TDA7572

200W mono bridge PWM amplifier with built-in step-up converter

Preliminary Data

Features

■ Input stage and gain compressor

■ Over-modulation protection and current limiting

■ Modulator

■ DAC

■ Step-up

■ Mode control

■ Diagnostics / safety

■ Power control

Description

TDA7572 is a highly integrated, highly versatile,

semi-custom IC switch mode audio amplifier. It

integrates audio signal processing and power

amplification tailored for standalone remote bass

box applications, while providing versatility for full

bandwidth operation in either automotive or

consumer audio environments. It's configured as

one full bridge channel, using two clocked PWM

modulators driving external, complementary

FET's.

Broad operating voltage is supported, allowing

operation from both 14V and 42V automotive

power buses, as well as from split supplies for

consumer electronics use.

A current mode control boost converter controller

is provided to allow high power operation in a 14V

environment. Turn-on and turn-off transients are

minimized by soft muting/unmuting and careful

control of offsets within the IC.

Digital Audio input is supported by an integrated

one channel DAC. Sophisticated diagnostics and

protection provide fault reporting via I

power shutdown for safety related faults.

TDA7572 is packaged in a HiQUAD-64 package.

HiQUAD-64

2

C and

Table 1. Device summary

Order code Package Packing

TDA7572 HiQUAD-64 Tray

September 2007 Rev 1 1/64

This is preliminary information on a new product now in development or undergoing evaluation. Details are subject to

change without notice.

www.st.com

1

Contents TDA7572

Contents

1 Detailed features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Interface description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Pins description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2 Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3.1 Operating voltage and current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3.2 Under voltage lockout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.3.3 Input stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.3.4 Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.3.5 Modulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.3.6 Gate drive and output stage control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.3.7 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.4 Voltage booster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.4.1 Digital to analog converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.4.2 I/O pin characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.4.3 Op. amp. cells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.4.4 Shunt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.4.5 Application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5I

2

C and mode control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.1 Input control register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.2 Faults 1 register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.3 Faults 2 register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.4 Control register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.5 Modulator register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.6 Testing register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6 Input stage and gain compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.1 Input stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2/64

TDA7572 Contents

6.2 Gain compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.2.1 Setting in I2C bus mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.2.2 Soft-mute function, without pre-limiter . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7 Modulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7.1 FET drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.2 ANTI-POP shunt driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8 DAC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9 Step-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

10 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

10.1 Faults during operation: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

10.1.1 DC offset across the speaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

10.1.2 Die temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

10.1.3 External temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

10.1.4 Output clipping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

10.1.5 Output over-current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

10.1.6 Power supply overcurrent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

10.1.7 Fault handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

10.1.8 Faults during power-up: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

11 Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

12 Under voltage lock out (UVLO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

12.1 VSP-UVLO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

12.2 V14 - UVLO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

12.3 SVR - UVLO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

13 Start-up procedures, modulator turn-on after a tristate condition. . . 56

13.1 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

13.2 Tristate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

14 Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

14.1 Single supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

14.2 Split supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

3/64

Contents TDA7572

14.3 THD+N step-up on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

15 Package information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

16 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4/64

TDA7572 List of tables

List of tables

Table 1. Device summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

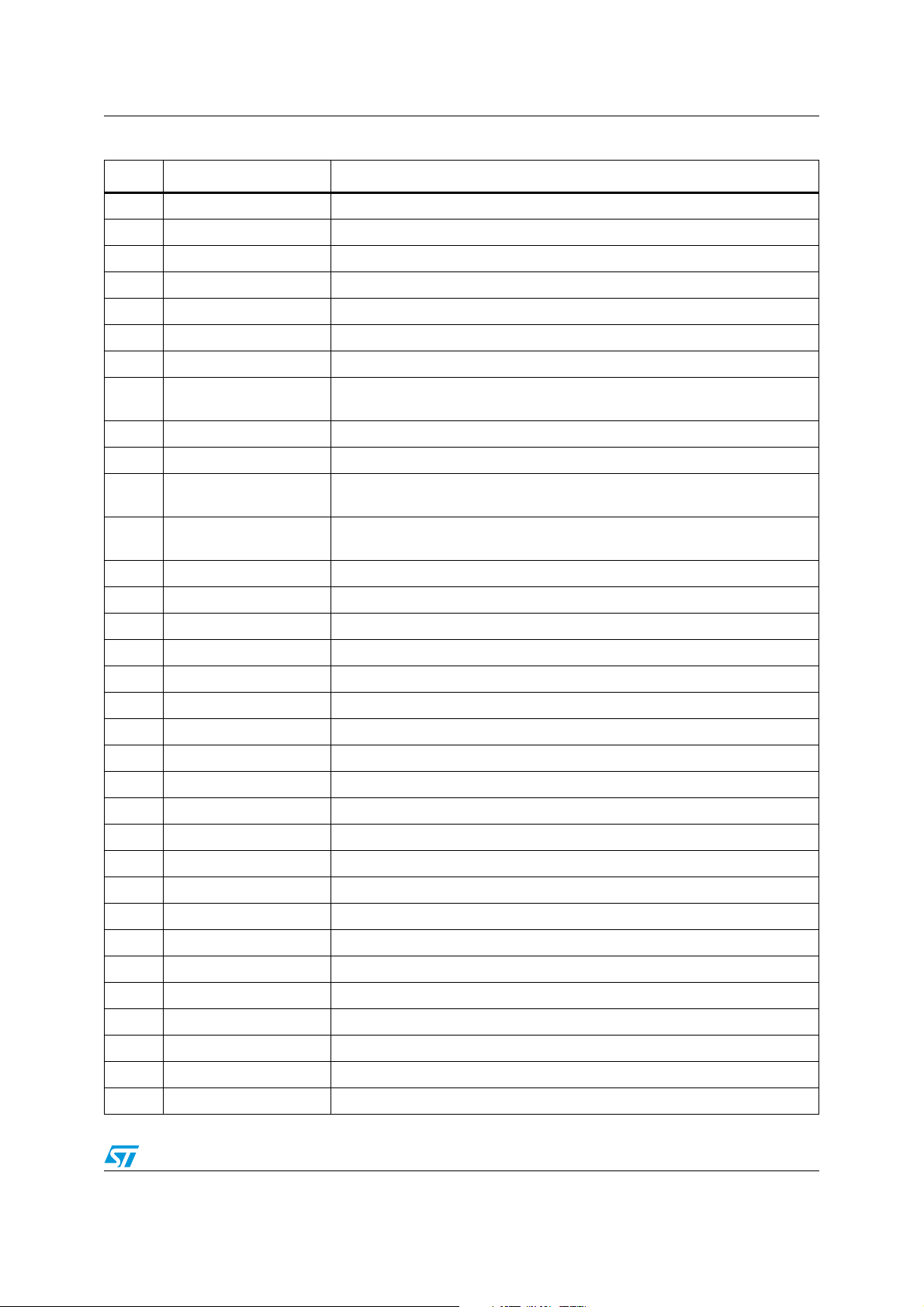

Table 2. Pin list by argument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 3. Pin list by pin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 4. Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 5. Thermal data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 6. Operating voltage and current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 7. Under voltage lockout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 8. Input stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 9. Oscillator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 10. Modulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 11. Gate drive and output stage control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 12. Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 13. Voltage booster. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 14. Digital to analog converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 15. I/O pin characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 16. Op. amp. cells. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 17. Shunt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 18. Analog operating characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 19. Power-up mode control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 20. Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 21. I

Table 22. Input control register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 23. Faults 1 register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 24. Faults 2 register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 25. Control register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 26. Modulator register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 27. Testing register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 28. Distortion versus gain step size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 29. Sets the maximum release rate of the gain compressor. . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 30. Sets the maximum attack rate of the gain compressor. . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 31. Attack/release rate and gain compression effort selection . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 32. PWMClock table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 33. Fault handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 34. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

2

C chip address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5/64

List of figures TDA7572

List of figures

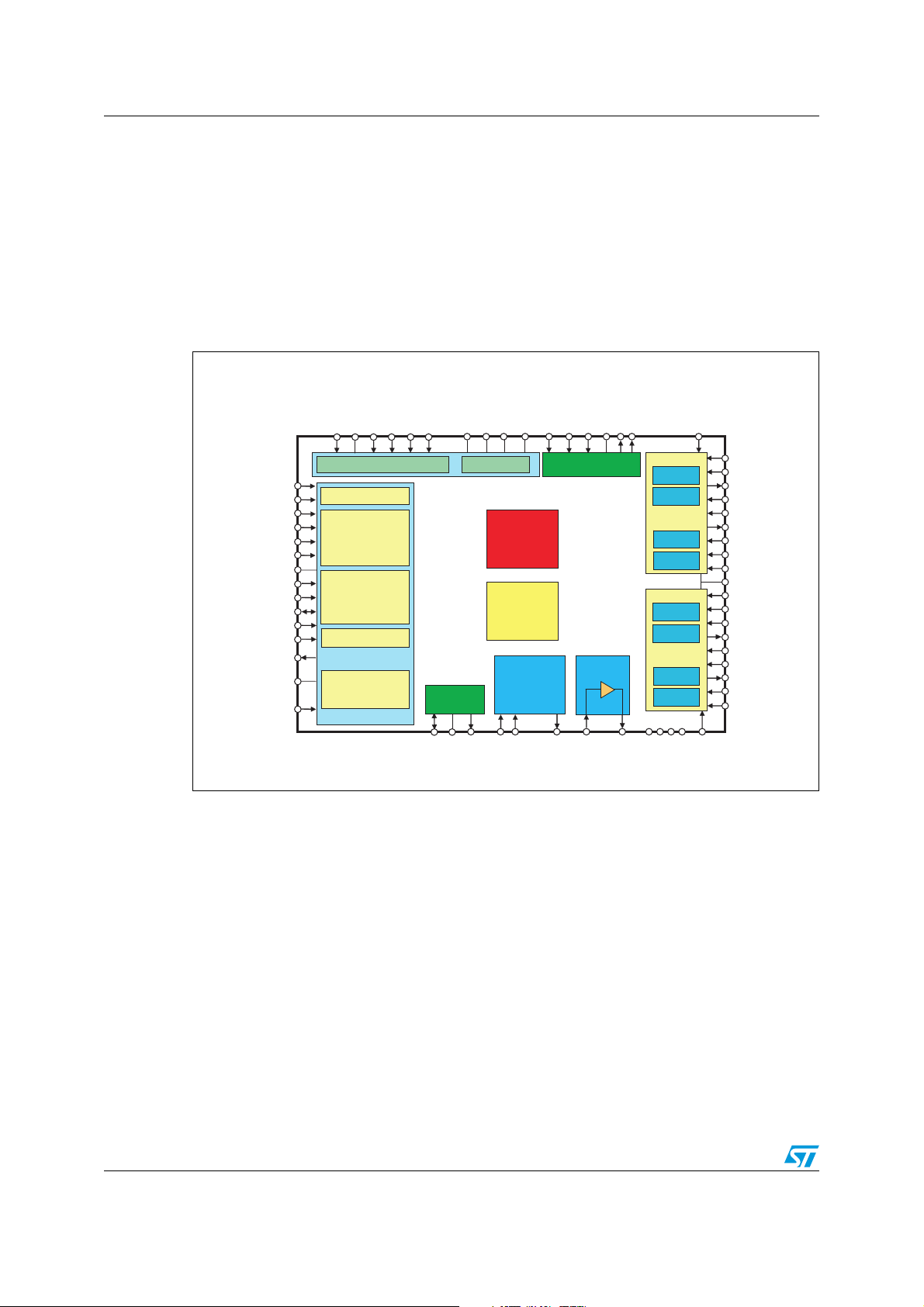

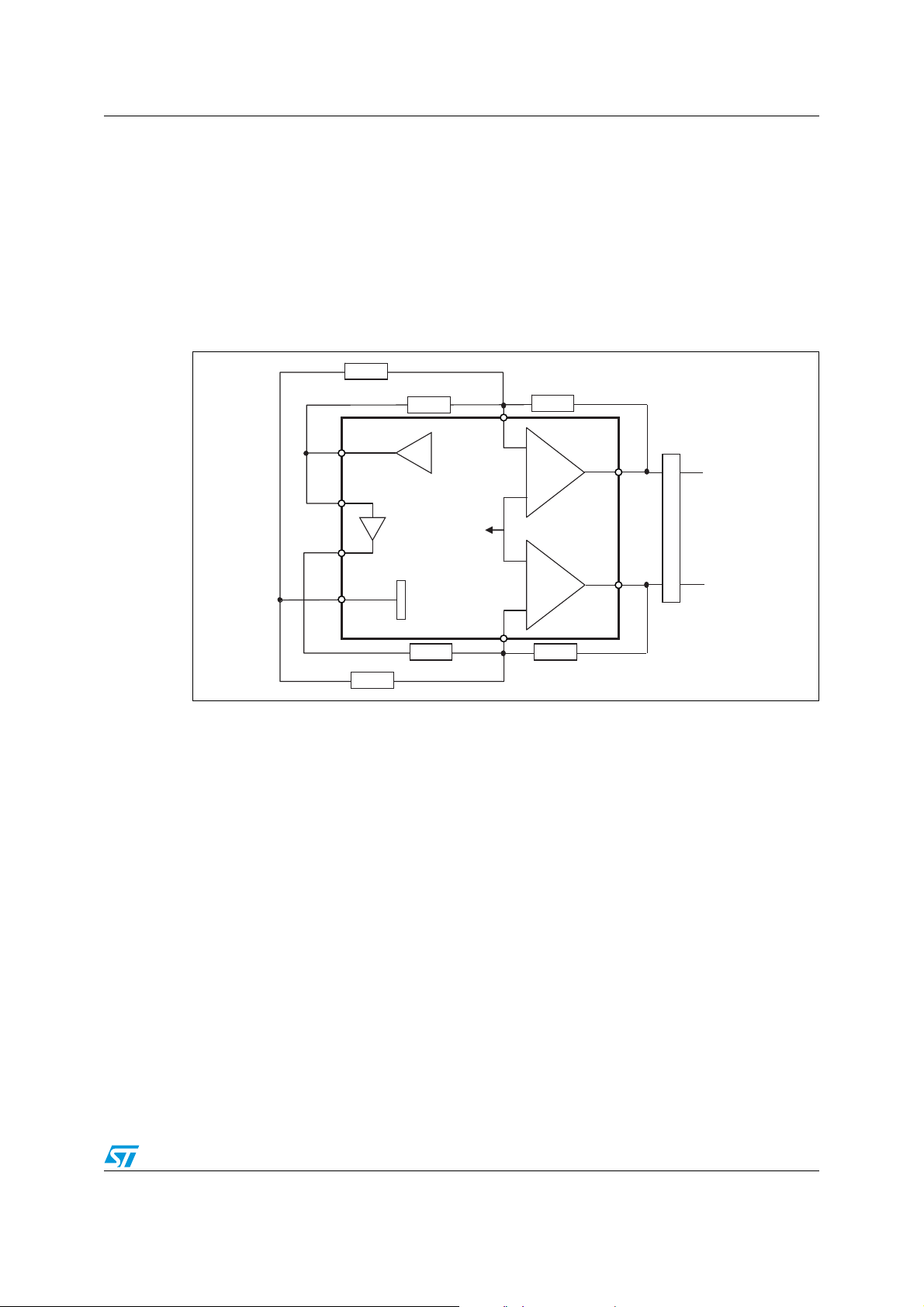

Figure 1. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

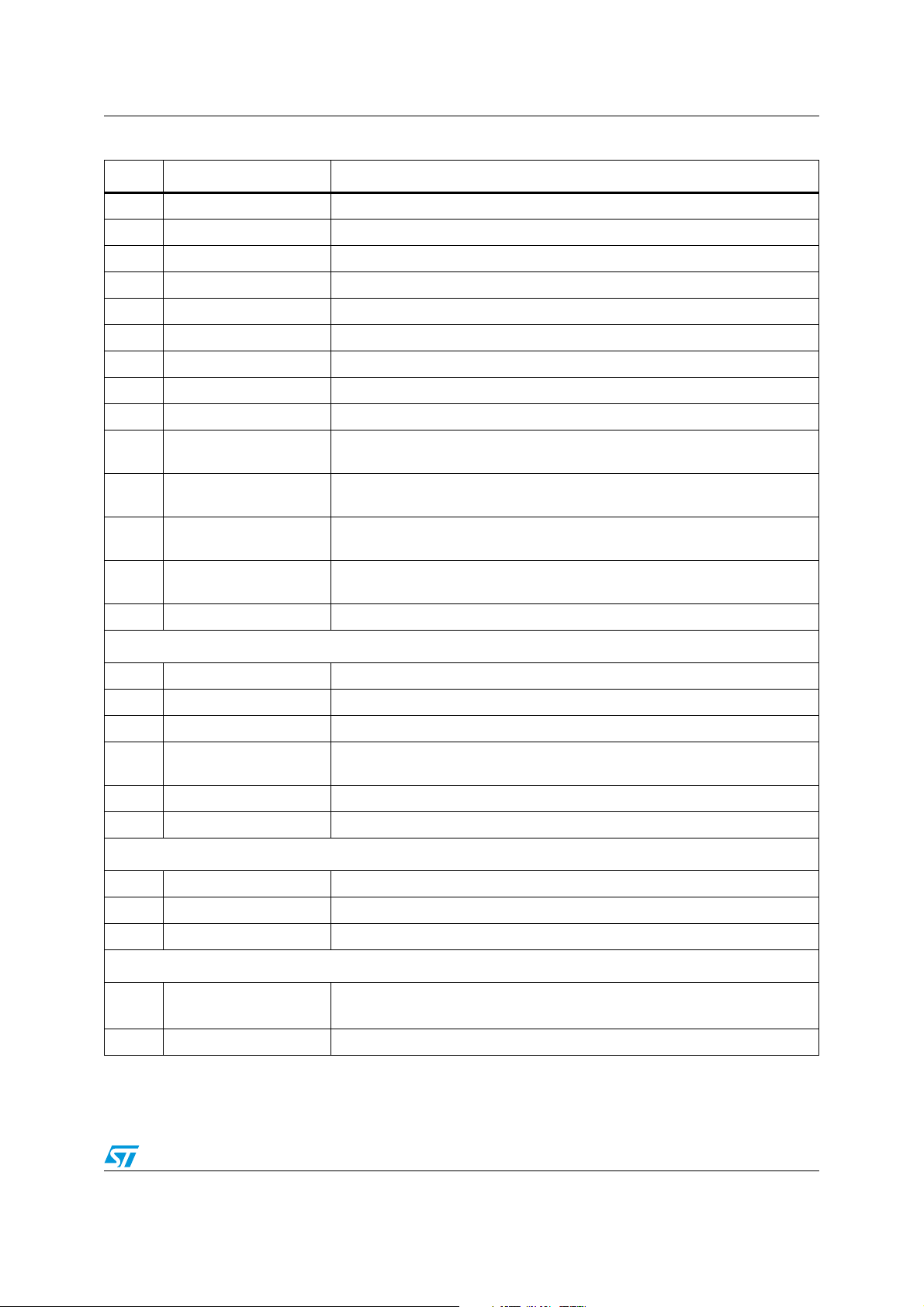

Figure 2. Pins connection (top view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 3. Mute by external command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 4. Mute by I

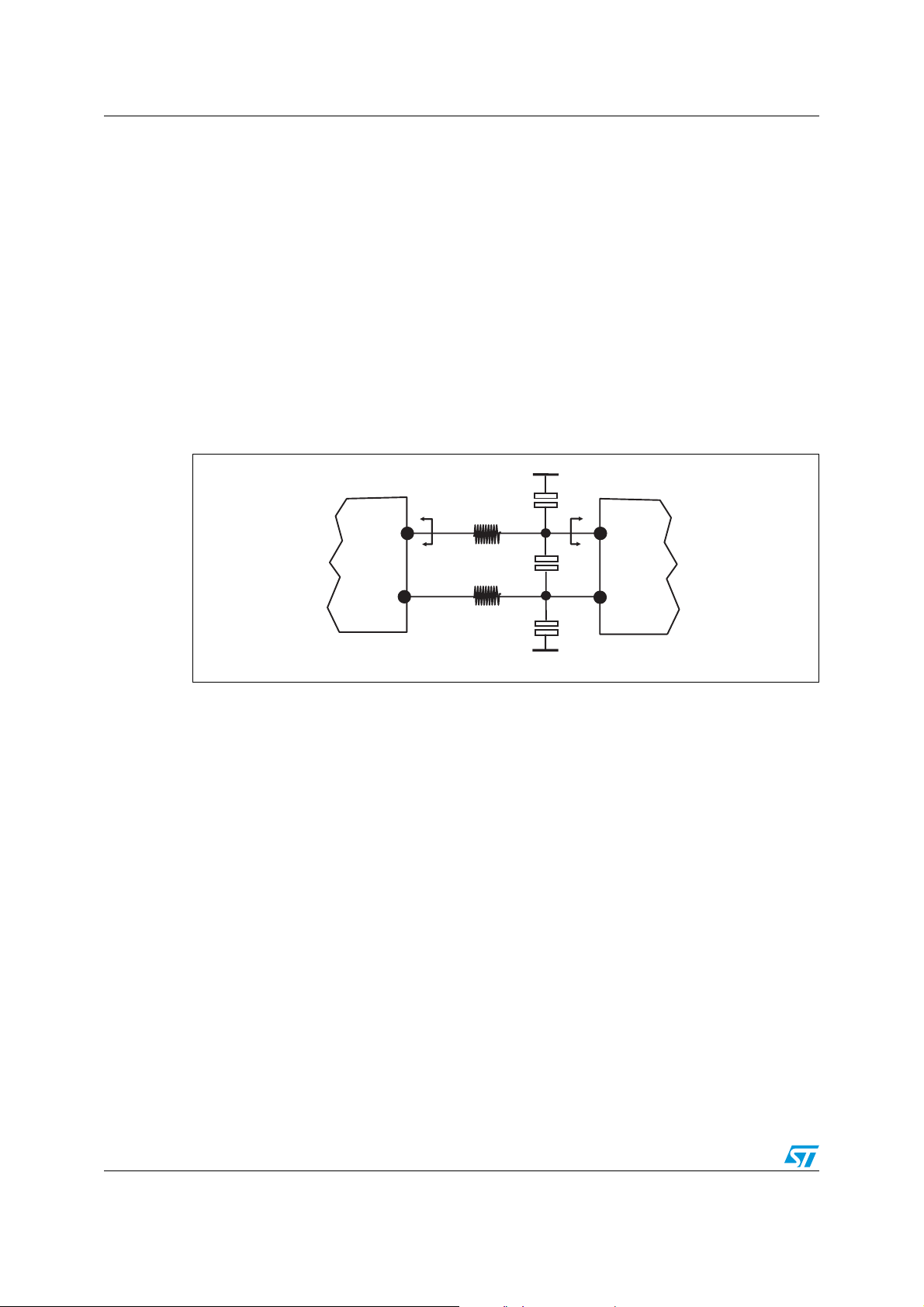

Figure 5. Modulator block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 6. Current sourced by the shunt pin in NO I

Figure 7. DAC circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 8. Two interpolator structure diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 9. I

Figure 10. Step-up application diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 11. Threshold of current limiting diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 12. Single supply evaluation board schematic.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 13. Single supply evaluation PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 14. Split supply evaluation board schematic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 15. Split supply evaluation PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 16. THD+N step-up on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 17. HiQUAD-64 mechanical data and package dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

2

S format diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

2

C bus command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2

Cbus mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6/64

TDA7572 Detailed features

1 Detailed features

● Input Stage and Gain Compressor

– Differential, high CMRR, analog input

– Programmable input attenuation/gain to support up to four drive levels

– Noiseless Gain compression of up to 16 dB with programmable attack and decay.

– Compressor controlled by monitoring estimated THD

– Soft mute / un-mute for pop control

● Over-modulation Protection and Current Limiting

– Adaptive pulse injection prevents missing pulses due to over modulation which

maximizes useful output swing.

– Programmable current limiting based on FET VDS

● Modulator

– Optimized for low distortion at low switching frequency (approximation 110KHz)

– Dual Clocked PWM modulators for 3 state switching

– External gain control / internal integrator components

– Controls 4 external FETS with switching optimized for low EMI

– Oscillation frequency selectable by I

– Anti-pop shunt driver

● DAC

– 18bit, mono

2

–I

S inputs 38-48KHz, 96KHz, 192 KHz

– Hybrid architecture, area optimized for Bass

– Full bandwidth supported by off loading the interpolator function

– Synchronization with modulator

● Step-Up

– On board STEP-UP step up converter, synchronized to the modulator frequency

– Drives external NFET switch

– Externally compensated

– Soft start and current limiting

● Mode Control

– Critical modes controllable by mode pins for bus-less operation

2

–I

C provides additional mode control

● Diagnostics / Safety

– Offset, short, open, overcurrent, over temperature

2

–I

C used to report errors, and for configuration control

– Faults pin used to report errors in bus-less environment

– Clipping reported at a separate pin

– Abnormal supply current detection disables input power for fail safe operation

– Output current limiting

– Power control

– Latching control of an external PMOS power switch for safety related faults.

– Power is switched off for safety related faults of abnormal supply current,

excessive internal or external temperature, or persistent output stage over-current

that fails to be controlled by the pulse-by-pulse current limiting method

2

C

7/64

Interface description TDA7572

2 Interface description

I2C bus and mode control pins are use to control operation. Default values of all the

operating modes are deterministic, some of these values are intrinsic to the IC and some

are determined by configurations pins. The configuration pins are read at power-up and

copied into registers, which may later be modified using the I

allows varied operation in an environment where NOI

2

control and override of pin programmed modes when used with I

Figure 1. Block diagram

CSense

V14

BSTVSource

BSTGate

BSTVSense

VP2.5

V14Sense

VM2.5

WS / CLIP_L

VDIG

DGND

2

C bus, if one is present. This

C bus is present, while allowing full

SDA / SCR_ENB

2

C.

SCL / InputLevel1

DACM

PLL / InLeve l0

DACP

MOD1

ISSENP

ISSENM

Mode 0

Automute Voltage Setting

Addr 0 / Fault / CLIP_L

Addr1 / CompEnable

Mode 1

Vs/2 or SVR

2

I

C data / attack sel.

2

I

C clock

ShuntDrive

Mute

NTC

TestC

Iset

DC/DC Converter

+Vs current

protection

Mode sel.

and

Mute

I2Cbus

Thermal management

Diagnostics

+

clipdet

Controls and Diagnostics

Oscillators

CLKin -out

Regulators

LOGIC

UVLO

Diff -to-S.E.

Compressor

and

Limiter

Channel 1

INP

INM

OscOut

DITH -sel

AOUT

DAC

-1

InvIn

PWM Channel 1

Pulse Inj.

Integrator

Drivers

Prot. & supply

PWM Channel 2

Pulse Inj.

Integrator

Drivers

Protections

VSM1,2,3,4

InvOut

LSD1SourceSensing

LSD1GateDrive

LSD1GateSensing

HB1OutFilter

HB1Out

ILimit threshold

HSD1GateSensing

HSD1GateDrive

HSD1SourceSensing

VSP_Pow1

HSD2SourceSensing

HSD2GateDrive

HSD2GateSensing

VSP_Pow2

HB2Out

LSD2OutFilter

LSD2GateSensing

LSD2GateDrive

LSD2SourceSensing

MOD2

AC00014

8/64

TDA7572 Pins description

3 Pins description

Figure 2. Pins connection (top view)

Iset

TestC

LSD2SS

LSD2GD

LSD2GS

HB2OutFilt

HB2Out

HSD2GS

HSD2GD

HSD2SS

VSP_POW2

VSP_POW1

HSD1SS

HSD1GD

HSD1GS

HB1Out

HB1OutFilt

LSD1GS

LSD1GD

LSD1SS

I2CLK

IlimitThresh

63

64

1

2

3

4

5

6

7

8

9

10

12

13

14

15

16

17

18

19

20

21 22 23 24 25

VSM4

ADDR1/CompEnable

ADDR0/Fault/Clip_L

I2CDATA/AttackSel

59

60

61

62

26

MUTE_L

AutoMuteVSetting

Mode0

VSM3

58

57 56 55 54 53

271128 29 30 31 32

Mode1

VP2.5

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

SVR

VM2.5

VDIG

DGND

NTC

SCL/InLevel1

WS/Clip_L

SDA/SCR_ENB

PLL/InLevel10

ShuntDriver

DITH

CLKIN/Out

OscOut

MOD2

MOD1

InvOut

InvIn

AOUT

INP

INM

BSTGate

BSTSource

CSense

V14Sense

V14

VSM2

AC00013

DAC2

VSM1

BSTVSense

ISSENM

ISSENP

DAC1

9/64

Pins description TDA7572

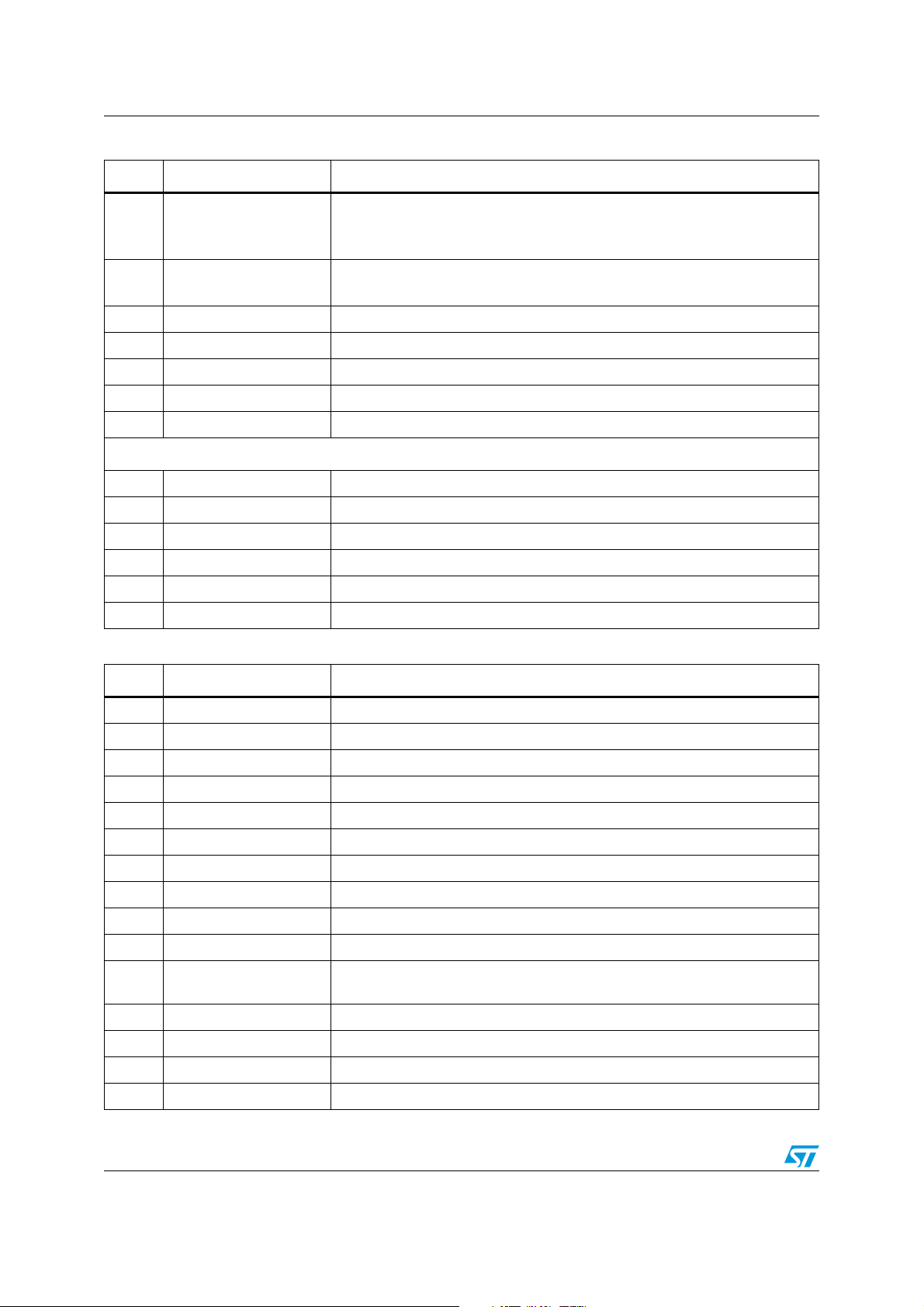

Table 2. Pin list by argument

Pin # Pin name Description

On/Off Circuitry

11 VSP_POW2

Positive supply power for low power, non gate-drive functions with a separate

bonding to power the gate drive of modulator two

53 VP2.5 +2.5V analog supply output

51 VM2.5 -2.5 V analog supply output

50 VDIG 5V logic supply decoupling

49 DGND Digital gnd

52 SVR Vs/2 analog reference filter capacitor. Reference for input stage.

55 Mode0 Mode control bit0, selects standby/normal/ I2C/diagnostic operation

2

54 Mode1 Mode control bit1, selects standby/normal/ I

C/diagnostic operation

57 MUTE_L Mute input and / or timing cap, assertion level low

56 AutoMuteVSetting Auto-mute Voltage Setting

Input/ Gain Compressor

34 INP Non inverting audio input

33 INM Inverting audio input

35 AOUT Compressed Audio Output

Input Stage gain selection – see PLL pin in DAC Section 8

Compressor attack/decay select – see I2C data pin in DAC Section 8

Inverter

36 InvIn Inverter input

37 InvOut Inverter Output

Modulator

64 IlimitThresh Output stage Current Limiting trip voltage set point

32 LVLSFT Gain program pin for SVR to HVCC level shifting

38 MOD1 Modulator1 Inverting / Summing node

20 LSD1SS Lowside1 Source Sensing

19 LSD1GD Lowside1 Gate Drive

18 LSD1GS Lowside1 Gate sense

17 HB1OutFilt Half bridge1 post-LC filter – for diagnostics

16 HB1Out Half-bridge1 output, HSD 1 drain sense, LSD1 Drain Sense

15 HSD1GS Highside1 Gate sense

14 HSD1GD Highside1 Gate Drive

13 HSD1SS Highside1 Source sense

12 VSP_POW1 Positive supply voltage connection for gate drive circuitry

10/64

TDA7572 Pins description

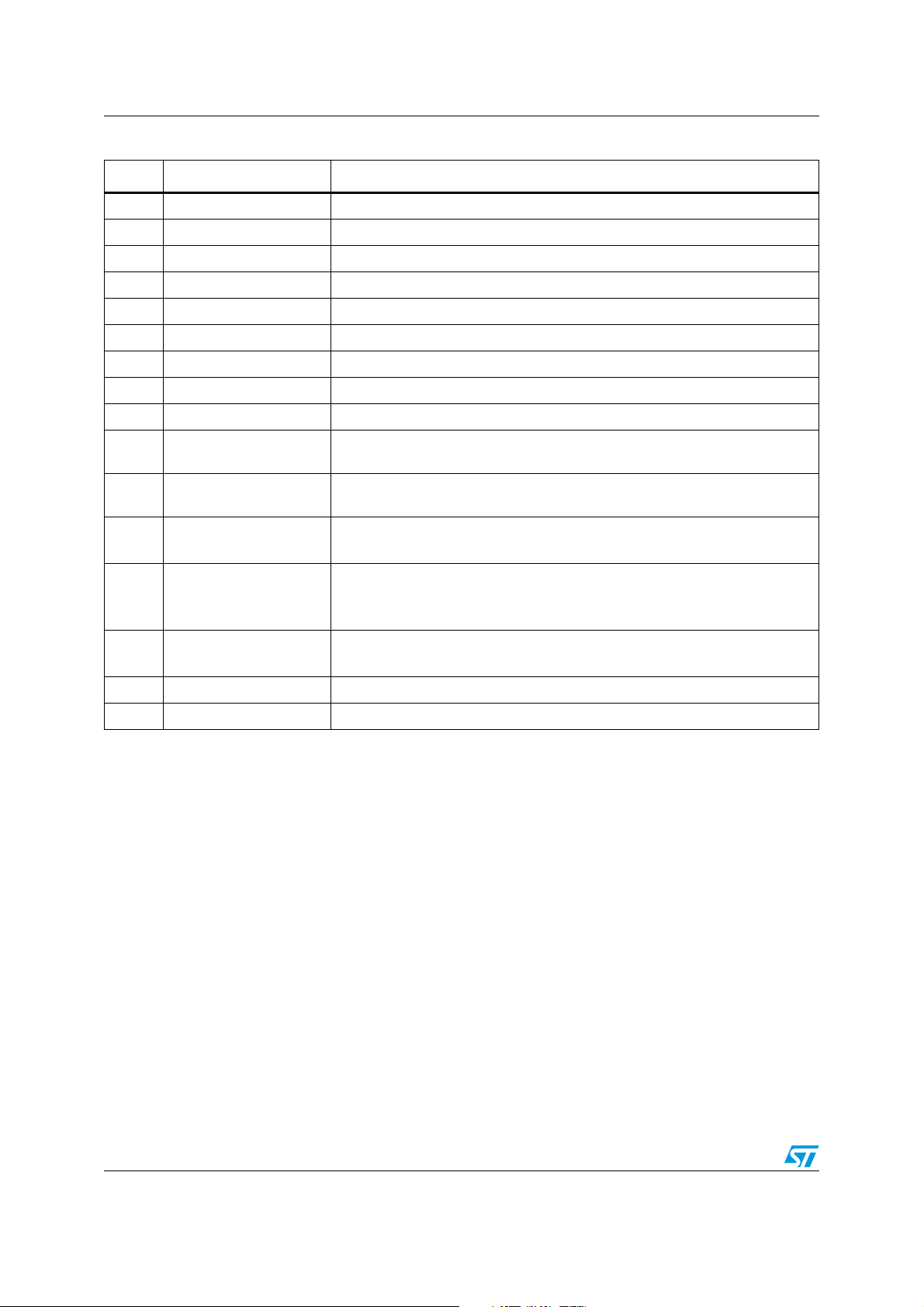

Table 2. Pin list by argument (continued)

Pin # Pin name Description

39 MOD2 Modulator2 Inverting / Summing node

10 HSD2SS Highside2 Source sense

9 HSD2GD Highside2 Gate Drive

8 HSD2GS Highside2 Gate sense

7 HB2Out Half-bridge2 output, HSD 1 drain sense, LSD1 Drain Sense

6 HB2OutFilt Half bridge2 post-LC filter – for diagnostics

5 LSD2GS Lowside2 Gate sense

4 LSD2GD Lowside2 Gate Drive

3 LSD2SS Lowside2 Source Sense

27 VSM1

26 VSM2

58 VSM3

Die tab connection to lowest supply voltage – gnd for single ended supplies,

negative supply for split supplies

Die tab connection to lowest supply voltage – gnd for single ended supplies,

negative supply for split supplies

Die tab connection to lowest supply voltage – gnd for single ended supplies,

negative supply for split supplies

59 VSM4

Die tab connection to lowest supply voltage – gnd for single ended supplies,

negative supply for split supplies

43 ShuntDriver Shunt Driver

DC-DC

28 BSTVSense Voltage feedback input for Voltage Booster

22 BSTSource Boost Converter NFET Source

21 BSTGate Boost Converter NFET gate drive

23 CSense

Inverting input for Booster Current Sensing and Digital Test Enable (operating

when is more then about 3V under the V14 pin level)

24 V14Sense Non-inverting input for Booster Current Sensing

25 V14 Power for Boost converter gate drive and Output LSD’s

Oscillator

41 CLKIN/Out Clock input

42 DITH Dither capacitor

40 OscOut Oscillator output

Diagnostics / Bus

2

I

62

CDATA/AttackSel

63 I

2

CLK I2C Clock

I2C data (I2C mode)

Compressor aggressiveness selection (non-bus mode)

11/64

Pins description TDA7572

Table 2. Pin list by argument (continued)

Pin # Pin name Description

2

I

C address set (I2C mode)

61 ADDR0/Fault/Clip_L

60 ADDR1/CompEnable

48 NTC Connection for NTC thermistor

2 TestC Test cap used to generate the slow current pulses

1 ISet Program pin for current level used in Short/Open test

30 ISSENP Supply non-inverting current sense

29 ISSENM Supply inverting current sense

DAC

46 WS / Clip_L I

45 SDA/SCR_ENB I

47 SCL/ InLevel1 I

44 PLL/InLevel0 DAC clock PLL filter/ Input Level selection bit 0 (non-DAC mode)

31 DAC2 DAC output voltage p

Fault output in non bus mode (non-bus mode)

Clipping indicator, assertion level low, (when DAC is enabled)

2

C address set (I2C mode)

I

Compressor Enable/disable (non-bus mode)

2

S Word select / Clipping indicator, assertion level low (non-DAC mode)

2

C serial data / SCR ENABLE (non DAC mode)

2

C serial data bit clock/ Input Level selection bit1 (non-DAC mode)

32 DAC1 DAC output voltage n

Table 3. Pin list by pin

Pin # Pin name Description

1 Iset Program pin for current level used in Short/Open test

2 TestC Test cap used to generate the slow current pulses

3 LSD2SS Lowside2 Source Sense

4 LSD2GD Lowside2 Gate Drive

5 LSD2GS Lowside2 Gate sense

6 HB2OutFilt Half bridge2 post-LC filter – for diagnostics

7 HB2Out Half-bridge2 output, HSD 1 drain sense, LSD1 Drain Sense

8 HSD2GS Highside2 Gate sense

9 HSD2GD Highside2 Gate Drive

10 HSD2SS Highside2 Source sense

11 VSP_POW2

Positive supply power for low power, non gate-drive functions with a separate

bonding to power the gate drive of modulator two

12 VSP_POW1 Positive supply voltage connection for gate drive circuitry

13 HSD1SS Highside1 Source sense

14 HSD1GD Highside1 Gate Drive

15 HSD1GS Highside1 Gate sense

12/64

TDA7572 Pins description

Table 3. Pin list by pin (continued)

Pin # Pin name Description

16 HB1Out Half-bridge1 output, HSD 1 drain sense, LSD1 Drain Sense

17 HB1OutFilt Half bridge1 post-LC filter – for diagnostics

18 LSD1GS Lowside1 Gate sense

19 LSD1GD Lowside1 Gate Drive

20 LSD1SS Lowside1 Source Sensing

21 BSTGate Boost Converter NFET gate drive

22 BSTSource Boost Converter NFET Source

23 CSense

Inverting input for Booster Current Sensing and Digital Test Enable (operating

when is more then about 3V under the V14 pin level)

24 V14Sense Non-inverting input for Booster Current Sensing

25 V14 Power for Boost converter gate drive and Output LSD’s

26 VSM2

27 VSM1

Die tab connection to lowest supply voltage – gnd for single ended supplies,

negative supply for split supplies

Die tab connection to lowest supply voltage – gnd for single ended supplies,

negative supply for split supplies

28 BSTVSense Voltage feedback input for Voltage Booster

29 ISSENM Supply inverting current sense

30 ISSENP Supply non-inverting current sense

31 DAC2 Half VCC (VSP- VSM)/2 Used for output stage reference.

32 DAC1 Gain program pin for SVR to HVCC level shifting

33 INM Inverting audio input

34 INP Non inverting audio input

35 AOUT Compressed Audio Output

36 InvIn Inverter input

37 InvOut Inverter Output

38 MOD1 Modulator1 Inverting / Summing node

39 MOD2 Modulator2 Inverting / Summing node

40 OscOut Oscillator output

41 CLKIN/Out Clock input

42 DITH Dither capacitor

43 ShuntDriver Shunt Driver

44 PLL/InLevel0 DAC clock PLL filter/ Input Level selection bit 0 (non-DAC mode)

2

45 SDA/SCR_ENB I

46 WS / Clip_L I

47 SCL/ InLevel1 I

C serial data / SCR ENABLE (non DAC mode)

2

S Word select / Clipping indicator, assertion level low (non-DAC mode)

2

C serial data bit clock/ Input Level selection bit1 (non-DAC mode)

48 NTC Connection for NTC thermistor

13/64

Pins description TDA7572

Table 3. Pin list by pin (continued)

Pin # Pin name Description

49 DGND GND logic supply decoupling

50 VDIG 5V logic supply decoupling

51 VM2.5 -2.5 V analog supply output

52 SVR Vs/2 analog reference filter capacitor. Reference for input stage.

53 VP2.5 +2.5 V analog supply output

2

54 Mode1 Mode control bit1, selects standby/normal/I

55 Mode0 Mode control bit0, selects standby/normal/ I

56 AutoMuteVSetting Auto-mute Voltage Setting

57 MUTE_L Mute input and / or timing cap, assertion level low

58 VSM3

59 VSM4

60 ADDR1/CompEnable

61 ADDR0/Fault/Clip_L

Die tab connection to lowest supply voltage – gnd for single ended supplies,

negative supply for split supplies

Die tab connection to lowest supply voltage – gnd for single ended supplies,

negative supply for split supplies

2

C address set (I2C mode)

I

Compressor Enable/disable (non-bus mode)

2

I

C address set (I2C mode)

Fault output in non bus mode (non-bus mode)

Clipping indicator, assertion level low, (when DAC is enabled)

C/diagnostic operation

2

C/diagnostic operation

62 I2CDATA/AttackSel

63 I

2

CLK I2C Clock

I2C data (I2C mode)

Compressor aggressiveness selection (non-bus mode)

64 IlimitThresh Output stage Current Limiting trip voltage setpoint

14/64

TDA7572 Electrical specifications

4 Electrical specifications

4.1 Absolute maximum ratings

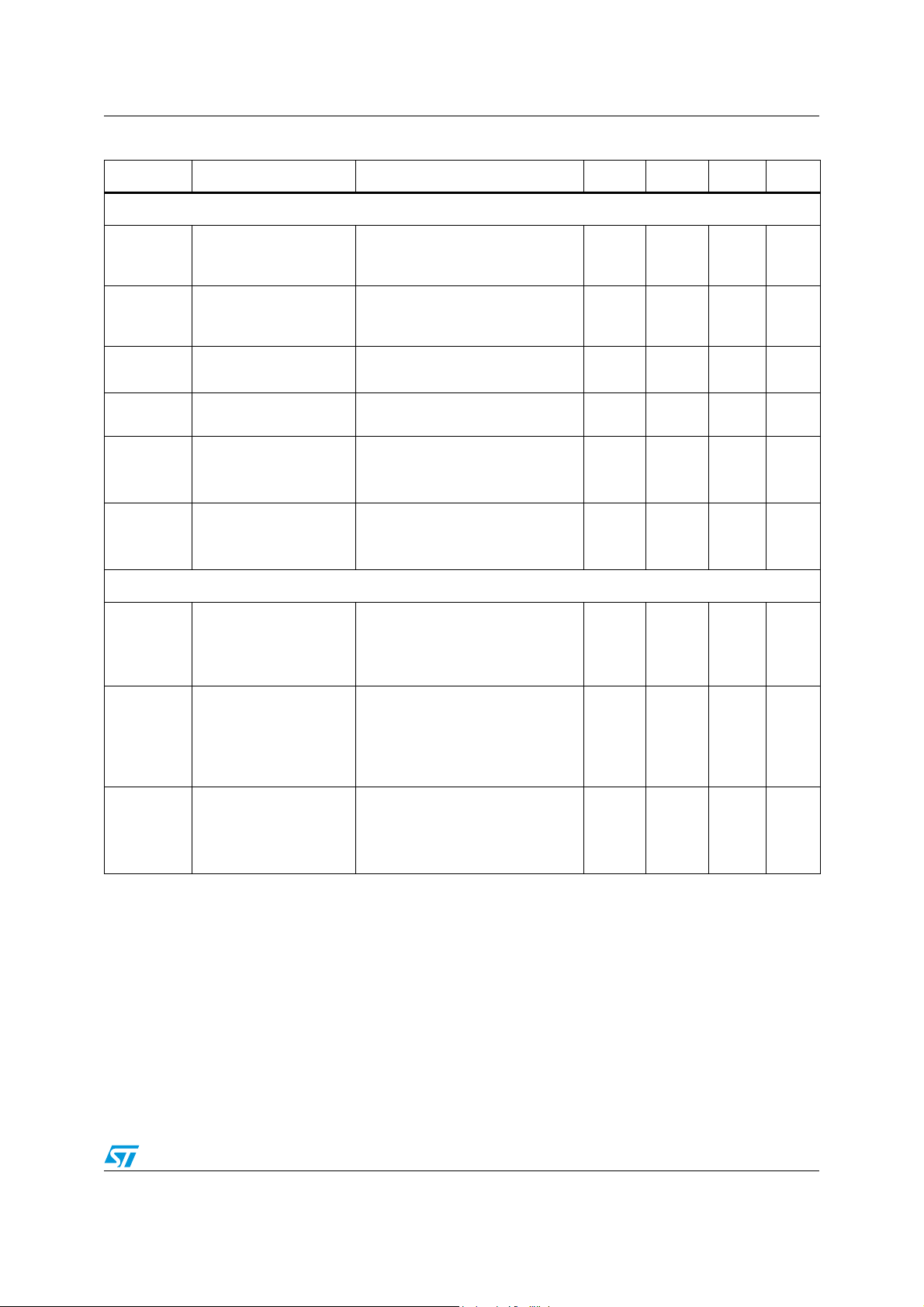

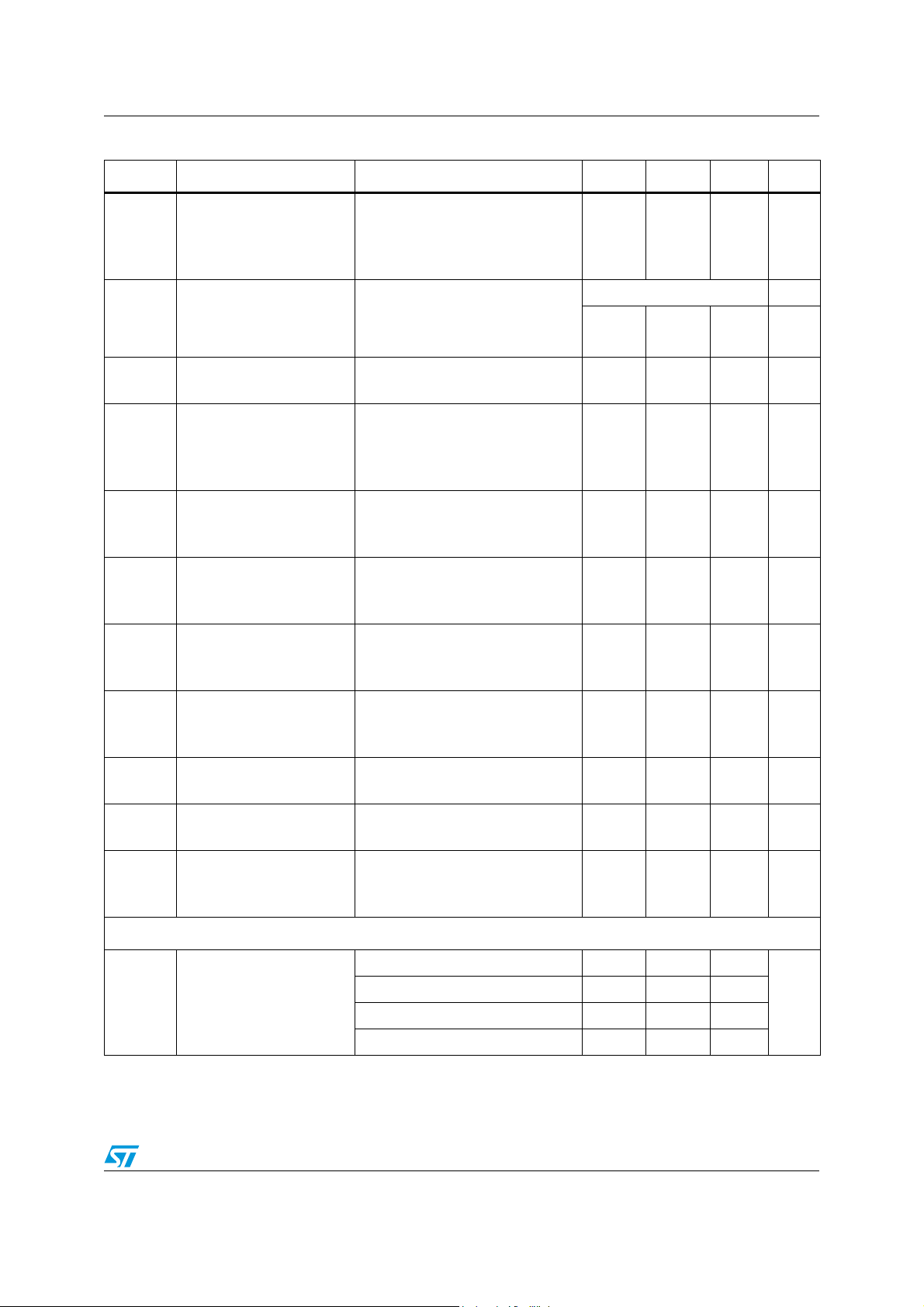

Table 4. Absolute maximum ratings

Symbol Parameters Test Conditions Min. Max. Units

V

V

V

T

P

DMAX

SP

peak

DATA

T

Stg

Supply voltage VSM -0.6 VSM +58 V

Peak supply voltage (VS+ - VS-) time ≤ 50ms 68 V

Data pin voltage w.r.t Dgnd VS—0.6 6V V

Junction temperature -40 150 C

J

Storage temperature -55 150 C

Power Dissipation

Any operating condition

For thermal budgeting

2.5 W

4.2 Thermal data

Table 5. Thermal data

Symbol Parameters Value Units

R

Th j-case

Thermal resistance junction to case 3 °C/W

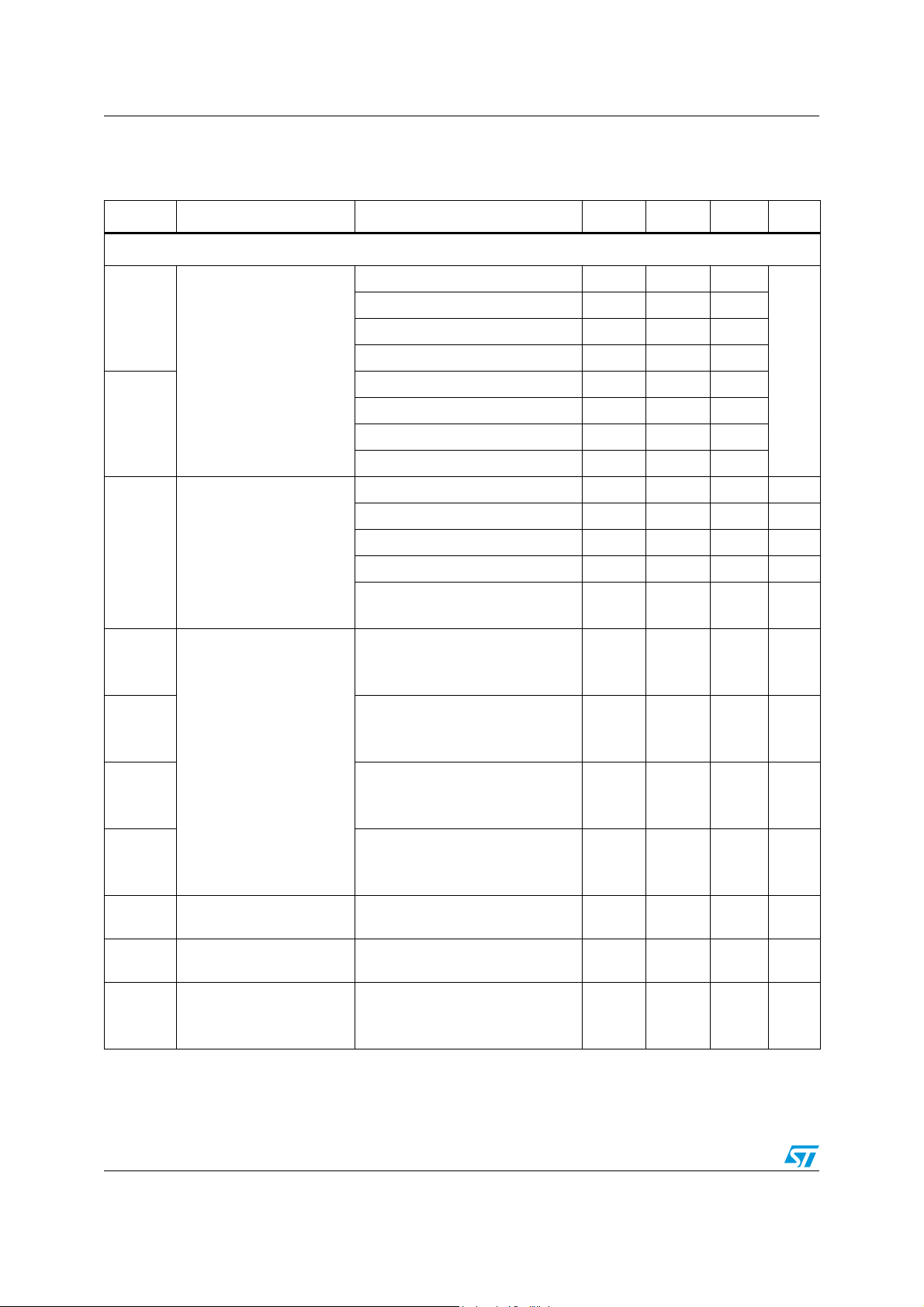

4.3 Electrical characteristics

Unless otherwise specified, all ratings below are for -40°C < TJ < 125°C, VSP = 42V, VSM =

0V and the application circuit of Figure 12. Operation of the IC above this junction

temperature will continue without audible artifacts until thermal shutdown, but these

parameters are not guaranteed to be within the specifications below. F

PWM

=110KHz,

Booster not enabled.

4.3.1 Operating voltage and current

Table 6. Operating voltage and current

Symbol Parameters Test conditions Min. Typ. Max. Units

V

SP42

V

SP14

Operating voltage 42V

automotive range

Operating voltage 14.4V

automotive range

Normal operation without audible

defects required

Single ended supply 42V

configuration, V

SM

=0

Normal operation without audible

defects required

Single ended supply 14V

configuration, V

SM

=0

15/64

30 42 58

9 14.4

V

Electrical specifications TDA7572

Table 6. Operating voltage and current (continued)

Symbol Parameters Test conditions Min. Typ. Max. Units

Normal operation required

V

I

SPLIT

stdby

Operating voltage VSP -

split supply rails

V

SM

Stand-by current

Split supply application

SVR

VSM<V

+4

SVR-4,

configuration,

VSP>V

IC in standby, Mode0, and Mode1

= 42V

low V

s

848 58 V

50 at

= 25°C

T

10 at

μA

T = 85°C

V14 13 20

VSP 15 25

I

tristate

Tristate current

Outputs tristated

Booster not running,

= nominal

F

pwm

V14 10

I

MUTE

Mute mode current MUTE asserted,

VSP 20

4.3.2 Under voltage lockout

Table 7. Under voltage lockout

Symbol Parameters Test conditions Min. Typ. Max. Units

V

LimAM

VSP UVLO

V

AM

VPO-

VPO+

V

V

UC

AutomuteVSetting pin

voltage limit

Auto-mute supply

voltage VSP

Auto-tristate supply

voltage VSP negative

slope

Auto-tristate supply

voltage VSP positive

slope

Auto-tristate supply

U

voltage VSP

Relative maximum value

Voltage limit respect to the SVR pin

Allowed voltage range on Automute

pin

Mute is forced if VSP-VSVR or

VSVR-VSM is less than this value

VautomuteVSetting-V

SVR

=VVSVR

The IC is set in tristate if VSP-VSM

is less than this value

Vautomute VSetting-V

=VVSVR

SVR

The IC is set out from tristate if

VSP-VSM is higher than this value

Vautomute VSetting-V

=VVSVR

SVR

The IC is set in tristate if VSP-VSM

is more than this value

Vautomute VSetting-V

=VVSVR

SVR

0.5 2.1 V

-15%

-15%

-15%

-15%

VVSVR*

7

VVSVR

*12

VVSVR

*13

VVSVR*

48

+15% V

+15% V

+15% V

+15% V

Auto-tristate supply

voltage

VSP

Absolute maximum

The IC is set in tristate if VSP-VSM

is higher than this value

60 63 66 V

value

mA

mA

16/64

TDA7572 Electrical specifications

Table 7. Under voltage lockout (continued)

Symbol Parameters Test conditions Min. Typ. Max. Units

V14 – UVLO

Auto-tristate supply

V14-

voltage V14 negative

slope

Auto-tristate supply

V14+

voltage V14 positive

slope

V14h

Auto-tristate 14V voltage

hysteresis

V14su Step-up tristate

Auto-mute supply

V14mute-

voltage V14 negative

slope

Auto-mute supply

V14mute+

voltage V14 positive

slope

SVR – UVLO

Vsvr-

Vsvr+

Auto-tristate SVR

voltage negative slope

Auto-tristate SVR

voltage positive slope

Auto-tristate SVR

VPOH

Voltage

hysteresis

The IC is kept in tristate if 14V VSM become lower than this value

The IC is goes out from tristate if

14V-VSM become higher than this

value

Comparator hysteresis for autotristate threshold

The step-up is in tristate when

voltage lower than this threshold

The IC goes in mute if 14V-VSM

become lower than this value

The IC goes in play if 14V-VSM

become higher than this value

The IC is kept in tristate if VSvr VSM become less than this value

Vautomute VSetting-V

=VVSVR

SVR

The IC is goes out from tristate if

Vvr - VSM become higher than this

value

Vautomute VSetting-V

=VVSVR

SVR

Comparator hysteresis for autotristate threshold

Vautomute VSetting-V

=VVSVR

SVR

5.5 7 V

6.5 8 V

0.8

V

58V

V14-

+

0.7V

V14V+

+

40mV

V14-

+

1.2V

V14V+

+

170mV

V

5

-15%

x

+15% V

VVSVR

6

-15%

x

+15% V

VVSVR

0.40

X

VVSVR

1.2V

X

VVSVR

V

17/64

Electrical specifications TDA7572

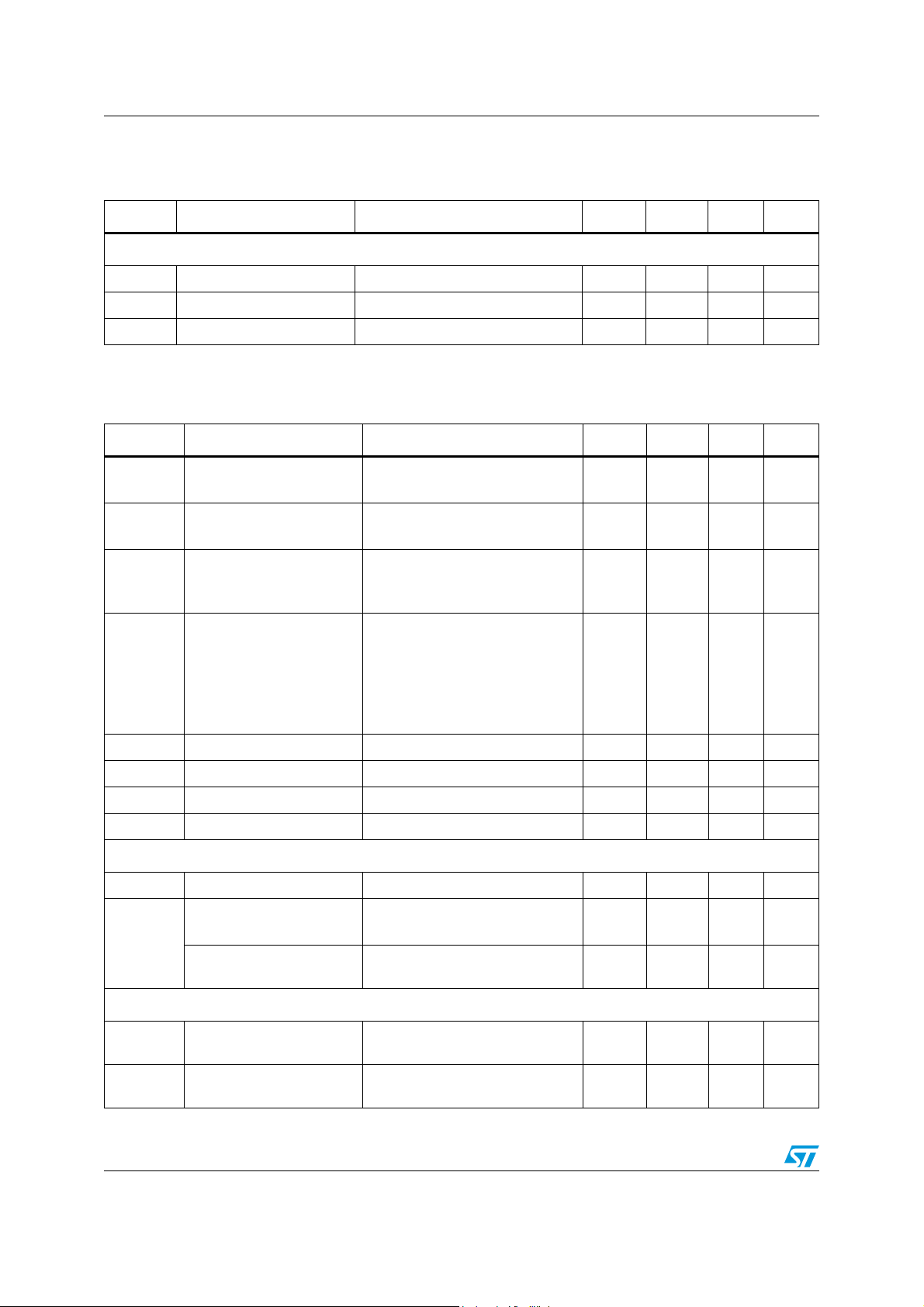

4.3.3 Input stage

Table 8. Input stage

Symbol Parameters Test conditions Min. Typ. Max. Units

Input diff. amp./ gain attenuator

R

IN,

No

compress

INLEVEL1=0, INLEVEL0=0 -30% 20 +30%

INLEVEL1=0, INLEVEL0=1 -30% 12 +30%

INLEVEL1=1, INLEVEL0=0 -30% 22 +30%

ion

INLEVEL1=1, INLEVEL0=1 -30% 12 +30%

Input resistance

INLEVEL1=0, INLEVEL0=0 -30% 15.6 +30%

R

max

IN

INLEVEL1=0, INLEVEL0=1 -30% 12 +30%

compress

ion

INLEVEL1=1, INLEVEL0=0 -30% 16 +30%

INLEVEL1=1, INLEVEL0=1 -30% 12 +30%

INLEVEL1=0, INLEVEL0=0 2 V

INLEVEL1=0, INLEVEL0=1 7 V

INLEVEL1=1, INLEVEL0=0 2.6 V

INLEVEL1=1, INLEVEL0=1 9.5 V

INLEVEL1=1,INLEVEL0=1

Not tested in production

(V

AOUT-VSVR

) / (VInP-VinM)

INLEVEL1=0, INLEVEL0=0,

-10 +10

-4 -3 -2 dB

V

A

InMax

IN_0

Input clipping level

Voltage level of the input

that trespassed cause

clipping in the preamplifier

no compression

KΩ

RMS

RMS

RMS

RMS

A

IN_2

A

IN_1

A

IN_3

V

outH

V

outL

AOUT

Input stage gain

AOUT output voltage swing

AOUT output swing

THD

THD

(V

- V

AOUT

) / (VInP-VinM)

SVR

INLEVEL1=0, INLEVEL0=1,

no compression

(V

- V

AOUT

) / (VInP-VinM)

SVR

INLEVEL1=1, INLEVEL0=0

no compression

(V

- V

AOUT

) / (VInP-VinM)

SVR

INLEVEL1=1, INLEVEL0=1,

no compression

With respect to SVR, 10K loading

to a buffered version of SVR

With respect to SVR, 10K loading

to a buffered version of SVR

Vin=1Vrms, f=20-20KHz,

INLEVEL1=0, INLEVEL0=0,

no compression

-15 -14 -13 dB

-6.3 -5.3 -4.3 dB

-17.6 -16.6 -15.6 dB

2V

-2 V

0.01 0.05 %

18/64

TDA7572 Electrical specifications

Table 8. Input stage

Symbol Parameters Test conditions Min. Typ. Max. Units

Vin=1KHz square wave, 2Vpp,

Output slew rate

INLEVEL1=0, INLEVEL0=0,

no compression

Time to transition from 10% to 90%

8µS

AOUT clip detector

f

-3dB

CMRR

Frequency response

Common Mode Rejection

Ratio

CG Common gain

CG Common gain

CG Common gain

CG Common gain

PSRR

V

offset

Power Supply Rejection,

Vsp supply

Output offset

Eno Noise

Duty cycle of the Clipping signal

TBD %

when there is 5% distortion at the

output of AOUT, f=1KHz,

=10kOhm

R

L

Vin=1Vrms,

INLEVEL1=0, INLEVEL0=0

=1V

V

CM

CMRR= A

@1KHz

RMS

VDIFF/AVCM

INLEVEL1=0, INLEVEL0=0

15 25

20 KHz

47 dB

No compressor

VCM=1V

INLEVEL1=0, INLEVEL0=0

RMS

@1KHz

51 dB

No compressor

V

=1V

CM

INLEVEL1=1, INLEVEL0=0

RMS

@1KHz

51 dB

No compressor

VCM=1V

INLEVEL1=0, INLEVEL0=1

RMS

@1KHz

51 dB

No compressor

VCM=1V

INLEVEL1=1, INLEVEL0=1

RMS

@1KHz

51 dB

No compressor

freq<10KHz 60 80 dB

V

with respect to SVR

Offset

Rin=100 ohms, Mute state

-4 0 +4 mV

Noise at output of this stage

f = 20-20KHz, R

= 100ohms

input

710µV

A weighting

RMS

Gain compressor

Maximum attenuation

INLEVEL1=0, INLEVEL0=0 -21 -19 -17

INLEVEL1=0, INLEVEL0=1 -30 -28 -26

dB

INLEVEL1=1, INLEVEL0=0 -25 -23 -21

INLEVEL1=1, INLEVEL0=1 -34 -32 -30

19/64

Electrical specifications TDA7572

Table 8. Input stage

Symbol Parameters Test conditions Min. Typ. Max. Units

Mute

0.5+

0.25

0.44+

0.25

dB

0.55+

0.25

0.48+

0.25

Attenuation step size

Gain Change ZC

comparator offset

(in the diff. – S.E. block)

offset

INLEVEL1=0, INLEVEL0=0 0.5-0.25 0.5

INLEVEL1=0, INLEVEL0=1

INLEVEL1=1, INLEVEL0=0

INLEVEL1=1, INLEVEL0=1

0.44-

0.25

0.55-

0.25

0.48-

0.25

0.44

0.55

0.48

Observed at AOUT pin

ZC crossing must be detected

within 50mV of the actual zero

-80 80 mV

crossing,

Gain Change ZC

comparator offset

(in the diff. – S.E. block)

Observed at InvOut pin

ZC crossing must be detected

-220 +220 mV

offset

Mute attenuation

Mute pin voltage = Dgnd

Vin=1Vrms

90 dB

Charge current Mute Pin Voltage(57) = 1.5V -30% 100 +30% µA

Discharge current Mute Pin Voltage(57) = 1.5V -30% 100 +30% µA

Mute threshold

Maximum voltage where we must

be in complete mute

1.5 V

Unmute threshold 2.5 V

Mute to unmute transition

voltage

Vol

IC in mute mode, FastMute=1

Iout=0

Voh IC in unmute, Iout=0

0.2 0.3 0.42 V

Digital

GND +

0.1

DIGITAL-

V

0.1

V

V

Fast mute Resistance

FASTMUTE=1

Vmutepin=1.5Volts

20/64

420 550 680 Ohm

TDA7572 Electrical specifications

4.3.4 Oscillator

Table 9. Oscillator

Symbol Parameters Test conditions Min. Typ. Max. Units

Internal oscillator

PWMCLOCK=[0 1] 100K 120 140K KHz

F

F

PWM_NOM

CLK

Switching frequency

PWMCLOCK=[1 0]

PWMCLOCK=[0 0]

Duty cycle 48 50 52 %

DC

PWM_NOM

*2

F

PWM_NOM

/2

Clock output high value

V

CLK_High

Maximum voltage level

Load = 20Kohm and 100pF

-0.1 V

V

P25

P25

to buffered SVR

Clock output low value

V

CLK_Low

Minimum voltage level

Load = 20Kohm and 100pF

-0.1 V

V

M25

M25

to buffered SVR

V

CLK-P-P

Peak-peak voltage

Load = 20Kohm and 100pF

to SVR

-10% 4.7 +10% V

Dither cap charge current Dither pin voltage= 2.5V -20% 100 +20% µA

Dither cap discharge

current

Peak-peak dither voltage

swing

Dither external clock

determination

Voltage at the dither pin at to

select external clock function

-20% 100 +20% µA

1.4 1.6 1.7 V

VDIG-0.2 V

V

V

No dither

Peak F

increase due

PWM

to dither

Peak F

decrease due

PWM

to dither

Triangular peak value

Voltage at the dither pin at

which no dither will occur

VDGND

+0.2

Cdither=100nF +8 +10 +12 %

Cdither=100nF -8 -10 -12 %

VGND+

1V

VDIG-

1V

21/64

V

Electrical specifications TDA7572

4.3.5 Modulator

Table 10. Modulator

Symbol Parameters Test conditions Min. Typ. Max. Units

Integrator op. amp.

Int_Voff Input offset voltage -2.5 +2.5 mV

Int_ibias Input bias current Guaranteed by design 500 nA

T

Maximum duty cycle Vsp =1 4.4 1.1 µs

off

4.3.6 Gate drive and output stage control

Table 11. Gate drive and output stage control

Symbol Parameters Test conditions Min. Typ. Max. Units

V

OL_LSD

V

OH_LSD

V

OL_HSD

LSG low voltage

LSG high voltage

HSG low voltage

I

sink

I

sink

I

source

I

source

I

sink

I

sink

= 0.5A

= 20mA

= 0.5A

= 20mA

= 0.5A

= 20mA

1.75

0.080

7

9.2

VSP-7

VSP-

9.2

V

V

V

V

OH_HSD

HSG high voltage

HSG low Z drive t

LSG low Z drive t

HSG HiZ sink current V

LSG HiZ source current V

Overcurrent sensing

I

limThresh

Range of I

Vilim

Vilim

Vitrip

Anti-shoo through

PV

PV

GS_ON

GS_OFF

PFET gate voltage that will

block NFET enhancement

PFET gate voltage that will

allow NFET enhancement

delay

delay

lim Trthresh

VSP-

I

source

I

source

= 0.5A

= 20mA

1.75

VSP-

0.080

After a commutation 2 10 µs

After a commutation 2 10 µs

HSG=VSP

LSG=VSM

t>5uS 150 mA

, t>5uS 150 mA

0.3 1.1 V

Engagement of the current limiting

VlimitTreshold=1V w.r.t. VM2p5

Start of cycle by cycle current

limiting

Vlim*

3.0

-15%

Vlim *

6.0

Vlim*

5.0

+15% V

-2.5 V

-3.5 V

V

V

22/64

TDA7572 Electrical specifications

Table 11. Gate drive and output stage control (continued)

Symbol Parameters Test conditions Min. Typ. Max. Units

NV

NV

GS_ON

GS_OFF

NFET gate voltage that will

block PFET enhancement

NFET gate voltage that will

allow PFET enhancement

2.5 V

3.5 V

4.3.7 Diagnostics

Table 12. Diagnostics

Symbol Parameters Test conditions Min. Typ. Max. Units

Turn-on diagnostics/ Power up diagnostics

I

TEST

V

LSSHRT

V

NOP

-15%

Test current for short/open

R

allowed range 5.6 ohm

ISET

set = 56ohm -15% 15 +15%

R

i

Short threshold to lower

supply rail

Normal operation

thresholds

-Vs+2 -Vs+5.5 V

2.45/(3*

Riset)

+15% mA

-Vs +1 V

Short to supply -Vs+8

Shorted load 6mV

Normal load .025 1 V

Open load 2 V

Test charge current -30% 10µA +30% µA

t

TEST

Test time 60 80 100 ms

Permanent Diagnostics

V

offACT

V

offACT

DC offset detected +-3 Volts

DC offset not detected,

normal operation allowed

+-1.2 Volts

Tem peratur e

T

WARN

Chip thermal warning 135 150 165 °C

Chip thermal warning

hysteresis

357

T Chip thermal shutdown 155 160 175 °C

Shutdown hysteresis 3 5 7 °C

External thermal warning -10% V

External thermal warning

hysteresis

Vdig*0.0

30

*.4 +10% V

DIG

Vdig*0.

044

V

23/64

Electrical specifications TDA7572

Table 12. Diagnostics (continued)

Symbol Parameters Test conditions Min. Typ. Max. Units

Supply I

Ext thermal shut down -15% V

Ext thermal shut down

hysteresis

sense

Vdig*0.0

32

*.36 +15% V

DIG

Vdig*0.

046

Supply sense trip voltage 16 20 25 mV

AOUT levels that allow

sensing of supply current

3V

Duration of AOUT under

threshold to allow supply

-25% 80 +25% ms

current sensing

I

ssenp

I

ssenM

200 700 µA

-500 500 nA

4.4 Voltage booster

Table 13. Voltage booster

Symbol Parameters Test conditions Min. Typ. Max. Units

Current mode control topology

BST

DCMAX

BST

BSTREF Vref -8% 2.5 +8% V

IBIAS

V

SENSE_UL

BSTVGain

BSTDC

C

sense_UL

C

sense gain

Csense

T

Max duty cycle 88 %

DCMIN

BSTREFVsense

Min duty cycle 0 %

V

sense

range

Voltage-error gain

ΔDuty cycle/ΔBSTVSense

Nominal duty cycle 55 65 %D.C.

NOM

C

sense

range

C

sense

ΔDuty cycle / ΔC

V

C_SENSE

Ilimit trip point 0.220 0.440 V

Tr i p

Soft-start step period

SS

not yet tested (to be

confirmed)

Soft start steps 16

input bias current -100 100 nA

pin allowed voltage

-0.6 58 V

0.4 0.8 1.2

pin allowed voltage

gain

sense

at max current

V

Vsense = Vreference

DC=0%

-0.6 58 V

0.120 0.350

3ms

V

%D.C.

per mV

%D.C.

per mV

24/64

TDA7572 Electrical specifications

Table 13. Voltage booster

Symbol Parameters Test conditions Min. Typ. Max. Units

V

OH_BST

V

OL_BST

BST gate high voltage

BST gate low voltage

I

source

I

source

I

sink

I

sink

= 0.5A

= 20mA

= 0.5A

= 20mA

7

9.2

1.75V

0.080

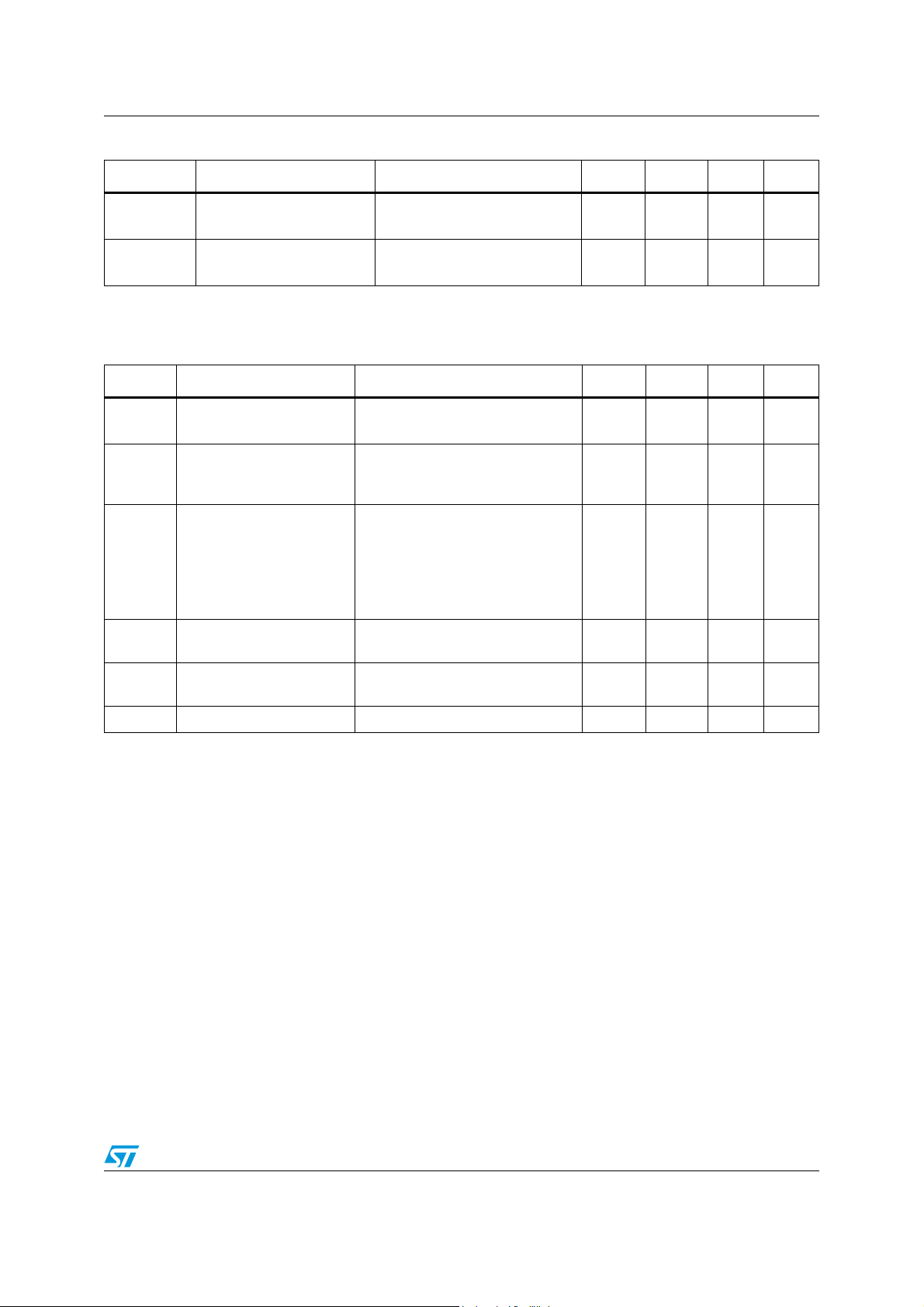

4.4.1 Digital to analog converter

Table 14. Digital to analog converter

Symbol Parameters Test conditions Min. Typ. Max. Units

Dynamic range at

-60dBFS

Noise floor

THD+N

at maximum useful input

level

Silent Mute

At output of analog filter

-60dBFS input 1KHz sine tone

At output of analog filter after >

25mS of –97dBFS input 20-20k Hz

flat

Input=-1.5dBFS

The DAC output is limited to

prevent operation in regions of

degraded DAC performance. This

spec represents the performance

at this maximum practical value

Must engage after 25mS of <96dbFS input signal

80 90 dB

20 µV

-60 dB

20 30 ms

V

V

Differential output voltage

Magnitude of –1.5dBFS sine,

1 KHz

-10% 2.1 +10% Vrms

Output resistance 1.8K 2.5K 2.8K Ohms

25/64

Electrical specifications TDA7572

4.4.2 I/O pin characteristics

Table 15. I/O pin characteristics

Symbol Parameters Test conditions Min. Typ. Max. Units

I

SCL/CLIP_L

I

SCL/CLIP_L

SCL/CLIP_L pin leakage

current

SCL/CLIP_L pin sink V

V

, digital output pins

OH

digital output pins

V

OL

V

INL

V

INH

ADDR0 ADDR1 threshold

low

ADDR0 ADDR1 threshold

high

SCL/CLIP_L

-15 15 µA

<375mV 1 mA

1.5 V

2.3 V

1

4

4.4.3 Op. amp. cells

Table 16. Op. amp. cells

Symbol Parameters Test conditions Min. Typ. Max. Units

Int_OLGain Open loop voltage gain Guaranteed by design 80 dB

PSRR = 20*log10(Vsp/=

F < 10KHz V

ripple=1Vrms

SP

Guaranteed by design

-50 dB

PSRR

V

power supply

SP

rejection

Int_Voff Input offset voltage Guaranteed by design -3 3 mV

Int_ibias Input bias current Guaranteed by design 500 nA

4.4.4 Shunt

Table 17. Shunt

Symbol Parameters Test conditions Min. Typ. Max. Units

I

source

I

sink

V

sd

V

sdh

Source current 70 100 130 µA

Sink current 70 100 130 µA

Shunt drive current

activation Vs. Mute pin

voltage

(the shunt current is

0.8 1.2 V

sourced when Vmute is

lower than the threshold).

Shunt drive current

activation hysteresis

80 140 mV

26/64

TDA7572 Electrical specifications

4.4.5 Application information

These are required parameters of the overall operation of the Cortina IC in its application

circuit and will form the overall functional testing for Cortina

Table 18. Analog operating characteristics

Symbol Parameters Test conditions Min. Typ. Max. Units

1W, 100Hz, V

Rl=2 ohm

Only modulator

(1)

THD+Noise

4W VCC = 14V and VCC = 42V

FR =1 00Hz

(1)

Output noise

Output offset

50W F

V

(1)

V

V

=1kHz VCC = 42V 0.4 %

R

=14.4V

SP

= 14.4V

CC

= 42V

CC

Output offset Offset modulator only (V

1. Note: the measure is affected by the testing board noise.

SP

=14.4

0.5 %

0.3 %

400 µVrms

-100

-200

=14.4V) -70 0 70 mV

CC

0

0

100

200

mV

27/64

I2C and mode control TDA7572

5 I2C and mode control

The Mode1 and Mode0 pins are used to enable TDA7572. These perform the function of

bringing the IC out of standby (typically handled by a single standby pin on most audio IC's)

as well as determining if the I

occurs.

The Auto-mute Voltage pin is used to provide an under-voltage-lockout for the IC. Using a

resistor divider between V2P5 and SVR a series of comparator prevent the IC from powerup further until sufficient voltage is present at VSP and SVR(equal to GND in the split supply

case. Once this voltage requirement is met, the chip is forced into mute (a special, direct

form of mute that does not use or act upon the MUTE pin) under a second, higher voltage

threshold is met. At this point the IC performs its normal power-up, controlled by the state of

the MODE pins and the various configuration pins. Refer to the under-voltage lockout

(UVLO) section of the documentation for details on these thresholds.

The Auto-mute Voltage pin is also used to provide an over-voltage shutdown based on

absolute voltage of VSP-VSM.

Table 19. Power-up mode control

Mode1 Mode0 State/function

2

C bus is active or if power-up Diagnostics shall automatically

0 0 Standby, or “Off”

NO I2C BUS mode

TDA7572 enabled

01

11

10

Configuration defaults read from pin

2

C disabled

I

Power-Up-Diagnostics disabled

2

C BUS mode

I

TDA7572 enabled

2

C enabled

I

Power-Up-Diagnostics disabled

TDA7572 enabled

Configuration defaults read from pins

2

C disabled

I

Power-Up-Diagnostics enabled

DIAGNOSTIC mode

TDA7572 enabled

Configuration defaults read from pins

2

C disabled

I

Power-Up-Diagnostics enabled

When I2C bus is active, determined by the Mode0 and Mode1 pins, any operating mode of

the IC may be modified and diagnostics may be controlled and results read back.

28/64

TDA7572 I2C and mode control

The protocol used for the bus is the following and comprises:

● a start condition (S)

● a chip address byte (the LSB bit determines read / write transmission)

● a subaddress byte

● a sequence of data (N-bytes + acknowledge)

● a stop condition (P)

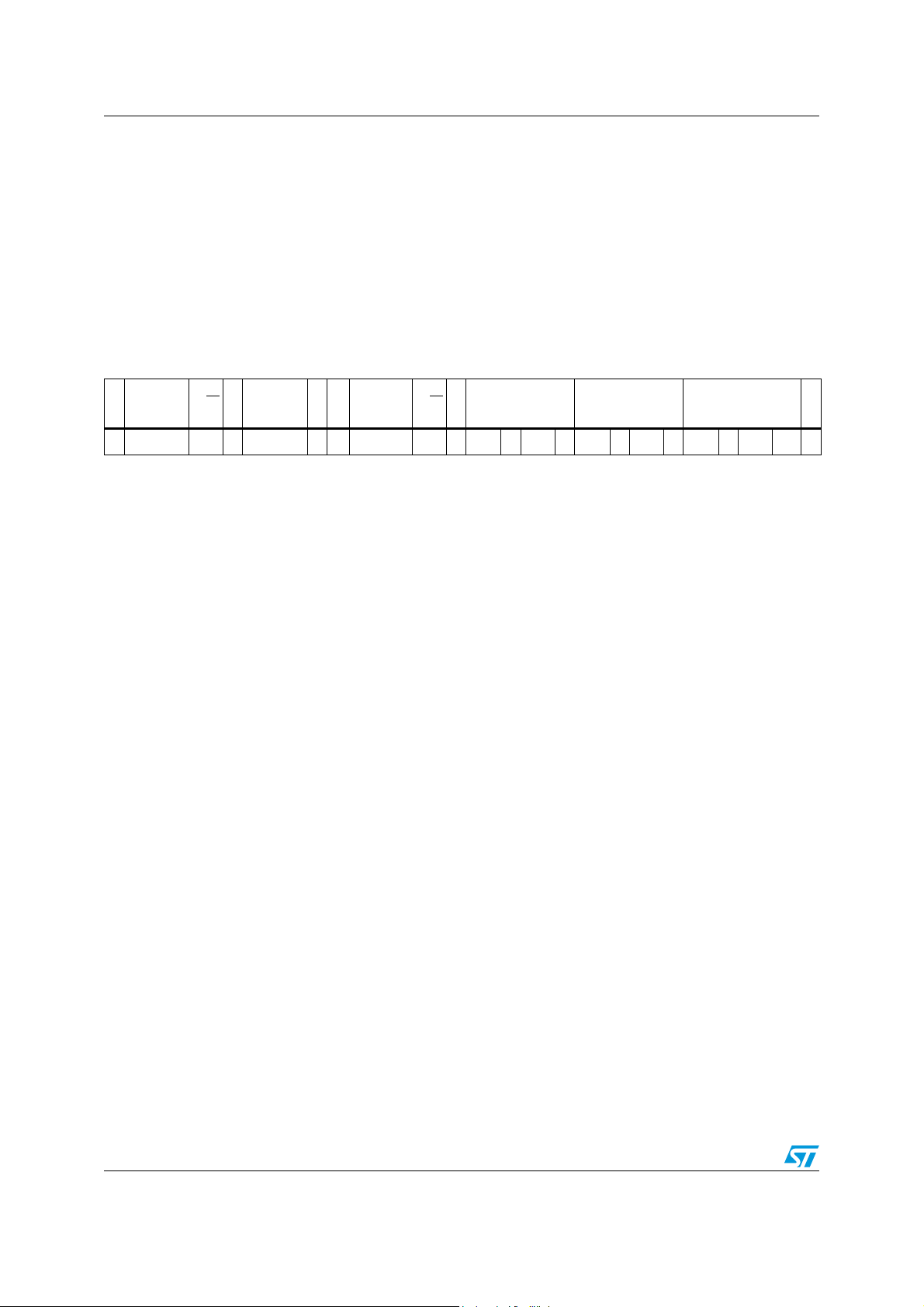

Table 20. Addresses

Chip address Subaddress Data [7:0]

MSBLSBMSBLSBMSBLSB

S A AAAAAAR/WACK X X I AAAA A ACK DATA ACKP

S = Start

R/W = "0" -> Receive-Mode (Chip could be programmed by µP)

"1" -> Transmission-Mode (Data could be received by µP)

I = Auto increment - when 1, the address is automatically increased for each byte transferred

X: not used

ACK = Acknowledge

P = Stop

MAX CLOCK SPEED 500kbits/s

The I2C address is user determined by pins ADDR1 and ADDR0. See table below:

Table 21. I2C chip address

MSB LSB

A6 A5 A4 A3 A2 A1 A0 R/W

01000ADDR1 ADDR0 X

Write procedure:

Two possible write procedures are possible:

1. without increment: the I bit is set to 0 and the register is addressed by the subaddress.

Only this register is written by the data following the subaddress byte.

2. with increment: the I bit is set to 1 and the first register read is the one addressed by

subaddress. Are written the register from this address up to stop bit or the reaching of

last register.

Example of write instruction with increment:

Device

Address

R/W

S 0011000 0 A ADDR A MS1 A LS1 A MS2 A LS2 A MSn A LSn A P

Register

Address

DATA 1 DATA 2 DATA n

29/64

I2C and mode control TDA7572

Read Procedure:

Two possible read procedures are possible:

1. without increment: the I bit is set to 0 and the register is addressed by the subaddress

sent in the previous write procedure. Only this register is written by the data following

the address.

2. with increment: the I bit is set to 1 and the first register read is the one addressed by

subaddress sent in the previous write procedure. Are written the register from this

address up to stop bit or the reaching of last register.

Example of read instruction with increment and previous addressing by write instruction and

restart bit (Sr)

Device

Address

S 0011000 0 A ADDR A Sr 0011000 1 A MS1 A LS1 A MS2 A LS2 A MSn A LSn NA P

R/W

In the following tables are reported the meaning of each I2C bus present in the device.

Register

Address

Device

Address

R/W

DATA 1 DATA 2 DATA n

30/64

TDA7572 I2C and mode control

5.1 Input control register

Subaddress: XXI00001.

Table 22. Input control register

MSB LSB

D

R/W

7

D

6

R/W

D

R/W

5

D

4

R/W

D

R/W

3

D

2

R/W

D

R/W

1

D

0

R/W

11110001

AttackSel

(pin)=1 → [11]

AttackSel

(pin)=0 → [10]

AttackSel

(pin)=1 → [11]

AttackSel

(pin)=0 → [10]

CompEnable

(pin)=1 → [01]

CompEnable

(pin)=0 → [00]

Read

from

PLL/Gain

pin

0

1

0

0

1

0

0

1

1

0

1

0

1

Function

Power-up default, I

2

enabled

Power-up default I

2

disabled

Mute

Mute

Play

INLEVEL0

Low Gain

High Gain

Gain table

Compressor disabled

THD=0.02; Nb. step=1

THD=3.0; Nb. step=2

THD=0.02; Nb. step=1

THD=3.0; Nb. step=2

THD=5.0; Nb. step=3

Not used

C

C

Release

(400kHz clock)

0

0

1

1

0

1

0

1

20.48ms

40.96ms

81.92ms

163.4ms

Attack

(400kHz clock)

0

0

1

1

0

1

0

1

160µs

320µs

640µs

1.28ms

31/64

I2C and mode control TDA7572

5.2 Faults 1 register

Subaddress: XXI 00010.

Table 23. Faults 1 register

MSB LSB

D

7

R/W1TC

D

6

R/W1TC

D

5

R/W1TC

D

R/W

4

D

3

R/W1TC

D

2

R/W1TC

D

1

R/W1TC

D

0

R/W1TC

00000

0

1

0

1

0

1

0

1

0

1

Function

Power-up

default

GNDshort

Short to ground

detected

short

V

CC

Short to a “Vcc” detected

Open/offset

Open load detected

during

LOADshort

Short across the load

detected

DiagnENB

Diagnostic disabled or

finished

To run the

Diagnostic/diagnostic

in progress

32/64

UVLO flag

UVLO event

NOT USED

NOT USED

TDA7572 I2C and mode control

5.3 Faults 2 register

Subaddress: XXI 00011.

Table 24. Faults 2 register

MSB LSB

D

D

D

7

6

5

R/W1TC

000000

D

4

R/W1TC

D

3

R/W1TC

D

2

R/W1TC

D

1

R/W1TC

D

0

R/W1TC

Power-up

default

Function

Clip

0

Clipping of modulator

1

and/or preamplifier

Offset

0

1

Offset detected

IsenTrip

0

1

Power supply current

threshold trespass

IoutTrip

0

1

Output stage current

limiting has been enabled

ExtTwarn

0

1

External thermal warning

threshold trespassed

TJwarn

0

1

Internal thermal warning

threshold trespassed

NOT USED

NOT USED

33/64

I2C and mode control TDA7572

5.4 Control register

Subaddress: XXI 00100.

Table 25. Control register

MSB LSB

D

R/W

D

7

R/W

D

6

R/W

D

5

4

R/W

D

R/W

3

D

2

R/W

D

R/W

D

1

0

R/W

0000 1 0 10

0 0 0 0 1 SDA/SCR_ENB 1 0

0

1

0

1

0

1

0

1

0

1

0

1

Function

2

Power-up default I

C

enabled

Power-up Default I

2

C

disabled

Mute speed

Slow Mute

Fast Mute

OffsetENB

Enable the offset

detection

PassFET Control ENB

Enable the SCR

intervention

BOOST

Enable the step-up

L/R

Read left channel from

2

S

I

Read right channel from

2

S

I

Fratio1

Fs = 96 kHz

Fs= 192 kHz

0

1

0

1

34/64

Fratio0

Bass range digital input

Fs= 38 to 48 kHz

Full band digital input

(Fs=96 or 192 kHz

selectable by Fratio1)

DACEnb

Enable DAC operation

TDA7572 I2C and mode control

5.5 Modulator register

Subaddress: XXI 00101.

Table 26. Modulator register

MSB LSB

D

R/W

D

7

R/W

D

6

R/W

D

5

4

R/W

D

R/W

3

D

2

R/W

D

R/W

D

1

0

R/W

01100 1 0

01000

SCL/InLevel1

pin

1

0

1

0

1

0

1

0

1

0

1

Function

2

Power-up default I

C

disabled

Power-up default I2C

enabled

SHUNT

Turn-on shunt

NOT USED

INLEVEL1

High level couple

DAC synchronization

Synchronize the modulator

with the DAC

SVR

Turn On the charge of SVR

Tristate

Tristate modulator

PWMClock

0

0

1

1

0

1

0

1

55kHz

110kHz

220kHz

110kHz

35/64

I2C and mode control TDA7572

5.6 Testing register

Subaddress: XXI 00110.

Table 27. Testing register

MSB LSB

D

R/W

D

7

6

R/W

D

R/W

5

D

4

R/W

D

R/W

3

D

R/W

2

D

1

R/W

D

R/W

0

0000

Power-up

default

Function

Or ZC

0

(nIN xnor pIN) or (nOUT xnor pOUT)

1

are put on the clipping output

Ramp

0

1

Generate a ramp on the compressor

gain

TestDriving

0

1

Turn off limitation of driving current for

the external MOS

Fast

0

1

All time constant used in the logic

block are devided by 100

Not used

36/64

Not used

TDA7572 Input stage and gain compressor

6 Input stage and gain compressor

6.1 Input stage

The input stage accepts differential analog audio and provides a single ended output that is

referenced to SVR, a slowly changing reference signal that is close to V

present on the pin 6 (SVR). Four input stage gains are selectable, chosen such that input

signal levels of either 2V

RMS

, 2.6V

RMS

, 7V

RMS

, or 9.7V

will provide full scale unclipped

RMS

output swing of this stage.

The variable gain is realized by a single ended input attenuator (with respect to SVR), such

that both differential and common-mode voltages are attenuated, and by, mean of a

reconfiguration of the Op-Amp feedback.

These are controlled by two bits, one controlling the input attenuator, and the other

controlling the Op-Amp configuration. The bits INLEVEL0 in the InputControl register

(register addr 1, bit 1) and INLEVEL1 in the Modulator register (register addr. 5, bit 2)

determine the gain selection. The default value of INLEVEL0 and INLEVEL1 bits are

determined by the voltage levels at power-up on pins PLL/INLEVEL0 (pin 63) pin and

SCL/INLEVEL1 (pin 62) respectively allowing gain selection without the requirement of an

2

I

C bus. INLEVEL0 controls the input attenuator, and INLEVEL1 controls the configuration

of the feedback around the op. amp.

. This signal is

CC/2

INP - pin 12 : positive input

INM - pin 13 : negative input

AOUT - pin 14 : output

SCL/INLEVEL1 - pin62 : gain selection bit 1

PLL/INLEVEL0 - pin63 : gain selection bit 0

This stage is powered from ±2.5Volts, centered around SVR. Output swing is nominally ±2

volts. The input common mode range is a function of the gain setting, the electrical

parameters section must be consulted for details. It is expected that the inputs will be ac

coupled, and because of this consideration must be given to the rate of change of SVR, as

rapid changes to SVR could cause the inputs of this amplifier to run out of common mode

range. i.e. the input decoupling capacitors can not charge fast enough to keep up with SVR

6.2 Gain compressor

A gain compressor is integrated in the front end of this stage, which provides up to 16dB of

differential attenuation in approximately 0.5dB steps, varying somewhat depending on gain

configuration. Compressor aggressiveness is programmable by the I

(providing a choice from two attack-time/decay-time pairs) in non-I

bus with 2 bits each for attack and decay and 2 bits for the distortion-to-attenuation table.

These are bits ATTACK[1:0], DECAY[1:0], and TABLE[1:0] in the InputControl register. The

ADDR1/CompEnable pin is used in non-I

entirely.

2

C data/AttackSel pin

2

C bus mode, or by I2C

2

C mode to enable or disable gain compression

The gain compressor operates by monitoring the estimated in THD due to clipping, overmodulation or over-current and commanding a change in the input attenuation based on the

THD estimate. The input attenuator has 32 discrete steps. THD is estimated by measuring

the time period between zero crossings where there is no clipping and the time when there

37/64

Input stage and gain compressor TDA7572

is clipping during that period. The THD estimate is calculated from the ratio between these

times. Clipping means are any of the following conditions occurred: maximum modulation

reached, output current limiting active, or voltage clipping at the AOUT pin. These are used

to estimate THD, which is then mapped to a desired number of discrete steps of gain

reduction. Attenuation is then changed at the next zero crossing of the signal at the Input

Stage block

The attack time sets the minimum time allowed between gain reductions. At low frequency

signals, where the time between zero crossings is greater than the attack time, the attack

rate is dictated by the signal frequency, rather than this setting. Similarly, the decay time sets

the minimum time allowed between gain increases, with the same caveats about rate

dictated by the signal frequency.

The major tuning control here is the distortion-to-attenuation lookup table. It will determine

how aggressively to operate and thus the relative amount of audible artifact. Decay time

adjustment can be varied for audible effect and to mange average power.

Following are reported the correspondence between I

2

C bus registers and coefficients for

Attack and decay time. The first table reports the one for compressor setting:

6.2.1 Setting in I2C bus mode

GainTable[1:0]: Selects the distortion versus gain step size table to be used, including the

ability to disable the gain compressor.

Table 28. Distortion versus gain step size

GainTable [1:0] Pseudo THD,% / T2/T1 ratio Number of gain steps

00 Gain compressor disabled

01

10

11

0.02

3.0

0.02

3.0

5.0

0.02

3.0

5.0

15.0

1

2

1

2

3

1

2

3

4

RELEASE[1:0]: Sets the maximum release rate of the gain compressor according to the

table below:

Table 29. Sets the maximum release rate of the gain compressor

Release [1:0] Clock counts Nominal time at 400KHz clock

00 2

01 2

10 2

11 2

13

14

15

16

20.48ms

40.96ms

81.92ms

163.4ms

38/64

TDA7572 Input stage and gain compressor

5

ATTACK[1:0]: Sets the maximum Attack rate of the gain compressor according to the table

below:

Table 30. Sets the maximum attack rate of the gain compressor

Attack [1:0] Clock counts Nominal time at 400KHz clock

00 2

01 2

10 2

11 2

6

7

8

9

160µs

320µs

640µs

1.28ms

Setting in NOI2CBUS mode:

2

I

CDATA/AttackSel - pin 51 -> Attack/release rate selection

ADDR1/CompEnable - pin 54 -> Gain compression effort selection

Table 31. Attack/release rate and gain compression effort selection

INPUT PIN/VALUE DGND VDIG

Pin 51

Attack[1:0] = “10”

Release[1:0] = “10”

Pin 54 GainTable[1:0]=”00” GainTable[1:0]=”01”

6.2.2 Soft-mute function, without pre-limiter

Well-behaved over-modulation protection and current-limiting allow this IC to not require a

pre-limiter before the modulator. This allows the amplifier to always take advantage of the

available supply voltage. A limited output voltage can be done in a crude manner by using

AOUT's max output swing, and counting on its clipping signal to drive the compressor.

A soft mute/unmute is incorporated at AOUT. It works by slowly muxing AOUT from the input

signal to SVR. In this way, dc offsets occurring in any upstream stages are kept inaudible.

The mux slew time is determined by the voltage slew rate at the MUTE_L pin (pin 10), which

is asserted low. Mute can by driven either be by external means, or controlled by I2C

command.

The MUTE bit, present in the input control register (D0, InputControl register), controls

muting by discharging or charging the MUTE_L pin. The default value for this bit for NOI2C

mode is 0 that lead to a charging of mute cap. Abrupt muting is available by use of the

MuteSpeed bit. When MuteSpeed is asserted, MUTE_L is rapidly charged and discharged

by a small resistance (approximately 500 ohms). In the pictures below are reported the two

application circuits and the internal circuitry of mute correspondent to.

Figure 3. Mute by external command

Attack[1:0] = “11”

Release[1:0] = “11”

100µA

AC0001

External

Mute

Mute_L

39/64

Input stage and gain compressor TDA7572

Figure 4. Mute by I2C bus command

Mute_L

100µA

200µA

500Ohm

Mute and

not(MuteSpeed)

Mute and

MuteSpeed

AC00016

Note: when the modulator is set in TRISTATE the mute pin is fast-discharged by the fast-mute

internal circuitry. When the modulator is take back out of TRISTATE the preamplifier is put in

play back by a fast un-mute transient.

40/64

TDA7572 Modulator

7 Modulator

The modulator PWM is the main function of device. Two modulators are provided which are

operated independently but configured for bridged mono operations. They are synchronized

by virtue of the common clock that drives them and operate as a three-state modulator

(phase shifting PWM modulation type) when the audio is inverted going to one modulator.

This inversion is accommodated by a dedicated inverter block present between the InvIn

and InvOut pin.

Figure 5. Modulator block diagram

RQ

R2

MOD1

MOD2

R2

HB1Out

HB2Out

VHB1OutF

VHB2OutF

AC00017

Aout

InvOut

InvIn

OSCOut

RQ

Inv

R1

MOD0

Diff -To S.E.

SVR

OSC

MOD1

R1

The above scheme reports the application circuits and internal block involved in the PWM

modulator. The analog signal is differential to single ended converted by the amplifier. The

signal obtained is inserted as current in the virtual ground of modulator MOD0. The

conversion is obtained trough R1 resistor. The same signal, output of AOUT, is inverted and

inserted in the virtual ground MOD1 through the resistor R1.

In order to obtain a PWM signal a square wave is inserted in both MOD0 and MOD1 through

the RQ resistor. The Gain of Modulator is equal to the ratio of R1/R2. In Order to choose the

value of RQ has to take into account the stability of modulator, guarantee if the following

relation is respected:

Equation 1

VP2.5

---------------- -

RQ

VAOUTmax

--------------------------------- -

R1

VSP VSVR–

----------------------------------- -+>

R2

Clocked PWM modulators using an integrated T-network double integrator are implemented.

The end user has the ability to trade distortion for EMI by switching faster or slower,

controlled by PWMClock[1:0] in the modulator register.

41/64

Modulator TDA7572

Table 32. PWMClock table

PWMClock [1:0] Ratio Nominal frequency

00 F

01 F

10 F

11 F

/2 55KHz

NOM

NOM

*2 220KHz

NOM

NOM

110KHz

110KHz

Pulse injection is being used with the clocked PWM scheme to prevent missing pulses from

an over-modulation condition. The minimum pulse width is dynamically determined by

looking at the delay from the comparator output to the actual switching of the FET stage.

This delay is used to extend any pulses from the modulator that would otherwise be too

short. Circuitry is provided to keep the integrator hovering near the level at which limiting

first occurred, which prevents transients once we leave the over modulation condition. This

is done by summing in a current that is proportional to the amount of time that the pulse is

extended.

Since only three- state modulation is supported, it may prove necessary to slightly delay the

clock going to one modulator to prevent the noise from the switching of one modulator

affecting the second modulator when there is no audio input. This can be done with a small

RC on the clock feeding one modulator. The same result could be obtained adding the RC

on the feedback feeding one modulator.

The reference voltage of the modulator changes from SVR at it's input, to Vcc/2 at its output.

This allows output signal to be centered between the supply rails, increasing unclipped

output voltage swing by preventing asymmetric clipping. This is accomplished using the

LVLSFT pin, as described in the previous paragraph. It has been pointed out that there is