Standard horizon P58 Owner Manual

•

OWNER’S GUIDE & INSTALLATION INSTRUCTIONS

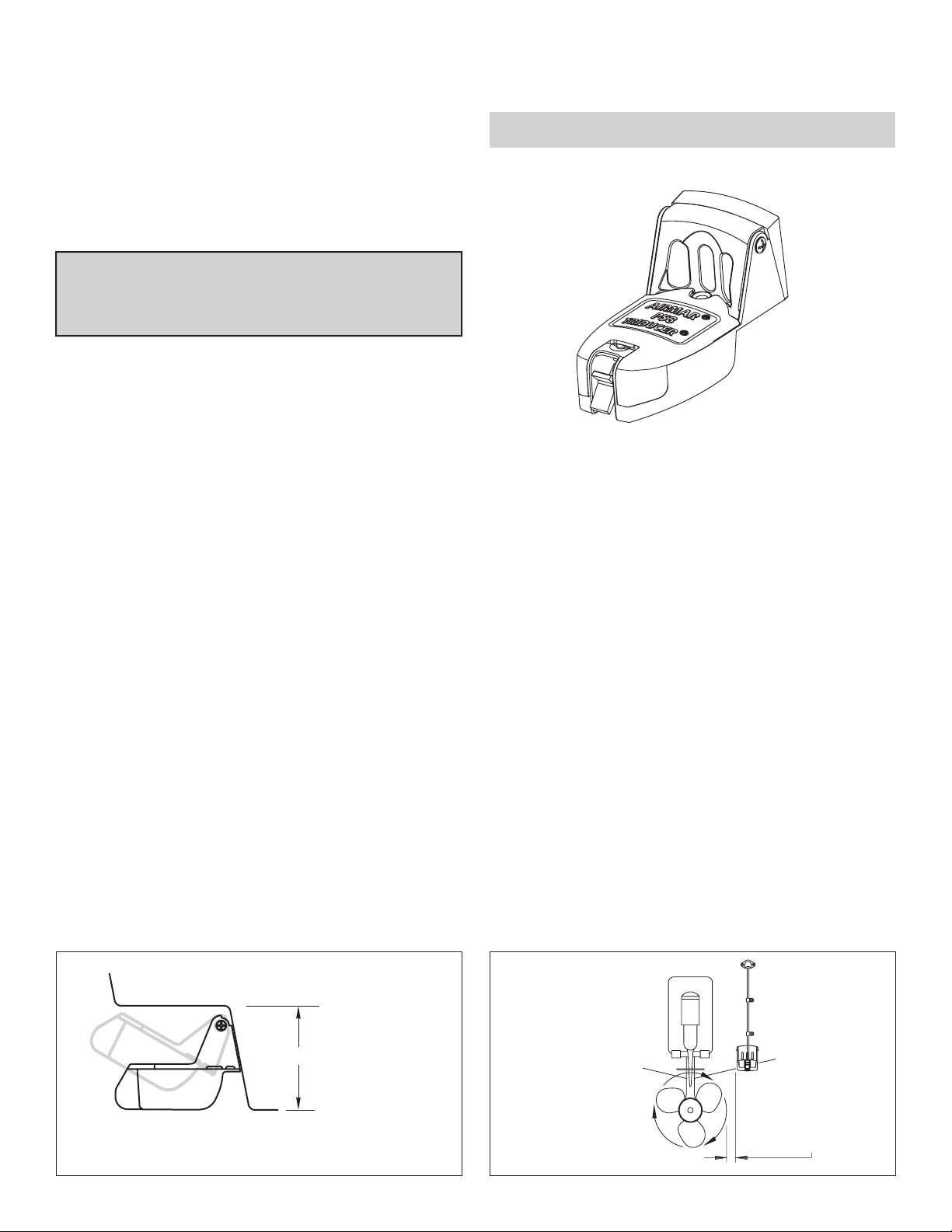

Transom Mount

TRIDUCER

U. S. Patents: 4,555,938; 4,644,787; 5,606,253; 5,719,824

IMPORTANT : Please read the instructions completely

before proceeding with the installation. These

instructions supersede any other instructions in your

instrument manual if they differ.

CAUTION : NEVER USE SOLVENTS

17-404-01 rev. 01 02/04

Cleaners, fuel, paint, sealants, and other products may

contain strong solvents, such as acetone, which attack

many plastics greatly reducing their strength.

Applications

•

Not

recommended for boats with large or twin screw inboard

engine(s)

• Requires 89mm (3-1/2") of headroom to install

• Good operation up to 44kn (50 MPH)

•Vertically orients sound beam on hull with deadrise angle up to 30°

• Accommodates transom angles from 2

•Bracket protects multisensor from frontal impact only

Tools & Materials

Screwdrivers

Pencil

Safety goggles

Dust mask

Electric drill

Drill bits:

Bracket holes 4mm, #23,

Tr ansom hole (optional) 18mm, 11/16",

Cable clamp holes 3mm

Masking tape

Marine sealant

Straight edge

Zip-ties

Water-based antifouling paint ( mandatory in salt water )

®

Multisensor

with Integral Release Bracket

Model P58

Canadian Patent 1,233,341

°

or

or

1/8"

–22

9/64"

or

°

3/4"

Record the information found on the cable tag for future reference.

Part No._________________Date___________Frequency________kHz

Pretest Speed & Temperature Functions

Connect the multisensor to the instrument and spin the

paddlewheel. Check for a speed reading and the approximate air

temperature. If there is no reading or it is inaccurate, return the

product to your place of purchase.

Mounting Location

For the best performance, the multisensor

aeration-free and turbulence-free water. Mount the multisensor on

the transom as close to the centerline (keel) of the boat as

possible. On slower heavier displacement hulls, positioning it

farther from the centerline is acceptable.

Headroom —Allow space above the bracket for it to release and

rotate the multisensor upward (see Figure 1).

Caution : Do not mount in an area of turbulence or bubbles:

Near water intake or discharge openings

Behind strakes, struts, fittings, or hull irregularities

Behind eroding paint (an indication of turbulence)

Caution : Avoid mounting the multisensor where the boat may be

supported during trailering, launching, hauling, or storage.

Single drive boat —Mount on the starboard side at least 75mm

(3") beyond the swing radius of the propeller (see Figure 2).

• Twin drive boat —Mount the multisensor between the drives.

must

be in contact with

AIRMAR

headroom

Figure 1. Headroom required on a stepped transom

minimum

89mm (3-1/2")

®

Figure 2.

Mounting

location

on single

drive boat

75 mm (3")

minimum beyond

swing radius

AIRMAR

®

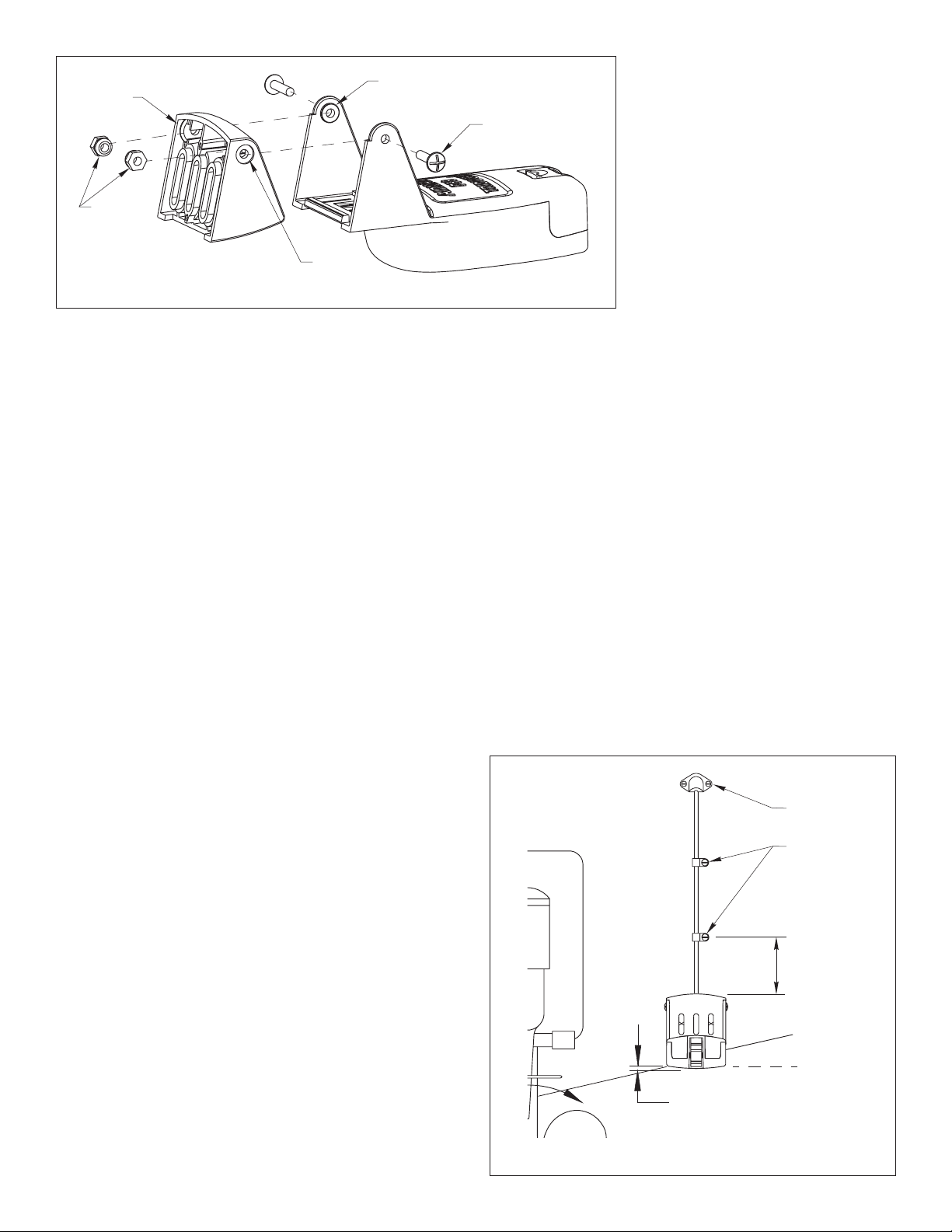

pivot post (2)

slot (2)

nuts

bracket

•

recess (2)

Figure 3. Assembling

Installation

Assembling

1. Insert the multisensor’s pivot posts into the recesses on the

sides of the bracket (see Figure 3).

2. Press the two nuts into the slots in the back of the bracket.

3. Align the holes in the multisensor, bracket, and nuts. Insert the

two machine screws capturing the nuts. Tighten the machine

screws until the multisensor will stay in the “up” (released)

position unaided.

Marking & Hole Drilling

1. At the selected location, position the multisensor, so it projects

3mm (1/8") below the bottom edge of the transom (see Figure 4).

2.

Being sure the bottom of the multisensor is parallel to the

waterline

center of the two outer most slots.

Warning : Always wear safety goggles and a dust mask.

3. Using a 4mm, #23, or 9/64" drill bit, drill two holes 22 mm (7/8")

deep at the locations indicated. To prevent drilling too deeply,

wrap masking tape around the bit 22mm (7/8") from the point.

Fiberglass hull —Minimize surface cracking by running the drill

in reverse until the gelcoat is penetrated.

Plastic Shims

Standard transom (13° transom angle)—The bracket is

designed for a standard 13° transom angle. The 9° shim is

needed for this installation. If your boat is capable of speeds

above 20kn (28 MPH), install the bracket with the 4.5° shim,

taper

will be in contact with the water at high speeds.

• Stepped transom and jet boats (3° transom angle) —Use the

9° shim with the taper

above 20kn (28 MPH), install the bracket with both the 9° and

4.5° shims, taper

paddlewheel will be in contact with the water at high speeds.

Install the 4.5° shim against the transom after shaving the

interfering portion of the rails and lower bump. Place the 9°

shim and bracket assembly on top.

•S mall aluminum and fiberglass boats (20° transom angle)—

Use the 9° shim with the taper

speeds above 20kn (28 MPH), install the bracket with only the

4.5° shim, taper

• If you are unsure about using the shim(s) , do one of below:

• Measure the transom angle of your boat using a digital level

• Experiment with the shims by following the instructions

, mark the location of the screw holes with an “X” in the

not

down

(see Figure 5). This ensures that the paddlewheel

down

. If your boat is capable of speeds

down

(see Figure 5). This ensures that the

up

. If your boat is capable of

up

.

or bubble level and protractor. Then follow the instructions for

your transom angle.

“Mounting & Adjusting”.

®

AIRMAR

Mounting & Adjusting

1. Apply marine sealant to the threads of

two, #10 x 1-1/4", self-tapping bracket

machine

screw (2)

screws to prevent water seepage into

the transom.

Be sure

the nuts are in the

slots in the back of the bracket and any

shim(s) is in place (see Figure 3).

Screw the multisensor to the hull (see

Figure 4).

Do not tighten the screws

completely at this time.

Caution : Do not position the bow of

the multisensor lower than the stern

because aeration will occur.

2. Using a straight edge, sight the

underside of the multisensor relative to

the underside of the hull (see Figure 5).

The stern of the multisensor should be 1–6mm (1/16–1/4")

below the bow of the multisensor.

Caution: Do not position the multisensor farther into the water

than necessary to avoid increasing drag, spray, and water noise

and reducing boat speed.

3. Using the vertical adjustment space in the bracket slots, slide

the multisensor up or down until the bottom left corner of the

multisensor projections 0–3mm (0–1/8") below the bottom of

the hull (see Figure 4). When you are satisfied with the position

of the multisensor, tighten the two bracket screws.

Testing on the Water

1. Become familiar with your echosounder’s performance at a

speed of 4kn (5MPH).

2. Gradually increase the boat speed and observe the gradual

decline in performance due to turbulent water flowing over the

multisensor’s active surface.

3. If the decline in performance is sudden (not gradual), identify

the boat speed at which the onset occurred. Return the boat to

this speed, then gradually increase speed while making

moderate turns in both directions.

cable cover

cable clamp

50mm (2")

Hull projection

0–3mm (0–1/8")

Figure 4. Vertical adjustment and cable routing

AIRMAR

parallel to

waterline

®

2

Loading...

Loading...