Page 1

®

ST52F510/F513/F514

8-BIT INTELLIGENT CONTROLLER UNIT (ICU)

Two Timer/PWMs, ADC, I2C, SPI, SCI

Memories

■ Up to 8 Kbytes Single Voltage Flash Memory

■ 256 bytes of Register Fi le

■ 256 bytes of RAM

■ Up to 4 Kbytes Data EEPROM

■ In Situ Programming in Flash devices (ISP)

■ Single byte and Page modes and In Application

Programming for writing data in Flash memory

■ Readout protection and flexible write protection

Core

■ Register File based architecture

■ 107 basic instructions

■ Hardware multiplication and division

■ Decision Processor for the implementation of

Fuzzy Logic algorithms

■ Deep System and User Stacks

Clock and Power Supply

■ Up to 24 MHz clock frequency

■ Programmable Oscillator modes:

– 10 MHz Internal Oscillator

– External Clock/ Oscillator

– External RC Oscillator

■ Power-On Reset (POR)

■ Programmable Low Voltage Detector (PLVD)

with 3 configurable thresholds

■ Power Saving features

Interrupts

■ 8 interrupt vectors with one SW Trap

■ Non-Maskable Interrupt (NMI)

■ Two Port Interrupts with up to 16 sources

I/O Ports

■ From 10 up to 22 I/O PINs configurable in pull-

up, push-pull, weak pull-up, open-drain and

high-impedance

■ High current sink/source in all pins

ST52F510/F513/F514

TARGET SPECIFICATION

Peripherals

■ On-chip 10-bit A/D Converter with 8 channel

analog multiplexer and Autocalibration.

■ 2 Programmable 16 bit Timer/PWMs with

internal 16-bit Prescaler featuring:

– PWM output

– Input capture

– Output compare

– Pulse generator mode

■ Watchdog timer

■ Serial Communication Interface (SCI) with

asynchronous protocol (UART).

2

■ I

C Peripheral with master and slave mode

■ 3-wire SPI

Master and Multi Master SPI modes

Development tools

■ High level Software tools

■ ‘C’ Compiler

■ Emulator

■ Low cost Programmer

■ Gang Programmer

Peripheral supporting Single

Rev. 1.18 -June 2003 1/106

This is preliminary information on a new product foreseen to be developed. Details are subject to change without notice.

Page 2

ST52F510/F513/F514

2/106

Page 3

ST52F510/F513/F514

TABLE OF CONTENTS

TABLE OF CONTENTS

1 GENERAL DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.2 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

1.2.1 Memory Programming Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2.2 Working Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3 Pin Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

2 INTERNAL ARCHITECTURE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.1 Control Unit and Data Processing Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

2.1.1 Program Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.1.2 Flags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.2 Arithmetic Logic Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

2.3 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

3 ADDRESSING SPACES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.1 Memory Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

3.2 Register File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

3.3 Program/Data Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

3.4 System and User Stacks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

3.5 Input Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

3.6 Output registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

3.7 Configuration Registers & Option Bytes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

4 MEMORY PROGRAMMING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.1 Program/Data Memory Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

4.2 Memory Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

4.2.1 Programming Mode start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.2.2 Fast Programming procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.2.3 Random data writing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.2.4 Option Bytes Programming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.3 Memory Verify. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

4.3.1 Fast read procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.3.2 Random data reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.4 Memory Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

4.5 ID Code. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

4.6 Error cases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

4.7 In-Situ Programming (ISP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

4.8 In-Application Programming (IAP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

4.8.1 Single byte write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.8.2 Block write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.8.3 Memory Corruption Prevention. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.8.4 Option Bytes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.8.5 Input Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3/106

Page 4

ST52F510/F513/F514

5 INTERRUPTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.1 Interrupt Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

5.2 Global Interrupt Request Enabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

5.3 Interrupt Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

5.4 Interrupt Maskability and Priority Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

5.5 Interrupt RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

5.6 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

6 CLOCK, RESET & POWER SAVING MODES . . . . . . . . . . . . . . . . . . . . . . . . 44

6.1 Clock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

6.2 Reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

6.2.1 External Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.2.2 Reset Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.3 Programmable Low Voltage Detector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

6.4 Power Saving modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

6.4.1 Wait Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.4.2 Halt Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.5 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

6.5.1 Configuration Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.5.2 Option Bytes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7 I/O PORTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

7.2 Input Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

7.3 Output Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

7.4 Interrupt Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

7.5 Alternate Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

7.6 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

7.6.1 Configuration Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.6.2 Input Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.6.3 Output Registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

8 FUZZY COMPUTATION (DP). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.1 Fuzzy Inference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

8.2 Fuzzyfication Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

8.3 Inference Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

8.4 Defuzzyfication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

8.5 Input Membership Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

8.6 Output Singleton. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

8.7 Fuzzy Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

9 INSTRUCTION SET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

9.1 Addressing Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

9.2 Instruction Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

10 10-bit A/D CONVERTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

10.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

4/106

Page 5

ST52F510/F513/F514

10.2 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

10.3 Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

10.3.1 One Channel Single Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

10.3.2 Multiple Channels Single Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

10.3.3 One Channel Continuous Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

10.3.4 Multiple Channels Continuous Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

10.4 Power Down Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

10.5 A/D Converter Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

10.5.1 A/D Converter Configuration Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

10.5.2 Input Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

11 WATCHDOG TIMER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

11.1 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

11.2 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

12 PWM/TIMERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

12.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

12.2 Timer Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

12.3 PWM Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

12.3.1 Simultaneous Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

12.4 Timer Interrupts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

12.5 PWM/Timer 0 Register Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

12.5.1 PWM/Timer 0 Configuration Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

12.5.2 PWM/Timer 0 Input Registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

12.5.3 PWM/Timer 0 Output Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

12.6 PWM/Timer 1 Register Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

12.6.1 PWM/Timer 1 Configuration Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

12.6.2 PWM/Timer 1 Input Registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

12.6.3 PWM/Timer 1 Output Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

13 SERIAL COMMUNICATION INTERFACE. . . . . . . . . . . . . . . . . . . . . . . . . . . 80

13.1 SCI Receiver block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

13.1.1 Recovery Buffer Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

13.1.2 SCDR_RX Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

13.2 SCI Transmitter Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

13.3 Baud Rate Generator Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

13.4 SCI Register Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

13.4.1 SCI Configuration Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

13.4.2 SCI Input Registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

13.4.3 SCI Output Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

14 I2C BUS INTERFACE (I2C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

14.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

14.2 Main Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

14.3 General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

5/106

Page 6

ST52F510/F513/F514

14.3.1 Mode Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

14.3.2 Communication Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

14.3.3 SDA/SCL Line Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

14.4 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

14.4.1 Slave Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

14.4.2 Master Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

14.5 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

14.5.1 I2C Interface Configuration Registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

14.5.2 I2C Interface Input Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

14.5.3 I2C Interface Output Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

15 SERIAL PERIPHERAL INTERFACE (SPI) . . . . . . . . . . . . . . . . . . . . . . . . . . 96

15.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

15.2 Main Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

15.3 General description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

15.4 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

15.4.1 Master Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

15.4.2 Slave Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

15.4.3 Data Transfer Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

15.4.4 Write Collision Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

15.4.5 Master Mode Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

15.4.6 Overrun Condition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

15.4.7 Single Master and Multimaster Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

15.4.8 Interrupts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

15.5 SPI Register Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

15.5.1 SPI Configuration Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

15.5.2 SPI Input Register. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

15.5.3 SPI Output Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

6/106

Page 7

ST52F510/F513/F514

1 GENERAL DESCRIPTION

1.1 Introduction

ST52F510/F513/F514 are devices of ST FIVE

family of 8-bit Intelligent Controller Units (ICU),

which can perform, both boolean and Fuzzy

algorithms in an efficient manner, in order to reach

the best performances that the two methodologies

allow.

Produced by STMicroelectronics using the reliable

high performance CMOS process for Single

Voltage Flash versions, ST52F510/F513/F514

include integrated on-chip peripherals that allow

maximization of system re liability, and decreased

system costs in orde r to minimize the number of

external components.

The flexible I/O co nfiguration of ST52F510/F513/

F514 allow one to interf ace with a wide range of

external devices (for example D/A converters or

power control devices), and to c ommunicate with

the most common serial standards.

ST52F510/F513/F514 pins are configurable. The

user can set input or output signals on each single

pin in 8 different modes, reducing the need for

external components in orde r to supply a suitable

interface with the port pins.

A hardware multiplier an d divider, together wit h a

wide instruction set, allow the implementation of

complex functions by using a single instruction.

Therefore, program memory utilization and

computational speed is optimized.

Fuzzy Logic dedicated structures in ST52F510/

F513/F514 ICU’s can be exploited to model

complex system with high accuracy in a useful and

simple manner.

Fuzzy Expert Systems for overall system

management and Fuzzy Real time Controls can be

designed to increase per formance at competitive

costs.

The linguistic approach characterizing Fuzzy Logic

is based on a set of IF-THEN rules, which describe

the control behavior and on Membership Functions

associated with input and output variables.

Up to 340 Membership Fun ctions, with triangular

and trapezoidal shapes, or singleton values are

available to describe fuzzy variables.

The Timer/PWM periph eral all ows o ne to m anage

power devices and timing signals, by implementing

different operating modes and high frequency

PWM (Pulse Width Modulation) controls. Input

Capture and Output Compare functions are

available on the Timers.

The Timer has a 16-bit programmable internal

Prescaler and a 16-bit Counter, which can use

internal or external START/STOP signals and

clock.

An internal programmable WATCHDOG is

available to avoid loop errors and reset the ICU.

ST52F510/F513/F514 includes a 10-bit, selfcalibrating, Analog to Digital Converter with an 8 analog channel Multiplexer. Single/Multiple

channels and Single/Sequence conversion modes

are supported. External reference can be supplied

to obtain more stability and precision in the

conversion.

ST52F510/F513/F514 supply differ ent per ipheral s

to implement the most common serial

communication protocols. SCI allows the

performance of serial asynchronous

communication (UART). I

allow the implementation of synchronous serial

protocols. I

2

C peripherals can work both in master

2

C and SPI peripherals

and slave mode. SPI imple ments S ingle and Mul ti

Master modes using 3-wire.

Up to 8 interrupt vectors are available, which allow

synchronization with peripherals and external

devices. Non-Maskable Int errupt and S/W TRAP

are available. All interrupts have configurable

priority levels and are maskable excluding the

Non-Maskable Interr upt, which has fixed top level

priority. Two versatile Por t Interru pts are avail able

for synchronization with external sources.

The ST52F510/F513/F514 also include an on-chip

Power-on-Reset (POR), which provides an internal

chip reset during power up situation and a

Programmable Low Voltage Detector (PLVD),

which causes the ICU to reset if the voltage source

V

dips below a thresho ld. Three progr ammable

DD

thresholds are available, allowing to work with

different supply voltages (from 2.7 to 5.5 V).

In order to optimize energy consumption, two

different power savin g modes are available: Wait

mode and Halt mode.

Internal Oscillator at 10 MHz ± 1% is available.

External clock, quartz oscillator or RC oscillator are

also applicable. The device alw ays starts with the

Internal Oscillator, then it reads an Option Byte

where the clock mode to be used is programmed.

Program Memory addressing capability addresses

up to 8 Kbytes of memory location to store both

program instructions and data.

Memory can be locked by the user in order to

prevent external undesired operations.

Operations may be performed on data stored in

RAM, allowing direct combination of new inputs

and feedback data. All RAM bytes are used like

Register File.

An additional RAM bench is added to the Program

Memory addressing space in order to allow the

management of the S y ste m/User Sta ck s an d u se r

data storage.

7/106

Page 8

ST52F510/F513/F514

ST52F510/F513/F514 supply the system stack

and the user stack located in the addit ional RAM

bench. The user stack can be located anywhere in

the additional RAM by writing the top address in

the configuration registers, in order to avoid

overlap with other data.

Single Voltage Flash allo ws the use r to reprogram

the devices on-board by means of the In Situ

Programming (ISP) feature. It is possible to store in

safe way up to 4K of data in the available EEPROM

memory benches. Perma nent data, both in Flash

and EEPROM can be man aged by means of the

In-Application-Programming (IAP) feature. Single

byte and Page write modes are supported. Flexible

write protection, of permanent data or program

instructions, is also available.

The Instruction Set composed of up to 107

instructions allows code compression and high

speed in the program implementation.

A powerful development environment consisting of

a board and software tools allows an easy

configuration and use of ST52F510/F513 /F514 .

The Visual FIVE software tool allows the

development and debugging of projects via a userfriendly graphical interface and optimization of

generated microcode.

Third-party Hardwa re Emulato rs and ‘C ’ Compiler

are available to speed-up the application

implementation and time-to-market.

1.2 Functional Description

ST52F510/F513/F514 ICU’s can work in two

modes according to the Vpp signal levels:

■ Memory Programming Mode

■ Working Mode

During Working Mode Vpp must be tied to Vss. To

enter the Memory Programming Mode, the Vpp pin

must be tied to Vdd.

A RESET signal must be appli ed to the device to

switch from one mode to the other.

1.2.1 Memory Programming Mode.

The ST52F510/F513/F514 memory is loaded in

the Memory Programming Mode. All instructions

and data are written inside the memory during this

phase.

The Option Bytes are l oaded during t his p hase b y

using the programming tools. The Option Bytes

can only be loaded in this phase and cannot be

modified run-time.

Data and commands are trans mitted by using the

2

I

C protocol, implemented using the internal I2C

peripheral. The In-Situ Programming protocol

(ISP) uses the following pins:

■ SDA and SCL for transmission

■ Vpp for entering in the mode

■ RESET for starting the protocol in a stable status

■ Vdd and Vss for the power supply.

The Internal clock is used in this phase.

1.2.2 Working Mode.

The processor starts the wor king phase following

the instructions, which have been previously

loaded in the first locations of the memory. The first

instruction must be a jump to the first program

instruction, skipping the data (interrupt vectors,

Membership Functions, user data) stored in the

first memory page.

ST52F510/F513/F514’s internal structure includes

two computational blocks, the CONTROL UNIT

(CU) and the DATA PROCESSING UNI T (DPU),

which performs boolean functions. The DECISION

PROCESSOR (DP) block cooperates with these

blocks to perform Fuzzy algorithms.

The DP can manage up to 340 different

Membership Function s for the antecedent part of

fuzzy rules. The conseq uent terms of the rules are

“crisp” values (real numbers). The maximum

number of rules that can be defi ned is limited by

the dimensions of the standard algorithm

implemented.

The Program/Data Memory is shared between

Fuzzy and standard algorithms. Within this

memory, the user d ata can be s tored both in n on

volatile memory as well as in the RAM locations.

The Control Unit (CU) reads informati on and the

status of the peripherals.

Arithmetic calculus can be performed on these

values by using t he inte rnal CU and Register File,

which supports all c omputations. The peripheral

inputs can be Fuzzy and/or arithmetic output

values contained in the Register File or Pr ogram/

Data Memory.

8/106

Page 9

ST52F510/F513/F514

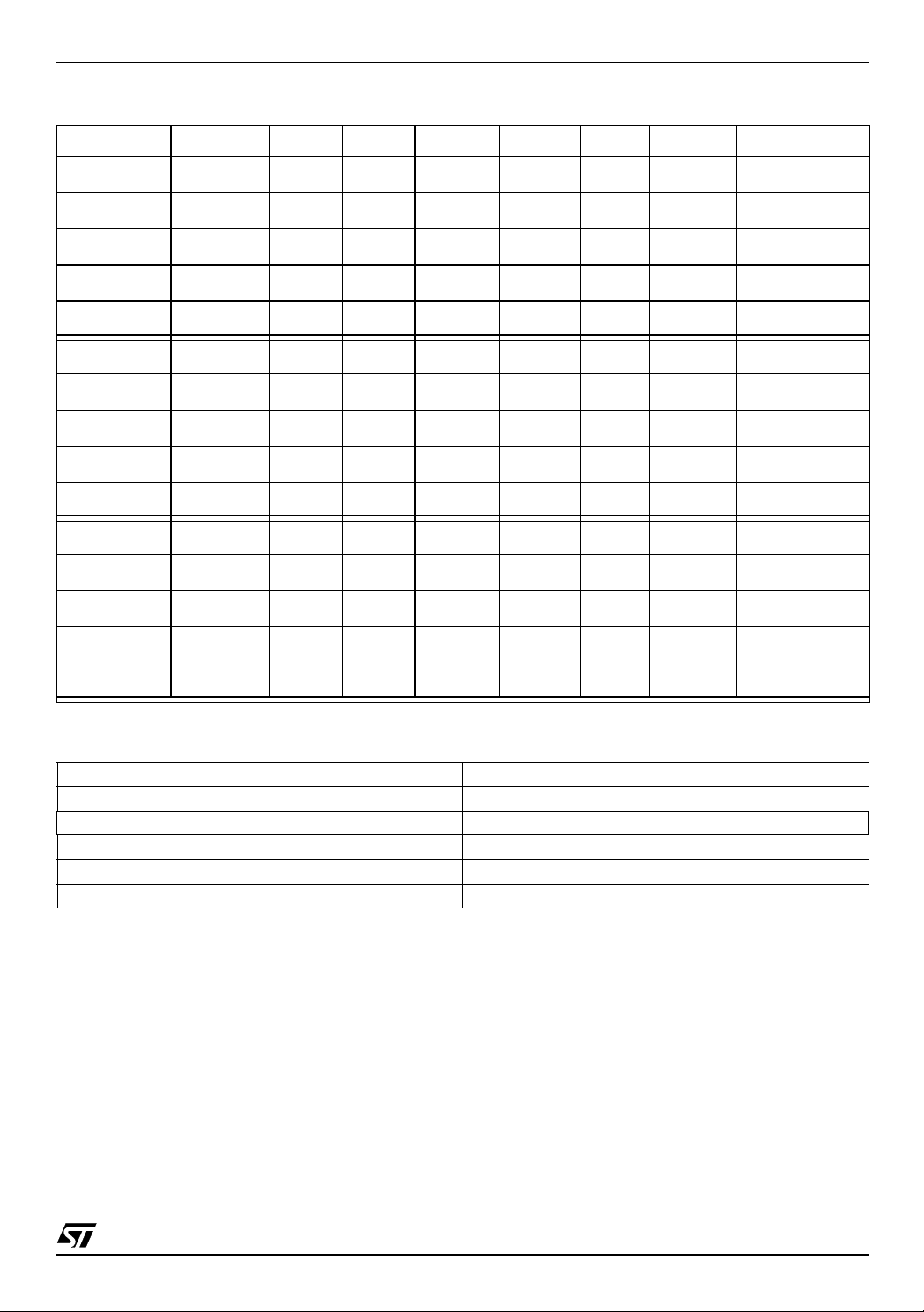

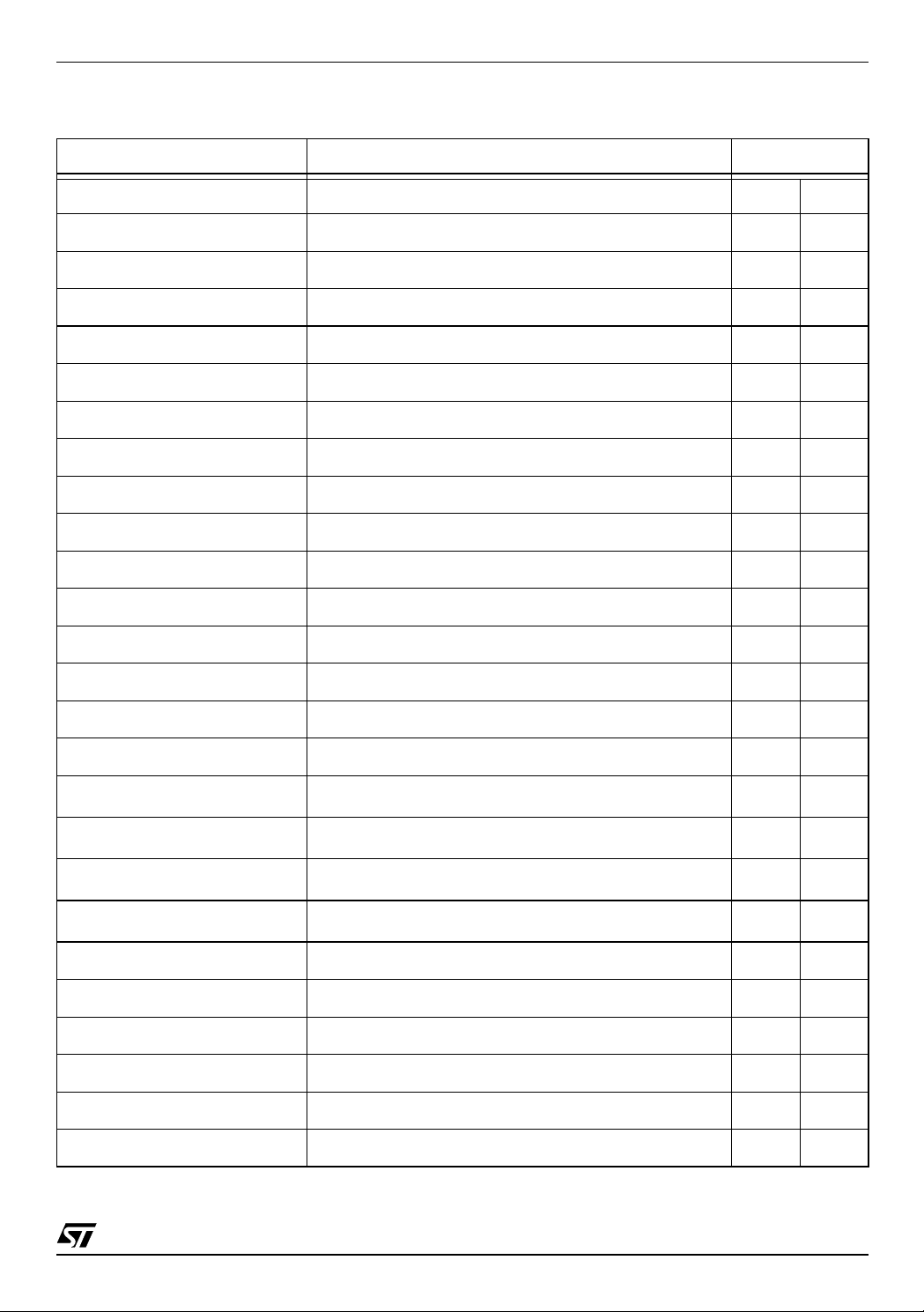

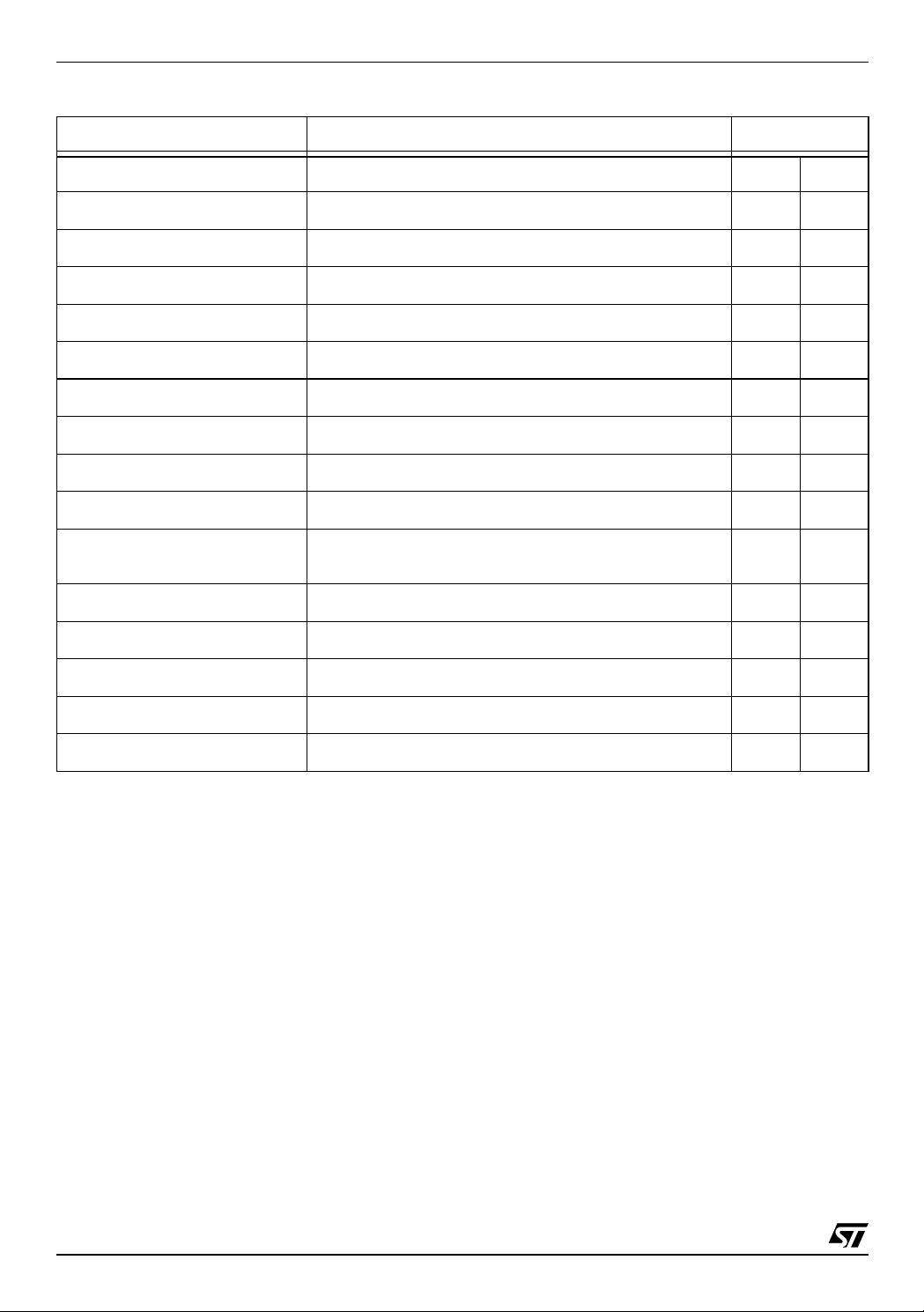

Table 1.1 ST52F510/F513/F514 Devices Summary

Device NVM RF RAM EEPROM Timers ADC Comms I/O Package

ST52F510YmM6 4/8 K FLASH 256 256 - 2X16-bit

ST52F510FmM6 4/8 K FLASH 256 256 - 2X16-bit

ST52F510FmB6 4/8 K FLASH 256 256 - 2X16-bit

ST52F510GmM6 4/8 K FLASH 256 256

ST52F510GmB6 4/8 K FLASH 256 256 - 2X16-bit

ST52F513YmM6 4/8 K FLASH 256 256 256 2X16-bit

ST52F513FmM6 4/8 K FLASH 256 256 256 2X16-bit

ST52F513FmB6 4/8 K FLASH 256 256 256 2X16-bit

ST52F513GmM6 4/8 K FLASH 256 256 256 2X16-bit

ST52F513GmB6 4/8 K FLASH 256 256 256 2X16-bit

ST52F514YmM6 4 K FLASH 256 256 1024 / 4096 2X16-bit

ST52F514FmM6 4 K FLASH 256 256 1024 / 4096 2X16-bit

ST52F514FmB6 4 K FLASH 256 256 1024 / 4096 2X16-bit

ST52F514GmM6 4 K FLASH 256 256 1024 / 4096 2X16-bit

ST52F514GmB6 4 K FLASH 256 256 1024 / 4096 2X16-bit

-

2X16-bit

10-bit

2 Ch

10-bit

6 Ch

10-bit

6 Ch

10-bit

8 Ch

10-bit

8 Ch

10-bit

2 Ch

10-bit

6 Ch

10-bit

6 Ch

10-bit

8 Ch

10-bit

8 Ch

10-bit

2 Ch

10-bit

6 Ch

10-bit

6 Ch

10-bit

8 Ch

10-bit

8 Ch

SCI I

SCI I

SCI I

SCI I

SCI I

SCI I

SCI I

SCI I

SCI I

SCI I

SCI I

SCI I

SCI I

SCI I

SCI I

2

C SPI

2

C SPI

2

C SPI

2

C SPI

2

C SPI

2

C SPI

2

2

2

2

2

2

2

2

2

C

C

C

C

C

C

C

C

C

10 So 16

14 So 20

14 Dip 20

22 So 28

22 SDip 32

10 So 16

14 So 20

14 Dip 20

22 So 28

22 SDip 32

10 So 16

14 So 20

14 Dip 20

22 So 28

22 SDip 32

COMMON FEATURES ST52F510/F513 /F5 14

Watchdog Yes

Other Features NMI, PLVD, POR

Temperature Range From -40° to +85

Operating Supply 2.7 - 5.5 V

CPU Frequency from 1 to 24 MHz.

Legend:

Sales code: ST52tnnncmpy

Memory type (t): F=FLASH

Subfamily (nnn): 510, 513, 514

Pin Count (c): Y=16 pins, F=20 pins, G=28 pins, K=32/34 pins

Memory Size (m):

Packages (p): B=PDIP, M=PSO, T=TQFP

Temperature (y): 0=+25, 1=0 +70, 3=-40 +125, 5=-10 +85, 6=-40 +85, 7=-40 +105

2=4 Kb, 3=8 Kb Flash (ST52F510 & ST52F513)

1=1024, 3=4096 EEPROM (only ST52F514)

°

9/106

Page 10

ST52F510/F513/F514

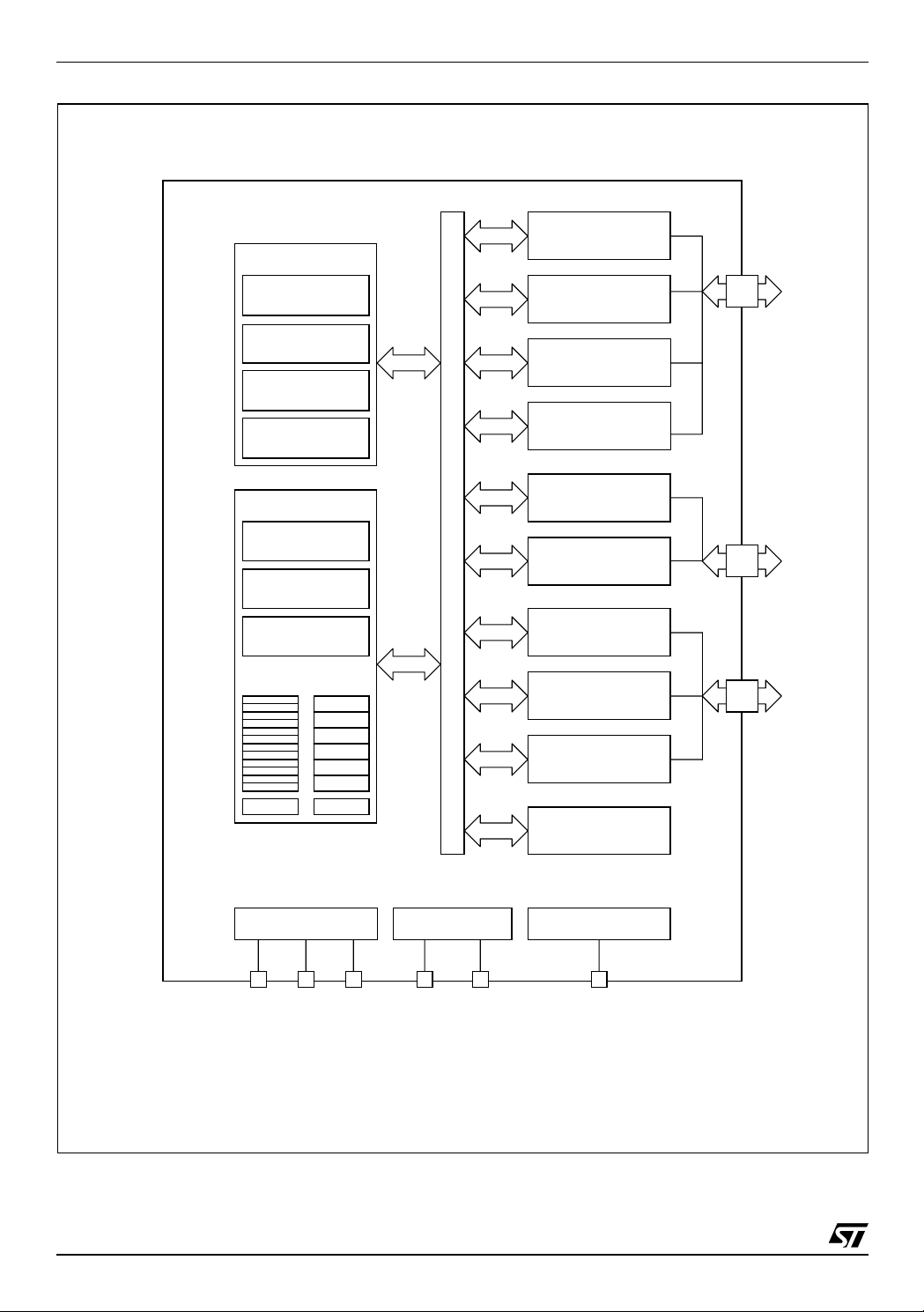

Figure 1.1 ST52F510/F513/F514 Block Diagram

MEMORY

FLASH

ISP/IAP

DATA RAM

256 bytes

DATA

EEPROM

MEMORY

INTERFACE

I2C

PA7:0

PORT A

TIMER/PWM 0

TIMER/PWM 1

CORE

ALU &

DPU

DECISION

PROCESSOR

CONTROL

UNIT

Register File

256 bytes

Input

registers

ADC

PORT B

SPI

PORT C

SCI

PC FLAGS

WATCHDOG

POWER SUPPLY

& PLVD

VDD VPP VSS OSCIN OSCOUT RESET

OSCILLATOR

POWER ON

RESET

PB7:0

PC5:0

10/106

Page 11

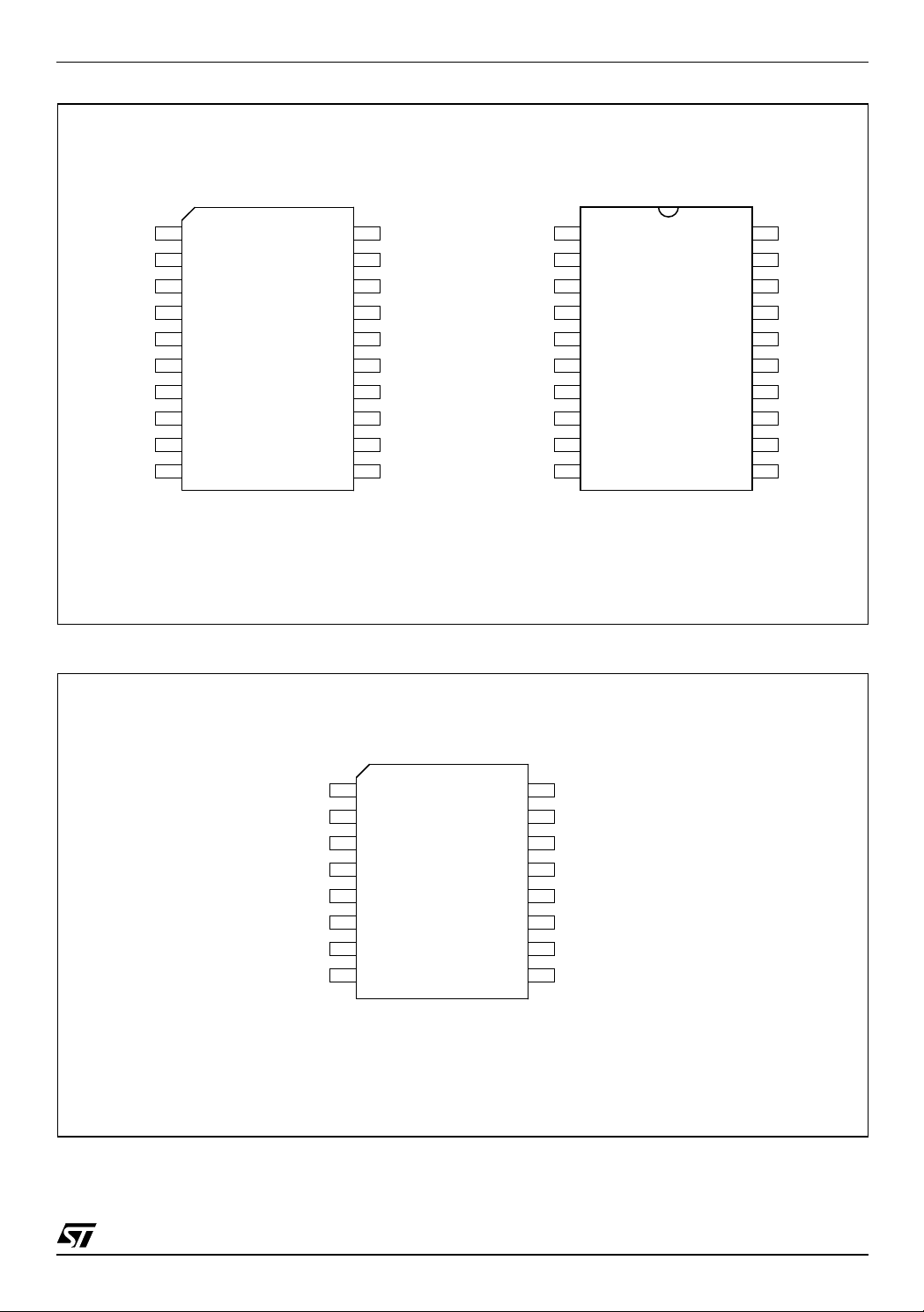

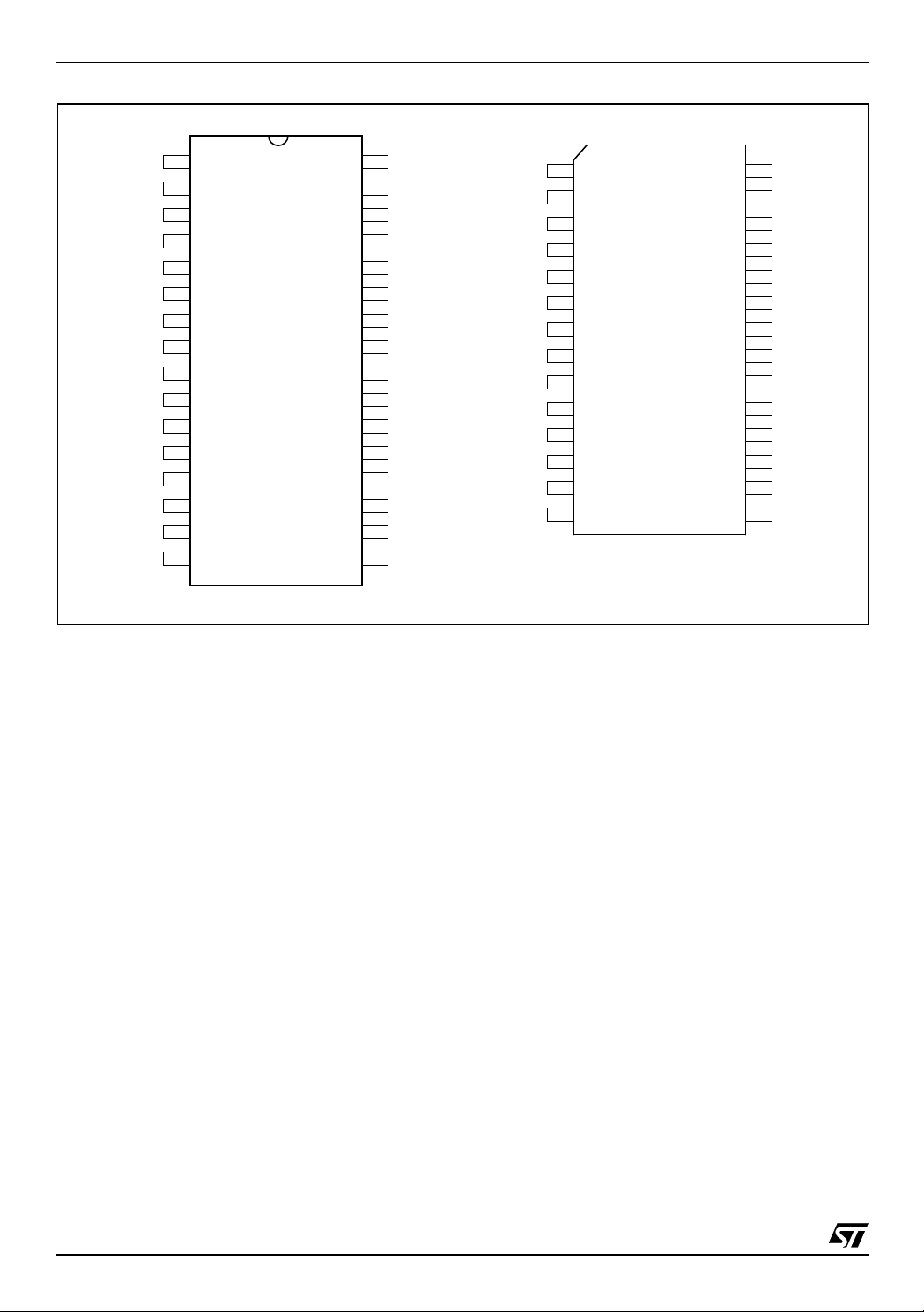

Figure 1.2 ST52F510/F513/F514 SO20/DIP20 Pin Configuration

ST52F510/F513/F514

Vdd

OscOut

OscIn

Vpp

PB0/VREF/AIN0

PB1/AIN1

PB2/AIN2

PB3/AIN3

PB4/AIN4

PB5/AIN5

1

2

3

4

5

6

7

8

9

10

SO20 DIP20

20

19

18

17

16

15

14

13

12

11

Vss

RESET

PA0/SCL

PA1/SDA

PA2/T1OUT

PA3/RX

PA4/TSTRT

PA5/TCLK/TX

PA6/T0OUT

PA7/INT

OscOut

PB0/VREF/AIN0

PB1/AIN1

PB2/AIN2

PB3/AIN3

PB4/AIN4

PB5/AIN5

Figure 1.3 ST52F510/F513/F514 SO16 Pin Configuration

Vdd

OscIn

Vpp

1

2

3

4

5

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

Vss

RESET

PA0/SCL

PA1/SDA

PA2/T1OUT

PA3/RX

PA4/TSTRT

PA5/TCLK/TX

PA6/T0OUT

PA7/INT

Vdd

OscOut

OscIn

Vpp

PB0/VREF/AIN0

PB1/AIN1

PA7/INT

PA6/T0OUT

1

2

3

4

5

6

7

8

SO16

16

15

14

13

12

11

10

9

Vss

RESET

PA0/SCL

PA1/SDA

PA2/T1OUT

PA3/RX

PA4/TSTRT

PA5/TCLK/TX

11/106

Page 12

ST52F510/F513/F514

Figure 1.4 ST52F510/F513/F514 SDIP32/DIP28 Pin Configuration

Vdd

VddIO

OscOut

OscIn

Vpp

PB0/VREF/AIN0

PB1/AIN1

PB2/AIN2

PB3/AIN3

PB4/AIN4

PB5/AIN5

PB6/AIN6

PB7AIN7

PC0/SCK

PC1/MOSI

N.C.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

SDIP32

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

Vss

VssIO

RESET

PA0/SCL

PA1/SDA

PA2/T1OUT

PA3/RX

PA4/TSTRT

PA5/TCLK/TX

PA6/T0OUT

PA7/INT

PC5/TRES

PC4/TX

PC3/SS

PC2MISO

N.C.

Vdd

OscOut

OscIn

Vpp

PB0/VREF/AIN0

PB1/AIN1

PB2/AIN2

PB3/AIN3

PB4/AIN4

PB5/AIN5

PB6/AIN6

PB7/AIN7

PC0/SCK

PC1/MOSI

1

2

3

4

5

6

7

8

9

10

11

12

13

14

SO28

28

27

26

25

24

23

22

21

20

19

18

17

16

15

Vss

RESET

PA0/SCL

PA1/SDA

PA2/T1OUT

PA3/RX

PA4/TSTRT

PA5/TCLK/TX

PA6/T0OUT

PA7/INT

PC5/TRES

PC4/TX

PC3/SS

PC2/MISO

12/106

Page 13

ST52F510/F513/F514

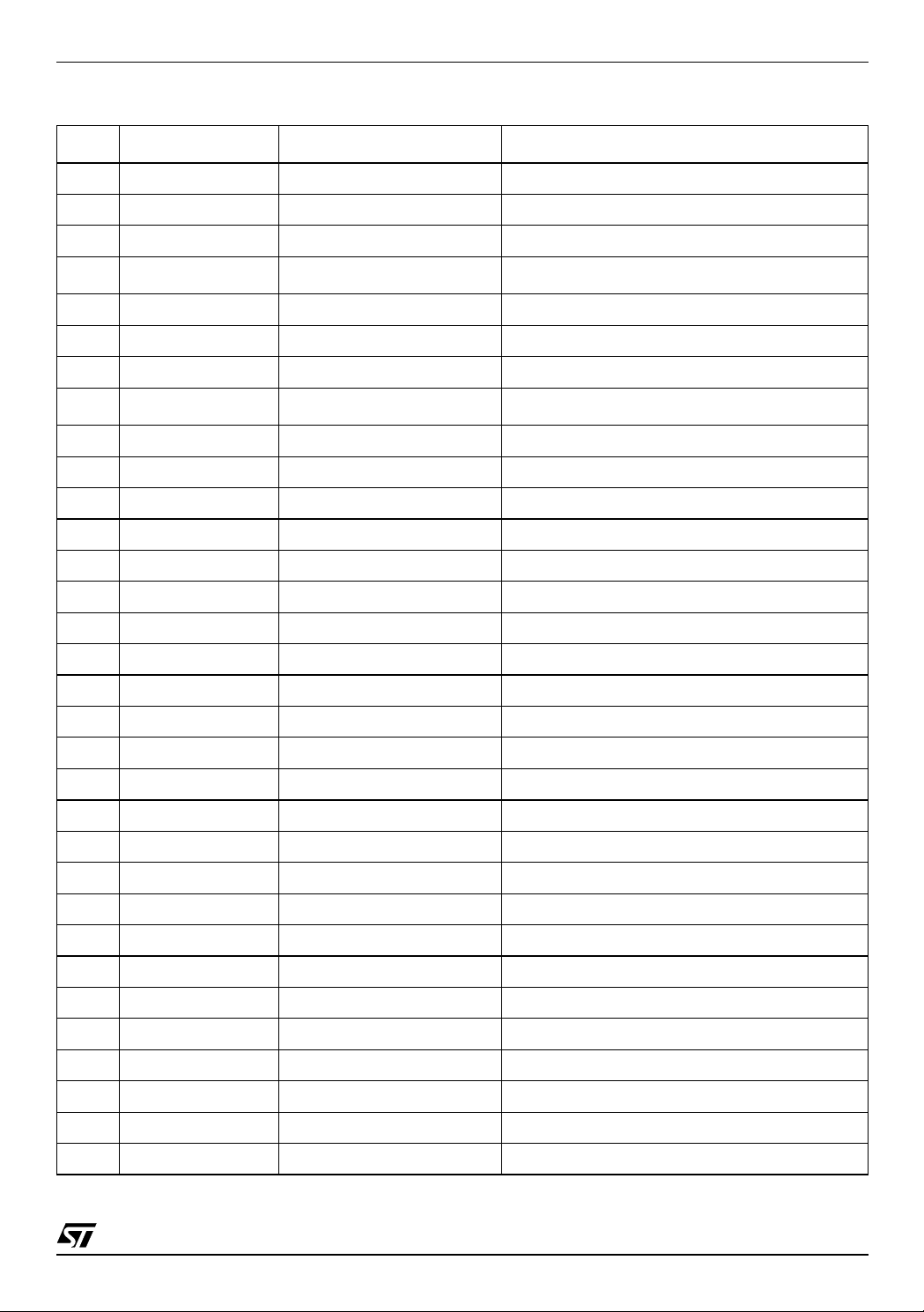

Table 1.2 ST52F510/F513/F514 SDIP32 Pin List

SDIP32 NAME Programming Phase Working Phase

1 Vdd Digital Power Supply Digital Power Supply

2 VddIO Digital Power Supply Digital I/O Ports Power Supply

3 OSCOUT Oscillator Output

4 OSCIN Oscillator Input

5 Vpp Programming Mode Selector Programming Mode Selector

6 PB0/VREF/AIN0 Digital I/O, A/D Voltage Reference, Analog Input

7 PB1/AIN1 Digital I/O, Analog Input

8 PB2/AIN2 Digital I/O, Analog Input

9 PB3/AIN3 Digital I/O, Analog Input

10 PB4/AIN4 Digital I/O, Analog Input

11 PB5/AIN5 Digital I/O, Analog Input

12 PB6/AIN6 Digital I/O, Analog Input

13 PB7/AIN7 Digital I/O, Analog Input

14 PC0/SCK Digital I/O, SPI Serial Clock

15 PC1/MOSI Digital I/O, SPI Master out Slave in

16 N.C Not Connected

17 N.C Not Connected

18 PC2/MISO Digital I/O, SPI Master in Slave out

19 PC3/SS Digital I/O, SPI Slave Select

20 PC4/TX Digital I/O, SCI Transmission

21 PC5/TRES Digital I/O, Timer/PWM 0 Reset

22 PA7/INT Digital I/O, Non Maskable Interrupt

23 PA6/T0OUT Digital I/O, Timer/PWM 0 output

24 PA5/TCLK/TX Digital I/O, Timer/PWM 0 clock

25 PA4/TSTRT Digital I/O, Timer/PWM 0 start/stop

26 PA3/RX Digital I/O, SCI Reception

27 PA2/T1OUT Digital I/O, Timer/PWM 1 output

28 PA1/SDA Serial Data I/O

29 PA0/SCL Serial Clock

30 RESET General Reset General Reset

Digital I/O, I

Digital I/O, I

2

C Serial Data I/O

2

C Serial Clock

31 VssIO Digital Ground Digital I/O Ports Ground

32 Vss Digital Ground Digital Ground

13/106

Page 14

ST52F510/F513/F514

Table 1.3 ST52F510/F513/F514 SO28 Pin List

SO28 NAME Programming Phase Working Phase

1 Vdd Digital Power Supply Digital Power Supply

2 OSCOUT Oscillator Output

3 OSCIN Oscillator Input

4 Vpp Programming Mode Selector Programming Mode Selector

5 PB0/VREF/AIN0 Digital I/O, A/D Voltage Reference, Analog Input

6 PB1/AIN1 Digital I/O, Analog Input

7 PB2/AIN2 Digital I/O, Analog Input

8 PB3/AIN3 Digital I/O, Analog Input

9 PB4/AIN4 Digital I/O, Analog Input

10 PB5/AIN5 Digital I/O, Analog Input

11 PB6/AIN6 Digital I/O, Analog Input

12 PB7/AIN7 Digital I/O, Analog Input

13 PC0/SCK Digital I/O, SPI Serial Clock

14 PC1/MOSI Digital I/O, SPI Master out Slave in

15 PC2/MISO Digital I/O, SPI Master in Slave out

16 PC3/SS Digital I/O, SPI Slave Select

17 PC4/TX Digital I/O, SCI Transmission

18 PC5/TRES Digital I/O, Timer/PWM 0 Reset

19 PA7/INT Digital I/O, Non Maskable Interrupt

20 PA6/T0OUT Digital I/O, Timer/PWM 0 output

21 PA5/TCLK/TX Digital I/O, Timer/PWM 0 clock

22 PA4/TSTRT Digital I/O, Timer/PWM 0 start/stop

23 PA3/RX Digital I/O, SCI Reception

24 PA2/T1OUT Digital I/O, Timer/PWM 1 output

25 PA1/SDA Serial Data I/O

26 PA0/SCL Serial Clock

27 RESET General Reset General Reset

28 Vss Digital Ground Digital Ground

Digital I/O, I

Digital I/O, I

2

C Serial Data I/O

2

C Serial Clock

14/106

Page 15

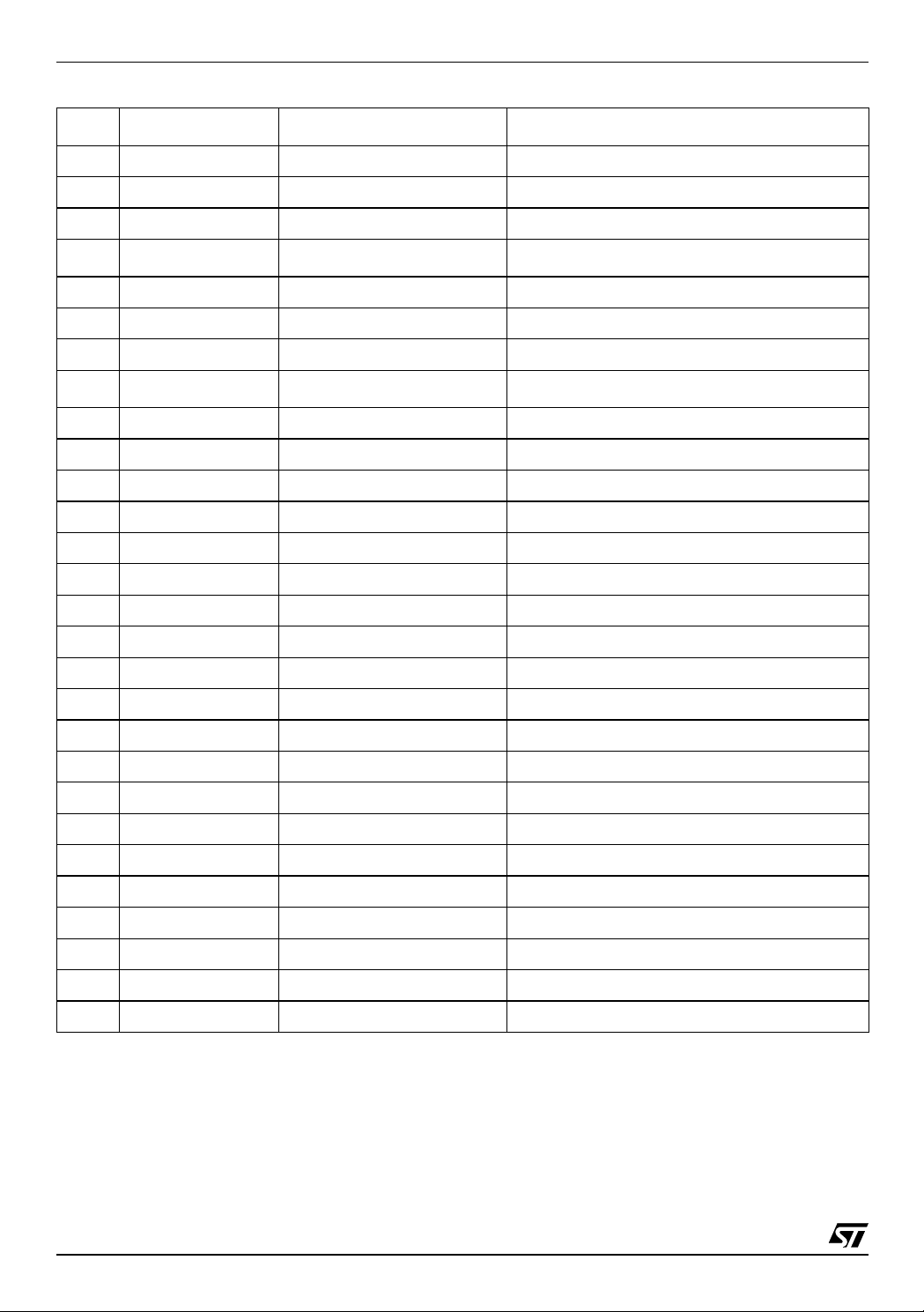

Table 1.4 ST52F510/F513/F514 SO20/DIP20/SO16 Pin List

ST52F510/F513/F514

SO20

DIP20

SO16 NAME Programming Phase Working Phase

1 1 Vdd Digital Power Supply Digital Power Supply

2 2 OSCOUT Oscillator Output

3 3 OSCIN Oscillator Input

4 4 Vpp Programming Mode Selector Programming Mode Selector

5 5 PB0/VREF/AIN0 Digital I/O, A/D Voltage Reference, Analog Input

6 6 PB1/AIN1 Digital I/O, Analog Input

7 - PB2/AIN2 Digital I/O, Analog Input

8 - PB3/AIN3 Digital I/O, Analog Input

9 - PB4/AIN4 Digital I/O, Analog Input

10 - PB5/AIN5 Digital I/O, Analog Input

11 7 PA7/INT Digital I/O, Non Maskable Interrupt

12 8 PA6/T0OUT Digital I/O, Timer/PWM 0 output

13 9 PA5/TCLK/TX Digital I/O, Timer/PWM 0 clock, SCI transmission

14 10 PA4/TSTRT Digital I/O, Timer/PWM 0 start/stop

15 11 PA3/RX Digital I/O , SCI Re ce ptio n

16 12 PA2/T1OUT Digital I/O, Timer/PWM 1 output

17 13 PA1/SDA Serial Data I/O

18 14 PA0/SCL Serial Clock

19 15 RESET General Reset General Reset

20 16 Vss Digital Ground Digital Ground

Digital I/O, I

Digital I/O, I

2

C Serial Data I/O

2

C Serial Clock

15/106

Page 16

ST52F510/F513/F514

1.3 Pin Description

ST52F510/F513/F514 pins can be set in digital

input mode, digital output mo de, i nterr upt mode or

in Alternate Functions. Pin configuration is

achieved by mean s of the config uration registe rs.

The functions of the ST52F510/F513/F514 pins

are described below:

V

Main Power Supply Voltage.

DD.

I/O Ports Power Supply Voltage. It is

V

DDIO.

reccomended to connect this pin with a supply

voltage de-coupled with V

in order to improve

DD

the immunity from the n oise generated by th e I/O

switching.

V

. Digital circuit Ground.

SS

. I/O Ports Ground. See V

V

SSIO

DDIO

VPP. Programming/Working mode selector. During

the Programming p hase V

In Working phase V

PP

must be set to VDD.

PP

must be equal to VSS.

OSCin and OSCout. These pins are internally

connected to the on-chip oscillator circuit. A quartz

crystal or a ceramic resonator can be connected

between these two pins in order to allow correct

use of ST52F510/F513/F514 with various stability/

cost trade-offs. An external clock signal can be

applied to OSCin: in this case OSCout must be

grounded. To reduce costs, an RC cir cuit can be

applied to the OSCin pi n to establish the internal

clock frequency, instead of the quartz. Without any

connection, the device can work with its internal

clock generator (10 MHz)

PA0-PA7, PB0-PB7,PC0-PC5. These lines are

organized as I/O ports. Each pin can be configured

as an input, output (with pull- up, pus h-pull, weakpull-up, open-drain, high-impedance), or as an

interrupt source.

VREF, AIN0-AIN7. These pins are used to input

the analog signals into the A/D Converter. An

analog multiplexer is available to switch these

inputs to the A/D Converter. The pin VREF is used

to input an external A/D Reference Voltage.

T0OUT, T1OUT. These pins output the signals

generated by the PWM/Timer 0 and PWM/Timer 1

peripheral.

TRES, TSTRT, TCLK . These pins are related to

the PWM/Timer 0 peripheral and are used for Input

Capture and event counting. The TRES pin is used

to set/reset the Timer; the TSTRT pin is used to

start/stop the counter. The Timer can be driven by

the internal clock or by an external signal

connected to the TCLK pin.

INT. This pin is used as input for the Non-Maskable

(top level) interrupt. The interrupt signal is detected

only if the pin is configured in Alternate Function.

SCL, SDA. These pin are used respectively as

Serial Clock and Serial Data I/O in I

2

C peripheral

protocol. They are used also in Programming

Mode to receive and transmit data.

TX, RX. Serial data output of SCI Transmitter block

(TX) and Serial data input of the SCI Receiver

block (RX).

RESET. This signal is used to reset the ST52F510/

F513/F514 and re-initialize the registers and

control signals. It is also used when switching from

the Programming Mode to Working Mode and vice

versa.

16/106

SCK, MISO, MOSI, SS. These pins are used by

the Serial Peripheral Interface (SPI) peripheral.

SCK is the serial clock line. MISO (Master In Slave

Out) and MOSI (Master Out Slave In) are the serial

data lines, which work in input or in output

depending on if the devic e is working in slave or

master mode. The SS pin allows the selection of

the device master/slave mode.

Page 17

ST52F510/F513/F514

Control

Signals

2 INTERNAL ARCHITECTURE

ST52F510/F513/F514’s architecture is Register

File based and is composed of the following blocks

and peripherals:

■ Control Unit (CU)

■ Data Processing Unit (DPU)

■ Decision Processor (DP)

■ ALU

■ Memory Interface

■ up to 256 bytes Register File

■ Program/Data Memory

■ Data EEPROM

■ Interrupts Controller

■ Clock Oscillator

■ PLVD and POR

■ Digital I/O ports

■ Analog Multiplexer and A/D Converter

■ Timer/PWMs

2

■ I

C

■ SPI

■ SCI

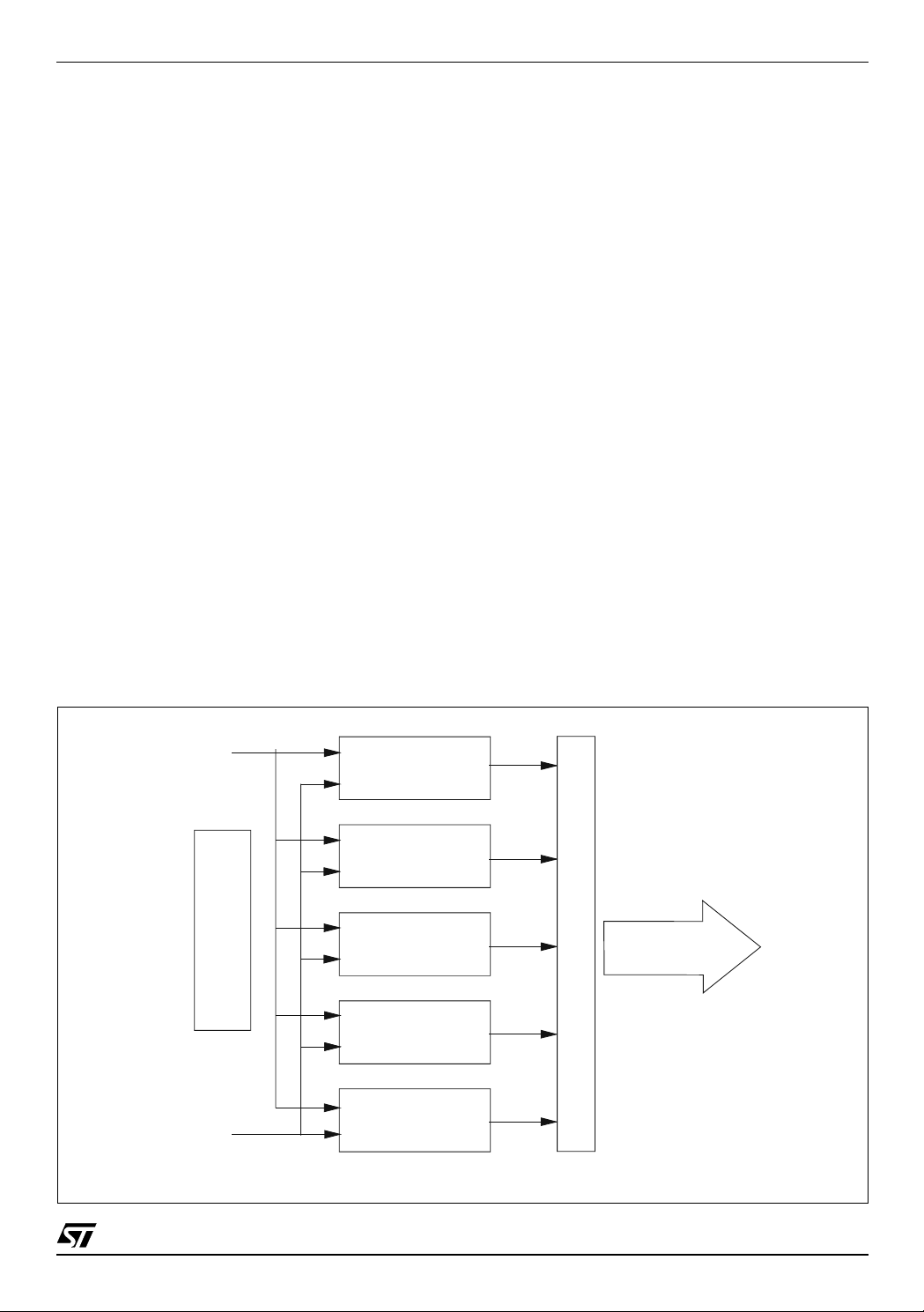

Figure 2.1 CU Block Diagram

2.1 Control Unit and Data Processing Unit

The Control Unit (CU) decodes the instructions

stored in the Program Mem ory and gene rates the

appropriate control s ignals. The main parts of the

CU are illustrated in Figure 2.1.

The five different parts of the CU manage Loading,

Logic/Arithmetic, Jump, Control and the Fuzzy

instruction set.

The block called “ Collector” manages the sig nals

deriving from the different parts of the CU. The

collector defines the signals for the Data

Processing Unit (DPU) and Decision Processor

(DP), as well as for th e different peripherals of the

ICU.

The block called “Arbiter” manages the different

parts of the CU, so that only one part of the system

is activated during working mode.

The CU structure is extremely flexible and was

designed with the purp ose of easily adapting the

core of the microcontroller to market need s. New

instruction sets or new pe ripherals can easil y be

included without changing the structure of the

microcontroller, maintaining code compatibility.

A set of 107 different instructions is available. Each

instruction requires a number of clock pulses to be

performed that depe nds on the complexity of the

instruction it self. The clock pulses t o execute the

instructions are driv en dir ec tly by the ma sterclock,

which has the same frequency of the oscillator

signal supplied.

MicroCode

A

R

B

I

T

E

R

Clock Master

Loading

Instruction Set

Logic Arithmetic

Instruction Set

Jump

Instruction Set

Control

Instruction Set

Decision Processor

Instruction Set

C

O

L

L

E

C

T

O

R

17/106

Page 18

ST52F510/F513/F514

Figure 2.2 Data Processing Unit (DPU)

Interrupts Unit

Program Memory

Input Registers

Peripherals

REGISTER FILE

ADDRESS

PROGRAM COUNTER

REGISTER

FILE

256 Bytes

ACCUMULATOR

FLAGS REG.

DECISION

PROCESSOR

REGISTERS

ALU

Memory Address

Control Unit

Peripherals

The DPU receives, stores and sends the

instructions deriving from the Program/Data

Memory, Register File or from the peripherals. It is

controlled by the CU on the basis of the dec oded

instruction. The Fuzzy registers store the partial

results of the f uz zy c om puta tion. The accumul ator

register is used by the ALU and i s not accessible

directly: the instructions used by the ALU can

address all the Register File locations as

operands, allowing a more compact code and a

faster execution.

The following addressing modes are available:

inherent, immediate, direct, indirect, bit direct.

2.1.1 Program Counter.

The Program Counter (PC) is a 16-bit register that

contains the addre ss of the next memory location

to be processed by the core. This memory location

may be both an instruction or data address.

The Program Counter’s 16-bit length allows the

direct addressing of a maximum of 64 Kbytes in the

Program/Data Memory space.

18/106

The PC can be changed in the following ways:

■ JP (Jump) PC = Jump Address

■ Interrupt PC = Interrupt Vector

■ RETI PC = Pop (stack)

■ RET PC = Pop (stack)

■ CALL PC = Subroutines address

■ Reset PC = Reset Vector

■ Normal Instruction PC = PC + 1

2.1.2 Flags.

The ST FIVE core includes differen t sets of flags

that correspond to 2 different modes: normal mode

and interrupt mode. Each set of fla gs consist of a

CARRY flag (C), ZERO flag (Z) and SIGN flag (S).

Each set is stacked: one set of flags is used during

normal operation and oth er sets are used during

each level of interrupt. Formally, the user has to

manage only one set of flags: C, Z and S since the

flag stack operation is performed automatically.

Page 19

ST52F510/F513/F514

Each interrupt leve l ha s i t s own set of flags, which

is saved in the Flag Stack during interrupt

servicing. These flags are restored from the Flag

Stack automatically when a RETI instruction is

executed.

If the ICU was in normal mode before an interrupt,

after the RETI instruction is executed, the normal

flags are restored.

Note: A subroutine CALL is a normal mode

execution. For this reason a RET instruction,

consequent to a CALL instruction, doesn’t affect

the normal mode set of flags.

Flags are not cleared during context switching and

remain in the state they were in at the exit of the

last interrupt routine switching.

The Carry flag is set when an overflow occurs

during arithmetic operations, otherwise it is

cleared. The Sign flag is set when an underflow

occurs during arithmetic operations, otherwise it is

cleared.

The flags, related to the current context, can be

checked by reading the FLAGS Input Register 38

(026h).

2.2 Arithmetic Logic Unit

The 8-bit Arithmetic Logic Unit (ALU) performs

arithmetic calcu lations and l ogic instructi ons such

as: sum, subtraction , bitwise AND, OR, XOR, bit

set and reset, bit test and branch, right/left shift and

rotate (see the Chapter 9 Instruction Set for further

details).

In addition, the ALU of ST52F510/F513/F514 can

perform multiplicati on (MULT) and division (DIV).

Multiplication is performed by using 8 bit operands

storing the result in 2 registers (16 bi t values); the

division instruction addresses the MSB of the

dividend (the LSB is stored in the next addres s):

the result and remainder are stored in these source

addresses (see Figure 2.3 and Figure 2.4).

In order to manage s igned type values, the ALU

also performs additio n and subtraction with offset

(ADDO and SUBO). These instructions

respectively subtract and add 128 to the overall

result, in order to ma nage values logically in the

range between -128,127.

Figure 2.3 Multiplication

RAM

000h

001h

002h

i

j-1

j

j+1

0FDh

0FEh

0FFh

REG. j REG. i

LSB

X

16 Bit

MSB

Figure 2.4 Division

REG. j REG. j+1

RAM

000h

001h

002h

i-1

i

i+1

j-1

j

j+1

0FDh

0FEh

0FFh

:

REMAINDER QUOTIENT

REG. i

19/106

Page 20

ST52F510/F513/F514

2.3 Register Description

Flags Register (FLAG)

Input Register 38 (026h) Read Only

Reset Value: 0000 0000 (00h)

70

-----ZSC

Bit 7-3: Not Used

Bit 2: Z Zero flag

Bit 1: S Sign flag

Bit 0: C Carry flag

20/106

Page 21

ST52F510/F513/F514

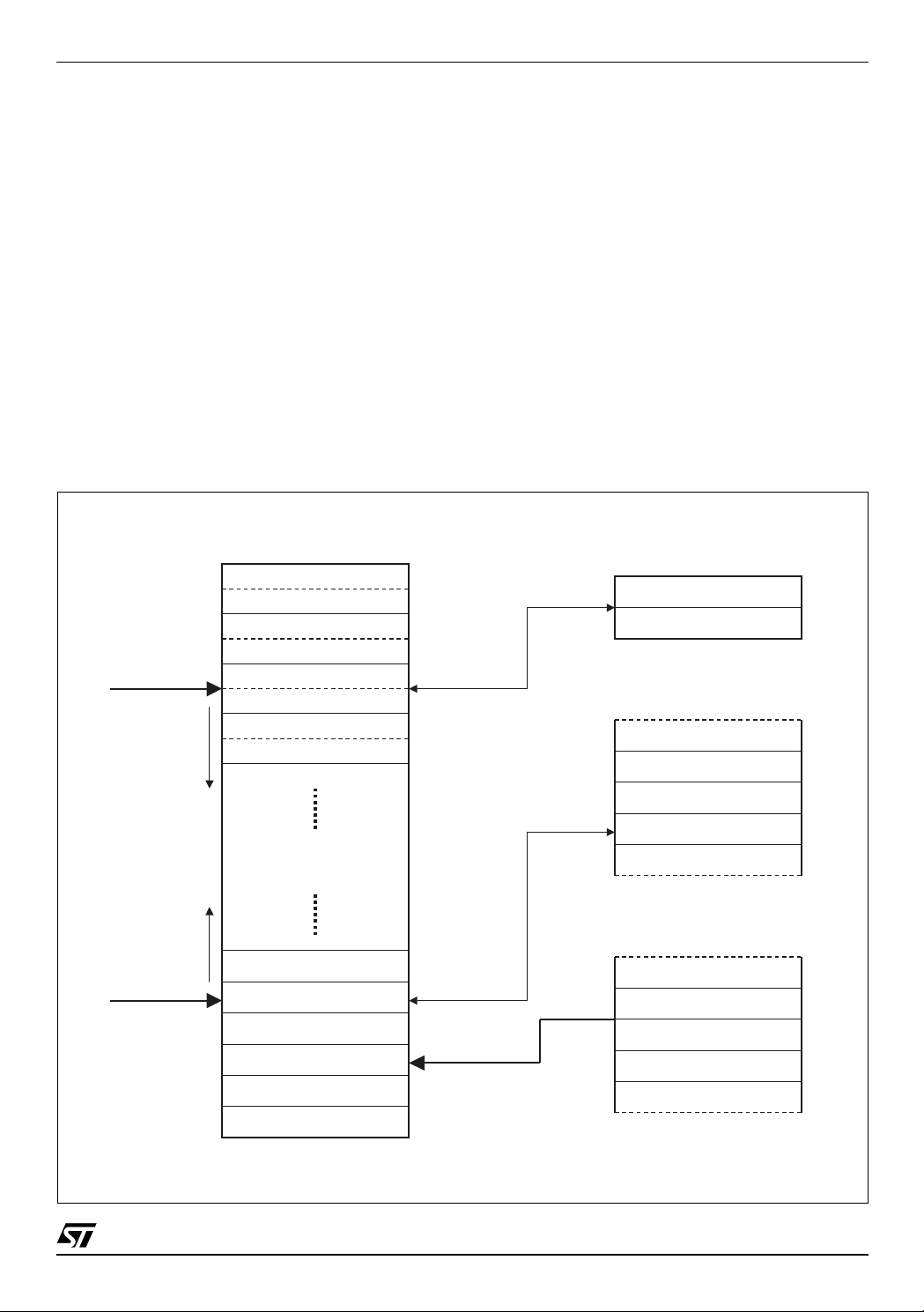

3 ADDRESSING SPACES

ST52F510/F513/F514 has six separate

addressing spaces:

■ Register File

■ Program/Data Memory

■ Stacks

■ In put Regi st er s

■ Output Registers

■ Configuration Registers

Each space is addressed by a load type instruction

that indicates the source and the destination space

in the mnemonic code (see Figure 3.1).

3.1 Memory Interface

The read/write operation in the s pace addresses

are managed by the Memo ry Inter face , whic h ca n

recognize the ty pe of memor y addressed a nd set

the appropriate access time and mode.

In addition, the Memory Interface manages the In

Application Program ming (IAP) functions in Flash

devices like writing cycle and memory write

protection.

Figure 3.1 Addressing Spaces

3.2 Register File

The Register File con sist s o f 2 56 g ene ra l p urpos e

8-bit RAM locations called “registers” in order to

recall the functionality.

The Register File exchanges data with all the other

addressing spaces and is used by the ALU to

perform all the arithmetic and logic instructions.

These instructions have any Register File address

as operands.

Data can be moved from one location to another by

using the LDRR inst ruction; see further ahead for

information on the instr uction used to move data

between the Register File and the other

addressing spaces.

3.3 Program/Data Memory

The Program/Data Memory con sists of both nonvolatile memory (Flash, EEPROM) and RAM

memory benches.

Non-volatil e memory (NV M) is mainly us ed to store

the user program and can al so be used to store

permanent data (constant, look-up tables).

Each RAM bench consists of 256 locations used to

store run-time user data. At least one bench is

present in the devices. RAM benches are also

used to implement both System and User Stacks .

PROGRAM/DATA MEMORY

NON VOLATILE MEMORY

RAM BANKS

AND STACKS

LDCE

LDPE

LDER

LDRE

STFive CORE

REGISTER FI LE

INPUT REGISTERS

LDFR

LDRI

LDCNF

GETPG

DECISION

PROCESSOR

REGISTERS

PGSETR

PROGRAM

COUNTER

CU

DPU

ALU

LDPR

LDCR

ON CHIP PERIPHERALS

OUTPUT

REGISTERS

PERIPHERAL

CONFIGURATION

REGISTERS

PERIPHERAL

PERIPHERAL

BLOCK

BLOCK

BLOCK

21/106

Page 22

ST52F510/F513/F514

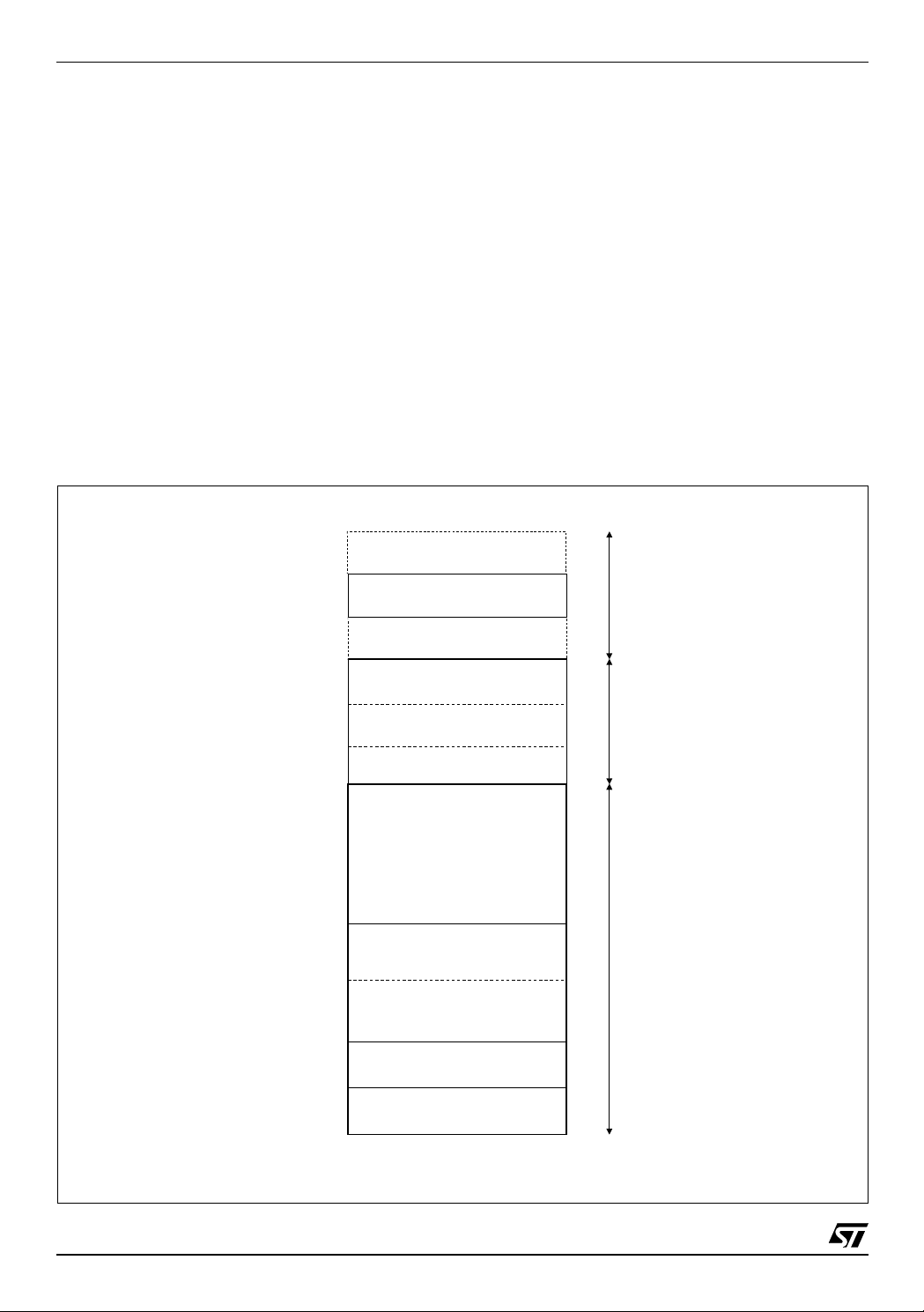

NVM is always located beginning after the first

locations of the addressing space. RAM banks are

always located after NVM.

NVM is organized in acco rdance to the following

blocks (see Figure 3.2):

■

Reset Vector block

(from address 0 to 2)

contains an absolute jump instruction to the first

user program instruction. The Assembler tool

automatically fills these locations with correct

data.

■

Interrupt Vectors block

(from location 3 up to

32) contains the interrupt vectors. Each address

is composed of three bytes (the jump opcode

and the 16 bit address). Interrupt vectors are set

by using IRQ pseudo-instruction (see the

Programming Manual).

Figure 3.2 Program/Data Memory Organization

FFFFh

~~

307Fh

OPTION BYTES

3000h

~~

20FFh

SYSTEM STACK

■

Mbfs Setting block

(just after the interrupt

vectors) contains the coordinates of the vertexes

of every Mbf defined in the program. The last

address that can be assigned to this block is

1023. This area is dynamically assigned

according to the size of the fuzzy routines. The

memory area that remains unused, if any, is

assigned to the Program Instructions block.

■

The Program Instructions block

(just after the

last Mbf data through the last NVM address)

contains the instruction of the user program and

the permanent data.

■

Option bytes block

(from location 3000h to

307Fh) is the addressing space reserved for the

option bytes. In ST 52F510/F513/F514, o nly the

location from 3000h to 3007h are used.

SPACE NOT

ADDRESSABLE

2000h

0400h

0021h

0003h

0000h

DATA

USER STACK

PROGRAM INSTRUCTIONS

AND PERMANENT DATA

PROGRAM INSTRUCTIONS

AND PERMANENT DATA

MEMBERSHIP FUNCTIONS

PARAMETERS

INTERRUPT VECTORS

RESET VECTOR

RAM

BENCH

NON

VOLATILE

MEMORY

22/106

Page 23

ST52F510/F513/F514

Flash and EEPROM are pr ogrammed electrically

just applying the supply voltage (2.7 V to 5.5 V) and

it is also erased electrically; this feature allows the

user to easily reprogram the memory without

taking the device off from the board (In Situ

Programming ISP). Data and commands are

transmitted through t he I

2

C serial communicatio n

protocol. Data can also be written run-time with the

In Application Programming (IAP)

NVM can be locked by the user during the

programming phase, in orde r to prevent external

operation such as rea ding the program code an d

assuring protection of user intellectual property.

Flash and EEPROM pages can be protected by

unintentional writings.

The operations that can be performed on the NVM

during the Programmin g Phase, ISP and IAP ar e

described in detail in the Section 4.

Figure 3.3 System and User Stack

RAM BENCH

20FFh

20FEh

SYSTEM STACK

POINTER

SYSTEM STACK

LEVEL 1

SYSTEM STACK

LEVEL 2

SYSTEM STACK

LEVEL 3

SYSTEM STACK

LEVEL 4

IRQ

3.4 System and User Stacks

The System and User Stacks are located in the

Program/Data memory in the RAM benches.

System Stacks are used to push the Program

Counter (PC) after an Interrupt Request or a

Subroutine Call. After a RET (Return from a

subroutine) or a RETI (Return from an interrupt)

the PC that is saved is popped from the stack and

restored. After an inter rupt request, the flags are

also saved in a r eserved s tack insi de the cor e, so

each interrupt has its own flags.

The System Stack is located in the last RAM bench

starting from the last address (255) inside the

bench page. The System Stack Pointer (SSP) can

be read and modified by the user. For each level of

stack 2 bytes of the RAM are used. The SSP points

to the first currently available stack position. When

a subroutine call or interrupt request occurs, the

content of the PC is stored in a couple of locations

pointed to by the SSP that is decreased by 2.

PROGRAM COUNTE R

RETI

LOCATION ADRESS

PAGE NUMBER

REGISTER FILE

LSB

MSB

USER STACK

POINTER

2001h

2000h

USER DATA

USER STACK LEVEL 4

USER STACK LEVEL 3

USER STACK LEVEL 2

USER STACK LEVEL 1

PUSH X

POP X

REGISTER X

CONFIGURATION REGISTERS

USER STACK TOP LSB

USER STACK TOP MSB

23/106

Page 24

ST52F510/F513/F514

When a return occurs (R ET or RETI instruction),

the SSP is increas ed by 2 and the data stored in

the pointed locations co uple is restored back into

the PC.

The current SSP can be read and write in the

couple of Configuration Reg isters 44 02Ch (MSB :

page number, always 32 020h) and 45 02Dh (LSB:

location address) ( see Figure 3.3). In ST52F51 0/

F513/F514 the user can only consider the LSB

because the MSB is always the same.

The User Stack is used to s tore user data and is

located beginning fr om a RAM bench locati on set

by the user (USTP) by writing the couple of

Configuration Registers 5 005h (MSB: page

number) and 6 005h (LSB: location address) (see

Figure 3.3). Register 5, which is the page number,

must always be set to a va lue between 32 (020h)

and 255 (0FFh): values higher than 32 always

address RAM on page 32.

Note: In ST52F510/F513/F514 MSB doesn’t have

to be set or read because the RAM is only 256

bytes. The LSB of the user stack is equal to 0 at

reset. The LSB of the system stack is equal to 255

at reset.

This feature allows a flexible use of the User Stack

in terms of dimensi on and to avoid ove rlaps. The

User Stack Pointer (USP) points to the first

currently availab le stack location. When the user

stores a byte value contain ed in the Register File

by using the PUSH in structi on, the valu e is store d

in the position pointed to by the USP that is

increased (the User Stack o rder is oppo site to the

System Stack one). Wh en the user takes a valu e

from the User Stack with the POP inst ruction, the

USP is decreased and the value pointed to is

copied in the specified Register File location.

By writing the USTP, the new address is

automatically written in the USP. The current USP

can be read from the Input Registers 11 0Bh

(MSB: page number, always 32 020h) and 12 0Ch

(LSB: location address) (see Figure 3.3). In

ST52F510/F513/F514 the user can only consider

the LSB because the MSB is always the same.

Note: The user must pay close attention to avoid

overlapping user and Stacks data. The User Stack

Top location and the System Stack Pointer should

be configured with c are in order to have enough

space between the two stacks.

3.5 Input Registers

The ST52F510/F513/F514 Input Regis ters bench

consists of a file of 8-bit regis ters containing data

or the status of the p eripherals. For exam ple, the

Input Registers contain data converted by the

ADC, Ports, serial communication peripherals,

Timers, etc.

The Input Registers can be accessed by using the

LDRI instruction that loads the specified Register

File address with the contents of the specified

Input Register. See the Programming Manual for

further details on this instruction. The Input

Registers are read-only registers.

In order to simplify the concept, a mnemonic name

is assigned to each register. The same name is

used in Visual FIVE devel opmen t tools. The list of

the Input Registers is shown in Table 3.1.

3.6 Output registers

The ST52F510/F513/F514 Output Registers

bench consists of a file of 8-bit registers containing

data sent to the Periphe rals and the I/O Port s (for

example: Timer Counter s, data to be transmitted

by the serial communication peripherals, data to be

sent to the Port pins in output, etc.).

The registers are located inside the Peripherals

and Ports, which allow flex ibility and modul arity in

the design of new family devices.

The Output Registers are write only. In order to

access the configuration Register the user can use

the following instructions:

■ LDPI: loads the immediate value in the specified

Output Register.

■ LDPR: loads the contents of the specified

Register File location into the output register

specified. This instruction allows computed data

to be sent to Peripherals and Ports.

■ LDPE direct: loads th e c ont ents of the sp ec ifi ed

Program/Data Memory l ocation into the output

register specified. This instruction allows data to

be sent to Peripherals and Ports from a table.

■ LDPE indirect: loads the contents of the

Program/Data Memo ry location whose address

is contained in the specified Register File

location into the output reg ister specified. This

instruction allows da ta to be se nt to Per ipheral s

and Ports from a table pointed to by a register.

See the Programming manual for further details

about these instructions.

In order to simplify the concept, a mnemonic name

is assigned to each register. The same name is

used in Visual FIVE devel opmen t tools. The list of

the Output Registers is shown in Table 3.2.

24/106

Page 25

ST52F510/F513/F514

3.7 Configuration Registers & Option Bytes

The ST52F510/F513/F514 Configuration

Registers bench con si st s o f a f il e of 8- bit r egi ste rs

that allows the configuration of all the ICU blocks.

The registers are located inside the block they

configure in order to ob tain greater flexibility and

modularity in the design of new f amily devices. In

the Configuration Registers, each bit has a

peculiar use, so the logic level of each of them

must be considered.

Some special c onfig urati on dat a, that needs to b e

load at the start-up and not further changed, are

stored in Option Bytes. These are loaded only

during the device program ming phase. See Tabl e

3.3 and Section 4 for a d etailed descr iption of the

Option Bytes.

The Configuration Registers are readable and

writable; the address es refer to the sam e register

both in read and in writ e. In order to access the

Configuration Register the user can work in

several modes by utilizing the following

instructions:

■ LDCI: loads the immediate value in the

Configuration Register specified and is the most

commonly used to write configuration data.

■ LDCR: loads the Configuration Register

specified with the contents of the specified

Register File location, allowing a parametric

configuration.

■ LDCE: loads the Configuration Register

specified with the contents of the specified

Program/Data Memory location, allowing the

configuration data to be taken from a table.

■ LDCNF: loads the Register File location

specified with the c ontents of the Con figuration

Register indicated, allowing for the inspection of

the configuration of the device (permitting s afe

run-time modifications).

In order to simplify the concept, a mnemonic name

is assigned to each register. The same name is

used in Visual FIVE devel opmen t tools. The list of

the Configuration Registers is shown in Table 3.4.

25/106

Page 26

ST52F510/F513/F514

Table 3.1 Input Registers

Mnemonic Description Address

PORT_A_IN Port A data Input Register 0 00h

PORT_B_IN Port B data Input Register 1 01h

PORT_C_IN Port C data Input Register 2 02h

- Not Used 3 03h

- Not Used 4 04h

SPI_IN Serial Peripheral Interface data Input Register 5 05h

I2C_IN

I2C_SR1

I2C_SR2

2

C Interface data Input Register

I

2

I

C Interface Status Register 1

2

I

C Interface Status Register 2

606h

707h

808h

- Not Used 9 09h

- Not Used 10 0Ah

USP_H User Stack Pointer (MSB) 11 0Bh

USP_L User Stack Pointer (LSB) 12 0Ch

- Not Used 13-2 0

0Dh-

014h

PWM0_COUNT_IN_H PWM/Timer 0 Counter Input Register (MSB) 21 015h

PWM0_COUNT_IN_L PWM/Timer 0 Counter Input Register (LSB) 22 016h

PWM0_STATUS PWM/Timer 0 Status Register 23 017h

PWM0_CAPTURE_H PWM/Timer 0 Capture Register (MSB) 24 018h

PWM0_CAPTURE_L PWM/Timer 0 Capture Register (LSB) 25 019h

PWM1_COUNT_IN_H PWM/Timer 1 Counter Input Register (MSB) 26 01Ah

PWM1_COUNT_IN_L PWM/Timer 1 Counter Input Register (LSB) 27 01Bh

PWM1_STATUS PWM/Timer 1 Status Register 28 01Ch

PWM1_CAPTURE_H PWM/Timer 1 Capture Register (MSB) 29 01Dh

PWM1_CAPTURE_L PWM/Timer 1 Capture Register (LSB) 30 01Eh

- Not Used 31-3 5

SCI_IN Serial Communication Interface RX data Input Register 36 024h

SCI_STATUS Serial Communication Interface Status Register 37 025h

FLAGS Flag Register 38 026h

AD_OVF 10-bit A/D Converter Overflow Register 39 027h

IAP_SR In Application Programming Status Register 40 028h

26/106

01Fh-

023h

Page 27

ST52F510/F513/F514

Table 3.1 Input Registers

Mnemonic Description Address

CHAN0_H 10-bit A/D Converter Channel 0 data Input Register (MSB) 41 029h

CHAN0_L 10-bit A/D Converter Channel 0 data Input Register (LSB) 42 02Ah

CHAN1_H 10-bit A/D Converter Channel 1 data Input Register (MSB) 43 02Bh

CHAN1_L 10-bit A/D Converter Channel 1 data Input Register (LSB) 44 02Ch

CHAN2_H 10-bit A/D Converter Channel 2 data Input Register (MSB) 45 02Dh

CHAN2_L 10-bit A/D Converter Channel 2 data Input Register (LSB) 46 02Eh

CHAN3_H 10-bit A/D Converter Channel 3 data Input Register (MSB) 47 02Fh

CHAN3_L 10-bit A/D Converter Channel 3 data Input Register (LSB) 48 030h

CHAN4_H 10-bit A/D Converter Channel 4 data Input Register (MSB) 49 031h

CHAN4_L 10-bit A/D Converter Channel 4 data Input Register (LSB) 50 032h

CHAN5_H 10-bit A/D Converter Channel 5 data Input Register (MSB) 51 033h

CHAN5_L 10-bit A/D Converter Channel 5 data Input Register (LSB) 52 034h

CHAN6_H 10-bit A/D Converter Channel 6 data Input Register (MSB) 53 035h

CHAN6_L 10-bit A/D Converter Channel 6 data Input Register (LSB) 54 036h

CHAN7_H 10-bit A/D Converter Channel 7 data Input Register (MSB) 55 037h

CHAN7_L 10-bit A/D Converter Channel 7 data Input Register (LSB) 56 038h

27/106

Page 28

ST52F510/F513/F514

Table 3.2 Output Registers

Mnemonic Description Address

PORT_A_OUT Port A data Output Register 0 00h

PORT_B_OUT Port B data Output Register 1 01h

PORT_C_OUT Port C data Output Register 2 02h

- Not Used 3 03h

- Not Used 4 04h

SPI_OUT Serial Peripher al Inte rfa ce data Outp ut Regis te r 5 05h

I2C_OUT

PWM0_COUNT_OUT_H PWM/Timer 0 Counter Output Register (MSB) 7 07h

PWM0_COUNT_OUT_L PWM/Timer 0 Counter Output Register (LSB) 8 08h

PWM0_RELOAD_H PWM/Timer 0 Reload Register (MSB) 9 09h

PWM0_RELOAD_L PWM/Timer 0 Reload Register (LSB) 10 0Ah

PWM1_COUNT_OUT_H PWM/Timer 1 Counter Output Register (MSB) 11 0Bh

PWM1_COUNT_OUT_L PWM/Timer 1 Counter Output Register (LSB) 12 0Ch

PWM1_RELOAD_H PWM/Timer 1 Reload Register (MSB) 13 0Dh

PWM1_RELOAD_L PWM/Timer 1 Reload Register (LSB) 14 0Eh

SCI_OUT Serial Communication Interface TX data Output Register 23 017h

2

C Interface data Output Register

I

606h

Table 3.3 Option Bytes

Mnemonic Description Address

OSC_CR Oscillator Control Register 0 00h

CLK_SET Clock Parameters 1 01h

OSC_SET Oscillator Set-Up 2 02h

PLDV_CR Programmable Low Voltage Detector Control Register 3 03h

WDT_EN HW/SW Watchdog selector 4 04h

PG_LOCK First Page Write Protected 5 05h

PG_UNLOCK First Page not Write Protected 6 06h

WAKEUP Wake Up from Halt Time 7 07h

28/106

Page 29

ST52F510/F513/F514

Table 3.4 Configuration Registers

Mnemonic Description Address

INT_MASK Interrupt Mask Register 0 00h

INT_POL Interrupts Polarity 1 01h

INT_PRL_H Interrupt Priority Reg ist er (hig he r priority ) 2 02h

INT_PRL_M In te rru pt Pri orit y Regist er (me di um prior ity) 3 03h

INT_PRL_L Interrupt Priority Register (lower prior ity) 4 04h

USTP_H User Stack Top Pointer (MSB) 5 05h

USTP_L User Stack Top Pointer (LSB) 6 06h

WDT_CR Watchdog Configurati on Re gis te r 7 07h

AD_CR1 10-bit A/D Converter Control Register 1 8 08h

PWM0_CR1 PWM/Timer 0 Configuration Register 1 9 09h

PWM0_CR2 PWM/Timer 0 Configuration Register 2 10 0Ah

PWM0_CR3 PWM/Timer 0 Configuration Register 3 11 0Bh

PWM1_CR1 PWM/Timer 1 Configuration Register 1 12 0Ch

PWM1_CR2 PWM/Timer 1 Configuration Register 2 13 0Dh

- Not Used 14 0Eh

- Not Used 15 0Fh

I2C_CR

I2C_CCR

I2C_OAR1

I2C_OAR2

2

I

C Interface Control Register

2

I

C Interface Clock Control Register

2

I

C Interface Own Address Register 1

2

I

C Interface Own Address Register 2

16 010h

17 011h

18 012h

19 013h

SPI_CR Serial Peripheral Inte rfa ce Con trol Regi ste r 20 014h

SPI_STATUS_CR Serial Peripheral Inte rfa ce Con trol-Status Register 21 015h

SCI_CR1 Serial Communication Interface Control Register 1 22 016h

SCI_CR2 Serial Communication Interface Control Register 2 23 017h

PORT_A_PULLUP Port A Pull Up enable/disable Register 24 018h

PORT_A_OR Port A Option Register 25 019h

29/106

Page 30

ST52F510/F513/F514

Table 3.4 Configuration Registers

Mnemonic Description Address

PORT_A_DDR Port A Data Direction Register 26 01Ah

PORT_A_AF Port A Alternate Function selection Register 27 01Bh

PORT_B_PULLUP Port B Pull Up enable/disable Register 28 01Ch

PORT_B_OR Port B Option Register 29 01Dh

PORT_B_DDR Port B Data Direction Register 30 01Eh

PORT_B_AF Port B Alternate Function selection Register 31 01Fh

PORT_C_PULLUP Port C Pull Up enable/disable Register 32 020h

PORT_C_OR Port C Option Register 33 021h

PORT_C_DDR Port C Data Direction Register 34 022h

PORT_C_AF Port C Alternate Function selection Register 35 023h

- Not Used 36-4 2

SCI_CR3 Serial Communication Interface Control Register 3 43 02Bh

SSP_H System Stack Pointer (MSB) 44 02Ch

SSP_L System Stack Pointer (LSB) 45 02Dh

CPU_CLK CPU Clock Prescaler 46 02Eh

AD_CR2 10-bit A/D Converter Control Register 2 47 02Fh

024h-

02Ah

30/106

Page 31

ST52F510/F513/F514

4 MEMORY PROGRAMMING

ST52F510/F513/F514 provides an on-chip user

programmable non-vo latile memory, whic h allows

fast and reliable storage of user data.

Program/Data Memory addressing space is

composed by a Singl e Vol tag e Fl ash Memory and

a RAM memory bench. The ST52F513/514

devices also have a Data EEPROM bench to store

permanent data with long term retention and a high

number of write/erase cycles.

All the Program Data memory addresses can

execute code, including RAM and EEPROM