Features

■ Operating input voltage range from 2.3 V to

5.5 V

■ ± 7.5% LED current accuracy

■ Two LEDs in series per channel

■ High side current source

■ Up to 125 mA of total LED current

■ 86% efficiency at 100 mA

■ PWM dimming with automatic shutdown time

window

■ 2.5 MHz switching frequency

■ CSP 12 bumps 0.4 mm. pitch 1.4 x 1.8 mm.

Applications

■ LCD backlight with up to 10 LEDs

■ Cellular phones

■ PDAs

Description

STLED25

5 channels step-up white LED driver

Datasheet − production data

Flip-Chip 12 bumps (1.4 x 1.8 mm.)

continue operating driver channels that are

functioning normally, while avoiding excessive

power consumption or associated thermal issues.

The control technique is able to maintain the

efficiency close to 87% at medium load and

higher than 85% at light or full load. The device

also includes soft-start control, inrush current

limit, thermal shutdown and inductor peak current

limit. The STLED25 is packaged in a 12-bump

CSP (1.4 x 1.8 mm, 0.5 mm height).

The STLED25 is a fixed frequency, high efficiency,

boost DC-DC converter with five parallel high side

current sources. It is capable of providing 125 mA

of total current with a maximum voltage of 7.5 V

on each channel. Each current source supports

single or dual LED connection. The output voltage

of the step-up converter is automatically set at

100 mV above the highest voltage required on

any driver, to guarantee proper operation of the

linear current sources. The device implements a

self-test feature to detect failure of any of the

LEDs and to disable the related channel. The

failure status is reset as soon the IC is disabled.

This mode of failure detection allows the device to

Table 1. Device summary

Order code Package Packaging

STLED25JR Flip-Chip12 Tape and reel

May 2012 Doc ID 022323 Rev 3 1/30

This is information on a product in full production.

www.st.com

30

Contents STLED25

Contents

1 Application schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Pin configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5 Typical application performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.1 Quiescent current consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.2 Switching frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.3 Continuous output current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.4 Efficiency at 100 mA I

5.5 Efficiency at 75 mA I

5.6 Efficiency at 50 mA I

5.7 Absolute channel accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.8 Current matching between LED strings . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.9 PWM dimming linearity 0.39 - 10% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.10 PWM dimming linearity 10 - 100% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.11 Inductor peak current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.12 Maximum continues output current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6 Detailed description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.1 Boost DC-DC converter operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.2 Current setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.3 EN13 and EN45 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.4 Modes of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.5 Undervoltage lockout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.6 Overtemperature protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.7 Open LED protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.8 Overvoltage protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.9 Short LED protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2/30 Doc ID 022323 Rev 3

STLED25 Contents

7 Application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7.1 External passive components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7.1.1 Inductor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7.1.2 Input and output capacitor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7.2 Recommended PCB layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

9 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Doc ID 022323 Rev 3 3/30

Application schematic STLED25

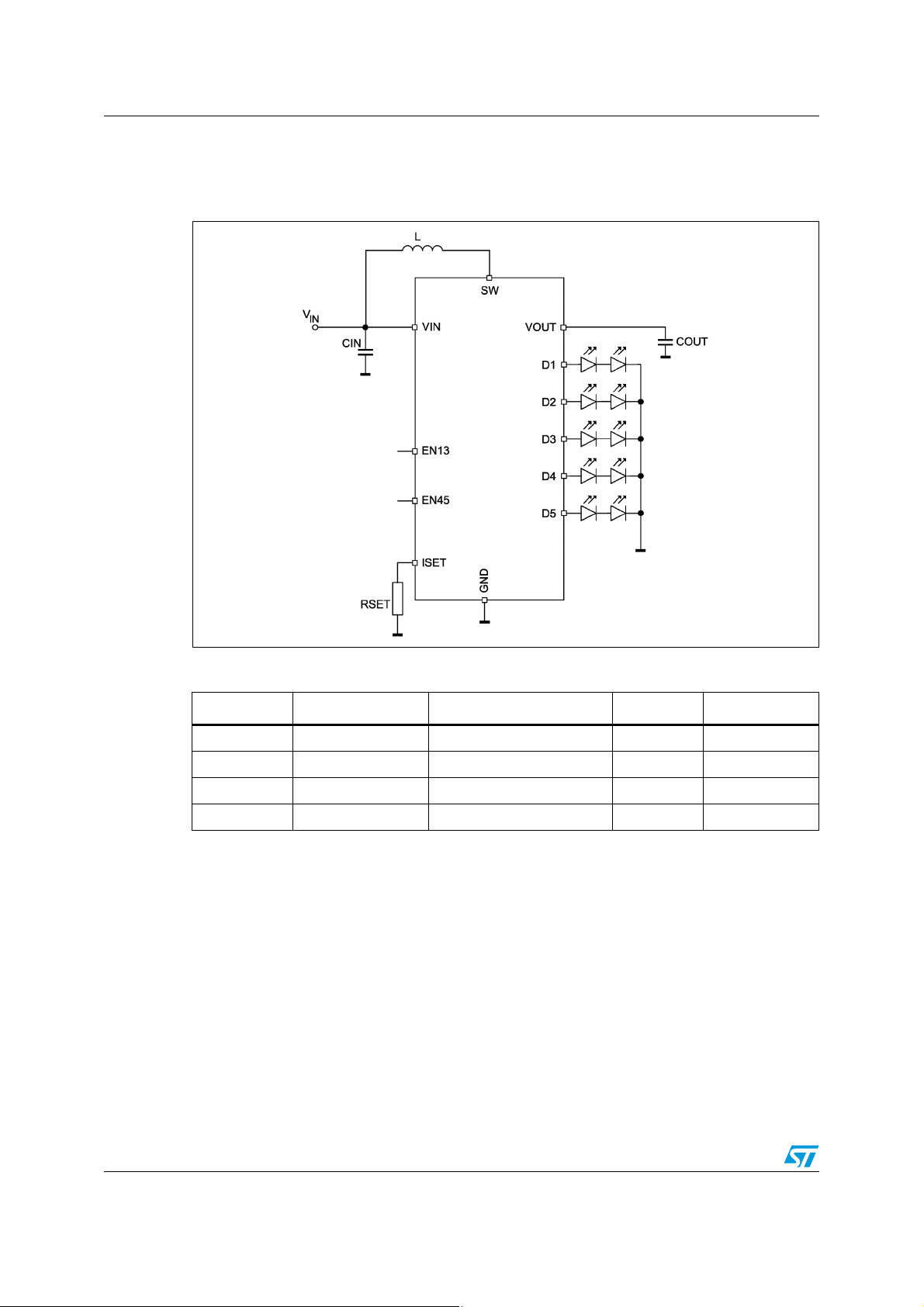

1 Application schematic

Figure 1. STLED25 application schematic

Table 2. Typical external components

Component Manufacturer Part number Value Size

C

IN

C

OUT

L Samsung CIG21K4R7SCE 4.7 µH 0805

R

SET

1. For 20 mA per branch.

Murata GRM155R60J155M 1.5 µF 0402

Murata GRM219R61A106ME47 10 µF 0805

(1)

25 k

0402

Note: All the above components refer to a typical application. Operation of the device is not limited

to the choice of these external components.

4/30 Doc ID 022323 Rev 3

STLED25 Application schematic

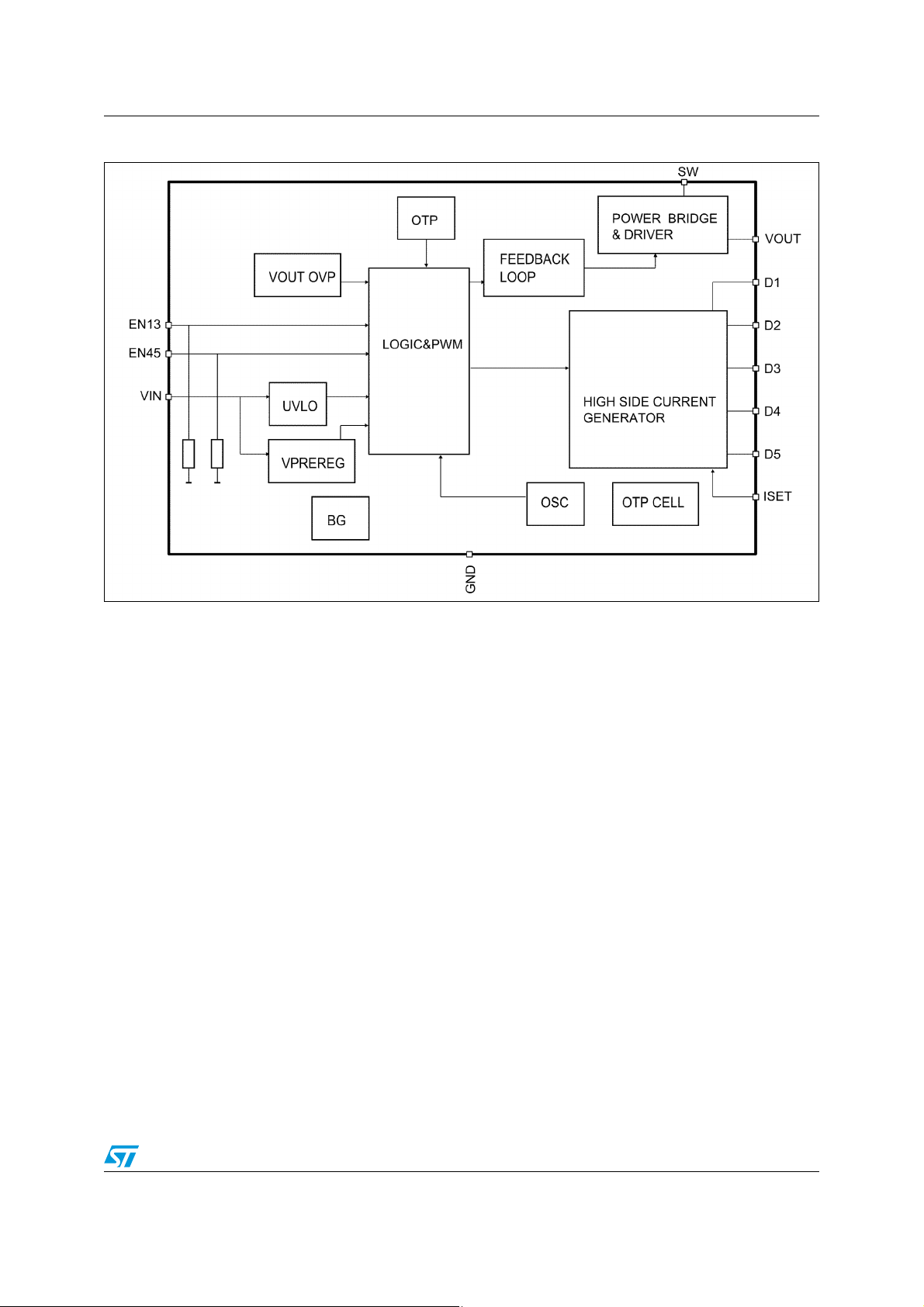

Figure 2. Functional block diagram

Doc ID 022323 Rev 3 5/30

Pin configuration STLED25

2 Pin configuration

Figure 3. Pin configuration (top view)

VIN ISET D1

EN13 EN45 D2

GND D5 D3

SW VOUT D4

AM09921v1

Table 3. Pin description

Pin name Pin number Description

VIN A1 Supply from battery

ISET A2

D1 A3 String 1 controlled by EN13

EN13 B1 Positive polarity. EN13 & 45 Low = IC shutdown

EN45 B2 Positive polarity. EN13 & EN45 Low = IC shutdown

D2 B3 String 2 controlled by EN13

GND C1 Power ground and IC ground

D5 C2 String 5 controlled by EN45

D3 C3 String 3 controlled by EN13

SW D1 Inductor connection to internal switch

VOUT D2 DC-DC output to V

D4 D3 String 4 controlled by EN45

Resistor to GND from 1.28 V (typ.) internal reference: 390x current

multiplier

capacitor

OUT

6/30 Doc ID 022323 Rev 3

STLED25 Maximum ratings

3 Maximum ratings

Table 4. Absolute maximum ratings

Symbol Parameter Value Unit

VIN Supply voltage -0.3 to +6 V

SW Switching node -0.3 to + 11 V

VOUT Output voltage -0.3 to +10 V

D1-D5 LED strings -0.3 to +10 V

EN13, EN45 Signal pins -0.3 to VIN V

ISET Current setting -0.3 V to 2 V

Machine model ± 200

ESD

Charged device model ± 500

VHuman body model ± 2000

T

T

AMB

T

J

STG

Operating ambient temperature -30 to 85 °C

Maximum operating junction temperature +150 °C

Storage temperature -65 to 150 °C

Table 5. Thermal data

Symbol Parameter Value Unit

R

THJA

1. This parameter corresponds to a 4-layer PCB board with 1 inch² of cooling area.

Junction to ambient thermal resistance

(1)

62 °C/W

Doc ID 022323 Rev 3 7/30

Electrical characteristics STLED25

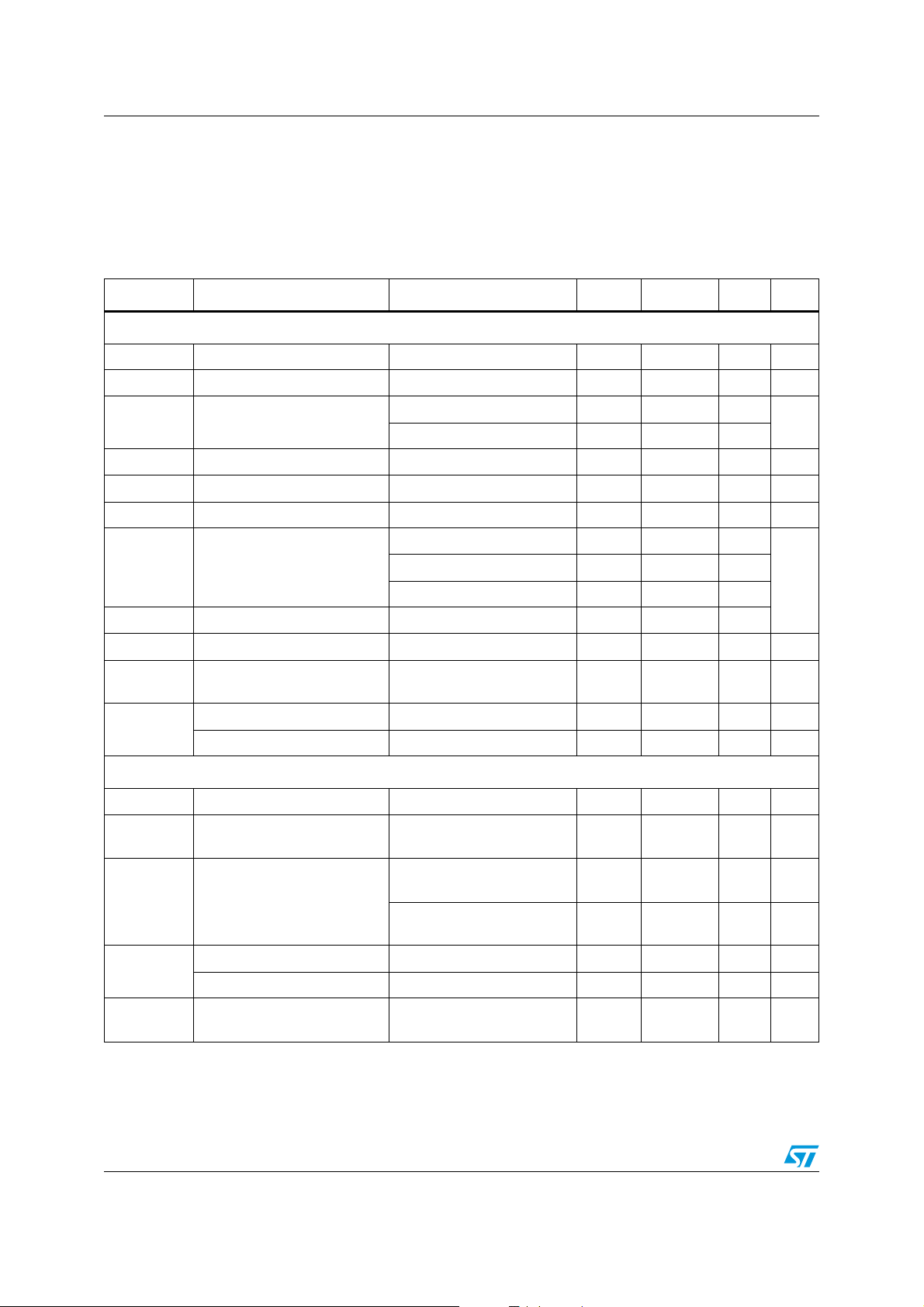

4 Electrical characteristics

- 30 °C < TA < 85 °C, VIN = 3.7 V; V

= 25 °C, unless otherwise specified.

T

A

Table 6. Electrical characteristics

= 7.5 V, EN13 = EN45 = VIN, typical values are at

OUT

Symbol Parameter Test conditions Min. Typ. Max. Unit

General section

V

IN

Operating input voltage 2.3 3.7 5.5 V

Iq Shutdown mode EN13 = EN45 = 0 0.5 2 µA

V

rising 1.9 2.0

V

ν

V

OVP

UVLO

f

SW

I

OUT

I

PK

ν

DC-DC

OVP

HYST

Undervoltage lockout

threshold

Switching frequency 2.25 2.5 2.75 MHz

Continuous output current

Inductor peak current 550 650 mA

OUT

(1)

= 6.2 V;

Application efficiency

(V

= 3.7 V; V

IN

see application schematic)

DC-DC converter efficiency I

Overvoltage protection 8.8 9.05 9.3 V

Overvoltage protection

hysteresis

IN

VIN falling 1.7 1.8

(1)

V

= 2.5 V, V

IN

I

= 50 mA 84

OUT

I

= 75 mA 86

OUT

I

= 100 mA 86

OUT

= 100 mA 88

OUT

= 6.2 V 125 mA

OUT

250 mV

V

%

T

SHDN

Hysteresis 20 °C

LEDs current

Thermal shutdown 150 °C

I

D1-D5

V

SCP

I

LED

I

SET

V

CSH

Current matching -5.5 +5.5 %

Short-circuit protection on

LEDs

Absolute channel accuracy

Voltage reference R

Current mirror I

Measured on the Dx pins 1.28 V

5 mA < I

= 2.5 V to 5.5 V

V

IN

2.5 mA < I

= 2.5 V to 5.5 V

V

IN

SET

/ I

LED

< 25 mA,

LED

< 5 mA,

LED

= 200 k to 15 k 1.28 V

SET

Current source headroom

voltage

8/30 Doc ID 022323 Rev 3

-7.5 +7.5 %

-10 10 %

390 A/A

135 mV

STLED25 Electrical characteristics

Table 6. Electrical characteristics (continued)

Symbol Parameter Test conditions Min. Typ. Max. Unit

I

RIPPLE

PWM

I

LED_LEAK

I

LED_MAX

LED peak-to-peak current

(1) (2)

ripple

LIN

PWM linearity

(1) (2)

LED driver leakage in OFF

state

LED driver max current 25 mA

Line_tr Line transient response

D

f

DIM

DIM

PWM dimming frequency 100 800 Hz

Duty cycle of PWM dimming 0.39 100 %

Logic inputs

R

I

V

V

LK-I

EN

IL

IH

Internal pull-down resistor 100 kΩ

EN low-level input voltage

EN high-level input voltage

EN input leakage current

(1)

VIN = 2.5 V; I

all channels,

EN13

PWM

= 2.5 V; I

V

IN

all channels,

EN13

PWM

1/255 PWM, 300 Hz, 20 mA

on all drivers, V

LED

= EN45

LED

= EN45

IN

= 20 mA at

PWM

= 20 mA at

PWM

= 2.5 V

(3)

500 µA

4000

10 %

25/255 PWM, 300 Hz, 20

mA on all drivers, VIN = 2.5 V

(3)

= 7.5 V 0.5 µA

V

OUT

2%

VINTR=+/-350mV,10µs step 30 %

V

= 2.7 V to 4.5 V 0.68

IN

= 2.3 V to 5.5 V 0.55

V

IN

V

= 2.7 V to 4.5 V 1.07

IN

= 2.3 V to 5.5 V 1.14

V

IN

= V

V

EN

internal pulldowns

= 4.2 V, 100 k

IN

42 µA

V

V

Power switches

P-channel on resistance 880

R

DSON

I

LKG-LX

1. Not tested in production

2. 10% value reduction at V

3. The PWM linearity is measured on the mean value of the output current in PWM mode in the 100 ms window. The

frequency of the PWM is 300 Hz

N-channel on resistance 450

LX leakage current VIN=VLX=4.8V; VEN=0 1 µA

= 2.3 V

IN

Doc ID 022323 Rev 3 9/30

mΩ

Typical application performance STLED25

5 Typical application performance

5.1 Quiescent current consumption

Figure 4. Quiescent current at different ambient temperatures

0.06

0.05

0.04

[µA]

0.03

Q

I

0.02

0.01

0

1.5 1.9 2.3 2.7 3.1 3.5 3.9 4.3 4.7 5.1 5.5 5.9

VIN[V]

AM09922v1

-30°C

25°C

85°C

5.2 Switching frequency

Figure 5. Switching frequency at different ambient temperatures

2.7

2.65

2.6

2.55

2.5

[MHz]

SW

2.45

F

2.4

2.35

2.3

1.5 1.9 2.3 2.7 3.1 3.5 3.9 4.3 4.7 5.1 5.5 5.9

AM09923v1

-30°C

25°C

85°C

VIN[V]

10/30 Doc ID 022323 Rev 3

STLED25 Typical application performance

5.3 Continuous output current

Figure 6. Output current when V

110

100

90

80

70

60

[mA]

50

OUT

40

I

30

20

10

0

1.5 1.9 2.3 2.7 3.1 3.5 3.9 4.3 4.7 5.1 5.5 5.9

5.4 Efficiency at 100 mA I

Figure 7. Efficiency when I

100

90

80

η [%]

70

= 8.5 V at different ambient temperatures

OUT

AM09924v1

VIN[V]

OUT

= 100 mA at different ambient temperatures

OUT

AM09925v1

-30°C

25°C

85°C

-30°C

25°C

60

50

1.5 1.9 2.3 2.7 3.1 3.5 3.9 4.3 4.7 5.1 5.5 5.9

VIN[V]

85°C

Doc ID 022323 Rev 3 11/30

Typical application performance STLED25

5.5 Efficiency at 75 mA I

Figure 8. APPL efficiency when I

100

90

80

η [%]

70

60

50

1.7 2.1 2.5 2.9 3.3 3.7 4.1 4.5 4.9 5.3 5.7

5.6 Efficiency at 50 mA I

Figure 9. APPL efficiency when I

100

OUT

OUT

= 75 mA at TA = 25 °C

OUT

VIN[V]

= 50 mA at TA = 25 °C

OUT

AM09926v1

AM09927v1

90

80

η [%]

70

60

50

1.7 2.1 2.5 2.9 3.3 3.7 4.1 4.5 4.9 5.3 5.7

VIN[V]

12/30 Doc ID 022323 Rev 3

STLED25 Typical application performance

5.7 Absolute channel accuracy

Figure 10. Absolute channel accuracy - set string current to 20 mA

2.1 2.3 2.5 2.7 2.9 3.1 3.33.5 3.7 3.9 4 .1 4.3 4.5 4.7 4.9 5.1 5.3 5.5 5.7 5.9

5

4

3

2

1

[%]

0

DEV

I

-1

-2

-3

-4

-5

VIN[V]

AM09928v1

-30°C-ID1

-30°C-ID2

-30°C-ID3

-30°C-ID4

-30°C-ID5

25°C-ID1

25°C-ID2

25°C-ID3

25°C-ID4

25°C-ID5

85°C-ID1

85°C-ID2

85°C-ID3

85°C-ID4

85°C-ID5

5.8 Current matching between LED strings

Figure 11. Current matching - set string current to 20 mA

2.1 2.3 2.5 2.7 2.9 3.1 3.33.5 3.7 3.9 4.1 4.3 4.5 4.7 4.9 5.1 5.3 5.5 5.7 5.9

4

3

2

1

[%]

0

DEV

I

-1

-2

-3

-4

VIN[V]

AM09929v1

-30°C-ID1

-30°C-ID2

-30°C-ID3

-30°C-ID4

-30°C-ID5

25°C-ID1

25°C-ID2

25°C-ID3

25°C-ID4

25°C-ID5

85°C-ID1

85°C-ID2

85°C-ID3

85°C-ID4

85°C-ID5

Doc ID 022323 Rev 3 13/30

Typical application performance STLED25

5.9 PWM dimming linearity 0.39 - 10%

Figure 12. PWM linearity 0.39 - 10% at TA = 25 °C

11

10

9

8

7

6

[mA]

5

OUT

4

I

3

2

1

0

0.00 1.00 2.00 3.00 4.00 5.00 6.00 7.00 8.00 9.00 10.00 11.00

DC [%]

AM09930v1

5.10 PWM dimming linearity 10 - 100%

Figure 13. PWM linearity 10 - 100% at TA = 25 °C

110

100

90

80

70

60

[mA]

50

OUT

I

40

30

20

10

0

0 102030405060708090100110

DC [%]

AM09931v1

14/30 Doc ID 022323 Rev 3

STLED25 Typical application performance

5.11 Inductor peak current

Figure 14. Inductor peak current at TA = 25 °C

650

600

550

500

450

400

350

[mA]

300

L

I

250

200

150

100

50

0

1.5 1.9 2.3 2.7 3.1 3.5 3.9 4.3 4.7 5.1 5.5 5.9

VIN[V]

AM09932v1

5.12 Maximum continues output current

Figure 15. Maximum output current at TA = 25 °C

180

170

160

150

140

130

120

110

100

[mA]

90

80

OUT

I

70

60

50

40

30

20

10

0

1.5 1.9 2.3 2.7 3.1 3.5 3.9 4.3 4.7 5.1 5.5 5.9

VIN[V]

AM09933v1

25kOhm/100mA

20kOhm/125mA

15kOhm/170mA

Doc ID 022323 Rev 3 15/30

Typical application performance STLED25

Figure 16. Startup waveform Figure 17. Line transient response

Figure 18. Line transient response

16/30 Doc ID 022323 Rev 3

STLED25 Detailed description

6 Detailed description

The STLED25 is a high efficiency white LED power supply which integrates a step-up

converter and 5 high-side current sources. The device is controlled by two enable inputs

called EN13 and EN45 according to the labels of the LED channels. EN13 enables LED

channels 1, 2, 3 and EN45 enables LED channels 4, 5. The device is protected against

shorted LED channels by short LED protection and against open LED channels by open

LED protection. The device is able to recognize which channel has failed, and switch off this

channel to maintain correct operation of the remaining channels. The STLED25 device is

125 mA total output current capable and works over a battery voltage range of 2.3 V to 5.5

V. The typical output voltage during operation corresponds to the voltage level equal to

V

+ 125 mV. The STLED25 device has an optimized switching power bridge to reach a

FLED

high level of application efficiency (86%) with the typical battery voltage of 3.7 V. The device

is also able to work at high efficiency when not all the LED channels of the device are used.

6.1 Boost DC-DC converter operation

The step-up bridge with current mode control of the regulation regulates the output voltage

level according to the LED channel with the highest V

voltage headroom for the related current sources. The typical headroom of the current

sources is in the range of 135 mV. The STLED25 contains a current limiter, with a typical

value 600 mA, and soft-start control to limit the supply current from the battery. The method

of regulation during startup and normal operation is explained in

, in order to maintain sufficient

FLED

Section 6.4

.

6.2 Current setting

Each LED channel regulates to the same current. The value of the LED current is set by

choosing the R

resistor. The current flowing through this resistor is mirrored in order to

SET

obtain the LED current. The multiplication factor is 390.

The LED current is calculated with the following formula:

Equation 1

where:

V

= 1.28 V typical

SET

6.3 EN13 and EN45

EN13 and EN45 play the dual role of enable pin and PWM dimming. EN13 drives strings

D1, D2, D3 while EN45 drives D4 and D5. Both EN13 and EN45 are pulled down internally

by 100 k resistors.

The EN pins accept a signal between 100 Hz and 800 Hz, at duty cycles from 0.39% to

100%. The output average current maximum error is 10% at 0.39%, PWM duty cycle at 300

Hz.

I

LED

V

SET

×=

390

R

SET

Doc ID 022323 Rev 3 17/30

Detailed description STLED25

6.4 Modes of operation

Shutdown mode

The device is in shutdown with minimum current consumption. It goes to PWM_start as

soon as EN13 or EN45 are pulled high.

PWM_start

Once ENxx is asserted, the DC-DC is turned ON with a soft-start procedure until V

OUT

reaches 7 V; this phase takes around 1.2 ms.

If ENxx remains asserted, the device will stay in this condition and wait for 10 ms

(PWM_start_up), then the STLED25 goes to PWM_normal mode. If the next EN is asserted

during the PWM_start_up mode, the device will immediately enable the LED current

sources and continue in PWM_normal mode.

PWM_normal

In this mode of operation the drivers are in the ON state delivering current to the LEDs, and

the DC-DC converter maintains the V

value with enough headroom to keep the high side

OUT

current sources in regulation.

When both EN pins are low, the drivers are turned off and the RUN_HOLD timer starts.

RUN_hold

The RUN_hold time lasts approximately 30 ms. During this time, the DC-DC converter

maintains the last optimum voltage on V

. If RUN_hold time elapses without EN

OUT

reassertion, then the STLED25 goes into shutdown mode. If EN is reasserted, the device

goes to PWM_normaL mode.

Figure 19. Modes of operation

18/30 Doc ID 022323 Rev 3

STLED25 Detailed description

6.5 Undervoltage lockout

The undervoltage lockout function prevents improper operation of the STLED25 when the

input voltage is not high enough. When the input voltage is below the UVLO threshold, the

device is in shutdown mode. The hysteresis of 100 mV prevents unstable operation when

the input voltage is close to the UVLO threshold.

6.6 Overtemperature protection

An internal temperature sensor continuously monitors the IC junction temperature. If the IC

temperature exceeds 150 °C (typical), the device stops operating. As soon as the

temperature falls below 135 °C (typical), normal operation is restored.

6.7 Open LED protection

The device is able to detect an “Open LED” failure in each LED channel independently.

When this failure appears, the DC-DC increases the output voltage to maintain the current

source headroom voltage until the OVP threshold is reached; the device detects which LED

channel is the root cause and switches off this LED channel. This state is maintained until

the STLED25 goes into shutdown mode.

6.8 Overvoltage protection

The device has overvoltage protection on the V

components against the high voltage coming from the DC-DC, in case of a disconnected

load. When the output voltage level reaches the OVP threshold (9.3 V typical), the DC-DC is

turned off until the output voltage level goes below the OVP threshold. The hysteresis of the

OVP threshold is approximately 250 mV.

6.9 Short LED protection

The device is able to detect a shorted LED in each LED channel independently; when the

protection detects a failure on any of the LED channels, it switches off this channel until the

STLED25 enters shutdown mode.

pin to protect the device and external

OUT

Doc ID 022323 Rev 3 19/30

Application information STLED25

7 Application information

7.1 External passive components

7.1.1 Inductor selection

The inductor is the key passive component for switching converters.

For the STLED25, an inductance of 4.7 µH is recommended. It is very important to select

the right inductor according to the maximum current the inductor can handle to avoid

saturation. The peak current for the step-up can be calculated with the following formula:

Equation 2

×

IV

OUTOUT

MIN

+

OUT

I

−

BOOSTPEAK

=

×η

VIN

−×

MINOUTMIN

×××

LfsV2

where:

V

: step-up output voltage. The boost control loop keeps it 135 mV higher than the

OUT

maximum among VD1-D5

I

: total output current

OUT

V

: input voltage of STLED25

IN

fs: switching frequency. Use the minimum value of 2.25 MHz for the worst case

η: efficiency of step-up converter. It is 0.87 at 75 mA load

Table 7. List of recommended inductors

Manufacturer Part number

Samsung CIG21K4R7SCE 4.7 0.6 0805

Murata LQM21PN4R7 4.7 0.6 0805

Inductance

[µH]

Saturation current [A] Size [mm]

7.1.2 Input and output capacitor selection

It is recommended to use ceramic capacitors with low ESR as input and output capacitors in

order to filter any disturbance present in the input line and to maintain stable operation of the

step-up converter. A minimum real capacitance value of 1 µF must be guaranteed for C

and 4.2 µF C

in all conditions.

OUT

)VINV(VIN

IN

20/30 Doc ID 022323 Rev 3

STLED25 Application information

Table 8. Input and output capacitor

Manufacturer Part number

C

IN

Murata GRM155R60J155M 1.5 6.3 0402

Samsung CL05A225MQ5NSKC 2.2 6.3 0402

C

OUT

Murata GRM219R61A106ME47 10 10 0805

Nominal

capacitance [µF]

Rated voltage [V] TCC Size [mm]

7.2 Recommended PCB layout

The STLED25 is a high-frequency power switching device, so it requires a proper PCB

layout in order to obtain the necessary stability and optimize line/load regulation and output

voltage ripple. Input and output capacitors must be as close as possible to their relative pins.

Figure 20. Top layer

Doc ID 022323 Rev 3 21/30

Application information STLED25

Figure 21. Mid layer 1

Figure 22. Mid layer 2

22/30 Doc ID 022323 Rev 3

STLED25 Application information

Figure 23. Bottom layer

Figure 24. Top overlay

Doc ID 022323 Rev 3 23/30

Application information STLED25

Figure 25. Photo of the application board

24/30 Doc ID 022323 Rev 3

STLED25 Package mechanical data

8 Package mechanical data

In order to meet environmental requirements, ST offers these devices in different grades of

ECOPACK

specifications, grade definitions and product status are available at:

ECOPACK

®

packages, depending on their level of environmental compliance. ECOPACK®

®

is an ST trademark.

www.st.com

.

Doc ID 022323 Rev 3 25/30

Package mechanical data STLED25

Flip-chip 12 mechanical data

mm.

Dim.

Min. Typ. Max.

A 0.45 0.50 0.55

A1 0.17 0.20 0.23

A2 0.28 0.300.32

b 0.22 0.26 0.30

D1.815 1.845 1.875

D1 1.20

E1.358 1.388 1.418

E1 0.80

e0.36 0.40 0.44

fD 0.313 0.323 0.333

fE 0.284 0.2940.304

ccc 0.05

26/30 Doc ID 022323 Rev 3

8116384-D

STLED25 Package mechanical data

Tape & reel Flip-Chip 12 mechanical data

mm. inch.

Dim.

Min. Typ. Max. Min. Typ. Max.

A180 7.087

C 12.8 13.2 0.504 0.520

D 20.2 0.795

N60 2.362

T 14.4 0.567

Ao 1.46 1.51 1.56 0.057 0.059 0.061

Bo 1.89 1.941.99 0.074 0.076 0.078

Ko 0.54 0.59 0.64 0.021 0.023 0.025

Po 3.9 4.1 0.154 0.161

P 3.9 4.1 0.154 0.161

Doc ID 022323 Rev 3 27/30

Package mechanical data STLED25

Figure 26. Footprint recommended data (mm.)

28/30 Doc ID 022323 Rev 3

STLED25 Revision history

9 Revision history

Table 9. Document revision history

Date Revision Changes

10-Oct-2011 1 Initial release.

13-Dec-2011 2

11-May-2012 3 Document status promoted from preliminary data to production data.

Modified: C

page 21

OUT

.

part number

Table 2 on page 4

and

Table 8 on

Doc ID 022323 Rev 3 29/30

STLED25

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY TWO AUTHORIZED ST REPRESENTATIVES, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2012 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

30/30 Doc ID 022323 Rev 3

Loading...

Loading...