NorthenLite G.lite DMT Transceiver

■

ATM transport

■ Forward Error correction & interleaving

■

Framing & de-framing

■

DMT modulation and demodulation

■

Start-up & showtime control processing

In addition, the STLC1510 provides the following features:

■

Serial and Parallel network interface at backend to CO equipment

■

Serial interface to the AFE chip STLC1511

■

Access to off chip memory

■

Power-up boot program stored in ROM

■ 132 balls 12x12x1.7 mm LBGA package

■

Power Consumption: 0.75 Watt

■

Power Supp.: 2.5 V (core) and 3.3 V (I/O ring)

■

STLC1510

PRODUCT PREVIEW

LBGA132

ORDERING NUMBER: STLC1510

1.0 GENERAL DESCRIPTION

The STLC1510 is a high-speed modem chip that provides the digital portion of a G.992.2 DSL access at a

Central Office (CO) site. It provides downstream and

upstream data transport between an ATM byte

stream and an analog front-end chip using Discrete

Multi-Tone (DMT) Modulation.

The STLC1510 is compliant with ITU-T G.992.2

(G.Lite), G.996.1 (G.Test), G.994.1 (G.Handshake),

G.997.1 (G.Ploam).

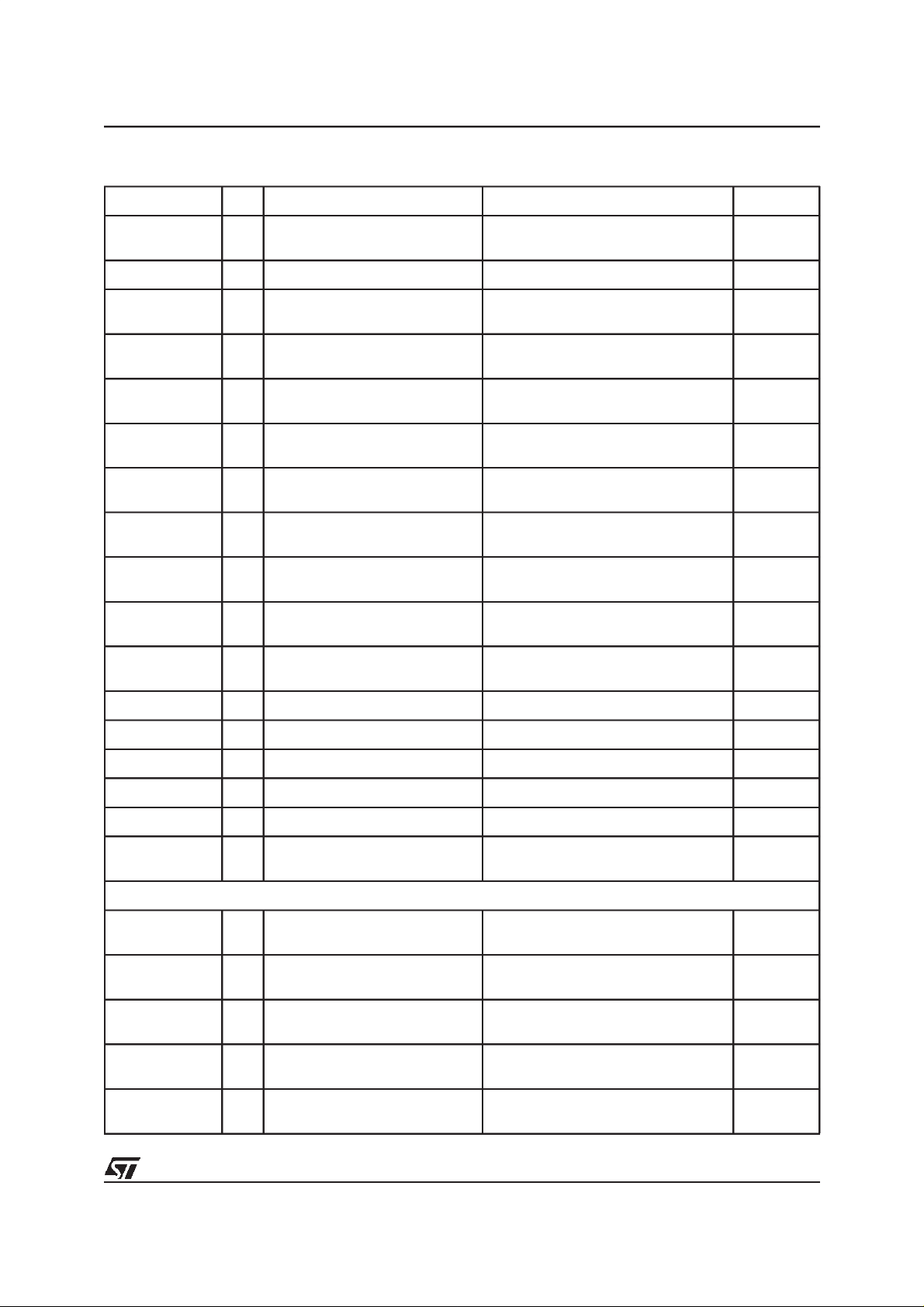

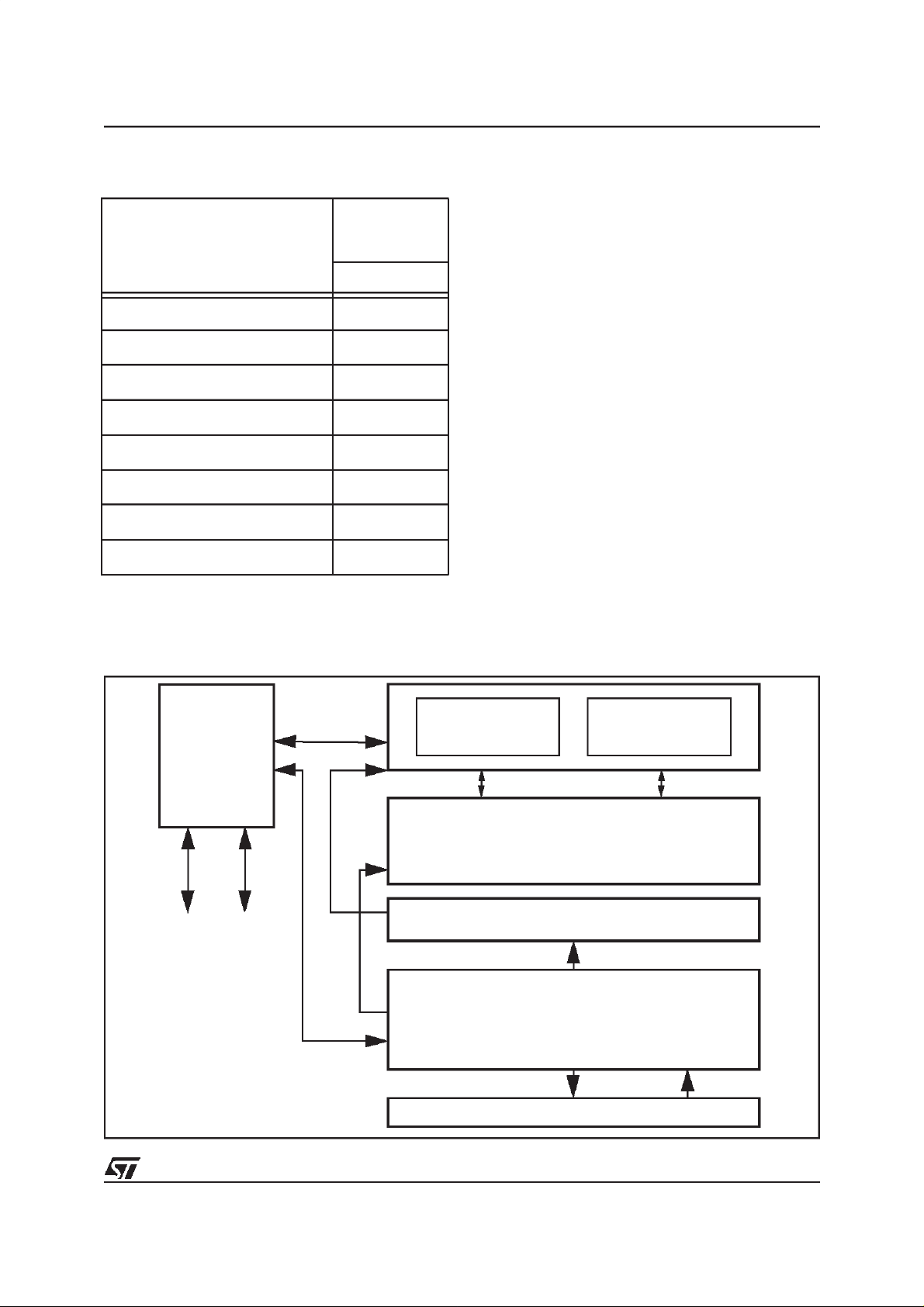

Figure 1. Block Diagram

TxClk

TxClav

TxEnb

TxSOC

UTxData[7:0]

TxAddr[4:0]

TxParity

TxBP

RxClk

RxClav

RxEnb

RxSOC

URxData[7:0]

RxAddr[4:0]

RxParity

VDD3_3

VDD2_5

VSS

HPI_Data[7:0]

HPI_Addr [2 :0]

HPI_RWN

HPI_ASN

83

HPI

NIF

FEC

MAP

7

7

14

TAP

TDI

TCK

TDO

EPM

LAMBA Bus

TMS

TRSTN

VDD_PLL

Guard_PLL

EN_D950_EMU

ARM2H P_INT

HPI_CSN

mem

VSS_PL L

ARM_MODE

HPI_CLK

BPU

mem

mem

D950ARM

22

Pmode[1:0]

CMode[1:0]

pgmctrl

Dual

MAC

TGB

8

VCODC

RESETN

GPIO[7:0 ]

D950_CMODE

LinDr_AGC2

LinDr_AGC1

LinDr_Peak

DFE

TxSOUT[1:0]

mem

mem

INF_OUT

REF_OUT

A_SCLK

CK35M

RxSIN[1:0]

REF_CLK

SPI_CLK

SPI_ENB

SPI_DTX

SPI_DRX

November 2000

This is preliminary information ona new product now in development. Details are subject to change without notice.

1/40

STLC1510

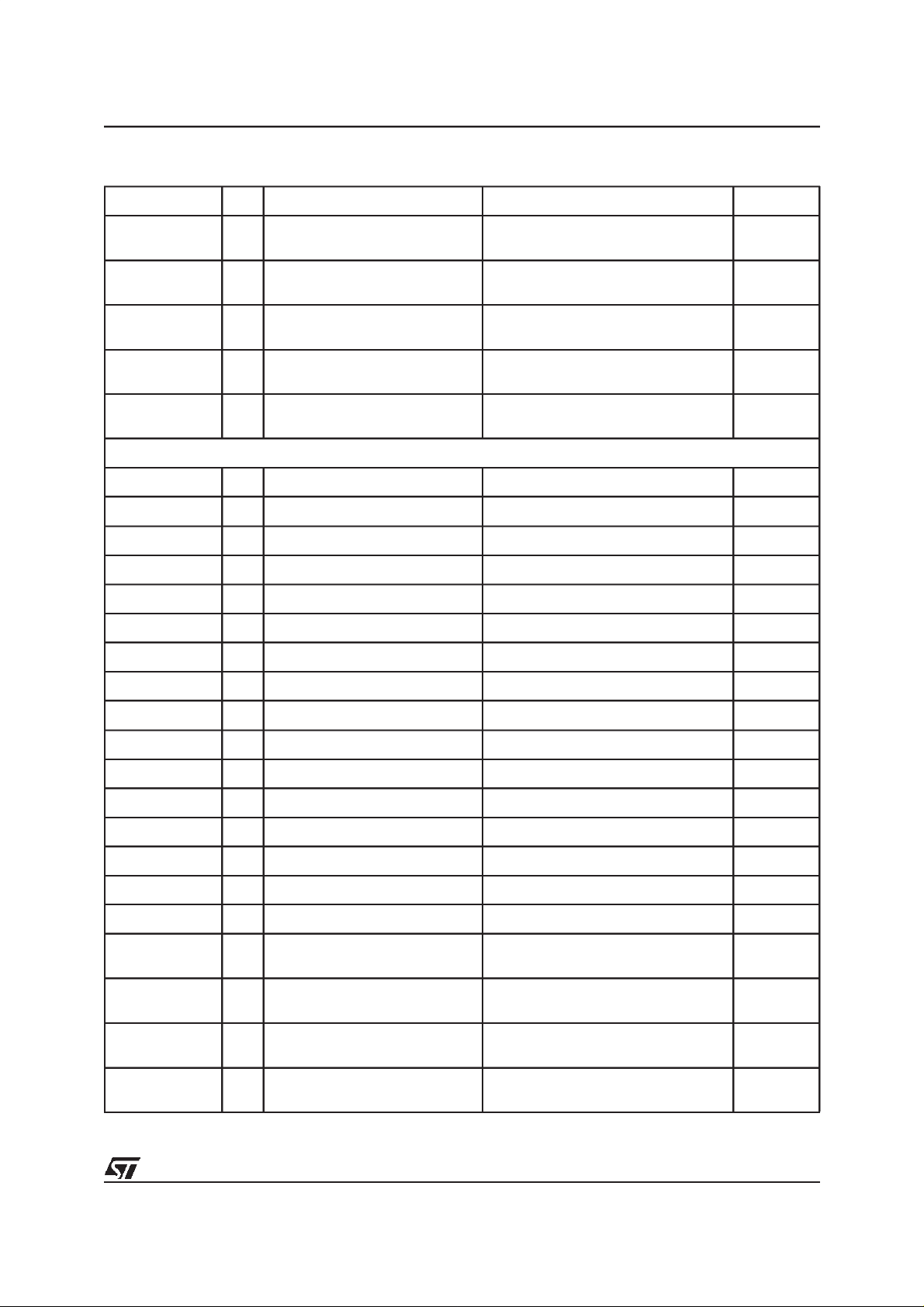

2.0 LIST OF MAIN BLOCKS

The STLC1510 G.lite DMT Transceiver is formed by

the following blocks (refer to Figure 1.):

Embedded Processor Module (EPM)

The EPM includes two embedded processor cores:

the ARM7TDMI, a RISC microprocessor, and the

D950, a 16-bit DSP processor. The RISC microprocessor handles the chip control, G.Lite start-up and

showtime control and DSP initialization. It also implements the Framing and Interleaving/Deinterleaving

function required by G.992.2 standard.

Block Processing Unit (BPU)

Computationally intensive digital signal processing

functions are performed in this engine. This engine

utilizes customized DSP architecture that includes

two multiplier/accumulator (MAC).

DigitalFront-End (DFE)

This block provides the interface to an external analog front-end (AFE) device. This block provides decimation, interpolation for the signal sample for the

ADC and DAC on the AFE and signal level monitoring for the analog AGC.

NetworkInterface (NIF)

The NIF is aselectable interface that carries the ATM

signals to and from the STLC1510. This interface

supports one parallel interface (Utopia Level 2) or a

serial data interface. The NIF includes a FIFO to buffer the data between the clock domains of the backend interface and the internal clock.

ForwardError-Correction (FEC)

The Forward Error Correction is done using ReedSolomon Coding. The R-S FEC encoding is performed byte-wise in the transceiver on the transmitted bytes. The two basic parameters that determine

the performance of the code are the code word size,

which consists ofone or more DMT symbols (S), and

the number of redundant check bytes R.

Timing Generation Block(TGB)

The timing generation block generates global clock

and synchronization signals for the STLC1510. It

uses the input clock signals to derive the main internal and output clock signals, as well as all synchronization pulses required to coordinate timing between

the sub-blocks.

Test Access Port (TAP)

This block provides the test access to the STLC1510

using JTAG and BIST techniques.

HPI Interface

A host processor interface is provided to allow the

STLC1510 to be optionally controlled by an external

microcontroller.

3.0 TRANSIENT ENERGY CAPABILITIES

3.1 ESD

ESD (Electronic Discharged) tests have been performed for the Human Body Model (HBM).

The pins of the device are to be able to withstand

minimum 2000V for the HBM.

3.2 Latch-up

The maximum sink or source current from any pin is

limited to 200mA to prevent latch-up.

4.0 ABSOLUTE MAXIMUM RATINGS

The absolute maximum ratings, as specified below,

are those ratings beyond which the device’s lifetime

may be impaired. The meeting of electrical specifications is not implied when the device is subjected to

the absolute limits.

The following table identifies the device’s minimum

and maximum ratings and along with the operatingconditions they define the limits for testing the device

Mapper/De-mapperBlock (MAP)

The Mapper/De-mapper Block (MAP) performs the

bit packing and un-packing and constellation encoder/decoder for a G.992.2 DSL modem. This block

also supports generation of Reverb and medley.

2/40

Table 1. ABSOLUTE MAXIMUM RATINGS

SYMBOL PARAMETER MINIMUM MAXIMUM UNITS

VDD3_3 3.3V Supply voltage w.r.t.VSS (0V) -0.5 4 V

VDD2_5 2.5V Supply voltage w.r.t.VSS (0V) -0.5 3.3 V

STLC1510

T

amb

V

IN,VOUT

V

IN5,VOUT5

I

IN,IOUT

P

D

Ambient temperature -40 85 °C

Voltage at any 3.3V standard input or output -0.5 VDD3_3 + 0.5 V

Voltage at any 5V compatible input or output

1

-0.8 6.3 V

Current at any input or outputs -20 20 mA

Power dissipation 0 0.75 W

Vesd Electrostatic Protection 2000 V

I latchup I/O Latch-up Current V < 0V, V > Vdd 200 mA

<1> -0.8V undershoots and 6.3V overshoots do not last longer than 4nS.

3/40

STLC1510

Figure 2. Ball Map.

STLC1510 Netlist

4/40

Table 2. Pad Description

Signal I/O Pad Type Description BGA

Clock Interface

STLC1510

REF_CLK I 5V TolCMOS input 17.168 MHzor 35.328 MHz reference

clock input.

RESETN I 5V TolCMOS input Hardware reset (active low) E13

D950_CMODE I 5V TolCMOS input ’1’ - Normal operation

’0’ - Reduced REF_CLK frequency in

bypass mode for chip test

PMode_1 I 5V TolCMOS input Power Mode Select G1

PMode_0 I 5V TolCMOS input Power Mode Select H1

CMode_1 I 5V TolCMOS input Clock Mode Select H2

CMode_0 I 5V TolCMOS input Clock Mode Select L1

STLC1511 AFE Interface

A_SCLK I 5V Tol CMOS input ADC/DAC sample frame clock H14

CK35M O 5V Tol3.3V TTL 2mA slew ltd

output

RxSIN_1 I 5V TolCMOS input ADC serial input data L14

RxSIN_0 I 5V TolCMOS input ADC serial input data K14

TxSOUT_1 O 5V Tol3.3V TTL 2mA slew ltd

output

35.328 MHz reference clock output. J14

DAC serial output data F14

1

K13

C13

TxSOUT_0 O 5V Tol3.3V TTL 2mA slew ltd

output

SPI_CLK O 5V Tol 3.3V TTL 2mA slew ltd

output

SPI_ENB O 5V Tol 3.3V TTL 2mA slew ltd

output

SPI_DTX O 5V Tol3.3V TTL 2mA slew ltd

output

SPI_DRX I 5V Tol CMOS input RX STLC1511 input Control Data L13

XTAL_CTRL O 5V Tol 3.3V TTL 2mA slew ltd

output

STLC1512 Line Driver Interface

LinDr_AGC1 O 5V Tol3.3V TTL 2mA slew ltd

output

LinDr_AGC2 O 5V Tol3.3V TTL 2mA slew ltd

output

LinDr_Peak O 5V Tol3.3V TTL 2mA slew ltd

output

DAC serial output data E14

STLC1511 control interface clock M14

TX/RX STLC1511 Enable Control

signal

TX STLC1511 Control Data N14

XTAL output control pin Not on

STLC1511 AGC Gain control 1 D13

STLC1511 AGC Gain control 2 D14

STLC1511 Peakcontrol

2

M13

BGA

C14

5/40

STLC1510

Table 2. Pad Description

Signal I/O Pad Type Description BGA

Test Interface

TCK I 5V TolCMOS input JTAGTest Clock N9

TMS I 5V Tol CMOS input JTAGTest Mode Select N7

TDI I 5V Tol CMOS input JTAGTestData Input P8

TDO O 5V Tol3.3V TTL2mA slew ltd

output

TRSTN I 5V Tol CMOS input dedicated TAPreset (active low) P9

Network Interface (UTOPIA / Serial Clock & Data)

TxClk I/O 5V TolCMOS input/ 5V Tol3.3V

TTL 2mA slew ltd output

TxClav O 5V Tol3.3V TTL2mA slew ltd

output

TxBP O 5V Tol 3.3V TTL 2mA slew ltd

output

TxEnb I 5V Tol.CMOS input Tx Enable. A6

TxSOC I 5V TolCMOS input Tx start of Cell C2

UTxData_7 I 5V TolCMOS input Utopia2 Transmitdata bit 7 G2

UTxData_6 I 5V TolCMOS input Utopia2 Transmitdata bit 6 F2

UTxData_5 I 5V TolCMOS input Utopia2 Transmitdata bit 5 F1

UTxData_4 I 5V TolCMOS input Utopia2 Transmitdata bit 4 E1

UTxData_3 I 5V TolCMOS input Utopia2 Transmitdata bit 3 E2

UTxData_2 I 5V TolCMOS input Utopia2 Transmitdata bit 2 D2

JTAG Test Data Output N8

Input Utopia2 Tx clock or output PSIF

Tx clock.

Tx cell available signal. B5

Tx back pressure signal. B4

A4

UTxData_1 I 5V TolCMOS input Utopia2 Transmitdata bit 1 D1

UTxData_0 I 5V TolCMOS input Utopia2 Transmitdata bit 0; also CDIF

input data

TxAddr_4 I 5V TolCMOS input Utopia2 TransmitAddress B1

TxAddr_3 I 5V TolCMOS input Utopia2 TransmitAddress A1

TxAddr_2 I 5V TolCMOS input Utopia2 TransmitAddress A2

TxAddr_1 I 5V TolCMOS input Utopia2 TransmitAddress A3

TxAddr_0 I 5V TolCMOS input Utopia2 TransmitAddress B2

TxParity I 5V Tol.CMOS input Odd parity bit of the data on

UTxData[7:0].

RxClk I/O 5V TolCMOS input/ 5V Tol3.3V

TTL 2mA slew ltd output

6/40

Input Utopia2 Rxclock or output PSIF

Rx clock.

C1

B3

N6

Table 2. Pad Description

Signal I/O Pad Type Description BGA

STLC1510

RxClav O 5V Tol3.3V TTL 2mA slew ltd

output

RxEnb I 5V Tol.CMOS input Rx Enable. N4

RxSOC O 5V Tol 3.3V TTL 2mA slew ltd

output

URxData_7 O 5V Tol 3.3V TTL 2mA slew ltd

output

URxData_6 O 5V Tol 3.3V TTL 2mA slew ltd

output

URxData_5 O 5V Tol 3.3V TTL 2mA slew ltd

output

URxData_4 O 5V Tol 3.3V TTL 2mA slew ltd

output

URxData_3 O 5V Tol 3.3V TTL 2mA slew ltd

output

URxData_2 O 5V Tol 3.3V TTL 2mA slew ltd

output

URxData_1 O 5V Tol 3.3V TTL 2mA slew ltd

output

URxData_0 O 5V Tol 3.3V TTL 2mA slew ltd

output

Rx cell available signal. P5

Rx start of Cell P4

Utopia2 Receive data bit 7 N3

Utopia2 Receive data bit 6 P3

Utopia2 Receive data bit 5 P2

Utopia2 Receive data bit 4 N2

Utopia2 Receive data bit 3 M2

Utopia2 Receive data bit 2 P1

Utopia2 Receive data bit 1 N1

Utopia2 Receive data bit 0; also CDIF

output data

M1

RxAddr_4 I 5V Tol.CMOS input Utopia2 Receive Address L2

RxAddr_3 I 5V Tol.CMOS input Utopia2 Receive Address K2

RxAddr_2 I 5V Tol.CMOS input Utopia2 Receive Address K1

RxAddr_1 I 5V Tol.CMOS input Utopia2 Receive Address J2

RxAddr_0 I 5V Tol.CMOS input Utopia2 Receive Address J1

RxParity O 5V Tol 3.3V TTL 2mA slew ltd

output

HPI

HPI_Data_7 I/O 5V TolCMOS input/ 5V Tol3.3V

TTL 2mA slew ltd output

HPI_Data_6 I/O 5V TolCMOS input/ 5V Tol3.3V

TTL 2mA slew ltd output

HPI_Data_5 I/O 5V TolCMOS input/ 5V Tol3.3V

TTL 2mA slew ltd output

HPI_Data_4 I/O 5V TolCMOS input/ 5V Tol3.3V

TTL 2mA slew ltd output

HPI_Data_3 I/O 5V TolCMOS input/ 5V Tol3.3V

TTL 2mA slew ltd output

Odd parity bit of the data on

URxData[7:0].

HPI Port Data B14

HPI Port Data A14

HPI Port Data B13

HPI Port Data A13

HPI Port Data B12

N5

7/40

STLC1510

Table 2. Pad Description

Signal I/O Pad Type Description BGA

HPI_Data_2 I/O 5V TolCMOS input/ 5V Tol3.3V

TTL 2mA slew ltd output

HPI_Data_1 I/O 5V TolCMOS input/ 5V Tol3.3V

TTL 2mA slew ltd output

HPI_Data_0 I/O 5V TolCMOS input/ 5V Tol3.3V

TTL 2mA slew ltd output

HPI_Addr_2 I 5V Tol.CMOS input HPI Port Address B7

HPI_Addr_1 I 5V Tol.CMOS input HPI Port Address A7

HPI_Addr_0 I 5V Tol.CMOS input HPI Port Address B8

HPI_CLK I 5V Tol.CMOS input HPI Clock Input B9

HPI_RWN I 5V Tol.CMOS input HPI Port Read/WriteN B10

HPI_CSN I 5V Tol.CMOS input HPI Port Chip Select A8

HPI_ASN I 5V Tol.CMOS input HPI Port Address Strobe Input A10

ARM2HP_INT O 5V Tol3.3V TTL 2mA slew ltd

output

Misc

VCODC I Analog Input VCO control voltage for stand alone

HPI Port Data A12

HPI Port Data A11

HPI Port Data B11

Active-low ARM7 To Host Processor

Interrupt

PLL testing

3

A9

P6

REF_OUT O 5V Tol3.3V TTL 2mA slew ltd

output

INF_OUT O 5V Tol3.3V TTL2mA slew ltd

output

EN_D950_EMU I 5V TolCMOS input EN_D950_EMU=0; D950 core held in

ARM_MODE I 5V Tol CMOS input ARM_MODE=0; Connects external

GPIO_7 I/O 5V TolCMOS input /5V Tol3.3V

TTL 2mA slew ltd output

GPIO_6 I/O 5V TolCMOS input / 5V Tol 3.3V

TTL 2mA slew ltd output

GPIO_5 I/O 5V TolCMOS input / 5V Tol 3.3V

TTL 2mA slew ltd output

PLL REF signal at input to phase

detector

PLL INF signal at input to phase

detector

reset by ARM7, GPIO pin #1,2,3 and

4 are normal mode

EN_D950_EMU=1; D950 core is not

held inreset by ARM7, GPIO pins

#1,2,3 and 4 are dedicated to the

D950 emulator

TAP pins directly to ARM_TAP

ARM_MODE=1; ARM_TAP in daisy

chain configuration after MTAP(i.e.

same as ALPHA configuration)

General Purpose I/O Ports N13

General Purpose I/O Ports P14

General Purpose I/O Ports P13

J13

H13

P7

P10

8/40

Table 2. Pad Description

Signal I/O Pad Type Description BGA

STLC1510

GPIO_4 I/O 5V TolCMOS input / 5V Tol 3.3V

TTL 2mA slew ltd output

GPIO_3 I/O 5V TolCMOS input / 5V Tol 3.3V

TTL 2mA slew ltd output

GPIO_2 I/O 5V TolCMOS input /5V Tol3.3V

TTL 2mA slew ltd output

GPIO_1 I/O 5V TolCMOS input / 5V Tol 3.3V

TTL 2mA slew ltd output

GPIO_0 I/O 5V TolCMOS input / 5V Tol 3.3V

TTL 2mA slew ltd output

Power Supply

VDD3_3_8 P 3.3 volt supply pad 3.3V I/O power supply D3

VDD3_3_7 P 3.3 volt supply pad 3.3V I/O power supply C5

VDD3_3_6 P 3.3 volt supply pad 3.3V I/O power supply C3

VDD3_3_5 P 3.3 volt supply pad 3.3V I/O power supply C4

VDD3_3_4 P 3.3 volt supply pad 3.3V I/O power supply L12

VDD3_3_3 P 3.3 volt supply pad 3.3V I/O power supply M12

VDD3_3_2 P 3.3 volt supply pad 3.3V I/O power supply K12

General Purpose I/O Ports/

D950_IDLE

General Purpose I/O Ports/

D950_SNAP

General Purpose I/O Ports/

D950_INCYCLE

General Purpose I/O Ports/

D950_NERQ

General Purpose I/O Ports/LCLK N10

N12

P12

N11

P11

VDD3_3_1 P 3.3 volt supply pad 3.3V I/O power supply M11

VDD2_5_8 P 2.5 volt supply pad 2.5V ASIC core power supply M3

VDD2_5_7 P 2.5 volt supply pad 2.5V ASIC core power supply L3

VDD2_5_6 P 2.5 volt supply pad 2.5V ASIC core power supply K3

VDD2_5_5 P 2.5 volt supply pad 2.5V ASIC core power supply C10

VDD2_5_4 P 2.5 volt supply pad 2.5V ASIC core power supply C11

VDD2_5_3 P 2.5 volt supply pad 2.5V ASIC core power supply C12

VDD2_5_2 P 2.5 volt supply pad 2.5V ASIC core power supply D12

VDD2_5_1 P 2.5 volt supply pad 2.5V ASIC core power supply M4

VSS_20 P common ground supply pad Ground return for VDD3_3 and

VDD2_5

VSS_19 P common ground supply pad Ground return for VDD3_3 and

VDD2_5

VSS_18 P common ground supply pad Ground return for VDD3_3 and

VDD2_5

VSS_17 P common ground supply pad Ground return for VDD3_3 and

VDD2_5

C9

J3

J12

H12

9/40

STLC1510

Table 2. Pad Description

Signal I/O Pad Type Description BGA

VSS_16 P common ground supply pad Ground return for VDD3_3 and

VDD2_5

VSS_15 P common ground supply pad Ground return for VDD3_3 and

VDD2_5

VSS_14 P common ground supply pad Ground return for VDD3_3 and

VDD2_5

VSS_13 P common ground supply pad Ground return for VDD3_3 and

VDD2_5

VSS_12 P common ground supply pad Ground return for VDD3_3 and

VDD2_5

VSS_11 P common ground supply pad Ground return for VDD3_3 and

VDD2_5

VSS_10 P common ground supply pad Ground return for VDD3_3 and

VDD2_5

VSS_9 P common ground supply pad Ground return for VDD3_3 and

VDD2_5

VSS_8 P common ground supply pad Ground return for VDD3_3 and

VDD2_5

VSS_7 P common ground supply pad Ground return for VDD3_3 and

VDD2_5

VSS_6 P common ground supply pad Ground return for VDD3_3 and

VDD2_5

M6

M5

H3

M7

G3

F3

E3

M9

C6

C7

C8

VSS_5 P common ground supply pad Ground return for VDD3_3 and

M10

VDD2_5

VSS_4 P common ground supply pad Ground return for VDD3_3 and

E12

VDD2_5

VSS_3 P common ground supply pad Ground return for VDD3_3 and

F12

VDD2_5

VSS_2 P common ground supply pad Ground return for VDD3_3 and

M8

VDD2_5

VSS_1 P common ground supply pad Ground return for VDD3_3 and

G12

VDD2_5

VDD_PLL P 2.5 volt supply pad 2.5V supply forPLL G14

VSS_PLL P ground pad Ground return for PLL F13

Guard_PLL P ground pad Ground Voltage reference for PLL G13

<1> 212 MHz in PLL bypass mode

<2> This pad is configured as a pseudo open drain connection and can only pull the output low, or go high impedance

<3> Add pullup to this pin on board. This pad is configured as a pseudo open drain connection and can only pull the output low, or go high

impedance

10/40

STLC1510

5.0 MAIN BLOCK DESCRIPTION

The following sections describe the sequence of

functions performed by the chip

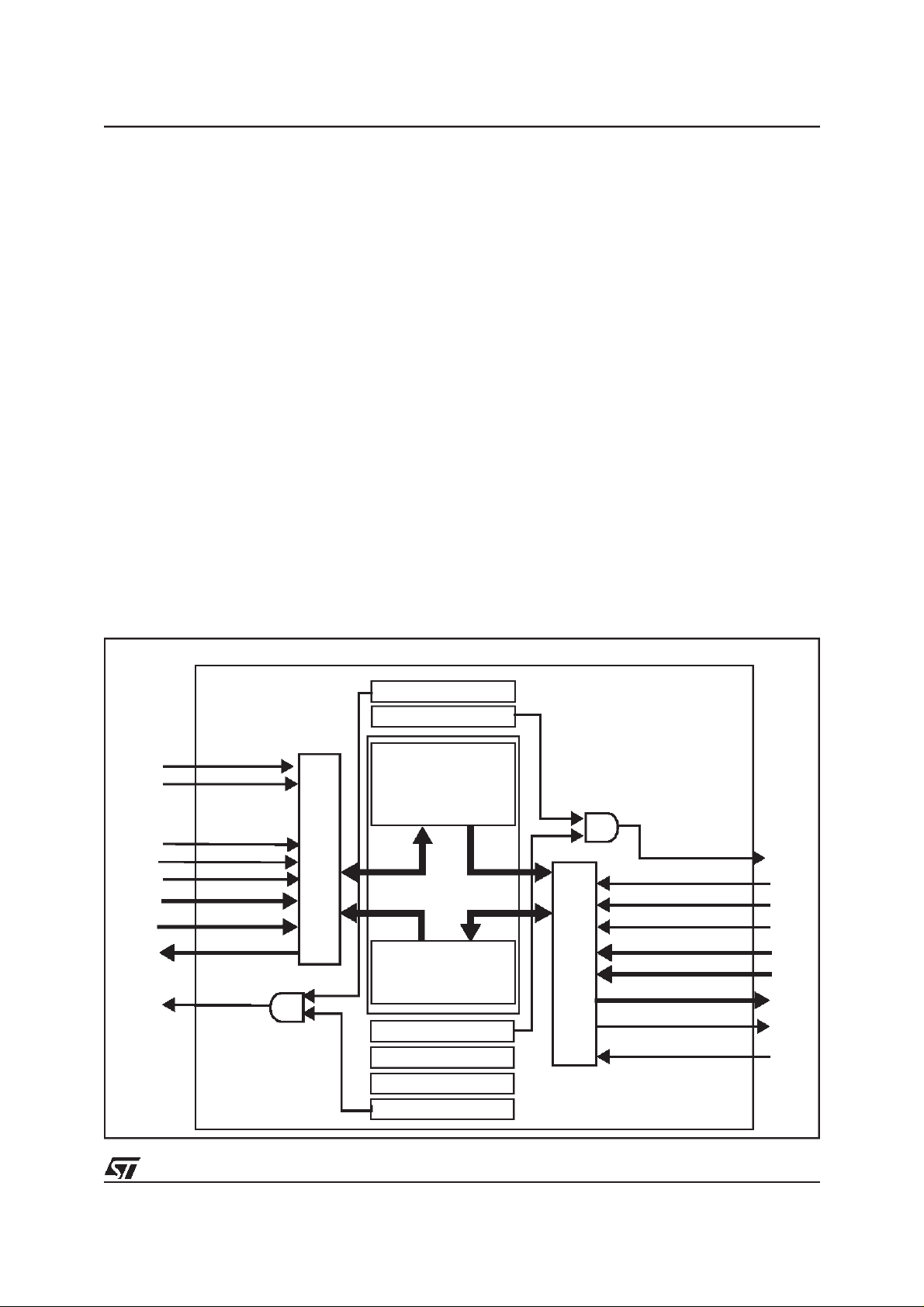

5.1 Network Interface and Controller (NIF)

The Network Interface and Controller block (NIF) is

responsible for transferring data between the

STLC1510 and the ATM network. The NIF has two

interfaces to the backplane: an 8-bit Utopia Level 2

Physical Interface (U2PHY) and a clock and data serial interface (CDIF). It communicates with the rest of

the STLC1510 via the LambaBus. Figure 3. shows a

functional/data path block diagram of the NIF (this diagram does not include all glue logic between the

major functional blocks). 37 external pins are required for the U2PHY and CDIF interfaces (19 for the

Tx direction, 18 for Rx). Pins are shared between the

two interfaces, as they will not both be active at the

same time.

5.1.1 Features

■

Utopia Level 2 8-bit parallel interface.

■ Up to 9 ATM cells (477 bytes) of rate adaptation

buffering for the Utopia Level 2 TX interface.

The amount of buffering is programmable via a

memory-mapped register.

■

Up to 2 ATM cells (106 bytes) of rate adaptation

buffering for the Utopia Level 2 RX interface.

The amount of buffering is programmable via a

memory-mapped register.

■

ATM Transconvergance (TC) layer cell

processor with 16-bit data path: performs

scrambling/descrambling, HEC calculation, cell

delineation with error detection (no error

correction) and cell rate decoupling by idle cell

insertion/detection.

■ Clock and Data serial interface.

■ Implemented as a hardware module on the

Lamba bus with an 8-bit data interface and 16bit control interface.

■ 4 ATM cells (212 bytes) of rate adaptation

buffering in each direction (TX and RX) for

interfacing to the Lamba bus.

■

Pads partial or runt cells (ATM cells of length

less than 53 bytes) to 53 bytes in the TX

direction to prevent loss of synchronization at

theCPE.

5.1.2 External Interface (Pins)

The STLC1510 connects to the ATM network via 37

external pins. These are illustrated in Figure 3. Note

that the pins TxClk and RxClk are bidirectional and,

along with UTxData[0] and URxData[0], are shared

between the CDIF and U2PHY

5.1.3 Clock and data serial Interface (CDIF)

The STLC1510 can communicate serially to an ATM

network through the CDIF. Two serial data lines,one

for the Tx path (CO to CPE), the other for the Rx path

(CPE to CO), and two respective clocks realize the

exchange of information and control signals between

the STLC1510 and the network.

The CDIF of the STLC1510 has the following attributes:

■

Synchronizes to the ATM network.

■

Provides Tx and Rx clocks to the ATM network.

Transfers data between the ATM network and the

STLC1510’s Lamba Bus

■

Accepts idle ATM cells inserted by the ATM

network in the Tx direction. These idle cells are

used by the ATM network to adapt to the clock

provided to it by the STLC1510.

■

Generates clock gapping in the Tx direction.

This serves two purposes: it is a flow control

mechanism to theATM network chip, andit can

be used for the byte alignment. In the bytealignment role, a clockgap longer thana pre-set

threshold indicates that the most significant bit

of a byte should be transmitted on the next

rising clock edge. This is useful for aligning data

bytes to the overhead bits inserted by the

STLC1510. In the flow control role, incoming

data is not sampled when the clock is off. The

threshold used to distinguish between byte

alignment and flow control clock gapping is

software programmable and has a range offrom

0 to 65535 clock cycles (a 16 bit register stores

the value).

■

Generates clock gapping in the Rx direction.

This serves asa flow-control mechanism; when

there is no data available for transmission to the

backplane, the clock is shutoff, ensuring that no

invalid data bits are sampled by the backplane.

11/40

STLC1510

Figure 3. NIF Off-Chip Signals

TxC lk

UTxData[0]

UTxData[7:1]

TxAddr[4:0]

TxParity

TxEnb

TxSOC

TxClav

TxBP

CDIF

TX

URxData[0]

8

5

U2PHY

TX

URxData[7:1]

RxClk

RxEnb

RxSOC

RxAddr[4:0]

RxClav

RxParity

8

5

CDIF

RX

U2PHY

RX

The following tasks are performed by the ATM network (in accordance with ITU-T Recommendation

I.432.1), and therefore do not have to be implemented in the STLC1510 when using the CDIF:

■

HCS generation (Tx).

■

Payload scrambling (Tx).

■

Optionally, enables clear channel mode, in

which HCS generation and payload scrambling

are disabled (Tx).

■

HCS cell delineation (Rx).

■ Payload descrambling (Rx).

■

Idle cell filtering (Rx).

■

Header error detection to recover valid ATM

cells (header correction is not implemented)

(Rx).

■

Optionally, enables clear channel mode, in

which every 53 x 8 = 424 bits are collected by

the receiver and sent to the backplane (Rx).

5.1.4 UTOPIA Level 2 Interface and Controller

The Universal Test and Operations Physical Interface forATM (UTOPIA) provides a standard that links

ATM layer orvarious management entities with a variety of physical (PHY) layers.

The UTOPIA IF has the following features:

■

provides clock decoupling mechanism.

■ throttles data flow from the ATM layer.

■

indicates to the ATM layer when the modem is

ready to receive data.

■ signals tothe ATM layer the presence of valid

data for transmission.

■

Recognizes the address when the modem is

selected for communication.

■ Supports octet-level and/or cell-level

handshaking.

■

UTOPIA Level 2 supports a multi-PHY

operation for up to n PHY devices where,

■

n=< 8 at ATM layers intended for 155 Mbps;

12/40

■

n=< 4 at ATM layers intended for 622 Mbps.

■ This interface is subdivided into two parts: the

Transmit Interface (TxIF) and the Receive

Interface (RxIF).

■ Both the TxIF and RxIF are controlled by the

ATM layer.

■

The ATMlayerprovides aninterface clock tothe

PHY layer for synchronizing all interface

transfers.

■

The PHY layer will incorporate rate-matching

buffers.

■

Transmit data is transferred from the ATM layer

to the PHY layer as follows: first, the PHY layer

indicates itcan accept data, then the ATM layer

drives data onto the data bus and asserts the

TxEnb.

■ The data flow is controlled by the PHY layer.

For a complete definition of TxIF signals and RxIF

signals please consult the UTOPIA Level 1 and UTOPIA Level 2 documents released by The ATM Forum

Technical Committee.

There is an additional signal added to the Utopia Interface in the TX direction: Back Pressure (TxBP).

This signal alerts the backplane when a software programmable depth has been reached in theTX Utopia

FIFO, while still allowing more data (up to the 10 cells

maximum) to be accepted by the FIFO.

5.1.5 ATM Transport Convergence (TC) Layer

Processor

The Cell TC block has the following attributes:

■

Idle cells inserted in the Tx direction for cell rate

de-coupling are discarded.

■

HEC bytes are generated inthe Tx direction as

described in ITU-T Recommendation I.432,

including the recommended modulo-2 addition

(XOR) of the pattern binary 01010101 to the

HEC bits.

■ Scrambling of the cell payload is used in the

transmit direction to improve the security and

robustness of the HEC cell delineation

mechanism. The cell payload isdescrambled by

the Cell TC block of an ATU receiver.

■

When interfacing ATM bytes to the bearer

channel, the most significant bit (msb) is sent

STLC1510

first.

■ Cell delineation isperformed usinga coding law

checking the HEC field in the cell header

according to the algorithm described in ITU-T

Recommendation I.432.

■

Error detection is performed asdefined in ITU-T

Recommendation I.432 with the exception that

any HEC error is considered a multiple-bit error.

Therefore, HEC error correction is not

performed.

■ The ATU-C transmitter preserves V-C and T-R

interface byte boundaries (explicitly present or

implied by ATM cell boundaries) at the U-C

interface.

■

Interfaces to the Lamba bus.

5.2 FIFO

The STLC1510 incorporates 4 FIFO buffers for rate

decoupling:

■

Utopia TX FIFO (8 bit input from the Utopia TX

interface, 16 bit output to the ATM-TC cell

processor): 243 words X 16 bits/word = 486

bytes >= 9 ATM cells @ 53 bytes/cell

■ Utopia RX FIFO (16 bit input from the ATM-TC

cell processor, 8 bit output to the Utopia RX

interface): 54 words X16 bits/word = 108 bytes

>= 2 ATM cells @ 53 bytes/cell

■

Lamba TX FIFO (16 bit input from the ATM-TC

cell processor, 8 bit output to the Lamba Bus):

106 words X 16 bits/word =212 bytes >= 4 ATM

cells @ 53 bytes/cell

■ Lamba RX FIFO (8 bit input from the Lamba

Bus, 16 bit output to the ATM-TC cell

processor): 106 words X 16 bits/word = 212

bytes >= 4 ATM cells @ 53 bytes/cell

■

All the FIFO’s share the following features:

■

Perform 8-bit to 16-bit word conversion or 16-bit

to 8-bit word conversion, with storage

implemented as 16-bit wide dual port RAMs.

■

Flags indicating when the FIFO is full, almost

full, empty, almost empty and half empty. (The

FIFO depths for the almost full and almost

empty flags are hard-wired).

■ Diagnostic input and an error flag.

■

The Utopia Tx FIFO has the following additional

attributes:

13/40

STLC1510

■

Software programmable generation of the flag

TX_CLAV (CeLl AVailable, TX direction) via

registers. This translates to the FIFO having a

software programmable depth.

■ Software programmable generation of the flag

TX_BP (Back Pressure, TX direction) via

registers. This allows the FIFO to throttle

incoming data flow, while still accepting data

that was already en route when the flag was

asserted.

The Utopia Rx FIFO has the following additional attributes:

■

Software programmable generation of the flag

RX_CLAV (CeLl AVailable, RX direction) via

registers. This translates to the FIFO having a

software programmable depth.

5.3 Reed Solomon Forward Error Correction

(RS-FEC)

Forward error correction is provided with byte-wise

Reed Solomon (RS) Encoding andDecodingin a 256

element Galois Field.

5.3.1 Parameters

The following parameter values for and are

SR

supported:

■

■

,,,=

R04816

S 124816,,,,=

Furthermore

■ is integer,

RS⁄

■

the combination and is

S1> D1

=

allowed, while not required.

■ byte wise coding over ,

■

and hence .

N

FEC

The Reed-Solomon Code Word length is , and

its value results from theselection of and , and

the number of data bytes per Data Frame, whereby for downstream, or

B2…48…144=

B1…16…60=

for upstream. The RS Data Word

GF 256()

255≤

B

N

FEC

SR

length is

K

FEC

+()⋅=

SB1

and theRS Code Word length is

N

FEC

The code word istransmitted over DMT symbols,

KR+=

S

and hence the number of bytes per Data Frame is

N

B’

FEC

-------------- - B1+

S

The Galois Field primitive element is defined by

R

--- -+==

S

α

the zero of the primitive polynomial

px() x8x4x3x21++++=

The Reed-Solomon generator polynomial is

–

R1

k

=

Gx() x α

k0

+

()

∑

=

The RS encoder does not introduce latency. RS decoding has a latency of at least , whereby the up-

N

per bound of the latency is given by the actual

decoder implementation.

The transmitter and receiver provide synchronization

of the RS Code Words.

5.4 Bit Mapper/Demapper Module (MAP)

5.4.1 Features

■

G.992.2 Compliant constellation encoder, up to

15 bits per sub-carrier capability.

■ Support for 1-bit per sub-carrier modulation

(BAM) and idle sub-carriers.

■

Constellation encoder, Q1.15 complex fixed

point output.

■

Bit unpacking and packing from/to 256-byte

data frame.

■ Support for pilot tone insertion.

■

Support for REVERB, SEGUE and MEDLEY

generation.

■ Support for random 4-QAM generation.

■

No trellis coding.

■

Implemented as a peripheral device.

14/40

5.4.2 Mapper Description

The mapper realizes the bit extraction and constellation encoding functions specified in G.922.2 (§ 7.8.1

and § 7.8.2 respectively); it is mainly intended to accelerate the main CPU in these bit manipulation operations.

The mapper consists of:

■ A Bit Unpack unit, extracting a variable length

bit string from the frame RAM

■

A Constellation Encoder, converting the bits to

a constellation point

■

Pseudo -random sequence generators PRBS,

& MAPPRG.

5.4.3 Demapper Description

The demapper consists of:

■

A Constellation Decoder, converting the input

constellation point to bits.

■

A Bit Pack unit, inserting the variable length bit

string into the frame RAM.

STLC1510

5.5 Embedded Processor Core - Functional

Description

The Embedded Processor Core consists of two programmable cores; the ARM7TDMI 32-bit microprocessor and the D950 16-bit DSP, their associated

peripherals/memory, a DPCOMM (Dual-Port Communications) for messaging, and a Bridge/Arbiter/

Decode (BAD) block. A block diagram of the EPM is

shown below.

There are two buses locally used by the ARM7 core

which are collectively known as the Advanced Microcontroller Bus Architecture (AMBA):

■

Advanced System Bus (ASB)

■ Advanced Peripheral Bus (APB) connected to

the ASB via an APB Bridge

The LAMBA Bus, a subset of the AMBA bus specification, connects all the blocks in the data pump portion of the STLC1510.

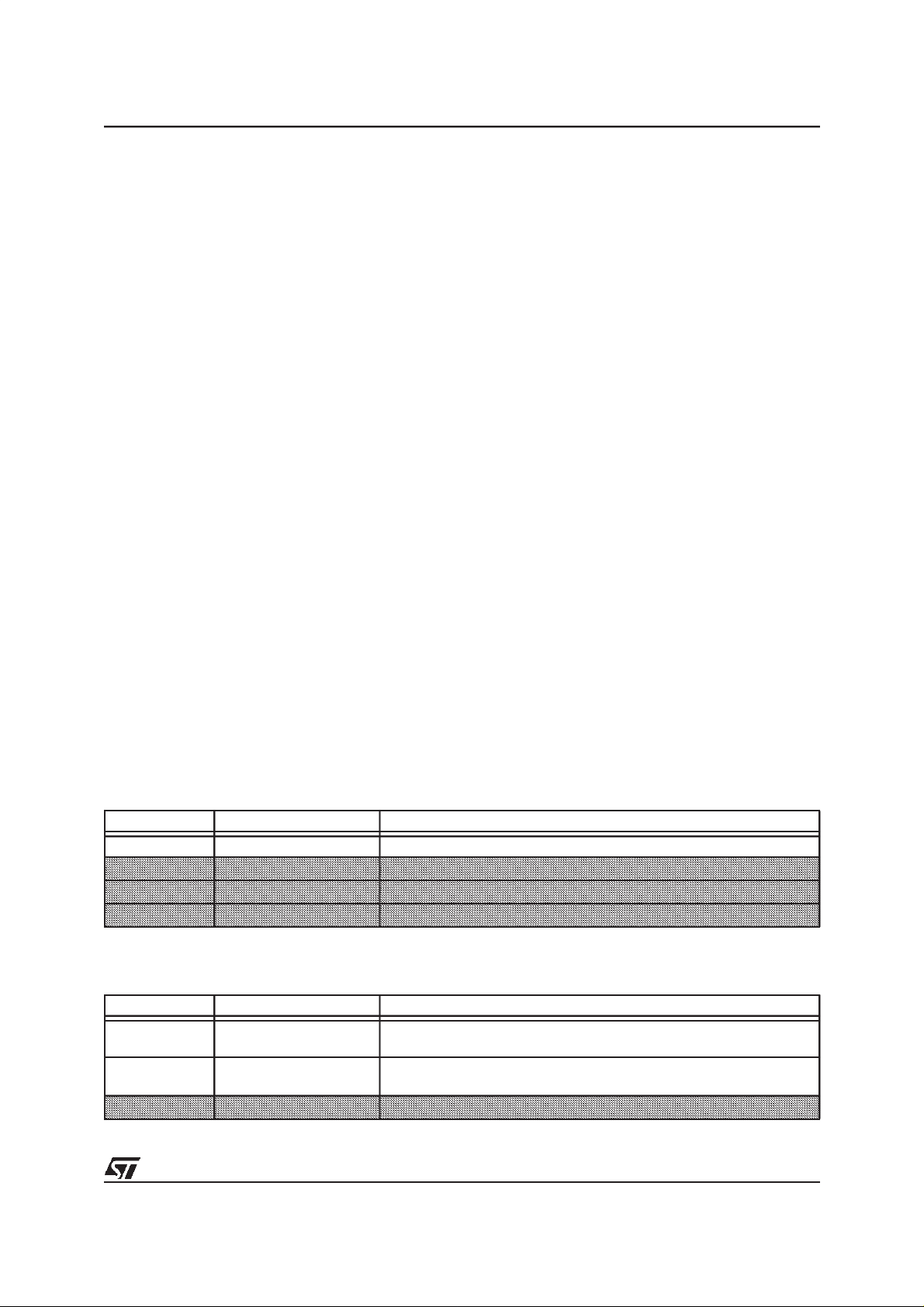

Figure 4. EPM and LAMBA Bus Block Diagram

EPM

ASB can extend to the APB,

X Bus , Y Bus, P Bus and

LAMBA Bus.

X Bus can extend to LAMB A

Bus.

APB

Tmr

ASB

Mem

APB

Bridge

Dec

HPI

I/F

Off Chip

ARM7

CORE

EMU TAP

Int

Cntl

Boot

ROM

Bridge/

Arbiter/

Decod e

DPCOMM

X BUS

Y BUS

P BUS

Xmem

Ymem

Pmem

LAMBA BUS

16

Int

Ctrl

Tmr

Dec

Dec

D950

COR E

EMU TAP

15/40

STLC1510

5.5.1 EPM Attributes

■ It provides access to internal registers for

control and monitoring of the various hardware

blocks.

■ Provides control to perform Software (SW)

download into the EPM and BPU memories as

part of the power up sequence.

■ Provides interrupt and exception handling for

various macro blocks.

■

Software on the EPM preforms several DSP

functions that are not implemented in the BPU

during Start-up, fast re-train or Show Time.

■

Address space is large enough to address the

internal registers, on-chip and some off-chip

memories

■

Provides debugging access through a JTAG

interface, for SW running on the processor.

■

Provides a dual port RAM to pass messages

between the D950 and ARM7 cores.

■ Supports an external Host Processor Interface

to pass messages to/from the ARM7

■

Both cores have embedded emulator blocks for

debug

5.5.2 ARM7TDMI MCU Core

The ARM7TDMI is a member of the Advanced RISC

Machines (ARM) family of general purpose 32-bit microprocessors. The architecture is based on the Reduced Instruction Set Computer (RISC) principle

which results in high instruction throughput and fast

real-time interrupt response.

Pipelining is employed so that all parts of the processing and memory systems can operate continuously. While one instruction is being executed, the

next is being decoded while the next is being fetched

from memory.

Attributes:

■

32-bit register bank

■

32-bit ALU

■ 32-bit shifter

■ 32-bit addressing

■

32x8 DSP multiplier

■

”Thumb” architectural extension which allows

generation of more memory efficient code

■

Peripherals include decoders, timer and

interrupt controller

5.6 D950 DSP Core

The D950 core is a 16-bit DSP based on the Harvard

architecture with three bidirectional 16-bit buses, two

for data and one for instruction. Each of these buses

is dedicated to a unidirectional 16-bit address bus

(XA/YA/IA).

The core is composed of three main units, a Data

Calculation Unit (DCU), an Address Calculation Unit

(ACU) and a Program Control Unit (PCU).

Attributes

■

Data Calculation Unit

■

Address Calculation Unit

■

Program Control Unit

■ 16x16 single cycle MAC

■

fast and flexible buses

The D950 top level consists of a D950 core, I mem,

X mem1 (8 bit), X mem2 (16 bit), Y mem, Timer, Emulator, Interrupt Controller and TAP peripherals.

5.6.1 BAD - Bridge, Arbiter, Decoder

The Bridge/Arbiter/Decoder (BAD) block controls the

data traffic among the ARM7, the D950 and the data

pump. It provides decoding circuitry, LAMBA bus arbitration and isolation buffers.

5.6.2 DPCOMM - Dual Port RAM Messaging

between ARM and D950

A Dual Port SRAM (1024x16) plus control registers,

is connected between the APB bus of the ARM7 and

the X bus of the D950. It is used as a mailbox to pass

data between the ARM and the D950 DSP.

5.7 Host Processor Interface (HPI)

■

The HPI resides on the APB bus of the ARM7.

The chip select for the HPI is generated by the

APB Bridge. Since the HPI resides on the APB,

it is treated as a 16 bit entity. This means that

APB Address 0isignored and allHPIaddresses

are on 16 bit boundaries. i.e. incremental

address location are h0000 h0002 h0004 etc...

■

The HPI is dual port SRAM based with control

that generates an interrupt when a message

wants to be passed. The DPSRAM is

implemented on-chip.

■

External to the ASIC, the pins of this interface

are 8 bidirectional data pins, 3 input address

pins, 1 input Read/Writen pin,1 Address Strobe,

1 clock, 1 input chip select pin and 1 output

interrupt pin.

16/40

■

A status register, an index register (for the Host

Processor), an interrupt mask register, and a

message buffer are required for both input and

output transactions.

■ The Input Status Register (ISR) is set by the

Host Processor by writing h01 and cleared by

writing h00 to the location. It is cleared by ARM

by writing anything to it.

■

The OutputStatus Registers (OSR)isset by the

ARM by writing h01 and cleared by writing h00.

It is cleared by the Host Processor by writing

anything to it.

■

The Input and Output Index Registers (IIR &

OIR respectively) are reset to their starting

value by writing h00 to their respective

addresses. They can also be cleared by the

Host Processor by writing anything to them.

■

The Input Interrupt Mask Register (IIM) resets to

h00, causing the Mask to be set (active low).

This means that before the ARM can receive

message ready interrupts from the Host

Processor, this register must be written with

STLC1510

h0001 (by ARM) to unmask the interrupt.

■ The Output Interrupt Mask Register (OIM)

resets toh00, causing the Mask to beset (active

low).This meansthat before theHostProcessor

can receive message ready interrupts from the

ARM, this register must be written with h01 (by

the Host Processor) to unmask the interrupt.

■ The Input and Output Message buffers are each

256 bytes long and 1 byte wide (an overflow in

the index register will not write to the other

message buffer, but will start to overwrite the

current message buffer).

■

Addressing of the Input and Output Message

Buffers by the Host Processor is implemented

indirectly via the Input and Output Index

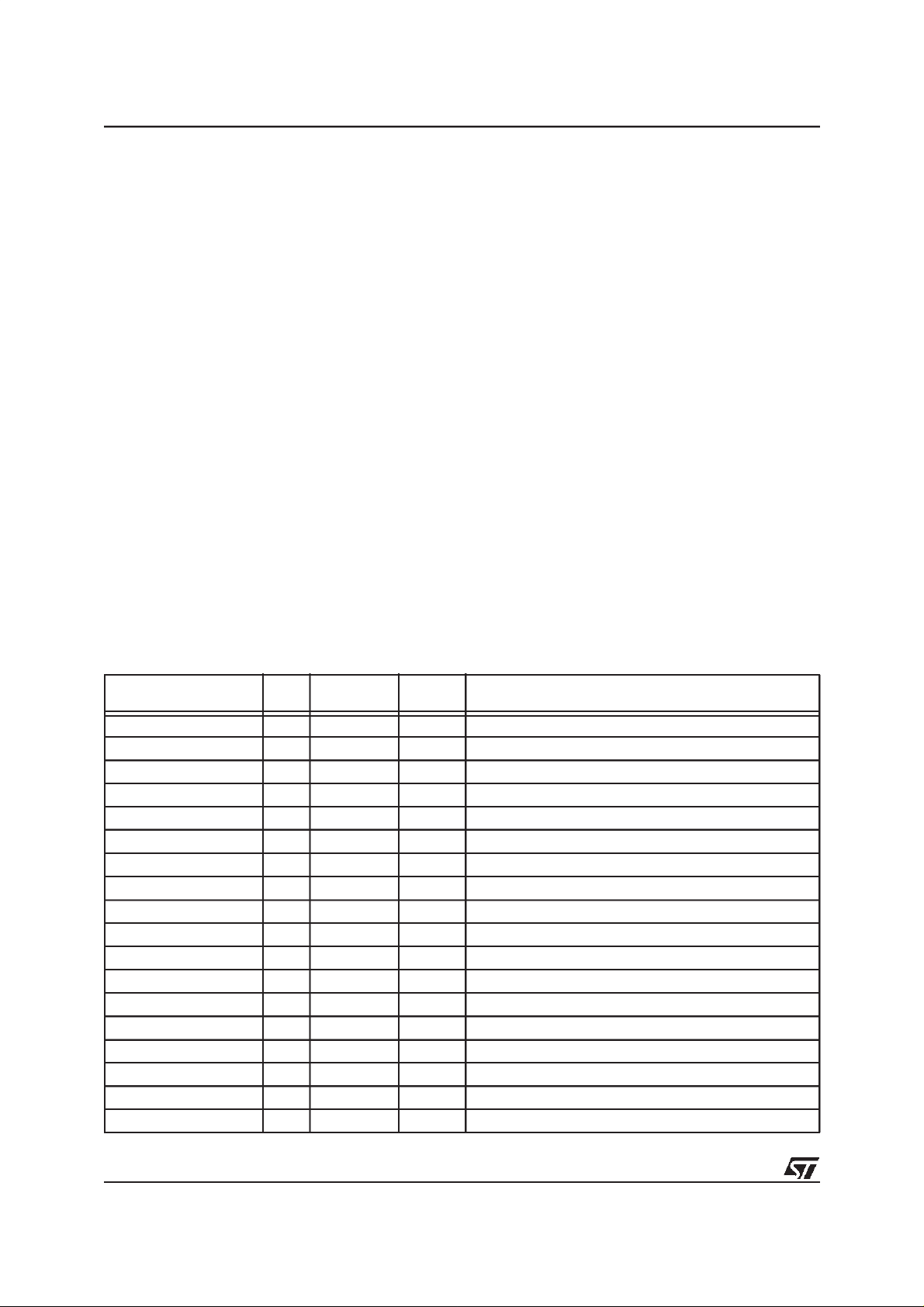

Registers.

■

An external interrupt signal is generated when

the output status register isset bytheARM7. An

ARM7 interrupt signal is generated when the

input status register is set by the Host

Processor.

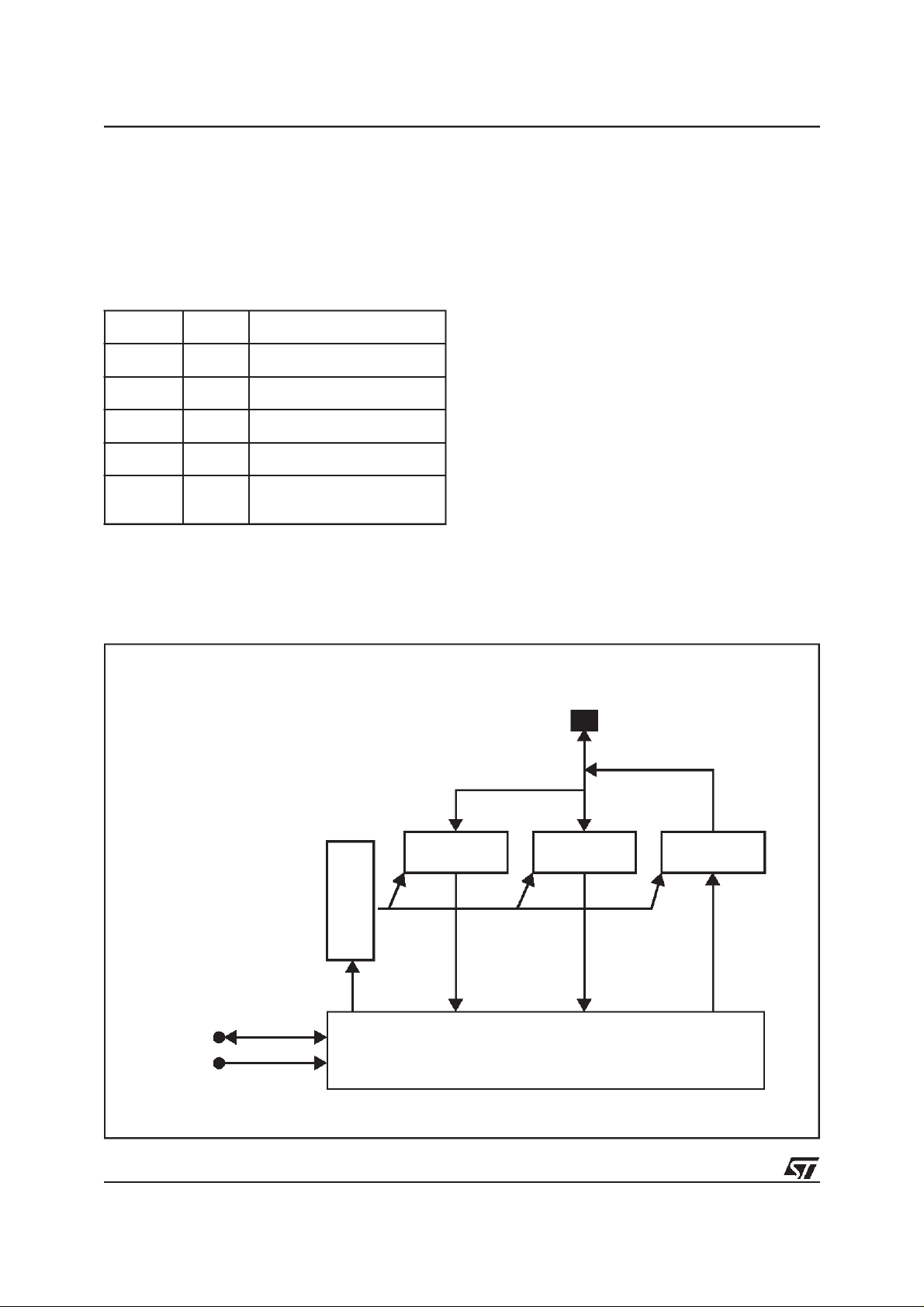

Figure 5. HPI Block Diagram

To/From

ARM

BCLK

BRESn

PSEL_HPI

PWR ITE

PENABL E

PADDR[10:1]

PD_W[7:0]

PD _R [15 :0]

H PI2 A RM_INT

InputInt M ask

O utput S tatus R e g

256 Bytes

Output

Message

S

L

A

A

P

V

B

E

Read/Write

Buffe r

Read

256 Bytes

InputMessage

Output Int M ask

Output IndexReg

Input IndexReg

Input StatusReg

Read

Read/Write

Buffer

H

P

To/From

HPI

ARM 2HP_ INT

HPI_CSN

HPI_RWN

HPI_ASN

C

HPI_ADDR[2:0]

N

HPI_DATA_IN[7:0]

T

R

HPI_DATA_OUT[7:0]

L

HPI_DATA_OEN

HPI_CLK

17/40

STLC1510

5.7.1 Send Message from Host Processor to

ARM

■

Read Input Status Register. Ifh01, the ARM has

not read out the last message. If h00, the ARM

has read the last message and the Input

Message Buffer is available for use.

■

Clear Input Index Reg by writing any value to its

address (b’100).

■

Write message into Input Message Buffer by

consecutively writing to its address (b’111). Each

write will cause the Input Index Register to

increment by 1 and access another byte location.

■

Write h01 to Input Status Register (address

b’011) to interrupt the ARM

5.7.2 Receive Message from ARM by Host

Processor

After receiving interrupt from ARM:

■

Clear Output Index Register (address b’001) by

writing any value.

■ Read message from Output Message Buffer by

consecutively reading from its address (b’110).

Each read will cause the Output Index Register to

increment by 1 and access another byte location.

■ Clear theOutput Status Reg (address b’000) by

writing any value (the ARM can clear the OSR

by writing 0 to it).

■ Send Message from ARM to Host Processor

■

Read Output Status Register. If h0001, the HP

has not read out the last message. Ifh0000, the

HP has read the last message and the Output

Message Buffer is available for use.

■

Write message into Output Message Buffer.

This buffer is directly addressable by the ARM.

■

Write h0001 to Output Status Register to

interrupt the HP

5.7.3 Receive Message from Host Processor

by ARM

After receiving interrupt from HP:

■ Read message from Input Message Buffer.This

buffer is directly addressable by the ARM.

■

Clear the InputStatus Reg by writing h0001 to its

address (the HP can clear the ISR by writing0 to it).

Table 3. Signal List

Name I/O

BRESn I Internal APB Active low master RESET

BCLK I Internal APB ASB clock

PSEL_HPI I Internal APB Active high block select from APB

PADDR[10:1] I Internal APB APB address [11:1]

PD_W[7:0] I Internal APB APB write data

PD_R[15:0] O Internal APB APB read data

PWRITE I Internal APB APB Write - Active high, Read - Active low

PENABLE I Internal APB APB enable signal for timing

HP2ARM_INT O Internal APB Interrupt from Host Processor to ARM

HPI_CLK I External HP Host Processor bus clock

HPI_CSN I External HP Active low select from Host Processor

HPI_ASN I External HP Address Strobe from Host Processor

HPI_RWN I External HP HP Read - Active high, Write - Active low

HPI_ADDR[2:0] I External HP Host Processor address

HPI_DATA_IN [7:0] I External HP Host Processor data in

HPI_DATA_OUT [7:0] O External HP Host Processor data out

HPI_DATA_OEN O External HP Host Processor data output enable

ARM2HP_INT O External HP Interrupt from ARM to Host Processor

Internal/

External

I/F Description

18/40

STLC1510

Table 4. HPI Memory Map 5.8 Block Processing Unit (BPU) Functional

Description

HPI Reg

Output Status Reg 000

Output Index Reg 001

Output Mask Reg 010

Input Status Reg 011

Input Index Reg 100

Input Mask Reg 101

Output Message Buffer 110

Input Message Buffer 111

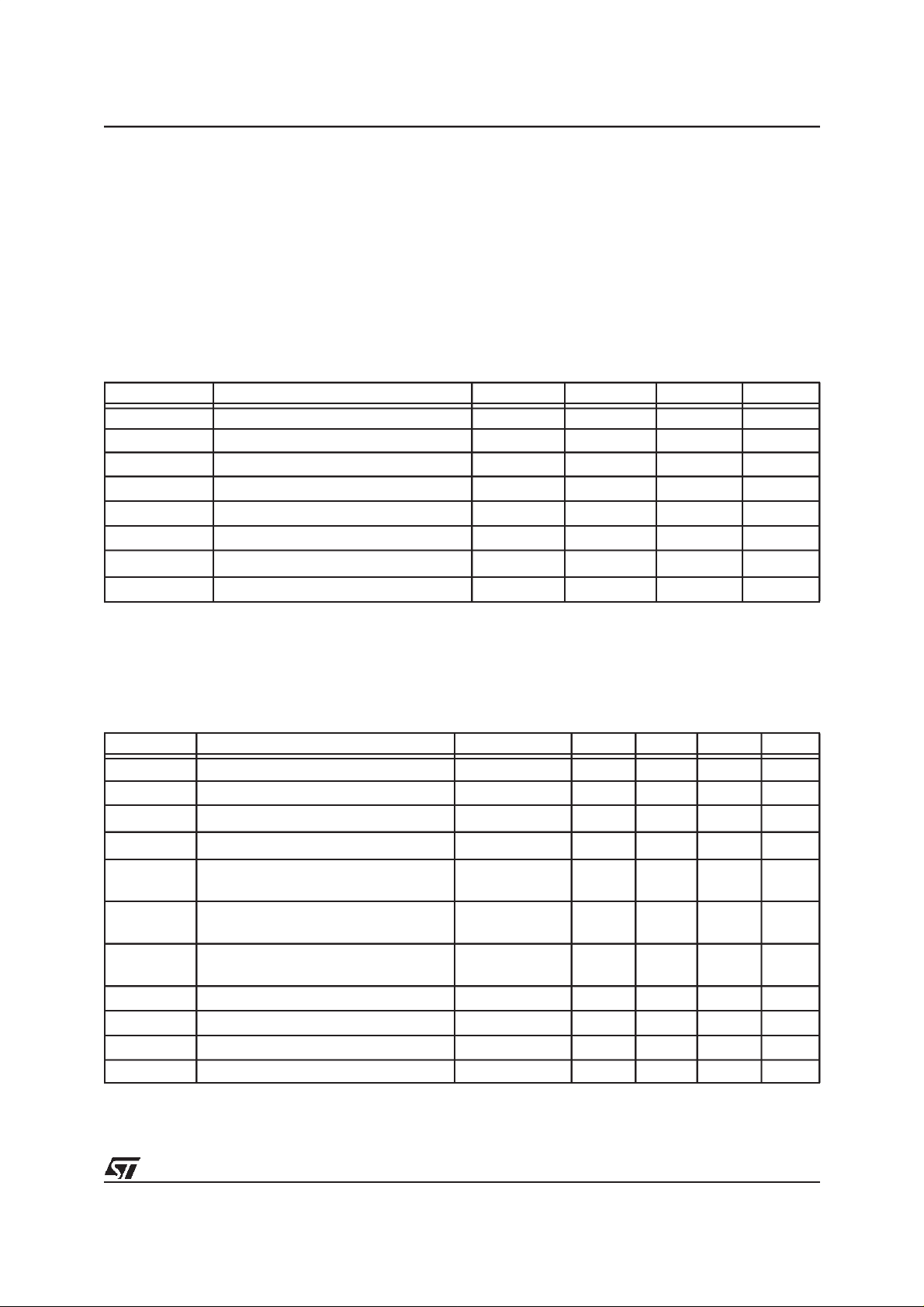

Figure 6. BPU Core Block Diagram

Host

Processor

Addr

BIN

5.8.1 Block Processing Unit - Core

The BPU is a programmable Digital Signal Processor

responsible for the bulk of the high rate signal processing required in the modem. This processor utilizes a dual multiply accumulate Arithmetic Unit (AU)

and Very Long Instruction Word (VLIW) format to

achieve high processing efficiencies.

The BPU is designed to perform the following functions:

■

Finite Impulse Filters (FIR)

■ (Infinite Impulse Response) IIR

■

FFT/IFFT

■

Compression/decompression for FFT/IFFT

■

FDEQ

■

Tx Gain

■ SNR calculation - recursive average

■

add/remove cyclic prefix

■ Slicer

■

Auto Correlation

■ FDEQ update

■

Digital AGC

MCU/DFE

DATA

MEMORY

INTERFACE

INTERFACE

DFE

STLC1510 BUS INTERFACE

DATA MEM CDATA MEM

X

(XDM)(C

PORT

X

DM

)

C

ARITHMETIC UNIT (AU)

CONTROL

AU

ADDRESS CALCULATION UNIT (ACU)

PROGRAM CONTROL UNIT (PCU)

CONTROL

AU

PROGRAM

MEMORY

ADDRESS

PROGRAM MEMORY

PORT

PROGRAM

MEMORY

DATA

19/40

STLC1510

5.9 Digital Front End (DFE)

The Digital Front End (DFE) block contains dedicated

hardware to map signals between the analog interface (AFE) and the BPU.

The DFE block has the following features:

■ It performs part of the sampling rate conversion

between the AFE sampling rate and the 2x

in CPE mode. This consists of a digital phase

interpolator and a digitalΣ∆ D/A convertor

■

Two loopback modes are provided in this block.

■

Various bypass modes are provided to allow

observation and isolation of any block in the

DFE for test purposes.

■

Interface to the LAMBA Bus.

symbol rate of the BPU.

■ It provides the necessary digital hardware to

implement ananalog-based AGC.

■

It provides the necessary buffering to provide

DMT symbol alignment within the BPU.

■

It provides the facilities to allow timing recovery

5.9.1 Application Description

Figure 7. shows the application of the various DFE

components when used in a CO (network) and CPE

(remote) applications.

Figure 7. DFE Application Diagram

STLC1510 (CO) STLC1520 (CPE)

PIF

PD

Dly

RSM

DFE

DFE

ADC

DAC

~4.416 MHz

CIC

Filter

~4.416 M H z

CIC

Filte r

Σ∆

optional

r

o

2.208 M Hz

CIC

Filter

2.208 M Hz

Interp

CSD

FIR

1.104 M Hz

IIR

FIFO

552 kHz

~2.208 M H z

t

a

l

o

p

r

e

t

n

I

e

s

a

~2.208M Hz

h

P

BPU

2.208 M Hz

IIR

FIFO

552 kH z

2.208 M Hz

Interpolating

CSD FIR

CIC

Filter

552 kHz

4.416MHz

DAC

Analog

4.416 MH z

Domain

ADC

RSM

2.208 M Hz

BPU

552 kHz

5.9.2 Interface Description

The registers accessible by the EPM are:

■

Decimator oversampling ratio

■ Decimator order.

■

Various loopback and bypass modes.

■

Number of bits transferred to the Aloha ASIC

DAC.

■

AFE control registers.

■ ADC clip counter.

■

RSM parameters such as time constant, peak

detector thresholds, peak detector modes,

20/40

integrator initialization, and detector outputs.

■ IIR coefficients.

■

Predictor IIR filter coefficients.

■ Frame synchronization buffer length

■

Timing recovery (crystal) control word.

■

Timing recoveryΣ∆ dither level selection.

■

CO/CPE mode selection.

■

Phase interpolator parameters such as alpha,

frequency error and frequency error gain.

■

CO peak detector parameters such as set-up

and hold delays, threshold, and slew rate.

5.10Timing Generation Block (TGB)

The timing and reset generation block generates the

device’s global clock and synchronization signals.

It uses the input clock signal (35.328 or 17.664 MHz)

to derive the main internal clock signals, as well as all

synchronization pulses required to coordinate timing

between the sub-blocks. It also synchronizes the external RESETN with the internal ASIC clock.

The PLL input source, and PLL bypass signals are decoded from the PMode[1:0] pins. The CMode[1:0] pins

are configured toalwaysprovidean 8.8 MHz inputto the

PLL when the PLL is not in bypass mode. Thus adivide

by 2 or 4 will be selected to divide down the 17 or 35

MHz input clock references to 8.8 MHz. When the PLL

is to be bypassed, it is powered down, and the input reference is used to bypass the PLL output.

The CK35M signals are generated by dividing down

the internal ASIC clock. A 3 bit memory mapped register is used to adjust the reset phase ofthe divide by

6 generator. This gives software control of the phase

of theCK35M signal which interfaces to the AFE device. There is also a programmable ”one shot” mode

which is used to reset the phase of the CK35M in the

event the interface cannot synchronously meet the

timing requirements.

The NIFTX_CLK and NIFRX_CLK are generated

when the NIF is in clock and data mode, i.e. not utopia mode.

5.10.1RESET Structure

The RESET structure for the STLC1510 has the following requirements/attributes:

STLC1510

■

Requires off-chip power supervisor to supply

10ms power-on reset (may also require push

button reset for test) and 5ms TRSTN (TAP

reset).

■

Reset initialization will begin when RESETN is

de-asserted by the off-chip power supervisor.

After 2 rising edges of 4.4MHz clock,

ASIC_RESETn is de-asserted and the

STLC1510 (minus the BPUand D950 cores) will

come out of reset. The ARM7 will follow its boot

procedure which at some point, will download

program code to the BPU and D950 cores then

release them individually from reset.

5.11Test Access Port Functional Description

The IEEE 1149.1 compliant Test Access Port (TAP)

serves three purposes:

■ TAP interface for both ASIC and board level

testing

■

RAMBIST interface for testing the embedded

memories during ASIC level test.

■

General Purpose I/O port for general and

miscellaneous control and monitoring.

In addition to these functions, there are two sets of

mode pins,

PMODE[1:0

], and

are used to put the STLC1510 into various modes.

The definition of these modes are given below, where

the shaded rows indicate special modes not to be

used in normal operations.

CMODE[1:0]

which

Table 5. Power Mode Pin Definition

PMODE[1:0] Mode State Description

00 Power Down Mode 0 Nothing is powered down.

01 Power Down Mode 1 ARM7 is powered down.

10 Power Down Mode 2 D950 is powered down.

11 Power Down Mode 3 BPU processor is powered down

Table 6. Clock Mode Pin Definition

CMODE[1:0] Mode State Description

00 Div2 Master clock is REFCLK divided by 2 and then multiplied by24. The

input REFCLK should be 17.664 MHz

01 Normal Master clock is REFCLK divided by 4 and then multiplied by 24. The

input REFCLK should be 35.328 MHz

1X Bypass Master clock is REFCLK

21/40

STLC1510

5.11.1DFT Interfaces

The STLC1510 incorporates certain features (Design

for Testability, DFT) to improve thecoverage of the final production test. Certain pins are dedicated to this

features, and should not be used duringnormal operation. The Test Interface pins need to be connected

as follows:

Signal BGA Connected to

TCK N9 Pull-Up

TMS N7 Pull-Up

TDI P8 Pull-Up

TDO N8 open

TRSTN P9 See “RESET Structure” on

page 21.

5.11.2General Purpose I/O (GPIO) Interface

The STLC1510 has a 8-bit General Purpose I/O port

Figure 8. GPIO Interface Block Diagram

to allow low speed control and monitoring of external

signals via the LAMBA bus. The block diagram for

this interface is shown in Figure 8.

The GPIO has the following attributes:

■

There are 8 GPIO pins.

■

Each pin can be individually set to one of 4

modes:

• Input mode: Input signals will be sampled with LAMBA bus clock and stored in

GPIO_in register.

• Output mode: The GPIO pin is driven

with the state in theGPIO_out register.

• Interrupt mode: The

GPIO_int

register

is set when there is a negative transition

detected on its corresponding GPIO pin.

The logic levelof each interrupt pin will as

well be stored in theGPIO_in register. An

interrupt condition on any of the GPIO

pins will result in an interrupt to the D950.

• Dedicated mode. The GPIO pin is configured to be its second function according to the Table below If the pin does not

have a second function, it will be configured as an input pin.

■

There isno external clock for the GPIOinterface

and as such no timing defined.

Lamba

Bus

GPIO[7:0]

GPIO_in GPIO_outGPIO_int

GPIO _state

Lamba BusInterface (LBI)

22/40

STLC1510

5.12Processor Emulation

There are three programmable processors on the

LAVA ASIC: an ARM microprocessor, a D950 Digital

Signal Processor, and a custom DSP engine (BPU).

All these are capable of JTAG based emulation with

the following attributes:

■

Stop on breakpoint.

■ Single step

■ Full register R/W.

■

Program modification and resume.

6.0 ELECTRICAL CHARACTERISTICS

This device shall meet the functional requirements

detailed herein when operated over the specified timing, electrical, and temperature range.

7.0 OPERATING RANGES

The operating ranges shall be in accordance with the

following table.

Table 7. Operating Ranges

SYMBOL PARAMETER MIN. NOM. MAX. UNITS

VDD3_3 CMOS 3.3v I/OSupply voltage 3.0 3.3 3.6 V

VDD2_5 CMOS 2.5v Core Supply voltage 2.25 2.5 2.75 V

I

DD3

I

DDS3

I

DD2

I

DDS2

T

A

T

J

<1> Assuming no air flow and a package thermal resistance of 30×C/watt

CMOS 3.3v I/O Supply current 11 mA

CMOS 3.3v I/O Static supply current TBD mA

CMOS 2.5v Core Supply current 240 mA

CMOS 2.5v Core Static supply current TBD mA

Ambient temperature under bias

1

-40 25 85 ×C

Operating junction temperature -40 25 105 ×C

7.1 DC Characteristics The following table identifies the general DC charac-

teristics for input and output pins.

Table 8. General Interface Electrical Characteristics

SYMBOL PARAMETER Conditions Min Typ Max Unit

V

il

V

ih

V

ol

V

oh

I

il

I

ih

I

oz

I

pu

I

pd

R

up

Rpd Equivalent pull-down resistance Vi = VDD2_5 50 k

<1> Takes into account 0.075*Vdd voltage drop in both supply lines.

<2> The leakage currents are generally very small, < 1nA. The value given here, i µA, is a maximum that can occur after an Electrostatic

Stress on the pin.

Low level i/p voltage 0.8 V

High level i/p voltage 2.0 V

Low level o/p voltage

High level o/p voltage

1

a

Low Level Input Current without pull-up

2

device

High Level Input Current without pull-

down device

b

Tri-state Output leakage without pull

up/down device

b

Iol= 2mA 0.4 V

Ioh= 2mA 2.4 V

Vi=0V 1.0 µA

Vi=VD3_3

Vi=VDD5

Vo=0Vor

2.0

4.0

µA

µA

1.0 µA

VDD3_3

Pullup current Vi= 0V -50 µA

Pulldown current Vi= VDD5 100 µA

Equivalent pull-up resistance Vi=0V 50 k

Ω

Ω

23/40

STLC1510

7.2 AC Characteristics

7.2.1 AFE Interface Timing

Figure 9. AFE Data Interface Timing (TTL)

CK 35M

Tx S OU T [1 :0 ]

tacc

tse

tho

RxSIN[1:0]

tse

tho

AS_CLK

Table 9. AFE Data Interface Timing

Pin Name Parameter Min. Max. Reference Pin

TxSOUT[1:0] tacc 0 10ns w.r.t. rising CK35M

TxSIN[1:0] tse 5ns w.r.t. rising CK35M

TxSIN[1:0] tho 5ns w.r.t rising CK35M

AS_CLK tse 5ns w.r.t. rising CK35M

AS_CLK tho 5ns w.r.trising CK35M

24/40

Figure 10. AFE Control Interface Timing (TTL)

SPI_CL K

SPI_ENB

SPI_DT X

STLC1510

ta c c

tacc

tse

SPI_D RX

tho

Table 10. AFE Control Interface Timing

Pin Name Parameter Min. Max. Reference Pin

SPI_ENB tacc 0 5ns w.r.t. rising SPI_CLK

SPI_DTX tacc 0 5ns w.r.t. rising SPI_CLK

SPI_DRX tse 5ns w.r.t. falling SPI_CLK

SPI_DRX tho 5ns w.r.tfalling SPI_CLK

25/40

STLC1510

Figure 11. Line Driver Control Interface Timing (TTL)

CK35M

tacc

LinDr_CTRL1

LinDr_CTRL2

LinDr_AGC

Table 11. Line Driver Control Interface Timing

Pin Name Parameter Min. Max. Reference Pin

LinDr_CTRL1 tacc 0 7ns w.r.t. rising CK35M

LinDr_CTRL2 tacc 0 7ns w.r.t. rising CK35M

LinDr_AGC tacc 0 7ns w.r.t. rising CK35M

26/40

Figure 12. Test Interface Timing (TTL)

TCK

TDO

STLC1510

tacc

tse

TDI

tse

TRSTN

tho

tho

Table 12. Test Interface Timing

Pin Name Parameter Min. Max. Reference Pin

TDO tacc 0 10ns w.r.t. rising TCK

TDI tse 5ns w.r.t. rising TCK

TDI tho 5ns w.r.trising TCK

TRSTN tse 5ns w.r.t. rising TCK

TRSTN tho 5ns w.r.trising TCK

27/40

STLC1510

Network Interface Timing

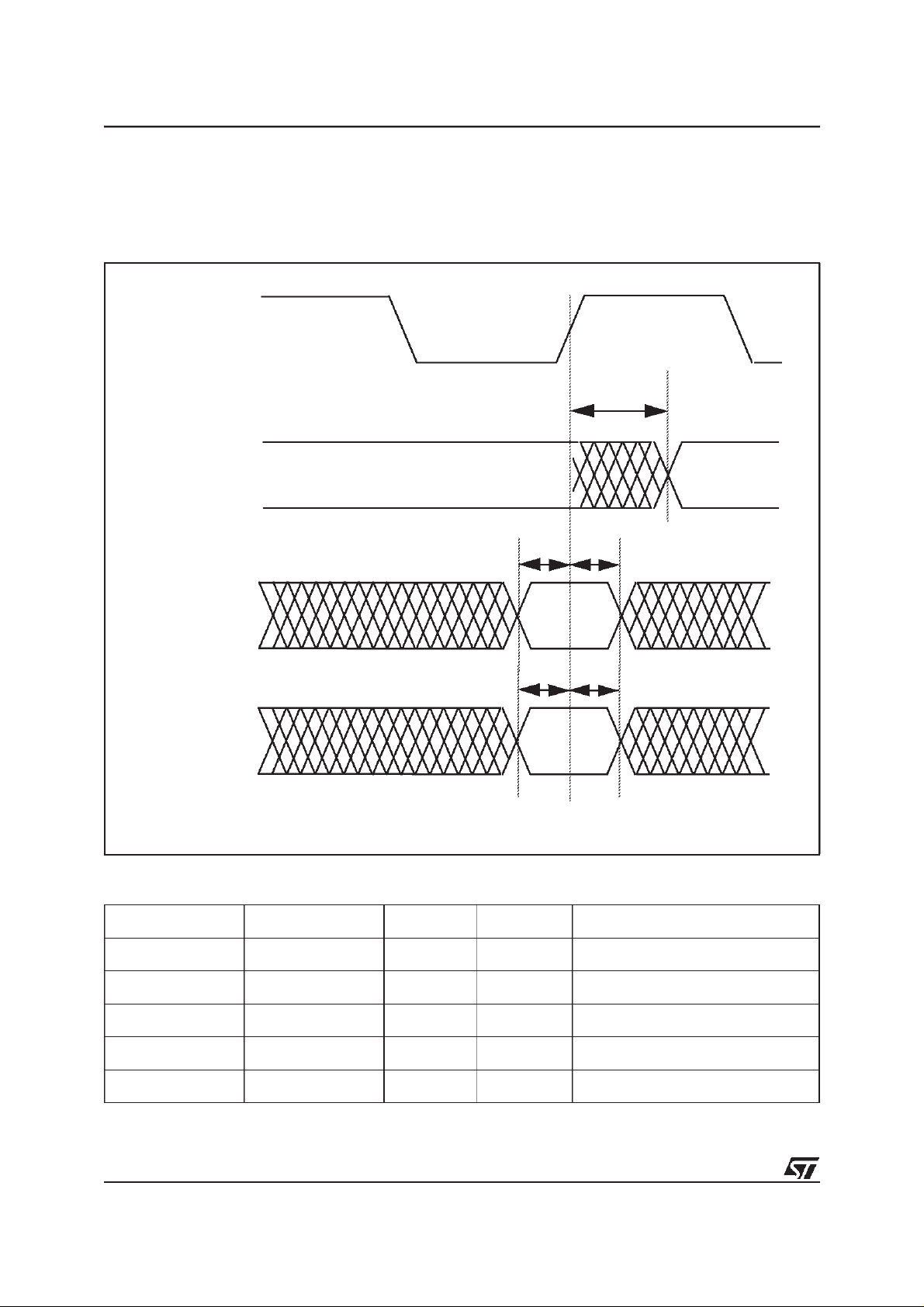

Figure 13. UTOPIA Transmit Interface Timing

TxCLK

TxClav

tacc

tse

TxEnb

TxSOC

UTxData[7:0]

Tx Ad dr[4:0 ]

TxParity

tho

Table 13. Transmit Utopia Interface Timing

Pin Name Parameter Min. Max. Reference Pin

TxClav tacc 0 10ns w.r.t. rising TxClk

TxSOC tse 5ns w.r.t.rising TxClk

TxSOC tho 2ns w.r.trising TxClk

TxEnb tse 5ns w.r.t. rising TxClk

TxEnb tho 2ns w.r.trising TxClk

UTxData[7:0] tse 5ns w.r.t. rising TxClk

UTxData[7:0] tho 2ns w.r.t.rising TxClk

TxAddr[4:0] tse 5ns w.r.t. rising TxClk

TxAddr[4:0] tho 2ns w.r.trising TxClk

TxParity tse 5ns w.r.t. rising TxClk

TxParity tho 2ns w.r.trising TxClk

28/40

Figure 14. UTOPIA Receive Interface Timing

RxCLK

RxClav

RxSOC

U R xData[7:0]

RxParity

RxEnb

R xA d dr [4:0]

tse

STLC1510

tacc

tho

Table 14. Receive Utopia Interface Timing

Pin Name Parameter Min. Max. Reference Pin

RxClav tacc 0 10ns w.r.t. rising RxClk

RxEnb tse 5ns w.r.t.rising RxClk

RxEnb tho 2ns w.r.trising RxClk

RxSOC tacc 0 10ns w.r.t. rising RxClk

URxData[7:0] tacc 0 10ns w.r.trising RxClk

RxAddr[4:0] tse 5ns w.r.t. rising RxClk

RxAddr[4:0] tho 2ns w.r.t.rising RxClk

RxParity tacc 5ns w.r.t. rising RxClk

29/40

STLC1510

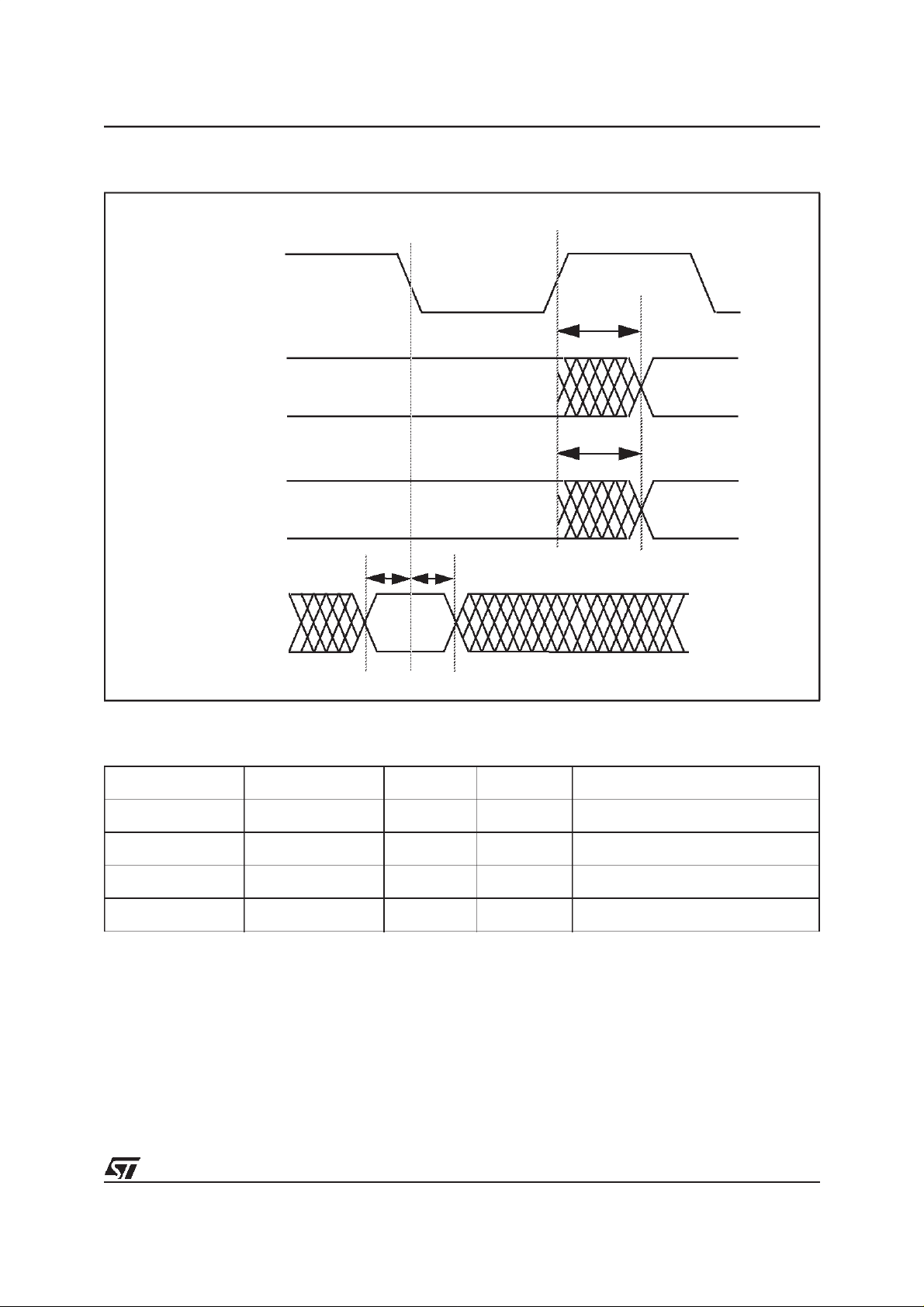

Figure 15. Serial Transmit Interface Timing

TxClk

tse

tho

UTxData[0]

Table 15. Transmit Serial Interface Timing

Pin Name Parameter Min. Max. Reference Pin

TxClk frequency

UTxData[0] tse 0ns w.r.t. rising TxClk

UTxData[0] tho 0ns w.r.t.rising TxClk

Figure 16. Serial Receive Interface Timing

RxClk

tac c

UR xData[0]

Table 16. Receive Serial Interface Timing

Pin Name Parameter Min. Max. Reference Pin

RxClk frequency

URxData[0] tacc 0 3ns w.r.t. falling RxClk

30/40

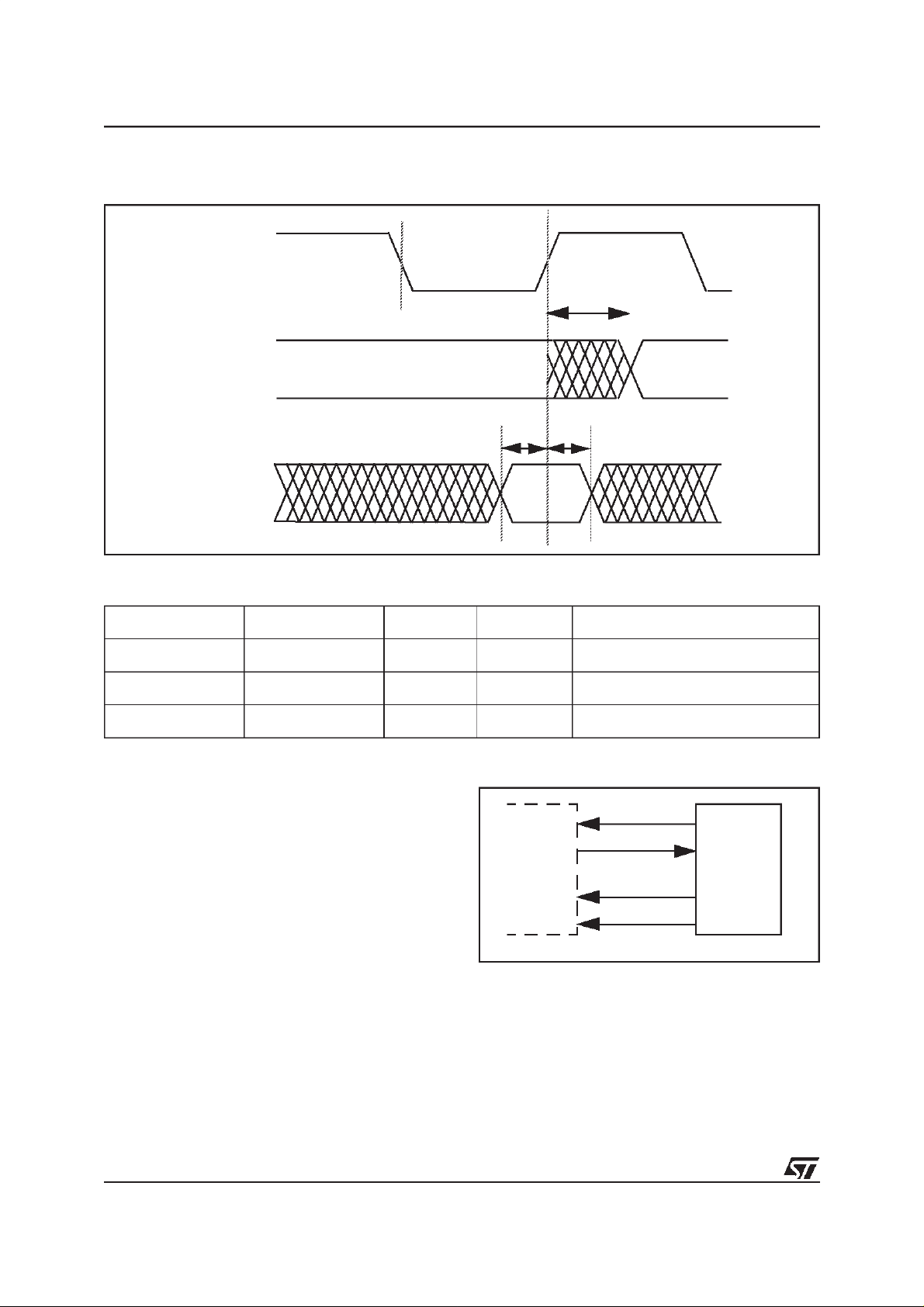

Host Processor Interface Timing

Figure 17. Host Processor Interface Timing (TTL)

HPI_BS

STLC1510

tse

tho

HPI_Addr[2:0]

HPI_RWN,HPI_CSN

HPI_D a ta[7 :0]

tacc

H PI_ D ata[7 :0]

Table 17. Host Processor Interface Timing

Pin Name Parameter Min. Max. Reference Pin

HPI_Addr[2:0] tse 2.45ns w.r.t. rising HPI_BS

HPI_Addr[2:0] tho 0.01ns w.r.t. rising HPI_BS

HPI_CSN tse 3.1ns w.r.t. rising HPI_BS

HPI_CSN tho 0.01ns w.r.t. rising HPI_BS

HPI_RWN tse 0.84ns w.r.t. rising HPI_BS

HPI_RWN tho 0.01ns w.r.t. rising HPI_BS

HPI_Data[7:0] tse 2.15ns w.r.t. rising HPI_BS

HPI_Data[7:0] tho 0.01ns w.r.t. falling HPI_CSN

HPI_Data[7:0] tacc 10ns w.r.t. falling HPI_CSN

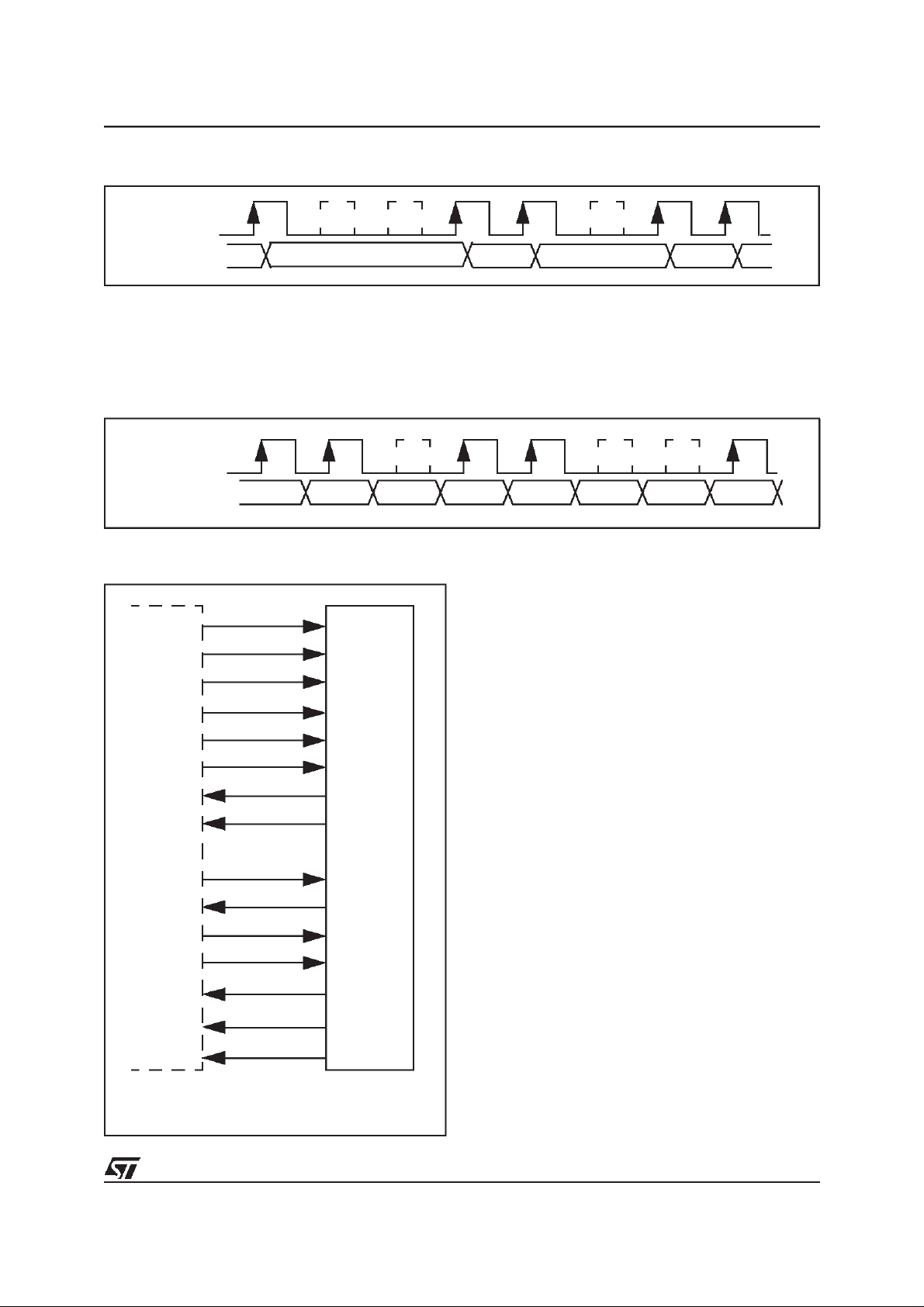

7.2.2 GPIO Interface Timing

The GPIO[7:0] pins are memory mapped programmable pins. These pins can be programmed as input

or output providing visibility to internal chip access

points, as well as an ability to latch external control

signals. A specialmode can be configured where the

LAMBA Bus Clock is made available on a configured

output pin GPIO[0]. For timing characterization, this

mode should be used to exercise the GPIO[7:1] pins

as both inputs and outputs. The diagram below refers

to this special mode.

31/40

STLC1510

Figure 18. GPIO Interface Timing

G PIO [0]

GP IO [1:7]

tacc

tse

GPIO[1:7]

tho

Table 18. GPIO Interface Timing

Pin Name Parameter Min. Max. Reference Pin

GPIO[1:7] tacc 0 10ns w.r.t. rising GPIO[0]

GPIO[1:7] tse 5ns w.r.t. rising GPIO[0]

GPIO[1:7] tho 2ns w.r.t. rising GPIO[0]

7.3 Power-up supply sequencing

Figure 19. The NIF Serial Interface

There are two power supply voltages that must be

applied to this chip to ensure correct functionality,

(3.3V and 2.5V). The chip itself will function correctly

regardless of the sequence in which the supplies are

applied on power-up.

However if the 3.3V supply is off and there isexternal

5V activity at the IOs, the internal ESD protection circuitry will clamp the external signalsat 2.8 Volts max-

Ne twork

TxClk

UTxData[0]

RxClk

URxData[0]

imum (by sinking as much current as provided by the

interface).

In the Tx direction, the reception of a data byte from

8.0 EXTERNAL INTERFACE TIMING

the network starts with the most significant bit. Bits

are sampled by STLC1510 on the rising edge of Tx-

8.1 NIF (Network Interface) Serial Interface

The NIF serial interface consists of separate clock

and data lines inthe RXand TX directions. This interface is illustrated briefly in Figure 19.

Clk. In the presence of clock gapping (which is generated by the STLC1510, as it supplies the clocks in

both directions), a previous bit persists until the next

rising edge of the clock. Figure 21. shows the relationship between TxClk and UTxData[0].

STLC1510

32/40

Figure 20. Network Serial Interface Tx Timing

TxClk

STLC1510

UTxData[0]

B(1)

B(0) B(7) B(6) B (5) B (4)

In the Rx direction, the most significant bit of a data

byte is transmitted to the network first, with the least

significant bit transmitted last. The serial data stream

is sampled by the network on the rising edge of Rx-

Figure 21. Network Serial Interface Rx Timing

RxClk

URxData[0]

B(1)

B(0)

X

Figure 22. The NIF Utopia Level 2 Interface

TxClk

UTxData[7:0]

Tx A d d r[4 :0 ]

TxEnb

TxSO C

TxParity

TxClav

TxBP

Network

(ATM

Layer)

RxClk

URxData[7:0]

RxAddr[4:0]

RxEnb

RxSOC

RxParity

RxClav

STLC1510

(MPHY

Layer)

Clk. Samples at the gapped positions are ignored.

Figure 21. illustrates the Rx timing diagram of the serial interface. Ignored samples are indicated by ’X’ in

the timing diagram.

B(7)

B(6)

X

X

B(5)

8.2 UTOPIA Level 2 Interface

The Utopia Level 2 Interface is an 8-bit interface, operating independently in the TX and RX directions.

The Utopia Level 2 Interface is briefly illustrated in

Figure 22.

General features:

■

Implemented according to The ATM Forum

Technical Committee’s Utopia Level 2

specification. Utopia Level 2is an extension of

Utopia Level 1 which provides for connecting

multiple MPHY layer devices to a single ATM

layer. Once a given MPHY layer device has

been selected for data transfer according tothe

mechanisms specified in Utopia Level 2, the

transfer itself is performed according to the

mechanisms specified in Utopia Level 1.

■

8-bit data transfer in each direction (TX and

RX), with a maximum clock speed of

approximately 21 MHz.

■

Clocks are provided bythe ATM layer through

the TxClk and RxClk ports. (ATM layer is the

master, PHY layer is the slave)

■

There are 5address lines for each ofthe TX and

RX interfaces. Up to 31 addresses are

supported, withthe 32ndaddress (11111) being

a reserved, idle address. Single PHY operation

is supported by leaving the address lines set to

the address of the PHY device.

■

For more information, please see the ATM

33/40

STLC1510

Forum Technical Committee’s Utopia Level 1

and Utopia Level 2 specifications, and Chapter

7 of this document, Network Interface and

Controller (NIF).

Features of MPHY Layer Cell-Level Handshake (Tx

Direction):

■

A single MPHY port at a time is selected for a

cell transmission. However, another MPHY port

may be polled for its TxClav status while the

selected MPHY port transfers data. The ATM

layer polls the TxClav status of a MPHY port by

placing its address on TxAddr. The MPHY port

(STLC1510 device) drives TxClav during each

cycle following one with its address on the

TxAddr lines.

■

The ATM layer selects a MPHY port for transfer

by placing the desired MPHY address onto

TxAddr, when TxEnb is deasserted (high)

during the current clock cycle, and asserted

(low) during the next clock cycle. All MPHY

devices only examine the value on TxAddr for

selection purposes when TxEnb is deasserted

(high). The MPHY port is selected starting from

the cycle after its address ison the TxAddrlines,

and TxEnb is deasserted (high); and ending in

the cycle a new MPHY port is addressed for

selection, and TxEnb is deasserted (high).

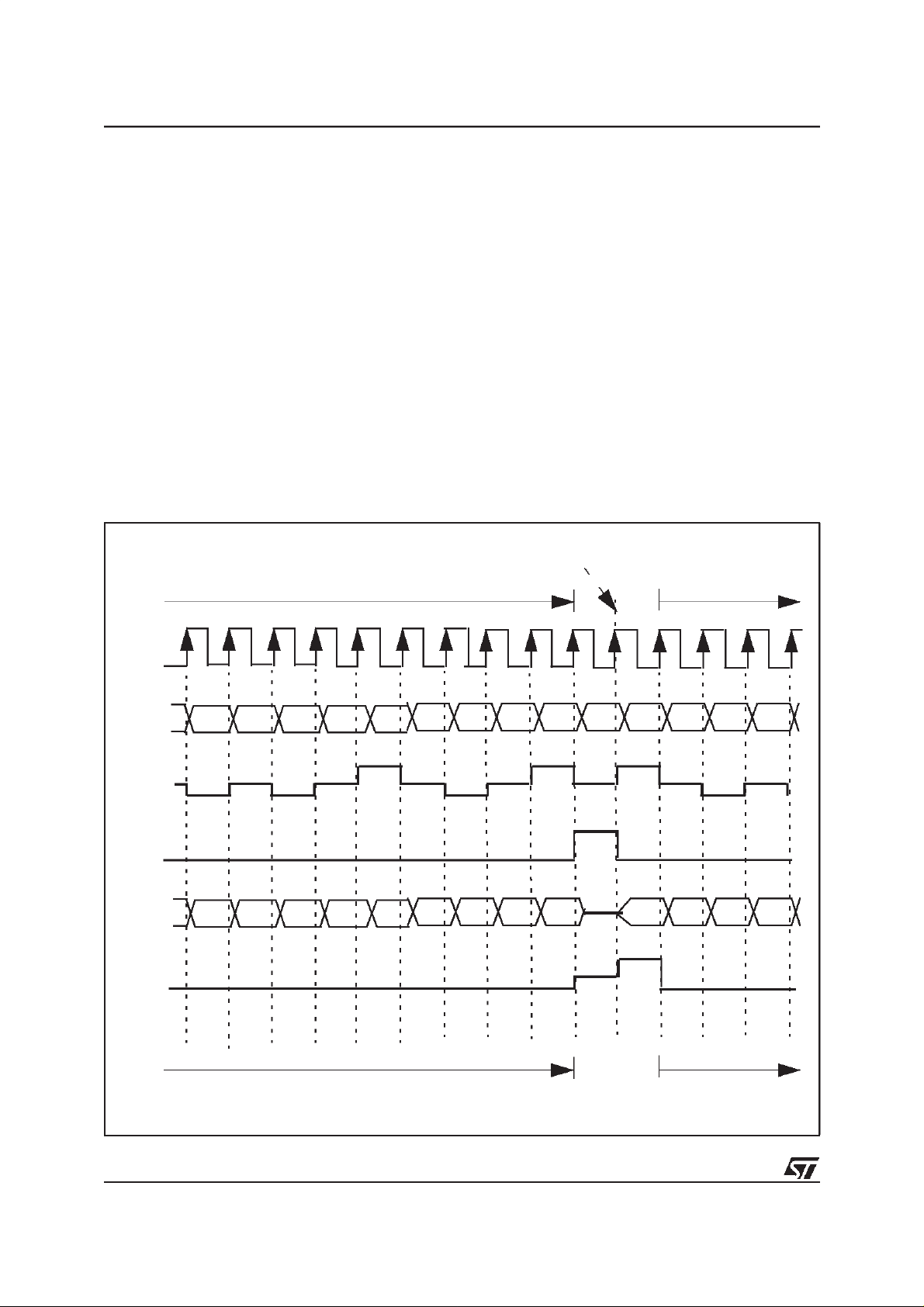

Figure 23. depicts the polling phase and the selection

phase of the UTOPIA2 transmit interface. After the

selection of the MPHY port, the cell transfer is executed the same way as in UTOPIA Level 1.

Figure 23. UTOPIA Level 2 transmit timing, polling phase and selection phase.

selection

po lling polling

TxClk

TxAddr

TxClav

TxEnb

UTxData

TxSOC

Cell transmission to:

1F 1F 1F

P40 P41 P42 P43

N+1N+3N-1

N+3

N-1

P44 P45

PHY N PHY N+3

1F 1F 1F 1F

NN+3

N+1

P46 P47

N+3N

P48 H1 H 2 H3 H 4

N+1

N+1

N-1

34/40

STLC1510

The TxBP pin is not part of the Utopia Level 2 specification, but its functionality does not interfere with

the operation of the Utopia Level 2 Interface. It canbe

left unconnected if necessary for a given application.

This signal is described in more detail in the NIF

chapter of this document.

RxAddr lines.

■ The ATM selects an MPHY port for transfer by

placing the desired MPHY port address onto

RxAddr, when RxEnb is deasserted (high)

during the current clock cycle and asserted

(low) during the following clock cycle. All MPHY

devices examine the value on RxAddr for

Features of MPHY Layer Cell-Level Handshake (Rx

Direction):

selection purposes when RxEnb is deasserted

(high). The MPHY port is selected starting from

the cycle after its address is on the RxAddr

■

A single MPHY port at a time is selected for a

cell transmission. However, another MPHY port

may be polled for its RxClav status while the

selected MPHY port transfers data. The ATM

lines, and RxEnb is deasserted (low); and

ending in the cycle a new MPHY port is

addressed for selection, and RxEnb is

deasserted (high).

layer polls the RxClav status of a MPHY port by

placing its address on RxAddr. The MPHY port

(STLC1510 device) drives RxClav during each

cycle following one with its address on the

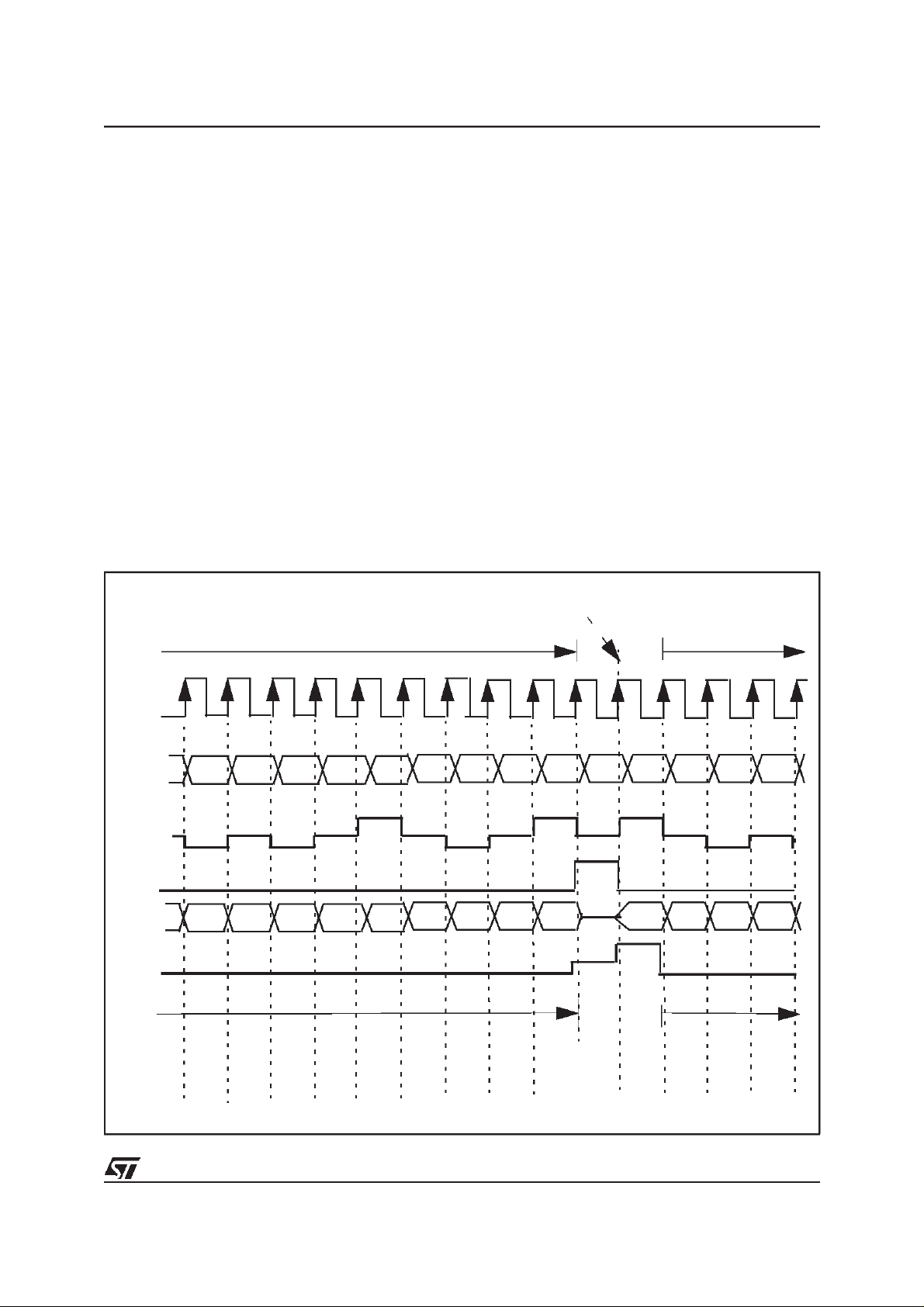

Figure 24. illustrates the timing diagram of the receive interface when a cell is received from PHY N

and theother PHYs are polled.

Figure 24. UTOPIA Level 2 receive timing, polling phase and selection phase.

sele ctio n

RxC lk

RxAddr

RxClav

RxEnb

URxData

RxSOC

C ell tra ns missio n fro m:

1F 1F 1F

P40 P41 P42 P43

po lling po l ling

N+1N+3N-1

N+3

N-1

P44 P45

PHY N PHY N+3

1F 1F 1F 1F

NN+3

N+1

P46 P4 7

P48 H1H2H3H4

N+3N

N+1

N+1

N-1

35/40

STLC1510

Figure 25. HPI Block Diagram

8.3 Host Processor Interface (HPI)

A host processor interface is provided to allow the

STLC1510 to be controlled by an external microcontroller. The design has been optimized for the Motorola MPC850. More details are provided in the EPM

STLC 1510

HPI

ARM2HP_INT

HPI_CSN

HPI_RWN

HPI_ASN

HPI_ADDR[2:0]

HPI_DATA[7:0]

HPI_CLK

External

Ho s t

Processo r

section of this document.

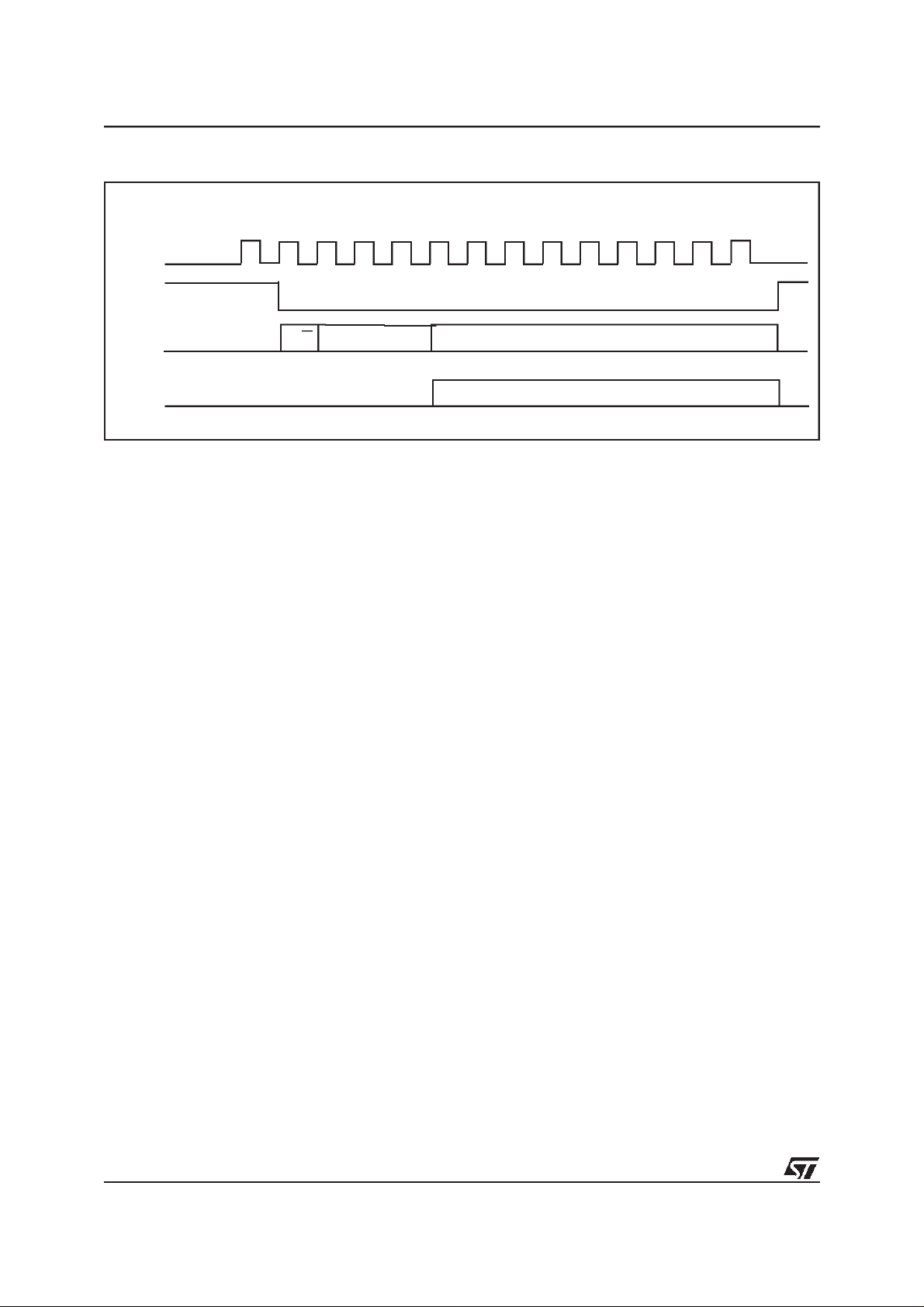

Figure 26. Host Processor Interface Timing Diagram

HPI_CLK

H P I_ Add r[2 :0 ]

HPI_CSN

HPI_ASN

HPI_RWN

H P I_ Da ta[7 :0 ]

0ns 25ns 50ns 75ns 100ns

WRITEWRITEREADREAD

addr_ su

csn_su

asn_su

rwn_ su

tda t_ su

trwn_dat_hztwrdat_valid

tdat_h

36/40

STLC1510

8.4 AFE Interface

The interface to the companion Analog Front-end device (STLC1511) operates ata rate of 35.328MHz. It

consists of two types:

■ A serial signal interface for transferring DAC

and ADC samples to and from the Aloha ASIC

ASIC.

■ A serial control interface for Aloha ASIC.

The serial signal interface to the Aloha ASIC provides

for transport of transmit and receive data between

the LAVA ASIC and Aloha ASIC. This is accomplished with a two bit wide data stream ineach direction plus the appropriate clocks. Refer to Figure 27.

for the timing diagram of this interface.

The serial signal interface consists of six pins:

■ A 35.328MHz continuous clock output

CK35M

(

);

■

A dual serial pin input pin for ADC samples

(RxSIN);

• It can carry up to 16 bits. The exact

number of bits carried is programmable

between 12 and 16. Refer to the AFE

interface definition for details.

■ A dual serial pin output pin for DAC samples

(TxSOUT);

■

It can carry up to 16 bits. The exact number of

bits carried is programmable between 14 and

16. Refer to the AFE interface definition for

details

■ An ADC and DAC sample clock input

(A_SCLK).

■

ForTX and RXinterface, data is sent on positive

edge of clock and sampled by the receiver on

the negative edge of the clock.

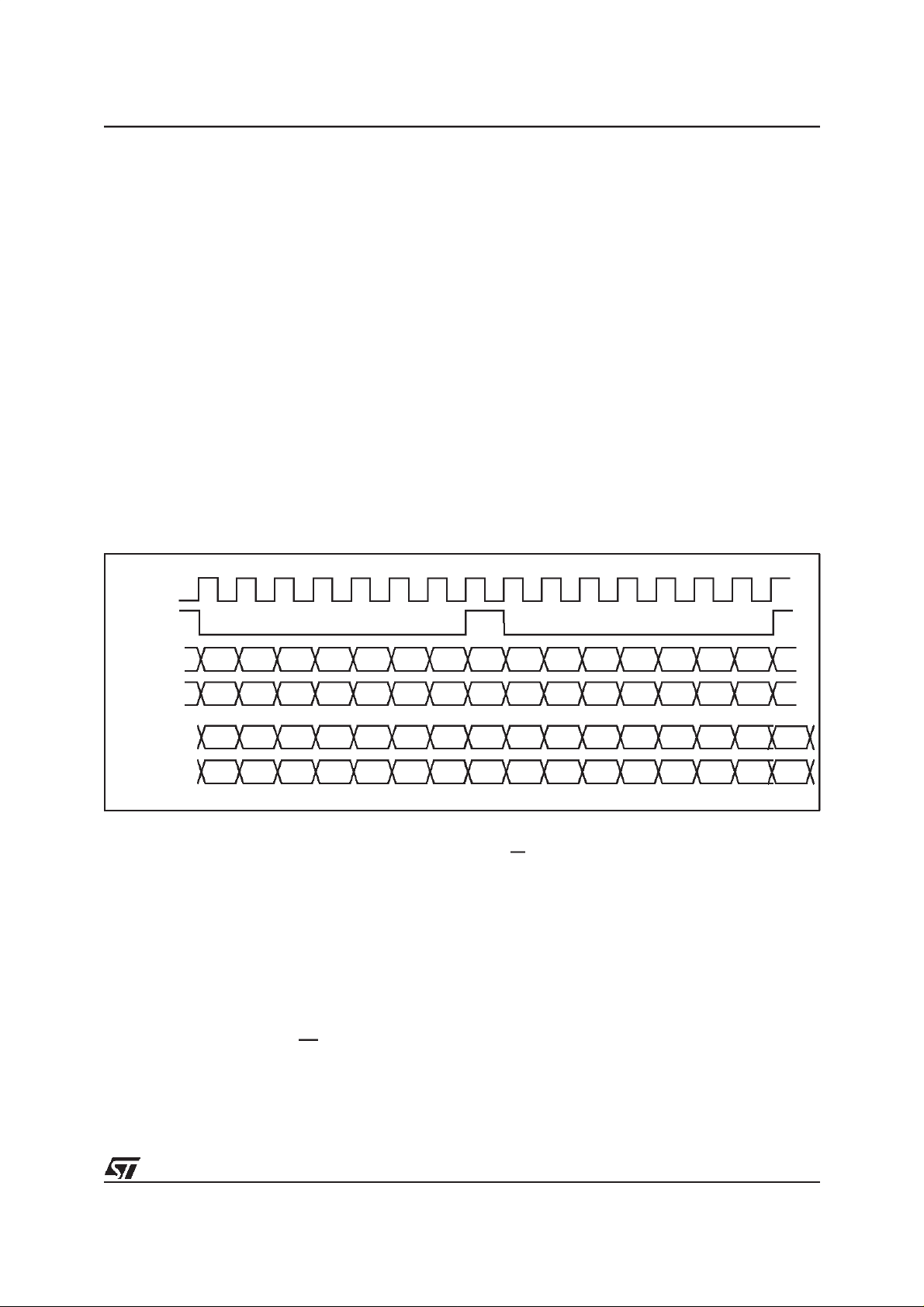

Figure 27. AFE ADC/DAC Sample Serial Interface Timing Diagram

C K35M

A _SC LK

TxSO UT[0]

TxSO UT[1]

RxSIN[0]

R xSIN [1]

a7

a15a6a1 4a5a13a4a12a3a11a2a1 0a1a9a0a8

b7

b15b6b14b5b1 3b4b12b3b11b2b10b1b9

The serial control I/F consists of 4 pins:

■

SPI_CLK: a gated 35.328MHz clock.

It is only

present during digital I/Fread/write cyclesand is

inactive otherwise.

■ SPI_ENB: an active lowenable pin which allows

selection between different AFEs if required.

■

SPI_DTX: an output data pin which is used to

send control information to the AFE ASIC.

■ SPI_DRX: an input data pin which is used

receive control information from the AFE ASIC.

It is enabled only when

R/W

is low.

b0

b8

The format for the serial interface is given below:

■

R/W

- determines the access mode for the

register

■

ADDR[b2:b0]

address[b1:b0]

.

- identifies the control register

accessed. These registers will correspond to

the mapping in the LAVA ASIC.

■

WR_DATA[b7:b0]

- the control data written to

the AFE ASIC.

37/40

STLC1510

Figure 28. AFE Control Interface Timing Diagram

SPI_CLK

(35M Hz)

SPI_ENB

SPI_DTX

SPI_DRX

R/W

AD DR ESS

[b2:b 0]

WR _D ATA{b7: b0]

R D_D ATA {b7:b0]

38/40

STLC1510

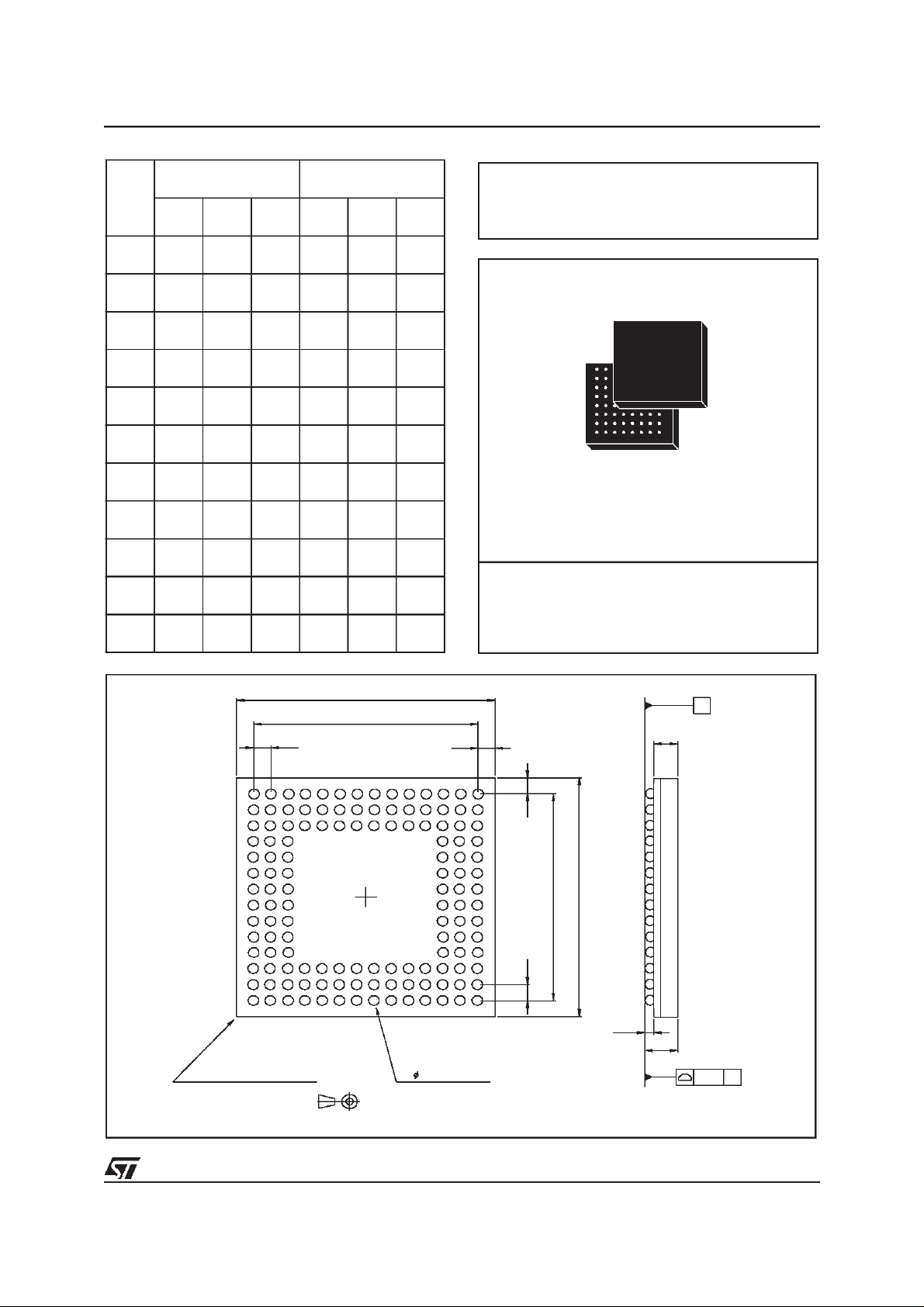

mm inch

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

A 1.210 1.700 0.047 0.067

A1 0.270 0.010

A2 1.120 0.044

b 0.450 0.500 0.550 0.018 0.02 0.021

D 11.75 12.00 12.15 0.462 0.472 0.478

D1 10.40 0.409

E 11.75 12.00 12.15 0.462 0.472 0.478

E1 10.40 0.409

e 0.720 0.800 0.880 0.028 0.031 0.034

f 0.650 0.800 0.950 0.025 0.031 0.037

ddd 0.120 0.004

OUTLINE AND

MECHANICAL DATA

Body: 12 x 12 x 1.7mm

LFBGA132

A1 CORNER INDEX

D

D1

e

P

N

M

L

K

J

H

G

F

E

D

C

B

A

1 2 3 4 5 6 7 8 9 10 11 12 13

AREA

(SEE NOTE.3)

BOTTOM VIEW

f

14

b (132 BALLS)

TING

SE

C

PLANE

A2

f

E

E1

e

A1

A

C

ddd

7146828

39/40

STLC1510

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights ofthird parties which may result from its use. No license is granted

by implicationor otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

2000 STMicroelectronics - All Rights Reserved

Australia - Brazil - China - Finland - France - Germany - Hong Kong - India - Italy - Japan - Malaysia - Malta - Morocco - Singapore - Spain

STMicroelectronics GROUP OF COMPANIES

- Sweden - Switzerland - United Kingdom - U.S.A.

http://www.st.com

40/40

Loading...

Loading...