L6997S

STEP DOWN CONTROLLER

FOR LOW VOLTAGE OPERATIONS

1 Features

■ FROM 3V TO 5.5V V

■ MINIMUM OUTPUT VOLTAGE AS LOW AS

0.6V

■ 1V TO 35V INPUT VOLTAGE RANGE

■ CONSTANT ON TIME TOPOLOGY

■ VERY FAST LOAD TRANSIENTS

■ 0.6V, ±1% VREF

■ SELECTABLE SINKING MODE

■ LOSSLESS CURRENT LIMIT, AVAILABLE

ALSO IN SINKING MODE

■ REMOTE SENSING

■ OVP,UVP LATCHED PROTECTIONS

■ 600µA TYP QUIESCENT CURRENT

■ POWER GOOD AND OVP SIGNALS

■ PULSE SKIPPING AT LIGTH LOADS

■ 94% EFFICIENCY FROM 3.3V TO 2.5V

RANGE

CC

2 Applications

■ NETWORKING

■ DC/DC MODULES

■ DISTRIBUTED POWER

■ MOBILE APPLICATIONS

■ CHIP SET, CPU, DSP AND MEMORIES

SUPPLY

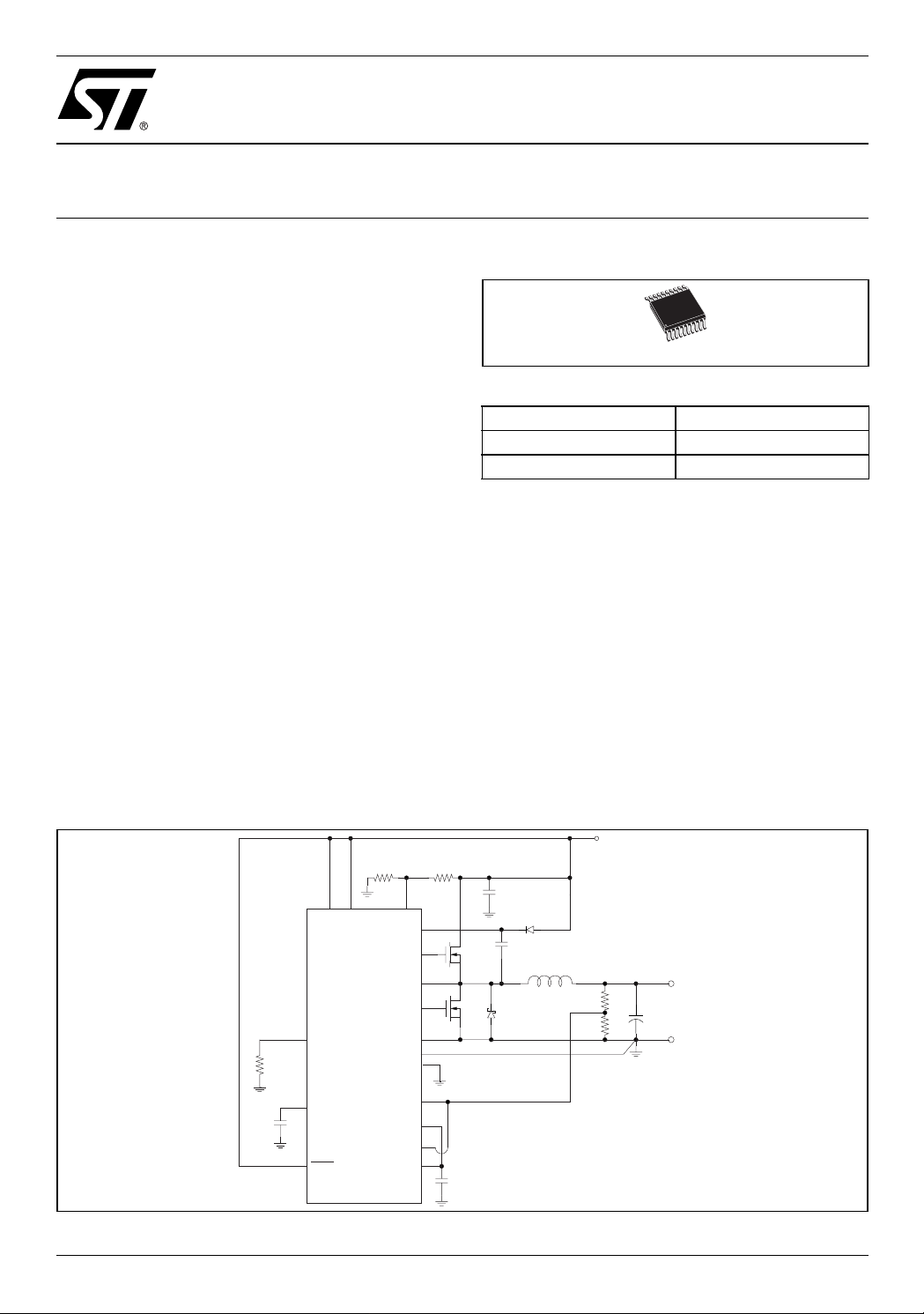

Figure 2. Minimum Component Count Application

Rin1Rin2

VDR

OSC

BOOT

HGATE

PHASE

LGATE

PGND

GND

GNDSENSE

Rilim

VCC

PGOOD

OVP

L6997S

ILIM

Figure 1. Package

TSSOP20

Table 1. Order Codes

Part Number Package

L6997S TSSOP20

L6997STR Tape & Reel

3 Description

The device is a high efficient solution for networking

dc/dc modules and mobile applications compatible

with 3.3V bus and 5V bus.

It's able to regulate an output voltage as low a s 0.6V.

The constant on time topology assures fast load tran-

sient response. The embedded voltage feed-forward

provides nearly constant switching frequency operation in spite of a wide input voltage range.

An integrator can be introduced in the control loop to

reduce the static output voltage error.

The remote sensing improves the static and dynamic

regulation, recovering the wires voltage drop.

Pulse skipping technique reduces power consumption at light loads. Drivers current capability allows

output currents in excess of 20A.

3.3V

Cin

Dboot

HS

Cboot

L

LS

DS

Ro1

Ro2

0.6V

Cout

June 2004

Css

SS

SHDN

VSENSE

INT

VFB

Vref

Cvref

REV. 1

1/30

L6997S

Table 2. Absolute Maximum Ratings

Symbol Parameter Value Unit

V

CC

V

DR

V

PHASE

BOOT, HGATE

and PHASE

PINS

OTHER PINS ±2000 V

P

tot

T

stg

Table 3. Thermal Data

Symbol Parameter Value Unit

R

th j-amb

T

j

VCC to GND -0.3 to 6 V

V

to GND -0.3 to 6 V

DR

HGATE and BOOT, to PHASE -0.3 to 6 V

HGATE and BOOT, to PGND -0.3 to 42 V

PHASE -0.3-to 36 V

LGATE to PGND -0.3 to V

ILIM, VFB, VSENSE, NOSKIP, SHDN, PGOOD, OVP, VREF,

INT, GND

SENSE

to GND

-0.3 to V

Maximum Withstandin g Voltage Range

+0.3 V

DR

+0.3 V

CC

±750 V

Test Condition:CDF-AEC-Q100-002 “Human Body Model”

Accepatance Criteria: “Normal Performance”

Power dissipation at T

= 25°C 1 W

amb

Storage temperature range -40 to 150 °C

Thermal Resistance Junction to Ambient 125 °C/W

Junction operating temperature range -40 to 125 °C

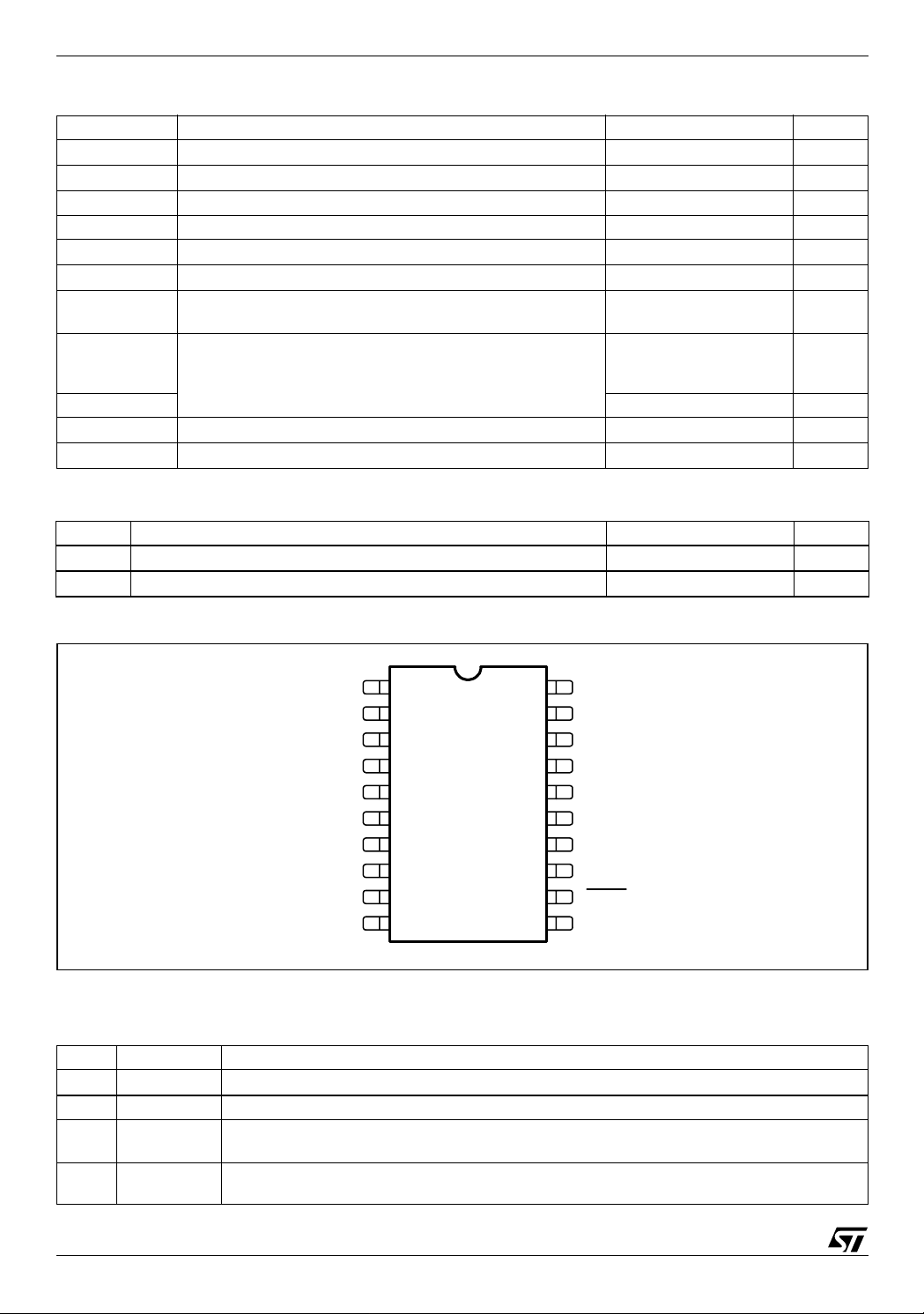

Figure 3. Pin Connection (Top View)

NOSKIP

GNDSENSE

INT

INT

VSENSE

VCC

GND

VREF

VFB

OSC

20

2

3

4

5

6

7

8

9

10SS

TSSOP20

19

18

17

16

15

14

13

12

11

BOOT1

HGATE

PHASE

VDR

LGATE

PGND

PGOOD

OVP

SHDN

ILIM

Table 4. Pin Function

N° Name Description

1 NOSKIP Connect to V

2 GNDSENSE Remote ground sensing pin

3 INT Integrator output. Short this pin to VFB pin and connect it via a capacitor to V

integrator in the control loop. If the integrator is not used, short this pin to VREF.

4 VSENSE This pin must be connected to the remote output voltage to detect overvoltage and

undervoltage conditions and to provide integrator feedback input.

to force continuous conduction mode and sink mode.

CC

to insert the

OUT

2/30

L6997S

Table 4. Pin Function (continued)

N° Name Description

5VCCIC Supply Voltage.

6 GND Signal ground

7 VREF 0.6V voltage reference. Connect a ceramic capacitor (max. 10nF) between this pin and

8 VFB PWM comparator feedback input. Short this pin to INT pin to enable the integrator function, or

9 OSC Connect this pin to the input voltage through a voltage divider in order to provide the feed-

10 SS Soft Start pin. A 5µA constant current charges an external capacitor. Itsvalue sets the soft-

11 ILIM An external resistor connected between this pin and GND sets the current limit threshold don’t

12 SHDN Shutdown. When connected to GND the device and the drivers are OFF. It cannot be left

13 OVP Open drain output. During the over voltage condition it is pulled up by an external resistor.

14 PGOOD Open drain output. It is pulled down when the output voltage is not within the specified

15 PGND Low Side driver ground.

16 LGATE Low Side driver output.

17 V

DR

18 PHASE Return path of the High Side dr iver.

19 HGATE High side driver output.

20 BOOT Bootstrap capacitor pin. High Side driver is supplied through this pin.

ground. This pin is capable to source or sink up to 250uA

to VSENSE to disable the integrator function.

forward function don’t leave floating.

start time do n’t leave floating.

leave floating..

floating.

thresholds. Otherwise is pulled up by external resistor. If not used it can be left floating.

Low Side driver supply.

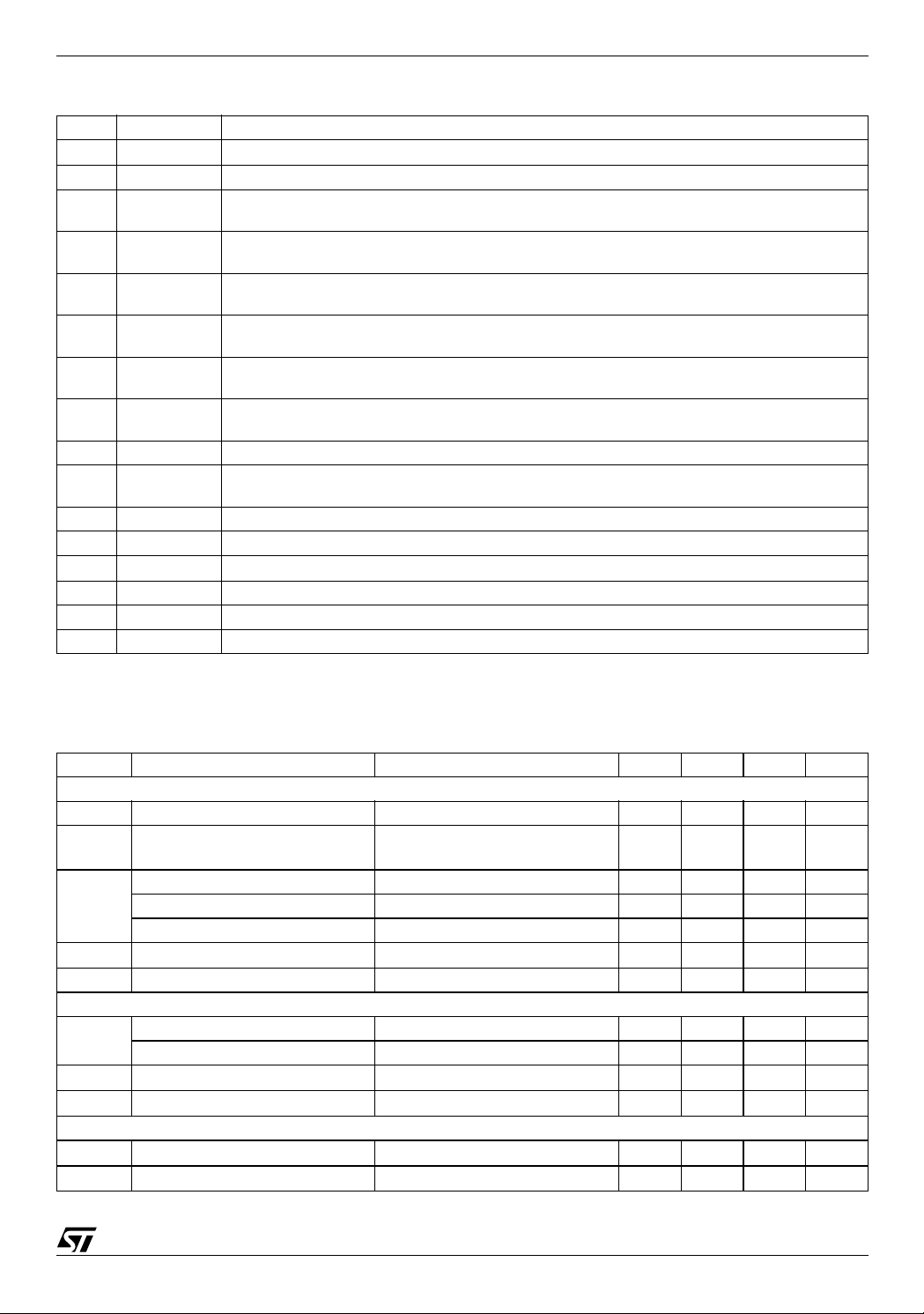

Table 5. Electrical Characteristics

(V

= VDR = 3.3V; T

CC

Symbol Parameter Test Condition Min. Typ. Max. Unit

SUPPLY SECTION

Vin Input voltage range Vout=Vref Fsw=110Khz Iout=1A 1 35 V

V

,

CC

V

DR

V

Turn-onvoltage 2.86 2.97 V

CC

Turn-off voltage 2.75 2.9 V

Hysteresis 90 mV

IqV

Drivers Quiescent Current VFB > VREF 7 20 µA

DR

IqVcc Device Quiescent current VFB > VREF 400 600 µA

SHUTDOWN SECTION

SHDN Device On 1.2 V

Device Off 0.6 V

I

SHVDR

I

SHVCC

Drivers shutdown current SHDN to GND 5 µA

Devices shutdown current SHDN to GND 1 15 µA

SOFT START SECTION

I

∆V

Soft Start current VSS = 0.4V 4 6 µA

SS

Active Soft start and voltage 300 400 500 mV

SS

= 0°C to 85°C unless otherwise specified)

amb

35.5V

3/30

L6997S

Table 5. Electrical Characteristics (continued)

= VDR = 3.3V; T

(V

CC

Symbol Parameter Test Condition Min. Typ. Max. Unit

CURRENT LIMIT AND ZERO CURRENT COMPARATOR

I

Input bias current R

LIM

Zero Crossing Comparator offset

Phase-gnd

K

Current limit factor 1.6 1.8 2 µA

ILIM

ON TIME

Ton On time duration V

OFF TIME

T

OFFMIN

Minimum off time 600 ns

K

OSC/TOFFMIN

VOLTAGE REFERENCE

VREF Voltage Accuracy 0µA < I

PWM COMPARATOR

Input voltage offset -2 +2 mV

I

Input Bias Current 20 nA

FB

INTEGRATOR

Over Voltage Clamp V

Under Voltage Clamp V

Integrator Input Offset Voltage

V

SENSE-VREF

I

VSENSE

Input Bias Current 20 nA

GATE DRIVERS

High side rise time V

High side fall time 50 100 ns

Low side rise time V

Low side fall time 50 90 ns

P

UVP/OVP PROTECTIONS

GOOD

OVP Over voltage threshold with respect to V

UVP Under voltage threshold 67 70 73 %

Upper threshold

(V

SENSE-VREF

Lower threshold

(V

SENSE-VREF

V

PGOOD

= 0°C to 85°C unless otherwise specified)

amb

= 2KΩ to 200KΩ 4.655.4µA

ILIM

REF=VSENSE

V

REF=VSENSE

V

REF=VSENSE

V

REF=VSENSE

OSC=125mV 720 800 880 ns

OSC=250mV 370 420 470 ns

OSC=500mV 200 230 260 ns

OSC=1000mV 90 115 140 ns

OSC=250mV 0.20 0.40

< 100µA 0.594 0.6 0.606 V

REF

= V

SENSE

SENSE

DR

CC

= GND 0.45 0.55 0.65 V

=3.3V; C=7nF

HGATE - PHASE from 1 to 3V

=3.3V; C=14nF

DR

LGATE from 1 to 3V

REF

V

rising 110 112 116 %

SENSE

)

V

falling 858891%

SENSE

)

I

=2mA 0.2 0.4 V

Sink

-2 2 mV

0.62 0.75 0.88 V

-4 -4 mV

50 90 ns

50 90 ns

118 121 124 %

4/30

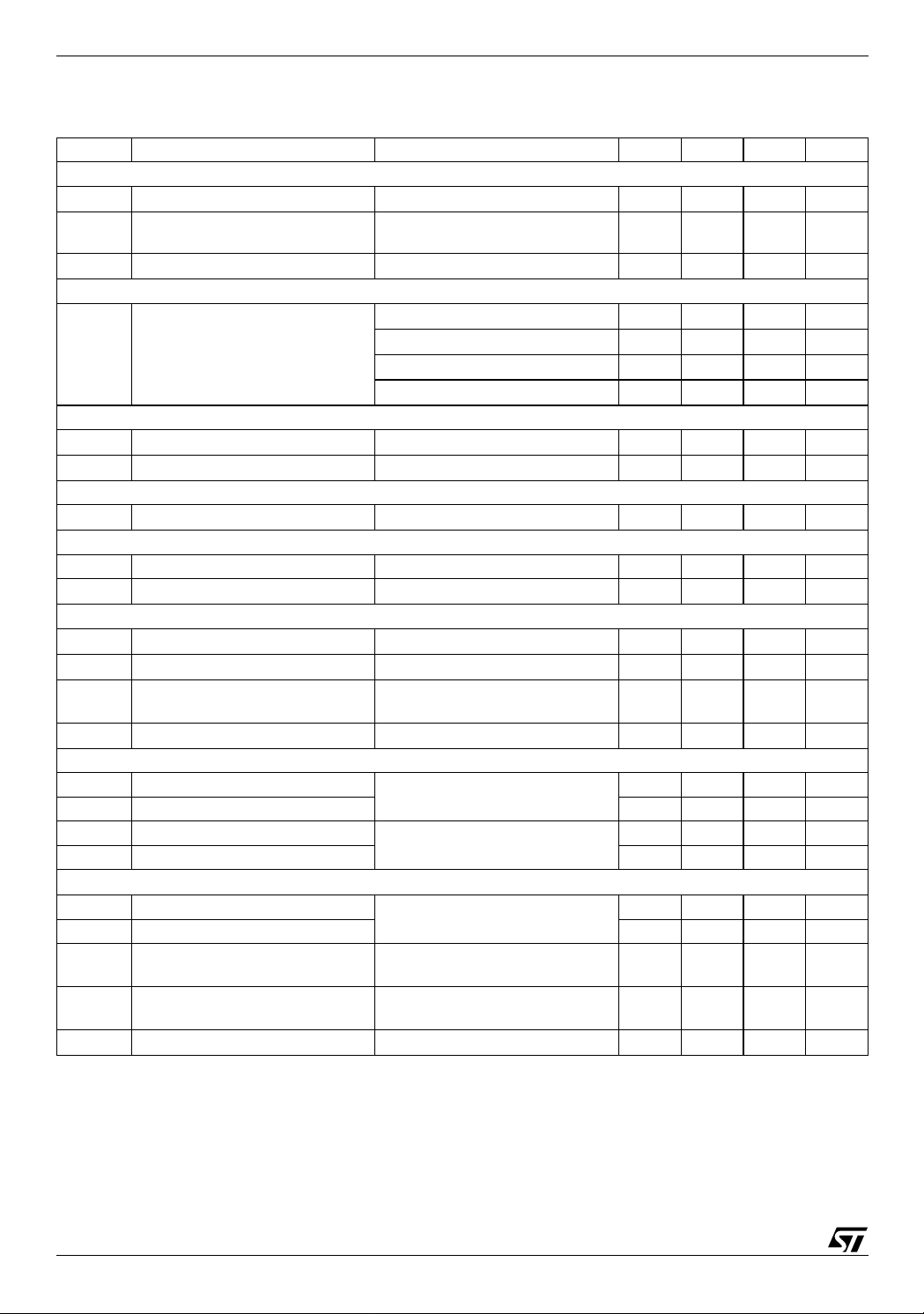

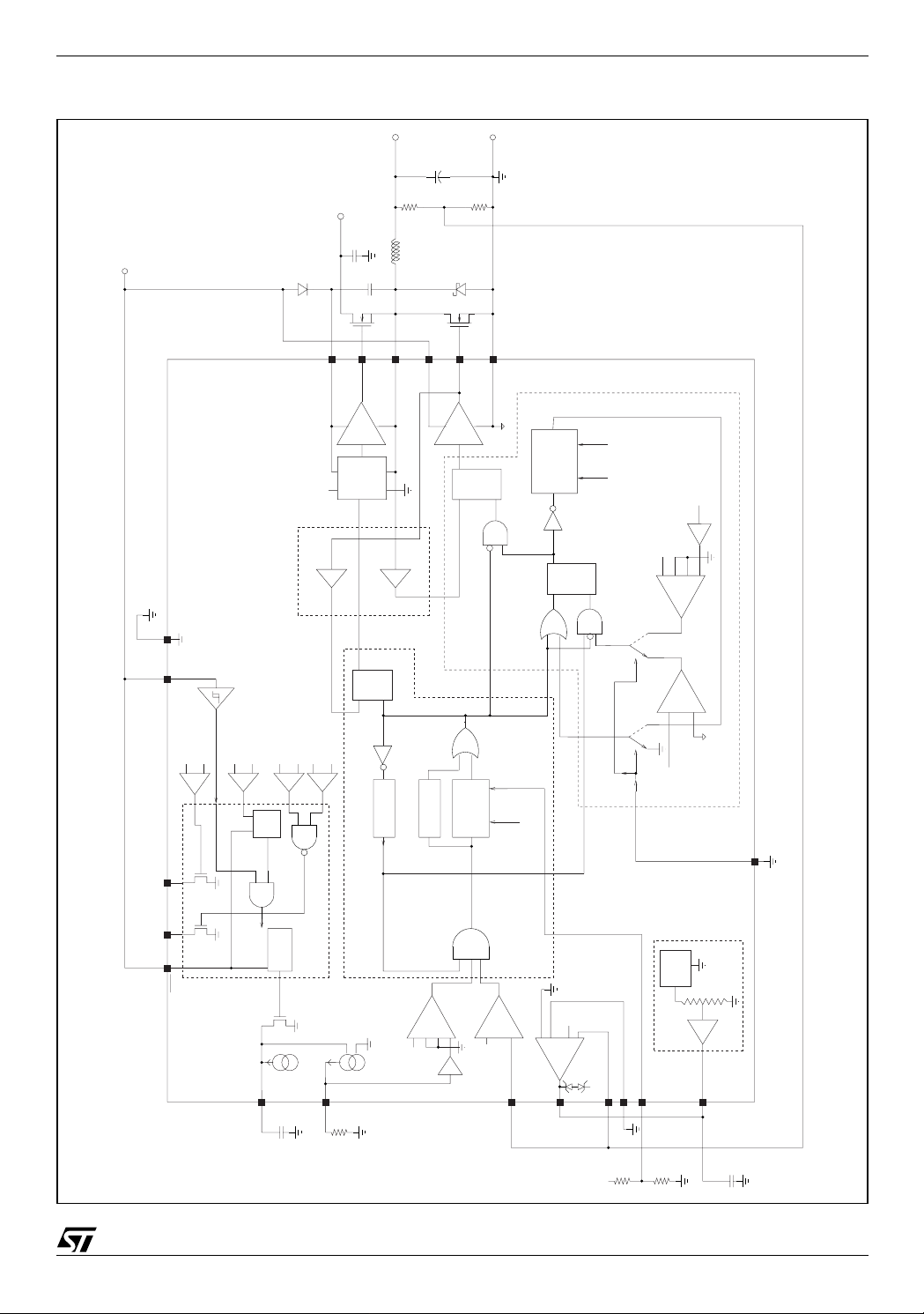

Figure 4. Functional & Block Diagram

IN

V

Vcc

L6997S

OUT

V

GNDVCCOVPPGOODSHDN

overvoltage comparator

VSENSE

+

1.12 VREF

-+undervoltage comparator

VSENSE

0.6 VREF

pgood comparators

SR

LS and HS anti-cross-conduction comparators

VSENSE

1.075 VREF

-

+

comp

V(LGATE)<0.5V

VSENSE

+

BOOT

VCC

0.925 VREF

-

HGATE

HS driver

level shifter

V(PHASE)<0.2V

Q

R

comp

S

Toff min

PHASE

delay

VDR

Ton min

one-shot

PGND

LGATE

LS driver

Q

R

Ton

one-shot

Ton

S

OSC

VSENSE

Q

S

one-shot

OSC

VSENSE

Ton= Kosc V(VSENSE)/V(OSC)

R

no-skipno-skip

mode

mode

comparator

negative current limit

PHASE

++-

-

+

PHASE

ILIM

0.05

zero-cross comparator

LS control

Ton= Kosc V(VSENSE)/V(OSC)

NOSKIP

IC enable

control

soft-start

SS

5 uA

power management

ILIM

comparator

positive current limit

-

PHASE

+-+

+VREF

0.05

FB

HS control

VREF

pwm comparator

-

-

-

+

+

Gm

VREF

INT

VSENSE

IN

V

SENSEGND

OSC

1.236V

bandgap

VREF

1.416

Reference chain

0.6V

5/30

L6997S

4 DEVICE DESCRIPTION

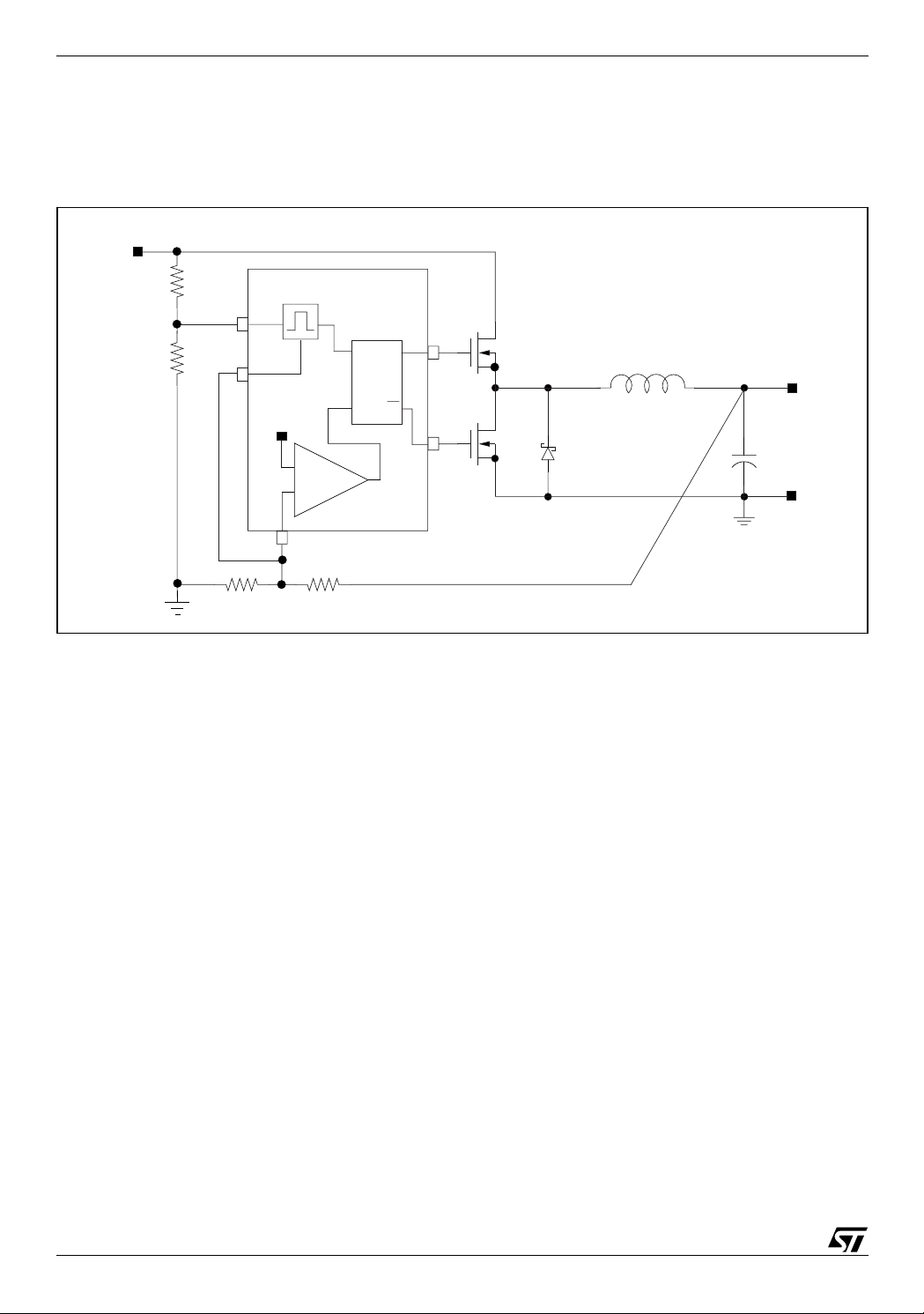

4.1 Constant On Time PWM topology Figure 5. Loop block schematic diagram

Vin

R1

R2

One-shot generator

OSC

Vsense

Vref

FFSR

Q

R

HGATE

S

Q

+

LGATE

HS

LS

Vout

DS

-

PWM comparator

FB

R4

R3

The device implements a Constant On Time control scheme, where the Ton is the high side MOSFET on time

duration forced by the one-shot generator. The On Time is directly proportional to VSENSE pin voltage and inverse to OSC pin voltage as in Eq1:

V

SENSE

T

ON

where K

= 180ns and τ is the internal propagation delay time (typ. 40ns). The system imposes in steady

OSC

state a minimum On Time corresponding to V

responding Ton will not decrease. Connecting the OSC pin to a voltage partition from V

steady-state switching frequency F

V

OUT

-------------- -

f

== =

SW

-----------

T

V

IN

--------------------- -

K

OSC

V

OSC

independent of VIN. It results:

SW

α

1

ON

OSC

-------------- -

α

OUT

τ+=

= 1V. In fact if the V

OSC

1

---------------

K

OSC

α

→ fSWK

OSC

(1)

voltage increases above 1V th e cor-

OSC

OSCαOUT

to GND, it allows a

IN

(2)

where

V

OSC

α

α

OSC

OUT

-------------- -

V

IN

V

FB

-------------- -

V

OUT

The above equations allow setting the frequency divider ratio α

that such equations hold only if V

<1V. Further the Eq2 shows how the system has a switching frequen-

OSC

cy ideally independe nt fr om the i npu t vo lta ge. T h e del ay in tro duc es a ligh t dep end enc e fr om V

R

2

--------------------==

R2R1+

R

4

--------------------==

R3R4+

(3)

(4)

once output voltage has been set; note

OSC

IN

. A mini-

mum Off-Time constraint of about 500ns is introduced in order to assure the boot capacitor charge and to

6/30

L6997S

limit the switchin g frequency after a loa d transient as well as to mask PWM comp arator output again st

noise and spikes.

The system has not an in ternal clock, becau se this is a hys teretic controller, so the turn on pulse wi ll start if thre e

conditions are met contemporarily: the FB pi n voltage i s lower than the r eference volt age, the minimum off time

is passed and the current limit comparator is not triggered (i.e. the inductor current is below the current limit

value). The voltage at the OSC pin must range between 50mV and 1V to ensure the system linearity.

4.2 Closing the loop

The loop is closed connecting the output voltage (or the output divider middle point) to the FB pin. The FB pin

is internally conncted to the comparator negative pin while the positive pin is connected to the reference voltage

(0.6V Typ.) as in Figure 5. When the FB goes lower than the reference voltage, the PWM comparator output

goes high and sets the flip-flop output, turning on the high side MOSFET. This condition is latched to avoid

noise. After the On-Time (calculated as described in the previous section) the system resets the flip-flop, turns

off the high side MOSFET and turns on the low side MOSFET. For more details refers to the Figure 4.

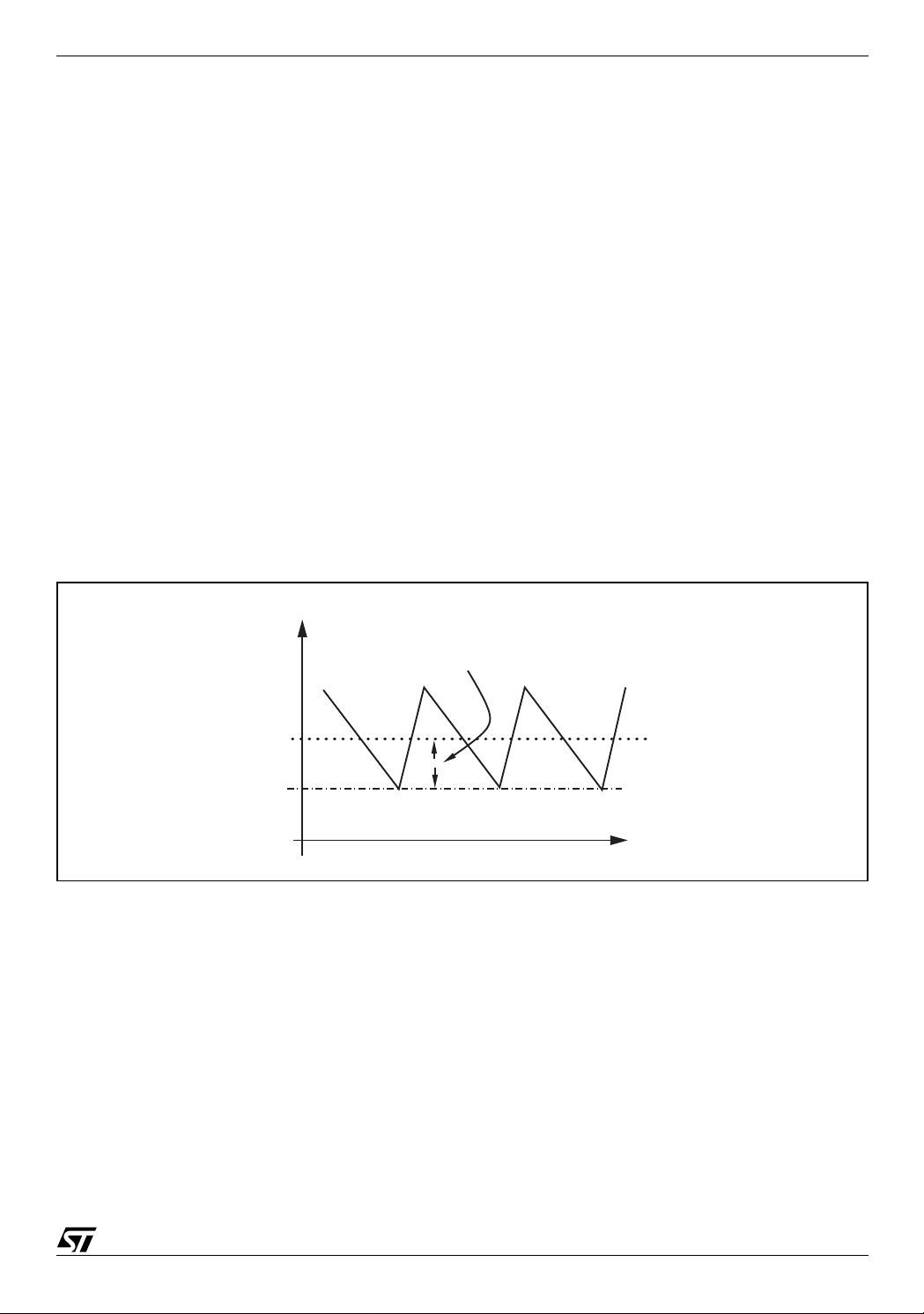

The voltage drop along ground and supply metal paths connecting output capacitor to the load is a source of

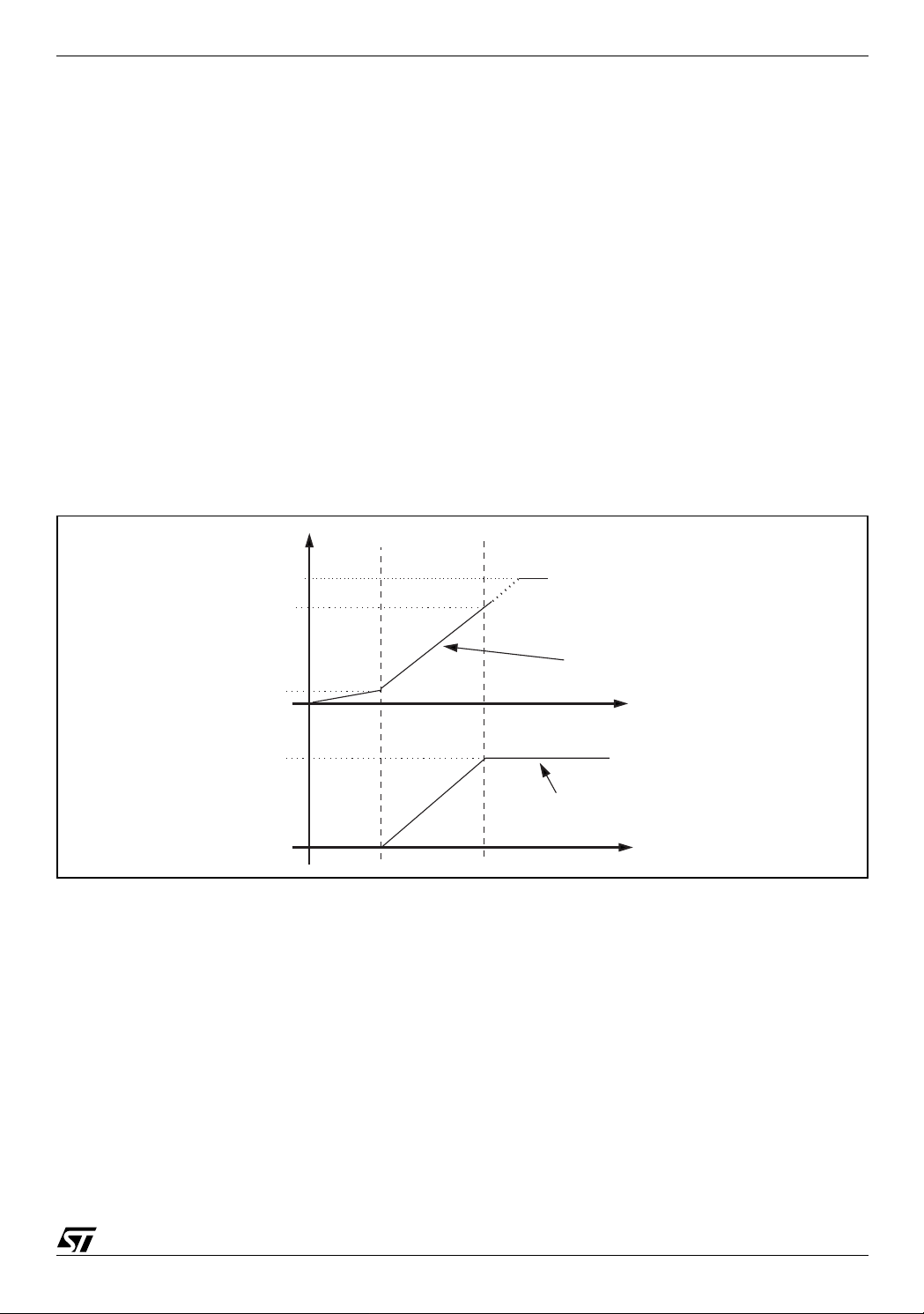

DC error. Further the system regulates the output voltage valley value not the average, as shown in Figure 6.

So, the voltage ripple on the output capacitor is a source of DC static error (well as the PCB traces). To compensate the DC errors, an integrator network must be introduced in the control loop, by connecting the output

voltage to the INT pin through a capacitor and the FB pin to the INT pin directly as in Figure 7. The internal integrator amplifier with t he extern al capacitor C

an AC path for output ripple.

introduces a DC pole in the control loop. C

INT1

also provides

INT1

Figure 6. Valley regulation

Vout

DC Error Offset

<Vout>

Vref

Time

The integrator amplifier generates a c urrent, proportional to the DC error s, that increases the output capaci tance

voltage in order to compensate the total st atic error. A v oltage clamp within the devi ce forces anINT pin v oltage

range (V

-50mV, V

REF

+150mV). This is useful to avoid or smooth output voltage overshoot during a load

REF

transient. Also, this means that the integrator is capable of recovering output error due to ripple when its peakto-peak amplitude is less than 150mV in steady state.

In case the ripple amplitude is larger than 150mV, a capacitor C

can be connected between INT pin and

INT2

ground to reduce ripple amplitude at INT pin, otherwise the int egrator will operate out of its linear range. Choose

C

according to the following equation:

INT1

g

⋅

INTαOUT

C

INT1

where g

=50 µs is the integrator transconductance,

INT

the close loop bandwidth. This equation holds if C

-------------------------------=

2 π F

⋅⋅

(5)

u

α

is the output divider ratio given from Eq4 and FU is

OUT

is connected between INT pin and ground. C

INT2

INT2

is given

by:

7/30

L6997S

Where

C

--------------- -

C

∆

V

is the output ripple and ∆V

OUT

INT2

INT1

∆

------------------=

∆V

V

OUT

INT

INT

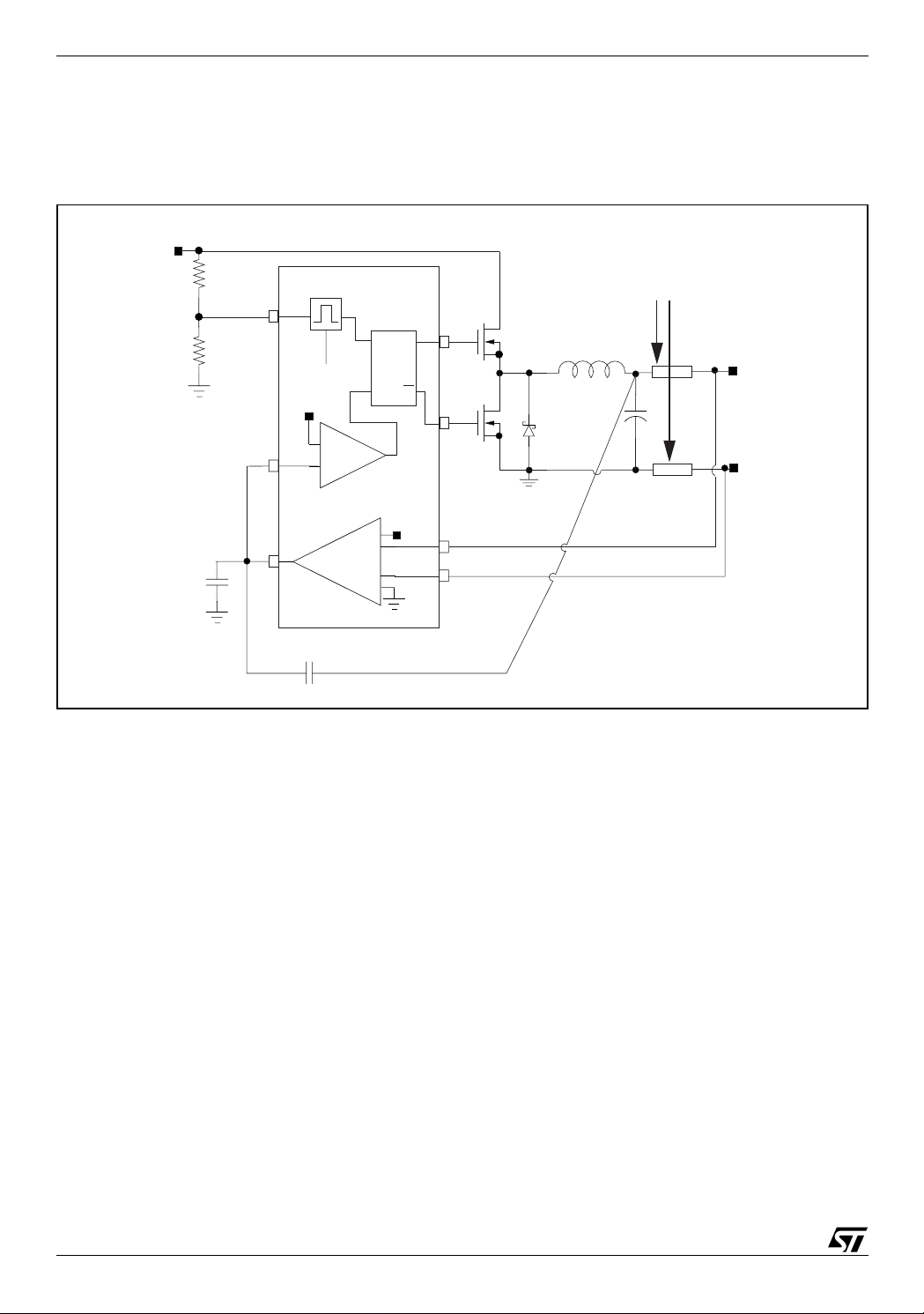

Figure 7. Integrator loop block diagram

Vin

R1

R2

Cint2

One-shot generator

OSC

From Vsense

Vref

FB

INT

Integrator amplifier

+

-

PWM comparator

+

-

+

(6)

is the required ripple at the INT pin (100mV typ).

PCB TRACES

FFSR

Q

R

HGATE

S

Q

LGATE

Vref

-

Vsense

Gndsense

HS

LS

DS

Vout

LOAD

Cint1

Respect to a traditional P WM con t roller, that has an internal oscil lator s etti ng the switching frequency, i n a hys teretic system the frequency can change with some parameters. Fo r example, while in a standard fixed s witc hing frequency topology, the increase of the losses (increasing the output current, for example) generates a

variation in the On Time and Off Time, in a fixed On Time topology , the increase of the losses generates only

a variation on the Off Time, changing the switching frequency. In the device is implemented the voltage feedforward circuit that allows constant swi tchi ng fr equency during s teady -sate oper atio n and withi nthe inp ut rang e

variation. Any way there are many factors affecting switching frequency accuracy in steady-state operation.

Some of these are internal as dead times, which depends on high side MOSFET driver. Others related to the

external components as high side MOSFET gate charge and gate resistance, voltage drops on supply and

ground rails, low side and high side RDSON and inductor parasitic resistance.

During a positive load transient, (the output current increases), the conve rter switches at its maximum frequency

(the period is TON+TOFFmin) to recover the output voltage drop. During a negative load transient, (the output

current decreases), the device stops to switch (high side MOSFET remains off).

4.3 Transition from PWM to PFM/PSK

To achieve high efficie ncy at light loa d conditi ons, PFM mode i s provided. The PFM mode differs fr om the PWM

mode essentially for the off phase; the on phase is the same. In PFM after a On cycle the system turns-on the

low side MOSFET until the inductor current goes down zero, when the zero-crossing comparator turns off the

low side MOSFET. In PWM mode, after On cycle, the system keeps t he low side MOSFET on unti l the next turnon cycle, so the energy stored in the output capacitor will flow through the low side MOSFET to ground. The

PFM mode is naturally implemented in an hysteretic controller enabling the zero current comparator by enabling, in fact in PFM mode the system reads the output voltage with a comparator and then turns on the high

side MOSFET when the output voltage goes down to reference value. The device wor ks in discontinuous mod e

8/30

L6997S

at light load and in continuous mode at high load. The transition from PFM to PWM occu rs when load curr ent is

around half the inductor current ripple. This threshold value depends on V

the inductor value is, the smaller the threshold is. On the other hand, the bigger the i nductor value is, the sl ower

the transient response is. The PFM waveforms may appear more noisy and asynchronous than normal operation, but this is normal behaviour mai nly due to the ver y low loa d. If the PFM i s not c ompati ble wi th the appl ic ation it can be disabled connecting to V

the NOSKIP pin.

CC

4.4 Softstart

After the device is turned on the SS pin voltage begin s to increase and the system star ts to switch. The softstart

is realized by gradually increasing the current limit threshold to avoid output overvoltage. The active soft start

range for the V

internal current source (5

voltage (where the output current limit increase linearly) is from 0.6V to 1V. In this range an

SS

µ

A Typ) charges the capacitor on the SS pi n; the reference curr ent (for the current li mit

comparator) forced through ILIM pin is proportional to SS pin voltage and it saturates at 5

voltage is close to 1V the maximum current lim it is active. Output protecti ons OVP & UVP are disab led until the

SS pin voltage reaches 1V (see figure 8).

Once the SS pin voltage reaches the 1V value, the voltage on SS pin doesn't impact the system operatio n anymore. If the SHDN pin is turned on before the supplies, the power section must be turned on before the logic

section. While if the supplies are applied with the SHND pin off, the start up sequence doesn't meter.

Figure 8. Soft -Start Diagram

Vss

, L, and V

IN

. Note that the higher

OUT

µ

A (Typ.). When SS

4.1V

1V

0.6V

Ilim current

5

A

µ

Soft-start active range

Time

Maximum current limit

Time

Because the system implements the s oft s tart by contr ol lin g the inductor current, the soft star t capac itor s houl d

be selected based on of the output capacitance, the current limit and the soft start active range (

∆

VSS).

In order to select the softstart capacitor i t must be imposed that the output voltage reaches the final value before

the soft start voltage reaches the under voltage value (1V). After this UVP and OVP are enable.

The time necessary to charge the SS capacitor up to 1V is given by:

1V

TSSCSS()

--------

Iss

CSS⋅=

(7)

In order to calculate the output voltage chargin time it should be considered that the inductor current function

can be supposed linear function of the time.

t,CSS()

I

L

R

ilim/RdsonKILIMISS

-------------------------------------------------------------------------- -=

V

⋅∆()

SSCSS

t⋅⋅⋅()

(8)

9/30

L6997S

so considering zero the output load the output voltage is given by:

V

out

t,CSS()

------------------------ -

Qt,C

()

SS

C

out

-----------------------------------------------------------------------------==

R

ilim/RdsonKILIMISS

C

out

⋅⋅⋅()

VSSCSS2⋅⋅∆⋅()

2

t

(9))

indicating with V

the minimum C

the final value, the output charging time can be estimated as:

out

V

outCout

--------------------------------------------------------------------------- -

V

()

outCSS

value is given imposing this condition:

SS

=

R

ilim/RdsonKILIMISS

T

=T

out

V

SSCSS

⋅⋅()

SS

0.5

2⋅⋅∆⋅⋅()

(10)

(11)

4.5 Current limit

The current limit comparator s enses the inductor current through the lo w si de MOSFET RDSON drop and compares this value with the ILIM pin voltage value. While the current is above the current limit value, the control

inhibits the high side MOSFET Turn On.

To properly set the current limit threshold, it sho uld be noted that thi s i s a valley cur rent li mit. The Av er age cur rent depends on the inductor value, V

IN VOUT

and switching frequency.

The average output current in current limit is given by:

I∆

I

OUT

CL

I

max va lley

---- -+=

(12)

2

Thus, to set the current threshold, choose RILIM according to the following equation:

R

ILim

I

max valley

-----------------

Rds

on

⋅=

K

(13)

ILIM

In overcurrent conditions the syst em keeps the current constant until the output v oltage meets the undervoltag e

threshold. The negative valley current lim it, for t he sink mode, is set automati cally at the same va lue of the positive valley current limit. The average negative current limit differs from the positive average current limit by the

ripple current; this difference is due to the valley control technique.

The current limit system accuracy is function of the precision of the resistance connected to the ILIM pin and

the low side MOSFET RDS

accuracy. Moreover the voltage on ILIM pin must range between 10mV and 1V

ON

to ensure the system linearity.

Figure 9. Current limit schematic

Positive and negative current limit

10/30

To inductor

LS

PGN

R

ILIM

D

Current

Comparator

5µA

PHASE

To

logic

L6997S

4.6 Protection and fault

The load protection is realized by using the VSENSE pin. Both OVP and UVP ar e latched, and the fault conditio n

is indicated by the PGOOD and the OVP pins. If the output voltage is between the 89% (typ.) and 110% (typ)

of the regulated value, PGOOD is high. If a hard overvoltage or an undervoltage occurs, the device is latched:

low side MOSFET and, high side MOSFET are turned off and PGOOD goes low. In case the system detects a n

overvoltage the OVP pin goes high.

To recover the functionality the device must be shut down and restarted the SHDN pin, or by remov ing the supply, and restarting the devicewith the correct sequence.

4.7 Drivers

The integrated high-current drivers allow using different size of power MOSFET, maintaining fast switchi ng transitions. The driver for the high side MOSFET uses the BOOT pin for supply and PHASE pin for return (floating

driver). The driver for the low side MOSFET uses the VDR pin for the supply and PGND pin for the return. The

drivers have the adaptive anti-cross-conduction protection, which prevents from having bothhigh side and low

side MOSFET on at the same time, avoi ding a high current to flow from VIN to GND. When high s ide MOSFET

is turned off the voltage on the PHASE pin begins to fall; the low side MOSFET is turned on only when the voltage on PHASE pin reaches 250mV. When low side is turned off, high side remains off until LGATE pin voltage

reaches 500mV. This is important since the driv er can work properly wi th a l arge range of external po wer MOSFETS.

The current necessary to switch the external MOSFETS flows through the device, and it is proportional to the

MOSFET gate charge the switching frequency and the driver voltage. So the power dissipati on of the devic e is

function of the external power MOSFET gate charge and switching frequency.

P

driver

VccQ

⋅⋅=

gTOTFSW

(14)

The maximum gate charge values for the low side and high side are given by:

f

SW0

Where f

Q

MAXHS

Q

MAXLS

= 500Khz. The equations above are valid for TJ = 150°C. If the system temperature is lower the Q

SW0

------------ -

f

SW

f

SW0

------------ -

f

SW

75nC⋅=

125nC⋅=

(15)

(16)

can be higher.

For the Low Side driver the max output gate charge meets another limit due to the internal traces degradation;

in this case the maximum value is Q

MAXLS

= 125nC.

The low side driver has been designed to have a low resistance pull-down transistor, approximately 0.5 ohms.

This prevents undesired LS MOSFET Turn On during the fast rise-time of the pin PHASE, due to the Miller effect.

When the 3.3V bus is used to supply the drivers, ULTRA LOGIC LEVEL MOSFETs should be selected , to be

sure that the MOSFETs work in properly way.

G

11/30

L6997S

5 APPLICATION INFORMATION

5.1 5A Demo board description

The demo board shows the device operation in this condition: VIN from 3.3V to 5V, I

evaluation board let use the system wi th 2 diffe rent volta ges ( V

the supply for the IC and VIN the power input

CC

for the conversion) so replacing the input capacitors the power input voltage could be also 35V. When instead

the input voltage (V

) is equal to the VCC it should be better joinin g them wi th a 10Ω resistor in order to filter the

IN

device input voltage. On the topside demo there are two different jumpers: one jumper, near the OVP and POWER GOOD test points, is used to shut down the device; when the jumper is present the device is in SHUTDOWN

mode, to run the device remove the jumper. The other jumper, near the V

test point, is used to set the PFM/

REF

PSK mode. When the jumper is present, at l ight load, the sy stem will go in PFM mode; if there i s not the jumper,

at light load, the syst em will remai n in PWM mo de. In the demo bottom si de there are two others di fferent j umpers. They are used to set or remove the INTEGRATOR configuration. When the jumpers named with INT label

are closed AND the jumpers named with the NOINT label are open the integrator configuration is set. Sometimes the integrator configuration needs a low frequency filter the to reduce the noise interaction. In this case

instead close the INT jumper s put there a r esistor and after a capaci tor to ground ( as in the s chematic diagram) ;

the pole value is around 500Khz but it should be higher enough than the switching frequency (ten times). On

the opposite when the jumpers named with the NOINT are closed and the jumpers named with INT are open

the NON INTEGRATOR configuration is selected. Refer to the Table 1 and 2 for the jumpers connection.

Figure 10. Demoboard Schematic Diagram

OUT

=5A V

=1.25V. The

OUT

Vcc

TP1

TP2

R9

R5

SD

R8

C9

C11

R10

C12

C10

R7

VCC

PGOOD

OVP

L6997S

ILIM

SS

SHDN

VDR

C8

R4

OSC

BOOT

HGATE

PHASE

LGATE

PGND

GND

NOSKIP

VSENSE

GNDSENSE

INT

VFB

VREF

C6

C5

R6

Q1

Q2

NOINT

TP3

C4

NOINT

INT

D2

C2

C7,C13

D1

R1

C1

NS

Cn

J1

VIin

GNDin

L1

C14,C15

C3

INT

Rn

VOUT

R3

R2

GNDOUT

12/30

5.2 Jumper Connection Table 6. Jumper connection with integrator

Component Connection

C1 Mounted

C2 Mounted *

INT Close

NOINT Open

* This component is not necessary, depends from the output ESR capacit or. See the integrator section.

Table 7. Jumper connection without integrator

Component Connection

C1 Not mounted

C2 Not Mounted

INT Open

NOINT Close

5.3 DEMOBOARD LAYOUT

Real dimensions: 4,7 cm X 2,7 cm (1.85 inch X 1. 063 inch)

L6997S

Figure 11. Top side components placement

Figure 12. Bottom side Jumpers distribution

Figure 13. Top side layout

Figure 14. Bottom side layout

13/30

L6997S

Table 8. PCB Layout guidelines

Goal Suggestion

To minimize radiation and magnetic

coupling with the adjacent circuitry .

To maximize the efficiency. Keep power traces and load connections short and wide.

To ensure high accuracy in the

current sense system.

To reduce the noise effect on the IC. 1) Put the feedback component (like output divider, integrator network, etc) as

1) Minimize switching current loop areas. (For example placing C

and Low side MOSFETS, Shottky diode as close as possible).

2) Place controller placed as close as possible to the power MOSFETs.

3) Group the gate drive components (Boot cap and diode) near the IC.

Make Kelvin connection for Phase pin and PGND pin and keep them as close

as possible to the Low Side MOSFETS.

close as possible to the IC.

2) Keep the feedback traces parallel and as close as possible. Moreover they

must be routed as far as possible from the switching current loops.

3) Make the controller ground connection like the figure 8.

, High Side

IN

Table 9. Component list

The component list is shared in two sections: the first for the general-purpose component, the second for

power section:

Part name Value Dim en sio n Notes

GENERAL-PURPOSE SECTION

RESISTOR

R1, R5, R9, R10 33kΩ 0603 Pull-up resistor

R2 1kΩ 0603 Output resistor divider (To set output voltage)

R3 1.1kΩ 0603

R4 0603 Input resistor divider (To set switching frequency)

R6 470kΩ 0603

R7 0Ω 0603

R8 0603 Current limit resistor

CAPACITOR

C1 330pF 0603 First integrator capacitor

C2 N.M. 0603 Second integrator capacitor

C3 1nF 0603

C4 100nF 0603

C5 1µFTantalum

C6 10nF 0603

C9 10nF 0603 Softstart capacitor

C10 100nF 0603

C11 100nF 0603

C8, C12 47pF 0603

DIODE

D1 BAR18

POWER SECTION

INPUT CAPACITORS

C7, C13 47µF ECJ4XF0J476Z

PANASONIC

14/30

L6997S

Table 9. Component list (continued)

The component list is shared in two sections: the first for the general-purpose component, the second for

power section:

Part name Value Dim en sio n Notes

OUTPUT CAPACITORS

C14, C15 220µF 2R5TPE220M

POSCAP

INDUCTOR

L1 2.7 µH DO3316P-272HC

POWER MOS

Q1,Q2 STS5DNF20V STMicroelectronics Double mosfet in sigle package

DIODE

D2 STPS340U STMicroelectronics 3

Notes: 1. N.M.=Not Mounted

2. The demoboard with this component list is set to give: V

3.3V-5V and with the integrator feature.

3. The diode efficiency impact is very low; it is not a nec essary component.

4. All cap acitors are intended ceramic type otherwise specified.

COILCRAFT

OUT

= 1.25V, FSW = 270kHz with an input voltage around VIN = VCC =

5.4 EFFICIENCY CURVES Source mode

V

= 3.3V V

IN

= 1.25V F

OUT

= 270kHz

SW

Figure 15. Efficiency vs output current

E ff [%]

100,0

90,0

80,0

70,0

60,0

50,0

40,0

30,0

20,0

10,0

0,0

0,0 1,0 2,0 3,0 4,0 5,0 6,0

PFM mode PWM mode

Cu rren t [ A]

15/30

L6997S

6 STEP BY STEP DESIGN

Application conditions: VIN = 3.3V, ±10% V

6.1 Input capacitor.

A pulsed current (with zero average value) flows through the input capacitor of a buck converter. The AC component of this current is quite high and dissipates a considerable amount of power on the ESR of the capacitor:

P

CIN

ESR

CIN

⋅⋅=

The RMS current, which the capacitor must provide, is given by:

OUT

Iout

= 1.25V I

2

Vin Vin Vout–()⋅

----------------------------------------------- -

OUT

Vin

2

= 5A FSW = 270kHz

(17)

2

I

∆()

L

(18)

Where

Icin

rms

δ

is the duty cycle of the application

Iout2δ 1 δ–()

δ

------

+=

12

Neglecting the last term, the equation reduces to:

Icin

which maximum value corresponds to to

rms

Iout δ 1 δ–()=

δ

= 1/2 and is equal I

(19)

out

/2

Therefore, in worst case, the input capacitors should be selected with a RMS ripple current rating as high as

half the respective maximum output current.

Electrolytic capacitors are the most used because theyare the cheapest ones and are available with a wide

range of RMS current ratings. The only drawback is that, for a givenripple cu rrent rating, they are physically larger than other capacitors. Very good tantalum capacitors are comi ng available, with very low ESR and s mall size.

The only problem is that they occasionally can burn i f subjected to v ery high c ur rent duri ng the char ge. So, i t is

better avoid this type of capacitors for the input filter of the device. In fact, they can be subjected to high surge

current when connected to the power supply. If availabl e for the requested capacitance value and vo ltage rating,

the ceramic capacitors have usually a hig her RMS current r ating for a given ph ysical di mension (due to the very

low ESR). The drawback is the quite high cost. Possible solutions:

10µF C34Y5U1E106ZTE12 TOKIN

22µF JMK325BJ226MM

47µF ECJ4XF0J476Z

33µF C3225X5R0J476M

TAIYO-YUDEN

PANASONIC

TDK

With our parameter from the equation 3 it is found:

Icin

= 2.42A

rms

6.2 Inductor

To define the inductor, it is necessary to determine firstly the inductance value. Its minimum value is given by:

where RF =

16/30

V

Lmin

∆

I/I

(basically it is approximately 30%).

OUT

-------------------------------------------------------------- -

≥

F

SWIout

Vin

o

–()⋅

maxVo

RF Vin

⋅⋅⋅

(20)

max

L6997S

With our parameters:

Lmin

≥ 2µ

H

The saturation current must be higher then 5A

6.3 Output capacitor and ripple voltage

The output capacitor is selected based on both static and dynamic output voltage accuracy. The static output

voltage accuracy depends mostly on the ERS of the output capacitor, while the dynamic accuracy usually depends both on the ESR and capacitance value.

If the static precision is ±1% for the 1.25V output voltage, the output ripple is ±12.5mV.

To determine the ESR value from the output precision is necessary to calculate the ripple current:

Where F

= 270kHz.

SW

I∆

Vin Vo–

---------------------- -

L

⋅⋅=

Vo

---------

Vin

T

(21)

sw

From the Eq. above the ripple current is around 1.25A.

So the ESR is given by:

ESR

ripple

---------------------

---- -

2

25mV

----------------= 20mΩ==

I∆

1.25

(22)

V

∆

The dynamic specifications are sometimes more relaxed than the static requir ements , Any way a mi nimum output capacitance must be ensur ed to avoid output voltage variation due to the charge an d discharge of Cout dur ing load transients.

To allow the device control loop to work properly, the zero introduced by the output capacitor ESR (

τ

= ESR ·

Cout) must be at least ten times smaller than switching frequency. Low ESR tantalum capacitors, which ESR

zero is close to ten kHz, are suitable for output filtering. Output capacitor value C

and its ESR, ESRC

OUT

OUT

should be large enough and small enough, respec tively, to keep o utput voltage within the accuracy range during

a load transient, and to give the device a minimum signal to noise ratio.

The current ripple flows through the output capacitors, so the should be calculated also to sustain this ripple:

the RMS current value is given by Eq. 18.

1

Icout

rms

---------- -

23

(23)

I

∆=

L

,

But this is usually a negligible constrain.

Possible solutions:

330µF EEFUE0D331R

PANASONIC

220µF2R5TPE220M

POSCAP

Multilayer capacitors can not be used because their very low ESR.

6.4 MOSFET’s and Schottky Diod es

A 3.3V bus powers the gate drivers of the device, the use ultra low level MOSFET is highly recommended, especially for high current applications. The MOSFET breakdown voltage V

must be greater than VINMAX

BRDSS

with a certain margin.

The RDS

can be selected once the allowable power dissipation has been established. By selecting identical

ON

17/30

L6997S

Power MOSFET for us and ls, the total power they dissipate does not depend on the duty cycle. Thus, if PON

is this power loss (few percent of the rated output power), the required

RDS

α

admitted temperature rise. It is worth noticing, however, that generally the lower RDS

charge Q

from the input source to ground, resulting in an equivalent drive current:

(@ 25 °C) can be derived from:

ON

P

RDS

ON

------------------------------------------------ -=

ON

(24)

Iout21 α T∆⋅+()⋅

is the temperature coefficient of RDSON (typically, α = 510-3 °C-1 for these low-voltage classes) and T the

, the higher is the gate

, which leads to a higher gate drive consumption. In fact, each switching cycle, a charge QG moves

G

ON

Iq Qg F

⋅=

SW

(25)

A SCHOTTKY diode can be added to increase the system efficiency at high switching frequency (where the

dead times could be an important part of total switching period).

This optional diode must be placed in parallel to the synchronous rectifier must have a reverse voltage VRRM

greater than VIN

. The current size of the diode must be selected in order to keep it i n safe operati ng condi -

MAX

tions. In order to use l ess space than pos sible, a do uble MOSFET in a single packag e is chos en: STS5DNF20V

6.5 Output voltage setting

The first step is choosing the output divider to set the output voltage. To select this value there isn't a criteria,

Ω

but a low divider network value (around 100

network (100K

R3 = 1K

R2 = 1.1K

Ω

) increase the noise effects. A network divider values from 1KΩ to 10KΩ is right. We chose:

Ω

Ω

) decries the efficiency at lo w current; ins tead a high v alue divi der

The device output voltage is adjustable by connecting a voltage divider from output to VSENSE pin. Minimum

output voltage is V

=VREF=0.6V. Once output divider and frequency divider have been designed as to obtain

OUT

the required output voltage and switching frequency, the following equation gives the smallest input voltage,

which allows L6997S to regulate (which corresponds to T

δ 1

α

OSC

-------------- -

α

OUT

--------------------------------------------- -

⋅–<

------------------------- -

T

1

K

OSC

OFF,MIN

MAX

OFF=TOFFMIN

):

(26)

6.6 Voltage Feedforward

From the equations 1,2 and 3, choosing the switching frequency of 270kHz the resistor divid er can be selected.

For example:

R3 = 470K

R4 = 8.5K

Ω

Ω

6.7 Current limit resistor

From the equation 8 the valley current limit can be set considering the RDSON STS5DNF20V and I

R8 = 120K

Ω

CIR

= 5A:

6.8 Integrator capacit or

Let’s assume FU = 15kHz, V

Since V

= 0.6V, from equation 2, of the device description, it follows αOUT = 0.348 and, from equation 5 it

REF

= 1.25V.

OUT

follows C = 250pF. The output ripple is around 22mV, so the system doe sn't need the secon d integrator capacitor.

18/30

L6997S

6.9 Soft start capacitor

Considering the soft start equations (Eq. 11) at page 10, it can be found:

C

= 150pF

SS

The equations are valid without load. When an ac tive load is present the equations resul t more complex ; further

some active loads have unexpected effect, as higher current than the expected one during the soft start, can

change the start up time.

In this case the capacitor value can be selected on the application; anyway the Eq11 gives an idea about the

C

value.

SS

6.10Sink mode

Figure 16. Efficiency vs output current

Eff [%]

100,0

90,0

80,0

70,0

60,0

50,0

40,0

30,0

20,0

10,0

0,0

0,01,02,03,04,05,0

Current [A]

7 15A DEMO BOARD DESCRIPTION

The evaluation board shows the device operation in these conditions: VIN = 3.3V V

= 200KHz without the integrator feature. The evaluation board has two di fferent input voltages: VCC [from 3V to

5.5V] used to supply the device and the V

er components configuration (C

, C

IN

[up to 35V] for the power conversion. In this way, changing the pow-

IN

, MOSFETs, L) it is possible evaluate the device performance in differ-

OUT

ent conditions. It is also possible to mount a linear regul ator on board used to generate the V

are also present two switches and four jumpers. The two switches have different goals: the one nearest to the

V

is used to turn on/off the device when the VCC and VIN are both present; the other one, near to R11 is used

CC

to turn on/off the PFM feature. The device can be turned on also with the power supply, but a correct start up

sequence is mandatory. V

has to be raised first and then the VCC can be applied too. If the correct sequence

IN

is not respected the device will not start up. The jumpers are used to set the integrator feature and to use the

remote sensing; for more info rmation refers to the Jumpers table. Sometimes when using the integrat or configuration a low frequency filter is required in order to reduce the noise interaction. The pole value should be at

least five times higher than the switching frequency. The low pass filter should be inserted in this way: the resistor, in the place of the INT jumper position and the capacitor between the resistor and ground (refers to the

schematic).

= 1.8V I

OUT

= 15A, F

OUT

. On the top side

CC

SW

19/30

L6997S

OU

Figure 17. L6997S Schematic diagram

C2

SW1

R12

TP1

R11

R7

C21

R6

TP2

C20

R8

C3

VCC

OSC

SS

L6997S

L6997

SHDN

NOSKIP

OVP

PGOOD

GND

R5

VDR

BOOT

HGATE

PHASE

GNDSENSE

LGATE

PGND

VSENSE

INT

VREF

FB

C22

D1

C19

Q4, Q5, Q6

C6

NOINT

INT

R3

R4

Q1, Q2, Q3

D2

NOINT

TP3

C25

C5

L

C7 C8 C9

C10, C11

C12

VCC

C13, C14, C15,

C16, C17, C18

R9

R10

C4

C7

R13

Vin

V

T

C23

C24

INT

R

C

7.1 UMPERS CONNECTION

Table 10. Jumper connection with integrator

Component Connection

C4 Mounted

C7 Mounted*

INT Close

NOINT Open

*This component is not necess ary, depends from the output ESR capacitor. See the integrator sec tion.

Table 11. Jumper connection without integrator

Component Connection

C4 Not mounted

C7 Not Mounted

INT Open

NOINT Close

20/30

7.2 DEMO BOARD LAYOUT

Real dimensions: 5.7cm x 7.7cm (2.28inch x 3. 08inch)

L6997S

Figure 18. PCB layout: bottom side

Figure 19. PCB Layout: Top side

Figure 20. Internal ground plane

Figure 21. Power & signal plane

Table 12. PCB Layout guidelines

Goal Suggestion

To minimize radiation and magnetic

coupling with the adjacent circuitry .

To maximize the efficiency. Keep power traces and load connections short and wide.

To ensure high accuracy in the

current sense system.

To reduce the noise effect on the IC. 1) Put the feedback component (like output divider, integrator network, etc) as

1) Minimize switching current loop areas. (For example placing C

and Low side MOSFETS, Shottky diode as close as possible).

2) Place controller placed as close as possible to the power MOSFETs.

3) Group the gate drive components (Boot cap and diode) near the IC.

Make Kelvin connection for Phase pin and PGND pin and keep them as close

as possible to the Low Side MOSFETS.

close as possible to the IC.

2) Keep the feedback traces parallel and as close as possible. Moreover they

must be routed as far as possible from the switching current loops.

3) Make the controller ground connection like the figure 8.

, High Side

IN

21/30

L6997S

Table 13. Component list

The component list is shared in two sections: the first for the general-purpose component, the second for

power section:

Part name Value Dimension Notes

GENERAL-PURPOSE SECTION

RESISTOR

R1 N.M. 0603 Output resistor divider for the linear regulator.

R2 N.M. 0603

R3 560kΩ 0603 Input r esi sto r div ide r (To set switchin g fre que ncy)

R4 5.6kΩ 0603

R5 47Ω 0603

R6, R7, R11, R12 33kΩ 0603

R8 62kΩ 0603 Current limit resistor (To set current limit)

R9 2.7kΩ 0603 Output resistor divider (To set output voltage)

R10 1.3kΩ 0603

R13 220Ω 0603

CAPACITOR

C1 220nF 0805

C2 47µF KEMET-16V

C3 220nF 0805

C4 150pF 0603 First integrator capacitor

C5 47pF 0603

C6 10nF 0603

C7 N.M. 0603 Second integrator capacitor

C19 220nF 0805

C20 220nF 0603 Softstart capacitor

C21 47pF 0603

C22 220nF 0805

C23 0603 N.M.

C24 1nF 0603

C25 1µFTantalum

DIODES

D1 BAT54 25V

POWER SECTION

OUTPUT CAPACITORS

C11-C12 2X680µF T510x687(1)004AS

INPUT CAPACITORS

C13, C14, C16, C17,

C15 C18

INDUCTOR

L1 1.8µH ETQF6F1R8BFA

POWER MOS

Q1,Q2 SI4442DY VISHAY Siliconix Q3 N.M.

Q5,Q6 SI4442DY VISHAY Siliconix Q4 N.M.

INTEGRATED CIRCUIT

U1 L6997S

100µF ECJ5YF0J1072

47µF ECJ5YF1A4767

KEMET

PANASONIC

PANASONIC

PANASONIC

Output capacitor C8, C9, C10 N.M.

Input capacitor

22/30

7.3 EFFICIENCY CURVES Figure 22. Efficiency vs output Current

100

95

90

85

Efficiency (%)

Vcc=Vin=3.3V

80

Fsw=200KHz

75

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Output Current (A)

L6997S

Vout=2.5V

Vout=1.8V

Vout=1.5V

Vout=1.2V

Vout=0.9V

Table 14. Efficiency Curves For Different Applications (V

up to 25V)

IN

Part name Value Dimension Notes

GENERAL-PURPOSE SECTION

RESISTOR

R1 100Ω 0603 Output resistor divider for the linear regulator.

R2 300Ω 0603

R3 560kΩ 0603 Input resistor divider (To set switching frequency)

R4 10kΩ 0603

R5 47Ω 0603

R6, R7, R11, R12 33kΩ 0603

R8 47kΩ 0603 Current limit resistor (To set current limit)

R9 2,7kΩ 0603 Output resistor divider (To set output voltage)

R10 1kΩ 0603

R13 220Ω 0603

CAPACITOR

C1 220 nF 0805

C2 47µFKEMET-16V

C3 220nF 0805

C4 150pF 0603 Fir st inte grator capa cit or

C5 47pF 0603

C6 10nF 0603

C7 330pF 0603 Second integrator capacitor

C19 220nF 0805

C20 10nF 0603 Softstart capacitor

C21 47pF 0603

C22 220nF 0805

C23 0603 N.M.

23/30

L6997S

Table 14. Efficiency Curves For Different Applications (VIN up to 25V) (continued)

Part name Value Dimension Notes

C24 1nF 0603

C25 1µFTantalum

DIODES

D1 BAT54 25V

POWER SECTION

OUTPUT CAPACITORS

C11-C12 2X100µF B45197-A3107-

K409

EPCOS

INPUT CAPACITORS

C13, C14, C16,

C17, C15 C18

10µF C34Y5U1E106Z

TOKIN

10µF C3225Y5V1E106Z

TDK

10µF ECJ4XF1E106Z

PANASONIC

10µF TMK325F106ZH

TAIYO YUDEN

INDUCTOR

L1 3 µH T50-52 Core, 7T

AWG15

POWER MOS

Q1,Q2 STS11NF3LL STMicroelectronics Q3 N.M.

Q5,Q6 STS11NH3LL STMicroelectronics Q4 N.M.

DIODES

D2 STPS2L25U STMicroelectronics 25V

INTEGRATED CIRCUIT

U1 L6997S

NOTE: For the 25V to 12V conversi on the inductor used is: 77120A core 7T.

Output capacitor C8, C9, C10 N.M.

Input capacitor

7.4 EFFICIENCY CURVES Figure 23. Efficiency vs output Current Figure 24. Efficiency vs output Current

100

95

90

85

Efficiency (%)

80

75

Vin = Vcc = 5V

70

Fsw = 200KHz

65

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

Output Current (A)

24/30

Vo = 3.3V

2.5V

1.8V

1.5V

1.2V

0.9V

100

95

90

85

80

75

70

Efficiency (%)

65

60

55

50

012345678910111213141516171819

Vin = 12V

Vcc = 5V

Fsw = 200KHz

Output Current (A)

Vo = 5V

3.3V

2.5V

1.8V

1.5V

1.2V

0.9V

L6997S

Figure 25. Efficiency Vs Output Current Figure 26. Efficiency Vs Output Current

100

= 5V

V

OUT

= 3.3V

V

OUT

Eff [%]

95

90

85

80

75

= 12V

V

OUT

70

65

V

= 25V

60

55

50

0 1 2 3 4 5 6 7 8 9

IN

VCC= 5V

FSW= 200KHz

Output Current [A]

10 11 12 13 14 15 16

7.5 DDR MEMORY AND TERMINATION SUPPLY

Double data rate (DDR) memories require a particular Power Management Architecture. This is due to fact that

the trace betw een the dri ving c hipset an d the mem ory inpu t must be terminat ed wit h resist ors. Sin ce the Chip set

driving the Mem ory has a p ush pu ll o ut put b uffer , the Ter min atio n vo ltag e mu st b e ca pabl e of s ourc ing and sin king current. Moreover, the Termination voltage must be equal to one half of the memory supply (the input of the

memory is a differential stage requiring a reference bias midpoint) and in tracking with it. For DDRI the Memory

Supply is 2.5V and the Termination voltage is 1.25Vwhile for the DDRII the Memory Supply is 1.8V and the Termination vol ta ge is 0.9 V . Fi gu re 27 shows a complete DDR I I Me mo r y an d Termination Sup pl y re al i z ed by us i ng

2 x L6997S. The 1.8V section is powering the memory, while the 0.9V section is providing the termination voltage.

100

90

80

70

60

50

Eff [%]

40

30

V

= 33V

20

10

0

0 1 2 3 4 5 6 7 8 9

IN

= 12V

V

OUT

Output Current [A]

10 11 12 13 14 15 16

Figure 27. Application Idea: DDRII Memory Supply

VCC

VIN

VCC

VREF

VREF

OSC

SS

ILIM

L6997S

L6997

NOSKIP

INT

SHDN PGOOD OVP

OSC

SS

ILIM

L6997S

NOSKIP

INT

SHDN

U1

VCC

U2

L6997

PGOOD

VCCDR

HGATE

LGATE

VSENSE

GNDSENSE

VCCDR

BOOT

LGATE

VSENSE

GNDSENSE

OVP

BOOT

PHASE

PGND

FB

HGATE

PHASE

PGND

FB

GND

GND

STS11NF3LL

STS11NF3LL

2R

VCC

STS8DNF3LL

2R

MEMORY

SUPPLY

TERMINATION

Vddq

1.8V@15A

R

NETWORK

BUS

VREF

R

Vtt

+

0.9V@- 5A

CHIPSET

+

25/30

L6997S

The current required by the Memory and Termination supply, depends on the memory type and

size. The figures 28 and 29 show the efficiency for

the termination section of the application shown in

fig. 27.

Figure 28. Eff. vs. Outp ut Current Source Mode

100

95

90

85

Vin=1.8V

Efficiency (%)

80

75

70

Vout = 0.9V

Vcc = 5V

Fsw = 200KHz

1

0234567

Vin = 12V

Output Current (A)

Figure 29. Eff. vs Output Current sink mode

Vin=12V

Vin = 1.8V

Vin = 12V

Efficiency (%)

100

95

90

85

80

75

70

65

60

Vout=0.9V

Vcc=5V

Fsw=200KHz

01234567

Output current (A)

8 Typical Operating Characteristics

Figure 30.

Ch1-> Inductor current

Ch2-> Phase Node

Ch3-> Output voltage

Figure 31. Normal functionality in SINK mode..

Load transient resp onse f ro m 0A t o 5 A .

.

26/30

Ch1-> Inductor current

Ch2-> Phase Node

Ch3-> Output voltage

L6997S

Figure 32. Normal functionality in PWM mode.

Ch1-> Inductor current

Ch2-> Phase Node

Ch3-> Output voltage

Figure 33. Normal functionality in PFM mode.

Figure 34. Start up waveform with 0A load.

Ch1-> Inductor current

Ch2-> Soft start Voltage

Ch3-> Output voltage

Figure 35. Start up waveform with 5A load..

Ch1-> Inductor current

Ch2-> Phase Node

Ch3-> Output voltage

Ch1-> Inductor current

Ch2-> Soft start Voltage

Ch3-> Output voltage

27/30

L6997S

Figure 36. TSSOP20 Mechanical Data & Package Dimensions

DIM.

A 1.20 0.047

A1 0.050 0.150 0.002 0.006

A2 0.800 1.000 1.050 0.031 0.039 0.041

b 0.190 0.300 0.007 0.012

c 0.090 0.200 0.004 0.008

D (1) 6.400 6.500 6.600 0.252 0.256 0.260

E 6.200 6.400 6.600 0.244 0.252 0.260

E1 (1) 4.300 4.400 4.500 0.170 0.173 0.177

e 0.650 0.026

L 0.450 0.600 0.750 0.018 0.024 0.030

L1 1.000 0.039

k 0˚ (min.) 8˚ (max.)

aaa 0.100 0.004

Note: 1. D and E1 does no t inclu de mo ld fla sh or prot rusi ons .

mm inch

MIN. TYP. MAX. MIN. TYP. MAX.

Mold flash or potrusions shall not exceed 0.15mm

(.006inch) per side.

OUTLINE AND

MECHANICAL DA TA

TSSOP20

Thin Shrink Small Outline Package

28/30

0087225 (Jedec MO-153-AC)

Table 15. Revision History

Date Revision Description of Chan g es

June 2004 1 First Issue.

L6997S

29/30

L6997S

Information furnished is believed to be accurate and reliable. However, STMicroe lectronics assumes no responsibility for the consequences

of use of such information nor for any infri ngement of patents or other rights of third parties which may result from its use. No licens e is granted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without no tice. This publication supersedes and replaces all inf ormation previously supplied. ST Microelectronics products are not

authorized for use as critical components in life support devic es or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics.

All other names are the property of their respective owners

© 2004 STMicroelectronics - All rights reserved

Australia - Belgium - Brazil - Canada - China - Czec h Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States

STMicroelectronics GROUP OF COMPANIES

www.st.com

30/30

Loading...

Loading...