Page 1

OPERATORS MANUAL

Standard Horizon PF-P310 Paper Folder

PF-P310/OM

Read this manual, and thoroughly

familiarize yourself with its

contents before operating or

servicing this equipment.

Page 2

Page 3

PAPER FOLDER

PF-P310

Important Information

- This manual is designed to help you to install, operate and maintain the Table Top

Folder PF-P310. Read, understand and keep this manual in a safe and convenient

place.

- Do not operate the PF-P310 until you read and understand the instructions in this

manual.

- Horizon International Inc. shall not be liable for incidental consequential damages

resulting from : improper or inadequate maintenance by customer; unauthorized modification or misuse; operation outside of the environmental specifications for the product.

- No Horizon dealer and distributor is authorized to make any modification, expression, or addition to the warranties written in contract.

- Horizon International Inc. pursues a policy of continuing improvement in design and

performance of the product. Therefore, the product design and specifications are subject to change without prior notice and without our legal obligation.

- All rights are reserved. No part of the manual may be photocopied, reproduced or

translated to another language without the prior written consent of Horizon International Inc.

I

010628/PFP310/03J/NO/MM/MM UM203001-03

Page 4

Safety Precautions

- The signal word WARNING indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

- The signal word CAUTION indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may also be used to alert against

unsafe practices.

- The signal word NOTE indicates a potentially hazardous situation which, if not

avoided, may result in damage on products.

- Read and understand all safety instructions with signal word such as WARNING,

CAUTION and NOTE. If safety instructions are ignored, personal injury will result.

- Observe the provisions of the federal, state, or local regulations, including OSHA.

- Horizon International Inc. cannot anticipate every possible situation that might involve a potential hazard. The instruction in this manual and warning labels on the

machine are therefore not all inclusive.

- All equipment shall be locked out or tagged out to protect against accidental or inadvertent operation when such operation could cause injury to personnel. Do not attempt

to operate any switch, valve, or other energy isolating device where it is locked or

tagged out.

- Do not operate the machines with any covers being removed.

- Some of the drawings in this manual shows the machine uncovered for explaining the

detail or inside of machine.

II

Page 5

Contents

1. Before You Begin ..................................................... 1

This section explains machine parts and their function.

1-1 Specifications ............................................................................2

1-2 Machine Parts Descriptions ...................................................... 3

1-2-1 General View ................................................................... 3

1-2-2 Operation Panel ...............................................................4

1-3 For Piling Sheets .......................................................................5

2. Operation Procedure ............................................... 7

This section explains setting up each parts and operation procedure.

2-1 Operation Procedure ................................................................. 8

2-2 Irregular Size Sheet Folding ..................................................... 12

2-3 Cross Fold/12-Page Letter Fold ................................................ 15

2-4 When Folding Is Not Even or Square .......................................19

2-4-1 To correct uneven fold ....................................................19

2-4-2 To correct not square fold ...............................................20

3. Trouble Shooting ..................................................... 21

This section shows quick reference of trouble which can be resolved

or prevented by operator.

3-1 Trouble Shooting ...................................................................... 22

4. Maintenance ............................................................. 25

This section explains maintenance for PF-P310.

4-1 Feed Roller/Double Feed Stop Pad Replacement .....................26

4-2 Fold Roller Replacement .......................................................... 28

4-3 Removal of Jammed Sheet........................................................30

4-4 Count Sensor Cleaning .............................................................31

4-5 Maintenance Kit (Option) .........................................................32

4-6 Option .......................................................................................32

III

Page 6

IV

Page 7

1. Before You Begin

This section explains machine parts and their function.

1. Before You Begin

1-1 Specifications ......................................................................................... 2

1-2 Machine Parts Descriptions.................................................................. 3

1-3 For Piling Sheets.................................................................................... 5

1

Page 8

1. Before You Begin

1-1 Specifications

Maximum Sheet Size : A3 (11" x 17")

Minimum Sheet Size : 65 mm x 44 mm (2.6" x 1.7")

Stock Weight : 50 to 105 gsm

Folding Speed : 140 sheets /min (A4, single fold)

Maximum Pile Height : 21 mm (0.85")

Power : 100 v 50/60 Hz (65 w)

(Power Consumption) : 115 v 50/60 Hz (65 w)

: 230 v 50 Hz (65 w)

Fold Patterns : Single Fold, Short Fold, Parallel Fold

: Letter Fold, Accordion Fold, Gate Fold

Dimension (W x D x H) : 711 mm x 485 mm x 316 mm (28" x 19.1" x 12.5")

Machine Weight : 29 kg (64 lb)

The machine design and specifications are subject to change without any notice.

2

Page 9

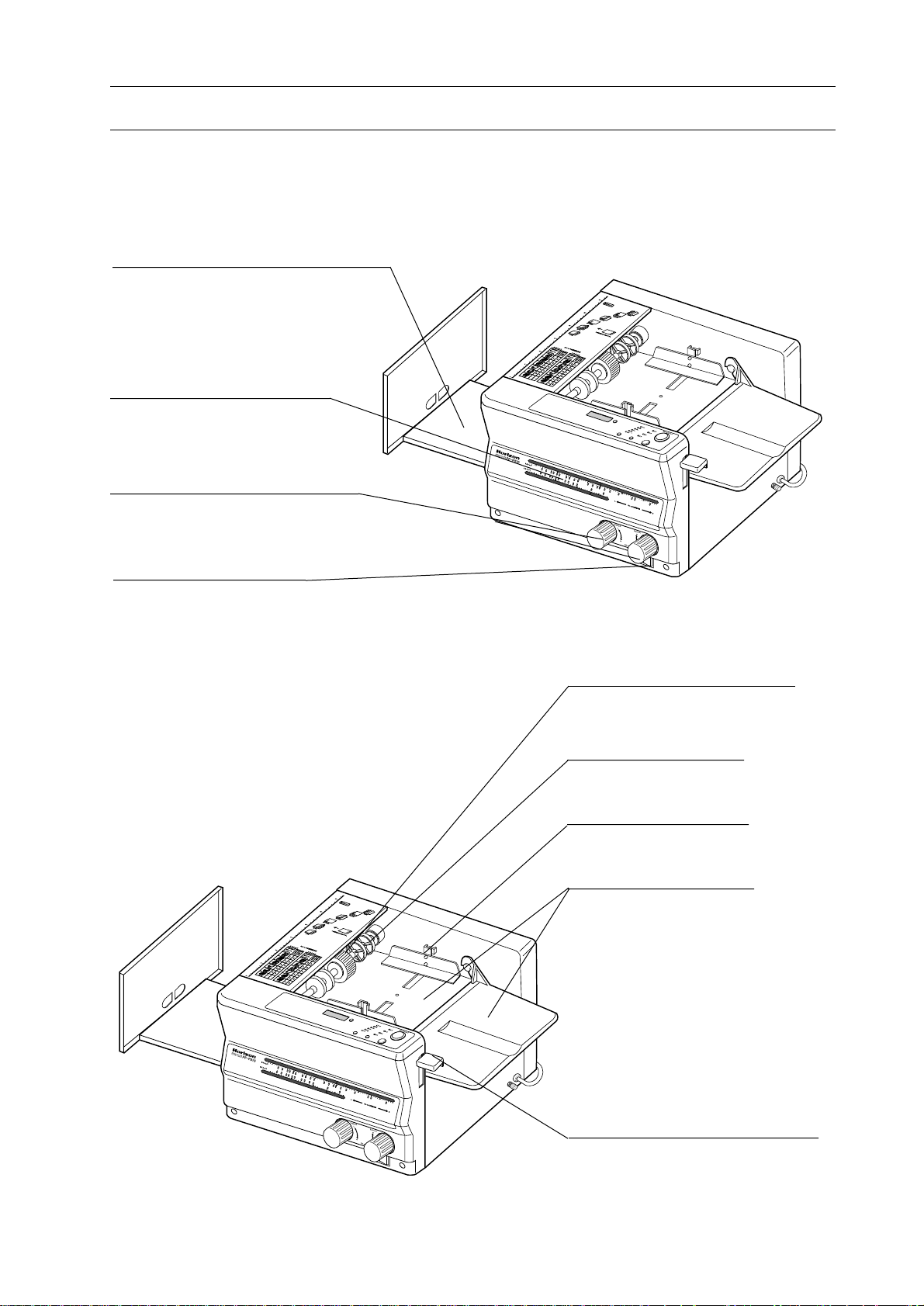

1-2 Machine Parts Descriptions

1-2-1 General View

Delivery Tray

Folded sheet is delivered

to this tray.

Stopper Position Indicator

Used to indicate position of

stopper with lamps.

Stopper Handle

Used to move stopper.

1. Before You Begin

Power Switch

Used to turn ON/OFF main

power.

Feed Roller

Feeds piled sheet to buckle

section.

Support Roller

Holds sheets for smooth

feeding.

Feed Guide

Guides sheet for straight

feeding.

Feed Tray

Used to pile sheets to be

folded.

Feed Tray Lever

Used to lower feed tray for

piling, to raise for folding.

3

Page 10

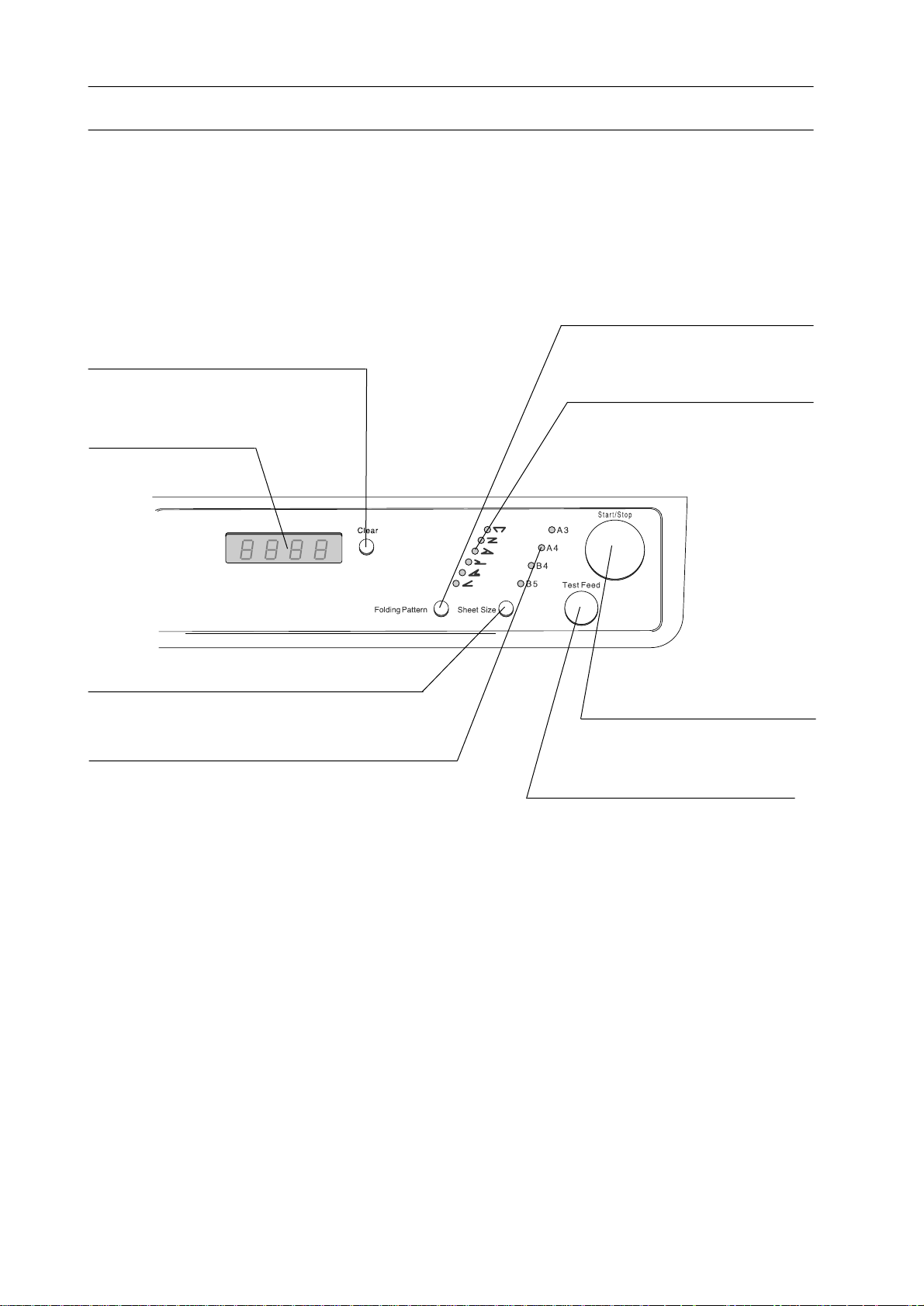

1. Before You Begin

1-2 Machine Pars Description

1-2-2 Operation Panel

Clear Button

Used to clear display.

Display

Indicates number of

folded sheets.

Fold Pattern Select Button

Used to select fold pattern.

Fold Pattern Lamp

Used to indicate fold pattern selected.

Sheet Size Select Button

Used to select sheet size.

Sheet Size Lamp

Indicates sheet size.

Start/Stop Button

Used to start/stop folding.

Test Feed Button

Used to feed one sheet for

testing.

4

Page 11

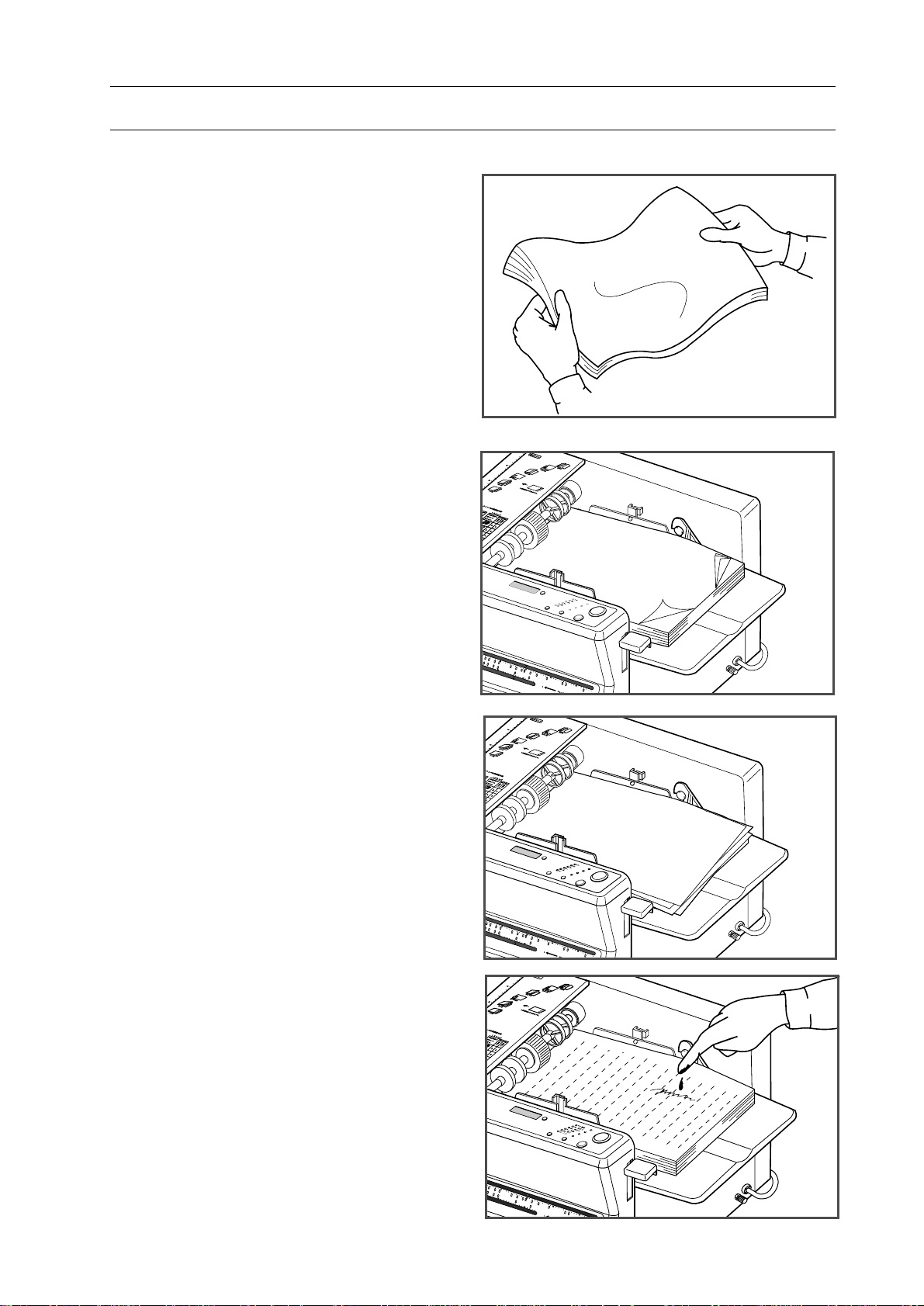

1-3 For Piling Sheets

- Fan well the sheet before piling on the

feed tray. Otherwise, double sheet feeding or miss feed occur.

- Straighten up the curled sheet or

folded sheet.

1. Before You Begin

- Jog well the sheet before piling on the

feed tray. Otherwise, jamming or miss

feed or fold on edge of sheet will occur.

- Make sure that printed ink is dry enough.

Otherwise, double sheet feed will occur.

The wet ink will not only be stain the

printed sheet but also make lower the

precision of folding of this machine.

5

Page 12

1. Before You Begin

6

Page 13

2. Operation Procedure

2. Operation Procedure

This section explains setting up each parts and operation procedure.

2-1 Operation Procedure............................................................................. 8

2-2 Irregular Size Sheet Folding .............................................................. 12

2-3 Cross Fold/12-page Letter Fold ......................................................... 15

2-4 When Folding Is Not Even or Square ............................................... 19

7

Page 14

2. Operation Procedure

PEPER FOLDER

2-1 Operation Procedure

1.Plug power cord to outlet.

2.Open delivery tray and feed tray.

3.Turn on power switch.

4.Lower feed tray lever.

Delivery Tray

PEPER FOLDER

PF-P310

Feed Tray

Feed Tray Lever

8

Page 15

2-1 Operation Procedure

5.Pile sheets on feed tray.

- Face printed surface downward.

- Jog well and true up sheets toward feed

roller.

- Place sheets center of feed tray.

6.Slide both feed guides so that feed

guides slightly touch piled sheets.

- Place support rollers at 10 mm inside of

sheet edge.

2. Operation Procedure

Feed Tray

Support

Roller

7.Select sheet size with sheet size select

button.

NOTE

When irregular size sheets are folded, refer

to "2-2 Irregular Size Sheet Folding" (Page

12 to 14).

8. Select folding pattern with folding

pattern select button.

Feed Guide

9

Page 16

2. Operation Procedure

ストッパの移動方向

1

ストッパ

2-1 Operation Procedure

9.Turn stopper handle so that orange mark

aligns with the illuminated orange lamp.

10.

Raise feed tray lever.

Lamp

Stopper Handle

Orange

Mark

L

S

ス

ト

ッ

パ

の

移

1

ス

ト

ッ

パ

S

L

動

方

向

11.

Press test button to fold one sheet in

order to check folding accuracy.

12. Check

folded sheet.

NOTE

- If sheet is folded uneven, correct it with

referring to "Adjustment Chart" on top

cover of PF-P310. Or refer to "2-4 When

Folding is not Even or Square" (page 19 to

20).

- Press test feed button and check folded

sheet after adjustment.

Adjustment Chart

Stopper Handle

5

1/2

8

6"x9"

"x8

1/2

11"x17"

1/2

"x11"

"

10

Page 17

2-1 Operation Procedure

13.

Press start/stop button. PF-P310 starts

folding.

14.

When you want to stop folding, press

start/stop button or lower feed tray lever.

6"x9"

1/2"x81/2"

5

11"x17"

1/2"x11"

8

2. Operation Procedure

15.

Number of folded sheets are indicated

on display.

- To delete display, press clear button.

- Number indicated on display is deleted

also when power switch is turned off.

16.

When your folding job is finished,

lower feed tray lever and turn off main

switch.

- Pull out power cord from outlet.

- Close delivery tray and feed tray.

11

Page 18

2. Operation Procedure

二つ折

片袖折

内三つ折

四つ折

二つ折

片袖折

内三つ折

四つ折

2-2 Irregular Size Sheet Folding

1.Fold one sheet by hands in your re-

quired fold pattern in order to make a

model.

2.Measure size of folding edge with ruler

and set stopper.

[ How to measure size of folding edge and

how to pile sheets ]

1 = length (position) for stopper 1

2 = length (position) for stopper 2

is printed side.

Single Fold (Buckle 2 is not used.)

Printed Surface

Downward

ABC

Appearance of delivered Sheet

ABC

折

つ

三

内

S

折

袖

片

S L

5

折

つ

四

折

つ

二

0

1

ABC

Parallel Fold

Printed Surface

Downward

ABC

ABC

Appearance of delivered Sheet

12

折

つ

三

内

S L

折

袖

片

S L

5

折

つ

四

折

つ

二

0

2

ABC

1

Page 19

観音折

ABC

ABC

2-2 Irregular Size Sheet Folding

2. Operation Procedure

1 = length (position) for stopper 1

2 = length (position) for stopper 2

Short Fold

Printed Surface

Upward

Letter Fold

Printed Surface

観

音

折

Downward

ABC

ABC

ABC

Appearance of delivered Sheet

Appearance of delivered Sheet

is printed side.

1

ABC

1

2

2

Accordion Fold

Printed Surface

Downward

1

ABC

ABC

ABC

Appearance of delivered Sheet

Gate Fold

Printed Surface

Downward

ABC

ABC

1

ABC

2

2

Appearance of delivered Sheet

13

Page 20

2. Operation Procedure

2-2 Irregular Size Sheet Folding

3.Complete step 1 to 6 in "2-1 Operation

Procedure" (Page 8 to 9) and select

folding pattern with folding pattern

select button.

4.Set stopper.

- Set stopper 1 to the length 1.

- Set stopper 2 to the length 2.

- Start folding with referring to "2-1 Operation Procedure" step 10 through 16

(Page 10 to 11).

Stopper Handle 2

Stopper Handle 1

03PFP310A70

14

Page 21

2-3 Cross Fold/12-Page Letter Fold

NOTE

- In case of cross fold or 12-page letter fold,

sheet wider than 210 mm (8.5") may not be

folded completely.

- Please use cross folding guide (option).

(Meaning of Cross Fold)

Sheet is folded into half, and then this

single folded sheet (signature) is folded

once again in half.

When folded sheet is opened, each crease

of this signature become crisscross

pattern.

2. Operation Procedure

Cross Fold

12-Page Letter Fold

(Meaning of 12-Page Letter Fold)

Sheet is folded into half, and then this

single folded sheet is folded in letter fold.

The following steps are an example to fold

A3 size sheet to cross-fold.

1.Fold A3 size sheet in single fold with

referring to "2-1 Operation Procedure"

(Page 8 to 11).

2.Press fold edge of sheet firmly.

NOTE

If fold edge of sheet is not pressed sufficiently, sheet (signature) will not be folded

correctly.

Folded Edge

15

Page 22

2. Operation Procedure

2-3 Cross Fold/12-Page Letter Fold

3.Perform step 1 through 4 in "2-1 Opera-

tion Procedure" (Page 8) and pile sheets

on feed tray so that fold edge faces to

near side.

NOTE

Do not pile sheet more than half height of

feed guide. If folded sheet is piled too much

on feed tray at once, sheet is not fed

straightly.

4.Set feed guides.

4-1.

When sheet width is less than 185 mm

(7.28").

Folded

Line

2

- Slide feed guide 1 fully far side and

then set feed guide 2 .

4-2.

When sheet width is more than 185 mm

(7.28").

- Slide feed guide 2 fully far side and

then set feed guide 1 .

5.Set support rollers.

Feed Guide

1

1

Feed Guide

2

- Place support roller on far side at 20 mm

inside from edge of sheets.

- Place support roller on near side as near

as possible to fold edge.

Support Roller

16

Page 23

ストッパの移動方向

1

ストッパ

2-3 Cross Fold/12-Page Letter Fold

6.Set stopper position.

- Press sheet size select button and select

A4.

- When sheet to be folded is irregular size

sheet, refer to "2-2 Irregular Size Sheet

Folding" (Page 12 to 13).

7.Turn stopper handle so that orange mark

is aligned with illuminating orange lamp.

2. Operation Procedure

Orange

Mark

8.Raise feed tray lever and press start/stop

button.

- Hold folded edge slightly with finger in

order to feed sheet straightly.

NOTE

Cross folding guide is provided as an optional equipment.

9.When your folding job is finished,

lower feed tray lever and turn off power

switch.

L

1

ス

ト

ッ

パ

S

S

ス

ト

ッ

パ

の

移

L

動

方

向

- Pull out power cord from outlet.

- Close delivery tray and feed tray.

17

Page 24

2. Operation Procedure

2-3 Cross Fold/12-Page Letter Fold

Cross Folding Guide (option)

Cross folding guide is used to hold folded

edge when second folding is performed.

Set cross folding guide along feed guide

on feed tray.

Roller

For far side

For near side

Roller

Cross Folding Guide

18

Page 25

2-4 When Folding Is Not Even or Square

2-4-1 To correct uneven fold

In case that one side of folded sheet is too

long or short, adjust stopper position with

stopper handle.

NOTE

- Following chart shows style of delivered

sheet.

- Turn stopper handle gradually. Perform

test feed after each adjustment in order to

check result of adjustment.

Stopper Handle

2. Operation Procedure

Appearance of

Delivered

Sheet

Gate Fold

Accordion Fold

Letter Fold

Adjustment for Stopper 2

is long

is short

is long

is short

is long

is short For S

is long For L

For L

For S

For L

For S

For L

Appearance of

Delivered

Sheet

Gate Fold

Accordion Fold

Letter Fold

Adjustment for Stopper 1

is long

is short For L

is long For S

is short For L

is long

is short For L

is long For S

For S

For S

Short Fold

Parallel Fold

Single Fold

is short For S

is long For L

is short For S

Short Fold

Parallel Fold

Single Fold

19

is short For L

is long

is short For L

is long

is short

For S

For S

For L

Page 26

2. Operation Procedure

2-4 When Folding Is Not Even or Square

2-4-2 To correct not square fold

When sheet is folded askew, correct folding

with skew adjust lever.

Appearance of not square folding

Appearance of not square folding

Skew Adjustment Lever

Skew Adjustment Lever

1/2

5

1/2

8

6"X9"

1/2

"X8

03PFP310A56

20

Page 27

3. Trouble Shooting

This section shows quick reference of trouble which can be resolved or

prevented by operator.

Trouble Shooting

3-1 Trouble Shooting ................................................................................. 22

21

Page 28

3. Trouble Shooting

3-1 Trouble Shooting

Symptom 1 : Folding result is not good.

Cause Countermeasure

1.Sheet thickness is out of specification.

2.Sheet is not cut square.

3.Sheet is wavy due to humidity.

4.Sheet is curled.

5.Feed guides are set improperly.

6.Fold rollers are dirty with ink or something alike.

1.Do not fold sheet out of specification.

("Refer to 1-1 Specification" in Page 2)

2.Cut sheet straightly.

3.Remove wavy sheet. (Refer to "1-3 For

Piling Sheet" in Page 5)

4.Straighten up curled sheet. (Refer to "1-3

For Piling Sheet" in Page 5)

5.Set feed guides so that sheets are fed

straightly.

6.Clean fold rollers with roller cleaner.

(Refer to "4-2 Fold Roller Replacement"

in Page 28, 29)

7.Feed roller and/or double feed stop pad

is worn out.

8.Fold rollers are worn out.

9.Sheet or something alike is jammed

inside.

10.Fold rollers are not set properly.

7.Replace feed roller or double feed stop

pad (Refer to "4-1 Feed Roller / Double

Feed Stop Pad Replacement" in Page 26,

27). Feed roller and double feed stop pad

should be replaced every 150,000 to

300,000 folds.

8.Replace fold rollers. (Refer to "4-2 Fold

Roller Replacement" in Page 28, 29)

9.Remove sheet or something alike. (Refer

to "4-3 Removal of Jammed Sheet" in

Page 30)

10.Check whether fold rollers are set properly.

(Refer to "4-2 Fold Roller Replacement"

in Page 28, 29)

22

Page 29

3-1 Trouble Shooting

Symptom 2 : Double Feed occurs.

Trouble Shooting

CountermeasureCause

1.Sheets stick each other due to static electricity or ink.

1.Fan well sheets.

Symptom 3 : Folded sheet is stained with ink.

Cause

1.Feed roller, double feed stop pad or fold

rollers are stained with ink.

Countermeasure

1.Clean feed roller, double feed stop pad or

Symptom 4 : Double Feed or Misfeed occurs.

Cause

1.Feed roller or double feed stop pad is worn

out.

Countermeasure

1.Replace feed roller or double feed stop

fold rollers with alcohol or cleaning

liquid soaked cloth. (Refer to "4-1 Feed

Roller / Double Feed Stop Pad Replacement" in Page 26, or "4-2 Fold Roller

Replacement" in Page 28, 29.)

pad. (Refer to "4-1 Feed Roller / Double

Feed Stop Pad Replacement" in Page 26,

27.) Feed roller and double feed stop pad

should be replaced every 150,000 to

300,000 folds.

2.Feed roller or double feed stop pad is dirty

with dust.

Symptom 5 : Sheet is jammed.

Cause

1.Sheet is jammed inside of machine or in

delivery section.

Symptom 6 : Folded sheet are crinkle

Cause

1.Fold rollers are deformed by friction after

long time use.

2.Sheets contain too much moisture.

3.Fold rollers are smeared with ink.

2.Clean it.

Countermeasure

1.Open cover and remove sheet. (Refer to

"4-3 Removal of Jammed Sheet" in Page

30.)

2.Check whether stopper position is properly adjusted.

.

Countermeasure

1.Replace fold roller. (Refer to "4-3 Fold

Roller Replacement" in Page 30.)

2.Dry sheets before fold.

3.Clean fold rollers, or replace them.

23

Page 30

3. Trouble Shooting

24

Page 31

4. Maintenance

This section explains maintenance for PF-P310.

4. Maintenance

4-1 Feed Roller/Double Feed Stop Pad Replacement............................. 26

4-2 Fold Roller Replacement .................................................................... 28

4-3 Removal of Jammed Sheet ................................................................. 30

4-4 Count Sensor Cleaning ....................................................................... 31

4-5 Maintenance Kit (Option) .................................................................. 32

4-6 Option ................................................................................................... 32

25

Page 32

4. Maintenance

PF-P310PF-P310

P

E

P

E

R

F

O

L

D

E

R

PEPER FOLDER

PF-P310

PEPER FOLDER

4-1 Feed Roller/Double Feed Stop Pad Replacement

- When feed roller and double feed stop pad

are stained with ink, or worn out, sheet feed

will be uncertainly. Clean or replace feed

roller or double feed stop pad.

- Feed roller and double feed stop pad

should be replaced every 150,000 to 300,000

folds.

WARNING

Delivery Tray

PEPER FOLDER

P

F

P

3

1

0

Feed Tray

Turn off power switch and pull out

power cord from outlet before replacement.

1. Open delivery tray and feed tray.

2. Open top cover.

3. Hold shaft and open lever.

Power Switch

Top Cover

Lever

Shaft

4. Slide feed roller shaft to direction of

arrow mark 1 and remove to 2 .

Remove support roller and then replace

feed roller.

1

Support Roller

2

Feed Roller

03PFP280A49

26

Page 33

4-1 Feed Roller/Double Feed Stop Pad Replacement

5. Pull double feed stop pad upward to

remove.

4. Maintenance

Double Feed

Stop Pad

6. Clean feed roller and double feed stop

pad with our original rubber cleaner

liquid, XPF-111.

- If feed roller or double feed stop pad is

worn out, replace it.

- Attach double feed stop pad and feed

roller in reverse order of detachment.

Feed Roller

27

Page 34

4. Maintenance

PF-P310

PEPER FOLDER

PEPER FOLDER

4-2 Fold Roller Replacement

If fold rollers are stained with ink, or worn

out, folding accuracy decreases.

WARNING

Turn off power switch and pull out

power cord from outlet before replacement.

1. Slide delivery tray and open top cover.

2. Hold shaft and open lever.

Top Cover

Delivery Tray

Lever

Shaft

PF-P310

R

E

D

L

O

F

R

E

P

E

P

3. Tilt up roller hanger and lay down roller

holder.

NOTE

Keep holding roller hanger during laying

down roller holder.

Roller Hanger

Roller Holder

Fold Rollers

R

E

D

L

O

F

R

E

P

E

P

28

Page 35

PEPER FOLDER

4-2 Fold Roller Replacement

4. Clean fold rollers with rubber cleaner

liquid XPF-111.

5. If fold rollers are worn out, replace

them.

4. Maintenance

- Install fold rollers so that ends of fold

rollers are placed on grooves indicated

with yellow arrow label.

Grooves

PEPER FOLDER

Yellow Arrow

29

Page 36

4. Maintenance

PEPER FOLDER

PF-P310PF-P310

P

E

P

E

R

F

O

L

D

E

R

PEPER FOLDER

4-3 Removal of Jammed Sheet

WARNING

Turn off power switch and pull out

power cord from outlet before removal.

1. Slide delivery tray and open cover.

2. Hold shaft and open lever.

Cover

Delivery Tray

Lever

Shaft

3. Tilt up roller hanger and lay down roller

holder.

NOTE

Keep holding roller hanger during laying

down roller holder.

4. Remove jammed sheet.

- Turn stopper handle to S to remove

sheet jammed inside of buckle.

- Close roller holder, lever and cover in

reverse order.

Roller Hanger

Roller Holder

R

E

D

L

O

F

R

E

P

E

P

Stopper Handle

30

Page 37

4-4 Count Sensor Cleaning

1

S

t

o

p

p

e

r

1 Stopper

2

S

t

o

p

p

e

r

2 Stopper

5

5

PF-P310PF-P310

P

E

P

E

R

F

O

L

D

E

R

PEPER FOLDER

4. Maintenance

The count sensor inside the delivery section

detects the sheets and counts the folded

sheets. If the paper dust stains on the sensor,

the sensor can not detect correctly. In that

case, clean the sensor.

1. Pull out the delivery tray and open the

cover to the direction that the arrow

shows.

2. Receiving part and projecting part of the

sensor is on the back of the cover.

Cover

Delivery

Tray

Sensor

3. Clean the lens using a cotton swab.

Sensor

Projecting Part/Receiving Part

31

Page 38

4. Maintenance

4-5 Maintenance Kit (Option)

2

3

4

4-6 Option

03PFP310A68

2. Double Feed Stop Pad : M002063-01 (4 pcs)

3. Feed Roller : M001978-04 (2 pcs)

4. Fold Roller : A941901-00 (2 pcs)

2

1

03PFP310A69

Cross Folding Guide : M850054-00

32

Page 39

Page 40

PF-P310/OM

Revised 09/2002

Standard Business Systems

10 Connector Road, Andover, MA 01810

(978) 470-1920 (978) 470-2771

Loading...

Loading...