150 mA dual DC-DC converter with LDO

Features

■ Step-up with LDO and inverter converters

■ Operating input voltage range from 2.3 V to

4.8 V

■ Synchronous rectification for both DC-DC

converters

■ Minimum 150 mA output current

■ LDO post regulator for 4.6 V fixed positive

output to provide line and load transient

response with minimum output voltage ripple

■ Programmable negative voltage by S

- 2.4 V to -5.4 V at 100 mV steps

■ Typical efficiency: 82%

■ Pulse skipping mode in light load condition

■ 1.5 MHz PWM mode control switching

frequency

■ Enable pin for shutdown mode

■ Low quiescent current in shutdown mode

■ Soft-start with inrush current protection

■ Overtemperature protection

■ Temperature range: -40 °C to 85 °C

■ True-shutdown mode

■ Package DFN (3 x 3) 12 leads 0.6 mm height

Applications

■ Active matrix AMOLED power supply in

portable devices

■ Cellular phones

■ Camcorders and digital still cameras

■ Multimedia players

WIRE

from

STOD03B

for powering AMOLED displays

DFN12L (3 x 3 mm)

Description

The STOD03B is a dual DC-DC converter for

AMOLED display panels. It integrates a step-up

and an inverting DC-DC converter making it

particularly suitable for battery operated products,

in which the major concern is the overall system

efficiency. It works in pulse skipping mode during

low load conditions and PWM-MODE at 1.5 MHz

frequency for medium/high load conditions. The

high frequency allows the value and size of

external components to be reduced. The 4.6 V

output is provided by an LDO in cascade with the

step-up converter. This allows a noise and ripple

free positive output for the AMOLED panel to

provide stable picture quality. The Enable pin

allows the device to be turned off, therefore

reducing the current consumption to less than

1 µA. The negative output voltage can be

programmed by an MCU through a dedicated pin

which implements single-wire protocol. Soft-start

with controlled inrush current limit and thermal

shutdown are integrated functions of the device.

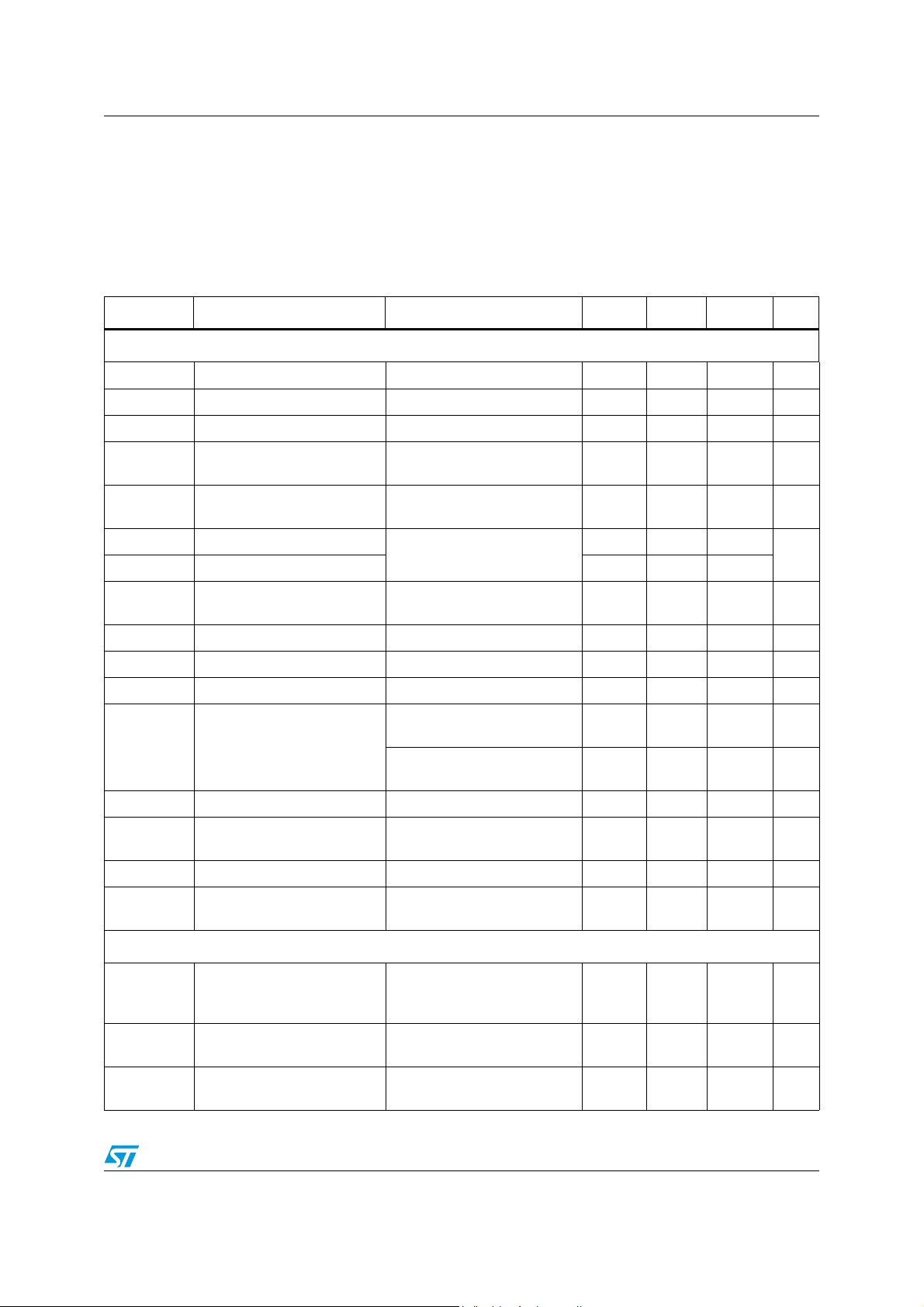

Table 1. Device summary

Order code Positive voltage Negative voltage Package Packaging

STOD03BTPUR 4.6V - 2.4V to - 5.4V DFN12L (3 x 3mm) 3000 parts per reel

December 2011 Doc ID 022613 Rev 1 1/22

www.st.com

22

Contents STOD03B

Contents

1 Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Pin configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5 Typical performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6 Detailed description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.1 S

6.1.1 S

6.1.2 S

6.1.3 S

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

WIRE

features and benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

WIRE

protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

WIRE

basic operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

WIRE

6.2 Negative output voltage levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

S

6.3 Enable and

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

WIRE

7 Application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

7.1 External passive components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

7.1.1 Inductor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

7.1.2 Input and output capacitor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7.2 Recommended PCB layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

8 Detailed description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8.1.1 Multiple operation modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8.1.2 Enable pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8.1.3 Soft-start and inrush current limiting . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8.1.4 Undervoltage lockout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8.1.5 Overtemperature protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

9 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

10 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2/22 Doc ID 022613 Rev 1

STOD03B Schematic

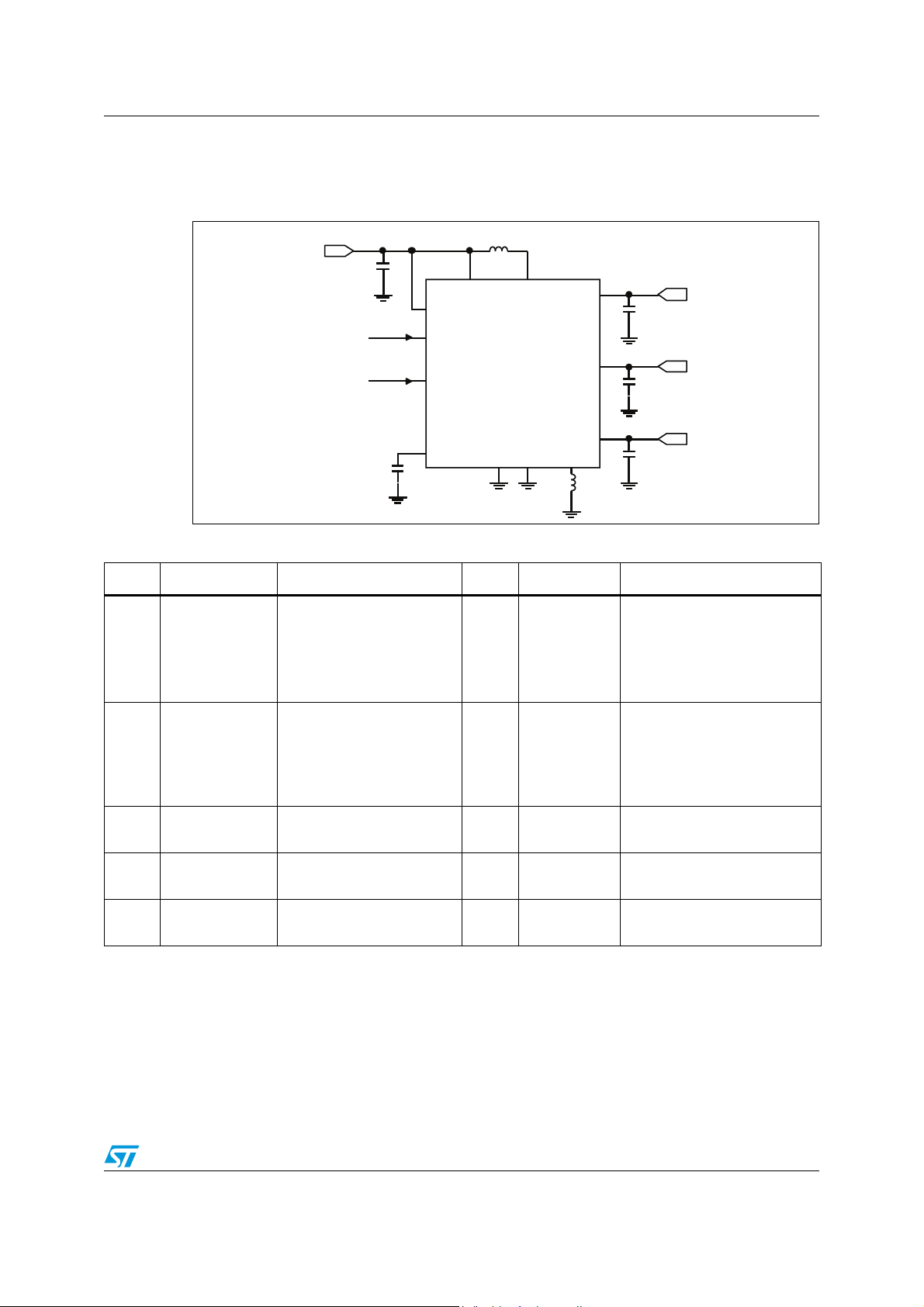

1 Schematic

Figure 1. Application schematic

VBAT

CIN

S-Wire

EN

VINA

Swire

EN

L1

VINP

STOD03B

LX1

VMID

CMID

VO1

CO1

CREF

Table 2. Typical external components

VREF

AGNDPGND

LX2

VO2

CO2

L2

AM10428v1

Comp. Manufacturer Part number Value Size Ratings

COILCRAFT

MURATA

(1)

L

1

SEMCO

ABCO

ABCO

COILCRAFT

(2)

L

2

MURATA

TOKO

ABCO

C

IN

C

O1

MURATA

TAIYO YUDEN

MURATA

TAIYO YUDEN

LPS4012-472ML

LQH3NPN4R7MJ0

CIG22B4R7MNE

LPF2810T-4R7M

LPF2807T-4R7M

LPS4012-472ML

LQH3NPN4R7MJ0

DFE252012C 1239AS-H-

4R7N

LPF2807T-4R7M

GRM219R61A106KE44

LMK212BJ106KD-T

GRM219R61A106KE44

LMK212BJ106KD-T

4.7µH

4.7µH

10µF

10µF

4.0 x 4.0 x 1.2

3.0 x 3.0 x 1.1

2.5 x 2.0 x 1.0

2.8 x 2.8 x 1.0

2.8 x 2.8 x 0.7

4.0 x 4.0 x 1.2

3.0 x 3.0 x 1.1

2.5 x 2.0 x 1.2

2.8 x 2.8 x 0.7

0805

0805

0805

0805

±20%, curr. 1.7A, res. 0.175Ω

±20%, curr. 1.1A, res. 0.156Ω

±20%, curr. 1.1A, res. 0.300Ω

±20%, curr. 0.85A, res. 0.33Ω

±20%, curr. 0.70A, res. 0.44Ω

±20%, curr. 1.7A, res. 0.175Ω

±20%, curr. 1.1A, res. 0.156Ω

±30%, curr. 1.2A, res. 0.252Ω

±20%, curr. 0.70A, res. 0.44Ω

±10%, X5R, 10V

±10%, X5R, 10V

±10%, X5R, 10V

±10%, X5R, 10V

C

O2

MURATA

TAIYO YUDEN

GRM219R61A106KE44

LMK212BJ106KD-T

10µF

0805

0805

±10%, X5R, 10V

±10%, X5R, 10V

Doc ID 022613 Rev 1 3/22

Schematic STOD03B

Table 2. Typical external components (continued)

Comp. Manufacturer Part number Value Size Ratings

C

C

MID

REF

MURATA

TAIYO YUDEN

MURATA

TAIYO YUDEN

GRM219R61A106KE44

LMK212BJ106KD-T

GRM185R60J105KE26

JMK107BJ105KK-T

10µF

1µF

0805

0805

0805

0805

±10%, X5R, 10V

±10%, X5R, 10V

±10%, X5R, 10V

±10%, X5R, 10V

1. A 200 mA load can be provided with inductor saturation current as a minimum of 0.6 A.

2. For V

in a range between - 4.9 V to -5.4 V, a load current of 150 mA to 200 mA can be provided using inductors with a

O2

saturation current as a minimum of 1 A. See Section 7.1.1.

Note: All the above components refer to the typical application performance characteristics.

Operation of the device is not limited to the choice of these external components. Inductor

values ranging from 3.3 µH to 6.8 µH can be used together with STOD03B.

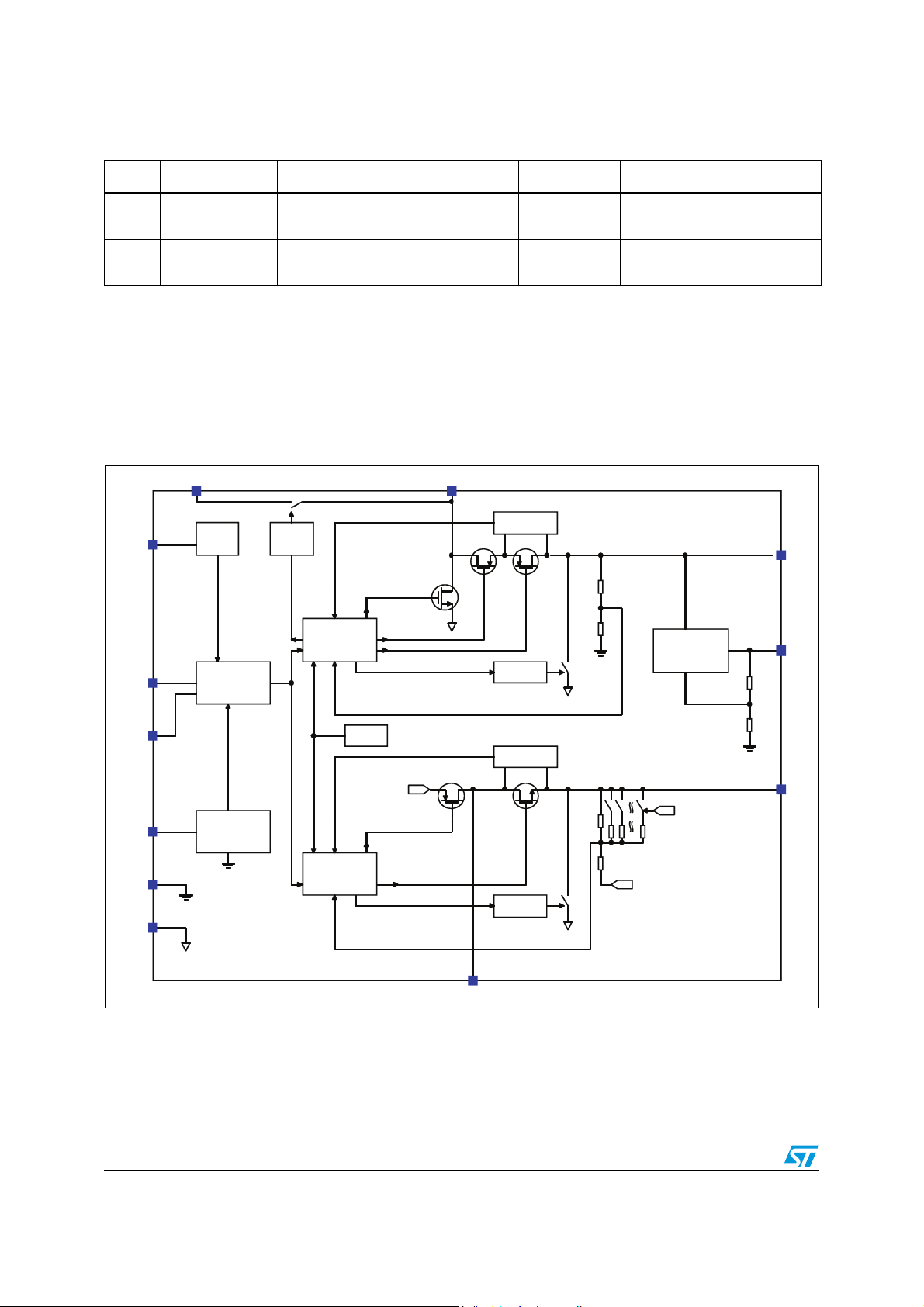

Figure 2. Block schematic

VINA

S-WIRE

VINP

UVLO

LOGIC CON TROL

OTP

S-WIRE

RING

KILLER

STEP-UP

CONTROL

LX1

DMD

FAST

DISCHARGE

LDO

VMID

VO1

INVERT ING

CONTROL

OSC

VINP

LX2

DMD

FAST

DISCHARGE

EN

VREF

AGND

PGND

VREF

4/22 Doc ID 022613 Rev 1

VREF

S-wire

control

VO2

AM10429v1

STOD03B Pin configuration

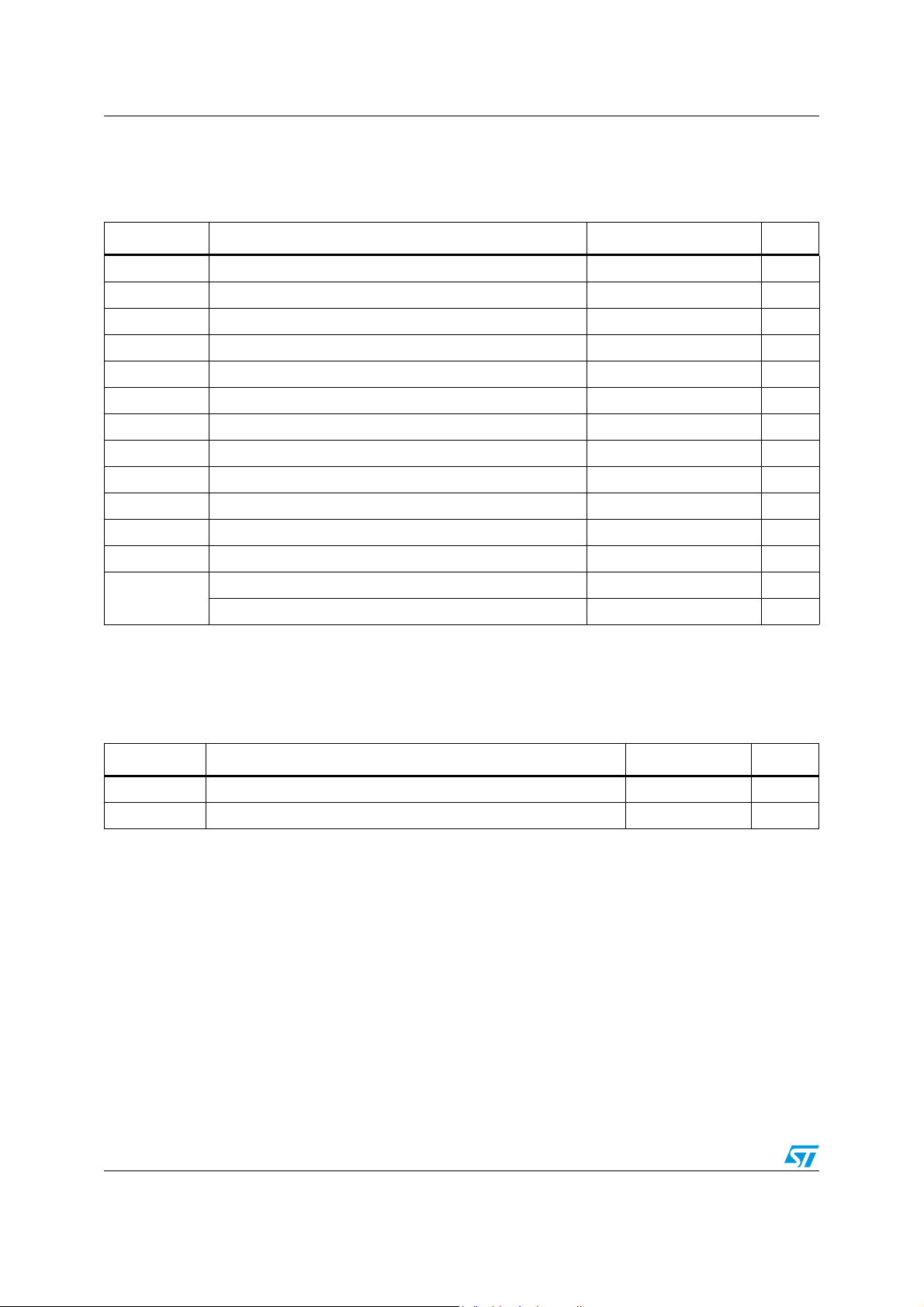

2 Pin configuration

Figure 3. Pin configuration (top view)

Table 3. Pin description

Pin name Pin n° Description

Lx

1

1 Boost converter switching node

PGND 2 Power ground pin

V

MID

V

O1

3 Step-up converter output voltage (4.9V)

4 4.6V fixed LDO output

AGND 5 Signal ground pin. This pin must be connected to the power ground layer

V

S

REF

WIRE

6

7 Negative voltage setting pin.

EN 8

V

O2

Lx

2

V

IN A

V

12 Power input supply voltage

iN P

9 Inverting converter output voltage

10 Inverting converter switching node

11 Analogic input supply voltage

Exposed

pad

1. No pull-up/pull-down resistors are needed.

Voltage reference output. 1µF bypass capacitor must be connected

between this pin and AGND

Enable control pin. High 1

converter on; low or floating = converter in shutdown mode

(1)

Internally connected to AGND. Exposed pad must be connected to ground

layers in the PCB layout in order to guarantee proper operation of the

device

Doc ID 022613 Rev 1 5/22

Maximum ratings STOD03B

3 Maximum ratings

Table 4. Absolute maximum ratings

Symbol Parameter Value Unit

V

INA

EN, S

IL

L

V

V

O1, VMID

L

IL

V

P

T

ESD

, V

WIRE

X2

X2

O2

X1

X1

REF

D

STG

T

J

DC supply voltage -0.3 to 6 V

INP

Logic input pins -0.3 to 4.6 V

Inverting converter switching current Internally limited A

Inverting converter switching node voltage -10 to V

+0.3 V

INP

Inverting converter output voltage -10 to AGND+0.3 V

LDO and step-up converter output voltage -0.3 to 6 V

Step-up converter switching node voltage -0.3 to V

+0.3 V

MID

Step-up converter switching current Internally limited A

Reference voltage -0.3 to 3 V

Power dissipation Internally limited mW

Storage temperature range -65 to 150 °C

Maximum junction temperature 150 °C

Human Body Model Protection ±

2kV

Machine Body Model Protection ± 200 kV

Note: Absolute maximum ratings are those values beyond which damage to the device may occur.

Functional operation under these condition is not implied.

Table 5. Thermal data

Symbol Parameter Value Unit

R

thJA

R

thJC

1. The package is mounted on a 4-layer (2S2P) JEDEC board as per JESD51-7.

Thermal resistance junction-ambient 33 °C/W

Thermal resistance junction-case (FR-4 PCB)

(1)

2.12 °C/W

6/22 Doc ID 022613 Rev 1

STOD03B Electrical characteristics

4 Electrical characteristics

TJ = 25 °C, V

C

= 2 x10 µF, C

O2

V

= -4.9 V unless otherwise specified.

O2

Table 6. Electrical characteristics

INA

= V

= 3.7 V, I

INP

= 1 µF, L1 = L2 = 4.7 µH, VEN = 2 V, V

REF

= 30 mA, CIN = 2 x10 µF, C

O1,2

= 2 x10 µF, CO1 = 10 µF,

MID

= 4.9 V, VO1 = 4.6 V,

MID

Symbol Parameter Test conditions Min. Typ. Max. Unit

General section

V

INA, VINP

UVLO_H Undervoltage lockout HIGH V

UVLO_L Undervoltage lockout LOW V

I_V

I

Q_SH

V

EN

V

EN

I

EN

f

S

D1

MAX

D2

MAX

Supply input voltage 2.3 4.8 V

rising 2.22 2.25 V

INA

falling 1.9 2.18 V

INA

Input current

I

Shutdown current

H Enable high threshold

L Enable low threshold 0.4

Enable input current

No load condition (sum of

and V

V

INA

=GND (sum of V

V

EN

V

); TJ=-40°C to +85°C;

INP

V

=2.3V to 4.8V,

INA

INP

)

and

INA

TJ=-40°C to +85°C;

V

EN=VINA

=-40°C to +85°C;

T

J

=4.8V;

1.2

1.3 1.7 mA

1µA

1µA

Switching frequency PWM mode 1.35 1.5 1.65 MHz

Step-up maximum duty cycle No load 87 %

Inverting maximum duty cycle No load 87 %

I

=10 to 30mA,

O1,O2

VO1=4.6V, VO2=-4.9V

75 %

η Total system efficiency

I

=30 to 150mA,

V

I

REF

REF

Voltage reference I

Voltage reference current

capability

O1,O2

V

=4.6V, VO2=-4.9V

O1

=10µA 1.195 1.207 1.219 V

REF

At 98.5% of no load

reference voltage

100 µA

82 %

OTP Overtemperature protection 140 °C

V

OTP

HYST

Overtemperature protection

hysteresis

Positive output section

Positive voltage total variation

Line transient

Load transient regulation

ΔV

ΔV

V

O1LT

O1

O1T

15 °C

V

INA=VINP

=-40°C to +85°C; IO1=5mA

T

J

=2.3V to 4.8V;

4.554 4.6 4.646 V

to 150mA, IO2 no load

=3.5V to 3.0V,

V

INA,P

=100mA; TR=TF=50µs

I

O1

=3 to 30mA and IO1=30 to

I

O1

3mA, TR=TF=150µs

-12 mV

±20 mV

Doc ID 022613 Rev 1 7/22

Electrical characteristics STOD03B

Table 6. Electrical characteristics (continued)

Symbol Parameter Test conditions Min. Typ. Max Unit

=5 to 100mA; IO2 no load

I

TDMA Noise TDMA noise immunity

(1)

O1

±20 mV

I

O1 MAX

Max. output current V

Positive voltage total variation

V

MID

Temperature accuracy

Step-up inductor peak

current

P-channel Static Drain-

P1

source On resistance

N-channel Static Drain-

N1

source On resistance

R

R

I-L

1MAX

DSON

DSON

Negative output

Negative output voltage

range

Negative output voltage total

V

O2

variation on default value

Temperature accuracy

ΔV

O2LT

Line transient

Load transient regulation

ΔV

O2T

Load transient regulation

TDMA Noise TDMA noise immunity I

I

O2 MAX

I-L

2MAX

Maximum output current V

Inverting peak current

=2.9V to 4.8V 150 mA

INA,P

V

INA=VINP

I

MID

=2.9V to 4.8V;

=5mA to 150mA;

4.8 4.9 5.0 V

IO2 no load; TJ=25°C

V

INA=VINP

I

O2

=3.7V; I

MID

no load; TJ=-40 to

=5mA;

-05 0.5 %

+85°C;

V

10% below nominal

MID

value

V

INA=VINP

I

SW-P1

V

INA=VINP

I

SW-P1

=3.7V,

=100mA

=3.7V,

=100mA

31 different values set by the

S

pin (see S

WIRE

V

INA=VINP

=25°C; IO2=5mA to

T

J

=2.9V to 4.8V;

WIRE

)

11.1A

1.0 1.6 Ω

0.4 0.7 Ω

-5.4 -2.4 V

-4.97 -4.9 -4.83 V

150mA, IO1 no load

V

INA=VINP

I

O2

=3.7V; IO2=5mA;

no load;

-0.5 0.5 %

TJ=-40°C to +85°C

=3.5V to 3.0V,

V

INA,P

=100mA, TR=TF=50µs

I

O2

=3 to 30mA and IO2=30 to

I

O2

3mA, T

I

=10 to 100mA and IO2=100

O2

to 10mA, T

=5 to 100mA; IO1 no load ±25 mV

O2

INA,P

below 10% of nominal

V

O2

value

=150µs

R=TF

=150µs

R=TF

=2.9V to 4.8V -150 mA

-1.2 -0.9 A

+12 mV

±20 mV

±25 mV

R

R

1. V

DSON

DSON

INA,P

source On resistance

N-channel Static Drain-

N2

source On resistance

= 4.2 to 3.7 V, 3.7 to 3.2 V, 3.4 to 2.9 V, f = 200 Hz, t

P-channel Static Drain-

P2

V

INA=VINP

I

SW-P2

V

INA=VINP

I

SW-P2

=3.7V;

=100mA

=3.7V;

=100mA

ON

= 3.65 ms, t

8/22 Doc ID 022613 Rev 1

0.42 0.8 Ω

0.43 0.8 Ω

= 1.25 ms, TR = TF = 50 µs, pulse signal.

OFF

STOD03B Typical performance characteristics

5 Typical performance characteristics

V

= -4.9 V; TJ = 25 °C; See Ta bl e 1 . for external components used in the tests below.

O2

Figure 4. Max power output vs. V

Figure 6. Positive output operation Figure 7. Negative output operation

IN

Figure 5. Efficiency vs. output current

IO1 = 100 mA

Figure 8. Soft-start inrush current Figure 9. Output current vs. input voltage

IO = 200 mA, V

= - 4.9 V

O2

IO2 = 100 mA

V

= V

INA

INAP

= 2.3 to 4.8 V, VO1 = 4.6 V

Doc ID 022613 Rev 1 9/22

Detailed description STOD03B

6 Detailed description

6.1 S

● Protocol: to digitally communicate over a single cable with single-wire components

● Single-wire’s 3 components:

1. An external MCU

2. Wiring and associated connectors

3. STOD03B device with a dedicated single-wire pin.

6.1.1 S

● Fully digital signal

● No handshake needed

● Protection against glitches and spikes though an internal low pass filter acting on falling

● Uses a single wire (plus analog ground) to accomplish both communication and power

● Simplify design with an interface protocol that supplies control and signaling over a

6.1.2 S

● Single-wire protocol uses conventional CMOS/TTL logic levels (maximum 0.6 V for

● Both master (MCU) and slave (STOD03B) are configured to permit bit sequential data

● Data is bit-sequential with a START bit and a STOP bit

● Signal is transferred in real time

● System clock is not required; each single-wire pulse is self-clocked by the oscillator

WIRE

features and benefits

WIRE

edge

control transmission

single-wire connection to set the output voltages.

protocol

WIRE

logic “zero” and a minimum 1.2 V for logic “one”) with operation specified over a supply

voltage range of 2.3 V to 4.8 V

to flow only in one direction at a time; master initiates and controls the device

integrated in the master and is asserted valid within a frequency range of 250 kHz

(maximum).

6.1.3 S

● The negative output voltage levels are selectable within a wide range (steps of 100 mV)

● The device can be enabled / disabled via S

10/22 Doc ID 022613 Rev 1

basic operations

WIRE

in combination with the Enable pin.

WIRE

STOD03B Detailed description

6.2 Negative output voltage levels

Table 7. Default output voltage

Pulse V

O2

1 -5.411-4.421-3.4

2 -5.312-4.322-3.3

3 -5.213-4.223-3.2

4 -5.114-4.124-3.1

5 -5.015-4.025-3.0

(1)

6

-4.9 16 -3.9 26 -2.9

7 -4.817-3.827-2.8

8 -4.718-3.728-2.7

9 -4.619-3.629-2.6

10 -4.5 20 -3.5 30 -2.5

1. Default value.

6.3 Enable and S

WIRE

Pulse V

O2

Pulse V

31 -2.4

O2

Table 8. EN and S

operation table

WIRE

(1)

Enable S

Low Low Device off

Low High Negative output voltage set by S

High Low Default negative output voltage

High High Default negative output voltage

1. The Enable pin must be set to AGND while using the S

WIRE

WIRE

Action

WIRE

function.

Doc ID 022613 Rev 1 11/22

Application information STOD03B

7 Application information

7.1 External passive components

7.1.1 Inductor selection

Magnetic shielded low ESR power inductors must be chosen as the key passive

components for switching converters.

For the step-up converter an inductance between 4.7 µH and 6.8 µH is recommended.

For the inverting stage the suggested inductance ranges from 3.3 µH to 4.7 µH.

It is very important to select the right inductor according to the maximum current the

inductor can handle to avoid saturation. The step-up and the inverting peak current can be

calculated as follows:

Equation 1

IV

×

I

−

=

BOOSTPEAK

OUTMID

VIN1

×η

+

MIN

MID

−×

×××

)VINV(VIN

MINMIDMIN

1LfsV2

Equation 2

MIN

xI)2VOVIN(

OUTMINMIN

+

2VOVIN

×

MINMIN

2Lfs)VIN2VO(2

MINMIN

××−×

I

−

INVERTINGPEAK

=

−

VIN2

×η

where

V

: step-up output voltage, fixed at 4.9 V;

MID

V

: inverting output voltage including sign (minimum value is the absolute maximum

O2

value);

I

: output current for both DC-DC converters;

O

V

: input voltage of STOD03B;

IN

f

: switching frequency. Use the minimum value of 1.35 MHz for the worst case;

s

η1: efficiency of step-up converter. Typical value is 0.70;

η2: efficiency of inverting converter. Typical value is 0.60.

The negative output voltage can be set via S

at -5.4 V. Accordingly, the inductor peak

WIRE

current, at the maximum load condition, increases. A proper inductor, with a saturation

current as a minimum of 1 A, is preferred.

STOD03B is capable of supplying a load current from 150 mA to 200 mA. Inductors with a

saturation current as a minimum of 1 A must be selected.

12/22 Doc ID 022613 Rev 1

STOD03B Application information

7.1.2 Input and output capacitor selection

It is recommended to use X5R or X7R low ESR ceramic capacitors as input and output

capacitors in order to filter any disturbance present in the input line and to obtain stable

operation for the two switching converters. A minimum real capacitance value of 6 µF must

be guaranteed for C

variation and DC polarization, 2 x 10 µF, 10 V ±10% as C

as C

and 2 x 10 µF 10 V ±10% as CO2 can be used to achieve the needed 6 µF.

O1

, CO1 and CO2 in all conditions. Considering tolerance, temperature

MID

, a 10 µF 10V ±10% capacitor

MID

7.2 Recommended PCB layout

The STOD03B is a high frequency power switching device and therefore requires a proper

PCB layout in order to obtain the necessary stability and optimize line/load regulation and

output voltage ripple.

Analog input (V

at the C

pad only. The input capacitor must be as close as possible to the IC.

IN

) and power input (V

INA

) must be kept separated and connected together

INP

In order to minimize ground noise, a common ground node for power ground and a different

one for analog ground must be used. In the recommended layout, the AGND node is placed

close to C

ground while the PGND node is centered at CIN ground. They are connected

REF

by a separated layer routing on the bottom through vias.

The exposed pad is connected to AGND through vias.

Figure 10. Top layer and top silk-screen (top view, not to scale)

Doc ID 022613 Rev 1 13/22

Application information STOD03B

Figure 11. Bottom layer and silk-screen (top view, not to scale)

14/22 Doc ID 022613 Rev 1

STOD03B Detailed description

8 Detailed description

8.1 General description

The STOD03B is a high efficiency dual DC-DC converter which integrates a step-up with an

LDO and inverting power stages suitable for supplying AMOLED panels. Thanks to the high

level of integration it needs only 6 external components to operate and it achieves very high

efficiency using a synchronous rectification technique for each of the two DC-DC converters.

This topology of a boost followed by an LDO regulator offers an efficient ripple reduction

solution for loads up to 200 mA. The controller uses an average current mode technique in

order to obtain good stability and precise voltage regulation in all possible conditions of input

voltage, output voltage, and output current. In addition, the peak inductor current is

monitored in order to avoid saturation of the coils. The STOD03B implements a power

saving technique in order to maintain high efficiency at very light load and it switches to

PWM operation as the load increases, in order to guarantee the best dynamic performance

and low noise operation. The STOD03B avoids battery leakage thanks to the true-shutdown

feature and it is self protected by overtemperature. Undervoltage lockout and soft-start

guarantee proper operation during startup.

8.1.1 Multiple operation modes

Both the step-up and the inverting stage of the STOD03B operate in three different modes:

pulse skipping mode (PSM), discontinuous conduction mode (DCM), and continuous

conduction mode (CCM). It switches automatically between the three modes according to

input voltage, output current, and output voltage conditions.

Pulse skipping operation:

The STOD03B works in pulse skipping mode when the load current is below a few mA.

The load current level at which this way of operating occurs depends on input voltage only

for the step-up converter and on input voltage and negative output voltage (V

inverting converter.

) for the

O2

Discontinuous conduction mode:

When the load increases above some tens of mA, the STOD03B enters DCM operation.

In order to obtain this type of operation the controller must avoid the inductor current going

negative. The discontinuous mode detector (DMD) blocks sense the voltage across the

synchronous rectifiers (P1B for the step-up and N2 for the inverting) and turn off the

switches when the voltage crosses a defined threshold which, in turn, represents a certain

current in the inductor. This current can vary according to the slope of the inductor current

which depends on input voltage, inductance value, and output voltage.

Continuous conduction mode:

At medium/high output loads, the STOD03B enters full CCM at constant switching

frequency mode for each of the two DC-DC converters.

Doc ID 022613 Rev 1 15/22

Detailed description STOD03B

8.1.2 Enable pin

The device operates when the EN pin is set high. If the EN pin is set low, the device stops

switching, and all the internal blocks are turned off. In this condition the current drawn from

V

INP/VINA

is below 1 µA in the whole temperature range. In addition, the internal switches

are in an OFF state so the load is electrically disconnected from the input, this avoids

unwanted current leakage from the input to the load.

8.1.3 Soft-start and inrush current limiting

After the EN pin is pulled high, or after a suitable voltage is applied to V

device initiates the startup phase. As a first step, the C

switch implements a current limiting technique in order to keep the charge current below

400 mA. This avoids the battery overloading during startup. After V

voltage level, the P1B switch is fully turned on and the soft-start procedure for the step-up is

started.

After around 2 ms the soft-start for the inverting is started. The positive and negative

voltages are under regulation by around 6 ms after the EN pin is asserted high.

8.1.4 Undervoltage lockout

The undervoltage lockout function avoids improper operation of the STOD03B when the

input voltage is not high enough. When the input voltage is below the UVLO threshold the

device is in shutdown mode. The hysteresis of 50 mV avoids unstable operation when the

input voltage is close to the UVLO threshold.

8.1.5 Overtemperature protection

An internal temperature sensor continuously monitors the IC junction temperature. If the IC

temperature exceeds 140 °C, typical, the device stops operating. As soon as the

temperature falls below 125 °C, typical, normal operation is restored.

, V

capacitor is charged and the P1B

MID

INP

reaches the V

MID

and EN, the

INA

INP

16/22 Doc ID 022613 Rev 1

STOD03B Package mechanical data

9 Package mechanical data

In order to meet environmental requirements, ST offers these devices in different grades of

ECOPACK

specifications, grade definitions and product status are available at:

is an ST trademark.

®

packages, depending on their level of environmental compliance. ECOPACK

www.st.com. ECOPACK

Doc ID 022613 Rev 1 17/22

Package mechanical data STOD03B

DFN12L (3 x 3 x 0.6 mm) mechanical data

mm. inch.

Dim.

Min. Typ. Max. Min. Typ. Max.

A 0.51 0.55 0.60 0.020 0.022 0.024

A1 0 0.02 0.05 0 0.001 0.002

A3 0.20 0.008

b 0.18 0.25 0.30 0.007 0.010 0.012

D2.85 33.15 0.112 0.118 0.124

D2 1.87 2.02 2.12 0.074 0.080 0.083

E2.85 33.15 0.112 0.118 0.124

E2 1.06 1.21 1.31 0.042 0.048 0.052

e 0.45 0.018

L0.30 0.40 0.50 0.012 0.016 0.020

18/22 Doc ID 022613 Rev 1

8085116/A

STOD03B Package mechanical data

Tape & reel QFNxx/DFNxx (3x3) mechanical data

mm. inch

DIM.

MIN. TYP MAX. MIN. TYP. MAX.

A 330 12.992

C 12.8 13.2 0.504 0.519

D 20.2 0.795

N 99 101 3.898 3.976

T 14.4 0.567

Ao 3.3 0.130

Bo 3.3 0.130

Ko 1.1 0.043

Po 4 0.157

P 8 0.315

Doc ID 022613 Rev 1 19/22

Package mechanical data STOD03B

Figure 12. DFN12L (3 x 3 mm) footprint recommended data

20/22 Doc ID 022613 Rev 1

STOD03B Revision history

10 Revision history

Table 9. Document revision history

Date Revision Changes

19-Dec-2011 1 Initial release.

Doc ID 022613 Rev 1 21/22

STOD03B

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY TWO AUTHORIZED ST REPRESENTATIVES, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2011 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

22/22 Doc ID 022613 Rev 1

Loading...

Loading...