查询ST72171供应商

8-BIT MCU with 8 K FLASH, ADC, WDG, SPI, SCI, TIMERS

SPGAs (Software Programmable Gain Amplifiers), OP-AMP

■ Memories

– 8K of single voltage Flash Program memory

with read-out protection

– In-Situ Programming (Remote ISP)

■ Clock, Reset and Supply Management

– Enhanced Reset System

– Low voltage supervisor (LVD) with 3 program-

mable levels

– Low consumption resonat or or RC oscillators

(internal or external) and by-pass for external

clock source, with safe control capabilities

– 3 Power Saving modes

■ 22 I/O Ports

– 22 multifunctional bidirectional I/O lines:

– 16 interrupt inputs on 2 independent lines

– 8 lines configurable as analog inputs

– 20 alternate functions

–EMI filtering

■ 2 Timers and Watchdog

– One 16-bit Timer with: 2 Input Captures, 2

Output Compares, external Clock input, PWM

and Pulse Generator modes

– One 8-bit Autoreload Timer (ART) with: 2

PWM output channels (internally connectable

to the SPGA inputs), 1 Input Capture, external

clock input

– Configurable watchdog (WDG)

■ 2 Communications Interfaces

– Synchronous Serial Peripheral Interface (SPI)

– Serial Co m munications Int e rface (SCI)

ST72C 171

PRODUCT PREVIEW

SO34

PSDIP32

■ 3 Analog peripherals

– 2 Software Programmable Gain Operational

Amplifie rs (SPGAs) with rail-to-rail inp ut and

output, V

grammable reference voltage (1/8 V

lution), Offset compensation, DAC & on/off

switching capability

– 1 rail-to-rail input and output Op-Amp

– 8-bit A/D Converter with up to 11 channels (in-

cluding 3 internal channels connected to the

Op-Amp & SPGA outpu ts)

■ Instruction Set

– 8-bit data manipulation

– 63 basic Instructi o n s

– 17 main addressing modes

– 8 x 8 unsigned multiply instruction

– True bit manipulation

■ Development Tools

– Full hardware/software development package

independent (band gap) and pro-

DD

DD

reso-

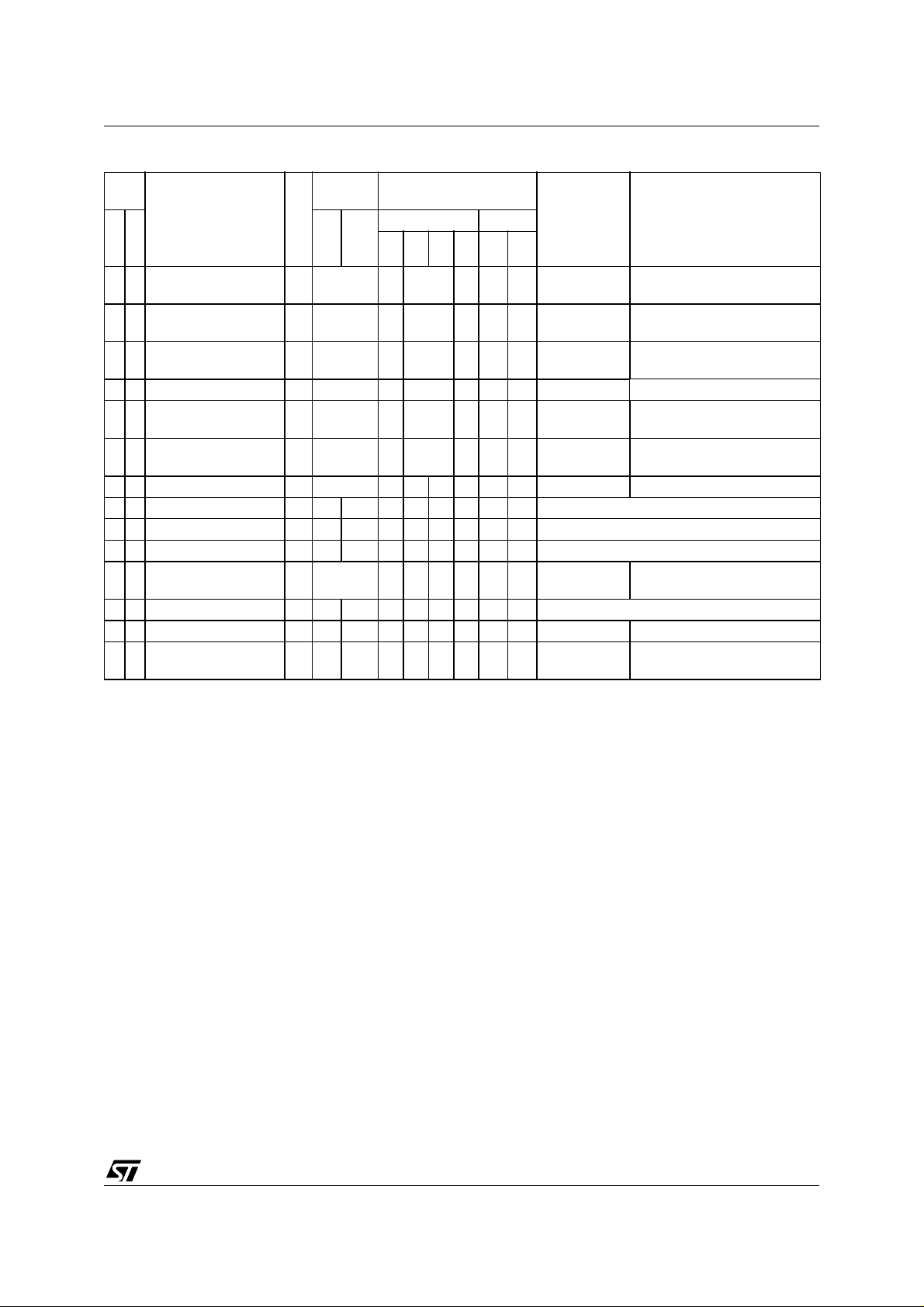

Device Summary

Features ST72C171K2M ST72C171K2B

Flash - bytes 8K Single Voltage

RAM (stack) - bytes 256 (128)

Peripherals

Operating Supply 3.2 V to 5.5 V

CPU Frequency Up to 8 MHz (with up to 16 MHz oscillator)

Temperature Rang e - 40°C to + 85°C

Package SO34 PSDIP32

Watchdog, 3 Timers, SPI, SCI, ADC (11 chan.)

2 SPGAs, 1 Op-Amp,

Watchdog, 3 Timers, SPI, SCI, ADC (11 chan.)

2 SPGAs,

Rev. 1.4

October 2000 1/152

This is preliminary information on a new product in development or undergoing evaluation. Details are subject to change without notice.

1

Table of Contents

1 GENERAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 PIN DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 MEMORY MAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 FLASH PROGRAM MEMORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2 MAIN FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3 STRUCTURAL ORGANISATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.4 IN-SITU PROGRAMMING (ISP) MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.5 MEMORY READ-OUT PROTECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 CENTRAL PROCESSING UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2 MAIN FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3 CPU REGISTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 SUPPLY, RESET AND CLOCK MANAGEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1 MAIN FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2 LOW VOLTAGE DETECTOR (LVD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.3 CLOCK SECURITY SYSTEM (CSS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.4 CLOCK, RESET AND SUPPLY REGISTER DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . 23

5 INTERRUPTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.1 NON MASKABLE SOFTWARE INTERRUPT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.2 EXTERNAL INTERRUPTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3 PERIPHERAL INTERRUPTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6 POWER SAVING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.2 SLOW MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.3 WAIT MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.4 HALT MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7 ON-CHIP PERIPHERALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.1 I/O PORTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.2 MISCELLANEOUS REGISTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.3 OP-AMP MODULE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.4 WATCHDOG TIMER (WDG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.5 16-BIT TIMER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.6 PWM AUTO-RELOAD TIMER (ART) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

7.7 SERIAL COMMUNICATIONS INTERFACE (SCI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

7.8 SERIAL PERIPHERAL INTERFACE (SPI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

7.9 8-BIT A/D CONVERTER (ADC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

8 INSTRUCTION SET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

8.1 ST7 ADDRESSING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

8.2 INSTRUCTION GROUPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

152

2/152

1

Table of Contents

9 ELECTRICAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

9.1 PARAMETER CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

9.2 ABSOLUTE MAXIMUM RATINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

9.3 OPERATING CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

9.4 SUPPLY CURRENT CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

9.5 CLOCK AND TIMING CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

9.6 MEMORY CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

9.7 EMC CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

9.8 I/O PORT PIN CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

9.9 CONTROL PIN CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

9.10TIMER PERIPHERAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

9.11COMMUNICATION INTERFACE CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . 136

9.128-BIT ADC CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

9.13OP-AMP MODULE CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

10 GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

10.1PACKAGE MECHANICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

10.2THERMAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

10.3SOLDERING AND GLUEABILITY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

10.4PACKAGE/SOCKET FOOTPRINT PROPOSAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

11 DEVICE CONFIGURATION AND ORDERING INFORMATION . . . . . . . . . . . . . . . . . . . . . . . 147

11.1OPTION BYTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

11.2DEVICE ORDERING INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

11.3DEVELOPMENT TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

11.4ST7 APPLICATION NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

11.5TO GET MORE INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

12 SUMMARY OF CHANGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

3/152

ST72C171

1 GENERAL DESCRIPTION

1.1 INTRODUCTION

The ST72C171 is a member of the ST7 family of

Microcontrollers. All devices are based on a com mon industry-standard 8-bit core, featuring an enhanced instruction set.

The ST72C171 features single-voltage FLASH

memory with byte-by-byte In-Situ Programming

(ISP) capability.

Under software control, the device can be placed

in WAIT, SLOW, or HALT mode, reducing po wer

consumption when the application is in idle or

standby state.

The enhanced instruction set and addressing

modes of the ST7 offer both power and flexibility to

software developers, enabling the design of highly

efficient and compact application code. In addition

to standard 8-bit data management, all ST7 microcontrollers feature true bit manipulation, 8x8 un-

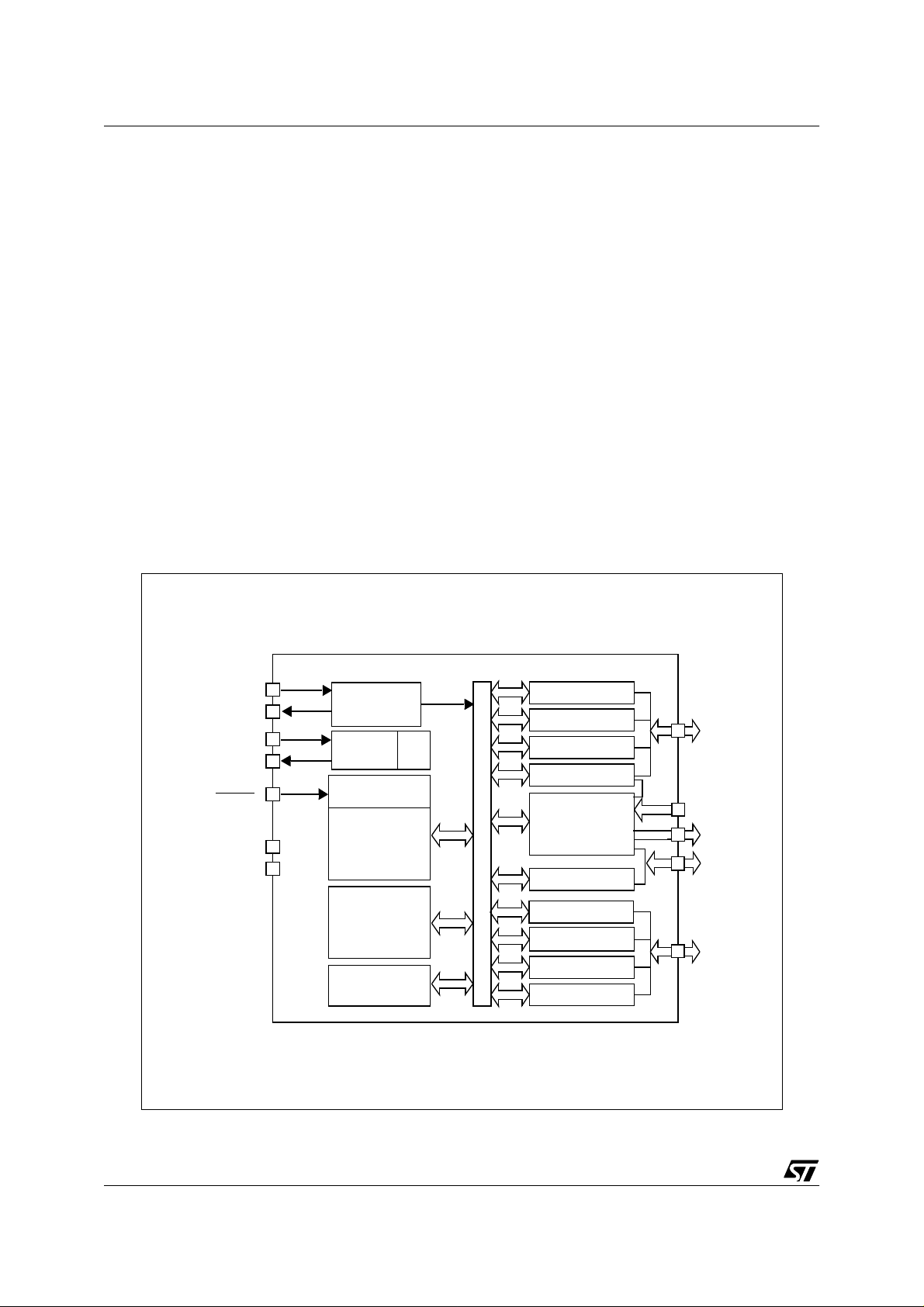

Figure 1. ST72C171 Block Diagram

OSCIN

OSCOUT

V

DD

V

RESET

V

DDA

V

SSA

SS

MULTIOSC

+

CLOCK FILTER

POWER

SUPPLY

CONTROL

8-BIT CORE

ALU

Internal

CLOCK

LVD

signed multiplication and indirect addressing

modes The device includes a low consumption

and fast start on-chip oscillator, CPU, Flash program memory, RAM, 22 I/O lines and the following

on-chip peripherals: Analog-to-Digital converter

(ADC) with 8 multiplexed a nalog inputs, Op-Amp

module, synchronous SPI serial interface, asyncronous serial interface (SCI), Watchdog timer, a

16-bit Timer featuring external Clock I nput, Pulse

Generator capabilities, 2 Input Captures and 2

Output Compares, an 8-bit Timer featuring external Clock Input, Pulse Generator Capabilities (2

channels), Autoreload and Input Capture.

The Op-Amp module adds on-chip analog features to the MCU, that usually require using external components.

PORT A

PWM/ART TIMER

16-BIT TIMER

ADDRESS AND DATA BUS

8-BIT ADC

OP-AMP

PORT C

PA[7:0]

OA3PIN*

OA1OUT

OA2OUT

OA3OUT*

PC[5:0]

4/152

*only on 34-pin devices

8K FLASH

MEMORY

256b-RAM

SCI

PORT B

SPI

WATCHDOG

PB[7:0]

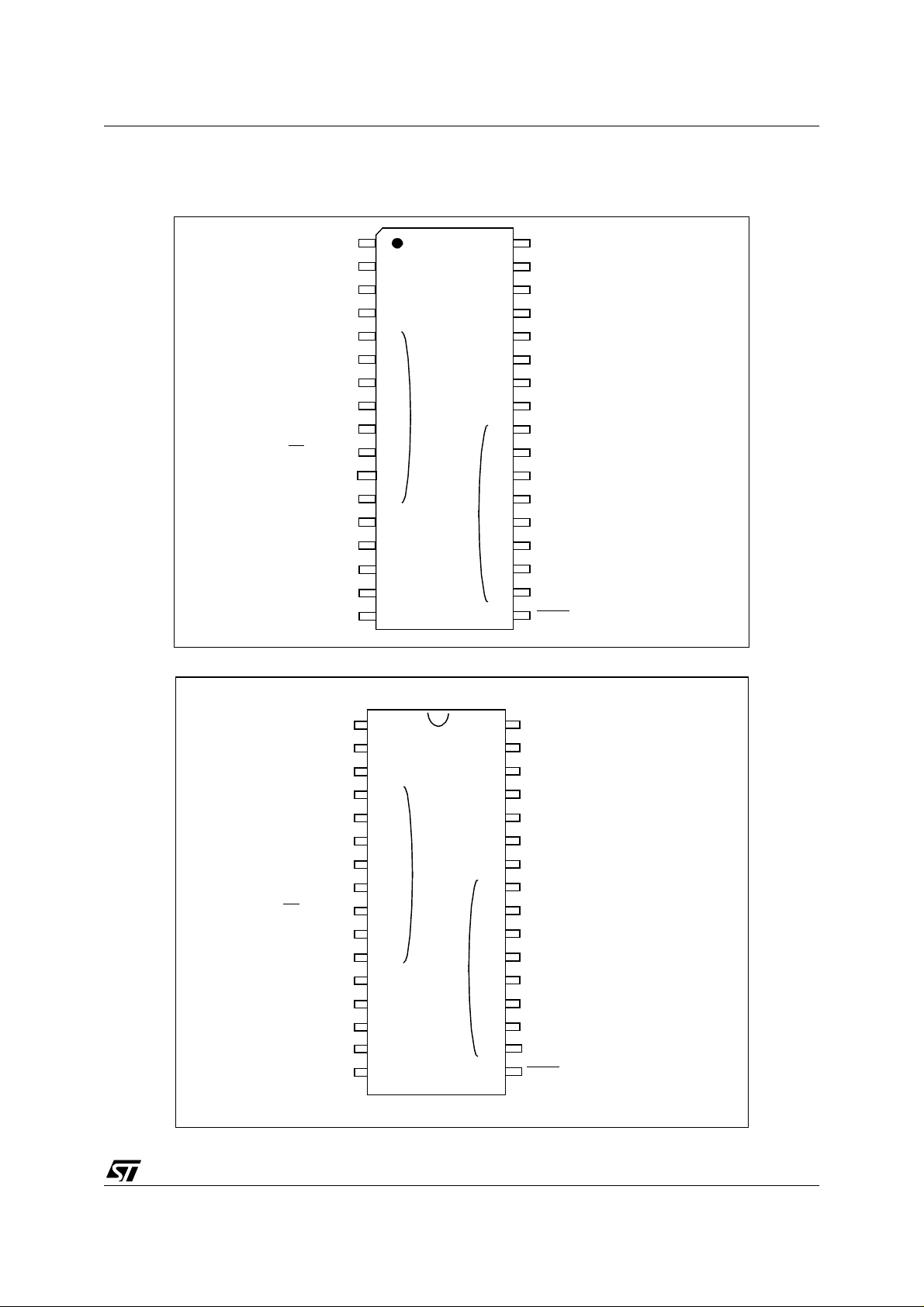

1.2 PIN DESCRI PTION

Figure 2. 34-Pin SO Package Pinout

ST72C171

OA2OUT

PWM1R / OA2PIN / PC1

OA2NIN / PC0

OA3PIN

TDO / PB7

RDI / PB6

ISPDATA / MISO / PB5

(HS)

SS

/

(HS)

(HS)

(HS)

(HS)

PB4

PB3

PB2

PB1

PB0

V

V

OSC2

OSC1

ISPSEL

DD

SS

MOSI /

ISPCLK / SCK /

ARTCLK /

EXTCLK /

Figure 3. 32-Pin SDIP Package Pinout

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

ei1

ei0

PC2 / OA1PIN / PWM0R

34

PC3 / OA1NIN

33

OA1OUT

32

PC4 / MCO/ OA3NIN

31

V

30

29

28

27

26

25

24

23

22

21

20

19

18

DDA

V

SSA

OA3OUT

PC5/ PWM0

PA7 / AIN7 / PWM1

PA6 / AIN6 / ARTICP0

PA5 / A IN5

PA4 / AIN4 / OCMP1

PA3 / AIN3 / OCMP2

PA2 / AIN2 / ICAP1

PA1 / AIN1 / ICAP2

PA0 / A IN0

RESET

(HS)

20mA high sink capability

OA2OUT

PWM1R / OA2PIN / PC1

OA2N IN / PC0

TDO / PB7

RDI / PB6

ISPDATA / MISO / PB5

(HS)

SS

/

(HS)

(HS)

(HS)

(HS)

PB4

PB3

PB2

PB1

PB0

V

V

OSC2

OSC1

ISPSEL

MOSI /

ISPCLK / SCK/

ARTCLK /

EXTCLK /

1

2

3

4

5

6

7

ei1

8

9

10

11

DD

SS

12

13

14

15

16

ei0

32

PC2 / OA1PIN / PWM0R

31

PC3 / OA1NIN

30

OA1OUT

29

PC4 / MCO

28

V

DDA

27

V

SSA

26

PC5 / PWM0

25

PA7 / AIN7 / PWM1

24

PA6 / AIN6 /ARTICP0

23

PA5 / AIN5

22

PA4 / AIN4 / OCMP1

21

PA3 / AIN3 / OCMP2

20

PA2 / AIN2 / ICAP1

19

PA1 / AIN1 / ICAP2

18

PA0 / AIN0

17

RESET

(HS)

20mA high sink capability

5/152

ST72C171

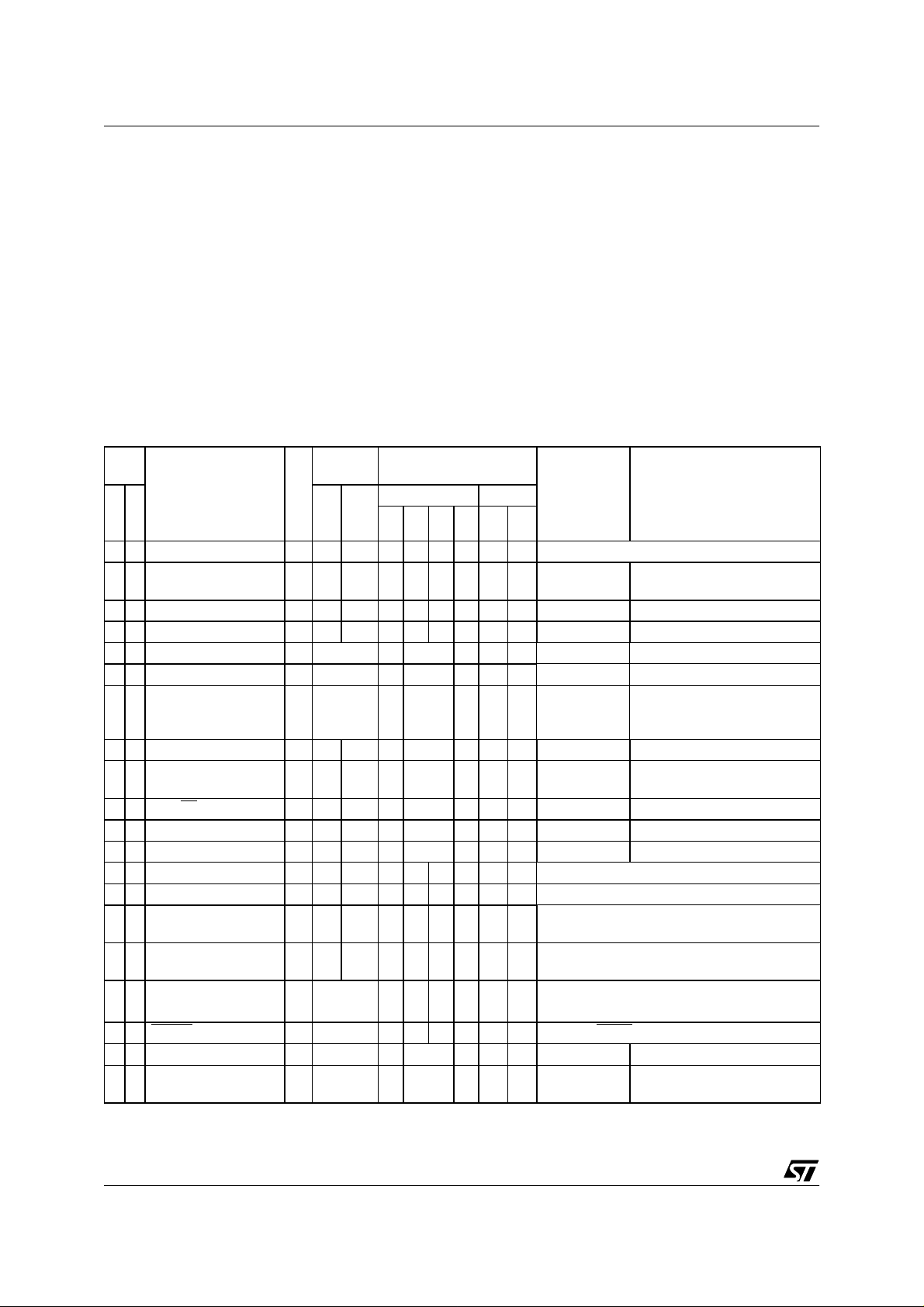

PIN DESCRIPTION (Cont’d)

Legend / Abbreviations:

Type: I = input, O = output, S = supply

In/Output level: C = CMOS 0.3V

C

= CMOS Levels with resistive output (1K)

R

A = Analog levels

Output level: HS = high sink (on N-buffer only),

Port configuration capabilities:

– Input:float = floating, wpu = weak pull-up, int = interrupt, ana = analog

– Output: OD = open drain, T = true open drain, PP = push-pull

Note: the Reset configuration of each pin is shown in bold.

Table 1. Device Pin Description

/0.7VDD,

DD

Pin

n°

Pin Name

SDIP32

SO34

1 1 OA2OUT O A OA2 output

PC1/OA2PIN/

22

PWM1R

3 3 PC0/OA2NIN I/O C/A C X X X X X Port C0 OA2 inverting input

- 4 OA3PIN I A OA3 noninverting input

4 5 PB7/TDO I/O C X ei1 X X Port B7 SCI transmit

5 6 PB6/RDI I/O C X ei1 X X Port B6 SCI receive

6 7 PB5/MISO/ISPDATA I/O C X ei1 X X Port B5

7 8 PB4/MOSI I/O C HS X ei1 X X Port B4 SPI data master out/slave in

8 9 PB3/SCK/ISPCLK I/O C HS X ei1 X X Port B3

910PB2/SS

10 11 PB1/ARTCLK I/O C HS X ei1 X X Port B1 ART External Clock

11 12 PB0/EXTCLK I/O C HS X ei1 X X Port B0 Timer16 External Clock

12 13 V

13 14 V

14 15 OSC2

15 16 OSC1

16 17 ISPSEL I C

17 18 RESET

18 19 PA 0/AIN 0 I/O C X ei0 X X X Port A0 ADC input 0

19 20 PA1/AIN1/ICAP2 I/O C X ei0 X X X Port A1

DD

SS

Level Port

Type

Input

Output

I/O C C/C

I/O C HS X ei1 X X Port B2 SPI Slave Select (active low)

S Digital Main Supply Voltage

S Digital ground voltage

I/O C X X External Reset

Input Output

int

wpu

float

X X X X X Port C1

R

ana

OD

Main

function

(after

reset)

PP

Resonator oscillator inverter output or capacitor input for RC oscillator

External clock input or Resonator oscillator inverter input or resistor input for RC oscillator

In Situ Programming Mode Select

Must be tied to V

Alternate function

OA2 noninverting input and/o r

ART PWM1 resistive output

SPI data master in/slave out or

In Situ Programming Data Input

SPI Clock or In Situ Programming Clock Output

in user mode

SS

ADC input 1 orTimer16 input

capture 2

6/152

ST72C171

Pin

n°

Pin Name

SDIP32

SO34

20 21 PA2/AIN2/ICAP1 I/O C X ei0 X X X Port A2

21 22 PA3/AIN3/OCMP2 I/O C X ei0 X X X Port A3

22 23 PA4 /AIN4/OCMP1 I/O C X ei0 X X X Port A4

23 24 PA5/AIN5 I/O C X ei0 X X X Port A5 ADC input 5

24 25 PA6/AIN6/ARTICP0 I/O C X ei0 X X X Port A6

25 26 PA7/AIN7/PWM1 I/O C X ei0 X X X Port A7

26 27 PC 5 / P W M0 I/O C X X X X Port C5 ART PWM0 output

- 28 OA3OUT O A OA3 output

27 29 V

28 30 V

29 31 PC4/MCO/OA 3NIN I/O C X X X X Port C4

30 32 OA1OUT O A OA1 output

31 33 PC3/OA1NIN I/O C/A C X X X X Port C3 OA1 inverting input

32 34

SSA

DDA

PC2/OA1PIN/

PWM0R

Level Port

Type

Input

Output

I/O C/A C/C

R

Main

Input Output

int

wpu

float

X X X X Port C2

OD

ana

function

(after

reset)

PP

Analog ground

Analog supply

Alternate function

ADC input 2

or Timer16 input capture 1

ADC input 3 or Timer16 output

compare 2

ADC input 4 or Timer16 output

compare 1

ADC input 6 or ART input capture

ADC input 7 or ART PWM1

output

Main Clock Out or OA3 inverting input

OA1 non-inverting input and/

or ART PWM0 resistive output

Notes:

1. In the interrupt input column, “eix” define s the associated external interrupt vect or. If the weak pull-up

column (wpu) is associated with the interrupt column (int), then the I/O configuration is p ull-up interrupt

input, else the configuration is floating interrupt input.

2. OSC1 and OSC2 pins connect a crystal or ceramic resonator, an external RC, or an external source to

the on-chip oscillator see dedicated See “PIN DESCRIPTION” on page 5. for more details.

7/152

ST72C171

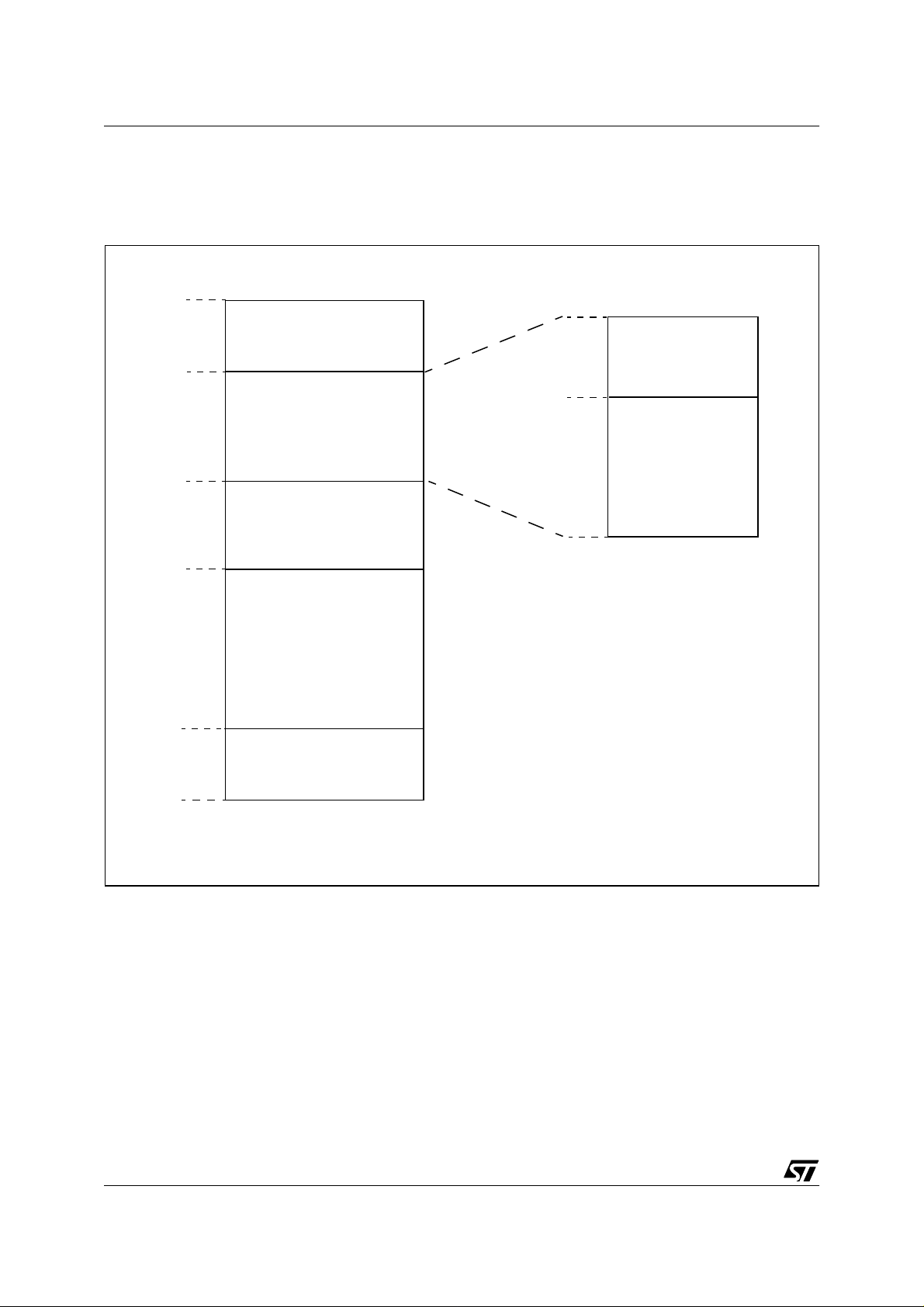

1.3 MEMORY MA P

1.3.1 Introd uct i on

Figure 4. Program Memory M ap

0000h

HW Registers

(see Table 1.3.2)

007Fh

0080h

256 bytes RAM

017Fh

0180h

0080h

00FFh

0100h

Short Addressing

RAM

Zero page

(128 Bytes)

Stack

(128 Bytes)

DFFFh

E000h

FFDFh

FFE0h

FFFFh

Reserved

8 Kbytes

FLASH

Interrupt & Reset Vectors

(see Table 4)

017Fh

8/152

ST72C171

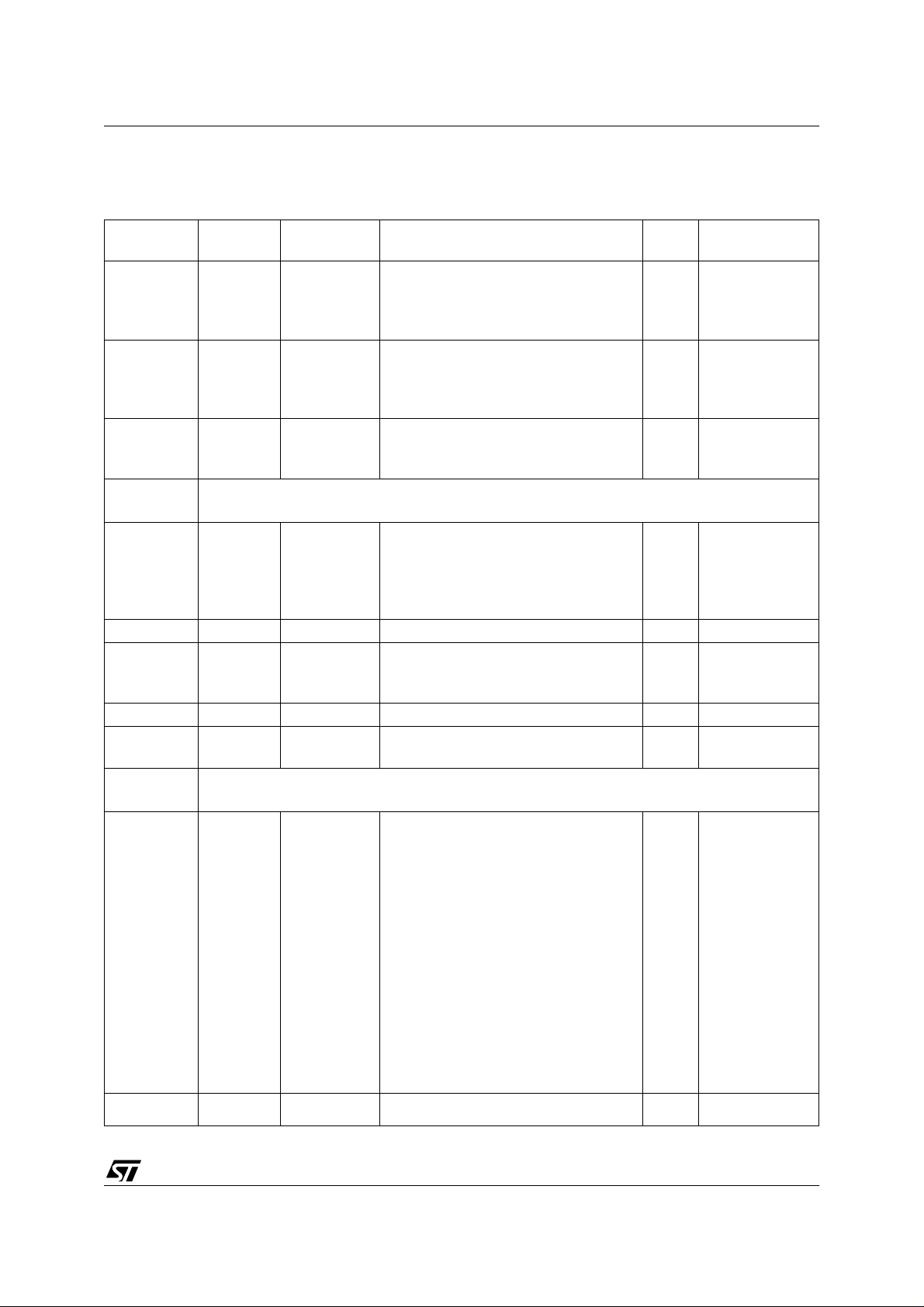

1.3.2 Data Register

Table 2. Hardware Register Mem ory Map

Address

0000h

0001h

0002h

0003h

0004h

0005h

0006h

0007h

0008h

0009h

000Ah

000Bh to

001Ah

001Bh

001Ch

001Dh

001Eh

001Fh

0020h MISC1 MISCR1 Miscellaneous Register 1 00h see Section 4.3.5

0021h

0022h

0023h

0024h WDG WDGCR Watchdog Control register 7Fh R/W

0025h CRS CRSR

0026h to

0030h

0031h

0032h

0033h

0034h0035h

0036h0037h

0038h0039h

003Ah003Bh

003Ch003Dh

003Eh003Fh

Block

Name

Port A

Port B

Port C

OPAMP

SPI

TIMER16

Register

Label

PADR

PADDR

PAOR

PBDR

PBDDR

PBOR

PCDR

PCDDR

PCOR

OA1CR

OA2CR

OA3CR

OAIRR

OAVRCR

SPIDR

SPICR

SPISR

TACR2

TACR1

TASR

TAIC1HR

TAIC1LR

TAOC1HR

TAOC1LR

TACHR

TACLR

TAACHR

TAACLR

TAIC2HR

TAIC2LR

TAOC2HR

TAOC2LR

Register name

Data Register

Data Direction Register

Option Register

Not Used

Data Register

Data Direction Register

Option Register

Not Used

Data Register

Data Direction Register

Option Register

Reserved Area (16 Bytes)

OA1 Control Register

OA2 Control Register

OA3 Control Register

OA Interrupt & Readout Register

OA Voltage Reference Control Register

Data I/O Register

Control Register

Status Register

Clock, Reset and Supply Control / Status

Register

Reserved Area (11 Bytes)

Control Register2

Control Register1

Status Register

Input Capture1 High Register

Input Capture1 Low Register

Output Compare1 High Register

Output Compare1 Low Register

Counter High Register

Counter Low Register

Alternate Counter High Register

Alternate Counter Low Register

Input Capture2 High Register

Input Capture2 Low Register

Output Compare2 High Register

Output Compare2 Low Register

Reset

Status

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

xxh

0xh

00h

00h R/W

00h

00h

xxh

xxh

xxh

80h

00h

FFh

FCh

FFh

FCh

xxh

xxh

80h

00h

Remarks

Section 7.3

Read Only

Read Only

Read Only

Read Only

Read Only

Read Only

Read Only

Read Only

Read Only

Read Only

Absent

Absent

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

0040h MISC2 MISCR2 Miscellaneous Register2 00h see Section 7.2.2

9/152

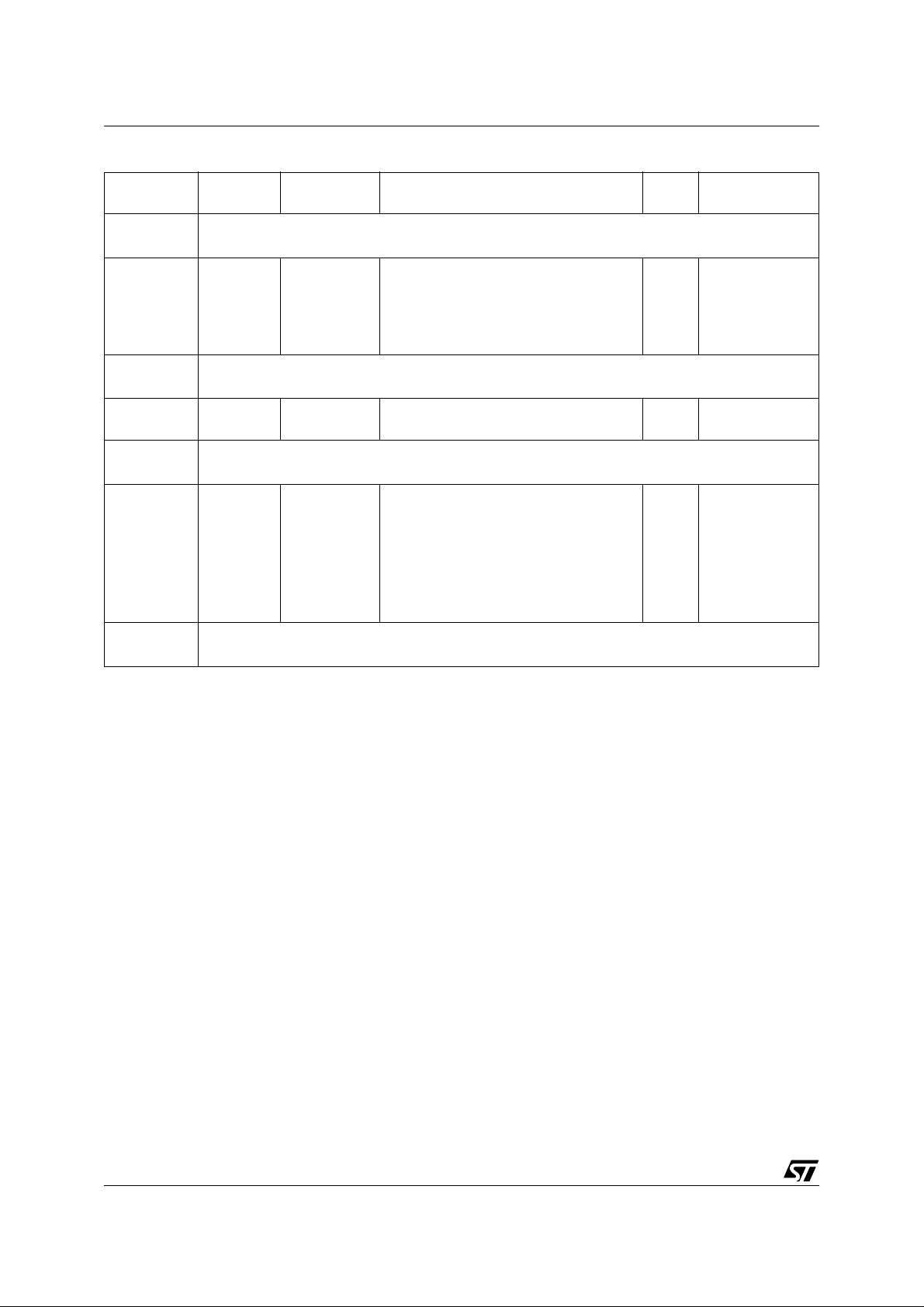

ST72C171

Address

0041h to

004Fh

0050h

0051h

0052h

0053h

0054h

0055h to

006Fh

0070h

0071h

0072h

0073h

0074h

0075h

0076h

0077h

0078h

0079h

007Ah

007Bh

007Ch to

007Fh

Block

Name

SCI

ADC

ART/PWM

Register

Label

SCISR

SCIDR

SCIBRR

SCICR1

SCICR2

ADCDR

ADCCSR

PWMDCR1

PWMDCR0

PWMCR

ARTCSR

ARTCAR

ARTARR

ARTICCSR

ARTICR1

Register name

Reserved Area (15 Bytes)

Status Register

Data Register

Baud Rate Register

Control Register 1

Control Register 2

Reserved Area (27 Bytes)

Data Register

Control/Status Register

Reserved Area (2 Bytes)

PWM Duty Cycle Register 1

PWM Duty Cycle Register 0

PWM Control Register

Control/Status Register

Counter Access Register

Auto Reload Register

Input Capture Control Status Register

Input Capture Register 1

Reserved Area (4 Bytes)

Reset

Status

0C0h

0xxh

0Xxh

0xxh

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

Remarks

Read Only

R/W

R/W

R/W

R/W

Read Only

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

Read Only

10/152

2 FLASH PROGRAM MEMORY

ST72C171

2.1 INTRODUCTION

FLASH devices have a single voltage non-volatil e

FLASH memory that may be programmed in-situ

(or plugged in a programming t ool) on a byte-bybyte basis.

2.2 MAIN FEATURES

■ Remote In-Situ Programming (ISP) mode

■ Up to 16 bytes programmed in the same cycle

■ MTP memory (Multiple Time Programmable)

■ Read-out memory protection against piracy

2.3 STRUCTURAL ORGANISATION

The FLASH program memory is organised in a

single 8-bit wide memory block which can be used

for storing both code and data constants.

The FLASH program memory is mapped in the upper part of the ST7 addressing space and includes

the reset and interrupt user vector area .

2.4 IN-SITU PROGRAMMING (ISP) MODE

The FLASH program memory can be programmed

using Remote ISP mode. This ISP mode allows

the contents of the ST7 program memory to be updated using a standard ST7 programming tools after the device is mounted on the application board.

This feature can be implem ented with a m inimum

number of added componen ts and bo ard area impact.

An example Remote ISP hardware interface to t he

standard ST7 programmi ng tool is described below. For more details on ISP programming, refer to

the ST7 Programming Specification.

Remote ISP Overview

The Remote ISP mode is initiated by a specific sequence on the dedicated ISPSEL pin.

The Remote ISP is performed in three steps:

– Selection of the RAM execution mode

– D ownl oad of Remote ISP code in RAM

– Execution of Remote ISP code in RAM to pro-

gram the user program into the FLASH

Remote ISP hardware configuration

In Remote ISP mode, the ST7 has to be supplied

with power (V

and VSS) and a clock signal (os-

DD

cillator and application crystal circuit for example).

This mode needs five signals (plus the V

DD

signal

if necessary) to be connected to the program m ing

tool. This signals are:

– RESET

–V

: device reset

: device ground power supply

SS

– I S PCLK: ISP output serial clock pin

– ISPDATA: ISP input serial data pin

– ISPSEL: Remote ISP mode selection. This pin

must be connected to V

board through a pull-down resistor.

on the application

SS

If any of these pins are used for other purposes on

the application, a serial resist or has to be implemented to avoid a conflict if the other device forces

the signal level.

Figure 1 shows a typical hardware interface to a

standard ST7 programming t ool. For more det ails

on the pin locations, refer t o t he d ev ice pin out description.

Figure 5. Typi ca l Remote ISP Inter fa ce

HE10 CONNECTOR TYPE

TO PROGRAMMING TOOL

ISPSEL

DD

V

V

RESET

ISPCLK

ISPDATA

10KΩ

SS

APPLICATION

1

47KΩ

C

XTAL

L0

OSC2

ST7

C

L1

OSC1

2.5 MEMORY READ-OUT PROTECTION

The read-out protection is enabled throug h an option bit.

For FLASH devices, when this option is selected,

the program and data stored in the FLASH memory are protected against read-out piracy (including

a re-write protection). When this protection opt ion

is removed the entire FLASH program memory is

first automatically erased. However, the E

2

PROM

data memory (when available) can be protected

only with ROM devices.

11/152

ST72C171

3 CENTRAL PROCE SSI NG UNIT

3.1 INTRODUCTION

This CPU has a full 8-bit architecture and contains

six internal registers allowing efficient 8-bit data

manipulation.

3.2 MAIN FEATURES

■ 63 basic instructions

■ Fast 8-bit by 8-bit multiply

■ 17 main addressing modes

■ Two 8-bit index registers

■ 16-bit stack pointer

■ Low po wer mo des

■ Maskable hardware interrupts

■ Non-maskable software interrupt

3.3 CPU REGISTERS

The 6 CPU registers shown in Figure 1 are not

present in the memory mapping and are accessed

by specific instructions.

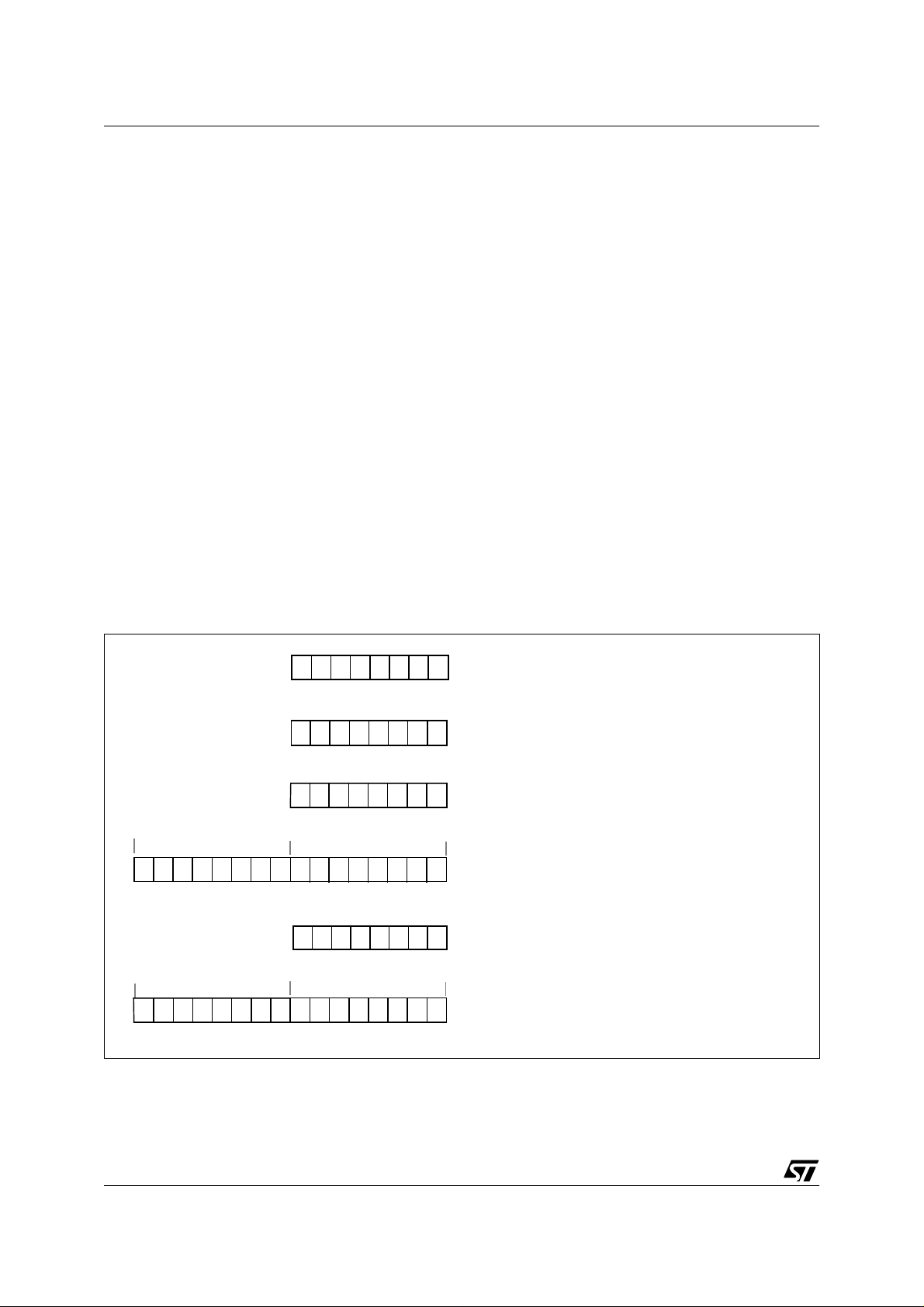

Figure 6. CPU Registers

70

RESET VALUE = XXh

70

RESET VALUE = XXh

70

RESET VALUE = XXh

Accumulator (A)

The Accumulator is an 8-bit general purpose register used to hold operan ds and the results of the

arithmetic and logic calculations and to manipulate

data.

Index Registers (X and Y)

In indexed addressing modes, these 8-bit registers

are used to create either effective addresses or

temporary storage areas for data manipulation.

(The Cross-Assembler generates a precede instruction (PRE) to indicate that the following instruction refers to the Y register.)

The Y register is not affected by the interrupt automatic procedures (not pushed to and popped from

the stack).

Program Cou nt er (P C )

The program counter is a 16-bit register containing

the address of the next instruction to be executed

by the CPU. It is made of two 8-bit registers PCL

(Program Counter Low which is the LSB) and PCH

(Program Counter High which is the MSB).

ACCUMULA T OR

X INDEX REGISTER

Y INDEX REGISTER

15 8

RESET VALUE = RESET VECTOR @ FFFEh-FFFFh

15

RESET VALUE = STACK HIGHER ADDRESS

12/152

PCH

RESET VALUE =

7

70

1C11HI NZ

1X11X1XX

70

8

PCL

0

PROGRAM COUNTER

CONDITION CODE REGISTER

STACK POINTER

X = Undefined Value

CPU REGISTERS (Cont’d)

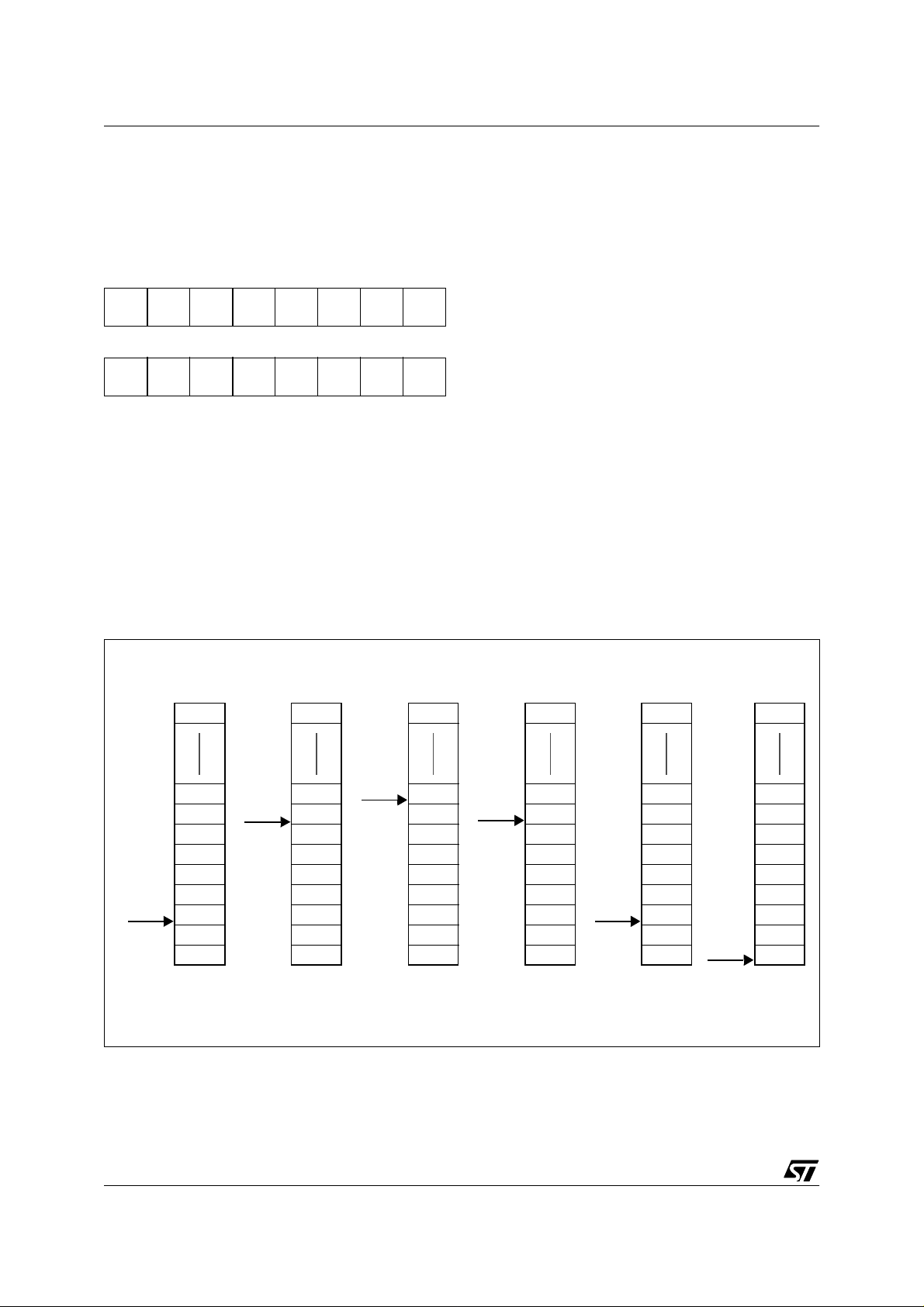

CONDITION CODE REGISTER (CC)

Read/Write

Reset Value: 111x1xxx

70

111HINZC

The 8-bit Condition Code register c ontains the interrupt mask and four flags represent ative of the

result of the instruction just executed. This register

can also be handled by the PUSH and POP instructions.

These bits can be individually tested and/or controlled by specific instructions.

because the I bi t is set by hardware at the start of

the routine and reset by the IRET instruction at the

end of the routine. If the I bit is cleared by software

in the interrupt routine, pending interrupts are

serviced regardless of the priority level of the current interrupt routine.

Bit 2 = N

Negative

.

This bit is set and cleared by hardware. It is representative of the result sign of the last arithmeti c,

logical or data manipulation. It is a copy of the 7

bit of the result.

0: The result of the last operation is positive or null.

1: The result of the last operation is negative

(i.e. the most significant bit is a logic 1).

This bit is accessed by the JRMI and JRPL instruc-

Bit 4 = H

Half carry

.

tions.

This bit is set by hardware when a carry occurs between bits 3 and 4 of t he ALU during an ADD or

ADC instruction. It is reset by hardware during the

same instructions.

0: No half carry has occurred.

1: A half carry has occurred.

This bit is tested using the JRH or JRNH instruction. The H bit is useful in BCD arithmetic subroutines .

Bit 1 = Z

This bit is set and cleared by hardware. This bit in-

dicates that the result of the last arithmetic, logical

or data manipulation is zero.

0: The result of the last operation is different from

zero.

1: The result of the last operation is zero.

Zero

.

This bit is accessed by the JREQ and JRNE test

instructions.

Bit 3 = I

Interrupt mask

This bit is set by hardware when entering in interrupt or by software to disable all interrup ts except

the TRAP software interrupt. This bit is cleared by

software.

0: Interrupts are enabled.

1: Interrupts are disabled.

This bit is controlled by the RIM, SIM and IRET instructions and is tested by the JRM and JRNM instructions.

Note: Interrupts requested while I is set are

latched and can be processed whe n I is cleared.

.

Bit 0 = C

Carry/borrow.

This bit is set and cleared b y hardware and software. It indicates an overflow or an underflow has

occurred during the last arithmetic operation.

0: No overflow or underflow has occurred.

1: An overflow or underflow has occurred.

This bit is driven by the SCF and RCF instructions

and tested by the JRC and JRNC instructions. It is

also affected by the “bit test and branch”, shift and

rotate instructions.

By default an interrupt routine is not in terruptable

ST72C171

th

13/152

ST72C171

CENTRAL PROCESSING UNIT (Cont’d)

Stack Pointer (SP)

Read/Write

Reset Value: 01 7Fh

15 8

00000001

70

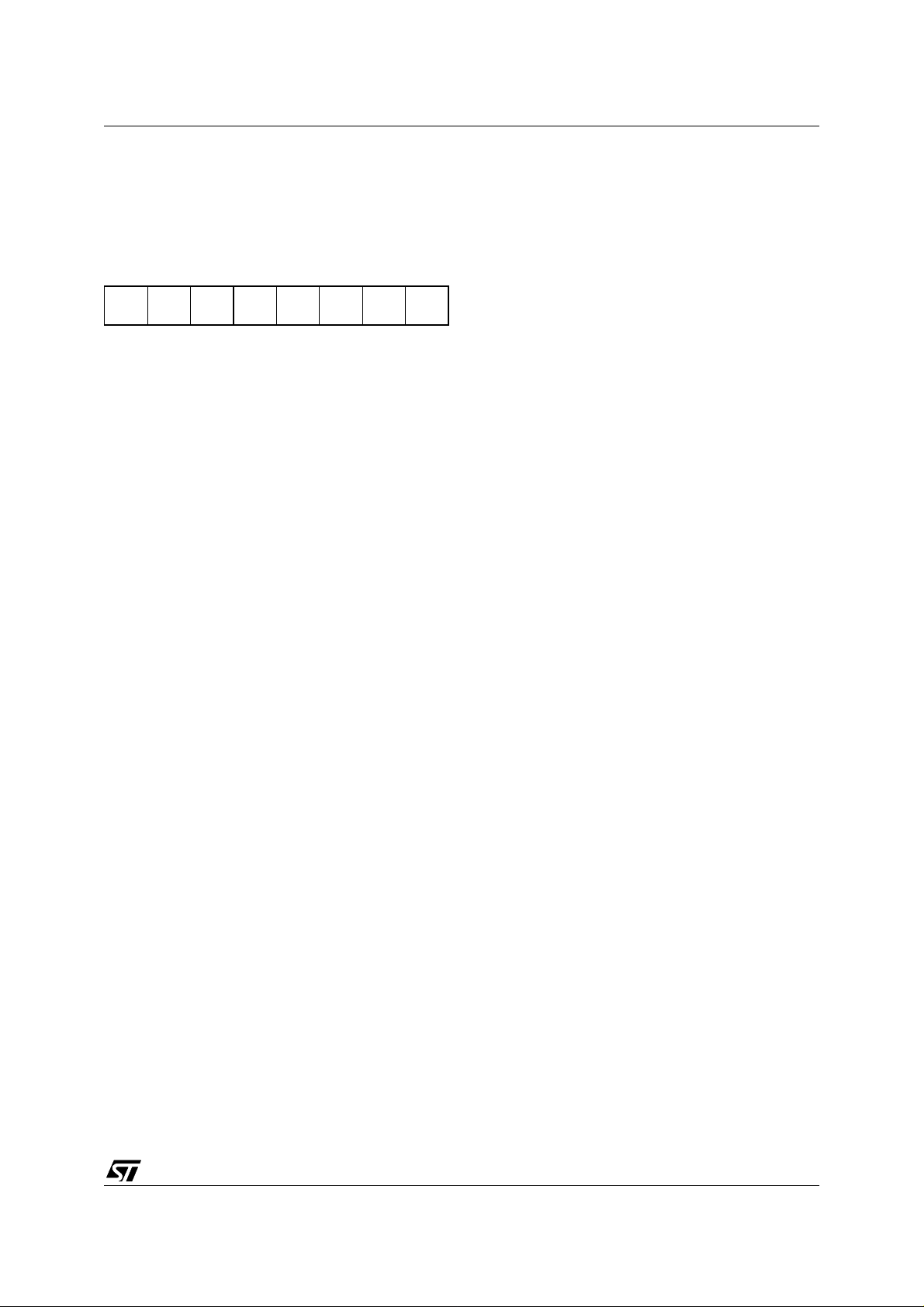

0 1 SP5 SP4 SP3 SP2 SP1 SP0

The Stack Pointer is a 16-bit register which is always pointing to the next free location in the stack.

It is then decremented after data has been pushed

onto the stack and incremented before data is

popped from the stack (see Figure 7).

Since the stack is 128 bytes deep, the 10 most significant bits are forced by hardw are. Following a n

MCU Reset, or after a Reset Stack Pointe r instruction (RSP), the Stack Pointer contains its reset value (the SP5 to SP0 bits are set) which is the stack

higher address.

The least significant byte of the Stack Pointer

(called S) can be directly accessed by a LD instruction.

Note: When the lower limit is exceeded, the Stack

Pointer wraps around to the stack upper limit, wi thout indicating the s tack overflow. The previously

stored information is then o verwritten and therefore lost. The stack also wraps in case of an underflow.

The stack is used to save the retu rn address during a subroutine call and the CPU context during

an interrupt. The user may also directly manipulate

the stack by means of the PUSH and POP instructions. In the case of an interrupt, the PCL is stored

at the first location point ed to by the SP. Then the

other registers are stored in the next locations as

shown in Figure 7.

– When an interrupt is received, the SP is decre-

mented and the context is pushed on the stack.

– On return from interrupt, the SP is incremented

and the context is popped from the stack.

A subroutine call occupies two locations and an interrupt five locat ions i n the sta ck ar ea.

Figure 7. Stack Manipulation Example

@ 0100h

SP

@ 017Fh

CALL

Subroutine

SP

PCH

PCL

Stack Higher Address = 017Fh

Stack Lower Address =

Interrupt

Event

SP

CC

A

X

PCH

PCL

PCH

PCL

0100h

PUSH Y POP Y IRET

SP

Y

CC

A

X

PCH

PCL

PCH

PCL

CC

A

X

PCH

PCL

PCH

PCL

SP

PCH

PCL

RET

or RSP

SP

14/152

ST72C171

4 SUPPLY, RES ET AND CLOCK

MANAGEMENT

The device includes a range of utility features for

securing the application in critical situations (for

example in case of a power brown-out), and reducing the number of external components. An

overview is shown in Figure 8.

4.1 Main Features

■ Supply Manager

– Main supply Low voltage detection (LVD)

Figure 8. Clock, Reset and Supply Block Diagram

MCO

OSCOUT

OSCIN

MULTI-

OSCILLATOR

(MO)

CLOCKSECURITYSYSTEM

CLOCK

FILTER

(CSS)

– Global power down

■ Reset Sequence Manager (RSM)

■ Multi-Oscillat o r (MO)

– 4 Cry stal/Ceramic res onator oscillators

– 2 External RC oscillators

– 1 Internal RC oscillator

■ Clock Security System (CSS)

–Clock Filter

– Backup Safe Oscillator

■ Main Clock controller (MCC)

f

SAFE

OSC

f

OSC

MAIN CLOCK

CONTROLLER

(MCC)

CPU

RESET

V

DD

V

SS

RESETSEQUENCE

MANAGER

(RSM)

LOW VOL T AG E

DETECTOR

(LVD)

FROM

WATCHDOG

PERIPH ER AL

CRSR

LVD

CF INTERRUPT

CSS- WDG

IE SOD0- - - RF RF

15/152

ST72C171

4.2 LOW VOLTAGE DETECTOR (LVD)

To allow the integration of power management

features in the application, the Low Voltage Detector function (LVD) generates a static reset when

the V

supply voltage is below a V

DD

reference

IT-

value. This means that it secures the power-up as

well as the power-down keeping the ST7 in reset.

The V

than the V

reference value for a voltage drop is lower

IT-

reference value for power-on in order

IT+

to avoid a parasitic reset when the MCU starts running and sinks current on the supply (hysteresis).

The LVD Reset circuitry generates a reset when

V

is below:

DD

when VDD is rising

–V

IT+

when VDD is falling

–V

IT-

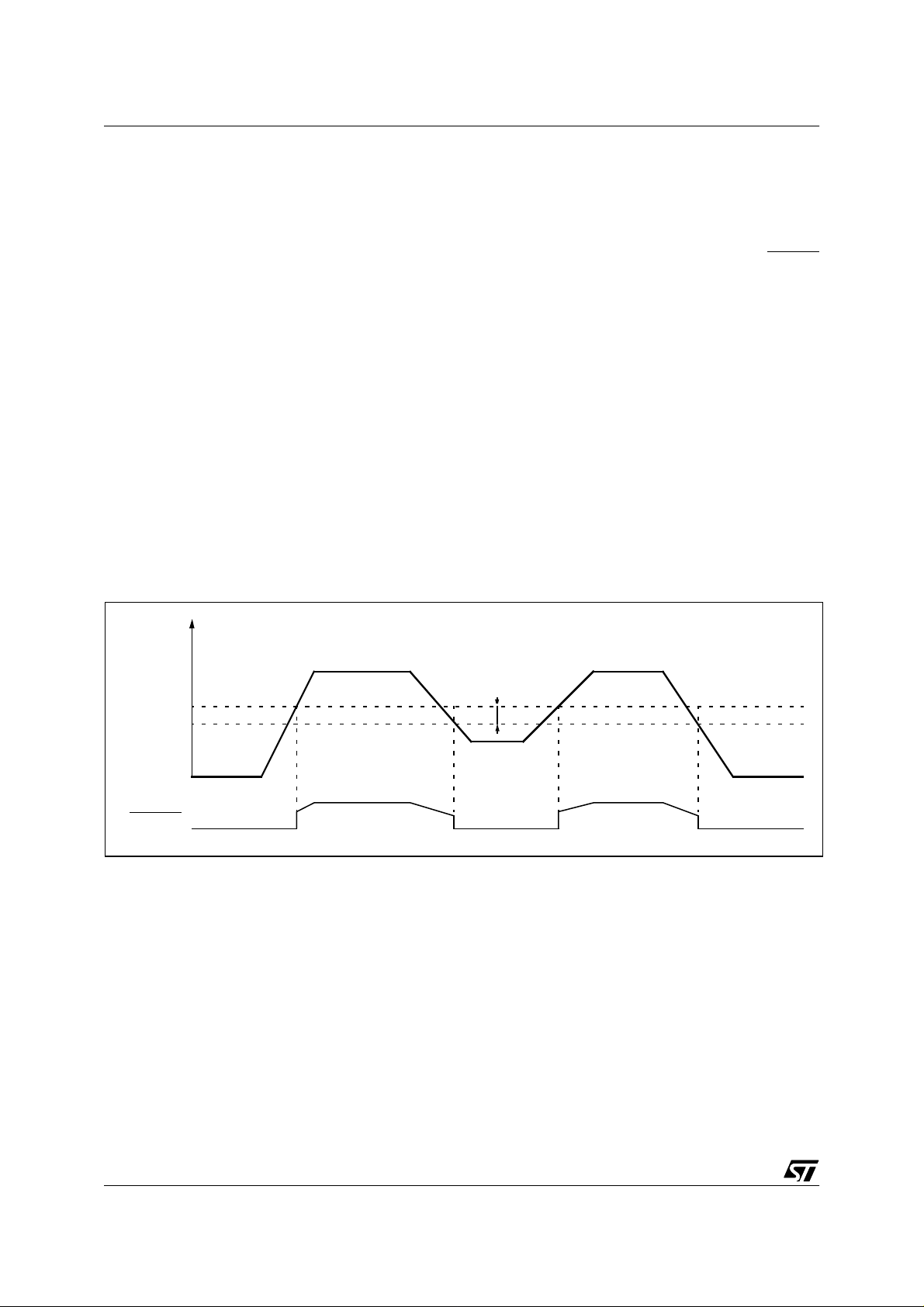

The LVD func t ion is illustrated in the Figure .

Provided the minimum V

the oscillator frequency) is above V

value (guaranteed for

DD

, the MCU

IT-

can only be in two modes:

– under fu ll software control

– in static safe reset

Figure 9. Low Voltage Detector vs Reset

V

DD

In these conditions, secure operation is always ensured for the application without the need for external reset hardware.

During a Low Voltage Detector Reset, the RESET

pin is held low, thus p ermitting the MCU to reset

other devices.

Notes:

1. The LVD allows the device to be used without

any external RESET circuitry.

2. Three different reference levels are selectable

through the option byte according to th e application requirement.

LVD application note

Application software can detect a reset caus ed by

the LVD by reading the LVDRF bit in the CRSR

register.

This bit is set by hardware when a LVD reset is

generated and cleared by software (writing zero).

V

IT+

V

IT-

RESET

V

hyst

16/152

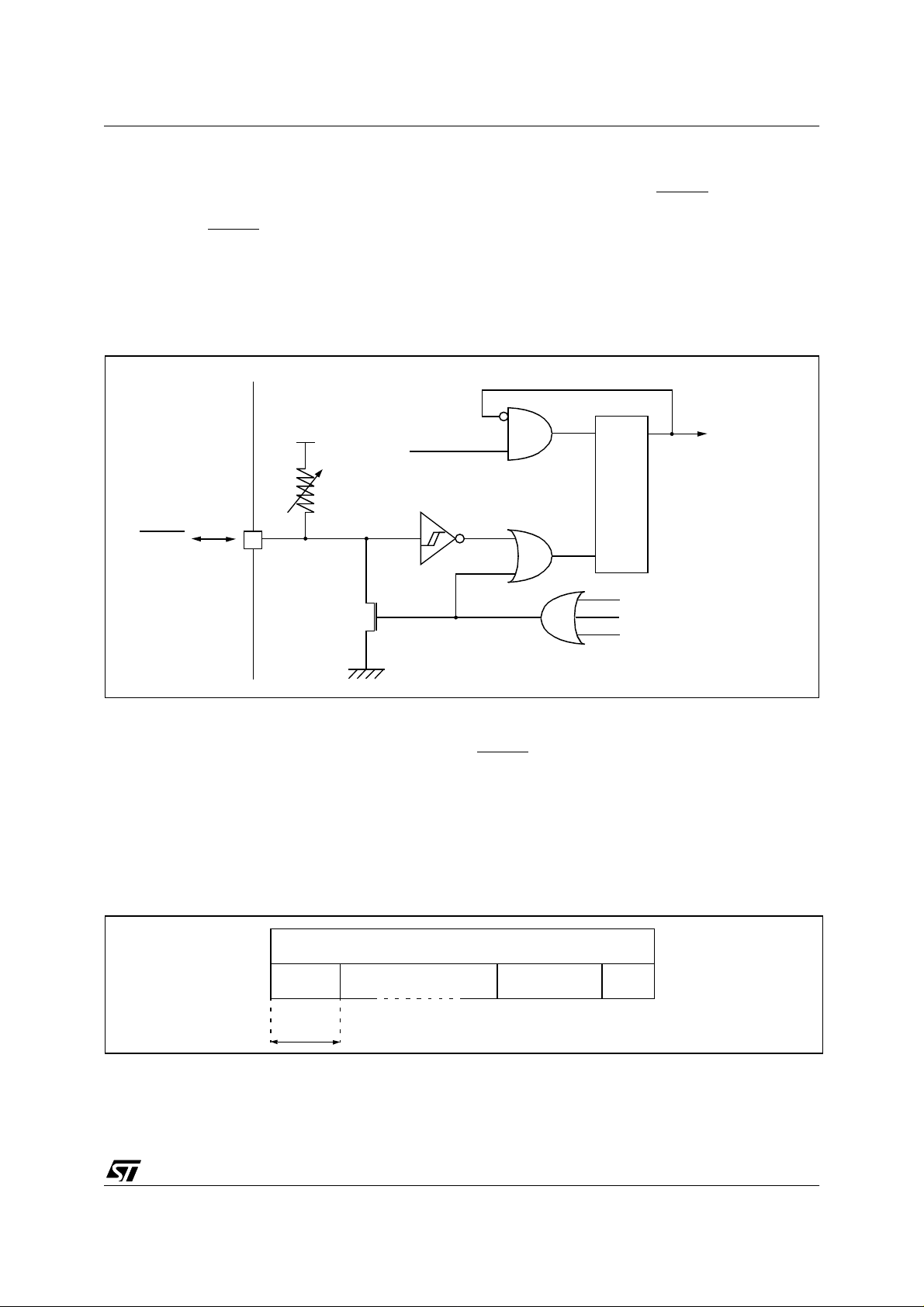

4.2.1 Reset Sequence Manager (RSM)

The RSM block of the CROSS Module includes

three RESET sources as shown in Figure 10:

■ EXTERNAL RESET SOURCE pulse

■ Internal LVD RESET (Low Voltage Detection)

■ Internal WATCHDOG RESET

Figure 10. Reset Block Diagram

ST72C171

These sources act on the RESET

ways kept low during the READ OPTION RESET

phase.

The RESET service routine vector is fixed at the

FFFEh-FFFFh addresses in the ST7 memory

map.

PIN and it is al-

V

DD

R

ON

f

CPU

RESET

The basic RESET s eque nc e cons i sts o f 4 p has es

as shown in Figure 11:

■ OPTION BYTE reading to configure the device

■ Delay depending on the RESET source

■ 4096 cpu clock cycle delay

■ RESET vector fetch

INTERNAL

RESET

COUNTER

WATCHDOG RESET

READ OPTION RESET

LVD RESET

The duration of the OPTION BY TE reading phase

) is defined in the Electrical Characteristics

(t

ROB

section. This first phase is initiated by an external

RESET

detection, or when V

pin pulse detection, a Watchdog RESET

rises up to V

DD

LVDopt

.

The 4096 cpu clock cycle delay al lows the osci llator to stabilise and to ensure that recovery has taken place from the Reset state.

The RESET vector fetch phase duration is 2 clock

cycles.

Figure 11. RESET Sequence Phases

READ

OPTION BYTE

t

ROB

DELAY

RESET

INTERNAL RESET

4096 CLOCK CYCL ES

FETCH

VECTOR

17/152

ST72C171

RESET SEQUENCE MANAGER (Cont’d)

4.2.2 Asynchronous External RES ET

The RESET

output with integrated R

pin is both an input and an open-drain

weak pull-up resistor.

ON

pin

This pull-up has no fixe d value but varies in accordance with the input voltage. It

can be pulled

low by external circuitry to reset the device. See

electrical characteristics section for more details.

A RESET signal originating from an external

source must have a duration of at least t

h(RSTL)in

in

order to be recognized. This detection is asynchronous and therefore the MCU can enter reset state

even in HALT mode.

The RESET

pin is an asynchronous signal which

plays a major role in EMS performance. In a noisy

environment, it is recommended to follow the

guidelines mentioned in the electr ical characteristics section.

Two RESET sequences can be associated with

this RESET source: short or long external reset

pulse (see Figure 12).

Starting from the external RESET pulse recognition, the device RESET

is pulled low during at least t

pin acts as an output that

w(RSTL)out

.

Figure 12. RESET Sequences

4.2.3 Inte r na l Lo w Volta ge Detection RESET

Two differen t RESET sequences caused by the internal LVD circuitry can be distinguished:

■ Power-On RESET

■ Voltage Drop RESET

The device RESET

pulled low when V

V

DD<VIT-

(falling edge) as shown in Figure 12.

The LVD filters spikes on V

pin acts as an output that is

DD<VIT+

(rising edge) or

larger than t

DD

g(VDD)

to

avoid parasitic resets.

4.2.4 Internal Watchdog RESET

The RESET sequence generated by a internal

Watchdog counter overflow is shown in Figure 12.

Starting from the Watchdog counter underflow, the

device RESET

low during at least t

pin acts as an output that is pulled

w(RSTL)out

.

V

V

EXTERNAL

RESET

SOURCE

RESET PIN

WATCHDOG

RESET

IT+

IT-

V

DD

RUN

LVD

RESET

DELAY

RUN

t

w(RSTL)out

t

h(RSTL)in

SHORT EXT.

RESET

DELAY

LONG EXT.

RESET

RUN RUN

DELAY

t

h(RSTL)in

WATCHDOG UNDERFLOW

WATCHDOG

RESET

RUN

DELAY

t

w(RSTL)out

INTERNALRESET(4096 T

FETCH V ECTOR

CPU

)

18/152

ST72C171

4.2.4.1 Multi-Oscillator (MO)

The Mu lti-Oscillato r (MO) blo ck is the m ain clock

supplier of the ST7. To insure an optimum integration in the application, it is based on an external

clock source and six different selectable oscillators.

The main clock of t he ST 7 ca n be generated by 8

different sources comming from the MO block:

■ an External source

■ 4 Crystal or Ceramic resonator oscillators

■ 1 Extern al RC os cill ators

■ 1 Internal H igh Fre quency RC os c illator

Each oscillator is optimized for a given frequenc y

range in term of consumption and is selectable

through the Option Byte.

External Clock Source

The default Option Byte value selects the External

Clock in the MO block. In this mode, a clock signal

(square, sinus or triangle) with ~50% duty cycle

has to drive the OSCin pin while the OSCout pin is

tied to ground (see Figure 13).

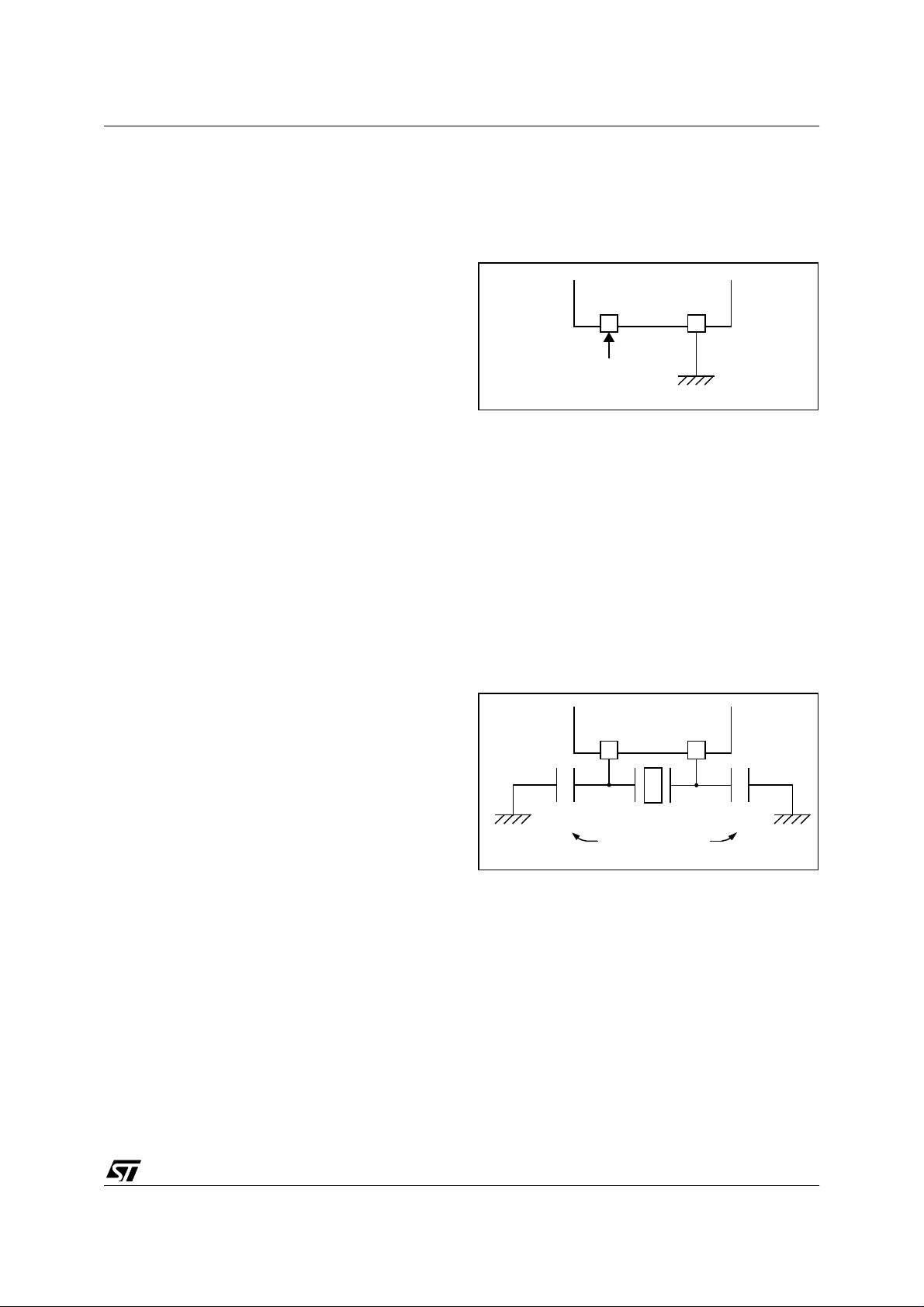

Figure 13. MO Ex te rn a l Cl ock

ST7

OSCin O SCout

EXTERNAL

SOURCE

Crystal/Ceramic Oscillators

This family of oscillators allows a high accuracy on

the main clock of the ST7. The selection within the

list of 4 oscillators has to b e done by Option Byte

according to the res onator frequency in order to

reduce the consum ption. In this mode of the MO

block, the resonator and the load capacitors have

to be connected as shown in Figure 14 a nd have

to be mounted as close as possible to the oscillator pins in order to minimize output distortion and

start-up stabilization time.

These oscillators, when selected via the Option

Byte, are not stopped during the RESET phas e to

avoid losing time in the oscillator starting phase.

Figure 14. MO Crystal/Ceramic Resonator

OSCin OSCout

C

L0

ST7

LOAD

CAPACIT ORS

C

L1

19/152

ST72C171

MULTIOSCILLATO R (MO) (Cont’d)

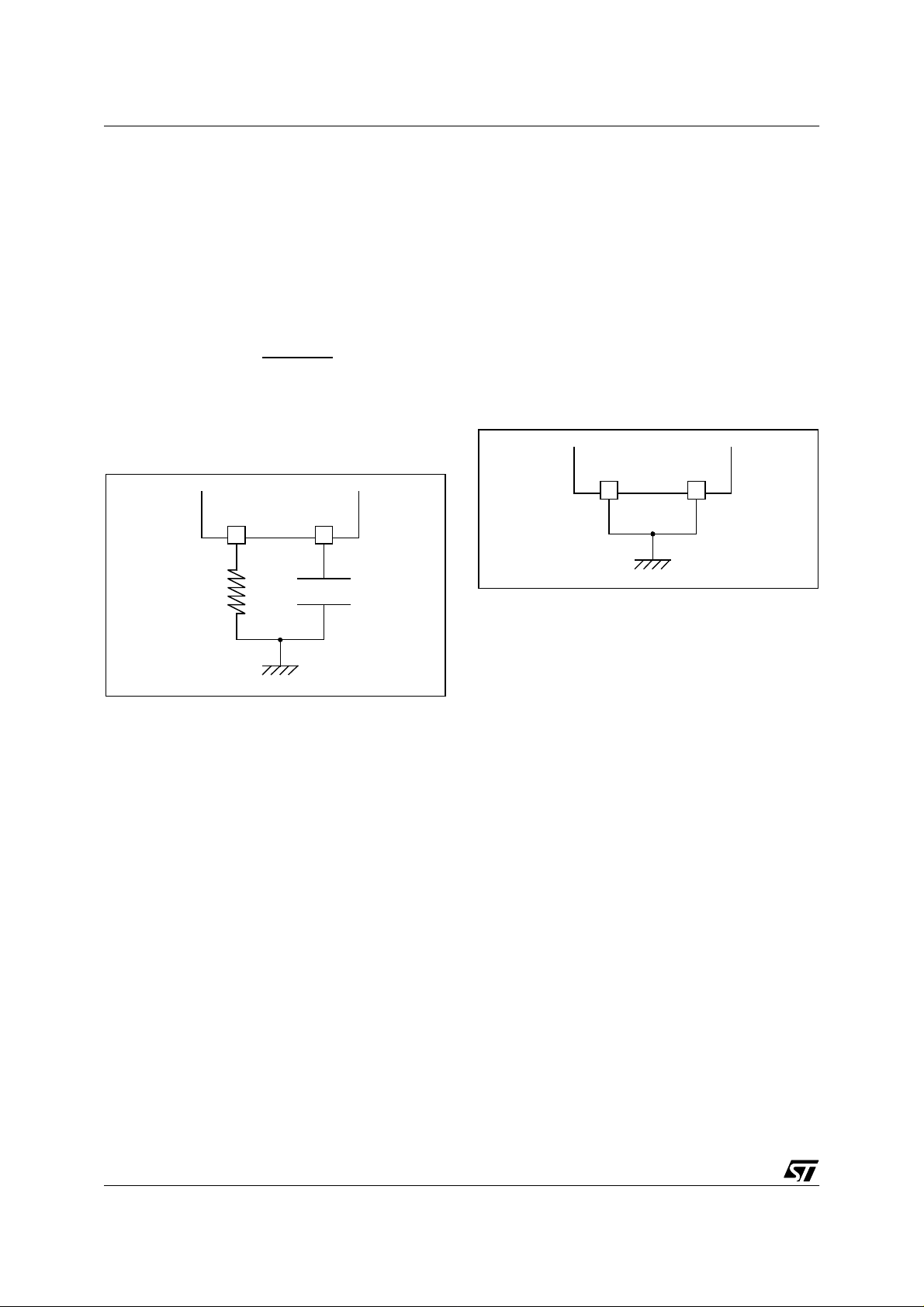

External RC Oscillator

This oscillator allows a low cost solution on the

main clock of the ST7 using only an external resistor and an external capacitor (see Figure 15). T he

selection of the ex ternal RC oscillator has to be

done by Option Byte.

The frequency of the external RC oscillator is fixed

by the resistor and the capacitor values:

R

EX

ST7

N

. C

EX

~

f

OSC

The previous formula shows that in this MO mode,

the accuracy of the clock is directly linked to the

accuracy of the discrete components.

Figure 15. MO External RC

OSCin OSCout

Internal RC Oscillator

The Internal RC oscil lator mode is based on the

same principle as the External RC one including

the an on-chip resistor and capacitor. This mode is

the most cost effective one with the drawback of a

lower frequency accuracy. Its frequency is in the

range of several MHz.

In this mode, the two oscillator pins have to be tied

to ground as shown in Figure 16.

The selection of the internal RC oscillator has to

be done by Option Byte.

Figure 16. MO Internal RC

ST7

OSCin OSCout

R

EX

C

EX

20/152

4.3 CLOCK SECURITY SYSTEM (CSS)

ST72C171

The Clock Security System (CSS) protects the

ST7 against main clock problems. To allow the integration of the security features in the applications, it is based on a clock filter control and an Internal safe oscillator. The CSS can be enabled or

disabled by option byte.

4.3.1 Clock Filter Control

The clock filter is based on a clock frequency limitation function.

This filter function is able to detect and filter high

frequency spikes on the ST7 main clock.

If the oscillator is not working p roperly (e.g. working at a harmonic fr equency of the resonator), the

current active oscillator clock can be totally filtered, and then no clock signal is available for the

ST7 from this oscillator anymore. If the original

clock source recovers, the f iltering is s topped automatically and the oscillator supplies the ST7

clock.

4.3.2 Safe Oscillator Control

The safe oscillator of the CSS block is a low frequency back-up clock source (see Figur e 17).

If the clock signal disappears (due to a broken or

disconnected resonator...) during a safe o scillator

period, the safe oscillator delivers a low frequency

clock signal which allows the ST7 to perform some

rescue operations.

Automatically, the ST7 clock source switches back

from the saf e osc illa tor if the o rig inal clo ck s ourc e

reco ve rs .

Limitat io n det ect i on

The automatic safe oscillator selection is notif ied

by hardware setting the CSSD bit of the CRSR

register. An interrupt can be generat ed if the CSSIE bit has been previously set.

These two bits are described in the CRSR register

description.

4.3.3 Low Power Modes

Mode Description

WAIT

HALT

No effect on CSS. CSS interrupt cause the

device to exit from Wait mode.

The CRSR register is frozen. The CSS (including the safe oscillator) is disabled until

HALT mode is exited. The previous CSS

configuration resumes when the MCU is

woken up by an interrupt with “exit from

HALT mode” capability or from the counter

reset value when the MCU is woken up by a

RESET.

4.3.4 Interrupts

The CSS interrupt event generates an interrupt if

the corresponding Enable Control Bit (CSSIE) is

set and the interrupt mask in the CC register is reset (RIM instruction).

Interrupt Event

CSS event detection

(safe oscillator activated as main clock)

Flag

Enable

Control

Bit

Event

CSSD CSSIE Yes No

Exit

from

Wait

Exit

from

Halt

1)

Note 1: This interrupt allows to exit from active-halt

mode if this mode is available in the MCU.

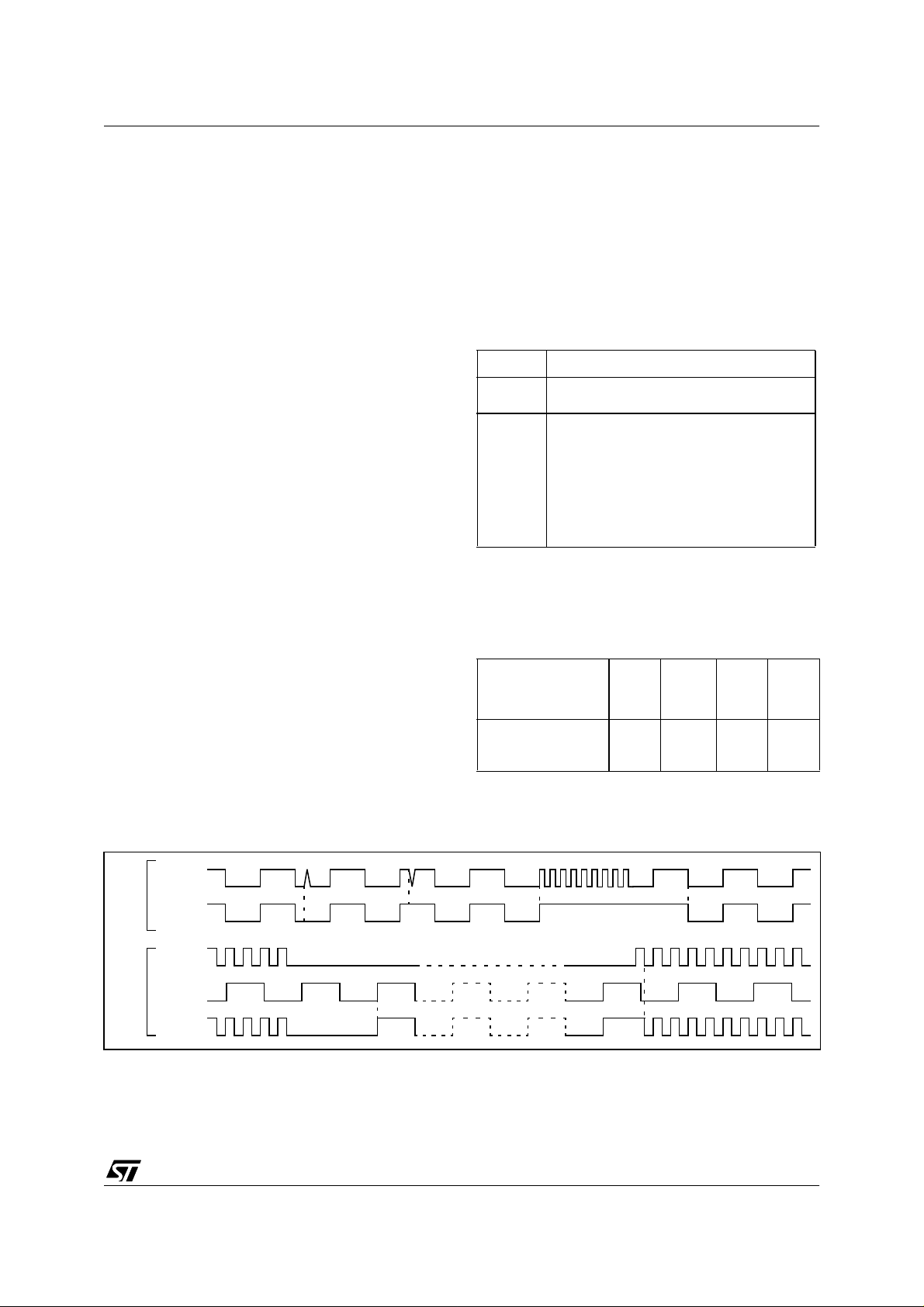

Figure 17. Clock Filter Function and Safe Oscillator Function

f

/2

OSC

f

FUNCTION

CPU

CLOCK FILTER

f

/2

OSC

f

SFOSC

FUNCTION

f

CPU

SAFE OSCILLATOR

21/152

ST72C171

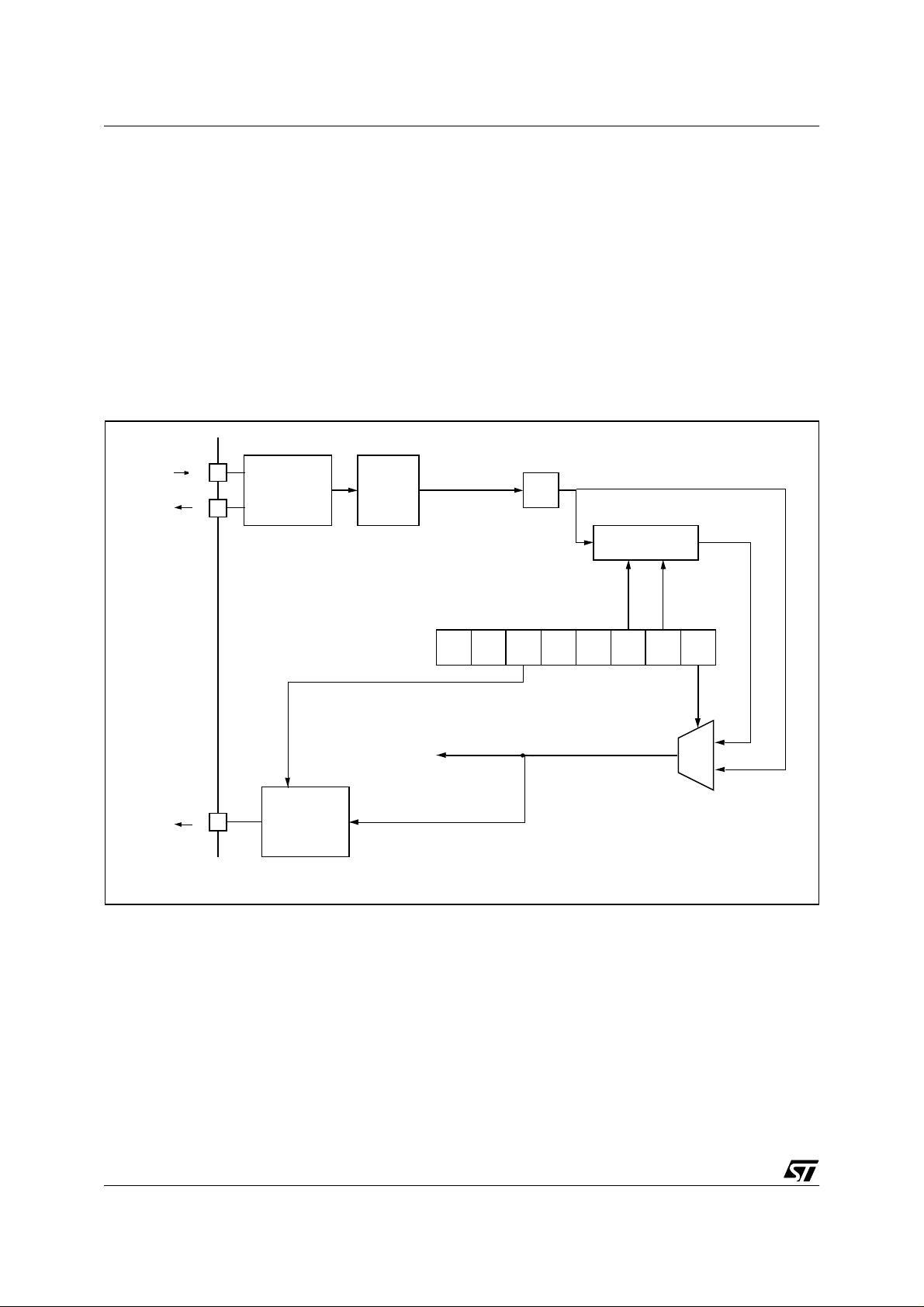

4.3.5 Main Clock Controller (MCC)

The MCC block supplies the clock for the ST7

CPU and its internal peripherals. It allows the power saving modes such as SLOW mode to be managed by the application.

All functions are managed by the Miscellaneous

Register 1 (MISCR1).

The MCC block consists of:

– a program mab le CPU clock prescaler

– a clock-out signal to supply external devices

Figure 18. Main Clock Controller (MCC) Block Diagram

The prescaler allows the selection of the main

clock frequency and is controlled with three bits of

the MISCR1: CP1, CP0 and SMS.

The clock-out capability is an Alternate Function of

an I/O port pin, providing the f

put for driving external devices. It is controlled by

the MCO bit in the MISCR1 register.

clock as an out-

CPU

OSCIN

OSCOUT

MCO

MULTI-

OSCILLATOR

(MO)

PORT

ALTERNATE

FUNCTION

CLOCK

FILTER

(CF)

CPU CLOCK

TO CPU AND

PERIPHERALS

f

OSC

DIV 2

MCO

f

CPU

DIV 2, 4, 8, 16

CP1 CP0

MISCR1

SMS

22/152

4.4 CLOCK, RESET AND SUPPLY REGISTER DESCRIPTION

CLOCK RESET AND SUPPLY REGISTER

(CRSR)

Read/Write

Reset Value: 000x 000x (00h)

70

---

LVD

RF

CSSIECSSDWDG

RF

Bit 7:5 = Reserved.

Bit 1 = CSSD

CSS Safe Osc. Detection

This bit indicates that the safe oscillator of the CSS

block has been selected. It is set by hardware and

cleared by reading the CRSR register when the

original o s cilla t o r r ec o v er s.

0: Safe oscillator is not active

1: Safe oscillator has been activated

Bit 0 = WDGRF

WatchDog Reset Flag

This bit indicates when set that the last Reset was

generated by the Watchdog peripheral. It is set by

hardware (watchdog reset) and cleared by soft-

Bit 4 = LV DRF

This bit indicates when set that the last Reset was

generated by the LVD block. It is set by hardware

(LVD reset) and cleared by software (writing zero)

or a Watchdog Reset. See WDGRF flag description for more details.

Bit 3 = Reserved.

LVD Reset Flag

ware (writing zero) or an LVD Reset.

Combined with the LVDRF flag information, the

flag description is given by the following table.

RESET Sources LVDRF WDGRF

External RESET

Watchdog 0 1

LVD 1 X

pin 0 0

ST72C171

Bit 2 = CSSIE

CSS Interrupt Enable

This bit allows to enable the interrupt whe n a distrurbance is detected by the Cloc k Security System (CSSD bit set). It is set and cleared by software.

0: Clock Filter interrupt disable

1: Clock Filter interrupt enable

Table 3. Supply, Reset and Clock Register Map and Reset Values

Address

(Hex.)

0020h

0025h

Register

Label

MISCR

Reset Value

CRSR

Reset Value

76543210

PEI3

0

-

0

PEI2

0

-

0

MCO

0

-

0

PEI1

0

LVDRF

x

PEI0

CP1

0

-

0

0

CSSIE0CSSD0WDGRF

CP0

0

SMS

0

x

23/152

ST72C171

5 INTE RRUPTS

The ST7 core may be interrupted by one of two different methods: maskable hardware interrupts as

listed in the Interrupt Mapping Table and a nonmaskable software interrupt (TRAP). The Interrupt

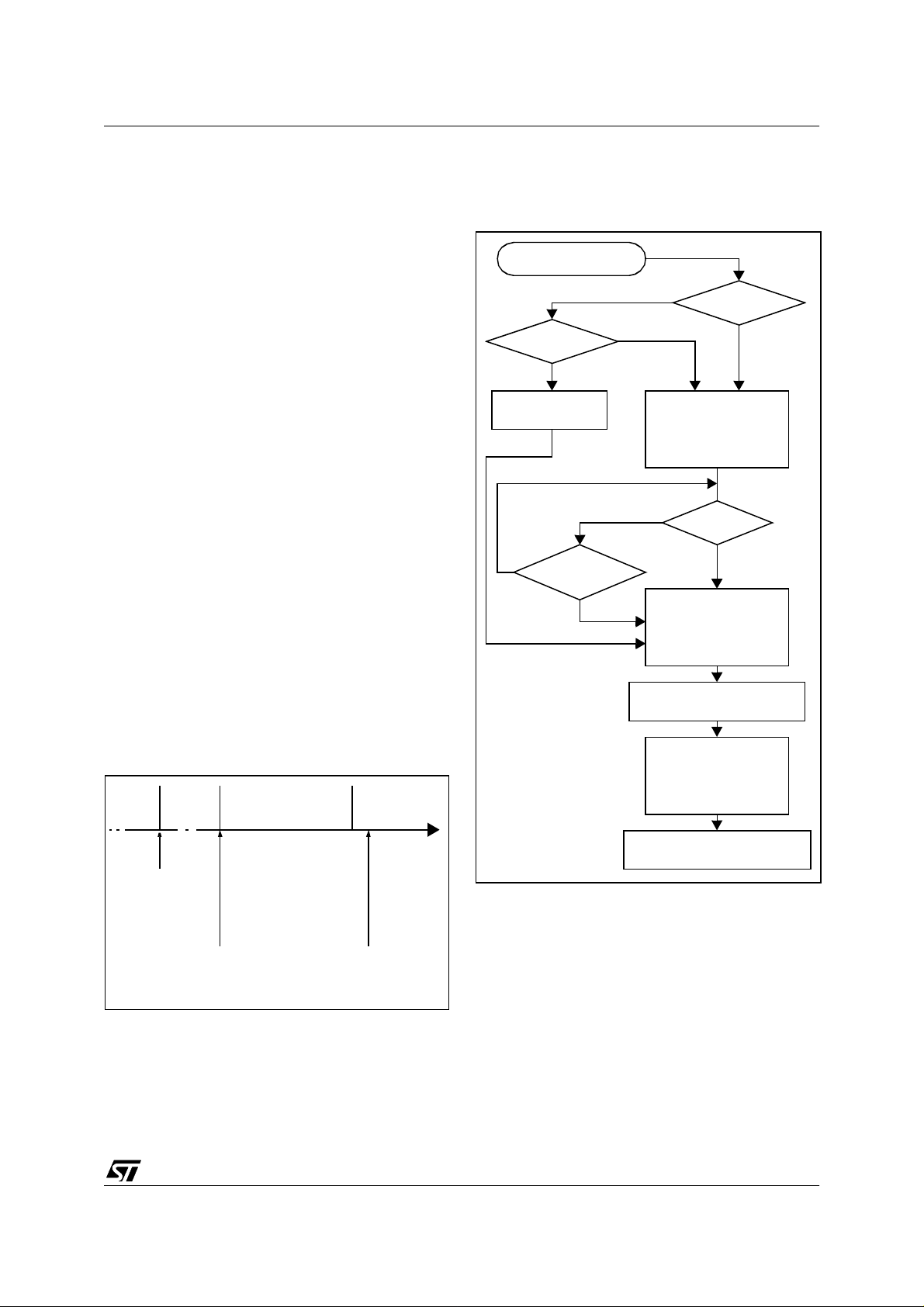

processing flowchart is shown in F igure 19.

The maskable interrupts must be enabled clearing

the I bit in order to be serviced. However, disabled

interrupts may be latched and processed when

they are enabled (see external interrupts subsec tion) .

When an interrupt has to be serviced:

– No rmal processing is susp ended at the end of

the current instruction execution.

– The PC, X, A and CC registers are saved onto

the stack.

– The I bit of the CC register is set to prevent addi-

tional interrupts.

– The PC is then loaded with the interrupt vector of

the interrupt to service and the first instruction of

the interrupt service routine is fetched (refer to

the Interrupt Mapping Table for vector addresses).

The interrupt service routine should finish with the

IRET instruction which c auses the contents o f the

saved registers to be recovered from the stack.

Note: As a consequence of the IRET instruction,

the I bit will be cleared a nd the main pro gram will

resume.

Priority Management

By default, a servicing interrupt cannot be interrupted because the I bit is set by hardware entering in interrupt routine.

In the case when several inte rrupt s ar e simultaneously pending, an hardware priority defines which

one will be serviced first (see the Interrupt Mapping Table).

Interrupts and Low Power Mode

All interrupts allow the processor to leave the

WAIT low power mode. Only external and specifically mentioned interrupts allow the proc essor to

leave the HALT low power mode (refer to the “Exit

from HALT“ column in the I nterrupt Mapping Table).

5.1 NON MASKABLE SOFTWARE INTERRUPT

This interrupt is entered when the TRAP instruction is executed regardless of the state of the I bit.

It will be serviced according to the flowchart on

Figure 19.

5.2 EXTERNAL INTERRUPTS

External interrupt vectors can be loaded into the

PC register if the corresponding ext ernal interrupt

occurred and if the I bit is cleared. These interrupts

allow the processor to leave the Halt low power

mode.

The external interrupt polarity is selected through

the miscellaneous register or interrupt register (if

available).

An external interrupt triggered on edge will be

latched and the interrupt request automatically

cleared upon entering the interrupt service routine.

If several input pins, connected to the same interrupt vector, are configured as interrupts, their signals are logically ANDed before entering the edge/

level detection block.

Caution: The type of sensitivity defined in the Miscellaneous or Interrupt register (if available) applies to the ei source. In case of an ANDed source

(as described on the I/O ports section), a low level

on an I/O pin configured as input with interrupt,

masks the interrupt request even in case of risingedge sensitivity.

5.3 PERIPHERAL INTERRUPTS

Different peripheral interrupt flags in the status

register are able to cause an interrupt when they

are active if both:

– The I bit of the CC register is cleared.

– The corresponding enable bit is set in the control

register.

If any of these two conditions is false, the interrupt

is latched and thus remains pending.

Clearing an interrupt request is done by:

– Writing “0” to the corresponding bit in the status

register or

– Access to the status register while the f lag i s set

followed by a read or write of an associated register.

Note: the clearing sequence resets the internal

latch. A pending interrupt (i.e. waiting for being enabled) will therefore be lost if the clear sequence is

executed.

24/152

INTERRUPTS (Cont’d)

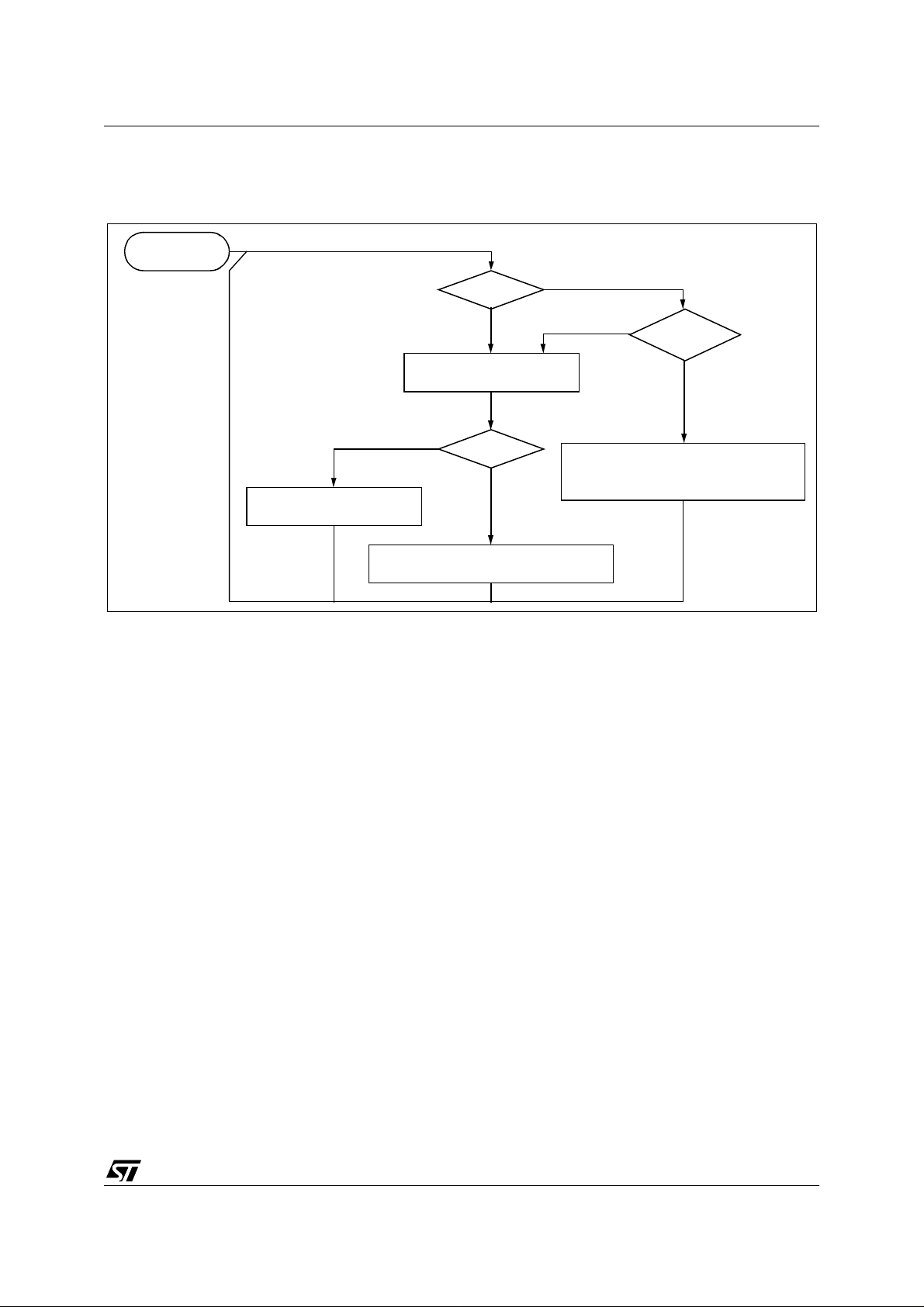

Figure 19. Inte rru pt P rocessing Flow chart

FROM RESET

ST72C171

EXECUTE INSTRUCTION

RESTORE PC, X, A, CC FROM STACK

I BIT SET?

Y

FETCH NEXT INSTRUCTION

N

THIS CLEARS I BIT BY DEFAULT

IRET?

Y

N

N

INTER RUPT

PENDING?

Y

STACK PC, X, A, CC

SET I BIT

LOAD PC FROM INTERRUPT VECTOR

25/152

ST72C171

INTERRUPTS (Cont’d)

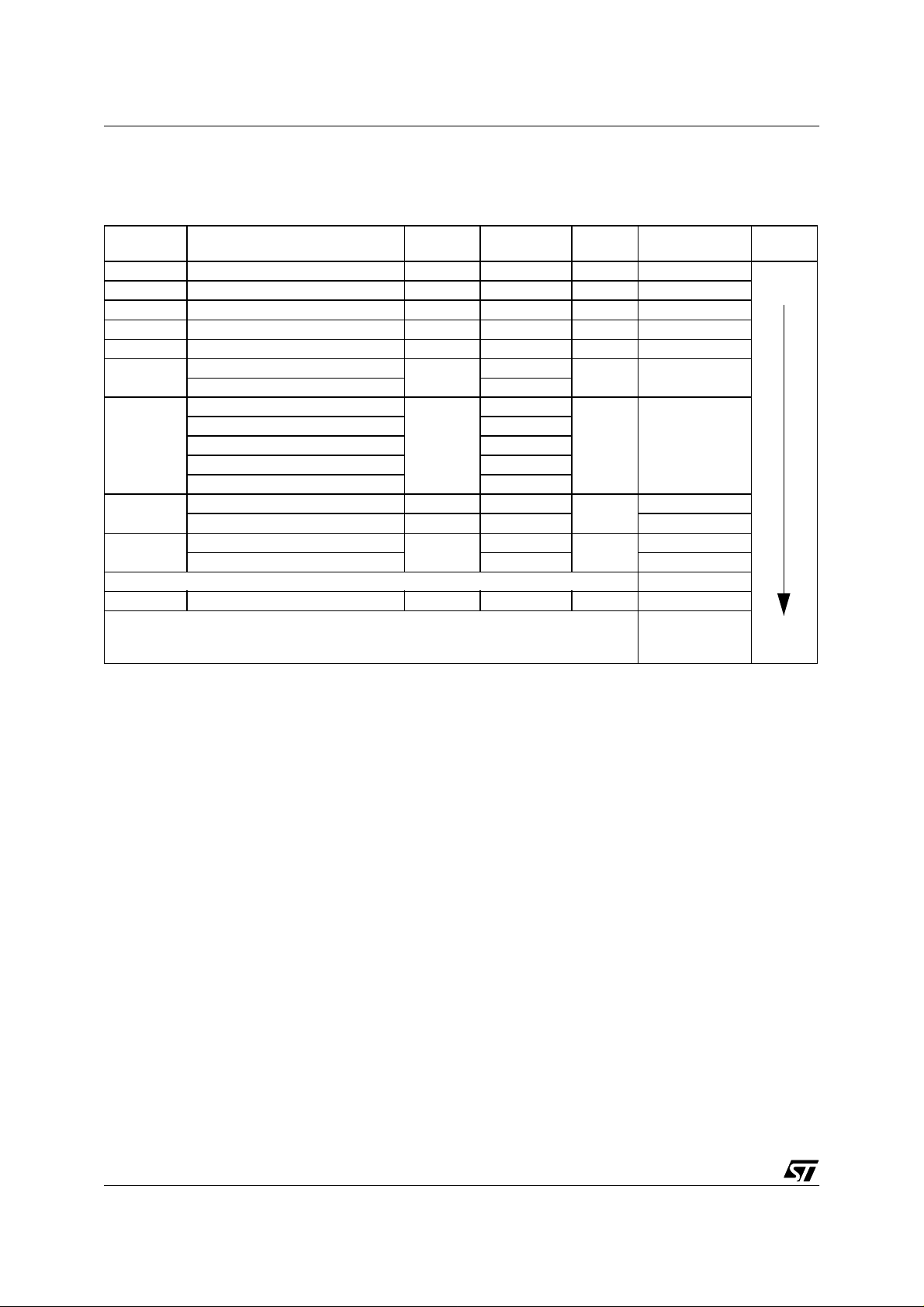

Table 4. Int errupt Mappin g

Source

Block

RESET Reset N/A N/A yes FFFEh-FFFFh

TRAP Software N/A N/A no FFFCh-FFFDh

ei0 Ext. Interrupt ei0 N/A N/A yes FFFAh-FFFBh

ei1 Ext. Interrupt ei1 N/A N/A yes FFF8h-FFF9h

CSS Clock Filter Interrupt CRSR CSSD no FFF6h-FFF7h

SPI

TIMER 16

ART/PWM

OP-AMP

SCI SCI Peripheral Interrupts no FFE4-FFE5

Transfer Complete

Mode Fault MODF

Input Capture 1

Output Compare 1 OCF1_1

Input Capture 2 ICF2_1

Output Compare 2 OCF2_1

Timer Overflow TOF_1

Input Capture 1 ARTICCSR ICF0

Timer Overflow ARTCSR OVF FFEEh-FFEFh

OA1 Interrupt

OA2 Interrupt OA2V FFEAh-FFEBh

Description

NOT USED FFE6-FFE9

Register

Label

SPISR

TASR

OIRR

Flag

SPIF

ICF1_1

OA1V

Exit from

HALT

no FFF4h-FFF5h

no FFF2h-FFF3h

yes

yes

Vector

Address

FFF0h-FFF1h

FFECh-FFEDh

Priority

Order

Highest

Priority

NOT USED FFE0h-FFE3h

Lowest

Priority

26/152

ST72C171

6 POWER SAVIN G MO DES

6.1 INTRODUCTION

To give a large measure of flexibility to the application in terms of power consumption, three main

power saving modes are implemented in the ST7

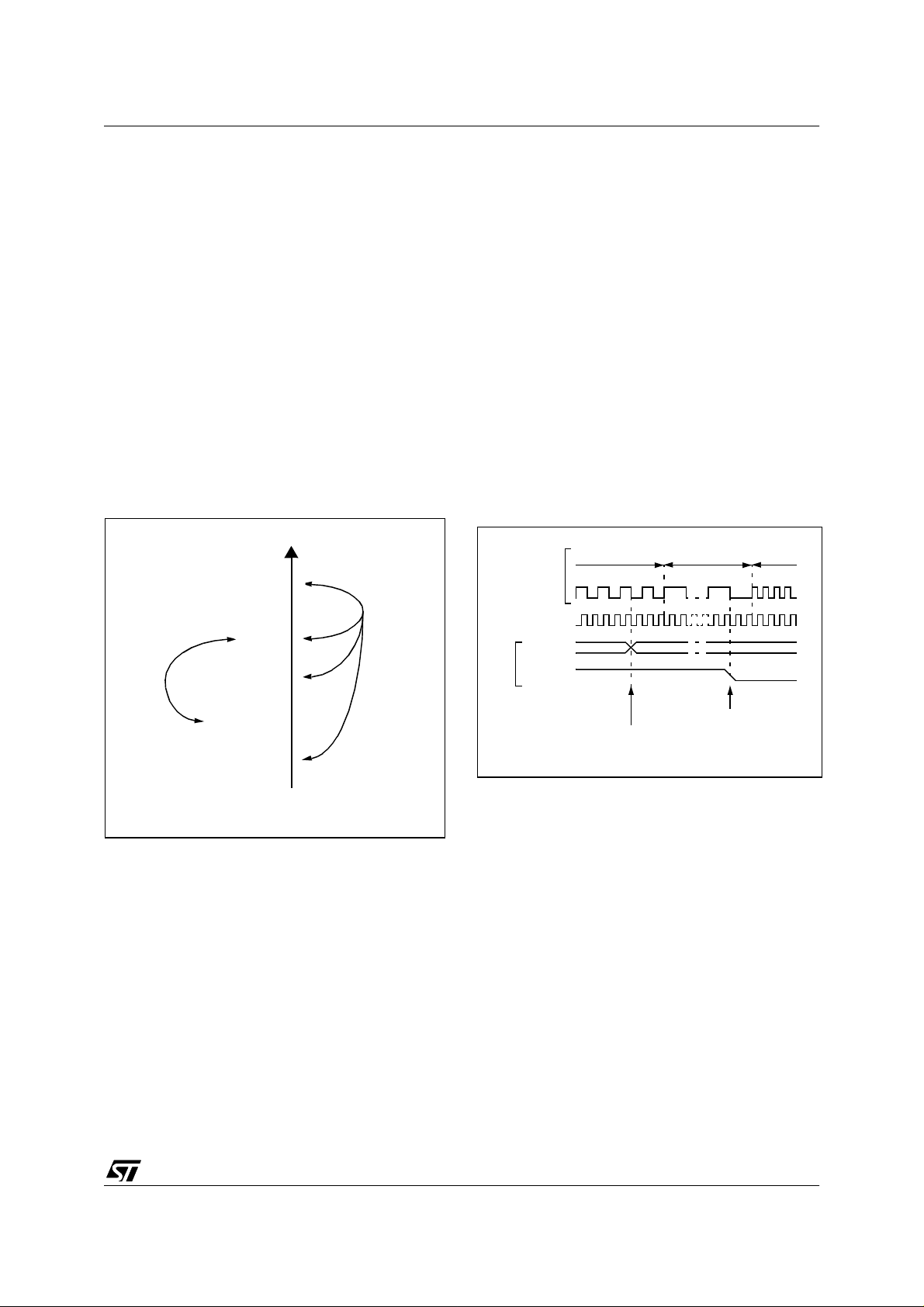

(see Figure 20).

After a RESET the normal operating mode is selected by default (RUN mode). This mode drives

the device (CPU and embedded peripherals) by

means of a master clock which is based on the

main oscillator frequency divided by 2 (f

From Run mode, the different power saving

modes may be selected by setting the relevant

register bits or by calling the specific ST7 software

instruction whose action depends on the the oscillator status.

Figure 20. P ower Saving Mo de Transitions

High

RUN

SLOW

CPU

).

6.2 SLOW MODE

This mode has two targets:

– To reduce power consumption by decreasing the

internal clock in the device,

– To adapt the internal clock frequency (f

CPU

) to

the available supply voltage.

SLOW mode is controlled by three bits in the

MISCR1 register: the SMS bit which enables or

disables Slow mode and two CPx bits which select

the internal slow frequency (f

CPU

).

In this mode, the oscillator frequency can be divided by 4, 8, 16 or 32 instead of 2 in norm al ope ra ting mode. The CPU and peripherals are clocked at

this lower frequency.

Note: SLOW-WAIT mode is activated when enterring the WAIT mode while the device is already in

SLOW mode.

Figure 21. SLOW Mode Clock Transitions

f

f

CPU

f

OSC

CP1:0

/2

/4 f

OSC

00 01

/8 f

OSC

OSC

/2

WAIT

SLOW WAIT

HALT

Low

POWER CONSUMPTION

SMS

MISCR1

NORMALRUN MODE

NEW SLOW

FREQUENCY

REQUEST

REQUEST

27/152

ST72C171

POWER SAVING MODES (Cont’d)

6.3 WAIT MODE

WAIT mode places the MCU in a low power consumption mode by stopping the CPU.

This pow er s av in g mode is s elected by ca llin g the

“WFI” ST7 software instruction.

All peripherals remain active. During WAIT mode,

the I bit of the CC register are forced to 0, to enable all interrupts. All other registers and memory

remain unchanged. The MCU remains in WAIT

mode until an interrupt or Reset occu rs, where upon the Program Counter branc hes to the starting

address of the interrupt or Reset service routine.

The MCU will r e main in W AIT mod e unt il a Rese t

or an Interrupt occurs, causing it to wake up.

Refer to Figure 22.

Figure 22. WAIT Mode Flow-chart

OSCILLATOR

WFI INSTRUCTION

N

INTERRUPT

Y

PERIPHERALS

CPU

I BIT

N

RESET

Y

OSCILLATOR

PERIPHERALS

CPU

I BIT

4096 CPU CLOCK CYCLE

DELAY

OSCILLATOR

PERIPHERALS

CPU

I BIT (s ee note)

ON

ON

OFF

0

ON

OFF

ON

1

ON

ON

ON

1

FETCH RESET VECTOR

OR SERVICE INTERRUPT

Note: Before servicing an interrupt, the CC register is pushed on the stack. The I bit of the CC register is set during the interrupt routine and cleared

when the CC register is popped.

28/152

POWER SAVING MODES (Cont’d)

ST72C171

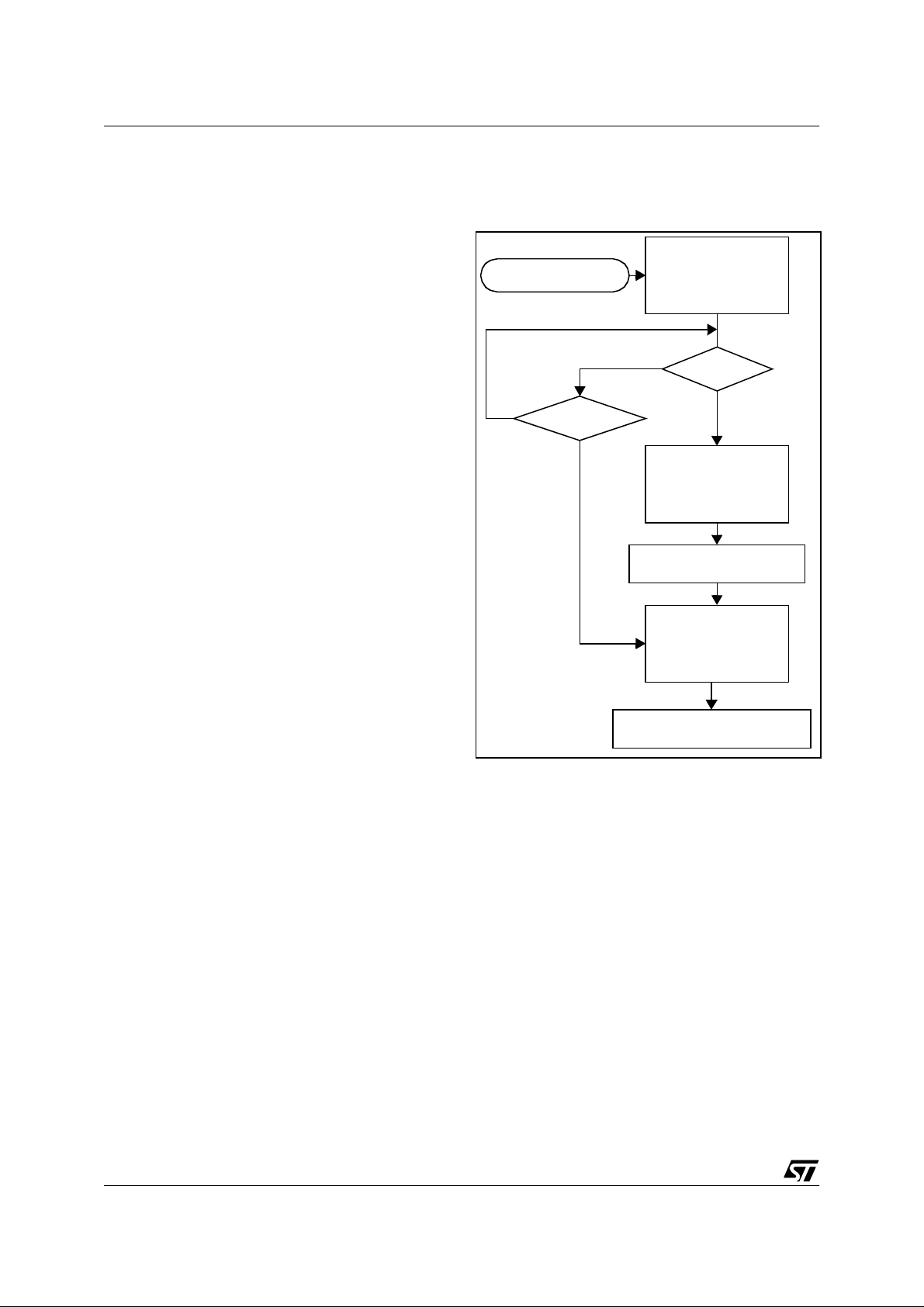

6.4 HALT MODE

The HALT mode is the lowest power consumption

mode of the MCU. It is entered by executing the

ST7 HALT instruction (see Figure 24).

The MCU can exit HALT m ode on reception of either an specific interrupt (see Table 4, “Interrupt

Mapping,” on page 26) or a RESET. When exiting

HALT mode by means of a RESET or an interrupt,

the oscillator is immediately turned on and the

4096 CPU cycle delay is used to stabilize the oscillator. After the start up delay, the CPU resumes

operation by servicing the i nterrupt or by fetching

the reset vector which woke it up (see Figure 23).

When entering HALT mode, the I bit in the CC register is forced to 0 to e nable interrupt s. Therefore,

if an interrupt is pending, the MCU wakes immediately.

In the HALT mode the m ain oscillator is t urned o ff

causing all internal processing to be stopped, including the operation of the on-chip peripherals.

All peripherals are not clocked except the ones

which get their clock supply from another clock

generator (such as an external or auxiliary oscillator).

The compatibility of Watchdog operation with

HALT mode is configured by t he “WD GHA LT” option bit of the option byte. The HALT instruction

when executed while the Watchdog system is enabled, can generate a Watchdog RESET (see

Section 11.1 OPTION BYTES for more details).

Figure 23. HALT Mode Timing Overview

HALTRUN RUN

HALT

INSTRUCTION

INTERRUPT

4096 CPU CYCLE

RESET

OR

DELAY

FETCH

VECTOR

Figure 24. HALT Mode Flow - chart

HALT INSTRUCTION

WDGHALT

1

WATCHDOG

RESET

N

INTERRUPT

Y

1)

ENABLE

0

OSCILLATOR

PERIPHERALS

CPU

I BIT

N

3)

OSCILLATOR

PERIPHERALS

CPU

I BIT

4096 CPU CLOCK CYCLE

OSCILLATOR

PERIPHERALS

CPU

I BIT

FETCH RESET VECTOR

OR SERVICE INTERRUPT

WATCHDO G

RESET

Y

DELAY

4)

DISABLE

OFF

2)

OFF

OFF

0

ON

OFF

ON

1

ON

ON

ON

1

Notes:

1. WDGHALT is an option bit. See option byte sec-

tion for more details.

2. Peripheral clocked with an external clock source

can still be active.

3. Only some spec ific interrupt s can exit the MCU

from HALT mode (su ch as ex ternal i nterrupt). Refer to Table 4, “Interrupt Mapping,” on page 26 for

more details.

4. Before servicing an interrupt, the CC register is

pushed on the stack. The I bit of the CC register is

set during the interrupt routine and cleared when

the CC register is popped.

29/152

ST72C171

7 ON-CHIP PERIPHERALS

7.1 I/O PORTS

7.1.1 Introd uct i on

The I/O ports offer different functional modes:

– transfer of data through digital inputs and outputs

and for specific pins:

– analog signal input (ADC)

– alternate signal input/output for the on-chip pe-

ripherals.

– external interrupt generation

An I/O port is composed of up to 8 pins. Each pin

can be programmed independently as digital input

(with or without interrupt generation) or digital output.

7.1.2 Functional Description

Each port is associated to 2 main registers:

– Data Register (DR)

– Data Direction Register (DDR)

and some of them to an optional register (see reg-

ister description):

– Option Register (OR)

Each I/O pin may be programmed using the corre-

sponding register bits in DDR and OR registers: bit

X corresponding to pin X of the port. The same correspondence is used for the DR register.

The following description takes into account the

OR register, for specific ports which do not provide

this register refer to the I/O Port Implementation

Section 7.1.2.5. The generic I/O block diagram is

shown on Figure 26.

7.1.2.1 Input Modes

The input configuration is sele cted by clearing the

corresponding DDR register bit.

In this case, reading the DR register returns the

digital value applied to the external I/O pin.

Different input modes can be selected by software

through the OR register.

Notes:

1. All the inputs are triggered by a Schmitt trigger.

2. When switching from input mode to output

mode, the DR register should be written first to

output the correct value as soon as the port is configured as an output.

Interrupt function

When an I/O is configured in Input with Interrupt,

an event on thi s I/O can generat e an external Interrupt request to the CPU. The interrupt sensitivity is given independently according to the description mentioned in the Miscellaneous register or in

the interrupt register (where available).

Each pin can independently generate an Interrupt

request.

Each external interrupt vector is linked t o a dedicated group of I/O port pins (see Interrupts section). If more than one input pin is selected simultaneously as interrupt source, this is logically

ORed. For this reason if one of the interrupt pins is

tied low, it masks the other ones.

7.1.2.2 Output Mode

The pin is configured in output mode by setting the

corresponding DDR register bit.

In this mode, writing “0” or “1” to the DR register

applies this digital value to the I/O pin through the

latch. Then reading the DR register returns the

previously stored value.

Note: In this mode, the interrupt function is disabled.

7.1.2.3 Digital Alternate Function

When an on-chip peripheral is configured to use a

pin, the alternate function is au tomatically selected. This alternate function takes priority over

standard I/O programming. When the signal is

coming from an on-chip peripheral, the I/O pin is

automatically configured in output mode (push-pull

or open drain according to the peripheral).

When the signal is goi ng to an on-chip peripheral,

the I/O pin ha s to be configured in i nput mode. In

this case, the pin’s state is a lso digitally readable

by addressing the DR register.

Notes:

1. Input pull-up configuration can cause an unex pected value at the input of the alternate peripheral input.

2. When the on-chip peripheral uses a pin as input

and output, this pin must be configured as an input

(DDR = 0).

Warning

vated as long as the pin is configured as input with

interrupt, in order to avoid generating spurious interrupts.

: The alternate func tion m us t not be a cti-

30/152

Loading...

Loading...