®

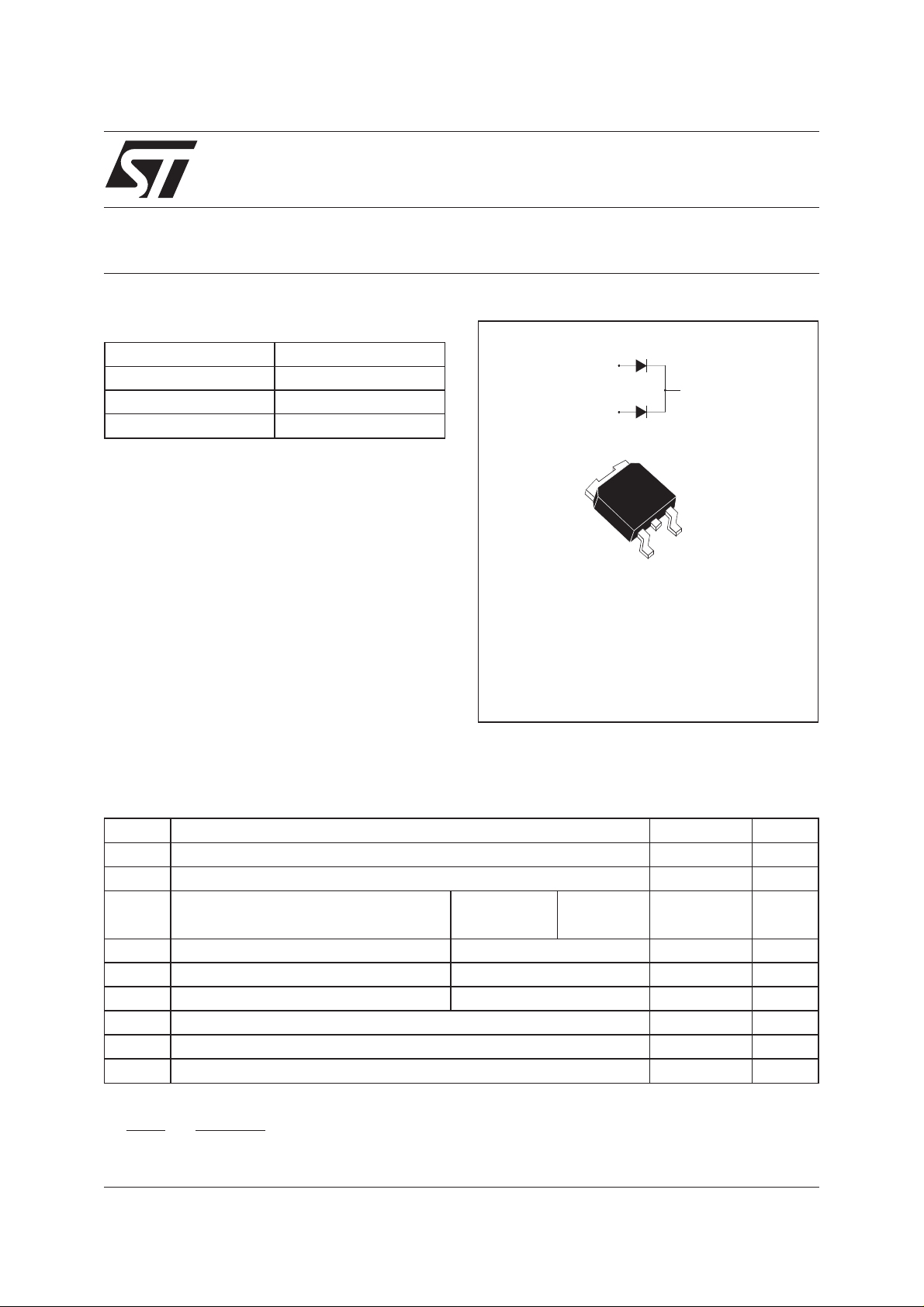

LOW DROP POWER SCHOTTKY RECTIFIER

MAIN PRODUCTS CHARACTERISTICS

I

F(AV)

V

RRM

Tj (max) 150 °C

V

(max) 0.46 V

F

2 x 7.5 A

45 V

STPS15L45CB

A1

K

A2

FEATURES AND BENEFITS

VERY SMALL CONDUCTION LOSSES

■

NEGLIGIBLE SWITCHING LOSSES

■

EXTREMELY FAST SWITCHING

■

LOW FORWARD VOLTAGE DROP

■

■ AVALANCHE CAPABILITY SPECIFIED

K

A2

A1

DPAK

DESCRIPTION

Dual center tab Schottky rectifier suited for Switch

Mode Power Supply and high frequency DC to DC

converters.

Package in DPAK, this device is intended for use

in low voltage, high frequency inverters,

free-wheeling and polarity protection applications.

ABSOLUTE RATINGS (limiting values, per diode)

Symbol Parameter Value Unit

V

RRM

I

F(RMS)

I

F(AV)

I

FSM

I

RRM

P

ARM

T

stg

Tj

dV/dt

Repetitive peak reverse voltage

RMS forward current

Average forward current Tc = 140°C

Surge non repetitive forward current tp = 10 ms sinusoidal

Peak repetitive reverse current tp=2 µs square F=1kHz

Repetitive peak avalanche power tp = 1µs Tj = 25°C

Storage temperature range

Maximum operating junction temperature *

Critical rate of rise reverse voltage

δ = 0.5

Per diode

Per device

45 V

10 A

7.5

15

75 A

1A

3700 W

-65 to+175 °C

150 °C

10000 V/µs

A

dPtot

*:

<

dTj Rth j a

July 2003 - Ed : 2A

thermal runaway condition for a diode on its own heatsink

−1()

1/4

STPS15L45CB

THERMAL RESISTANCES

Symbol Parameter Value Unit

R

th(j-c)

Junction to case

Per diode

Total

R

th(c)

Coupling

When the diodes 1 and 2 are used simultaneously :

∆ Tj(diode 1) = P(diode1) x R

(Per diode) + P(diode 2) x R

th(j-c)

th(c)

STATIC ELECTRICAL CHARACTERISTICS (per diode)

Symbol Parameter Tests Conditions Min. Typ. Max. Unit

*

I

R

Reverse leakage current Tj = 25°C V

R=VRRM

Tj = 125°C

V

*

F

Forward voltage drop Tj = 25°CI

Pulse test : * tp = 380 µs, δ <2%

Tj = 125°C I

Tj=25°CI

Tj = 125°C I

Tj=25°CI

Tj = 125°C I

= 7.5 A

F

= 7.5 A

F

=12A

F

=12A

F

=15A

F

=15A

F

4

°C/W

2.4

0.7

1mA

23 45 mA

0.52 V

0.40 0.46

0.60

0.49 0.57

0.64

0.53 0.63

To evaluate the conduction losses use the following equation :

P=0.29xI

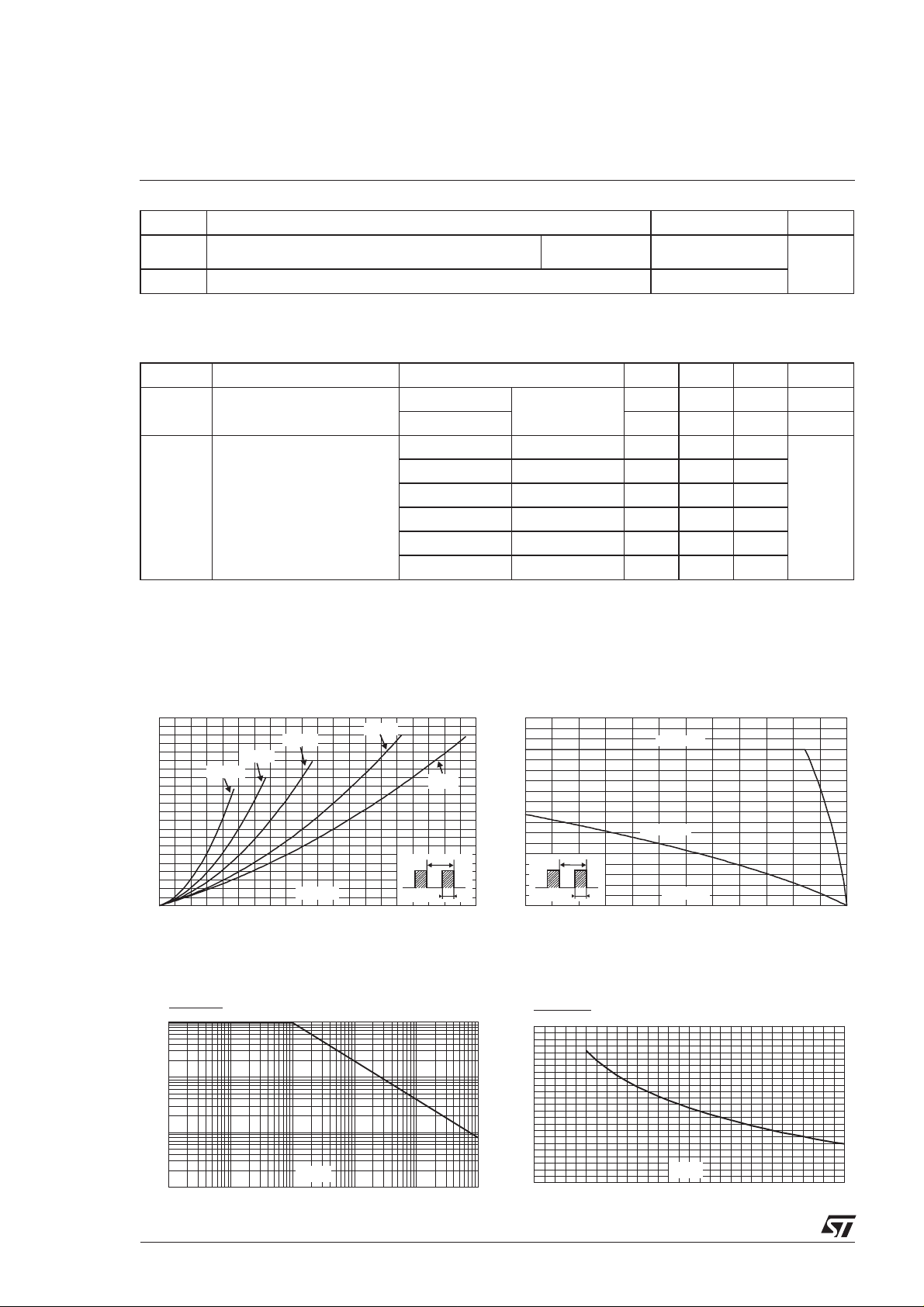

Fig.1:Conductionlossesversus average current.

F(AV)

+ 0.023 I

F2(RMS)

Fig. 2: Average forward current versus ambient

temperature (δ = 0.5).

PF(av)(W)

5.5

5.0

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0.0

012345678910

δ = 0.05

δ = 0.2

δ = 0.1

IF(av)(A)

δ = 0.5

δ

=tp/T

δ = 1

T

tp

Fig. 3: Normalized avalanche power derating

versus pulse duration.

P(t)

ARM p

P (1µs)

ARM

1

0.1

0.01

t (µs)

0.001

0.10.01 1

p

10 100 1000

IF(av)(A)

9

8

7

6

5

4

3

2

1

=tp/T

δ

0

0 25 50 75 100 125 150

Fig. 4: Normalized avalanche power derating

versus junction temperature.

P(t)

ARM p

P (25°C)

ARM

1.2

1

0.8

0.6

0.4

0.2

0

0 25 50 75 100 125 150

Rth(j-a)=Rth(j-c)

Rth(j-a)=70°C/W

T

tp

Tamb(°C)

T (°C)

j

2/4

STPS15L45CB

Fig. 5: Non repetitive surge peak forward current

versus overload duration (maximum values).

IM(A)

100

90

80

70

60

50

40

30

20

IM

10

0

1.E-03 1.E-02 1.E-01 1.E+00

δ=0.5

t

t(s)

Tc=25°C

Tc=75°C

Tc=125°C

Fig. 7: Reverse leakage current versus reverse

voltage applied (typical values).

IR(mA)

1.E+02

1.E+01

Tj=150°C

Tj=125°C

Tj=100°C

Fig. 6: Relative variation of thermal impedance

junction to case versus pulse duration.

Zth(j-c)/Rth(j-c)

1.0

0.9

0.8

0.7

δ = 0.5

0.6

0.5

0.4

δ = 0.2

δ = 0.1

0.3

0.2

Single pulse

0.1

0.0

1.E-03 1.E-02 1.E-01 1.E+00

tp(s)

δ

=tp/T

T

tp

Fig. 8 Junction capacitance versus reverse voltage

applied (typical values).

C(nF)

10.0

F=1MHz

Vosc=30mV

Tj=25°C

1.E+00

1.E-01

1.E-02

0 5 10 15 20 25 30 35 40 45

Tj=75°C

Tj=50°C

Tj=25°C

VR(V)

Fig.9: Forward voltagedrop versus forwardcurrent.

IFM(A)

100

Tj=125°C

Tj=125°C

(Typical values)

(Typical values)

10

1

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8

Tj=125°C

Tj=125°C

(Maximum values)

(Maximum values)

Tj=25°C

(Maximum values)

VFM(V)

1.0

VR(V)

0.1

1 10 100

Fig. 10: Thermal resistance junction to ambient ver-

sus copper surface under tab (epoxy printed board

FR4, Cu = 35µm).

Rth(j-a)(°C/W)

100

90

80

70

60

50

40

30

20

10

0

02468101214161820

S(cm²)

3/4

STPS15L45CB

PACKAGE MECHANICAL DATA

DPAK

FOOTPRINT (dimensions in mm)

6.7

DIMENSIONS

REF.

Millimeters Inches

Min. Max Min. Max.

A 2.20 2.40 0.086 0.094

A1 0.90 1.10 0.035 0.043

A2 0.03 0.23 0.001 0.009

B 0.64 0.90 0.025 0.035

B2 5.20 5.40 0.204 0.212

C 0.45 0.60 0.017 0.023

C2 0.48 0.60 0.018 0.023

D 6.00 6.20 0.236 0.244

E 6.40 6.60 0.251 0.259

G 4.40 4.60 0.173 0.181

H 9.35 10.10 0.368 0.397

L2 0.80 typ. 0.031 typ.

L4 0.60 1.00 0.023 0.039

V2 0° 8° 0° 8°

6.7

3

3

1.61.6

2.32.3

Ordering type Marking Package Weight Base qty Delivery mode

STPS15L45CB S15L45C DPAK 0.30 g 75 Tube

STPS15L45CB-TR S15L45C DPAK 0.30g 2500 Tape & reel

■

EPOXY MEETS UL94,V0

Informationfurnishedis believed to be accurate and reliable. However, STMicroelectronics assumes no responsibilityforthe consequences of

useof such information nor for any infringement of patentsor other rights of third parties which mayresultfrom its use. No license is granted by

implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject to

change without notice. This publication supersedes and replaces all information previously supplied.

STMicroelectronics products are not authorized for use as critical components in life support devices or systems without express written

approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

© 2003 STMicroelectronics - Printed in Italy - All rights reserved.

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - Canada - China - Finland - France - Germany

Hong Kong - India - Israel - Italy - Japan - Malaysia - Malta - Morocco - Singapore

Spain - Sweden - Switzerland - United Kingdom - United States.

http://www.st.com

4/4

Loading...

Loading...