ST STGIPN3H60 User Manual

SLLIMM™-nano (small low-loss intelligent molded module)

IPM, 3 A - 600 V 3-phase IGBT inverter bridge

Features

■ IPM 3 A, 600 V, 3-phase IGBT inverter bridge

including control ICs for gate driving and

freewheeling diodes

■ Optimized for low electromagnetic interference

■ V

■ 3.3 V, 5 V, 15 V CMOS/TTL inputs

comparators with hysteresis and pull down/pull

up resistors

■ Undervoltage lockout

■ Internal bootstrap diode

■ Interlocking function

■ Smart shutdown function

■ Comparator for fault protection against

overtemperature and overcurrent

■ Op amp for advanced current sensing

■ Optimized pinout for easy board layout

Applications

■ 3-phase inverters for motor drives

■ Dish washers, refrigerator compressors,

heating systems, air-conditioning fans,

draining and recirculation pumps

negative temperature coefficient

CE(sat)

STGIPN3H60

Datasheet − production data

NDIP-26L

Description

This intelligent power module implements a

compact, high performance AC motor drive in a

simple, rugged design. It is composed of six

IGBTs with freewheeling diodes and three halfbridge HVICs for gate driving, providing low

electromagnetic interference (EMI) characteristics

with optimized switching speed. The package is

optimized for thermal performance and

compactness in built-in motor applications, or

other low power applications where assembly

space is limited. This IPM includes an operational

amplifier, completely uncommitted, and a

comparator that can be used to design a fast and

efficient protection circuit. SLLIMM™ is a

trademark of STMicroelectronics.

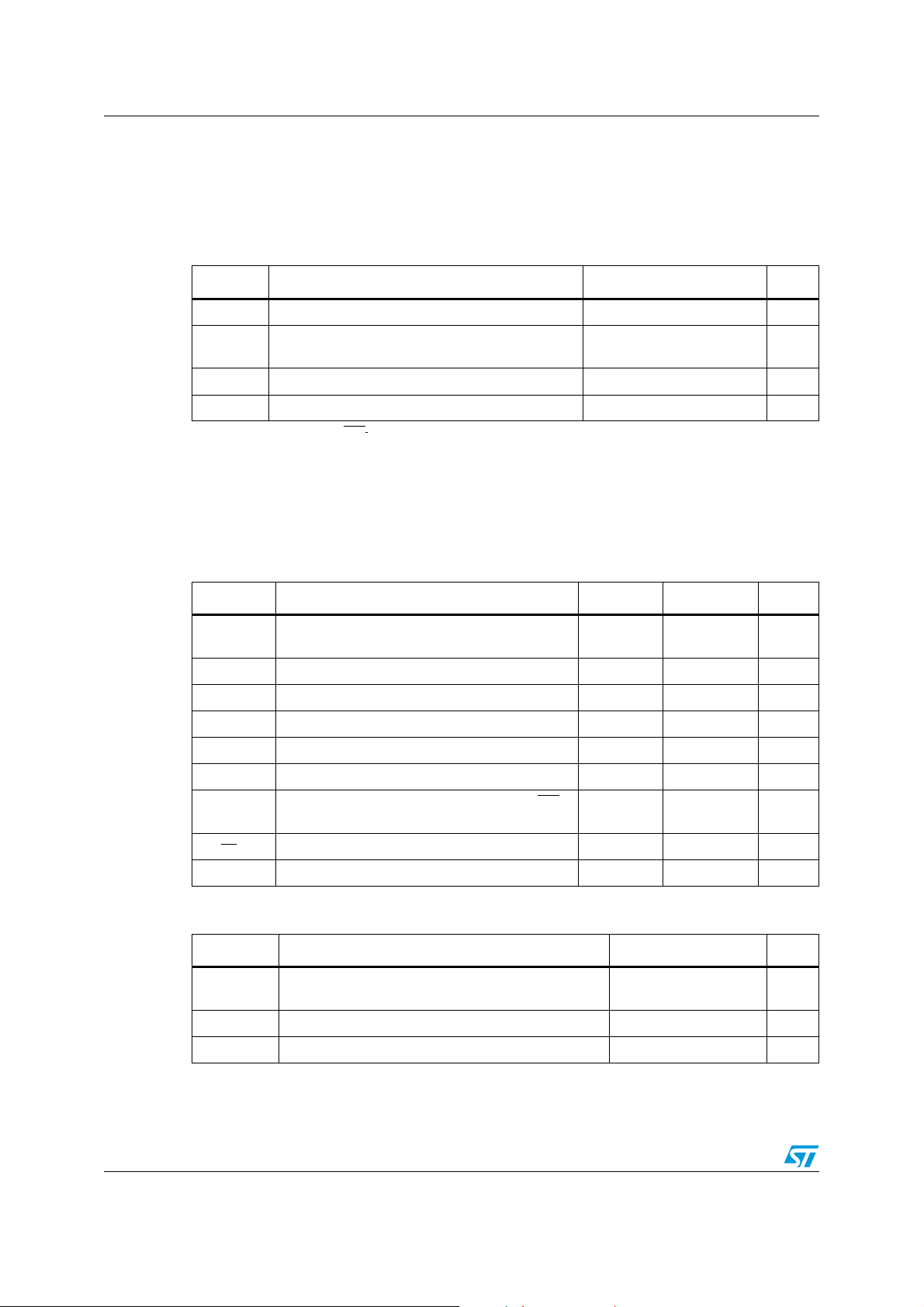

Table 1. Device summary

Order code Marking Package Packaging

STGIPN3H60 GIPN3H60 NDIP-26L Tube

May 2012 Doc ID 018957 Rev 3 1/21

This is information on a product in full production.

www.st.com

21

Contents STGIPN3H60

Contents

1 Internal schematic diagram and pin configuration . . . . . . . . . . . . . . . . 3

2 Electrical ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Control part . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Waveform definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Smart shutdown function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5 Application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1 Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2/21 Doc ID 018957 Rev 3

STGIPN3H60 Internal schematic diagram and pin configuration

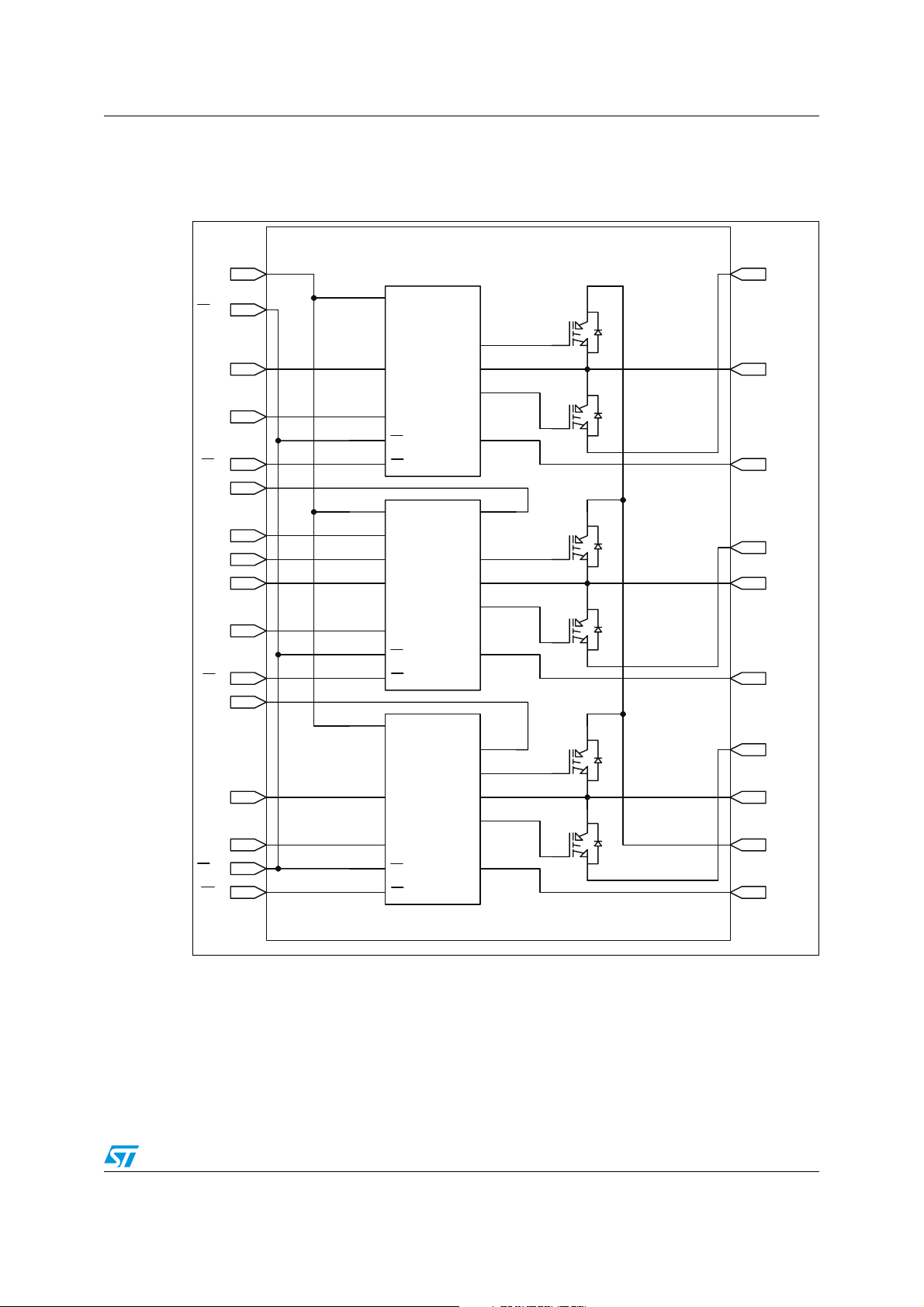

1 Internal schematic diagram and pin configuration

Figure 1. Internal schematic diagram

GND

SD-OD

Vcc W

HIN W

LIN W

OP+

OPOUT

OP-

Vcc V

HIN V

LIN V

CIN

Vcc U

HIN U

SD-OD

LIN U

PIN 1

GND

VCC

HIN

SD-OD

LIN

GND

OPOUT

OP-

VCC

HIN

SD-OD

LIN

GND

VCC

HIN

SD-OD

LIN

HVG

OUT

LVG

VBOOT

OP+

HVG

OUT

LVG

VBOOT

CIN

HVG

OUT

LVG

VBOOT

PIN 26

N W

W, OU T W

Vboot W

N V

V, O UT V

Vboot V

N U

U,OUT U

P

Vboot U

PIN 16 PIN 17

AM09916v1

Doc ID 018957 Rev 3 3/21

Internal schematic diagram and pin configuration STGIPN3H60

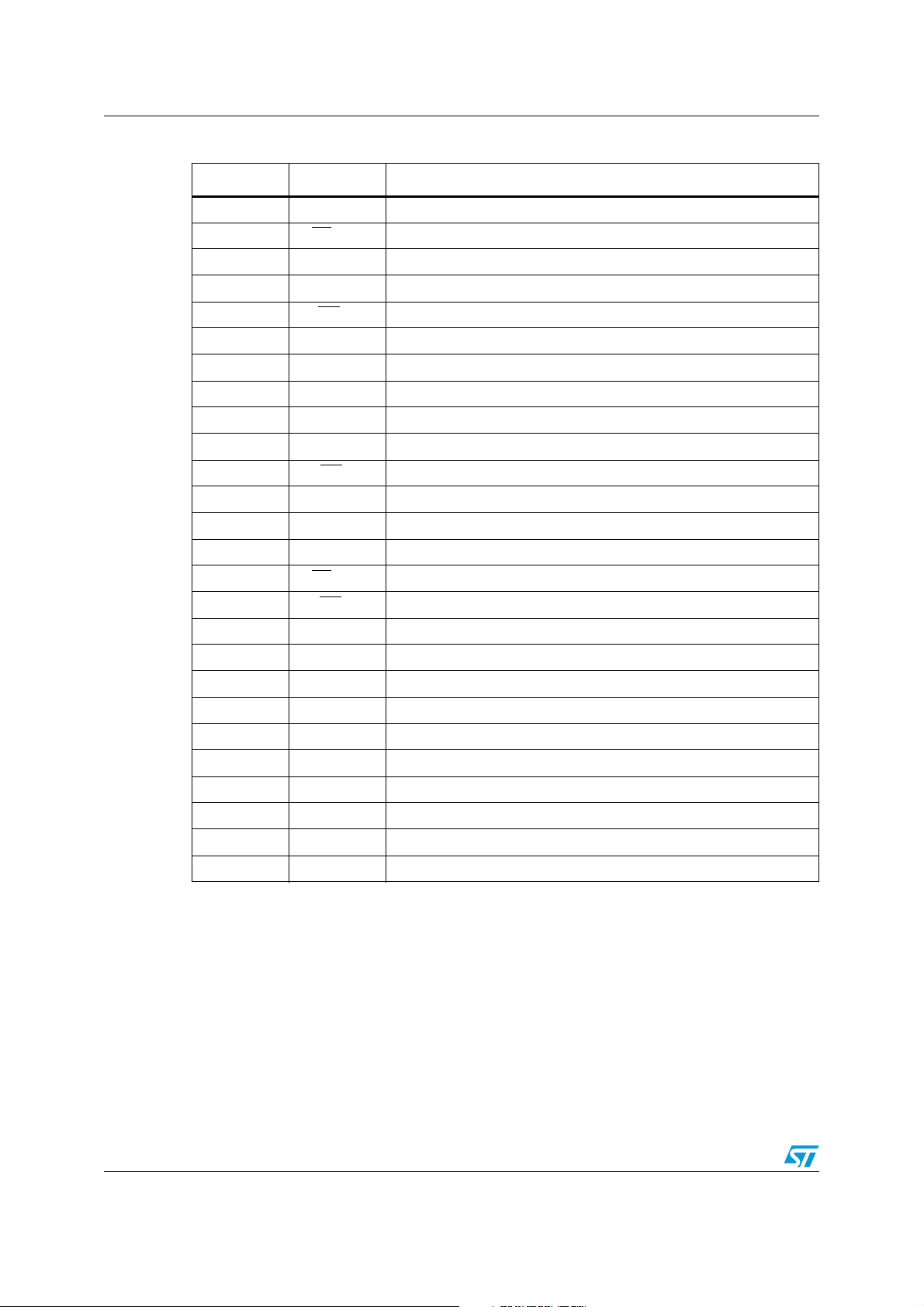

Table 2. Pin description

Pin Symbol Description

1 GND Ground

2SD / OD Shut down logic input (active low) / open drain (comparator output)

3V

W Low voltage power supply W phase

CC

4 HIN W High side logic input for W phase

5LIN

W Low side logic input for W phase

6 OP+ Op amp non inverting input

7OP

OUT

Op amp output

8 OP- Op amp inverting input

9V

V Low voltage power supply V phase

CC

10 HIN V High side logic input for V phase

11 LIN

V Low side logic input for V phase

12 CIN Comparator input

13 V

U Low voltage power supply for U phase

CC

14 HIN U High side logic input for U phase

15 SD

16 LIN

17 V

/ OD Shut down logic input (active low) / open drain (comparator output)

U Low side logic input for U phase

U Bootstrap voltage for U phase

BOOT

18 P Positive DC input

19 U, OUT

20 N

21 V

U

BOOT

22 V, OUT

23 N

24 V

V

BOOT

25 W, OUT

26 N

W

U phase output

U

Negative DC input for U phase

V Bootstrap voltage for V phase

V phase output

V

Negative DC input for V phase

W Bootstrap voltage for W phase

W phase output

W

Negative DC input for W phase

4/21 Doc ID 018957 Rev 3

STGIPN3H60 Internal schematic diagram and pin configuration

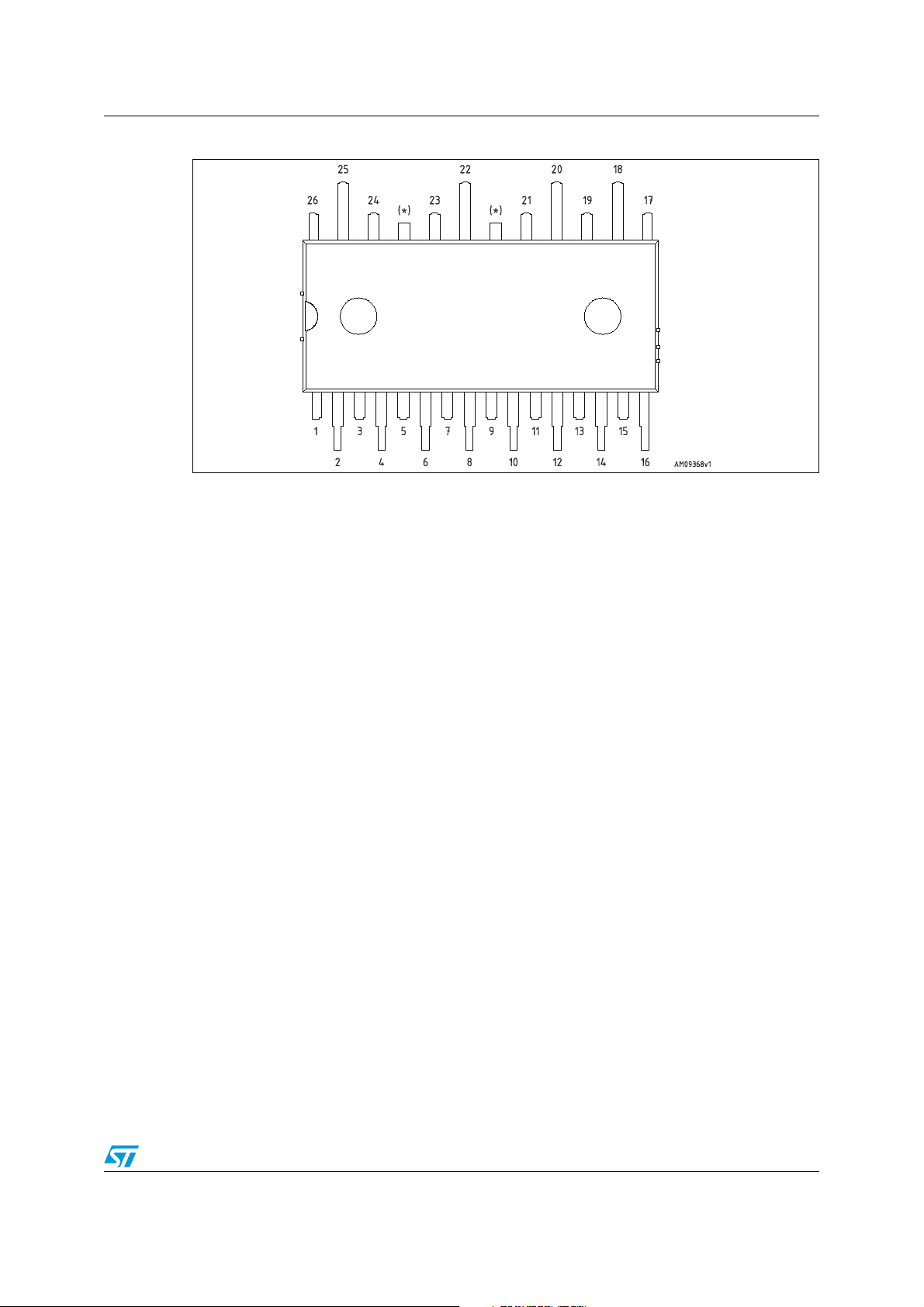

Figure 2. Pin layout (top view)

(*) Dummy pin internally connected to P (positive DC input).

Doc ID 018957 Rev 3 5/21

Electrical ratings STGIPN3H60

2 Electrical ratings

2.1 Absolute maximum ratings

Table 3. Inverter part

Symbol Parameter Value Unit

V

CES

± I

C

± I

CP

P

TOT

1. Applied between HIN

2. Calculated according to the iterative formula:

3. Pulse width limited by max junction temperature

Each IGBT collector emitter voltage (V

Each IGBT continuous collector current

(2)

(3)

= 25°C

at T

C

Each IGBT pulsed collector current 18 A

Each IGBT total dissipation at TC = 25°C 8 W

, LINi and GND for i = U, V, W

i

ICTC()

------------ ------------- ------------- ------------ ------------- ------------- ------------- ------------ --=

R

thj c–

V

(1)

= 0)

IN

–

T

jmax()TC

CE sat()max()Tjmax()ICTC

(),()×

600 V

3A

Table 4. Control part

Symbol Parameter Min. Max. Unit

V

OUT

V

CC

V

CIN

V

op+

V

op-

V

boot

V

IN

V

SD/OD

ΔV

OUT/dT

Table 5. Total system

Output voltage applied between OUTU, OUTV,

- GND

OUT

W

V

boot

- 21 V

+ 0.3 V

boot

Low voltage power supply - 0.3 21 V

Comparator input voltage - 0.3 VCC +0.3 V

OPAMP non-inverting input - 0.3 VCC +0.3 V

OPAMP inverting input - 0.3 VCC +0.3 V

Bootstrap voltage - 0.3 620 V

Logic input voltage applied between HIN, LIN

and GND

- 0.3 15 V

Open drain voltage - 0.3 15 V

Allowed output slew rate 50 V/ns

Symbol Parameter Value Unit

V

ISO

T

T

C

Isolation withstand voltage applied between each

pin and heatsink plate (AC voltage, t = 60 sec.)

Power chips operating junction temperature -40 to 150 °C

j

1000 V

Module case operation temperature -40 to 125 °C

6/21 Doc ID 018957 Rev 3

STGIPN3H60 Electrical ratings

2.2 Thermal data

Table 6. Thermal data

Symbol Parameter Value Unit

R

thJA

Thermal resistance junction-ambient 50 °C/W

Doc ID 018957 Rev 3 7/21

Loading...

Loading...