■

SUPPLY VOLTAGE RANG E: 4. 8 TO 18V

■

OUTPUT VOLTAGE UP TO 40V

■

OUTPUT VOLTAGE CLAMP DURING

RECIRCULATION OF INDUCTIVE LOADS

■

OUTPUT CURRENT CAPABIL ITY 2 X 5A AND

2 X 3A

■

LOW POWER DISSIPATION DURING

RECIRCULATION OF INDUCTIVE LOADS BY

INTEGRATED FREE WHEELING DIODES

(3A-DRIVER S ONLY)

■

LOW ON-RESISTANCE 2 X 0.2Ω , 2 X 0.35Ω (TYP.)

■

OUTPUT SHORT CIRCUIT CURRENT

PROTECTION

■

REAL TIME DIAGNOSTIC FUNCTIONS

■

OVERTEMPERATURE SHUTDOWN

■

SIGNAL- AND POWER-GROUND-LOSS

SHUTDOWN

L9348

QUAD LOW SIDE DRIVER

PowerSO-36 BARE DIE

ORDERING NUMB ERS :

L9348 L9348-DIE1

■

3.3V CMOS COMPATIBLE INPUTS AND

STATUS

DESCRIPTION

The L9348 is a monolithic integrated quad low side

driver realized in advanced Multipower-BCD technology. It is intended to drive inductive loads (relays,

electromagnetic valves) in automotive and industrial

applications.

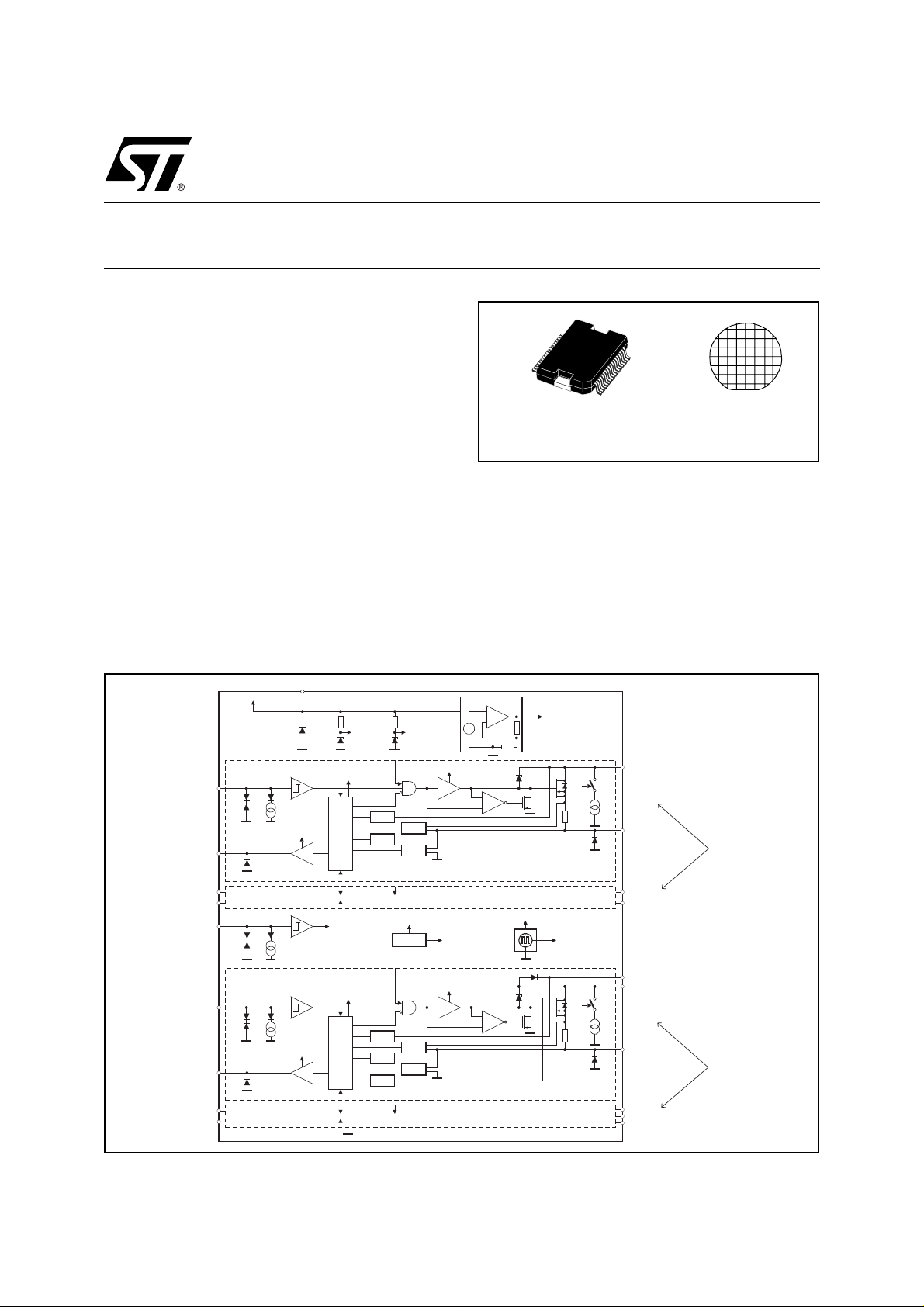

Figure 1. Block Diagram

V

S

IN1

ST1

IN2

ST2

ENA

IN3

ST3

IN4

ST4

99AT0073

March 2002

VS

C 166kHz

V

DD

V

REG

Diagnostic

PWRES

C 166kHz EN

PWRES

EN

C 166kHz

V

DD

V

REG

Diagnostic

PWRES

C 166kHz EN

PWRES

GND

Voltage Regulator

+

–

=

V

S

≥

1

PWRES C 166kHz

V

S

≥

1

TSD

TSD

V

CC

EN

OL

SCP

GL

V

DD

PWRES

EN

OL

SCP

GL

FB

V

DD

FAIL

FAIL

VREG

Q1

EN

PGND1

5A - DRIVER

CHANNEL1

CHANNEL2

V

S

EN

CHANNEL3

CHANNEL4

Q2

PGND2

D3

Q3

PGND3

D4

Q4

PGND4

3A - DRIVER

1/13

L9348

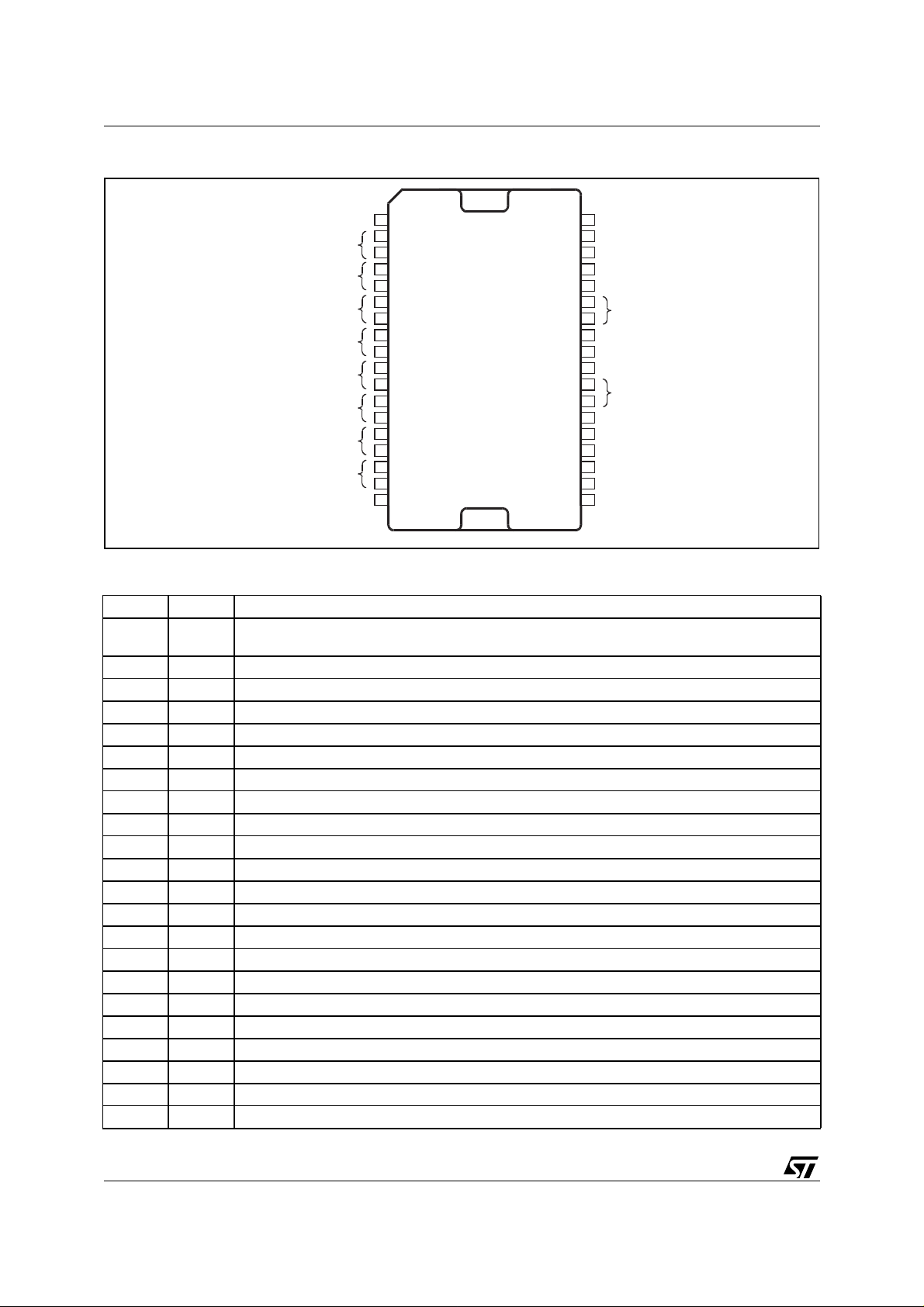

Figure 2. Pin Connection

N.C.

PGND3

Q3

D3

Q1

Q2

D4

Q4

PGND4

N.C.

99AT0074

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Table 1. Pin Description

N° Pin Function

1, 18,

19, 36

2, 3 PGND3 Power Ground Channel 3

4, 5 Q3 Power Output Channel 3 (3A switch)

6, 7 D3 Recircula tion Diode Chan nel 3

8, 9 Q1 Power Output Channel 1 (5A switch)

10, 11 Q2 Power Output Channel 2 (5A switch)

12, 13 D4 Recircula tion Diode Chan nel 4

14, 15 Q4 Power Output Channel 4 (3A switch)

16, 17 PGND4 Power Ground Channel 4

20 ST4 Status Output Channel 4

21 IN2 Control Input Channel 2

22 IN4 Control Input Channel 4

23 ST2 Status Output Channel 2

24 ENA Enable

25, 26 PGND2 Power Ground Channel 2

27 GND Signal Ground

28 VS Supply Voltage

29 N.C. Not Connected

30, 31 PGND1 Power Output Channel 3

32 ST1 Status Output Channel 1

33 IN3 Control Input Channel 3

34 IN1 Control Input Channel 1

N.C. (GND)

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

N.C.

ST3

IN1

IN3

ST1

PGND1

N.C.

VS

GND

PGND2

ENA

ST2

IN4

IN2

ST4

N.C.

2/13

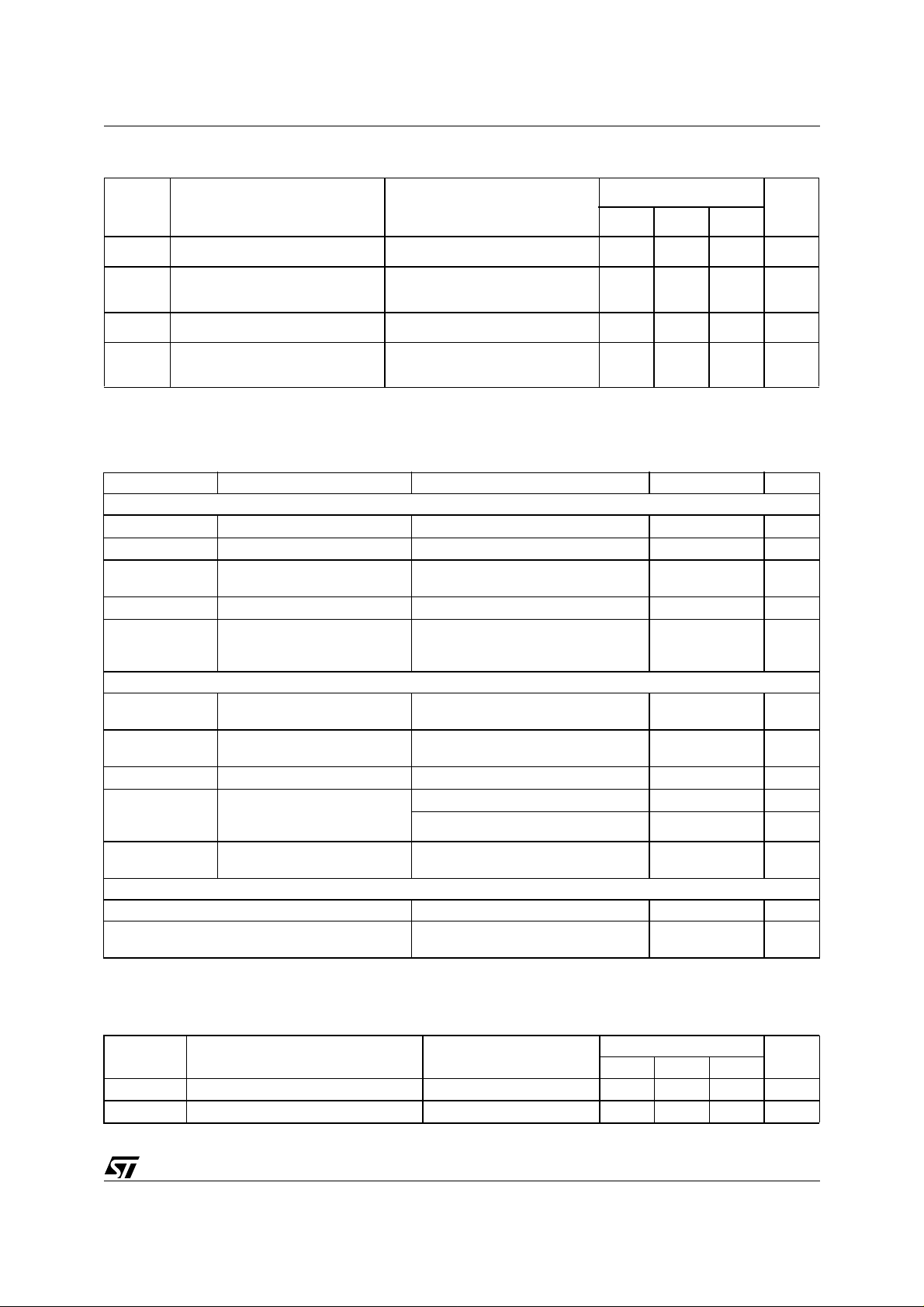

Table 2. Thermal Data

Symbol Parameter Test Conditions

T

Junction temperature -40 150 °C

j

L9348

Values

Unit

Min. Typ. Max.

T

T

R

th j-case

Junction temperature during

jc

clamping (life time)

Storage temperature -55 150 °C

stg

t = 30min

Σ

t = 15min

Σ

Thermal resistance junction to

175

190

2 °C/W

°C

°C

case

Table 3. Absolute Maximum Ratings

The absolute maximum ratings are the limiting values for this device. Damage may occur if this device is

subjected to conditions which are beyond these values

Symbol Parameter Test Conditions Value Unit

Voltages

V

S

V

, V

Q

D

, V

V

IN

EN

V

ST

V

DRmax

Currents

I

Q 1/2

I

Q 3/4

I

ST

E

Q1/2

I

FDmax

ESD Protection

Supply and Signal pins versus GND ±2kV

Output pins (Q

Supply voltage range -0.3 to 40 V

max. static Output voltage 40 V

Input voltage range

|II | < 10mA -1.5 to 6 V

(IN1 to IN4, EN)

Status output voltage range |II | < 1mA -0.3 to 6 V

max. Reverse breakdown

= 100 µA

I

R

voltage free wheeling diodes

D3, D4

Output current at reversal

supply for Q1, Q2

Output current at reversal

supply for Q3, Q4

Status output current range -1 to 1 mA

max. Discharging energy for

inductive loads per channel

Q1, Q2

max. load current free

= 25°C 50 mJ

T

j

T

= 150°C 30 mJ

j

t < 5ms 3 A

wheeling diodes

, DX) versus common ground (=short of

X

.

55 V

-4 A

-2 A

±4kV

SGND with all PGND)

Note: Human Body Model according to MIL883C. The device withstands ST1 class level.

Table 4. Operating Range

.

Symbol Parameter Test Conditions

V

S

T

Supply voltage 4.8 18 V

Junction temperature -40 150 °C

j

Values

Min. Typ. Max.

Unit

3/13

L9348

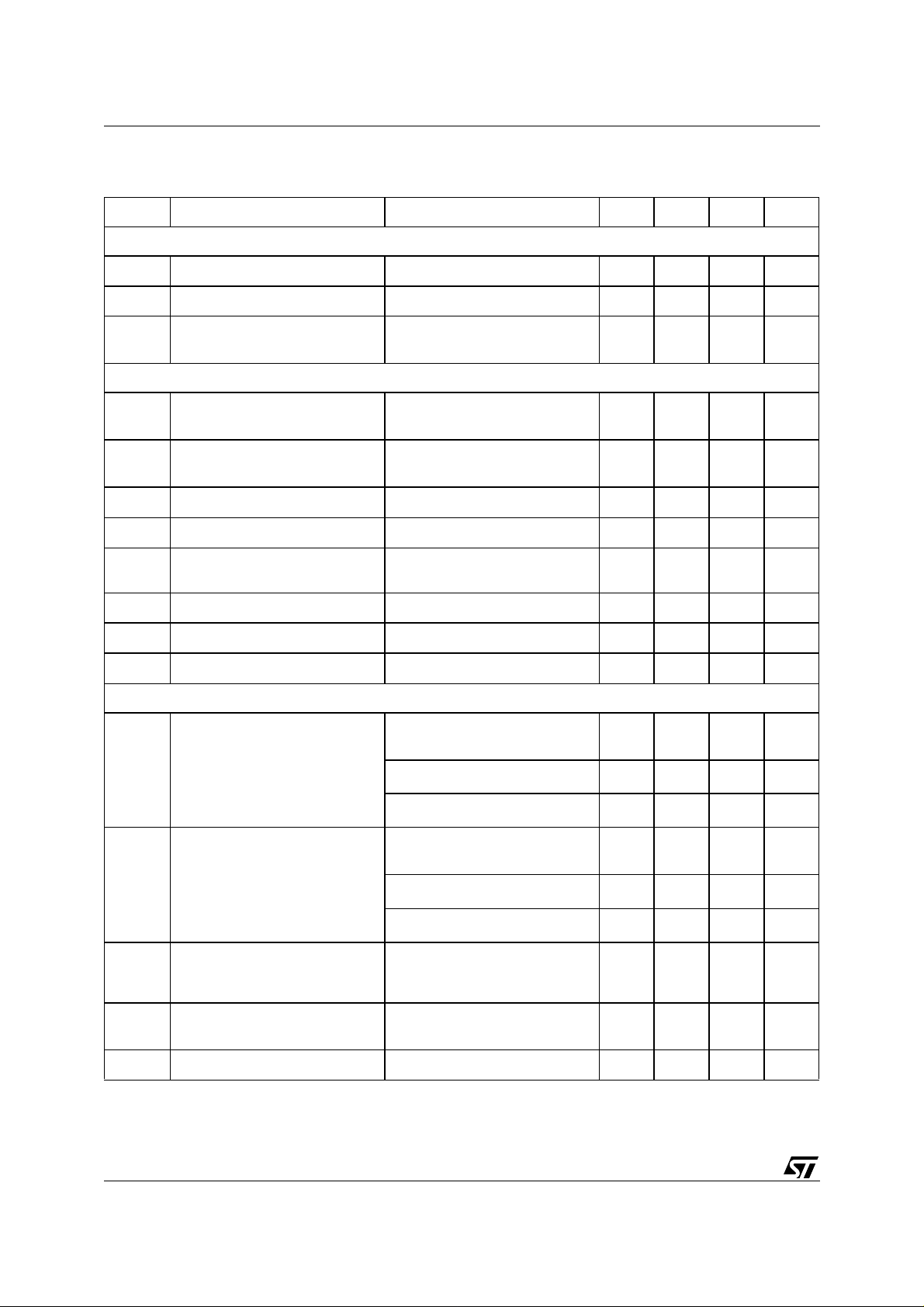

Table 5. Electrical Characteristcs

The electrical characteristics are valid within the operating range

Symbol Parameter Test Condition Min. Typ. Max. Unit

Power Supply

I

Supply current V

S

I

Quiescent current (outputs OFF) V

Q

IN1...IN4, ENA

= L 6 mA

ENA

= H 8 mA

(Table 4)

, unless otherwise specified

I

D3/4

Quiescent current at pins D3/4

Diagnostic Functions

V

QU1 to 4

Output open load voltage

threshold

I

QU1 to 4

Output open load current

threshold

I

QO1/2

I

QO3/4

Overload current threshold Q 1, 2

Overload current threshold Q 3, 4

TthOvertemperature shutdown

threshold

V

V

T

thPGL

thSGL

Overtemperature hysteresis 10 °C

hy

Power-GND-loss threshold 1.5 2.5 3.5 V

Signal-GND -loss thresh old 150 330 510 mV

Power Outputs (Q1 to Q4)

R

DSON1/2

Static drain-source ON-resistance

Q1, Q2

≤ 18V;

V

D3/4

V

= L

IN3/4

≥ 6.5V

V

S

VEN = X; VIN = L

≥ 6.5V

V

S

VEN = H; VIN = H

≥ 6.5V

V

S

≥ 6.5V

V

S

2)

= 1A; VS ≥ 9.5V

I

Q

Tj = 25°C

Tj = 125°C

3)

10 400

0.3 0.33 0.36 x V

A

µ

S

50 140 mA

57.59 A

358A

175 210 °C

0.2

0.5

Ω

Ω

R

DSON3,4

V

Z

V

C

I

PD

4/13

Static drain-source ON-resistance

Q3, Q4

Z-diode clamping voltage

= threshold of flyback detection

Q3/4

Clamping voltage

Output pull down current V

Tj = 150°C

= 1A; VS ≥ 9.5V

I

Q

T

= 25°C

j

T

= 125°C

j

T

= 150°C

j

≥ 100mA,

I

Q

pos. supply V

≥ 100mA,

I

Q

neg. supply V

ENA

4)

0.35 Ω

3)

4)

45 60 V

D3/4

410V

D3/4

= H, VIN = L 10 20 50

0.5

0.75 Ω

0.75 Ω

µ

Ω

A

L9348

Table 5. Electrical Characteristcs

The electrical characteristics are valid within the operating range

Symbol Parameter Test Condition Min. Typ. Max. Unit

(Table 4)

, unless otherwise specified

V

I

FD3/4

Output leakage current V

Qlk

Forward voltage of

free wheeling diodes D3, D4

R

Gate pull down resistor for

PD0

nonsupplied V

S

Timings

t

t

OFF

t

DSO

t

filter

t

OLOFF

Output ON delay time

ON

t

Output ON fall time

f

Output OFF delay time

t

Output OFF rise time

r

Overload switch-OFF delay time 6 30 65

t

Output OFF status delay time 0.75 1.5 2.25 ms

D

error detection filter time

OLOFF error detection filter time 20 70

Digital Inputs (IN1 to IN4, ENA)

= L,Tj = 25°C 1

ENA

T

= 125°C 5

j

I

= -1.5A 0.5 1.75 V

D3/4

VS = 0V,

≥ 6.5V

V

D3/4

= 1A

I

Q

IQ = 1A

IQ = 1A

IQ = 1A

2)

1)

1)

1)

1)

0.3 3 kΩ

0520

0.5 1.5 8

01030

0.5 1.5 5

5.8 35

A

µ

A

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

V

V

V

I

Input low voltage -1.5 1 V

IL

Input high voltage 2 6 V

IH

Input voltage hysteresis

IHy

Input pull down current

IN

2)

= 5V, VS ≥ 6.5V

V

IN

50 100 mV

82040

Digital Outputs (ST1 to ST4)

V

V

R

DIAGLROUT

R

DIAGHROUT

Status output voltage in low state

STL

5)

Status output voltage in high state

STH

5)

+ R

+ R

chapter 2.0 Timing Di ag rams

(1).See

(2).This parameter will not be tested but assured by design

(3).Wafer-measurement

(4).Measured on P-SO36 devices

(5).Short circuit between two d i gi tal output s (one in high th e other in low st ate) will lea d to the define d result "LO W"

in low state 0.3 0.64 1.5

DSON

in high state 1.5 3.2 7

DSON

IST ≤ 40µA

IST ≥ -40µA

≥ -120µA

I

ST

; resistive load condition; VS ≥ 9V

0 0.4 V

2.5 3.45 V

23.45V

A

µ

k

Ω

k

Ω

5/13

L9348

1.0 FUNCTIONAL DESCRIPTION

1.1 Overview

The four low-side switches are designed to drive inductive loads (relays, electromagnetic valves). For the 3A

switches (Q3/4) integrated free-wheeling diodes (D3/4) are available and can be used as recirculation path for

inductive loads. If either integrated nor external free-wheeling diodes are used the output voltage is clamped

internally during discharge of inductive loads. The switches are controlled by CMOS compatible inputs (IN1-4)

if the enable input is set to “high”. The status of each switch is monitored by the related status output (ST1-4).

1.2 Input Circuit s

The control and enable inputs are activ e high, featur ing switching thr es holds with hy ster esis and pull-dow n current sources. Not c onnected i nputs are i nter preted as “LO W”. If the enable input i s set to “LOW” the output s are

switched off independent of the control input state (IN1-4).

1.3 Switching Stages

The four power outputs consist of DMOS-power transistors. The output stages are protected against short ci rcuit

to supply. Integrated output voltage clamp limits the output voltage in case of inductive load current flyback. Internal pull down current sources are provided at the outputs to assure a defined conditon in OFF mode. They

will be disconnected in the disable mode (ENA=L). If the supply of the device gets lost but the loads and D3/4

are still supplied, an internal pull down resistor discharges the gate of the DMOS-power transistor to avoid

switch on due to capacitive coupling.

1.4 Status O u t puts

The CMOS compatible status outputs indicate the state of the drivers (LOW-level indicates driver in OFF state,

HIGH-level indicates driver in ON state). If an error occurs the status output voltage changes like described in

chapter 1.6 Error Detection

.

1.5 Protective Circuits

The outputs are protected against current overload, overtemperature, and Power-GND-loss.

1.6 Error Detection

Two main error types are distinguished in the diagnostic logic. If current overload, overtemperature, signalGND-loss or a power-GND-loss occurs, the status output signal is inverted, an internal register is set and the

driver is shutdown. The reset is done by switching off the corresponding control input or the enable input for at

least the time t

(defined to 1.5ms typ.). See also

D

Figure 6

chapter 2.0 Timing Diagrams

in

.

All other errors (openload, activ e output voltage c lamp) only cause an i nverted status o utput signal but no shutdown of the driver. An internal register is set too, but the reset is triggered automatically after the time t

error condition is no longer valid (see

Figure 7

and

Figure 8

).

, if the

D

Excepting the detection of the active output voltage clamp all errors are digitally filtered before they are interpreted by the diagnostic logic.

The table 6 below shows the different failure conditions monitored in ON and OFF state:

Table 6.

Overloading of output

(also shorted load to supply)

Open load

(under voltage detection)

ON State

ENA = HIGH,

IN = HIGH

X

OFF State

ENA = HIGH,

IN = LOW

X

typ. Filter

time

s

µ

18

44

s

µ

Reset done by

ENA or INx = “LOW”

for t

1.5ms (typ.)

≥

internal timer (1.5ms typ.)

6/13

Table 6.

L9348

ON State

ENA = HIGH,

IN = HIGH

Open load

(under current detection)

Overtemperature X

Power-GND-loss X X

Signal-GND-loss X X

Output voltage clamp active

(Q3/4 only)

X

OFF State

ENA = HIGH,

IN = LOW

X - internal timer (1.5ms typ.)

typ. Filter

time

s

18

µ

18

s

µ

s

18

µ

s

18

µ

Reset done by

internal timer (1.5ms typ.)

ENA or INx = “LOW”

for t

1.5ms (typ.)

≥

ENA or INx = “LOW”

for t

1.5ms (typ.)

≥

ENA or INx = “LOW”

for t

1.5ms (typ.)

≥

1.7 Diagnostic Output at Pulse Width Operation (PWM)

If an input is operated with a pulsed signal (f

An internal delay t

Diagrams

).

of typ. 1.5ms leads to a continuous status output signal (see

D

≥ 1/

tD = 667 Hz typ.), the status does not follow each single pulse.

Figure 4

chapter 2.0 Timing

in

1.8 Diagnostic Table

In general the diagnostic follows the input signal in normal operating conditions. If any error is detected the diagnostic is inverted.

Table 7.

Operating Condition Enable

Input

ENA

Normal function L

L

H

H

Open load or short to ground L

L

H

H

Overload or short to supply

Latched overload

Reset latch

Overtemperature

Latched overtemperature

Reset latch

H

H

H –> L

H

H

H

H –> L

H

Control

Input

IN

L

H/PWM

L

H/PWM

L

H/PWM

L

H/PWM

H/PWM

H/PWM

X

H/PWM –> L

H/PWM

H/PWM

X

H/PWM –> L

Power

Output

Q

OFF

OFF

OFF

ON

OFF

OFF

OFF

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

Status

Output

ST

L

L

L

H

X

X

H

L

L

L

L

L

L

L

L

L

7/13

L9348

2.0 TIMING DIAGRAMS

Figure 3. Output slope with Resistive Load

V

IN

t

ONtf

V

Q

100% V

Q

85% V

Q

15% V

Q

99AT0061

note: parameters are not shown proportionally

t

OFFtr

t

t

Figure 4. Diagnostic Output at PWM operation

V

IN

I

Q

I

QU

V

ST

t

D

99AT0063

note: parameters are not shown proportionally

t

t

t

D

t

delayed status signal

8/13

Figure 5. Overload Detection

V

IN

L9348

overload detected

I

Q

I

QO

I

QU

t

V

ST

99AT0062

note: parameters are not shown proportionally

Figure 6. Driver Shut Down in Case of Overload

V

IN

filter

t

DSO

t

t

t

driver shut down

error condition

signalized

driver is shuted

down and locked

error is signalized

99AT0064

I

Q

I

QO

V

ST

note: parameters are not shown proportionally

t

D

t

driver is now free again

t

t

D

t

9/13

L9348

Figure 7. Under C urr ent Condition

V

IN

I

Q

I

QU

t

filter

under current condition detected

V

ST

t

t

under current condition signalized

99AT0065

note: parameters are not shown proportionally

Figure 8. Open Load Condit io n in Off Stat e

V

IN

V

Q

V

QU

t

openload condition detected

but not signalized due to:

t

< t

detection

OLOFF

V

ST

detection

t

OLOFF

t

t

detection

D

t

status signal is changed by internal reset

t

t

t

OLOFF

openload condition detected

and signalized due to:

t

> t

detection

OLOFF

10/13

99AT0066

note: parameters are not shown proportionally

t

D

t

Figure 9. Out put V ol t age C l am p D et ect i on

V

IN3/4

V

Q3/4

V

Z

V

ST3/4

L9348

t

t

99AT0067

3.0 PAD POSITIONS

Chip Size: 5.17 x 2.76 mm

Figure 10.

PGND4 Q4 D4 D3Q2 Q1 Q3 PGND3

2

t

clamp

t

clamp

t

time between two clamping periods is

t

D

note: parameters are not shown proportionally

shorter than internal delay time

-> status signal remains low

PGND1PGND2 GND VS

ST1 IN3 IN1 ST3ENAST2IN4IN2ST4

11/13

L9348

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

mm inch

A 3.60 0.141

a1 0.10 0.30 0.004 0.012

a2 3.30 0.130

a3 0 0 .10 0 0.004

b 0.22 0 .38 0.008 0.015

c 0.23 0.32 0.009 0.012

D (1) 15.80 16.00 0.622 0.630

D1 9.40 9.80 0.370 0.385

E 13.90 14.50 0.547 0.570

e 0.65 0.0256

e3 11.05 0.435

E1 (1) 10.90 11.10 0.429 0.437

E2 2.90 0.114

E3 5.80 6.20 0.228 0.244

E4 2.90 3.20 0.114 0.126

G 0 0.10 0 0.004

H 15.50 15.90 0.610 0.626

h 1.10 0.043

L 0.80 1.10 0.031 0.043

N10°(max.)

S8°(max.)

(1): "D" and "E1" do not include mold flash or protrusions

- Mold flash or protrusions shall not exceed 0.15mm (0.006 inch)

- Critical dimensions are "a3", "E" and "G".

OUTLINE AND

MECHANICAL DATA

PowerSO36

NN

a2

A

1936

0.12 AB

⊕

e

M

E1

DETAIL B

lead

a3

B

Gage Plane

PSO36MEC

BOTTOM VIEW

DETAIL B

0.35

S

E

DETAIL A

L

E2

h x 45˚

DETAIL A

118

A

e3

H

D

b

c

a1

slug

E3

D1

- C -

SEATING PLANE

GC

(COPLANARITY)

12/13

L9348

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implic ation or otherwise under any pat ent or pat ent rights of STMicroe l ectronics . Specificat i ons menti oned in thi s publicati on are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as cri t i cal compone nts in life support device s or systems without express written approval of STM i croelectr o nics.

The ST logo is a registered trademark of STMicroelectronics

2002 STMi croelectronics - All Ri ghts Rese rved

Australia - Brazil - Canada - Ch i na - F i nl and - France - Germany - Hong Kong - In di a - Israel - Ital y - Japan -Mal aysia - Malta - Morocco -

Singap ore - Spain - Sweden - Swit zerland - Uni ted Kingdom - United St ates.

STMicroelectronics GROUP OF COMPANIES

http://www.s t. com

13/13

Loading...

Loading...