Features

■ Monochip SLIC optimized for WLL & VoIP

applications

■ Implements all Borsht function key features

■ Single supply (4.5 V to 12 V) for fly-back

configuration

■ Single supply (5.5 V to 12 V) for buck-boost

configuration

■ Built in DC/DC converter controller

■ Soft battery reversal with programmable

transition time

■ On-hook transmission

■ Programmable off-hook detector threshold

■ Metering pulse generation and filter

■ Integrated ringing

■ Integrated ring trip

■ Parallel control interface (3.3 V logic level)

■ Programmable constant current feed

■ Surface mount package

■ Integrated thermal protection

■ Dual gain value option

■ Automatic recognition flyback and buckboost

configuration

■ BCDIIIS 90V technology

■ -40 °C to +85 °C operating range

Description

The STLC3075 is a SLIC device specifically

designed for WLL (Wireless Local Loop), and

ISDN terminal adaptors and VoIP applications.

One distinctive characteristic of this device is its

ability to operate with a single supply voltage

(from +4.5 V to +12 V) and to self generate the

negative battery by means of an on-chip DC/DC

converter controller that drives an external MOS

switch.

STLC3075

Integrated POTS interface

for home access gateway and WLL

LQFP44

The battery level is properly adjusted depending

on the operating mode. A useful characteristic for

these applications is the integrated ringing

generator.

The control interface is parallel with open drain

output and 3.3 V logic levels.

The metering pulses are generated on-chip

starting from two logic signals (0 and 3.3 V): one

signal defining the metering pulse frequency, the

other signal defining the metering pulse duration.

An on-chip circuit then provides the proper

shaping and filtering. Metering pulse amplitude

and shaping (rising and decay time) can be

programmed by external components.

A dedicated cancellation circuit avoids possible

codec input saturation due to metering pulse

echo.

Constant current feed can be set from 20 mA to

40 mA. Off-hook detection threshold is

programmable from 5 mA to 9 mA.

The device, which is developed in BCDIIIS

technology (90 V process), operates in the

extended temperature range and integrates a

thermal protection that sets the device in power

down when T

Table 1. Device summary

Order code

E-STLC3075

1. ECOPACK® (see Section 9)

exceeds 140 °C.

j

Package Packing

(1)

LQFP44 Tray

March 2009 Rev 8 1/36

www.st.com

1

Contents STLC3075

Contents

1 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Electrical specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Absolute maximum rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Operating range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1 DC/DC converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2 Operating modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.2.1 Power down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.2.2 High impedance feeding (HI-Z) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.2.3 Active . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2.4 Ringing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5 Application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.1 Layout recommendation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2 External components list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.1 Test circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7 Over voltage protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8 Typical state diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

9 Package information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2/36

STLC3075 List of tables

List of tables

Table 1. Device summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table 2. Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 3. Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 4. Operating range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 5. Thermal data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 6. SLIC operating modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 7. Gain set in active mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 8. SLIC states in active mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 9. CREST factor values @ 20 and 25Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 10. External components for buckboost configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 11. VBAT values in RING and ACTIVE modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 12. External components for flyback configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 13. Coilcraft type FA2469-AL electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 14. Coilcraft type FA2470-AL electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 15. External components @gain set = 0. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 16. External components @gain set = 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 17. Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 18. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3/36

List of figures STLC3075

List of figures

Figure 1. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2. Pin connection (top view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 3. DC characteristics in HI-Z mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 4. DC characteristics in active mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 5. TIP/RING typical transition from direct to reverse polarity . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 6. Metering pulse generation circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 7. TIP/RING typical ringing waveform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 8. Application diagram with N-channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 9. Application diagram without metering pulse generation with N-channel. . . . . . . . . . . . . . . 23

Figure 10. Application diagram with P-channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 11. Application diagram without metering pulse generation . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 12. 2W return loss 2WRL = 20Log(|Zref + Zs|/|Zref-Zs|) = 20Log(E/2Vs) . . . . . . . . . . . . . . . . 28

Figure 13. THL trans hybrid loss THL = 20Log|Vrx/Vtx/ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 14. G24 transmit gain G24 = 20Log|2Vtx/E| . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 15. G42 receive gain G42 = 20Log|VI/Vrx| . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 16. PSRRC power supply rejection VPOS to 2W port PSSRC = 20Log|Vn/Vl| . . . . . . . . . . . . 30

Figure 17. L/T longitudinal to transversal conversion L/T = 20Log|Vcm/Vl| . . . . . . . . . . . . . . . . . . . . . 30

Figure 18. T/L transversal to longitudinal conversion T/L = 20Log|Vrx/Vcm|. . . . . . . . . . . . . . . . . . . . 30

Figure 19. VTTX metering pulse level on line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 20. V2Wp and W4Wp: Idle channel sophometric noise at line and TX.

V2Wp = 20Log|Vl/0.774l|; V4Wp = 20Log|Vtx/0.774l| . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 21. Simplified configuration for indoor over voltage protection . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 22. Standard over voltage protection configuration for K20 compliance . . . . . . . . . . . . . . . . . 32

Figure 23. Typical state diagram for STLC3075 operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 24. LQFP44 (10 x 10 x 1.4 mm) mechanical data and package dimensions . . . . . . . . . . . . . . 34

4/36

STLC3075 Block diagram

1 Block diagram

Figure 1. Block diagram

PD D0 D1 D2 DET

GAIN

SETTING

TX

RX

ZAC1

ZAC

RS

ZB

CKTTX

CTTX1

CTTX2

FTTX

INPUT LOGIC AND DECODER

Status and functions

SUPERVISION

AC PROC

TTX PROC

RTTX CAC ILTF RD IREF RLIM RTH

REFERENCE

OUTPUT LOGIC

LINE

DRIVER

DC PROC

Vcc

Vss

Agnd

OUTPUT

STAGE

DC/DC

CONV.

VOLT.

REG.

AGND

BGND

TIP

RING

CREV

CSVR

CLK

RSENSE

GATE

VF

CZ

CVCC

VPOS

VBAT

Vbat

5/36

Pin description STLC3075

2 Pin description

Figure 2. Pin connection (top view)

VBAT1

CREV

N.C.

TIP

N.C.

N.C.

GAIN SET

N.C.

DET

CKTTX

CTTX1

CTTX2

RTTX

RING

N.C.

44 43 42 413940 38 37 36 35 34

1

D0

2

D1

3

D2

4

PD

5

6

7

8

9

10

12 13 14 15 16

RX

FTTX

ZAC1

171118 19 20 21 22

ZB

RS

ZAC

CAC

TXCZVF

VBAT

BGND

CSVR

N.C.

33

32

31

30

29

28

27

26

25

24

23

ILTF

RD

RTH

IREF

RLIM

AGND

CVCC

VPOS

RSENSE

GATE

CLK

D00TL488

Table 2. Pin description

N° Pin Function

1 D0 Control interface: input bit 0

2 D1 Control interface: input bit 1

3 D2 Control interface: input bit 2

4 PD Power down input. Normally connected to CVCC (or to logic level high)

5 Gain SET

6, 22, 38,

39, 40, 42

Control gain interface: 0 Level R

NC Not connected

1 Level R

xgain

xgain

= 0dB T

= +6dB T

xgain

xgain

= -12dB

= -12dB

7 DET Logic interface output of the supervision detector (active low)

8 CKTTX Metering pulse clock input (12 kHz or 16 kHz square wave)

9 CTTX1 Metering burst shaping external capacitor

10 CTTX2 Metering burst shaping external capacitor

11 RTTX

12 FTTX

Metering pulse cancellation buffer output. TTX filter network should be connected to

this point. If not used, should be left open.

Metering pulse buffer input this signal is sent to the line and used to perform TTX

filtering

4 wires input port (RX input). A 100 kΩ external resistor must be connected to AGND

13 RX

via the bias input stage. This signal refers to AGND. If connected to single supply

CODEC output it must be DC decoupled with proper capacitor.

14 ZAC1 RX buffer output (the AC impedance is connected from this node to ZAC)

15 ZAC AC impedance synthesis

6/36

STLC3075 Pin description

Table 2. Pin description (continued)

N° Pin Function

16 RS Protection resistors image (the image resistor is connected from this node to ZAC)

17 ZB

Balance network for 2 to 4 wire conversion (the balance impedance ZB is connected

from this node to AGND. ZA impedance is connected from this node to ZAC1).

18 CAC AC feedback input, AC/DC split capacitor (CAC)

19 TX

4 wire output port (TX output). The signal is referred to AGND. If connected to single

supply CODEC input it must be DC decoupled with proper capacitor.

20 CZ Flyback compensation

21 VF Feedback input for DC/DC converter controller

Power switch controller clock (typ. 125 kHz). This pin can also be connected to CVCC

23 CLK

or AGND. When the CLK pin is connected to CVCC an internal auto-oscillation is

internally generated and it is used instead of the external clock. When the CLK pin is

connected to AGND, the GATE output is disabled.

24 GATE

25 R

SENSE

Driver for external power MOS transistor (P-channel in buckboost configuration, Nchannel in flyback configuration).

Voltage input for current sensing. R

pin and V

pin (Buckboost) or GND (Flyback). The PCB layout should minimize the

POS

resistor should be connected close to this

SENSE

extra resistance introduced by the copper tracks.

26 V

POS

Positive supply input

27 CVCC Internal positive voltage supply filter

28 AGND Analog ground. Must be shorted with BGND.

29 RLIM

30 IREF

Constant current feed programming pin (via RLIM). RLIM should be connected close

to this pin and AGND pin to avoid noise injection.

Internal bias current setting pin. RREF should be connected close to this pin and

AGND pin to avoid noise injection.

31 RTH

32 RD

Off-hook threshold programming pin (via RTH). RTH should be connected close to this

pin and AGND pin to avoid noise injection.

DC feedback and ring trip input. RD should be connected close to this pin and AGND

pin to avoid noise injection.

33 ILTF Transversal line current image output

34 CSVR Battery supply filter capacitor

35 BGND Battery ground, must be shorted with AGND

36 VBAT

Regulated battery voltage self generated by the device via DC/DC converter. Must be

shorted to VBAT1.

37 RING 2 wire ports; RING wire (Ib is the current sunk into this pin)

41 TIP 2 wire ports; TIP wire (Ia is the current sourced from this pin)

Reverse polarity transition time control. A proper capacitor connected between this pin

43 CREV

and AGND is setting the reverse polarity transition time. This is the same transition

time used to shape the ’trapezoidal ringing’ during ringing injection.

44 VBAT1 Frame connection. Must be shorted to VBAT

7/36

Electrical specification STLC3075

3 Electrical specification

3.1 Absolute maximum rating

Table 3. Absolute maximum ratings

Symbol Parameter Value Unit

V

POS

Positive supply voltage -0.4 to +13 V

A/BGND AGND to BGND -1 to +1 V

V

dig

T

j

(1)

V

btot

Pin D0, D1, D2, DET, CKTTX -0.4 to 5.5 V

Max. junction temperature 150 °C

Vbtot=|V

device supply pins).

Human body model ±1750 V

ESD rating

Charged device model ±500 V

1. Vbat is self generated by the on-chip DC/DC converter and can be programmed via RF1 and RF2. RF1

and RF2 must be selected in order to fulfil the a.m. limits (see components tables).

3.2 Operating range

Table 4. Operating range

Symbol Parameter Value Unit

V

POS

A/BGND AGND to BGND -100 to +100 mV

V

dig

T

op

(1)

V

bat

1. Vbat is self generated by the on-chip DC/DC converter and can be programmed via RF1 and RF2. RF1

and RF2 must be selected in order to fulfil the a.m. limits (see Table 10: External components for

buckboost configuration)

Positive supply voltage 4.5 to +12 V

Pin D0, D1, D2, DET, CKTTX, PD -0.25 to 5.25 V

Ambient operating temperature range -40 to +85 °C

Self generated battery voltage -74 max. V

|+|Vbat|. (Total voltage applied to the

POS

90 V

3.3 Thermal data

Table 5. Thermal data

Symbol Parameter Value Unit

R

th j-amb

8/36

Thermal resistance junction to ambient typical. 60 °C/W

STLC3075 Functional description

4 Functional description

The STLC3075 is a device specifically developed for WLL VoIP and ISDN-TA applications. It

is based on a SLIC core, on purpose optimized for these applications, with the addition of a

DC/DC converter controller to meet the WLL and ISDN-TA design requirements.

The SLIC performs the standard feeding, signalling and transmission functions.

STLC3075 can be set in three different operating modes via the D0, D1, D2 pins of the

control logic interface (0 to 3.3 V logic levels). The loop status is carried out on the DET

(active low).

pin

The DET

pin is an open drain output to allow easy interfacing with both 3.3 V and 5 V logic

levels.

The four possible SLIC’s operating modes are:

– Power down

– High impedance feeding (HI-Z)

– Active

– Ringing

Ta bl e 6 shows how to set the different SLIC operating modes.

Table 6. SLIC operating modes

PD D0 D1 D2 Operating mode

000XPower down

1 0 0 X H.I. feeding (HI-Z)

1 0 1 0 Active normal polarity

1011Active reverse polarity

1 1 1 0 Active TTX injection (N.P.)

1 1 1 1 Active TTX injection (R.P.)

1 1 0 0/1 Ring (D2 bit toggles @ fring)

4.1 DC/DC converter

The DC/DC converter controller drives an external power MOS transistor N-Ch plus

transformer (Flyback configuration) or P-Ch plus inductor (Buckboost configuration), in order

to generate the negative battery voltage needed for the device operation.

The DC/DC converter controller is synchronized with an external CLK (125 kHz typ.) or with

an internal clock generated when the pin CLK is connected to CVCC. One R

to PGND supply (Flyback) or to V

input peak current.

This feature is implemented in order to avoid overload on V

transient (ex. ring trip detection). The 110 mΩ typical value guarantees an average current

consumption from V

guarantees an average current consumption from V

POS

in series

supply (Buckboost) allows to fix the maximum allowed

POS

supply in case of line

POS

SENSE

< 700 mA for buckboost configuration. The 220 mΩ typical value

< 800 mA for flyback configuration.

POS

9/36

Functional description STLC3075

The self generated battery voltage is set to a predefined value in on-hook state.

The typical value of -50 V can be adjusted via one external resistor (RF1). When RING

mode is selected this typical value is increased to -70 V.

Once the line goes in off-hook condition, the DC/DC converter automatically adjusts the

generated battery voltage in order to feed the line with a fixed DC current (programmable via

RLIM) optimizing the power dissipation.

4.2 Operating modes

4.2.1 Power down

When this mode is selected the SLIC is switched off and the TIP and RING pins are in high

impedance. The line detectors are also disabled therefore the off-hook condition cannot be

detected.

The power down mode can be selected in emergency condition when it is necessary to cut

any current delivered to the line.

The power down mode is also forced by STLC3075 in case of thermal overload

(T

> 140 °C). In this case the device goes back to the previous status as soon as the

j

junction temperature decrease under the hysteresis threshold.

No AC transmission is possible.

4.2.2 High impedance feeding (HI-Z)

This operating mode is normally selected when the telephone is in on-hook in order to

monitor the line status keeping the power consumption at the minimum.

The output voltage in on-hook condition is equal to the self generated battery voltage (-50 V

typical).

When off-hook occurs the DET

The off-hook threshold value in HI-Z mode is the same as the programmed value in ACTIVE

mode.

The DC characteristics in HI-Z mode are equal to the self generated battery with

2x(1600 Ω+Rp) in series (see Figure 3), where Rp is the external protection resistance.

No AC transmission is possible.

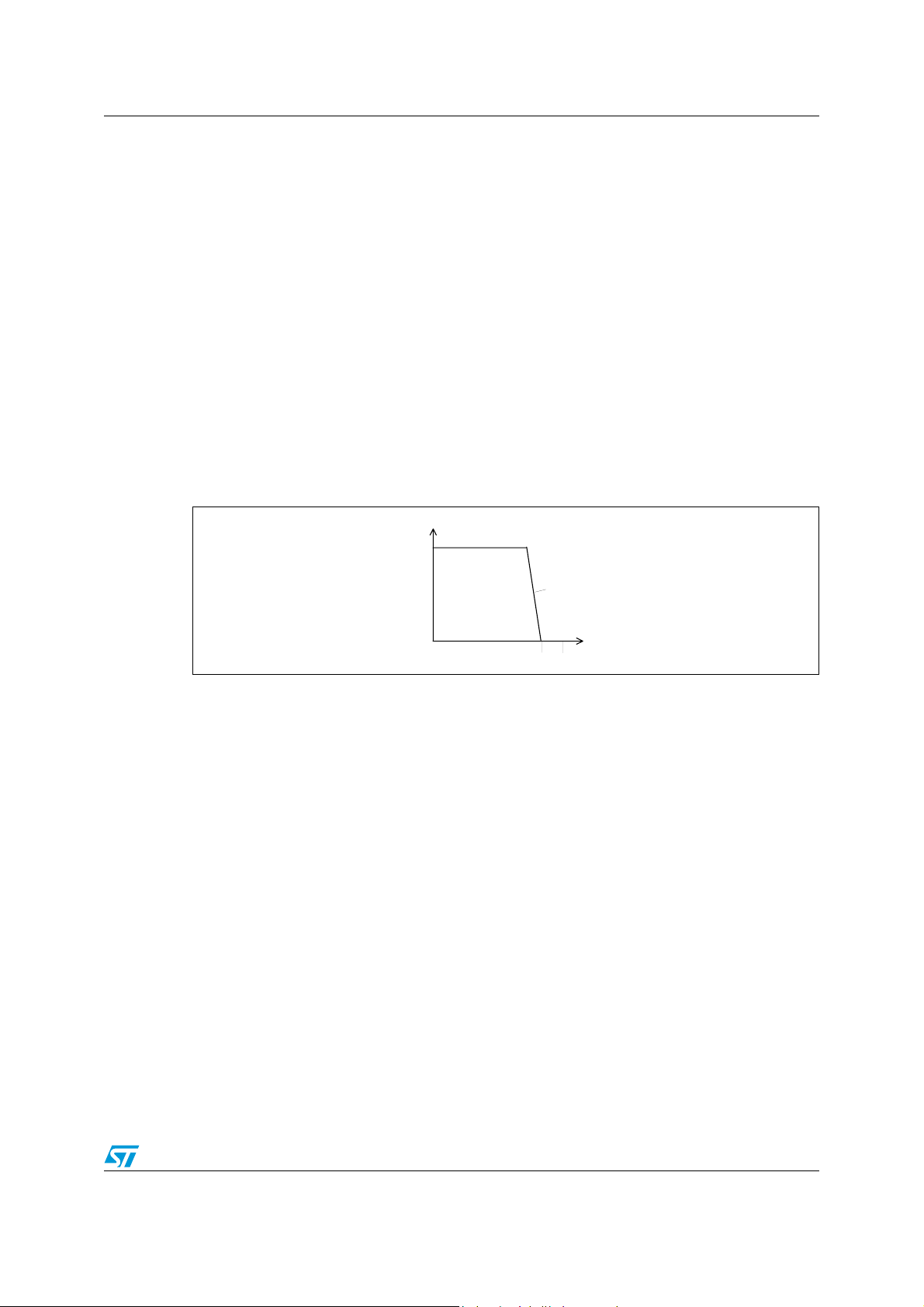

Figure 3. DC characteristics in HI-Z mode.

becomes active (low logic level).

IL

Vbat

2x(R1+Rp)

Slope: 2x(R1+Rp)

(R1=1600ohm)

10/36

VL

Vbat (-50V)

STLC3075 Functional description

4.2.3 Active

DC characteristics & supervision

When this mode is selected the STLC3075 provides both DC feeding and AC transmission.

The STLC3075 feeds the line with a constant current fixed by RLIM (20 mA to 40 mA

range). The on-hook voltage is typically 40 V allowing on-hook transmission; the self

generated Vbat is -50 V typical.

If the loop resistance is very high and the line current cannot reach the programmed

constant current feed value, the STLC3075 behaves like a 40 V voltage source with a series

impedance equal to the protection resistors 2xRp (typ. 2x50 Ω). Figure 4. shows the typical

DC characteristics in active mode.

The line status (on/off hook) is monitored by the SLIC’S supervision circuit. The off-hook

threshold can be programmed via the external resistor RTH in the range from 5mA to 9mA.

Independently on the programmed constant current value, the TIP and RING buffers have a

current source capability limited to 80mA typical.

Figure 4. DC characteristics in active mode

IL

Ilim

(20 to

40mA)

2Rp

VL

10V

Vbat (-50V)

Moreover the power available at Vbat is controlled by the DC/DC converter that limits the

peak current drawn from the V

R

SENSE

resistor.

supply. The maximum allowed current peak is set by

POS

11/36

Loading...

Loading...