APPLICATIONNOTE

ST62 MICROCONTROLLERS DRIVE HOME APPLIANCE

MOTOR TECHNOLOGY

By Bruno MAURICE

INTRODUCTION

Most domestic appliances are driven by an electric motor; for the most part, these motors are

controlled in a simple and rudimentary fashion, and electronics isonly nowbeginning to be applied.This article describes the three main motor families – Universal, Induction and Electronically Commutated – as well as the relevant electronic control techniques, now possible

thanks to the intrinsic characteristics of STMicroelectronics ST62 Family of microcontrollers.

ST62 MCUs, with their wide range of on-chip peripherals, their wide supply voltage range,

their built-in ruggedness and their legendary noise immunity allow truly low total system cost,

thus favouring the technological advancement of electrical motor design.

Basic electrical topologies are described, together with their associated power and signal

electronics. The relative strengths and weaknesses are explored, usingpractical examples, in

order to illustrate the advantages of electronic control using ST62 MCUs.

AN885/1196 1/18

1

Table of Contents

INTRODUCTION . . . . . . . . . . . . . . . . . ......................................1

1 ELECTRIC MOTORS IN DOMESTIC APPLIANCES . . ........................3

2THERIGHTMOTORFORTHEJOB ......................................4

2.1 CONVENTIONAL ELECTRIC MOTORS . ..............................4

3UNIVERSALMOTORCONTROL .........................................6

3.1 PHASE ANGLE CONTROL MODE . . .................................6

3.2 CHOPPERCONTROLMODE .......................................8

3.3 HARMONICS AND POWER DRAWN FROM THE MAINS . . . . . . . . . . . . . . . . . 9

4INDUCTIONMOTORCONTROL ........................................10

4.1 INDUCTION MOTOR SUPPLIED BY MONOPHASE AC . .................10

4.2 VARIABLE SPEED CONTROL FOR MONOPHASE INDUCTION MOTORS . . 11

5ELECTRONICMOTORS ..............................................12

5.1 PERMANENT MAGNET SYNCHRONOUS MOTOR (PMDC) . . . . . . . . . . . . . . 13

5.2 SWITCHED RELUCTANCE MOTOR(SRM) . ..........................14

5.3 SIMPLIFIED TOPOLOGY FOR SWITCHED RELUCTANCE MOTORS . . ....15

5.4 ST6260 OFFERS THE SIMPLEST SRM DRIVER . . . . . . . . . . . . . . .........17

5.5 ST62:LOWESTTOTALSYSTEMCOST..............................17

6 STMICROELECTRONICS APPLICATION NOTES . . .......................18

2/18

1

AN885 - ELECTRIC MOTORS IN DOMESTIC APPLIANCES

1 ELECTRIC MOTORS IN DOMESTIC APPLIANCES

In hom e appliances and light household equipment, electronics is commonly found in the

man-machine interface (dashboards, control panels, remote controls, etc...), as well as in the

management of complex operating sequences, such as in washing machines; however, it is

only just beginning to be used to control the electric motors which power them.

Energy saving,silence, flexibility and simplicity are requirements of growing importance: in applications such as drills, vacuum-cleaners and refrigerators, variable speed control is the principal means of obtaining such performance features.

Up to 46 motors are to be found in the variousitems of domestic equipment in a typical American home

of home appliance motors.

Electronics will initially become more common in the control of conventional electric motors,

and will subsequently lead to the popularisation of brushless electronic motors, which offer the

advantages of beingmore rugged and of requiring lower cost mechanical parts. These motors

naturally require more complex electronic control systems, which will become increasingly viable as the cost of electronic systems falls, thanks to the use of STMicroelectronics ST62

Family of MCUs and low-cost integrated power ICs.

(*)

Emerson in Appliance Manufacturer August ’94

(*)

. This illustrates the important role that electronics is bound to play in the control

3/18

1

AN885 - THE RIGHT MOTORFOR THE JOB

2 THE RIGHT MOTOR FOR THE JOB

2.1 CONVENTIONAL ELECTRIC MOTORS

Three main families of electric motors are commonly used in home appliances. Their power

can range from 50W to 1.5 kW. The first two families, Brush Motors (i.e. Universal Motors)

andBrushless Motors (i.e. Induction Motors) are the most popular and these cheap and well

known motor designs may be connected directly to the AC mains.

Figure 1. Features and typical applications of the three main types of electric

applicance motors

BRUSHLESS ELECTRONIC

WITH BRUSHES

BRUSHLESS

COMMUTATION

UNIVERSAL

– AC or DC supplied

– High torque at starting

– Washing machine (EU)

– Hand tools

– AC supplied

– Robust

– Washing machine (WW)

– Heating-Ventilation-Air

conditioning

INDUCTION

FEATURES

APPLICATIONS FIELDS

AUTOCOMMUTATED

Perm. Magnet or Var. Reluctance

– Electronic replaces brushes

– High torque at starting

– Washing machine

– H.V.A.C.

– Pump / Fan

– Immersed pump / Com-

pressor / Fan

– Food processor

– Vacuum cleaner

– Dish washer / Tumble drier

– Freezer / Refrigerator

– Food processor

– Vacuum cleaner

– Freezer / Refrigerator

– Universal (Brush) Motors are used in applications where high torque and/or variable speed

are required (e.g. drills, food-processors, hand-tools, vacuum cleaners, etc.). They can be

powered either by an AC or DC supply, and are currently the most popular motors in appliances. Dueto their poor efficiency and relatively limited life, universal motors are tending to

4/18

1

AN885 - THE RIGHT MOTOR FOR THE JOB

be replaced by newertypes when the cost of the necessary electronic controlsystems drops

to sufficiently low levels.

– Induction (Brushless) Motors are mainlyused in applications requiring silent operation, long

life and high safety levels (i.e. pumps, compressors, refrigerators, fans, etc.). These motors

are AC supplied and rotational speed does not vary easily, since it is synchronised with the

electrical mains frequency.

In the third family, electronic acts as an electronic commutator and takes the place of brushes.

– These Electronically Commutated Brushless Motors include Permanent Magnet Syn-

chronous Motors and Switched Reluctance Motors. Both types are controlled by electronically switching the current in the windings. Electronically Commutated Brushless Motors

combine the high torque and variable speed performance of the universal motor withtheabsence of brushes and the intrinsic ruggedness of the induction motor.

5/18

1

AN885 - UNIVERSAL MOTOR CONTROL

3 UNIVERSAL MOTOR CONTROL

3.1 PHASE ANGLE CONTROL MODE

Universal motor speed may be simply and economically varied by phase angle control using

a TRIAC: this is therefore a very popular solution [1]. The motor current is directly drawn from

the mains and, because of its large peak to peak value, power losses in the iron are high.

When the TRIAC conduction angle is less than full wave, the current drawn from the mains

contains low frequency harmonic components with high amplitudes which can easily exceed

the authorised IEC levels.

Figure 2. Universal brush motor driven by phase-angle triggered TRIAC switched AC

supply.

ST6210 MCU

strength

Directly on the mains

Cheap solution

Variable speed

TRIAC

M

Umot

Imot

weakness

High current ripple

Brushes Noise

Sparkes, RFI pertubations

Low life time (3000hrs)

t

∆

Ι

t

6/18

1

AN885 - UNIVERSAL MOTOR CONTROL

In the example of a washing machine motor controller (Figure 3.), the gate of the TRIAC is directly controlled by a low-cost ST6210 microcontroller. Each high current I/O pin on ST62

Family devices can drive 20 mA, thus one or more pins may be paralleled, depending on the

TRIAC’s gate drive requirements.

The ST62 Familymicrocontroller, thanks to its wide voltage supply range andbuilt-in noise immunity, can be directly supplied from the 220V mains using only a few low-cost external components, as illustrated in F igure 3. The ST6210 manages the various washing cycles, the

man-machine interfaces and motor speed control. Motor speed regulation can make use of a

tacho-generator, or can be sensorless [4].

The ST62 controlled solution is extremely economical, while providing maximum flexibility:

changes are simply, rapidly and economically implemented by modifying the ST62 control

program.

Figure 3. Speed regulation using ST6210 MCU driven TRIAC in a washing machine

application

LINE

TRIAC

230V

LOAD

NEUTRAL

FUSE

BTA 16-600CW

M

820-1/2W

47

5V6

0V

220nF/400V

10K

220nF

1N4148

+5V

0V0V

100ÿF

6V

INVER SION

0V

10K

+5V

0V

1M

+5V

1

VDD RESET

19

PA0

18

PA1

17

PA2

16

PA3

13

PB2

12

PB3

PB4

11

PB5

10

OSCIN OSCOUT

34

22p

PB0

S

T

PB1

6

PB6

2

PB7

1

NMI

TEST

0

VSS

PIEZO

22p

8MHz

0V

+5V

TEMPER ATUR E

15

WASH

0V

14

9

8

5

6

20

RAMP

LIMIT

0V0V

0V

+5V

+5V

0V0V

SPIN

RAMP

DURATION

7/18

1

AN885 - UNIVERSAL MOTOR CONTROL

3.2 CHOPPER CONTROL MODE

The universal motorcan be supplied by a rectified AC voltage, switched at a high frequency by

a power MOS transistor [3] [6]. Speed control is achieved by adjusting the chopper duty cycle

[9]. Because of the rectified voltage, the current ripple is low, and iron losses are therefore low

as well. (Figure 4.)

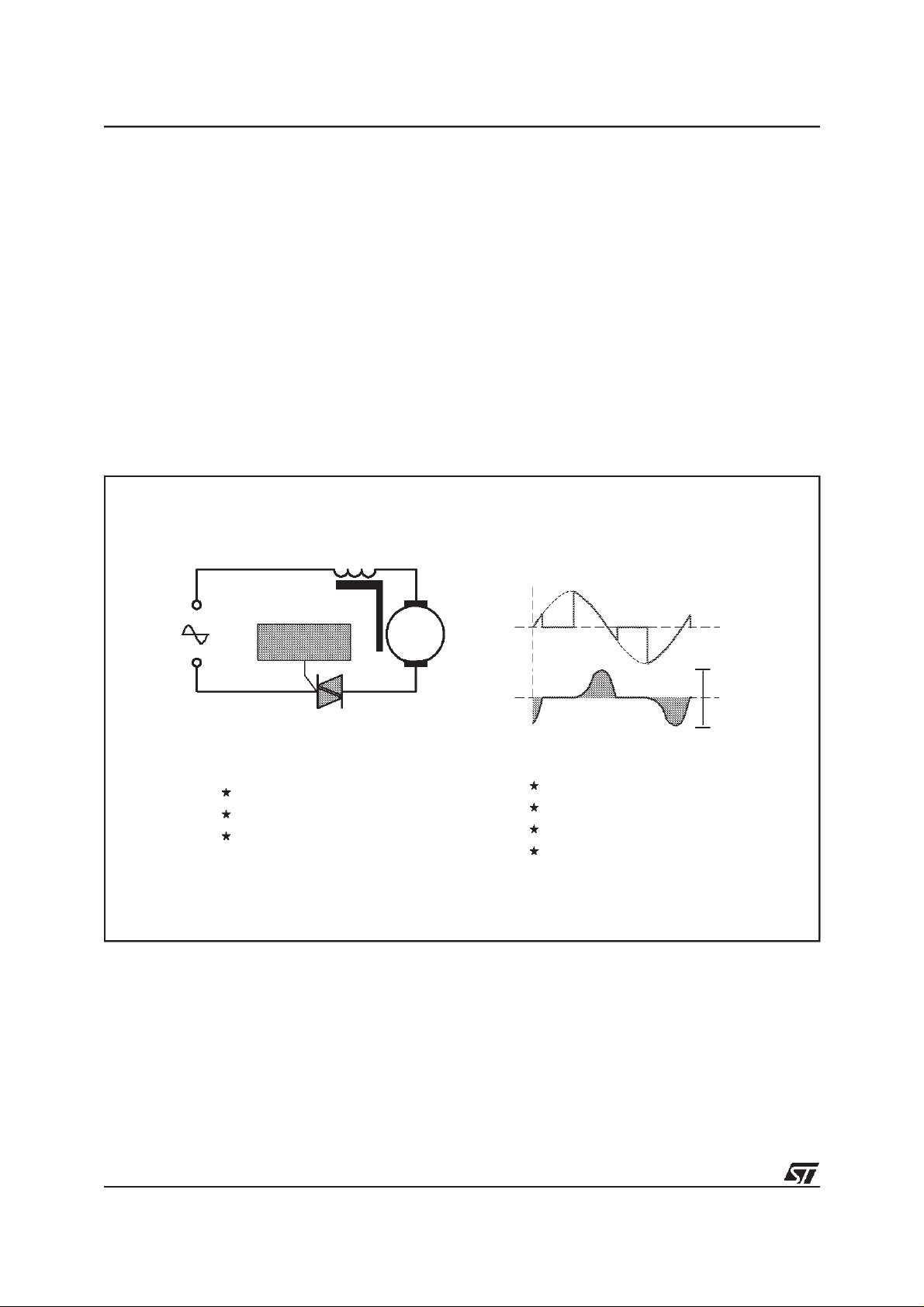

Figure 4. Chopper controlled Universal motor. mode

Umot

USER

Imot

weakness

20 kHz switching

Need RFI filtering

t

∆

Ι

t

230 V

TURBOSWITCH

Power

MOS

strength

Low current ripple

Reduced acoustic noise

M

TD300

SUPPLY

15 V

BUFFER

PEAK CURRENT

DETECTOR

5V

0V

Vdd

Ud

PWM

ST6265

Vss

MCU

INTERFACE

Ic

Better efficiency

The m ains current waveform is sinusoidal and thus does not generate low frequency harmonics.

Chopper control mode is an efficient means of complying with the IEC 1000-2-3 harmonics

standard. The pulsed current at the chopper frequencymust be filtered to remove components

at the switching frequency and above, but the filtering inductance need only be small, and

therefore low-cost, since the chopper frequency can be high (5 - 20kHz).

The chopper circuit comprises a power MOS transistor and a fast Turboswitch

TM

freewheeling

diode. The pulse width modulated (PWM) drive signal is generated by the ST62 microcontroller, via the STMicroelectronics TD300 MOS driver IC, which level shifts the 5V microcontroller output to the 15V level needed to drive the gate of the power MOS device. The MOS

driver IC also affords protection against short-circuits and over current. The ST62 microcontroller monitors the mains voltage and manages the user interfaces (signals and control).

8/18

1

AN885 - UNIVERSAL MOTOR CONTROL

3.3 HARMONICS AND POWER DRAWN FROM THE MAINS

The low frequency harmonics content generated on the mains strongly depends on the kind of

motor control used (phase angle or chopper).

For example, a vacuum cleaner operating in phase angle mode at reduced speed (i.e. conduction phase angle at around 90°), produces a very high level of even harmonics (Figure 5.).

The harmonics do not represent realoractive power, but nevertheless they lead to substantial

copper and iron losses. Consequently,the power supplied to the vacuum cleanerfor the same

mechanical output power is twice as high using phase angle control as it is when the chopping

control method is used.

Briefly, the chopper methodminimisesharmonicson the mains and increases motor efficiency

by a factor of two with respect to the phase angle control mode, as illustrated in Figure 5.

Motor size can thus be reduced and brush lifetime is much greater. In addition, in most applications no low frequency filtering or power factor correction is necessary to comply with the

IEC1000-2-3 standard. However, the high frequency harmonics generated by the chopper circuit (over 10kHz) must be blocked from the mains by means of a high frequency filter.

Figure 5. Current waveform and harmonics in phase angle control mode and chopper

control mode

5 A/[]

2ms

5 A/[]

2ms

Amps

5

4

3

2

1

0

12345

Amps

5

4

3

2

1

0

12345

= Standard limit

1000 W

Harmonics #

= Standard limit

600 W

Harmonics #

Example of a vacuum cleaner at reduced speed = 15 000 rpm

PHASE CONTROL

M

CHOPPER CONTROL

M

The mechanical load

of Motor remains

unchanged

9/18

1

AN885 - INDUCTION MOTOR CONTROL

4 INDUCTION MOTOR CONTROL

4.1 INDUCTION MOTOR SUPPLIED BY MONOPHASE AC

An induction m otor (also known as an asynchronous m otor) is directly supplied from the

monophase mains and can be controlled simply in “ON/OFF” mode using a TRIAC driven directly by a low-cost ST62 Familymicrocontroller (Figure 6.).

The reverse direction of rotation is obtained by using a second TRIAC controlled by the same

microcontroller.

Despite their low cost, these solutions give a great flexibility for design and operation, thanks

to the use of a microcontroller, allowing such functions as monitoring of motor torque and

mains voltage. Motor losses can be optimized by controlling undervoltage or Figure 3. Speed

regulation using ST6210 MCU driven TRIAC in a washing machine application overvoltage

according to working conditions and load (rotation speed, acceleration or deceleration, torque

demand).

Using this basic control, the motor speed cannot be easily adjusted, as it is fixed by the 50 or

60Hz mains frequency.

Figure 6. Induction Motor controlled in ON-OFF mode using TRIAC.

direct rotating

TRIAC

ST62xx

MCU

strength

Directly on the mains

Very silent

weakness

direct / reverse rotating

TRIAC

Fixed speed by mains frequency

Low starting torque

High lifetime (30 000 hrs)

ST62xx

MCU

10/18

1

AN885 - INDUCTION MOTOR CONTROL

4.2 VARIABLE SPEED CONTROL FOR MONOPHASE INDUCTION MOTORS

Variable speed is obtained by supplying the induction motor with a variable frequency AC

supply. An economical way of achieving this, is to use a four switch converter generating two

“8-step” square wave voltages phase shifted by 90° (Figure 7.). The start-up capacitor which

is normally used, is no longer necessary and the frequency (motor speed) can be adjusted

over a wide range. During start-up or speed-up/ speed-down sequences, the voltage can be

adapted to the frequency bythe ST62 Familymicrocontroller, providing the motor with a much

higher starting torque than is generally reached with the common “split capacitor” scheme illustrated in Figure 6.

Control of the low side transistors, which are referenced to ground, is via a dual low-side driver

STMicroelectronics IC. Two high side drivers drive the floating high-side transistors.

A low cost ST62 microcontroller generates the PWM signal, using the on-chip auto-reload

timer; this signal is used to adjust the motor voltage. It also produces the necessary information for sequential motor phase commutation.

Figure 7. Economical solution for variable speed control with a monophase Induction

Motor

L6380

S

PWM

T

T1

6

T2

2

T3

6

T4

5

L6380

TD 300

T3

13

2

T4

4

+

Motor

-

Variable speed

Standard MCU

Common induction motor technology

11/18

1

AN885 - ELECTRONIC MOTORS

5 ELECTRONIC MOTORS

Electronic motors have no brushes and are electronically commutated (electronics replacing

brushes). They offer the advantages of both variable speed and high starting torque of the universal motor, together with the absence of brushes, silence and long lifetime of the induction

motor. Nevertheless, electronically commutated motors require sophisticated electronics to

ensure commutation in the windings; they also require a rotor position detector.

Two basic types exist (Figure 8.):

Figure 8. Two types of electronically controlled motors which will be increasingly

adopted in home appliance applications

ELECTRONIC MOTOR SPECIFICS:

high life time 30 000 h

need rotor position detection

high torque at low speed

SN

S

N

Permanent Magnet brushless DC

silent

mature technology

N

S

S

N

Switched Reluctance

high speed (50 000 rpm)

emerging technology

compact

Synchronous motors with permanent magnet (PMDC).

This technology is already used in

the appliance field for fans and air-conditioners, mainly in the USA. Several manufacturers are

planning to use this motor type for other appliance applications.

Switc hed reluctan ce m oto r s (SRM ).

Switc he d re lu ctance technol ogy is cu rrent ly reemerging in appliance applications thanks to the rapidly falling cost of electronic control solutions. Many appliance manufacturers and research organisations are presently evaluating

feasibility, characteristics and total system cost in order to define acceptable solutions.

12/18

1

AN885 - ELECTRONIC MOTORS

5.1 PERMANENT MAGNET SYNCHRONOUS MOTOR (PMDC)

An autocommutated permanent magnet synchronous motor is driven by a common three

phase bridge, which sequentially supplies the current in the three phase motor windings in

both polarities (Figure 9.).

The ST62 Family microcontroller receives rotor position information and directly controls the

transistors, thus sequentially commutating the windings. The microcontroller also generates

the PWM signal, controlling the voltage across the motor.

Three standard high side driver STMicroelectronics ICs (L6380) shift the ground-referred control signals to the high side floating transistors. These ICs sustain >500V and can be used in

applications on 230V m ains. Another standard STMicroelectronics IC (TD300), a triple low

side driver, combines the phase commutation with the PWM signal for each of the three low

side transistors. It also monitors the current and acts for current limitation.

Figure 9. Common triphase bridge topology with driver ICs and ST microcontroller

controlling brushless PMDC motor in “6-step mode” with rotor position

sensors.

L6380

S

T1

T3

T

T5

6

2

PWM

x

T2

x

T4

T6

L6380

L6380

EN

TD 300

T3

T5

T2

T4

135

246

t

Motor

13/18

1

AN885 - ELECTRONIC MOTORS

5.2 SWITCHED RELUCTANCE MOTOR (SRM)

There are various power stage topologies to drive Switched Reluctance Motors. The most

common uses an asymmetrical bridge structure for each phase winding (Figure 10.).

This scheme recovers the corresponding energy in the power supply; it also authorises the

overlappi n g of conduction p hase se quen ces (simultaneo us conduction of two adjace nt

phases) giving maximum torque and speed [8]. This topology is versatile and robust, as there

is no risk of short circuits in the bridge-leg, because each motor winding is in series with the

two leg transistors.

Usually, global control includes two control loops: the autocommutation loop, including the

same number of position sensors as the number of phase windings, and the speed regulation

loop adjusting current in the phase by controlling the PWM duty cycle.

Figure 10. Common topology for a triple asymmetrical bridge driving a Switched

Reluctance Motor (SRM) using three rotor position sensors.

POSITION

SENSORS

SWITCHING

LOGIC

SPEED

REGULATION

CURRENT DEMAND

LIMITATION

&

CURRENT

CONTROL

+

-

14/18

1

AN885 - ELECTRONIC MOTORS

5.3 SIMPLIFIED TOPOLOGY FOR SWITCHED RELUCTANCE MOTORS

In home appliance applications, cost reduction is the major challenge. The objective is to reduce total system cost, and consequently the number of electronic components. ST62 Family

MCUs make a valuable contribution in this direction, since their wide operating supply range,

their built-in ruggedness, their legendary noise immunity and the wide range of available onchip peripherals drastically reduce external component count and cost

One solution uses a single sensor. The missing sensor signals are reconstructed by the ST62

Family microcontroller, saving two sensors. The microcontroller also measures speed, executes the control algorithm, and adjusts its internal PWM duty cycle to ensure the required

motor speed. [8]

The simplified topology in Figure 11. saves two power transistors and two fast diodes. Only

one hi gh side transistor remains, adjusting (PWM) and distributing current in each phase

winding when the low side transistors are successively switched.

An ST62 Family microcontroller drives the high side transistor via the L6380 high side driver

IC. The three low side transistors are driven via the triple low side driver IC (TD300), which

also ensures short circuit and over current protection.

The power stage includes four power MOS transistors and four fast diodes. Onlythe high side

transistor with its associated freewheeling fast diodes are switched at high frequency, and

have to be sized to carry the current of the three windings.

Each of the three low side transistors can be smaller, since they only have to switch the cur-

rent of one winding at low frequency.

15/18

1

AN885 - ELECTRONIC MOTORS

Figure 11. Simplified low cost ST62 MCU solution driving three phase SRM using a

single rotor position sensor.

PWM

L6380

220uF/385V

TD 300

220V

220uF/25V

4.7V

5.1V

5.1V

22uF

ST6260

10K

2.2K

15K

POSITION

SENSOR

16/18

1

AN885 - ELECTRONIC MOTORS

5.4 ST6260 OFFERS THE SIMPLEST SRM DRIVER

As an example, we can imagine an ideal SRM drive in terms of cost as shown in Figure 12.

This is a single phase motor, running only at high speed, controlled by an ST62 microcontroller. The component count is low and the circuitcan be assembled on an single board within

the motor casing: this is an excellent example of ultra low total system cost.

Figure 12. Simplest motor drive for a single phase switched reluctance motor supplied

in current mode, controlled by an ST6260 MCU

SET CURRENT

230vV

5.5 ST62: LOWEST TOTAL SYSTEM COST

DERIVATOR

PWM

ST6260

L6382

ΦΑ

Delay angle

adjustment

POSITION SENSOR

&

SPEED MEASUREMENT

The use of MCU driven electronic control systems indomestic appliance motor control will become moreand more commonthanks to the availability of flexible, reliableand low-cost MCUs

such as ST M icro electronics ST 62 Fa mil y, w here the i ntegration o f powerful on-chip resources, wide operating supply voltages, built-in ruggedness and legendary noise immunity

allow the designer to achieve very low total system costs.

In this way, large volume markets will be created, leading to further economies of scale and

greater market penetration.

17/18

AN885 - STMICROELECTRONICS APPLICATION NOTES

6 STMICROELECTRONICS APPLICATION NOTES

[1] Microcontroller and Triacs on the 110/240V Ph.RABIER/L.PERIER A.N 392

P.GUILLEMIN

[2] Digital P.F.C with Non-Sinewave Current

[3] “Controlling a brush DC motor with an ST6265 J.NICOLAI/T.CASTAGNET A.N.414

[4] “Sensorless Motor Drive with ST62MCU + Triac T.CASTAGNET A.N.416

[5] “An approach to Motor Control with Fuzzy Logic P.GUILLEMIN A.N.419

/J.M CHARRETON

/B.MAURICE

A.N.412

[6] “Improved Universal Motor Drive

[7] “Versatile and Costeffectiveinduction motor drive with

digital three phase generation

[8] “Simplified electronics bring the Switched-Reluctance

motor to the mass market

[9] “PWM techniques for acoustic noise reduction in power application

J.M BOURGEOIS

/J.M.CHARRETON/P.RAULT

B.MAURICE

/J.M BOURGEOIS/B.SABY

AN422

A.N.424

J.NICOLAI EPE ’95

J.M BOURGEOIS AN519

[10] “Inverter Design for mass production J.M BOURGEOIS PCIM’95

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information norfor any infringementof patents or other rights of third parties which may resultfrom its use. No license isgranted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without notice. This publication supersedes and replaces all informationpreviously supplied. STMicroelectronics products are not

authorized for use as criticalcomponents in life support devices or systems without the express writtenapproval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

2

Purchase of I

Australia - Brazil - Canada - China - France - Germany - Italy - Japan - Korea - Malaysia - Malta - Mexico - Morocco - The Netherlands -

18/18

C Components by STMicroelectronicsconveys a license under the Philips I2C Patent. Rights touse these components in an

2

C system is granted provided that the system conforms to the I2C Standard Specification as defined by Philips.

I

Singapore - Spain - Sweden - Switzerland - Taiwan - Thailand - United Kingdom - U.S.A.

1998 STMicroelectronics - All Rights Reserved.

STMicroelectronics Group of Companies

Loading...

Loading...