Page 1

Single-chip hardware accelerated encryption engine for

computer and peripherals applications

Features

■ World class encryption engine

– HardCache™ Crypto module

– FIPS 140-2 security level 3

– NIST Certificate #1599

■ Symmetric algorithms (NIST FIPS approved)

– AES Rijndael block cipher: Key length

128/192/256 bits, ECB/CBC/CBC-FVE

modes, NIST Certificate #1068

– Triple DES: Key length 112/168 bits,

ECB/CBC modes, NIST Certificate #798

– SHA-256, SHA-384 and SHA-512 with

associated HMAC: NIST SHS Certificate

#1015, NIST HMAC Certificate #606

■ Asymmetric Algorithms

– ECDSA, 256- and 384-bit elliptic curves

– RSA PKCS#1 v2.1 padding scheme

– 2048 bit operands

■ Algorithm control policy

– Easy algorithm configuration

– Export control

■ PCI Express

■ Advanced 65 nm process technology

■ Windows XP, Windows 2000, Windows Vista,

Windows 7

ECOPACK® ROHS compliant

■

®

x1 interface

(a)

STM7007

Data brief

■ Best in class performance / power ratio

■ Secure key management protected inside a

tamper resistant cryptographic boundary

■ Resists attacks that use software and/or

instrumentation monitors

■ Enables secure remote administration

■ Shielded locations and protected operations

Applications

■ Desktop PC clients

■ Laptop and mobile PC

■ Server and workstation

■ Entire volume encryption

■ Data loss protection

■ Cryptographic service provider

■ Secure messaging

System benefits

Description

■ Off-loads intensive cryptographic calculations

(asymmetric and symmetric) from the system

CPU

■ Out performs SW based solutions and 3 GHz

processors

■ Full duplex DMA operation

a. Windows is a trademark of Microsoft Corporation.

October 2011 Doc ID 022239 Rev 1 1/27

For further information contact your local STMicroelectronics sales office.

The STM7007 is a PCI Express encryption

engine built on the STMicroelectronics’

HardCache™ cryptographic channel controller

(a

high performance core computing block, with

FIPS 140-2 security level 3 certification).

The

STM7007 provides hardware acceleration for

commonly used algorithms, including AES, 3DES,

SHA, HMAC, RSA, and ECC.

www.st.com

1

Page 2

Contents STM7007

Contents

1 Device pinout and package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Device pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Device package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2.1 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2.2 Recommended footprint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2.3 Markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.2.4 Recommended land pad layout and solder reflow profile . . . . . . . . . . . 11

1.2.5 Rework guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.1 Recommended operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.2 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.3 Environment maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.4 Power dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.5 DC electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.5.1 PCI, miscellaneous 3.3V interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.5.2 PHY 1.2V and 2.5V interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.6 AC electrical specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.7 Differential interface electrical characteristics . . . . . . . . . . . . . . . . . . . . . 17

2.7.1 PCIe test circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3 PCB layout guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.1 PCB Routing of RX/TX differential signals . . . . . . . . . . . . . . . . . . . . . . . . 20

3.1.1 Example: PCB impedance calculation . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.2 PCB power and ground decoupling guidelines . . . . . . . . . . . . . . . . . . . . 22

3.3 Power sequencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4 Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2/27 Doc ID 022239 Rev 1

Page 3

STM7007 Device pinout and package

1

1 Device pinout and package

Device pinout, top view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Device pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Signal types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Signal groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

STM7007 pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Device package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

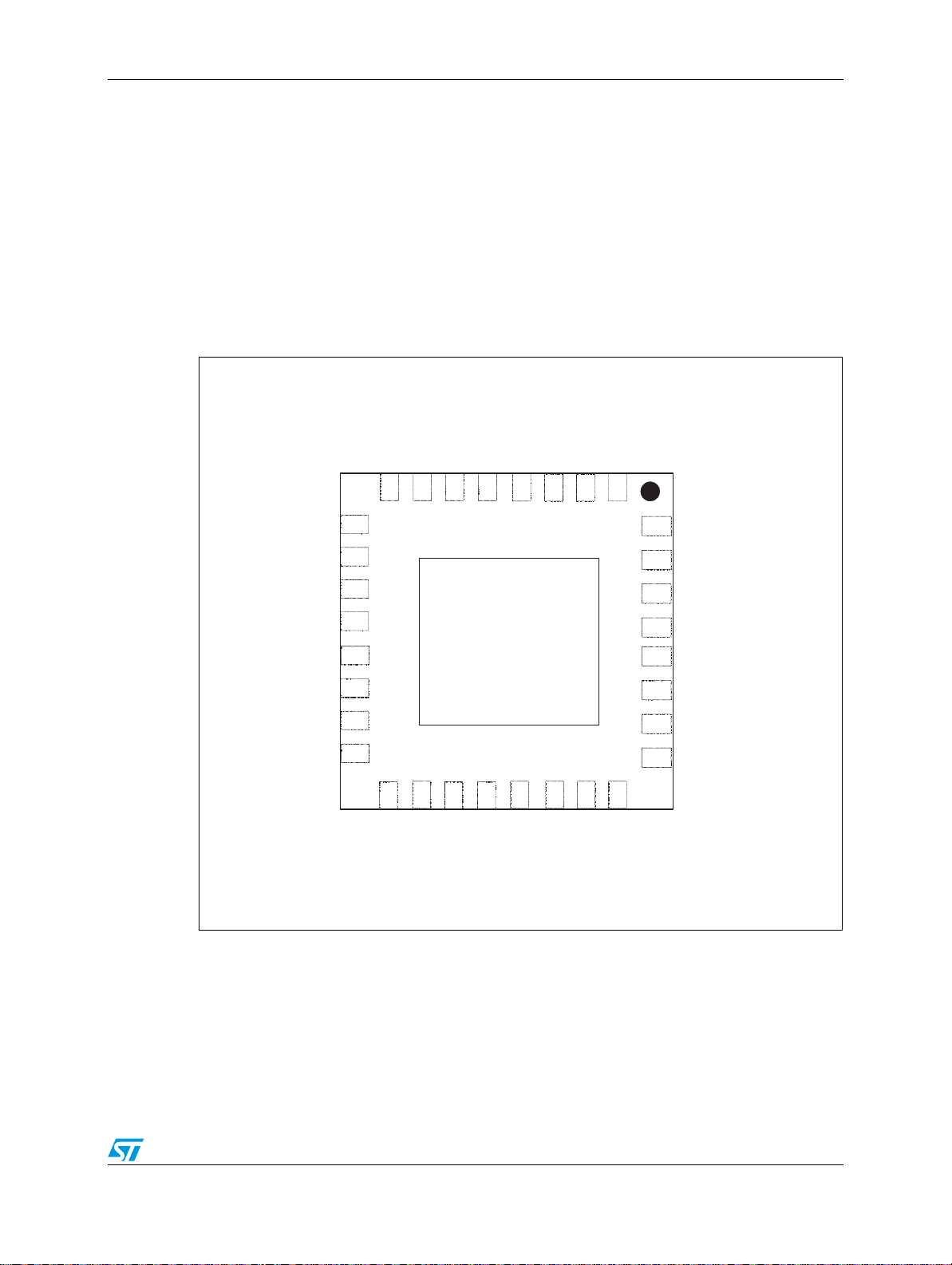

Figure 1. Device pinout, top view

PETn

PETp

VDD1V2

rsvd

rsvd

rsvd

PERST#

rsvd

10

11

12

13

14

15

16

VDDR1V2

PERn

7

PERp

6

GND

5

rsvd

8

9

STM7007

32-Pin

LGA 5x5

18

17

VDD3V3

rsvd

19

rsvd

20

rsvd

VDDT1V2

4

21

VDD2V5

VDDPLL1V2

3

22

rsvd

REFCLKn

2

23

rsvd

REFCLKp

24

CLKREQ#

32

31

30

29

28

27

26

25

REFRES

GND_PLL

VDDPLL2V5

VDD1V2

rsvd

rsvd

rsvd

PGOOD

Doc ID 022239 Rev 1 3/27

Page 4

Device pinout and package STM7007

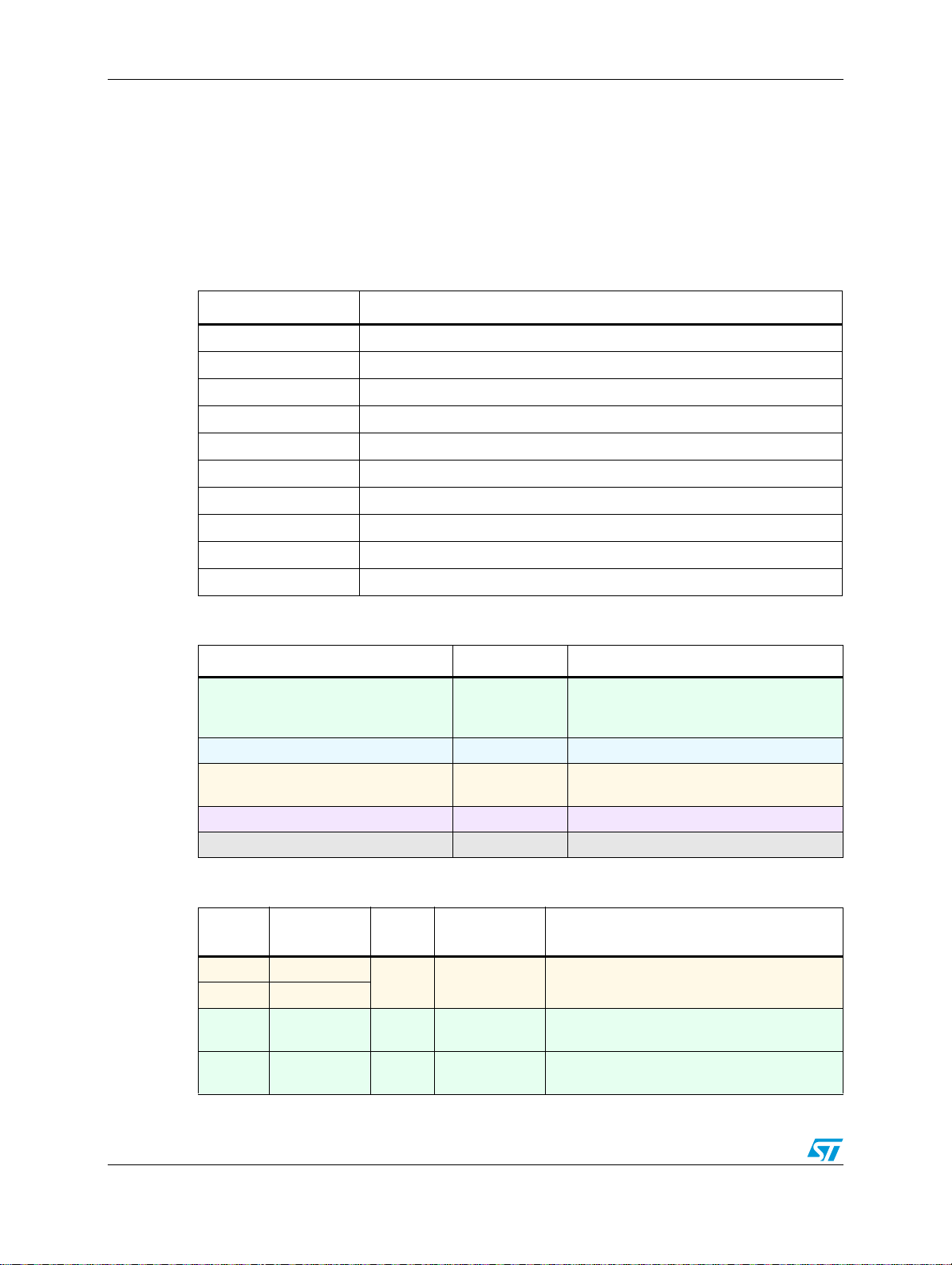

1.1 Device pins

● Ta b le 1 lists the abbreviations used for the signal type names in Tabl e 3 .

Note that abbreviations may be combined, as with APWR (Analog power supply).

● Ta b le 2 lists device signals and how they are grouped, color coding each group.

● Ta b le 3 lists device pins, and uses the same color coding as Tab le 2 to indicate pin

grouping.

Table 1. Signal types

Abbreviation Description

AAnalog

DI Digital input

DO Digital output

GND Ground

I Input

LVDSI Low voltage differential input

LVDSO Low voltage differential output

NC No connection

O Output

PWR Power supply

Table 2. Signal groups

Signal Group Count (32-pin LGA 5x5 package)

VDD1V2, VDD2V5, VDD3V3,

VDD1V2, VDDPLL1V2, VDDPLL2V5,

Power (VDD) 8

VDDR1V2, VDDT1V2

VSS_PLL, VSS Ground (VSS) 2 (GND pad slug on bottom of device)

PETp, PETn, PERp, PERn, REFCLKp,

REFCLKn, CLKREQ#, PERST#

PCI Express 8

REFRES, PGOOD MISC 3

RSVD Not connected 3

Table 3. STM7007 pins

Pin

number

1 REFCLKp

Pin

name

Signal

(1)

type

External

component

Description

LV DS I — Low voltage differential clock input

2 REFCLKn

3 VDDPLL1V2 APWR

4 VDDT1V2 APWR

Decoupling

capacitor

Decoupling

capacitor

1.2 volt analog power input for the internal

PLL block

1.2 volt analog power input for PCIe transmit

channel

4/27 Doc ID 022239 Rev 1

Page 5

STM7007 Device pinout and package

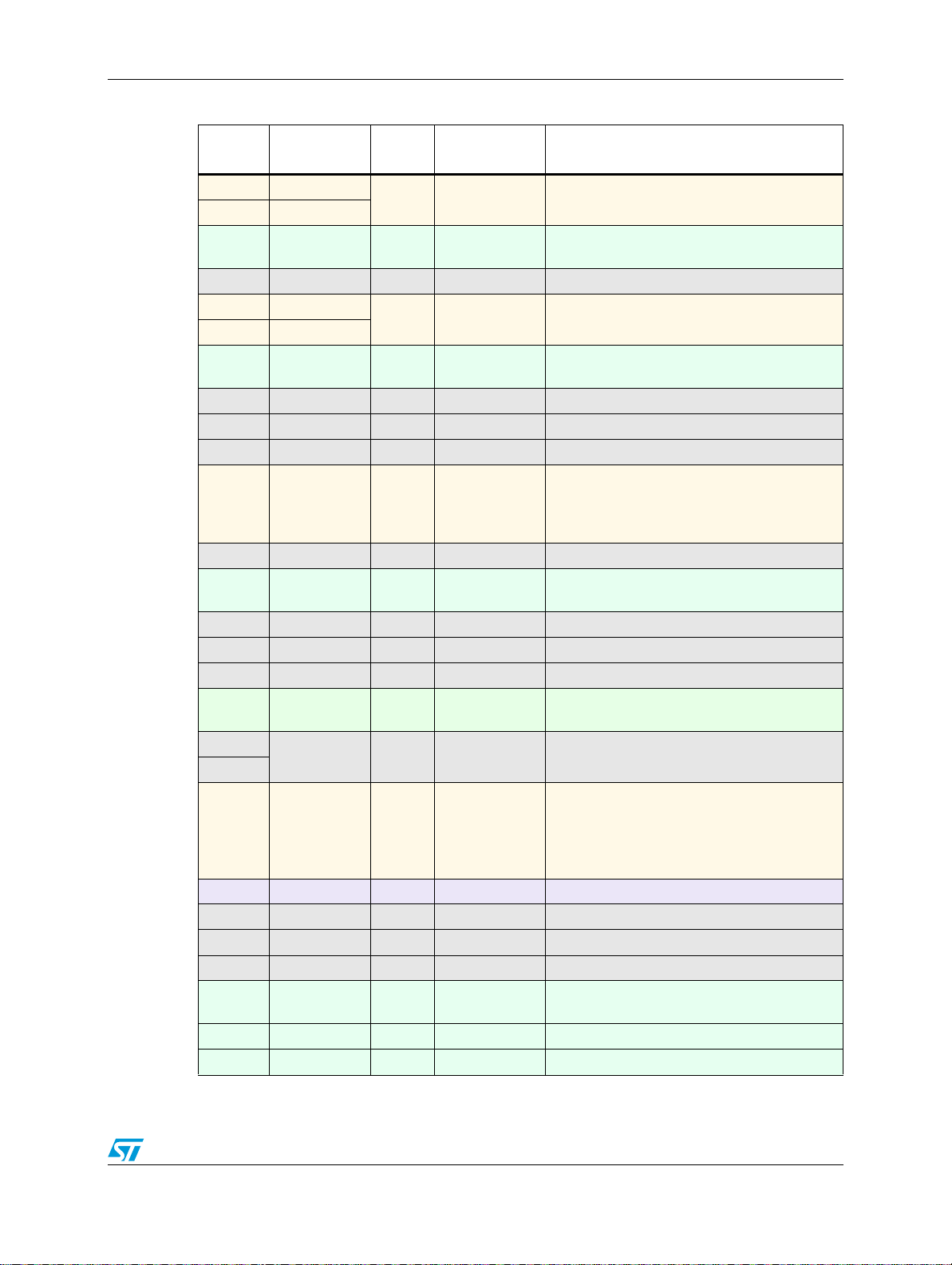

Table 3. STM7007 pins (continued)

Pin

number

Pin

name

Signal

(1)

type

External

component

Description

5 PERn

6 PERp

7 VDDR1V2 APWR

8 RSVD NC Reserved pins, do not connect

9 PETn

10 PETp

11 VDD1V2 PWR

12 RSVD NC — Reserved

13 RSVD NC — Reserved

14 RSVD NC — Reserved

15 PERST# DI —

16 RSVD NC — Reserved

17 VDD3V3 PWR

18 RSVD NC — Reserved

19 RSVD NC — Reserved

20 RSVD NC — Reserved

21 VDD2V5 PWR

22

RSVD NC — Reserved pins, do not connect

23

24 CLKREQ# DO —

25 PGOOD DI — Power on reset, used to reset the core.

26 RSVD NC — Reserved

27 RSVD NC — Reserved

28 RSVD NC — Reserved

29 VDD1V2 PWR

30 VDDPLL2V5 PWR —

31 GND_PLL GND — DC return pin for PLL block

LV DS I — Low voltage differential receive pair

Decoupling

capacitor

LV DS O — Low voltage differential transmit pair

Decoupling

capacitor

Decoupling

capacitor

Decoupling

capacitor

Decoupling

capacitor

1.2 volt analog power input for PCIe receive

channel

1.2 volt power supply input for core

Asynchronous device reset input from

system. When asserted, STM7007 resets all

volatile content and executes a reboot after

de-assertion of signal.

3.3 volt power supply input for I/O logic

2.5 volt power supply

Informs the host controller that the reference

clock input is required by the STM7007. It is

an open drain active low output; when 0, the

reference clock is required, otherwise the

reference clock can be off.

1.2 volt power supply input for core

Doc ID 022239 Rev 1 5/27

Page 6

Device pinout and package STM7007

Table 3. STM7007 pins (continued)

Pin

number

32 REFRES AI Resistor

— GND GND - DC return pad

1. For acronym definitions, see Table 1: Signal types on page 4.

Pin

name

Signal

(1)

type

External

component

Description

Reference resistor input for PLL block. This

pin is tied to 1.2V PLL using a 475_1% ohm

resistor

6/27 Doc ID 022239 Rev 1

Page 7

STM7007 Device pinout and package

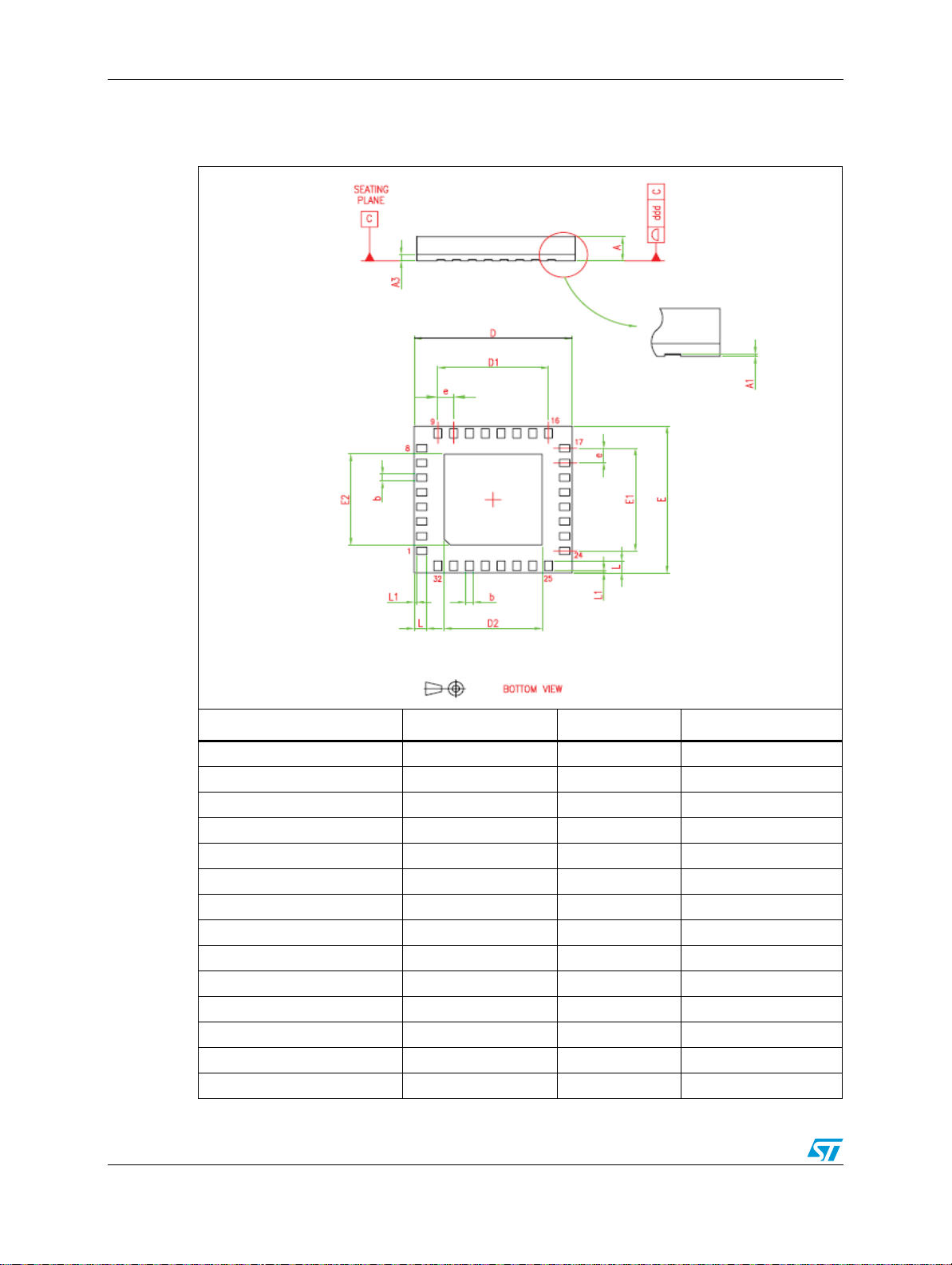

1.2 Device package

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Recommended footprint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

This device uses a 32-Lead, 5 x 5 x 0.82 mm land grid array (LGA) package.

Note: 1 This package is not yet defined in JEDEC publications.

2 The exact shape of each corner is optional.

Doc ID 022239 Rev 1 7/27

Page 8

Device pinout and package STM7007

1.2.1 Dimensions

Table 4. Package dimensions (mm)

Reference Minimum Typical Maximum

A 0.74 0.82 0.88

A1 0.00 0.035

A3 0.22

b 0.18 0.25 0.30

D 4.90 5.00 5.10

D1 3.50

D2 2.65 2.70 2.75

E 4.90 5.00 5.10

E1 3.50

E2 2.65 2.70 2.75

e0.50

L0.35 0.45

L1 0.075

ddd 0.100

8/27 Doc ID 022239 Rev 1

Page 9

STM7007 Device pinout and package

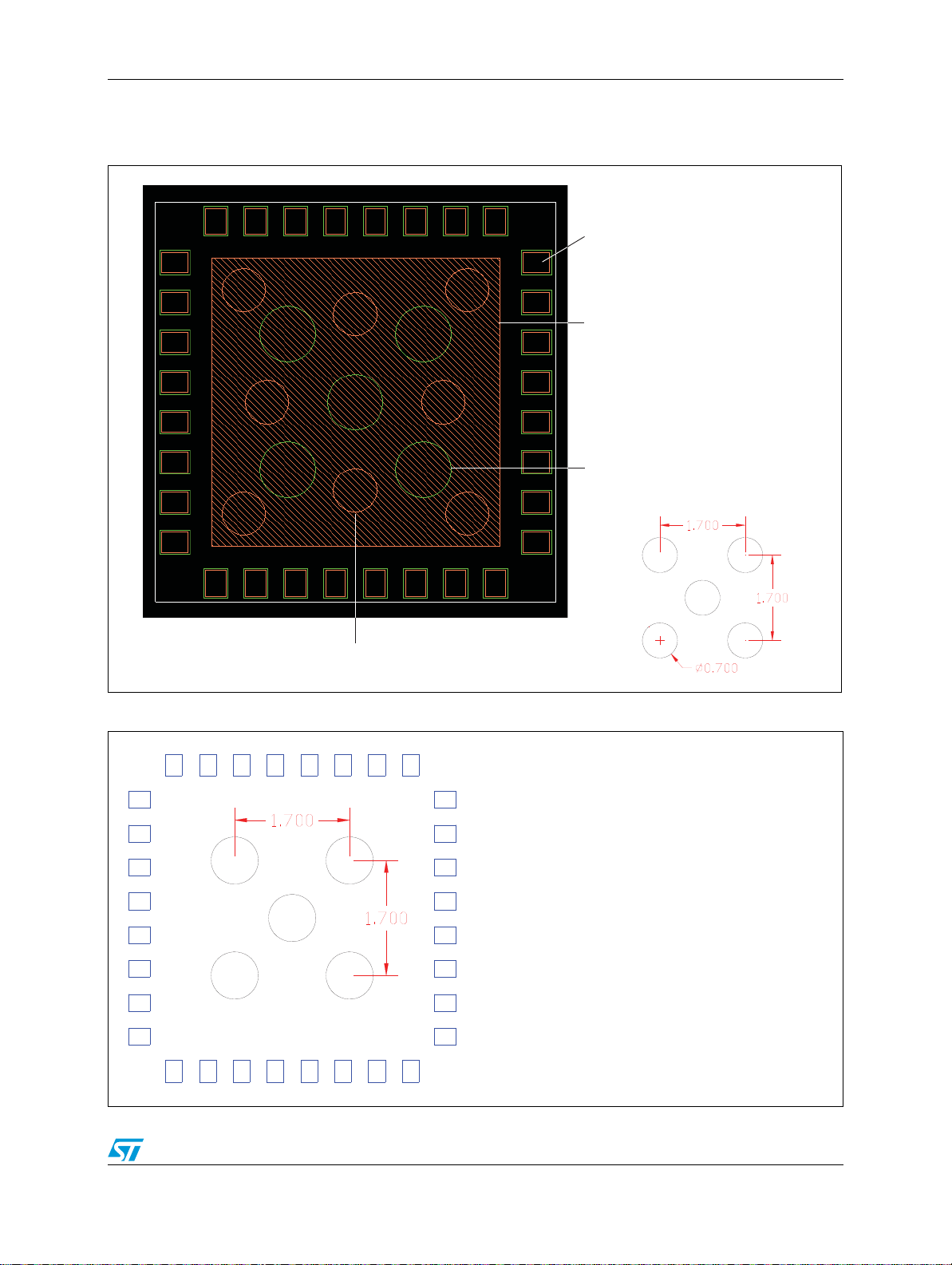

GND VIA (8)

PCB_Metal: 250 x 325 µm

(1 to 1 ratio to package pad)

PCB_Solder Mask Opening: 300 x 375 µm

GND Pad

PCB Metal: 3600 x 3600 µm

ePad Soldering Area (5)

PCB_Solder Mask Opening: 700 µm dia.

Stencil thickness: 4 mils

Land aperture: 250 x 325 µm (1 to 1 ratio)

ePad soldering aperture: 750 u dia. (slight increase)

Thicker stencil option

Stencil thickness: 5 mils

Land aperture: 275 x 357 µm (10% increase)

ePad soldering aperture: 800 µm dia.

For a thicker stencil, slightly increase the aperture size

for robust solder paste release

(increase area ratio:

area of pad / area of aperture wall).

1.2.2 Recommended footprint

Figure 2. PCB layout recommendation

Figure 3. Stencil layout recommendation

Doc ID 022239 Rev 1 9/27

Page 10

Device pinout and package STM7007

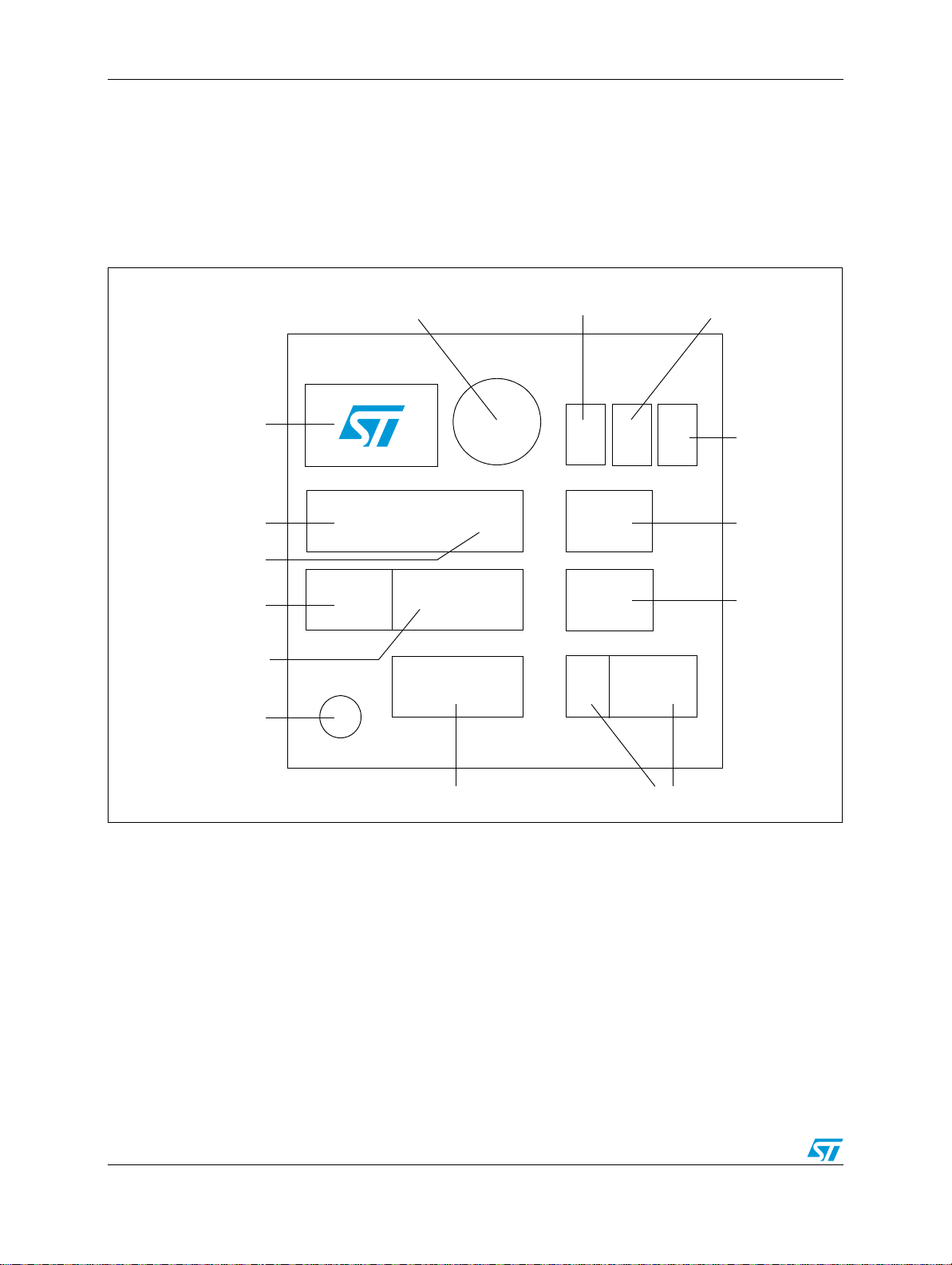

Assembly date (y/ww)

ST logo

2nd level interconnect (e2)

(an ECOPACK

®

parameter)

ECOPACK

®

grade

Metal revision #

(n of N.n)

Assembly sub lot

Diffusion plant

Device base number

Country of origin

Assembly plant

Back-end sequence

Orientation dot

n

7007N

Full-layer revision #

(N of N.n)

PCI GEN1 or GEN2

(1 or 2)

1.2.3 Markings

Device base number: 7007 (four digits)

Device revision number: N.n

N = Full-layer revision number (one digit)

n = Metal revision number (one digit)

Figure 4. Device markings (package face: top)

10/27 Doc ID 022239 Rev 1

In order to meet environmental requirements, ST offers these devices in different grades of

ECOPACK

specifications, grade definitions and product status are available at:

ECOPACK® is an ST trademark.

®

packages, depending on their level of environmental compliance. ECOPACK®

www.st.com.

Page 11

STM7007 Device pinout and package

1.2.4 Recommended land pad layout and solder reflow profile

Pay special attention to the traces connecting to the metal pads on the board. Trace

cracking can occur during normal handling of the board. This trace cracking usually occurs

at the edge of the solder mask opening, around the metal pad.

To avoid this mode of failure, make the trace under the solder mask edge wider than the rest

of the trace, as shown in

connection, the wider part of the trace might need to be as wide as 50 to 75% of the metal

pad width.

Figure 5. Wider trace connection to avoid cracking

Figure 5. Depending on the reliability requirements of the

Doc ID 022239 Rev 1 11/27

Page 12

Device pinout and package STM7007

Solder flow profile

Reflow profile and peak temperature have a strong influence on void formation. Follow the

profile recommendation of the paste suppliers, because this is specific to the requirements

of flux formation. The following two profiles can serve as reference for fine tuning the final

profile that works for your application.

Figure 6. SnPb solder flow profile

Figure 7. Pb-free solder flow profile

12/27 Doc ID 022239 Rev 1

Page 13

STM7007 Device pinout and package

1.2.5 Rework guidelines

Because solder joints are not fully exposed with QFN packages, any touch-up is limited. For

defects underneath the package, the whole package must be removed. Because reflow of

adjacent parts is not desirable during rework, the proximity may complicate the rework

process. Because of the product-dependent complexities, the following provides only a

guideline and a starting point for the development of a successful rework process for this

package.

The rework process comprises the following steps:

1. Component removal

The first step in removal of the component is the reflow of solder joints attaching the

component to the PCB board. Ideally the reflow profile for part removal and attachment

should be the same, but this is not always possible.

– Heat the board from the top side of the component.

– Use a special nozzle to direct the heating in the component area.

– Minimize the heating of adjacent components.

– Start with an air velocity of 15 to 20 liters per minute.

– Avoid excess heating and pad liftoff.

2. Site redress

After removing the component, clean the site properly.

– Use de-soldering braid to remove excess solder.

– Once the residual solder is removed, clean the lands with solvent. The solvent is

usually specific to the type of paste used in the original assembly.

3. Solder paste printing

To achieve a uniform and precise deposition, use a miniature stencil specific to the

component.

Avoid tinning the lands, because the amount of solder applied to the lands cannot be

controlled.

4. Component placement and attachment

Although this type of package does display self-centering abilities, use care in its

placement.

Ideally, the reflow profile for part removal and attachment should be the same, but this

is not always possible.

Heat the board from the top side of the component.

Doc ID 022239 Rev 1 13/27

Page 14

Electrical characteristics STM7007

2 Electrical characteristics

Note: The values in this section are preliminary, and subject to change.

Recommended operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Environment maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Power dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

DC electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

PCI, miscellaneous 3.3V interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

PHY 1.2V and 2.5V interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

AC electrical specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Differential interface electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.1 Recommended operating conditions

Note: Operation beyond recommended conditions is neither recommended nor guaranteed.

Table 5. Recommended operating conditions

Parameter Minimum Typical Maximum Units Notes

VDD1V2 1.14 1.2 1.26 V Core voltage

VDD2V5 2.375 2.5 2.625 V Antifuse charge-pump

VDD3V3 3.0 3.3 3.6 V I/O voltage for PCIe interface

VDDT1V2 1.14 1.2 1.26 V Transmit channel VDD

VDDR1V2 1.14 1.2 1.26 V Receive channel VDD

VDDPLL1V2 1.14 1.2 1.26 V PLL Core

VDDPLL2V5 2.375 2.5 2.625 V PLL

Ta 0 - 70 C Ambient temperature

14/27 Doc ID 022239 Rev 1

Page 15

STM7007 Electrical characteristics

2.2 Absolute maximum ratings

Caution: Stresses beyond those listed in Tab l e 6 may cause permanent damage to the device;

because these are stress ratings, functional operation is not implied at these or any other

conditions beyond those indicated in Table 5 on page 14. Exposure to the conditions listed

in Ta b le 6 for extended periods may affect device reliability.

Table 6. Absolute maximum ratings

Parameter Minimum(V) Maximum (V) Notes

VDD1V2 -0.5 1.5 Core voltage

VDD2V5 -0.5 3.0 Antifuse charge-pump

VDD3V3 -0.5 4.0 PCI IO Ring

VDDT1V2 -0.5 1.5 Transmit Channel VDD

VDDR1V2 -0.5 1.5 Receive channel VDD

VDDPLL1V2 -0.5 1.5 PLL core

VDDPLL2V5 -0.5 3.0 PLL

1. These are stress ratings, not functional operation ratings.

(1)

2.3 Environment maximum ratings

Table 7. Environment maximum ratings

Parameter Minimum Maximum Units Notes

ESD HBM — 2000 V Human body model

ESD CDM — 500 V Charged device model

Tstorage -40 150 C Storage temperature

2.4 Power dissipation

Table 8. Power dissipation typical mode

Current (mA)

Symbol/mode

Power rails (V)

3.3 2.5 1.2

L0 - AF programming 2 48 216 385.8

L0 - bulk 2 17 222 315.5

L0 - average 2 17 173.4 257.18

L0 - idle 2 17 168 250.7

L0s 2 17 139 215.9

L1 - CLKREQ# asserted 2 17 126 200.3 Clock power management disabled

L1 - CLKREQ# deasserted 1 3 20 34.8 Clock power management enabled

for

Total

(mW)

Notes

Average power, assuming 10% duty cycle

(0.1 * L0-Bulk + 0.9 * L0-Idle)

Doc ID 022239 Rev 1 15/27

Page 16

Electrical characteristics STM7007

2.5 DC electrical specifications

2.5.1 PCI, miscellaneous 3.3V interfaces

Note: 1 While I/O is in high impedance state

2 Does not include current flowing through termination resistors.

Table 9. 3.3V interface pin DC specifications

Parameter Symbol

Test

condition

Minimum Typical Maximum Units Notes

Input low level VIL -0.3 — 0.8 V

Input high level VIH 2.0 — 0.3 + VDD3V3 V

Output low level VOL 8 mA — — 0.4 V

Output high level VOH 8 mA VDD3V3 - 0.4 — — V

Input leakage

current

IIL 0<VIN<VDD3V3 < 1 (25

o

C) — 2 (125o C) μA1;2

Pin capacitance CPin 30 — pF

2.5.2 PHY 1.2V and 2.5V interfaces

Table 10. 1.2 and 2.5 PHY interface pin dc specifications

1.2V supply voltage range VDD1V2 1.14 1.2 1.26 V

Supply ripple (1 MHz to 3 GHz) VDD1V2ripple — — 50 mV (pk-pk)

2/5V supply voltage range VDD2V5 2.375 2.5 2.625 V

Supply ripple (1 GHz to 3 GHz) VDD2V5ripple — — 50 mV (pk-pk)

Maximum reference clock input jitter.

RJ component bounded at +/- 7 sigma

Parameter Symbol Minimum Typical Maximum Units

TJrefclk — — 30 ps (pk-pk)

16/27 Doc ID 022239 Rev 1

Page 17

STM7007 Electrical characteristics

2.6 AC electrical specification

Table 11. PCI Express clock input

Parameter Description Minimum Typical Maximum Units

PCIe pin RefClkp, RefClkn

Fref

The clock must be compliant

with the LVDS input driver level.

99.97 100 100.03 MHz

2.7 Differential interface electrical characteristics

Table 12. PCIe Interface driver and receiver characteristics

Description Symbol Minimum Maximum Units

Baud rate BR 2.5 Gbps

Unit interval UI 399.88 400.12 ps

Baud rate tolerance BRtol -300 300 ppm

Driver parameters

Differential peak to peak output voltage VTXpp 800 1200 mV

Minimum Tx eye width TTxeye 0.750 UI

Differential return loss TRLdiff 10 dB

Common mode return loss TRLcomm 6 dB

DC differential TX impedance ZTXdiff 85 115

Ω

Receiver parameters

Differential peak to peak voltage VRXpp 0.175 1.2 V

Minimum Rx eye width TRxeye 0.4 UI

Differential return loss TRLdiff 10 dB

Common mode return loss RRLcomm 6 dB

DC differential RX impedance ZRXdiff 85 115

DC single-ended input impedance ZRXDC 40 60

Ω

Ω

Doc ID 022239 Rev 1 17/27

Page 18

Electrical characteristics STM7007

2.7.1 PCIe test circuit

When measuring transmitter output parameters, C_TX is an optional portion of the

test/measurement load.

When used, the value of C_TX must be in the range of 75 to 200 nF. C_TX must not be used

when the test/measurement load is placed in the receiver package reference plane.

Figure 8. PCIe test circuit

18/27 Doc ID 022239 Rev 1

Page 19

STM7007 PCB layout guidelines

3 PCB layout guidelines

PCB Routing of RX/TX differential signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

PCB power and ground decoupling guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Power sequencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

The STM7007 uses high speed, low voltage differential signal pairs for the PCIe interface.

For a successful board design, follow the placement and layout guidelines in this chapter for

critical signals. Additional application notes may be provided for more detailed requirements.

The STM7007 is designed for optimized wiring for both a motherboard or PCI Express

mini-card form factor. Pin locations of the critical high speed LVDS signals are designed to

support a seamless flow from the STM7007 to the upstream host controller.

See also, Figure 1: Device pinout, top view.

Doc ID 022239 Rev 1 19/27

Page 20

PCB layout guidelines STM7007

3.1 PCB Routing of RX/TX differential signals

Ensure that the board design meets the following criteria:

● To avoid skew, make signal pair lengths equal from the ball to the connector:

TXP length = TXN length, and RXP length = RXN length

Lengths may differ if required to compensate for length mismatch due to poor package

substrate routing.

● Route signal pairs in parallel

● Ensure a 100Ω differential impedance trace:

– Route signals on an external layer with a full or partial ground plane layer as the

next internal adjacent layer. A partial ground plane must cover and exceed the

area below the TX and RX signal routing.

– Between the package pin and the PCI-Express connectors, ensure equal signal

trace interspace distance on each pair along the entire trace length.

● To avoid crosstalk:

– Separate TX and RX pairs a minimum of 5 mm, with no other signals interleaved.

– If several ports are routed, do not route the TX and RX traces of each port one

above the other on different layers.

● Do not use:

– Right angles or 45-degree trace angles; curved traces are preferred

–PCB vias

● Make all traces:

– As direct and straight as possible

– As short as possible. Signal line attenuation may be compensated for by selecting

a higher buffer swing, but if the largest swing is specified for the application, there

is no capacity for swing compensation.

● If components (such as AC coupling capacitors) are required on the high speed signal

traces, choose the smallest SMD packages and place them close to connectors.

● PCB trace crossing: if two differential traces from different ports must cross, cross the

traces at 90

º (perpendicular) to each other.

20/27 Doc ID 022239 Rev 1

Page 21

STM7007 PCB layout guidelines

3.1.1 Example: PCB impedance calculation

The PCB manufacturer should provide the board designer with all relevant parameters for

calculating trace impedance:

● trace thickness

● trace width

● PCB material, giving E

●

distance between layer 1 and internal layer 2

● coating thickness

Example calculation

Differential pair routed on top layer (1)

Trace width: 7 mils

Inter-space trace distance: 7 mils

r

Ground plane on internal layer 2, giving 5.9 mils dielectric height (E

= 3.9)

r

Trace thickness: 40 μm = 1.6 mils.

The calculator shown in Figure 9 gives a theoretical Z

= 101.6Ω.

diff

The PCB manufacturer double-checked with its tools and a more complex calculator, taking

into account the cross-section form of the top layer trace and the coating used. The PCB

manufacturer’s calculation gives a theoretical Z

= 100.2Ω.

diff

Figure 9. UltraZ calculation for differential pair impedance

Doc ID 022239 Rev 1 21/27

Page 22

PCB layout guidelines STM7007

3.3V I/O Rail

PCI Express Mini Card connector

For mobile form-factor: support for clock power management (CLKREQ#)

PCI Express connector

For ATX/mini-ATX form-factor: no support for clock power management (CLKREQ#)

PCI Express connector

REG

REG

1.2V RX

2.5V Antifuse

2.5V PLL

1.2V Core

1.2V PLL

1.2V TX

STM7007

3.2 PCB power and ground decoupling guidelines

Figure 10. Power map

All grounds: Connect directly to the PCB common ground plane

Power pins VDDR1V2 and VDDT1V2:

● Directly connect to the board’s 1.2V common supply dedicated to the PHY

● Decouple locally using:

– Murata Ferrite BLM15AG121 or equivalent

–1.0 μF ceramic capacitor

–0.1 μF RF capacitor (low series access resistor)

–0.01 μF RF capacitor (low series access resistor)

Power pin VDDPLL1V2:

● Directly connect to the board’s 1.2V common supply dedicated to the PHY

● Filter locally using:

–1Ω resistor

–10 μF ceramic capacitor

–0.1 μF RF capacitor (low series access resistor)

–0.01 μF RF capacitor (low series access resistor)

Power pin VDD2V5:

● Directly connect to the board‘s 2.5V common supply dedicated to the PHY

● Filter locally using:

–1Ω resistor

–1.0 μF ceramic capacitor

– 100 pF RF capacitor (low series access resistor)

– 10 nF RF capacitor (low series access resistor)

22/27 Doc ID 022239 Rev 1

Page 23

STM7007 PCB layout guidelines

Power pin VDDPLL2V5:

● Directly connect to the board’s 2.5V common supply dedicated to the PHY

● Filter locally using:

–30Ω resistor (±5% maximum tolerance)

–0.1 μF RF capacitor (low series access resistor)

–0.01 μF RF capacitor (low series access resistor)

3.3 Power sequencing

The STM7007 requires proper supply voltage and PGOOD (power good) sequencing for the

internal power-on-self-test and the antifuse blocks.

requirements.

The primary requirement for this device is PGOOD timing; PGOOD must provide a valid

status of the supply voltages during power sequencing.

The PGOOD signal:

● remains inactive until all voltages are within their required tolerance bands during

power up

● goes inactive before the supply voltages exit their required tolerance bands during

power down

The first indication that power-down sequencing is occurring, is the dropping of the 3v3

input supply voltage.

Figure 11 shows the timing and level

The PGOOD input pin and the PERST# input pin are logically combined internally to ensure

the proper reset state of the device during sequencing.

The 2v5 and 1v2 regulators must be sourced by the 3v3 supply such that the recommended

order of supply sequencing at power up is 1v2 first and then 2v5, and at power down 2v5

drops first, and then 1v2.

Because of an internal ESD protection diode, it is expected that when the 1v2 is applied to

the VDDPLL1V2 pin, the VDDPLL2V5 pin will source voltage at a level equal to the 1v2

voltage minus the forward voltage drop of a diode. To limit the diode current, and to provide

lowpass filtering of the PLL 2V5 power source, place a 30

Ω, 5% resistor between the

VDOPLL2V5 pin and the 2V5 source. Position the bypass capacitors close to the

VDDPLL2V5 pin (pad).

Doc ID 022239 Rev 1 23/27

Page 24

PCB layout guidelines STM7007

3v3 Input

1v2

2v5

PGOOD

Power Up

Power Down

950 mV Min.

100 mV

Max.

2.25 V Min.

10 us Min.

800 mV

Max.

2.0 V Min.

3.6 V Max.

3.60 V Max.

3.00 V Min.

2.25 V Min.

2.75 V Max.

800 mV

Max.

10 us Min.

100 mV

Max.

2.25 V Min.

3.00 V Min.

PERST#

(alternate)

1.32 V Max.

1.08 V Min.

10 us Min.

2.0 V Min.

3.6 V Max.

800 mV

Max.

3.00 V Min.

0.0 us Typ.

10 us Min.

800 mV

Max.

1.08 V Min.

Figure 11. Power up / down timing requirements

24/27 Doc ID 022239 Rev 1

Page 25

STM7007 Ordering information

4 Ordering information

When ordering parts, use the information below and contact your local STMicroelectronics

sales office, field applications engineer, or manufacturer’s representative for further

information.

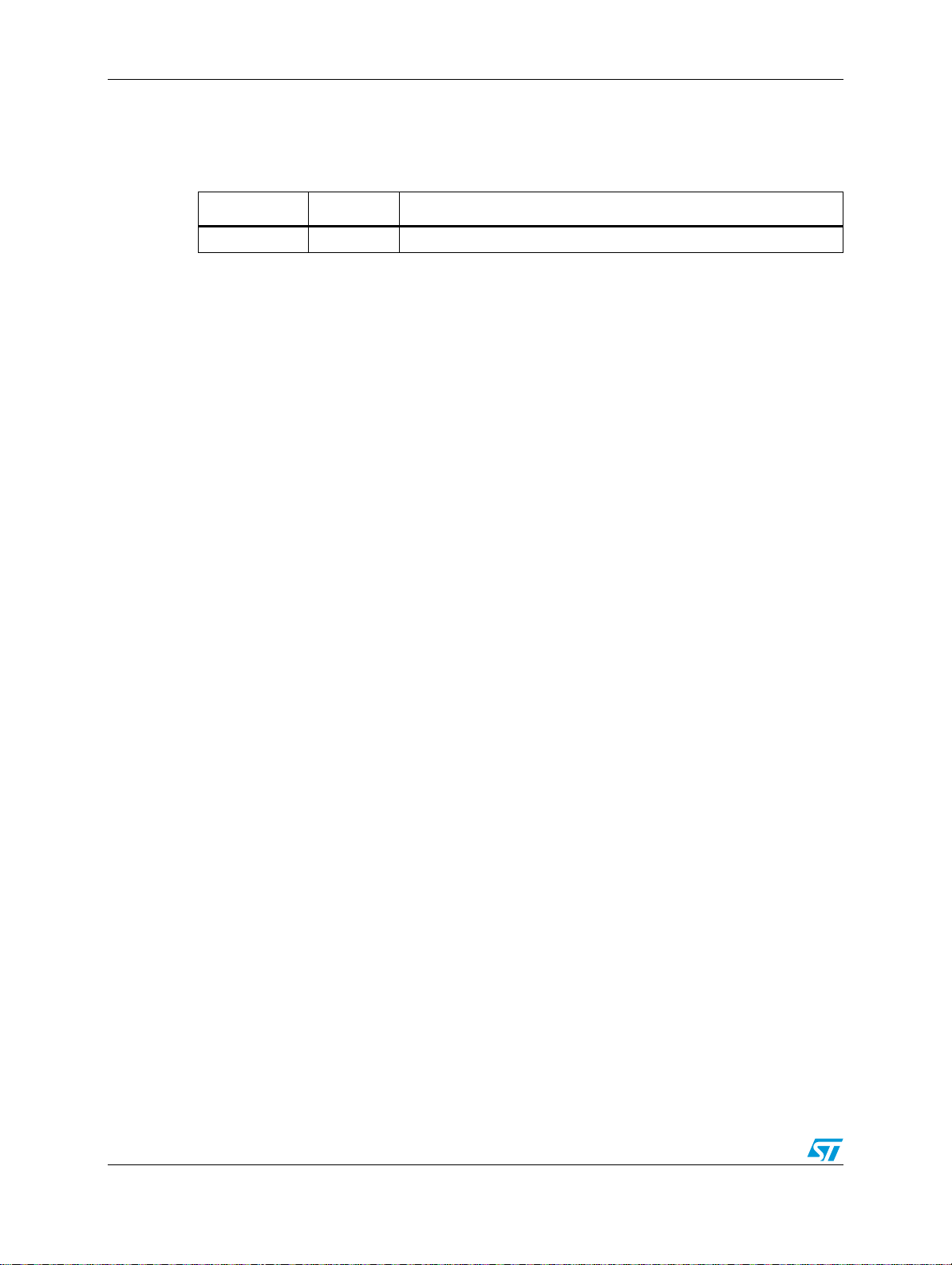

Table 13. STM7007 ordering information

Order code Package type Note

STM7007 32-Pin LGA 5x5 Commercial RoHS and halogen free package

Doc ID 022239 Rev 1 25/27

Page 26

Revision history STM7007

5 Revision history

Table 14. Document revision history

Date Revision Changes

06-Oct-2011 1 Initial release.

26/27 Doc ID 022239 Rev 1

Page 27

STM7007

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY TWO AUTHORIZED ST REPRESENTATIVES, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2011 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 022239 Rev 1 27/27

Loading...

Loading...