Datasheet STP6NC80ZFP, STP6NC80Z, STB6NC80ZT4, STB6NC80Z-1, STB6NC80Z Datasheet (SGS Thomson Microelectronics)

1/13December 2002

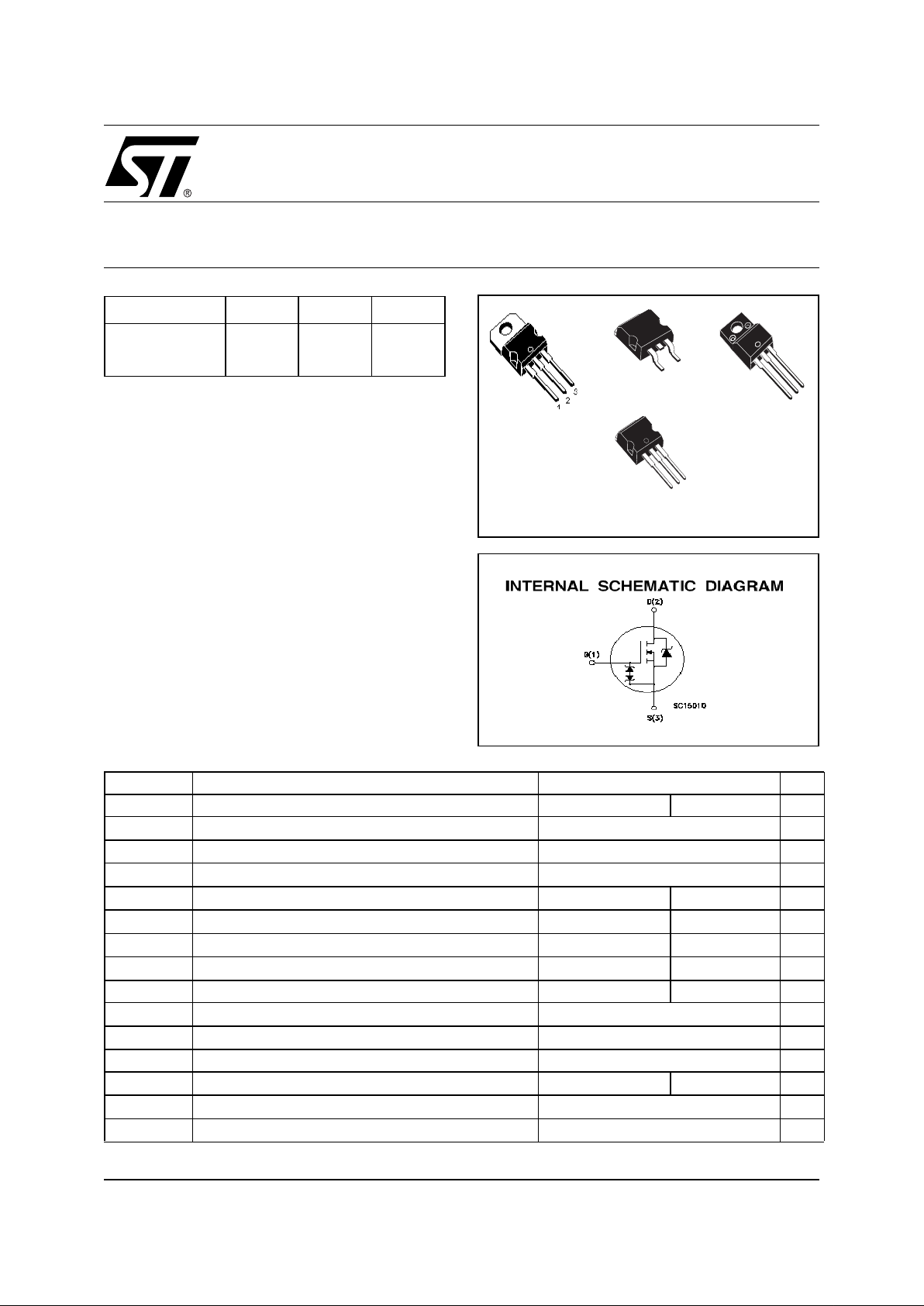

STP6NC80Z - STP6NC80ZFP

STB6NC80Z - STB6NC80Z-1

N-CHANNEL 800V - 1.5Ω - 5.4A TO-220/FP/D²PAK/I²PAK

Zener-Protected PowerMESH™III MOSFET

■ TYPICAL R

DS

(on) = 1.5 Ω

■ EXTREMELY HIGH dv/dtAND CAPABILITY

GATE-TO- SO URCE ZENER DIODES

■ 100% AVALANCHE TESTED

■ V ER Y LOW GATE INPUT RESISTANCE

■ GAT E CHARGE MINIMIZED

DESCRIPTION

The third generation of MESH OVERLAY™ Power

MOSFETs for very high voltage exhibits unsurpassed

on-resistance per unit area while integrating back-toback Zener diodes bet ween gate and source. Such arrangement gives extra ESD capability with higher ruggedness performance as requested b y a large variety

of single-switch applications.

APPLICATIONS

■ S INGLE -ENDED S MPS IN MONITORS,

COMPUTER AND INDUSTRIAL APPLICATION

■ WELDING EQUIPMENT

ABSOLUTE MAXIMUM RATINGS

(•)Pulse width limited by safe operating area

TYPE V

DSS

R

DS(on)

I

D

STP6NC80Z/FP 800V < 1.8 Ω 5.4 A

STB6NC80Z/-1 800V < 1.8 Ω 5.4 A

Symbol Parameter Value Unit

STP(B)6NC80Z(-1) STP6NC80ZFP

V

DS

Drain-source Voltage (VGS=0)

800 V

V

DGR

Drain-gate Voltage (RGS=20kΩ)

800 V

V

GS

Gate- source Voltage ± 25 V

I

D

Drain Current (continuous) at TC= 25°C

5.4 5.4(*) A

I

D

Drain Current (continuous) at TC= 100°C

3.4 3.4(*) A

I

DM

(1)

Drain Current (pulsed) 21 21(*) A

P

TOT

Total Dissipation at TC= 25°C

125 40 W

Derating Factor 1 0.32 W/°C

I

GS

Gate-source Current (●)±50mA

V

ESD(G-S)

Gate source ESD(HBM-C=100pF, R=15KΩ) 3KV

dv/dt Peak Diode Recovery voltage slope 3 V/ns

V

ISO

Insulation Winthstand Voltage (DC) -- 2000 V

T

stg

Storage Temperature –65 to 150 °C

T

j

Max. Operating Junction Temperature 150 °C

(1)ISD≤5.4A,di/dt ≤100A/µs, VDD≤ V

(BR)DSS,Tj≤TJMAX

.

(*)Pulse width Limited by maximum temperature allowed

TO-220

1

2

3

TO-220FP

1

2

3

I²PAK

(Tabless TO-220)

1

3

D²PAK

STP6NC80Z/FP/STP6NC80Z-1

2/13

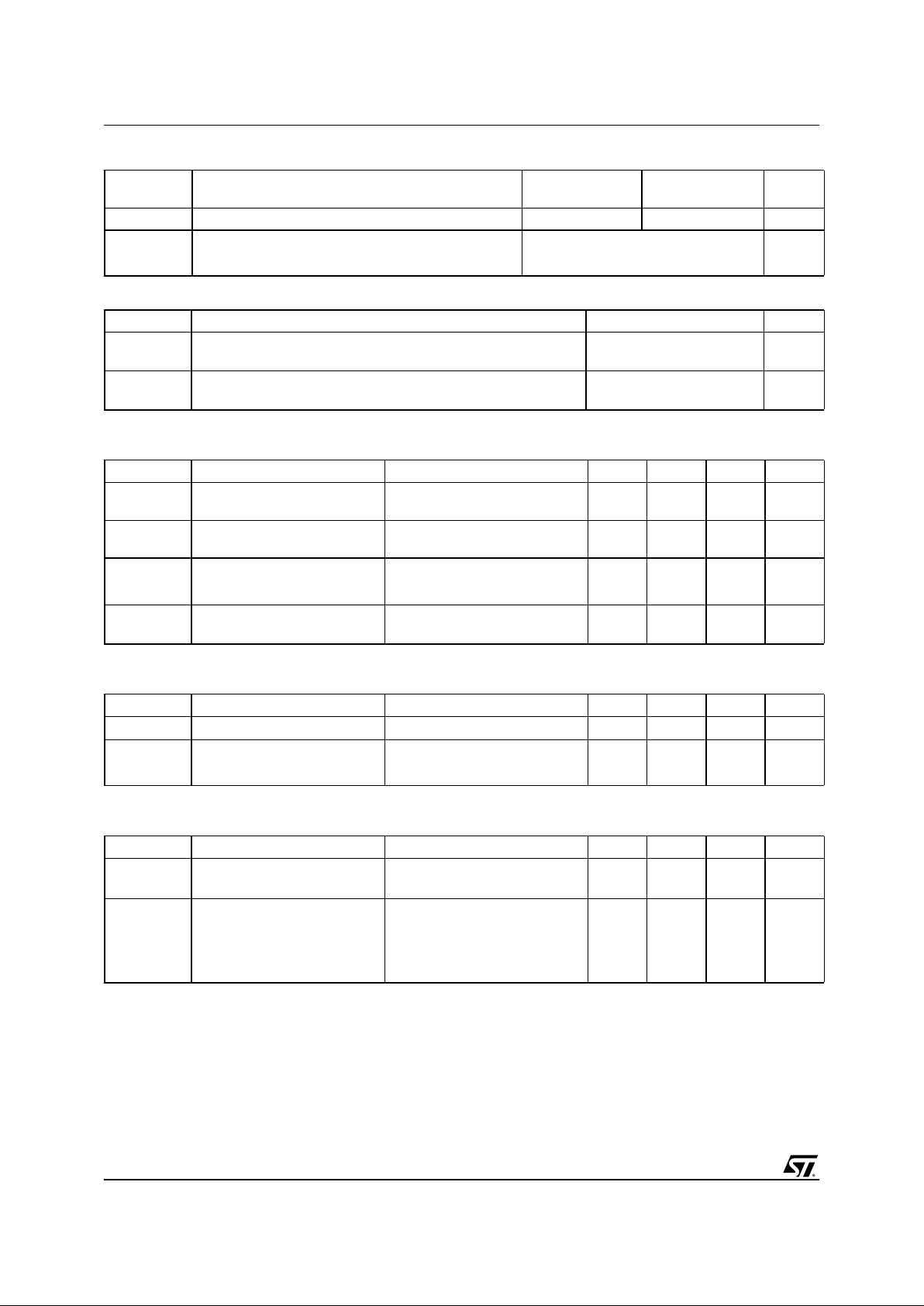

THERMAL DATA

AVALANCHE CHARACTERISTICS

ELECTRICAL CHARACTERISTICS (TCASE = 25 °C UNLESS OTHERWISE SPECIFIED)

OFF

ON (1)

DYNAMIC

TO-220 / D²PAK /

I²PAK

TO-220FP

Rthj-case Thermal Resistance Junction-case Max 1 3.13 °C/W

Rthj-amb Thermal Resistance Junction-ambient Max 30 °C/W

T

l

Maximum Lead Temperature For Soldering Purpose 300 °C

Symbol Parameter Max Value Unit

I

AR

Avalanche Current, Repetitive or Not-Repetitive

(pulse width limited by T

j

max)

5.4 A

E

AS

Single Pulse Avalanche Energy

(starting T

j

= 25 °C, ID=IAR,VDD=50V)

237 mJ

Symbol Parameter Test Conditions Min. Typ. Max. Unit

V

(BR)DSS

Drain-source

Breakdown Voltage

I

D

= 250 µA, VGS=0

800 V

∆BV

DSS

/∆T

J

Breakdown Voltage Temp.

Coefficient

I

D

=1mA,VGS=0

0.9 V/°C

I

DSS

Zero Gate Voltage

Drain Current (V

GS

=0)

V

DS

= Max Rating

1µA

V

DS

= Max Rating, TC= 125 °C

50 µA

I

GSS

Gate-body Leakage

Current (V

DS

=0)

V

GS

= ±20V

±10 µA

Symbol Parameter Test Conditions Min. Typ. Max. Unit

V

GS(th)

Gate Threshold Voltage

V

DS=VGS,ID

= 250µA

345V

R

DS(on)

Static Drain-source On

Resistance

VGS=10V,ID=3A

1.5 1.8 Ω

Symbol Parameter Test Conditions Min. Typ. Max. Unit

g

fs

(1) Forward Transconductance VDS>I

D(on)xRDS(on)max,

ID=3A

7S

C

iss

Input Capacitance

V

DS

=25V,f=1MHz,VGS=0

1600 pF

C

oss

Output Capacitance 125 pF

C

rss

Reverse Transfer

Capacitance

12 pF

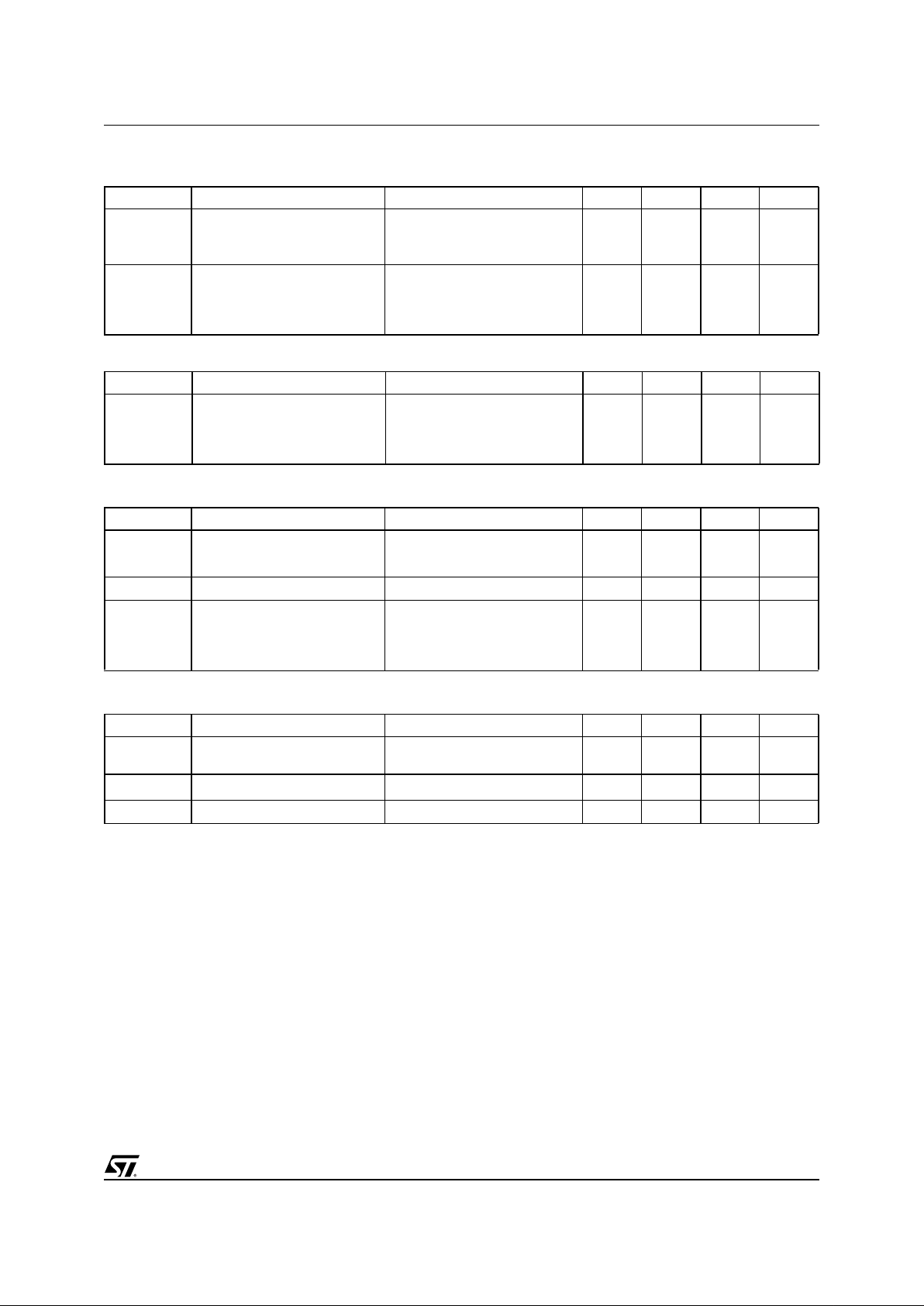

3/13

STP6NC80Z/FP/STP6NC80Z-1

ELECTRICAL CHARACTERISTICS (CONTINUED)

SWITCHING ON

SWITCHING OFF

SOURCE DRAIN DIODE

GATE-SOURCE ZENER DIODE

Note: 1. Pulsed: Pulse duration = 300 µs, duty cycle 1.5 %.

2. Pulse width limited by safe operating area.

3. ∆V

BV

= αT(25°-T)BV

GSO

(25°)

PROTECTION FEATURES OF GATE-TO-SOURCE ZENER DIOD ES

The built-in back-to-back Zener diodes have specifically been designed to enhance not only the device’ s

ESD capability, but also t o make them safely absorb possible voltage transients that may occasionally

be applied from gate to source. In this respect the Zen er voltage is ap propriat e to achieve an efficient

and cost-effective intervention to prot ec t the device’s integrity. These integrated Zener diodes thus avoid

the usage of external components.

Symbol Parameter Test Conditions Min. Typ. Max. Unit

t

d(on)

Turn-on Delay Time

V

DD

=400V,ID=3A

RG= 4.7Ω VGS=10V

(see test circuit, Figure 3)

26 ns

t

r

Rise Time 10 ns

Q

g

Total Gate Charge

V

DD

=640V,ID= 6A,

VGS=10V

45 nC

Q

gs

Gate-Source Charge 12 nC

Q

gd

Gate-Drain Charge 18 nC

Symbol Parameter Test Conditions Min. Typ. Max. Unit

t

r(Voff)

Off-voltage Rise Time

V

DD

= 640V, ID=6A,

R

G

=4.7Ω, VGS= 10V

(see test circuit, Figure 5)

11 ns

t

f

Fall Time 13 ns

t

c

Cross-over Time 19 ns

Symbol Parameter Test Conditions Min. Typ. Max. Unit

I

SD

Source-drain Current 5.4 A

I

SDM

(2)

Source-drain Current (pulsed) 21 A

V

SD

(1)

Forward On Voltage

ISD= 5.4 A, VGS=0

1.6 V

t

rr

Reverse Recovery Time

ISD= 6 A, di/dt = 100A/µs,

VDD=50V,Tj= 150°C

(see test circuit, Figure 5)

850 ns

Q

rr

Reverse Recovery Charge 8.1 µC

I

RRM

Reverse Recovery Current 19 A

Symbol Parameter Test Conditions Min. Typ. Max. Unit

BV

GSO

Gate-Source Breakdown

Voltage

Igs=± 1mA (Open Drain) 25 V

αT Voltage Thermal Coefficient T=25°C Note(3) 1.3

10

-4

/°C

Rz Dynamic Resistance

I

D

=50mA,VGS=0

90 Ω

STP6NC80Z/FP/STP6NC80Z-1

4/13

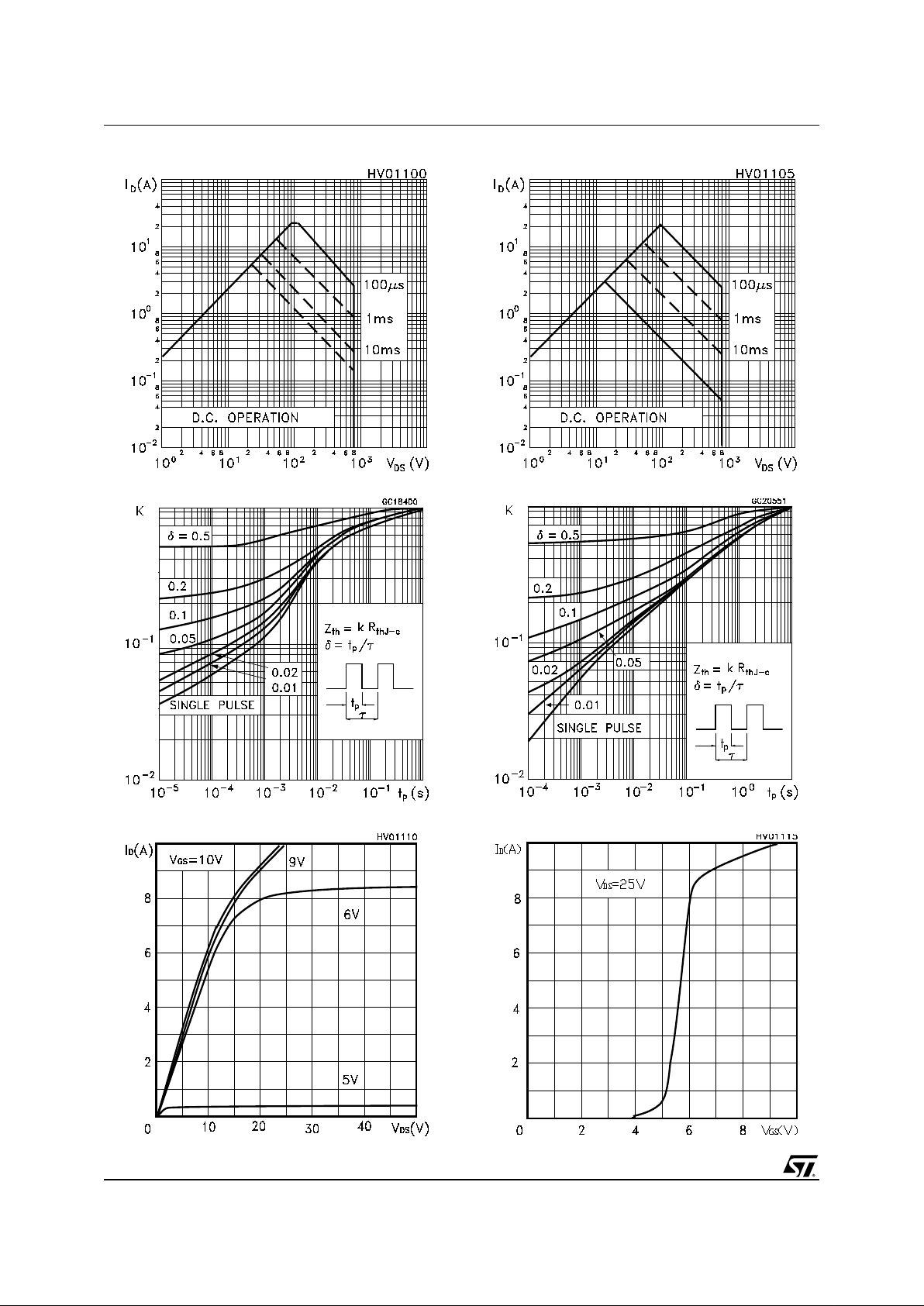

Safe Operating Area For TO-220FPSafe Operating Area For TO-220 /D²PAK/I²PAK

Thermal Impedance For TO-220 /D²PAK/I²PAK

Output Characteristics

Thermal Impedance For TO-220FP

Transfer Characteristics

5/13

STP6NC80Z/FP/STP6NC80Z-1

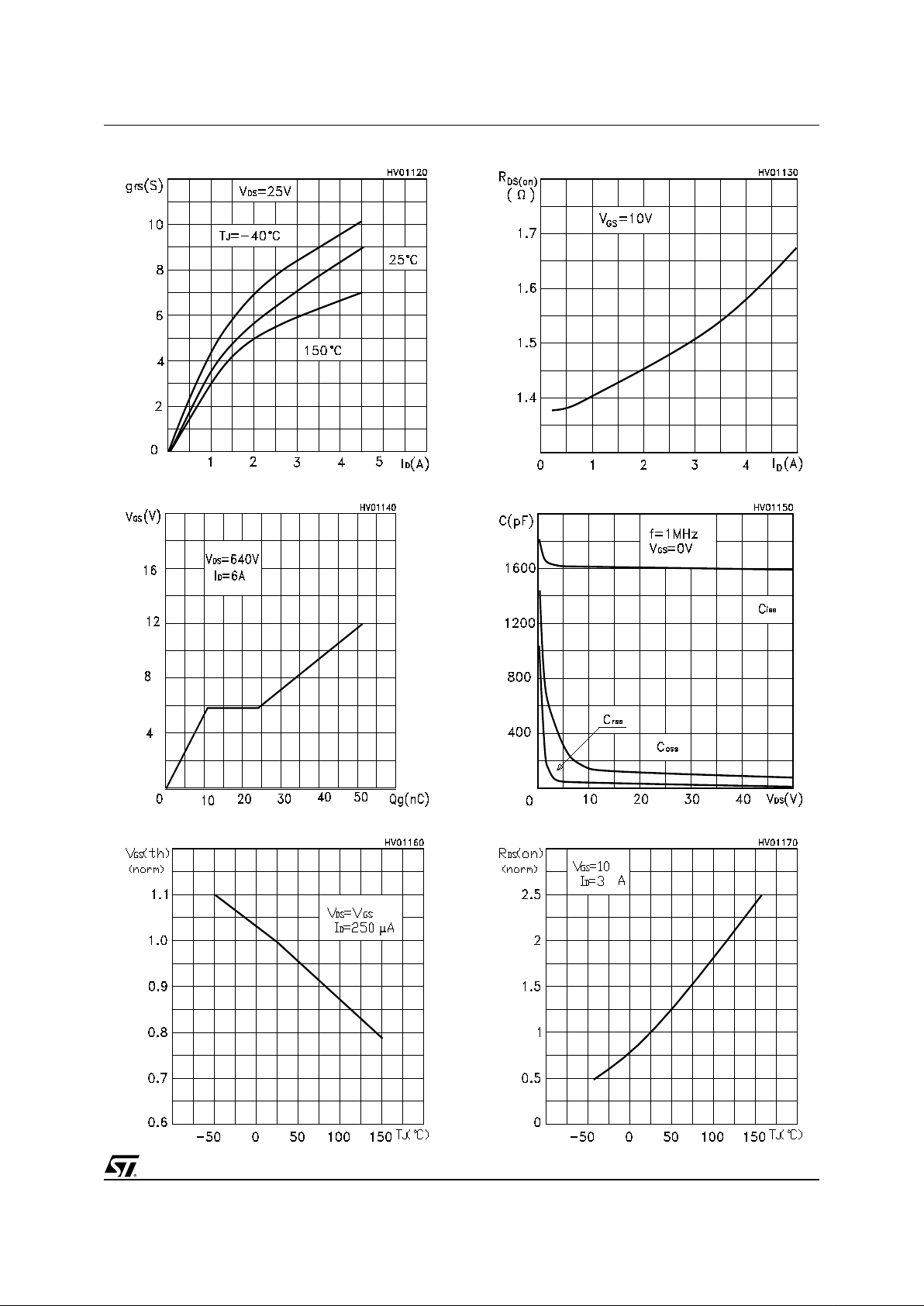

Capacitance Variations

Normalized On Resistance vs TemperatureNormalized Gate Threshold Voltage vs Temp.

Gate Charge vs Gate-source Voltage

Static Drain-source On ResistanceTransconductance

6/13

STP6NC80Z/FP/STP6NC80Z-1

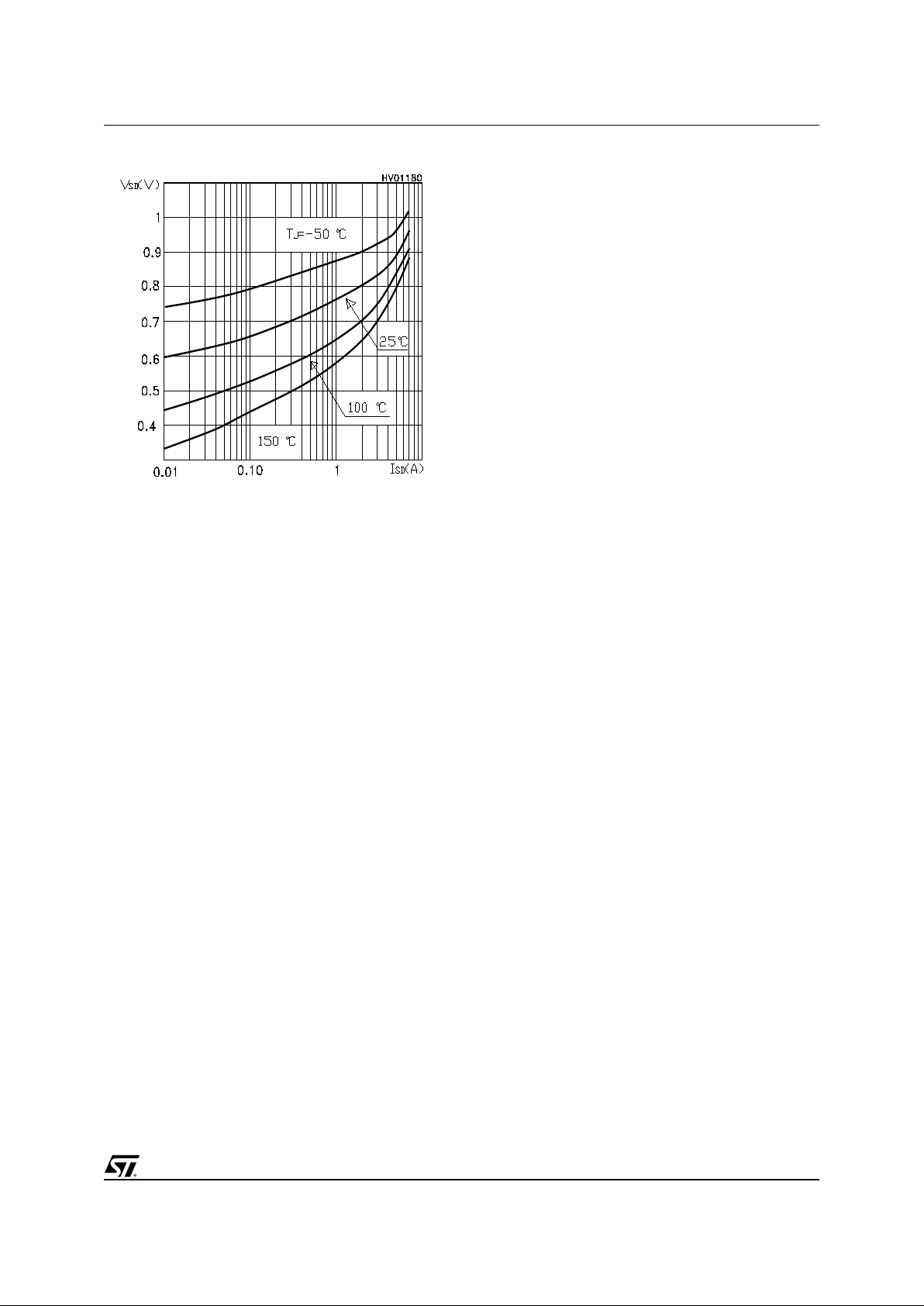

Source-drain Diode Forward Characteristics

7/13

STP6NC80Z/FP/STP6NC80Z-1

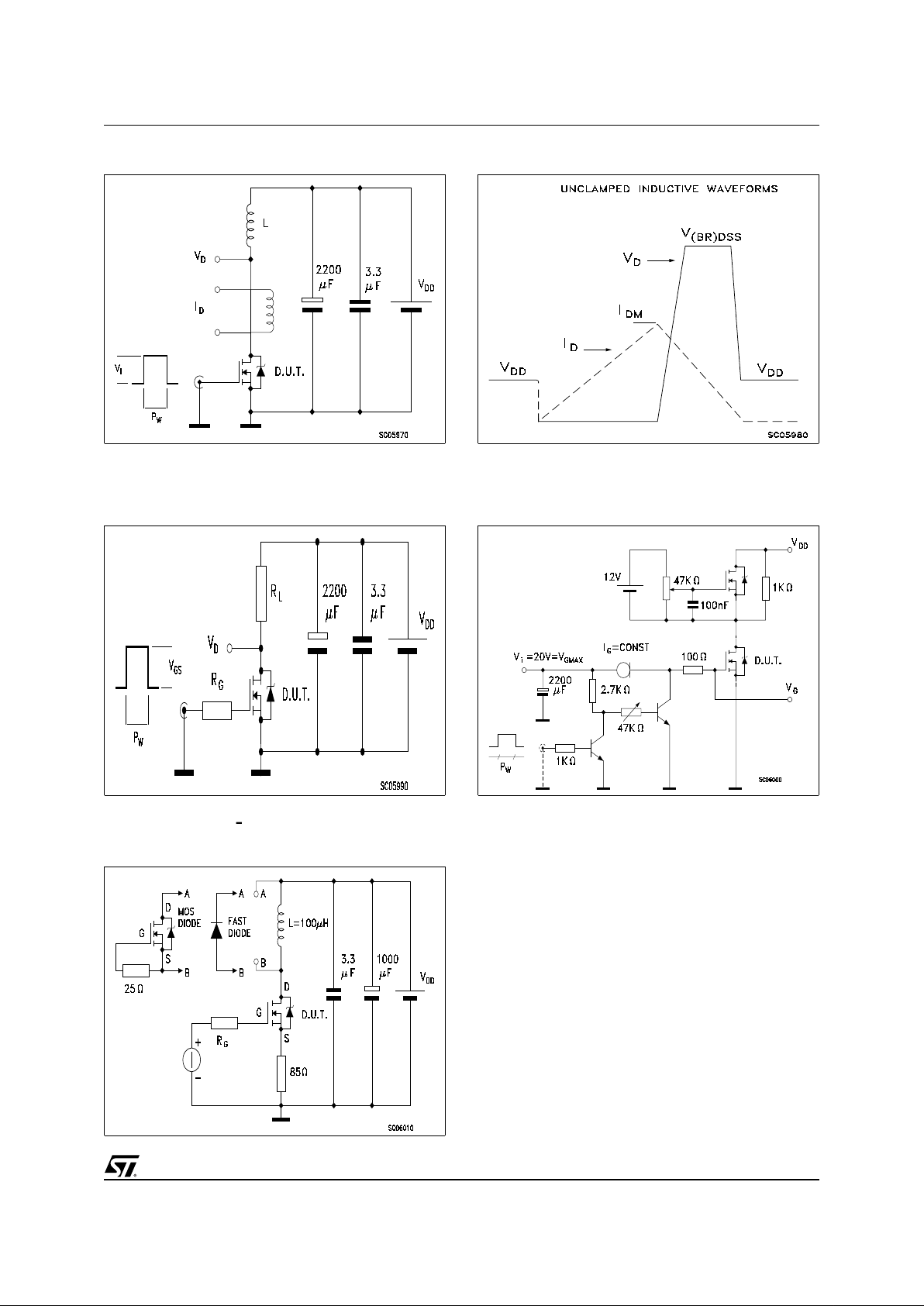

Fig. 5: Test Circuit For Inductive Load Switching

And Di ode Recovery Times

Fig. 4: Gate Charge test Circuit

Fig. 2: Unclamped Inductive WaveformFig. 1: Unclamped Inductive Load Test Circuit

Fig. 3: Switching Times Test Circuits For

Resistive Load

STP6NC80Z/FP/STP6NC80Z-1

8/13

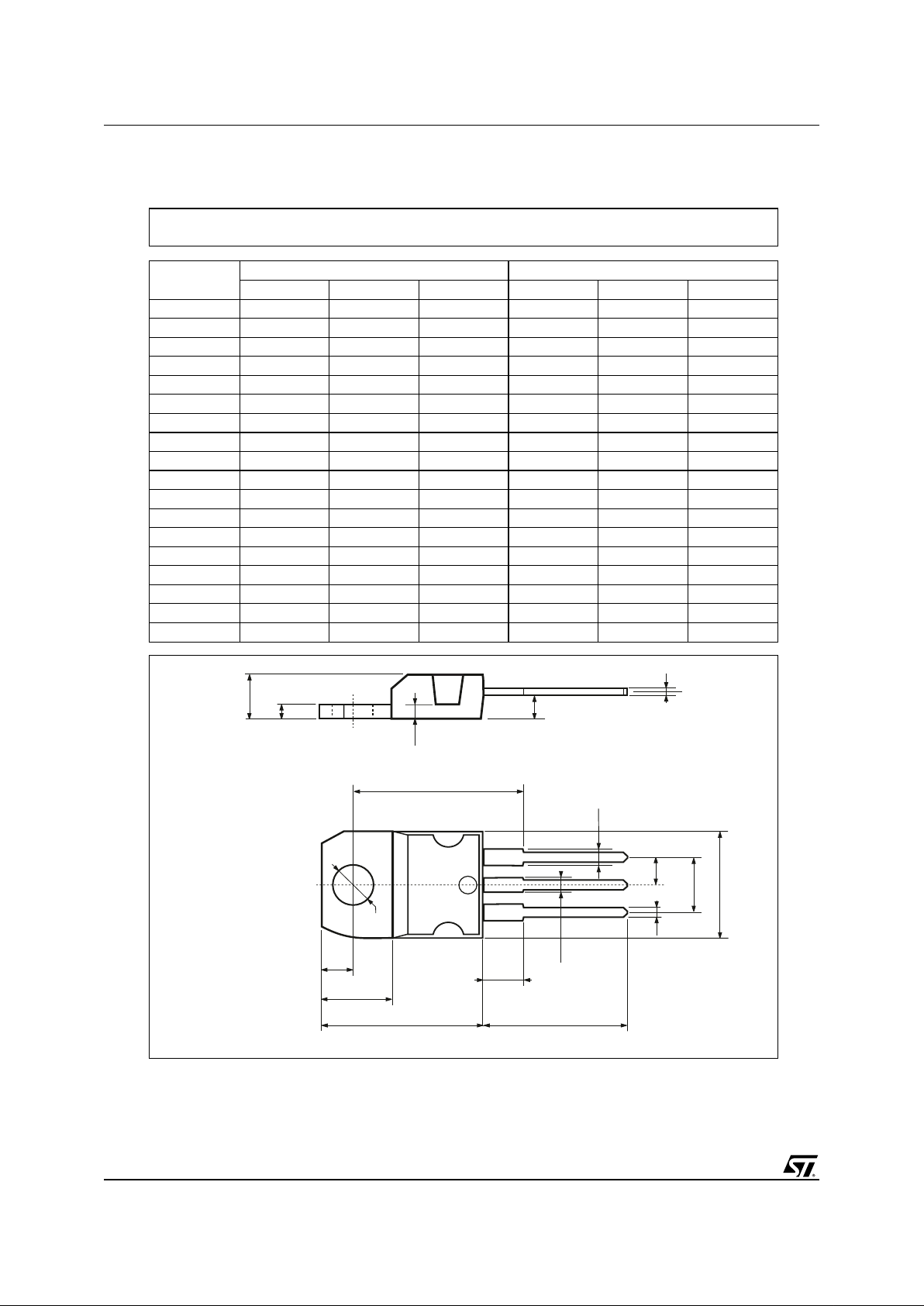

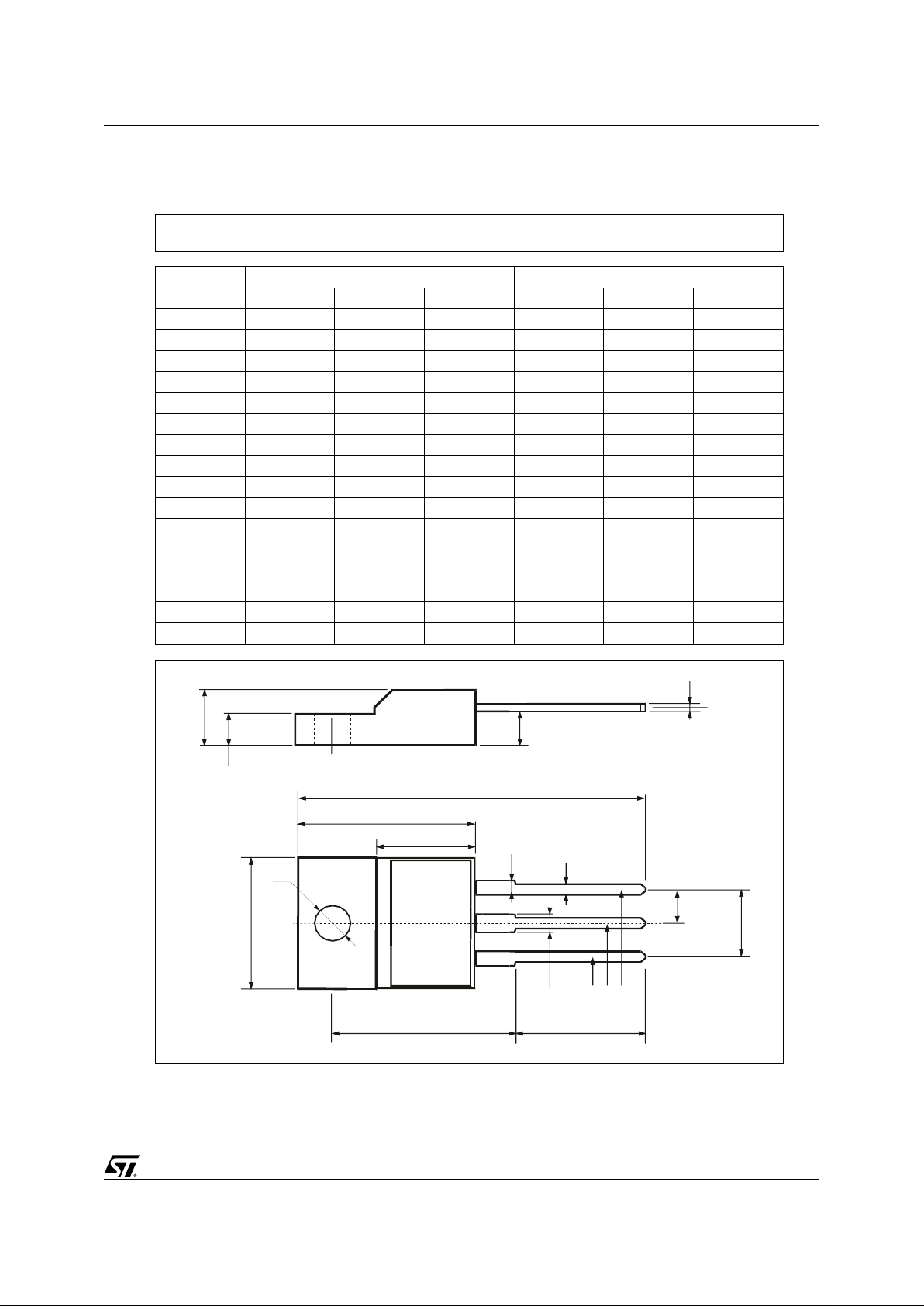

DIM.

mm inch

MIN. TYP. MAX. MIN. TYP. MAX.

A 4.40 4.60 0.173 0.181

C 1.23 1.32 0.048 0.051

D 2.40 2.72 0.094 0.107

D1 1.27 0.050

E 0.49 0.70 0.019 0.027

F 0.61 0.88 0.024 0.034

F1 1.14 1.70 0.044 0.067

F2 1.14 1.70 0.044 0.067

G 4.95 5.15 0.194 0.203

G1 2.4 2.7 0.094 0.106

H2 10.0 10.40 0.393 0.409

L2 16.4 0.645

L4 13.0 14.0 0.511 0.551

L5 2.65 2.95 0.104 0.116

L6 15.25 15.75 0.600 0.620

L7 6.2 6.6 0.244 0.260

L9 3.5 3.93 0.137 0.154

DIA. 3.75 3.85 0.147 0.151

L6

A

C

D

E

D1

F

G

L7

L2

Dia.

F1

L5

L4

H2

L9

F2

G1

TO-220 MECHANICAL DATA

P011C

9/13

STP6NC80Z/FP/STP6NC80Z-1

DIM.

mm inch

MIN. TYP. MAX. MIN. TYP. MAX.

A 4.4 4.6 0.173 0.181

B 2.5 2.7 0.098 0.106

D 2.5 2.75 0.098 0.108

E 0.45 0.7 0.017 0.027

F 0.75 1 0.030 0.039

F1 1.15 1.7 0.045 0.067

F2 1.15 1.7 0.045 0.067

G 4.95 5.2 0.195 0.204

G1 2.4 2.7 0.094 0.106

H 10 10.4 0.393 0.409

L2 16 0.630

L3 28.6 30.6 1.126 1.204

L4 9.8 10.6 0.385 0.417

L6 15.9 16.4 0.626 0.645

L7 9 9.3 0.354 0.366

Ø 3 3.2 0.118 0.126

L2

A

B

D

E

H

G

L6

¯

F

L3

G1

123

F2

F1

L7

L4

TO-220FP MECHANICAL DAT A

STP6NC80Z/FP/STP6NC80Z-1

10/13

DIM.

mm inch

MIN. TYP. MAX. MIN. TYP. MAX.

A 4.4 4.6 0.173 0.181

A1 2.49 2.69 0.098 0.106

B 0.7 0.93 0.027 0.036

B2 1.14 1.7 0.044 0.067

C 0.45 0.6 0.017 0.023

C2 1.23 1.36 0.048 0.053

D 8.95 9.35 0.352 0.368

e 2.4 2.7 0.094 0.106

E 10 10.4 0.393 0.409

L 13.1 13.6 0.515 0.531

L1 3.48 3.78 0.137 0.149

L2 1.27 1.4 0.050 0.055

L

L1

B2

B

D

E

A

C2

C

A1

L2

e

P011P5/E

TO-262 (I2PAK) MECHANICAL DATA

11/13

STP6NC80Z/FP/STP6NC80Z-1

DIM.

mm inch

MIN. TYP. MAX. MIN. TYP. MAX.

A 4.4 4.6 0.173 0.181

A1 2.49 2.69 0.098 0.106

B 0.7 0.93 0.027 0.036

B2 1.14 1.7 0.044 0.067

C 0.45 0.6 0.017 0.023

C2 1.21 1.36 0.047 0.053

D 8.95 9.35 0.352 0.368

E 10 10.4 0.393 0.409

G 4.88 5.28 0.192 0.208

L 15 15.85 0.590 0.624

L2 1.27 1.4 0.050 0.055

L3 1.4 1.75 0.055 0.068

L2

L3

L

B2

B

G

E

A

C2

D

C

A1

DETAIL "A"

DETAIL "A"

A2

P011P6/E

TO-263 (D2PAK) MECHANICAL DATA

STP6NC80Z/FP/STP6NC80Z-1

12/13

TAPE AND REEL SHIPMENT (suffix ”T4”)*

TUBE SHIPMENT (no suffix)*

D2PAK FOOTPRINT

* on sales type

DIM.

mm inch

MIN. MAX. MIN. MAX.

A 330 12.992

B 1.5 0.059

C 12.8 13.2 0.504 0.520

D 20.2 0795

G 24.4 26.4 0.960 1.039

N 100 3.937

T 30.4 1.197

BASE QTY BULK QTY

1000 1000

REEL MECHANICAL DATA

DIM.

mm inch

MIN. MAX. MIN. MAX.

A0 10.5 10.7 0.413 0.421

B0 15.7 15.9 0.618 0.626

D 1.5 1.6 0.059 0.063

D1 1.59 1.61 0.062 0.063

E 1.65 1.85 0.065 0.073

F 11.4 11.6 0.449 0.456

K0 4.8 5.0 0.189 0.197

P0 3.9 4.1 0. 153 0.161

P1 11.9 12.1 0.468 0.476

P2 1.9 2.1 0. 075 0.082

R 50 1.574

T 0.25 0.35 0.0098 0.0137

W 23.7 24.3 0.933 0.956

TAPE MECHANICAL DATA

STP6NC80Z/FP/STP6NC80Z-1

13/13

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility f or t he

consequences of use of su ch in formation nor for any in fringement of patents or other rights of third parties w hich may result from

its use. No license is granted by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications

mentioned in this publication are subject to change without notice. This publication supersedes and replaces all information

previously suppli ed. STMi croelect ronics pr oducts are not author ized for use as cr itical component s in li fe suppo rt devi ces or

systems without express written approval of STMicroelectronics.

© The ST logo is a registered trademark of STMicroelectronics

© 2002 STMicroelectronics - Printed in Italy - All Rights Reserved

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - Canada - China - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan - Malaysia - Malta - Morocco

Singapore - Spain - Sweden - Switzerland - United Kingdom - United States.

© http://www.st.com

Loading...

Loading...