I²C interfaced, advanced LED controller/driver with keyscan,

standby power management and real time clock (RTC)

Features

■ LED controller driver with 13 outputs

(8 segments/5 digits)

■ Standby power management to host

■ Integrated low-power, accurate RTC

■ Integrated remote control decoding:

– Philips (RC5, RCMM)

– Thomson (RCA, R2000)

– NEC and R-STEP

■ Wake-up using front panel keys, remote

control, real time clock (RTC), extra pin (AV or

CEC)

■ Battery or super-cap back up mode for real

time clock (RTC)

■ Keyscanning (8x2 matrix)

■ Low power consumption in standby mode

2

■ I

C serial bus interface (SCL, SDA)

■ 16-step dimming circuit to control the display

brightness

■ 5.0 V (± 10%) for V

■

Built-in thermal protection circuit

■ External crystal with internal oscillator for real

time clock (RTC)

Applications

■ Set-top boxes

■ White goods

■ Home appliances

■ DVD players, VCRs, DVD-R

CC

STLED325

QFN32

(5 x 5 mm)

Description

The STLED325 is a compact LED controller/

driver that interfaces microprocessors to LED

displays through serial I

LEDs connected in common anode configuration

and includes keyscanning for an 8 x 2 key matrix

which automatically scans and de-bounces a

matrix of up to 16 switches.

Furthermore, the STLED325 provides standby

power management to the host. It also integrates

a low-power, highly-accurate RTC and a remotecontrol decoder. All functions are programmable

using the I

2

C bus. Low power consumption during

standby mode is achieved.

The STLED325 controller/driver is ideal as a

single peripheral device to interface the front

panel display with a single-chip host IC like CPU.

2

C interface. It drives

Table 1. Device summary

Order code Temp range (°C) Package Comments

STLED325QTR -40 to +85 °C QFN32 250 parts per reel

April 2011 Doc ID 17576 Rev 1 1/62

www.st.com

62

Contents STLED325

Contents

1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

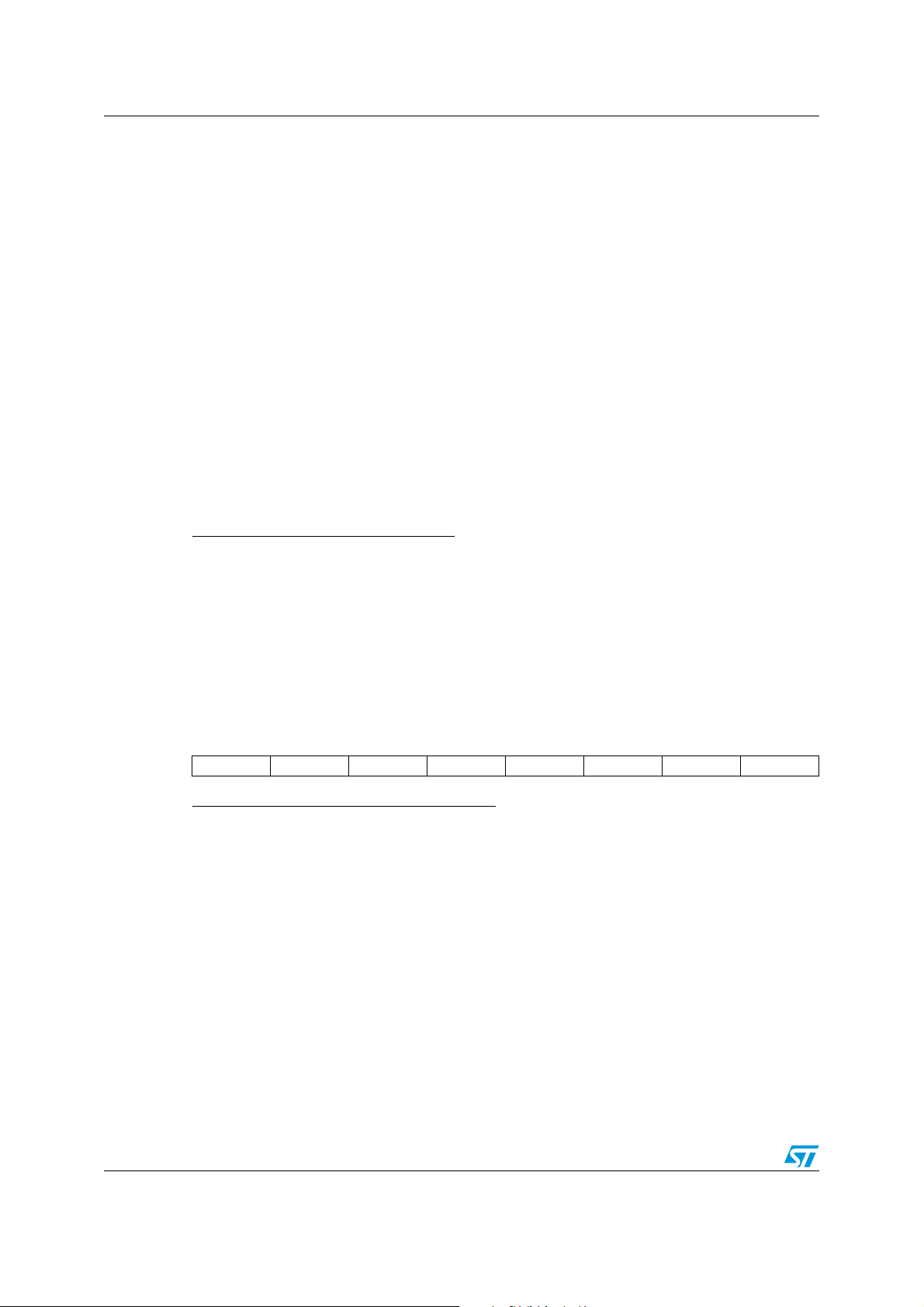

2 Functional and application diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Low power mode of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 I2C serial interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.3 Initial power up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.4 Display types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.5 Keyscan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.6 Timers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.6.1 Guard timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.6.2 Watchdog timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.7 Power-on-reset and soft-start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.8 LED drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.9 Over temperature cut-off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.10 Standby mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.10.1 Cold boot up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.10.2 Entering standby mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.10.3 Wake-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.11 Real time clock (RTC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.11.1 Reading the real time clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.11.2 Writing to the real time clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.11.3 Register table for RTC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.11.4 Setting alarm clock registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.11.5 Century bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.11.6 Initial power-on defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.11.7 Programmable display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.11.8 Lookup table with ppm against the calibration register values . . . . . . . . 24

3.12 Remote control decoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.13 Interrupt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.14 Ready . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.15 Mute . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2/62 Doc ID 17576 Rev 1

STLED325 Contents

3.16 GPIO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.17 Power sense circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.17.1 Switchover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.17.2 Battery low warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.17.3 Different power operation modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.18 Bus characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4 Electrical ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.1 Absolute maximum ratings (TA = 25 °C, GND = 0 V) . . . . . . . . . . . . . . . . 33

4.2 Recommended operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.2.1 DC electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.3 Power consumption estimation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.4 Oscillator and crystal characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.5 ESD performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5 Display RAM address and display mode . . . . . . . . . . . . . . . . . . . . . . . 41

6 KEY matrix and key-input data storage RAM . . . . . . . . . . . . . . . . . . . . 42

7 Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.1 Configuration mode setting command . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.2 Data setting command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.3 Configuration data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.3.1 Interrupt flags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.4 Address setting command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.5 Display control and hotkey setting command . . . . . . . . . . . . . . . . . . . . . . 51

7.6 Keyscanning and display timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8 State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

8.1 Default state upon power-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

8.2 Initial state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

9 Remote control protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

10 Application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

10.1 Power supply sequencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Doc ID 17576 Rev 1 3/62

Contents STLED325

10.2 ISET variation with RSET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

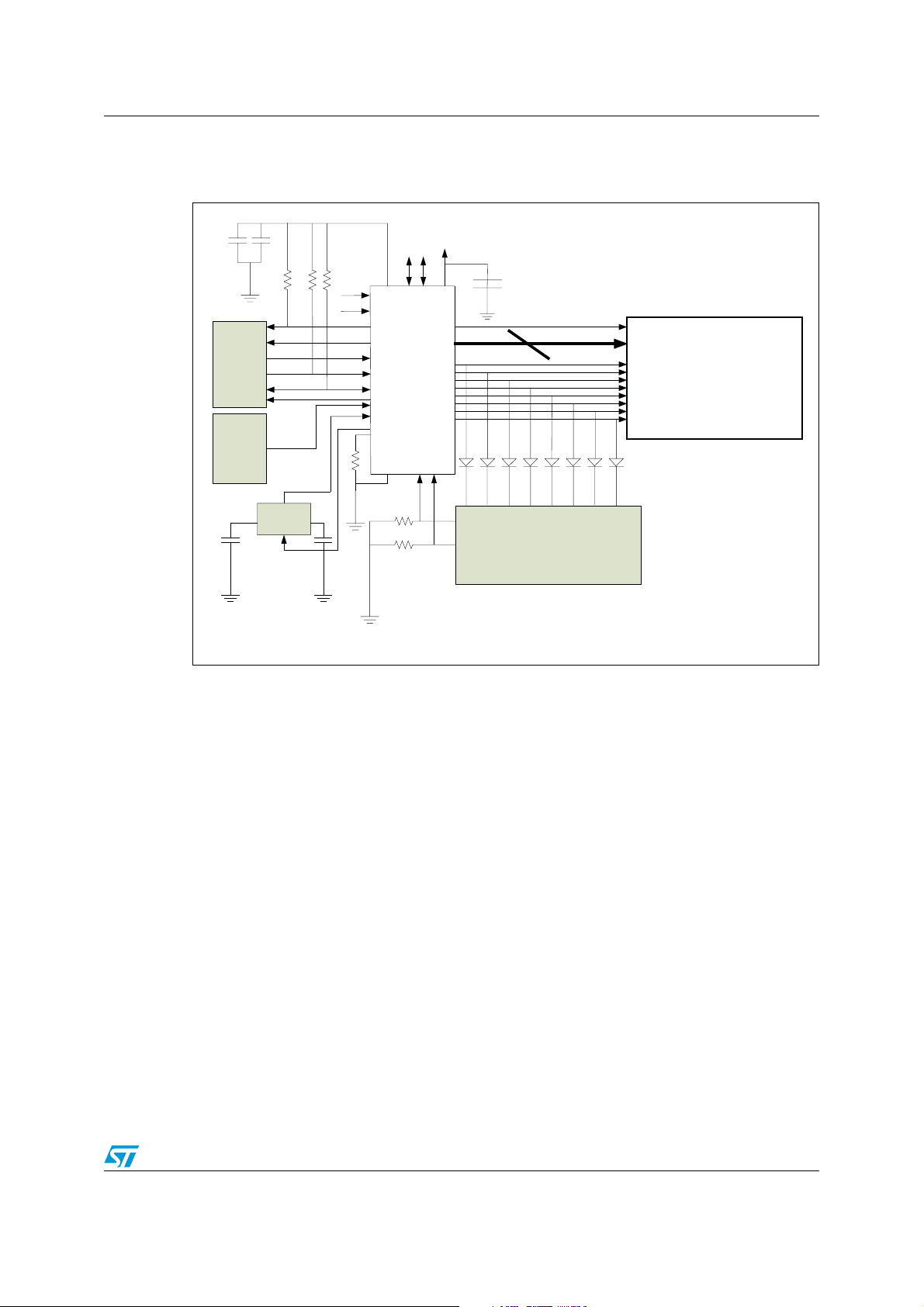

10.3 Application diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

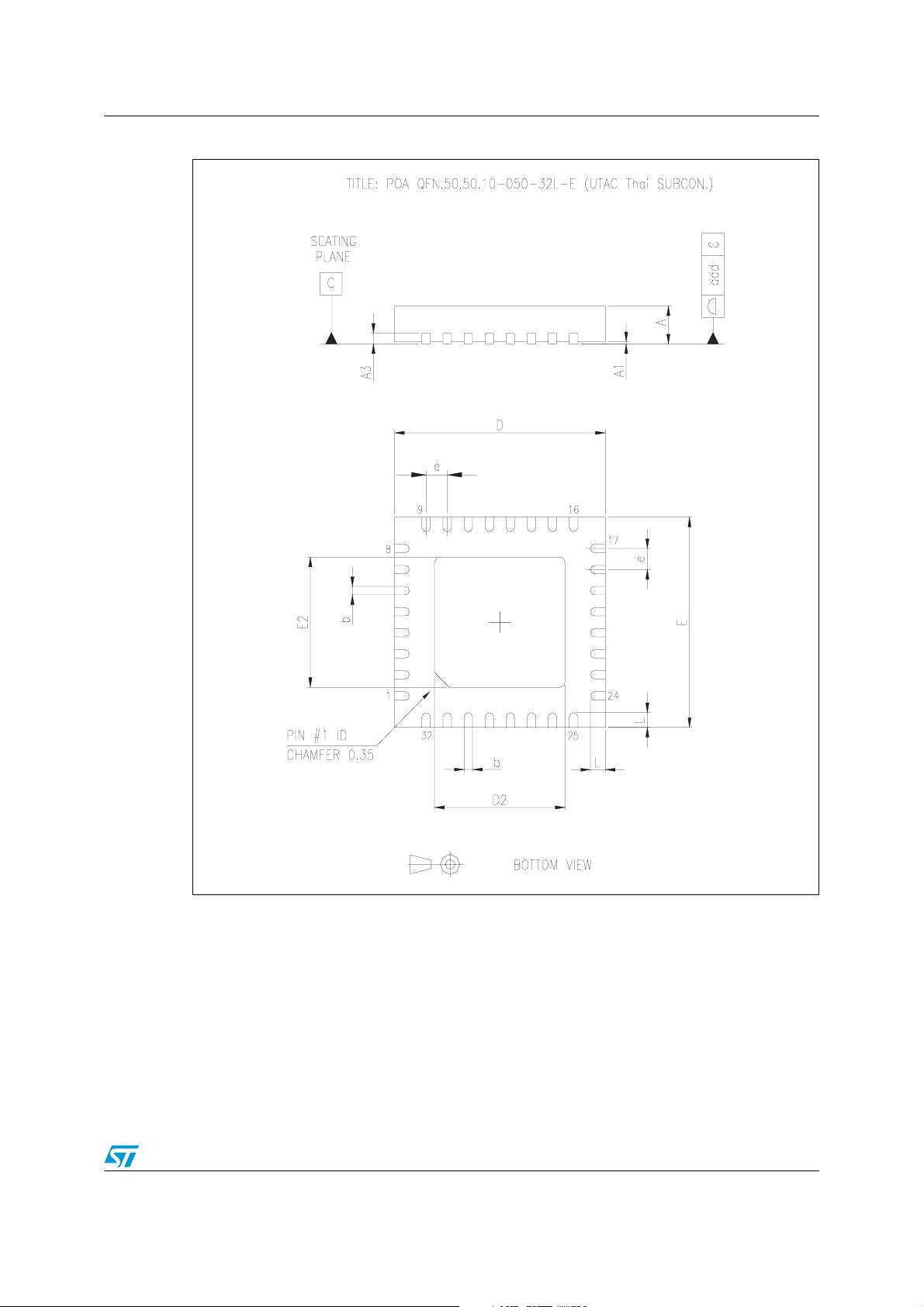

11 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

12 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4/62 Doc ID 17576 Rev 1

STLED325 List of tables

List of tables

Table 1. Device summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table 2. Register table for RTC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 3. Alarm repeat modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 4. Century bits examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 5. Initial power-on defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 6. RTC display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 7. LUT with ppm against the calibration register values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 8. Different power operation modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 9. Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 10. Absolute maximum ratings (TA = 25 °C, GND = 0 V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 11. Thermal data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 12. DC electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 13. Voltage drop estimation with RGB LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 14. Capacitance (TA = 25°C, f = 1 MHz) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 15. Power supply characteristics (TA = -40 to 85°C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 16. Dynamic switching characteristics (TA = -40 to +85 °C, VCC = 5.0V ± 10%, GND=0.0V, Typ-

ical values are at 25°C). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 17. Timing characteristics (TA = -40 to +85 °C, VCC = 5.0 V ± 10%, GND=0.0 V, typical values

are at 25 °C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 18. Oscillator characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 19. Crystal electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 20. ESD performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 21. Battery range and battery detect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 22. Power down/up AC characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 23. Power down/up trip points DC characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 24. Thermal shutdown characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 25. Bit map for segment 1 to segment 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 26. Data write command. b5 b4: 00 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 27. Data Write 2 command. B5 b4: 01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 28. Data Read 1 command. b5 b4: 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 29. Data Read 2 command. b5 b4: 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 30. Power-up defaults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 31. QFN32 (5 x 5 mm) mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Table 32. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Doc ID 17576 Rev 1 5/62

List of figures STLED325

List of figures

Figure 1. Functional block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 2. Application diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

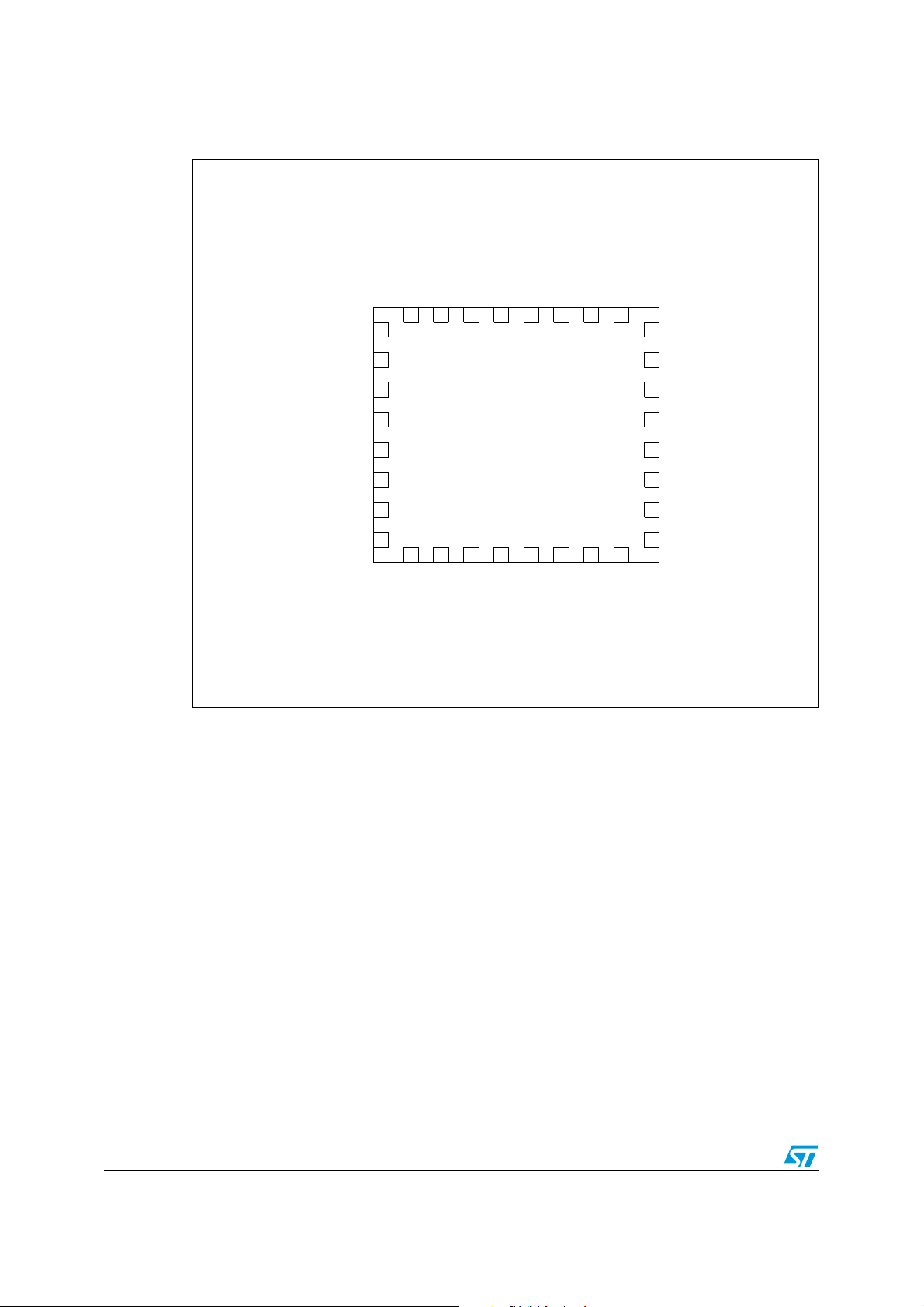

Figure 3. Pin configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 4. Display types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 5. Power-up condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 6. Power down condition (normal behavior) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 7. Standby condition (normal behavior) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 8. Keyscan and digit mapping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 9. Interrupt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 10. Power sense circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 11. Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 12. Battery switchover waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 13. Power down/up mode ac waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 14. VCC characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 15. KEY matrix and key-input data storage RAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 16. Data write command (b7 b6) for GPIO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 17. Interrupt bit mapping in Byte 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 18. Interrupt bit mapping in Byte 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 19. Blanking time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 20. Keyscanning and display timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 21. Rext versus Iseg curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 22. Application schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 23. QFN32 package dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 24. QFN32 carrier tape . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6/62 Doc ID 17576 Rev 1

STLED325 Description

1 Description

The STLED325 is a compact LED controller/driver that interfaces microprocessors to LED

displays through serial I

figuration. The STLED325 drives up to 40 discrete LEDs in 8 segment/5 digit configuration

while functioning from a supply voltage of 5 V. The maximum segment current for the display

digits is set through a single external resistor. Individual digits may be addressed and

updated without rewriting the entire display. Additionally it includes keyscanning for an 8 x 2

key matrix which automatically scans and de-bounces a matrix of up to 16 switches.

Furthermore, it provides standby power management to the host. The STLED325 also

integrates a low-power, highly-accurate RTC and a remote-control decoder. All functions are

pro-grammable using the I

achieved. STLED325 supports numeric-type displays and reduces the overall BOM costs

through high integration. Also it provides ESD protection of greater than 2 kV HBM.

The LED controller/driver is ideal as a single peripheral device to interface the front panel

display with a single-chip Host IC like CPU.

2

C interface. It drives LED connected in common anode con-

2

C bus. Low power consumption during standby mode is

Doc ID 17576 Rev 1 7/62

Functional and application diagram STLED325

2 Functional and application diagram

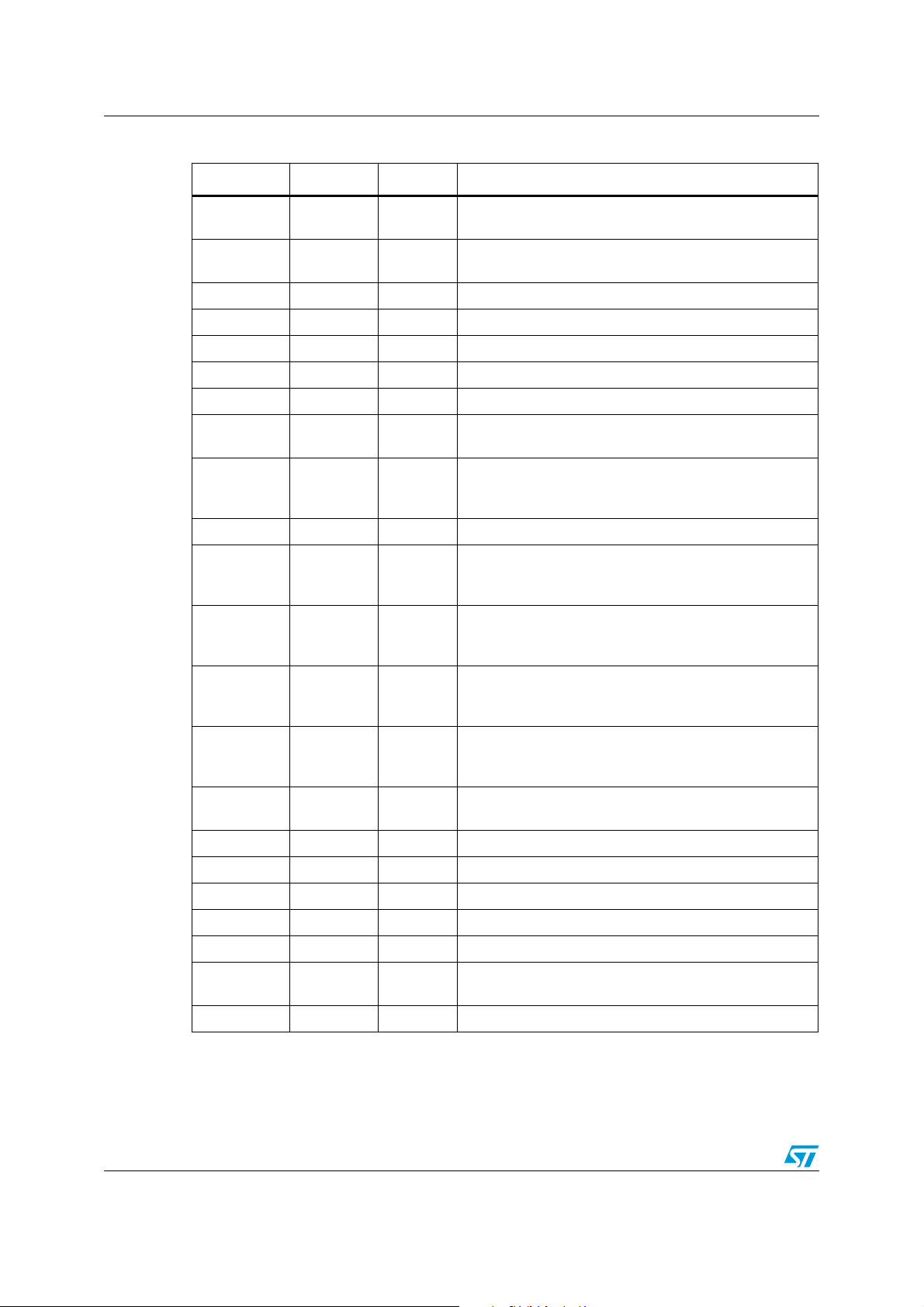

Figure 1. Functional block diagram

Thermal

Vbat

8

5

Remote Ctrl

protection

Decoder &

Guard

timer

drivers

Segment

Grid

Digit

drivers

Drivers

STDBY

IRQ_N

SEG1/KS1

SEG8/KS8

DIG5

DIG4

DIG1

GND

(0V)

ISET

Vcc

SCL

SDA

WAKE_UP

GPIO1

GPIO2

VREG

MUTE

KEY1-KEY2

Current

source

regulator

XOUT

Voltage

2

2

XIN

SPI

I2C

Seria

Serial

l I/F

I/F

OSC

OSC

(Fixed

Freq)

Output

segments

Internal

core

supply

RTC +

32KHz

Osc

VBAT

Command

Command

Decoder

Decoder

Display Mem

Display Mem

(20 x 16)

(5 x 8)

Timing Gen

Timing Gen

Key Scan &

Key Scan &

Dimming

Dimming

KeyData Mem

KeyData Mem

(2 x 12)

(2 x 8)

IR_IN

and UVLO

RC

decoder

POR &

Soft-start

Bandgap

8-bit

20- bit

output

Output

latch

Latch

16- bit

5-bit

Shift

Shift

Register

Register

READY

Internal

reset

VCC

Detect

Detect

Powe r

management

8/62 Doc ID 17576 Rev 1

AM04143V1

STLED325 Functional and application diagram

Figure 2. Application diagram

Microcontroller or

CPU

External

32.768KHz crystal

From remote

control sensor

R

SCL

SDA

READY

STBY

IRQ_N

MUTE

WAKE_UP

VBAT

STLED325

XIN

XOUT

IR_IN

ISET

KEY1-KEY2

Key scan

(8x2 matrix)

DIG1-DIG4

SEG1/KS1-

SEG8/KS8

DIG5

GPIO1

GPIO2

VREG

2

LED 4-digit 7-segment (+dot-point) display panel

4

8

PWR STBY REC MUTE

From sensor/To LED

From sensor/To LED

Connect to external

capacitor

!-6

Doc ID 17576 Rev 1 9/62

Functional and application diagram STLED325

Figure 3. Pin configurations

MUTE

IRQ_N

GPIO1

GPIO2

IR_IN

SDA

SCL

WAKE_UP

XOUT

30

STLED325

11

DIG3

XIN

29

12

DIG2

GND

28

13

DIG1

VREG

27

14

VCC

VBAT

26

15

KEY2

ISET

25

16

KEY1

24

23

22

21

20

19

18

17

SEG1/KS1

SEG2/KS2

SEG3/KS3

SEG4/KS4

SEG5/KS5

SEG6/KS6

SEG7/KS7

SEG8/KS8

STBY

READY

31

32

1

2

3

4

5

6

7

8

9

10

DIG4

DIG5

!-6

10/62 Doc ID 17576 Rev 1

STLED325 Functional description

3 Functional description

The STLED325 is a common anode LED driver controller which can be used to drive red,

green or blue LEDs as the current is adjustable through the external resistor. In the common

anode configuration, the digit outputs source the current to the anodes while the segment

outputs sink the current from the cathodes. The configurable output current can be used to

drive LEDs with different current ratings (red, green or blue). The brightness can be

controlled through the I

together in parallel to drive a single LED. In this case, two parallel current sources of equal

value drive a single LED. The external resistor value can be set accordingly to determine the

desired output current.

Soft-start limits the inrush current during power-up. The built-in thermal protection turns off

the display when the temperature exceeds 140°C with a small hysteresis of 15°C. The

display is blanked (LEDs are turned off or in high-Z state) on power-up.

3.1 Low power mode of operation

When not used, the STLED325 goes into low power mode of operation wherein the current

consumption drops to less than 1 mA. During this mode, the data configured is maintained

as long as the supply voltage is still present (the contents of the internal RAM need the

supply voltage to be present). Port configuration and output levels are restored when the

STLED325 is taken out of shutdown. For minimum supply current in shutdown mode, logic

inputs should be at GND or V

2

C interface as described later. The outputs can be connected

.

CC

3.2 I2C serial interface

The interface is used to write configuration and display data to the STLED325. The serial

interface comprises of a shift register into which SDA is clocked on the rising edge of the

SCL after a valid start of communication. When communication is stopped, transitions on

SCL do not clock in the data. During this time, the data are parallel-loaded into a latch. The

8-bit data is then decoded to determine and execute the command.

For an overflow condition, if more bytes are written, then they are ignored whereas if more

bytes are read, then the extra bytes are stuffed with 1’s.

3.3 Initial power up

On initial power-up, all control registers are reset, the display is blanked and the STLED325

is in the low-power mode. All the outputs are in high-impedance state at initial power-up.

The SDA is pulled high by an external pull-up resistor. The display driver has to be

configured before the display can be used.

Doc ID 17576 Rev 1 11/62

Functional description STLED325

3.4 Display types

Figure 4. Display types

Seven segment display with dot point and common-anode LED panel

3.5 Keyscan

The full keyscan is illustrated in the later section of the datasheet. One diode is required per

key switch. The keyscan circuit detects any combination of keys being pressed during each

de-bounce cycle.

The keyscan matrix on the STLED325 passes command from the front panel to the host

processor through the SDA pin on STLED325. The STLED325 can be programmed to

wake-up the system from standby using any of the 16 keys pressed on the front panel.

These wake-up keys are also referred to as hot-keys.

3.6 Timers

3.6.1 Guard timer

For safety related applications, a guard timer is integrated in the STLED325. The guard

timer gives enhanced reliability to the device.

The guard timer can be used to detect an out of-control microprocessor. The user programs

the guard timer by setting the desired amount of time-out into the Guard timer. This guard

time has an initial de-fault value of 10s upon first power-up and subsequently can be

configured from 1s to 15s during normal operation. If a time period of longer than 15s is

desired, then the watchdog timer from RTC can be used. It can also be disabled after first

power-up. If the processor does not clear the timer within the specified period, the

STLED325 puts the system in the standby mode.

This is only active from L to H transition on READY or WAKE_UP pin but it is not level-

based. The guard timer count is cleared by the guard timer clear/reset bit. While in normal

mode, the count starts from the previously count value that was in the register. During the

cold boot up or warm boot up, the count starts from the configured value.

12/62 Doc ID 17576 Rev 1

STLED325 Functional description

3.6.2 Watchdog timer

Another watchdog timer is present in the Watchdog timer register at address 09h of the RTC

register map. This watchdog timer can be used to program timer values of greater than 15s.

Bits BMB4-BMB0 store a binary multiplier and the three bits RB2-RB0 select the resolution

where:

000 = 1/16 second (16 Hz);

001 = 1/4 second (4 Hz);

010 = 1 second (1 Hz);

011 = 4 seconds (1/4 Hz); and

100 = 1 minute (1/60 Hz).

The Watchdog timer is programmed by setting the desired timeout into the Watchdog

register, address 09h. The amount of timeout time is determined to be the multiplication of

the 5-bit multiplier value with the resolution values depicted by the watchdog resolution bits.

The Watchdog timer is disabled when its register is cleared by writing a value of 00h.

Hence the Watchdog function is not enabled upon power on. It is enabled when a non-zero

value is written into its register. The Watchdog timer is reset by performing a write to the

watchdog register, then the time-out period starts over.

If the processor does not reset the timer within the specified timeout period, and when the

timeout occurs, the watchdog flag is set. The watchdog timer of RTC is cleared by writing a

00 value and starts again whenever any new value is written to it.

The WatchDogEn Flag can be disabled or enabled by writing to the register bit and the reset

of watchdog timer is done by writing to the register.

3.7 Power-on-reset and soft-start

The device integrates two internal power-on-reset circuits which initialize the digital logic

upon power up. One circuit is for the V

soft-start circuit limits the inrush current and high peak current during power-up. This is done

by delaying the input circuit’s response to the external applied voltage. During soft-start, the

input resistance is higher which lowers the in-rush current when the supply voltage is

applied.

power and the other is for the V

CC

power. The

BAT

Doc ID 17576 Rev 1 13/62

Functional description STLED325

3.8 LED drivers

The constant current capability is up to 40 mA per output segment and is set for all the

outputs using a single external resistor. When acting as digit drivers, the outputs source

current to the display anodes. When acting as segment drivers, the LED outputs sink current

from the display common cathodes. The outputs are high impedance when not being used

as digit or segment drivers.

Each port configured as a LED segment driver behaves as a digitally-controlled constant

current sink. The LED drivers are suitable for both discrete LEDs and common anode (CA)

numeric LED digits. When fully configured as a LED driver, the STLED325 controls up to 8

LED segments in a single digit with individual 8-step adjustment of the constant current

through each LED segment. A single resistor sets the maximum segment current for all the

segments, with a maximum of 40 mA per segment. The STLED325 drives any combination

of discrete LEDs and common anode (CA) digits for numeric displays.

The recommended value of RSET is the minimum allowed value, since it sets the display

driver to the maximum allowed segment current. RSET can be a higher value to set the

segment current to a lower maximum value where desired. The user must also ensure that

the maximum current specifications of the LEDs connected to the drivers are not exceeded.

3.9 Over temperature cut-off

The STLED325 contains an internal temperature sensor that turns off all outputs when the

die temperature exceeds 140°C. The outputs are enabled again when the die temperature

drops below 125°C. Register contents are not affected, so when a driver is over-dissipating,

the external symptom will be the load LEDs cycling between on and off as the driver

repeatedly overheats and cools, alternately turning the LEDs off and then back on again.

This feature will protect the device from damage due to excessive power dissipation. It is

important to have good thermal conduction with a proper lay-out to reduce thermal

resistance.

3.10 Standby mode

By utilizing the standby function, the host processor and other ICs can be turned off to

reduce power consumption. The STLED325 is able to wake-up the system when

programmed hotkeys are detected to signal that the full operation of the system is required.

The hotkeys can be entered to the system through the front panel keys or through the

infrared (IR) remote control or the Real Time Clock (RTC) alarm or through the wake-up pin.

STLED325 supports multiple remote control protocols decoding by setting the appropriate

register.

The STLED325 is able to cut-off the power to the main board for standby operation for good

power management. STBY will be set to high when READY signal goes from high to low, I

command for standby is seen or when the guard timer has finished counting down to 0,

whichever occurs first.

In the normal mode of operation, the STBY is asserted only when the guard timer has

finished counting down to 0. This is meant to put the system into stand-by even though

standby command was not issued by the host or READY signal did not go low. This occurs

as the guard timer register was not cleared before it finished counting down to 0.

2

C

14/62 Doc ID 17576 Rev 1

STLED325 Functional description

3.10.1 Cold boot up

When power is first applied to the system, the STLED325 is reset. It will then manage the

power to the main board by bringing the STBY pin to a low level.

This wakes up the main processor which asserts the READY pin to a high level to indicate to

STLED325 of a proper boot-up sequence.

If the microprocessor does not assert the READY pin to a high within 10s (default), the

STLED325 cuts off the power to the Host by asserting the STBY pin. The high level on

READY pin signifies that the processor is ready. After this, the processor can configure the

STLED325 by sending the various I

RTC display mapping, hot-keys.

The power-up behavior in 2 conditions is shown in Figure 5.

2

C commands for configuration of display, RC protocol,

Doc ID 17576 Rev 1 15/62

Functional description STLED325

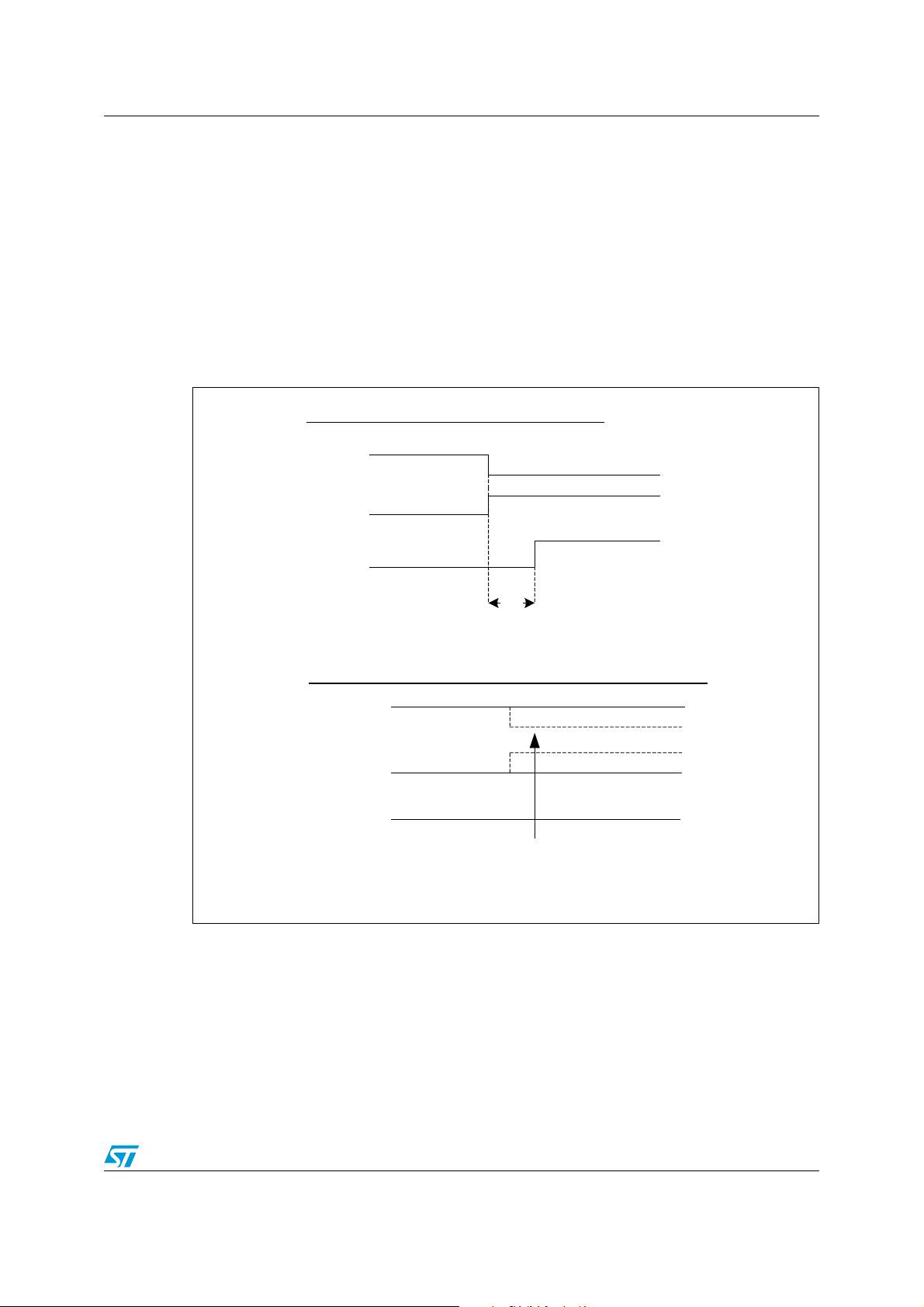

Figure 5. Power-up condition

1a) Power-up condition (normal behavior )

VCC to STLED325I

Internal POR

1b) Power-up condition (processor not responding)

VCC to STLED325I

Internal POR

STBY

READY

MUTE

Guard timer counts up to 10s

STBY

READY

MUTE

READY asserts within 10s which is the desired

behavior, processor is active and not hung

Count over

Guard timer counts up to 10s

READY continues to remain low/high

Due to abnormality in the processor, READY did not

change state from low to high, leading to STBY

assertion

Note: 1 Guard timer is turned off by default upon READY assertion.

2 If Guard timer is to be kept on during READY high condition, the guard timer registers must

be set accordingly by proper commands through I

2

C bus.

3 In this power-up condition, Guard timer is triggered by internal POR pulse.

4 During power-up, the Guard timer value is 10s.

16/62 Doc ID 17576 Rev 1

!-6

STLED325 Functional description

3.10.2 Entering standby mode

The STLED325 controls the power to the main board using the STBY pin. During normal

operation, the STBY pin is a low level which externally controls a Power MOS switch to

enable power to the main board. The STLED325 asserts the STBY pin to a high when any

one of the following conditions occur:

– Processor fails to respond by enabling the READY pin within 10s upon first power-up

(cold boot up)

– Guard timer counts down to 0s

– Processor makes the READY pin to low (can happen in various conditions such as

user presses STBY key on front panel, STBY key on remote control, etc).

Figure 6. Power down condition (normal behavior)

2a) Power-down condition (normal behavior )

READY

MUTE

STBY

2 us

Guard timer is not required here

2b) Power-down condition (abnormal behavior of processor)

READY

MUTE

STBY

In this case the READY remains high and as long as

READY is high, the MUTE is low and STBY is low.

READY continues to remain high

!-6

– Guard timer can be kept on during normal condition when READY is high (depending

on the user).

– In this condition, the guard timer can be disabled or enabled. If the guard timer is

enabled, the timer needs to be cleared before the programmed count of the timer is

reached. If the programmed count is reached, the STBY will be asserted.

– It is advisable not to enable the guard timer during normal operation.

Doc ID 17576 Rev 1 17/62

Functional description STLED325

3.10.3 Wake-up

The STLED325 can wake-up from any one of the following sources:

– Front-panel keys

– Remote-control keys

– Real time clock (RTC) in 3 conditions (alarm, watchdog timer, oscillator fail)

– External wake-up pin (by a low to high transition on this pin)

– GPIO status changes

– READY pin goes from low to high

Figure 7. Standby condition (normal behavior)

3a) Standby condition (normal behavior)

or Key pad or RTC or WAKE_UP for wake up

Hot key command from IR

Guard timer triggers

STBY

READY

MUTE

3b) Standby condition (abnormal behavior, processor is not responding)

Hot key command from IR

or Key pad or RTC or WAKE_UP for wake up

STBY

READY

MUTE

READY asserts within programmed timer value (1s-15s)

Guard timer

triggers

Signals STBY after

guard timer count is over

READY continues to remain low

!-6

– When the hot-key is detected either from front-panel or remote control or RTC or from

a transition (low to high transition) on WAKE_UP pin during stand-by, the STBY pin

de-asserts.

– The de-assertion of the STBY triggers the guard timer.

– The timer value is the programmed value by the user (1-15s). If the user did not

change the value before entering standby, then it remains 10s.

– Also note that the guard timer is off when the STLED325 is in the standby mode.

The guard timer is thus triggered by a de-assertion of the STBY signal or by internal power

on reset signal.

18/62 Doc ID 17576 Rev 1

STLED325 Functional description

3.11 Real time clock (RTC)

The STLED325 integrates a low power Serial RTC with a built-in 32.768 kHz oscillator

(external crystal controlled). Eight bytes of the SRAM are used for the clock/calendar

function and are configured in binary coded decimal (BCD) format. An additional 12 bytes of

SRAM provide status/ control of alarm and watchdog functions. Addresses and data are

transferred serially via a two line, bi-directional I

incremented automatically after each WRITE or READ data byte. Note that all 4 digits must

be enabled before using the RTC display.

Functions available to the user include a non-volatile, time-of-day clock/calendar, alarm

interrupts and watchdog timer. The eight clock address locations contain the century, year,

month, date, day, hour, minute, second and tenths/hundredths of a second in 24 hour BCD

format. Corrections for 28, 29 (leap year - valid until year 2100), 30 and 31 day months are

made automatically.

The RTC operates as a slave device through the slave address of the STLED325 on the

serial bus. Access is obtained by implementing a start condition followed by the correct

device slave address. The 16 bytes contained in the device can then be accessed

sequentially in the following order:

–1. Reserved

– 2. Seconds register

– 3. Minutes register

– 4. Hours register

– 5. Day register

– 6. Date register

– 7. Century/month register

– 8. Year register

– 9. Calibration register

– 10. Watchdog register

– 11 - 16. Alarm registers

2

C interface. The built-in address register is

The RTC keeps track of the date and time. Once the date and time are set, the clock works

when the STLED325 is in normal operation and standby operation. Wake-up alarm feature

is also included in the RTC module. The accuracy of the RTC is approximately 20 ppm

(±50secs/month). How-ever this much depends on the accuracy of the external crystal

used.

The wake-up alarm is programmed to wake up once the date and time set are met. This

feature is present in normal and standby mode of operation. Only one date and time is

available for setting.

The real time clock (RTC) uses an external 32.768 kHz quartz crystal to maintain an

accurate internal representation of the second, minute, hour, day, date, month, and year.

The RTC has leap-year correction. The clock also corrects for months having fewer than 31

days.

3.11.1 Reading the real time clock

The RTC is read by initiating a Read command and specifying the address corresponding to

the register of the real time clock. The RTC registers can then be read in a sequential read

mode. Alarms occurring during a read are unaffected by the read operation.

Doc ID 17576 Rev 1 19/62

Functional description STLED325

3.11.2 Writing to the real time clock

The time and date may be set by writing to the RTC registers. The new RTC time can be

updated by writing to the RTC registers. The new time only takes affect after a complete

write cycle. If the write cycle is incomplete, the new time value is discarded. A single byte

may be written to the RTC without affecting the other bytes.

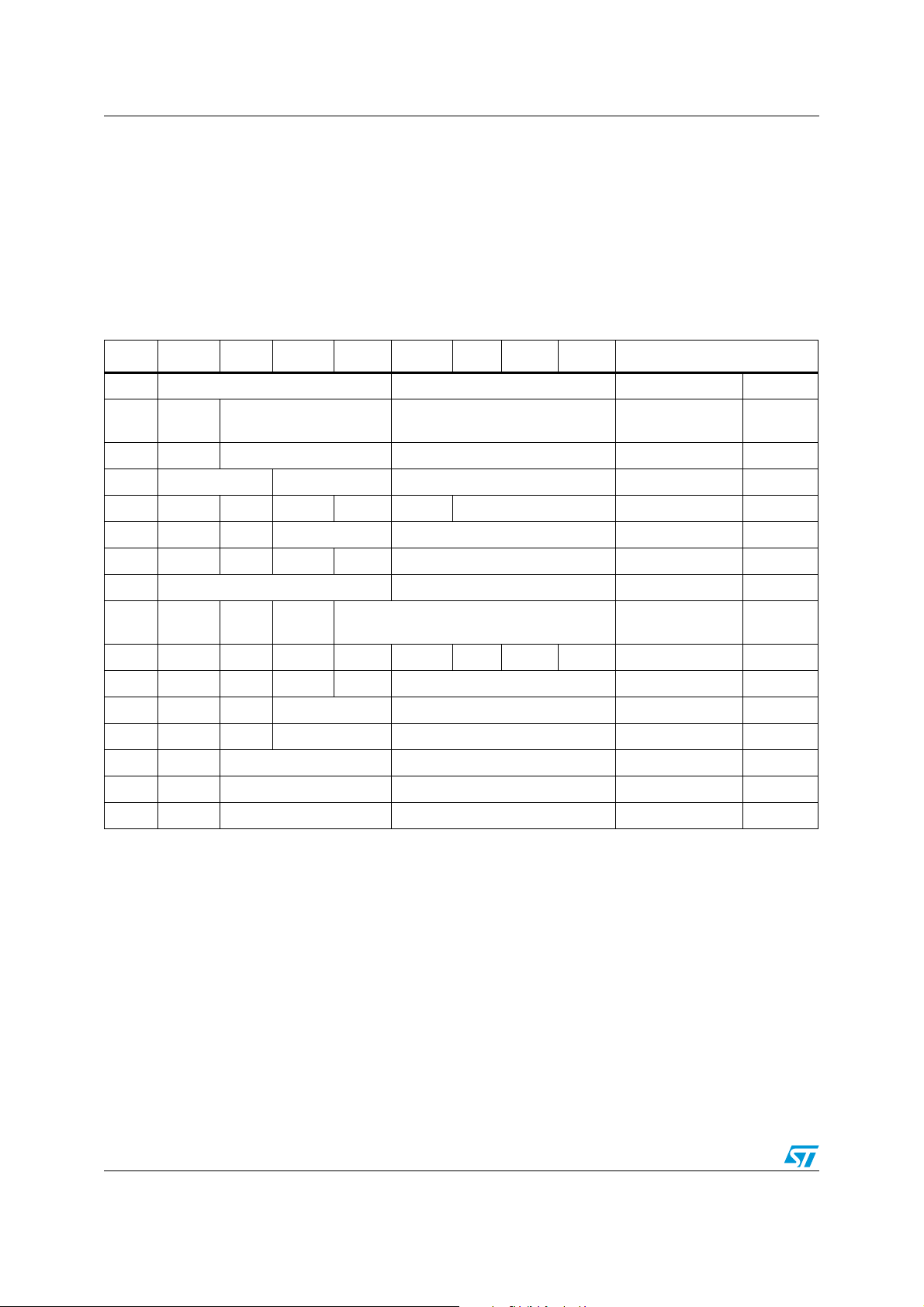

3.11.3 Register table for RTC

Table 2. Register table for RTC

Addr D7 D6 D5 D4 D3 D2 D1 D0 Functional/range BCD format

00h Reserved Reserved

OSC_S

01h

02h Rsvd 10 minutes Minutes Minutes 00-59

03h MD_HM_MS 10 hours Hours (24 hours format) Hours 00-23

04h Rsvd Rsvd Rsvd Rsvd Rsvd Day of week Day 01-7

05h Rsvd Rsvd 10 date Day of month Date 01-31

06h CB1 CB0 Rsvd 10M Month Century/month 0-3/01-12

T

10 seconds Seconds Seconds 00-59

07h 10 years Year Year 00-99

08h 12/24 Rsvd

09h RB2 BMB4 BMB3 BMB2 BMB1 BMB0 RB1 RB0 Watchdog

0Ah AFE Rsvd ABE AI 10M Alarm month Al month 01-12

0Bh RPT4 RPT5 AI 10 date Alarm date Al date 01-31

0Ch RPT3 RPT6 AI 10 hour AIarm hour AI hour 00-23

0Dh RPT2 Alarm 10 minutes Alarm minutes Al min 00-59

0Eh RPT1 Alarm 10 seconds Alarm seconds Al sec 00-59

0Fh WDFEn Alarm: day of week Rsvd (bypass mode) Flags

Cal_sig

n

Calibration Calibration

Legend:

Cal_Sign = Sign bit

OSC_ST = Oscillator Stop bit

BMB0 – BMB4 = watchdog multiplier bits

CB = Century bits

ABE = Alarm in battery back up mode enable bit

AFE = Alarm flag enable

RB0 – RB2 = watchdog resolution bits

RPT1 – RPT6 = alarm repeat mode bits

20/62 Doc ID 17576 Rev 1

STLED325 Functional description

WDFEn = watchdog flag enable

12/24 = 12 hour or 24 hour format (‘0’ for 24-hour format and ‘1’ for 12-hour format). For 12

hour PM display, the 8th segment of last digit (digit 4) is driven to indicate PM mode through

a dot on the last digit.

It is recommended to fill the unused bits in the register map to 0 upon a cold boot up. The

timekeepers and alarm store data in BCD format, while the calibration, watchdog bits are in

binary format.

The structure of the frame is shown below. For RTC, all the Dig1 to Dig4 must be configured

to show the proper time.

Figure 8. Keyscan and digit mapping

Digit 5

Keyscan

(used for

discrete LED)

If the date programmed in the RTC exceeds a valid date value, then the RTC does not

function as desired. So the invalid dates should never be programmed into the RTC.

3.11.4 Setting alarm clock registers

Address locations 0Ah-0Eh contain the alarm settings. The alarm can be configured to go

off at a prescribed time on a specific month, date, hour, minute, or second or repeat every

year, month, day, hour, minute, or second. It can also be programmed to go off while the

STLED325 is in the standby mode to serve as a system wake-up call.

Bits RPT6-RPT1 put the alarm in the repeat mode of operation. Codes not listed in the table

default to the once per second mode to quickly alert the user of an incorrect alarm setting.

Note that by default, the alarm repeat mode is enabled and by default the repeat frequency

is set to “once per year”.

Dig 1 Dig 2

Dig 3

Dig 4

AM08722V1

Address locations 0Ah to 0Eh contain the alarm settings. The alarm can be configured to go

off at a prescribed time. The default repeat alarm mode is once per year. Programming the

RPT[6:1] bits changes the repeat alarm mode.

Doc ID 17576 Rev 1 21/62

Functional description STLED325

Table 3. Alarm repeat modes

RPT5 RPT4 RPT3 RPT2 RPT1 RPT6 Repeat alarm mode

1 1 1 1 1 1 Once per week

1 1 1 1 1 0 Once per second

1 1 1 1 0 0 Once per minute

1 1 1 0 0 0 Once per hour

1 1 0 0 0 0 Once per day

1 0 0 0 0 0 Once per month

00 0 0 0 0Once per year

If the RPT value is other than the valid ones listed in the table, the default repeat alarm

mode is once per second so as to quickly alert the user of an incorrect alarm setting.

When the clock information matches the alarm clock settings based on the match criteria

defined by RPT[6:1], then the alarm flag is set. Then if the alarm flag enable bit, is also set,

this will activate the alarm interrupt. Interrupt is cleared by reading the Interrupt registers.

3.11.5 Century bits

The clock shall include correction for leap years. The clock shall also correct for months

fewer than 31 days. Corrections for 28, 29 (leap year –valid until year 2100), 30, 31 day

months must be made automatically.

The two Century bits increment in a binary fashion at the turn of the century, and handles all

leap years correctly. See table for additional explanation.

Table 4. Century bits examples

CB[0] CB[1] Leap year? Example

00Yes2000

0 1 No 2100

1 0 No 2200

1 1 No 2300

1. Leap year occurs every 4 years (for years evenly divisible by 4), except for years evenly divisible by 100.

The only exceptions are those years evenly divisible by 400. (The year 2000 was a leap year, year 2100 is

not.)

(1)

22/62 Doc ID 17576 Rev 1

STLED325 Functional description

3.11.6 Initial power-on defaults

Upon application of power to the device, the register bits in the RTC initially power-on in the

state indicated in table below.

Table 5. Initial power-on defaults

OSC_ST AFE WDFEn

000

Initial power-on defaults value of the RTC registers.

Note: All other control bits power-up in a default state of 0 unless otherwise specified.

Doc ID 17576 Rev 1 23/62

Functional description STLED325

3.11.7 Programmable display

The default display of the RTC time is the 2 MSB digit for hour and the 2 LSB digit for

minutes. However, if the MD_HM_MS bit is set, then the RTC display for the digits can be

changed according to Ta bl e 6 .

Table 6. RTC display

MD_HM_MS RTC display

10 Date-month

00 Hour-minute (default and recommended)

01 Minute-second

11 Month-date

3.11.8 Lookup table with ppm against the calibration register values

The lookup table of the calibration register values for the equivalent ppm is shown in Tab l e 7

below:

Table 7. LUT with ppm against the calibration register values

Sign bit Counts/bit PPM

0000000

0000012

0000104

0000116

0001008

00010110

00011012

00011114

00100016

00100118

00101020

00101122

00110024

00110126

00111028

00111131

01000033

01000135

01001037

01001139

01000041

01000143

01001045

01001147

24/62 Doc ID 17576 Rev 1

STLED325 Functional description

Table 7. LUT with ppm against the calibration register values (continued)

Sign bit Counts/bit PPM

01110049

01110151

01111053

01111155

01110057

01110159

01111061

01111163

1000000

100001-4

100010-8

100011-12

100100-16

100101-20

100110-24

100111-28

101000-33

101001-37

101010-41

101011-45

101100-49

101101-53

101110-57

101111-61

110000-65

110001-69

110010-73

110011-77

110000-81

110001-85

110010-90

110011-94

111100-98

111101-102

111110-106

111111-110

111100-114

111101-118

111110-122

111111-126

Doc ID 17576 Rev 1 25/62

Functional description STLED325

3.12 Remote control decoder

The remote control (RC) decoder module decodes the signal coming from IR_IN pin. The IR

remote control protocols recognized by STLED325 are Philips-RC-5, RCMM, Thomson

RCA, R2000, NEC and R-STEP protocols. The selection of remote control protocol to use is

done by setting the RC protocols register. The command from the remote control is used to

wake-up from standby and resume normal operation. All RC keys can be programmed to act

like RC hotkeys. Upon receiving any one of the designated hotkeys, wake-up operation

begins.

The address of the appliance (8-bit) is stored first into the internal RAM. Then, the command

for the hotkeys is programmed into the internal RAM. Each hotkey memory address could

accommodate one byte (8-bit). Usually one byte is reserved for one command. The hot-keys

can be configured to wake-up the system by more than one RC device address (up to a

maximum of 8 device addresses).

3.13 Interrupt

The STLED325 interrupts the Host by pulling the IRQ_N pin to a low-level both in normal

mode of operation and during wake-up. The interrupt is enabled by STLED325 when any of

the conditions occur:

– Front panel key press in normal operation or during system standby state

– Remote control key press in normal operation or during system standby state

(including the toggle bit changes for all RC protocols)

– A low-to-high on the external pin, WAKE_UP

– Real time clock triggers (alarm, watchdog timer, 32 kHz oscillator fails)

– GPIO input changes

– Low battery indication

– Thermal shutdown

The IRQ_N is an active low level signal and is cleared only after the Interrupt buffer is read.

After reading the interrupt buffer, the Host will know the actual source of the interrupt. This

allows the Host to exactly know the event which caused the interrupt (e.g STBY key on the

Front Panel). The interrupt signal is used to inform the Host of any events detected by the

STLED325. Note that the IRQ_N pin is an open-drain pin which requires an external pull-up

resistor.

Figure 9. Interrupt

The interrupt output is of active low level type.

26/62 Doc ID 17576 Rev 1

STLED325 Functional description

While the interrupt is being read by the MCU and a new GPIO or key data comes in, no new

interrupt is generated but the register for GPIO and KEY data is updated so that the MCU

does not miss the new KEY and GPIO data.

3.14 Ready

The STLED325 supports cutting-off power to the main board for standby operation for good

power management. STBY will be set to high when the READY transitions from high to low.

During a cold boot up or wake up from standby, if the READY pin stays low, the STLED325

will assert the STBY when the guard timer has finished counting down to 0.

When the READY drops to a low, MUTE goes high immediately and soon after (2µs

minimum) the STBY is asserted.

In the normal mode of operation, when READY is a high, the STBY is asserted only when

the guard timer is enabled and has finished counting down to 0. This is meant to put the

system into stand-by as the READY pin was stuck at high and the guard timer register was

not cleared before it finished counting down to 0. It is advised to disable the guard timer

during normal operation.

3.15 Mute

The MUTE pin will be set to logic high to mute the audio output before power is cut to the

host processor. In wake up mode, the MUTE pin will be set to logic low to enable the audio

output immediately after the high assertion of the READY pin. In general, MUTE follows

READY pin with an inverted polarity. This pin is used to prevent pop-up sound during powerup and power-down states.

3.16 GPIO

The STLED325 supports 2 additional GPIOs that can be configured as inputs or outputs. As

an input, the GPIO can be used to interface to a sensor or a switch or key and as an output,

the GPIO can be used to drive individual indicator LEDs.

3.17 Power sense circuits

The STLED325 has a built-in power sense circuit which detects power failures and

automatically switches to the battery or super-cap supply when a power failure occurs. The

energy needed to sustain the SRAM and clock operations can be supplied by small lithium

button supply or a super-cap when a power failure occurs. When operating from the battery

or super-cap, all the inputs and outputs are driven to a known state (generally L).

Doc ID 17576 Rev 1 27/62

Functional description STLED325

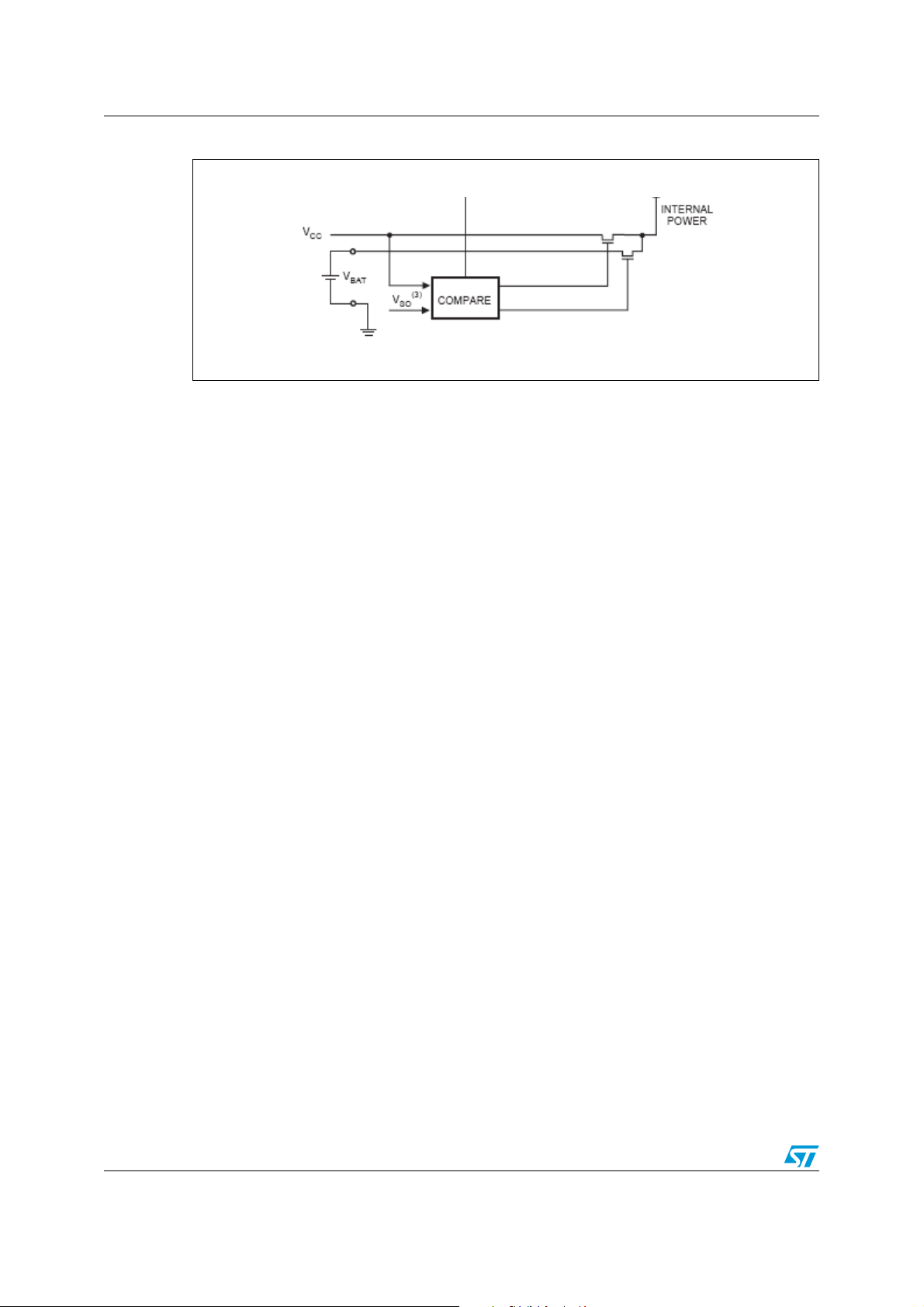

Figure 10. Power sense circuit

For the STLED325 itself, there is the normal operational mode where the supply is from the

5V V

from the V

To conserve power and maintain long battery life in this battery supply mode, only the RTC

and the clock to the RTC remain operational.

1. The system will only go into battery mode while:

. When the VCC drops below a pre-defined low level, the supply source is switched

CC

to the battery or super-cap supply.

CC

Vcc < 3.5 V and Vcc < Vbat.

So, it means that the system will only switch to battery mode when Vcc drop below 3.5V and

Battery voltage is higher V

voltage.

CC

2. The system will enter back into Vcc mode from battery mode while:

V

> V

CC

bat

It means that the system will switch back to Vcc mode as soon as the VCC is higher than

Vbat.

The STLED325 continually monitors Vcc for an out-of-tolerance condition. Should V

below the Switchover voltage (V

= 3.5 V), the device goes into a low-power mode. Inputs

SO

CC

fall

to the device will not be recognized at this time to prevent any erroneous data or outcome

from device. The device also automatically switches over to the battery and powers down

into an ultra low current mode of operation to maximize the super-cap or battery duration. As

system power returns and V

and the power supply is switched to the external V

rises above Vbat, the battery or super-cap is disconnected

CC

. During the battery or super-cap back-

CC

up mode, the clock registers of RTC are maintained by the attached battery or super-cap.

On power-up, when V

returns to a nominal value, write protection continues for t

CC

REC

(refer

to timing diagram in later part of spec).

Upon power-up, the device switches from battery to V

when VCC > Vbat. When VCC rises

CC

above Vbat, it will recognize the inputs.

28/62 Doc ID 17576 Rev 1

STLED325 Functional description

Figure 11. Circuit

The minimum operating voltage of STLED325 is 2.5 V with a typical VBAT voltage of VCCVF (diode). Therefore, the typical delta voltage swing across the capacitor is

ΔV = V

– VF – V

CC

where VF is approximately 0.5 V. Therefore,

ΔV = 5 – 0.5 – 2.5 = 2 V

Since the typical battery current (IBAT) is limited to 7 µA, the capacitance and duration of

power-out time can be calculated using the formula:

I = CΔV/Δt

Where I = 7µA, ΔV=2V, C= capacitance in Farads and Δt is power-out time in seconds.

Using a 0.1F super-cap, for example, the equation would be:

7µA = 0.1F x 2V/Δt

Solving for Δt, the typical power-down time is about 28,571 seconds = 8 hours.

3.17.1 Switchover

During the period the VCC falls, in order for the battery switchover circuit to work reliably, the

fall time of V

trigger and switch from V

period from 0V to 5V, the rise time of V

Figure 12. Battery switchover waveform

from 5V to 0V should be at least 100µs. This is to allow the comparator to

CC

CCmin

CC

to V

mode should there be a need. During the VCC rise

BAT

is not critical. This is indicated by the Figure 12.

CC

Also note that for battery operation, there will be a current spike of 5mA in 10us into the

battery when V

CC

to V

switchover happens. From V

BAT

Doc ID 17576 Rev 1 29/62

to VCC switching, the current

BAT

Functional description STLED325

spike is very low into the battery. The battery must be protected against such spikes. This is

not relevant for super-cap.

During the switching from V

to VCC, the I2C is active after a minimum of 5ms.

BAT

3.17.2 Battery low warning

The STLED325 automatically performs battery voltage monitoring upon power-up. If the

interrupt for this condition (ABE) is enabled, the RTC will generate an interrupt pulse if the

battery voltage is found to be less than a minimum of 2.5V. However, this condition is

unlikely to go away very quickly as time is needed for the battery to be replaced, and it is not

desirable to keep issuing an interrupt.

Therefore when this bit is set, this condition is checked once every week. If the condition is

still true, then interrupt is sent again.

The ABE bit is an enable bit for battery status check. If the ABE bit was set and the battery

low is generated during a power up sequence, this indicates that the battery is below

approximately 2.5 V and may not be able to maintain data integrity. At this point, a fresh

battery needs to be installed or the super-cap recharged.

This situation only occurs when a battery is used but not with a super-cap as the super-cap

re-charges when the supply is present.

3.17.3 Different power operation modes

The device is capable to support the different power modes as shown in the Table 8.

Table 8. Different power operation modes

V

CC

V

BAT

Present Present V

Present Absent (Float or 0V)

V

Absent (Float or 0V) Present V

V

< 3.5V V

CC

Absent (Float or 0V) Absent (Float or 0V)

BAT

> V

CC

V

Condition Operation

Normal operation of

chip from V

Normal operation of

chip from V

CC until VCC

is 3.5V

CC

V

CC

> V

CC

> V

BAT

BAT

> 3.5V

and

Chip operations from

BAT

> 2.5V

V

in a low power

BAT

mode of operation

Chip operations from

V

in a low power

BAT

mode of operation

< 3.5V and

CC

V

< 2.5V

BAT

Chip does not function.

Completely shutdown.

CC

30/62 Doc ID 17576 Rev 1

STLED325 Functional description

3.18 Bus characteristics

The bus is intended for communication between different ICs. It consists of two lines: a bidirectional data signal (SDA) and a clock signal (SCL). Both the SDA and SCL lines must be

connected to a positive supply voltage (typical voltage is 3.3 V) via a pull-up resistor (typical

value is 10 K). The following protocol has been defined.

- Data transfer may be initiated only when the bus is not busy.

- During data transfer, the data line must remain stable whenever the clock line is High.

- Changes in the data line, while the clock line is High, will be interpreted as control

signals.

Accordingly, the following bus conditions have been defined:

Bus not busy: Both data and clock lines remain High.

Start data transfer: A change in the state of the data line, from high to Low, while the clock

is High, defines the START condition.

Stop data transfer: A change in the state of the data line, from Low to High, while the clock

is High, defines the STOP condition.

Data valid: The state of the data line represents valid data when after a start condition, the

data line is stable for the duration of the high period of the clock signal. The data on the line

may be changed during the Low period of the clock signal. There is one clock pulse per bit

of data.

Each data transfer is initiated with a start condition and terminated with a stop condition.

The number of data bytes transferred between the start and stop conditions is not limited.

The information is transmitted byte-wide and each receiver acknowledges with a ninth bit.

By definition a device that gives out a message is called “transmitter,” the receiving device

that gets the message is called “receiver.” The device that controls the message is called

“master.” The devices that are controlled by the master are called “slaves.”

Acknowledge: Each byte of eight bits is followed by one Acknowledge Bit. This

Acknowledge Bit is a low level put on the bus by the receiver whereas the master generates

an extra acknowledge related clock pulse. A slave receiver which is addressed is obliged to

generate an acknowledge after the reception of each byte that has been clocked out of the

master transmitter.

The device that acknowledges has to pull down the SDA line during the acknowledge clock

pulse in such a way that the SDA line is a stable Low during the High period of the

acknowledge related clock pulse. Of course, setup and hold times must be taken into

account. A master receiver must signal an end of data to the slave transmitter by not

generating an acknowledge on the last byte that has been clocked out of the slave. In this

case the transmitter must leave the data line High to enable the master to generate the

STOP condition.

Note: Refer to Philips I

2

C specification or contact STMicroelectronics for more information on I2C.

Doc ID 17576 Rev 1 31/62

Functional description STLED325

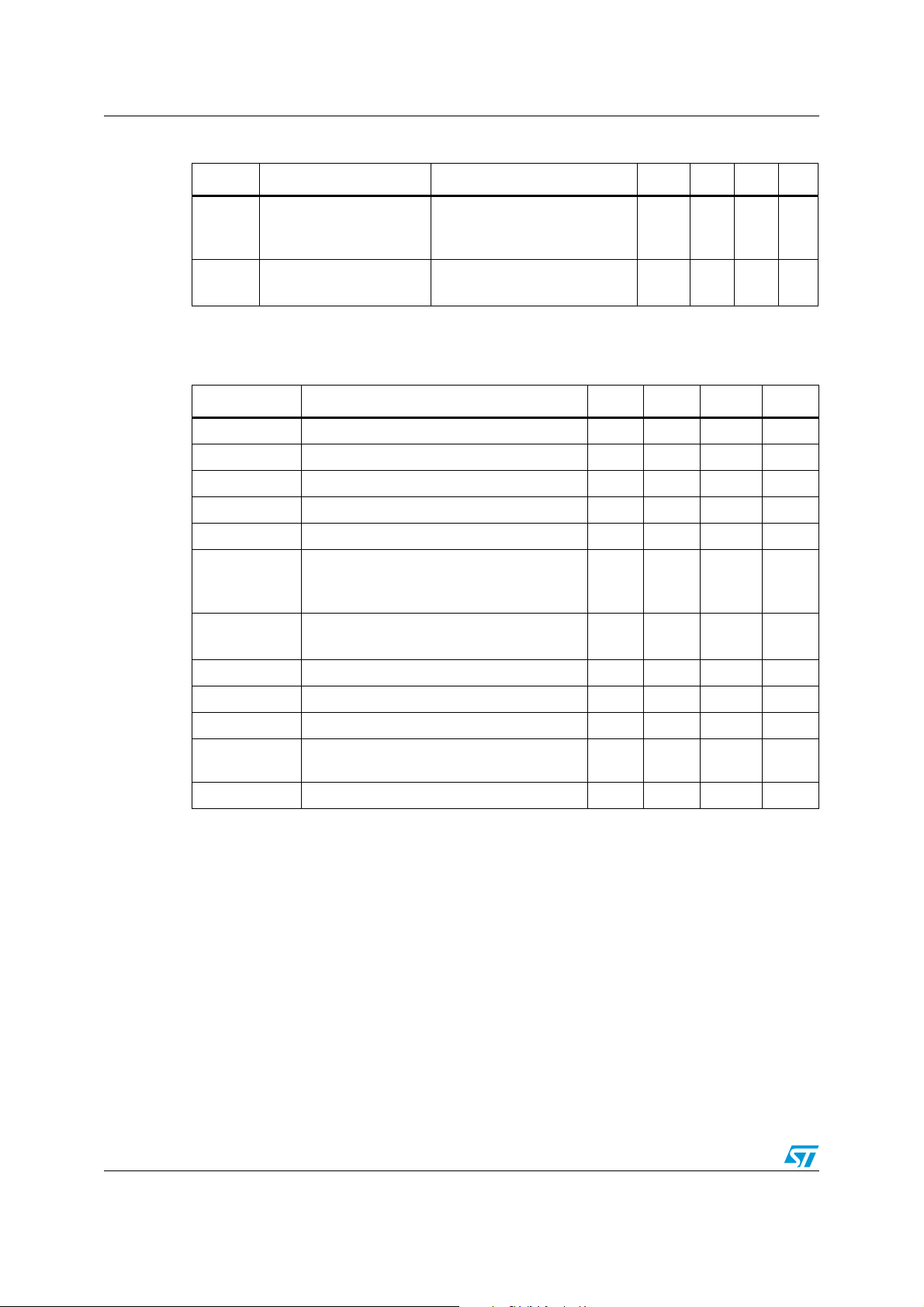

Table 9. Pin description

Pin number Symbol Type Name and function

1 MUTE OUT

2IRQ_NOUT

Output from the STLED325 to gracefully mute the audio

before entering standby mode

Interrupt output (active low level type) to interrupt the

MCU under various conditions

3 GPIO0 IN/OUT GPIO0 that can be configured as an input or output

4 GPIO1 IN/OUT GPIO1 that can be configured as an input or output

5 IR_IN IN Remote control data input

2

6 SDA IN/OUT I

7SCLINI

8 WAKE_UP Input

C compatible serial data I/O

2

C compatible serial clock input

Wake-up pin (can be used for wake-up on detecting a low

to high transition). AV wake-up or CEC wake-up.

Digit output pin. Can be used in conjunction with 8

9DIG5OUT

segment outputs to control 8 discrete LEDs on the front

panel.

10 - 13 DIG4 –DIG1 OUT Digit output pins

5.0 V ± 10% main supply voltage. Bypass to GND

14 VCC PWR

through a 0.1 µF capacitor as close to the pin as

possible.

Input data to these pins from external keyboard are

15, 16 KEY2-KEY1 IN

latched at end of the display cycle (maximum keyboard

size is 8 x 2). 5V digital input.

SEG8/KS8

17 - 24

to

OUT Segment output pins (dual function as key source)

SEG1/KS1

Current sense input. Connect resistor to ground to set

25 ISET IN

constant current through LEDs. Connect to GND through

a resistor to set the peak segment current.

26 VBAT Input

Battery power supply for the RTC when there is no

supply to the chip

27 VREG Output 1.8V regulator output. Connect to an external capacitor.

28 GND PWR Connect this pin to system GND

29 XIN IN Connect to an external crystal or apply external clock

30 XOUT OUT Output of the external crystal. Open when external clock

31 STBY OUT Hardware pin to control the power to the Host

32 READY IN

Input to the device from the Host to indicate that Host is

ready

EPAD Exposed pad. Connect to PCB GND.

32/62 Doc ID 17576 Rev 1

STLED325 Electrical ratings

4 Electrical ratings

4.1 Absolute maximum ratings (TA = 25 °C, GND = 0 V)

Absolute maximum ratings are those values above which damage to the device may occur.

Functional operation under these conditions is not implied. Exposure to absolute maximum

rating conditions for extended periods may affect device reliability. All voltages are

referenced to GND.

Table 10. Absolute maximum ratings (T

Symb

ol

V

Supply voltage to ground -0.5 to +7.0 V

CC

Logic input voltage (KEY1, KEY2 inputs) -0.5 to +7.0 V

V

I

V

Logic input voltage (all input pins except KEY1, KEY2) -0.5 to +3.6 V

I

Power dissipation

P

D

Operating ambient temperature -40 to 85 °C

T

A

T

Junction temperature 150 °C

J

T

V

Table 11. Thermal data

Storage temperature -65 to +150 °C

STG

Lead temperature (10 sec) 300 °C

T

L

Electrostatic discharge voltage on all

pins

2

ESD

Parameter Value

1

= 25 °C, GND = 0 V)

A

1200 mW

Human body model -2 to +2 kV

Symbol Parameter QFN 32 Unit

R

Tj-c

Thermal resistance junction-case TBD °C/W

Uni

t

Doc ID 17576 Rev 1 33/62

Electrical ratings STLED325

4.2 Recommended operating conditions

4.2.1 DC electrical characteristics

(TA = -40 to +85 °C, VCC = 5.0 V ± 10%, GND = 0 V)

Table 12. DC electrical characteristics

Symbol Parameter Test conditions Min Typ Max

V

V

REG

V

V

V

V

I

IH

V

HYS

V

I

OLEAK

I

SEG

I

DIG

I

TOLSEG

External supply voltage 4.5 5.0 5.5 V

CC

Internal logic supply voltage and

regulator output

HIGH level input voltage (all digital

IH

pins except KEY1 and KEY2)

LOW level input voltage (all digital

IL

pins except KEY1 and KEY2)

HIGH level input voltage (KEY1 and

IH

KEY2 pins)

LOW level input voltage (KEY1 and

IL

KEY2 pins)

, I

Input current (all pins) VIN = VIH or V

IL

High level

guaranteed

Low level

guaranteed

High level

guaranteed

Low level

guaranteed

1.62 1.8 1.98 V

1.35 1.98 V

00.45V

35.5V

02V

IL

-2 2 µA

Hysteresis voltage (digital pins) 0.2 V

Low level output voltage (Digital

OL

output pins)

= 4 mA 0.4 V

I

OL2

Driver leakage current Drivers off -150 µA

V

= VF = 2.5 V

Segment drive LED sink current

Digit drive LED source current V

Segment drive current matching

LED

= VCC – 1.0

V

DIGIT

= VCC – 1.0 240 320 400 mA

DIGIT

=5.0 V,

V

CC

T

=25°C

A

=2.5V; LED

V

LED

-30 -40 -50 mA

±4.0 %

current = 40 mA

R

SET

External current setting reference

resistor (precision = ±1% tolerance)

I

= 40 mA 360 Ω

SEG

Uni

t

34/62 Doc ID 17576 Rev 1

STLED325 Electrical ratings

4.3 Power consumption estimation

Each port of the STLED325 can sink a maximum current of 40 mA into an LED with a 3.4 V

forward voltage drop when operated from a supply voltage of 5.0 V. The minimum voltage

drop across the internal LED drivers is thus 5.0 - 3.4 = 1.6 V. The STLED325 can sink

8 x 40 = 320 mA when all outputs are operating as LED segment drivers at full current. On a

5.0 V supply, a STLED325 dissipates (5.0 V-3.4 V) x 320 mA = 512 mW when driving 8 of

these 3.4 V forward voltage drop LEDs at full current. If the application requires high drive

current, consider adding a series resistor to each LED to drop excessive drive voltage offchip.

If the forward voltage of the LED is lesser than 4.4 V (say 2.4 V), then the maximum power

dissipation of STLED325 when all segments are turned on will be (5 - 2.4) V x 320 mA =

832 mW. To lower the power dissipation, consider adding a small series resistor in the

supply. Another alternative is to in-crease the value of the RSET to lower the current of the

LEDs from 40 mA to say 30 or 20 mA.

The efficiency will be the power consumption in the LEDs divided by the input power

consumed.

Equation 1 Efficiency = Vdiode x Idiode / V

CC

x I

CC

As an example, consider LED with forward voltage of VF = 2.4 V, Ipeak = 40 mA, VCC (max)

= 5.5 V, N=number of segments=8(max), D=duty cycle=15/16,

Power dissipation, PD (max) = 5 mA x 5.5 V + (5.5-2.4) V x (15/16) x 40 mA x 8 = 27.5 + 780

= 807.5 mW. To lower this value, add a series resistor with the supply.

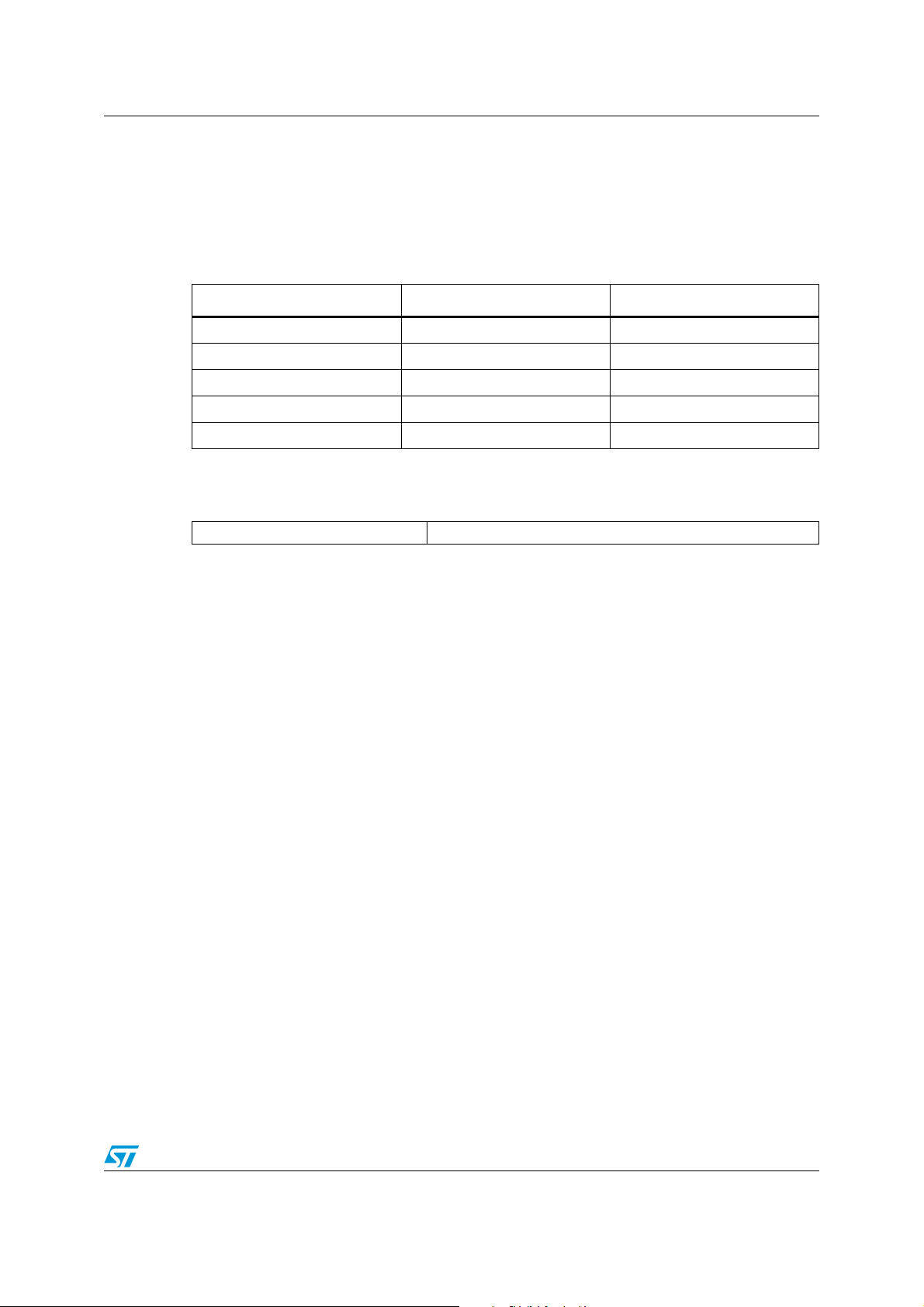

Table 13. Voltage drop estimation with RGB LED

Typica l forwa rd

LED

Red 2.2 V 40 mA 5 V 1 V 2.2 V 1.8

Green 2.5 V 40 mA 5 V 1 V 2.5 V 1.5

Blue 3V 40mA 5V 1V 3V 1V

voltage

VF

Typica l

current

Typical supply

voltage

Digit driver

drop

External

VF

Segment

driver

drop

Note that the above analysis is for a typical condition. If the VF is higher and the supply

voltage is lower than 5V, then it is recommended to operate the LED at a lower current than

40mA in order to have enough headroom for the digit and segment drivers so as not to affect

the brightness and matching.

Table 14. Capacitance (TA = 25°C, f = 1 MHz)

Symbol Parameter Test conditions Min Typ Max Unit

C

IN

Input capacitance

(all digital pins)

Doc ID 17576 Rev 1 35/62

15 pF

Electrical ratings STLED325

Table 15. Power supply characteristics (T

= -40 to 85°C)

A

Symbol Parameter Test conditions Min Typ Max Unit

All blocks of chip ON except

that no display load

= 5.5V

V

CC

Display OFF

= 5.5V

V

CC

TBD mA

2mA

I

CC

I

CC(Q)

Operating power supply

current

Quiescent supply current

)

Table 16. Dynamic switching characteristics (TA = -40 to +85 °C, VCC = 5.0V ± 10%,

GND=0.0V, Typical values are at 25°C)

Symbol Parameter Min Typ Max Units

f

SCL

t

LOW

t

HIGH

t

R

t

F

tHD:STA

tSU:STA

tSU:DAT Data setup time* 100 ns

SCL clock frequency 0 400 kHz

Clock low period 1.3 µs

Clock high period 600 ns

SDA and SCL rise time 300 ns

SDA and SCL fall time 300 ns

START condition hold time

(after this period the first clock pulse is

600 ns

generated)

START condition setup time

(only relevant for a repeated start condition)

600 ns

tHD:DAT Data hold time 0 µs

tSU:STO STOP condition setup time 600 ns

tBUF

Time the bus must be free before a new

transmission can start

1.3 µs

trec Watchdog output pulse width 96 98 ms

Note: The transmitter must internally provide a hold time to bridge the undefined region (300ns

max) of the falling edge of the SCL.

36/62 Doc ID 17576 Rev 1

STLED325 Electrical ratings

Table 17. Timing characteristics (T

= -40 to +85 °C, VCC = 5.0 V ± 10%, GND=0.0 V,

A

typical values are at 25 °C)

Parameter Symbol Min Typ Max Unit Test conditions

Propagation delay

time

t

t

t

TZH1

Rise time

t

TZH2

Fall t ime t

Input capacitance C

Mute active to

standby active

GPIO edge to

interrupt trigger

TM-S 2µs

T

PLZ

PZL

THZ

irq

I

8µs

300 ns

100 ns

2µs

0.5 µs

CLK -> SDA

= 15 pF, RL = 10 kΩ

C

L

Seg1 to Seg12

CL =

300

pF

Grid1 to Grid8,

Seg13/Grid16 to

Seg20/Grid9

120 µs CL = 300 pF, Segn, Dign

15 pF

Doc ID 17576 Rev 1 37/62

Electrical ratings STLED325

4.4 Oscillator and crystal characteristics

Table 18. Oscillator characteristics

Symbol Parameter Conditions Min Typ Max Unit

V

STA

tSTA Oscillator start time V

CL1 X

CL2 X

1. Reference value. TA = 25 deg C, VCC = 3.0 V, CFM-145 (CL = 6 pF, 32.768 KHz) manufactured by Citizen.

Oscillator start voltage ≤ 10 seconds 1.5 V

= 3.0 V 1 s

CC

IN

OUT

IC-to-IC frequency

variation

(1)

-20 +20 Ppm

25 pF

25 pF

Table 19. Crystal electrical characteristics

Symbol Parameter Conditions Min Typ Max Unit

fo

Rs Series resistance

CL Load capacitance 12.5 pF

1. Externally supplied. ST recommends the Citizen CFS-145 (1.5 x 5 mm) and the KDS DT-38 (3 x 8 mm) for

thru-hole, or the KDS DMX-26S(3.2x8mm) for surface-mount, tuning fork-type quartz crystals. KDS can be

contacted at kouhou@kdsj.co.jp or http://www.kdsj.co.jp. Citizen can be contacted at csd@citizenamerical.com or http://www.citizencrystal.com

2. Circuit board layout considerations for the 32.768KHz crystal of minimum trace lengths and isolation from

RF generating signals should be taken into account.

Resonant

frequency

(1)

(2)

32.768 KHz

35 40

(3)

kΩ

Note: 1 Oscillator is not production tested.

2 Externally supplied. ST recommends the Citizen CFS-145 (1.5 x 5 mm) and the KDS DT-38

(3 x 8 mm) for thru-hole, or the KDS DMX-26S(3.2x8mm) for surface-mount, tuning forktype quartz crystals. KDS can be contacted at kouhou@kdsj.co.jp or http://www.kdsj.co.jp

Citizen can be contacted at csd@citizen-americal.com or http://www.citizencrystal.com

3 Circuit board layout considerations for the 32.768KHz crystal of minimum trace lengths and

isolation from RF generating signals should be taken into account.

4 Guaranteed by design.

38/62 Doc ID 17576 Rev 1

STLED325 Electrical ratings

4.5 ESD performance

Table 20. ESD performance

Symbol Parameter Test conditions Min Typ Max Unit

ESD

MIL STD 883 method 3015

(all pins)

HBM ±2kV

Table 21. Battery range and battery detect

Symbol Parameter Conditions Min Typ Max Unit

VBAT

(1)

Battery supply voltage 2.5 3 3.5

(2)

V

TA=25C,

I

BAT

1. STMicroelectronics recommends the RAYOVAC BR1225 or BR1632 (or equivalent) as the battery supply.

2. For rechargeable back-up, V

Battery supply current

(max) may be considered VCC.

BAT

VCC= 0 V, Oscillator

BAT

=3 V

ON, V

710 uA

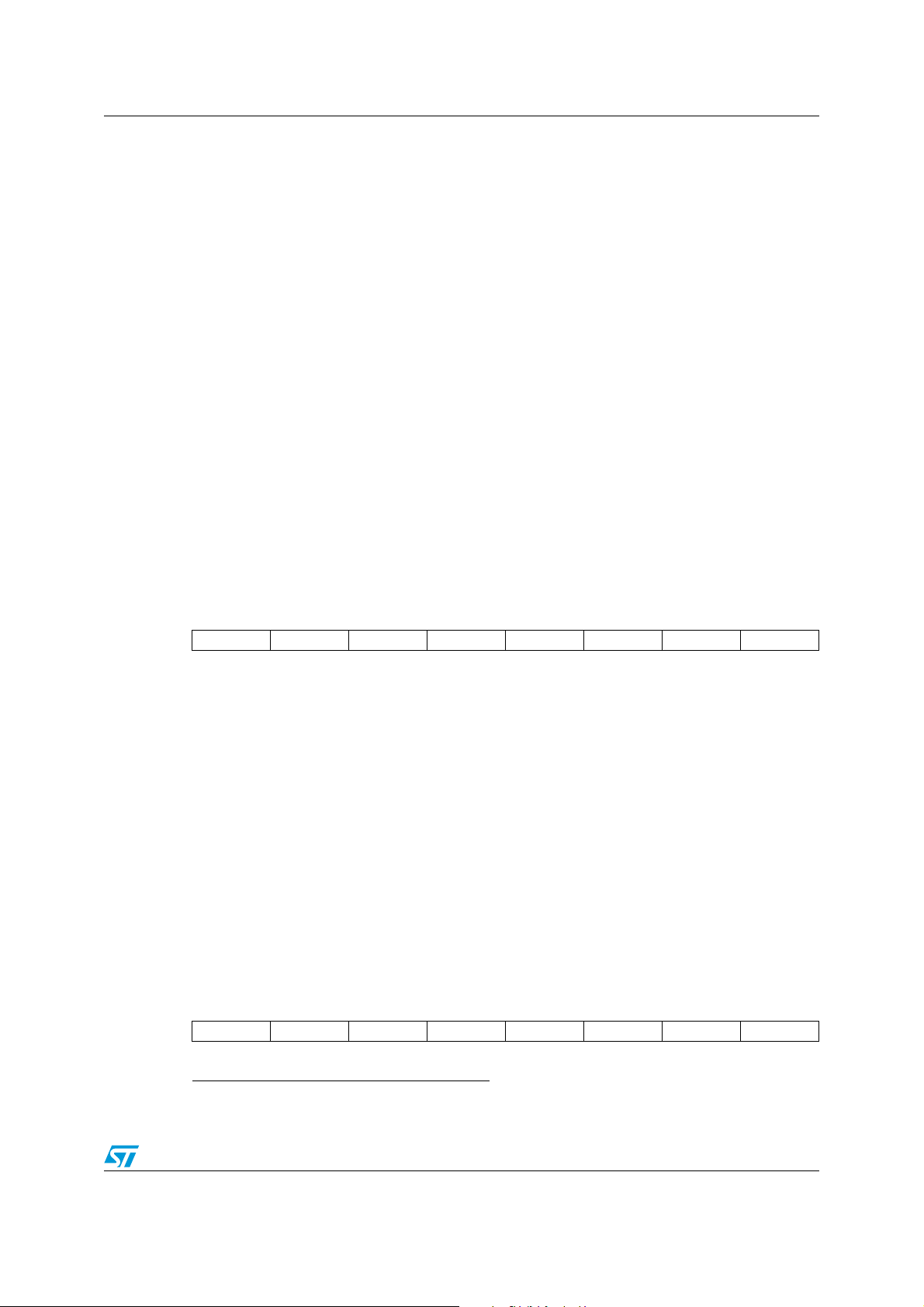

Figure 13. Power down/up mode ac waveforms

Table 22. Power down/up AC characteristics

Symbol Parameter

tpD SCL and SDA at V

trec SCL and SDA at V

1. VCC fall time should not exceed 5mV/µs.

2. Valid for ambient operating temperature: T

Table 23. Power down/up trip points DC characteristics

Symbol Parameter

V

SO

V

SO

Battery back-up switchover voltage

(from VCC to V

Battery back-up switchover voltage

BAT

to VCC)

(from V

Doc ID 17576 Rev 1 39/62

(1)(2)

before power down 0 ns

IH

after power-up 10 µs

IH

(1)(2)

=-40 to 85, V

A

= 2.5V to 5.5V (except where noted)

CC

Min Typ Max Unit

Min Typ Max Unit

V

)

BAT

V

V

CC

CC

CC

< 3.5V

and

< V

> V

BAT

BAT

V

V

Electrical ratings STLED325

1. All voltages are referenced to GND.

2. Valid for ambient operating temperature: T

=-40 to 85, V

A

= 2.5V to 5.5V (except where noted)

CC

Table 24. Thermal shutdown characteristics

(1)

Symbol Parameter Conditions Min Typ Max Unit

TSD

Thermal shutdown

threshold

VCC=5V 140 Deg C

THYS Hysteresis VCC=5V 15 Deg C

1. Thermal shutdown is not production tested.

Figure 14. V

characteristics

CC

40/62 Doc ID 17576 Rev 1

STLED325 Display RAM address and display mode

5 Display RAM address and display mode

The display RAM stores the data transmitted from an external device to the STLED325

through the serial interface. The addresses are as follows, in 8-bits unit:

Table 25. Bit map for segment 1 to segment 8

Seg1 Seg4 Seg8

10 H

11 H

12 H

13 H

14 H

L

L

L

L

L

10 H

11 H

12 H

13 H

14 H

U

U

U

U

U

Dig1

Dig2

Dig3

Dig4

Dig5

b0 b3 b4 b7

XX H

L

“0” in memory means GND on outpu; ‘1” in memory means V

XX H

U

on output.

CC

Doc ID 17576 Rev 1 41/62

KEY matrix and key-input data storage RAM STLED325

6 KEY matrix and key-input data storage RAM

The key matrix is of 8x2 configuration, as shown below:

Figure 15. KEY matrix and key-input data storage RAM

The data of each key are stored as illustrated below, and are read by the appropriate read

command, starting from the least significant bit.

Key 1 Key 2 Key 1 Key 2 Key 1 Key 2 Key 1 Key 2

Seg1 KS1 Seg2 KS2 Seg3 KS3 Seg4 KS4

Seg5 KS5 Seg6 KS6 Seg7 KS7 Seg8 KS8

b0 b1 b2 b3 b4 b5 b6 b7

All the front panel keys can be configured as hot keys using the “configuration mode setting