STM690A, STM692A, STM703

STM704, STM802, STM805, STM817/8/9

5 V supervisor with battery switchover

Features

■ 5 V operating voltage

■ NVRAM supervisor for external LPSRAM

■ Chip-enable gating (STM818 only) for external

LPSRAM (7 ns max prop delay)

■ RST and RST outputs

■ 200 ms (typ) t

■

Watchdog timer - 1.6 sec (typ)

■ Automatic battery switchover

■ Low battery supply current - 0.4 µA (typ)

■ Power-fail comparator (PFI/PFO)

■ Low supply current - 40 µA (typ)

■ Guaranteed RST (RST) assertion down to

V

= 1.0 V

CC

■ Operating temperature:

–40 °C to +85 °C (industrial grade)

■ RoHS compliance

– Lead-free components are compliant with

the RoHS directive

rec

8

1

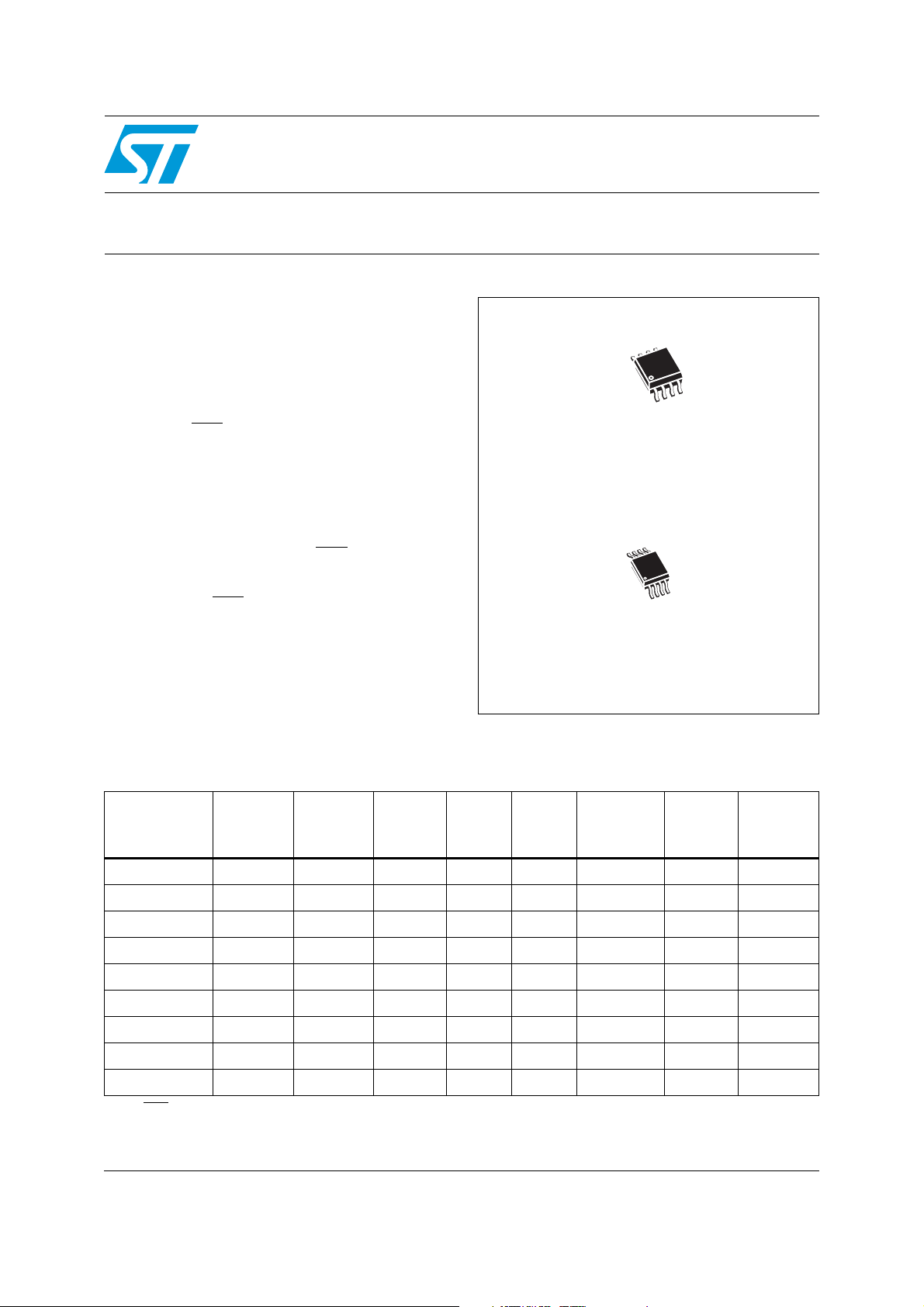

SO8 (M)

TSSOP8 3 x 3 (DS)

1. Contact local ST sales office for availability.

(1)

Table 1. Device summary

(1)

Battery

switch-

over

Power-fail

comparator

Chip-

enable

gating

Battery

freshness

seal

www.st.com

1

Manual

reset

input

Part number

STM690A ✓✓ ✓✓

STM692A ✓✓ ✓✓

STM703 ✓✓✓✓

STM704 ✓✓✓✓

STM802L/M ✓✓ ✓✓

STM805L ✓✓✓✓

STM817L/M ✓✓ ✓✓ ✓

STM818L/M ✓✓ ✓ ✓✓

STM819L/M ✓✓✓✓ ✓

1. All RST and RST outputs are push-pull.

August 2010 Doc ID 10522 Rev 10 1/43

Watchdog

input

Active-low

RST

(1)

Active-

high RST

Contents STM690A/692A/703/704/802/805/817/818/819

Contents

1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 Pin descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.1.1 MR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.1.2 WDI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.1.3 RST

1.1.4 RST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.1.5 V

1.1.6 V

1.1.7 E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1.8 E

1.1.9 PFI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1.10 PFO

OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

BAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

CON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.1 Reset output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.2 Push-button reset input (STM703/704/819) . . . . . . . . . . . . . . . . . . . . . . . 13

2.3 Watchdog input (NOT available on STM703/704/819) . . . . . . . . . . . . . . . 13

2.4 Backup battery switchover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.5 Chip-enable gating (STM818 only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.6 Chip-enable input (STM818 only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.7 Chip-enable output (STM818 only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.8 Power-fail input/output (NOT available on STM818) . . . . . . . . . . . . . . . . 16

2.9 Applications information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.10 Using a SuperCap™ as a backup power source . . . . . . . . . . . . . . . . . . . 17

2.11 Negative-going V

transients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

CC

2.12 Battery freshness seal (STM817/818/819) . . . . . . . . . . . . . . . . . . . . . . . . 19

3 Typical operating characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4 Maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5 DC and AC parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2/43 Doc ID 10522 Rev 10

STM690A/692A/703/704/802/805/817/818/819 Contents

6 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7 Part numbering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Doc ID 10522 Rev 10 3/43

List of tables STM690A/692A/703/704/802/805/817/818/819

List of tables

Table 1. Device summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table 2. Signal names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 3. Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 4. I/O status in battery backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 5. Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 6. Operating and AC measurement conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 7. DC and AC characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 8. SO8 - 8-lead plastic small outline, 150 mils body width, package mechanical data . . . . . . 38

Table 9. TSSOP8 - 8-lead, thin shrink small outline, 3 x 3 mm body size, mechanical data . . . . . . 39

Table 10. Ordering information scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 11. Marking description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 12. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4/43 Doc ID 10522 Rev 10

STM690A/692A/703/704/802/805/817/818/819 List of figures

List of figures

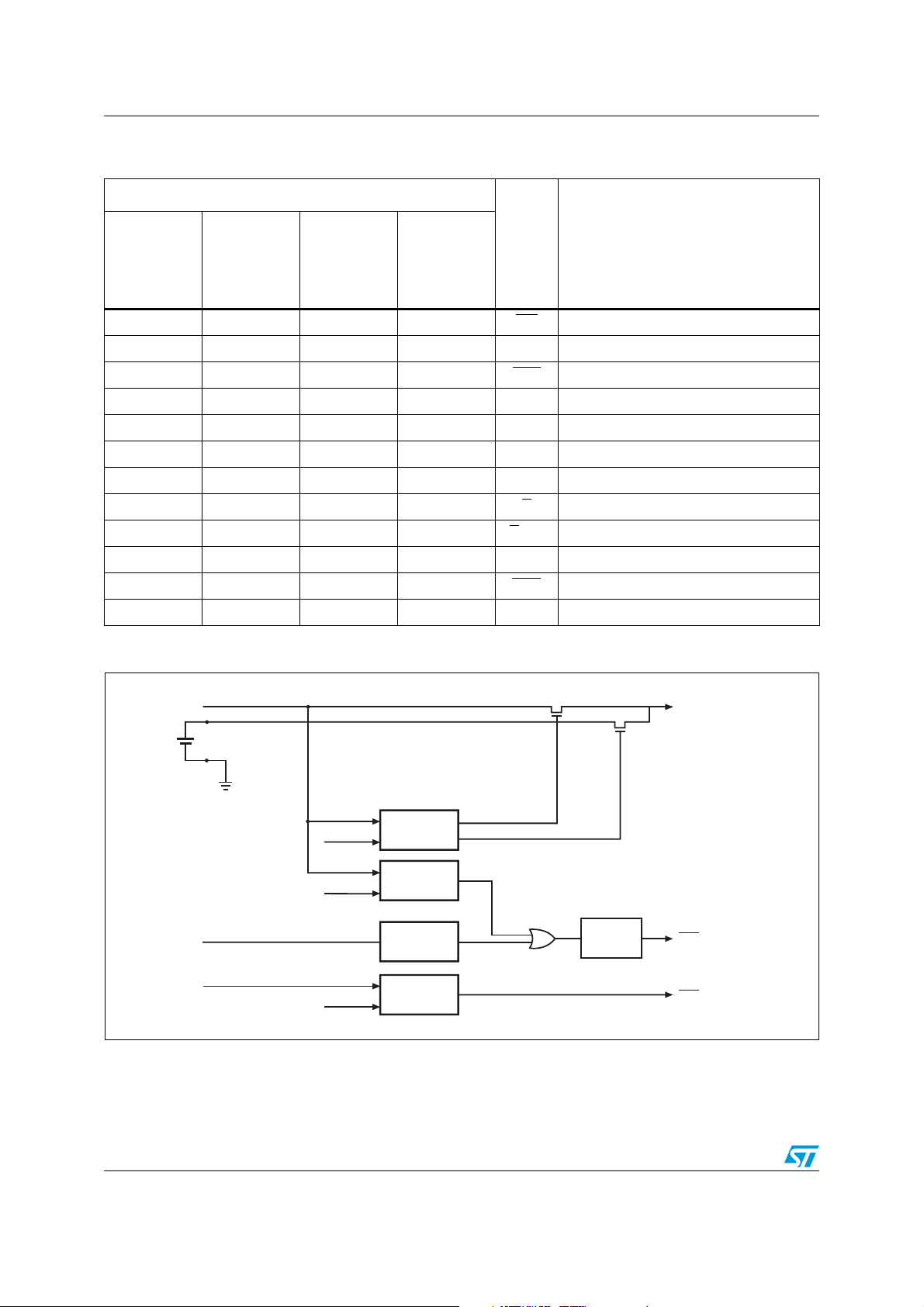

Figure 1. Logic diagram (STM690A/692/802/805/817) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 2. Logic diagram (STM703/704/819) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 3. Logic diagram (STM818) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 4. STM690A/692A/802/805/817 connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 5. STM703/704/819 connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 6. STM818 connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

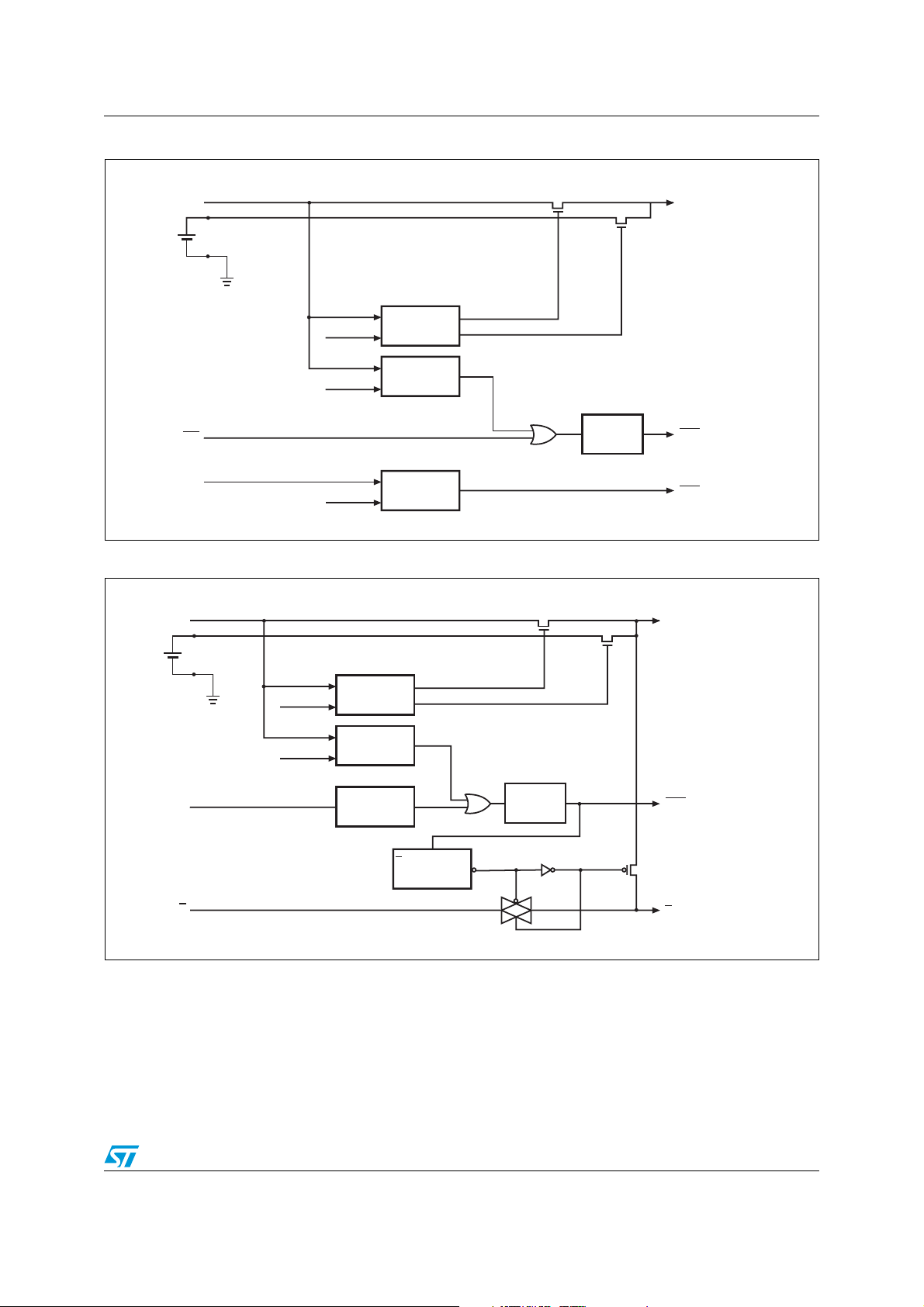

Figure 7. Block diagram (STM690A/692A/802/805/817) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 8. Block diagram (STM703/704/819) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 9. Block diagram (STM818) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

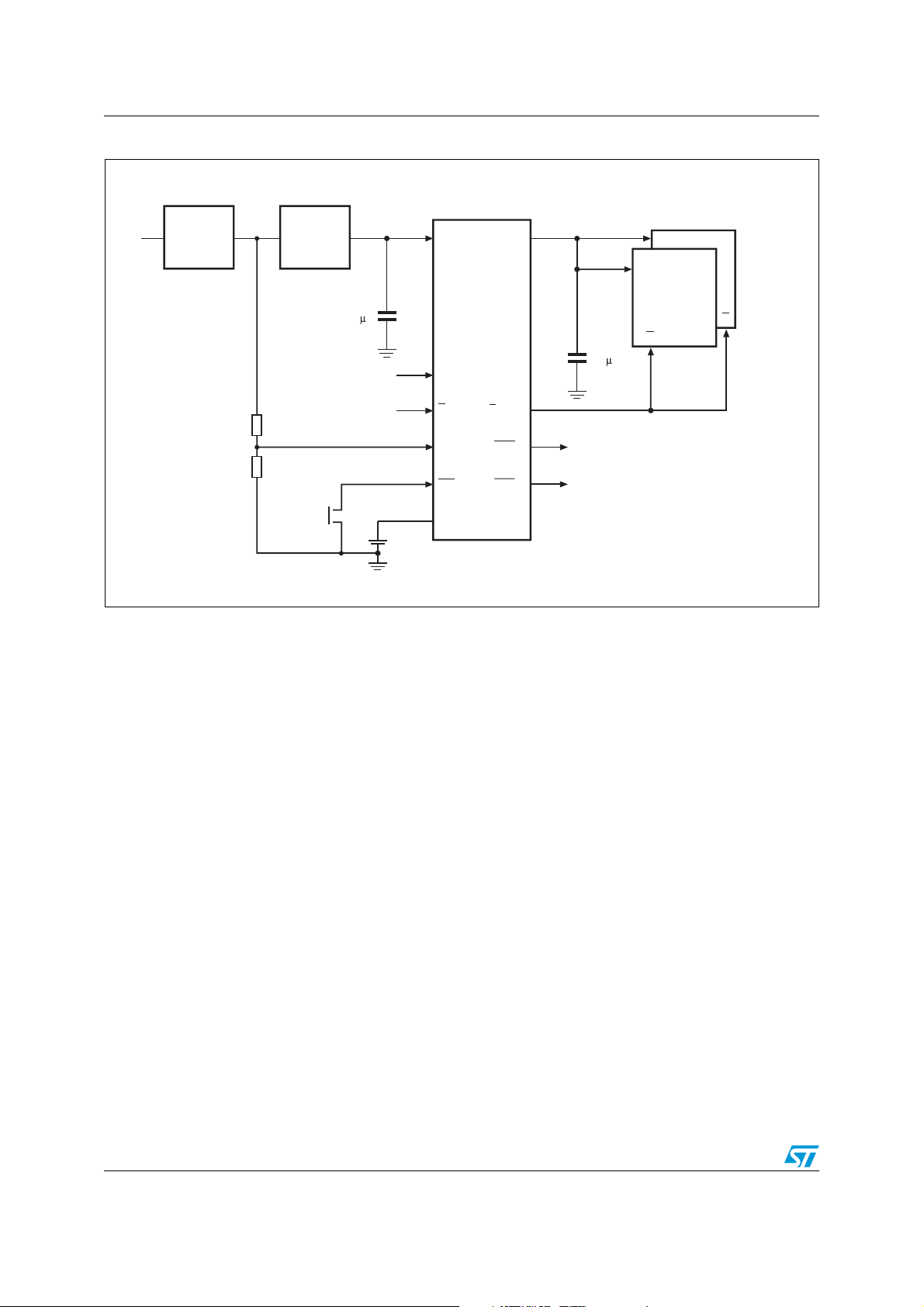

Figure 10. Hardware hookup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 11. Chip-enable gating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 12. Chip-enable waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 13. Power-fail comparator waveform (STM817/818/819) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 14. Power-fail comparator waveform (STM690A/692A/703/704/802/805) . . . . . . . . . . . . . . . . 17

Figure 15. Using a SuperCap™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 16. Freshness seal enable waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 17. V

Figure 18. V

Figure 19. Supply current vs. temperature (no load) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 20. Battery current vs. temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 21. V

Figure 22. Reset comparator propagation delay vs. temperature (other than STM817/818/819) . . . . 22

Figure 23. Reset comparator propagation delay vs. temperature (V

Figure 24. Power-up t

Figure 25. Normalized reset threshold vs. temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 26. Watchdog time-out period vs. temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 27. E

Figure 28. PFI to PFO

Figure 29. Output voltage vs. load current (V

Figure 30. Output voltage vs. load current (V

Figure 31. RST

Figure 32. RST output voltage vs. supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 33. RST

Figure 34. RST response time (assertion) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 35. Power-fail comparator response time (assertion) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 36.

Figure 37. Maximum transient duration vs. reset threshold overdrive . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 38. E

Figure 39. E

Figure 40. AC testing input/output waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 41. MR

Figure 42. Watchdog timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 43. SO8 - 8-lead plastic small outline, 150 mils body width, package mechanical drawing . . . 38

Figure 44. TSSOP8 - 8-lead, thin shrink small outline, 3 x 3 mm body size, outline . . . . . . . . . . . . . . 39

to V

CC

to V

BAT

threshold vs. temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

PFI

to E

CON

on-resistance vs. temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

OUT

on-resistance vs. temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

OUT

= 3.0 V; STM817/818/819) . 23

vs. temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

REC

BAT

on-resistance vs. temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

propagation delay vs. temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

= 5 V; V

CC

= 0 V; V

CC

= 2.8 V; TA = 25 °C) . . . . . . . . . . . . . . . 26

BAT

= 2.8 V; TA = 25 °C) . . . . . . . . . . . . . . . 26

BAT

output voltage vs. supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

response time (assertion) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Power-fail comparator response time (de-assertion) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

to E

to E

propagation delay vs. temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

CON

propagation delay test circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

CON

timing waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Doc ID 10522 Rev 10 5/43

Description STM690A/692A/703/704/802/805/817/818/819

1 Description

The STM690A/692A/703/704/802/805/817/818/819 supervisors are self-contained devices

which provide microprocessor supervisory functions with the ability to non-volatize and

write-protect external LPSRAM. A precision voltage reference and comparator monitors the

V

input for an out-of-tolerance condition. When an invalid V

CC

output (RST

) is forced low (or high in the case of RST). These devices also offer a watchdog

timer (except for STM703/704/819) as well as a power-fail comparator (except for STM818)

to provide the system with an early warning of impending power failure.

These devices are available in a standard 8-pin SOIC package or a space-saving 8-pin

TSSOP package.

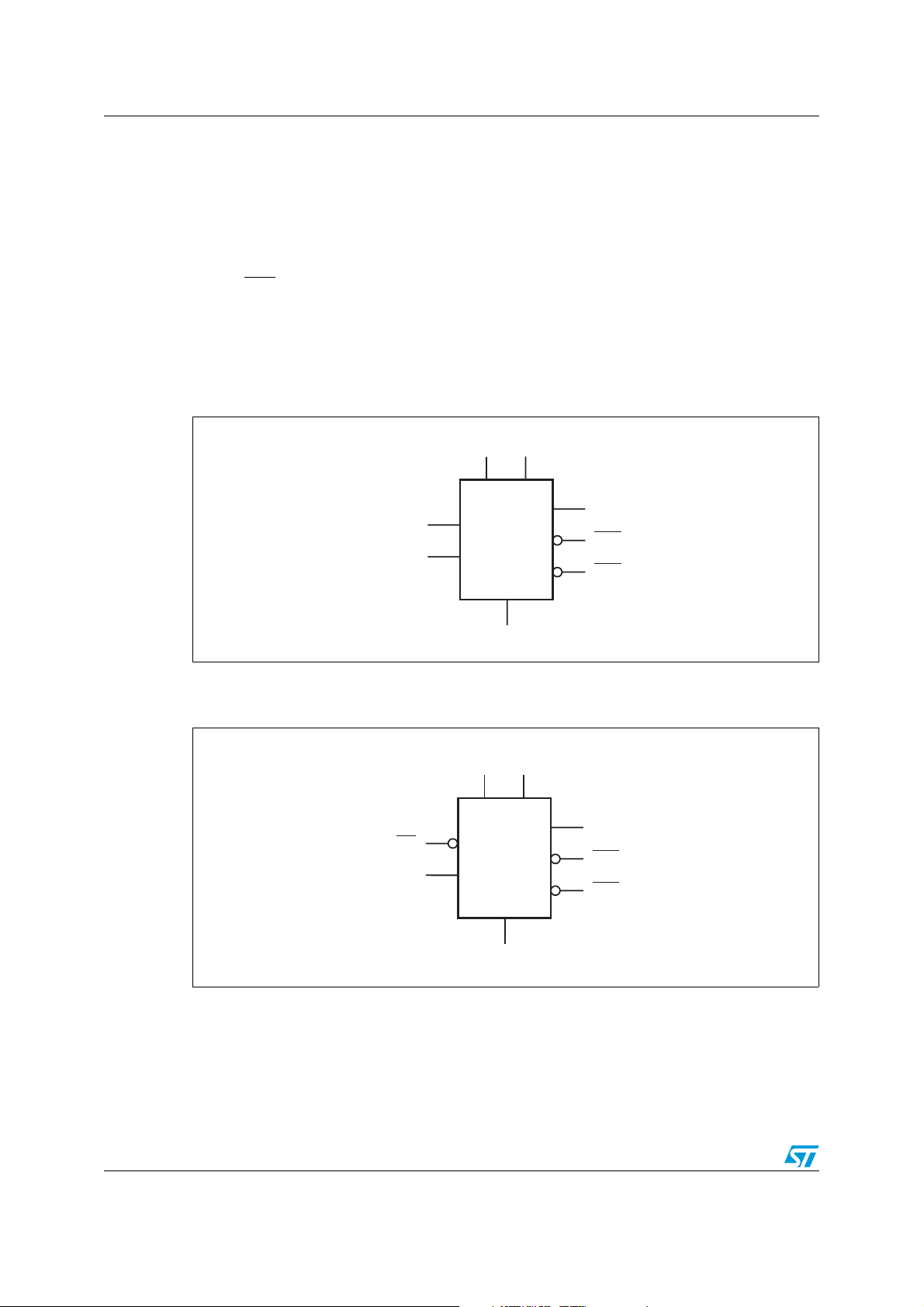

Figure 1. Logic diagram (STM690A/692/802/805/817)

VCCV

BAT

WDI

PFI

STM690A/

692A/802/

805/817

condition occurs, the reset

CC

V

OUT

RST(RST)

PFO

(1)

V

SS

1. For STM805, reset output is active-high.

Figure 2. Logic diagram (STM703/704/819)

VCCV

MR

PFI

STM703/

704/819

V

SS

BAT

V

OUT

RST

PFO

AI07894

AI07895

6/43 Doc ID 10522 Rev 10

STM690A/692A/703/704/802/805/817/818/819 Description

Figure 3. Logic diagram (STM818)

VCCV

BAT

V

WDI

STM818

E

V

SS

OUT

RST

E

CON

AI07896

Table 2. Signal names

MR Push-button reset input

WDI Watchdog input

RST

Active-low reset output

RST Active-high reset outpu

(1)

E

E

CON

V

OUT

V

V

(1)

CC

BAT

Chip-enable input

Conditioned chip-enable output

Supply voltage output

Supply voltage

Backup supply voltage

PFI Power-fail input

PFO Power-fail output

Ground

1. STM818

V

SS

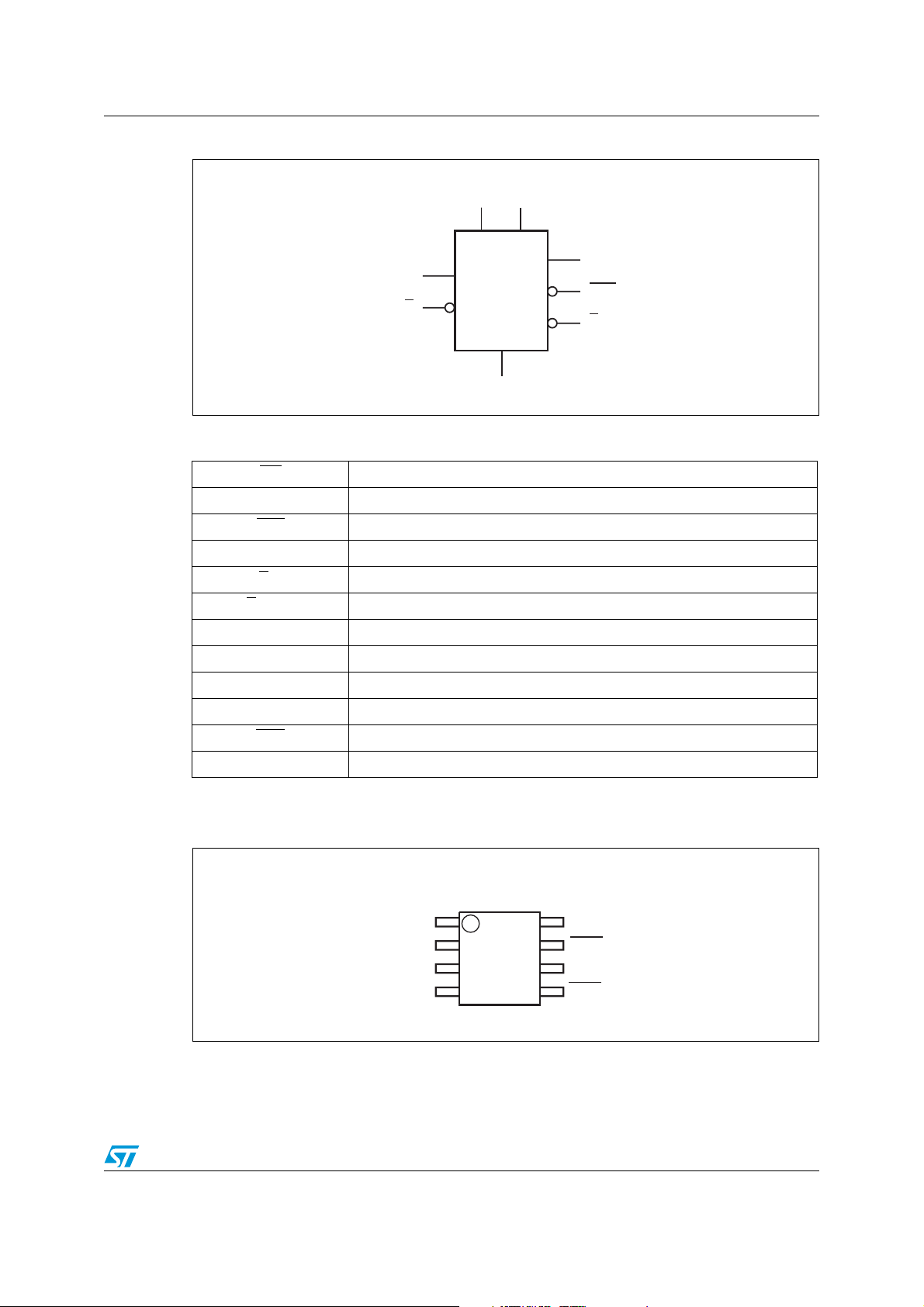

Figure 4. STM690A/692A/802/805/817 connections

SO8/TSSOP8

V

OUT

V

CC

V

SS

PFI

1

2

3

4

8

7

6

5

V

BAT

RST(RST)

WDI

PFO

(1)

AI07889

1. For STM805, reset output is active-high.

Doc ID 10522 Rev 10 7/43

Description STM690A/692A/703/704/802/805/817/818/819

Figure 5. STM703/704/819 connections

SO8/TSSOP8

V

OUT

V

CC

V

PFI

SS

1

2

3

4

V

BAT

8

RST

7

MR

6

PFO

5

AI07890

Figure 6. STM818 connections

SO8/TSSOP8

V

OUT

V

V

CC

SS

1

2

3

E

4

V

BAT

8

7

RST

WDI

6

E

5

CON

AI07892

1.1 Pin descriptions

1.1.1 MR

A logic low on MR asserts the reset output. Reset remains asserted as long as MR is low

and for t

driven from a TTL or CMOS logic line, or shorted to ground with a switch. Leave open if

unused.

1.1.2 WDI

If WDI remains high or low for 1.6 sec, the internal watchdog timer runs out and reset is

triggered. The internal watchdog timer clears while reset is asserted or when WDI sees a

rising or falling edge.

The watchdog function can be disabled by allowing the WDI pin to float.

1.1.3 RST

Pulses low for t

or when MR

threshold, the watchdog triggers a reset, or MR

1.1.4 RST

Pulses high for t

threshold or when MR

reset threshold, the watchdog triggers a reset, or MR

after MR returns high. This active-low input has an internal pull-up. It can be

rec

when triggered, and stays low whenever V

rec

is a logic low. It remains low for t

after either V

rec

is below the reset threshold

CC

rises above the reset

CC

goes from low to high.

when triggered, and stays high whenever VCC is above the reset

rec

is a logic high. It remains high for t

after either VCC falls below the

rec

goes from high to low.

8/43 Doc ID 10522 Rev 10

STM690A/692A/703/704/802/805/817/818/819 Description

1.1.5 V

OUT

When VCC is above the switchover voltage (VSO), V

channel MOSFET switch. When V

1.1.6 V

BAT

When VCC falls below VSO, V

hysteresis, V

used.

1.1.7 E

The input to the chip-enable gating circuit. Connect to ground if unused.

1.1.8 E

E

CON

CON

asserted, E

disabled mode, E

1.1.9 PFI

When PFI is less than V

otherwise, PFO

is connected to VCC through a P-

OUT reconnects to V

OUT

falls below VSO, V

CC

switches from V

. V

CC

may exceed VCC. Connect to V

BAT

CC

OUT

to V

connects to V

BAT

. When V

BAT

goes low only when E is low and reset is not asserted. If E

will remain low for 15 µs or until E goes high, whichever occurs first. In the

CON

is pulled up to V

CON

PFI

.

OUT

or when VCC falls below 2.4 V (or VSO), PFO goes low;

remains high. Connect to ground if unused.

.

OUT

rises above V

CC

is low when reset is

CON

if no battery is

CC

SO

+

1.1.10 PFO

When PFI is less than V

PFO

remains high. Leave open if unused. Output type is push-pull.

, or VCC falls below 2.4 V (or VSO), PFO goes low; otherwise,

PFI

Doc ID 10522 Rev 10 9/43

Description STM690A/692A/703/704/802/805/817/818/819

Table 3. Pin description

Pin

STM690A

STM818

STM692A

STM802

STM817

--6-MR

STM703

STM704

STM819

Name Function

STM805

Push-button reset input

6 6 - 6 WDI Watchdog input

777 -RSTActive-low reset output

- - - 7 RST Active-high reset output

1111V

2222V

8888V

4-- -E

5-- -E

Supply output for external LPSRAM

OUT

Supply voltage

CC

Backup battery input

BAT

Chip-enable input

Conditioned chip-enable output

CON

- 4 4 4 PFI Power-fail input

-555PFOPower-fail output (push-pull)

3333V

SS

Ground

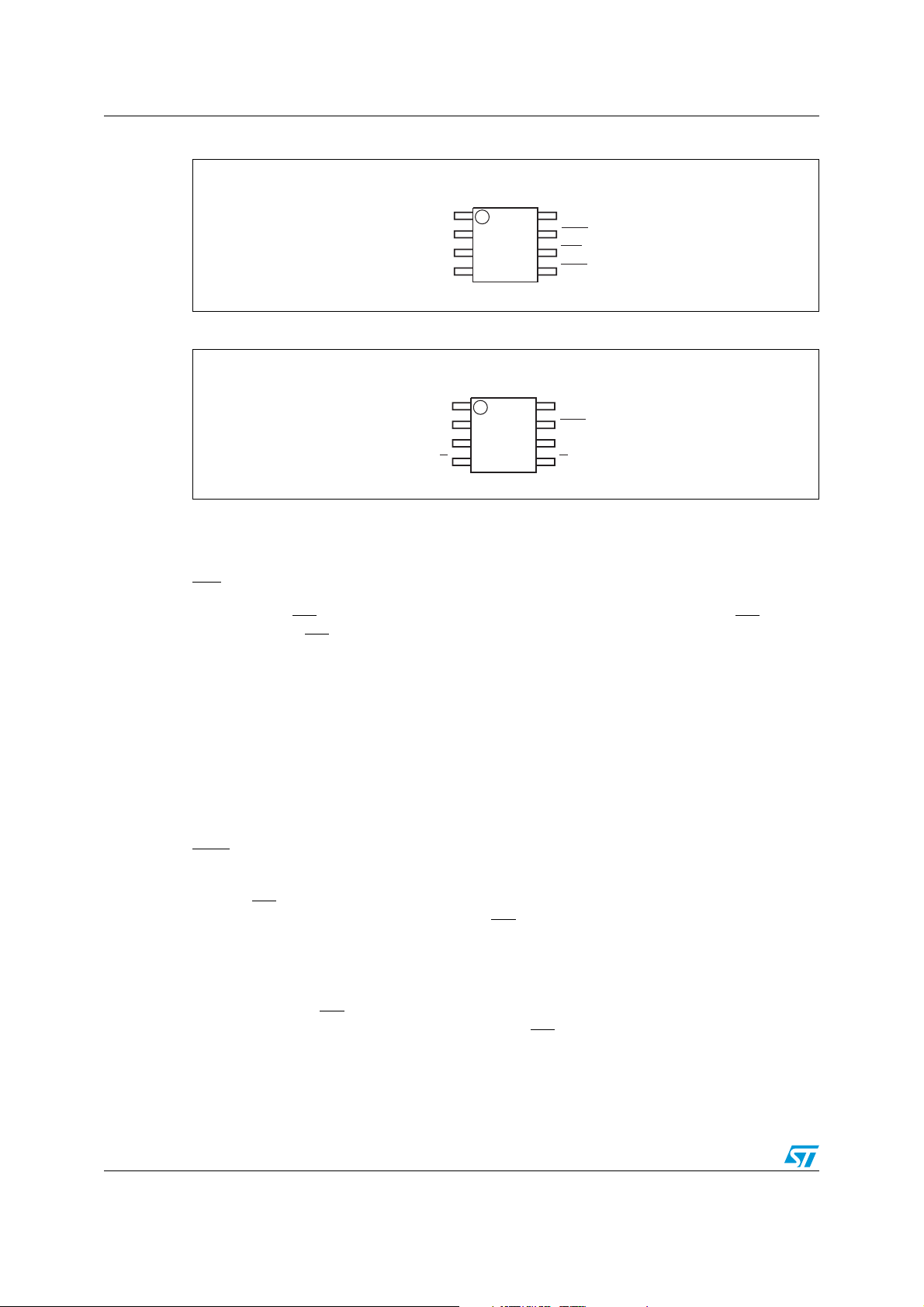

Figure 7. Block diagram (STM690A/692A/802/805/817)

V

CC

V

BAT

WDI

PFI

1. For STM805, reset output is active-high.

V

OUT

V

SO

V

RST

V

PFI

COMPARE

COMPARE

WATCHDOG

TIMER

COMPARE

t

rec

Generator

RST(RST)

PFO

(1)

AI07897

10/43 Doc ID 10522 Rev 10

STM690A/692A/703/704/802/805/817/818/819 Description

Figure 8. Block diagram (STM703/704/819)

V

CC

V

BAT

V

SO

V

RST

MR

PFI

V

PFI

Figure 9. Block diagram (STM818)

V

CC

COMPARE

COMPARE

COMPARE

t

rec

Generator

V

OUT

RST

PFO

AI07898

V

OUT

WDI

V

BAT

V

SO

V

RST

E

COMPARE

COMPARE

WATCHDOG

TIMER

E

OUTPUT

CON

CONTROL

t

rec

Generator

RST

E

CON

AI07899a

Doc ID 10522 Rev 10 11/43

Description STM690A/692A/703/704/802/805/817/818/819

Figure 10. Hardware hookup

Unregulated

Voltage

Regulator

V

IN

From Microprocessor

R1

R2

1. For STM690A/692A/802/805/817/818.

2. For STM818 only.

3. Not available on STM818.

4. For STM703/704/819.

5. Active high on STM805.

V

CC

0.1

Push-Button

V

CC

LPSRAM

V

CC

E

V

CC

V

OUT

STM690A/692A/

F

703/704/802/805/

817/818/819

E

0.1 F

(1)

WDI

E

PFI

MR

V

(2)

(3)

(4)

BAT

(2)

E

CON

(3)

PFO

(5)

RST To Microprocessor Reset

To Microprocessor NMI

AI07893

12/43 Doc ID 10522 Rev 10

STM690A/692A/703/704/802/805/817/818/819 Operation

2 Operation

2.1 Reset output

The STM690A/692A/703/704/802/805/817/818/819 Supervisor asserts a reset signal to the

MCU whenever V

when the Push-button Reset Input (MR

(logic high for STM805) for 0V < V

battery, RST

is guaranteed valid down to VCC =1 V.

goes below the reset threshold (V

CC

) is taken low. RST is guaranteed to be a logic low

CC

< V

if VBAT is greater than 1 V. Without a backup

RST

, a watchdog time-out occurs, or

RST)

During power-up, once V

the reset time-out period, t

If V

drops below the reset threshold, RST goes low. Each time RST is asserted, it stays

CC

low for at least the reset time-out period (t

the internal timer clears. The reset timer starts when V

exceeds the reset threshold an internal timer keeps RST low for

CC

. After this interval RST returns high.

rec

). Any time VCC goes below the reset threshold

rec

returns above the reset threshold.

CC

2.2 Push-button reset input (STM703/704/819)

A logic low on MR asserts reset. Reset remains asserted while MR is low, and for t

Figure 41) after it returns high. The MR

input has an internal 40 kΩ pull-up resistor, allowing

it to be left open if not used. This input can be driven with TTL/CMOS-logic levels or with

open-drain/collector outputs. Connect a normally open momentary switch from MR

to create a manual reset function; external debounce circuitry is not required. If MR

from long cables or the device is used in a noisy environment, connect a 0.1 µF capacitor

from MR

to GND to provide additional noise immunity. MR may float, or be tied to VCC when

not used.

2.3 Watchdog input (NOT available on STM703/704/819)

The watchdog timer can be used to detect an out-of-control MCU. If the MCU does not

toggle the Watchdog Input (WDI) within t

watchdog timer is cleared by either:

1. a reset pulse, or

2. by toggling WDI (high-to-low or low-to-high), which can detect pulses as short as 50ns.

If WDI is tied high or low, a reset pulse is triggered every 1.8 sec (t

The timer remains cleared and does not count for as long as reset is asserted. As soon as

reset is released, the timer starts counting (see Figure 42).

(1.6 sec typ), the reset is asserted. The internal

WD

+ t

WD

rec

).

(see

rec

to GND

is driven

Note: 1 The watchdog function may be disabled by floating WDI or tri-stating the driver connected to

WDI. When tri-stated or disconnected, the maximum allowable leakage current is 10 µA and

the maximum allowable load capacitance is 200 pF.

2 Input pulses less than 20 ns will be ignored.

Doc ID 10522 Rev 10 13/43

Operation STM690A/692A/703/704/802/805/817/818/819

2.4 Backup battery switchover

In the event of a power failure, it may be necessary to preserve the contents of external

SRAM through V

automatically switch the SRAM to the backup supply when V

Note: When the battery is first connected without V

immediately provide backup battery voltage on V

switchover operate as described below. This mode allows a battery to be attached during

manufacturing but not used until after the system has been activated for the first time. As a

result, no battery power is consumed by the device during storage and shipment. For the

STM81x devices, the battery freshness seal can be initiated again by following the

procedure outlined in Section 2.12. If the backup battery is not used, connect both V

V

to V

OUT

Whenever V

CC

.

CC

100 Ω switch. V

be powered by V

battery life.

. With a backup battery installed with voltage V

OUT

power applied, the device does not

CC

falls below the switchover voltage, VSO, V

is the lesser of V

SO

for as long as possible before switching over thereby maximizing the

CC

BAT

and V

RST

. Only after VCC exceeds V

OUT

OUT

. Choosing the lesser allows the device to

falls.

CC

is connected to V

, the devices

BAT

will the

RST

through a

BAT

BAT

and

Assuming V

before V

OUT

external SRAMs. When V

point. V

OUT

> 2.0 V, switchover at VSO ensures that battery backup mode is entered

BAT

gets too close to the 2.0 V minimum required to reliably retain data in most

recovers, hysteresis is used to avoid oscillation around the VSO

CC

is connected to VCC through a 3 Ω PMOS power switch.

Note: The backup battery may be removed while V

decoupled (0.1 µF typ), without danger of triggering a reset.

Table 4. I/O status in battery backup

V

OUT

V

CC

PFI Disabled

PFO

E

E

CON

WDI Watchdog timer is disabled

MR

RST

RST Logic high

V

BAT

Connected to V

Disconnected from V

Logic low

High impedance

Logic high

Disabled

Logic low

Connected to V

through internal switch

BAT

OUT

OUT

is valid, assuming V

CC

is adequately

BAT

14/43 Doc ID 10522 Rev 10

STM690A/692A/703/704/802/805/817/818/819 Operation

2.5 Chip-enable gating (STM818 only)

Internal gating of the chip-enable (E) signal prevents erroneous data from corrupting the

external CMOS RAM in the event of an undervoltage condition. The STM818 uses a series

transmission gate from E

asserted), the E

transmission gate is enabled and passes all E transitions. When reset is

to E

(see Figure 11). During normal operation (reset not

CON

asserted, this path becomes disabled, preventing erroneous data from corrupting the CMOS

RAM. The short propagation delay from E

most µPs. If E

is low when reset asserts, E

goes high) to permit the current WRITE cycle to complete. Connect E

to E

CON

enables the STM818 to be used with

CON

remains low for typically 15 µs (or until E

to VSS if unused.

2.6 Chip-enable input (STM818 only)

The chip-enable transmission gate is disabled and E is high impedance (disabled mode)

while reset is asserted. During a power-down sequence when V

threshold, the chip-enable transmission gate disables and E

impedance if the voltage at E

is high. If E is low when reset asserts, the chip-enable

transmission gate will disable 15 µs after reset asserts (see Figure 12). This permits the

current WRITE cycle to complete during power-down.

passes the reset

CC

immediately becomes high

Any time a reset is generated, the chip-enable transmission gate remains disabled and E

remains high impedance (regardless of E

activity) for the reset time-out period. When the

chip-enable transmission gate is enabled, the impedance of E

series with the load at E

gate depends on V

on E

. The chip-enable propagation delay is production tested from the 50% point on E to

CON

the 50% point on E

CC

CON

. The propagation delay through the chip-enable transmission

CON

, the source impedance of the drive connected to E, and the loading

using a 50 Ω driver and a 50 pF load capacitance (see Figure 39).

For minimum propagation delay, minimize the capacitive load at E

impedance driver.

2.7 Chip-enable output (STM818 only)

When the chip-enable transmission gate is enabled, the impedance of E

a 40 Ω resistor in series with the source driving E

gate is off and an active pull-up connects E

off when the transmission gate is enabled.

Figure 11. Chip-enable gating

V

CC

V

RST

COMPARE

. In the disabled mode, the transmission

to V

CON

Generator

appears as a 40 Ω resistor in

and use a low-output

CON

is equivalent to

CON

(see Figure 11). This pull-up turns

OUT

t

rec

RST

V

OUT

E

OUTPUT

CON

CONTROL

E

Doc ID 10522 Rev 10 15/43

E

CON

AI08802

Operation STM690A/692A/703/704/802/805/817/818/819

Figure 12. Chip-enable waveform

V

E

RST

E

CC

CON

V

RST

V

BAT

t

rec

XX XX

t

rec15µs

2.8 Power-fail input/output (NOT available on STM818)

The Power-fail Input (PFI) is compared to an internal reference voltage (independent from

the V

Output (PFO

signal a failing power supply. Typically PFI is connected through an external voltage divider

(see Figure 12) to either the unregulated DC input (if it is available) or the regulated output

of the V

below V

STM690A/692A/703/704/802/805/817/818/819 Supervisor or before the microprocessor

drops below the minimum operating voltage. This provides several milliseconds of advanced

warning that power is about to fail.

comparator). If PFI is less than the power-fail threshold (V

RST

), the Power-Fail

PFI

) will go low. This function is intended for use as an undervoltage detector to

regulator. The voltage divider can be set up such that the voltage at PFI falls

CC

several milliseconds before the regulated VCC input to the

PFI

AI08803b

During battery backup, the power-fail comparator turns off and PFO

(see Figure 13 below and Figure 14). This occurs after V

When power returns, PFO

WRITE protect time (t

PFO

follows PFI. If the comparator is unused, PFI should be connected to VSS and PFO left

unconnected. PFO

may be connected to MR on the STM703/704/818 so that a low voltage

is forced high (STM817/819 only), irrespective of V

). At the end of this time, the power-fail comparator is enabled and

rec

on PFI will generate a reset output.

2.9 Applications information

These supervisor circuits are not short-circuit protected. Shorting V

excluding power-up transients such as charging a decoupling capacitor - destroys the

device. Decouple both V

the device as possible.

CC

and V

BAT

goes (or remains) low

drops below 2.4 V (or VSO).

CC

to ground -

OUT

for the

PFI

pins to ground by placing 0.1 µF capacitors as close to

16/43 Doc ID 10522 Rev 10

STM690A/692A/703/704/802/805/817/818/819 Operation

Figure 13. Power-fail comparator waveform (STM817/818/819)

V

CC

V

RST

VSO (or 2.4V)

t

PFO

(STM817/819)

PFO follows PFI PFO follows PFI

rec

RST

E

CON

RST to E

(STM818)

Delay (STM818)

CON

Figure 14. Power-fail comparator waveform (STM690A/692A/703/704/802/805)

V

CC

V

RST

2.4V (or V

PFO

RST

)

SO

PFO follows PFI PFO follows PFI

t

rec

AI08804a

AI08832a

2.10 Using a SuperCap™ as a backup power source

SuperCaps™ are capacitors with extremely high capacitance values (e.g., 0.47 F) for their

size. Figure 15 shows how to use a SuperCap as a backup power source. The SuperCap

may be connected through a diode to the 5 V supply. Since V

is above the reset threshold, there are no special precautions for using these supervisors

with a SuperCap.

Doc ID 10522 Rev 10 17/43

can exceed VCC while VCC

BAT

Operation STM690A/692A/703/704/802/805/817/818/819

2.11 Negative-going VCC transients

The STM690A/692A/703/704/802/805/817/818/819 Supervisors are relatively immune to

negative-going V

reset comparator overdrive (for which the STM690A/692A/703/704/802/805/817/818/819

will NOT generate a reset pulse). The graph was generated using a negative pulse applied

to V

, starting at V

CC

indicated (comparator overdrive). The graph indicates the maximum pulse width a negative

V

transient can have without causing a reset pulse. As the magnitude of the transient

CC

increases (further below the threshold), the maximum allowable pulse width decreases. Any

combination of duration and overdrive which lies under the curve will NOT generate a reset

signal. Typically, a V

or less will not cause a reset pulse. A 0.1 µF bypass capacitor mounted as close as possible

to the V

pin provides additional transient immunity.

CC

transients (glitches). Figure 37 shows typical transient duration versus

CC

+ 0.3 V and ending below the reset threshold by the magnitude

RST

transient that goes 100 mV below the reset threshold and lasts 40 µs

CC

18/43 Doc ID 10522 Rev 10

STM690A/692A/703/704/802/805/817/818/819 Operation

2.12 Battery freshness seal (STM817/818/819)

The battery freshness seal disconnects the backup battery from internal circuitry and V

until it is needed. This allows an OEM to ensure that the backup battery connected to V

OUT

BAT

will be fresh when the final product is put to use. To enable the freshness seal:

1. Connect a battery to V

BAT

2. Ground PFO

3. Bring VCC above the reset threshold and hold it there until reset is deasserted following

the reset timeout period and

4. Bring V

Use the same procedure for the STM818, but ground E

down again (Figure 16)

CC

instead of PFO. Once the

CON

battery freshness seal is enabled (disconnecting the backup battery from internal circuitry

and anything connected to V

), it remains enabled until VCC is brought above V

OUT

RST

.

Figure 15. Using a SuperCap™

5V

V

V

CC

STMXXX

BAT

GND

V

OUT

RST

To external SRAM

To µP

Figure 16. Freshness seal enable waveform

V

RST

V

CC

t

rec

RST

(Externally held at 0V)

E

CON

(STM818)

(Externally held at 0V)

PFO

(STM817/819)

out state latched

E

CON

at 1/2 t

,

Freshness

rec

Seal enabled

PFO out state latched

at 1/2 t

,

Freshness

rec

Seal Enabled

AI08805

AI08806

Doc ID 10522 Rev 10 19/43

Typical operating characteristics STM690A/692A/703/704/802/805/817/818/819

3 Typical operating characteristics

Note: Typical values are at TA = 25 °C.

Figure 17. V

on-resistance ( )

OUT

to V

CC

V

Figure 18. V

to V

CC

5.0

4.0

3.0

2.0

1.0

0.0

–40 –20

to V

BAT

on-resistance vs. temperature

OUT

020406080 100 120

Temperature (° C)

on-resistance vs. temperature

OUT

VCC = 3.0V

VCC = 4.5V

VCC = 5.5V

AI10498

160

)

140

120

100

80

on-resistance (

OUT

60

to V

40

BAT

20

V

0

–40 –20 0 20 40 60 80 100 120

Temperature (° C)

20/43 Doc ID 10522 Rev 10

V

V

V

V

BAT

BAT

BAT

BAT

= 2.0V

= 3.0V

= 3.3V

= 3.6V

AI09140b

STM690A/692A/703/704/802/805/817/818/819 Typical operating characteristics

Figure 19. Supply current vs. temperature (no load)

30

25

20

15

VCC = 2.7V

10

Supply Current (µA)

5

0

–40 –20 0 20 40 60 80 100 120

Temperature (°C)

VCC = 3.0V

VCC = 3.6V

VCC = 4.5V

VCC = 5.5V

AI09141b

Figure 20. Battery current vs. temperature

1000

100

10

Battery Supply Current (nA)

1

0.1

–40 –20 0 20 40 60 80 100 120

V

= 2.0V

BAT

V

= 3.0V

BAT

V

= 3.6V

BAT

Temperature (° C)

AI10499

Doc ID 10522 Rev 10 21/43

Typical operating characteristics STM690A/692A/703/704/802/805/817/818/819

Figure 21. V

1.270

1.265

1.260

1.255

1.250

1.245

Threshold (V)

PFI

1.240

V

1.235

1.230

1.225

–40 –20 0 20 40 60 80 100 120

threshold vs. temperature

PFI

VCC = 3.0V

VCC = 4.5V

VCC = 4.75V

VCC = 5.5V

Temperature (°C)

AI09142c

Figure 22. Reset comparator propagation delay vs. temperature (other than STM817/818/819)

30

28

26

24

22

20

18

16

Propagation Delay (µs)

14

12

10

–40 –20 0 20 40 60 80 100 120

Temperature (° C)

AI09143b

22/43 Doc ID 10522 Rev 10

STM690A/692A/703/704/802/805/817/818/819 Typical operating characteristics

Figure 23. Reset comparator propagation delay vs. temperature (V

350

300

250

200

150

100

Propagation Delay (µs)

50

0

–40 –20 0 20 40 60 80 100 120

Temperature (°C)

Figure 24. Power-up t

vs. temperature

REC

= 3.0 V; STM817/818/819)

BAT

1v/ms

10V/ms

AI11100

240

235

230

225

(ms)

rec

t

220

215

210

–40 –20 0 20 40 60 80 100 120

Temperature (°C)

VCC = 3.0V

VCC = 4.5V

VCC = 5.5V

AI09144b

Doc ID 10522 Rev 10 23/43

Typical operating characteristics STM690A/692A/703/704/802/805/817/818/819

Figure 25. Normalized reset threshold vs. temperature

1.004

1.002

1.000

0.998

Normalized Reset Threshold

0.996

–40 –20 0 20 40 60 80 100 120

Temperature (°C)

AI09145b

Figure 26. Watchdog time-out period vs. temperature

1.90

1.85

1.80

1.75

1.70

Watchdog Time-out Period (sec)

1.65

1.60

–40 –20 0 20 40 60 80 100 120

Temperature (°C)

VCC = 3.0V

VCC = 4.5V

VCC = 5.5V

AI09146b

24/43 Doc ID 10522 Rev 10

STM690A/692A/703/704/802/805/817/818/819 Typical operating characteristics

Figure 27. E to E

60

50

40

30

CON

On-Resistance ( )

CON

20

E to E

10

0

–40 –20 0 20 40 60 80 100 120

Figure 28. PFI to PFO

on-resistance vs. temperature

Temperature (°C)

propagation delay vs. temperature

VCC = 3.0V

VCC = 4.5V

VCC = 5.5V

AI09147b

4.0

VCC = 3.0V

3.0

2.0

1.0

VCC = 3.6V

VCC = 4.5V

VCC = 5.5V

PFI to PFO Propagation Delay (µs)

0.0

–40 –20 0 20 40 60 80 100 120

Temperature (°C)

AI09148b

Doc ID 10522 Rev 10 25/43

Typical operating characteristics STM690A/692A/703/704/802/805/817/818/819

Figure 29. Output voltage vs. load current (VCC = 5 V; V

5.00

4.98

(V)

OUT

V

4.96

4.94

01020304050

I

(mA)

OUT

Figure 30. Output voltage vs. load current (V

= 0 V; V

CC

= 2.8 V; TA = 25 °C)

BAT

= 2.8 V; TA = 25 °C)

BAT

AI10496

2.80

2.78

2.76

2.74

(V)

OUT

2.72

V

2.70

2.68

2.66

0.0 0.2 0.4 0.6 0.8 1.0

I

(mA)

OUT

AI10497

26/43 Doc ID 10522 Rev 10

STM690A/692A/703/704/802/805/817/818/819 Typical operating characteristics

Figure 31. RST output voltage vs. supply voltage

5

4

3

(V)

RST

2

V

1

0

500ms/div

Figure 32. RST output voltage vs. supply voltage

5

4

V

V

V

RST

V

CC

RST

CC

5

4

3

2

1

0

AI09149b

5

4

(V)

CC

V

(V)

RST

V

3

3

(V)

CC

2

2

1

0

500ms/div

V

1

0

AI09150b

Doc ID 10522 Rev 10 27/43

Typical operating characteristics STM690A/692A/703/704/802/805/817/818/819

Figure 33. RST response time (assertion)

5V

V

CC

5V

RST

Figure 34. RST response time (assertion)

5µs/div

1V/div

4V

4V

1V/div

0V

AI09151b

V

CC

1V/div

RST

1V/div

0V

5µs/div

5V

4V

4V

AI09152b

28/43 Doc ID 10522 Rev 10

STM690A/692A/703/704/802/805/817/818/819 Typical operating characteristics

Figure 35. Power-fail comparator response time (assertion)

5V

PFO

1.3V

PFI

500ns/div

Figure 36. Power-fail comparator response time (de-assertion)

1V/div

0V

500mV/div

0V

AI09153b

5V

PFO

0V

PFI

0V

1V/div

1.3V

500mV/div

500ns/div

AI09154b

Doc ID 10522 Rev 10 29/43

Typical operating characteristics STM690A/692A/703/704/802/805/817/818/819

Figure 37. Maximum transient duration vs. reset threshold overdrive

6000

5000

4000

Reset occurs

above the curve.

3000

2000

Transient Duration (µs)

1000

0

Figure 38. E

4.0

3.0

2.0

Propagation Delay (ns)

CON

1.0

E to E

0.0

–40 –20 0 20 40 60 80 100 120

to E

Reset Comparator Overdrive, V

propagation delay vs. temperature

CON

Temperature (°C)

– VCC (V)

RST

0111.010.0100.0

AI09156b

VCC = 3.0V

VCC = 4.5V

VCC = 5.5V

AI09157b

30/43 Doc ID 10522 Rev 10

STM690A/692A/703/704/802/805/817/818/819 Maximum ratings

4 Maximum ratings

Stressing the device above the rating listed in the absolute maximum ratings table may

cause permanent damage to the device. These are stress ratings only and operation of the

device at these or any other conditions above those indicated in the operating sections of

this specification is not implied. Exposure to absolute maximum rating conditions for

extended periods may affect device reliability.

Table 5. Absolute maximum ratings

Symbol Parameter Value Unit

T

STG

(1)

T

SLD

V

IO

V

CC/VBAT

I

O

P

D

1. Reflow at peak temperature of 260 °C. The time above 255 °C must not exceed 30 seconds.

Storage temperature (VCC off) –55 to 150 °C

Lead solder temperature for 10 seconds 260 °C

Input or output voltage –0.3 to VCC +0.3 V

Supply voltage –0.3 to 6.0 V

Output current 20 mA

Power dissipation 320 mW

Doc ID 10522 Rev 10 31/43

DC and AC parameters STM690A/692A/703/704/802/805/817/818/819

5 DC and AC parameters

This section summarizes the operating measurement conditions, and the DC and AC

characteristics of the device. The parameters in the DC and AC characteristics Tables that

follow, are derived from tests performed under the measurement conditions summarized in

Table 6: Operating and AC measurement conditions. Designers should check that the

operating conditions in their circuit match the operating conditions when relying on the

quoted parameters.

Table 6. Operating and AC measurement conditions

Parameter

VCC/V

supply voltage 1.0 to 5.5 V

BAT

Ambient operating temperature (T

) –40 to 85 °C

A

STM690A/692A/703/704/802/805/

817/818/819

Unit

Input rise and fall times ≤ 5ns

Input pulse voltages 0.2 to 0.8V

Input and output timing ref. voltages 0.3 to 0.7V

Figure 39. E

to E

propagation delay test circuit

CON

V

CC

V

CC

V

BAT

3.6V

STMXXX

25 Equivalent

Source Impedance

E

50

50

Cable

50

GND

E

CON

50pF C

CC

CC

(1)

L

V

V

1. CL includes load capacitance and scope probe capacitance.

32/43 Doc ID 10522 Rev 10

AI08854

STM690A/692A/703/704/802/805/817/818/819 DC and AC parameters

Figure 40. AC testing input/output waveforms

0.8V

0.2V

CC

CC

0.7V

0.3V

CC

CC

AI02568

Figure 41. MR

MR

RST

timing waveform

t

MLRL

(1)

t

MLMH

1. RST for STM805.

Figure 42. Watchdog timing

V

CC

t

RST

WDI

rec

t

rec

t

WD

AI07837a

AI07891

Doc ID 10522 Rev 10 33/43

DC and AC parameters STM690A/692A/703/704/802/805/817/818/819

Table 7. DC and AC characteristics

V

V

I

CC

I

BAT

V

V

Sym

CC

BAT

(4)

OUT1

OUT2

Alter-

native

,

(2)

Description Test condition

Operating voltage TA = –40 to +85 °C 1.2

V

supply current Excluding I

CC

V

supply current in

CC

battery backup mode

V

supply current in

BAT

battery backup mode

V

voltage (active)

OUT

V

voltage (battery

OUT

Excluding I

VCC = 2.0 V, MR = VCC)

I

OUT2

OUT

OUT

Excluding I

(V

= 3.6 V)

BAT

I

= 5 mA

OUT1

I

= 75 mA

OUT1

I

= 250 µA,

OUT1

> 2.5 V

V

CC

= 250 µA, V

(1)

Min Typ Max Unit

(3)

5.5 V

(VCC < 5.5 V) 25 60 µA

(V

= 2.3 V,

BAT

OUT

(5)

(5)

BAT

= 2.3 V

VCC –

0.03

–

V

CC

0.3

VCC –

0.0015

–

V

BAT

0.1

25 35 µA

0.4 1.0 µA

– 0.015 V

V

CC

V

– 0.15 V

CC

VCC –

0.0006

V

– 0.034 V

BAT

V

backup)

I

to V

V

CC

OUT

on-resistance

OUT2

= 1 mA, V

= 2.3 V V

BAT

– 0.14 V

BAT

34Ω

V

to V

BAT

on-resistance

Input leakage current

(MR

Input leakage current

I

LI

(PFI)

Input leakage current

(WDI)

V

IH

V

IH

V

IL

V

IL

Input high voltage (MR) 4.5 V < VCC < 5.5 V 2.0 V

Input high voltage (WDI) V

Input low voltage (MR) 4.5 V < VCC < 5.5 V 0.8 V

Input low voltage (WDI) V

Output low voltage (PFO,

RST

V

OL

Output low voltage

(E

V

OL

Output low voltage (RST)

)

, RST)

CON

(6)

OUT

4.5 V < V

0 V < V

WDI = V

< 5.5 V 75 125 300 µA

CC

< V

IN

CC

, time average 120 160 µA

CC

–25 2 +25 nA

100 Ω

WDI = GND, time average –20 –15 µA

(max) < VCC < 5.5 V 0.7V

RST

(max) < VCC < 5.5 V 0.3V

RST

= V

V

CC

I

SINK

= V

V

)

CC

I

= 1.6 mA, E = 0 V

OUT

I

= 50 µA, VCC = 1.0 V,

SINK

V

= V

BAT

CC

I

= 100 µA, VCC = 1.2 V,

SINK

V

(max),

RST

= 3.2 mA

(max),

RST

, TA = 0°C to 85°C

= V

BAT

CC

CC

0.3 V

0.2V

0.3 V

0.3 V

CC

CC

V

V

V

34/43 Doc ID 10522 Rev 10

STM690A/692A/703/704/802/805/817/818/819 DC and AC parameters

Table 7. DC and AC characteristics (continued)

Sym

Alter-

native

Description Test condition

Output high voltage

, RST)

V

V

V

OHB

OH

OH

(RST

Output high voltage

)

(E

CON

Output high voltage

)

(PFO

Output high voltage

VOH battery backup

, RST)

(RST

battery backup

V

OH

(E

)

CON

I

OUT

I

SOURCE

V

= V

BAT

I

SOURCE

V

V

VCC = V

V

I

VCC = V

I

SOURCE

CC

I

CC

Power-fail comparator (NOT available on STM818)

PFI falling

(V

V

PFI

PFI input threshold

CC

= 5 V)

(1)

= V

= 1 mA

(max)

RST

(max),

RST

I

SOURCE

CC

= 1.6 mA, E= V

SOURCE

= 75 µA,

(max)

RST

= 4 µA, VCC = 1.1 V,

, TA = 0°C to 85°C

CC

= 4 µA, VCC = 1.2 V,

V

= V

BAT

CC

= 100 µA,

= 0, V

SOURCE

= 0, V

= 2.8 V

BAT

= 75 µA,

= 2.8 V

BAT

All other

versions

CC

Min Typ Max Unit

2.4 V

0.8V

CC

0.8V

CC

0.8 V

0.9 V

0.8V

BAT

0.8V

BAT

1.20 1.25 1.30 V

V

V

V

V

t

PFD

I

SC

PFI to PFO propagation

delay

PFO output short to GND

current

Battery switchover

Battery backup

switchover voltage

VSO

(VCC < V

V

Hysteresis 40 mV

Reset thresholds

V

RST

Reset threshold

Reset threshold

hysteresis

V

V

10 V/ms)

&

BAT

< V

CC

to RST delay (from

CC

RST

)

RST

(9)

, VCC falling at

(7)(8)

STM802 1.225 1.250 1.275 V

2µs

Power-down

= 5 V, V

V

CC

Power-up

= 0 V 0.1 0.75 2.0 mA

PFO

V

V

V

V

RST

RST

RST

RST

> V

< V

> V

< V

BAT

BAT

BAT

BAT

V

V

V

V

BAT

RST

BAT

RST

STM690A/703, STM8XXL 4.50 4.65 4.75 V

STM692A/704, STM8XXM 4.25 4.40 4.50 V

25 mV

STM817/818/819 100 µs

V

V

V

V

Doc ID 10522 Rev 10 35/43

DC and AC parameters STM690A/692A/703/704/802/805/817/818/819

Table 7. DC and AC characteristics (continued)

Sym

t

REC

Alter-

native

Description Test condition

RST pulse width 140 200 280 ms

(1)

Min Typ Max Unit

Push-button reset input (STM703/704/819)

STM703/704 150 ns

t

MLMHtMR

MR pulse width

STM819 1 µs

STM703/704 250 ns

t

MLMRtMRD

MR to RST output delay

STM819 120 ns

glitch immunity STM819 100 ns

MR

MR

pull-up resistor MR = 0 V, VCC = 5 V 45 63 85 kΩ

Watchdog timer (NOT available on STM703/704/819)

t

Watchdog timeout period V

WD

WDI pulse width V

(max) < VCC < 5.5 V 1.12 1.60 2.24 s

RST

(max) < VCC < 5.5 V 50 ns

RST

Chip-enable gating (STM818 only)

E to E

to E

E

delay

Reset to E

E

CON

1. Valid for ambient operating temperature: TA = –40 to 85 °C; VCC = 4.75 V to 5.5 V for “L” versions; VCC = 4.5 V to 5.5 V for

“M” versions; and V

supply current, logic input leakage, watchdog functionality, push-button reset functionality, PFI functionality, state of

2. V

CC

RST and RST tested at V

Either V

3. V

CC

4. Tested at V

5. Guaranteed by design.

6. WDI input is designed to be driven by a three-state output device. To float WDI, the “high impedance mode” of the output

device must have a maximum leakage current of 10 µA and a maximum output capacitance of 200 pF. The output device

must also be able to source and sink at least 200 µA when active.

7. When V

8. When V

9. For V

or V

CC

(min) = 1.0 V for TA = 0 °C to +85 °C.

BAT

RST

falling.

CC

can go to 0 V if the other is greater than 2.0 V.

BAT

= 3.6 V, VCC = 3.5 V and 0 V.

BAT

> VCC > V

> VCC > V

resistance VCC = V

CON

propagation

CON

high delay (Power-down) 15 µs

CON

short circuit current

= 2.8 V (except where noted).

BAT

= 3.6 V, and VCC = 5.5 V. The state of RST or RST and PFO is tested at VCC = VCC (min).

BAT

, V

RST

BAT

remains connected to VCC until VCC drops below V

OUT

, V

remains connected to VCC until VCC drops below the battery voltage (V

OUT

RST

4.5 V < V

V

= 5 V, disable mode,

CC

= logic high, E

E

CC

(max) 40 150 Ω

< 5.5 V 2 7 ns

CON

= 0 V

0.1 0.75 2.0 mA

.

RST

) – 75 mV.

BAT

36/43 Doc ID 10522 Rev 10

STM690A/692A/703/704/802/805/817/818/819 Package mechanical data

6 Package mechanical data

In order to meet environmental requirements, ST offers these devices in different grades of

ECOPACK

specifications, grade definitions and product status are available at: www.st.com.

ECOPACK

®

packages, depending on their level of environmental compliance. ECOPACK®

®

is an ST trademark.

Doc ID 10522 Rev 10 37/43

Package mechanical data STM690A/692A/703/704/802/805/817/818/819

Figure 43. SO8 - 8-lead plastic small outline, 150 mils body width, package

mechanical drawing

A2

B

e

8

1

Note: Drawing is not to scale.

Table 8. SO8 - 8-lead plastic small outline, 150 mils body width, package

mechanical data

Symbol

Typ Min Max Typ Min Max

A

ddd

D

E

H

mm inches

C

LA1

SO-A

A - 1.35 1.75 - 0.053 0.069

A1 - 0.10 0.25 - 0.004 0.010

B - 0.33 0.51 - 0.013 0.020

C - 0.19 0.25 - 0.007 0.010

D - 4.80 5.00 - 0.189 0.197

ddd - - 0.10 - - 0.004

E - 3.80 4.00 - 0.150 0.157

e 1.27 - - 0.050 - -

H - 5.80 6.20 - 0.228 0.244

h - 0.25 0.50 - 0.010 0.020

L - 0.40 0.90 - 0.016 0.035

α - 0° 8° - 0° 8°

N8 8

38/43 Doc ID 10522 Rev 10

STM690A/692A/703/704/802/805/817/818/819 Package mechanical data

Figure 44. TSSOP8 - 8-lead, thin shrink small outline, 3 x 3 mm body size, outline

D

8

1

CP

Note: Drawing is not to scale.

Table 9. TSSOP8 - 8-lead, thin shrink small outline, 3 x 3 mm body size,

mechanical data

Symbol

Typ Min Max Typ Min Max

5

EE1

4

A1

A2A

eb

mm inches

c

L

L1

TSSOP8BM

A - - 1.10 - - 0.043

A1 - 0.05 0.15 - 0.002 0.006

A2 0.85 0.75 0.95 0.034 0.030 0.037

b - 0.25 0.40 - 0.010 0.016

c - 0.13 0.23 - 0.005 0.009

CP - - 0.10 - - 0.004

D 3.00 2.90 3.10 0.118 0.114 0.122

e 0.65 - - 0.026 - -

E 4.90 4.65 5.15 0.193 0.183 0.203

E1 3.00 2.90 3.10 0.118 0.114 0.122

L 0.55 0.40 0.70 0.022 0.016 0.030

L1 0.95 - - 0.037 - -

α -0°6° - 0° 6°

N8 8

Doc ID 10522 Rev 10 39/43

Part numbering STM690A/692A/703/704/802/805/817/818/819

7 Part numbering

Table 10. Ordering information scheme

Example: STM690A M 6 E

Device type

STM690A/692A/703/704/802/805/817/818/819

Threshold voltage

STM690A, STM703: blank: V

STM692A, STM704: blank: V

STM8xx: L: V

M: V

= 4.50 V to 4.75 V

RST

= 4.25 V to 4.50 V

RST

Package

M = SO8

(1)

DS

= TSSOP8

= 4.50 V to 4.75 V

RST

= 4.25 V to 4.50 V

RST

Temperature range

6: –40 °C to 85 °C

Shipping method

E = ECOPACK

F = ECOPACK

1. Contact local ST sales office for availability.

®

package, tubes

®

package, tape & reel

For other options or for more information on any aspect of this device, please contact the ST

sales office nearest you.

40/43 Doc ID 10522 Rev 10

STM690A/692A/703/704/802/805/817/818/819 Part numbering

Table 11. Marking description

Part number Reset threshold Package Topside marking

STM690A 4.65 V SO8 690A

STM692A 4.40 V SO8 692A

STM703 4.65 V SO8 703

STM704 4.40 V SO8 704

STM802L 4.65 V SO8 802L

STM802M 4.40 V SO8 802M

STM805L 4.65 V SO8 805L

STM817L 4.65 V

STM817M 4.40 V

STM818L 4.65 V

SO8

817L

TSSOP8

SO8

817M

TSSOP8

SO8

818L

TSSOP8

STM818M 4.40 V

STM819L 4.65 V

STM819M 4.40 V

SO8

818M

TSSOP8

SO8

819L

TSSOP8

SO8

819M

TSSOP8

Doc ID 10522 Rev 10 41/43

Revision history STM690A/692A/703/704/802/805/817/818/819

8 Revision history

Table 12. Document revision history

Date Revision Changes

Oct-2003 1 Initial release.

31-Oct-2003 1.1 Update DC characteristics (Ta bl e 7 ).

22-Dec-2003 2

Reformatted; updated characteristics (cover page, Figure 2, 3, 6, 7, 8, 9,

10, 11, 12, 13, 14, 16, Ta bl e 3 , 4, 7, 9, 11).

16-Jan-2004 2.1

Add typical characteristics (Figure 18, 19, 21, 22, 24, 25, 26, 27, 28, 31,

32, 33, 34, 35, 36, 37, 38).

08-Apr-2004 2.2 Update characteristics (Figure 12, 22, 28, 32, 33, 34, 37; Ta bl e 1 , 7).

25-May-2004 3

05-Jul-2004 4

Remove references to “open drain” (cover page, 4, 7; Ta b l e 2 ); update

characteristics (Ta bl e 3 , 7).

Update package availability, pin description; promote document (cover

page, Figure 13, 14; Ta bl e 3 , 7, 10).

29-Sep-2004 5 Clarify root part numbers, pin descriptions (Figure 10, 12, 39; Tabl e 7 , 10).

01-Mar-2005 6

Update characteristics (Figure 17, 18, 19, 20, 21, 22, 23, 24, 25, 26, 27,

28, 29, 30, 31, 32, 33, 34, 35, 36, 37, 38)

20-Jan-2006 7 Correct marking, update lead-free text (Ta bl e 1 0 , 11)

21-Oct-2008 8

Reformatted, minor text changes; updated Ta bl e 3 , 4, 7, 10, Figure 9, 10,

11, 12,

16, 39, Section 6: Package mechanical data.

20-Nov-2009 9 Updated text in Section 6, Ta bl e 5 .

18-Aug-2010 10 Updated Section 2.4: Backup battery switchover.

42/43 Doc ID 10522 Rev 10

STM690A/692A/703/704/802/805/817/818/819

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2010 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 10522 Rev 10 43/43

Loading...

Loading...