ST ST6215C, ST6225C User Manual

查询ST6215C供应商

TWO TIMERS, OSCILLATOR SAFEGUARD & SAFE RESET

■ Memories

– 2K or 4K bytes Program memory (OTP,

EPROM, FASTROM or ROM) with read-out

protection

– 64 bytes RAM

■ Clock, Re set and Supply M a nagement

– Enhanced reset system

– Low Voltage Detector (LVD) for Safe Reset

– Clock sources: crystal/ceramic resonator or

RC netwo rk, ex tern al cloc k, bac kup o scillat or

(LFAO)

– Oscillator Safeguard (OSG)

– 2 Power Saving Modes: Wait and Stop

■ Interrupt Management

– 4 interrupt vectors plus NMI and RESET

– 20 external interrupt lines (on 2 vectors)

– 1 external non-interrupt line

■ 20 I/ O P o rts

– 20 multifunctional bidirectional I/O lines

– 16 alternate function lines

– 4 high sink outputs (20mA)

■ 2 Timers

– Configurable watchdog timer

– 8-bit timer/counter with a 7-bit prescaler

■ Analog Peripheral

– 8-bit ADC with 16 input channels

■ Instructio n Set

– 8-bit data manipulation

– 40 basic instructions

– 9 addressing modes

– Bit manipulation

ST6215C/ST6225C

8-BIT MCUs WITH A/D CONVERTER,

PDIP28

S028

SS0P28

CDIP28W

(See Section 12.5 for Ordering Information)

■ Development Tools

– Full hardware/software development package

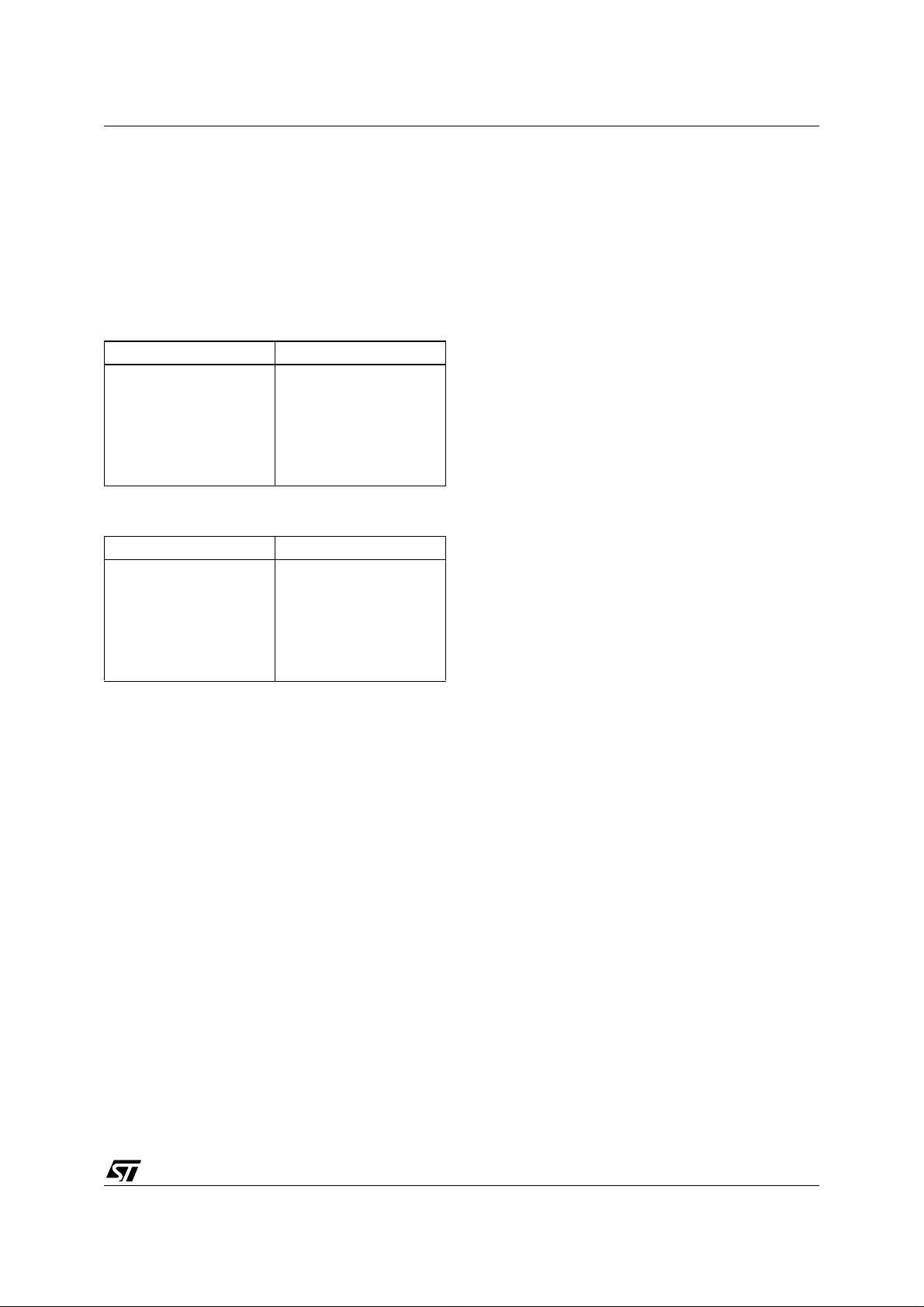

Device Summary

Features

Program memory - bytes 2K 4K

RAM - byte s 64

Operati ng S upply 3.0V to 6V

Clock Fre quency 8MHz Max

Operati ng T em perature -40°C to +125°C

Packages PDIP28 / S O28 / SSOP28 CDIP28 W

ST62T15C(OTP)

ST6215C(ROM)

ST62P15C(FASTROM)

ST62T25C(OTP)

ST6225C(ROM)

ST62P25C(FASTROM

ST62E25C(EPROM)

Rev. 3.2

July 2001 1/105

1

Table of Contents

1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 PIN DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 MEMORY MAPS, PROGRAMMING MODES AND OPTION BYTES . . . . . . . . . . . . . . . . . . . . . . 9

3.1 MEMORY AND REGISTER MAPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1.2 Program Space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1.3 Readout Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1.4 Data Space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1.5 Stack Space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1.6 Data ROM Window Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 PROGRAMMING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2.1 Program Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2.2 EPROM Erasing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.3 OPTION BYTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4 CENTRAL PROCESSING UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2 MAIN FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.3 CPU REGISTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5 CLOCKS, SUPPLY AND RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.1 CLOCK SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.1.1 Main Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.1.2 Oscillator Safeguard (OSG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.1.3 Low Frequency Au xi liary Osc illator (LFAO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.1.4 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.2 LOW VOLTAGE DETECTOR (LVD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.3 RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3.2 RESET Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3.3 RESET

5.3.4 Watchdog Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.3.5 LVD Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6 INTERRUPTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.1 INTERRUPT RULES AND PRIORITY MANAGEMENT . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.2 INTERRUPTS AND LOW POWER MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.3 NON MASKABLE INTERRUPT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.4 PERIPHERAL INTERRUPTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.5 EXTERNAL INTERRUPTS (I/O PORTS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.5.1 Notes on using External Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.6 INTERRUPT HANDLING PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.6.1 Interrupt Response Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.7 REGISTER DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

105

2/105

2

Table of Contents

7 POWER SAVING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.2 WAIT MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 4

7.3 STOP MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.4 NOTES RELATED TO WAIT AND STOP MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.4.1 Exit from Wait and Stop Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.4.2 Recommended MCU Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8 I/O PORTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 8

8.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8.2 FUNCTIONAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8.2.1 Digital Input Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8.2.2 Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8.2.3 Output Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8.2.4 Alternate Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8.2.5 Instructions NOT to be used to access Port Data registers (SET, RES, INC and DEC)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.2.6 Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.3 LOW POWER MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.4 INTERRUPTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.5 REGISTER DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

9 ON-CHIP PERIPHERALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 3

9.1 WATCHDOG TIMER (WDG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

9.1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

9.1.2 Main Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

9.1.3 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9.1.4 Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9.1.5 Low Power Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.1.6 Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.1.7 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

9.2 8-BIT TIMER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9.2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9.2.2 Main Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9.2.3 Counter/Prescaler Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

9.2.4 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9.2.5 Low Power Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

9.2.6 Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

9.2.7 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

9.3 A/D CONVERTER (ADC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

9.3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

9.3.2 Main Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

9.3.3 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

9.3.4 Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

9.3.5 Low Power Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

9.3.6 Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

9.3.7 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

3/105

3

Table of Contents

10 INSTRUCTION SET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

10.1 ST6 ARCHITECTURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

10.2 ADDRESSING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

10.3 INSTRUCTION SET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

11 ELECTRICAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

11.1 PARAMETER CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

11.1.1 M inimu m and M axim um Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

11.1.2Typical Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

11.1.3Typical Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

11.1.4Loading Capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

11.1.5 Pin Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

11.2 ABSOLUTE MAXIMUM RATINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

11.2.1Voltage Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

11.2.2Current Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

11.2.3Thermal Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

11.3 OPERATING CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

11.3.1 G eneral Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

11.3.2Operating Conditions with Low Voltage Detector (LVD) . . . . . . . . . . . . . . . . . . . . . 66

11.4 SUPPLY CURRENT CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

11.4.1RUN Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

11.4.2 W AIT Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

11.4.3STOP Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

11.4.4Supply and Clock System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

11.4.5On-Chip Peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

11.5 CLOCK AND TIMING CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

11.5.1 G eneral Timings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

11.5.2External Clock Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

11.5.3Cry st al and Ceramic Resonator Oscillators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

11.5.4RC Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

11.5.5Oscillator Safeguard (OSG) and Low Frequency Auxiliary Oscillator (LFAO) . . . . . 76

11.6 MEMORY CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

11.6.1RA M and Hardware Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

11.6.2EPROM Program Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

11.7 EMC CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

11.7.1 F unct ional EMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

11.7.2Absolute Electrical Sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

11.7.3ESD Pin Protection Strategy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

11.8 I/O PORT PIN CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

11.8.1General Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

11.8.2Output Driving Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

11.9 CONTROL PIN CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

11.9.1A sy nchronous RE SET Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

11.9.2NMI Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

11.10 TIMER PERIPHERAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

11.10.1Watchdog Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

11.10.28-Bit Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

105

4/105

1

Table of Contents

11.11 8-BIT ADC CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

12 GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

12.1 PACKAGE MECHANICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

12.2 THERMAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

12.3 SOLDERING AND GLUEABILITY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

12.4 PACKAGE/SOCKET FOOTPRINT PROPOSAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

12.5 ORDERING INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

12.6 TRANSFER OF CUSTOMER CODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

12.6.1FASTROM Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

12.6.2ROM Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

13 DEVELOPMENT TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

14 ST6 APPLICATION NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

15 SUMMARY OF CHANGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

16 TO GET MORE INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

5/105

1

ST6215C/ST6225C

1 INTRODUCTION

The ST6215C, 25C devices are low cost members

of the ST62xx 8-bit HCMOS family of microcontrollers, which is targeted at low to medium complexity

applications. All ST62xx devices are based on a

building block approach: a common core is surrounded by a number of on-chip peripherals.

The ST62E25C is the erasable EPROM version of

the ST62T15C, T25C devices, which may be used

during the development phase for the ST62T15C,

T25C target devices, as well as the respective

ST6215C, 25C ROM devices.

OTP and EPROM devices are functional ly identical. OTP devices offer a ll the advantages of us er

programmability at low cost, which make them the

ideal choice in a wide range of applications where

frequent code changes, multiple c ode vers ions or

last minute programmabilit y are required.

The ROM based versions offer the same functionality, selecting the options defined in the program-

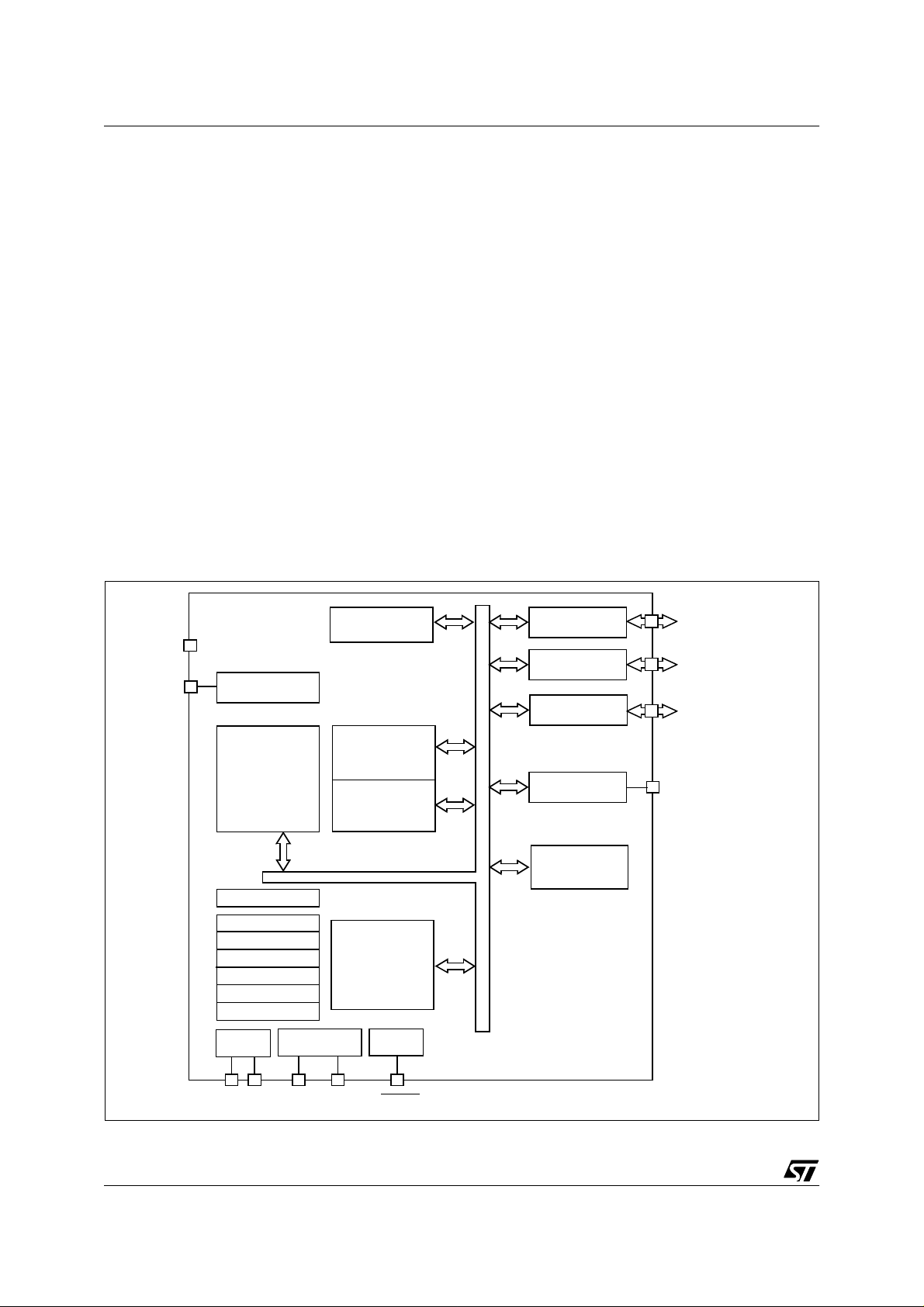

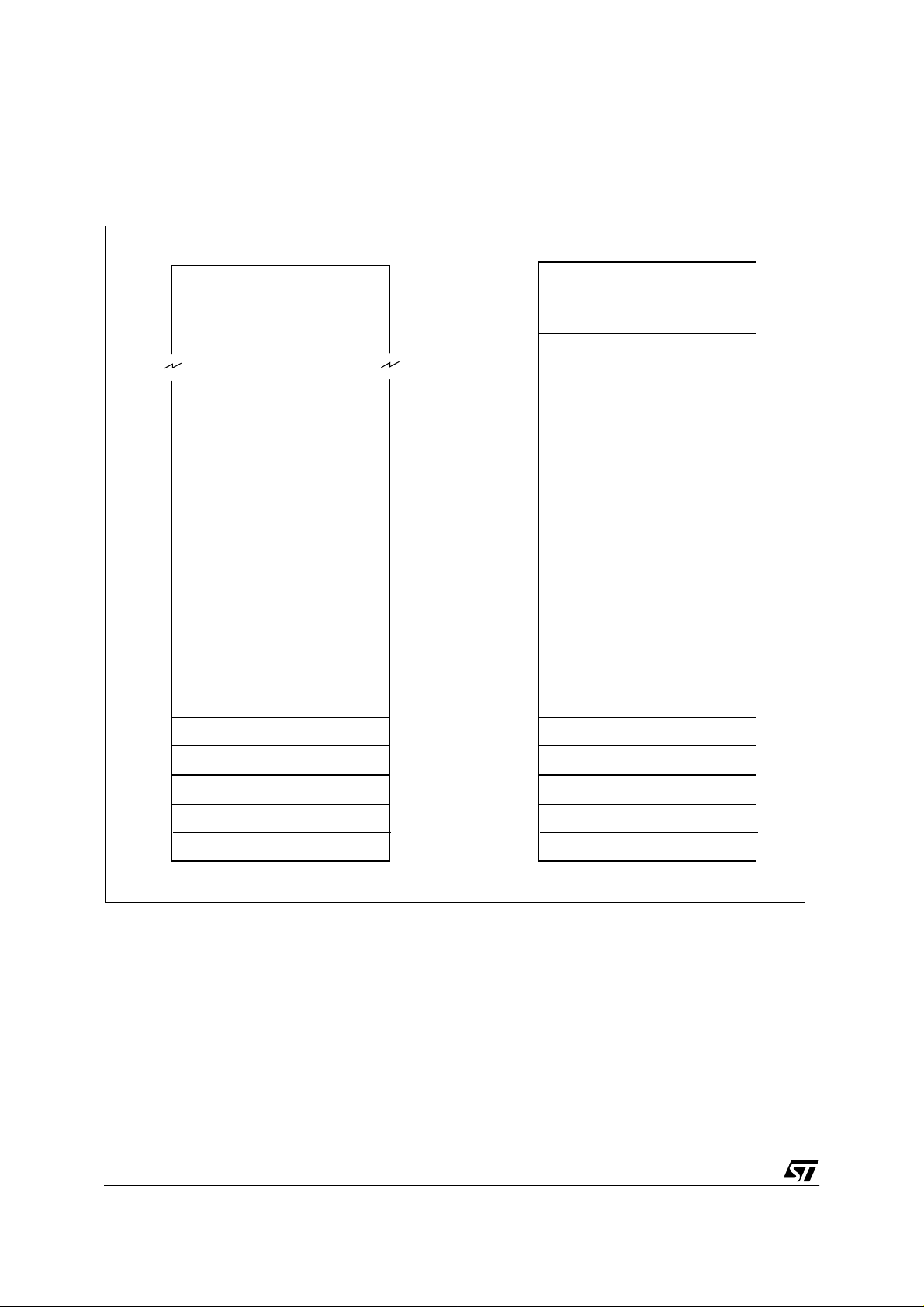

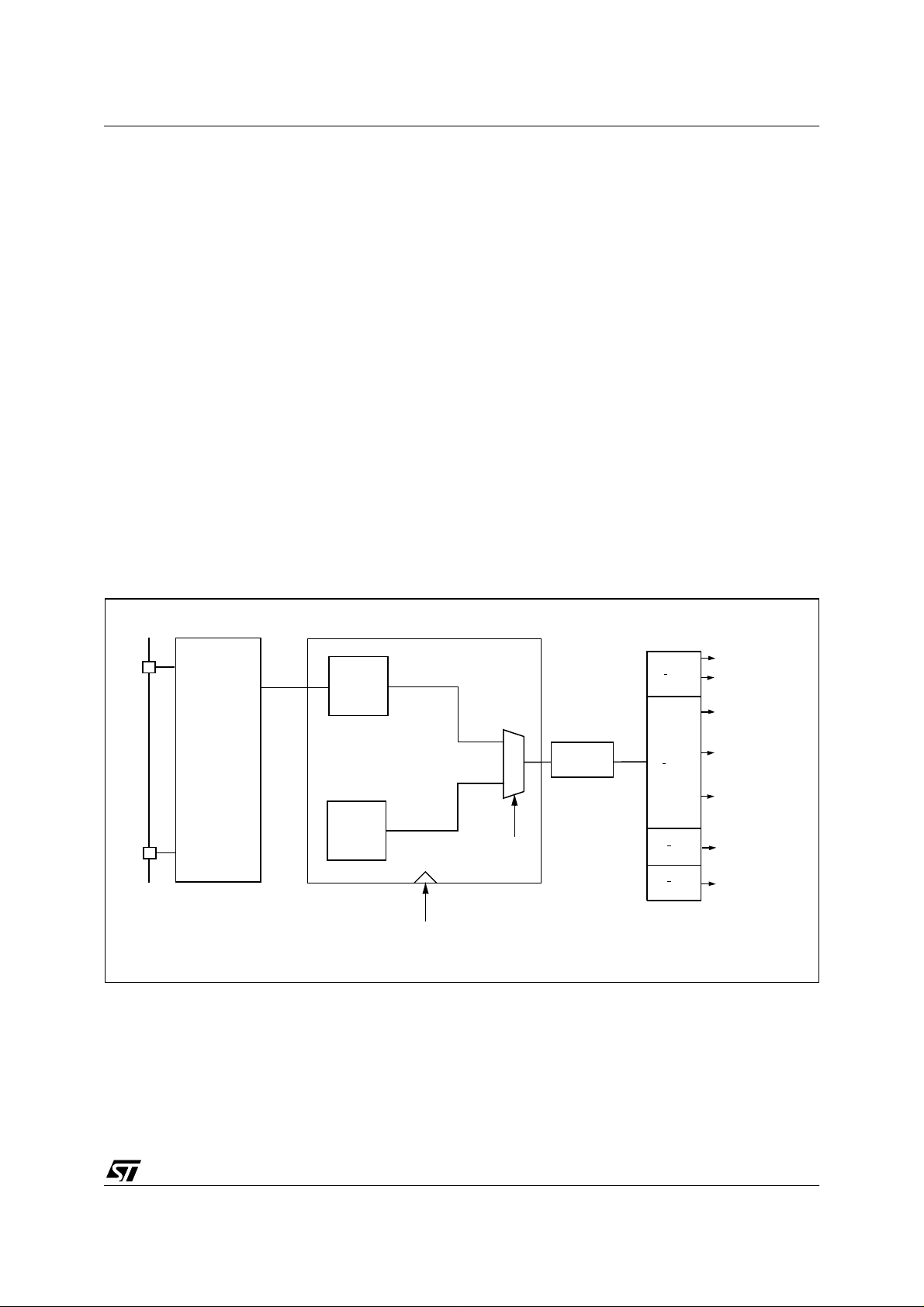

Figure 1. Block Diagram

8-BIT

A/D CONVERTER

V

PP

NMI

INTERRUPTS

mable option bytes of the OTP/EPR OM versions

in the ROM option list (See Section 12.6 on page

97).

The ST62P15C/P2 5C are the Factory Advanced

Service Technique ROM (FASTROM) versions of

ST62T15C,T25C OTP devices.

They offer the same functionality as OTP devices,

but they do not have to be programmed by the

customer (See Section 12 on page 91).

These compact low -cost devices feature a Timer

comprising an 8-bit counter with a 7-bit programmable prescaler, an 8-bit A/D Converter with 16

analog inputs and a Digital Wa tchdog timer, making them well suited for a wide range of automotive, appliance and industrial applications.

For easy reference, all parametric data is locat ed

in Section 11 on page 63.

PORT A

PORT B

PORT C

PA0..PA3 (20mA Sink)

PA4..PA7 / Ain

PB0..PB7 / Ain

PC4..PC7 / Ain

6/105

4

PROGRAM

:

MEMORY

(2K or 4K Bytes)

PC

STACK LEVEL 1

STACK LEVEL 2

STACK LEVEL 3

STACK LEVEL 4

STACK LEVEL 5

STACK LEVEL 6

POWER

SUPPLY

V

DDVSS

OSCILLATOR

OSCin OSCout RESET

DATA RO M

USER

SELECTABLE

DATA RAM

64 Bytes

8-BIT CO RE

RESET

TIMER

WATCHDOG

TIMER

TIMER

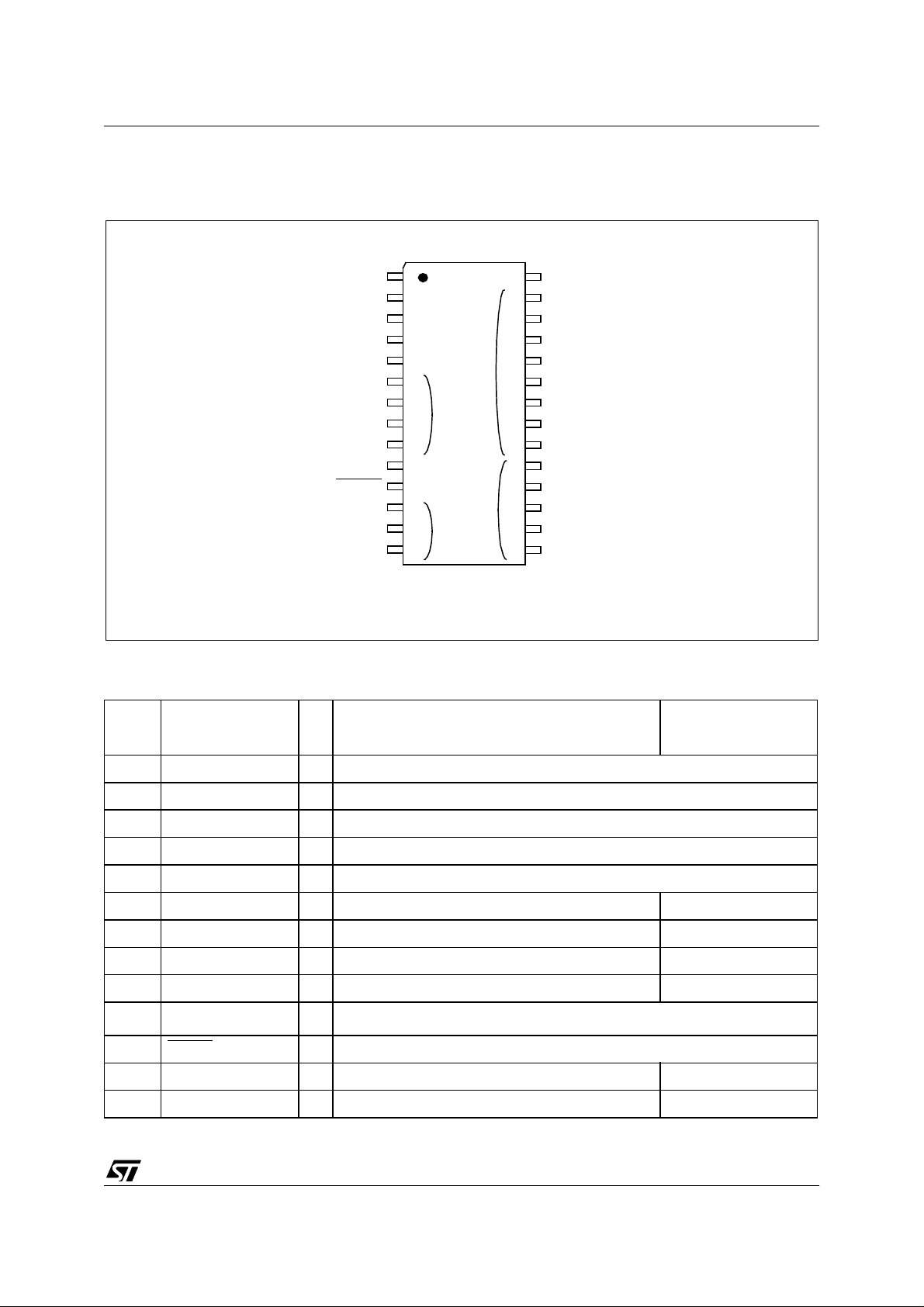

2 PIN DESCRI PTION

Figure 2. 28-Pin Package Pinout

ST6215C/ST6225C

Table 1. Device Pin Description

Pin n° Pin Name

Type

V

DD

TIMER

OSCin

OSCout

NMI

Ain/PC7

Ain/PC6

Ain/PC5

Ain/PC4

V

PP

RESET

Ain/PB7

Ain/PB6

Ain/PB5

1

2

3

4

5

6

7

8

9

10

11

12

13

14

it2

it2

28

27

26

25

24

it1

23

22

21

20

19

18

it2

17

16

15

Main Function

(after Reset)

V

SS

PA0/20mA Sink

PA1/20mA Sink

PA2/20mA Sink

PA3/20mA Sink

PA4/Ain

PA5/Ain

PA6/Ain

PA7/Ain

PB0/Ain

PB1/Ain

PB2/Ain

PB3/Ain

PB4/Ain

itX associated interrupt vector

Alternate Function

1 V

2

DD

TIMER

S Main power supply

I/O Timer input or output

3 OSCin I External clock input or resonator oscillator inverter input

4 OSCout O Resonator oscillator inverter output or resistor input for RC oscillator

5 NMI I Non maskable interrupt (falling edge sensitive)

6 PC7/Ain I/O Pin C7 (IPU) Analog input

7 PC6/Ain I/O Pin C6 (IPU) Analog input

8 PC5/Ain I/O Pin C5 (IPU) Analog input

9 PC4/Ain I/O Pin C4 (IPU) Analog input

10 V

PP

11 RESET

I/O Top priority non maskable interrupt (active low)

Must be held at Vss for normal operation, if a 12.5V level is applied to the pin

during the reset phase, the device enters EPROM programming mode.

12 PB7/Ain I/O Pin B7 (IPU) Analog input

13 PB6/Ain I/O Pin B6 (IPU) Analog input

7/105

5

ST6215C/ST6225C

Pin n° Pin Name

14 PB5/Ain I/O Pin B5 (IPU) Analog input

15 PB4/Ain I/O Pin B4 (IPU) Analog input

16 PB3/Ain I/O Pin B3 (IPU) Analog input

17 PB2/Ain I/O Pin B2 (IPU) Analog input

18 PB1/Ain I/O Pin B1 (IPU) Analog input

19 PB0/Ain I/O Pin B0 (IPU) Analog input

20 PA7/Ain I/O Pin A7 (IPU) Analog input

21 PA6/Ain I/O Pin A6 (IPU) Analog input

22 PA5/Ain I/O Pin A5 (IPU) Analog input

23 PA4/Ain I/O Pin A4 (IPU) Analog input

24 PA3/ 20mA Sink I/O Pin A3 (IPU)

25 PA2/ 20mA Sink I/O Pin A2 (IPU)

26 PA1/ 20mA Sink I/O Pin A1 (IPU)

27 PA0/ 20mA Sink I/O Pin A0 (IPU)

28 V

SS

Type

S Ground

Main Function

(after Reset)

Alternate Function

Legend / Abbreviations for Table 1:

I = input, O = output, S = supply, IPU = input pull-up

The input with pull-up configuration (reset state) is valid as long as the user software does not change it.

Refer to Section 8 "I/O PORTS" on page 38 for more details on the software configuration of the I/O ports.

8/105

6

ST6215C/ST6225C

3 MEMORY MAPS, PROGRAMMING MODES AND OPTION BYTES

3.1 MEMORY AND REGISTER MAPS

3.1.1 Introd uct i on

The MCU operates in three separate memory

spaces: Program space, Data space, and Stack

space. Operation in these three memory spaces is

described in the following paragraphs.

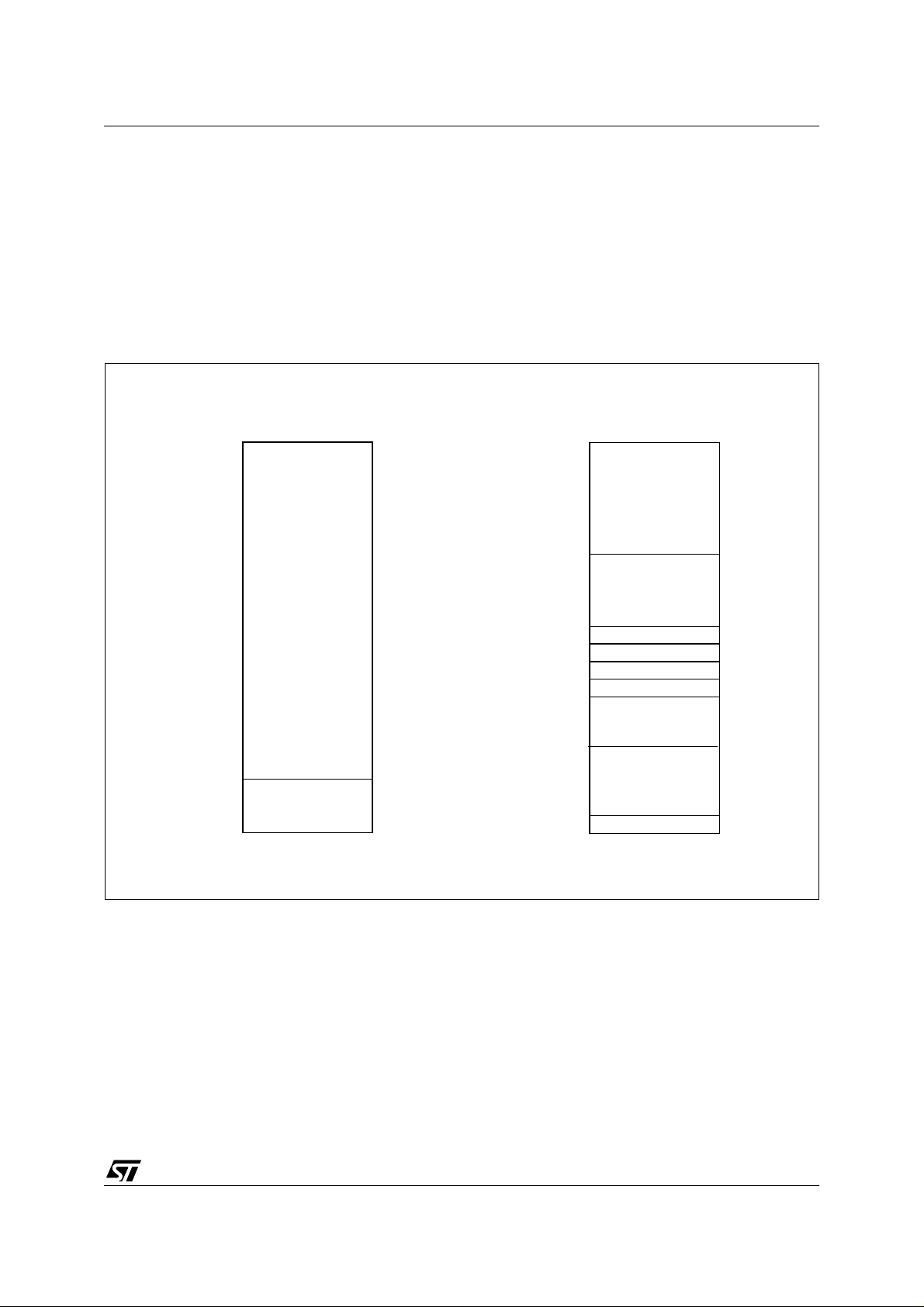

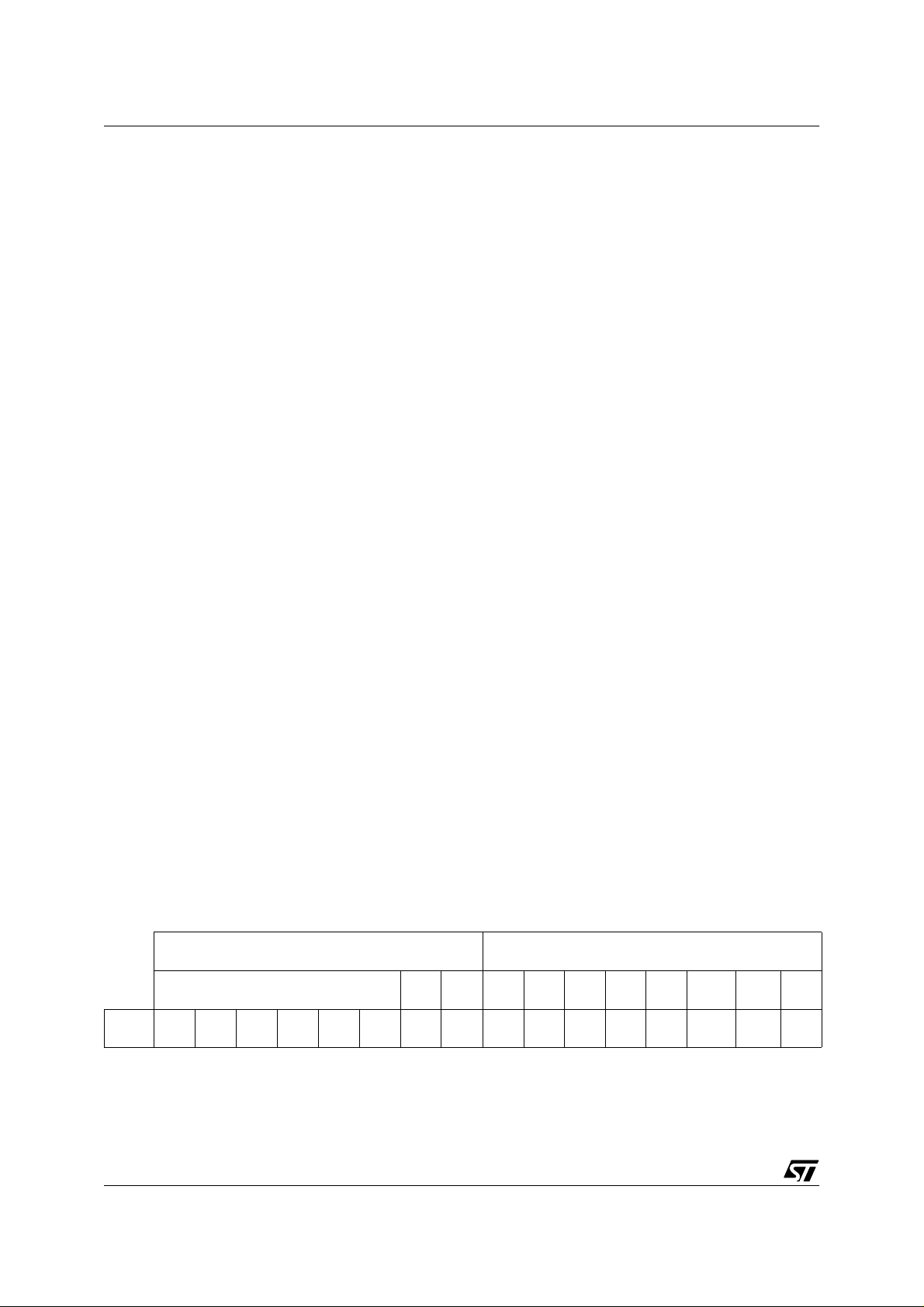

Figure 3. Mem ory Addressing Dia gram

PROGRAM SPACE

000h

PROGRAM

MEMORY

(see Figure 4

on page 10)

0FF0h

INTERRUPT &

RESET VECTORS

0FFFh

Briefly, Program space contains user program

code in OTP and user vectors; Data space contains user data in RAM and in OTP, and Stack

space accommodat es six levels of stack for subroutine and interrupt service routine nesting.

DATA SPACE

000h

RESERVED

03Fh

040h

DATA READ-ONLY

MEMORY WINDOW

07Fh

080h

081h

082h

083h

084h

0BFh

0C0h

0FFh

X REGISTER

Y REGISTER

V REGISTER

W REGISTER

RAM

HARDWARE

CONTROL

REGISTERS

(see Table 2)

ACCUMULATOR

9/105

1

ST6215C/ST6225C

MEMORY MAP (Cont’d)

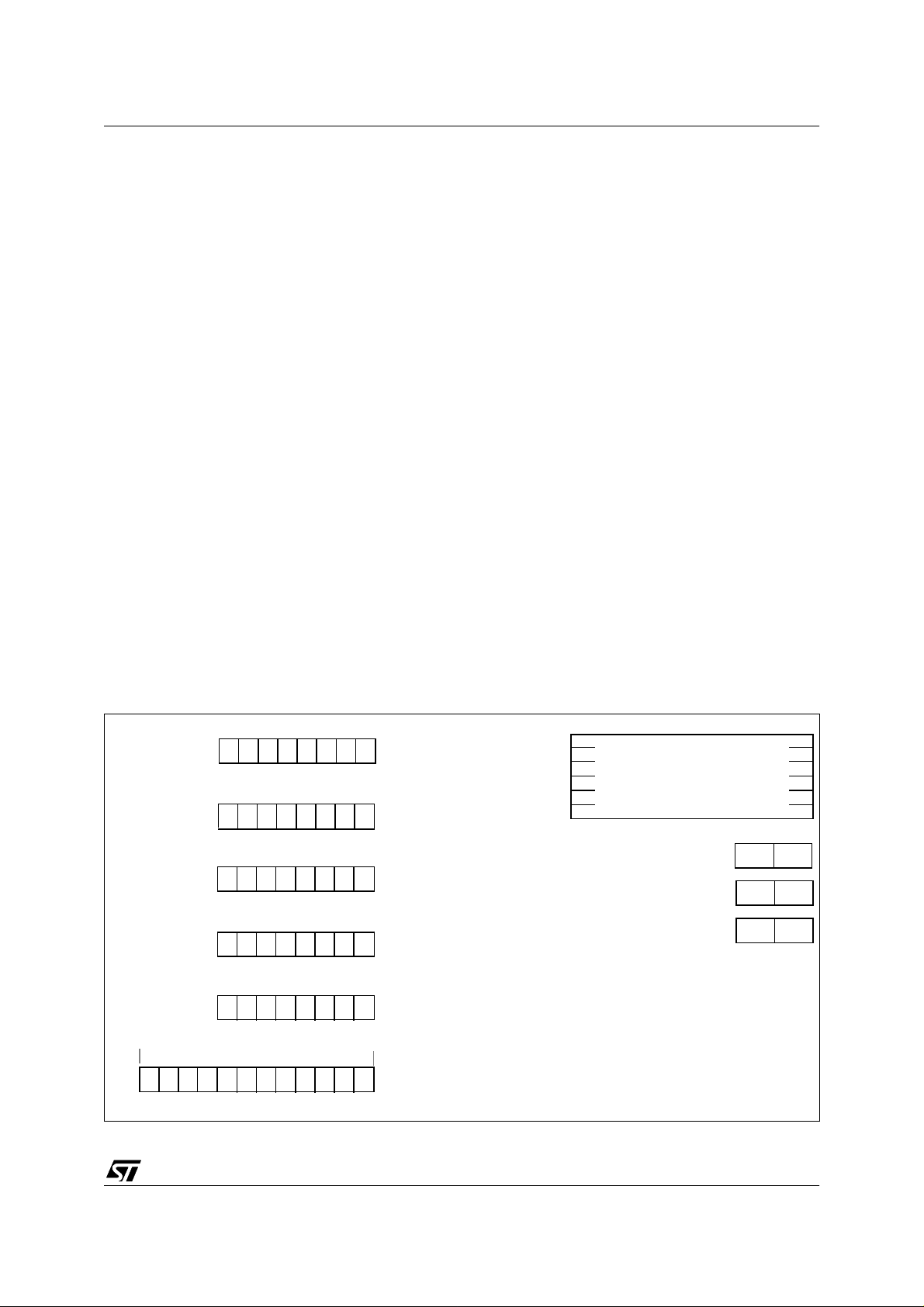

Figure 4. Program Memory Map

ST6215C ST6225C

0000h

NOT IMPLEMENTED

07FFh

0800h

RESERVED

087Fh

0880h

USER

PROGRAM MEMORY

1824 BYTES

*

0000h

07Fh

080h

RESERVED

*

USER

PROGRAM ME M OR Y

3872 BYTES

0F9Fh

0FA0h

0FEFh

0FF0h

0FF7h

0FF8h

0FFBh

0FFCh

0FFDh

0FFEh

0FFFh

RESERVED

INTE RR U PT VECTOR S

RESERVED

NMI VECTOR

USER RESET VECTOR

*

*

(*) Reserved areas should be filled with 0FFh

0F9Fh

0FA0h

0FEFh

0FF0h

0FF7h

0FF8h

0FFBh

0FFCh

0FFDh

0FFEh

0FFFh

RESERVED

*

INTERRUPT VECTORS

RESERVED

*

NMI VECTOR

USER RESET VECTOR

10/105

1

MEMORY MAP (Cont’d)

3.1.2 Program Space

Program Space comprises the instructions to b e

executed, the data required for immediate addressing mode instructions, the reserved factory

test area and the user v ectors. Program Space is

addressed via the 12-bit Program Counter register

(PC register). Thus, the MCU is capable of addressing 4K bytes of memory directly.

3.1.3 Readout Protection

The Program Mem ory i n O TP or E P ROM devices

can be protected against external readout of memory by setting the Readout Protection bit in the opti on byte (Section 3.3 on page 16).

In the EPROM parts, Readout Protection option

can be desactivated only by U.V. erasure that also

results in the whole EPROM context being erased.

Note: Once the Readout Protection is activated, it

is no longer possible, even for STMicroelectronics,

to gain access to the OTP contents. Returned

parts can therefore not be accepted if the Readout

Protection bit is set.

3.1.4 Data Space

Data Space accommodates all the data necessary

for processing the user program. This space comprises the RAM resource, the proc essor core an d

peripheral registers, as well as read-only data

ST6215C/ST6225C

such as constants and look-up tables in OTP/

EPROM.

3.1.4.1 Data ROM

All read-only data is physically stored in program

memory, which also accommodates the Program

Space. The program m emory consequently contains the program code to be executed, as well as

the constants and look-up tables required by t he

application.

The Data Space locations in which the different

constants and look-up tables are addressed by the

processor core may be thought of as a 64-byte

window through which it is possible to acc ess the

read-only data stored in OTP/EPROM.

3.1.4.2 Data RAM

The data space includes the user RAM area, the

accumulator (A), the indirect registers (X), (Y), the

short direct registers (V), (W), the I/O port registers, the peripheral data and control registers, the

interrupt option register and the Data ROM Window register (DRWR register).

3.1.5 Stack Space

Stack space consists of six 12-bit registers which

are used to stack subroutine and interrupt return

addresses, as well as the current program counter

contents.

11/105

1

ST6215C/ST6225C

MEMORY MAP (Cont’d)

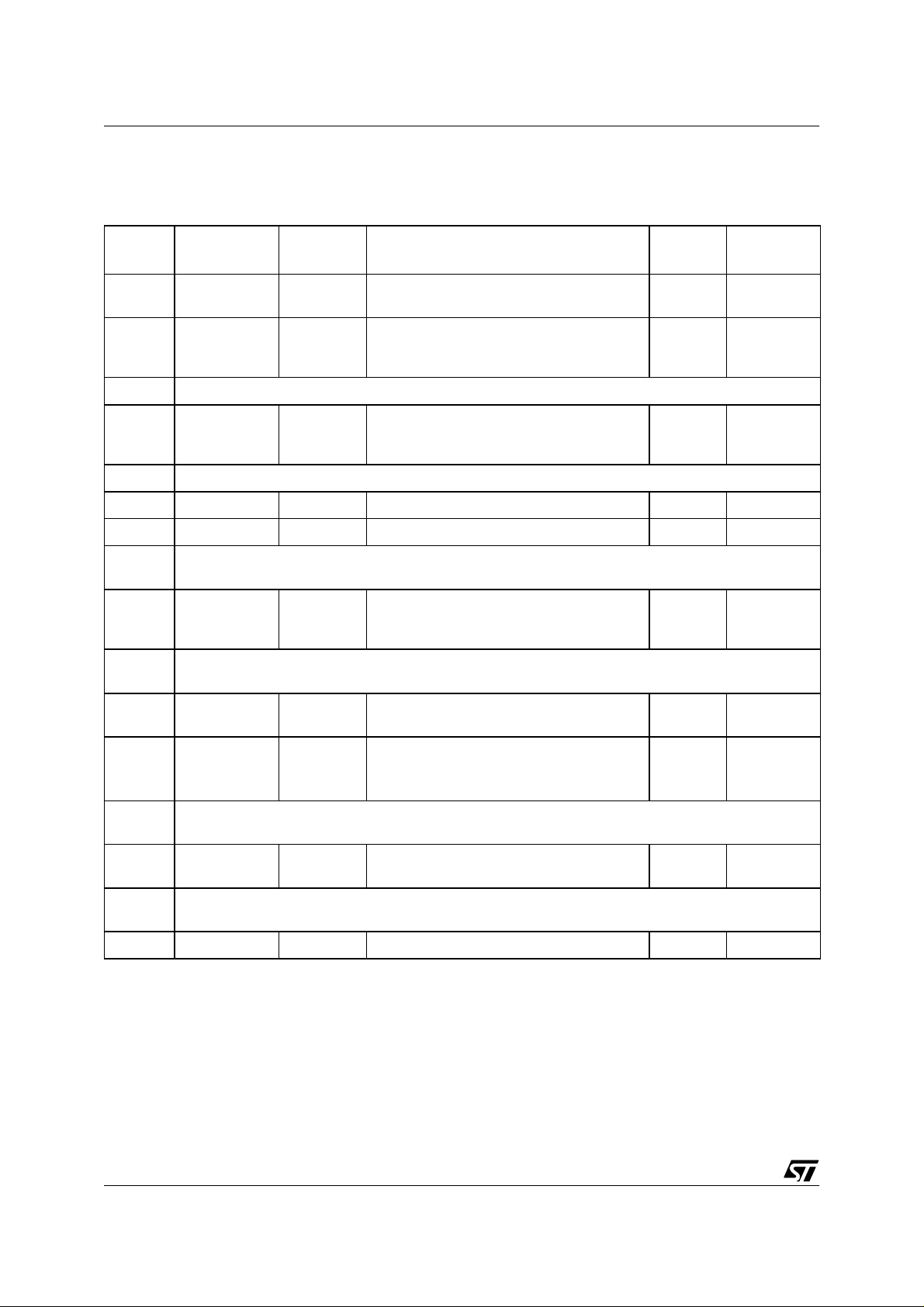

Table 2. Hardware Register Map

Address Block

080h

to 083h

0C0h

0C1h

0C2h

0C3h Reserved (1 Byte)

0C4h

0C5h

0C6h

0C7h Reserved (1 Byte)

0C8h CPU IOR Interrupt Option Register xxh Write-only

0C9h ROM DRWR Data ROM Window register xxh Write-only

0CAh

0CBh

0CCh

0CDh

0CEh

0CFh Reserved (1 byte)

CPU X,Y,V,W

I/O Ports

I/O Ports

I/O Ports

Register

Label

1) 2) 3)

DRA

1) 2) 3)

DRB

1) 2) 3)

DRC

DDRA

DDRB

DDRC

2)

ORA

2)

ORB

2)

ORC

2)

X,Y index registers

V,W short direct registers

Port A Data Register

Port B Data Register

Port C Data Register

Port A Direction Register

2)

Port B Direction Register

2)

Port C Direction Register

Port A Option Register

Port B Option Register

Port C Option Register

Register Name

Reserved (2 Bytes)

Reset

Status

xxh R/W

00h

00h

00h

00h

00h

00h

00h

00h

00h

Remarks

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

0D0h

0D1h

0D2h

0D3h

0D4h

0D5h

to 0D7h

0D8h

0D9h

to 0FEh

0FFh CPU A Accumulator xxh R/W

ADC

Timer1

Watchdog

Timer

ADR

ADCR

PSCR

TCR

TSCR

WDGR Watchdog Register 0FEh R/W

A/D Converter Data Register

A/D Converter Control Register

Timer 1 Prescaler Register

Timer 1 Counter Register

Timer 1 Status Control Register

Reserved (3 Bytes)

Reserved (38 Bytes)

xxh

40h

7Fh

0FFh

00h

Read-only

Ro/Wo

R/W

R/W

R/W

Legend:

x = undefined, R/W = Read/Write, Ro = Read-only Bit(s) in the register, Wo = Write-only Bit(s)

in the register.

Notes:

1. The contents of the I/O p ort D R registers are read able only in output configuration. In i nput c onfiguration, the values of the I/O pins are returned instead of the DR register contents.

2. The bits associated with unavailable pins must always be kept at their reset value.

3. Do not use single-bit instructions (SET, RES...) on Port Data Registers if any pin of the port is configured

in input mode (refer to Section 8 "I/O PORTS" on page 38 for more details).

12/105

1

MEMORY MAP (Cont’d)

3.1.6 Data ROM Window Mechanism

The Data read-only memory window is located

from address 0040h to address 007Fh in Data

space. It allows direct reading of 64 consecutive

bytes located anywhere in program memory, between address 0000h and 0FFFh.

There are 64 blocks of 64 bytes in a 4K device:

– Block 0 is related to the address range 0000h to

003Fh.

– Block 1 is related to the address range 0040h to

007Fh.

and so on...

All the program memory can therefore be used to

store either instructions or read-only data. The

Data ROM window can be moved in st eps of 64

bytes along the program memory by writing the

appropriate code in the Data ROM Window Register (DRWR).

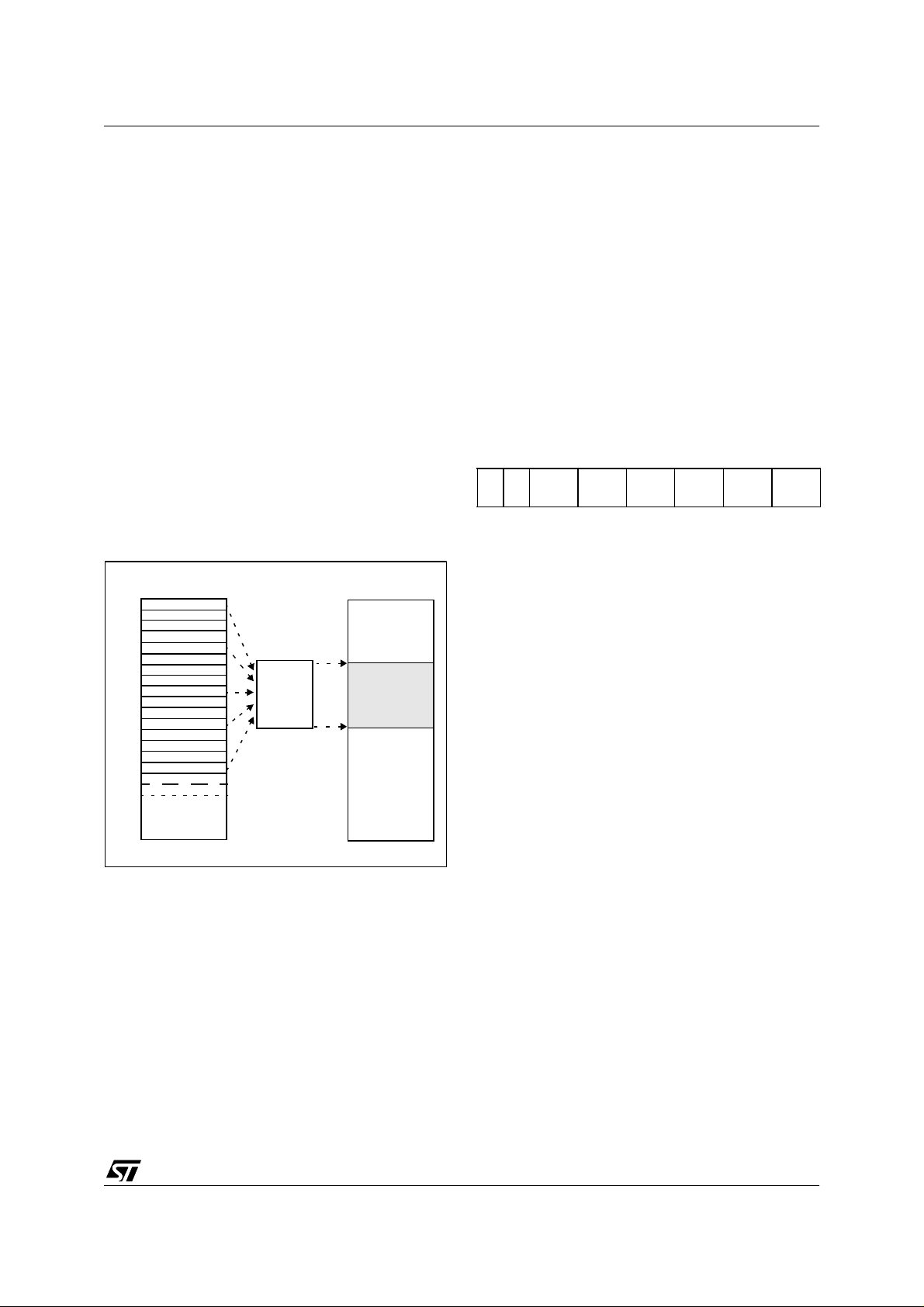

Figure 5. Data R OM Window

0000h

PROGRAM

SPACE

64-BYTE

ROM

DATA SPACE

000h

040h

DATA ROM

07Fh

WINDOW

ST6215C/ST6225C

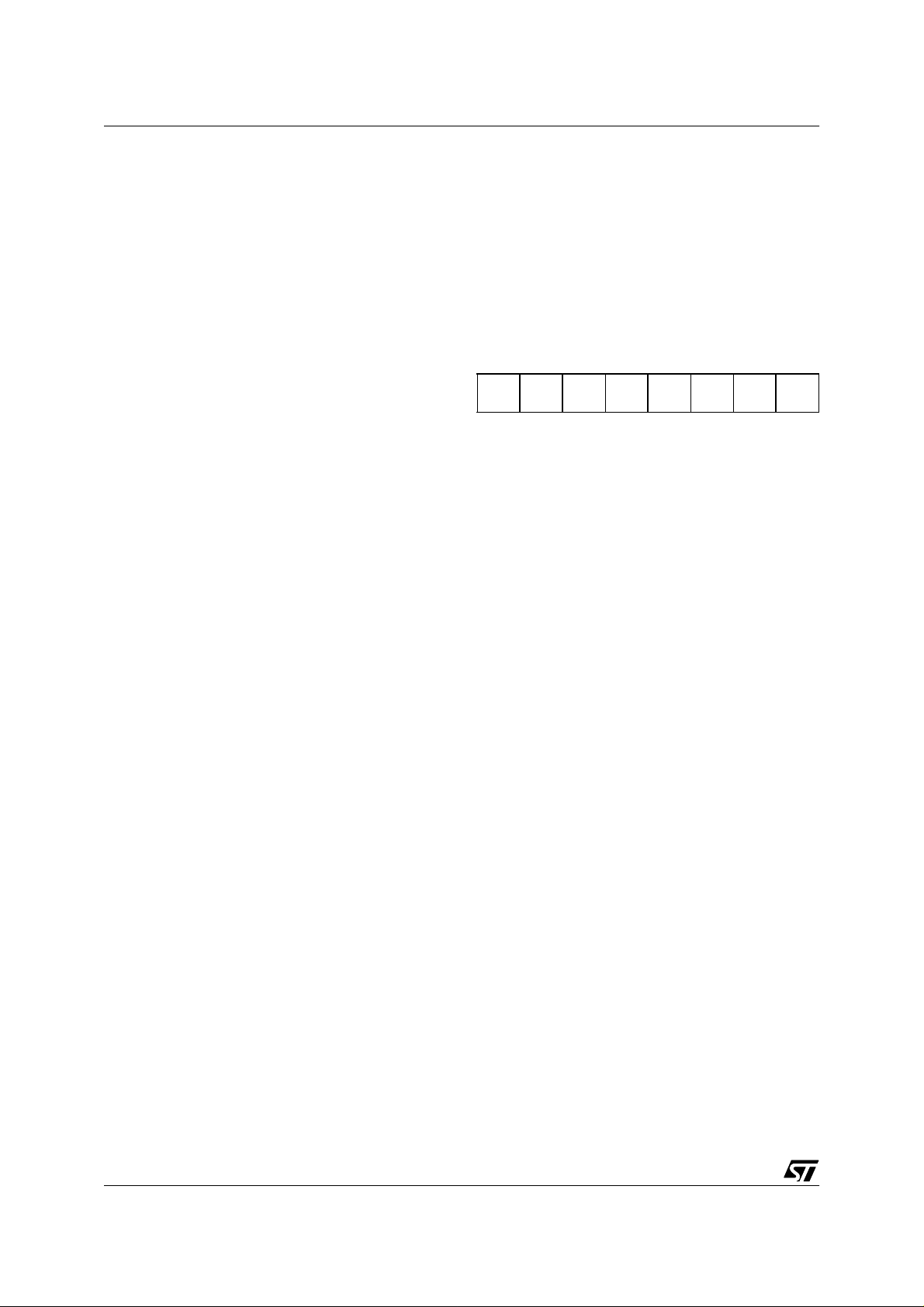

3.1.6.1 Data ROM Window Register (DRWR)

The DRWR can be a ddressed li ke any RAM location in the Data Space.

This register is used to sele ct the 64-byt e blo ck of

program memory to be read in the Data ROM window (from address 40h to address 7Fh in Data

space). The DRWR register is not clea red on reset, therefore it must be written to before accessing the Data read-on ly memory window area for

the first time .

Address: 0C9h — Write Only

Reset Value = xxh (undefined)

70

- - DRWR5 DRWR4 DRWR3 DRWR2 DRWR1 DRWR0

Bits 7:6 = Reserved, must be cleared.

Bits 5:0 = DRWR[5:0]

Window Register Bits.

only memory Window bits that correspond to the

upper bits of the data read-only memory space.

Caution:

This register is undefined on reset, it is

write-only, therefore do not read it nor access it using Read-Modify-Write instructions (SET, RES,

INC and DEC).

Data read-only memory

These are the Data read-

0FFFh

0FFh

13/105

1

ST6215C/ST6225C

MEMORY MAP (Cont’d)

3.1.6.2 Data ROM Window memory addressing

In cases where some data (look-up tables for example) are stored in program memory, reading

these data requires the use of the Data ROM window mechanism. To do this:

1. The DRWR register ha s to be loaded with the

64-byte block number where the data are located

(in program memory). This number also gives the

start address of the block.

2. Then, the offset address of the byte in th e Data

ROM Window (corresponding to the offset in the

64-byte block in program memory) has to be loaded in a register (A, X,...).

When the above two steps are completed, the

data can be read.

To understand how to determine the DRWR and

the content of th e register, please refer to t he example shown in Figure 6. I n any c ase t he c alcul a-

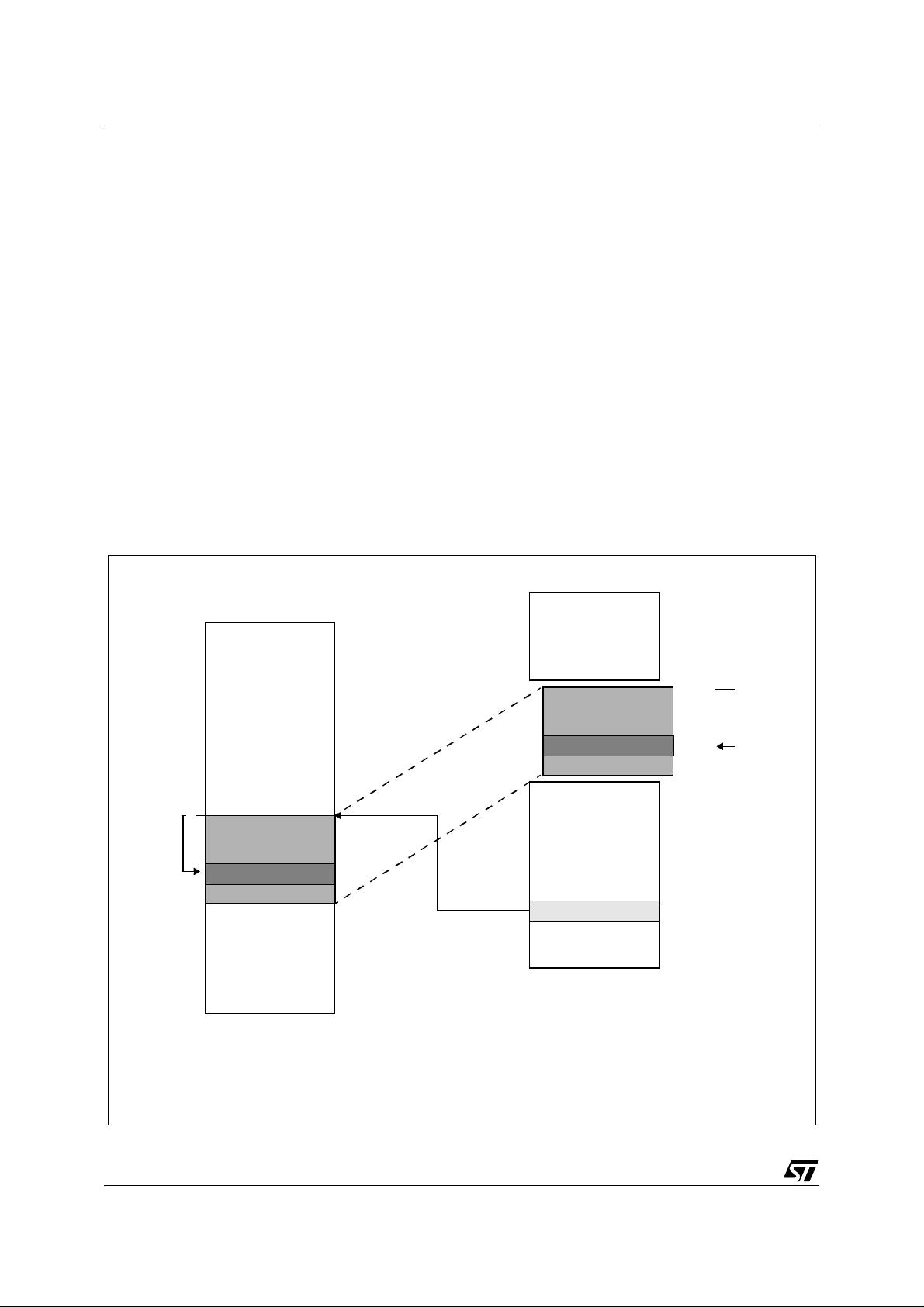

Figure 6. Data read-only memory Window Memo ry Add ressi ng

tion is automatically hand led by the ST6 deve lopment tools.

Please refer to the user manual of the corres poding tool.

3.1.6.3 Recommendations

Care is required when handling the DRWR register as it is write only. For this reason, the DRWR

contents should not be chan ged while executing

an interrupt service routine, as the service routine

cannot save and then restore the register’s previous contents. If it is imp ossible to avoi d writing to

the DRWR during the interrupt service routine, an

image of the register must be saved in a RAM location, and each time the program writes to the

DRWR, it must also write to the image register.

The image register must be written first so that, if

an interrupt occurs between the two instructions,

the DRWR is not affected.

0000h

0400h

OFFSET

0421h

07FFh

PROGRAM SPACE

64 bytes

DATA

DATA SPACE

DATA

10h

000h

040h

061h

07Fh

DRWR

0FFh

OFFSET

21h

DATA address in Program memory : 421h

DRWR content : 421h / 3Fh (64) = 10H data is located in 64-bytes window number 10h

64-byte window start address : 10h x 3Fh = 400h

Register (A, X,...)content : Offset = (421h - 400h) + 40h ( Data ROM Window start address in data space) = 61h

14/105

1

3.2 PROGRAMMING MODES

ST6215C/ST6225C

3.2.1 Program Memory

EPROM/OTP programming mode is set by a

+12.5V voltage a pplied to the T EST/V

pin. The

PP

programming flow of the ST62T15C,T25C/E25C is

described in the User Manual of the EPROM Programming Board.

Table 3. ST6215C Program Memo ry M ap

Device Address Description

0000h-087F h

0880h-0F9F h

0FA0h-0FEF h

0FF0h-0FF7 h

0FF8h-0FFB h

0FFCh-0FFD h

0FFEh-0FFF h

Reserved

User ROM

Reserved

Interrupt Vectors

Reserved

NMI Interrupt Vector

Reset Vector

Table 4. ST6225C Program Memo ry M ap

Device Address Description

0000h-007F h

0080h-0F9F h

0FA0h-0FEF h

0FF0h-0FF7 h

0FF8h-0FFB h

0FFCh-0FFD h

0FFEh-0FFF h

Reserved

User ROM

Reserved

Interrupt Vectors

Reserved

NMI Interrupt Vector

Reset Vector

Note: OTP/EPROM devices can be programm ed

with the development tools available from

STMicroelectronics (please refer to Section 13 on

page 100).

3.2.2 EPROM Erasing

The EPROM devices can be erased by exposure

to Ultra Violet light. The characteristics of the MCU

are such that erasure begins when the memory is

exposed to light with a wave lengths shorter than

approximately 4000Å. It should be noted that sunlight and some types of fluorescent lamps have

wavelengths in the range 3000-4000Å.

It is thus recommended that the window of the

MCU packages be covered by an opaque label to

prevent unintentional erasure problems when testing the application in such an environment.

The recommended erasure procedure is exposure

to short wave u ltraviolet light whi ch have a wavelength 2537Å. The integrated dose (i.e. U.V. intensity x exposure time) for erasure should be a minimum of 30W-sec/cm

dosage is approximately 30 to 40 minutes using an

ultraviolet lamp with 12000µW/cm

2

. The erasure time with this

2

power rating.

The EPROM device should be placed within

2.5cm (1inch) of the lamp tubes during erasure.

15/105

1

ST6215C/ST6225C

3.3 OPTION BYTES

Each device is available for production in user programmable versions (OTP) as well as in factory

coded versions (ROM). O TP d evices are shippe d

to customers with a default content (00h), while

ROM factory coded parts contain the code supplied by the customer. This implies that OTP devices have to be configured by the customer using

the Option Bytes while the ROM devices are factory-configured.

The two option b ytes allow t he hardware configuration of the microcontroller to be selected.

The option bytes have no address in the memory

map and can be accessed only in programming

mode (for example using a standard ST6 programming tool).

In masked ROM devices, the option bytes are

fixed in hardware by the ROM code (see Section

12.6.2 "ROM Versio n" on page 98 ). It is therefore

impossible to read the option bytes.

The option bytes can be only programmed once. It

is not possible to change the selected options after

they have been programmed.

In order to reach the power consumption value indicated in Section 11.4, the option byte must be

programmed to its default value. Otherwise, an

over-consumption will occur.

MSB OPTION BY TE

Bits 15:10 = Reserved, must be always cleared.

0: Low Voltage Detector disabled

1: Low Voltage Detector enabled.

LSB OPTION BYTE

Bit 7 = PROTECT

Readout Protection.

This option bit enables or disables external access

to the internal program memory.

0: Program memory not read-out protected

1: Program memory read-out protected

Bit 6 = OSC

Oscillator s elec tion

.

This option bit selects the main oscillator type.

0: Quartz crystal, ceramic resonator or external

clock

1: RC network

Bits 5:4 = Reserved, must be always cleared.

Bit 3 = NMI PULL

NMI Pull-Up

on/off.

This option bit enables or disables the internal pullup on the NMI pin.

0: Pull-up disabled

1: Pull-up enabled

Bit 2 = TIM PULL

TIMER Pull-Up

on/off.

This option bit enables or disables the internal pullup on the TIMER pin.

0: Pull-up disabled

1: Pull-up enabled

Bit 9 = EXTCNTL

External STO P MO DE control.

0: EXTCNTL mode not available. STOP mode is

not available with the watchdog active.

1: EXTCNTL mode available. STOP mode is avail-

able with the watchdog active by setting NMI pin

to one.

Bit 8 = LVD

Low Voltage Detector

on/off

.

This option bit enable or disable the Low Voltage

Dete ctor (LVD ) feature.

MSB OPTION BYTE

15 8

EXT

CTL

Default

Value

16/105

Reserved

XXXXXXXXXXXXX X X X

Bit 1 = WDACT

Hardware or software watchdog.

This option bit selects the watchdog type.

0: Software (watchdog to be enabled by software)

1: Hardware (watchdog always enabled)

Bit 0 = OSGEN

Oscillator Safeguard

on/off.

This option bit enables or disables the oscillator

Safeguard (OSG) feature.

0: Oscillator Safeguard disabled

1: Oscillator Safeguard enabled

LSB OPTION BYTE

70

LVD

PRO-

OSC Res. Res.

TECT

NMI

PULL

TIM

PULLWDACT

OSG

EN

1

4 CENTRAL PROCE SSI NG UNIT

ST6215C/ST6225C

4.1 INTRODUCTION

The CPU Core of ST6 devices is independent of the

I/O or Memory conf iguration. As such, it may b e

thought of as an independent central processor

communicating with on-chip I/O, Memory and Peripherals via internal address, data, and control

buses.

4.2 MAIN FEATURES

■ 40 basic instructions

■ 9 main addressing modes

■ Two 8-bit index registers

■ Two 8-bit short direct registers

■ Low power modes

■ Maskable hardware interrupts

■ 6-level hardware stack

4.3 CPU REGISTERS

The ST6 Family CPU core features six registers and

three pairs of flags available to the programmer.

These are described in the following paragraphs.

Accumulator (A). The accumulator is an 8-bit

general purpose register used in all arithmetic calculations, logical operations, and data manipula-

tions. The accumulator can be addressed i n Data

Space as a RAM lo cation at address FFh. Thus

the ST6 can manipulate the accumulator just like

any other register in Data Space.

Index Registers (X, Y). Th ese two registers are

used in Indirect addressing mode as pointers to

memory locations in Data Space. They can also

be accessed in Direct, Short Direct, or Bi t Direct

addressing modes. They are mapped in Data

Space at addresses 80h (X ) and 81h (Y) an d can

be accessed like any other memory location.

Short Direct Registers (V, W). These two registers are used in Short Direct addressing mode.

This means that the data stored in V or W can be

accessed with a one-byte instruction (four CPU cycles). V and W can also be accessed using Di rect

and Bit Direct addressing modes. They are

mapped in Data Space at addresses 82h (V) and

83h (W) and can be accessed like any other memory location.

Note: The X and Y registers can also be used as

Short Direct registers in the same way as V and W.

Program Counter (PC). The program counter is a

12-bit register which cont ains the address of the

next instruction to be executed by the c ore. This

ROM location may be an opc ode, an operand, or

the address of an operand.

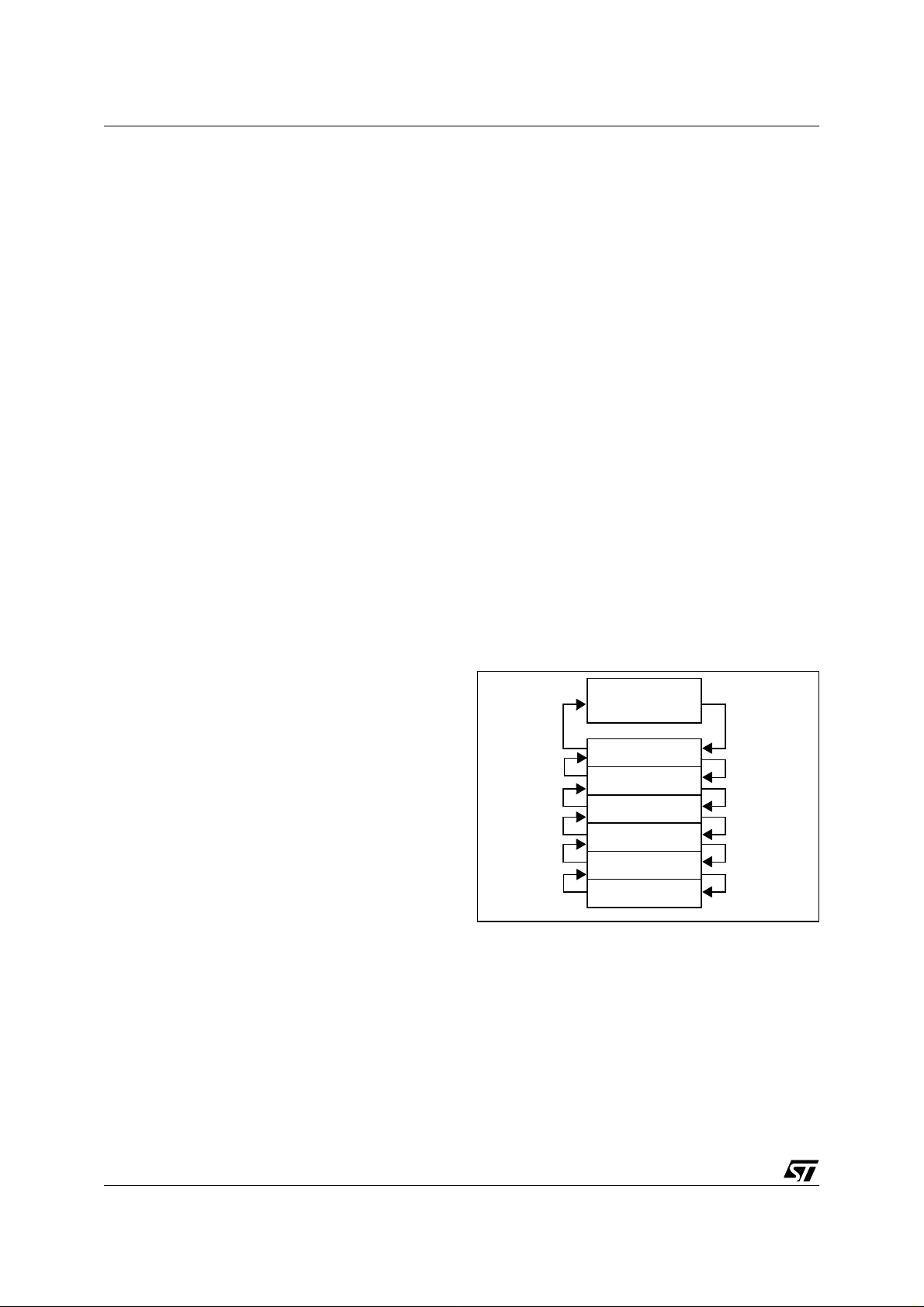

Figure 7. CPU Registers

70

ACCUMULA T OR

RESET VALUE = xxh

70

X INDEX REGISTER

RESET VALUE = xxh

70

Y INDEX REGISTER

RESET VALUE = xxh

70

RESET VALUE = xxh

70

RESET VALUE = xxh

11

RESET VALUE = RESET VECTOR @ 0FFEh-0FFFh

V SHORT INDIRECT

W SHORT INDIRECT

0

PROGRAM COUNTER

REGISTER

REGISTER

SIX LEVEL

STACK

NORMAL FLAGS

INTERRUPT FLAGS

NMI FLAGS

CN ZN

CI ZI

CNMI ZNMI

x = Undefined value

17/105

1

ST6215C/ST6225C

CPU REGISTERS (Cont’d)

The 12-bit length allows the direct addressing of

4096 bytes in Program Space.

However, if the program space contains more than

4096 bytes, the additional memory in program

space can be addressed by using the Program

ROM Page register.

The PC value is incremented after reading the address of the current instruction. To execute relative

jumps, the PC and the offset are shifted through

the ALU, where they are added; the result is then

shifted back into the PC. The program counter can

be changed in the following ways:

– JP (Jump) instruction PC = Jump address

– CALL instruction PC = Call address

– Relative Branch InstructionPC = PC +/- offset

– Interrupt PC = Interrupt vector

– Reset PC = Reset vector

– RET & RETI instructions PC = Pop (stack)

– Normal instruction PC = PC + 1

Flags (C, Z). The ST6 CPU includes three pairs of

flags (Carry and Zero), each pair being associated

with one of the three normal modes of operation:

Normal mode, Interrupt mode and Non Maskabl e

Interrupt mode. Each pair consists of a CARRY

flag and a ZERO flag. One pair (CN, ZN) is u sed

during Normal operation, another pair is used during Interrupt mode (CI, ZI), and a third pair is used

in the Non Maskable Interrupt m ode (CNMI, ZNMI).

The ST6 CPU uses the pair of flags associated

with the current mode: as soon as an interrupt (or

a Non Maskable I nterrupt) is generated, the ST 6

CPU uses the Interrupt flags (or the NMI flag s) instead of the Normal flags. When the RETI instruction is executed, the previously used set of flags is

restored. It should be noted that ea ch flag s et can

only be addressed in its own context (Non Maskable Interrupt, Normal Interrupt or Main routine).

The flags are not cleared during context swi tching

and thus retain their status.

C : Carry flag.

This bit is set when a carry or a borrow occurs dur-

ing arithmetic operations; otherwise it is cleared.

The Carry flag is also set to the val ue of the bit

tested in a bit test instruction; it also participates in

the rotate left instruction.

0: No carry has occured

1: A carry has occured

Z : Zero flag

This flag is set if the result of the last arithmetic or

logical operation was equal to zero; otherwise it is

cleared.

0: The result of the last operation is different from

zero

1: The result of the last operation is zero

Switching between the three sets of flags is per-

formed automatically when an NMI, an interrupt or

a RETI instruction occurs. As NMI mode is automatically selected after the reset of the MCU, the

ST6 core uses the NMI flags first.

Stack. The ST6 CPU includes a true LIFO (Last In

First Out) hardware stack which eliminates the

need for a stack pointer. The stack consists of six

separate 12-bit RAM locations that do not belong

to the data space RAM area. When a subroutine

call (or interrupt request) oc curs, the contents of

each level are shifted into the next level down,

while the content of the PC is shifted into the first

level (the original contents of the sixth stack level

are lost). When a subroutine or interrupt return occurs (RET or RETI instructions), the first level register is shifted back into the PC and the value of

each level is popped back into the previous level.

Figure 8. Stack manipulation

PROGRAM

COUNTER

ON RETURN

FROM

INTERRUPT,

OR

SUBROUTINE

LEVEL 1

LEVEL 2

LEVEL 3

LEVEL 4

LEVEL 5

LEVEL 6

ON

INTERRUPT,

OR

SUBROUTINE

CALL

Since the accumulator, in common with all other

data space registers, is not stored in this stack,

management of these registers should be performed within the subroutine.

Caution: The stack will remain in its “deepest” position if more than 6 nested calls or interrupts are

executed, and consequently the last return address will be lost.

It will also remain in its highest position if the stack

is empty and a RET or RETI is executed. In this

case the nex t in s truc t io n w ill be ex e c ut e d.

18/105

1

5 CLOCKS, SUPPLY AND RESET

5.1 CLOCK SYSTEM

ST6215C/ST6225C

The main oscillator of the MCU can be driven by

any of these cl ock sourc es:

– external clock signal

– external AT-cut parallel-resonant crystal

– external ceramic resonator

– external RC network (R

NET

).

In addition, an on-chip Low Frequency Auxiliary

Oscillator (LFAO) is available as a back-up c lock

system or to reduce power consumption.

An optional Oscillator Safeguard (OSG) filters

spikes from the oscillator lines, and switches to the

LFAO backup oscillator in t he event of m ain oscillator failure. It also automatically limits the internal

clock frequency (f

) as a function of VDD, in order

INT

to guarantee correct operation. These functions

are illustrated in Figure 10, and F igure 11.

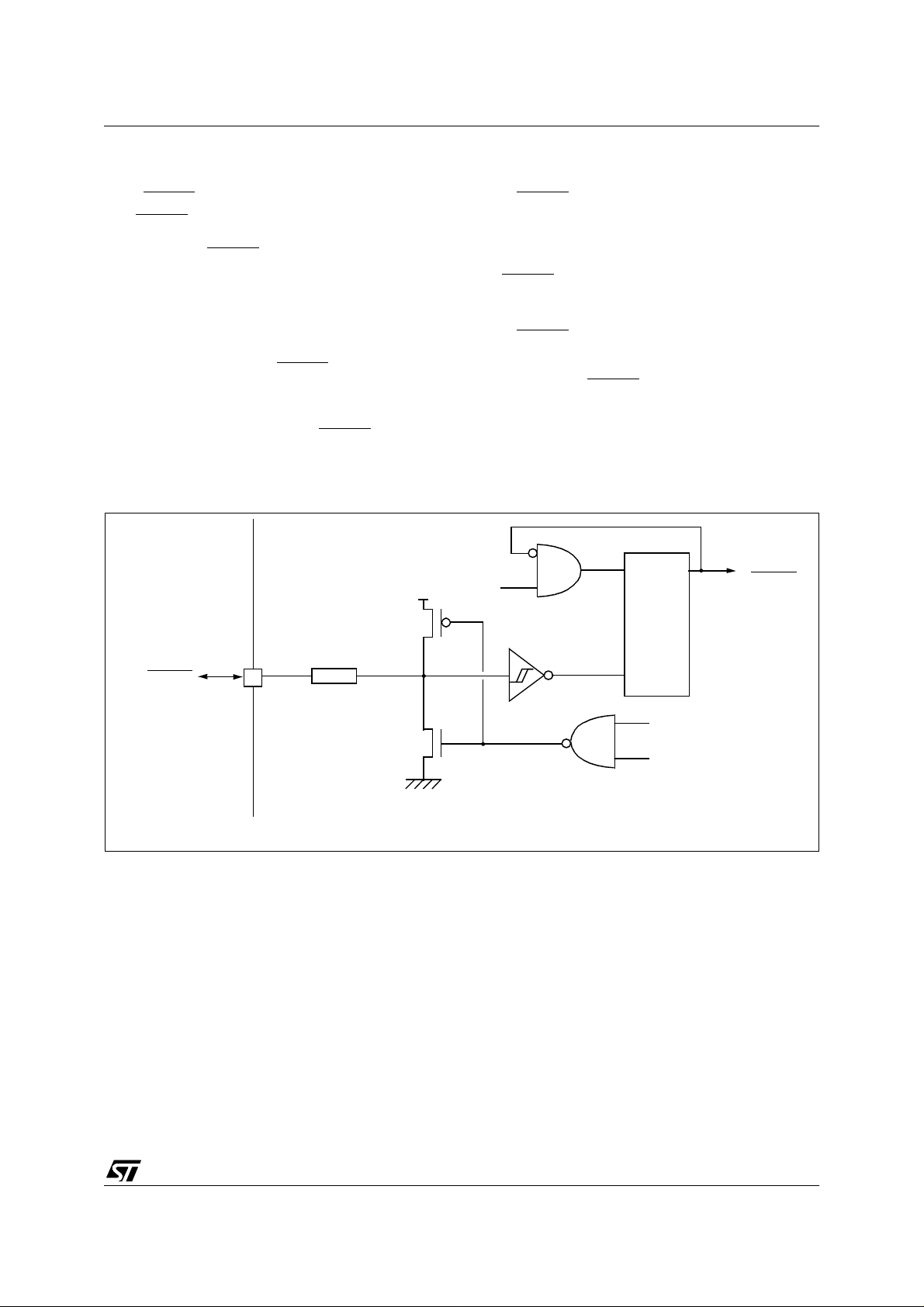

Figure 9. Clock Circuit Block Diagram

OSCILLATOR SAFEGUA RD (OSG)

f

OSC

OSG

filtering

Table 5 illustrat es var ious poss ible os cillator c on-

figurations using an external crystal or ceramic

resonator, an external clock input, an external resistor (R

), or the lowest cost solution using only

NET

the LFAO.

For more details on c onfiguring the c lock options,

refer to the Option Bytes section of this document.

The internal MCU clock frequency (f

) is divided

INT

by 12 to drive the T imer, the Wat chdog timer and

the A/D converter, by 13 to drive the CPU core and

the SPI and by 1 or 3 to drive the ARTIMER, as

shown in Figure 9.

With an 8 M Hz o s c illat o r, the fastes t CP U cycle is

therefore 1.625µs.

A CPU cycle is the smallest unit of time needed to

execute any operation (f or instance, to increment

the Program Counter). An instruction may require

two, four, or five CPU cycles for execution.

:

13

SPI

CORE

8-BIT TIMER

MAIN

OSCILLATOR

0

1

LFAO

OSCOFF BIT

(ADCR REGISTER)

OSG ENABLE OPTION BIT (See OPTION BYTE SECTION)

Oscillator

Divider

f

INT

:

12

: 1

: 3

WATCHDOG

ADC

8-BIT ARTIMER

8-BIT ARTIMER

19/105

1

ST6215C/ST6225C

CLOCK SYSTEM (Cont’d)

5.1.1 Main Oscillator

The oscillator configuration is specified by selecting the appropriate option in the option bytes (refer

to the Option Bytes section of this document).

When the CRYSTAL/RESONATOR option is selected, it must be used with a quartz crystal, a ceramic resonator or an external signal provided on

the OSCin pin. When the RC NETWORK option is

selected, the system clock is generated by an external resistor (the capacitor is imple men ted internally).

The main oscillator can be turned off (when the

OSG ENABLED option is selected) by setting the

OSCOFF bit of the ADC Control Register (not

available on some devices). This will automatically

start the Low Frequency Auxiliary Oscillator

(LFAO).

The main oscillator can be turned off by resetting

the OSCOFF bit of the A/D Converter Control Register or by resetting the MCU. When the main oscillator starts there is a delay made up of the oscillator start-up delay period plus the duration of the

software instruction at a clock frequency f

Caution: It should be noted that when t he RC network option is selected, the accuracy of the frequency is about 20% so it may not be suitable for

some applications (For more details, please refer

to the Electrical Characteristics Section).

LFAO

.

Table 5. Oscillator Configurations

Hardware Configuration

1)

Crystal/Resonator Option

1)

C

Crystal/Resonator Option

1)

External Clock

OSCin OSCout

EXTERNAL

CLOCK

Crystal/Resonator Clock

OSCin OSCout

L1

OSCin OSCout

ST6

ST6

LOAD

CAPACITORS

RC Network

ST6

NC

3)

2)

C

L2

NC

R

NET

RC Network Option

1)

OSG Enabled Option

Notes:

1. To select the options sho wn in column 1 of the abo ve

table, refer to the Option Byte section.

2.This schematic are given for guidance only and are subject to the schematics given by the crystal or ceramic resonator manufacturer.

3. For more details, plea se refer to the Electric al Char acteristics Section.

LFAO

ST6

OSCin OSCout

NC

20/105

1

CLOCK SYSTEM (Cont’d)

5.1.2 Oscillator Safeguard (OSG)

The Oscillator Safeguard (OSG) feature is a

means of dramatically improving the operational

integrity of the MCU. It is available when the OSG

ENABLED option is selected in the option byte (refer to the Option Bytes section of this document).

The OSG acts as a filter whose cross-over frequency is device dependent and provides three

basic functions:

– F iltering spikes o n the os c illator lines whic h

would result in driving the CPU at excessive frequencies

– M anag ement of the Low Frequency Auxiliar y

Oscillator (LFAO), (useable as low cost internal

clock source , backup clock i n ca se of main oscillator failure or for low power consumption)

– Automatically limiting the f

clock frequency as

INT

a function of supply voltage, to ensure correct

operation even if the power supply drops.

5.1.2.1 Spike Filtering

Spikes on the oscillator lines result in an effectively

increased internal clock frequency. In the absence

of an OSG circuit, this may lead to an over frequency for a given power supply voltage. The

OSG filters out such spikes (as illustrated in Figure

10). In all cases, when the OSG is active, the max-

ST6215C/ST6225C

imum internal clock frequency, f

f

, which is supply voltage dependent.

OSG

5.1.2.2 Management of Supply Voltage

Variations

Over-frequency, at a given power supp ly level, is

seen by the OSG as spikes; it therefore filte rs out

some cycles in order that the internal clock frequency of the device is kept within the range t he

particular device can stand (depending o n V

and below f

: the maximum authorised frequen-

OSG

cy with OSG enabled.

5.1.2.3 LFAO Managemen t

When the OSG is enabled, the Low Frequency

Auxiliary Oscillator can be used (see Section

5.1.3).

Note: The OSG should be used wherever possible

as it provides maxim um security for the ap plication. It should be noted however, that it can increase power consumption and reduce the maximum operating frequency to f

Characteristics section).

Caution: Care has to be taken when using the

OSG, as the internal frequency is defined between

a minimum and a maximum value and may vary

depending on both V

and temperature. For pre-

DD

cise timing measurement s, it is not recom men ded

to use the OSG.

, is limited to

INT

(see Electrical

OSG

DD

),

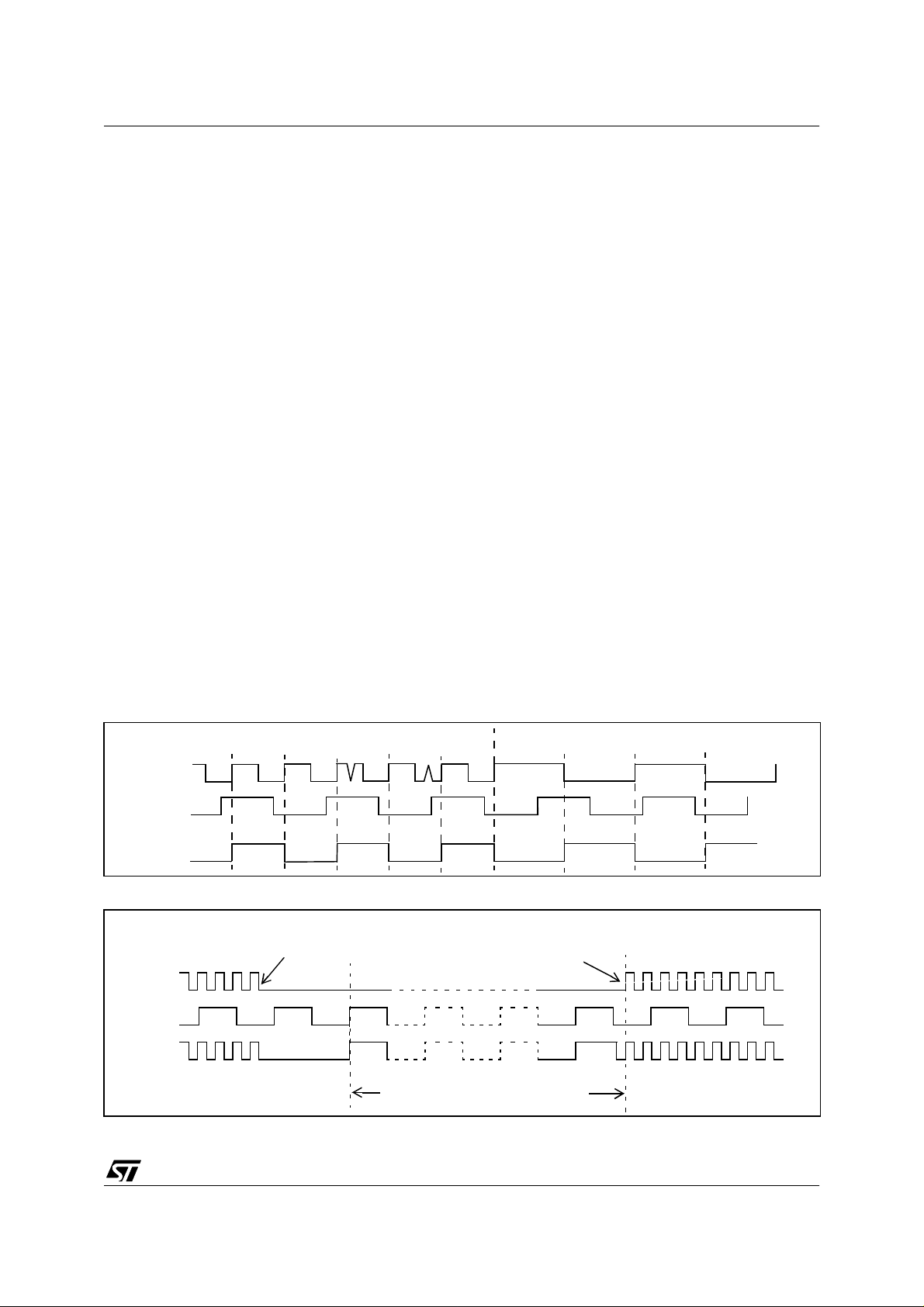

Figure 10. OSG Filtering Function

f

OSC>fOSG

f

OSC

f

OSG

f

INT

Figure 11. LFAO Oscillato r Function

MAIN OSCILLATOR

STOPS

f

OSC

f

LFAO

f

INT

MAIN OSCILLA T OR

RESTARTS

INTERNAL CLOCK DRIVEN BY LFAO

f

OSC<fOSG

21/105

1

ST6215C/ST6225C

CLOCK SYSTEM (Cont’d)

5.1.3 Low Frequency Auxiliary Oscillator

(LFAO)

The Low Frequency Auxiliary Oscillator has three

main purposes. Firstly, it can be used to reduce

power consumption in non timing critical routines.

Secondly, it offers a fully integrated system clock,

without any external components. Lastly, it acts as

a backup oscillator in case of m ain oscillator failure.

This oscillator is available when the OSG ENABLED option is selected in the option byte (refer to

the Option Bytes section of this document). In this

case, it automatically starts one of its periods after

the first missing edge of t he m ain os cillator, whatever the reason for the failure (main oscillator defective, no clock circuit ry prov i ded, m ain o scillat or

switched off...). See Figure 11.

User code, normal interrupts, WAIT and STOP instructions, are processed as normal, at the reduced f

cy is decreased, since the internal frequency is below 1.2 MHz .

At power on, until the main oscillator starts, the reset delay counter is driven by the LFAO. If the

main oscillator starts before the 2048 or 32768 cycle delay has elapsed, it takes over.

frequency. The A/D converter accura-

LFAO

The Low Frequency Auxiliary Oscillator is automatically switched off as soon as the main oscillator starts.

5.1.4 Register Description

ADC CONTROL REGISTER (ADCR)

Address: 0D1h — Read/Write

Reset value: 0100 0000 (40h)

70

ADCR7ADCR6ADCR5ADCR4ADCR3OSC

Bit 7:3, 1:0 = ADCR[7:3], ADCR[1:0]

Register

.

ADCR1ADCR

OFF

ADC Control

0

These bits are used to control the A/D converter (if

available on the device) otherwise they are not

used.

Bit 2 = OSCOFF

Main Oscillator Off.

0: Main oscillator enabled

1: Main oscillator disabled

Note: The OSG must be enabled using the OSGEN option in the Opt ion Byte, otherw ise t he OSCOFF setting has no effect.

22/105

1

5.2 LOW VOLTAGE DETECTOR (LVD)

ST6215C/ST6225C

The on-chip Low Voltage De tector is enabled by

setting a bit in the option bytes (refer to the Option

Bytes section of this document).

The LVD allows the device to be used without any

external RESET circuitry. In this ca se , th e RESET

pin should be left unconnected.

If the LVD is not used, an external circuit is mandatory to ensure correct Power On R eset operation,

see figure in the Reset section. For more details,

please refer to the application note AN669.

The LVD generates a static Reset when the supply

voltage is below a reference value. This means

that it secures the power-up as well as the powerdown keeping the ST6 in reset.

The V

than the V

reference value for a voltage drop is lower

IT-

reference value for power-on in order

IT+

to avoid a parasitic reset when the MCU starts running and sinks current on the supply (hysteresis).

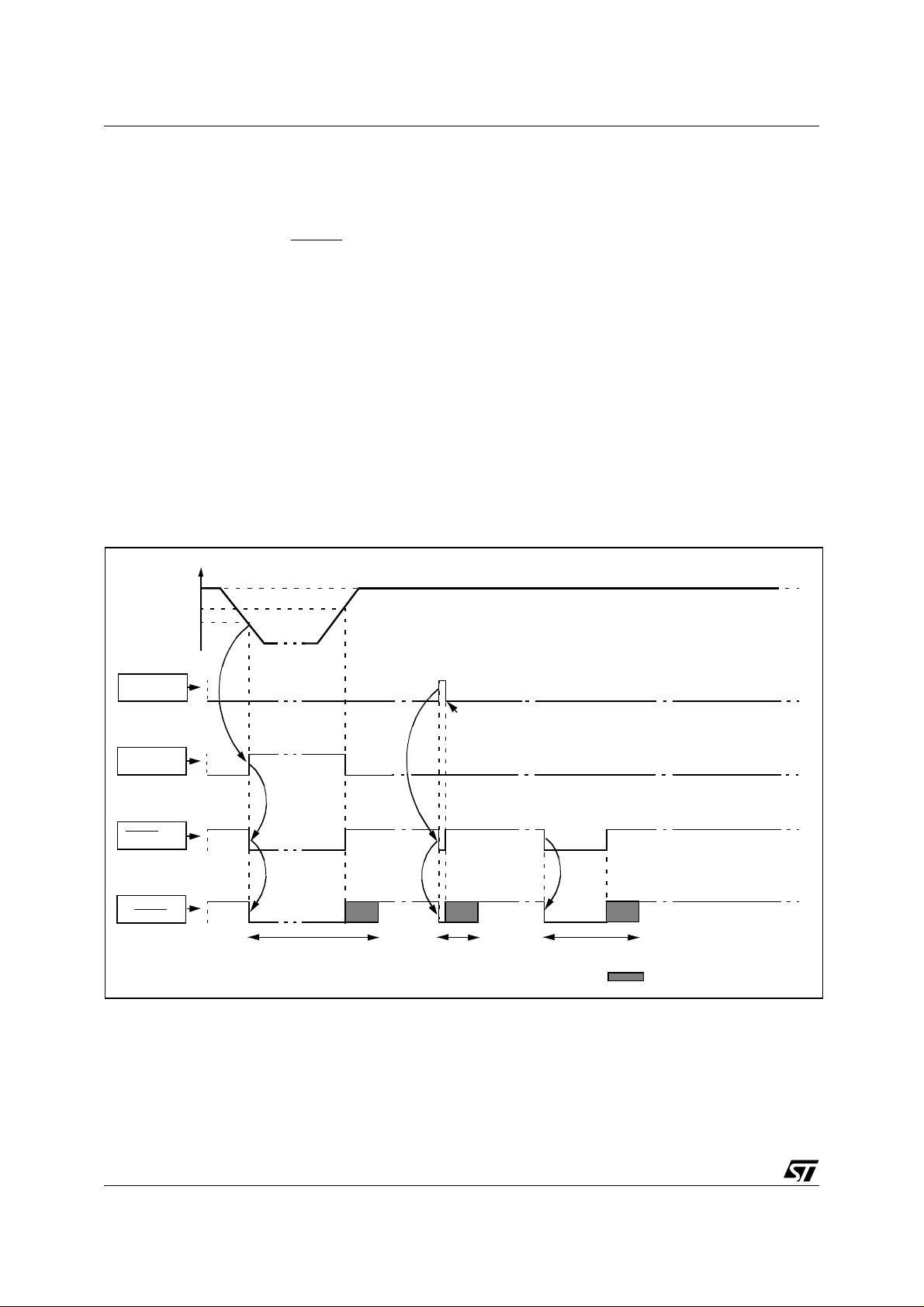

Figure 12. Low Voltage Detector Reset

V

DD

V

IT+

V

IT-

The LVD Reset circuitry gene rates a reset when

is below:

V

DD

– V

when VDD is rising

IT+

when VDD is falling

– V

IT-

The LVD function is illustrated in Figu re 12.

If the LVD is enabled, the MCU can be in only one

of two states:

– Over the input threshold voltage, it is running un-

der full software control

– Below the input threshold voltage, it is in static

safe reset

In these conditions, secure operation is guaranteed without the need for external reset hardware.

During a Low Voltage Detector Reset, the RESET

pin is held low, thus p ermitting the MCU to reset

other devices.

V

hyst

RESET

23/105

1

ST6215C/ST6225C

5.3 RESET

5.3.1 Introd uction

The MCU can be reset in three ways:

■ A low pulse input on the RESET pin

■ Internal Watchdog reset

■ Internal Low Voltage Detector (LVD) reset

5.3.2 RESET Sequence

The basic RESET sequence consists of 3 main

phases:

■ Internal (watchdog or LVD) or external Reset

event

■ A delay of 2048 or 32768 clock (f

) cycles

INT

(selected through the option bytes)

■ RESET vector fetch

The reset delay allows the oscillator to stabilise

and ensures that recovery ha s taken place from

the Reset state.

Figure 13. RESET Sequence

V

DD

V

IT+

V

IT-

The RESET vector fetch phase duration is 2 clock

cycles.

When a reset occurs:

– The stack is cleared

– The PC is loaded with the address of the Reset

vector. It is located in program ROM starting at

address 0FFEh.

A jump to the beginning of the us er program m ust

be coded at this address.

– The interrupt flag is automatically set, so that the

CPU is in Non Maskable Interrupt mode. This

prevents the initialization routine from being interrupted. The initialization routine should therefore be terminated by a RETI instruction, in order

to go back to normal mode.

WATCHDOG

RESET

LVD

RESET

RESET PIN

INTERNAL

RESET

RUN

RESET

WATCHDOG UNDERFLOW

RUN RUN RUN

RESET RESET

2048 CLOCK CYCLE (f

INT

) DELAY

24/105

1

RESET (Cont’d)

5.3.3 RESET

The RESET

Pin

pin may be co nnecte d to a device on

the application board in order to reset the MCU if

required. The RESET

pin may be pulled low in

RUN, WAIT or STOP mode. This input can be

used to reset the internal state of the MCU and ensure it starts-up correctly. The pin, which i s connected to an internal pull-up, is active low and features a Schmitt trigger input. A delay (2048 clock

cycles) added to the external signal ensures that

even short pulses on the RESET

as valid, provided V

has completed its rising

DD

pin are accepted

phase and that the oscillator is running correctly

(normal RUN or WAIT modes). The MCU is kept in

the Reset state as long a s the RESET

pin is held

low.

Figure 14. Reset Block Diagram

ST6215C/ST6225C

If the RESET

RUN or WAIT modes, processing of the user program is stopped (RUN mode only), the I/O ports

are configured as inputs with pull-up resistors and

the main oscillator is restarted. When the level on

the RESET

quence is executed at the end of the internal delay

period.

If the RESET

STOP mode, the oscillator starts up and all the I/O

ports are configured as inputs with pull-up resistors. When the RESET

the initialization sequence is executed at th e end

of the internal delay period.

A simple external RESET circuitry is shown in Fig-

ure 15. For more details, please refer to the appli-

cation note AN669.

pin is grounded while the MCU is in

pin then goes high, the initialization se-

pin is grounded while the MCU is in

pin level then go es high,

V

DD

R

PU

RESET

1) Resistive ESD protection.

2) The reset delay value is selected through the option bytes.

R

ESD

1)

f

IN T

INTERNAL

2)

COUNTER

clock cycles

2048 or 32768

WATCHDOG RESET

LVD RESET

RESET

25/105

1

ST6215C/ST6225C

RESET (Cont’d)

5.3.4 Watchdog Reset

The MCU provides a Wat chdog timer function in

order to be able to recover from software hangups. If the Watchdog register is not refreshed before an end-of-count condition is reached, a

Watchdog reset is generated.

After a Watchdo g reset, the MCU resta rts in the

same way as if a Reset was generated by the RESET pin.

Note: When a watchdog reset occurs, the RESET

pin is tied low for very short time period, to flag the

reset phase. This time is n ot long enough to reset

external circuits.

For more details refer to the Watchdog Timer

chapter.

5.3.5 LVD Reset

Two different RESET sequences caused by the internal LVD circuitry can be distinguished:

■ Power-On RESET

■ Voltage Drop RESET

During an LVD reset, the RESET

when V

DD

<V

(rising edge) or VDD<V

IT+

edge).

For more details, refer to the LVD chapter.

Caution: Do not externally connect directly the

RESET

pin to VDD, this may cause damage to the

component in case of internal RESET (Watchdog

or LVD).

Figure 15. Simple External Reset Circuitry

pin is pulled low

(falling

IT-

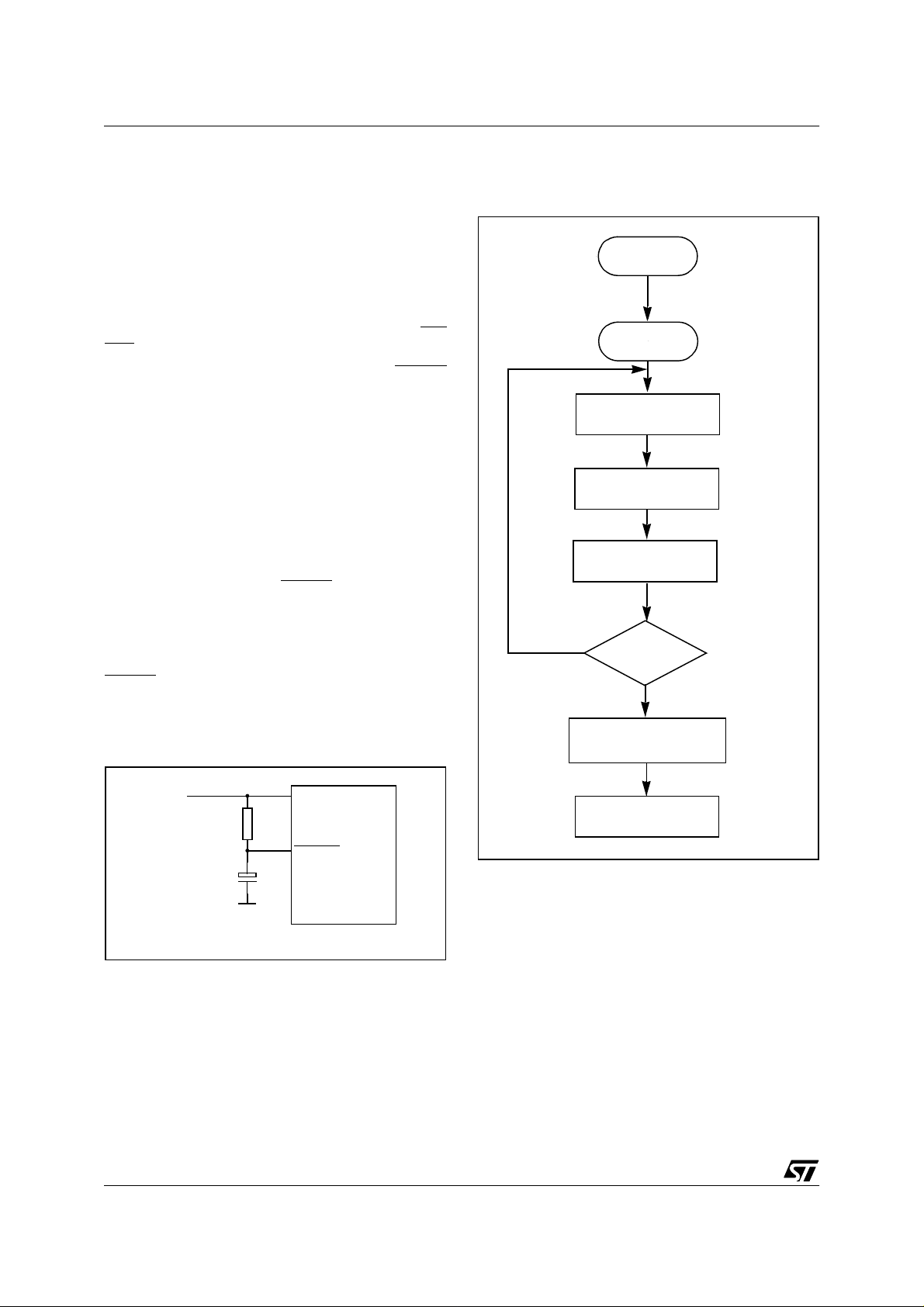

Figure 16. Reset Processing

RESET

2048 OR 327 68

CLOCK CYC LE

INTERNAL

RESET

NMI MASK SET

INT LATCH CLEARED

(IF PRESENT)

SELECT

NMI MODE FLA G S

PUT FFEh

ON ADDRESS BUS

YES

FROM RESET LOCATIONS

IS RESET STILL

PRESENT?

NO

LOAD PC

FFEh/FFFh

DELAY

V

DD

Typical: R = 10K

C = 10nF

26/105

1

V

DD

R

RESET

C

ST62xx

R > 4.7 K

FETCH INSTRUCTION

6 INTE RRUPTS

ST6215C/ST6225C

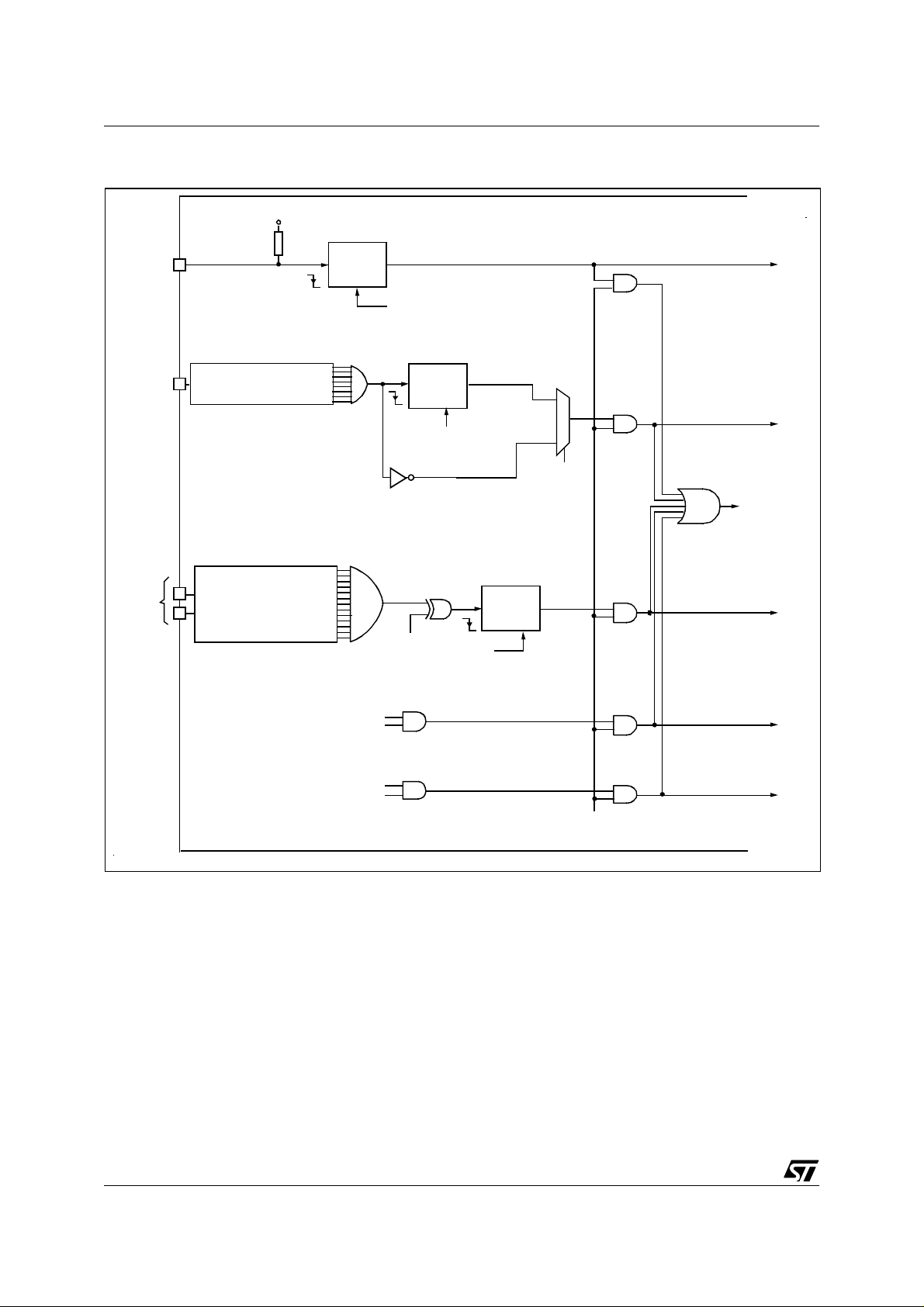

The ST6 core may be interrupted by four maskable interrupt sources, in addition to a Non Maskable Interrupt (NMI) source. The interrupt processing flowchart is shown in Figure 18.

Maskable interrupts must be enabled by setting

the GEN bit in the IOR register. However, even if

they are disabled (GEN bit = 0 ), interrupt events

are latched and may be processed as soon as the

GEN bit is set.

Each source is associated with a specific Interrupt

Vector, located in Program space (see Interrupt

Mapping table). In the vector location, the user

must write a Jump instruction to the associated interrupt service routine.

When an interrupt source generates an i nterrupt

request, the PC register is loaded with the address

of the interrupt vector, which then causes a Jum p

to the relevant interrupt service routine, thus servicing the int e r ru pt.

Interrupts are triggered by events either on external pins, or from the on-chip periphe rals. Several

events can be ORed on the same interrupt vector.

On-chip peripherals have flag registers to determine which event triggered the interrupt.

27/105

1

ST6215C/ST6225C

Figure 17. Interrupts Block Diagram

V

DD

NMI

PA0..PA7

PB0..PB7

PC4..PC7

I/O PORT REGISTER

“INPUT WITH INTER RUP T”

CONFIGURATION

I/O PORT REGISTER

“INPUT WITH INTER RUP T”

CONFIGURATION

LATCH

CLEARED BY H/W

AT START OF VECTOR #0 ROUTINE

CLEARED BY H/W

AT START OF

VECTOR # 1 ROUTINE

(IOR REGISTER)

ESB BIT

LATCH

(IOR REGISTER)

LATCH

CLEARED

BY H/W AT START OF

VECTOR #2 ROUTINE

VECTOR #0

0

VECTOR #1

1

LES BIT

EXIT FROM

STOP/WAIT

VECTOR #2

TIMER

(TSCR REGISTER)

A/D CONVERTER

(ADCR REG I ST ER)

TMZ BIT

ETI BIT

EAI BIT

EOC BIT

VECTOR #3

VECTOR #4

GEN BIT

(IOR REGISTER)

28/105

1

ST6215C/ST6225C

6.1 INTERRUPT RULES AND PRIORITY

MANAGEMENT

■ A Reset can interrupt the NMI and peripheral

interrupt routines

■ The Non Maskable Interrupt request has the

highest priority and can interrupt any peripheral

interrupt routine at any time but cannot interrupt

another NMI interrupt.

■ No peripheral interrupt can in terrupt another. If

more than one interrupt request is pending,

these are processed by the processor core

according to their priority level: vector #1 has the

highest priority while vector #4 the lowest. The

priority of each interrupt source is fixed by

hardware (see Interrupt Mapping table).

6.2 INTERRUPTS AND LOW POWER MODES

All interrupts cause the processor to exit from

WAIT mode. Only the external and som e specific

interrupts from the on-chip peripherals cause the

processor to exit from STOP mode (refer to the

“Exit from STOP“ column in the Interrupt Mapping

Table).

6.3 NON MASKABLE INTERRUPT

This interrupt is t riggered when a fallin g edge occurs on the NMI pin regardless of the state of the

GEN bit in the IOR register. An interrupt request

on NMI vector #0 is latched by a flip flop which is

automatically reset by the core at the beginning of

the NMI service routine.

6.4 PERIPHERAL INTERRUPTS

Different peripheral interrupt flags in the peripheral

control registers are able to cause an interrupt

when they are active if both:

– The GEN bit of the IOR register is set

– The corresponding enable bit is set in the periph-

eral control register.

Peripheral interrupts are linked to vectors #3 and

#4. Interrupt requests are flagged by a bit in their

corresponding control register. This means that a

request cannot be lost, because the flag bit m ust

be cleared by user software.

29/105

1

ST6215C/ST6225C

6.5 EXTERNAL INTERRUPTS (I/O Ports)

External interrupt vectors can be loaded into the

PC register if the corresponding external interrupt

occurred and if the GEN bit is set. These interrupts

allow the processor to exit from STOP mode.

The external interrupt polarity is selected t hrough

the IOR register.

External interrupts are linked to vectors #1 and #

2.

Interrupt requests on vector #1 can be configu red

either as edge or le vel-s ensitive us in g t he LES bit

in the IOR Register.

Interrupt requests from vector #2 are always edge

sensitive. The edge polarity can be configured using the ESB bit in the IOR Register.

In edge-sensitive mode, a latch is set when a edge

occurs on the interrupt source li ne and is cleared

when the associated interrupt routine is started.

So, an interrupt request can be stored until completion of the currently executing interrupt routine,

before being processed. If several interrupt requests occurs before comp let ion o f the cu rrent interrupt routine, only the first request is stored.

Storing of interrupt requests is not possible i n level

sensitive mode. To be taken into account, the lo w

level must be present on the interrupt pin when the

MCU samples the line after instruction execution.

6.5.1 Notes on using External Interrupts

ESB bit Spuri ous Interrupt on Ve c tor # 2

If a pin associated with interrupt vector #2 is configured as interrupt with pull-up, whenever vector

#2 is configured to be rising edge sensitive (by setting th e ESB b it in the I OR register ), a n interrupt i s

latched although a rising edge may not have occured on the associated pin.

This is due to the vector #2 circuitry.The workaround is to discard this first interrupt request in the

routine (using a flag for example).

Masking of One Interrupt by Another on Vector

#2.

When two or more port pins (associated with interrupt vector #2) are configured together as input

with int errupt (falling edge sensitive ), as long as

one pin is stuck at ’0’, the other pin can never generate an interrupt even if an act ive edge occurs at

this pin. The same thin g occurs when one pin is

stuck at ’1’ and interrupt vector #2 is configured as

rising edge sensitive.

To avoid this the f irst pin must input a signal that

goes back up to ’1’ right after the falling edge. Otherwise, in the interrupt rou tine for the first pin, de-

activate the “input with interrupt” mode using the

port control registers (DDR, OR, DR). An active

edge on another pin can then be latched.

I/O port Configuration Spurious Interrupt on

Vector #2

If a pin associated with interrupt vector #2 is in ‘input with pull-up’ st ate, a ‘0’ level is present on t he

pin and the ESB bit = 0, when the I/O pin is configured as interrupt with pull-up by writing to the

DDRx, ORx and DRx register bits, an interrupt is

latched although a falling edge may not have occurred on the associated pin.

In the opposite case, if the pin is in interrupt with

pull-up state , a 0 level is present on the pin and

the ESB bit =1, when the I/O po rt is con figured as

input with pull-up by writing to the DDRx, ORx and

DRx bits, an interrupt is latched although a rising

edge may not have occurred on the associated

pin.

30/105

1

Loading...

Loading...