealer.

NOTE

If above is performed, memorized folding size in

Memory 1 and Memory 2 will be erased.

3-1 Trouble Message Is Indicated on LCD.

In case of miss operation or improper process of function, trouble message is indicated on

LCD. Follow countermeasure listed below.

INDICATION 1

Error ................. Check Breaker

(CAUSE 1)

Circuit breaker for buckle is tripped

because of paper jam.

(CAUSE 2)

Stopper in 1st or 2nd buckle is

locked at top dead end.

(CAUSE 3)

Stopper in 1st or 2nd buckle is

locked at bottom dead end.

Breaker

Page 33

3. Troubleshooting

27

3-1 Trouble Message Is Indicated on LCD.

(CAUSE )

This is indicated when feed tray will

be empty.

INDICATION 3

Raise Tray

(CAUSE )

This is indicated when start/stop

button is depressed with being feed

tray lever at down position.

INDICATION 4

Close Buckle

(CAUSE )

This is indicated when buckle lever

is opened.

INDICATION 5

0/0 ......... Jamming

(CAUSE )

This message is indicated when

sheet is jammed in buckle or between folding rollers.

INDICATION 6

0/0 .......... Feed Error

(CAUSE )

This message is indicated when

sheet is not fed.

(COUNTERMEASURE)

Pile sheets on feed tray.

NOTE

This message will be reset with depressing Start/

Stop Button.

(COUNTERMEASURE)

Raise feed tray and depress start/stop button.

(COUNTERMEASURE)

Close buckle and set buckle lever in position.

(Refer to "4-3 How to Remove Jammed

Sheets" in page 37.)

(COUNTERMEASURE)

Remove jammed sheet from buckle and

between folding rollers.

( Refer to "4-3 How to Remove Jammed

Sheets" in page 37.)

(COUNTERMEASURE)

Fun well piled sheets once again. Moreover,

set pad pressure to weak position or set feed

tray pressure to strong position.

INDICATION 2

Empty Tray

Page 34

3. Troubleshooting

28

CONDITION 1

Folding result is not good.

(CAUSE )

1. Sheet is too thin or too thick.

2 Sheet is not square.

3. Sheet is wavy because of humidity.

4. Sheet is curled.

5. Feed guides are set improperly.

6. Folding rollers are stained with ink.

7. Feed roller and/or double sheet stop pad

are/is worn out.

8. Folding rollers are worn out.

9. A piece of sheet is jammed in buckle.

10. Folding rollers are not set properly.

(COUNTERMEASURE)

1. Sheets out of specification may be difficult to fold. (Refer to "1-1 Specifications" in page 2.)

2. Use 100% square sheets.

3. Remove waved sheets.

4. Straighten up curled sheets.

5. Adjust feed guide so that sheet are fed

straightly.

6. Clean folding rollers with roller cleaning

liquid. (Refer to "4-2 How to Replace

Folding Roller" in page 35 to 36.)

7. Replace feed roller and/or double sheet

stop pad. It is recommended to replace

pad and double sheet stop pad after

150,000 to 300,000 folding. (Refer to "41 How to Replace Double Sheet Stop

Pad and Feed Roller" in page 34.)

8. Replace folding rollers. (Refer to "4-2

How to Replace Folding Roller" in page

35 to 36 )

9. Open buckle and remove jammed sheet.

(Refer to "4-3 How to Remove Jammed

Sheet" in page 37.)

10. Make sure that folding rollers are set

completely. (Refer to "4-2 How to

Replace Folding Roller" in page 35 to

37.)

3-2 Before Calling Your Local Dealer

Page 35

3. Troubleshooting

29

CONDITION 2

Double feed often occur.

(CAUSE )

1. Sheets are stuck together because of ink

or static electricity.

2. Double feed stop pad pressure is set at

weak position.

3. Feed tray pressure is set at strong position.

CONDITION 3

Folded sheets are stained with ink.

(CAUSE )

1. Feed roller, double feed stop pad or

folding rollers are stained with ink.

CONDITION 4

(CAUSE )

1. Double feed stop pad or feed roller is

worn out.

2. Feed roller or double feed stop pad is

contaminated with ink or alike.

CONDITION 5

Sheet jam often occur.

(CAUSE )

1. A Piece of paper or torn sheet stopped in

buckle.

(COUNTERMEASURE)

1. Fun well sheets once again.

2. Set pressure at normal position. (Refer to

"2-4 Pad Pressure and Tray Pressure

Adjustment" in page 19.)

3. Set pressure at normal position. (Refer to

"2-4 Pad Pressure and Tray Pressure

Adjustment" in page 19.)

(COUNTERMEASURE)

1. Clean stained parts with alcohol or roller

cleaning liquid soaked cloth.

(COUNTERMEASURE)

1.Replace feed roller and/or double feed

stop pad. It is recommended to replace

pad and feed roller after 150,000 to

300,000 folding. (Refer to "44-1 How to

Replace Double Sheet Stop Pad and

Feed Roller" in page 34.)

2.Clean double feed stop pad and feed roller.

(COUNTERMEASURE)

1. Open buckle and remove sheet. (Refer to

"4-3 How to Remove Jammed Sheet" in

page 37 )

Both double feed and misfeed often occur.

3-2 Before Calling Your Local Dealer

Page 36

3. Troubleshooting

30

CONDITION 6

Sheets are wrinkled.

(CAUSE )

1. Sheets are curly or wavy.

2. Folding rollers are deformed by friction

after long time use.

3. Sheets contain too much moisture.

4. Folding roller is wet with ink.

CONDITION 7

(CAUSE )

1. Memory function in folder shows some

irregular condition.

(COUNTERMEASURE)

1. Set double feed stop pad and feed tray

pressure at weak. Also slow down operation speed with speed select button.

2. Replace folding rollers to new one.

(Refer to "4-2 How to Replace Folding

Roller" in page 35 to 36 )

3. Dry sheets before fold.

4. Clean folding rollers with roller cleaning

liquid or replace it to new one.

(COUNTERMEASURE)

Turn off power switch , then turn on it

again with depressing clear button.

NOTE

If above is performed, memorized folding

size in Memory 1 and Memory 2 will be

erased.

In case above will not correct function,

please contact your local dealer.

Fold pattern lamp or sheet size lamp is flashing. Or alarm starts as soon as

power is ON.

3-2 Before Calling Your Local Dealer

Page 37

4. Maintenance

31

4. Maintenance

This section explains maintenance for PF-P310.

4-1 How to Replace Feed Roller and Double Feed Stop Pad. ............... 32

4-2 How to Replace Folding Roller. ......................................................... 33

4-3 How to Remove Jammed Sheets ........................................................ 35

4-4 How to Clean Count Sensor ............................................................... 36

4-5 Maintenance Kit (Option) .................................................................. 37

4-6 Cross Folding Guide (Option) ............................................................ 37

4-7 Accessories ........................................................................................... 37

Page 38

4. Maintenance

32

1

2

4-1 How to Replace Feed Roller and Double Feed Stop Pad.

- When feed roller or double feed stop pad

getting contaminated with paper dust or

ink, sheet feeding becomes uncertain.

Firstly, clean roller and/or pad. If necessary replace them to new one.

It is recommended to replace feed roller

and pad after 150,000 to 300,000 folding.

NOTE

Total number of folding is indicated on LCD

by turning on power with "2" in number

entry key being depressed at same time.

WARNING

Turn off power before replacing feed

roller and/or double feed stop pad.

(Feed Roller Replacement)

1.Push feed roller shaft to arrow 1 , then

pull shaft to arrow 2 .

2.Remove support roller and then replace

feed roller to new one.

(Double Feed Stop Pad Replacement)

1.Remove feed roller shaft.

2.Pull up double feed stop pad. And

replace it to new one.

(Cleaning)

1.Clean feed roller and pad with roller

cleaning liquid or alcohol soaked cloth.

Double Feed

Stop Pad

Feed Roller

Feed Roller

Support Roller

Double Feed

Stop Pad

Power Switch

Page 39

4. Maintenance

33

1

2

Folding roller contaminated with ink/dust or

worn our folding roller may effect on folding

accuracy.

WARNING

Turn off power and pull out power

cord whenever folding rollers are

replaced.

1.Push delivery roller shaft to arrow 1 ,

then pull delivery roller to arrow 2.

2.Pull down buckle hook.

3.Remove two rubber folding rollers

under buckle.

4.Clean folding rollers with roller clean-

ing liquid or alcohol soaked cloth, or

replace them to new one if necessary.

Folding

Roller

4-2 How to Replace Folding Roller.

Buckle Hook

Delivery

Roller

Page 40

4. Maintenance

34

P

A

P

E

R

F

O

L

D

E

R

H

O

R

I

Z

O

N

PF-P32

(How to Install Folding Rollers)

1.Place folding roller shaft on roller

holding plate which is showed with

yellow arrow mark.

2.Close buckle hook.

3.Check whether rubber rollers rotate

freely by hand. If not pull down buckle

hook and make sure that rollers are

properly positioned. And then close

buckle hook.

4-2 How to Replace Folding Roller.

Roller Holding

Plate

Folding Rollers

Buckle Hook

Yellow Allow Mark

Page 41

4. Maintenance

35

WARNING

Turn off power before removing

jammed sheet.

1.Push delivery roller shaft to arrow 1 ,

then pull delivery roller to arrow 2 .

2.Pull down buckle hook.

3.Lay down buckle to arrow direction.

NOTE

Lay down buckle carefully with both hand as

Buckle is quite heavy.

4.Remove jammed sheet in buckle.

After removed jammed sheet, revert

buckle, buckle hook and delivery roller in

operating condition.

4-3 How to Remove Jammed Sheets

1

2

Buckle Hook

Delivery

Roller

Jammed

Sheet

Buckle

Page 42

4. Maintenance

36

4-4 How to Clean Count Sensor

1

2

Buckle Hook

Delivery

Roller

Buckle

If the dust or paper powder covers the

counter sensor, the folded sheet may not be

counted.

WARNING

Turn off power before removing

jammed sheet.

1. Push delivery roller shaft to arrow 1 ,

then pull delivery roller to arrow 2 .

2. Pull down buckle hook.

3. Lay down buckle to arrow direction.

NOTE

Lay down buckle carefully with both hand as

Buckle is quite heavy.

4. Clean the counter sensor with brush

softly.

NOTE

Clean the reciever of the sensor also.

After cleaning the counter sensor, revert

buckle, buckle hook and delivery roller in

operating condition.

Counter Sensor

Page 43

4. Maintenance

37

Maintenance Kit M792048-00

1. Roller Cleaning Liquid XPF-111 (2 bottles)

2. Double Feed Stop Pad M002063-00 (4 piece)

3. Feed Roller M001978-00 (2 piece)

4. Folding Roller M015029-00 (2 piece)

4-5 Maintenance Kit (Option)

4-6 Cross Folding Guide (Option)

1. Cross Folding Guide for right side

2. Cross Folding Guide for left side.

M850054-00

1

2

1

2

3

4

4-7 Accessories

2

1

3

T

O

T

A

L

B

I

N

D

I

N

G

S

Y

S

T

E

M

TOTAL BINDING SYSTEM

T

O

T

A

L

B

I

N

D

I

N

G

S

Y

S

T

E

M

O

P

E

R

A

TIN

M

A

N

U

A

L

1. Operation Manual (1 book)

2. Delivery Roller M001966-01 (1 piece)

3. Brush 4000972-00 (1 piece)

Page 44

THIS PAGE LEFT BLANK INTENTIONALLY

Page 45

Page 46

PF-P320/OM

10 Connector Road, Andover, MA 01810

Revised 11/2002

Standard Business Systems

(978) 470-1920 (978) 470-2771

Loading...

Loading...